Progress in the Research of the Mechanism of Ethyl Lactate Production and ''Ethyl Lactate Reduction'' Techniques in the Baijiu Brewing Process

-

摘要: 白酒中乳酸乙酯的含量与白酒酿造过程密切相关,这使得白酒中乳酸乙酯的含量难以控制。乳酸乙酯含量偏高会负面影响白酒风味和人体饮后舒适度。因此,分析乳酸乙酯的产生机理,确保其在不同香型白酒中的适宜浓度,对酒企生产和消费者的健康饮用具有重要指导意义。本文阐述了白酒中乳酸乙酯由乳酸和乙醇经酯化反应和化学反应合成的机理,总结了其在白酒中产香增味的作用及不同香型白酒中乳酸乙酯含量的标准,并探讨了在酿造原料、酒曲、乳酸降解菌、微生物相互作用、封窖方式、蒸馏设备、蒸馏压力、摘酒顺序、白酒陈化工艺中的“降乳”措施;分析了“降乳”措施对白酒品质、感官、出酒率的影响,以及部分酒企的实际应用情况,并提出了未来应从生物技术、基因工程、代谢工程方面探索和优化更加高效、环保的“降乳”技术。本研究旨在为“降乳”技术在白酒酿造中的进一步应用提供一些参考。Abstract: The content of ethyl lactate in baijiu is difficult to control owing to its high dependent on the brewing process. However, high levels of ethyl lactate can negatively affect the flavor of Baijiu and the after-effects of consumption. Therefore, analyzing the production mechanism of ethyl lactate and ensuring its appropriate concentration in different flavored baijiu holds significant guiding implications for both the production of distilleries and the healthy consumption of consumers. This article elaborates on the mechanism of ethyl lactate production from lactic acid and ethanol through esterification and chemical reactions in Baijiu, summarizes its effects on aroma production and taste enrichment, and sets standards for ethyl lactate content in different flavored Baijiu. Furthermore, this review discusses the measures utilized to control the content of ethyl lactate in Baijiu production, including raw materials, Jiuqu, lactic acid-degrading bacteria, microbial interactions, sealing methods, distillation equipment, distillation pressure, sequence, and aging process. It also analyzes the effects of lactate reduction measures on the quality, taste, and yield of baijiu, as well as the practical application of these measures in some Baijiu enterprises. The study proposes that future exploration and optimization of more efficient and environmentally friendly techniques of lactate reduction should focus on biotechnology, including genetic and metabolic engineering to provide reference for the further application of lactate reduction techniques in Baijiu brewing.

-

Keywords:

- Baijiu /

- ethyl lactate /

- produce mechanism /

- ethyl lactate reduction /

- fermentation

-

白酒是中国传统固态发酵酿造的蒸馏酒,其口感和风味主要由酒体中的风味物质及其含量决定[1−2]。在白酒发酵过程中产生了上百种对白酒香气、口感、品质、功能起作用的重要酯类物质[3]。乳酸乙酯是白酒四大酯(乳酸乙酯、己酸乙酯、乙酸乙酯、丁酸乙酯)之一,在成品酒中含量较高(496.83~2210 mg/L)[4−6],是白酒中重要的风味物质之一,对白酒的口感和品质有重要影响。白酒中乳酸乙酯含量与发酵过程密切相关,乳酸乙酯主要由乳酸和乙醇在酯化酶的作用下合成[7]。乳酸乙酯能增加白酒的醇厚感,丰富酒体,调节白酒口味,延长白酒后味[8−10];但乳酸乙酯含量过高会导致酒香不足、后味偏涩,从而影响白酒口感和降低白酒品质[11−13]。长期以来,“降乳”一直是我国部分酒企面临的技术问题。因此,探究乳酸乙酯的产生机理及“降乳”技术对提高白酒品质、促进白酒行业的可持续发展具有重要意义。

高校和酒企研究了较多的“降乳”技术,包括在酿造原料[14−15]、酒曲[5]、乳酸降解菌[16−18]、微生物相互作用[19]、封窖方式[20]、蒸馏设备[21]、蒸馏压力[22]、接酒顺序[5]、白酒陈化工艺[23]中的“降乳”技术。其中,筛选和应用乳酸降解菌可有效降低不同香型白酒中的乳酸乙酯含量,并提高白酒质量,且经济效益显著[16−18]。但其它较多“降乳”技术存在研究成本高、操作复杂、研究周期长等问题,在酒企实际生产中的应用面临挑战。

本文旨在对白酒中乳酸乙酯的产生机理和“降乳”技术研究及应用现状进行综述,阐述了白酒中乳酸乙酯的产生机理,总结了白酒中乳酸乙酯的作用和标准,探讨了白酒酿造中的“降乳”技术,分析了不同技术对白酒质量的影响及企业实际应用情况。为酒企在生产中将乳酸乙酯控制在适宜浓度提供一些参考,有助于我国白酒行业的健康可持续发展。

1. 白酒中乳酸乙酯的产生机理

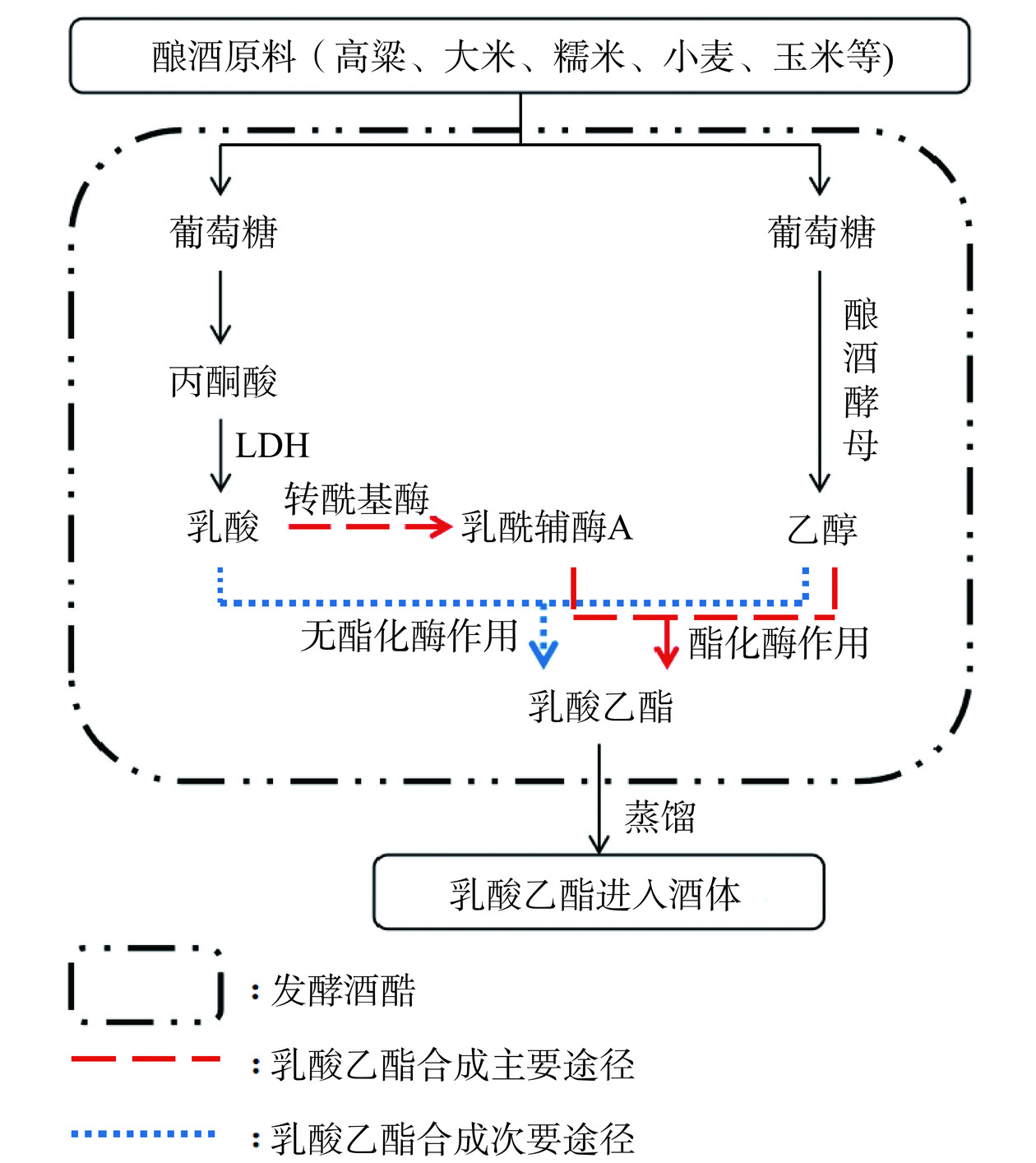

白酒中乳酸乙酯的合成主要来源于微生物作用。在发酵过程中,乳酸(由乳酸菌产生)在转酰基酶的作用下被活化为乳酰辅酶A,乳酰辅酶A在酯化酶(由各种霉菌产生)的作用下与乙醇(由酵母菌产生)反应合成乳酸乙酯[24−26],这是合成乳酸乙酯的主要途径,如图1所示。在没有酯化酶的情况下,游离的乳酸、乙醇发生单纯的有机化学反应合成乳酸乙酯,该反应在常温下反应速率很低,这是合成乳酸乙酯的次要途径[24−26],通过蒸馏,一部分乳酸乙酯被带入酒体,另一部分乳酸乙酯继续留在酒醅中。

2. 白酒中乳酸乙酯的作用和标准

2.1 白酒中乳酸乙酯的作用

乳酸乙酯呈柔和的果香,能缓冲和平衡酒香,具有使白酒更加醇厚、谐调、甘甜、回味悠长的作用[9−10,27]。但乳酸乙酯沸点较高,易降低其它组分的挥发速率,其含量超过一定范围时,酒体会呈现香气不突出,主体香受抑制,香味失调,并有闷甜感,酸涩度增加,进而降低白酒的品质[11−13]。

2.2 白酒中乳酸乙酯的标准

不同香型白酒的国家标准[28−30]、团体标准[31−33]和业界标准[34−37]对乳酸乙酯的标准要求不一致,见表1。此外,国家标准规定,优级浓香型白酒绵甜醇厚,谐调爽净,余味悠长[38];优级芝麻香型白酒醇和细腻,香味协调,余味悠长[30];两者均以己酸乙酯为主体酯。特级清香型白酒醇厚绵甜,丰满细腻,谐调爽净[39];优级酱香型白酒酒体醇和,协调,味长[40];两者均以乙酸乙酯为主体酯。不同香型白酒中乳酸乙酯含量不宜超过其主体酯含量,否则易影响不同香型白酒所规定的典型风格[5]。因此,酒企可根据酒体中乳酸乙酯含量偏高对白酒的影响[11−13]以及上述标准与规定判断酒体的乳酸乙酯含量是否符合标准。

表 1 不同香型白酒酒体中乳酸乙酯的含量标准Table 1. Standard of ethyl lactate in different flavor baijiu finish product白酒类型(酒精度) 优级 一级 参考文献 浓香型白酒 已酸乙酯/乳酸乙酯(1:0.5~0.8) [34] 清香型白酒 乙酸乙酯/乳酸乙酯(1:0.6~0.8) [36] 凤香型白酒 乙酸乙酯/乳酸乙酯(1:0.6~0.8) [37] 凤香型白酒 乳酸乙酯0.3~0.8 g/L [35] 老白干香型(41%vol~68%vol) 乳酸乙酯≥0.50 g/L 乳酸乙酯≥0.40 g/L [28] 老白干香型(18%vol~40%vol) 乳酸乙酯≥0.40 g/L 乳酸乙酯≥0.30 g/L 老白干白酒 乳酸乙酯/乙酸乙酯≥0.8 米香型白酒(41%vol~68%vol) 乳酸乙酯≥0.50 g/L 乳酸乙酯≥0.40 g/L [29] 米香型白酒(25%vol~40%vol) 乳酸乙酯≥0.30 g/L 乳酸乙酯≥0.20 g/L 芝麻香型白酒(40%vol~68%vol) 乳酸乙酯≥0.60 g/L [30] 芝麻香型白酒(25%vol~40%vol) 乳酸乙酯≥0.30 g/L 绵柔型白酒(21%vol~69%vol) 乳酸乙酯≥0.30 g/L 乳酸乙酯≥0.20 g/L [31] 糟烧白酒(45%vol~60%vol) 乳酸乙酯≥0.30 g/L [32] 绵柔酱香型白酒(53%vol±1%vol) 乳酸乙酯≥0.80 g/L [33] 3. 白酒酿造过程中降低乳酸乙酯含量的措施

在白酒酿造过程中,乳酸乙酯含量偏高主要与酿造原料、酒曲、季节温度、发酵时间、发酵温度、酿造环境和封窖方法有关。酿造原料淀粉含量高,易导致在发酵时乳酸菌利用淀粉产生大量乳酸,进而合成乳酸乙酯[41];酒曲中的乳酸菌较多,可进入酒醅产生乳酸,合成乳酸乙酯[42];在酒醅中添加高温曲和堆积曲发酵,易导致窖池温度偏高,乳酸菌耐高温易代谢产生大量乳酸,进而合成乳酸乙酯[43];夏季生产时,环境温度高、湿度大,乳酸菌耐高温能广泛分布在酒醅中产生乳酸,进而合成乳酸乙酯[44];发酵时间长和温度高致使酒醅中产生大量乳酸,合成乳酸乙酯[43];酿造外界环境中的乳酸菌进入酒醅产生乳酸,进而合成乳酸乙酯[45];使用窖泥封窖,窖泥干裂引起环境中的乳酸菌侵入酒醅产生乳酸,进而合成乳酸乙酯[46]。

基于上述原因,可分别在原料挑选、酒曲控制、发酵过程、蒸馏过程和白酒存放过程中采取措施来降低白酒中乳酸乙酯的含量。

3.1 挑选酿造原料来降低白酒中的乳酸乙酯

3.1.1 低淀粉原料降低白酒中的乳酸乙酯

琅琊台浓香型白酒以高粱为酿造原料,新疆高粱淀粉含量(68.49%)低于澳大利亚高粱(69.70%),晁进福等[47]发现,新疆高粱酿造的白酒中乳酸乙酯含量(1.41 g/L)低于澳大利亚高粱(1.57 g/L),且出酒率最高(36.35%),白酒口感最佳,其己乳比(1:0.79)更符合浓香型白酒的要求。通过对白酒出酒率、理化指标和感官品质的综合分析,新疆高粱更适合酿造该白酒。此外,常强等[48]还发现,纯高粱(淀粉含量为65.8%)酿造的白酒比纯大米(淀粉含量73.4%)酿造的白酒中乳酸乙酯含量低24%;范志勇等[49]发现,辽宁高粱(淀粉含量为59.8%)酿造的白酒中乳酸乙酯含量(0.999 g/L)低于河北高粱(淀粉含量为62.6%)酿造的白酒中乳酸乙酯含量(1.457 g/L)。

3.1.2 酿酒专用粮降低白酒中的乳酸乙酯

四川省农业科学院[14−15]培育出一种杂交糯高粱“45A”(淀粉含量75.56%),泸州老窖用该粮酿造的浓香型白酒中乳酸乙酯含量比本地糯高粱低22.15%,出酒率高1.27%,酒质显著提高。同时,“45A”经泸州市酿酒科学研究所试验,酿造酱香型、浓香型、清香型白酒的出酒率比常规糯高粱酿造高1.2%~2%;经重庆市农业科学院酿造小曲酒试验,出酒率比北方粳高粱酿造高8%;经四川天之娇子酿造酱香型白酒试验,出酒率提高6.26%,优质品率提高11.28%[14−15]。据上述己收到应用证明的几家酒企统计,效益有所增加。

应用低淀粉含量的原料和酿酒专用粮可降低白酒中的乳酸乙酯,原因是白酒酿造过程中,淀粉通过糖化作用转化为糖类和有机物等,为酿酒微生物的生长代谢提供物质基础和能量来源;糖类是乳酸乙酯生成的主要碳源,而低淀粉含量原料降低了乳酸乙酯生成的条件[26−28]。此外,淀粉结构(直链淀粉、支链淀粉)也影响发酵中乳酸乙酯的含量[47,50],原因是直链淀粉易导致原料在蒸煮中老化,不利于酿酒微生物对原料中营养物质的利用,而乳酸菌则可能作用于老化淀粉进而产生乳酸[51],为乳酸乙酯生成提供前体物质;而支链淀粉分子由于分支较多,易吸水糊化,有利于多种酿酒微生物的生长。不同原料含有物质差异不一致,大米的淀粉含量普遍较高,而特香型、米香型、豉香型白酒均是以纯大米为原料[52],因此可通过挑选淀粉含量相对较低的大米来降低以上三种香型白酒中的乳酸乙酯含量;高粱根据淀粉结构的差异分为梗高粱(直链淀粉含量高)和糯高粱(支链淀粉含量高);而酱香型、浓香型、清香型白酒均主要以高粱为酿造原料[52];因此可通过挑选不同品种的糯高粱来降低以上三种香型白酒中的乳酸乙酯含量。且目前已有较多酿酒专用粮被研制出,并已应用于白酒实际生产中,例如郎酒酒厂应用“郎糯红19号”(郎酒公司联合四川省农业科学院培育)[53],五粮液酒厂应用“宜糯红2号”(四川众望种业有限责任公司研发)[54]。但从挑选原料开始调控酒体中的乳酸乙酯,需考虑较多生产成本(原料价格、物流价格、运输时间、人工成本、研发时间等),因此该方式较适合大型酒厂创新酒体和开发新酒使用。未来,可进一步研究酿酒原料对乳酸乙酯生成的影响,以及在提升白酒品质方面的潜力。

3.2 控制酒曲中的乳酸菌来降低白酒中的乳酸乙酯

酒曲为酒醅中乳酸菌的主要来源之一,Yu等[55]发现酒曲中优势乳酸菌的数量与白酒中乳酸乙酯的含量成正比,因此控制酒曲中乳酸菌的数量有可能有效控制白酒酿造中乳酸乙酯的生成。在白酒酿造中,可通过提高酒曲本身糖化力和液化力等,使乳酸菌处于相对被抑制状态[36];使用陈曲或使用陈放3~6个月的新曲(使酒曲中的水分减少),使一些不适合在干燥环境中生长的乳酸菌受到抑制[5]。鉴于控制酒曲中的乳酸菌处于白酒酿造过程的早期阶段,且研究周期较长,因此较适合大型酒厂使用。

3.3 筛选和应用乳酸降解菌来降低白酒中的乳酸乙酯

乳酸乙酯性质稳定,不易分解,要降低乳酸乙酯含量可降低其前体物质乳酸的含量[56]。乳酸降解菌是一类分布在大曲、窖泥和糟醅中并以乳酸作为碳源的微生物,其产物主要包括醇类、酸类和酯类[56]。因此,可通过在白酒酿造过程中筛选和应用乳酸降解菌来降低白酒中的乳酸乙酯,具体措施如下:

为解决牛栏山酒厂清香型白酒因乙乳比失调而导致的酒体不协调问题,宋克伟等[16]将从大曲中分离筛选的降乳菌(枯草芽孢杆菌)制作成麸曲,按投粮量1.7%和大曲混合后随酒醅入池,研究显示,与对照组相比,试验组白酒中乳酸乙酯降低了0.378 g/L,乙酸乙酯增长了0.336 g/L,且其总酸、总酯及出酒率变化不大。为降低四特酒酒厂特香型白酒中乳酸乙酯含量和提升白酒品质,吴生文等[17]将从窖泥中分离筛选的降乳菌(丙酸菌),以6.7×105个/g添加到糟醅中进行生产试验,研究显示,与对照组相比,试验组白酒中乳酸乙酯降低了0.806 g/L,丙酸乙酯提高了5 mg/L。原因是丙酸菌以乳酸为碳源发酵生成丙酸,在生物酶的作用下与乙醇酯化生成丙酸乙酯。丙酸乙酯是特香型白酒的主体风味物质,应用丙酸菌可起到“增丙降乳”的效果。随后,四特酒酒厂[17−18]通过诱变育种得到高产丙酸并耐酸的丙酸菌,该菌可使白酒中丙酸乙酯提高30%以上,经法定机构检测,产品已达到优质特香型白酒的国家标准。将其应用于该酒厂实际生产中,通过提高白酒品质和消费者满意度,酒厂一年的新增销售额显著增加。

乳酸降解菌来自酿酒环境,可降低白酒中的乳酸乙酯。不同酿造环境中筛选出的降乳菌具有差异,例如从清香型白酒酿造环境中筛选出的降乳菌以芽孢杆菌为主,如解淀粉芽孢杆菌[57]、枯草芽孢杆菌等[16];从特香型白酒酿造环境中筛选出的降乳菌以丙酸菌为主[17−18];从浓香型白酒酿造环境中筛选出的降乳菌以丙酸菌[56]、梭状芽孢杆菌[58]为主。目前,应用降乳菌降低白酒中乳酸乙酯的研究较多,该方式适合降低不同香型白酒中的乳酸乙酯,并增加其主体酯,如清香型白酒的“增乙降乳”,特型酒的“增丙降乳”,浓香型白酒的“增己降乳”。因此,降乳菌的筛选应用较适合资金充裕、且需降低白酒中乳酸乙酯含量和提高白酒主体酯含量的中大型酒厂。

3.4 利用微生物相互作用来降低白酒中的乳酸乙酯

微生物相互作用可降低白酒中的乳酸乙酯。例如,为提高白酒产量与品质,王松等[19]将长孢洛德酵母(Lodderomyces elongisporus)添加到糟醅中进行发酵,研究显示,白酒中乳酸乙酯含量从1 g/L显著下降至0.5 g/L;此外,实验组中有害物质甲醇从0.15 g/L降至0.09 g/L,出酒率提高25%,感官评价更高。贾智勇等[59]将复合功能菌(米曲霉、产酯酵母、汉逊酵母、拟内孢霉)添加到凤香型白酒大曲中进行试验,研究发现,白酒中乳酸乙酯相比对照组降低了70 mg/L。何宏魁等[60]将从老窖泥中筛选的“增己降乳”组合菌(反刍球菌细菌、酪丁酸梭菌、乳杆菌、乳酸杆菌、木犀科细菌、拜氏梭菌),按比例制成混合菌液,投入到窖池底部进行发酵生产,相比对照组,乳酸乙酯降低了183.69 mg/L。

白酒是由多种酿酒微生物通过广泛而复杂的相互作用的固态发酵过程生产的,这些相互作用是维持菌群结构共生的关键因素,从而影响白酒发酵过程中的微生物代谢,进而影响白酒的风味和质量[61−62]。白酒发酵的微生物种类繁多,不同微生物之间的作用机制不同,这种方法可能会对白酒生产带来不利的影响,如添加不同菌种易造成其它微生物种类不稳定,数量难控制,量比关系不协调等问题。因此,未来还需花费较多人力、时间、资金来探究微生物相互作用降低乳酸乙酯含量在酒企实际生产中的应用。

3.5 更换封窖方式来降低白酒中乳酸乙酯的含量

3.5.1 封窖材料

近年来,由于酿酒技术的不断提高,窖封技术也在不断进步和探索创新。目前密封材料包括不锈钢盖封窖[63]、塑料薄膜封窖[20,64]、竹席隔离封窖[65]、麻布辅助封窖[66]等。其中不锈钢盖封窖具有机械化操作强,密封效率高,密封性强,耐酸耐腐蚀,可重复使用等优点[46];但不锈钢窖盖自身较重,须使用机械化吊装设备;同时,不锈钢价格昂贵,窖盖也须专门定制;应用该方式成本较高,较适合于资金充裕的中大型酒企和机械化新车间应用。“化纤窖池布”具有密封性能好、耐酸碱、耐腐蚀、拉伸力强、无塑化剂的优点[67],其成本远低于使用不锈钢,但随着使用次数的增多,窖布也会出现收缩的现象,因此较适合中小型酒厂使用。

3.5.2 封窖方式

酒窖是白酒发酵的容器,封窖的目的是为酒醅中的微生物代谢提供厌氧环境,避免杂菌污染[68]。传统的封窖是采用腐殖质少、含沙量低的黏性泥土作为封窖材料[69],窖泥与外界环境直接接触,易出现干燥、开裂、鼓胀等现象,导致环境中的乳酸菌侵入酒醅[70]。因此,可通过使用密封性更强的封窖方法来降低白酒中的乳酸乙酯。为提高白酒质量及产量,赵扬扬等[63]使用不锈钢盖对酒窖进行密封,研究显示实验组乳酸乙酯降低了0.2 g/L,出酒率提高了1.5%、白酒感官评分提高了5.5分,能有效提高白酒质量及产量。赊店酒厂使用普通塑料布封窖,具有不耐酸不耐腐蚀易破损的缺点[20],封明振等[20,64]使用化纤窖池布对该酒厂的两个窖池进行封窖,研究显示白酒中乳酸乙酯的含量减少了0.498 g/L,产酒量提升了3.9 t,泸型酒的主体酯己酸乙酯提高了0.105 g/L。在本次中式试验中,成本降低,效益增加,之后该酒厂便应用化纤窖池布进行封窖。

3.6 调整蒸馏设备降低白酒中乳酸乙酯含量

3.6.1 改变甑桶形状

甑桶是特殊的填料塔,将发酵好的酒醅放入甑桶形成填料层,通过蒸馏得到白酒[71]。在直径小、高度高的甑桶中进行蒸馏,由于酒醅自身重力的影响,酒醅的空隙率和疏松度降低,导致白酒中的乳酸乙酯含量有所下降[71]。因此可通过改变甑桶的形状来降低白酒中乳酸乙酯的含量。杨平等[71]在泸州老窖酒厂研究了相同体积、不同高度的甑桶对白酒中乳酸乙酯含量变化的影响,结果显示A甑桶(高度1 m)组白酒中乳酸乙酯(3.651 g/L)低于B甑桶(高度0.7 m)组白酒中乳酸乙酯(4.843 g/L)。此外,与B甑桶相比,A甑桶组出酒量高出1.9 kg,己酸乙酯含量高出0.098 g/L,感官评定更好。

甑桶的高径比越大,乙醇浓度越高,有利于降低白酒中乳酸乙酯的含量,并提高白酒酒质。但高度过高,重力的影响会导致酒醅的空隙率下降,阻碍正常的生产操作。因此,如何控制甑桶的高径比,以保证蒸馏效率,不影响白酒质量,使酒体中的乳酸乙酯在合适的范围内,有待进一步研究。此外,甑桶是不锈钢材料定制的,价格较贵,定制过程涉及人工、时间成本等,企业在研究时,需考虑成本方面的因素。

3.6.2 改变封甑方式

目前,国内普遍使用的白酒蒸馏甑在甑盖与甑桶连接处有一水封槽,利用槽内的水层进行密封,这种水封甑易造成甑内酒蒸汽的外泄,而酒蒸汽大量外泄会造成较大酒损[21]。气封甑是通过在封闭槽内进行充气,气封甑的密封性能较好,不易造成酒蒸汽的流失[21],因此气封甑内酒蒸汽的酒精浓度较高,对水溶性酯乳酸乙酯的提取量会减少。为提升产量和提高酒质,陈全庚等[21]应用气封甑和水封甑进行白酒蒸馏对照试验,研究发现,气封甑蒸馏能降低白酒中的乳酸乙酯(降低1.02 g/L)。应用于华丰酒厂实际生产中,产酒量稳定提高5 %以上,浓香型白酒主体酯己酸乙酯提高0.54 g/L。通过提升白酒产量和提高白酒酒质,该酒厂效益增加。

企业应用气封甑具有科学稳定、安全卫生、方便实用,成本较低,经济效益显著等优点[21]。陈全庚[72]又进一步拓展了气封甑在清香型小曲白酒生产中的应用,取得了和上述相似的结果。四川成都长城川兴酒厂[73]坚持使用气封甑进行白酒生产,此外,其还对气封甑的使用方法、效果以及应用机理等开展进一步的探讨。由于气封甑内酒精浓度高、对水溶性酯的提取量会减少、对醇溶性酯的提取量会增加的特点,该方法较适合于需降低乳酸乙酯量、增加醇溶性酯含量和提高产酒率的酒厂使用。

3.7 低压蒸馏降低白酒中乳酸乙酯含量

蒸馏是白酒生产中的重要高温处理过程。不同的蒸馏气压提供了不同的环境压力与反应温度[22],从而导致酒醅中组分物质汽化和冷凝过程有所差异,进而影响乳酸乙酯的馏出效果[74]。管桂坤等[22]在兰陵美酒厂进行不同压力蒸馏试验,结果显示低压蒸馏(上甑气压0.06 MPa,蒸酒气压0.03 MPa)白酒中的乳酸乙酯(0.577 g/L)显著低于高压蒸馏(上甑气压0.1 MPa,蒸酒气压0.1 MPa)白酒中的乳酸乙酯(1.092 g/L),且白酒口感更纯正、净爽。原因是低压蒸馏酒醅中乙醇的提取率高,水溶性物质乳酸乙酯的提取率有所下降。

低压蒸馏可用于解决白酒实际生产中乳酸乙酯含量过高的问题。因为不同蒸馏气压对酒醅中各种醇类、酯类、酸类等物质的提取率不同,同时对白酒的质量、口感和风味的影响也不同。因此,需进行连续对比试验,探究出适合不同白酒的最适蒸馏气压。

3.8 控制摘酒顺序降低白酒中乳酸乙酯含量

乳酸乙酯是水溶性酯且沸点高(154 ℃),蒸馏前期,酒精度较高和温度偏低,较难从酒醅中扩散出来;随着蒸馏的进行,酒精度下降和温度上升,乳酸乙酯溶于水易从酒醅中扩散出来[5,75]。可通过蒸馏前期接酒来降低白酒中的乳酸乙酯,但高度摘酒会导致蒸馏后期的馏分被浪费,并损失了部分风味物质。因此,在酒企生产中,未有通过高度摘酒来降低白酒中乳酸乙酯含量的实际应用。不同蒸馏阶段的酒具有不同的成分和特点,蒸馏前段的白酒酒精度高,酯溶性物质含量高,水溶性物质含量低;蒸馏后端的白酒酒精度低,水溶性物质含量高,酯溶性物质含量低[75]。因此,将不同蒸馏阶段(前段、中段、后端)的酒进行分类储存,将有利于在酒体设计环节调控白酒中的乳酸乙酯含量。

3.9 白酒陈化工艺降低乳酸乙酯含量

刚蒸馏的新酒呈现香气较冲、辅料味明显、口感辛辣等缺陷,因此会经过一段时间的存放(自然老熟)或人工催陈(人工老熟)来减少酒的辛辣刺激感,使酒变得绵柔醇厚[23]。杏花村汾酒厂的某65vol%清香型白酒出现了乙乳比(1:1.11)失调的问题,马转转等[23]在该厂探究了白酒陈化工艺(添加陈化液并结合磁化催陈处理)在该白酒中的应用,与对照组相比,试验组乙乳比(1:0.75)恢复了正常,且口感更加绵甜、细腻、醇厚,余味更加悠长。目前,白酒人工陈化方法较多,包括物理(微波、超声波、电磁场)催陈法、化学(氧气、臭氧、高锰酸钾)催陈法、生物(脂肪酶、植物提取物)催陈法[76−77]。未来,可广泛探究不同白酒陈化工艺对酒企实际生产中乳酸乙酯的作用。因为白酒陈化工艺处于白酒酿造的后期,因此适合需降低乳酸乙酯含量的较多酒企应用。

4. 结论与展望

综上,研究“降乳”技术对于提高白酒品质具有重要意义。白酒中“降乳”技术的研究取得了一定进展,主要集中在发酵过程和蒸馏过程的研究。酒企可根据白酒中乳酸乙酯的标准判定不同白酒中的乳酸乙酯含量是否偏高。若出现偏高现象,可通过挑选低淀粉含量原料(糯高粱等),控制酒曲中乳酸菌,在发酵过程(应用乳酸降解菌、利用微生物相互作用、更换封窖方法),在蒸馏过程(控制蒸馏设备、低压蒸馏、控制接酒顺序),在白酒存放过程(应用白酒陈化工艺)来降低白酒中的乳酸乙酯。适合的调控方式需根据不同酒企的具体情况(规模、资金状况等)和具体要求(乳酸乙酯调控程度、出酒率、优质率等)来选择。其中,应用乳酸降解菌于实际生产能有效降低白酒中的乳酸乙酯并提高白酒质量,且经济效益显著。但目前,许多“降乳”技术存在研究成本高、操作复杂、研究周期长等问题,应用在酒企实际生产中还面临挑战,因此如何提高“降乳”效果和降低成本、并实现大规模应用需进一步探索。

未来,还需深入研究白酒中乳酸乙酯的产生机理,包括结合现代分析技术和计算机模拟技术,深入研究乳酸乙酯产生的分子机制和动力学过程,以便更好地理解其在酿造过程中的变化规律。此外,随着生物技术和酿酒工艺的不断发展,探索和优化更加高效、环保的降低乳酸乙酯含量的方法,包括利用基因工程和代谢工程等手段对微生物进行改造等势在必行。同时,加强产学研合作,促进科技成果的转化和应用;加强降乳技术在实际生产中的应用研究,提高技术的可行性和实用性,以期为实现中国白酒产业的健康可持续发展做贡献。

-

表 1 不同香型白酒酒体中乳酸乙酯的含量标准

Table 1 Standard of ethyl lactate in different flavor baijiu finish product

白酒类型(酒精度) 优级 一级 参考文献 浓香型白酒 已酸乙酯/乳酸乙酯(1:0.5~0.8) [34] 清香型白酒 乙酸乙酯/乳酸乙酯(1:0.6~0.8) [36] 凤香型白酒 乙酸乙酯/乳酸乙酯(1:0.6~0.8) [37] 凤香型白酒 乳酸乙酯0.3~0.8 g/L [35] 老白干香型(41%vol~68%vol) 乳酸乙酯≥0.50 g/L 乳酸乙酯≥0.40 g/L [28] 老白干香型(18%vol~40%vol) 乳酸乙酯≥0.40 g/L 乳酸乙酯≥0.30 g/L 老白干白酒 乳酸乙酯/乙酸乙酯≥0.8 米香型白酒(41%vol~68%vol) 乳酸乙酯≥0.50 g/L 乳酸乙酯≥0.40 g/L [29] 米香型白酒(25%vol~40%vol) 乳酸乙酯≥0.30 g/L 乳酸乙酯≥0.20 g/L 芝麻香型白酒(40%vol~68%vol) 乳酸乙酯≥0.60 g/L [30] 芝麻香型白酒(25%vol~40%vol) 乳酸乙酯≥0.30 g/L 绵柔型白酒(21%vol~69%vol) 乳酸乙酯≥0.30 g/L 乳酸乙酯≥0.20 g/L [31] 糟烧白酒(45%vol~60%vol) 乳酸乙酯≥0.30 g/L [32] 绵柔酱香型白酒(53%vol±1%vol) 乳酸乙酯≥0.80 g/L [33] -

[1] LIU H L, SUN B G. Effect of fermentation processing on the flavor of Baijiu[J]. J Agric Food Chem,2018,66(22):5425−5432. doi: 10.1021/acs.jafc.8b00692

[2] YAN Q, ZHANG K Z, ZOU W, et al. Three main flavour types of Chinese Baijiu:Characteristics, research, and perspectives[J]. Journal of the Institute of Brewing,2021,127(4):317−326. doi: 10.1002/jib.669

[3] QIAO L, WANG J, WANG R F, et al. A review on flavor of Baijiu and other world-renowned distilled liquors[J]. Food Chemistry:X, 2023:100870.

[4] LI T, WANG J, XU B Z, et al. Comparative analysis of the differences among Langya flavor Baijiu and strong and soy sauce flavor Baijiu by targeted flavor analysis[J]. Journal of Food Composition and Analysis, 2023:105479.

[5] 杨望军. 利用微生物降低牛栏山原酒乳酸乙酯含量的研究与应用[D]. 郑州:河南工业大学, 2012. [YANG W J. Research on reducing ethyl lactate content in niulanshan base liquor by microorganisms and its application[D]. Zhengzhou:Henan University of Technology, 2012.] YANG W J. Research on reducing ethyl lactate content in niulanshan base liquor by microorganisms and its application[D]. Zhengzhou: Henan University of Technology, 2012.

[6] FAN W L, XU Y, QIAN M. Current practice and future trends of aroma and flavor research in Chinese Baijiu[M]. American Chemical Society, 2019:145-175.

[7] WANG X S, WANG B W, SUN Z G, et al. Effects of modernized fermentation on the microbial community succession and ethyl lactate metabolism in Chinese baijiu fermentation[J]. Food Research International,2022,159:111566. doi: 10.1016/j.foodres.2022.111566

[8] WANG G N, JING S, WANG X L, et al. Evaluation of the perceptual interaction among ester odorants and nonvolatile organic acids in Baijiu by GC-MS, GC-O, odor threshold, and sensory analysis[J]. Journal of Agricultural and Food Chemistry,2022,70(43):13987−13995. doi: 10.1021/acs.jafc.2c04321

[9] LEITE A M O, MAYO B, RACHID C T C C, et al. Assessment of the microbial diversity of Brazilian kefir grains by PCR-DGGE and pyrosequencing analysis[J]. Food Microbiol,2012,31(2):215−221. doi: 10.1016/j.fm.2012.03.011

[10] PANG X N, HAN B Z, HUANG X N, et al. Effect of the environment microbiota on the flavour of light-flavour Baijiu during spontaneous fermentation[J]. Sci Rep,2018,8(1):3396. doi: 10.1038/s41598-018-21814-y

[11] XU Y Q, ZHAO J R, LIU X, et al. Flavor mystery of chinese traditional fermented baijiu:The great contribution of ester compounds[J]. Food Chemistry,2022,369:130920. doi: 10.1016/j.foodchem.2021.130920

[12] ZHAO Q S, YANG J G, ZHANG K Z, et al. Lactic acid bacteria in the brewing of traditional Daqu liquor[J]. Journal of the Institute of Brewing,2020,126(1):14−23. doi: 10.1002/jib.593

[13] WANG Z, WANG Y, ZHU T T, et al. Characterization of the key odorants and their content variation in Niulanshan Baijiu with different storage years using flavor sensory omics analysis[J]. Food Chemistry,2022,376:131851. doi: 10.1016/j.foodchem.2021.131851

[14] 丁国祥. 高淀粉高配合力糯质高粱不育系45A的创制与应用[R]. 成都:四川省农业科学院水稻高粱研究所, 2014. [DING G X. Creation and application of glutinous sterile sorghum line 45A with high starch and high combining ability[R]. Chengdu:Rice and Sorghum Research Institute, Sichuan Academy of Agricultural Sciences, 2014.] DING G X. Creation and application of glutinous sterile sorghum line 45A with high starch and high combining ability[R]. Chengdu: Rice and Sorghum Research Institute, Sichuan Academy of Agricultural Sciences, 2014.

[15] 唐玉明. 杂交糯高粱酿酒生产工艺研究及产业化应用[R]. 成都:四川省农业科学院水稻高粱研究所, 2012. [TANG Y M. Research and industrialization application of hybrid glutinous sorghum brewing technology[R]. Chengdu:Rice and Sorghum Research Institute, Sichuan Academy of Agricultural Sciences, 2012.] TANG Y M. Research and industrialization application of hybrid glutinous sorghum brewing technology[R]. Chengdu: Rice and Sorghum Research Institute, Sichuan Academy of Agricultural Sciences, 2012.

[16] 宋克伟, 周森, 魏金旺, 等. 乳酸利用菌的筛选及应用[J]. 酿酒科技,2015(3):74−76. [SONG K W, ZHOU S, WEI J W, et al. Screening and application of a bacterial strain for the degradation of lactic acid[J]. Liquor-Making Science & Technology,2015(3):74−76.] SONG K W, ZHOU S, WEI J W, et al. Screening and application of a bacterial strain for the degradation of lactic acid[J]. Liquor-Making Science & Technology, 2015(3): 74−76.

[17] 吴生文, 辛秀明, 邓丹雯, 等. 丙酸菌的分离鉴定及对特型酒风格风味的影响[J]. 中国食品添加剂,2011(4):130−134,199. [WU S W, XIN X M, DENG D W, et al. Isolation and identification of propionibacterium in pit mud and how it to affect style and flavor of Te-type liquor[J]. China Food Additives,2011(4):130−134,199.] WU S W, XIN X M, DENG D W, et al. Isolation and identification of propionibacterium in pit mud and how it to affect style and flavor of Te-type liquor[J]. China Food Additives, 2011(4): 130−134,199.

[18] 廖昶. 提高特香型白酒特征性香味成分丙酸乙酯含量关键技术研究与应用[R]. 樟树:四特酒有限责任公司, 2013. [LIAO C. Research and application of key techniques to improve the content of ethyl propionate, the characteristic flavor component of special flavor liquor[R]. Zhangshu:Four Special Wine Co., Ltd., 2013.] LIAO C. Research and application of key techniques to improve the content of ethyl propionate, the characteristic flavor component of special flavor liquor[R]. Zhangshu: Four Special Wine Co., Ltd., 2013.

[19] 王松, 陈雪玲, 游玲. 1株产香酵母在浓香型白酒复糟酒生产中的应用[J]. 中国酿造,2020,39(9):42−47. [WANG S, CHEN X L, YOU L. Application of aroma-producing yeast in the strong-flavor Baijiu production with reusing distiller's grain[J]. China Brewing,2020,39(9):42−47.] WANG S, CHEN X L, YOU L. Application of aroma-producing yeast in the strong-flavor Baijiu production with reusing distiller's grain[J]. China Brewing, 2020, 39(9): 42−47.

[20] 封明振, 张国杰, 王贤. 化纤窖池布在夏季压排窖中的应用[J]. 酿酒科技, 1999(5):29,31. [FENG M Z, ZHANG G J, WANG X. Application of amylosa enzyme in the production of Sichuan Xiaoqu Liquor[J]. Liquor-Making Science & Technology, 1999(5):29,31.] FENG M Z, ZHANG G J, WANG X. Application of amylosa enzyme in the production of Sichuan Xiaoqu Liquor[J]. Liquor-Making Science & Technology, 1999(5): 29,31.

[21] 陈全庚, 陈珊, 黄应华, 等. 气封甑和水封甑蒸馏对比试验研究[J]. 酿酒科技,2012(4):88−91. [CHEN Q G, CHEN S, HUANG Y H, et al. Contrast test of liquor distillation by gas-sealing steamer and by water-sealing steamer[J]. Liquor-Making Science & Technology,2012(4):88−91.] CHEN Q G, CHEN S, HUANG Y H, et al. Contrast test of liquor distillation by gas-sealing steamer and by water-sealing steamer[J]. Liquor-Making Science & Technology, 2012(4): 88−91.

[22] 管桂坤, 万自然. 不同蒸馏气压对浓香型白酒质量的影响[J]. 酿酒科技,2016(7):75−77. [GUAN G K, WAN Z R. Effects of different distillation vapor pressure on the quality of Nongxiang Baijiu[J]. Liquor-Making Science & Technology,2016(7):75−77.] GUAN G K, WAN Z R. Effects of different distillation vapor pressure on the quality of Nongxiang Baijiu[J]. Liquor-Making Science & Technology, 2016(7): 75−77.

[23] 马转转, 姚家琪, 杨枭勇, 等. 白酒陈化工艺在清香白酒中的应用[J]. 酿酒科技,2022(2):69−73. [MA Z Z, YAO J Q, YANG X Y, et al. Application of artificial aging technology in the production of qingxiang baijiu[J]. Liquor-Making Science & Technology,2022(2):69−73.] MA Z Z, YAO J Q, YANG X Y, et al. Application of artificial aging technology in the production of qingxiang baijiu[J]. Liquor-Making Science & Technology, 2022(2): 69−73.

[24] PANG X N, CHEN C, HUANG X N, et al. Influence of indigenous lactic acid bacteria on the volatile flavor profile of light-flavor Baijiu[J]. Food Science & Technology,2021,147:111540.

[25] ZHAO Z, SUGIMACHI M, YOSHIZAKI Y, et al. Correlation between key aroma and manufacturing processes of rice-flavor Baijiu and awamori, Chinese and Japanese traditional liquors[J]. Food Bioscience,2021,44:101375. doi: 10.1016/j.fbio.2021.101375

[26] XING L H, DE L W, WU J Z, et al. The production of the Chinese Baijiu from sorghum and other cereals[J]. Journal of the Institute of Brewing,2017,123(4):600−604. doi: 10.1002/jib.450

[27] LANGOS D, GRANVOGL M, SCHIEBERLE P. Characterization of the key aroma compounds in two bavarian wheat beers by means of the sensomics approach[J]. Journal of Agricultural and Food Chemistry,2013,61(47):11303−11311. doi: 10.1021/jf403912j

[28] 中华人民共共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. GB/T 20825-2007 老白干香型白酒[S]. 北京:中国标准出版社, 2007. [General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of People’s Republic of China. GB/T 20825-2007 Laobaigan-flavor liquor[S]. Beijing:Standards Press of China, 2007.] General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of People’s Republic of China. GB/T 20825-2007 Laobaigan-flavor liquor[S]. Beijing: Standards Press of China, 2007.

[29] 中华人民共共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. GB/T 10781.3-2006 米香型白酒[S]. 北京:中国标准出版社, 2006. [General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of People's Republic of China. GB/T 10781.3-2006 Rice-flavour liquor[S]. Beijing:Standards Press of China, 2006.] General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of People's Republic of China. GB/T 10781.3-2006 Rice-flavour liquor[S]. Beijing: Standards Press of China, 2006.

[30] 中华人民共共和国国家市场监督管理总局, 中国国家标准化管理委员会. GB/T 10781.9-2021 芝麻香型白酒[S]. 北京:中国标准出版社, 2021. [General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of People's Republic of China. GB/T 10781.9-2021 Sesame-flavor liquor[S]. Beijing:Standards Press of China, 2021.] General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of People's Republic of China. GB/T 10781.9-2021 Sesame-flavor liquor[S]. Beijing: Standards Press of China, 2021.

[31] 中国酒业协会团体标准. T/CBJ 2104-2019 绵柔型白酒[S]. 北京:中国标准出版社, 2019. [China Alcoholic Drinks Association group standard. T/CBJ 2104-2019 Mianrouxing Baijiu[S]. Beijing:Standards Press of China, 2019.] China Alcoholic Drinks Association group standard. T/CBJ 2104-2019 Mianrouxing Baijiu[S]. Beijing: Standards Press of China, 2019.

[32] 中国酒业协会团体标准. T/ZZB 1594-2020 糟烧白酒[S]. 北京:中国标准出版社, 2020. [China Alcoholic Drinks Association group standard. T/ZZB 1594-2020 Zaoshao Baijiu[S]. Beijing:Standards Press of China, 2020.] China Alcoholic Drinks Association group standard. T/ZZB 1594-2020 Zaoshao Baijiu[S]. Beijing: Standards Press of China, 2020.

[33] 中国酒业协会团体标准. T/CNFIA 169-2023 绵柔酱香型白酒[S]. 北京:中国标准出版社, 2023. [China Alcoholic Drinks Association group standard. T/CNFIA 169-2023 Mianrou sauce-flavor Baijiu[S]. Beijing:Standards Press of China, 2023.] China Alcoholic Drinks Association group standard. T/CNFIA 169-2023 Mianrou sauce-flavor Baijiu[S]. Beijing: Standards Press of China, 2023.

[34] 姜超. 浓香型白酒主体香气成分分析及品质提升技术研究[D]. 秦皇岛:河北科技师范学院, 2018. [JIANG C. Research main aroma component analysis and quality improvement technology of flavor liquor[D]. Qinhuangdao:Hebei Normal University of Science and Technology, 2018.] JIANG C. Research main aroma component analysis and quality improvement technology of flavor liquor[D]. Qinhuangdao: Hebei Normal University of Science and Technology, 2018.

[35] 傅国城. 西凤酒酿造工艺写实与创新的研究[J]. 酿酒,2016,43(4):9−14. [FU G C. Realistic and innovative research on Xifeng liquor making technology[J]. Liquor Making,2016,43(4):9−14.] FU G C. Realistic and innovative research on Xifeng liquor making technology[J]. Liquor Making, 2016, 43(4): 9−14.

[36] 王进明, 刘忠军. 清香型白酒乳酸乙酯偏高的原因及解决措施[J]. 酿酒,2012,39(4):81−84. [WANG J M, LIU Z J. Reason for higher concentration of ethyl lactate in fen flavor liquor and its solving measurements[J]. Liquor Making,2012,39(4):81−84.] WANG J M, LIU Z J. Reason for higher concentration of ethyl lactate in fen flavor liquor and its solving measurements[J]. Liquor Making, 2012, 39(4): 81−84.

[37] 肖东光. 白酒生产技术[M]. 北京:化学工业出版社, 2023:389−390. [XIAO D G. Production technology of Baijiu[M]. Beijing:Chemical Industry Press, 2023:389−390.] XIAO D G. Production technology of Baijiu[M]. Beijing: Chemical Industry Press, 2023: 389−390.

[38] 国家质量监督检验检疫总局, 国家标准化管理委员会. GB/T 10781.1-2021 浓香型白酒[S]. 北京:中国标准出版社, 2021. [General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of People's Republic of China. GB/T 10781.9-2021 Luzhou-flavor liquor[S]. Beijing:Standards Press of China, 2021.] General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of People's Republic of China. GB/T 10781.9-2021 Luzhou-flavor liquor[S]. Beijing: Standards Press of China, 2021.

[39] 国家市场监督管理总局, 国家标准化管理委员会. GB/T 10781.2-2022 清香型白酒[S]. 北京:中国标准出版社, 2022. [General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of People's Republic of China. GB/T 10781.2-2022 fen-flavor liquor[S]. Beijing:Standards Press of China, 2022.] General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of People's Republic of China. GB/T 10781.2-2022 fen-flavor liquor[S]. Beijing: Standards Press of China, 2022.

[40] 国家质量监督检验检疫总局, 国家标准化管理委员会. GB/T 26760-2011 酱香型白酒[S]. 北京:中国标准出版社, 2011. [General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of People's Republic of China. GB/T 26760-2011 Maotai-flavour liquor[S]. Beijing:Standards Press of China, 2011.] General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of People's Republic of China. GB/T 26760-2011 Maotai-flavour liquor[S]. Beijing: Standards Press of China, 2011.

[41] 宋瑞滨, 邵泽良, 宋军. 浓香型白酒生产过程中乳酸乙酯含量控制措施探讨[J]. 酿酒,2020,47(5):22−27. [SONG R B, SHAO Z L, SONG J. Discussion on control measures of ethyl lactate content in luzhou-flavor liquor production[J]. Liquor Making,2020,47(5):22−27.] SONG R B, SHAO Z L, SONG J. Discussion on control measures of ethyl lactate content in luzhou-flavor liquor production[J]. Liquor Making, 2020, 47(5): 22−27.

[42] 李大和. 浓香型曲酒乳酸乙酯偏高的原因及解决措施[J]. 酿酒科技, 2007, 152(2):100−103. [LI D H. Causes of excessive high ethyl lactate content in luzhou- flavor daqu liquor and its solutions[J]. Liquor-Making Science & Technology, 2007, 152(2):100−103.] LI D H. Causes of excessive high ethyl lactate content in luzhou- flavor daqu liquor and its solutions[J]. Liquor-Making Science & Technology, 2007, 152(2): 100−103.

[43] 杨海波, 于飞跃, 李行. 乾酱白酒酿造关键工艺的研究[J]. 酿酒,2022,49(3):131−134. [YANG H B, YU F Y, LI X. Study on the key technology of qian jiang Baijiu brewing[J]. Liquor Making,2022,49(3):131−134.] YANG H B, YU F Y, LI X. Study on the key technology of qian jiang Baijiu brewing[J]. Liquor Making, 2022, 49(3): 131−134.

[44] SUN W N, XIAO H Z, PENG Q, et al. Analysis of bacterial diversity of Chinese Luzhou-flavor liquor brewed in different seasons by Illumina Miseq sequencing[J]. Annals of Microbiology,2016,66:1293−1301. doi: 10.1007/s13213-016-1223-5

[45] 张萌, 田真, 魏建平, 等. 基于气相色谱-离子迁移谱法和固相微萃取-气相色谱-质谱法分析6种香型白酒挥发性风味物质[J]. 食品安全质量检测学报,2023,14(5):226−235. [ZHANG M, TIAN Z, WEI J P, et al. Analysis of volatile flavor compounds in 6 flavor types of Baijiu based on gas chromatography-ion mobility spectrometry and solid phase microextraction-gas chromatography-mass spectrometry[J]. Journal of Food Safety & Quality,2023,14(5):226−235.] ZHANG M, TIAN Z, WEI J P, et al. Analysis of volatile flavor compounds in 6 flavor types of Baijiu based on gas chromatography-ion mobility spectrometry and solid phase microextraction-gas chromatography-mass spectrometry[J]. Journal of Food Safety & Quality, 2023, 14(5): 226−235.

[46] 王洪彬, 李刚, 陈新建, 等. 北方复合型封窖方法的研究和应用[J]. 酿酒,2020,47(5):27−30. [WANG H B, LI G, CHEN X J, et al. Research and application of compound pit sealing method in north China[J]. Liquor Making,2020,47(5):27−30.] WANG H B, LI G, CHEN X J, et al. Research and application of compound pit sealing method in north China[J]. Liquor Making, 2020, 47(5): 27−30.

[47] 晁进福, 徐广祥, 于水见, 等. 不同产地(品种)高粱对浓香型大曲白酒出酒率和质量的影响研究[J]. 酿酒科技,2023,345(3):70−74,78. [CHAO J F, XU G X, YU S J, et al. Study on liquor yield and quality of sorghum from different producing areas[J]. Liquor-Making Science & Technology,2023,345(3):70−74,78.] CHAO J F, XU G X, YU S J, et al. Study on liquor yield and quality of sorghum from different producing areas[J]. Liquor-Making Science & Technology, 2023, 345(3): 70−74,78.

[48] 常强, 吴再节, 孙伟, 等. 浓香型白酒纯大米酿造工艺技术研究[J]. 酿酒科技,2022(2):51−55. [CHANG Q, WU Z J, SUN W, et al. Production of nongxiang Baijiu with pure rice[J]. Liquor-Making Science & Technology,2022(2):51−55.] CHANG Q, WU Z J, SUN W, et al. Production of nongxiang Baijiu with pure rice[J]. Liquor-Making Science & Technology, 2022(2): 51−55.

[49] 范志勇, 左国营, 杜新勇, 等. 高粱原料的不同对酱香型白酒产酒情况的影响[J]. 酿酒,2014,41(4):36−41. [FAN Z Y, ZUO G Y, DU X Y, et al. Sorghum materials of different effects on wine of maotai-flavor liquor[J]. Liquor Making,2014,41(4):36−41.] FAN Z Y, ZUO G Y, DU X Y, et al. Sorghum materials of different effects on wine of maotai-flavor liquor[J]. Liquor Making, 2014, 41(4): 36−41.

[50] 牛姣, 沈毅, 张贵虎, 等. 白酒酿造原料与酒体品质关系的研究进展[J]. 食品与发酵工业,2023,49(3):322−328. [NIU J, SHEN Y, ZHANG G H, et al. Research progress on the relationship between raw materials and Baijiu quality[J]. Food and Fermentation Industries,2023,49(3):322−328.] NIU J, SHEN Y, ZHANG G H, et al. Research progress on the relationship between raw materials and Baijiu quality[J]. Food and Fermentation Industries, 2023, 49(3): 322−328.

[51] 李萌, 徐一涵, 张建华. 乳酸菌发酵对淀粉类食品品质的影响[J]. 中国酿造,2020,39(2):13−18. [LI M, XU Y H, ZHANG J H. Effect of lactic bacteria fermentation on the quality of starchy foods[J]. China Brewing,2020,39(2):13−18.] LI M, XU Y H, ZHANG J H. Effect of lactic bacteria fermentation on the quality of starchy foods[J]. China Brewing, 2020, 39(2): 13−18.

[52] 任金玫, 陈君平, 李志健, 等. 十二种香型白酒相关研究概况[J]. 中国酿造,2022,41(4):13−19. [REN J M, CHEN J P, LI Z J, et al. Research overview of twelve flavor types Baijiu[J]. China Brewing,2022,41(4):13−19.] REN J M, CHEN J P, LI Z J, et al. Research overview of twelve flavor types Baijiu[J]. China Brewing, 2022, 41(4): 13−19.

[53] 刘天朋, 杨凯, 伍燕翔, 等. 郎糯红19号绿色高效关键种植技术[J]. 中国种业,2023(6):125−127. [LIU T P, YANG K, WU Y X, et al. Green and high efficient key planting technology of langnuohong 19[J]. China Seed Industry,2023(6):125−127.] LIU T P, YANG K, WU Y X, et al. Green and high efficient key planting technology of langnuohong 19[J]. China Seed Industry, 2023(6): 125−127.

[54] 李红军. 酿酒专用高粱新品种“宜糯红2号”成果转化[R]. 成都:四川众望种业有限责任公司, 2021-09-14. [LI H J. Transformation of the new sorghum variety "Yi Nuohong 2" for winemaking[R]. Chengdu:Sichuan Zhongwang Seed Industry Limited Liability Co., Ltd., 2021-09-14.] LI H J. Transformation of the new sorghum variety "Yi Nuohong 2" for winemaking[R]. Chengdu: Sichuan Zhongwang Seed Industry Limited Liability Co., Ltd., 2021-09-14.

[55] YU X Y, HUANG T T, HUANG Z J, et al. Effects of six commercially available koji (Chinese Xiaoqu) on the production of ethyl acetate, ethyl lactate, and higher alcohols in Chinese Baijiu (distilled spirit) brewing[J]. Heliyon, 2023, 9(7):e17739.

[56] 王新叶, 李芳香, 张依香, 等. 乳酸降解菌在白酒酿造中的研究进展[J]. 中国酿造,2021,40(6):7−10. [WANG X Y, LI F X, ZHANG Y X, et al. Research progress on lactic acid-degrading bacteria in Baijiu-making process[J]. China Brewing,2021,40(6):7−10.] WANG X Y, LI F X, ZHANG Y X, et al. Research progress on lactic acid-degrading bacteria in Baijiu-making process[J]. China Brewing, 2021, 40(6): 7−10.

[57] 李伟, 李佳, 王宇鹏, 等. 清香型白酒乳酸利用菌的筛选及鉴定[J]. 中国酿造,2017,36(9):87−91. [LI W, LI J, WANG Y P, et al. Screening and identification of lactic acid-utilizing bacteria from Fen-flavor Baijiu[J]. China Brewing,2017,36(9):87−91.] LI W, LI J, WANG Y P, et al. Screening and identification of lactic acid-utilizing bacteria from Fen-flavor Baijiu[J]. China Brewing, 2017, 36(9): 87−91.

[58] 栗连会. 泸型酒酒醅中乳酸菌和乳酸降解菌的多样性和代谢特性[D]无锡:江南大学, 2017. [LI L H. Diversity and metabolic characteristics of lactic acid bacteria and lactate-degrading bacteria in fermented grains of Luzhou-flavor liquor[D]. Wuxi:Jiangnan University, 2017.] LI L H. Diversity and metabolic characteristics of lactic acid bacteria and lactate-degrading bacteria in fermented grains of Luzhou-flavor liquor[D]. Wuxi: Jiangnan University, 2017.

[59] 贾智勇, 范文权, 董占斌, 等. 复合功能菌在凤型白酒生产中的应用[J]. 酿酒科技,2009(10):65−67. [JIA Z Y, FAN W Q, DONG Z B, et al. Application of composite functional bacteria in the production of xifeng-flavor liquor[J]. Liquor-Making Science & Technology,2009(10):65−67.] JIA Z Y, FAN W Q, DONG Z B, et al. Application of composite functional bacteria in the production of xifeng-flavor liquor[J]. Liquor-Making Science & Technology, 2009(10): 65−67.

[60] 何宏魁, 曹润洁, 周庆伍, 等. “增己降乳”组合菌制剂在浓香型白酒中的应用研究[J]. 酿酒科技,2021(9):87−93,106. [HE H K, CAO R J, ZHOU Q W, et al. Application of mixed bacteria preparation in the production of nongxiang Baijiu to increase the content of ethyl caproate and reduce the content of Ethyl Lactate[J]. Liquor-Making Science & Technology,2021(9):87−93,106.] HE H K, CAO R J, ZHOU Q W, et al. Application of mixed bacteria preparation in the production of nongxiang Baijiu to increase the content of ethyl caproate and reduce the content of Ethyl Lactate[J]. Liquor-Making Science & Technology, 2021(9): 87−93,106.

[61] GAO L, ZHOU J, HE G Q. Effect of microbial interaction on flavor quality in Chinese Baijiu fermentation[J]. Frontiers in Nutrition, 2022, 9.

[62] TU W Y, CAO X N, CHENG J, et al. Chinese Baijiu:The perfect works of microorganisms[J]. Frontiers in Microbiology,2022,13:919044. doi: 10.3389/fmicb.2022.919044

[63] 赵扬扬. 不同窖帽高度和不同封窖方式对浓香型白酒品质的影响研究[D]. 重庆:重庆大学, 2015. [ZHAO Y Y. Study of pit cap with different heights and different sealing ways impacting on the quality of Luzhou-Flavor liquor[D]. Chongqing:Chongqing University, 2015.] ZHAO Y Y. Study of pit cap with different heights and different sealing ways impacting on the quality of Luzhou-Flavor liquor[D]. Chongqing: Chongqing University, 2015.

[64] 封明振, 张国杰, 王贤. 提高浓香型曲酒优质品率的措施[J]. 酿酒科技,2000(2):28−29. [FENG M Z, ZHANG G J, WANG X. Treatments of increasing the rate of quality product in the production of Luzhou-flavour liquor[J]. Liquor-Making Science & Technology,2000(2):28−29.] FENG M Z, ZHANG G J, WANG X. Treatments of increasing the rate of quality product in the production of Luzhou-flavour liquor[J]. Liquor-Making Science & Technology, 2000(2): 28−29.

[65] 冯海燕, 卢君, 王凡, 等. 酱香型白酒封窖工艺研究[J]. 中国酿造,2022,41(11):210−216. [FENG H Y, LU J, WANG F, et al. Pit-sealing technology of sauce-flavor Baijiu[J]. China Brewing,2022,41(11):210−216.] FENG H Y, LU J, WANG F, et al. Pit-sealing technology of sauce-flavor Baijiu[J]. China Brewing, 2022, 41(11): 210−216.

[66] 杨刚仁, 曾凡君, 吴徐建, 等. 麻布辅助封窖在酱香型习酒中的应用研究[J]. 酿酒科技,2020(8):33−35. [YANG G R, ZENG F J, WU X J, et al. Application of sackcloth in pit sealing in Jiangxiang Xijiu production[J]. Liquor-Making Science & Technology,2020(8):33−35.] YANG G R, ZENG F J, WU X J, et al. Application of sackcloth in pit sealing in Jiangxiang Xijiu production[J]. Liquor-Making Science & Technology, 2020(8): 33−35.

[67] 三虹牌化纤窖池专用布[J]. 酿酒, 2017, 44(6):6. [Sanhong chemical fiber cellar special cloth[J]. Liquor Making, 2017, 44(6):6.] Sanhong chemical fiber cellar special cloth[J]. Liquor Making, 2017, 44(6): 6.

[68] LI L S, FAN M, XU Y, et al. Comparative analysis of volatile flavor compounds in strongly flavored Baijiu under two different pit cap sealing processes[J]. Foods,2023,12(13):2579. doi: 10.3390/foods12132579

[69] 涂昌华, 汪地强, 吉小超, 等. 大曲酱香型白酒生产中辅料的应用研究[J]. 酿酒科技,2019(8):72−74. [TU C H, WANG D Q, JI X C, et al. Application of auxiliary materials in Daqu Jiangxiang Baijiu production[J]. Liquor-Making Science & Technology,2019(8):72−74.] TU C H, WANG D Q, JI X C, et al. Application of auxiliary materials in Daqu Jiangxiang Baijiu production[J]. Liquor-Making Science & Technology, 2019(8): 72−74.

[70] 尹倩倩. 封窖方式对泸型酒酿造中不同层酒醅品质差异的影响研究[D]. 无锡:江南大学, 2022. [YIN Q Q. Effects of cellar sealing method on the quality difference of different layers of Jiupei in the brewing of Luzhou-flavor liquor[D]. Wuxi:Jiangnan University, 2022.] YIN Q Q. Effects of cellar sealing method on the quality difference of different layers of Jiupei in the brewing of Luzhou-flavor liquor[D]. Wuxi: Jiangnan University, 2022.

[71] 杨平, 涂荣坤, 钱志伟, 等. 甑桶醅层高度及结构设计对蒸馏效率及酒质的影响研究[J]. 酿酒科技,2012(10):94−98. [YANG P, TU R K, QIAN Z W, et al. Effects of the height of fermented grains layer and the structure design of steaming barrel on liquor distillation efficiency and liquor quality[J]. Liquor-Making Science & Technology,2012(10):94−98.] YANG P, TU R K, QIAN Z W, et al. Effects of the height of fermented grains layer and the structure design of steaming barrel on liquor distillation efficiency and liquor quality[J]. Liquor-Making Science & Technology, 2012(10): 94−98.

[72] 陈全庚, 赖登燡, 陈林, 等. 气封甑在清香型小曲白酒生产中的应用实验[J]. 酿酒,2015,42(1):41−44. [CHEN Q G, LAI D H, CHEN L, et al. Application trial of gas sealed distiller in fen flavor xiaoqu liquor production[J]. Liquor Makin,2015,42(1):41−44.] doi: 10.3969/j.issn.1002-8110.2015.01.010 CHEN Q G, LAI D H, CHEN L, et al. Application trial of gas sealed distiller in fen flavor xiaoqu liquor production[J]. Liquor Makin, 2015, 42(1): 41−44. doi: 10.3969/j.issn.1002-8110.2015.01.010

[73] 孙庆文, 陈全庚, 侯勇, 等. 气封甑蒸馏效果分析研究[J]. 酿酒科技,2014,238(4):57−59. [SUN Q W, CHEN Q G, H Y, et al. Study on the distilling effects of gas-sealed steamer[J]. Liquor-Making Science & Technology,2014,238(4):57−59.] SUN Q W, CHEN Q G, H Y, et al. Study on the distilling effects of gas-sealed steamer[J]. Liquor-Making Science & Technology, 2014, 238(4): 57−59.

[74] 赵红平, 罗惠波, 刘淼, 等. 不同上甑条件对浓香型白酒乙醇及风味物质馏出的影响[J]. 食品与发酵工业,2023,49(5):101−108. [ZHAO H P, LUO H B, LIU M, et al. Effect of different steaming conditions on ethanol and aroma compounds of Luzhou-flavor Baijiu[J]. Food and Fermentation Industries,2023,49(5):101−108] ZHAO H P, LUO H B, LIU M, et al. Effect of different steaming conditions on ethanol and aroma compounds of Luzhou-flavor Baijiu[J]. Food and Fermentation Industries, 2023, 49(5): 101−108

[75] LI H L, WANG C, ZHU L I, et al. Variations of flavor substances in distillation process of Chinese Luzhou-flavor liquor[J]. Journal of Food Process Engineering,2012,35(2):314−334. doi: 10.1111/j.1745-4530.2010.00584.x

[76] 何庆, 唐克纯, 韩秋月, 等. 白酒陈化机理及陈化方法研究进展[J]. 中国酿造,2023,42(7):7−12. [HE Q, TANG K C, HAN Q Y, et al. Research progress on aging mechanism and aging methods of Baijiu[J]. China Brewing,2023,42(7):7−12.] HE Q, TANG K C, HAN Q Y, et al. Research progress on aging mechanism and aging methods of Baijiu[J]. China Brewing, 2023, 42(7): 7−12.

[77] HE J, CHEN Q, JIA X, et al. The effects of gamma irradiation and natural aging on the composition of nongxiangxing Baijiu[J]. Journal of Food Processing and Preservation,2022,46(12):e17146.

-

期刊类型引用(0)

其他类型引用(1)

下载:

下载:

下载:

下载: