Effect of High Hydrostatic Pressure Sterilization on the Physicochemical Properties, Taste, and Flavor of Large Yellow Croaker (Larimichthys crocea)

-

摘要: 以甬岱1号大黄鱼为对象,通过菌落总数、色泽、质构、保水性、脂肪氧化、肌原纤维蛋白特性、呈味核苷酸、游离氨基酸等指标分析,并结合气相离子迁移色谱(gas chromatography-ion mobility spectrometry,GC-IMS)技术,系统探究了超高压(200、250、300 MPa,10 min)杀菌对大黄鱼理化性质及滋味、风味物质的影响。结果表明:超高压可有效杀菌,200~300 MPa处理下,杀菌率达98.10%以上,而鱼体特征黄色区域体表色泽及脂肪氧化程度无变化。200 MPa下,肌肉色泽保持良好,ΔE值仅2.90;质构和保水性显著改善,回复性较对照组(常压处理)提高16.92%,蒸煮损失率则显著下降了14.35%;肌原纤维蛋白表面疏水性无显著变化,巯基含量及Ca2+-ATPase活性显著高于250、300 MPa组,蛋白变性程度相对较低。超高压显著提高了鱼体中的呈味核苷酸、游离氨基酸含量及味精当量值,鲜甜滋味明显提升改善。GC-IMS结果显示,超高压显著提高了鱼肉风味组分,尤其是醇、醛及酮类等特征挥发性物质,果香、花香、青香、甜香味增强。综合杀菌效果、理化特性及滋味、风味变化,200 MPa较适用于大黄鱼的杀菌。该研究为大黄鱼超高压保鲜加工技术的应用提供了理论依据。Abstract: To explore the effect of high hydrostatic pressure sterilization (HHP) on the physicochemical properties, taste and flavor of large yellow croaker (Larimichthys crocea), Yongdai 1 (Daiqu sp.) samples were subjected to different HHP treatments (200, 250, and 300 MPa, 10 min). The total viable count, color, textural properties, water retention ability, lipid oxidation, biochemical properties of the myofibrillar proteins, flavor nucleotides, and free amino acids were analyzed. In addition, volatile flavor profiles were analyzed using gas chromatography-ion mobility spectrometry (GC-IMS). The results showed that HHP, a treatment of 200~300 MPa, effectively inactivated microorganisms with a sterilization rate of ≥98.10%. No significant changes were observed in surface color and lipid oxidation levels compared to those of the atmospheric pressure treated samples (control group). Muscle color was maintained better in the 200 MPa group, with ΔE 2.90. Treatment at 200 MPa significantly improved the textural properties and water retention ability. Compared to the control group, the resilience of fish muscle increased significantly by 16.92%, whereas cooking loss decreased significantly by 14.35% in the 200 MPa samples. HHP treatment at 200 MPa had fewer negative effects on protein denaturation than treatment at higher pressures. The surface hydrophobicity of myofibrillar proteins exhibited no significant changes compared with those in the control group, whereas the thiol groups content and Ca2+-ATPase activity in the 200 MPa samples were significantly increased compared with those in the 250 and 300 MPa groups. In addition, flavor nucleotide, free amino acid, and equivalent umami concentration levels significantly increased after HHP treatment, resulting in an improved fresh and sweet taste. GC-IMS analysis revealed that HHP treatments significantly enhanced the flavor components of L. crocea, particularly characteristic odorants, including alcohols, aldehydes, and ketones, thereby increasing fruity, floral, green, and sweet flavors. Considering both the sterilization efficiency and changes in physicochemical characteristics, taste, and flavor, a pressure of 200 MPa was determined to be most suitable for L. crocea sterilization. These results provide a theoretical basis for the application of HHP in the preservation and processing of L. crocea.

-

Keywords:

- large yellow croaker /

- high hydrostatic pressure /

- sterilization /

- physicochemical properties /

- taste /

- flavor

-

大黄鱼(Larimichthys crocea)是我国养殖规模最大且产量最高的海洋主导经济鱼类[1−2]。新鲜大黄鱼含有大量水分和蛋白,内源酶活性高且易受微生物侵染,极易腐败变质,进而造成严重经济损失[3]。因此,研发简便、高效的大黄鱼保鲜技术具有重要的经济和科学意义。

超高压(high hydrostatic pressure,HHP)作为一种新型非热加工技术,可在室温或低温下实现杀菌、钝酶而不破坏食物营养,是提高水产品质量安全及货架期的有效手段[4−5]。Wu等[5]研究发现,HHP(300 MPa、5 min)可有效杀死醉蟹中的假单胞菌、大肠杆菌及金黄色葡萄球菌并钝化多酚氧化酶,进而有效抑制黑变、脂肪氧化及生物胺前体氨基酸生成,延长货架期。Ahmed等[6]发现,HHP在有效杀灭单增李斯特菌的同时,可有效维持黄鳍鲷鱼的营养品质,脂肪酸及氨基酸谱无明显变化。近年来,HHP亦被应用于大黄鱼保鲜,相关研究主要集中在HHP处理对其营养品质[7]、肌原纤维蛋白功能特性[8]及空间结构影响[9]等领域。杨华等[10]发现200~500 MPa可显著降低养殖大黄鱼组织中蛋白酶、脂肪酶及ATP酶活力,有效杀灭大肠杆菌,并基于GC-MS分析了冷藏过程中500 MPa下鱼肉腥臭物质变化情况。另有研究显示,基于电子鼻分析,200~500 MPa高压下大黄鱼中的挥发性成分基本保留[7]。大黄鱼营养丰富、味道鲜美、香味浓郁,与鱼肉中丰富的脂肪、蛋白、游离氨基酸、呈味核苷酸及其挥发性物质等密切相关,然而目前HHP对大黄鱼脂肪氧化、蛋白氧化、滋味成分影响研究及HHP大黄鱼风味变化可视化分析研究却鲜有报道。

本文以甬岱1号大黄鱼为研究对象,在明确杀菌效果基础上,综合色泽、质构、脂肪氧化、蛋白氧化等相关指标系统分析超高压杀菌对大黄鱼理化特性的影响,同时结合高效液相色谱、气相离子迁移色谱(gas chromatography-ion mobility spectrometry,GC-IMS)可视化分析技术探明其滋味、风味变化,旨在为HHP在大黄鱼保鲜加工中的应用提供理论依据和指导。

1. 材料与方法

1.1 材料与仪器

新鲜网箱养殖大黄鱼(甬岱1号,400±25 g) 象山一桥水产养殖专业合作社,捕捞上岸后,冰藏送回实验室,冰水洗净、沥干后置于冰上备用;丙二醛试剂盒、Ca2+-ATP酶活试剂盒 南京建成生物工程研究所;三羟甲基氨基甲烷马来酸盐(Tris-maleate)、异硫氰酸苯酯、氨基酸混标及肌苷酸(inosine 5’-monophosphate,IMP)、鸟苷酸(guanosine 5’-monophosphate,GMP)、腺苷酸(adenosine 5’-monophosphate,AMP)标准品 美国Sigma公司;甲醇、磷酸二氢钾、磷酸氢二钾、乙腈、乙酸钠、正己烷等为色谱纯,其他试剂均为分析纯 国药集团化学试剂有限公司。

CQC2L-600型全液相超高压设备 北京速原中天股份有限公司;SPM-168型智能生化培养箱 宁波江南仪器厂;Ci6X便携式色差仪 爱色丽(上海)色彩科技有限公司;TA.XT Plus质构仪 英国Stable Micro Systems公司;FE-28型pH计 梅特勒-托利多仪器(上海)有限公司;ReadMax1900型光吸收型全波长酶标仪 上海闪谱生物科技有限公司;LC-20A型高效液相色谱仪 日本岛津公司;LC-100型高效液相色谱仪 上海伍丰科学仪器有限公司;FlavourSpec®气相离子迁移色谱仪 德国G.A.S.公司;T18型均质机 德国IKA公司;5415D型冷冻离心机 德国Eppendorf公司;MS105DU电子分析天平 Mettler Toledo仪器有限公司。

1.2 实验方法

1.2.1 样品处理

将大黄鱼剖杀,去除鱼鳞、内脏及鱼鳃后,流水洗净血污及杂质,沥水后沿背部将脊骨剔除,取下两侧片鱼肉后切块。

将鱼块随机分成4组,分别为对照组(CK组)和3个超高压处理组。在预实验基础上,超高压处理组分别于200(H200组)、250(H250组)、300 MPa(H300组)压力下常温保压10 min(鱼块装袋封口,每包80 g鱼块、80 mL水)。以水为传压介质,升压速率3 MPa/s,3 s内完成卸压时间,腔内水温约15℃。泄压后取出样品,随即进行菌落总数(total viable counts,TVC)、色差、质构、pH、保水性等指标测定,剩余样品液氮速冻后置于−80 ℃冰箱保存,以用于蛋白、滋味及风味相关指标测定。对照组鱼块同超高压处理组装袋封口,常压放置相同时间后取样检测。每组设置3个平行。

1.2.2 菌落总数测定

参照国标GB/T 4789.2-2022《食品微生物学检验 菌落总数测定》进行,结果以lg CFU/g表示。

1.2.3 色泽测定

分别对背部肌肉及腹部黄色区域表皮颜色进行测定,记录L*、a*和b*值,每块选取2个测试点,每组进行3次平行试验。以白度(WI)及与对照组间总色差(∆E)计算背部肌肉色泽变化程度,以处理前后∆E计算腹部黄色区域表皮颜色变化程度。

WI=100−[(100−L∗)2+(a∗)2+(b∗)2]1/2 (1) ΔE=[(ΔL∗)2+(Δa∗)2+(Δb∗)2]1/2 (2) 式中:背部肌肉:∆L*、∆a*、∆b*分别为处理组与对照组L*、a*和b*值之差;腹部黄色区域表皮:∆L*、∆a*、∆b*分别为处理前后L*、a*和b*值之差。

1.2.4 质构测定

参考文献[11]方法,以TPA模式对背部肌肉全质构参数(硬度、弹性、咀嚼性、回复性)进行测定。选用P5柱形探头,设置下行速度为2.0 mm/s,下压、回升速度为1.0 mm/s,触发力为5 g,下压深度为5 mm,每组样品测8次,取平均值。

1.2.5 pH测定

参照《食品安全国家标准 食品pH值的测定》(GB/T 5009.237-2016)进行,每组做3次平行。

1.2.6 保水性测定

肌肉保水性以蒸煮损失率进行评价,测定方法参考Zhang等[12]方法并略加修改。鱼肉称重后装袋封口,80 ℃水浴蒸煮30 min,冷却、吸干表面水分后称重,结果以损失重量占蒸煮前质量百分比(%)表示。每组做3次平行。

1.2.7 TBARS值测定

参照试剂盒操作进行测定,结果以μmol/100 g表示,每组做3次平行。

1.2.8 肌原纤维蛋白提取

参考Yang等[13]方法,稍作修改。取3 g背部肌肉,加入10倍体积4 ℃预冷Tris-maleate缓冲溶液A(50 mmol/L KCl-20 mmol/L Tris-maleate,pH7.0),匀浆后4 ℃、10000 r/min离心10 min,弃上清,沉淀中加入6倍体积预冷Tris-maleate缓冲溶液B(0.6 mol/L KCl-20 mmol/L Tris-maleate,pH7.0),匀浆后4 ℃提取1 h,4 ℃、10000 r/min离心10 min,上清液即为肌原纤维蛋白溶液。考马斯亮蓝法测定蛋白含量。

1.2.9 表面疏水性测定

表面疏水性测定参照文献[14]方法进行,稍作修改。取1 mL肌原纤维蛋白溶液,加入200 μL溴酚蓝溶液(1 mg/mL),室温下振荡反应10 min,随后10000 r/min离心15 min,取上清液稀释10倍后测定595 nm处吸光度,以Tris-maleate缓冲溶液B作空白样。其值以每毫克蛋白质所结合的溴酚蓝量表示(μg/mg prot)。

1.2.10 总巯基及活性巯基含量测定

参考文献[15−16]采用Ellman试剂法对样品中的总巯基(total sulfhydryl,T-SH)及活性巯基(reactive sulfhydryl,A-SH)含量进行测定。0.25 mL肌原纤维蛋白溶液中加入2.5 mL磷酸盐缓冲液(0.1 mol/L,pH8.0,含8 mol/L尿素),混匀后加入50 μL 5,5’-二硫代双(2-硝基苯甲酸)溶液(10 mmol/L)。T-SH含量测定中,反应液于40 ℃水浴30 min后测定412 nm处吸光值,A-SH含量测定中则于4 ℃反应1 h后测定412 nm处吸光值。以反应产物2-硝基-5-硫代苯甲酸在412 nm波长、pH8.0下的摩尔消光系数13600 L/(mol·cm)计算,T-SH、A-SH含量以nmol/mg prot表示。

1.2.11 Ca2+-ATP酶活测定

按照试剂盒操作说明测定,结果以μmol Pi/mg prot/h表示。

1.2.12 呈味核苷酸测定

参考Duan等[17]方法,略有改动。0.2 g样品中加入1 mL高氯酸溶液(5 mol/L),匀浆后超声提取30 min,加入1 mL 70%甲醇,混匀,4 ℃静置30 min,12000 r/min离心15 min。取上清液,用2 mol/L KOH调至pH6.8,0.08 mol/L磷酸钾缓冲液(pH7.0)定容、0.22 μm微孔滤膜过滤后待测。

HPLC分析条件:LC-20A型高效液相色谱仪;C18反相色谱柱(4.6 mm×150 mm,3 μm);柱温30 ℃;流动相A(100%甲醇),流动相B(0.05 mol/L磷酸钾缓冲液,pH7.0);梯度洗脱:0~25 min,流动相A比列由10%线性下降至5%,随后5 min内线性下降至1%,再15 min内线性下降至0.5%,随后10 min内线性上升至10%,继续保持5 min,总运行时间60 min;进样量10 μL;流速0.8 mL/min;紫外检测波长254 nm。

1.2.13 游离氨基酸测定

参考宣晓婷等[18]的方法进行。0.2 g样品中加入1.5 mL 70%甲醇溶液,8000 r/min均质30 s,超声提取40 min后,12000 r/min离心10 min,重复提取2次,合并上清液。上清液经干燥后,加入0.3 mL超纯水,样品充分溶解后,12000 r/min离心5 min。取200 μL上清液,加入100 μL三乙胺,100 μL 0.2 mol/L异硫氰酸苯酯溶液,混匀后室温放置1 h。随后加入400 μL正己烷,剧烈振荡15 s后12000 r/min离心2 min,取100 μL下层溶液加入400 μL超纯水混匀,0.22 μm微孔滤膜过滤待测。

HPLC分析条件:LC-100型高效液相色谱仪;氨基酸专业色谱柱(4.6 mm×250 mm,5 μm);柱温35 ℃;流动相A:0.05 mol/L乙酸钠溶液(pH6.50),流动相B:甲醇:乙腈:水=20:60:20(v:v:v);梯度洗脱:0~39 min,流动相A比例由95%线性下降至52%,随后1 min内线性下降至40%,再5 min内线性上升至45%,1 min内又线性上升至95%,随后保持14 min,总运行时间60 min;流速1 mL/min;进样量10 μL;紫外检测波长254 nm。

1.2.14 味精当量(equivalent umami concentration,EUC)的计算

EUC值参照文献[19]的方法进行计算,结果以每100 g样品味精当量(g MSG/100 g)表示。

1.2.15 挥发性物质(volatile organic compounds,VOCs)测定

参考Wu等[20]方法,采用GC-IMS法对样品中的挥发性组分进行测定,每组做3次平行。称取5 g样品置于20 mL顶空瓶中,60 ℃孵育15 min后进样;进样体积500 µL,不分流;进样针温度85 ℃。

GC条件:MXT-WAX毛细管色谱柱(0.53 mm×15 m,1.0 μm);进样口温度80 ℃;柱温60 ℃;载气为高纯N2(纯度≥99.999%),流速:起始2.0 mL/min,保持2 min,随后8 min内线性上升至10.0 mL/min,再10 min内线性上升至100.0 mL/min,随后保持10 min,总运行时间30 min。

IMS条件:电离源氚源(3H);迁移管长度98 mm;电场强度:500 V/cm;迁移管温度45 ℃;漂移气为高纯N2(纯度≥99.999%),流速150 mL/min;正离子模式。

1.3 数据处理

挥发性物质采用GC-IMS仪器自带VOCal软件内置的GC保留指数数据库(2020NIST)和IMS迁移时间数据库对样品中的特征风味物质进行分析,利用Reporter、Gallery Plot等插件生成不同样品间挥发性组分指纹图谱。其他各组数据以平均值±标准差(mean±SD)表示,应用SPSS 18.0软件以one-way ANOVA法及Duncan检验对实验数据进行组间比较和差异显著性分析。以P<0.05为存在显著性差异。

2. 结果与分析

2.1 不同超高压处理对大黄鱼减菌效果的影响

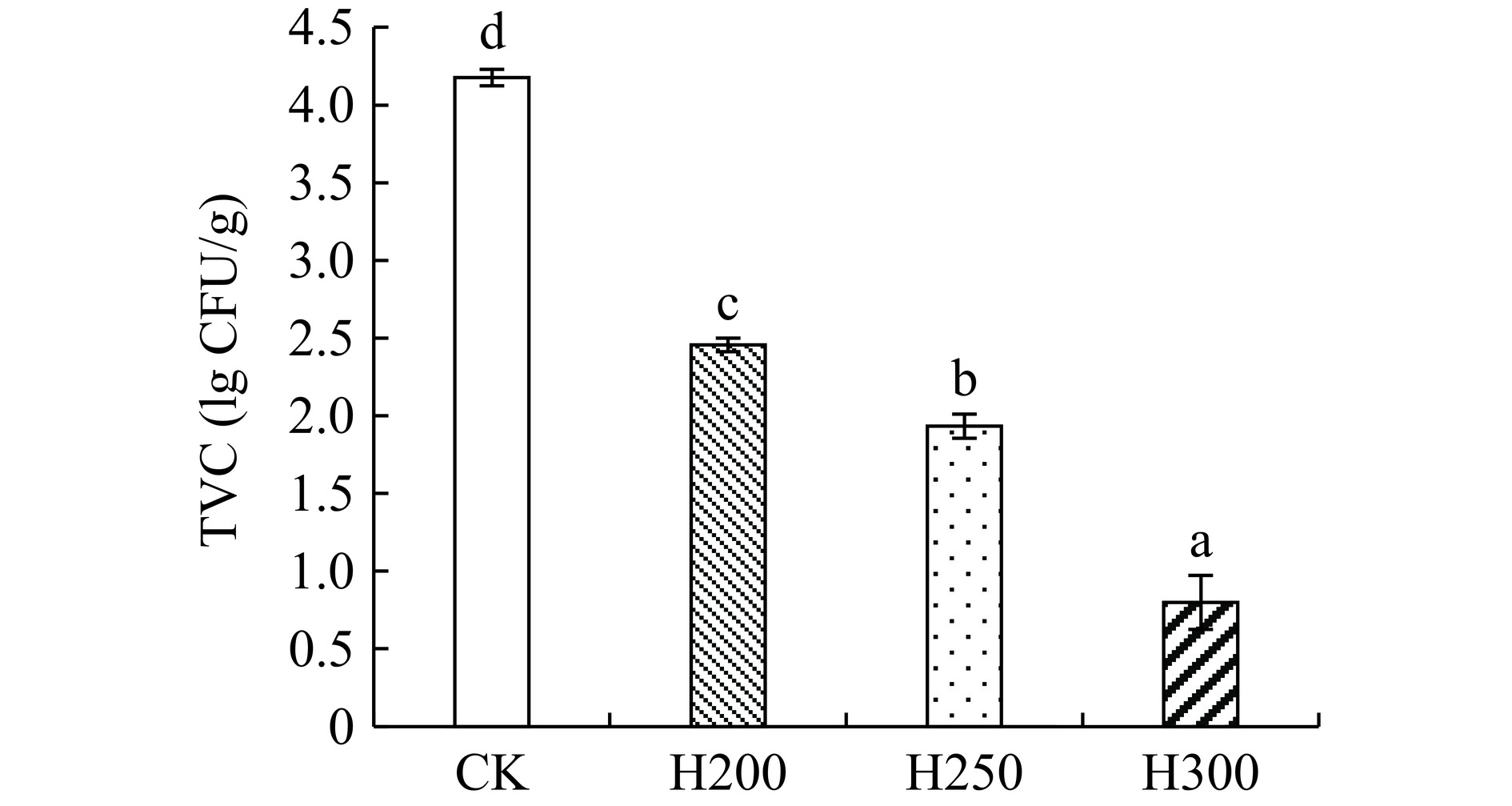

TVC是反映鱼体新鲜度的重要参数,影响着鱼体品质优劣及货架期长短。不同压力下TVC变化如图1所示,样品初始TVC为4.18 lg CFU/g,处于新鲜状态。200~300 MPa压力下,鱼体中TVC较CK组显著下降1.72~3.38 lg CFU/g(P<0.05),且杀菌效果随压力上升而显著增强(P<0.05)。本实验再次证实了HHP的杀菌效果,结果与对虾[21]、欧洲黑鲈[22]等HHP研究中的发现相似。研究显示,HHP可有效杀死水产品中主要腐败微生物,如假单胞菌、希瓦氏菌等,100 MPa下假单胞菌、希瓦氏菌菌数显著下降,200~300 MPa下失活[23−25],超高压下大黄鱼样品中TVC的大幅下降推测与主要致腐菌对压力敏感密切相关。TVC的下降可能是由于HHP作用下,菌体细胞膜磷脂双分子层发生凝胶化、膜蛋白变性,细胞中重要酶失活、遗传物质亚基分解,导致细胞膜通透性改变、细胞生理功能不同程度丧失,甚至细胞破裂,最终导致死亡[23,26−27]。

2.2 超高压杀菌对大黄鱼理化品质的影响

2.2.1 色泽

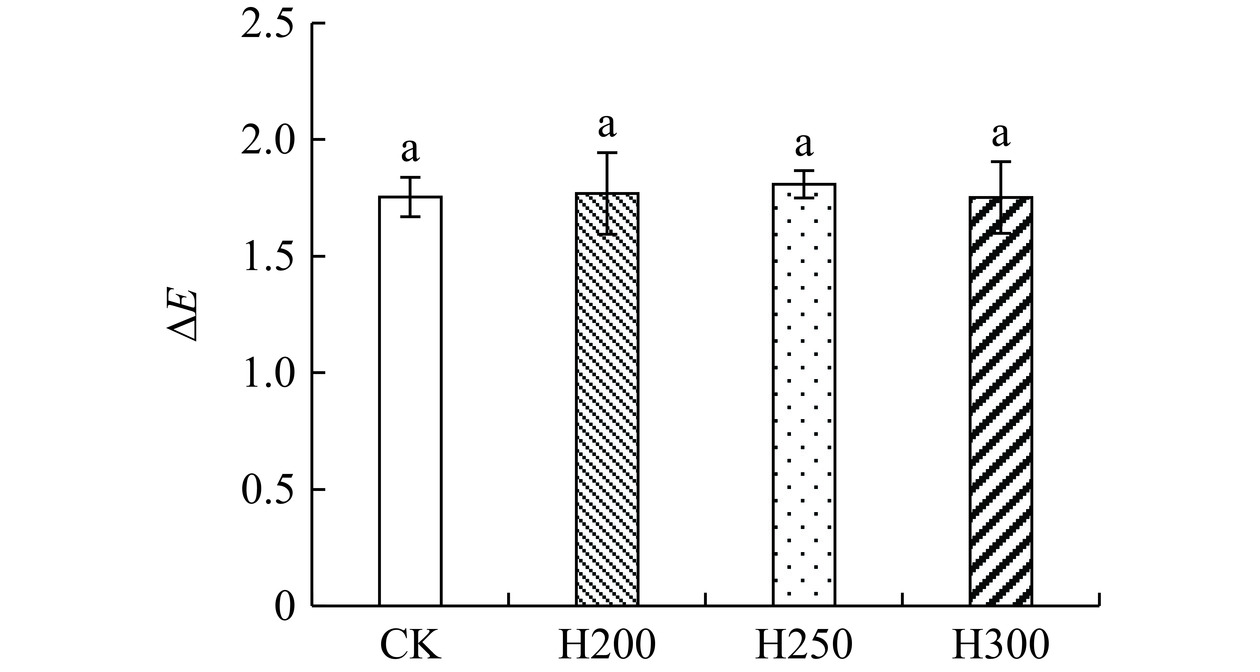

大黄鱼内部肌肉及其腹部黄色区域色泽是评价其品质的重要指标之一。如表1所示,HHP会导致背部肌肉亮度L*及WI值显著上升,并随压力增加呈现显著上升趋势(P<0.05),肌肉白度增加、透明度下降,≥250 MPa时鱼体出现明显熟化外观。Humaid等[28]在龙虾尾、Huang等[29]在鲭鱼片以及Tsai等[30]在虱目鱼HHP加工中也发现了类似结果,这主要是由于HHP引发了鱼体中肌原纤维蛋白、肌浆蛋白等变性凝固,致使肌肉白度增加。各组间a*值无显著差异(P>0.05),表明200~300 MPa超高压未对肌肉红绿值产生影响。大黄鱼背部肌肉b*值为正,体内色泽偏黄,≥250 MPa时b*值显著上升(P<0.05),这可能是由于超高压下肌红蛋白变性等引起的。这一结果与HHP对龙虾尾[28]、鲳鱼[11]、海鲈鱼及皱纹盘鲍[31]b*值的影响一致。但Tsai等[30]发现300~600 MPa处理下虱目鱼肉b*值显著下降,马荣荣[32]认为HHP可使鳗鱼鱼糜的黄度下降,≥300 MPa时b*值明显降低。这是因为水产品色泽变化是超高压下肌红蛋白变性、色素降解等共同作用结果,不同水产品中所含的肌红蛋白、色素不同,造成超高压对其b*值影响不同[29−30,33]。与CK组相比,背部肌肉ΔE值随压力增加而上升,其中H200组最小,仅为2.90,整体色泽变化不大,肉眼观察下外观色泽与新鲜鱼体无明显差异。

表 1 超高压杀菌对大黄鱼背部肌肉色泽的影响Table 1. Effect of high hydrostatic pressure sterilization on the color of Larimichthys crocea dorsal muscle对比各组处理前后腹部黄色区域体表色泽(图2),ΔE值在1.75~1.81之间,均较小,且各组间无显著差异(P>0.05),表明≤300 MPa超高压对大黄鱼特征黄色区域体表色泽无影响。

2.2.2 质构

不同HHP处理下质构参数变化如表2所示。随着压力上升,鱼肉的硬度、弹性、咀嚼性逐渐增大,变化趋势与虱目鱼[30]、鲳鱼[11]等HHP研究中的发现一致。其中,咀嚼性变化最为明显,200 MPa下咀嚼性较CK组显著增加了19.81%(P<0.05),而硬度、弹性的显著变化分别始于250和300 MPa。200 MPa下,鱼体的回复性显著高于其他组(P<0.05),分别为CK、H250及H300组的1.17、1.14、1.29倍。超高压引起的质构变化推测源于压力导致的肌原纤维蛋白变性、聚集,进而引发组织结构收缩,硬度、弹性、咀嚼性增大[34−35]。另有研究显示,硬度的增加与HHP下新的氢键网络结构形成有关[36]。

表 2 超高压杀菌对大黄鱼质构的影响Table 2. Effect of high hydrostatic pressure sterilization on the TPA properties of Larimichthys crocea组别 硬度(N) 弹性 咀嚼性(N) 回复性(%) CK 2.40±0.23a 0.73±0.03a 1.09±0.07a 0.26±0.02a H200 2.41±0.19a 0.72±0.04a 1.31±0.12b 0.31±0.04b H250 2.83±0.25b 0.75±0.02ab 1.52±0.12c 0.27±0.03a H300 4.73±0.30c 0.77±0.04b 2.12±0.13d 0.24±0.04a 2.2.3 pH

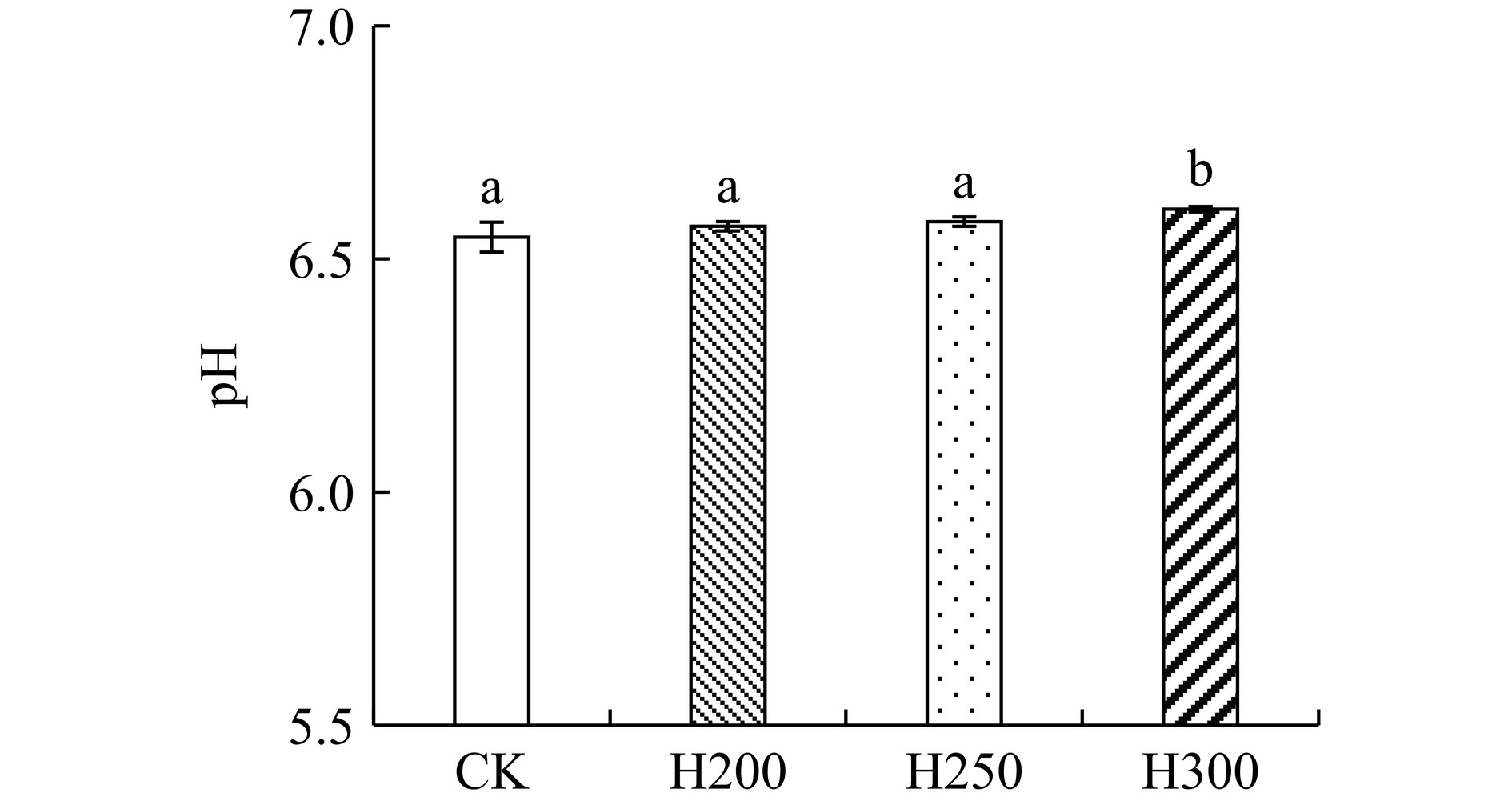

研究显示,HHP会引起水产品pH上升[37−38],本研究在大黄鱼中也发现了相似的现象。如图3所示,经HHP处理后,各组pH随压力的上升逐渐变大,300 MPa下显著高于CK组(P<0.05),推测pH上升可能是由于超高压诱发蛋白构象变化,促使碱性基团暴露及酸性基团埋藏[38]。

2.2.4 保水性

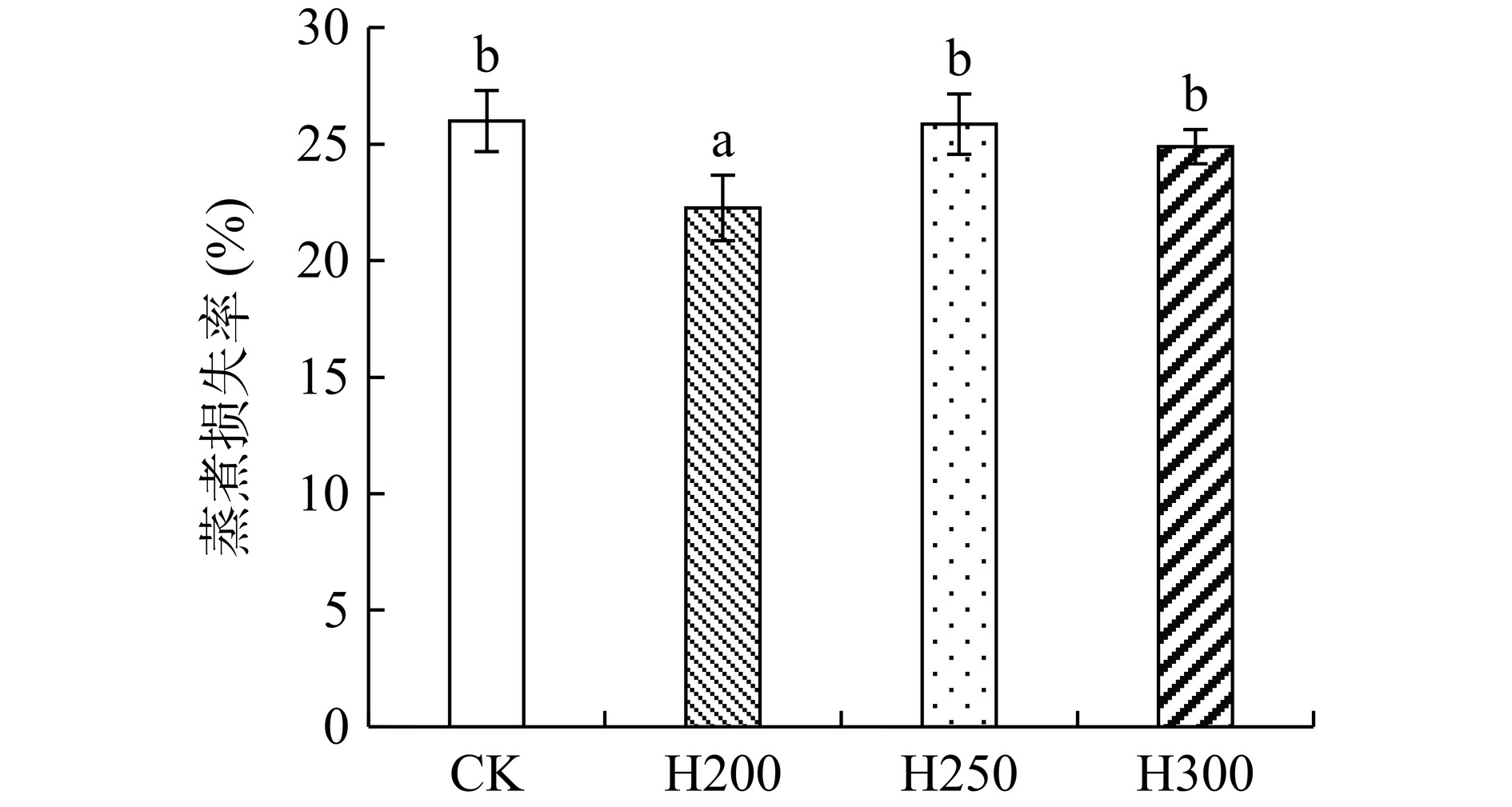

为探究HHP对大黄鱼保水性的影响,实验中对各组蒸煮损失率进行测定。如图4所示,200 MPa下蒸煮损失率较CK组显著下降了14.35%(P<0.05),表明鱼肉保水性得到了有效提高。然而,随着压力的继续上升,蒸煮损失率增加并显著高于H200组水平(P<0.05),但与CK组间无显著差异(P>0.05)。Yang等[39]发现100~200 MPa压力下,随着压力的增加,猪肉肠的蒸煮损失率逐渐下降,而当压力>200 MPa后,其值上升并显著高于200 MPa处理组,但水平均低于对照组,结果与本实验中的发现相一致。以上结果表明,适当的高压可显著提高大黄鱼肌肉的保水能力,推测是由于肌球蛋白头部对压力的高敏感性影响了肌动球蛋白复合物的形成,进而抑制了肌原纤维及纤维丝收缩引起的水分流失。此外,蒸煮损失率的下降亦可能是由于超高压下肌球蛋白尾部及肌动蛋白稳定性提高,更好保持了组织完整性,进而提高肌肉的保水能力[38,40]。

2.2.5 脂肪氧化

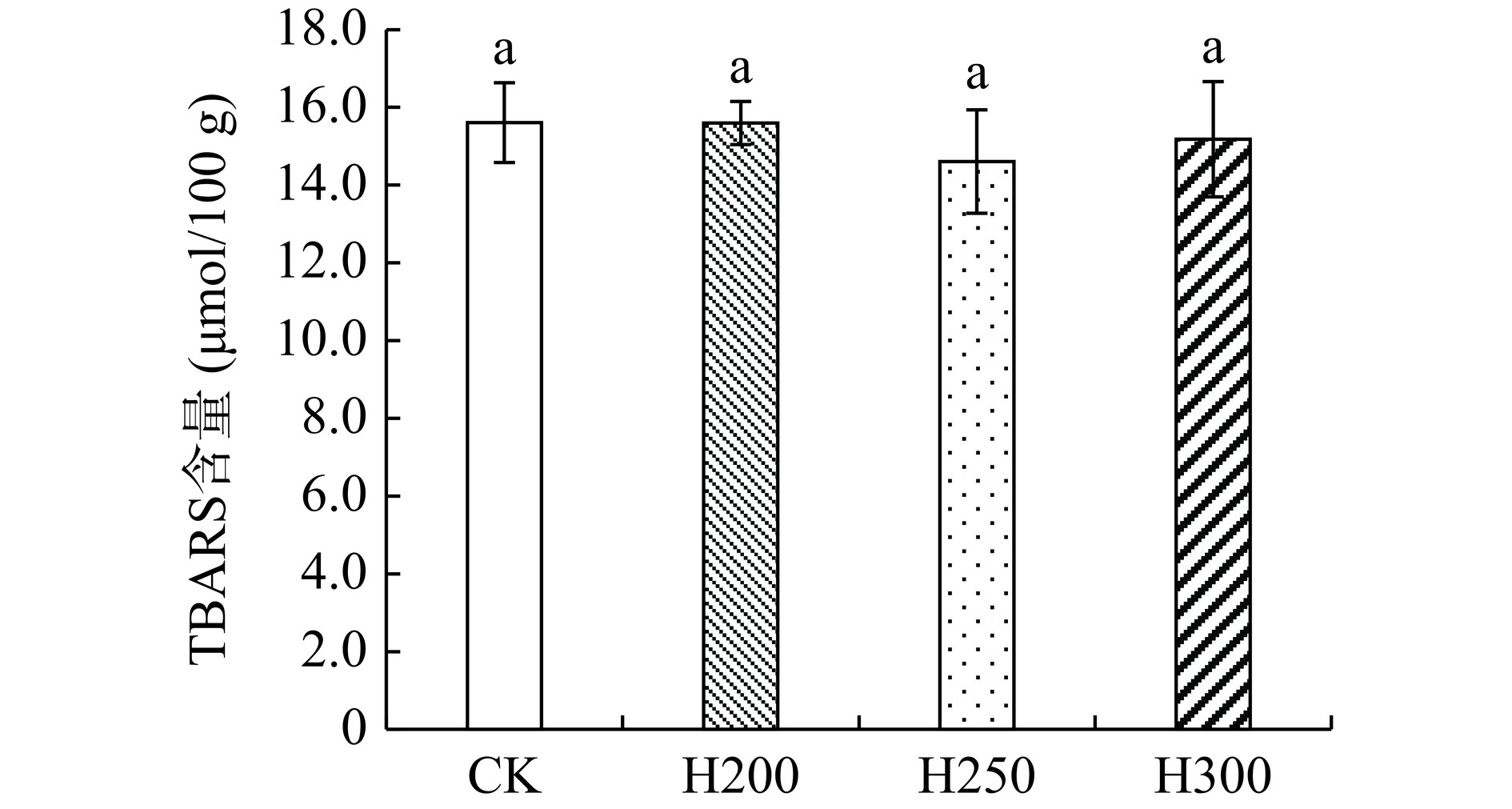

大黄鱼富含不饱和脂肪酸,在加工及贮藏中极易发生脂肪氧化,导致品质发生劣变。如图5所示,200~300 MPa压力下,大黄鱼的脂肪氧化程度未发生明显变化,TBARS值与CK组无显著差异(P>0.05),与鲳鱼[11]、鲍鱼[41]超高压研究结果一致。但另有研究发现,超高压会加速鲜活小龙虾[42]、黑鱼[43]等的脂肪氧化,表明超高压对肌肉脂肪氧化的影响因品种、肌肉类型、压力大小及保压时间等而异。

2.3 超高压杀菌对大黄鱼肌原纤维蛋白特性的影响

2.3.1 表面疏水性

HHP对大黄鱼肌原纤维蛋白表面疏水性的影响如表3所示。与前期研究结果相似[11,42,44−45],超高压诱导了蛋白表面疏水性的增加,压力≥250 MPa时表面疏水性急剧上升,250~300 MPa下较CK组显著提高了45.50%~175.89%(P<0.05),表明肌原纤维蛋白结构发生了构象变化。HHP作用下,大黄鱼肌肉蛋白变性,肽链伸展,分子内部疏水基团暴露,导致表面疏水性上升,肌球蛋白间疏水相互作用增强[46]。

表 3 超高压杀菌对大黄鱼肌原纤维蛋白特性的影响Table 3. Effect of high hydrostatic pressure sterilization on the myofibrillar protein properties of Larimichthys crocea组别 表面疏水性(μg/mg prot) 总巯基含量(nmol/mg prot) 活性巯基含量(nmol/mg prot) Ca2+-ATP酶活性(μmol Pi/mg prot/h) CK 7.36±0.72a 85.01±3.37d 81.31±5.12c 0.74±0.02d H200 7.50±0.70a 57.57±4.14c 45.32±2.04b 0.54±0.02c H250 10.71±1.02b 25.41±1.54b 20.71±1.24a 0.39±0.04b H300 20.32±1.26c 20.52±2.52a 18.29±0.63a 0.16±0.02a 2.3.2 总巯基及活性巯基含量

由表3可以看出,HHP诱发了巯基含量的显著下降(P<0.05),随着压力的升高,总巯基和活性巯基含量均表现为下降趋势,与CK组相比,HHP组总巯基和活性巯基分别下降了32.29%~75.57%、44.26%~77.51%。Li等[45]在虾姑HHP研究中也发现了相似结果,300~350 MPa下虾姑蛋白总巯基和活性巯基含量逐渐下降,且水平显著低于对照组,并认为这可能是由于超高压引发了蛋白活性位点离子键断裂,导致巯基和酪氨酸残基暴露,进而被氧化形成二硫键,导致巯基含量下降。

2.3.3 Ca2+-ATP酶活性

Ca2+-ATP酶活性是反映肌原纤维蛋白变性程度的重要指标。如表3所示,与巯基含量变化趋势一致,HHP处理下Ca2+-ATP酶活性显著下降(P<0.05),其活性分别保留了73.00%、53.11%和21.13%,表明超高压下肌原纤维蛋白发生了不同程度的变性。类似结果也在克氏螯虾[47]、鲳鱼[11]等水产品中被发现。超高压下Ca2+-ATP酶活性的下降可能是由于压力改变了巯基与疏水氨基酸的相互作用,导致蛋白分子间相互作用增强,进而引发蛋白聚合、构象变化,致使酶活下降[45]。另有研究认为巯基,尤其是肌球蛋白头部巯基的氧化是超高压下Ca2+-ATP酶活性下降的另一原因[48],本实验中巯基含量的显著下降正好解释了其活性下降的可能原因。

2.4 超高压杀菌对大黄鱼滋味的影响

2.4.1 呈味核苷酸

IMP、GMP和AMP是呈现鲜甜味的重要核苷酸组分。HHP处理后,大黄鱼中呈味核苷酸含量变化如表4所示。AMP是大黄鱼中的主要呈味核苷酸,其次是GMP和IMP。与CK组相比,HHP显著提高了大黄鱼中的IMP、GMP、AMP及总呈味核苷酸含量,其中H250组最高,分别为CK组的13.07(IMP)倍、1.46(GMP)倍、1.50(AMP)倍和1.53(总呈味核苷酸)倍(P<0.05)。王芝妍等[49]用200 MPa处理中华管鞭虾3 min后也发现AMP和IMP含量显著增加;宣晓婷等[18]在中华绒螯蟹超高压研究中亦得到类似结果。以上结果表明,适当的HHP处理能促进呈味核苷酸的生成,有利于提高大黄鱼鱼肉的鲜甜滋味。

表 4 超高压杀菌对大黄鱼呈味核苷酸、游离氨基酸含量及味精当量的影响Table 4. Effect of high hydrostatic pressure sterilization on the nucleotide contents, free amino acid contents and EUC value of Larimichthys crocea滋味组分 CK H200 H250 H300 呈味核苷酸(mg/100 g湿重) IMP(鲜味) 0.23±0.02a 1.30±0.17b 3.05±0.13c 1.25±0.11b GMP(鲜味) 3.24±0.09a 3.89±0.22b 4.73±0.30c 4.62±0.26c AMP(甜味) 84.69±1.50a 104.89±4.47b 127.33±2.77c 124.79±4.37c 总呈味核苷酸 88.16±1.43a 110.07±4.35b 135.11±2.82c 130.66±4.18c 游离氨基酸(mg/100 g湿重) 天冬氨酸* 3.85±0.19a 5.55±0.17c 5.75±0.48c 4.44±0.18b 谷氨酸* 2.57±0.27a 8.88±0.19c 10.36±0.53d 3.88±0.02b 鲜味氨基酸 6.42±0.32a 14.43±0.35c 16.11±0.80d 8.32±0.18b 丝氨酸** 2.73±0.13a 7.91±0.49c 9.11±0.36d 4.98±0.42b 甘氨酸** 3.40±0.38a 15.13±0.54c 16.59±0.84d 9.36±0.26b 苏氨酸** 6.47±0.35a 13.11±0.52c 15.25±0.50d 10.23±0.60b 丙氨酸** 2.16±0.16a 6.34±0.17c 8.22±0.26d 3.64±0.22b 脯氨酸** 21.39±0.96a 55.48±2.00c 66.96±2.01d 46.58±3.00b 甜味氨基酸 36.15±1.57a 97.97±2.35c 116.13±2.74d 74.80±3.09b 组氨酸 2.86±0.31a 6.77±0.40c 6.34±0.22c 4.09±0.35b 精氨酸 1.78±0.16a 2.05±0.10b 2.75±0.14c 1.97±0.11ab 酪氨酸 0.88±0.03a 2.20±0.21c 2.45±0.07d 1.57±0.12b 缬氨酸 1.32±0.13a 3.24±0.17c 4.95±0.48d 2.30±0.18b 蛋氨酸 0.62±0.03a 0.96±0.02c 1.22±0.03d 0.81±0.06b 胱氨酸 17.11±0.85a 16.93±0.46a 16.84±0.47a 17.07±0.33a 异亮氨酸 1.02±0.09a 2.39±0.11c 3.16±0.33d 1.87±0.21b 亮氨酸 1.53±0.10a 5.72±0.52c 6.75±0.62d 2.46±0.23b 苯丙氨酸 3.04±0.31a 5.55±0.48c 7.44±0.69d 4.05±0.31b 赖氨酸 5.50±0.42a 9.13±0.47b 13.76±0.99c 8.05±0.79b 总氨基酸 78.24±3.00a 167.34±2.23c 197.90±4.03d 127.37±1.32b ECU(g MSG/100 g) 0.08±0.01a 0.34±0.01c 0.50±0.02d 0.18±0.01b 注:*表示鲜味氨基酸,**表示甜味氨基酸;同行不同字母表示同一指标差异显著(P<0.05);表5同。 2.4.2 游离氨基酸

大黄鱼中17种游离氨基酸含量变化如表4所示。超高压下,除胱氨酸外,其他氨基酸含量均显著提高(P<0.05),尤其是250 MPa下,鲜味、甜味、总氨基酸含量分别上升至CK组的2.40倍、3.12倍、2.49倍,鱼肉的鲜、甜味显著增加。宣晓婷等[18]研究发现,超高压可显著提高中华绒螯蟹蟹黄中鲜、甜味氨基酸含量。由表4可知,游离氨基酸含量在200~250 MPa下随着压力增加显著上升(P<0.05),而在300 MPa呈现显著下降趋势(P<0.05),结果与新西兰蛤超高压研究中的相似[50],推测较低压下游离氨基酸浓度的增加可能是由于低压下蛋白酶活性被激活诱发蛋白水解上升,而较高压下游离氨基酸的降低则可能由某些氨基酸代谢途径被激活所引起[50]。

鲜味氨基酸(天冬氨酸、谷氨酸等)与呈味核苷酸具有增鲜协同效应,通常以EUC值进行评价[19]。研究显示,HHP可显著提高中华管鞭虾[49]、鱿鱼[51]等水产品的EUC值,本研究中亦得到了相同结果。如表4所示,HHP后样品的EUC值显著上升至0.18~0.50 g MSG/100 g(P<0.05),为CK组的2.18~5.98倍,表明HHP可大幅提升大黄鱼鱼肉的鲜味,这与超高压诱导呈味核苷酸、鲜味氨基酸显著提升密切相关。

2.5 超高压杀菌对大黄鱼风味的影响

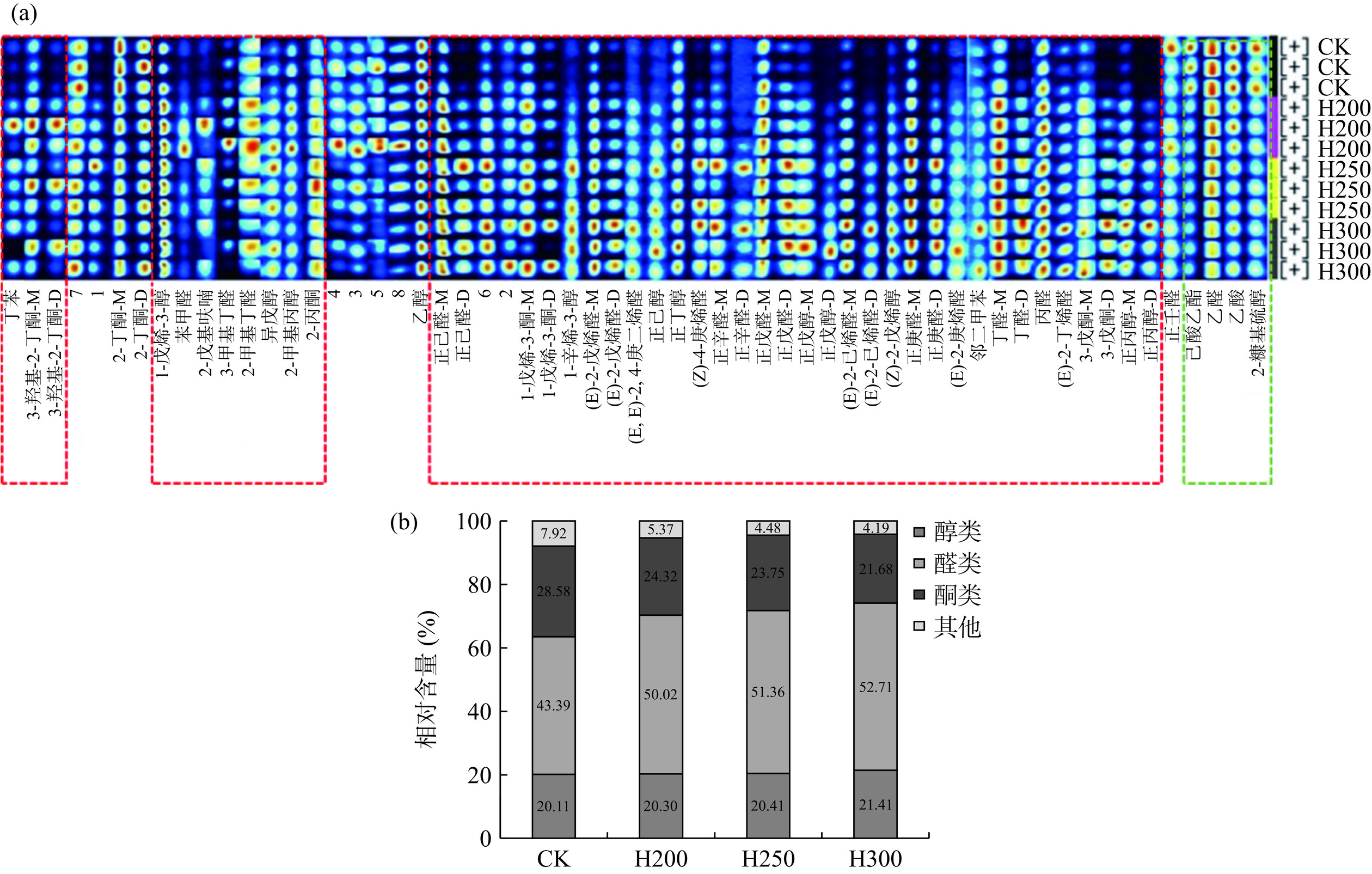

挥发性物质组成是影响水产品风味的重要因素。为探究超高压杀菌对大黄鱼风味的影响,采用GC-IMS对其VOCs变化进行测定。基于GC-IMS分析,共定性得到38种VOCs(表5),包括11种醇、17种醛、5种酮及5种其他类物质。为明确超高压处理后的风味变化,利用网站PubChem(https://pubchem.ncbi.nlm.nih.gov/)、The Good Scents Company Information System(http://www.the good scents company.com/)、食品百科(http://www.foodbk.com/)和Chemical Book(https://m.chemicalbook.com/)对各VOCs的风味特征进行描述,具体描述见表5。

表 5 超高压杀菌对大黄鱼挥发性物质的影响Table 5. Effect of high hydrostatic pressure sterilization on the volatile organic compounds of Larimichthys crocea序号 挥发性物质 保留指数 保留时间(s) 迁移时间(ms) 备注 峰体积 风味特征 CK H200 H250 H300 醇类 1 1-辛烯-3-醇 1462.8 883.673 1.16045 68.26±1.12a 145.57±3.42b 212.07±8.11c 226.77±19.59c 蘑菇味 2 2-糠基硫醇 1434.0 828.586 1.10456 220.58±12.89b 186.81±4.98a 195.07±8.47a 179.91±6.39a 硫磺烧焦烟熏气味 3 正己醇 1376.1 727.735 1.32744 77.85±6.82a 125.38±7.04b 153.16±9.88c 155.40±8.55c 果香、青草香 4 (Z)-2-戊烯醇 1343.1 676.005 0.94604 351.92±19.14a 850.95±52.22b 1078.19±56.74c 1256.92±79.27d 果香、青草香 5 正戊醇 1262.5 543.841 1.25455 M 246.62±2.82a 639.65±46.57b 908.94±40.95c 1136.48±13.57d 杂醇气味 1264.2 546.971 1.50857 D 6 异戊醇 1217.9 467.807 1.24482 104.05±9.49a 182.39±13.45b 178.11±2.83b 164.61±9.01b 果香 7 1-戊烯-3-醇 1171.2 397.964 0.94494 1817.32±82.73a 3044.71±80.30b 3129.05±3.18b 3129.32±21.65b 青草香 8 正丁醇 1155.4 376.099 1.18079 206.45±18.11a 230.86±12.84a 229.60±2.55a 257.54±11.80b 酒精味 9 2-甲基丙醇 1106.7 316.108 1.17096 130.31±6.39a 190.55±11.69d 167.75±4.82c 151.86±1.85b 青香 10 正丙醇 1049.6 263.407 1.112 M 330.55±13.41a 1062.22±74.99b 1444.89±92.24c 1673.53±61.06d 酒香、甜香 1051.1 264.607 1.25105 D 11 乙醇 939.8 193.885 1.12744 2935.64±65.85b 2623.02±25.07a 2769.34±95.38a 2951.79±102.27b 酒精味 小计 6489.55±173.27a 9282.11±236.19b 10466.17±184.77c 11284.13±86.03d 醛类 12 苯甲醛 1504.7 970.549 1.15075 114.12±8.39a 330.43±21.69c 173.82±12.70b 120.98±9.46a 杏仁香、果香 13 (E,E)-2,4-庚二烯醛 1486.5 931.768 1.19366 99.86±6.61a 177.84±11.18b 187.76±10.26b 231.95±8.96c 青草香 14 正壬醛 1401.4 770.237 1.47188 214.97±12.52a 213.43±15.92a 207.24±10.68a 216.02±9.25a 青草香、玫瑰花香 15 (E)-2-庚烯醛 1338.2 668.519 1.25717 28.53±2.49a 46.74±2.51b 58.30±2.20c 70.34±4.52d 青草香 16 正辛醛 1299.5 613.083 1.4076 M 311.57±14.27a 466.46±11.83b 708.35±39.33c 806.16±37.60d 果香 1299.7 613.35 1.82116 D 17 (Z)-4-庚烯醛 1251.7 524.391 1.14741 122.26±5.53a 513.92±26.07b 821.65±49.31c 825.65±62.51c 青草香、果香 18 (E)-2-已烯醛 1227.9 483.936 1.17955 M 321.94±12.63a 707.93±28.98b 885.76±40.04c 1143.00±76.30d 青草香、果香 1228.1 484.198 1.51379 D 19 正庚醛 1193.6 431.043 1.33662 M 1119.32±91.02a 2119.78±76.09b 2721.89±258.04c 2916.87±153.04c 脂肪香 1193.3 430.482 1.69742 D 20 (E)-2-戊烯醛 1145.6 363.203 1.10639 M 844.26±77.69a 1573.44±0.76b 1753.13±75.84c 2267.56±93.37d 青草香、果香 1144.7 362.082 1.36189 D 21 正己醛 1097.1 305.456 1.25941 M 1404.06±136.57a 3332.83±246.02b 4764.77±427.55c 4732.20±314.55c 青草味 1098.6 307.138 1.56265 D 22 (E)-2-丁烯醛 1060.8 272.757 1.03505 267.89±20.15a 417.31±10.35b 444.81±23.99b 552.55±39.14c 辛辣味 23 正戊醛 997.9 224.161 1.185 M 1387.21±136.33a 2315.28±157.15b 2734.62±187.46c 2658.44±157.52c 果香、发酵面包香 998.7 224.721 1.41805 D 24 2-甲基丁醛 922.5 185.73 1.15759 135.15±7.83a 165.90±4.91b 158.58±12.71b 130.86±11.01a 发酵烘培味 25 3-甲基丁醛 924.4 186.604 1.40305 312.12±30.21ab 821.52±79.37c 386.58±28.89b 261.69±28.66a 发酵烘培味 26 丁醛 883.3 168.574 1.11444 M 866.73±70.67a 1949.30±85.43b 2376.89±110.03c 2670.17±78.59d 青草香 884.2 168.929 1.28141 D 27 丙醛 800.7 137.39 1.1448 4800.48±312.31a 6161.73±65.92b 6436.99±358.28bc 6757.36±159.99c 坚果香、酒香 28 乙醛 675.9 100.891 0.95682 1649.36±12.30c 1556.49±36.19b 1512.04±59.52b 1416.50±21.00a 刺激性醛味 小计 13999.83±772.02a 22870.33±678.15b 26333.18±1239.28c 27778.30±662.10c 酮类 29 3-羟基-2-丁酮 1300.6 614.638 1.06018 M 1134.90±71.44a 2304.29±213.51d 1933.98±174.59c 1621.42±148.97b 甜香、脂肪香 1298.9 612.305 1.32954 D 30 1-戊烯-3-酮 1037.1 253.315 1.0769 M 787.33±69.73a 1246.00±116.89b 1563.19±151.48c 1726.93±166.80c 鱼香、甜香 1037.1 253.315 1.30855 D 31 3-戊酮 997 223.501 1.11094 M 267.54±18.15a 723.96±7.08b 943.31±79.40c 1276.27±94.26d 甜香、果香 996.5 223.146 1.3538 D 32 2-丁酮 905.6 178.142 1.06073 M 4662.69±215.99c 3702.89±264.24a 4168.20±186.32b 3650.89±267.80a 果香、青草香 909.6 179.914 1.24404 D 33 2-丙酮 825 145.895 1.11911 2366.95±121.13a 3142.52±166.82b 3566.89±226.57c 3151.47±248.54b 果香 小计 9219.41±60.88a 11119.65±635.29b 12175.57±476.00c 11426.98±656.32bc 其他 34 乙酸 1476.4 911.053 1.05252 1603.03±17.22c 1452.55±48.78b 1305.97±65.12a 1313.10±87.14a 刺激性酸味 35 丁苯 1317.8 638.756 1.22241 125.72±10.89a 353.99±30.16c 358.92±32.46c 276.62±30.54b 36 己酸乙酯 1242.3 508.054 1.34026 693.65±26.32c 462.71±15.99b 441.74±13.86ab 421.12±18.66a 脂肪味 37 2-戊基呋喃 1238.2 501.1 1.25341 27.82±1.81a 64.83±6.90b 77.90±7.17c 64.98±5.14b 果香 38 邻二甲苯 1232.6 491.699 1.06081 103.80±1.22a 119.48±3.20b 114.33±9.57ab 134.91±10.11c 甜香、杏仁香 小计 2554.02±54.41c 2453.56±77.35bc 2298.86±97.07ab 2210.72±105.21a 总计 32262.82±950.70a 45725.65±685.11b 51273.79±1023.14c 52700.13±387.64d 注:M为单体,D为二聚体。 由图6(a)显示,HHP处理后大黄鱼的VOCs指纹图谱发生了明显变化。CK组中含有丰富的2-糠基硫醇(硫磺烧焦烟熏气味)、乙酸(刺激性酸味)、乙醛(刺激性醛味)和己酸乙酯(脂肪味),HHP处理后这些物质信号强度显著降低,表明超高压有助于改善整体风味。HHP后大黄鱼中的VOCs丰富度增加(红框部分),尤其是醇、醛及酮类信号强度明显增强,表明HHP可提高大黄鱼中这些挥发性组分的含量,风味变得浓郁,该结果在定量分析中亦得到了证实(表5)。Ma等[52]在牡蛎中也发现了类似现象,HHP下牡蛎中的醇、醛类VOCs种类及含量均明显上升。周明珠等[53]研究发现,400 MPa处理下鲈鱼中的醇、醛及酮类物质显著提高。

为进一步深入探究HHP处理后大黄鱼的特征VOCs差异,以峰体积值对不同处理组的VOCs进行了定量分析。各处理组VOCs值变化如表5所示,200~300 MPa超高压处理后,样品中的总VOCs值随着压力增加显著提高(P<0.05),分别上升至CK组的1.42倍、1.59倍和1.63倍。Yue等[51]、Ma等[52]、周明珠等[53]在HHP对鱿鱼、牡蛎、鲈鱼挥发性组分影响研究中亦得到了类似结果。

如表5所示,在检测到的11种醇类中,1-辛烯-3-醇、正己醇、(Z)-2-戊烯醇、正戊醇、异戊醇、1-戊烯-3醇、正丁醇、2-甲基丙醇和正丙醇等9种物质在HHP处理后显著上升(P<0.05)。其中,1-戊烯-3-醇的含量较高,HHP下其水平较CK组显著增加了67.54%~72.19%,表明HHP处理赋予了大黄鱼更多的青香。1-辛烯-3-醇、正己醇和异戊醇的气味阈值较低[52,54],具有蘑菇、果香、青香等特征香气,对鱼类的风味起着重要作用,HHP下其值显著上升,大黄鱼的蘑菇、果香等风味大幅提升。

醛类是各组大黄鱼中最主要的挥发性物质(图6(b)),占总VOCs的43%以上,且其阈值较低,因此在大黄鱼的风味中起着重要作用。HHP处理下,除正壬醛、乙醛外,(E,E)-2,4-庚二烯醛、(E)-2-庚烯醛、正辛醛、(Z)-4-庚烯醛、(E)-2-己烯醛、正庚醛、(E)-2-戊烯醛、正己醛、(E)-2-丁烯醛、正戊醛、丙醛、丁醛等12种醛类物质含量均显著上升,苯甲醛、2-甲基丁醛和3-甲基丁醛则在H200组中达到最高,并随着压力增加而逐渐下降(P<0.05)。这些VOCs大多带有果香和青草香,表明HHP可增强大黄鱼的宜人气味。通常认为,醛类是由水产品中多不饱和脂肪酸在脂肪氧合酶作用下形成的氢过氧化物裂解生成[52,55],推测HHP下醛类VOCs的增加可能与超高压下脂肪氧合酶活性的变化有关[56]。

酮类主要由多不饱和脂肪酸、氨基酸降解及美拉德反应产生,具有甜香、花香、果香等特征香气[57]。如表5所示,HHP作用下,样品中的酮类物质(3-羟基-2-丁酮、1-戊烯-3-酮、3-戊酮、2-丙酮和总酮)含量显著上升(P<0.05),表明HHP可能有助于提高大黄鱼的甜香、花香和果香味,这可能与超高压诱发脂肪氧化、氨基酸降解等相关[51,58]。此外,丁苯、2-戊基呋喃(果香)和邻二甲苯(甜香、杏仁味)含量亦显著增加。

综上,HHP处理后大黄鱼的风味发生了明显变化,果香、花香、青香、甜香味增强,整体风味变得浓郁。有研究显示,超高压下VOCs的变化亦与压力作用下美拉德反应、香气物质及其前体物质传质过程、食品基质微观结构等改变相关[56]。

3. 结论

超高压具有良好的减菌效果,且对大黄鱼特征黄色区域体表色泽及脂肪氧化无明显负面影响。200 MPa下,鱼体背部肌肉色泽、pH无显著变化,而回复性、蒸煮损失率则分别显著高于和低于其他组,质构及保水性得到显著提升。200~300 MPa下,随着压力的增加,表面疏水性逐渐上升,巯基含量及Ca2+-ATP酶活性则逐渐下降,蛋白变性程度显著上升。200~300 MPa超高压处理可显著提高大黄鱼的鲜甜滋味,呈味核苷酸、鲜味氨基酸、甜味氨基酸及EUC值较CK组显著增加。GC-IMS分析结果表明,超高压处理后,大黄鱼中的挥发性组分发生了明显变化,尤其是醇类、醛类及酮类等VOCs物质浓度显著增加,果香、花香、青香、甜香味增强,整体风味变得浓郁。

综合减菌效果、色泽、质构、保水性、蛋白变性、滋味、风味等品质指标影响以及使用成本,200 MPa超高压较适用于大黄鱼的减菌加工。超高压在有效杀菌的同时,改善了鱼体的质构特性,并提高了鱼肉的鲜甜滋味及风味,在养殖大黄鱼等水产品保鲜加工中具有潜在的应用前景,值得更深入的研究。

-

表 1 超高压杀菌对大黄鱼背部肌肉色泽的影响

Table 1 Effect of high hydrostatic pressure sterilization on the color of Larimichthys crocea dorsal muscle

表 2 超高压杀菌对大黄鱼质构的影响

Table 2 Effect of high hydrostatic pressure sterilization on the TPA properties of Larimichthys crocea

组别 硬度(N) 弹性 咀嚼性(N) 回复性(%) CK 2.40±0.23a 0.73±0.03a 1.09±0.07a 0.26±0.02a H200 2.41±0.19a 0.72±0.04a 1.31±0.12b 0.31±0.04b H250 2.83±0.25b 0.75±0.02ab 1.52±0.12c 0.27±0.03a H300 4.73±0.30c 0.77±0.04b 2.12±0.13d 0.24±0.04a 表 3 超高压杀菌对大黄鱼肌原纤维蛋白特性的影响

Table 3 Effect of high hydrostatic pressure sterilization on the myofibrillar protein properties of Larimichthys crocea

组别 表面疏水性(μg/mg prot) 总巯基含量(nmol/mg prot) 活性巯基含量(nmol/mg prot) Ca2+-ATP酶活性(μmol Pi/mg prot/h) CK 7.36±0.72a 85.01±3.37d 81.31±5.12c 0.74±0.02d H200 7.50±0.70a 57.57±4.14c 45.32±2.04b 0.54±0.02c H250 10.71±1.02b 25.41±1.54b 20.71±1.24a 0.39±0.04b H300 20.32±1.26c 20.52±2.52a 18.29±0.63a 0.16±0.02a 表 4 超高压杀菌对大黄鱼呈味核苷酸、游离氨基酸含量及味精当量的影响

Table 4 Effect of high hydrostatic pressure sterilization on the nucleotide contents, free amino acid contents and EUC value of Larimichthys crocea

滋味组分 CK H200 H250 H300 呈味核苷酸(mg/100 g湿重) IMP(鲜味) 0.23±0.02a 1.30±0.17b 3.05±0.13c 1.25±0.11b GMP(鲜味) 3.24±0.09a 3.89±0.22b 4.73±0.30c 4.62±0.26c AMP(甜味) 84.69±1.50a 104.89±4.47b 127.33±2.77c 124.79±4.37c 总呈味核苷酸 88.16±1.43a 110.07±4.35b 135.11±2.82c 130.66±4.18c 游离氨基酸(mg/100 g湿重) 天冬氨酸* 3.85±0.19a 5.55±0.17c 5.75±0.48c 4.44±0.18b 谷氨酸* 2.57±0.27a 8.88±0.19c 10.36±0.53d 3.88±0.02b 鲜味氨基酸 6.42±0.32a 14.43±0.35c 16.11±0.80d 8.32±0.18b 丝氨酸** 2.73±0.13a 7.91±0.49c 9.11±0.36d 4.98±0.42b 甘氨酸** 3.40±0.38a 15.13±0.54c 16.59±0.84d 9.36±0.26b 苏氨酸** 6.47±0.35a 13.11±0.52c 15.25±0.50d 10.23±0.60b 丙氨酸** 2.16±0.16a 6.34±0.17c 8.22±0.26d 3.64±0.22b 脯氨酸** 21.39±0.96a 55.48±2.00c 66.96±2.01d 46.58±3.00b 甜味氨基酸 36.15±1.57a 97.97±2.35c 116.13±2.74d 74.80±3.09b 组氨酸 2.86±0.31a 6.77±0.40c 6.34±0.22c 4.09±0.35b 精氨酸 1.78±0.16a 2.05±0.10b 2.75±0.14c 1.97±0.11ab 酪氨酸 0.88±0.03a 2.20±0.21c 2.45±0.07d 1.57±0.12b 缬氨酸 1.32±0.13a 3.24±0.17c 4.95±0.48d 2.30±0.18b 蛋氨酸 0.62±0.03a 0.96±0.02c 1.22±0.03d 0.81±0.06b 胱氨酸 17.11±0.85a 16.93±0.46a 16.84±0.47a 17.07±0.33a 异亮氨酸 1.02±0.09a 2.39±0.11c 3.16±0.33d 1.87±0.21b 亮氨酸 1.53±0.10a 5.72±0.52c 6.75±0.62d 2.46±0.23b 苯丙氨酸 3.04±0.31a 5.55±0.48c 7.44±0.69d 4.05±0.31b 赖氨酸 5.50±0.42a 9.13±0.47b 13.76±0.99c 8.05±0.79b 总氨基酸 78.24±3.00a 167.34±2.23c 197.90±4.03d 127.37±1.32b ECU(g MSG/100 g) 0.08±0.01a 0.34±0.01c 0.50±0.02d 0.18±0.01b 注:*表示鲜味氨基酸,**表示甜味氨基酸;同行不同字母表示同一指标差异显著(P<0.05);表5同。 表 5 超高压杀菌对大黄鱼挥发性物质的影响

Table 5 Effect of high hydrostatic pressure sterilization on the volatile organic compounds of Larimichthys crocea

序号 挥发性物质 保留指数 保留时间(s) 迁移时间(ms) 备注 峰体积 风味特征 CK H200 H250 H300 醇类 1 1-辛烯-3-醇 1462.8 883.673 1.16045 68.26±1.12a 145.57±3.42b 212.07±8.11c 226.77±19.59c 蘑菇味 2 2-糠基硫醇 1434.0 828.586 1.10456 220.58±12.89b 186.81±4.98a 195.07±8.47a 179.91±6.39a 硫磺烧焦烟熏气味 3 正己醇 1376.1 727.735 1.32744 77.85±6.82a 125.38±7.04b 153.16±9.88c 155.40±8.55c 果香、青草香 4 (Z)-2-戊烯醇 1343.1 676.005 0.94604 351.92±19.14a 850.95±52.22b 1078.19±56.74c 1256.92±79.27d 果香、青草香 5 正戊醇 1262.5 543.841 1.25455 M 246.62±2.82a 639.65±46.57b 908.94±40.95c 1136.48±13.57d 杂醇气味 1264.2 546.971 1.50857 D 6 异戊醇 1217.9 467.807 1.24482 104.05±9.49a 182.39±13.45b 178.11±2.83b 164.61±9.01b 果香 7 1-戊烯-3-醇 1171.2 397.964 0.94494 1817.32±82.73a 3044.71±80.30b 3129.05±3.18b 3129.32±21.65b 青草香 8 正丁醇 1155.4 376.099 1.18079 206.45±18.11a 230.86±12.84a 229.60±2.55a 257.54±11.80b 酒精味 9 2-甲基丙醇 1106.7 316.108 1.17096 130.31±6.39a 190.55±11.69d 167.75±4.82c 151.86±1.85b 青香 10 正丙醇 1049.6 263.407 1.112 M 330.55±13.41a 1062.22±74.99b 1444.89±92.24c 1673.53±61.06d 酒香、甜香 1051.1 264.607 1.25105 D 11 乙醇 939.8 193.885 1.12744 2935.64±65.85b 2623.02±25.07a 2769.34±95.38a 2951.79±102.27b 酒精味 小计 6489.55±173.27a 9282.11±236.19b 10466.17±184.77c 11284.13±86.03d 醛类 12 苯甲醛 1504.7 970.549 1.15075 114.12±8.39a 330.43±21.69c 173.82±12.70b 120.98±9.46a 杏仁香、果香 13 (E,E)-2,4-庚二烯醛 1486.5 931.768 1.19366 99.86±6.61a 177.84±11.18b 187.76±10.26b 231.95±8.96c 青草香 14 正壬醛 1401.4 770.237 1.47188 214.97±12.52a 213.43±15.92a 207.24±10.68a 216.02±9.25a 青草香、玫瑰花香 15 (E)-2-庚烯醛 1338.2 668.519 1.25717 28.53±2.49a 46.74±2.51b 58.30±2.20c 70.34±4.52d 青草香 16 正辛醛 1299.5 613.083 1.4076 M 311.57±14.27a 466.46±11.83b 708.35±39.33c 806.16±37.60d 果香 1299.7 613.35 1.82116 D 17 (Z)-4-庚烯醛 1251.7 524.391 1.14741 122.26±5.53a 513.92±26.07b 821.65±49.31c 825.65±62.51c 青草香、果香 18 (E)-2-已烯醛 1227.9 483.936 1.17955 M 321.94±12.63a 707.93±28.98b 885.76±40.04c 1143.00±76.30d 青草香、果香 1228.1 484.198 1.51379 D 19 正庚醛 1193.6 431.043 1.33662 M 1119.32±91.02a 2119.78±76.09b 2721.89±258.04c 2916.87±153.04c 脂肪香 1193.3 430.482 1.69742 D 20 (E)-2-戊烯醛 1145.6 363.203 1.10639 M 844.26±77.69a 1573.44±0.76b 1753.13±75.84c 2267.56±93.37d 青草香、果香 1144.7 362.082 1.36189 D 21 正己醛 1097.1 305.456 1.25941 M 1404.06±136.57a 3332.83±246.02b 4764.77±427.55c 4732.20±314.55c 青草味 1098.6 307.138 1.56265 D 22 (E)-2-丁烯醛 1060.8 272.757 1.03505 267.89±20.15a 417.31±10.35b 444.81±23.99b 552.55±39.14c 辛辣味 23 正戊醛 997.9 224.161 1.185 M 1387.21±136.33a 2315.28±157.15b 2734.62±187.46c 2658.44±157.52c 果香、发酵面包香 998.7 224.721 1.41805 D 24 2-甲基丁醛 922.5 185.73 1.15759 135.15±7.83a 165.90±4.91b 158.58±12.71b 130.86±11.01a 发酵烘培味 25 3-甲基丁醛 924.4 186.604 1.40305 312.12±30.21ab 821.52±79.37c 386.58±28.89b 261.69±28.66a 发酵烘培味 26 丁醛 883.3 168.574 1.11444 M 866.73±70.67a 1949.30±85.43b 2376.89±110.03c 2670.17±78.59d 青草香 884.2 168.929 1.28141 D 27 丙醛 800.7 137.39 1.1448 4800.48±312.31a 6161.73±65.92b 6436.99±358.28bc 6757.36±159.99c 坚果香、酒香 28 乙醛 675.9 100.891 0.95682 1649.36±12.30c 1556.49±36.19b 1512.04±59.52b 1416.50±21.00a 刺激性醛味 小计 13999.83±772.02a 22870.33±678.15b 26333.18±1239.28c 27778.30±662.10c 酮类 29 3-羟基-2-丁酮 1300.6 614.638 1.06018 M 1134.90±71.44a 2304.29±213.51d 1933.98±174.59c 1621.42±148.97b 甜香、脂肪香 1298.9 612.305 1.32954 D 30 1-戊烯-3-酮 1037.1 253.315 1.0769 M 787.33±69.73a 1246.00±116.89b 1563.19±151.48c 1726.93±166.80c 鱼香、甜香 1037.1 253.315 1.30855 D 31 3-戊酮 997 223.501 1.11094 M 267.54±18.15a 723.96±7.08b 943.31±79.40c 1276.27±94.26d 甜香、果香 996.5 223.146 1.3538 D 32 2-丁酮 905.6 178.142 1.06073 M 4662.69±215.99c 3702.89±264.24a 4168.20±186.32b 3650.89±267.80a 果香、青草香 909.6 179.914 1.24404 D 33 2-丙酮 825 145.895 1.11911 2366.95±121.13a 3142.52±166.82b 3566.89±226.57c 3151.47±248.54b 果香 小计 9219.41±60.88a 11119.65±635.29b 12175.57±476.00c 11426.98±656.32bc 其他 34 乙酸 1476.4 911.053 1.05252 1603.03±17.22c 1452.55±48.78b 1305.97±65.12a 1313.10±87.14a 刺激性酸味 35 丁苯 1317.8 638.756 1.22241 125.72±10.89a 353.99±30.16c 358.92±32.46c 276.62±30.54b 36 己酸乙酯 1242.3 508.054 1.34026 693.65±26.32c 462.71±15.99b 441.74±13.86ab 421.12±18.66a 脂肪味 37 2-戊基呋喃 1238.2 501.1 1.25341 27.82±1.81a 64.83±6.90b 77.90±7.17c 64.98±5.14b 果香 38 邻二甲苯 1232.6 491.699 1.06081 103.80±1.22a 119.48±3.20b 114.33±9.57ab 134.91±10.11c 甜香、杏仁香 小计 2554.02±54.41c 2453.56±77.35bc 2298.86±97.07ab 2210.72±105.21a 总计 32262.82±950.70a 45725.65±685.11b 51273.79±1023.14c 52700.13±387.64d 注:M为单体,D为二聚体。 -

[1] MA X, MEI J, XIE J. Effects of multi-frequency ultrasound on the freezing rates, quality properties and structural characteristics of cultured large yellow croaker (Larimichthys crocea)[J]. Ultrasonics Sonochemistry,2021,76:105657. doi: 10.1016/j.ultsonch.2021.105657

[2] SUN X Y, BAO N, RUI C, et al. Identification of large yellow croakers (Larimichthys crocea) scavenger receptor genes:Involvement in immune response to Pseudomonas plecoglossicida infection and hypoxia-exposure experiments[J]. Fish and Shellfish Immunology,2024,144:109307. doi: 10.1016/j.fsi.2023.109307

[3] YAN Q, GUO M, CHEN B, et al. Molecular characterization of spoilage microbiota in high CO2 refrigerated large yellow croaker (Larimichthys crocea) fillets using metagenomic and metabolomic approaches[J]. Food Bioscience,2023,56:103227. doi: 10.1016/j.fbio.2023.103227

[4] HUANG H W, WU S J, LU J K, et al. Current status and future trends of high-pressure processing in food industry[J]. Food Control,2017,72:1−8. doi: 10.1016/j.foodcont.2016.07.019

[5] WU S H, YANG R J. Effect of high-pressure processing on polyphenol oxidase, melanosis and quality in ready-to-eat crabs during storage[J]. LWT,2023,178:114607. doi: 10.1016/j.lwt.2023.114607

[6] AHMED J, HABEEBULLAH S F K, ALAGARSAMY S, et al. Impact of high-pressure treatment on amino acid profile, fatty acid compositions, and texture of yellowfin seabream (Acanthopagrus arabicus) filets[J]. Frontiers in Sustainable Food Systems,2022,6:857072. doi: 10.3389/fsufs.2022.857072

[7] 杨华, 陆森超, 张慧恩, 等. 超高压处理对养殖大黄鱼风味及品质的影响[J]. 食品科学,2014(16):244−249. [YANG H, LU S C, ZHANG H E, et al. Effects of high hydrostatic pressure processing on the flavor and quality of cultured yellow croaker (Pseudosciaena crocea)[J]. Food Science,2014(16):244−249.] YANG H, LU S C, ZHANG H E, et al. Effects of high hydrostatic pressure processing on the flavor and quality of cultured yellow croaker (Pseudosciaena crocea)[J]. Food Science, 2014(16): 244−249.

[8] 雷叶斯, 陈娇, 张登科, 等. 超高压处理对养殖大黄鱼肉肌原纤维蛋白理化特性的影响[J]. 食品安全质量检测学报,2018,8:1750−1758. [LEI Y S, CHEN J, ZHANG D K, et al. Effects of high hydrostatic pressure processing on the physicochemical properties of myofibrillar protein of cultured large yellow croaker[J]. Journal of Food Safety and Quality,2018,8:1750−1758.] LEI Y S, CHEN J, ZHANG D K, et al. Effects of high hydrostatic pressure processing on the physicochemical properties of myofibrillar protein of cultured large yellow croaker[J]. Journal of Food Safety and Quality, 2018, 8: 1750−1758.

[9] 张登科, 张慧恩, 朱艳杰, 等. 超高压处理对养殖大黄鱼肌原纤维蛋白结构的影响[J]. 食品科学,2019,40(9):61−67. [ZHANG D K, ZHANG H E, ZHU Y J, et al. Effect of high hydrostatic pressure treatment on myofibrillar protein structure of cultured large yellow croaker[J]. Food Science,2019,40(9):61−67.] ZHANG D K, ZHANG H E, ZHU Y J, et al. Effect of high hydrostatic pressure treatment on myofibrillar protein structure of cultured large yellow croaker[J]. Food Science, 2019, 40(9): 61−67.

[10] 杨华, 梅清清, 张慧恩. 超高压处理和贮藏对养殖大黄鱼中微生物、酶及风味的影响[J]. 食品科学,2013,34(21):209−216. [YANG H, MEI Q Q, ZHANG H E. Effect of high hydrostatic pressure and storage on microorganisms, enzymes and flavor compounds in cultured yellow croaker (Pseudosciaena crocea)[J]. Food Science,2013,34(21):209−216.] YANG H, MEI Q Q, ZHANG H E. Effect of high hydrostatic pressure and storage on microorganisms, enzymes and flavor compounds in cultured yellow croaker (Pseudosciaena crocea)[J]. Food Science, 2013, 34(21): 209−216.

[11] CUI Y, XUAN X T, LING J G, et al. Effects of high hydrostatic pressure-assisted thawing on the physicohemical characteristics of silver pomfret (Pampus argenteus)[J]. Food Science and Nutrition,2019,7(5):1573−1583. doi: 10.1002/fsn3.966

[12] ZHANG L M, YU D W, XU Y S, et al. Changes in quality and microbial diversity of refrigerated carp fillets treated by chitosan/zein bilayer film with curcumin/nisin-loaded pectin nanoparticles[J]. Food Bioscience,2023,54:102941. doi: 10.1016/j.fbio.2023.102941

[13] YANG H J, CHEN Z Z, WANG H F, et al. Uncovering the rheological properties basis for freeze drying treatment-induced improvement in the solubility of myofibrillar proteins[J]. Current Research in Food Science,2024,8:100651. doi: 10.1016/j.crfs.2023.100651

[14] HE D, YI X, XIA G, et al. Effects of fish oil on the gel properties and emulsifying stability of myofibrillar proteins:A comparative study of tilapia, hairtail and squid[J]. LWT,2022,161:113373. doi: 10.1016/j.lwt.2022.113373

[15] ELLMAN G L. Tissue sulfhydryl groups[J]. Archives of Biochemistry and Biophysics,1959,82(1):70−77. doi: 10.1016/0003-9861(59)90090-6

[16] CHOI Y J, PARK J W. Acid-aided protein recovery from enzyme-rich Pacific whiting[J]. Journal of Food Science,2002,67(8):2962−2967. doi: 10.1111/j.1365-2621.2002.tb08846.x

[17] DUAN Z L, ZHOU Y G, LIU W J, et al. Variations in flavor according to fish size in rainbow trout (Oncorhynchus mykiss)[J]. Aquaculture,2020,526:735398. doi: 10.1016/j.aquaculture.2020.735398

[18] 宣晓婷, 王瑛, 尚海涛, 等. 超高压辅助中华绒螯蟹脱壳及对其品质的影响[J]. 沈阳农业大学学报,2023,54(2):149−156. [XUAN X T, WANG Y, SHANG H T, et al. Effects of high pressure processing on the shucking and quality of Chinese mitten crab (Eriocheir sinensis)[J]. Journal of Shenyang Agricultural University,2023,54(2):149−156.] XUAN X T, WANG Y, SHANG H T, et al. Effects of high pressure processing on the shucking and quality of Chinese mitten crab (Eriocheir sinensis)[J]. Journal of Shenyang Agricultural University, 2023, 54(2): 149−156.

[19] LÜ Y A, BAI X T, ZHAO H L, et al. Flavor characteristics of large yellow croaker soup served with different dried edible fungi[J]. Food Chemistry:X,2024,21:101059.

[20] WU Y, WU Q, LIN H, et al. Effects of cold atmospheric plasma pre-treatment on maintaining the quality of ready-to-eat drunken red shrimp (Solenocera crassicornis) stored at chilled conditions[J]. Food Chemistry:X,2023,20:100934.

[21] CHEN L H, JIAO D X, ZHOU B H, et al. Shrimp (Penaeus monodon) preservation by using chitosan and tea polyphenol coating combined with high-pressure processing[J]. Food Science and Nutrition,2022,10(10):3395−3404. doi: 10.1002/fsn3.2939

[22] TSIRONI T, ANJOS L, PINTO P I S, et al. High pressure processing of European sea bass (Dicentrarchus labrax) fillets and tools for flesh quality and shelf life monitoring[J]. Journal of Food Engineering,2019,262:83−91. doi: 10.1016/j.jfoodeng.2019.05.010

[23] 赵宏强. 超高压处理对冷藏鲈鱼片品质变化的影响及对腐败希瓦氏菌的作用机制研究[D]. 上海:上海海洋大学, 2018:42−49. [ZHAO H Q. Effects of high hydrostatic pressure (HHP) treatment on the quality of Lateolabrax japonicus during chilled storage and its antibactial mechanism[D]. Shanghai:Shanghai Ocean University, 2018:42−49.] ZHAO H Q. Effects of high hydrostatic pressure (HHP) treatment on the quality of Lateolabrax japonicus during chilled storage and its antibactial mechanism[D]. Shanghai: Shanghai Ocean University, 2018: 42−49.

[24] TRUONG B Q, BUCKOW R, STATHOPOULOS C E, et al. Advances in high-pressure processing of fish muscles[J]. Food Engineering Reviews,2015,7(2):109−129. doi: 10.1007/s12393-014-9084-9

[25] AMANATIDOU A, SCHLÜTER O, LEMKAU K, et al. Effect of combined application of high pressure treatment and modified atmospheres on the shelf life of fresh Atlantic salmon[J]. Innovative Food Science and Emerging Technologies,2000,1(2):87−98. doi: 10.1016/S1466-8564(00)00007-2

[26] HUANG H W, LUNG H M, YANG B B, et al. Responses of microorganisms to high hydrostatic pressure processing[J]. Food Control,2014,40:250−259. doi: 10.1016/j.foodcont.2013.12.007

[27] GEORGET E, SEVENICH R, REINEKE K, et al. Inactivation of microorganisms by high isostatic pressure processing in complex matrices:A review[J]. Innovative Food Science and Emerging Technologies,2015,27:1−14. doi: 10.1016/j.ifset.2014.10.015

[28] HUMAID S, NAYYAR D, BOLTON J, et al. Physicochemical properties and consumer acceptance of high-pressure processed, sous vide-cooked lobster tails[J]. Journal of Food Science,2019,84(12):3454−3462. doi: 10.1111/1750-3841.14954

[29] HUANG C H, LIN C S, LEE Y C, et al. Quality improvement in mackerel fillets caused by brine salting combined with high-pressure processing[J]. Biology-Basel,2022,11(9):1307.

[30] TSAI Y H, KUNG H F, LIN C S, et al. Combined effect of brine salting and high-hydrostatic-pressure processing to improve the microbial quality and physicochemical properties of milkfish fillet[J]. International Journal of Food Properties,2022,25(1):872−884. doi: 10.1080/10942912.2022.2066120

[31] 叶安妮. 超高压处理不同水产品的品质变化及其机理研究[D]. 广州:华南理工大学, 2019:37-38. [YE A N. Study on high pressure process on quality changes of different aquatic products and its mechanism[D]. Guangzhou:South China University of Technology, 2019:37-38.] YE A N. Study on high pressure process on quality changes of different aquatic products and its mechanism[D]. Guangzhou: South China University of Technology, 2019: 37-38.

[32] 马荣荣. 超高压技术对鳗鱼鱼糜品质和肌原纤维蛋白性能的影响及其关联性的研究[D]. 厦门:厦门大学, 2019:22−23. [MA R R. Effects of high hydrostatic pressure on the quality of eel surimi and the properties of myofibrillar protein and the correlation between them[D]. Xiamen:Xiamen University, 2019:22−23.] MA R R. Effects of high hydrostatic pressure on the quality of eel surimi and the properties of myofibrillar protein and the correlation between them[D]. Xiamen: Xiamen University, 2019: 22−23.

[33] TEIXEIRA B, FIDALGO L, MENDES R, et al. Effect of high pressure processing in the quality of sea bass (Dicentrarchus labrax) fillets:Pressurization rate, pressure level and holding time[J]. Innovative Food Science and Emerging Technologies,2014,22:31−39. doi: 10.1016/j.ifset.2013.12.005

[34] YAGIZ Y, KRISTINSSON H G, BALABAN M O, et al. Effect of high pressure processing and cooking treatment on the quality of Atlantic salmon[J]. Food Chemistry,2009,116(4):828−835. doi: 10.1016/j.foodchem.2009.03.029

[35] YAGIZ Y, KRISTINSSON H G, BALABAN M O, et al. Effect of high pressure treatment on the quality of rainbow trout (Oncorhynchus mykiss) and mahi mahi (Coryphaena hippurus)[J]. Journal of Food Science,2010,72(9):509−515.

[36] ANGSUPANICH K, LEDWARD D A. High pressure treatment effects on cod (Gadus morhua) muscle[J]. Food Chemistry,1998,63(1):39−50. doi: 10.1016/S0308-8146(97)00234-3

[37] SINGHA K K R, SWAMI HULLE N R, DEB S, et al. Physicochemical and microbiological characteristics of high-pressure-processed ready-to-eat hilsa (Tenualosa ilisha) curry[J]. Journal of Biosystems Engineering,2020,45(2):94−103. doi: 10.1007/s42853-020-00049-8

[38] OLIVEIRA F A D, NETO O C, SANTOS L M R D, et al. Effect of high pressure on fish meat quality-A review[J]. Trends in Food Science and Technology,2017,66:1−19. doi: 10.1016/j.jpgs.2017.04.014

[39] YANG H J, HAN M Y, WANG X, et al. Effect of high pressure on cooking losses and functional properties of reduced-fat and reduced-salt pork sausage emulsions[J]. Innovative Food Science and Emerging Technologies,2015,29:125−133. doi: 10.1016/j.ifset.2015.02.013

[40] HEDGES N D, GOODBAND R M. The influence of high hydrostatic pressure on the water holding capacity of fish muscle[C]//11-14 first joint trans-atlantic fisheries technology conference-TAFT 2003 33rd WEFTA and 48th AFTC meetings. Reykjavik-Iceland:Innovative handling and processing, 2003:48−50.

[41] JO Y J, JUNG K H, LEE M Y, et al. Effect of high-pressure short-time processing on the physicochemical properties of abalone (Haliotis discus Hannai) during refrigerated storage[J]. Innovative Food Science and Emerging Technologies,2014,23:33−38. doi: 10.1016/j.ifset.2014.02.011

[42] 叶韬, 陈志娜, 吴盈盈, 等. 超高压对鲜活小龙虾脱壳效率, 肌原纤维蛋白和蒸煮特性的影响[J]. 食品与发酵工业,2020,46(1):149−156. [YE T, CHEN Z N, WU Y Y, et al. Impact of high pressure processing on the shelling efficacy, myofibrillar protein, and cooking characteristics of fresh crayfish[J]. Food and Fermentation Industries,2020,46(1):149−156.] YE T, CHEN Z N, WU Y Y, et al. Impact of high pressure processing on the shelling efficacy, myofibrillar protein, and cooking characteristics of fresh crayfish[J]. Food and Fermentation Industries, 2020, 46(1): 149−156.

[43] 孙良格, 徐佳美, 吕经秀, 等. 肌肽联合超高压对黑鱼肉脂质氧化及肌原纤维蛋白的影响[J]. 食品工业科技,2022,43(4):114−122. [SUN L G, XU J M, LÜ J X, et al. Effects of carnosine combined with ultra high pressure on the lipid oxidation and myofibrillary protein of snakehead fish[J]. Science and Technology of Food Industry,2022,43(4):114−122.] SUN L G, XU J M, LÜ J X, et al. Effects of carnosine combined with ultra high pressure on the lipid oxidation and myofibrillary protein of snakehead fish[J]. Science and Technology of Food Industry, 2022, 43(4): 114−122.

[44] 吴顺红. 超高压技术对生腌醉蟹品质的影响及其对蟹黑斑形成的调控机制[D]. 无锡:江南大学, 2023:41−42. [WU S H. Effects of HPP on the quality of wine-marinade crab and its regulation mechanism on the formation of crab melanosis[D]. Wuxi:Jiangnan University, 2023:41−42.] WU S H. Effects of HPP on the quality of wine-marinade crab and its regulation mechanism on the formation of crab melanosis[D]. Wuxi: Jiangnan University, 2023: 41−42.

[45] LI G S, CHEN Y T, XUAN S F, et al. Effects of ultra-high pressure on the biochemical properties and secondary structure of myofibrillar protein from Oratosquilla oratoria muscle[J]. Journal of Food Process Engineering,2019,42(6):e13231. doi: 10.1111/jfpe.13231

[46] 闫春子. 超高压处理对淡水鱼冷藏保鲜效果的影响[D]. 无锡:江南大学, 2016:40-41. [YAN C Z. Effect of ultra-high pressure treatment on preservation of freshwater fish during refrigerated storage [D]. Wuxi:Jiangnan University, 2016:40-41.] YAN C Z. Effect of ultra-high pressure treatment on preservation of freshwater fish during refrigerated storage [D]. Wuxi: Jiangnan University, 2016: 40-41.

[47] SHI L, XIONG G Q, YIN T, et al. Effects of ultra-high pressure treatment on the protein denaturation and water properties of red swamp crayfish (Procambarus clarkia)[J]. LWT,2020,133:110124. doi: 10.1016/j.lwt.2020.110124

[48] WANG T T, LI Z X, MI N S, et al. Effects of brown algal phlorotannins and ascorbic acid on the physiochemical properties of minced fish (Pagrosomus major) during freeze–thaw cycles[J]. International Journal of Food Science and Technology, 2017, 52(3).

[49] 王芝妍, 官爱艳, 吕梁玉, 等. 超高压处理对中华管鞭虾虾肉风味的影响[J]. 食品科学,2017,38(18):156−162. [WANG Z Y, GUAN A Y, LÜ L Y, et al. Effect of ultra-high pressure (UHP) on the flavor of Solenocera melantho meat[J]. Food Science,2017,38(18):156−162.] WANG Z Y, GUAN A Y, LÜ L Y, et al. Effect of ultra-high pressure (UHP) on the flavor of Solenocera melantho meat[J]. Food Science, 2017, 38(18): 156−162.

[50] HOW M S, HAMID N, LIU Y, et al. Using OPLS-DA to fingerprint key free amino and fatty acids in understanding the influence of high pressure processing in New Zealand clams[J]. Foods,2023,12(6):1162. doi: 10.3390/foods12061162

[51] YUE J, ZHANG Y F, JIN Y F, et al. Impact of high hydrostatic pressure on non-volatile and volatile compounds of squid muscles[J]. Food Chemistry,2016,194:12−19. doi: 10.1016/j.foodchem.2015.07.134

[52] MA Y Y, WANG R F, ZHANG T T, et al. High hydrostatic pressure treatment of oysters (Crassostrea gigas)-Impact on physicochemical properties, texture parameters, and volatile flavor compounds[J]. Molecules,2021,26(19):5731. doi: 10.3390/molecules26195731

[53] 周明珠, 乔宇, 廖李, 等. 超高压处理不同时间对鲈鱼挥发性风味的影响[J]. 食品科技,2019,44(12):125−130. [ZHOU M Z, QIAO Y, LIAO L, et al. Effect of ultra-high pressure treatment on volatile flavor of bass at different time[J]. Food Science and Technology,2019,44(12):125−130.] ZHOU M Z, QIAO Y, LIAO L, et al. Effect of ultra-high pressure treatment on volatile flavor of bass at different time[J]. Food Science and Technology, 2019, 44(12): 125−130.

[54] LEI Y L, AI M Y, LU S F, et al. Effect of raw material frozen storage on physicochemical properties and flavor compounds of fermented mandarin fish (Siniperca chuatsi)[J]. Food Chemistry:X,2023,20:101027.

[55] 周蓓蓓, 陈小雷, 鲍俊杰, 等. ROAV法分析超高压处理对小龙虾仁关键挥发性成分的影响[J]. 食品工业科技,2018,39(8):215−220,225. [ZHU B B, CHEN X L, BAO J J, et al. Analysis of ultra high pressure treatment influence on key volatile components of Freshwater Crawfish tailmeat by ROAV[J]. Science and Technology of Food Industry,2018,39(8):215−220,225.] ZHU B B, CHEN X L, BAO J J, et al. Analysis of ultra high pressure treatment influence on key volatile components of Freshwater Crawfish tailmeat by ROAV[J]. Science and Technology of Food Industry, 2018, 39(8): 215−220,225.

[56] XIA Q, ZHENG Y R, LIU Z M, et al. Nonthermally driven volatilome evolution of food matrices:The case of high pressure processing[J]. Trends in Food Science and Technology,2020,106:365−381. doi: 10.1016/j.jpgs.2020.10.026

[57] LUO X Y, XIAO S T, RUAN Q F, et al. Differences in flavor characteristics of frozen surimi products reheated by microwave, water boiling, steaming, and frying[J]. Food Chemistry,2022,372:131260. doi: 10.1016/j.foodchem.2021.131260

[58] CRUZ-ROMERO M C, KERRY J P, KELLY A L. Fatty acids, volatile compounds and colour changes in high-pressure-treated oysters (Crassostrea gigas)[J]. Innovative Food Science and Emerging Technologies,2008,9(1):54−61. doi: 10.1016/j.ifset.2007.05.003

下载:

下载:

下载:

下载: