| [1] |

Leistner L. Shelf-stabile products and intermediate moisture foods based on meat. Water activity: Theory and applications to food[M]. New York: Marcel Dekker, 1987: 295−327.

|

| [2] |

Hu Y Y, Zhang L, Zhang H, et al. Physicochemical properties and flavor profile of fermented dry sausages with a reduction of sodium chloride[J]. LWT-Food Science and Technology,2020,124:109061. doi: 10.1016/j.lwt.2020.109061

|

| [3] |

Chen Q, Kong B H, Han Q, et al. The role of bacterial fermentation in lipolysis and lipid oxidation in Harbin dry sausages and its flavor development[J]. LWT-Food Science and Technology,2017,77:389−396. doi: 10.1016/j.lwt.2016.11.075

|

| [4] |

王卫. 栅栏技术及其在食品加工与质量安全控制中的应用[M]. 北京: 科学出版社, 2015: 45−70.

|

| [5] |

李燕利. 腊肉和香肠贮藏期间品质变化研究[D]. 重庆: 西南大学, 2012.

|

| [6] |

|

| [7] |

Moy Y S, Lu T J, Chou C C. Volatile components of the enzyme-ripened sufu, a Chinese traditional fermented product of soy bean[J]. Journal of Bioscience & Bioengineering,2012,113(2):196−201.

|

| [8] |

|

| [9] |

|

| [10] |

李杉杉, 肖龙泉, 刘海强, 等. 红曲红色素替代亚硝酸盐在川式香肠中的应用研究[J]. 成都大学学报(自然科学版),2015,34(2):121−125.

|

| [11] |

Foteini G Pavli, Anthoula A Argyri, Nikos G C Chorianopoulos, et al. Effect of Lactobacillus plantarum L125 strain with probiotic potential on physicochemical, microbiological and sensorial characteristics of dry-fermented sausages[J]. Lwt-Food Science and Technology,2020,118:108810. doi: 10.1016/j.lwt.2019.108810

|

| [12] |

吉莉莉, 王卫, 陈林, 等. 成都地区传统酱风肉加工及其产品特性和浅发酵特征研究[J]. 食品科技,2020,45(5):106−112.

|

| [13] |

Wang W, Jürgen S. Chinese and German sausages are similar[J]. Fleisch Wirtschaft International,2015,3:30−35.

|

| [14] |

|

| [15] |

王卫, 吉莉莉, 陈林, 等. 四川省肉类加工产业发展战略[M]. 成都: 四川科学技术出版社, 2014: 28−29.

|

| [16] |

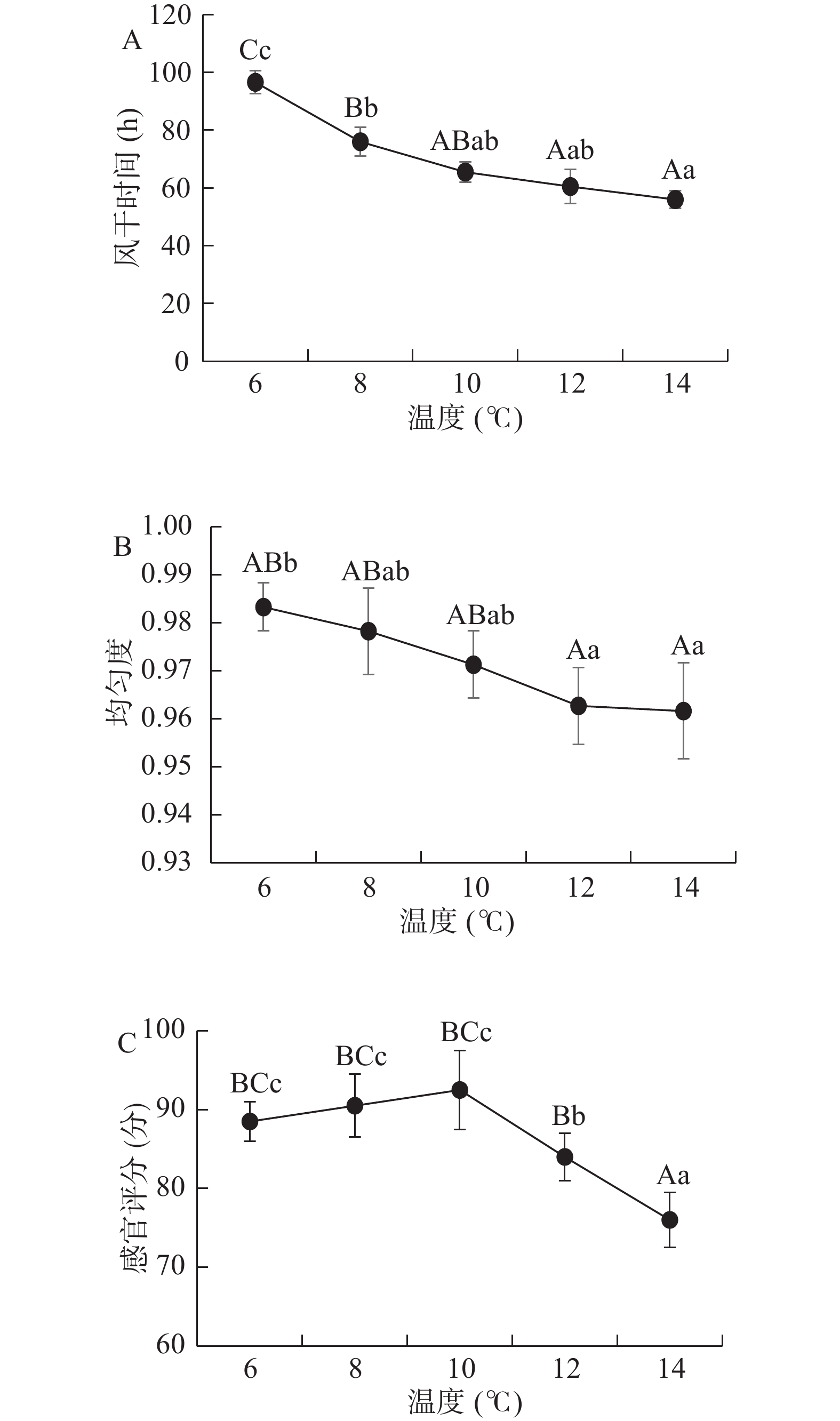

康峻, 王卫, 吉莉莉, 等. 浅发酵香肠加工进程理化、微生物及风味特性[J]. 成都大学学报(自然科学版), 2020(3): 234−240.

|

| [17] |

张佳敏, 唐占敏, 冉渺, 等. 响应面优化重组牛排加工工艺[J]. 食品工业科技,2017,38(4):263−266.

|

| [18] |

文冉, 吕青涛, 李娜, 等. 基于综合加权评分Box-Behnken响应面法优化半枝莲的提取工艺[J]. 中药材, 2020(5): 1183−1187.

|

| [19] |

|

| [20] |

Gök Veli, Ersel O, Levent A. Effects of packaging method and storage time on the chemical, microbiological, and sensory properties of Turkish pastirma-A dry cured beef product[J]. Meat Science,2008,80(2):335−344. doi: 10.1016/j.meatsci.2007.12.017

|

| [21] |

魏效玲. 多指标试验设计综合加权评分值的确定[J]. 河北工程大学学报(自然科学版),2003,20(4):68−72.

|

| [22] |

Komprda T, Smělá D, Pechová P, et al. Effect of starter culture, spice mix and storage time and temperature on biogenic amine content of dry fermented sausages[J]. Meat Science,2004,67(4):607−616. doi: 10.1016/j.meatsci.2004.01.003

|

| [23] |

杨玲, 陈建, 杨屹立, 等. 甘蓝型油菜籽热风干燥特性及其数学模型[J]. 现代食品科技,2014,30(10):30−35.

|

| [24] |

R Thomas, A S R Anjaneyulu, N Kondaiah. Development of shelf stable pork sausages using hurdle technology and their quality at ambient temperature (37±1 ℃) storage[J]. Meat Science,2008,79(1):1−12. doi: 10.1016/j.meatsci.2007.07.022

|

| [25] |

周悦, 李雪峰, 姜国川,等. 响应面分析法对重组牛肉脯色泽的改善[J]. 肉类工业,2013(7):28−30.

|

| [26] |

徐显睿, 李翠凤, 隋勇军, 等. 响应面法优化乳双歧杆菌Z-1冷冻干燥保护剂配方[J]. 乳业科学与技术,2020(3):6−11.

|

| [27] |

张乐, 李鹏, 王赵改, 等. 板栗片微波真空干燥动力学模型及品质分析[J]. 现代食品科技, 2020, 36(4): 235−243.

|

| [28] |

|

| [29] |

刘斌雄, 李长城, 陈锦权, 等. 牛肉过热蒸汽干燥特性及薄层干燥动力学研究[J]. 食品工业,2018,39(12):36−40.

|

DownLoad:

DownLoad: