Research Progress on Aroma Quality of High-pressure Processing Fruit and Vegetable Juices

-

摘要: 香气是果蔬汁倍受关注的品质特征之一。在保留果蔬汁特征香气以及减少加工异味方面,超高压处理(high-pressure processing,HPP)比热杀菌更具优势。本文综述了HPP果蔬汁加工及贮藏过程中的香气品质变化。HPP处理过程对果蔬汁整体香气品质和感官属性的影响较小,香气品质的劣变主要发生在后续的贮藏期内。本文从HPP对酶的激活或钝化及基质分子与香气相互作用等方面阐明HPP果蔬汁香气品质变化机制,总结了目前常见的HPP果蔬汁香气品质调控措施,可通过温压结合、优化加压模式以及HPP协同CO2、超滤等技术提高钝酶效果,也可通过改善贮藏条件来提高产品品质。本文综述超高压果蔬汁香气品质研究进展,以期为后续产品研发和香气变化机制研究提供思路和参考。Abstract: Aroma is a critical quality of fruit and vegetable juices, drawing considerable attention. High-pressure processing (HPP) is demonstrated to possess more advantageous than thermal sterilization in preserving the aroma quality of fruit and vegetable juices and reducing processing off-flavors. In this paper, the changes in aroma quality of HPP fruit and vegetable juices during processing and storage are reviewed. The HPP treatment process has little effect on the overall aroma quality and sensory attributes of fruit and vegetable juices. The deterioration of aroma quality mainly occurs during the subsequent storage period. This paper elucidates the mechanism of aroma quality change of HPP fruit and vegetable juices from aspects such as the activation or inactivation of enzymes by HPP and the interaction between matrix molecules and aroma. It summarizes the currently common aroma quality control measures for HPP fruit and vegetable juices. The enzyme inactivation effects could be improved by combining temperature and pressure, optimizing the pressurization mode, and using technologies such as HPP in combination with CO2 and ultrafiltration. Product quality could also be improved by improving storage conditions. This paper reviews the research progress on aroma quality of ultra-high pressure fruit and vegetable juices, in order to provide ideas and references for subsequent product research and development and the study of aroma change mechanisms.

-

香气品质是决定消费者对果蔬汁满意度的重要因素之一,研究果蔬汁香气品质有助于优质原料的挖掘和产品开发,以满足消费者的个性化需求,提高产品差异化竞争力[1]。果蔬汁产品的香气品质受加工方式的影响,虽然热杀菌在食品加工中被广泛应用,然而果蔬原料大多具有热敏性[2],在热杀菌过程中,特征香气成分容易发生劣变,甚至产生令人不悦的蒸煮异味,这对产品品质产生不利影响[3−5],影响了消费者的购买欲。超高压(high-pressure processing,HPP)作为一种新型非热加工技术受到广泛关注,在柑橘类[6−8]、核果类[9]、仁果类[10]、浆果类[11−14]、瓜果类[15−17]等各类果汁及蔬菜汁[18]或混合果蔬汁[19−21]中均有应用。

目前众多研究表明,经HPP杀菌处理产品香气感官品质更接近于新鲜产品,可以有效解决热杀菌处理产品香气劣变和异味问题。HPP对共价键的作用很小,基本上不会影响香气化合物的分子结构,然而对非共价键(如氢键、静电相互作用)的作用明显,HPP会对香气化合物生成途径中酶的二、三、四级结构产生影响[22]。因此,虽然HPP可以较好地保持新鲜果蔬汁的香气感官品质,但因为HPP处理对果蔬汁杀菌过程钝酶效果不一,以及分子间复杂的相互作用和化学反应,HPP处理之后香气化合物的成分或浓度会有所变化,且产品在贮藏期仍然面临香气损失和劣变等难题。因此不仅有必要明确HPP对果蔬汁香气品质影响规律,还需要分析研究贮藏期香气品质的变化,以期实现香气稳态化调控技术的提升。

本文综述了超高压果蔬汁加工及贮藏过程中香气品质的变化情况,并讨论了相关的变化机制及现有的调控措施,旨在为提高超高压果蔬汁香气品质稳定性提供理论参考和指导,同时也为促进HPP工业化发展提供依据。

1. 超高压果蔬汁加工及贮藏过程中香气品质的变化

1.1 超高压加工对果蔬汁香气品质的影响

HPP相较于热处理,对果蔬汁香气感官属性的影响更小,其果蔬汁香气品质更接近于新鲜(未经处理)的产品。Ma等[23]通过感官评价HPP处理(500 MPa/10 min/室温)前后甜瓜汁香气品质,发现不同处理间并没有显著性差异。但热处理甜瓜汁由于生成了二甲基硫醚等硫化物,产生了明显蒸煮异味,严重影响了甜瓜汁的感官体验[5]。关于橙汁加工的研究也发现,在500~600 MPa、1~5 min、20~40 ℃处理后,HPP橙汁香气感官品质均优于热杀菌产品,更接近新鲜橙汁[7]。刘凤霞[24]发现HPP芒果汁感官得分显著高于热处理芒果汁,分析挥发性香气成分发现,热处理芒果汁中二甲基硫醚(蒸煮味)含量显著升高,给芒果汁香气感官品质带来了不利影响。而HPP处理后(200~600 MPa/15 min/室温),芒果汁的果香、甜香、花香、青草香和松香得到了很好的保留[25]。除此之外,HPP处理所得桃汁[9]、樱桃汁[26]、桑椹汁[27]、百香果汁[28]、黄瓜汁[18]等果蔬汁的香气品质也与新鲜产品高度相似。但是,由于果蔬原料差异、HPP处理参数改变或是贮藏条件的不同,HPP果蔬汁香气感官属性仍然会发生变化(表1)。

表 1 HPP果蔬汁加工及贮藏过程中香气品质变化Table 1. Changes in aroma quality of juices during high-pressure processing and storage果蔬种类 产品 处理条件 挥发性物质或香气感官属性变化 贮藏期 参考文献 浆果类 猕猴桃汁 400~600 MPa,

5~15 min,室温HPP处理后,醇和酯的总含量显著下降,而总醛含量显著增加;贮藏过程中,醛的总含量下降,而醇、酮、酯和酸的含量增加;其中500 MPa/15 min和600 MPa/

15 min在贮藏过程中对特征香气的保护效果较好(己醛和反-2-己烯醛)4 ℃

40 d[29] 猕猴桃汁 400 MPa,

15 min,室温HPP处理后,醇类和酯类物质的种类和含量降低,酮类和醛类物质的种类和含量增加;贮藏过程中,酮类和醛类物质先增加后减少 4 ℃

28 d[12] 草莓汁 热烫1 min,600 MPa,

4 min,室温贮藏过程中,草莓汁特征香气物质含量呈下降趋势,其中酯类物质损失显著,芳樟醇、反式-橙花叔醇含量则随贮藏时间的延长而增加,醛类、酮类等物质在贮藏过程中逐渐减少 4 ℃

210 d[11] 杨桃汁 600 MPa,

150 s,10 ℃HPP果蔬汁的香气感官评分与新鲜产品没有显著性差异,虽然贮藏过程中香气逐渐下降,但仍优于热处理样品 4 ℃

40 d[30] 百香果汁 600 MPa,

6 min,22 ℃HPP处理后酯类、醇类、酮类、醛类和烯烃类物质的相对含量在贮藏期间逐渐降低,酸类物质的相对含量在贮藏期间逐渐增加。HPP对特征香气的保留率大于热处理,并减少了异味物质的生成 4 ℃

25 d[31] 仁果类 苹果汁 400 MPa,

15 min,室温HPP处理后香气含量接近新鲜产品,但贮藏过程中香气物质含量变化显著,到4周时降低了26.13% 4 ℃

28 d[10] 柑橘类 橙汁 500 MPa,

10 min,25℃HPP处理后,萜烯和酯类含量显著减少,醛醇类含量增加 4 ℃

28 d[7] 瓜果类 西瓜汁 600 MPa,

5 min,室温HPP处理后,壬醛、柠檬醛、反-2,顺6-壬二烯醇显著降低,己醛、2-己烯醛、反式-2-辛烯-1-醇、6-甲基-5-庚烯-2-酮显著增加 3 ℃

12 d[15] 蔬菜 黄瓜汁 500 MPa,

5 min,室温HPP处理后,具有青香属性的反-2-,顺-6-壬二烯醛和反-2-壬烯醛含量显著增加;贮藏至20 d时,香气感官评分有所降低,但HPP组仍高于热处理组 4 ℃

20 d[18] 番茄汁 400 MPa,

30 min,25℃通过电子鼻分析HPP番茄汁贮藏过程中风味变化,相较于热处理组,HPP组的香气更接近新鲜番茄汁且在贮藏期间更稳定 4 ℃

90 d[32] 绿芦笋汁 200/400/600 MPa,

10/20 min,室温HPP处理后,酮类和主要香气贡献的醛类物质含量显著上升,酸类物质含量在200 MPa下最高,醇类物质含量稍有下降,酯类物质浓度不受HPP影响。 − [33] 混合果蔬 苹果汁/苹果-猕猴桃汁 600 MPa,

3 min,室温贮藏过程中乙酸丁酯、2-甲基乙酸丁酯和乙酸戊酯均有所下降,但苹果-猕猴桃汁的变化小于苹果汁,添加猕猴桃果浆明显减少了果味香气的损失 4 ℃

28 d[34] 胡萝卜-菠萝汁,橙子-芒果-猕猴桃汁 550 MPa,

5 min,室温挥发性香气化合物在贮藏过程中变化明显,大量醛、醇类化合物减少,但部分萜类化合物含量增加;贮藏期间,胡萝卜-菠萝汁的香气品质比橙子-芒果-

猕猴桃汁更稳定4 ℃

90 d[19] 苹果-草莓-香蕉-橙子汁 450~600 MPa,

5~10 min,20 ℃贮藏过程中所有挥发性香气化合物均有所降低,特别是与“新鲜/绿色/青草味”有关的化合物;贮藏30 d后,相较于新鲜产品,感官评分降低了近50% 4 ℃

30 d[35] 从表1及上述结果可以发现,相较于传统的热加工,HPP更能保留果蔬汁原有的香气品质,生产出高品质的果蔬汁产品。但HPP对果蔬汁香气品质的作用受加工参数(温度、压力、保压时间)的影响,不同HPP加工参数对果蔬汁的香气品质可能产生不同的影响。以压力为例,HPP处理中过高的压力可能会引起香气品质的劣变。HPP沃柑汁随着处理压力上升(350~550 MPa)感官上甜味、柑橘味和水果味均减弱[36]。Hurtado等[37]采用三角感官测试发现,较低的压力下(350、450 MPa)处理的混合果汁(苹果、草莓、橙子、香蕉)更接近于新鲜产品,而较高压力处理(600 MPa)后,香气品质发生了明显的变化,难以被消费者接受,但由于方法的限制无法明确是何种香气品质的变化导致的差异。除此之外,加工温度和时间也会影响香气变化。Ferrari等[14]通过电子鼻研究HPP石榴汁的香气变化(400~600 MPa/5~10 min/25~50 ℃),发现HPP石榴汁的香气主要受操作温度和加工时间影响,压力对果汁香气影响不显著。但也有研究表明处理压力对HPP果蔬汁香气品质的影响不显著,当压力从400 MPa升高到550 MPa时,主成分分析结果表明,黄瓜汁整体香气并没有发生显著变化[38]。加工参数对HPP果蔬汁香气品质的影响还可能受到原料的影响。如果蔬种类、种植区域、种植条件、采摘时间等因素都会对果蔬汁香气品质产生影响,例如Kaushik等[39]发现超过600 MPa/10 min/60 ℃的处理条件会显著改变芒果果浆的感官属性,但对荔枝汁的影响不明显。总之,HPP虽然相较于热加工可以很好地保留果蔬汁原有的香气品质,但处理压力、时间和温度都会对果蔬汁香气品质产生一定的影响,且原料不同产生的影响也各不相同,因此针对不同原料的超高压加工参数需单独分析,优化加工条件,以获得营养安全且风味俱佳的高品质产品。此外,加工后续的贮藏环节香气品质的变化也不容忽视。

1.2 超高压果蔬汁贮藏过程中的香气品质变化

果蔬汁产品品质保持,不仅包含加工过程变化,还有货架期过程,这些变化决定着消费者对于产品的偏爱和喜好等。HPP果蔬汁化学成分和品质的变化主要集中在贮藏过程,而非加工过程[15]。因此有必要明确HPP处理对于香气品质保留的优势,在贮藏期内是否持续存在。Aaby等[40]发现草莓果浆和果汁主要是在贮藏期间发生质量变化而不是HPP过程中,具有低初始酶活性的原材料可能比果浆更适合HPP加工,如过滤处理后的果汁。Hurtado等[41]观察到HPP处理不会显著改变混合果汁(橙、草莓、苹果、香蕉、黑葡萄、黑莓、醋栗、白葡萄、青柠)的香气感官品质,但贮藏过程中香气稳定性低于热杀菌产品,在4℃仅可存放14 d。HPP脐橙汁(600 MPa/60 s)在4 ℃和10 ℃分别贮藏12周后,整体香气强度和甜味感官评分下降,同时消费者接受度评分均值分别由6.83和4.83下降至5.56和4.44,进一步分析发现,香气强度和甜味感官评分下降与(E)-2-戊烯醛、辛醛、丙酸乙酯、丁酸甲酯和丁酸乙酯含量降低显著相关[42]。HPP果蔬汁在货架期过程中的香气品质极其不稳定,除香气损失外还可能由于关键香气化合物含量及种类的变化导致整体香气品质失衡,甚至发生劣变的现象。若无法探明HPP果蔬汁在贮藏期间的香气品质变化规律,将难以把握HPP果蔬汁产品的品质控制,不利于HPP果蔬汁的发展。因此明确HPP对果蔬汁香气品质的影响机理,将有利于HPP果蔬汁香气品质调控技术的发展,有望使HPP果蔬汁的香气品质在贮藏期间保持稳定。

2. 超高压果蔬汁香气变化机制

果蔬汁是复杂的系统,HPP对香气品质的影响取决于原材料和特定的工艺参数(图1)。Patterson[43]总结发现,不同食品原料会显著影响HPP处理的杀菌效果,例如蛋白质、碳水化合物和脂质可以对微生物起到保护作用,低水分活度也可以保护微生物免受压力的影响,随着pH的降低,细胞更容易受到压力而失活。已有学者综述了HPP工艺参数对果蔬汁感官质量的影响和消费者接受度[44],HPP处理的压力大多介于400~600 MPa,处理时间5~15 min,温度为室温(20~25 ℃)。本文主要阐述酶、基质分子-香气相互作用以及其他物理化学作用对HPP果蔬汁香气品质的影响。

2.1 酶的激活或钝化

果蔬中的挥发性香气成分包括酯类、醛类、醇类、酮类、酸类及萜烯类等,通常在酶的作用下,通过一系列的生化路径形成。在众多香气代谢路径中,脂肪酸代谢途径是植物特有的香气代谢途径,主要通过脂氧合酶(Lipoxygenase,LOX)催化亚油酸、亚麻酸等脂肪酸前体物质生成氢过氧化物,再通过氢过氧化物裂解酶(Hydroperoxide lyase,HPL)、脱氢酶(Alcohol dehydrogenase,ADH)和酰基转移酶(Acyltransferase,AAT)等酶的催化生成相应的醛、醇和酯类等物质[45],由于该途径的限速酶为LOX,这一途径又被称为LOX途径。果蔬汁中重要的“青草”香气属性的代表性香气物质C6、C9醛醇类香气物质,如2,6-壬二烯醛、3-己烯醛、2-己烯醇等由该途径生成。因此,香气代谢途径中关键酶的活性是影响果蔬香气属性的重要因素之一,其变化也会影响香气物质种类及含量的变化。

HPP可以通过影响酶的活性,从而影响果蔬汁的香气品质。在有关甜瓜汁[46]、树莓汁[47]、番茄汁[48]和西瓜汁[49]的研究中均发现,HPP处理后LOX途径的关键酶活性都发生了显著变化。其中关于甜瓜汁[46]和树莓汁[47]的研究中还发现,HPP导致甜瓜汁中ADH被激活,进而C6和C9醛醇类关键香气物质含量显著上升,青草香气属性评分提高;然而树莓汁中ADH的钝化,导致了正己醛和顺-3-己烯醛含量显著降低,青草香气属性评分显著下降。此外在番茄汁[48]的研究中发现,当压力低于400 MPa时HPP对LOX表现为激活作用,高于400 MPa则表现为钝化作用,但对香气品质的影响有待研究。综上,HPP对LOX途径酶活性的影响会间接导致果蔬汁香气品质的变化,此外HPP既可以激活也可以钝化LOX途径中的关键酶,这可能与HPP处理条件和果蔬汁的种类有关。除LOX途径的相关酶外,β-葡萄糖苷酶也是果蔬汁香气品质的重要影响因素之一。研究显示,HPP对β-葡萄糖苷酶活性的影响各不相同,也存在激活和钝化两种截然相反的结果,且果蔬种类和HPP处理条件均会影响HPP对β-葡萄糖苷酶活性的作用效果[50−52]。但相关研究均停留在HPP对β-葡萄糖苷酶活性的影响层面,缺乏对香气品质影响的研究,只有在β-葡萄糖苷酶活性与果蔬汁香气品质显著相关时,HPP对其活性的影响才有可能使HPP果蔬汁的香气品质有所变化。因此研究HPP对果蔬汁内源酶活性和挥发性香气物质的影响有利于进一步了解HPP对果蔬汁香气品质的影响机制,为HPP果蔬汁香气调控提供理论依据。综上,HPP对果蔬汁内源酶的激活或钝化机制如何,是否对HPP果蔬汁香气品质产生影响等问题亟待解决。

根据上述研究结果,HPP能通过改变关键香气物质形成途径中关键酶的活性,间接影响到HPP果蔬汁中关键香气的含量及构成,从而对产品的香气属性产生影响。但HPP影响酶活性的作用机制较为复杂,在较高的压力下,酶的螺旋结构被破坏而变得不稳定,在压力协同温度(>50 ℃)作用下,酶结构中的共价键和非共价键受到影响,酶结构(三级或四级)发生不可逆的展开,导致酶功能的立即丧失[53]。至于酶的激活,HPP处理导致蛋白质结构的可逆变化,在可逆的蛋白质变性过程中,压力释放会导致蛋白质缓慢重新折叠,更多活性位点暴露,从而使酶部分或完全恢复活性。但HPP对每一种不同来源的酶活性在不同的处理条件下均有可能产生不同的效果,需要具体问题具体分析。因此HPP等相关非热加工技术对香气合成关键酶活性影响机制研究的缺乏会阻碍非热加工技术的工业化进程。

2.2 果蔬汁基质中果胶与香气的相互作用

果蔬汁中的多糖主要以果胶为主,其与挥发性香气成分存在各种类型和不同程度的相互作用,影响着风味物质的保留和释放。同时,HPP处理会影响基质-香气相互作用,进而影响香气化合物在果蔬汁中的释放行为。探究基质大分子在HPP果蔬汁加工及贮藏过程中的结构变化和降解情况,研究挥发性香气成分与基质大分子的相互作用,可进一步解释果蔬汁香气的释放途径,对HPP果蔬汁香气品质的调控具有重要意义。

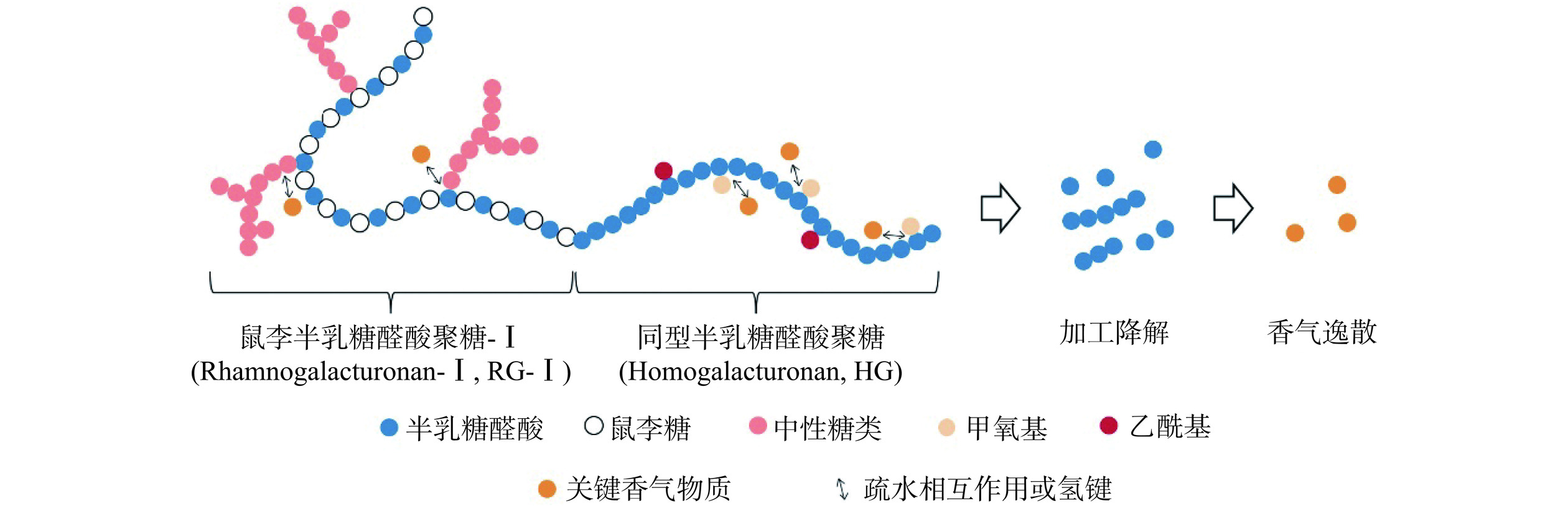

果胶是一种杂多糖,广泛存在于植物细胞壁和胞间层。果胶与挥发性香气成分之间的相互作用受到果胶含量、组分和精细结构等的影响。Li等[54]发现番茄酱中的活性香气化合物苯乙醇的释放与果胶含量呈高度负相关,并通过紫外可见光、荧光光谱、核磁以及分子动力学模拟等手段分析苯乙醇与果胶的相互作用,表明疏水作用力、静电相互作用和范德华力起主导作用。除果胶含量外,不同的果胶组分也会影响食品风味的释放。Li等[55]发现离心诱导的橙汁香气变化与螯合型果胶和碱溶性果胶高度相关,果胶组分与萜烯类香气化合物呈显著正相关,与醇类香气化合物呈显著负相关。果胶精细结构的变化可能也会改变香气物质的释放,HPP处理后树莓果胶在同型半乳糖醛酸聚糖区域发生了结构解聚,这可能会破坏基质疏水性微环境,降低基质对关键香气的疏水相互作用,导致HPP果蔬汁加工过程中关键香气的逸散(图2)[13]。以上结果说明果胶对香气具有明显的控释作用,且随着果胶的组成、精细结构以及溶解性等不同,其对香气的控释作用也不同。研究果胶与香气化合物的相互作用机制,可以为果蔬汁香气品质调控提供理论依据。

此外,纤维素也是果蔬基质的重要组成部分,其同样可以与挥发性香气成分互作。Vukoja等[56]研究纤维素作为树莓香气载体的可能性时发现,纤维素/树莓复合物可以有效保留树莓汁的挥发性香气物质,39种树莓汁挥发性物质中有28种可以在复合物中检出,且复合物很好的保留了树莓汁“浆果味”的风味属性。但由于纤维素不溶于水,在加工过程中大部分纤维素已被去除,因此其对果蔬汁香气的影响可忽略不计。

目前关于果蔬基质与香气物质相互作用研究的文献较少,主要为碳水化合物与香气互作研究,且加工方式对基质-香气物质复合物影响的研究存在空缺。但随着研究人员对食品体系内物质间相互作用的研究逐渐形成体系,这部分欠缺有望在不久的将来得到补充。

2.3 其他机制

果蔬汁基质中的小分子物质也会影响挥发性香气成分的释放或保留。一方面,添加糖类物质会引起盐析效应而促进挥发性香气物质的释放;另一方面,基质黏度增大又会减少香气的释放。Pan等[57]研究了蔗糖、葡萄糖和果糖对HPP芒果汁中活性香气化合物释放的影响,发现糖类物质与香气组分主要通过疏水作用以及氢键结合,HPP处理后加强了基质中香气物质的保留。关于酚类与挥发性香气成分的相互作用在葡萄酒中有较多研究,相关思路也可以借鉴到果蔬汁研究中。Mitropoulou等[58]研究了丹宁对模拟葡萄酒体系中特征香气化合物顶空释放的影响,发现在低浓度下添加丹宁,通常会增加酯类香气的释放。

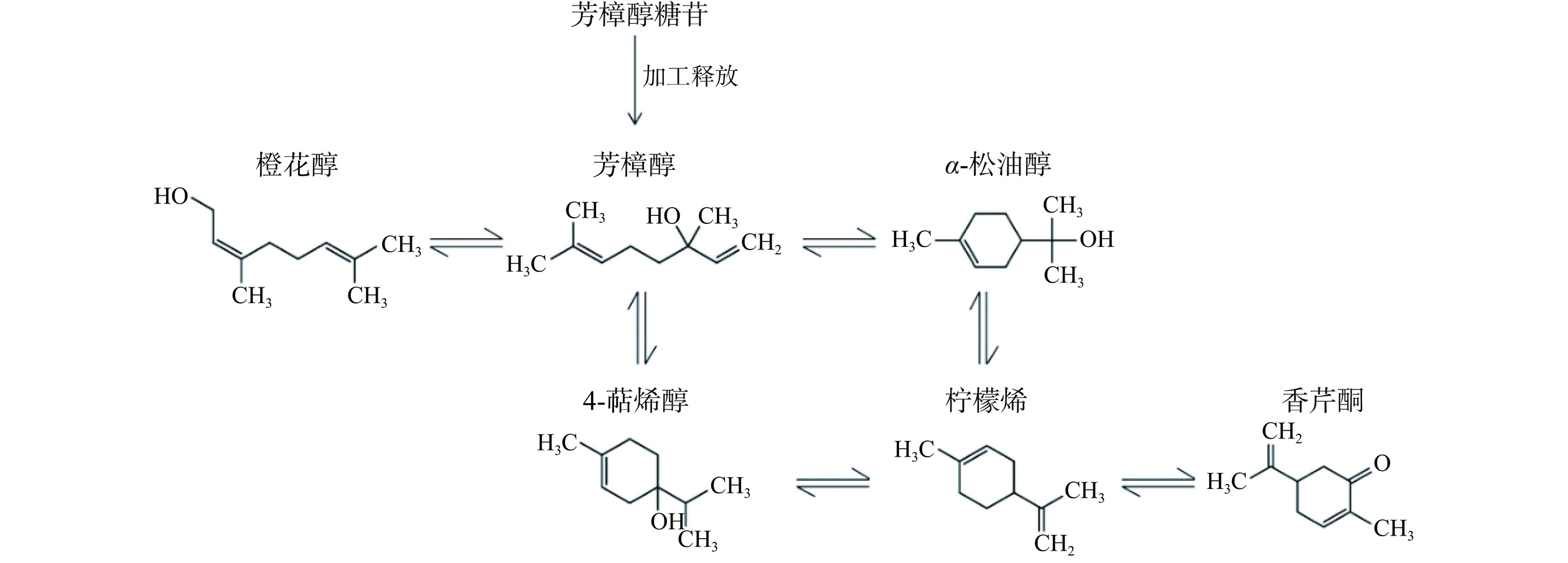

HPP可以增强或者延缓某些化学反应,从而影响香气化合物的组成或浓度。Aganovic等[59]研究发现HPP处理番茄汁后2-己烯醛和2-己烯醇等C6/C9醇醛类物质含量增加,可能是高压条件下脂质和脂肪酸的氧化反应增强[60−61]。Bi等[7]指出HPP加工后醇类香气含量增加主要来源于碳氢萜烯和其他前体物质的一系列氧化水合-脱水反应(图3),HPP橙汁中香芹酮是新鲜橙汁中的2~40倍,这可能是高压条件下橙汁中的溶解氧含量增加了,柠檬烯通过氧化反应途径生成了香芹酮,而在橙汁中带有香菜气味的香芹酮通常被认为是一种异味物质。总的来说,研究HPP果蔬汁香气变化机制,可帮助预判加工及贮藏过程中香气的变化,采取适当的调控措施,提高HPP果蔬汁香气感官品质。

3. 超高压果蔬汁香气品质调控措施

果蔬汁的风味是决定消费者接受度的直接因素之一,在贮藏期间HPP果蔬汁由于钝酶不完全、果蔬汁基质与风味物质的相互作用等原因,原有风味轮廓不可避免地会发生改变,从而影响HPP果蔬汁的感官品质,甚至可能会缩短产品的货架期。因此,采取恰当的香气调控措施对于HPP果蔬汁风味的稳态化有重要意义。但目前关于HPP果蔬汁风味稳态化措施的研究还相当缺乏,残存酶活和贮藏环境是HPP果蔬汁产品香气品质变化的主要因素,因此本文简要概述了目前有关提高HPP果蔬汁钝酶效果以及贮藏条件对产品品质影响的研究,以期为后续HPP果蔬汁的香气调控研究提供思路。

3.1 提高钝酶效果

根据2.1部分的叙述,HPP果蔬汁中的残存酶活,是导致产品贮藏期香气损失和劣变的主要因素之一。因此,HPP果蔬汁加工中提高钝酶效果是解决该问题的有效途径。但由于缺少对香气代谢途径中关键酶活性钝化的研究,本文列举了在HPP果蔬汁酶活钝化研究中常见的多酚氧化酶(Polyphenol oxidase,PPO)、过氧化物酶(Peroxidase,POD)和果胶甲酯酶(pectin methylesterase,PME)三种酶在不同处理措施下的钝化效果(表2)。以期为后续HPP果蔬汁中香气代谢途径关键酶活性钝化提供研究思路。

表 2 提高超高压果蔬汁钝酶效果的常见措施Table 2. Measures to improve the efficacy of passivating enzymes in HPP juices调控措施 果蔬汁类型 工艺参数 对酶活性的影响 品质变化 参考文献 温压结合 桃子草莓

混合果浆600 MPa/

10 min/50 ℃4 ℃贮藏21 d后,相较于温压处理组,HPP组PPO和POD活性增加了2.6倍 温压处理组和HPP组的香气组分相近,颜色差异较大 [62] 芒果果浆 600 MPa/

10 min/52 ℃酶活性降低约50%(PME、PPO、POD),5 ℃可贮藏120 d 色泽、质构和香气与新鲜样品无差异 [53] 橙汁牛奶

饮料450~600 MPa,

15 min,30 ℃/

50 ℃450 MPa/15 min/30 ℃未观察到PME的失活,压力升高到650 MPa时失活80%,调整为650 MPa/

15 min/50℃时失活90.5%在较低的压力下挥发性香气化合物的含量有所增加,但在650 MPa/50 ℃下的损失与热处理(85 ℃/1 min)相当。 [63] 荔枝-柠檬汁-椰汁混合汁 200~600 MPa,0~20 min,30~

70 ℃该混合果蔬汁中,相较于PME、POD,PPO是耐压性最强的酶,200 MPa/5 min/30 ℃时失活约12%,

500 MPa/20 min/70 ℃时几乎完全失活− [64] 荔枝汁 300~450 MPa,10~30 min,10、40~70 ℃ 在300~450 MPa/20 min/室温条件下,POD被激活,而在中温范围内(40~70 ℃)温度越高,PPO失活效果越明显 中温协同HPP处理后果汁的亮度增加,但随着温度的升高,总色差ΔE*逐渐增大,果汁的色泽变化增大。 [65] 菠萝果浆 200~600 MPa,0~20 min,

30~70 ℃压力>400 MPa,温度在50~70 ℃之间,可以降低POD和PPO的活性 − [66] 猕猴桃汁 200~600 MPa,0~30 min,

10~50 ℃压力>400 MPa,协同热处理(≤50 ℃),可以加速对POD活性的抑制作用 − [67] 循环加压 荔枝汁 300~600 MPa,1 s~45 min,室温,循环次数1~3 1~3次脉冲式HPP会激活PPO和POD;而600 MPa三次循环加压,每次保压时间15 min,PPO和POD最大失活率分别为39.7%和29.1% − [68] 苹果汁 室温处理,

300 MPa,

5 min,循环3次;600 MPa/5 min300 MPa/5 min/循环3次有助于将产品保质期延长至与600 MPa/5 min处理组相同的水平(4 ℃,12周);但两个处理对多聚半乳糖醛酸酶的活性没有显著影响,但是其活性在贮藏过程中显著降低 在储存期间,HPP处理的每种果汁的L值降低和褐变指数增加,果汁颜色变得更深。 [69] HPP协同CO2 菲油果浆 200~600 MPa,1~13 min,室温,通入饱和CO2 通入CO2会显著降低酶活性,最佳工艺条件为

600 MPa/13 min时,POD、PPO、和PME的残存活性分别为74.3%±3.3%、70.9%±2.6% 和 53.9%±0.9%− [70] 橙汁 200~600 MPa,30~300 s,15~50 ℃,通入12 psig CO2 600 MPa/25 ℃时,添加12 psig CO2可以使处理时间从300 s减少到100 s,而PME活性降低的程度相当 − [71] 注:“−”表示没有相关内容;多酚氧化酶(Polyphenol oxidase,PPO);过氧化物酶(Peroxidase,POD);果胶甲酯酶(pectin methylesterase,PME)。 3.1.1 温压结合作用

压力处理过程中,温度会对酶的活性产生显著影响,使用温和的热处理(<60 ℃)和HPP处理相结合,可以延长果蔬汁货架期,提高产品的贮藏稳定性,Patterson[43]提出可以使用温压结合的方式来生产耐贮藏的低酸食品。Kaushik等[72]探究了温压处理(400~600 MPa/5~15 min/40~60 ℃)芒果果浆的最优参数,发现在600 MPa/10 min/52 ℃条件下可以取得最优的灭酶效果。但另一方面,升高温度也会对产品香气品质带来不利影响[62]。一般来说,使用较为温和的温度(<60 ℃)联合HPP技术才有实用意义,需要结合实际生产情况和不同种类果蔬汁的pH等,探究最优的工艺参数。

3.1.2 优化加压模式

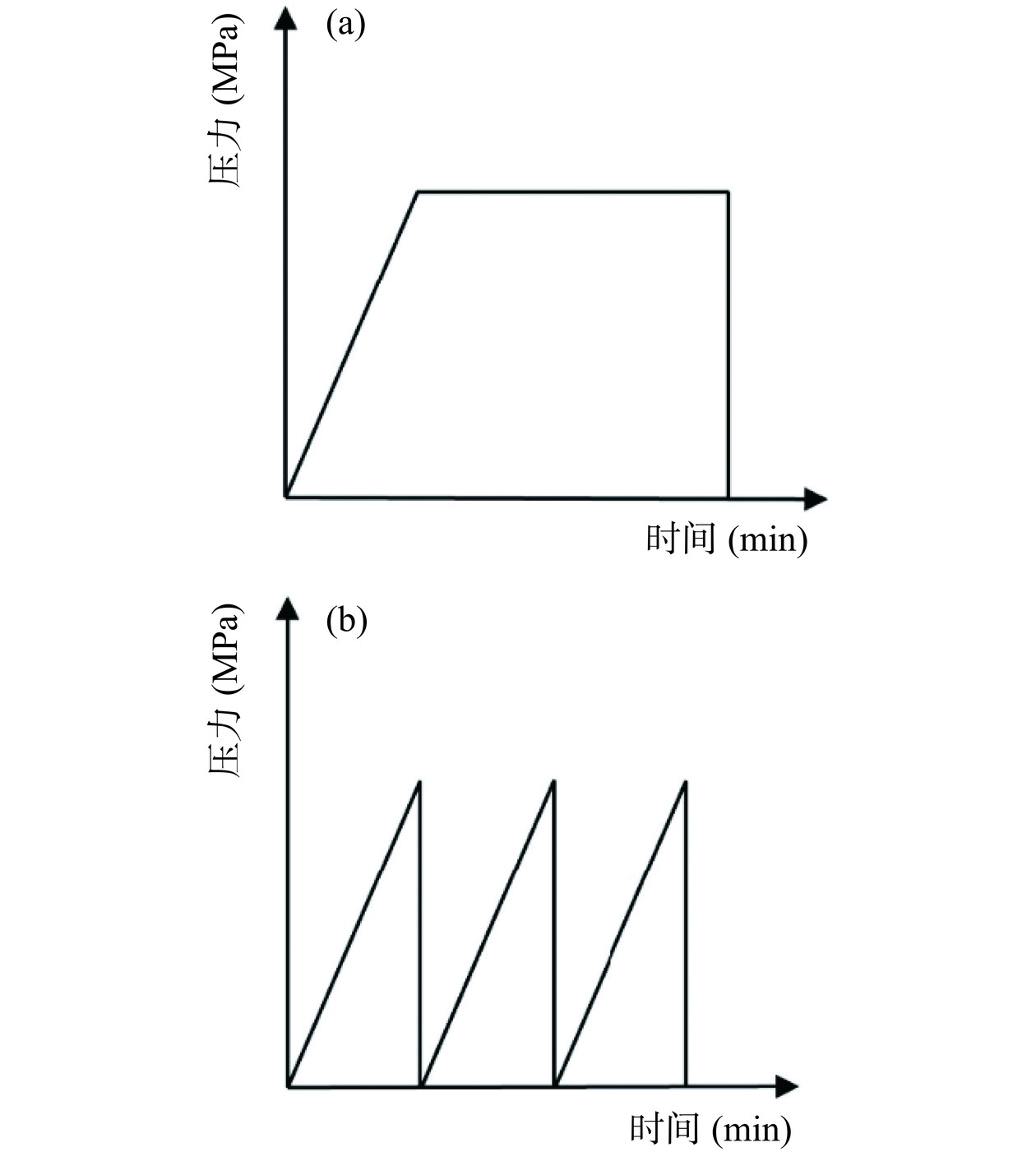

HPP加工中,有两种常见模式[73],其中最常使用的是单次静态HPP(图4a),该过程包括三部分,升压、保压和降压。研究发现升压速率会影响杀菌、钝酶效果,Ratphitagsanti等[74]研究发现,在保压时间≤2 min时,低升压速率的杀菌效果优于高升压速率。还有脉冲式HPP(图4b),该处理没有保压时间,只有升压和降压过程。此外,还有多次静态HPP组合(循环加压)或者多次脉冲式HPP组合等多种加工方式。Kaushik等[68]发现1~3次脉冲式HPP会激活PPO和POD,不适合荔枝汁的保存,循环加压比单次静态HPP处理更适合于灭活酶,并且随着循环次数的增加,在相对较低的压力水平或较短的保压时间下,就可以获得酶失活的类似效果。

3.1.3 HPP协同其他技术

为提高HPP果蔬汁钝酶效果,延长产品货架期,有学者研究了HPP协同CO2处理[70−71]、HPP协同热超声处理[75]以及HPP协同pH[76]等技术,都取得了不错的效果。Boff等[77]研究了HPP协同CO2处理对橙汁挥发性香气化合物的影响,发现相较于热处理组或单独使用HPP组,HPP+CO2处理橙汁香气损失最低,贮藏过程中更稳定。关于HPP协同CO2钝酶的机理,有学者表示,可能是CO2引起了酸化效应[78],降低了体系pH,导致酶活性的改变。还有研究指出,CO2可能会与精氨酸或者蛋白质外部的氨基酸结合,形成碳酸盐复合物或者氨基甲酸盐,引起电荷转移受阻,从而导致酶活性的改变[79]。Chen等[75]评估了热超声(25 ℃、45 ℃/40 kHz 240 W)联合HPP(200~600 MPa)对蓝莓汁酶活性的影响发现,无论是热超声还是HPP均能有效降低PPO活性,且随着压力的增加PPO活性显著降低;但单独使用HPP和25 ℃热超声、25 ℃热超声与HPP的联合使用时都会激活POD,只有45 ℃热超声及其与HPP联合使用时才能将其活性降低至50%以下。宋丽军等[76]研究了HPP协同pH钝化哈密瓜汁中POD和PPO活性的效果发现,常温下单纯HPP(25 ℃/500 MPa/30 min)处理哈密瓜汁很难钝化POD和PPO(残存酶活分别为0.9401和0.9),当哈密瓜汁pH为4时HPP则能较好的钝化POD(0.7360)和PPO(0.0308)。虽然HPP技术的钝酶效果差强人意,但是通过HPP与其他技术的结合可能可以实现协同灭酶的作用,“HPP+”或许是解决HPP果蔬汁酶活趋势不明的有效手段,但目前相关研究较为缺乏,有待进一步完善。

3.2 改善贮藏条件

由于HPP仅能灭活致病微生物和腐败微生物的营养体,而无法灭活细菌芽孢、导致细菌进入亚致死状态或活的非培养状态而无法轻易检出,以及HPP对酶活性的影响不可预测等原因[80−81],HPP产品的运输和贮藏只能在低温下进行。这是因为冷藏可以使果蔬汁中微生物停止生长降低各种生物化学反应的速率,从而达到延长保质期的目的。王凤玲等[82]采用加速货架期实验预测猕猴桃-菠萝-芒果复配果汁的货架期,基于贮藏期间的感官品质评分(香气30%、口感滋味40%、色泽外观30%)的变化判断货架期终点,结果显示HPP(450 MPa/15 min/25 ℃)复配果汁4 ℃和20 ℃下货架期分别为103和70 d。Hulle等[83]在物理化学和感官基础上的货架期综合分析测定,HPP处理(600 MPa/15 min/56 ℃)的芦荟-荔枝混合饮料在4、15和25 ℃保存时的货架期分别为100、30和5 d。Juarez-Enriquez等[84]研究发现,在34 d的贮藏期间,4 ℃保存的苹果汁在风味口感上优于20 ℃保存的苹果汁,香气品质保留得更好。综上,毋庸置疑的是,相较于常温低温下的HPP果蔬汁拥有更好的风味和更长的保质期,但是全程冷链的产品销售模式成本高昂,能耗高环境不友好,贮藏技术的更新势在必行。

在制汁时,天然存在于果蔬细胞间隙中的氧气由于细胞破碎混合到果汁中,为各类氧化反应提供了原料。而且,HPP过程中随着压力的升高,果蔬汁中氧气的溶解度也会增加,进而加速氧化反应,从而影响果蔬汁的品质(如香气、颜色),产品保质期缩短[85]。因此,降低产品中溶解氧含量有利于维持HPP果蔬汁产品品质。就苹果汁而言,已发现使用臭氧气体对苹果汁进行处理会有效延长果汁的保质期,这表明减少溶解氧有利于产品保质期的延长[86]。降低溶解氧含量可能对果汁的香气品质也有益处。李维[87]采用氮气置换处理显著降低荔枝混合果汁中溶解氧含量后发现,果汁中的挥发性香气成分并没有减少,而且在贮藏期中,还可以有效减少HPP果汁中香气成分的流失,提高果汁香气品质。路遥等[88]低温低氧工艺所制苹果汁也表现出相较于传统果汁更好的香气品质。除了优化制汁工艺以外,还可以通过包装材料的选择来控制贮藏期间果汁溶解氧含量的变化,达到稳定果汁品质的目的。黄林华等[89]研究了3种不同透氧率的包装材料对NFC橙汁常温贮藏期长短的影响发现,可接受感官品质(感官指标加权评分>60分,其中香气评分占30%)样品对应的贮藏时间与包装材料的透氧率呈极显著负相关,且样品溶解氧含量的变化速度与包装材料的透氧率差异一致,透氧率最差的玻璃材料样品的可接受感官品质贮藏时间高达60 d。虽然降低果蔬汁中的溶解氧含量可以稳定延长保质期稳定香气品质,但由于挥发性香气物质的形成途径复杂很难量化溶解氧含量与香气成分之间的关系,无法确定溶解氧含量的最高限,因此我们仍需研究溶解氧直接影响挥发性香气物质的相关机理。

此外,一些新的贮藏技术正在发展中,室温高压储存(hyperbaric storage at room temperature,HS-RT)就是其中一种,它在较温和的压力水平(25~220 MPa)对食品进行保存[90]。由于只需要在施压过程消耗能量,不用额外的能量来维持压力,相较于冷藏能源成本和碳排放都更低,因此被称为冷藏的可能替代方案[90−91]。多项研究表明,HS-RT可以有效抑制微生物生长从而延长果汁保质期,可能是一种有效的果汁保存方法[92−95]。Bermejo-Prada等[93]研究发现,HS-RT(25~200 MPa/20 ℃)草莓汁在25 MPa下就可以延缓微生物的生长,随着压力的升高,微生物损害加重贮藏期延长,当压力大于50 MPa即可达到抑制微生物生长的效果。在关于HS-RT西瓜汁[94]和甜瓜汁[95]的研究中也观察到相似的结果。此外,相较于传统的冷藏方法,HS-RT能更好的保留果汁的香气品质。Bermejo-Prada等[96]深入研究对比了传统冷藏(0.1 MPa/5 ℃)和HS-RT对草莓汁挥发性特征的影响,发现HS-RT的样品在贮藏15 d后关键香气物质的丰度基本保持不变,通过层次聚类分析发现,相较于传统冷藏样品HS-RT样品的香气组成与对照果汁更为相似。进一步进行感官分析发现,在100/220 MPa的压力下HS-RT草莓汁贮藏15 d不会产生任何颜色、气味、滋味或整体接受度的明显变化,相比之下,在25 MPa压力下贮藏15 d后尽管颜色和气味保持不变,但滋味和整体接受度的喜好度得分显著下降[97]。综上,HS-RT可以抑制微生物生长,在某些条件下甚至可以减少微生物负荷,而且对产品的感官属性的保留也优于传统冷藏方法。HS-RT在食品贮藏方面具有巨大的潜力。然而,在工业化之前,还需要更多的研究来阐明储存条件对HPP果蔬汁产生的影响及其相对于传统贮藏技术的优势。

4. 结论与展望

HPP作为最先实现工业化的非热加工技术,已有大量关于HPP对果蔬汁各类品质影响的研究证明HPP在果蔬汁加工中的优越性。然而由于果蔬汁是一个复杂体系,且HPP钝酶效果有限以及HPP对果蔬基质大分子与香气分子互作等众多影响,HPP果蔬汁在贮藏过程中广泛存在香气逸散、损失和劣变问题,并且不同工艺参数和不同种类果蔬汁处理后,货架期有非常大的区别,所以针对不同产品还应具体研究。为提高HPP果蔬汁贮藏期香气品质,可通过HPP协同温度、CO2、超滤等技术,也可以利用香气与食品基质相互作用机制来研究食品清洁标签或者构建相关乳液体系,同时还可以改善贮藏条件采用低温、隔氧和高压等贮藏技术来稳定贮藏期间HPP果蔬汁的香气品质。因此,研究HPP果蔬汁挥发性香气成分的动态变化、与基质分子的相互作用以及生物合成途径及其相关酶活性的变化规律,可以为产品加工中及贮藏中香气的稳态化控制、提高果蔬汁香气品质提供理论支撑,为进一步开发高品质的HHP果蔬汁加工新技术与产品提供支撑。HPP果蔬汁在水果高端产品的产业发展中有着巨大的潜力和良好的市场前景,但HPP果蔬汁贮藏期短、香气品质不稳定等问题阻碍着它的发展,厘清果蔬汁基质与香气活性物质之间的相互作用原理以及如何运用二者的互作关系以稳定HPP果蔬汁贮藏期间香气品质的相关研究势在必行,此外通过HPP与其他技术结合使用以延长产品贮藏期的相关研究也有望成为新的热点。

-

表 1 HPP果蔬汁加工及贮藏过程中香气品质变化

Table 1 Changes in aroma quality of juices during high-pressure processing and storage

果蔬种类 产品 处理条件 挥发性物质或香气感官属性变化 贮藏期 参考文献 浆果类 猕猴桃汁 400~600 MPa,

5~15 min,室温HPP处理后,醇和酯的总含量显著下降,而总醛含量显著增加;贮藏过程中,醛的总含量下降,而醇、酮、酯和酸的含量增加;其中500 MPa/15 min和600 MPa/

15 min在贮藏过程中对特征香气的保护效果较好(己醛和反-2-己烯醛)4 ℃

40 d[29] 猕猴桃汁 400 MPa,

15 min,室温HPP处理后,醇类和酯类物质的种类和含量降低,酮类和醛类物质的种类和含量增加;贮藏过程中,酮类和醛类物质先增加后减少 4 ℃

28 d[12] 草莓汁 热烫1 min,600 MPa,

4 min,室温贮藏过程中,草莓汁特征香气物质含量呈下降趋势,其中酯类物质损失显著,芳樟醇、反式-橙花叔醇含量则随贮藏时间的延长而增加,醛类、酮类等物质在贮藏过程中逐渐减少 4 ℃

210 d[11] 杨桃汁 600 MPa,

150 s,10 ℃HPP果蔬汁的香气感官评分与新鲜产品没有显著性差异,虽然贮藏过程中香气逐渐下降,但仍优于热处理样品 4 ℃

40 d[30] 百香果汁 600 MPa,

6 min,22 ℃HPP处理后酯类、醇类、酮类、醛类和烯烃类物质的相对含量在贮藏期间逐渐降低,酸类物质的相对含量在贮藏期间逐渐增加。HPP对特征香气的保留率大于热处理,并减少了异味物质的生成 4 ℃

25 d[31] 仁果类 苹果汁 400 MPa,

15 min,室温HPP处理后香气含量接近新鲜产品,但贮藏过程中香气物质含量变化显著,到4周时降低了26.13% 4 ℃

28 d[10] 柑橘类 橙汁 500 MPa,

10 min,25℃HPP处理后,萜烯和酯类含量显著减少,醛醇类含量增加 4 ℃

28 d[7] 瓜果类 西瓜汁 600 MPa,

5 min,室温HPP处理后,壬醛、柠檬醛、反-2,顺6-壬二烯醇显著降低,己醛、2-己烯醛、反式-2-辛烯-1-醇、6-甲基-5-庚烯-2-酮显著增加 3 ℃

12 d[15] 蔬菜 黄瓜汁 500 MPa,

5 min,室温HPP处理后,具有青香属性的反-2-,顺-6-壬二烯醛和反-2-壬烯醛含量显著增加;贮藏至20 d时,香气感官评分有所降低,但HPP组仍高于热处理组 4 ℃

20 d[18] 番茄汁 400 MPa,

30 min,25℃通过电子鼻分析HPP番茄汁贮藏过程中风味变化,相较于热处理组,HPP组的香气更接近新鲜番茄汁且在贮藏期间更稳定 4 ℃

90 d[32] 绿芦笋汁 200/400/600 MPa,

10/20 min,室温HPP处理后,酮类和主要香气贡献的醛类物质含量显著上升,酸类物质含量在200 MPa下最高,醇类物质含量稍有下降,酯类物质浓度不受HPP影响。 − [33] 混合果蔬 苹果汁/苹果-猕猴桃汁 600 MPa,

3 min,室温贮藏过程中乙酸丁酯、2-甲基乙酸丁酯和乙酸戊酯均有所下降,但苹果-猕猴桃汁的变化小于苹果汁,添加猕猴桃果浆明显减少了果味香气的损失 4 ℃

28 d[34] 胡萝卜-菠萝汁,橙子-芒果-猕猴桃汁 550 MPa,

5 min,室温挥发性香气化合物在贮藏过程中变化明显,大量醛、醇类化合物减少,但部分萜类化合物含量增加;贮藏期间,胡萝卜-菠萝汁的香气品质比橙子-芒果-

猕猴桃汁更稳定4 ℃

90 d[19] 苹果-草莓-香蕉-橙子汁 450~600 MPa,

5~10 min,20 ℃贮藏过程中所有挥发性香气化合物均有所降低,特别是与“新鲜/绿色/青草味”有关的化合物;贮藏30 d后,相较于新鲜产品,感官评分降低了近50% 4 ℃

30 d[35] 表 2 提高超高压果蔬汁钝酶效果的常见措施

Table 2 Measures to improve the efficacy of passivating enzymes in HPP juices

调控措施 果蔬汁类型 工艺参数 对酶活性的影响 品质变化 参考文献 温压结合 桃子草莓

混合果浆600 MPa/

10 min/50 ℃4 ℃贮藏21 d后,相较于温压处理组,HPP组PPO和POD活性增加了2.6倍 温压处理组和HPP组的香气组分相近,颜色差异较大 [62] 芒果果浆 600 MPa/

10 min/52 ℃酶活性降低约50%(PME、PPO、POD),5 ℃可贮藏120 d 色泽、质构和香气与新鲜样品无差异 [53] 橙汁牛奶

饮料450~600 MPa,

15 min,30 ℃/

50 ℃450 MPa/15 min/30 ℃未观察到PME的失活,压力升高到650 MPa时失活80%,调整为650 MPa/

15 min/50℃时失活90.5%在较低的压力下挥发性香气化合物的含量有所增加,但在650 MPa/50 ℃下的损失与热处理(85 ℃/1 min)相当。 [63] 荔枝-柠檬汁-椰汁混合汁 200~600 MPa,0~20 min,30~

70 ℃该混合果蔬汁中,相较于PME、POD,PPO是耐压性最强的酶,200 MPa/5 min/30 ℃时失活约12%,

500 MPa/20 min/70 ℃时几乎完全失活− [64] 荔枝汁 300~450 MPa,10~30 min,10、40~70 ℃ 在300~450 MPa/20 min/室温条件下,POD被激活,而在中温范围内(40~70 ℃)温度越高,PPO失活效果越明显 中温协同HPP处理后果汁的亮度增加,但随着温度的升高,总色差ΔE*逐渐增大,果汁的色泽变化增大。 [65] 菠萝果浆 200~600 MPa,0~20 min,

30~70 ℃压力>400 MPa,温度在50~70 ℃之间,可以降低POD和PPO的活性 − [66] 猕猴桃汁 200~600 MPa,0~30 min,

10~50 ℃压力>400 MPa,协同热处理(≤50 ℃),可以加速对POD活性的抑制作用 − [67] 循环加压 荔枝汁 300~600 MPa,1 s~45 min,室温,循环次数1~3 1~3次脉冲式HPP会激活PPO和POD;而600 MPa三次循环加压,每次保压时间15 min,PPO和POD最大失活率分别为39.7%和29.1% − [68] 苹果汁 室温处理,

300 MPa,

5 min,循环3次;600 MPa/5 min300 MPa/5 min/循环3次有助于将产品保质期延长至与600 MPa/5 min处理组相同的水平(4 ℃,12周);但两个处理对多聚半乳糖醛酸酶的活性没有显著影响,但是其活性在贮藏过程中显著降低 在储存期间,HPP处理的每种果汁的L值降低和褐变指数增加,果汁颜色变得更深。 [69] HPP协同CO2 菲油果浆 200~600 MPa,1~13 min,室温,通入饱和CO2 通入CO2会显著降低酶活性,最佳工艺条件为

600 MPa/13 min时,POD、PPO、和PME的残存活性分别为74.3%±3.3%、70.9%±2.6% 和 53.9%±0.9%− [70] 橙汁 200~600 MPa,30~300 s,15~50 ℃,通入12 psig CO2 600 MPa/25 ℃时,添加12 psig CO2可以使处理时间从300 s减少到100 s,而PME活性降低的程度相当 − [71] 注:“−”表示没有相关内容;多酚氧化酶(Polyphenol oxidase,PPO);过氧化物酶(Peroxidase,POD);果胶甲酯酶(pectin methylesterase,PME)。 -

[1] 肖作兵, 蒋新一, 牛云蔚. 水果香气物质分析研究进展[J]. 食品科学技术学报,2021,39(2):14−22. [XIAO Z B, JIANG X Y, NIU Y W. Research progress on analysis of aroma compounds in fruits[J]. Science and Technology of Food Industry,2021,39(2):14−22.] doi: 10.12301/j.issn.2095-6002.2021.02.003 XIAO Z B, JIANG X Y, NIU Y W. Research progress on analysis of aroma compounds in fruits[J]. Science and Technology of Food Industry, 2021, 39(2): 14−22. doi: 10.12301/j.issn.2095-6002.2021.02.003

[2] 庞雪莉, 胡小松, 廖小军, 等. 热敏性果蔬香气特征及其在加工过程中的变化研究新进展[J]. 食品与发酵工业,2011,37(5):127−131. [PANG X L, HU X S, LIAO X J, et al. The new progress of research on odor characteristics of thermo sensitive fruits and vegetables and their changes during processing[J]. Food and Fermentation Industries,2011,37(5):127−131.] PANG X L, HU X S, LIAO X J, et al. The new progress of research on odor characteristics of thermo sensitive fruits and vegetables and their changes during processing[J]. Food and Fermentation Industries, 2011, 37(5): 127−131.

[3] LIU Y Y, YANG C, WANG Q, et al. Identification and confirmation of key compounds causing cooked off-flavor in heat-treated tomato juice[J]. Journal of Food Science,2022,87(6):2515−2526. doi: 10.1111/1750-3841.16168

[4] AN K J, LIU H C, FU M Q, et al. Identification of the cooked off-flavor in heat-sterilized lychee (Litchi chinensis Sonn.) juice by means of molecular sensory science[J]. Food Chemistry,2019,301:125282. doi: 10.1016/j.foodchem.2019.125282

[5] LUO D, XU X, BI S, et al. Study of the inhibitors of cooked off-flavor components in heat-treated Xizhou melon juice[J]. Journal of Agricultural and Food Chemistry,2019,67(37):10401−10411. doi: 10.1021/acs.jafc.9b03398

[6] DHENGE R, LANGIALONGA P, ALINOVI M, et al. Evaluation of quality parameters of orange juice stabilized by two thermal treatments (helical heat exchanger and ohmic heating) and non-thermal (high-pressure processing)[J]. Food Control,2022,141:109150. doi: 10.1016/j.foodcont.2022.109150

[7] BI S, SUN S C, LAO F, et al. Gas chromatography–mass spectrometry combined with multivariate data analysis as a tool for differentiating between processed orange juice samples on the basis of their volatile markers[J]. Food Chemistry,2020,311:125913. doi: 10.1016/j.foodchem.2019.125913

[8] 黄晓玲, 王永涛, 廖小军, 等. 超高压和高温短时杀菌对NFC橙汁品质的影响[J]. 食品工业科技,2021,42(6):1−8. [HUANG X L, WANG Y T, LIAO X J, et al. Effects of ultra-high pressure and high temperature short-time sterilization on the quality of NFC orange juice[J]. Science and Technology of Food Industry,2021,42(6):1−8.] HUANG X L, WANG Y T, LIAO X J, et al. Effects of ultra-high pressure and high temperature short-time sterilization on the quality of NFC orange juice[J]. Science and Technology of Food Industry, 2021, 42(6): 1−8.

[9] RAO L, GUO X F, PANG X L, et al. Enzyme activity and nutritional quality of peach (Prunus persica) juice:Effect of high hydrostatic pressure[J]. International Journal of Food Properties,2014,17(6):1406−1417. doi: 10.1080/10942912.2012.716474

[10] 邓红, 雷佳蕾, 杨天歌, 等. 超高压和高温短时杀菌对NFC苹果汁贮藏期品质的影响[J]. 中国农业科学,2019,52(21):3903−3923. [DENG H, LEI J L, YANG T G, et al. Effect of ultra-high pressure and high temperature short-time sterilization on the quality of NFC apple juice during storage[J]. Scientia Agricultura Sinica,2019,52(21):3903−3923.] doi: 10.3864/j.issn.0578-1752.2019.21.018 DENG H, LEI J L, YANG T G, et al. Effect of ultra-high pressure and high temperature short-time sterilization on the quality of NFC apple juice during storage[J]. Scientia Agricultura Sinica, 2019, 52(21): 3903−3923. doi: 10.3864/j.issn.0578-1752.2019.21.018

[11] 许文文, 曹霞敏, 刘凤霞, 等. 超高压处理的草莓果肉饮料在贮藏过程中的品质变化[J]. 高压物理学报,2013,27(1):137−146. [XU W W, CAO X M, LIU F X, et al. Quality changes of strawberry nectar processed by ultra high pressure during storage[J]. Chinese Journal of High Pressure Physics,2013,27(1):137−146.] doi: 10.11858/gywlxb.2013.01.020 XU W W, CAO X M, LIU F X, et al. Quality changes of strawberry nectar processed by ultra high pressure during storage[J]. Chinese Journal of High Pressure Physics, 2013, 27(1): 137−146. doi: 10.11858/gywlxb.2013.01.020

[12] 邓红, 刘旻昊, 马婧, 等. UHP与 HTST杀菌处理的猕猴桃NFC果汁贮藏期品质变化[J]. 食品工业科技,2020,41(9):269−277. [DENG H, LIU M H, MA J, et al. Quality changes of kiwifruit NFC juice during storage with UHP and HTST sterilization treatment[J]. Science and Technology of Food Industry,2020,41(9):269−277.] DENG H, LIU M H, MA J, et al. Quality changes of kiwifruit NFC juice during storage with UHP and HTST sterilization treatment[J]. Science and Technology of Food Industry, 2020, 41(9): 269−277.

[13] ZHANG W T, XU S J, GAO M, et al. Profiling the water soluble pectin in clear red raspberry (Rubus idaeus L. cv. Heritage) juice:Impact of high hydrostatic pressure and high-temperature short-time processing on the pectin properties[J]. Food Hydrocolloids,2022,125:107439. doi: 10.1016/j.foodhyd.2021.107439

[14] FERRARI G, MARESCA P, CICCARONE R. The application of high hydrostatic pressure for the stabilization of functional foods:Pomegranate juice[J]. Journal of Food Engineering,2010,100(2):245−253. doi: 10.1016/j.jfoodeng.2010.04.006

[15] AGANOVIC K, GRAUWET T, SIEMER C, et al. Headspace fingerprinting and sensory evaluation to discriminate between traditional and alternative pasteurization of watermelon juice[J]. European Food Research and Technology,2016,242(5):787−803. doi: 10.1007/s00217-015-2586-8

[16] 刘野, 赵晓燕, 胡小松, 等. 超高压对鲜榨西瓜汁杀菌效果和风味的影响[J]. 农业工程学报,2011,27(7):370−376. [LIU Y, ZHAO X Y, HU X S, et al. Effect of high hydrostatic pressure on microorganism and flavor of fresh watermelon juice[J]. Transactions of the Chinese Society of Agricultural Engineering,2011,27(7):370−376.] doi: 10.3969/j.issn.1002-6819.2011.07.065 LIU Y, ZHAO X Y, HU X S, et al. Effect of high hydrostatic pressure on microorganism and flavor of fresh watermelon juice[J]. Transactions of the Chinese Society of Agricultural Engineering, 2011, 27(7): 370−376. doi: 10.3969/j.issn.1002-6819.2011.07.065

[17] 侯思涵, 裴龙英, 陈计峦. 超高压处理对哈密瓜汁中酶活性与香气的影响[J]. 食品科学,2018,39(22):202−206. [HOU S H, PEI L Y, CHEN J L. Effect of ultra-high pressure treatment on enzymatic activities and aroma compounds in hami melon juice[J]. Food Science,2018,39(22):202−206.] doi: 10.7506/spkx1002-6630-201822031 HOU S H, PEI L Y, CHEN J L. Effect of ultra-high pressure treatment on enzymatic activities and aroma compounds in hami melon juice[J]. Food Science, 2018, 39(22): 202−206. doi: 10.7506/spkx1002-6630-201822031

[18] LIU F X, ZHANG X X, ZHAO L, et al. Potential of high-pressure processing and high-temperature/short-time thermal processing on microbial, physicochemical and sensory assurance of clear cucumber juice[J]. Innovative Food Science & Emerging Technologies,2016,34:51−58.

[19] LI M B, LIU Q H, ZHANG W Z, et al. Evaluation of quality changes of differently formulated cloudy mixed juices during refrigerated storage after high pressure processing[J]. Current Research in Food Science,2021,4:627−635. doi: 10.1016/j.crfs.2021.09.002

[20] 黄鹏, 王丽萍, 李云飞. 超高压处理对胡萝卜果肉饮料中果粒品质的影响[J]. 食品工业科技,2017,38(1):106−111. [HUANG P, WANG L P, LI Y F. Impact of high hydrostatic pressure processing on fruit granule qualities in carrot nectar[J]. Science and Technology of Food Industry,2017,38(1):106−111.] doi: 10.1590/1678-457x.02817 HUANG P, WANG L P, LI Y F. Impact of high hydrostatic pressure processing on fruit granule qualities in carrot nectar[J]. Science and Technology of Food Industry, 2017, 38(1): 106−111. doi: 10.1590/1678-457x.02817

[21] 康欢, 马涛, 户昕娜, 等. 超高压处理对南瓜复合汁杀菌效果与品质的影响[J]. 食品工业,2019,40(5):153−159. [KANG H, MA T, HU X N, et al. Effect of ultra high pressure treatment on the sterilization and quality of pumpkin juice[J]. The Food Industry,2019,40(5):153−159.] KANG H, MA T, HU X N, et al. Effect of ultra high pressure treatment on the sterilization and quality of pumpkin juice[J]. The Food Industry, 2019, 40(5): 153−159.

[22] 刘德讲, 陈计峦, 裴龙英. 超高压和热处理对果蔬中四种香气合成酶活性与结构的影响[J]. 食品工业科技,2020,41(8):82−89. [LIU D J, CHEN J L, PEI L Y. Effect of ultra-high pressure and heat treatment on activity and structure of four aroma synthesis enzymes in fruits and vegetables[J]. Science and Technology of Food Industry,2020,41(8):82−89.] LIU D J, CHEN J L, PEI L Y. Effect of ultra-high pressure and heat treatment on activity and structure of four aroma synthesis enzymes in fruits and vegetables[J]. Science and Technology of Food Industry, 2020, 41(8): 82−89.

[23] MA Y K, HU X S, CHEN J L, et al. Effect of UHP on enzyme, microorganism and flavor in cantaloupe (Cucumis melo L.) juice[J]. Journal of Food Process Engineering,2010,33(3):540−553. doi: 10.1111/j.1745-4530.2008.00289.x

[24] 刘凤霞. 基于超高压技术芒果汁加工工艺与品质研究[D]. 北京:中国农业大学, 2014. [LIU F X. Research on processing technology and quality of mango juice based on ultra high pressure technology[D]. Beijing:China Agricultural University, 2014.] LIU F X. Research on processing technology and quality of mango juice based on ultra high pressure technology[D]. Beijing: China Agricultural University, 2014.

[25] ZHANG W T, DONG P, LAO F, et al. Characterization of the major aroma-active compounds in Keitt mango juice:Comparison among fresh, pasteurization and high hydrostatic pressure processing juices[J]. Food Chemistry,2019,289:215−222. doi: 10.1016/j.foodchem.2019.03.064

[26] 彭思嘉, 侯志强, 徐贞贞, 等. 超高压和高温短时杀菌对樱桃汁品质的影响[J]. 食品工业科技,2018,39(17):71−78. [PENG S J, HOU Z Q, XU Z Z, et al. Effects of high pressure and high temperature short time sterilization on the quality of cherry juice[J]. Science and Technology of Food Industry,2018,39(17):71−78.] PENG S J, HOU Z Q, XU Z Z, et al. Effects of high pressure and high temperature short time sterilization on the quality of cherry juice[J]. Science and Technology of Food Industry, 2018, 39(17): 71−78.

[27] 吴琼, 冯卫敏, 蒋和体. 不同杀菌方式对桑葚原汁品质的影响[J]. 食品科学,2016,37(9):144−149. [WU Q, FENG W M, JIANG H T. Effect of sterilization methods on the quality of mulberry juice[J]. Food Science,2016,37(9):144−149.] doi: 10.7506/spkx1002-6630-201609027 WU Q, FENG W M, JIANG H T. Effect of sterilization methods on the quality of mulberry juice[J]. Food Science, 2016, 37(9): 144−149. doi: 10.7506/spkx1002-6630-201609027

[28] 牛慧慧, 张慧云, 邹文惠, 等. 不同杀菌方式对百香果汁感官和营养品质的影响[J]. 食品与发酵工业,2022,48(20):145−151. [NIU H H, ZHANG H Y, ZOU W H, et al. Effects of sterilization methods on the sensory related characteristics and nutritional quality of passion fruit juice[J]. Food and Fermentation Industries,2022,48(20):145−151.] NIU H H, ZHANG H Y, ZOU W H, et al. Effects of sterilization methods on the sensory related characteristics and nutritional quality of passion fruit juice[J]. Food and Fermentation Industries, 2022, 48(20): 145−151.

[29] CHEN Y J, FENG X P, REN H, et al. Changes in physicochemical properties and volatiles of kiwifruit pulp beverage treated with high hydrostatic pressure[J]. Foods,2020,9(4):485. doi: 10.3390/foods9040485

[30] HUANG H W, CHEN B Y, WANG C Y. Comparison of high pressure and high temperature short time processing on quality of carambola juice during cold storage[J]. Journal of Food Science and Technology,2018,55(5):1716−1725. doi: 10.1007/s13197-018-3084-3

[31] 冉露霞, 王俊杰, 成臣, 等. 超高压和巴氏杀菌对百香果汁贮藏期品质的影响[J]. 食品工业科技,2023,44(3):56−66. [RAN L X, WANG J J, CHENG C, et al. Effect of ultra-high pressure sterilization and pasteurization on the quality of passion fruit juice during storage[J]. Science and Technology of Food Industry,2023,44(3):56−66.] RAN L X, WANG J J, CHENG C, et al. Effect of ultra-high pressure sterilization and pasteurization on the quality of passion fruit juice during storage[J]. Science and Technology of Food Industry, 2023, 44(3): 56−66.

[32] 马越, 王欢欢, 王宇滨, 等. 贮藏时间对超高压处理鲜榨番茄汁品质的影响[J]. 食品科学技术学报,2019,37(1):72−77. [MA Y, WANG H H, WANG Y B, et al. Effect of storage time on qualities of high pressure treated fresh tomato juice[J]. Journal of Food Science and Technology,2019,37(1):72−77.] doi: 10.3969/j.issn.2095-6002.2019.01.011 MA Y, WANG H H, WANG Y B, et al. Effect of storage time on qualities of high pressure treated fresh tomato juice[J]. Journal of Food Science and Technology, 2019, 37(1): 72−77. doi: 10.3969/j.issn.2095-6002.2019.01.011

[33] CHEN X, QIN W, MA L, et al. Effect of high pressure processing and thermal treatment on physicochemical parameters, antioxidant activity and volatile compounds of green asparagus juice[J]. LWT-Food Science and Technology, 2015, 62(1):927−933.

[34] 易俊洁. 基于清洁标签理念的苹果与猕猴桃复合浊汁品质研究[D]. 北京:中国农业大学, 2017. [YI J J. Research on the quality of apple and kiwi compound turbidity juice based on the clean label concept[D]. Beijing:China Agricultural University, 2017.] YI J J. Research on the quality of apple and kiwi compound turbidity juice based on the clean label concept[D]. Beijing: China Agricultural University, 2017.

[35] KEENAN D F, BRUNTON N P, MITCHELL M, et al. Flavour profiling of fresh and processed fruit smoothies by instrumental and sensory analysis[J]. Food Research International,2012,45(1):17−25. doi: 10.1016/j.foodres.2011.10.002

[36] 张馨文. 超高压处理对沃柑汁品质的影响[D]. 南宁: 广西大学, 2022. [ZHANG X W. The effect of ultra high pressure treatment on the quality of wogan juice[D]. Nanning:Guangxi University, 2022.] ZHANG X W. The effect of ultra high pressure treatment on the quality of wogan juice[D]. Nanning: Guangxi University, 2022.

[37] HURTADO A, PICOUET P, JOFRÉ A, et al. Application of high pressure processing for obtaining “fresh-like” fruit smoothies[J]. Food and Bioprocess Technology,2015,8(12):2470−2482. doi: 10.1007/s11947-015-1598-5

[38] 马辉, 王亚超, 马永昆, 等. 基于主成分分析法分析超高压处理对黄瓜水香气的影响[J]. 现代食品科技,2014,30(3):220−226. [MA H, WANG Y C, MA Y K, et al. Effect of ultra-high pressure treatment on aroma compounds in cucumber water analyzed by principal component[J]. Modern Food Science and Technology,2014,30(3):220−226.] MA H, WANG Y C, MA Y K, et al. Effect of ultra-high pressure treatment on aroma compounds in cucumber water analyzed by principal component[J]. Modern Food Science and Technology, 2014, 30(3): 220−226.

[39] KAUSHIK N, GONDI A R, RANA R, et al. Application of fuzzy logic technique for sensory evaluation of high pressure processed mango pulp and litchi juice and its comparison to thermal treatment[J]. Innovative Food Science & Emerging Technologies,2015,32:70−78.

[40] AABY K, GRIMSBO I H, HOVDA M B, et al. Effect of high pressure and thermal processing on shelf life and quality of strawberry puree and juice[J]. Food Chemistry,2018,260:115−123. doi: 10.1016/j.foodchem.2018.03.100

[41] HURTADO A, DOLORS GUARDIA M, PICOUET P, et al. Stabilisation of red fruit-based smoothies by high-pressure processing. Part II:effects on sensory quality and selected nutrients[J]. Journal of the Science of Food and Agriculture,2017,97(3):777−783. doi: 10.1002/jsfa.7795

[42] BAXTER I A, EASTON K, SCHNEEBELI K, et al. High pressure processing of Australian navel orange juices:Sensory analysis and volatile flavor profiling[J]. Innovative Food Science & Emerging Technologies,2005,6(4):372−387.

[43] PATTERSON M F. Microbiology of pressure-treated foods[J]. Journal of Applied Microbiology,2005,98(6):1400−1409. doi: 10.1111/j.1365-2672.2005.02564.x

[44] SONG Q S, LI R J, SONG X, et al. The effect of high-pressure processing on sensory quality and consumer acceptability of fruit juices and smoothies:A review[J]. Food Research International,2022,157:111250. doi: 10.1016/j.foodres.2022.111250

[45] SALAS J J, SANCHEZ C, GARCIA-GONZALEZ D L, et al. Impact of the suppression of lipoxygenase and hydroperoxide lyase on the quality of the green odor in green leaves[J]. Journal of Agricultural and Food Chemistry,2005,53(5):1648−1655. doi: 10.1021/jf040331l

[46] 裴龙英. 不同处理对哈密瓜汁香气底物、关键酶、香气组分及其相关性研究[D]. 石河子:石河子大学, 2018. [PEI L Y. Study on the aroma substrates, key enzymes, aroma components, and their correlation in Hami melon juice treated with different methods[D]. Shihezi:Shihezi University, 2018.] PEI L Y. Study on the aroma substrates, key enzymes, aroma components, and their correlation in Hami melon juice treated with different methods[D]. Shihezi: Shihezi University, 2018.

[47] 张文涛. 超高压树莓汁C6醛类关键香气的形成与调控机制[D]. 北京: 中国农业大学, 2022. [ZHANG W T. The formation and regulation mechanism of key aromas of C6 aldehydes in ultra-high pressure raspberry juice[D]. Beijing:China Agricultural University, 2022.] ZHANG W T. The formation and regulation mechanism of key aromas of C6 aldehydes in ultra-high pressure raspberry juice[D]. Beijing: China Agricultural University, 2022.

[48] RODRIGO D, JOLIE R, VAN L A, et al. Thermal and high pressure stability of tomato lipoxygenase and hydroperoxidelyase[J]. Journal of Food Engineering,2007,79(2):7.

[49] 包洪亮, 马永杰, 王瑞杰, 等. 超高压对西瓜汁香气相关酶的活性影响研究[J]. 中国果菜,2021,41(11):20−25. [BAO H L, MA Y J, WANG R J, et al. Effect of ultra high pressure on aroma related enzyme activities of watermelon juice[J]. China Fruit and Vegetable,2021,41(11):20−25.] BAO H L, MA Y J, WANG R J, et al. Effect of ultra high pressure on aroma related enzyme activities of watermelon juice[J]. China Fruit and Vegetable, 2021, 41(11): 20−25.

[50] CAO X M, ZHANG Y, ZHANG F S, et al. Effects of high hydrostatic pressure on enzymes, phenolic compounds, anthocyanins, polymeric color and color of strawberry pulps[J]. Journal of the Science of Food and Agriculture,2011,91(5):877−885. doi: 10.1002/jsfa.4260

[51] GARCIA-PALAZON A, SUTHANTHANGJAI W, KAJDA P, et al. The effects of high hydrostatic pressure on β-glucosidase, peroxidase and polyphenoloxidase in red raspberry (Rubus idaeus) and strawberry (Fragaria×ananassa)[J]. Food Chemistry,2004,88(1):7−10. doi: 10.1016/j.foodchem.2004.01.019

[52] ZHANG W J, SHEN Y X, LI Z D, et al. Effects of high hydrostatic pressure and thermal processing on anthocyanin content, polyphenol oxidase and beta-glucosidase activities, color, and antioxidant activities of blueberry (Vaccinium Spp.) puree[J]. Food Chemistry, 2021, 342:128564.

[53] KAUSHIK N, RAO P S, MISHRA H N. Comparative analysis of thermal-assisted high pressure and thermally processed mango pulp:Influence of processing, packaging, and storage[J]. Food Science and Technology International,2018,24(1):15−34. doi: 10.1177/1082013217724578

[54] LI X J, ZENG X Q, XI Y, et al. Effects of non-covalent interactions between pectin and volatile compounds on the flavor release of tomato paste[J]. Food Hydrocolloids,2022,133:107886. doi: 10.1016/j.foodhyd.2022.107886

[55] LI M B, ZHANG W Z, ZHANG M Q, et al. Effect of centrifugal pre-treatment on flavor change of cloudy orange juice:Interaction between pectin and aroma release[J]. Food Chemistry,2022,374:131705. doi: 10.1016/j.foodchem.2021.131705

[56] VUKOJA J, PICHLER A, IVIĆ I, et al. Cellulose as a delivery system of raspberry juice volatiles and their stability[J]. Molecules,2020,25(11):2624. doi: 10.3390/molecules25112624

[57] PAN X, WU J H, ZHANG W T, et al. Effects of sugar matrices on the release of key aroma compounds in fresh and high hydrostatic pressure processed Tainong mango juices[J]. Food Chemistry,2021,338:128117. doi: 10.1016/j.foodchem.2020.128117

[58] MITROPOULOU A, HATZIDIMITRIOU E, PARASKEVOPOULOU A. Aroma release of a model wine solution as influenced by the presence of non-volatile components. Effect of commercial tannin extracts, polysaccharides and artificial saliva[J]. Food Research International,2011,44(5):1561−1570. doi: 10.1016/j.foodres.2011.04.023

[59] AGANOVIC K, GRAUWET T, KEBEDE B T, et al. Impact of different large scale pasteurisation technologies and refrigerated storage on the headspace fingerprint of tomato juice[J]. Innovative Food Science & Emerging Technologies,2014,26:431−444.

[60] KEBEDE B T, GRAUWET T, PALMERS S, et al. Effect of high pressure high temperature processing on the volatile fraction of differently coloured carrots[J]. Food Chemistry,2014,153:340−352. doi: 10.1016/j.foodchem.2013.12.061

[61] OEY I, LILLE M, VAN LOEY A, et al. Effect of high-pressure processing on colour, texture and flavour of fruit-and vegetable-based food products:A review[J]. Trends in Food Science & Technology,2008,19(6):320−328.

[62] BLEOANCA I, PATRAȘCU L, BORDA D. Quality and stability equivalence of high pressure and/or thermal treatments in peach-strawberry puree[J]. Foods,2021,10(11):2580. doi: 10.3390/foods10112580

[63] SAMPEDRO F, GEVEKE D J, FAN X, et al. Effect of PEF, HHP and thermal treatment on PME inactivation and volatile compounds concentration of an orange juice–milk based beverage[J]. Innovative Food Science & Emerging Technologies,2009,10(4):463−469.

[64] JAYACHANDRAN L E, CHAKRABORTY S, RAO P S. Inactivation kinetics of the most baro-resistant enzyme in high pressure processed litchi-based mixed fruit beverage[J]. Food and Bioprocess Technology,2016,9(7):1135−1147. doi: 10.1007/s11947-016-1702-5

[65] 李汴生, 朱悦夫, 张微, 等. 低温和中温协同超高压对鲜榨荔枝汁灭酶处理和色泽影响的研究[J]. 现代食品科技,2017,33(7):151−156. [LI B S, ZHU Y F, ZHANG W, et al. Effect of high pressure processing (HPP) combined with low and moderate temperature treatments on the color and enzyme inactivation in freshly squeezed lychee juice[J]. Modern Food Science and Technology,2017,33(7):151−156.] LI B S, ZHU Y F, ZHANG W, et al. Effect of high pressure processing (HPP) combined with low and moderate temperature treatments on the color and enzyme inactivation in freshly squeezed lychee juice[J]. Modern Food Science and Technology, 2017, 33(7): 151−156.

[66] CHAKRABORTY S, RAO P S, MISHRA H N. Kinetic modeling of polyphenoloxidase and peroxidase inactivation in pineapple (Ananas comosus L.) puree during high-pressure and thermal treatments[J]. Innovative Food Science & Emerging Technologies,2015,27:57−68.

[67] FANG L, JIANG B, ZHANG T. Effect of combined high pressure and thermal treatment on kiwifruit peroxidase[J]. Food Chemistry,2008,109(4):802−807. doi: 10.1016/j.foodchem.2008.01.017

[68] KAUSHIK N, KAUR B P, RAO P S. Inactivation of polyphenol oxidase and peroxidase enzymes during pulsed, static and cyclic pressurization of litchi (Litchi chinensis) juice[J]. Food and Bioproducts Processing,2016,100:412−423. doi: 10.1016/j.fbp.2016.07.015

[69] SZCZEPAŃSKA J, PINTO C A, SKĄPSKA S, et al. Effect of static and multi-pulsed high pressure processing on the rheological properties, microbial and physicochemical quality, and antioxidant potential of apple juice during refrigerated storage[J]. LWT-Food Science and Technology,2021,150:112038. doi: 10.1016/j.lwt.2021.112038

[70] DUONG T, BALABAN M. Optimisation of the process parameters of combined high hydrostatic pressure and dense phase carbon dioxide on enzyme inactivation in feijoa (Acca sellowiana) puree using response surface methodology[J]. Innovative Food Science & Emerging Technologies,2014,26:93−101.

[71] TRUONG T T, BOFF J M, MIN D B, et al. Effects of carbon dioxide in high-pressure processing on pectinmethylesterase in single-strength orange juice[J]. Journal of Food Science,2002,67(8):3058−3062. doi: 10.1111/j.1365-2621.2002.tb08859.x

[72] KAUSHIK N, RAO P S, MISHRA H N. Process optimization for thermal-assisted high pressure processing of mango (Mangifera indica L.) pulp using response surface methodology[J]. LWT-Food Science and Technology,2016,69:372−381. doi: 10.1016/j.lwt.2016.01.062

[73] BUZRUL S. Multi-pulsed high hydrostatic pressure inactivation of microorganisms:A review[J]. Innovative Food Science & Emerging Technologies,2014,26:1−11.

[74] RATPHITAGSANTI W, AHN J, BALASUBRAMANIAM V M, et al. Influence of pressurization rate and pressure pulsing on the inactivation of Bacillus amyloliquefaciens spores during pressure-assisted thermal processing[J]. Journal of Food Protection,2009,72(4):775−782. doi: 10.4315/0362-028X-72.4.775

[75] CHEN T S, LI B, SHU C, et al. Combined effect of thermosonication and high hydrostatic pressure on bioactive compounds, microbial load, and enzyme activities of blueberry juice[J]. Food Science and Technology International,2022,28(2):169−179. doi: 10.1177/10820132211004316

[76] 宋丽军, 张丽, 史学伟, 等. 超高压协同pH对哈密瓜汁中两种酶钝化效果的研究[J]. 食品科技,2010,35(8):69−75. [SONG L J, ZHANG L, SHI X W, et al. Effect of ultra high pressure-pH synergistic treatment on the inactivative effect of two enzymes in hami melon juice[J]. Food Science and Technology,2010,35(8):69−75.] SONG L J, ZHANG L, SHI X W, et al. Effect of ultra high pressure-pH synergistic treatment on the inactivative effect of two enzymes in hami melon juice[J]. Food Science and Technology, 2010, 35(8): 69−75.

[77] BOFF J M, TRUONG T T, MIN D B, et al. Effect of thermal processing and carbon dioxide-assisted high-pressure processing on pectinmethylesterase and chemical changes in orange juice[J]. Journal of Food Science,2003,68(4):1179−1184. doi: 10.1111/j.1365-2621.2003.tb09621.x

[78] HU W F, ZHOU L Y, XU Z Z, et al. Enzyme inactivation in food processing using high pressure carbon dioxide technology[J]. Critical Reviews in Food Science and Nutrition,2013,53(2):145−161. doi: 10.1080/10408398.2010.526258

[79] CUNDARI T R, WILSON A K, DRUMMOND M L, et al. CO2-Formatics:How do proteins bind carbon dioxide?[J]. Journal of Chemical Information and Modeling,2009,49(9):2111−2115. doi: 10.1021/ci9002377

[80] PINTO C A, MOREIRA S A, FIDALGO L G, et al. Effects of high‐pressure processing on fungi spores:Factors affecting spore germination and inactivation and impact on ultrastructure[J]. Comprehensive Reviews in Food Science and Food Safety,2020,19(2):553−573. doi: 10.1111/1541-4337.12534

[81] ROOBAB U, ABIDA A, AFZAL R, et al. Impact of high-pressure treatments on enzyme activity of fruit-based beverages:An overview[J]. International Journal of Food Science & Technology,2022,57(2):801−815.

[82] 王凤玲, 朱琳, 柴瑾, 等. 超高压处理对鲜榨复配果汁品质及货架期的影响[J/OL]. 食品工业科技:1−13[2023-12-22]. https: //doi.org/10.13386/j.issn1002-0306.2023060060. [WANG F L, ZHU L, CHAI J, et al. Effects of ultra-high pressure treatment on quality and its shelf life of freshly squeezed compound juice[J/OL]. Science and Technology of Food Industry: 1−13[2023-12-22]. https://doi.org/10.13386/j.issn1002-0306.2023060060.] WANG F L, ZHU L, CHAI J, et al. Effects of ultra-high pressure treatment on quality and its shelf life of freshly squeezed compound juice[J/OL]. Science and Technology of Food Industry: 1−13[2023-12-22]. https://doi.org/10.13386/j.issn1002-0306.2023060060.

[83] HULLE N R S, RAO P S. Effect of high pressure and thermal processing on quality changes of aloe vera-litchi mixed beverage (ALMB) during storage[J]. Journal of Food Science and Technology-Mysore,2016,53(1):359−369. doi: 10.1007/s13197-015-2056-0

[84] JUAREZ-ENRIQUEZA E, SALMERON-OCHOAA I, GUTIERREZ-MENDEZA N, et al. Shelf life studies on apple juice pasteurised by ultrahigh hydrostatic pressure[J]. LWT-Food Science and Technology,2015,62(1):915−919. doi: 10.1016/j.lwt.2014.07.041

[85] GARCÍA‐TORRES R, PONAGANDLA N R, ROUSEFF R L, et al. Effects of dissolved oxygen in fruit juices and methods of removal[J]. Comprehensive Reviews in Food Science and Food Safety,2009,8(4):409−423. doi: 10.1111/j.1541-4337.2009.00090.x

[86] PATIL S, VALDRAMIDIS V P, TIWARI B K, et al. Quantitative assessment of the shelf life of ozonated apple juice[J]. European Food Research and Technology,2011,232:469−477. doi: 10.1007/s00217-010-1416-2

[87] 李维. 溶氧量对超高压处理荔枝混合果汁贮藏特性的影响[D]. 广州:华南农业大学, 2018. [LI W. The effect of dissolved oxygen content on the storage characteristics of lychee mixed juice treated with ultra-high pressure[D]. Guangzhou:South China Agricultural University, 2018.] LI W. The effect of dissolved oxygen content on the storage characteristics of lychee mixed juice treated with ultra-high pressure[D]. Guangzhou: South China Agricultural University, 2018.

[88] 路遥, 张凯杰, 李根, 等. 低温低氧工艺对苹果汁品质与香气特征的影响[J]. 食品研究与开发,2021,42(12):183−188. [LU Y, ZHANG K J, LI G, et al. Effects of processes involving low-temperature and low-oxygen concentrations on the quality and aroma of apple juice[J]. Food Research and Development,2021,42(12):183−188.] doi: 10.12161/j.issn.1005-6521.2021.12.029 LU Y, ZHANG K J, LI G, et al. Effects of processes involving low-temperature and low-oxygen concentrations on the quality and aroma of apple juice[J]. Food Research and Development, 2021, 42(12): 183−188. doi: 10.12161/j.issn.1005-6521.2021.12.029

[89] 黄林华, 蔡德萍, 郭莉, 等. 不同包装材料对NFC橙汁常温贮藏品质的影响[J]. 华中农业大学学报,2022,41(4):142−150. [HUANG L H, CAI D P, GUO L, et al. Effects of different packaging materials on storage quality of NFC orange juice at room temperature[J]. Journal of Huazhong Agricultural University,2022,41(4):142−150.] doi: 10.3969/j.issn.1000-2421.2022.4.hznydx202204019 HUANG L H, CAI D P, GUO L, et al. Effects of different packaging materials on storage quality of NFC orange juice at room temperature[J]. Journal of Huazhong Agricultural University, 2022, 41(4): 142−150. doi: 10.3969/j.issn.1000-2421.2022.4.hznydx202204019

[90] FERNANDES P A R, MOREIRA S A, FIDALGO L G, et al. Food preservation under pressure (hyperbaric storage) as a possible improvement/alternative to refrigeration[J]. Food Engineering Reviews,2015,7:1−10. doi: 10.1007/s12393-014-9083-x

[91] OTERO L. Hyperbaric storage at room temperature for fruit juice preservation[J]. Beverages,2019,5(3):49. doi: 10.3390/beverages5030049

[92] LEMOS Á T, RIBEIRO A C, FIDALGO L G, et al. Extension of raw watermelon juice shelf-life up to 58 days by hyperbaric storage[J]. Food Chemistry,2017,231:61−69. doi: 10.1016/j.foodchem.2017.03.110

[93] BERMEJO-PRADA A, LÓPEZ-CABALLERO M E, OTERO L. Hyperbaric storage at room temperature:Effect of pressure level and storage time on the natural microbiota of strawberry juice[J]. Innovative Food Science & Emerging Technologies,2016,33:154−161.

[94] PINTO C, MOREIRA S A, FIDALGO L G, et al. Impact of different hyperbaric storage conditions on microbial, physicochemical and enzymatic parameters of watermelon juice[J]. Food Research International,2017,99:123−132. doi: 10.1016/j.foodres.2017.05.010

[95] QUEIRÓS R P, SANTOS M D, FIDALGO L G, et al. Hyperbaric storage of melon juice at and above room temperature and comparison with storage at atmospheric pressure and refrigeration[J]. Food Chemistry,2014,147:209−214. doi: 10.1016/j.foodchem.2013.09.124

[96] BERMEJO-PRADA A, VEGA E, PÉREZ-MATEOS M, et al. Effect of hyperbaric storage at room temperature on the volatile profile of strawberry juice[J]. LWT-Food Science and Technology,2015,62(1):906−914. doi: 10.1016/j.lwt.2014.08.020

[97] BERMEJO-PRADA A. Hyperbaric storage of foods at room temperature:Characterization in strawberry juice[D]. Universidad Complutense de Madrid, 2015.

-

期刊类型引用(1)

1. 盛周杨,邹波,肖更生,徐玉娟,吴继军,余元善,程丽娜,温靖,安可婧. 超高压联合DMDC和Nisin处理对杨梅汁贮藏期间品质的影响. 食品工业科技. 2025(05): 296-308 .  本站查看

本站查看

其他类型引用(2)

下载:

下载:

下载:

下载: