Suitability of Different Cuts of Yak Meat for Shabu-shabu Processing

-

摘要: 本研究以牦牛肉大黄瓜条、外脊、臀肉、上脑、肩肉、腱子为研究对象,分析其涮制前营养品质、肌纤维特性、理化特性和涮制加工后理化性质及食用品质指标差异,采用相关性分析、主成分分析和聚类分析方法确定涮制加工的关键品质指标。结果表明,牦牛原料肉红度值a*、脂肪含量、加压失水率、凝胶硬度、涮制后黄度值b*、咀嚼性为涮制加工关键品质指标,建立涮制牦牛肉综合品质评价方程:Y=0.1644X1+0.0561X2+0.3630X3+0.1102X4+0.1609X5+0.1453X6。根据涮制牦牛肉综合品质评价方程计算出各部位肉得分(Y),再由K-means聚类分析得出不同部位牦牛肉涮制加工适宜性,最终结果表明,牦牛肉上脑和大黄瓜条Y值大于等于0.61,适宜涮制;外脊和臀肉Y值在0.50~0.61之间,较适宜涮制;而腱子和肩肉Y值小于等于0.50,不适宜涮制。以涮制牦牛肉的综合品质得分为自变量、消费者的感官评价整体可接受性得分为因变量,建立回归方程y=5.0914x−2.2958(R²=0.8232),进一步证明了该综合品质评价模型能够准确地评估不同部位牦牛肉的涮制加工适宜性。本实验明确了不同部位牦牛肉涮制加工适宜性,为牦牛肉涮制加工的合理化及标准化提供依据。Abstract: This study examined the silverside, striploin, rump, high rib, shoulder, and shank of yak meat. Specifically, the differences in nutritional quality, muscle fiber characteristics, and physicochemical properties before shabu-shabu processing, as well as physicochemical properties and edible quality indices after shabu-shabu processing were analyzed. Through correlation analysis, principal component analysis (PCA), and cluster analysis, key quality indicators for shabu-shabu yak meat processing were identified. Rsults showed that, the raw yak meat redness (a*), fat content, water loss rate under pressure, gel hardness, shabu-shabu yak meat yellowness (b*), and chewiness were the key quality indicators for shabu-shabu yak meat processing. A comprehensive quality evaluation equation for shabu-shabu yak meat was established: Y=0.1644X1+0.0561X2+0.3630X3+0.1102X4+0.1609X5+0.1453X6. This equation was employed to calculate scores for different shabu-shabu yak meat cuts. K-means cluster analysis was used to assess the suitability of various cuts for shabu-shabu processing, indicating that high rib and silverside cuts with Y values greater than or equal to 0.61 were suitable, striploin and rump with Y values between 0.50 and 0.61 were relatively suitable, and shank and shoulder with Y values less than or equal to 0.50 were unsuitable. The regression equation, y=5.0914x−2.2958 (R²=0.8232), correlating comprehensive quality scores as the independent variable with overall acceptability scores of consumer sensory evaluations as the dependent variable, validates the accuracy of the quality assessment model in determining the suitability of different yak meat cuts for shabu-shabu. This study provides distinct evidence validating the suitability of different yak meat cuts for shabu-shabu, as well as a basis for the rationalization and standardization of yak meat processing.

-

Keywords:

- yak meat /

- shabu-shabu /

- different cuts /

- processing suitability

-

随着近年来电商等新型销售形式的兴起,以及以冷链物流为代表的配送体系的不断发展,牦牛产品的消费范围已经由西藏、青海等地区的小范围区域性消费,逐渐转变为全国范围内的常态化消费[1]。有数据表明,到2023年全国牦牛肉消费总量的近半数都来源于非牦牛产区,并呈现出持续增长的态势[2]。

牦牛肉凭借其高蛋白、低脂、低胆固醇等特性,受到了人们越来越多的关注[3]。“绿色、健康”正在成为影响消费者购买产品的重要因素,与传统的炖煮和卤制牛肉相比,涮制作为一种烹饪方式,具有耗时短、操作简单方便的特点,更符合现代人快节奏的生活方式,因此越来越受到人们的喜爱。涮制,也称速煮法,是以100 ℃左右高温沸腾的水为介质,将切好的原料肉薄片在沸水中烫制数秒,捞出即可食用。该方法完成升温处理所需加热时间很短,能够保持肉的鲜嫩多汁,这是区别于其他中式烹饪方法的关键所在[4]。Lawrence等[5]研究表明,在相同中心温度和相同烹饪条件下,牛肉的不同部位原料肉加工损失率也会存在较大差异。王可等[6]研究发现,牦牛肉不同部位的品质指标存在着显著差异,对于脂肪含量较高的原料肉,更适合采用煎制、烤制等加工方式。宋洁等[7]筛选出剪切力、凝胶保水性、凝胶粘聚性、脂肪含量和原料肉红度值为涮制羊肉的关键品质指标,建立了涮制羊肉综合品质评价方程Y=0.2683A1+0.2141A2+0.1177A3+0.1851A4+0.2148A5(式中,A1~A5分别代表脂肪含量、剪切力、凝胶保水性、凝胶粘聚性、红度值)。刘雪霏等[8]运用多元统计分析方法,确定了烤制加工过程中影响牛肉品质的关键指标,并建立了综合品质评价方程,结合此方程和K-means聚类分析,确定了不同部位牛肉烤制加工适宜性。前人研究大多集中于烤制烹饪方式下测定羊肉、牛肉营养、理化指标及食用品质等指标,相比之下涮制烹饪方式及牦牛肉涮制加工方法的研究较少,不同部位牦牛肉涮制加工适宜性尚未明确。

本研究以牦牛肉大黄瓜条、外脊、臀肉、上脑、肩肉、腱子为研究对象,分析了其涮制前营养品质、肌纤维特性、理化特性和涮制加工后理化性质及食用品质指标差异,确定涮制牦牛肉的关键品质指标,明确不同部位牦牛肉涮制加工适宜性,并建立适宜性评价模型,为牦牛肉涮制加工的合理化及标准化提供依据。

1. 材料与方法

1.1 材料与仪器

牦牛 源自青海省海晏县夏华清真肉食品有限公司,选取36月龄左右经过育肥的6头牦牛,屠宰后在0~4 ℃条件下排酸48 h后,然后参照DB 63/T 1784-2020《牦牛胴体分割》分别取上脑、臀肉、肩肉、腱子、外脊、大黄瓜条6个部位肉并剔除表面筋膜,置于−18 ℃冷库冷冻保藏,备用;硫酸铜 天津市光复科技发展有限公司;浓盐酸 北京通广精细化工公司;溴甲酚绿、甲基红 上海麦克林生化科技有限公司;无水乙酸钠、磷酸氢二钠、氯化钠、氯化钾、磷酸二氢钠、一水合柠檬酸 国药集团化学试剂有限公司;氢氧化钠、硼酸 福晨(天津)化学试剂有限公司;所有化学试剂均为分析纯。

Kjeltec2300全自动凯氏定氮仪 丹麦FOSS集团有限公司;SER 148全自动粗脂肪测定仪 意大利VELP公司;GJ101A电热恒温鼓风干燥箱 广州仪智实验仪器有限公司;TA.XT plus C质构仪 英国Stable Micro Systems公司;NJA型全自动切片机 美国查维斯机械制造有限公司;C19S04-A苏泊尔电磁炉 浙江苏泊尔炊具股份有限公司;6100紫外可见分光光度计 上海信达仪器有限公司;FJ-200高速分散均质机 北京固本模型厂制造;TGL16MB高速冷冻台式离心机 惠达离心机仪器有限公司;II-3水浴锅 上海莱斯仪器有限公司。

1.2 实验方法

1.2.1 牦牛肉涮制加工

参考郎玉苗等[9]的方法,略作修改。将不同部位冷冻牦牛肉样品在4 ℃放置1 h后,修整成一定形状,用全自动切片机将牦牛肉切成厚度为1.5 mm的肉片(厚度由前期市场调查结果确定)。固定水量,等待水完全沸腾翻滚,放入牦牛肉片,计时25 s捞出,晾凉至室温,以进行后续实验。涮制过程不加入葱姜蒜等任何调味品。

1.2.2 牦牛原料肉理化品质指标测定

1.2.2.1 蛋白质、脂肪、水分含量测定

根据《食品中蛋白质的测定》(GB/T 5009.5-2016),将原料肉经浓硫酸处理后,由凯氏定氮法测定牦牛肉蛋白质质量分数[10];根据《食品中脂肪的测定》(GB/T 5009.6-2016),采用索氏抽提法对牦牛肉脂肪质量分数进行测定[11],根据《食品中水分的测定》(GB/T 5009.3-2016),利用105 ℃烘箱,对牦牛肉糜进行干燥,从而测定牦牛肉水分质量分数[12]。

1.2.2.2 pH测定

参考张中会等[13]的方法,将不同部位牦牛肉用绞肉机绞碎,配制0.1 mol/L氯化钾溶液,将碎肉与氯化钾溶液以1:10比例混匀,置于玻璃烧杯中,插入玻璃电极,待数字稳定后读数。

1.2.2.3 肉色分析

将肉样于测定色差前12 h拿出,放置于4 ℃冰箱中解冻,测定色差前按照垂直于肌纤维方向切出一个面,肉样在室温条件下暴露30 min后,使用色差计尽量避开含有脂肪的位置,在肉样表面随机选取3~6个点进行测定,记下肉样的亮度值(L*)、红度值(a*)和黄度值(b*)。

1.2.2.4 保水性的测定

原料肉加压失水率测定:参考徐焕等[14]的方法略作修改。采用压力滤纸法,将每种牦牛肉样品切大约4~5 cm2、厚1 cm,记为m1(g),将牦牛肉样放置在两层医用纱布之间,分别用16层滤纸垫于纱布两侧,用35 kg大小均匀的力对牦牛肉样品进行加压并保持5 min,然后撤除压力并立即称重,记为m2(g),每块肉样进行3 次重复试验,加压失水率计算如式(1)所示。

加压失水率(%)=m1−m2m1×100 (1) 1.2.2.5 肌纤维直径及肌节长度的测定

参考文献[15−16]的方法,使用Image-Pro Plus 6.0软件,对肌节长度和肌纤维直径进行测量,每张图片测定6组肌纤维数据,结果取平均值。

1.2.2.6 凝胶特性的测定

参照Xiong等[17]的方法,对牦牛肉肌原纤维蛋白进行提取,全程保持4 ℃提取。并以BSA(牛血清白蛋白)作为标准蛋白,用双缩脲法对蛋白质进行浓度测定。提取后的牦牛肌原纤维蛋白保存在4 ℃下,72 h内用完。参考Xia等[18]的方法,利用牦牛肌原纤维蛋白制备热诱导凝胶。选用P/0.5R探头,测试参数:测试前速率1.0 mm/s、测试速率0.5 mm/s、测试后速率1.0 mm/s、压缩比50%、引发力5 g进行牦牛肉热诱导凝胶质构分析。参考Sun等[19]的方法,采用离心法(4 ℃,8000×g,10 min)测定牦牛肉肌原纤维蛋白所制备的热诱导凝胶的保水性。

1.2.3 牦牛肉涮制加工特性指标的测定

1.2.3.1 出品率的测定

每组分别取3片牦牛肉,称量涮制前牦牛肉质量m3(g),涮制25 s。将涮制后的牦牛肉样品晾凉至室温,用柔性洁净纸吸去表面水分,称取涮制后牦牛肉片质量m4(g),由公式(2)计算涮制牦牛肉出品率。实验重复进行3~6次,结果取其平均值。

出品率(%)=m3m4×100 (2) 1.2.3.2 剪切力的测定

参照宋洁等[7]的方法,首先将涮制牦牛肉片沿肌纤维方向切成2 cm×1 cm×1.5 mm的小片,然后利用TA.XT Plus C质构仪的HDP/BSK探头进行垂直剪切测试。测试参数设定:测试前速度为1.0 mm/s,测试速度为3.0 mm/s,测试后速度为10.0 mm/s。实验重复进行6次,排除异常值后取平均值作为最终结果。

1.2.3.3 质构特性测定

采用直径1.27 cm中空取样器取涮制牦牛肉片,用TA.XT PlusC质构仪进行牦牛肉咀嚼性等指标的测定。测试参数:探头类型P35R、测试前速率2.00 mm/s、测中速率1.00 mm/s、测试后速率2.00 mm/s、压缩比50%、2次下压间隔时间为5.0 s、负载力5.0 g、触发类型auto、数据收集率200 pps。实验重复进行6 次,结果取平均值。

1.2.3.4 感官评价

根据Oury等[20]和宋洁等[7]的方法,我们挑选了12名喜欢食用涮牛肉、身体状况良好、年龄范围22~25岁的食品专业研究生(男女各6名),共同参与涮制牦牛肉感官评价。试验前准备好矿泉水、牙签、一次性小盘子等,实验在室内无异味的品鉴室进行,房间最多可容纳15名感官评价员,温度保持在室温(20~25 ℃)。按照GB/T 22210-2008肉与肉制品感官评定规范对涮制牦牛肉嫩度、多汁性等食用品质指标进行打分[21]。所有涮制牦牛肉样品均使用三位随机数字编号进行盲标,呈递给感官评价员。感官评价得分范围从1到10,用于衡量涮制牦牛肉的品质。

1.3 数据处理

首先,涉及量纲有差异和不同指标单位的数据需要进行正向化处理。接着,采用极差变换法对各个指标进行标准化处理[22]。参考张文霖[23]的方法,使用主成分分析法来确定关键指标的权重。实验数据处理使用Excel软件,并将结果表示为平均值±标准差,使用SPSS Statistics 22.0软件进行不同理化、肌纤维特性、营养品质指标之间的主成分分析、相关性分析和聚类分析,采用Duncan多重比较来进行差异显著性检验,取显著性水平为P<0.05。

2. 结果与分析

2.1 不同部位牦牛肉品质比较

2.1.1 不同部位原料肉理化性质

根据表1数据可知,不同部位的牦牛肉在水分含量、pH、蛋白质量分数和脂肪质量分数上存在明显的差异。在这六个部位中,牦牛大黄瓜条部位的肉质蛋白质含量最高,达到了24.96%,与其他五个部位相比具有显著差异(P<0.05)。牦牛肉外脊部位的脂肪含量最高,达到了4.88%;腱子部位的脂肪含量明显低于其他部位,并存在显著差异(P<0.05)。各部位牦牛肉的水分含量也有所不同,呈现出一定的差异性。如表1所示,与其它四个部位相比,腱子部位和肩肉的含水量显著高于它们(P<0.05);外脊、上脑、臀肉以及大黄瓜条四个部位的肉质含水量无显著性差异(P>0.05)。不同部位肉的理化数据差异,深层次地反映了肉品嫩度、香气和滋味等食用品质之间的差异,进而影响消费者的感官评价[24−25]。不同部位牦牛肉的pH存在显著差异,其中牦牛肉腱子部位pH显著高于其他五个部位(P<0.05)。造成不同部位肉pH存在差异的原因,是不同部位牦牛肉糖原酵解能力、强度和速率不同[26]。

表 1 不同部位原料肉理化品质差异Table 1. Difference in physicochemical quality of different cuts of yak meat部位 水分质量

分数(%)脂肪质量

分数(%)蛋白质质量

分数(%)pH 外脊 72.35±0.64b 4.88±0.78a 23.01±0.41bc 5.36±0.10d 上脑 73.29±0.94b 4.05±0.68ab 22.01±0.6d 5.61±0.04b 肩肉 74.46±0.50a 2.13±0.31c 23.36±0.24b 5.56±0.06b 大黄瓜条 73.15±0.77b 2.59±0.80bc 24.96±0.57a 5.41±0.08cd 臀肉 72.74±0.52b 4.00±0.85ab 22.40±0.45cd 5.50±0.10bc 腱子 74.82±0.61a 0.88±0.14d 23.11±0.86bc 5.76±0.13a 注:同列肩标小写字母不同表示差异显著(P<0.05);表2~表7同。 2.1.2 不同部位原料肉色泽差异

由表2可知,不同部位牦牛肉的亮度值L*存在显著差异(P<0.05)、红度值a*和黄度值b*也存在一定差异,其中上脑部位的亮度值L*、红度值a*和黄度值b*均显著高于其他部位(P<0.05),而臀肉的L*、a*、b*均低于其他部位,大黄瓜条、腱子、肩肉和外脊四个部位的红度值a*和黄度值b*均无显著差异(P>0.05)。L*值用来反映肉色亮度,通常情况下L*值越小,肉色越好;上脑的黄度值b*最高,臀肉的最低,其差异性可能是不同部位牦牛肉中肌红蛋白含量不同[27]。a*值与牦牛肉色呈现显著正相关关系[28],其差异性可能是不同部位牦牛肉间的肌肉氧合肌红蛋白含量不同所致[29]。

表 2 不同部位原料肉色泽差异Table 2. Differences in color parameters of different cuts of yak meat部位 亮度值L* 红度值a* 黄度值b* 外脊 32.53±2.95cd 21.16±2.90bc 10.00±1.87bc 上脑 38.75±2.80a 24.64±3.16a 13.12±2.68a 肩肉 35.01±2.84b 23.47±3.60ab 10.69±2.30b 大黄瓜条 34.58±3.50bc 20.70±2.77bc 10.47±1.43b 臀肉 29.70±1.58e 19.28±3.15c 8.50±1.70c 腱子 30.69±2.82de 20.96±4.25bc 9.46±2.49bc 2.1.3 不同部位原料肉肌纤维特性差异

肌纤维直径与肌节长度对肉品质如嫩度等有重要影响[30−31]。由表3可知,牦牛肉腱子部位的肌纤维直径最长,为43.44 μm,显著高于其余部位(P<0.05),一般而言后躯腱子部位运动量大,肌纤维相应较粗[9]。前中躯牦牛肉上脑、肩肉和外脊部位的肌纤维直径显著低于其他部位(P<0.05)。牦牛肉外脊部位的肌节长度显著高于其他部位(P<0.05)。Holman等[32]通过研究肌节长度、剪切力等客观指标与消费者感官评价之间的关系,表明肌肉肌节长度与肉的嫩度呈现正相关性,肌节越长,肉质就越嫩。

表 3 不同部位原料肉肌纤维特性差异Table 3. Difference in muscle fiber characteristics of different cuts of yak meat部位 肌纤维直径(μm) 肌节长度(μm) 外脊 25.01±1.96d 3.37±0.07a 腱子 43.44±1.52a 2.52±0.06d 臀肉 36.54±3.42b 2.54±0.07d 肩肉 21.80±1.37e 3.13±0.10b 上脑 22.96±1.55de 3.16±0.05b 大黄瓜条 32.06±1.48c 2.90±0.16c 2.1.4 不同部位原料肉保水性差异

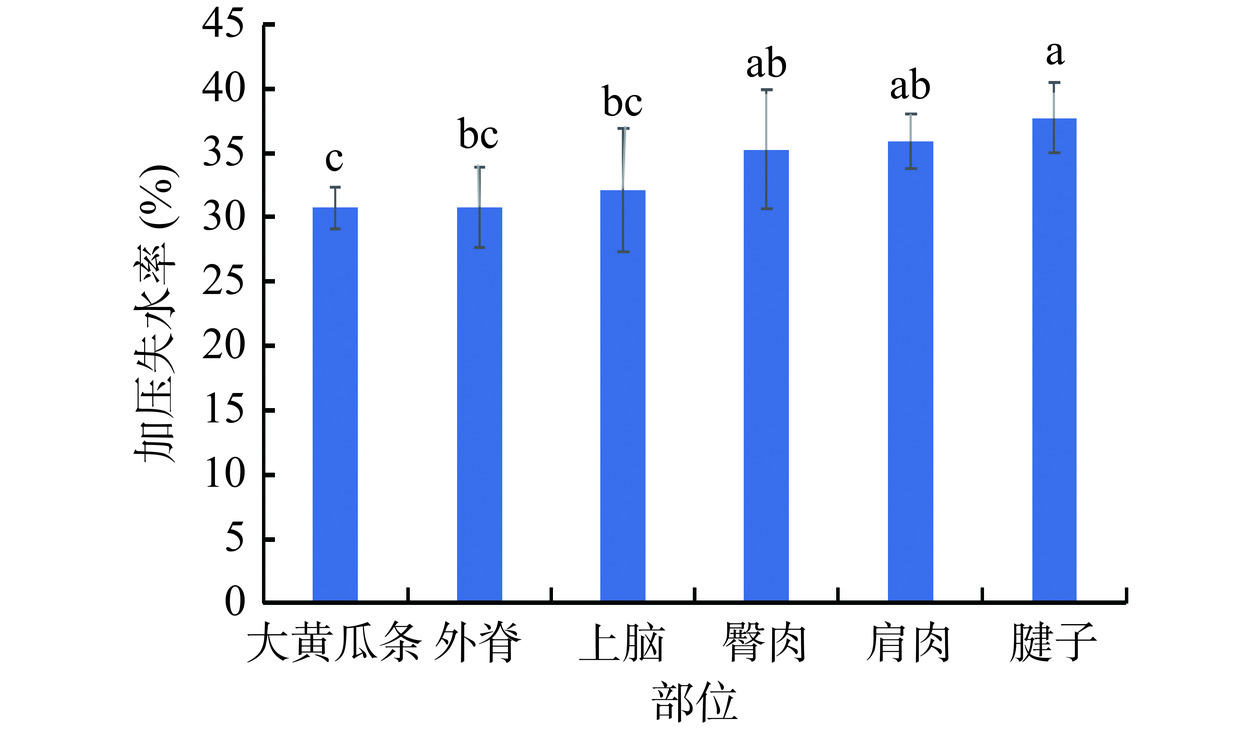

保持水分的能力对不同部位肉的出品率、消费者感官评价中多汁性的打分情况有所影响,也可间接说明肉质的好坏并反映牦牛肉的食用品质[14]。加压失水率主要突出的是肉的保水能力,由图1可知,不同部位牦牛肉加压失水率存在一定差异,牦牛大黄瓜条部位的加压失水率显著低于臀肉、腱子、肩肉(P<0.05),外脊、上脑、臀肉、肩肉的加压失水率无显著差异(P>0.05)。综上所述,说明大黄瓜条持水力较好,肉质较好;而腱子的保水能力较差,肉质较硬。

2.1.5 不同部位原料肉肌原纤维蛋白凝胶特性差异

凝胶特性是反映牦牛肉蛋白质加工性能的重要指标之一,肉制品中的凝胶是由蛋白质分子相互交联形成三维空间网络结构,从而将水分、脂肪、风味物质等物质更好的包裹在里面,研究表明该特性与肉制品的质构、外观、出品率等有着密切联系[33−34]。为了全面衡量肌纤维蛋白的凝胶特性,可以采用多个指标,包括凝胶弹性、粘聚性、咀嚼性、胶着性、硬度和保水性。由表4可知,不同部位牦牛肉肌原纤维蛋白所制成的热诱导凝胶其硬度、凝胶弹性、凝胶咀嚼性均存在较大差异。外脊、肩肉的凝胶硬度、凝胶咀嚼性和凝胶弹性显著低于其他四个部位(P<0.05),外脊、臀肉的凝胶保水性显著高于其他四个部位(P<0.05),综合来看,牦牛肉外脊形成的凝胶网络结构均匀,具有较好的凝胶品质。

表 4 不同部位原料肉肌原纤维蛋白凝胶特性差异Table 4. Difference in gel properties of different cuts of yak meat部位 凝胶硬度(g) 凝胶弹性 凝胶粘聚性 凝胶胶着性(g) 凝胶咀嚼性(g) 凝胶保水性(%) 外脊 21.87±2.40d 0.65±0.08d 0.52±0.06ab 11.37±1.24d 7.66±1.13d 74.62±2.23a 腱子 49.61±2.85a 0.77±0.05ab 0.52±0.04ab 25.62±2.97a 19.78±2.58a 64.48±1.80c 臀肉 40.00±2.71b 0.86±0.07a 0.55±0.08a 22.39±1.81b 17.67±3.21b 75.87±2.12a 肩肉 20.23±1.65d 0.73±0.06cd 0.48±0.05bc 10.05±1.33d 7.74±1.20d 68.06±1.54bc 上脑 30.89±2.98c 0.77±0.03bc 0.45±0.07c 14.49±1.23c 11.21±0.75c 64.48±1.80c 大黄瓜条 32.66±1.85c 0.84±0.04ab 0.51±0.03ab 16.82±1.47c 14.14±1.46c 69.82±3.36b 2.2 不同部位牦牛肉涮制加工特性指标分析结果

牦牛肉涮制出品率是指牦牛肉经过涮制后的质量与所消耗的原料肉质量的比例,出品率越高,说明涮制后所得成品越多。由表5可知,外脊、腱子、臀肉经涮制后出品率存在显著差异(P<0.05),肩肉、上脑、大黄瓜条之间无显著差异(P>0.05)。其中外脊具有最高出品率(P<0.05),相较而言,肩肉部位出品率较小,仅有66.55%;可能的原因是,牦牛肉的不同部位之间水分和脂肪的质量分数存在差异。肉的质地与嫩度密切相关,嫩度是评估牛肉品质的关键因素之一,而剪切力则是评估肌肉嫩度的重要指标。一般而言,剪切力越低,肌肉的嫩度就越好,反之则表明嫩度较差[34]。腱子涮制后的剪切力最高(P<0.05),肉质较硬;大黄瓜条、上脑剪切力较低;外脊、肩肉和臀肉三者剪切力无显著差异(P>0.05),不同部位之间的嫩度差异,可能与肌原纤维蛋白的含量及其变性程度有关[26]。咀嚼性是由硬度、弹性和粘聚性共同决定的特性,它反映了从咀嚼到吞咽过程中所需的能量[7]。在一定范围内,咀嚼性越大,通常意味着肉样口感更加有嚼劲[8]。涮制后,腱子的咀嚼性显著高于除外脊、臀肉外的其他部位(P<0.05)。上脑、大黄瓜条和肩肉的硬度、胶着性和咀嚼性的差异较小并且低于其他部位,大黄瓜条回复性最高,外脊粘聚性最低。

表 5 不同部位原料肉涮制加工后质构品质和出品率差异Table 5. Difference in texture properties and yield of roast beef from different cuts部位 剪切力

(kg)硬度

(kg)弹性 粘聚性 胶着性

(kg)咀嚼性

(kg)回复性 出品率

(%)外脊 1.80±0.24b 2.20±0.22a 0.71±0.09ab 0.52±0.06c 1.51±0.29a 1.03±0.22ab 0.19±0.01c 77.84±1.22a 腱子 2.13±0.18a 2.47±0.55a 0.66±0.07ab 0.61±0.05a 1.32±0.37ab 1.07±0.29a 0.23±0.03ab 74.78±0.97b 臀肉 1.88±0.59b 2.17±0.59a 0.70±0.09ab 0.55±0.05bc 1.15±0.41bc 0.90±0.20ab 0.20±0.02bc 70.38±0.26c 肩肉 1.96±0.30ab 1.59±0.27b 0.75±0.07a 0.59±0.04ab 1.01±0.18bc 0.79±0.14bc 0.21±0.02bc 66.55±1.49d 上脑 1.46±0.24c 1.57±0.32b 0.65±0.10b 0.57±0.05ab 0.96±0.23c 0.69±0.25c 0.19±0.03c 67.95±1.49cd 大黄瓜条 1.65±0.37bc 1.61±0.15b 0.64±0.08b 0.61±0.03a 1.12±0.31bc 0.73±0.25c 0.24±0.05a 67.10±0.57d 如表6所示,外脊亮度值L*最大,涮制牦牛肉腱子、大黄瓜条和臀肉的亮度值L*差异较小,但显著低于外脊和肩肉;大黄瓜条的黄度值b*显著高于其它五个部位(P<0.05),上脑、外脊、臀肉、腱子四个部位的b*值无显著差异(P>0.05)。上脑、肩肉在涮制后,其红度值a*明显低于外脊、大黄瓜条和腱子(P<0.05)。与表2牦牛原料肉的色泽进行对比发现,经过涮制加工后的牦牛肉红度值a*低于原料肉的红度值a*。这可能是由于涮制过程中肌肉中的肌红蛋白发生了变性,以及氧合肌红蛋白的相对含量有所降低,因此导致涮制后牦牛肉的红度值a*有所降低[4,35]。

表 6 不同部位涮制牦牛肉色泽差异Table 6. Difference in color of shabu-shabu yak meat from different cuts部位 涮制后亮度值L* 涮制后红度值a* 涮制后黄度值b* 外脊 56.87±0.61a 6.76±0.42ab 13.41±0.22b 上脑 53.50±1.48bc 5.48±0.40c 12.86±0.85b 肩肉 55.32±1.39ab 5.31±0.29c 10.95±0.97c 大黄瓜条 50.92±0.83cd 7.01±0.74a 15.07±0.05a 臀肉 49.15±1.14d 5.75±0.76bc 12.83±0.86b 腱子 50.36±2.05d 6.03±0.49ab 12.97±0.66b 消费者感官评价过程中嫩度的评判根据牙齿对于牦牛肉的咀嚼难易程度,多汁性的评判根据咀嚼过程中及咀嚼后牦牛肉中所释放出的汁液量来确定,而风味则是根据咀嚼时所感受到的滋味和香气评判[31,36]。如表7所示,上脑整体可接受性、嫩度以及多汁性分数均为最高,与其他部位具有显著差异(P<0.05),可能是由于上脑部位脂肪含量较高,脂肪作为肉和肉制品的关键成分,对提升肉的营养价值和嫩度具有至关重要的作用,在一定范围内,肉中脂肪含量越多,嫩度越好,多汁性越好[24−25]。各部位肉滋味和气味评分在统计学上无显著性差异(P>0.05),原因可能是涮制牦牛肉切片厚度仅有1.5 mm,经涮制后温度立马大幅度下降,造成评价员极难分辨其滋味和气味[7,36]。由感官评价结果可知,不同部位牦牛肉的多汁性、嫩度及总体可接受性这三方面较容易在品尝过程中被感知,而涮后牦牛肉的滋味和气味不易被感知。

表 7 不同部位涮制牦牛肉感官评分差异Table 7. Differences in sensory scores of shabu-shabu yak meat from different cuts部位 嫩度 气味 多汁性 滋味 整体可

接受性外脊 5.51±0.46bc 5.33±0.41a 5.61±0.44b 5.48±0.50a 5.89±0.13bc 上脑 6.83±0.83a 5.89±0.52a 6.83±0.68a 6.26±0.95a 7.53±0.56a 肩肉 4.29±0.83c 5.78±0.65a 4.74±0.10bc 5.42±0.80a 5.13±0.81cd 大黄瓜条 5.93±0.61b 5.85±0.67a 5.74±0.74b 5.56±0.85a 6.11±0.67b 臀肉 5.26±0.35bc 5.18±0.46a 4.25±0.32c 5.35±0.53a 5.35±0.18c 腱子 2.39±0.25d 4.94±0.58a 3.66±0.52d 5.48±0.50a 4.29±0.35d 2.3 不同部位涮制牦牛肉加工适宜性分析结果

2.3.1 不同部位牦牛肉品质指标数据分析结果

为最终确定涮制牦牛肉关键品质评价指标,首先计算各指标变异系数,其结果可作为加工适宜性关键评价指标筛选的一项重要依据。统计结果如表8所示,变异系数小于7%,说明各部位因素对其影响程度不大,因此删去变异系数小于7%的牦牛原料肉pH、蛋白质及水分含量、凝胶特性中的粘聚性、涮制牦牛肉出品率、弹性、粘聚性、以及涮制后亮度值L*。

表 8 不同部位原料肉和涮制牦牛肉品质指标的统计分析结果Table 8. Statistical analysis of quality indexes of raw yak meat and shabu-shabu yak meat from different cuts指标 范围 平均值 变异系数(%) 指标 范围 平均值 变异系数(%) 水分质量分数(%) 72.35~74.82 73.47 1.32 凝胶硬度(g) 20.23~49.61 32.54 34.08 脂肪质量分数(%) 0.88~4.88 3.08 48.05 凝胶弹性 0.65~0.86 0.77 9.89 蛋白质量分数(%) 22.01~24.96 23.14 4.41 凝胶粘聚性 0.45~0.55 0.51 6.94 pH 5.36~5.76 5.53 2.61 凝胶胶着性(g) 10.05~25.62 16.79 36.66 原料肉亮度值L* 29.70~38.75 33.54 9.82 凝胶咀嚼性(g) 7.74~19.78 13.03 38.89 原料肉红度值a* 19.28~24.64 21.70 9.09 凝胶保水性(%) 64.48~75.87 69.56 7.02 原料肉黄度值b* 8.50~13.12 10.37 15.02 剪切力(kg) 1.51~2.13 1.77 13.19 肌纤维直径(μm) 21.80~36.54 30.30 28.34 硬度(kg) 1.57~2.47 1.94 20.27 肌节长度(μm) 2.52~3.37 2.94 11.87 弹性 0.64~0.75 0.69 6.18 加压失水率(%) 30.72~37.74 33.77 8.76 粘聚性 0.52~0.61 0.58 6.20 出品率(%) 66.55~77.84 70.77 6.49 胶着性 0.96~1.51 1.18 17.40 涮制后亮度值L* 49.15~56.87 52.69 5.77 咀嚼性(kg) 0.69~1.07 0.87 18.20 涮制后红度值a* 5.31~7.01 6.06 11.41 回复性 0.19~0.24 0.21 9.99 涮制后黄度值b* 10.95~15.07 13.02 10.14 2.3.2 不同部位牦牛肉涮制加工品质指标主成分分析结果

本研究共涉及27个指标,包含牦牛肉涮制前营养品质、肌纤维特性、理化特性和涮制加工后理化性质及食用品质指标,这些数据之间可能存在相关性。主成分分析可以将这些相关的变量转化为少数几个不相关的主成分,从而简化数据集,使其更易于处理和分析。主成分分析结果已在表9中详细列出。在此表中,牦牛肉不同部位的涮制加工品质指标被归纳为7个主要成分。这些主成分的特征值均大于1,其累积方差贡献率高达84.714%,这意味着它们能有效地代表大部分的品质信息。基于主成分分析的结果,进一步计算了各涮制牦牛肉品质指标的权重,以便进行后续的聚类分析。

表 9 牦牛肉涮制加工品质指标主成分分析Table 9. Principal component analysis of quality indices of shabu-shabu yak meat品质指标 主成分1 主成分2 主成分3 主成分4 主成分5 主成分6 主成分7 权重 水分含量 0.208 −0.650 −0.207 0.440 0.002 0.167 −0.171 −0.0936 蛋白质含量 −0.002 0.152 −0.642 0.600 −0.044 −0.361 −0.055 −0.2542 脂肪含量 −0.545 0.547 0.082 −0.493 −0.091 −0.070 0.086 −0.0539 pH 0.517 −0.608 0.221 −0.242 −0.022 0.307 −0.212 0.0946 原料肉亮度值L* −0.712 −0.203 0.119 −0.091 0.024 0.196 0.487 −0.0165 原料肉红度值a* −0.823 0.006 −0.279 0.249 0.138 0.250 0.043 −0.1588 原料肉黄度值b* −0.756 0.124 −0.169 0.264 0.102 0.290 0.193 −0.0977 肌纤维直径 0.936 0.194 0.032 0.102 0.138 0.085 0.155 0.1768 肌节长度 −0.899 −0.092 0.106 0.138 −0.189 0.132 −0.081 −0.1032 涮制后亮度值L* −0.764 −0.033 0.328 0.276 −0.152 0.123 −0.308 0.0067 涮制后红度值a* −0.051 0.628 −0.433 0.284 0.223 0.290 −0.126 −0.0756 涮制后黄度值b* 0.139 0.609 −0.592 −0.015 0.054 0.335 0.043 −0.1546 凝胶硬度 0.940 0.068 −0.013 −0.072 −0.057 0.225 0.108 0.1059 凝胶弹性 0.580 0.124 −0.409 −0.481 0.07 −0.163 0.066 −0.0903 凝胶粘聚性 0.454 0.518 0.128 0.236 −0.048 −0.047 −0.348 0.1186 凝胶胶着性 0.952 0.137 0.086 −0.081 0.020 0.128 0.058 0.1626 凝胶咀嚼性 0.947 0.005 −0.055 −0.032 0.004 0.096 0.136 0.0967 凝胶保水性 −0.195 0.714 0.202 −0.096 0.432 −0.296 −0.060 0.1859 加压失水率 0.318 −0.306 0.543 0.130 0.521 0.056 −0.052 0.3487 剪切力 0.434 −0.005 0.333 0.507 0.243 −0.335 −0.122 0.2033 硬度 0.305 0.514 0.507 0.117 0.095 0.367 −0.041 0.3090 弹性 −0.115 −0.454 0.338 0.336 0.332 −0.191 0.445 0.1862 粘聚性 0.484 −0.486 −0.369 0.143 −0.425 0.125 −0.052 −0.2120 胶着性 0.028 0.471 0.181 0.230 −0.647 −0.249 0.200 −0.0231 咀嚼性 0.522 0.118 0.402 0.322 −0.504 −0.026 0.215 0.1396 回复性 0.408 −0.046 −0.623 0.365 0.220 −0.022 0.251 −0.1375 出品率 0.112 0.542 0.544 0.357 −0.088 0.271 0.136 0.2761 特征值 9.003 4.133 3.315 2.329 1.729 1.310 1.053 方差贡献率(%) 33.345 15.307 12.280 8.624 6.404 4.853 3.902 累计方差贡献率(%) 33.345 48.652 60.931 69.555 75.959 80.812 84.714 2.3.3 不同部位牦牛肉涮制加工品质指标聚类分析结果

将牦牛肉涮制加工涉及到的27个品质指标进行聚类,分析结果如图2所示。结合表8所示变异系数、表9所示主成分分析结果和各品质指标权重、表10所示相关性分析结果,最终,将27个品质指标归为5类。

表 10 不同部位牦牛肉涮制加工品质指标相关性分析Table 10. Correlation analysis of quality indexes of shabu-shabu yak meat from different cuts指标 剪切力 硬度 胶着性 咀嚼性 涮制后红

度值a*涮制后黄

度值b*加压

失水率指标 脂肪

含量凝胶

硬度凝胶

咀嚼性凝胶

胶着性肌纤维

直径肌节

长度剪切力 1 脂肪含量 1 硬度 0.263 1 凝胶硬度 −0.455* 1 胶着性 0.065 0.269 1 凝胶咀嚼性 −0.526** 0.955** 1 咀嚼性 0.272 0.360 0.535** 1 凝胶胶着性 −0.412* 0.965** 0.936** 1 涮制后红度值a* −0.084 0.164 0.029 −0.086 1 肌纤维直径 −0.476* 0.914** 0.900** 0.938** 1 涮制后黄度值b* −0.291 0.143 0.035 −0.065 0.789** 1 肌节长度 0.354 −0.804** −0.842** −0.854** 0.789** 1 加压失水率 0.450* 0.246 −0.289 0.168 −0.183 −0.399 1 第一类指标中,涮制后牦牛肉粘聚性、牦牛原料肉pH及水分含量变异系数均小于7%,因此直接删除以上指标。凝胶硬度指标变异系数为34.08,对应表4中不同部位肉间凝胶硬度具有显著性差异(P<0.05),由此进一步说明部位因素对该指标影响程度较大。由表10可以看出,凝胶硬度与肌纤维直径、凝胶咀嚼性、凝胶胶着性之间存在极显著的相关性,相关系数分别为0.914、0.955和0.965。综合来看,最终选取凝胶硬度作为第一类代表指标。第二类指标首先删去变异系数小于7%的弹性指标,还包括剪切力和加压失水率,二者权重分别为0.2333和0.3487,加压失水率与弹性、剪切力存在显著的相关性,相关系数为0.432、0.450,而剪切力与弹性的相关系数仅有0.205,综合分析最终选取加压失水率为第二类代表性指标。第三类指标中,删去变异系数小于7%的凝胶粘聚性、出品率以及权重为−0.0231的胶着性指标。硬度与胶着性、咀嚼性的相关系数分别是0.269、0.360,无显著相关性,咀嚼性与胶着性具有极显著相关性,相关系数为0.535,且咀嚼性的权重较大(0.1396),则选取咀嚼性作为第三类代表指标。第四类指标包括蛋白质量分数、回复性、涮制后红度值a*、涮制后黄度值b*,由于蛋白质含量变异系数仅有4.41%,因此将该指标删去。回复性(权重-0.104、变异系数10.14)均小于涮制后黄度值b*,涮制后红度值a*与涮制后黄度值b*极显著相关(P<0.01),相关系数为0.789,则可用涮制后黄度值b*代表涮制后红度值a*,最终确定涮制后黄度值b*为第四类代表性指标。第五类指标中首先删去涮制后亮度度值L*和凝胶保水性(变异系数小于7%),该类指标中脂肪含量的变异系数为48.05,说明部位因素对该指标影响程度较大;原料肉a*与L*、肌节长度、b*均呈现极显著相关(P<0.01),相关系数分别为0.632、0.710、0.930,故选取脂肪含量、a*作为第五类代表指标。

通过分析牦牛肉营养品质、肌纤维特性、理化特性指标之间相关性,继续进行主成分分析、聚类分析,最终筛选牦牛原料肉脂肪含量、凝胶硬度、涮制后黄度值b*、加压失水率、原料肉红度值a*及咀嚼性作为涮牦牛肉的关键品质指标,其权重大小如表11所示。

表 11 涮制牦牛肉关键品质指标权重Table 11. Weight of key quality indices of shabu-shabu yak meat指标 原料肉红

度值a*脂肪

含量加压失

水率凝胶

硬度涮制后黄

度值b*咀嚼性 主成分分

析权重0.1579 0.0539 0.3487 0.1059 0.1546 0.1396 归一化 0.1644 0.0561 0.3630 0.1102 0.1609 0.1453 2.3.4 不同部位涮牦牛肉综合品质评价以及涮制适宜性分析结果

经过正向化和标准化处理后,我们使用以下公式来计算牦牛肉涮制加工的综合品质得分:Y=0.1644X1+0.0561X2+0.3630X3+0.1102X4+0.1609X5+0.1453X6。该得分Y与K-means聚类分析的结果相结合,用于评估不同部位牦牛肉涮制加工的适宜性。具体来说,如果Y值小于等于0.50,泽判定该部位牦牛肉不适宜涮制加工;如果Y值在0.50~0.61之间,则判定该部位牦牛肉较适宜涮制加工;如果Y值大于等于0.61,则判定该部位牦牛肉适宜涮制加工。以上分析和聚类结果可以参考表12。

表 12 涮制牦牛肉综合品质评价得分K-means聚类分析结果Table 12. K-means cluster analysis of comprehensive quality evaluation scores of shabu-shabu yak meat from different cuts部位 Y 适宜性 臀肉 0.55 较适宜 大黄瓜条 0.65 适宜 外脊 0.53 较适宜 肩肉 0.49 不适宜 腱子 0.50 不适宜 上脑 0.61 适宜 2.3.5 不同部位涮牦牛肉综合品质评价方程验证分析

对不同部位涮制牦牛肉的感官评价分数进行标准化处理,以涮制牦牛肉的综合品质评价分数(Y)为自变量,以感官评价中的整体可接受性为因变量,构建线性回归模型并验证其有效性。最终回归模型的公式为y=5.0914x−2.2958,且R²=0.8232。这表明不同部位涮制牦牛肉的综合品质评价模型能够较为精确地预测感官评价的整体可接受性,同时,该模型能够在一定程度上反映牦牛肉涮制加工的适宜性。

3. 结论

综上所述,实验筛选出涮制牦牛肉的关键品质评价指标为脂肪含量、凝胶硬度、涮制后黄度值b*、加压失水率、原料肉红度值a*及咀嚼性。建立了涮制牦牛肉综合品质评价方程Y=0.1644X1+0.0561X2+0.3630X3+0.1102X4+0.1609X5+0.1453X6。研究结果显示,牦牛肉上脑和大黄瓜条适宜涮制加工,外脊和臀肉较适宜涮制食用,而腱子和肩肉不适宜涮制加工。

-

表 1 不同部位原料肉理化品质差异

Table 1 Difference in physicochemical quality of different cuts of yak meat

部位 水分质量

分数(%)脂肪质量

分数(%)蛋白质质量

分数(%)pH 外脊 72.35±0.64b 4.88±0.78a 23.01±0.41bc 5.36±0.10d 上脑 73.29±0.94b 4.05±0.68ab 22.01±0.6d 5.61±0.04b 肩肉 74.46±0.50a 2.13±0.31c 23.36±0.24b 5.56±0.06b 大黄瓜条 73.15±0.77b 2.59±0.80bc 24.96±0.57a 5.41±0.08cd 臀肉 72.74±0.52b 4.00±0.85ab 22.40±0.45cd 5.50±0.10bc 腱子 74.82±0.61a 0.88±0.14d 23.11±0.86bc 5.76±0.13a 注:同列肩标小写字母不同表示差异显著(P<0.05);表2~表7同。 表 2 不同部位原料肉色泽差异

Table 2 Differences in color parameters of different cuts of yak meat

部位 亮度值L* 红度值a* 黄度值b* 外脊 32.53±2.95cd 21.16±2.90bc 10.00±1.87bc 上脑 38.75±2.80a 24.64±3.16a 13.12±2.68a 肩肉 35.01±2.84b 23.47±3.60ab 10.69±2.30b 大黄瓜条 34.58±3.50bc 20.70±2.77bc 10.47±1.43b 臀肉 29.70±1.58e 19.28±3.15c 8.50±1.70c 腱子 30.69±2.82de 20.96±4.25bc 9.46±2.49bc 表 3 不同部位原料肉肌纤维特性差异

Table 3 Difference in muscle fiber characteristics of different cuts of yak meat

部位 肌纤维直径(μm) 肌节长度(μm) 外脊 25.01±1.96d 3.37±0.07a 腱子 43.44±1.52a 2.52±0.06d 臀肉 36.54±3.42b 2.54±0.07d 肩肉 21.80±1.37e 3.13±0.10b 上脑 22.96±1.55de 3.16±0.05b 大黄瓜条 32.06±1.48c 2.90±0.16c 表 4 不同部位原料肉肌原纤维蛋白凝胶特性差异

Table 4 Difference in gel properties of different cuts of yak meat

部位 凝胶硬度(g) 凝胶弹性 凝胶粘聚性 凝胶胶着性(g) 凝胶咀嚼性(g) 凝胶保水性(%) 外脊 21.87±2.40d 0.65±0.08d 0.52±0.06ab 11.37±1.24d 7.66±1.13d 74.62±2.23a 腱子 49.61±2.85a 0.77±0.05ab 0.52±0.04ab 25.62±2.97a 19.78±2.58a 64.48±1.80c 臀肉 40.00±2.71b 0.86±0.07a 0.55±0.08a 22.39±1.81b 17.67±3.21b 75.87±2.12a 肩肉 20.23±1.65d 0.73±0.06cd 0.48±0.05bc 10.05±1.33d 7.74±1.20d 68.06±1.54bc 上脑 30.89±2.98c 0.77±0.03bc 0.45±0.07c 14.49±1.23c 11.21±0.75c 64.48±1.80c 大黄瓜条 32.66±1.85c 0.84±0.04ab 0.51±0.03ab 16.82±1.47c 14.14±1.46c 69.82±3.36b 表 5 不同部位原料肉涮制加工后质构品质和出品率差异

Table 5 Difference in texture properties and yield of roast beef from different cuts

部位 剪切力

(kg)硬度

(kg)弹性 粘聚性 胶着性

(kg)咀嚼性

(kg)回复性 出品率

(%)外脊 1.80±0.24b 2.20±0.22a 0.71±0.09ab 0.52±0.06c 1.51±0.29a 1.03±0.22ab 0.19±0.01c 77.84±1.22a 腱子 2.13±0.18a 2.47±0.55a 0.66±0.07ab 0.61±0.05a 1.32±0.37ab 1.07±0.29a 0.23±0.03ab 74.78±0.97b 臀肉 1.88±0.59b 2.17±0.59a 0.70±0.09ab 0.55±0.05bc 1.15±0.41bc 0.90±0.20ab 0.20±0.02bc 70.38±0.26c 肩肉 1.96±0.30ab 1.59±0.27b 0.75±0.07a 0.59±0.04ab 1.01±0.18bc 0.79±0.14bc 0.21±0.02bc 66.55±1.49d 上脑 1.46±0.24c 1.57±0.32b 0.65±0.10b 0.57±0.05ab 0.96±0.23c 0.69±0.25c 0.19±0.03c 67.95±1.49cd 大黄瓜条 1.65±0.37bc 1.61±0.15b 0.64±0.08b 0.61±0.03a 1.12±0.31bc 0.73±0.25c 0.24±0.05a 67.10±0.57d 表 6 不同部位涮制牦牛肉色泽差异

Table 6 Difference in color of shabu-shabu yak meat from different cuts

部位 涮制后亮度值L* 涮制后红度值a* 涮制后黄度值b* 外脊 56.87±0.61a 6.76±0.42ab 13.41±0.22b 上脑 53.50±1.48bc 5.48±0.40c 12.86±0.85b 肩肉 55.32±1.39ab 5.31±0.29c 10.95±0.97c 大黄瓜条 50.92±0.83cd 7.01±0.74a 15.07±0.05a 臀肉 49.15±1.14d 5.75±0.76bc 12.83±0.86b 腱子 50.36±2.05d 6.03±0.49ab 12.97±0.66b 表 7 不同部位涮制牦牛肉感官评分差异

Table 7 Differences in sensory scores of shabu-shabu yak meat from different cuts

部位 嫩度 气味 多汁性 滋味 整体可

接受性外脊 5.51±0.46bc 5.33±0.41a 5.61±0.44b 5.48±0.50a 5.89±0.13bc 上脑 6.83±0.83a 5.89±0.52a 6.83±0.68a 6.26±0.95a 7.53±0.56a 肩肉 4.29±0.83c 5.78±0.65a 4.74±0.10bc 5.42±0.80a 5.13±0.81cd 大黄瓜条 5.93±0.61b 5.85±0.67a 5.74±0.74b 5.56±0.85a 6.11±0.67b 臀肉 5.26±0.35bc 5.18±0.46a 4.25±0.32c 5.35±0.53a 5.35±0.18c 腱子 2.39±0.25d 4.94±0.58a 3.66±0.52d 5.48±0.50a 4.29±0.35d 表 8 不同部位原料肉和涮制牦牛肉品质指标的统计分析结果

Table 8 Statistical analysis of quality indexes of raw yak meat and shabu-shabu yak meat from different cuts

指标 范围 平均值 变异系数(%) 指标 范围 平均值 变异系数(%) 水分质量分数(%) 72.35~74.82 73.47 1.32 凝胶硬度(g) 20.23~49.61 32.54 34.08 脂肪质量分数(%) 0.88~4.88 3.08 48.05 凝胶弹性 0.65~0.86 0.77 9.89 蛋白质量分数(%) 22.01~24.96 23.14 4.41 凝胶粘聚性 0.45~0.55 0.51 6.94 pH 5.36~5.76 5.53 2.61 凝胶胶着性(g) 10.05~25.62 16.79 36.66 原料肉亮度值L* 29.70~38.75 33.54 9.82 凝胶咀嚼性(g) 7.74~19.78 13.03 38.89 原料肉红度值a* 19.28~24.64 21.70 9.09 凝胶保水性(%) 64.48~75.87 69.56 7.02 原料肉黄度值b* 8.50~13.12 10.37 15.02 剪切力(kg) 1.51~2.13 1.77 13.19 肌纤维直径(μm) 21.80~36.54 30.30 28.34 硬度(kg) 1.57~2.47 1.94 20.27 肌节长度(μm) 2.52~3.37 2.94 11.87 弹性 0.64~0.75 0.69 6.18 加压失水率(%) 30.72~37.74 33.77 8.76 粘聚性 0.52~0.61 0.58 6.20 出品率(%) 66.55~77.84 70.77 6.49 胶着性 0.96~1.51 1.18 17.40 涮制后亮度值L* 49.15~56.87 52.69 5.77 咀嚼性(kg) 0.69~1.07 0.87 18.20 涮制后红度值a* 5.31~7.01 6.06 11.41 回复性 0.19~0.24 0.21 9.99 涮制后黄度值b* 10.95~15.07 13.02 10.14 表 9 牦牛肉涮制加工品质指标主成分分析

Table 9 Principal component analysis of quality indices of shabu-shabu yak meat

品质指标 主成分1 主成分2 主成分3 主成分4 主成分5 主成分6 主成分7 权重 水分含量 0.208 −0.650 −0.207 0.440 0.002 0.167 −0.171 −0.0936 蛋白质含量 −0.002 0.152 −0.642 0.600 −0.044 −0.361 −0.055 −0.2542 脂肪含量 −0.545 0.547 0.082 −0.493 −0.091 −0.070 0.086 −0.0539 pH 0.517 −0.608 0.221 −0.242 −0.022 0.307 −0.212 0.0946 原料肉亮度值L* −0.712 −0.203 0.119 −0.091 0.024 0.196 0.487 −0.0165 原料肉红度值a* −0.823 0.006 −0.279 0.249 0.138 0.250 0.043 −0.1588 原料肉黄度值b* −0.756 0.124 −0.169 0.264 0.102 0.290 0.193 −0.0977 肌纤维直径 0.936 0.194 0.032 0.102 0.138 0.085 0.155 0.1768 肌节长度 −0.899 −0.092 0.106 0.138 −0.189 0.132 −0.081 −0.1032 涮制后亮度值L* −0.764 −0.033 0.328 0.276 −0.152 0.123 −0.308 0.0067 涮制后红度值a* −0.051 0.628 −0.433 0.284 0.223 0.290 −0.126 −0.0756 涮制后黄度值b* 0.139 0.609 −0.592 −0.015 0.054 0.335 0.043 −0.1546 凝胶硬度 0.940 0.068 −0.013 −0.072 −0.057 0.225 0.108 0.1059 凝胶弹性 0.580 0.124 −0.409 −0.481 0.07 −0.163 0.066 −0.0903 凝胶粘聚性 0.454 0.518 0.128 0.236 −0.048 −0.047 −0.348 0.1186 凝胶胶着性 0.952 0.137 0.086 −0.081 0.020 0.128 0.058 0.1626 凝胶咀嚼性 0.947 0.005 −0.055 −0.032 0.004 0.096 0.136 0.0967 凝胶保水性 −0.195 0.714 0.202 −0.096 0.432 −0.296 −0.060 0.1859 加压失水率 0.318 −0.306 0.543 0.130 0.521 0.056 −0.052 0.3487 剪切力 0.434 −0.005 0.333 0.507 0.243 −0.335 −0.122 0.2033 硬度 0.305 0.514 0.507 0.117 0.095 0.367 −0.041 0.3090 弹性 −0.115 −0.454 0.338 0.336 0.332 −0.191 0.445 0.1862 粘聚性 0.484 −0.486 −0.369 0.143 −0.425 0.125 −0.052 −0.2120 胶着性 0.028 0.471 0.181 0.230 −0.647 −0.249 0.200 −0.0231 咀嚼性 0.522 0.118 0.402 0.322 −0.504 −0.026 0.215 0.1396 回复性 0.408 −0.046 −0.623 0.365 0.220 −0.022 0.251 −0.1375 出品率 0.112 0.542 0.544 0.357 −0.088 0.271 0.136 0.2761 特征值 9.003 4.133 3.315 2.329 1.729 1.310 1.053 方差贡献率(%) 33.345 15.307 12.280 8.624 6.404 4.853 3.902 累计方差贡献率(%) 33.345 48.652 60.931 69.555 75.959 80.812 84.714 表 10 不同部位牦牛肉涮制加工品质指标相关性分析

Table 10 Correlation analysis of quality indexes of shabu-shabu yak meat from different cuts

指标 剪切力 硬度 胶着性 咀嚼性 涮制后红

度值a*涮制后黄

度值b*加压

失水率指标 脂肪

含量凝胶

硬度凝胶

咀嚼性凝胶

胶着性肌纤维

直径肌节

长度剪切力 1 脂肪含量 1 硬度 0.263 1 凝胶硬度 −0.455* 1 胶着性 0.065 0.269 1 凝胶咀嚼性 −0.526** 0.955** 1 咀嚼性 0.272 0.360 0.535** 1 凝胶胶着性 −0.412* 0.965** 0.936** 1 涮制后红度值a* −0.084 0.164 0.029 −0.086 1 肌纤维直径 −0.476* 0.914** 0.900** 0.938** 1 涮制后黄度值b* −0.291 0.143 0.035 −0.065 0.789** 1 肌节长度 0.354 −0.804** −0.842** −0.854** 0.789** 1 加压失水率 0.450* 0.246 −0.289 0.168 −0.183 −0.399 1 表 11 涮制牦牛肉关键品质指标权重

Table 11 Weight of key quality indices of shabu-shabu yak meat

指标 原料肉红

度值a*脂肪

含量加压失

水率凝胶

硬度涮制后黄

度值b*咀嚼性 主成分分

析权重0.1579 0.0539 0.3487 0.1059 0.1546 0.1396 归一化 0.1644 0.0561 0.3630 0.1102 0.1609 0.1453 表 12 涮制牦牛肉综合品质评价得分K-means聚类分析结果

Table 12 K-means cluster analysis of comprehensive quality evaluation scores of shabu-shabu yak meat from different cuts

部位 Y 适宜性 臀肉 0.55 较适宜 大黄瓜条 0.65 适宜 外脊 0.53 较适宜 肩肉 0.49 不适宜 腱子 0.50 不适宜 上脑 0.61 适宜 -

[1] 李向阳, 张莉. 我国居民肉类产品电商消费的信任研究[J]. 中国禽业导刊,2022,39(12):17−21. [LI Xiangyang, ZHANG Li. A study of trust in e-commerce consumption of meat products amo-ng Chinese residents[J]. China Avian Industry Directory,2022,39(12):17−21.] LI Xiangyang, ZHANG Li. A study of trust in e-commerce consumption of meat products amo-ng Chinese residents[J]. China Avian Industry Directory, 2022, 39(12): 17−21.

[2] 黄纯, 阎萍, 梁春年. 中国牦牛种业现状与发展方向[J]. 中国畜禽种业,2023,19(7):121−127. [HUANG Chun, YAN Ping, LIANG Chunnian. Current situation and development direction of China's yak breeding industry[J]. China Livestock and Poultry Breeding Industry,2023,19(7):121−127.] doi: 10.3969/j.issn.1673-4556.2023.07.019 HUANG Chun, YAN Ping, LIANG Chunnian. Current situation and development direction of China's yak breeding industry[J]. China Livestock and Poultry Breeding Industry, 2023, 19(7): 121−127. doi: 10.3969/j.issn.1673-4556.2023.07.019

[3] 赵改名, 王可, 祝超智, 等. 青海高原型牦牛不同部位肉的品质差异研究[J]. 食品研究与开发,2020,41(13):60−65. [ZHAO Gaiming, WANG Ke, ZHU Chaozhi, et al. Study on meat quality differences of different parts of Qinghai high-prototype yak[J]. Food Research and Development,2020,41(13):60−65.] doi: 10.12161/j.issn.1005-6521.2020.13.010 ZHAO Gaiming, WANG Ke, ZHU Chaozhi, et al. Study on meat quality differences of different parts of Qinghai high-prototype yak[J]. Food Research and Development, 2020, 41(13): 60−65. doi: 10.12161/j.issn.1005-6521.2020.13.010

[4] 高玲玲, 王振宇, 张彩霞, 等. 欧拉型藏羊肉的涮制加工特性[J]. 肉类研究,2017,31(2):16−20. [GAO Lingling, WANG Zhenyu, ZHANG Caixia, et al. Instant boiling characteristics of oula Tibetan sheep meat[J]. Meat Research,2017,31(2):16−20.] doi: 10.7506/rlyj1001-8123-201702004 GAO Lingling, WANG Zhenyu, ZHANG Caixia, et al. Instant boiling characteristics of oula Tibetan sheep meat[J]. Meat Research, 2017, 31(2): 16−20. doi: 10.7506/rlyj1001-8123-201702004

[5] LAWRENCE T E, KING D A, OBUZ E, et al. Evaluation of electric belt grill, forced-air convection oven, and electric broiler cookery methods for beef tenderness research[J]. Meat Science,2001,58(3):239−246. doi: 10.1016/S0309-1740(00)00159-5

[6] 王可. 不同部位青海高原型牦牛肉加工特性与加工适宜性研究[D]. 郑州:河南农业大学, 2020. [WANG Ke. Study on processing characteristics and suitability of Qinghai plateau yak meat from different parts[D]. Zhengzhou:Henan Agricultural University, 2020.] WANG Ke. Study on processing characteristics and suitability of Qinghai plateau yak meat from different parts[D]. Zhengzhou: Henan Agricultural University, 2020.

[7] 宋洁, 侯成立, 袁有云, 等. 不同部位羊肉烤制加工适宜性研究[J]. 食品科学,2017,38(15):108−114. [SONG Jie, HOU Chengli, YUAN Youyun, et al. Suitability of different cuts of lamb for roasting[J]. Food Science,2017,38(15):108−114.] doi: 10.7506/spkx1002-6630-201715018 SONG Jie, HOU Chengli, YUAN Youyun, et al. Suitability of different cuts of lamb for roasting[J]. Food Science, 2017, 38(15): 108−114. doi: 10.7506/spkx1002-6630-201715018

[8] 刘雪霏, 游佳伟, 程可欣, 等. 不同部位牛肉烤制加工的适宜性[J]. 食品科学,2021,42(11):86−93. [LIU Xuefei, YOU Jiawei, CHENG Kexin, et al. Roasting suitability of different beef from different cuts[J]. Food Science,2021,42(11):86−93.] doi: 10.7506/spkx1002-6630-20200608-105 LIU Xuefei, YOU Jiawei, CHENG Kexin, et al. Roasting suitability of different beef from different cuts[J]. Food Science, 2021, 42(11): 86−93. doi: 10.7506/spkx1002-6630-20200608-105

[9] 郎玉苗, 沙坤, 李海鹏, 等. 运用多元统计方法筛选涮食牛肉食用品质评价指标[C]//北京:第八届中国牛业发展大会, 2013:437−442. [LANG Yumiao, SHA Kun, LI Haipeng, et al. A multivariate statistical approach to screen the food quality indicators of shabu-shabu beef[C]//Beijing:The 8th China Cattle Industry Development Conference,2013:437−442.] LANG Yumiao, SHA Kun, LI Haipeng, et al. A multivariate statistical approach to screen the food quality indicators of shabu-shabu beef[C]//Beijing: The 8th China Cattle Industry Development Conference, 2013: 437−442.

[10] 国家卫生和计划生育委员会, 国家食品药品监督管理总局. GB/T 5009.5-2016食品安全国家标准 食品中蛋白质的测定[S]. 北京:中国标准出版社, 2016. [National Health and Family Planning Commission, State Food and Drug Administration. GB/T 5009.5-2016 National standard for food safety. Determination of protein in food[S]. Beijing:Standards Press of China, 2016.] National Health and Family Planning Commission, State Food and Drug Administration. GB/T 5009.5-2016 National standard for food safety. Determination of protein in food[S]. Beijing: Standards Press of China, 2016.

[11] 国家卫生和计划生育委员会, 国家食品药品监督管理总局. GB/T 5009.6-2016食品安全国家标准 食品中脂肪的测定[S]. 北京:中国标准出版社, 2016. [National Health and Family Planning Commission, State Food and Drug Administration. GB/T 5009.6-2016 National standard for food safety. Determination of fat in food[S]. Beijing:Standards Press of China, 2016.] National Health and Family Planning Commission, State Food and Drug Administration. GB/T 5009.6-2016 National standard for food safety. Determination of fat in food[S]. Beijing: Standards Press of China, 2016.

[12] 国家卫生和计划生育委员会, 国家食品药品监督管理总局. GB/T 5009.3-2016食品安全国家标准 食品中水分的测定[S]. 北京:中国标准出版社, 2016. [National Health and Family Planning Commission, State Food and Drug Administration. GB/T 5009.3-2016 National standard for food safety. Determination of moisture in food[S]. Beijing:Standards Press of China, 2016.] National Health and Family Planning Commission, State Food and Drug Administration. GB/T 5009.3-2016 National standard for food safety. Determination of moisture in food[S]. Beijing: Standards Press of China, 2016.

[13] 张中会, 盖圣美, 邹玉峰, 等. 不同注水量对猪肉食用品质的影响[J]. 食品工业科技,2018,39(3):1−5,11. [ZHANG Zhonghui, GAI Shengmei, ZOU Yufeng, et al. Effects of different water-injected ratios on eating quality of pork[J]. Food Industry Science and Technology,2018,39(3):1−5,11.] ZHANG Zhonghui, GAI Shengmei, ZOU Yufeng, et al. Effects of different water-injected ratios on eating quality of pork[J]. Food Industry Science and Technology, 2018, 39(3): 1−5,11.

[14] 徐焕, 郝力壮, 刘书杰, 等. 不同部位牦牛肉品质比较分析[J]. 食品研究与开发,2021,42(9):31−36. [XU Huan, HAO Lizhuang, LIU Shujie, et al. Comparison analysis of yak meat quality in different parts of muscles[J]. Food Research and Development,2021,42(9):31−36.] doi: 10.12161/j.issn.1005-6521.2021.09.005 XU Huan, HAO Lizhuang, LIU Shujie, et al. Comparison analysis of yak meat quality in different parts of muscles[J]. Food Research and Development, 2021, 42(9): 31−36. doi: 10.12161/j.issn.1005-6521.2021.09.005

[15] PALKA K. Changes in intramuscular connective tissue and collagen solubility of bovine m. semitendinosus during retorting[J]. Meat Science,1999,53(3):189−194. doi: 10.1016/S0309-1740(99)00047-9

[16] MESTRE P J A, GARCIA E C F J S, RIBEIRO A M R, et al. Contribution of major structural changes in myofibrils to rabbit meat tenderisation during ageing[J]. Meat Science,2002,61(1):103−113. doi: 10.1016/S0309-1740(01)00175-9

[17] XIONG Y L, LOU X, WANG C, et al. Protein Extraction from chicken myofibrils irrigated with various polyphosphate and NaCl solutions[J]. Journal of Food Science,2000,65(1):96−100. doi: 10.1111/j.1365-2621.2000.tb15962.x

[18] XIA X, KONG B, XIONG Y, et al. Decreased gelling and emulsifying properties of myofibrillar protein from repeatedly frozen-thawed porcine longissimus muscle are due to protein denaturation and susceptibility to aggregation[J]. Meat Science,2010,85(3):481−486. doi: 10.1016/j.meatsci.2010.02.019

[19] SUN J, WU Z, XU X, et al. Effect of peanut protein isolate on functional properties of chicken salt-soluble proteins from breast and thigh muscles during heat-induced gelation[J]. Meat Science,2012,91(1):88−92. doi: 10.1016/j.meatsci.2011.12.010

[20] OURY M P, PICARD B, BRIAND M, et al. Interrelationships between meat quality traits, texture measurements and physicochemical characteristics of M. rectus abdominis from Charolais heifers[J]. Meat Science,2009,83(2):293−301. doi: 10.1016/j.meatsci.2009.05.013

[21] 国家质量监督检验检疫总局, 国家标准化管理委员会. GB/T 16291.1-2012 感官分析选拔、培训与管理评价员一般导则第1部分:优选评价员[S]. 北京:中国标准出版社, 2012. [General Administration of Quality Supervision, Inspection and Quarantine, Standardization Administration of PRC. GB/T 16291.1-2012 General guidelines for sensory analysis selection, training and management evaluators part 1:Preferred evaluator[S]. Beijing:Standards Press of China, 2012.] General Administration of Quality Supervision, Inspection and Quarantine, Standardization Administration of PRC. GB/T 16291.1-2012 General guidelines for sensory analysis selection, training and management evaluators part 1: Preferred evaluator[S]. Beijing: Standards Press of China, 2012.

[22] 宋洁. 巴寒杂交羔羊不同部位肉加工适宜性研究[D]. 甘肃:甘肃农业大学, 2016. [SONG Jie. Research on processing suitability of different parts of Hybrid Lamb between Bamei Sheep and Small Tailed Han Sheep[D]. Gansu:Gansu Agricultural University, 2016.] SONG Jie. Research on processing suitability of different parts of Hybrid Lamb between Bamei Sheep and Small Tailed Han Sheep[D]. Gansu: Gansu Agricultural University, 2016.

[23] 张文霖. 主成分分析在满意度权重确定中的应用[J]. 市场研究,2006(6):18−22. [ZHANG Wenlin. Application of principal component analysis in the determination of satisfaction weights[J]. Market Research,2006(6):18−22.] doi: 10.3969/j.issn.1672-4216.2006.06.007 ZHANG Wenlin. Application of principal component analysis in the determination of satisfaction weights[J]. Market Research, 2006(6): 18−22. doi: 10.3969/j.issn.1672-4216.2006.06.007

[24] FAROUK M M, STAINCLIFFE M, HOPKINS D L, et al. Visible fat content of hotpot beef acceptability by New Zealand Chinese, Japanese, and Korean consumers[J]. Journal of Food Quality,2019(2019):1−11.

[25] 黄红涛, 冯若楠, 夏天宇, 等. 脂肪对肉品质的影响[J]. 畜牧兽医杂志,2018,37(1):59−60. [HUNAG Hongtao, FENG Ruonan, XIA Tianyu, et al. Effects of fat on meat quality[J]. Journal of Animal Husbandry and Veterinary Medicine,2018,37(1):59−60.] doi: 10.3969/j.issn.1004-6704.2018.01.024 HUNAG Hongtao, FENG Ruonan, XIA Tianyu, et al. Effects of fat on meat quality[J]. Journal of Animal Husbandry and Veterinary Medicine, 2018, 37(1): 59−60. doi: 10.3969/j.issn.1004-6704.2018.01.024

[26] 郝婉名. 西门塔尔杂交牛不同部位肉的品质特性与加工传统牛肉产品适宜性研究[D]. 郑州:河南农业大学, 2020. [HAO Wanming. Study on quality characteristics and suitability of processing traditional beef products in different parts of Simmental hybrid cattle[D]. Zhengzhou:Henan Agricultural University, 2020.] HAO Wanming. Study on quality characteristics and suitability of processing traditional beef products in different parts of Simmental hybrid cattle[D]. Zhengzhou: Henan Agricultural University, 2020.

[27] 姚喜喜, 王伟, 徐成体, 等. 放牧与舍饲对大通牦牛生长性能、瘤胃发酵参数、屠宰性能及肉品质的影响[J]. 动物营养学报,2022,34(6):3768−3776. [YAO Xixi, WANG Wei, XU Chengti, et al. Effects of grazing and barn feeding on growth performance, rumen fermentation parameters, slaughter performance and meat quality of Datong yaks (bos grunniens)[J]. Journal of Animal Nutrition,2022,34(6):3768−3776.] doi: 10.3969/j.issn.1006-267x.2022.06.037 YAO Xixi, WANG Wei, XU Chengti, et al. Effects of grazing and barn feeding on growth performance, rumen fermentation parameters, slaughter performance and meat quality of Datong yaks (bos grunniens)[J]. Journal of Animal Nutrition, 2022, 34(6): 3768−3776. doi: 10.3969/j.issn.1006-267x.2022.06.037

[28] 赵改名, 秦可梦, 李佳麒, 等. 不同部位新疆褐牛肉的品质差异分析[J]. 肉类研究,2021,35(1):1−6. [ZHAO Gaiming, QIN Kemeng, LI Jiaqi, et al. Differences in meat quality among different carcass parts of Xinjiang brown cattle[J]. Meat Research,2021,35(1):1−6.] ZHAO Gaiming, QIN Kemeng, LI Jiaqi, et al. Differences in meat quality among different carcass parts of Xinjiang brown cattle[J]. Meat Research, 2021, 35(1): 1−6.

[29] 方雷. 饲养方式对夏季牦牛生长性能、屠宰性能、牛肉品质和瘤胃细菌多样性的影响[D]. 北京:中国农业大学, 2015. [FANG Lei. Effects of feeding patterns in summer on yaks' growth performance, carcass traits, meat quality and rumen bacteria diversity[D]. Beijing:China Agricultural University, 2015.] FANG Lei. Effects of feeding patterns in summer on yaks' growth performance, carcass traits, meat quality and rumen bacteria diversity[D]. Beijing: China Agricultural University, 2015.

[30] ŞIRIN E. The relationship between muscle fiber characteristics and some meat quality parameters in Turkish native sheep breeds[J]. Small Ruminant Research,2017,3(150):46−51.

[31] 付洋洋, 高彦华, 彭忠利, 等. 采用MSA体系对川西北牦牛肉食用品质的评价研究[J]. 中国畜牧杂志,2018,54(7):112−117. [FU Yangyang, GAO Yanhua, PENG Zhongli, et al. Evaluation of edible quality of yak meat from Northwest Sichuan using MSA system Evaluation study[J]. China Animal Husbandry Magazine,2018,54(7):112−117.] FU Yangyang, GAO Yanhua, PENG Zhongli, et al. Evaluation of edible quality of yak meat from Northwest Sichuan using MSA system Evaluation study[J]. China Animal Husbandry Magazine, 2018, 54(7): 112−117.

[32] HOLMAN B W B, COLLINS D, KILGANNON A K, et al. Using shear force, sarcomere length, particle size, collagen content, and protein solubility metrics to predict consumer acceptance of aged beef tenderness[J]. Journal of Texture Studies,2020,51(4):559−566. doi: 10.1111/jtxs.12523

[33] SHON S R, CHIN K B. Evaluation of rheological properties of pork myofibrillar protein with tapioca starch and its utilization to the pork model sausages[J]. Korean Journal for Food Science of Animal Resources,2012,32(3):323−329. doi: 10.5851/kosfa.2012.32.3.323

[34] 游佳伟. 不同部位牛肉烤制加工适宜性研究[D]. 锦州:渤海大学, 2020. [YOU Jiawei. Roasting suitability of different beef from different cuts[D]. Jinzhou:Bohai University, 2020.] YOU Jiawei. Roasting suitability of different beef from different cuts[D]. Jinzhou: Bohai University, 2020.

[35] SUMAN S P, JOSEPH P. Myoglobin chemistry and meat color[J]. Annual Review of Food Science and Technology,2013,4:79−99. doi: 10.1146/annurev-food-030212-182623

[36] 宋洁, 侯成立, 王振宇, 等. 不同月龄羊肉原料肉品质与涮食羊肉品质的关系[J]. 食品科学,2017,38(5):154−159. [SONG Jie, HOU Chengli, WANG Zhenyu, et al. Relationship between raw mutton quality and instant-boiled mutton quality from sheep at different months of age[J]. Food Science,2017,38(5):154−159.] SONG Jie, HOU Chengli, WANG Zhenyu, et al. Relationship between raw mutton quality and instant-boiled mutton quality from sheep at different months of age[J]. Food Science, 2017, 38(5): 154−159.

-

期刊类型引用(5)

1. 潘冠均,段淋渊,赵嘉科,帅平,戴国礼,田维素,王金源,黄佳鹏,闭晓彤,林恩照,秦垦,郝志龙,张波. 摊放程度对枸杞芽叶茶风味品质的影响. 食品工业科技. 2025(04): 117-126 .  本站查看

本站查看

2. 吴宗杰,欧晓西,林宏政,余欣茹,程守悦,吴晴阳,李鑫磊,孙云. 武夷肉桂加工中挥发性成分糖苷结合物和香气品质形成研究. 茶叶科学. 2024(01): 84-100 .  百度学术

百度学术

3. 潘冠均,封娇,段淋渊,张炫鹂,戴国礼,帅平,秦垦,郝志龙,张波. 不同单株枸杞芽叶茶风味品质分析. 食品工业科技. 2024(15): 264-273 .  本站查看

本站查看

4. 徐晓俞,李程勋,李爱萍,郑开斌,潘键,侯明香. 肉桂茶纯露挥发性成分分析. 福建农业科技. 2024(06): 49-55 .  百度学术

百度学术

5. 占鑫怡,杨云,陈彬,黄慧清,赵梦莹,李鑫磊,孙云. 不同摇青程度春闺闽北乌龙茶品质差异分析. 食品工业科技. 2023(11): 271-279 .  本站查看

本站查看

其他类型引用(2)

下载:

下载:

下载:

下载: