Optimization of Bran-koji Production and Its Impact on Huangjiu Quality

-

摘要: 为明确麸皮种类和固态发酵条件对接种青霉菌Penicillium oxalicum M1816麸曲的酶活力影响,将酶活力最高条件下的麸曲应用于黄酒生产,评价了其对黄酒酚类物质含量、理化及感官指标的影响。结果表明,当麸皮直径20目时,麸曲的酶活力表现为玉米麸皮>小麦麸皮>燕麦麸皮>黑麦麸皮。选择玉米麸皮制作麸曲,酶活力最高的制曲条件为:冰醋酸调节培养基pH为6.5,麸曲初始含水量为85%(V/W),培养温度为30 ℃,培养时间为120 h。与工厂黄酒相比,添加玉米麸曲生产的玉米麸曲黄酒中酚酸总量为116.48 mg/L,相比对照组(55.53 mg/L)提高了约1.1倍,挥发性酚类化合物4-乙基苯酚、4-乙基愈创木酚、4-乙烯基愈创木酚、愈创木酚和香兰素均显著增加(P<0.05),黄酒药香明显增强,理化指标均符合黄酒国家标准。本研究明确了利用青霉菌制备玉米麸曲的最佳工艺条件,玉米麸曲可有效提高玉米麸曲黄酒酚酸类物质含量,为具有药香气特征且富含酚类物质的黄酒酿制提供了技术参考。Abstract: The effects of bran types and solid-state fermentation conditions on the enzyme activity of bran-koji inoculated with Penicillium oxalicum M1816 were investigated, and the bran-koji with the highest enzyme activity was applied to Huangjiu production to evaluate its effects on the phenolic content, physicochemical indexes, and sense of Huangjiu. The results showed that when the diameter of bran was 20-mesh, the enzyme activity of bran-koji was corn bran>wheat bran>oat bran>rye bran. The highest enzyme activity in corn bran-koji was achieved under the following conditions: Glacial acetic acid was used to adjust the pH of the solid medium to 6.5, the initial moisture content of the bran-koji was 85% (V/W), the incubation temperature was 30 ℃, and the incubation time was 120 h. Compared with factory Huangjiu, the total amount of phenolic acids in the Huangjiu produced by adding corn bran-koji was 116.48 mg/L, which increased to 1.1-folds in comparison with that of the Huangjiu produced by adding no-corn bran-koji (55.53 mg/L). The volatile phenolic compounds of 4-ethylphenol, 4-ethylguaiacol, 4-vinylguaiacol, guaiacol, and vanillin were increased significantly (P<0.05), the medicinal aroma of the Huangjiu was obviously enhanced, and the physicochemical indexes were all in accordance with the national standard of Huangjiu. The optimal fermentation condition of corn bran-koji with Penicillium spp. was confirmed, and corn bran-koji could improve the contents of phenolic acids in Huangjiu. The research provides a technical reference for the brewing of Huangjiu with medicinal aroma characteristics and rich in phenolic substances.

-

Keywords:

- Huangjiu /

- grain bran /

- solid-state fermentation /

- phenolic acid /

- Penicillium /

- sensory evaluation

-

黄酒是我国最古老的发酵酒之一,其风味独特,富含功能性成分,深受消费者喜爱。传统的黄酒酿制方法通常以糯米、大米为原料,加入麦曲做糖化发酵剂,在多种微生物如细菌、霉菌等的共同作用下进行发酵[1]。麸曲是以粮食谷物的麸皮为原料,经蒸煮高温灭菌后,接种特定微生物,经培养烘干后得到的散曲,常用于白酒酿造[2]。在白酒发酵过程中,麸曲中所含的微生物代谢产生大量的酯类、醇类、醛类和酚类等风味化合物,赋予白酒浓郁的香气[3−4]。然而,传统的黄酒酿造通常只依靠麦曲进行糖化发酵,鲜有将其他谷物制作麸曲并用于黄酒发酵生产的研究报道。

谷物麸皮富含以酚酸为主的酚类物质,如阿魏酸、香草酸和咖啡酸等[5],具有抗氧化、抗炎活性及细胞保护能力,近年来受到研究者的广泛关注[6−7]。通常情况下,谷物麸皮中的主要酚酸以酯键或醚键的形式与细胞壁中的多糖结合。因此,如何有效提取谷物麸皮中的结合态酚酸,使其最终释放至产品中,是当前研究的重点。现已有多种谷物处理方法用于提取酚酸,例如物理加工法[8]、酸碱水解法[9]、酶法[10]及微生物发酵法[11],其中微生物发酵法因高效性和环境友好性受到了研究者青睐,在制药、酿造等领域展开了深入研究[12]。微生物发酵法即指通过菌种发酵产生的酶类物质分解麸皮的纤维和细胞壁,如纤维素酶、阿魏酸酯酶等,将结合型酚酸转化为游离型酚酸。研究发现,采用好食脉孢菌发酵小麦麸皮能显著提高阿魏酸酯酶活力[13],利用筛选出的优势曲霉菌株Aspergillus niger固态发酵小麦麸皮,使阿魏酸释放量提高至4.05 mg/g麦麸[14],当添加黑曲霉、里氏木霉及米曲霉时,发酵后的小麦麸皮释放的游离酚酸含量显著增加[15]。微生物发酵可以有效促进谷物麸皮中的酚酸释放,但上述研究大多采用小麦麸皮为研究对象,对于其他谷物麸皮如玉米、燕麦的研究较少。因此,利用麸曲生产黄酒,并探究酚酸在黄酒发酵中的变化规律,对黄酒功能性和感官品质提升具有重要意义。

近年来,随着市场竞争的加剧和产业发展需要,黄酒产品多样化、高端化趋势明显,而单一麦曲生产的黄酒风味同质化严重。本研究以接种青霉菌Penicillium oxalicum M1816的高产酶强化麸曲为对象,探究了麸皮种类和固态发酵条件对麸曲的酶活力影响,并将酶活力最高条件下的麸曲应用于黄酒生产,评价了其对黄酒酚类物质含量、理化指标及感官的影响,为谷物麸皮的开发利用及富含酚类物质黄酒的生产提供技术参考。

1. 材料与方法

1.1 材料与仪器

玉米麸皮、燕麦麸皮、黑麦麸皮、小麦麸皮、大米 均为当季市售;青霉菌P. oxalicum M1816、酵母菌B661 江南大学(绍兴)产业技术研究院保藏菌株;黄酒麦曲 浙江古越龙山绍兴酒股份有限公司提供;液化酶(2×104 U/mL)、糖化酶(1×105 U/mL) 上海源叶生物科技有限公司;阿魏酸、4-乙烯基愈创木酚、4-乙基愈创木酚、香草醛、香草酸、丁香酸、反香豆酸、咖啡酸、绿原酸和没食子酸等标准品 阿拉丁试剂有限公司;YPD(Yeast extract peptone dextrose)固体培养基 上海哈灵生物科技;乙腈、甲醇(均为色谱纯试剂)、磷酸、氢氧化钠、可溶性淀粉、无水葡萄糖、碘化钾、三氯乙酸、磷酸二氢钠等分析纯试剂 国药集团有限公司。

PHS-25型pH计 梅特勒-托利多仪器有限公司;JIDI-21D高速离心机 安徽中科中佳有限公司;CH1015恒温水浴锅 浙科仪器设备有限公司;JC-100-SE恒温恒湿培养箱 施都凯仪器设备有限公司;UV-1800紫外可见光分光光度计 浙江普津仪器有限公司;BKQ-B50II灭菌锅 济南童鑫有限公司;SHP-160生化培养箱 常州普天仪器制造有限公司;Agilent 8890-7000D气相色谱质谱联用仪并配备PAL3 CTC三合一自动进样器、安捷伦1260高校液相色谱仪 美国安捷伦公司。

1.2 实验方法

1.2.1 青霉菌P. oxalicum M1816强化麸曲的制作及参数优化

以一定直径的新鲜谷物麸皮为麸曲制备的培养基,利用调酸剂调节培养基初始pH,控制培养基初始含水量,于121 ℃灭菌30 min,冷却至室温后在无菌操作台摇散料块,接种5%的P. oxalicum M1816(2×105 spores/g)孢子液并摇匀,在曲筐内恒温发酵培养一定时长。培养期结束后,采用低温烘干,并在无菌环境下粉碎曲饼,装于经121 ℃灭菌30 min的牛皮纸袋内封口,用于分析麸曲中的酶活力(4 ℃保存)。

1.2.1.1 调酸剂种类对麸曲中的酶活力影响

采用单因素实验方法,选取直径为20目的玉米、小麦、黑麦和燕麦四类麸皮,分别用冰醋酸、乳酸和柠檬酸调节培养基初始pH为5.0,初始含水量为80%(V/W),在曲筐内于32 ℃培养箱中发酵培养96 h,测定麸曲中阿魏酸酯酶、纤维素酶和木聚糖酶活力。

1.2.1.2 麸皮种类和直径对麸曲中的酶活力影响

在最优调酸剂处理条件下,调整玉米、小麦、黑麦和燕麦四类麸皮直径为10目、20目和30目,分别测定麸曲中阿魏酸酯酶、纤维素酶和木聚糖酶活力。

1.2.1.3 麸曲制作参数优化

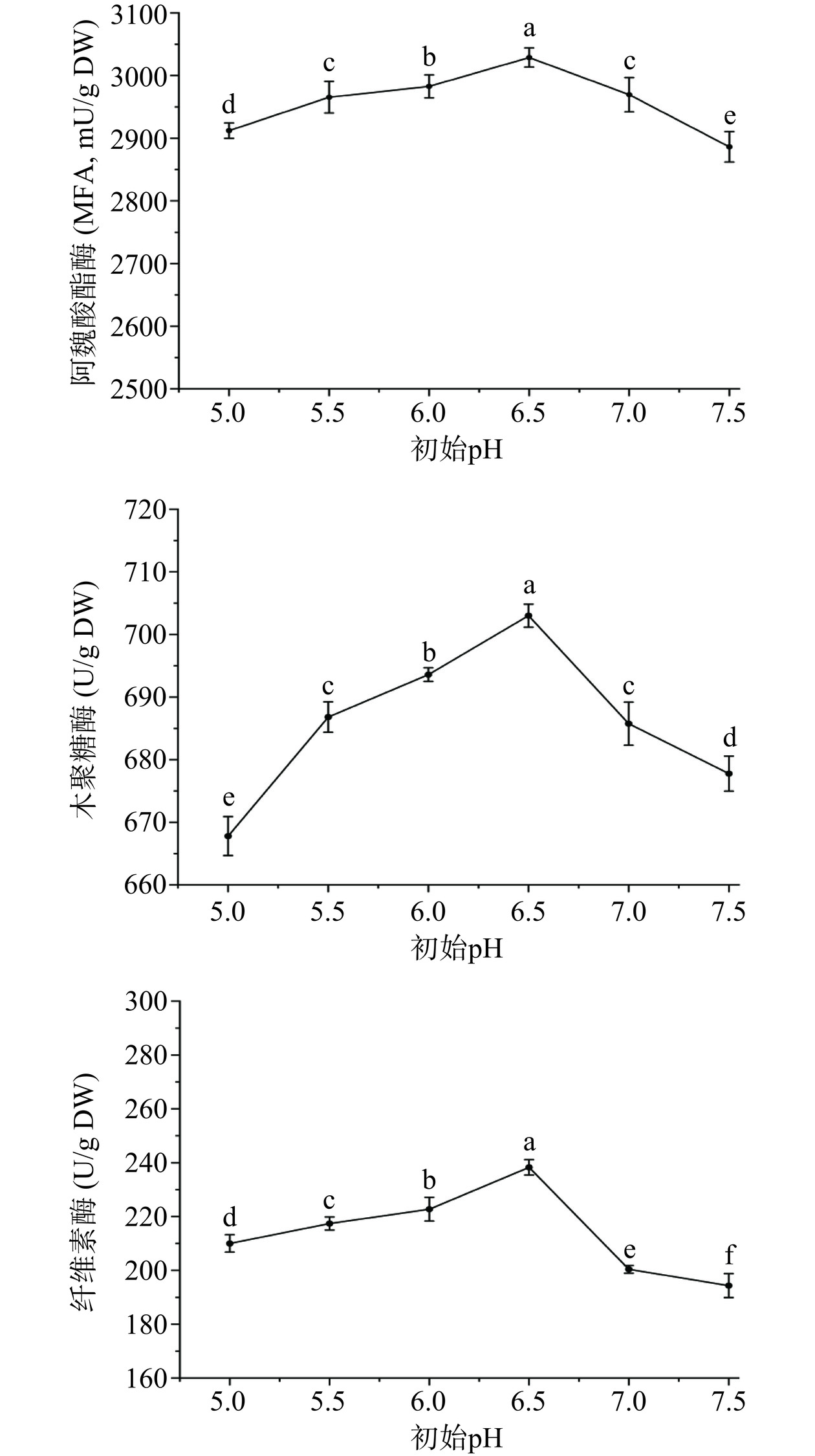

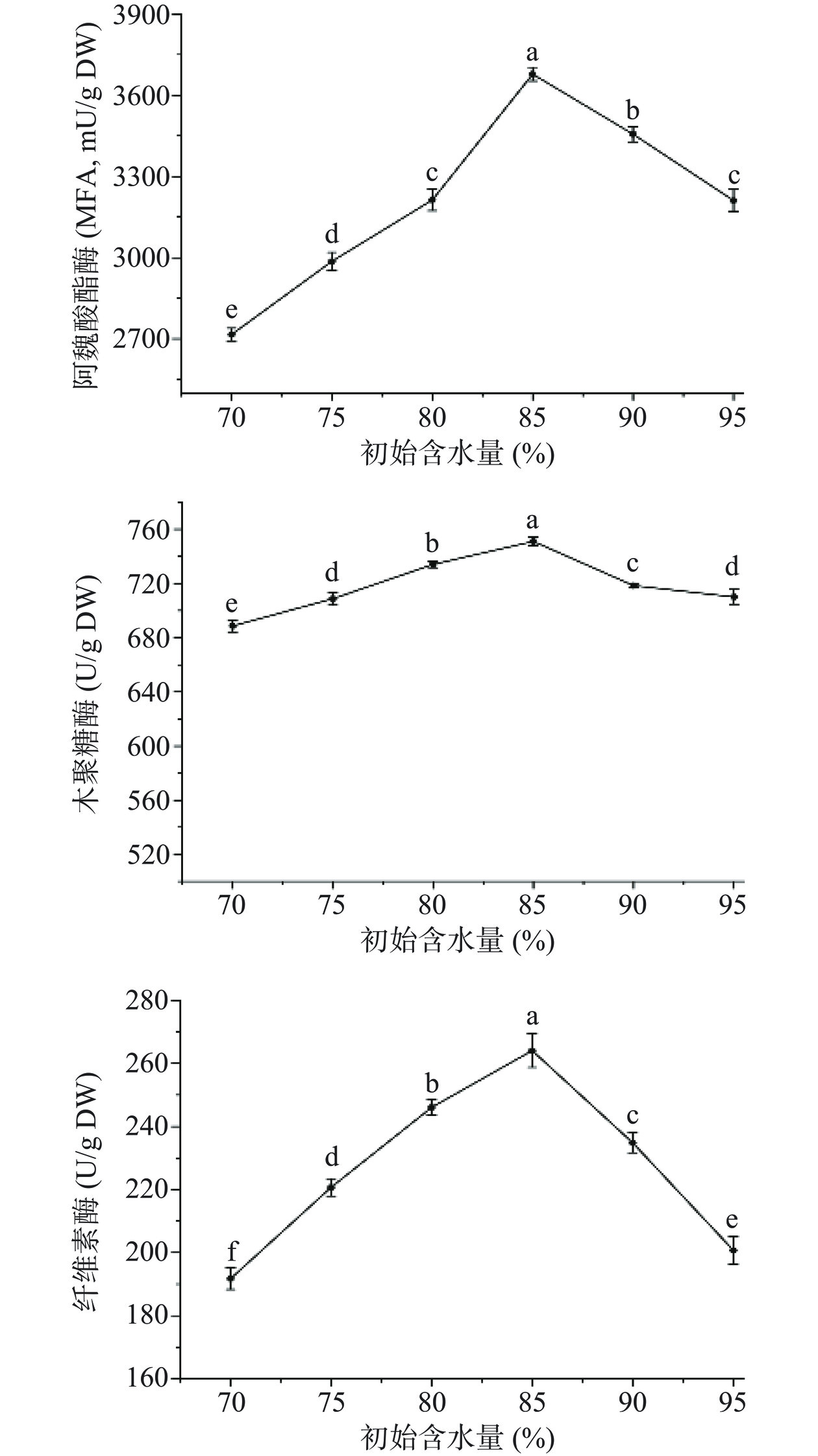

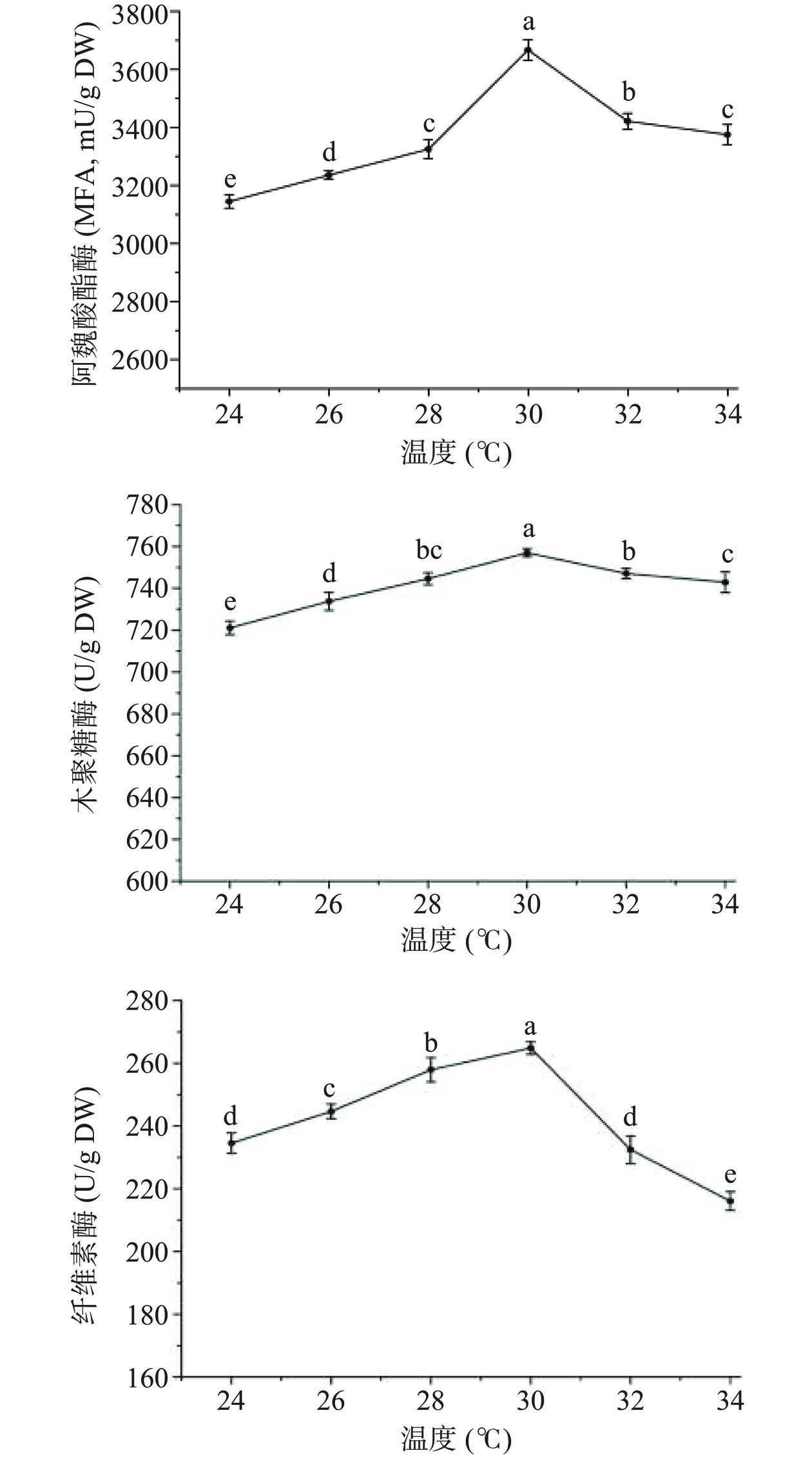

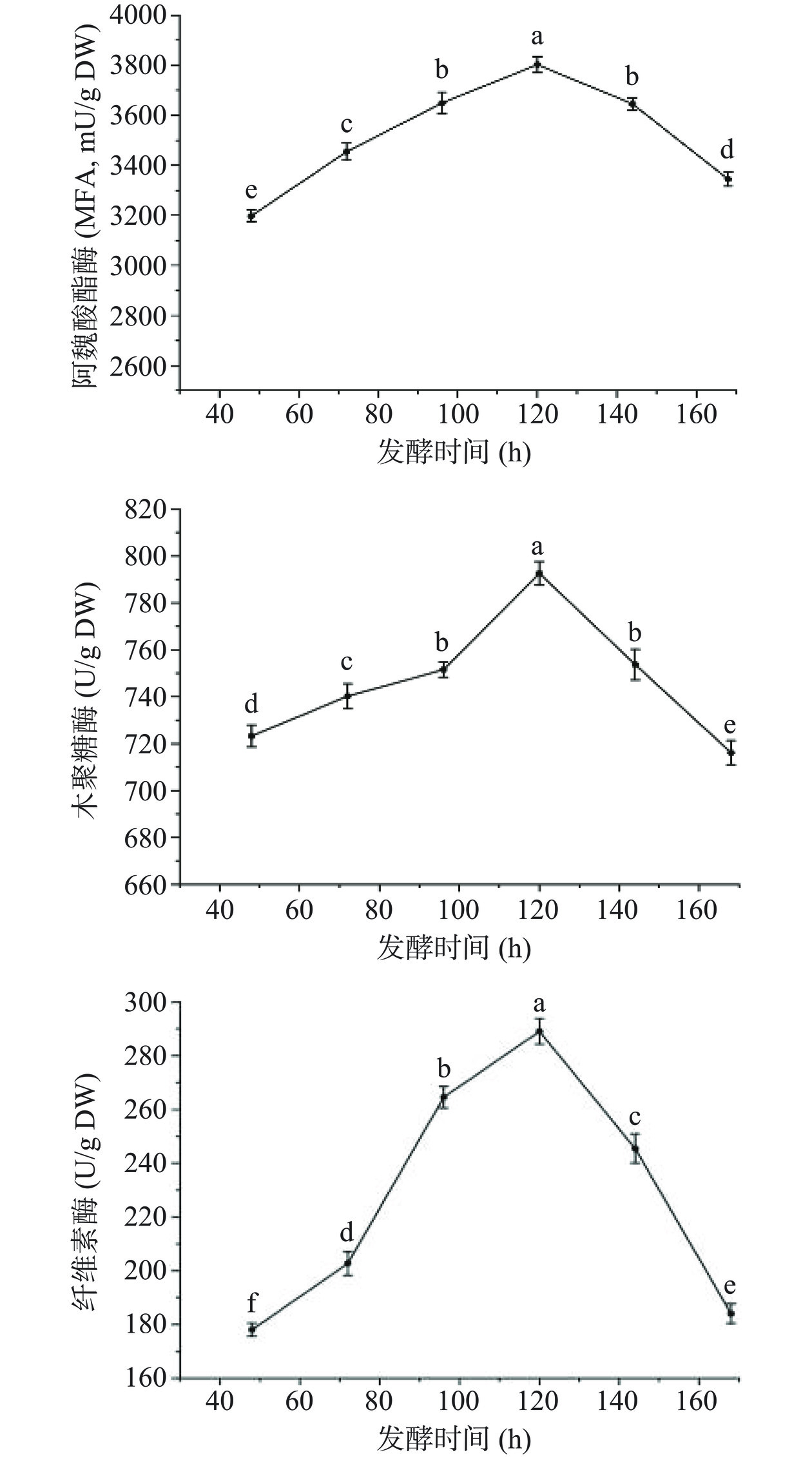

选择最优的调酸剂、麸皮种类和直径,采用单因素实验方法优化麸曲制作参数。固定条件为培养基初始含水量为75%(V/W),在曲筐内于30 ℃培养箱中发酵培养96 h,调节初始pH分别为5.0、5.5、6.0、6.5、7.0和7.5,评价麸曲中阿魏酸酯酶、纤维素酶和木聚糖酶活力,优化培养初始pH。在最优的培养基初始pH、30 ℃条件下培养96 h,调整麸曲初始含水量分别为70%、75%、80%、85%、90%和95%(V/W),评价麸曲中的酶活力,优化初始含水量。在最优的培养基初始pH、初始含水量85%(V/W)条件下培养96 h,调整麸曲培养温度分别为24、26、28、30、32和34 ℃,优化麸曲发酵温度。在最优的培养基初始pH、初始含水量为85%(V/W)条件下于30 ℃培养麸曲,调整麸曲培养时间分别为48、72、96、120、144和168 h,优化麸曲发酵时间。

1.2.2 麸曲中的酶活力测定

准确称取5 g麸曲(计算时换算成绝干麸曲,DW),置于250 mL灭菌的三角瓶中,加入60 mL的醋酸-醋酸钠缓冲溶液(pH4.6,100 mmol/L),置于30 ℃恒温摇床中180 r/min浸提1 h,12000 r/min离心15 min,取上清液作为待测粗酶液[16]。以阿魏酸甲酯(Methyl ferulic acid,MFA)为底物测定麸曲中的阿魏酸酯酶活力[17],纤维素酶[18]和木聚糖酶[19]活力测定分别参照国家标准NY/T 912-2020和GB/T 23874-2009。

1.2.3 黄酒酿造

1.2.3.1 酿酒酵母的活化与扩培

配制一定量的YPD培养基,115 ℃灭菌20 min备用。在无菌操作台将甘油保藏管中的B661酵母菌接种(接种量5‰)到YPD培养基中,置于28 ℃,150 r/min条件下,培养24 h。将常压下蒸熟摊凉的米饭与水按照1:4的比例混合,然后加入1‰的糖化酶、1‰的液化酶和10%的黄酒麦曲混合均匀后在55~65 ℃温度糖化4~5 h,糖化结束后测定其外观糖度不得低于12°Bx,115 ℃灭菌20 min,接入5%的B661酵母种子培养液,置于28 ℃,150 r/min 条件下,培养24 h,培养成熟后即得扩培酒母。

1.2.3.2 落缸与工厂黄酒发酵

参考工厂黄酒酿造工艺,以大米质量为基准,将蒸熟的大米、水、扩培酒母、黄酒麦曲分别按照150%、125%、11.4%和13.6%比例混合均匀落缸发酵。前发酵温度为28 ℃,发酵时间5 d,头耙搅拌时间为发酵第8 h,之后每24 h搅拌开耙一次;后发酵温度为15±1 ℃,发酵时间为360 h,期间每48 h搅拌开耙一次。

1.2.3.3 麸曲黄酒酿造

参照工厂黄酒酿造工艺的基础上,在黄酒发酵的落缸阶段添加原料质量2.0%的青霉菌P. oxalicum M1816强化麸曲,发酵参数与工厂黄酒相同,以不添加强化麸曲的工厂黄酒为对照组(Control)。

1.2.4 指标检测

当工厂黄酒和麦曲黄酒发酵结束时取样,每次取样前搅拌均匀,于10000 r/min,4 ℃离心取上清液用于理化指标、酚酸、挥发性酚类物质含量的测定及感官评测。

1.2.4.1 黄酒酚酸的测定

酚酸标准曲线的构建[20]:采用HPLC方法测定,色谱柱为XBridgeTM C18(4.6×250 mm,5 μm);流动相A:0.118%磷酸水溶液;流动相B:乙腈,梯度洗脱(0~5 min,B相维持5%不变;5~65 min,B相从5%线性改变至30%;65~66 min,B相从30%线性改变至5%;66~80 min,B相维持5%不变);流速:1.0 mL/min;柱温:30.0 ℃;检测波长:280 nm;进样量:10 μL。

黄酒中酚酸的提取:取10 mL黄酒样品,加入30 mL无水甲醇,在温度30 ℃,功率30 W下超声30 min提取游离酚酸,12000 r/min离心10 min。移去上清液,重复三次提取,合并上清液,用0.45 μm微孔滤膜过滤。将过滤后的上清液放置于旋转蒸发仪中,设置45 ℃,在真空条件下蒸干,并用甲醇定容至10 mL。使用0.22 μm滤膜过滤后保存于−80 ℃,测定黄酒中酚酸含量[10]。

1.2.4.2 黄酒挥发性酚类化合物的测定

利用HS-SPME结合GC-MS方法对黄酒中的挥发性酚类化合物进行定量分析[21−22]。HS-SPME方法:取2 mL样品于15 mL顶空瓶中,依次加入2 g NaCl、4 mL超纯水、10 μL 2-辛醇溶液(无水乙醇溶解,101.8 mg/L)作为内标,由PAL3 CTC系统自动进样。加热温度50 ℃,平衡时间10 min,样品吸附时间40 min,进样口解析时间5 min;色谱柱为SH-Rtx-Wax极性毛细管柱(30 m×2.25 mm×0.25 μm);GC参数:进样口温度250 ℃,不分流模式,载气:氦气(>99.999%),恒定流量1 mL/min,柱箱升温程序:40 ℃保持2 min,5 ℃/min升温至230 ℃,保持10 min;MS参数:电离方式EI,电离能量70 eV,离子源温度230 ℃,传输线温度250 ℃,采用MS1全扫描模式,扫描范围30~350 m/z。通过建立挥发性酚类化合物的标准曲线进行定量分析,测定两种黄酒中挥发性酚类化合物含量。

1.2.4.3 黄酒理化指标测定

两种黄酒中的酒精度、总酸和氨基酸态氮的测定,参照国家标准(GB/T 13662-2018 黄酒,半干型传统黄酒)。还原糖含量测定,采用3,5-二硝基水杨酸(DNS)比色法[23]。

1.2.4.4 黄酒感官评价

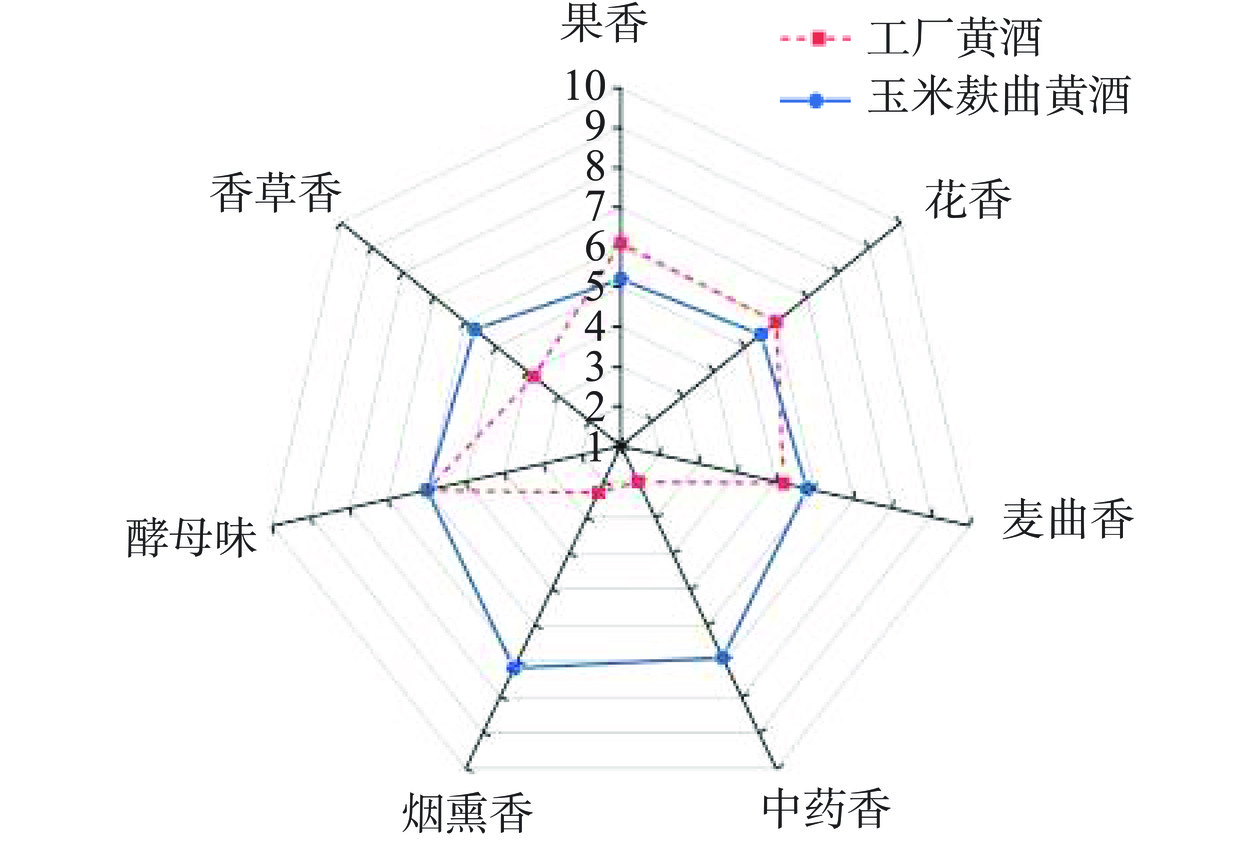

10位(4位男性,6位女性,年龄范围20~30岁之间)经过专业训练的品酒人员进行感官分析,感官分析小组在对样品进行分析前经过三轮的闻香训练过程。第一轮训练中,感官分析小组分别对近30种香气标准品进行闻香训练,每次30 min,连续一个月。第二轮训练中,感官分析小组分别对不同黄酒样品进行感官分析,熟悉黄酒的香气特征。第三轮训练中,以王栋等[24−25]绘制的黄酒风味轮为基础,感官分析小组对7种黄酒香气描述语进行10分制打分训练(表1)。在20 ℃室温环境下,两种黄酒以三位随机数字编码的形式由感官分析人员进行香气分析,以0~10分计[24]。

表 1 黄酒感官评分表Table 1. Sensory evaluation table of Huangjiu感官属性 定义 评分标准(0分表示无滋味,

10分表示滋味强烈)花香 类似花朵的花香味 0~10分 果香 苹果或橘子等香甜水果香气 0~10分 烟熏香 愈创木酚香气 0~10分 麦曲香 生麦曲块浸提液的气味 0~10分 酵母味 酵母溶于水的味道 0~10分 香草味 香草醛的味道 0~10分 中药香 4-乙烯基愈创木酚的味道 0~10分 1.3 数据处理

所有实验均重复三次,采用Excel 2019处理原始数据。采用SPSS 26.0软件,通过Duncan分析比较多组间的统计学差异,P<0.05为差异显著。采用Origin 2020绘制图表。

2. 结果与分析

2.1 麸曲制作工艺优化

2.1.1 不同类型调酸剂调节的pH对麸曲酶活力的影响

环境pH对微生物的生长具有显著影响,其通过改变微生物细胞膜内外的电荷差,改变细胞膜的通透性,进而影响细胞对营养物质吸收,影响酶在代谢过程中的活性,且强酸和强碱会对一般微生物造成致死作用,因此控制发酵环境的pH具有十分重要的意义。食品级酸度调节剂是一类常见的酸,可以有效地调节食品中的酸度[26],常见的有柠檬酸、乳酸和醋酸。实验利用柠檬酸、乳酸和醋酸三种调酸剂分别调节麸皮的pH为5,以探究不同类型调酸剂对麸曲中酶活力的影响。由表2可知,对于不同麸皮制作的麸曲,当利用冰醋酸调酸时,玉米麸曲、小麦麸曲和燕麦麸曲中的三种酶活力均显著高于其它调酸剂(P<0.05)。仅黑麦麸曲中的阿魏酸酯酶(623.16 mU/g)和纤维素酶(126.36 U/g)的酶活力弱于乳酸调酸剂,这可能与黑麦麸皮中结构及酚酸的特异性组成有关,乳酸对黑麦麸皮中的阿魏酸酯酶和纤维素酶有更好的激活作用。冰醋酸是一种天然有机酸,对人体和环境的影响较小、价格相对较低,且相较于其它调酸剂,麸曲表现的酶活力更高,有利于微生物降解谷物麸皮。综上所述,选择使用冰醋酸调节麸曲发酵pH。

表 2 不同酸调节pH对四种麸曲酶活力的影响Table 2. Effects of pH with different acid regulators on the enzyme activity of four bran-koji酶的类型 玉米 小麦 黑麦 燕麦 冰醋酸 柠檬酸 乳酸 冰醋酸 柠檬酸 乳酸 冰醋酸 柠檬酸 乳酸 冰醋酸 柠檬酸 乳酸 阿魏酸酯酶

(MFA,mU/g)2946.76±

28.41a2334.66±

32.37c2695.87±

21.17b1245.25±

748.34a1203.37±

43.67c1238.12±

46.79b623.16±

42.86b612.23±

33.94c1245.25±

48.34a673.25±

30.66a638.38±

32.25b609.26±

29.46c木聚糖酶(U/g) 640.64±

16.77a515.5±

13.72b504.57±

12.33c540.44±

16.02a523.23±

11.22b456.07±

18.28c432.64±

16.77a342.23±

13.72b340.64±

16.77b541.23±

16.77a515.5±

16.72b502.57±

16.33c纤维素酶(U/g) 226.06±

16.25a220.24±

12.69b191.38±

9.72c195.32±

12.46a181.31±

9.63b168.43±

11.19c126.36±

10.25b120.24±

12.69c226.06±

16.25a140.76±

13.75a125.37±

11.23b122.58±

7.67b注:同行不同小写字母分别表示四种麸曲组内差异显著(P<0.05)。 2.1.2 麸皮种类与直径对麸曲酶活力的影响

青霉菌属于真菌,代谢类型为异养需氧型,在通气良好的条件下更适宜生长[27]。麸皮直径过细,会影响麸曲的通风透气性能,而直径过粗,原料结合不充分,导致发酵效果不佳。由表3可知,麸皮直径为20目时,玉米、黑麦和燕麦麸曲中的阿魏酸酯酶、木聚糖酶和纤维素酶活力均显著高于10目及30目麸曲(P<0.05)。麸皮的主要成分是纤维素和木质素,这些成分组成比例是相对稳定的,麸皮直径大小在对酶活力和微生物的生长和作用中的影响较小。而不同谷物麸皮的组成成分比例差异巨大,当直径为20目时,麸曲培养基初始含水量为80%、发酵时间为96 h、用冰醋酸调节培养基pH为5时,对比玉米麸曲、小麦麸曲、燕麦麸曲和黑麦麸曲发现,玉米麸曲发酵效果最佳,阿魏酸酯酶、木聚糖酶及纤维素酶活力最高分别为2960.57 mU/g、664.35 U/g和231.73 U/g(P<0.05),故后续麸曲发酵条件的优化以直径20目的玉米麸皮为实验对象。

表 3 麸皮直径对麸曲酶活力的影响Table 3. Effects of bran diameter on the enzyme activity of bran-koji酶的类型 10目麸曲酶活力 20目麸曲酶活力 30目麸曲酶活力 玉米 小麦 黑麦 燕麦 玉米 小麦 黑麦 燕麦 玉米 小麦 黑麦 燕麦 阿魏酸酯酶

(MFA,mU/g)2880.28±

55.76a1165.85±

23.65b583.64±

19.42d647.86±

14.65c2960.57±

35.73a1252.51±

34.32b632.64±

31.63d672.23±

28.65c2611.64±

28.53a1265.83±

34.85b612.64±

19.63d631.86±

14.65c木聚糖酶(U/g) 623.69±

43.19a501.43±

22.64c411.54±

18.53d512.75±

22.96b664.35±

21.34a529.43±

27.22c429.53±

12.84d537.62±

29.65b632.86±

26.19a481.85±

24.83c402.64±

11.43d504.75±

17.31b纤维素酶(U/g) 210.06±

17.84a176.44±

10.94b107.67±

6.83d121.45±

12.66c231.73±

32.29a197.43±

11.73b123.53±

9.41d146.61±

9.58c220.46±

24.24a165.58±

12.89b114.53±

8.37d132.65±

14.74c注:同行不同小写字母分别表示不同目数时组内差异显著(P<0.05)。 2.2 玉米麸曲固态发酵产酶条件的参数优化

2.2.1 初始pH的优化

在酸性浓度的影响下,当微生物细胞膜上的电荷性质发生变化时,影响细胞正常的物质代谢活动和酶的功能[28]。由图1可知,当固定初始含水量、温度和发酵时间条件时,pH为5.0~6.5时,随着pH升高阿魏酸酯酶、木聚糖酶及纤维素酶活力也随之上升。青霉菌P. oxalicum M1816作为高产阿魏酸酯酶、木聚糖酶和纤维素酶的菌株,其生物活性决定了酶活力的高低。pH升高,酸度减弱,青霉菌P. oxalicum M1816逐渐达到其最适产酶pH。而pH过高抑制了青霉菌P. oxalicum M1816生物活力,致使在pH为6.5~7.5时酶活力呈下降趋势[16]。当玉米麸曲初始pH为6.5时,玉米麸曲阿魏酸酯酶、木聚糖酶及纤维素酶活力达到最高分别为3028.83 mU/g、703.41 U/g和238.62 U/g(P<0.05),综上分析可得最佳麸曲制作的初始pH为6.5。

2.2.2 初始含水量的优化

水分是微生物生长必需的培养条件之一,水分含量过于低时,微生物的生长就会中断;当水分含量过高时,麸皮之间没有缝隙导致麸曲结成团状,空气无法充分进入到麸曲中,阻碍微生物的生长[29]。由图2可知,当固定初始pH、温度和发酵时间相同情况下,随着玉米麸曲初始含水量的增加,酶活力呈现先增加后减少的趋势。培养基水分上升,青霉菌P. oxalicum M1816生长代谢旺盛,逐渐达到最高酶活力。但如果水分过多会导致麸曲粘连结块,微生物缺乏氧气致使生长受阻,麸曲酶活力下降[16]。当玉米麸曲初始含水量为85%时,玉米麸曲阿魏酸酯酶、木聚糖酶及纤维素酶活力达到最高分别为3678.22 mU/g、751.18 U/g和265.23 U/g(P<0.05),综上分析最适初始含水量为85%(V/W)。

2.2.3 发酵温度的优化

温度是影响微生物生长代谢的关键因素,随着温度的升高,细胞的生化反应和生长速度明显加快,当温度升高超过一定的临界值,会对微生物产生不良影响,严重时会导致细胞死亡[30]。如图3所示,当麸曲固态发酵温度从24 ℃上升到30 ℃时,玉米麸曲阿魏酸酯酶、木聚糖酶及纤维素酶活力均达到了最高值(P<0.05),分别为3667.63 mU/g、756.92 U/g和264.81 U/g,这可能是由于随着温度的升高,青霉菌P. oxalicum M1816生长和代谢活动逐渐活跃,但如果温度过高,青霉菌P. oxalicum M1816的生物量和产酶量降低。故麸曲制作最适发酵温度为30 ℃。

2.2.4 发酵时间的优化

微生物的生长有着固定的发展周期,培养时间太短,会导致菌体生长数目较少,产酶量较少;随时间的延长,微生物逐步老化失去活力,养分逐步耗费殆尽,有害产物也一直积聚,使酶活力下降[31]。因此在实际生产中,必须优化微生物产酶最高的时间,以此减少生产成本。由图4可知,随着麸曲发酵时间的延长,玉米麸曲酶活力呈先增长后下降的趋势。在120 h时,玉米麸曲阿魏酸酯酶、木聚糖酶及纤维素酶活力均达到最高值(P<0.05),分别为3802.23 mU/g、792.64 U/g和286.83 U/g。故麸曲制作最佳的发酵时间为120 h。

2.3 添加玉米麸曲对黄酒质量的影响

2.3.1 玉米麸曲对黄酒酚酸含量的影响

在黄酒酿造过程中,添加经上述最优条件下生产的玉米麸曲通过发酵生产玉米麸曲黄酒。当黄酒发酵结束后,玉米麸曲黄酒的酚酸总量为116.48 mg/L,与未添加玉米麸曲的工厂黄酒酚酸总量(55.53 mg/L)相比,添加玉米麸曲共同发酵能显著提高玉米麸曲黄酒中的酚酸含量(P<0.05),其中阿魏酸(55.76 mg/L)、咖啡酸(7.64 mg/L)、绿原酸(34.04 mg/L)提升最为明显(P<0.05)(表4)。麸曲中的青霉菌P. oxalicum M1816代谢产生高活性的阿魏酸酯酶、木聚糖酶及纤维素酶,降解玉米麸皮,促进了结合态酚酸的释放,同时这些酶也可以同步降解麦曲及大米原料中的细胞壁,促进酚酸类物质释放,并最终在发酵过程转移至黄酒酒体中,共同提高了玉米麸曲黄酒中酚酸的含量[12]。

表 4 工厂黄酒及玉米麸曲黄酒发酵结束后酚酸含量Table 4. Phenolic acid contents at the end of fermentation of factory Huangjiu and corn bran-koji Huangjiu酚酸类型 工厂黄酒(mg/L) 玉米麸曲黄酒(mg/L) 阿魏酸 1.17±0.34b 55.76±6.34a 香草醛 0.17±0.03b 1.43±0.34a 香草酸 32.95±5.61a 1.12±0.13b 咖啡酸 0.53±0.06b 7.64±0.89a 绿原酸 1.54±0.67b 34.04±3.92a 没食子酸 19.11±3.05a 11.34±2.19b 反香豆酸 0.15±0.03b 1.12±0.22a 丁香酸 0.22±0.04b 4.38±0.78a 合计 55.53±6.34b 116.48±6.89a 注:同行字母不同表示差异显著(P<0.05);表6同。 2.3.2 玉米麸曲对黄酒理化特性的影响

测定工厂黄酒和玉米麸曲黄酒各项理化指标,结果如表5所示。其中,工厂黄酒酒精度为15.89%vol,还原糖含量为15.21 g/L,总酸为4.34 g/L,氨基酸态氮含量为0.67 g/L,均符合传统半干型黄酒国家标准(GB/T 13662-2018 黄酒)。玉米麸曲黄酒氨基态氮含量为1.32 g/L,比工厂黄酒高约1倍,酒精度及还原糖均显著高于工厂黄酒(P<0.05)。可能是由于P. oxalicum M1816代谢产生较高的纤维素酶和木聚糖酶活力,将原料中的部分纤维素、木聚糖等降解成为还原糖,从而提高了玉米麸曲黄酒的酒精度和还原糖含量。

表 5 黄酒理化指标Table 5. Physicochemical indexes of various Huangjiu黄酒类型

(发酵20 d)酒精度(%vol) 还原糖(g/L) 氨基酸态氮(g/L) 总酸(g/L) 工厂黄酒 15.89±0.51b 15.21±0.22b 0.67±0.03b 4.34±0.32b 玉米麸曲黄酒 16.84±0.46a 15.63±0.26a 1.32±0.12a 5.02±0.62a 注:同列字母不同表示差异显著(P<0.05)。 2.3.3 玉米麸曲对黄酒中挥发性酚类化合物的影响

酚类物质是存在于大部分酒中的风味物质,对酒风味品质控制具有重要意义[32]。利用HS-SPME结合GC-MS检测黄酒中的挥发性酚类化合物(表6),与工厂黄酒相比,玉米麸曲黄酒中的挥发性酚类物质均显著增加(P<0.05),主要有4-乙烯基愈创木酚、愈创木酚、4-乙基苯酚和香兰素等。与工厂黄酒相比,玉米麸曲黄酒中的愈创木酚提高了33.4倍、4-乙烯基愈创木酚提高了0.67倍、4-乙基愈创木酚提高了2.32倍、4-乙基苯酚提高了3.07倍、香兰素提高了0.29倍。大部分谷物酚类在发酵、蒸馏过程中分解或残留在酒糟内,而在发酵过程中,玉米麸曲中的酚酸经微生物降解,会转变成一部分对香气有益的挥发性酚类物质,如4-乙基愈创木酚和4-甲基愈创木酚等。已有多项研究表明,阿魏酸在高温或阿魏酸脱羧酶的作用下可转化形成4-乙烯基愈创木酚[33−34],最终这些挥发性酚类物质可能赋予黄酒独特的烟熏和药香等。

表 6 黄酒中挥发性酚类物质含量Table 6. Contents of volatile phenols in Huangjiu酚酸类型 工厂黄酒(μg/L) 玉米麸曲黄酒(μg/L) 愈创木酚 1.43±0.12b 49.19±2.16a 4-乙烯基愈创木酚 21.76±4.23b 36.33±4.34a 4-乙基愈创木酚 3.45±0.56b 11.45±2.04a 4-乙基苯酚 102.87±3.67b 419.06±5.34a 香兰素 339.07±3.49b 437.76±4.22a 2.3.4 玉米麸曲对黄酒感官的影响

由图5感官结果可知,添加玉米麸曲的黄酒中药香(6.9)、烟熏香(7.2)及香草香(5.7)强度显著高于工厂黄酒,这与上述挥发性酚类物质定量的结果相一致。愈创木酚呈强烈烟熏似香甜香气且略有草药和苯酚气味,4-乙基愈创木酚呈现香辛料和草药香气,4-乙烯基苯酚具有苯酚样化学和药物香气[35]。相比工厂黄酒,玉米麸曲黄酒中的果香(6.0→5.2)和花香(6.0→5.5)强度稍有下降。从工厂黄酒和玉米麸曲黄酒中均闻到了丰富的香草香、麦曲香和酵母味,这是由于黄酒发酵过程中添加酵母菌和黄酒麦曲共同发酵。在发酵结束后,添加玉米麸曲黄酒中的香兰素含量升高,香兰素具有香荚兰豆香气及浓郁的奶香,可能导致了添加玉米麸曲黄酒的香草味显著增强[25]。

3. 结论

接种青霉菌P. oxalicum M1816的高产酶强化麸曲,弥补了单一麦曲作为糖化发酵剂风味单一及酚酸含量低的不足。本研究进一步筛选多种谷物麸皮制曲,并优化制曲条件,发现玉米麸皮制曲表现出了高活性的酶活力,最优制曲发酵条件为:直径20目,冰醋酸调节固态培养基pH为6.5,麸曲初始含水量为85%(V/W),培养温度为30 ℃,培养时间为120 h。将该条件下的玉米麸曲用于酿制玉米麸曲黄酒,相比未添加麸曲的工厂黄酒,酚酸总量(116.48 mg/L)提高了约1.1倍,挥发性酚类物质如4-乙基苯酚、4-乙基愈创木酚、4-乙烯基愈创木酚、愈创木酚、香兰素均显著增加(P<0.05),感官结果表明这些挥发性酚类物质可能为黄酒的药香、烟熏和香草香做出了重要贡献。在市场竞争加剧和黄酒高质量产业发展战略的背景下,健康和风味多元化是黄酒发展的必然趋势。本研究为谷物麸皮的开发利用及高产酶强化麸曲的工业应用提供了基础数据,也为特征香型的黄酒产品开发提供了一定思路。但是,关于添加麸曲的黄酒酚酸的代谢通路仍需进一步研究确定。

-

表 1 黄酒感官评分表

Table 1 Sensory evaluation table of Huangjiu

感官属性 定义 评分标准(0分表示无滋味,

10分表示滋味强烈)花香 类似花朵的花香味 0~10分 果香 苹果或橘子等香甜水果香气 0~10分 烟熏香 愈创木酚香气 0~10分 麦曲香 生麦曲块浸提液的气味 0~10分 酵母味 酵母溶于水的味道 0~10分 香草味 香草醛的味道 0~10分 中药香 4-乙烯基愈创木酚的味道 0~10分 表 2 不同酸调节pH对四种麸曲酶活力的影响

Table 2 Effects of pH with different acid regulators on the enzyme activity of four bran-koji

酶的类型 玉米 小麦 黑麦 燕麦 冰醋酸 柠檬酸 乳酸 冰醋酸 柠檬酸 乳酸 冰醋酸 柠檬酸 乳酸 冰醋酸 柠檬酸 乳酸 阿魏酸酯酶

(MFA,mU/g)2946.76±

28.41a2334.66±

32.37c2695.87±

21.17b1245.25±

748.34a1203.37±

43.67c1238.12±

46.79b623.16±

42.86b612.23±

33.94c1245.25±

48.34a673.25±

30.66a638.38±

32.25b609.26±

29.46c木聚糖酶(U/g) 640.64±

16.77a515.5±

13.72b504.57±

12.33c540.44±

16.02a523.23±

11.22b456.07±

18.28c432.64±

16.77a342.23±

13.72b340.64±

16.77b541.23±

16.77a515.5±

16.72b502.57±

16.33c纤维素酶(U/g) 226.06±

16.25a220.24±

12.69b191.38±

9.72c195.32±

12.46a181.31±

9.63b168.43±

11.19c126.36±

10.25b120.24±

12.69c226.06±

16.25a140.76±

13.75a125.37±

11.23b122.58±

7.67b注:同行不同小写字母分别表示四种麸曲组内差异显著(P<0.05)。 表 3 麸皮直径对麸曲酶活力的影响

Table 3 Effects of bran diameter on the enzyme activity of bran-koji

酶的类型 10目麸曲酶活力 20目麸曲酶活力 30目麸曲酶活力 玉米 小麦 黑麦 燕麦 玉米 小麦 黑麦 燕麦 玉米 小麦 黑麦 燕麦 阿魏酸酯酶

(MFA,mU/g)2880.28±

55.76a1165.85±

23.65b583.64±

19.42d647.86±

14.65c2960.57±

35.73a1252.51±

34.32b632.64±

31.63d672.23±

28.65c2611.64±

28.53a1265.83±

34.85b612.64±

19.63d631.86±

14.65c木聚糖酶(U/g) 623.69±

43.19a501.43±

22.64c411.54±

18.53d512.75±

22.96b664.35±

21.34a529.43±

27.22c429.53±

12.84d537.62±

29.65b632.86±

26.19a481.85±

24.83c402.64±

11.43d504.75±

17.31b纤维素酶(U/g) 210.06±

17.84a176.44±

10.94b107.67±

6.83d121.45±

12.66c231.73±

32.29a197.43±

11.73b123.53±

9.41d146.61±

9.58c220.46±

24.24a165.58±

12.89b114.53±

8.37d132.65±

14.74c注:同行不同小写字母分别表示不同目数时组内差异显著(P<0.05)。 表 4 工厂黄酒及玉米麸曲黄酒发酵结束后酚酸含量

Table 4 Phenolic acid contents at the end of fermentation of factory Huangjiu and corn bran-koji Huangjiu

酚酸类型 工厂黄酒(mg/L) 玉米麸曲黄酒(mg/L) 阿魏酸 1.17±0.34b 55.76±6.34a 香草醛 0.17±0.03b 1.43±0.34a 香草酸 32.95±5.61a 1.12±0.13b 咖啡酸 0.53±0.06b 7.64±0.89a 绿原酸 1.54±0.67b 34.04±3.92a 没食子酸 19.11±3.05a 11.34±2.19b 反香豆酸 0.15±0.03b 1.12±0.22a 丁香酸 0.22±0.04b 4.38±0.78a 合计 55.53±6.34b 116.48±6.89a 注:同行字母不同表示差异显著(P<0.05);表6同。 表 5 黄酒理化指标

Table 5 Physicochemical indexes of various Huangjiu

黄酒类型

(发酵20 d)酒精度(%vol) 还原糖(g/L) 氨基酸态氮(g/L) 总酸(g/L) 工厂黄酒 15.89±0.51b 15.21±0.22b 0.67±0.03b 4.34±0.32b 玉米麸曲黄酒 16.84±0.46a 15.63±0.26a 1.32±0.12a 5.02±0.62a 注:同列字母不同表示差异显著(P<0.05)。 表 6 黄酒中挥发性酚类物质含量

Table 6 Contents of volatile phenols in Huangjiu

酚酸类型 工厂黄酒(μg/L) 玉米麸曲黄酒(μg/L) 愈创木酚 1.43±0.12b 49.19±2.16a 4-乙烯基愈创木酚 21.76±4.23b 36.33±4.34a 4-乙基愈创木酚 3.45±0.56b 11.45±2.04a 4-乙基苯酚 102.87±3.67b 419.06±5.34a 香兰素 339.07±3.49b 437.76±4.22a -

[1] 陈双. 中国黄酒挥发性组分及香气特征研究[D]. 无锡:江南大学, 2013. [CHEN S. Characterization of the volatile and aroma profile of Chinese rice wine[D]. Wuxi:Jiangnan University, 2013.] CHEN S. Characterization of the volatile and aroma profile of Chinese rice wine[D]. Wuxi: Jiangnan University, 2013.

[2] 傅金泉. 中国酒曲技术的发展与展望[J]. 酿酒,2002,29(2):7−9. [FU J Q. Development and prospect of Jiuqu technology in China[J]. Liquor Making,2002,29(2):7−9.] doi: 10.3969/j.issn.1002-8110.2002.02.004 FU J Q. Development and prospect of Jiuqu technology in China[J]. Liquor Making, 2002, 29(2): 7−9. doi: 10.3969/j.issn.1002-8110.2002.02.004

[3] 彭思婕, 张立强, 郭佳, 等. 加热熟化小麦制曲对清香型白酒风味的影响研究[J]. 酿酒科技,2022,6:30−37,44. [PENG S J, ZHANG L Q, GUO J, et al. Effect of making Daqu with heat-treated wheat on the flavor of Qingxiang Baijiu[J]. Liquor-Making Science & Technology,2022,6:30−37,44.] PENG S J, ZHANG L Q, GUO J, et al. Effect of making Daqu with heat-treated wheat on the flavor of Qingxiang Baijiu[J]. Liquor-Making Science & Technology, 2022, 6: 30−37,44.

[4] DONG W W, YANG Q, LIAO Y X, et al. Characterisation and comparison of the microflora of traditional and pure culture Xiaoqu during the Baijiu liquor brewing process[J]. Journal of The Institute of Brewing,2020,126(2):213−220. doi: 10.1002/jib.597

[5] 石松业, 温纪平, 刘远晓. 小麦麸皮多糖提取、结构及生物活性研究进展[J]. 食品工业科技,2023,44(13):466−473. [SHI S Y, WEN J P, LIU Y X. Recent advances in wheat bran polysaccharides:Extraction, structure and bioactivities[J]. Science and Technology of Food Industry,2023,44(13):466−473.] SHI S Y, WEN J P, LIU Y X. Recent advances in wheat bran polysaccharides: Extraction, structure and bioactivities[J]. Science and Technology of Food Industry, 2023, 44(13): 466−473.

[6] 任雪荣, 齐景伟, 刘娜, 等. 微生物发酵对麦麸水溶性多酚含量、组成及抗氧化活性的影响研究[J]. 食品工业科技,2020,41(3):104−109. [REN X R, QI J W, LIU N, et al. Effect of microbial fermentation on content, composition and antioxidant activity of water-soluble polyphenols in wheat bran[J]. Science and Technology of Food Industry,2020,41(3):104−109.] REN X R, QI J W, LIU N, et al. Effect of microbial fermentation on content, composition and antioxidant activity of water-soluble polyphenols in wheat bran[J]. Science and Technology of Food Industry, 2020, 41(3): 104−109.

[7] 熊乐文, 张龙霏, 李佳, 等. 金银花酚酸类成分的提取优化及其成分分布[J]. 中药材,2022,45(8):1939−1945. [XIONG L W, ZHANG L F, LI J, et al. Extraction optimization and its distribution of phenolic acid in Lonicera japonica Thunb J]. Journal of Chinese Medicinal Materials,2022,45(8):1939−1945.

[8] CENGIZ M F, BABACAN U, AKINCI E, et al. Extraction of phenolic acids from ancient wheat bran samples by ultrasound application[J]. Journal of Chemical Technology and Biotechnology,2021,96(1):134−141. doi: 10.1002/jctb.6519

[9] FERRI M, HAPPEL A, ZANAROLI G, et al. Advances in combined enzymatic extraction of ferulic acid from wheat bran[J]. New Biotechnology,2020,56:38−45. doi: 10.1016/j.nbt.2019.10.010

[10] WANG J, SUN B, CAO Y, et al. Optimisation of ultrasound-assisted extraction of phenolic compounds from wheat bran[J]. Food Chemistry,2007,106(2):804−810.

[11] 孙晓明, 辛嘉英, 王艳, 等. 微生物发酵产阿魏酸酯酶及释放阿魏酸研究概述[J]. 食品研究与开发,2019,40(1):201−206. [SUN X M, XIN J Y, WANG Y, et al. Summary on the conditions of ferulic acid esterase and ferulic acid production by microorganism fermentation[J]. Food Research and Development,2019,40(1):201−206.] doi: 10.3969/j.issn.1005-6521.2019.01.033 SUN X M, XIN J Y, WANG Y, et al. Summary on the conditions of ferulic acid esterase and ferulic acid production by microorganism fermentation[J]. Food Research and Development, 2019, 40(1): 201−206. doi: 10.3969/j.issn.1005-6521.2019.01.033

[12] KOISTINEN V M, NORDLUND E, KATINA K, et al. Effect of bioprocessing on the in vitro colonic microbial metabolism of phenolic acids from rye bran fortified breads[J]. Journal of Agricultural and Food Chemistry,2017,65(9):1854−1864. doi: 10.1021/acs.jafc.6b05110

[13] 孙晓明. 好食脉孢菌发酵小麦麸皮释放阿魏酸及其衍生物研究[D]. 哈尔滨:哈尔滨商业大学, 2020. [SUN X M. Ferulic acid and its derivatives release from wheat bran by Neurospora sitophila fermentation[D]. Harbin:Harbin University of Commerce, 2020.] SUN X M. Ferulic acid and its derivatives release from wheat bran by Neurospora sitophila fermentation[D]. Harbin: Harbin University of Commerce, 2020.

[14] 尹志娜. 小麦麸皮固态发酵过程中活性成分释放的机理研究[D]. 广州:华南理工大学, 2019. [YIN Z N. Study on mechanism of active component released by solid-state fermentation of wheat bran[D]. Guangzhou:South China University of Technology, 2019.] YIN Z N. Study on mechanism of active component released by solid-state fermentation of wheat bran[D]. Guangzhou: South China University of Technology, 2019.

[15] 凌阿静, 李小平, 刘柳, 等. 真菌发酵对麦麸酚酸及其抗氧化活性的影响[J]. 食品与生物技术学报,2019,38(4):136−142. [LING A J, LI X P, LIU L, et al. Effect of fungal fermentation on wheat bran phenolic acids contents and antioxidant activity[J]. Journal of Food Science and Biotechnology,2019,38(4):136−142.] doi: 10.3969/j.issn.1673-1689.2019.04.020 LING A J, LI X P, LIU L, et al. Effect of fungal fermentation on wheat bran phenolic acids contents and antioxidant activity[J]. Journal of Food Science and Biotechnology, 2019, 38(4): 136−142. doi: 10.3969/j.issn.1673-1689.2019.04.020

[16] 张晶. 黄酒麦曲中产阿魏酸功能菌群解析及Penicillium oxalicum M1816在黄酒中的强化应用[D]. 无锡:江南大学, 2022. [ZHANG J. Analysis of functional microbiota for ferulic acid production in Huangjiu wheat Qu and bioaugmentation of Penicillium oxalicum M1816 in Huangjiu[D]. Wuxi:Jiangnan University, 2022.] ZHANG J. Analysis of functional microbiota for ferulic acid production in Huangjiu wheat Qu and bioaugmentation of Penicillium oxalicum M1816 in Huangjiu[D]. Wuxi: Jiangnan University, 2022.

[17] ZHANG S B, PEI X Q, WU Z L. Multiple amino acid substitutions significantly improve the thermostability of feruloyl esterase A from Aspergillus niger[J]. Bioresource Technology,2012,117(10):140−147.

[18] 中华人民共和国农业农村部. 饲料添加剂 纤维素酶活力的测定 分光光度法:NY/T 912-2020[S]. 北京:中国农业出版社, 2021. [Ministry of Agriculture and Rural Affairs of the People's Republic of China. Determination of cellulase activity in feed additives-spectrophotometry:NY/T 912-2020[S]. Beijing:China Agriculture Press, 2021.] Ministry of Agriculture and Rural Affairs of the People's Republic of China. Determination of cellulase activity in feed additives-spectrophotometry: NY/T 912-2020[S]. Beijing: China Agriculture Press, 2021.

[19] 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 饲料添加剂 木聚糖酶活力的测定 分光光度法:GB/T 23874-2009[S]. 北京:中国标准出版社, 2009. [General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China. Determination of xylanase activity in feed additives-spectrophotometry:GB/T 23874-2009[S]. Beijing:Standards Press of China, 2009.] General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China. Determination of xylanase activity in feed additives-spectrophotometry: GB/T 23874-2009[S]. Beijing: Standards Press of China, 2009.

[20] 杨春霞. 高效液相色谱法测定枸杞中9种酚酸化合物含量[J]. 食品研究与开发,2021,42(20):148−153. [YANG C X. Determination of nine kinds of phenolic acids in Lycium barbarum L. using high-performance liquid chromatography[J]. Food Research and Development,2021,42(20):148−153.] doi: 10.12161/j.issn.1005-6521.2021.20.022 YANG C X. Determination of nine kinds of phenolic acids in Lycium barbarum L. using high-performance liquid chromatography[J]. Food Research and Development, 2021, 42(20): 148−153. doi: 10.12161/j.issn.1005-6521.2021.20.022

[21] 姚烨岑, 郭明, 叶博, 等. 新型水果时尚黄酒中风味物质的GC-MS检测分析及指纹图谱构建[J]. 酿酒科技,2022,4:127−131. [YAO Y C, GUO M, YE B, et al. GC-MS analysis and fingerprinting of flavor substances in a new-type fruit Huangjiu[J]. Liquor-Making Science & Technology,2022,4:127−131.] YAO Y C, GUO M, YE B, et al. GC-MS analysis and fingerprinting of flavor substances in a new-type fruit Huangjiu[J]. Liquor-Making Science & Technology, 2022, 4: 127−131.

[22] MO X, FAN W, XU Y. Changes in volatile compounds of Chinese rice wine wheat Qu during fermentation and storage[J]. Journal of the Institute of Brewing,2009,115(4):300−307. doi: 10.1002/j.2050-0416.2009.tb00385.x

[23] 刘彩华, 曾嘉童, 包竹君, 等. 3, 5-二硝基水杨酸比色法测定芒果的可溶性糖含量[J]. 食品安全质量检测学报,2022,13(9):2892−2900. [LIU C H, ZENG J T, BAO Z J, et al. Determination of soluble sugar content in Mangifera indica Linn. by 3, 5-dinitrosalicylic acid colorimetry[J]. Journal of Food Safety and Quality,2022,13(9):2892−2900.] LIU C H, ZENG J T, BAO Z J, et al. Determination of soluble sugar content in Mangifera indica Linn. by 3, 5-dinitrosalicylic acid colorimetry[J]. Journal of Food Safety and Quality, 2022, 13(9): 2892−2900.

[24] 王栋, 经斌, 徐岩, 等. 中国黄酒风味感官特征及其风味轮的构建[J]. 食品科学,2013,34(5):90−95. [WANG D, JING B, XU Y, et al. Sensory flavor characteristics of Chinese yellow rice wine and construction of flavor wheel[J]. Food Science,2013,34(5):90−95.] WANG D, JING B, XU Y, et al. Sensory flavor characteristics of Chinese yellow rice wine and construction of flavor wheel[J]. Food Science, 2013, 34(5): 90−95.

[25] 王蒙, 周志磊, 姬中伟, 等. 黄酒感官质量评价体系研究——以绍兴黄酒为例[J]. 食品与发酵工业,2023,49(8):7−13. [WANG M, ZHOU Z L, JI Z W, et al. Research on sensory quality evaluation system of Huangjiu:Taking Shaoxing rice wine as an example[J]. Food and Fermentation Industries,2023,49(8):7−13.] WANG M, ZHOU Z L, JI Z W, et al. Research on sensory quality evaluation system of Huangjiu: Taking Shaoxing rice wine as an example[J]. Food and Fermentation Industries, 2023, 49(8): 7−13.

[26] 孙宝国. 孙宝国院士专访:躲不开的食品添加剂[J]. 食品研究与开发,2013,34(19):3. [SUN B G. Exclusive interview of Sun Baoguo:Unavoidable additives[J]. Food Research and Development,2013,34(19):3.] SUN B G. Exclusive interview of Sun Baoguo: Unavoidable additives[J]. Food Research and Development, 2013, 34(19): 3.

[27] 赵君哲. 食品的pH值与微生物控制[J]. 肉类工业,2015,406(2):40−42. [ZHAO Z Z. pH Value and microbial control of food[J]. Meat Industry,2015,406(2):40−42.] ZHAO Z Z. pH Value and microbial control of food[J]. Meat Industry, 2015, 406(2): 40−42.

[28] 霍佳欢, 李双民, 温晓蕾, 等. 不同培养条件对栗仁菌核青霉菌生长的影响[J]. 江苏农业科学,2021,49(23):129−132. [HUO J H, LI S M, WEN X L, et al. Various culture conditions on the growth of Penicillium sclerotiorum in chestnut kernel[J]. Jiangsu Agricultural Sciences,2021,49(23):129−132.] HUO J H, LI S M, WEN X L, et al. Various culture conditions on the growth of Penicillium sclerotiorum in chestnut kernel[J]. Jiangsu Agricultural Sciences, 2021, 49(23): 129−132.

[29] 侯海峰, 李群伟, 李晓梅. 温度和湿度对黄绿青霉菌生长和产毒的影响[J]. 中国地方病防治杂志,2010,25(2):104−106. [HOU H F, LI Q W, LI X M, et al. Effect of temperature and water activity on growth and toxin production of Penicillium citreoviride[J]. Chinese Journal of Control of Endemic Diseases,2010,25(2):104−106.] HOU H F, LI Q W, LI X M, et al. Effect of temperature and water activity on growth and toxin production of Penicillium citreoviride[J]. Chinese Journal of Control of Endemic Diseases, 2010, 25(2): 104−106.

[30] 丁丽, 李会荣, 杨智国, 等. 温度、水分含量及贮藏期对玉米、DDGS及花生粕霉菌与霉菌毒素B1的影响[J]. 山东畜牧兽医,2014,35(6):3−4. [DING L, LI H R, YANG Z G, et al. Effects of temperature, water content and storage time on the moulds and mycotoxin B1 in corn, DDGS and peanut meal[J]. Shandong Journal of Animal Science and Veterinary Medicine,2014,35(6):3−4.] DING L, LI H R, YANG Z G, et al. Effects of temperature, water content and storage time on the moulds and mycotoxin B1 in corn, DDGS and peanut meal[J]. Shandong Journal of Animal Science and Veterinary Medicine, 2014, 35(6): 3−4.

[31] 周涛. 储藏稻谷中霉菌的生长演替规律及霉变稻谷的品质研究[D]. 武汉:武汉轻工大学, 2020. [ZHOU T. Study on the growth, succession laws of mold and the quality of mildew in stored paddy rice[D]. Wuhan:Wuhan Polytechnic University, 2020.] ZHOU T. Study on the growth, succession laws of mold and the quality of mildew in stored paddy rice[D]. Wuhan: Wuhan Polytechnic University, 2020.

[32] 祝贺, 杨涛, 郝哲兵, 等. 酚类对酒的风味影响及白酒酚类控制策略[J]. 食品工业科技,2019,40(18):361−367. [ZHU H, YANG T, HAO Z B, et al. Effect of phenols on liquor flavor and control strategy of phenols in Baijiu[J]. Science and Technology of Food Industry,2019,40(18):361−367.] ZHU H, YANG T, HAO Z B, et al. Effect of phenols on liquor flavor and control strategy of phenols in Baijiu[J]. Science and Technology of Food Industry, 2019, 40(18): 361−367.

[33] 陈青柳. 绍兴机械化黄酒风味形成途径和功能微生物的研究[D]. 无锡:江南大学, 2018. [CHEN Q L. Study on the flavor formation and functional microorganism of Shaoxing mechanized Huangjiu[D]. Wuxi:Jiangnan University, 2018.] CHEN Q L. Study on the flavor formation and functional microorganism of Shaoxing mechanized Huangjiu[D]. Wuxi: Jiangnan University, 2018.

[34] MO X L, XU Y. Ferulic acid release and 4-vinylguaiacol formation during Chinese rice wine brewing and fermentation[J]. Journal of the Institute of Brewing,2010,116(3):304−311. doi: 10.1002/j.2050-0416.2010.tb00435.x

[35] 解铜. 绍兴地区传统黄酒的香气特征及其协同作用的研究[D]. 上海:上海应用技术大学, 2021. [XIE T. Study on aroma characteristics and synergistic mechanism of traditional Huangjiu[D]. Shanghai:Shanghai Institute of Technology, 2021.] XIE T. Study on aroma characteristics and synergistic mechanism of traditional Huangjiu[D]. Shanghai: Shanghai Institute of Technology, 2021.

-

期刊类型引用(0)

其他类型引用(1)

下载:

下载:

下载:

下载: