Research Progress in the Recovery of Bioactive Substances from Agricultural Product Processing Waste by Pulsed Electric Field

-

摘要: 脉冲电场(Pulsed electric fields,PEF)是一种新型物理场加工技术,具有处理时间短、能耗低以及绿色环保等优点,近年来在回收农产品加工废弃物中活性物质的应用上展现出一定的潜力。本文对脉冲电场强化活性物质提取的作用机理以及优点进行了综述。此外,本文也针对脉冲电场技术在回收不同类型加工废弃物中活性物质的应用进展进行了分类和详细概述,以期为农产品加工过程中副产物的高值化利用提供参考和指导。Abstract: Pulsed electric field (PEF) is a new type of physical field processing technology, which has the advantages of short treatment time, low-energy consumption and eco-friendly. In recent years, pulsed electric field (PEF) has shown potential in the application of recycling active substances in agricultural product processing wastes. In this paper, the mechanism and advantages of pulsed electric field enhanced extraction are reviewed. In addition, the application progress of pulsed electric field technology in the recovery of bioactive substances in different types of processing wastes is classified and summarized in detail to provide reference and guidance for the high-value utilization of by-products in the processing of agricultural products.

-

Keywords:

- pulsed electric field (PEF) /

- processing waste /

- bioactive substances /

- recovery

-

随着农产品加工行业的快速发展,如何高值化利用其加工过程中大量产生的废弃物是近年来研究者们关注的重点[1−3]。农产品加工过程中产生的废弃物主要分为植物类、动物类和微生物类三大类[4−9]。其中,植物类废弃物主要指果蔬加工过程中产生的果渣果皮;动物类废弃物主要指禽畜肉和海鲜加工过程中产生的骨、内脏和壳;微生物废弃物主要指发酵过后酒糟中的酵母等微生物(如图1所示)。目前,对于废弃物的处理方式主要为直接堆填或初步处理后作为饲料售卖[10],造成了环境污染和资源浪费,因为这些废弃物中还含有黄酮、多糖和蛋白质等多种高附加值活性物质未被充分利用[11]。因此,如何从这些废弃物中高效回收活性物质对于农产品加工废弃物的高值化利用具有重要意义。

传统溶剂提取法是从农产品加工废弃物中回收活性物质最常用的方法,但是该方法存在能耗高、时间长以及溶剂消耗大等缺点[12]。此外,传统溶剂提取过程中较高的处理温度也会使一些热敏性活性物质出现降解,影响目标成分的回收[13]。为了解决上述问题,研究者们尝试将一些物理场加工技术与传统溶剂法联用[14−17],以提高活性物质的提取效率并减少有机萃取溶剂的使用。脉冲电场(Pulsed electric fields,PEF)是一种新型物理场加工技术,具有瞬时功率大、作用时间短以及工作参数可以灵活调节的特点,近年来在液态食品低温杀菌和强化果蔬干燥等应用上展现出较好的效果[18−20]。在电场作用下,细胞膜的两端会产生跨膜电位,随着电场强度的增加,细胞膜两端的跨膜电位逐渐增大最终使细胞膜发生电穿孔,促进胞内物质的溶出[21]。基于该原理,脉冲电场技术也常被用于多酚[22]、黄酮[23]、多糖[24]、色素[25]、氨基酸[26]和蛋白质[27]等活性物质的提取。相较于传统溶剂提取,脉冲电场辅助提取具有能耗低、时间短、溶剂消耗少以及低温提取等优点,在农产品加工废弃物中活性物质的回收上也展现出一定的应用潜力[28]。为了进一步了解脉冲电场技术在活性物质提取上的应用,本文对脉冲电场技术强化提取的机理以及优点进行了详细综述。此外,本文也对该技术在回收不同类型农产品加工废弃物中活性物质的应用进展进行了概述,以期为农产品副产物的高值化利用提供参考和指导。

1. PEF强化活性物质提取的机理

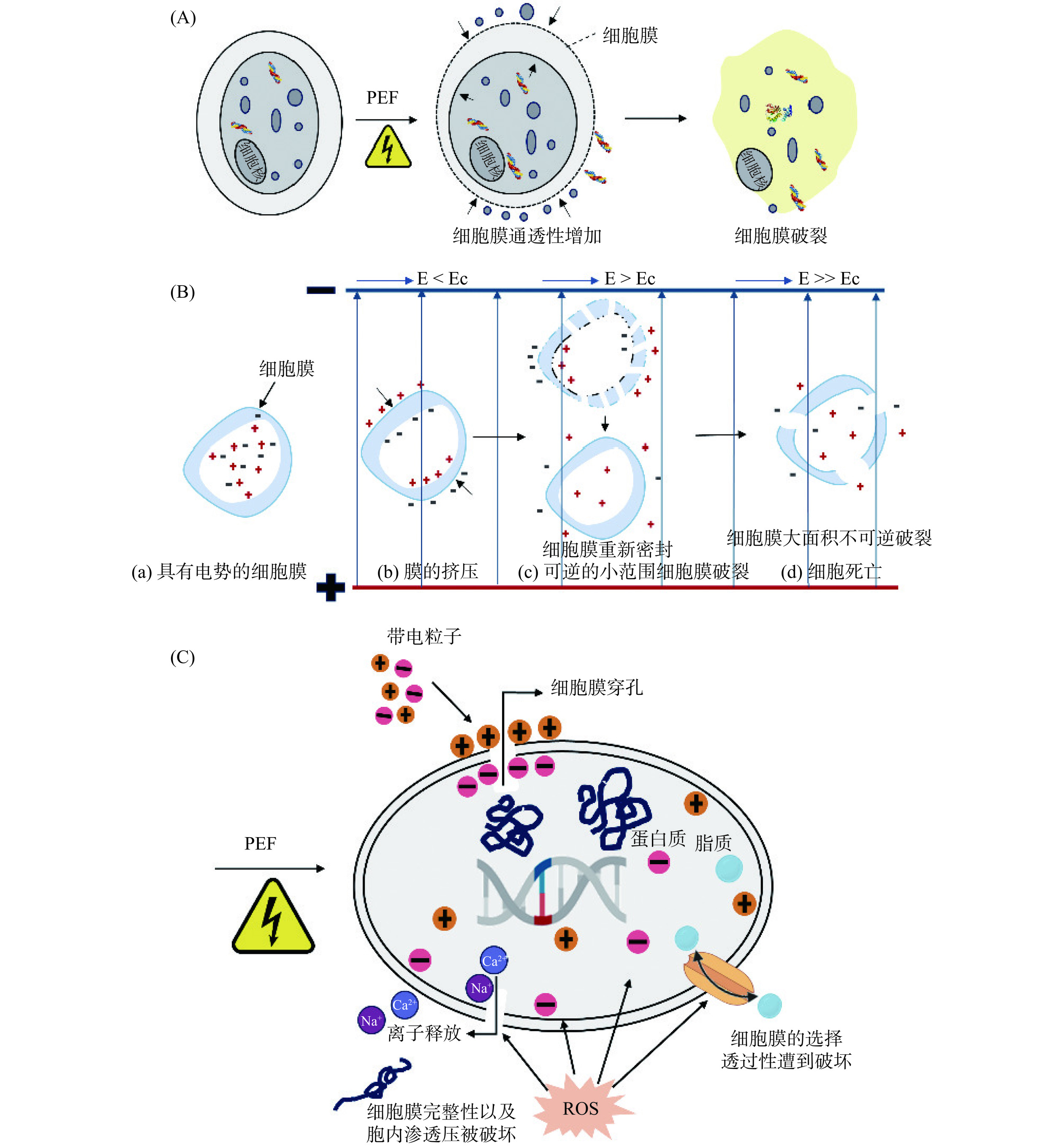

PEF强化活性物质回收提取机理的研究在国内外已有50多年的历史,主要形成了电崩解、电穿孔和自由基理论等观点。Tsong等[29]提出的电穿孔理论认为穿孔形成的前提是细胞膜内外存在足够的电位差,外加电场能够诱导微生物细胞膜局部结构改变,导致细胞膜上出现微小孔洞[30-31],电场持续作用下,孔径不断变大的同时数量也逐渐增加,从而使得细胞膜丧失选择透过性,细胞内化合物泄露,最终导致细胞死亡[32](如图2A所示)。Zimmerann等[33]提出的电崩解假说则把细胞膜看作为一个电容器,在外加电场作用下细胞膜两端的跨膜电位差将随着电场强度的增强而增大,此时细胞膜上电荷分离,细胞膜两端积累的大量电荷相反的离子相互吸引形成挤压力,当电位差达到临界崩解电位差(通常为0.5~1.5 V),此时挤压力大于膜的恢复力,细胞膜破裂。而在电位差作用下的小范围的细胞膜破裂是可逆的,若外加电场超过了临界电场强度或作用时间过长,此时细胞膜大面积不可逆破裂,最终导致细胞结构破坏,促进胞内物质溶出(如图2B所示)[34−37]。而自由基理论则认为,电极间介质为水分子时,电解会产生大量超氧阴离子自由基,其中羟基自由基通过攻击细胞膜的脂质从而对其造成氧化损伤,细胞膜通透性增加,在电场持续作用下,细胞膜破裂,促进了细胞内容物的释放,导致目标物提取率的增加(如图2C所示)[38−39]。

2. PEF在回收不同来源加工废弃物中活性物质的应用进展

2.1 植物来源

PEF已被应用于回收植物来源加工废料中的活性物质,如表1所示,PEF处理可有效增加这些植物废料中果胶、多酚以及天然色素的回收率。殷涌光等[40]研究了PEF处理参数对回收苹果果渣中果胶的影响,结果表明,电场强度15 kV/cm、脉冲数10、pH3、提取温度62 ℃和料液比为1:19的条件下,提取果胶的得率为14.12%,显著高于酸提法(10.33%)、超声波提取法(11.63%)、微波法(10.98%)和草酸铵提取法(9.88%)。Rajha等[41]发现PEF在场强10 kV/cm、脉宽10 μs、频率40 Hz、脉冲数25和提取温度50 ℃的条件下,其对石榴皮中鞣花酸的回收量与热水提取法和超声提取法相比分别增加了约11.45倍和2.57倍。Salgado等[42]研究表明,相较于水热提取,经过优化后,PEF在场强3 kV/cm、脉宽100 ms、频率2 Hz和脉冲数45的处理条件下其对杏仁壳中总酚的回收率提高了19.71%。此外,PEF还能够显著增加植物废料中一些天然色素的回收率。Chatzimitakos等[43]利用PEF回收葡萄果渣中的花青素,研究发现PEF辅助回收花青素的得率为14.05±1.53 mg/g,分别比热水提取法、超声提取法和超高压提取法提高了77.18%、81.06%和25.33%。赵旭彤[44]用单因素实验和响应面法优化得到PEF回收蓝莓废弃物花青素最佳工艺条件:场强20 kV/cm,脉冲数10,料液比为1:6(V/V),结果发现PEF辅助回收蓝莓废弃物中花青素的得率比超声提取法高14.2 mg/L。Andreou等[45]在最佳PEF提取条件下(场强2 kV/cm、脉宽15 μs、频率20 Hz、脉冲数200)得到番茄红素的回收率为14.29±1.01 mg/100 g,明显高于传统有机溶剂提取法(9.84±0.1 mg/100 g)。Koubaa等[46]研究也发现,与水提法和超声提取法相比,PEF辅助提取回收红刺梨果皮甜菜素的得率分别提高了119.29%和11.11%。由此可见,PEF作为辅助手段应用于植物类加工废料中活性物质的回收效果较好,具有较大的应用潜力。

表 1 植物来源废弃物中的活性物质以及处理参数Table 1. Active substances in wastes of plant origin and extraction parameters植物来源 主要活性物质 PEF提取参数 结果 参考文献 苹果渣 果胶 场强15 kV/cm,脉宽2 μs,频率256 Hz,脉冲数10,

pH3,62 ℃,料液比1:19回收率高达14.12% [40] 石榴皮 鞣花酸 场强10 kV/cm,脉宽10 μs,频率40 Hz,脉冲数25,50 ℃ 回收量高达740±74 μg/g DM,是热水提取法的11.45倍,

超声提取法的2.57倍[41] 杏仁壳 总酚 场强3 kV/cm,脉宽100 ms,频率2 Hz,脉冲数45 回收量高达30.92 mg GAE/g DW,比传统水提法提高了19.71% [42] 葡萄果渣 花青素 场强3 kV/cm,脉宽2~15 μs,频率2 Hz,脉冲数30 回收量高达14.05±1.53 mg/g [43] 蓝莓废弃物 花青素 电场强度18.70 kV/cm,

场强20 kV/cm,脉宽2 μs,频率100~3000 Hz,脉冲数10,

料液比1:6(V/V)回收量高达223.13 mg/L [44] 番茄果渣 番茄红素 场强2 kV/cm,脉宽15 μs,频率20 Hz,脉冲数200 回收量高达14.29±1.01 mg/100 g,比对照组提高了45% [45] 红刺梨果皮 色素

(甜菜素)场强20 kV/cm,脉宽10 μs,频率0.5 Hz,脉冲数50 回收量高达50 mg/100 g,比水提法和超声提取法分别

提高了119.29%、11.11%[46] 2.2 动物来源

国内外已有研究表明PEF技术也可用于回收动物源加工废料中的活性物质,目前该方面的研究主要还是集中于回收处理水产品加工过程中产生废弃料如内脏和鱼骨等。如表2所示,于真真[47]通过正交试验优化了PEF回收鲍鱼内脏中不饱和脂肪酸的工艺条件。结果表明,PEF的最佳条件为场强22.5 kV/cm、脉冲数16和液料比2:1,在该条件下不饱和脂肪酸的得率为60.63%,约为Bligh-Dyer法的1.4倍。He等[48]利用PEF辅助NaOH提取鱼骨中的硫酸软骨素(CS),研究表明PEF辅助提取可显著增加CS的回收率,其回收率可达6.92 g/L,较酶提法、碱提取法和超声提取法分别提高了101.74%、84.04%和42.09%。PEF应用于回收鱼骨中的钙和胶原蛋白时也表现出同样的趋势。周亚军等[49]使用PEF强化鱼骨中钙元素的回收,结果表明在最佳的提取条件下,PEF的加入可以使鱼骨中钙元素的回收率达到84.2%,显著高于酶解法的23.2%和超声提取法的67%。He等[50]也发现与单一的酶解法相比,使用PEF先对鱼骨进行预处理随后再加入胃蛋白酶对鱼骨进行酶解其胶原蛋白的回收率能提高32.42%,这可能是由于PEF处理破坏了鱼骨的表面结构更加利于胃蛋白酶作用于鱼骨内部所致。至今为止,国内外学者对于PEF技术回收动物类加工废弃物方面的研究较少,目前的研究大部分只关注于目标物质的回收率,但很少有研究关注回收过程中PEF处理对蛋白质、壳聚糖等大分子目标物质结构和功能的影响,仍需开展进一步的研究。

表 2 动物来源废弃物中的活性物质以及提取参数Table 2. Active substances in wastes of animal origin and extraction parameters动物来源 提取物质 PEF提取参数 结果 参考文献 鲍鱼内脏 不饱和脂肪酸 场强22.5 kV/cm,脉宽0.25 µs,频率16 Hz,脉冲数16,液料比为2:1 回收率为60.63% [47] 鱼骨 硫酸软骨素(CS) 场强16.88 kV/cm,脉宽18 µs,频率40~3000 Hz,脉冲数9,料液比1:15 g/mL,NaOH浓度3.24% 回收量为6.92 g/L [48] 鱼骨 钙 场强25 kV/cm,脉宽2 µs,频率10~5000 Hz,脉冲数8,液料比12:1 回收率为84.2% [49] 鱼骨 胶原蛋白 场强20 kV/cm,脉宽18 µs,频率40~3000 Hz,脉冲数8,料液比1:10,胃蛋白酶添加量为1% 回收量为16.13 mg/mL [50] 2.3 微生物来源

在酿酒过程中会产生大量的酒糟,其中还含有酿酒酵母等微生物未被充分利用。研究发现PEF处理可显著提高啤酒酵母废料中活性物质的回收率(如表3所示)。Liu等[51]用单因素实验和二次回归正交试验优化得到PEF回收废弃啤酒酵母中蛋白质的最佳提取条件为场强为10 kV/cm、脉冲数为8和液固比为40:1。在该条件下啤酒酵母中蛋白质的回收率可达2.78%,约为水提法的0.53倍。Jin等[52]应用PEF技术强化提取啤酒酒糟中废弃酵母胞内的海藻糖,经过优化后的PEF回收酵母胞内海藻糖的得率较微波提取法和超声处理法分别提高了2.12%和2.66%。Dimopoulos等[53]则应用PEF技术促进废弃啤酒酵母中游离氨基酸的溶出,结果发现在最佳PEF处理条件下(场强20 kV/cm、脉宽15 μs、频率300 Hz和脉冲数14)其α-游离氨基酸溶出率为1.0 mg/mL,比酸解法提高了37%,且PEF处理后的废弃酿酒酵母所需自溶时间减少22%。以上研究的结果表明PEF在回收废弃酿酒酵母中高附加值产物方面也具有广阔的应用前景,通过控制PEF处理条件可以提高目标物质的回收率,为酵母抽提物的大规模生产和酒糟废料的高值化利用提供了参考。

表 3 微生物来源废弃物中的活性物质以及提取参数Table 3. Active substances in wastes of microbial origin and extraction parameters3. PEF技术的优势与存在的问题

PEF在回收农产品加工废料中活性物质时主要有三大优点:a.处理时间短。由表1~表3可知,PEF无论处理何种物料,其处理时间都在微秒至毫秒级,相较于微波和超声等物理场几十分钟甚至几个小时的处理时间,PEF处理效率更高且能耗更低;b.处理温升少。PEF主要利用电穿孔、电崩解或者产生自由基来破坏细胞的膜壁结构,其作用原理使之并不会像微波场和超声场那样在强化提取的过程中引起物料内部分子震动产热以及气泡破裂摩擦产热。其次,由于PEF处理时间短,不需要长时间连续处理,能够进一步降低温升,有效减少提取过程中一些热敏性成分如花青素、番茄红素等天然色素的降解。c.适用性广,PEF技术对植物源、动物源和微生物源的物料都能适用,应用范围较广,但值得注意的是,物料的性质也显著影响PEF处理参数的选择。由表1可知,PEF处理如番茄果渣、葡萄果渣一些含水分较多的植物基物料时,其使用的场强一般为2~3 kV/cm,而当使用PEF处理鱼骨和虾壳等较坚硬的物料时,其处理场强往往要高于15 kV/cm(表2),这表明在处理不同物料时,PEF的处理参数也要根据物料的性质进行适当调整。

除上述优点外,还存在一些问题制约了PEF在活性物质回收方面的产业化应用。例如在PEF提取蛋白质的过程中往往需要使用到高场强的脉冲电场(19~20 kV/cm),而目标蛋白可能会在高场强PEF的极化效应下发生结构改变,从而影响其性质和功能[54−56]。然而,目前的研究大多仅关注蛋白质的回收率,很少有研究关注PEF在提取过程中对蛋白质性质和结构的影响。为了更好地将PEF应用于功能性蛋白的回收,还需对该问题进行进一步的研究。此外,由于缺乏相应的PEF工业化设备,关于PEF回收活性物的研究大多还只停留在实验室规模。研发参数可调范围广的高压电源、稳定可靠的高压开关和继电器等核心元件将有助于PEF技术在活性物质回收产业上的工业化应用。

4. 总结与展望

本文围绕PEF技术的作用机理、PEF技术在回收不同类型加工废料中活性物质的应用进展以及该技术的优势与局限进行了综述。从以上分析总结中可以得出PEF具有处理效率高、温升少且适用性广等优点,能够有效提高不同来源农产品加工废料中活性物质的回收量与回收效率,在农产品加工废料高值化利用方面表现出较好的应用潜力。与传统溶剂提取法相比,PEF辅助提取能够有效减少有机溶剂的使用、热敏性活性成分的损失并降低能耗,更加符合绿色加工的要求。在回收色素、海藻糖等生物活性物质时,PEF的回收效率甚至要优于酶解法和其它物理场辅助提取法。然而,PEF技术在工业化应用上还有一些关键问题需要探明与解决。首先,根据原料以及所回收目标物质的不同,PEF处理的参数都有其对应的最适区间,在后续研究中需要建立“原料类型-目标物质-PEF处理参数”的相关性模型,以便于实际应用中PEF处理参数的选择。其次,现有研究大多仅关注PEF对目标物质回收效率的影响,很少有研究关注PEF处理对目标物质结构和性能的影响,探明PEF处理对蛋白质、多糖等生物大分子结构和性能的影响规律将有助于减少回收过程中PEF处理对目标物质的负面影响。此外,国内PEF设备大多还只是一些实验机,缺少工业化成套系的PEF装备,开发性能更稳定、参数上限更高的电源、开关和继电器等核心元件和模块将有助于大功率PEF工业化装备的设计与搭建。总之,推动PEF技术相关基础研究与设备核心元件开发的进行,对PEF技术的产业化应用具有重要意义。

-

表 1 植物来源废弃物中的活性物质以及处理参数

Table 1 Active substances in wastes of plant origin and extraction parameters

植物来源 主要活性物质 PEF提取参数 结果 参考文献 苹果渣 果胶 场强15 kV/cm,脉宽2 μs,频率256 Hz,脉冲数10,

pH3,62 ℃,料液比1:19回收率高达14.12% [40] 石榴皮 鞣花酸 场强10 kV/cm,脉宽10 μs,频率40 Hz,脉冲数25,50 ℃ 回收量高达740±74 μg/g DM,是热水提取法的11.45倍,

超声提取法的2.57倍[41] 杏仁壳 总酚 场强3 kV/cm,脉宽100 ms,频率2 Hz,脉冲数45 回收量高达30.92 mg GAE/g DW,比传统水提法提高了19.71% [42] 葡萄果渣 花青素 场强3 kV/cm,脉宽2~15 μs,频率2 Hz,脉冲数30 回收量高达14.05±1.53 mg/g [43] 蓝莓废弃物 花青素 电场强度18.70 kV/cm,

场强20 kV/cm,脉宽2 μs,频率100~3000 Hz,脉冲数10,

料液比1:6(V/V)回收量高达223.13 mg/L [44] 番茄果渣 番茄红素 场强2 kV/cm,脉宽15 μs,频率20 Hz,脉冲数200 回收量高达14.29±1.01 mg/100 g,比对照组提高了45% [45] 红刺梨果皮 色素

(甜菜素)场强20 kV/cm,脉宽10 μs,频率0.5 Hz,脉冲数50 回收量高达50 mg/100 g,比水提法和超声提取法分别

提高了119.29%、11.11%[46] 表 2 动物来源废弃物中的活性物质以及提取参数

Table 2 Active substances in wastes of animal origin and extraction parameters

动物来源 提取物质 PEF提取参数 结果 参考文献 鲍鱼内脏 不饱和脂肪酸 场强22.5 kV/cm,脉宽0.25 µs,频率16 Hz,脉冲数16,液料比为2:1 回收率为60.63% [47] 鱼骨 硫酸软骨素(CS) 场强16.88 kV/cm,脉宽18 µs,频率40~3000 Hz,脉冲数9,料液比1:15 g/mL,NaOH浓度3.24% 回收量为6.92 g/L [48] 鱼骨 钙 场强25 kV/cm,脉宽2 µs,频率10~5000 Hz,脉冲数8,液料比12:1 回收率为84.2% [49] 鱼骨 胶原蛋白 场强20 kV/cm,脉宽18 µs,频率40~3000 Hz,脉冲数8,料液比1:10,胃蛋白酶添加量为1% 回收量为16.13 mg/mL [50] 表 3 微生物来源废弃物中的活性物质以及提取参数

Table 3 Active substances in wastes of microbial origin and extraction parameters

-

[1] SKOET J, FABI C, CATTANEO A. Measuring food loss and waste:An FAO perspective[J]. EuroChoices,2020,19(1):22−23. doi: 10.1111/1746-692X.12251

[2] 车金鑫, 郭虹雨, 陈珂琴, 等. 柑橘废弃物利用的研究进展[J]. 食品与发酵工业,2022,48(20):300−306. [CHE J X, GUO H Y, CHEN K Q, et al. Research progress on citrus waste utilization[J]. Food and Fermentation Industry,2022,48(20):300−306.] CHE J X, GUO H Y, CHEN K Q, et al. Research progress on citrus waste utilization[J]. Food and Fermentation Industry, 2022, 48(20): 300−306.

[3] 周琦, 藕志强, 饶鑫, 等. 椰子果皮废弃物的高值化利用现状及发展趋势[J]. 广州化工,2020,48(18):16−19. [ZHOU Q, OU Z Q, RAO X, et al. The current situation and development trend of high-value utilization of coconut peel waste[J]. Guangzhou Chemical Industry,2020,48(18):16−19.] doi: 10.3969/j.issn.1001-9677.2020.18.007 ZHOU Q, OU Z Q, RAO X, et al. The current situation and development trend of high-value utilization of coconut peel waste[J]. Guangzhou Chemical Industry, 2020, 48(18): 16−19. doi: 10.3969/j.issn.1001-9677.2020.18.007

[4] SOCAS-RODRÍGUEZ B, ÁLVAREZ-RIVERA G, VALDÉS A, et al. Food by-products and food wastes:are they safe enough for their valorization?[J]. Trends in Food Science & Technology,2021,114:133−147.

[5] FAN W, FENG N, XU G, et al. Preparation of CeO2@C nanomaterials by adsorption of metal ions on microbial waste[J]. Nanotechnology,2022,33(31):315702. doi: 10.1088/1361-6528/ac6885

[6] PERDANA T, KUSNANDAR K, PERDANA H H, et al. Circular supply chain governance for sustainable fresh agricultural products:Minimizing food loss and utilizing agricultural waste[J]. Sustainable Production and Consumption,2023,41:391−403. doi: 10.1016/j.spc.2023.09.001

[7] BURKE H J, KERTON F. Sequential extraction of valuable bio-products from snow crab (Chionoecetes opilio) processing discards using eco-friendly methods[J]. Marine Drugs,2023,21(6):366. doi: 10.3390/md21060366

[8] LEE M, HOADLEY A, PATEL J, et al. Techno-economic analysis for direct processing of wet solid residues originated from grain and inedible plant wastes[J]. BioEnergy Research,2023,16(2):940−953. doi: 10.1007/s12155-022-10501-6

[9] ORTIZ-SANCHEZ M, OMARINI A B, GONZALEZ-AGUIRRE J A, et al. Valorization routes of citrus waste in the orange value chain through the biorefinery concept:The Argentina case study[J]. Chemical Engineering and Processing:Process Intensification,2023,189:109407. doi: 10.1016/j.cep.2023.109407

[10] De EVAN T, MARCOS C N, RANILLA M J, et al. In vitro and in situ evaluation of broccoli wastes as potential feed for ruminants[J]. Animals,2020,10(11):1989. doi: 10.3390/ani10111989

[11] KUMAR K, YADAV A N, KUMAR V, et al. Food waste:A potential bioresource for extraction of nutraceuticals and bioactive compounds[J]. Bioresources and Bioprocessing,2017,4(1):1−14. doi: 10.1186/s40643-016-0134-4

[12] KAUR S, PANESAR P S, CHOPRA H K. Sequential extraction of functional compounds from citrus reticulata pomace using ultrasonication technique[J]. Food Chemistry Advances,2023,2:100155. doi: 10.1016/j.focha.2022.100155

[13] 刘曦然, 方婷. 高压脉冲电场在提取天然产物中的应用[J]. 食品工业,2017,38(1):249−253. [LIU X R, FANG T. Application of high voltage pulsed electric field in the extraction of natural products[J]. Food Industry,2017,38(1):249−253.] LIU X R, FANG T. Application of high voltage pulsed electric field in the extraction of natural products[J]. Food Industry, 2017, 38(1): 249−253.

[14] XI J, YAN L. Optimization of pressure-enhanced solid-liquid extraction of flavonoids from Flos Sophorae and evaluation of their antioxidant activity[J]. Separation and Purification Technology,2017,175:170−176. doi: 10.1016/j.seppur.2016.10.013

[15] 朱芙蓉, 王霜秀, 毛德源, 等. 芒果核中芒果苷的超声辅助提取工艺优化[J]. 食品工业科技,2024,45(2):161−167. [ZHU F R, WANG S X, MAO D Y, et al. Optimization of ultrasonic-assisted extraction process of mangiferin from mango kernel[J]. Food Industry Science and Technology,2024,45(2):161−167.] ZHU F R, WANG S X, MAO D Y, et al. Optimization of ultrasonic-assisted extraction process of mangiferin from mango kernel[J]. Food Industry Science and Technology, 2024, 45(2): 161−167.

[16] 徐洁, 李霁昕, 毕阳, 等. 超声波和微波辅助提取苦水玫瑰鲜花和花渣中原花青素的工艺优化及其比较[J]. 食品科学,2018,39(12):268−275. [XU J, LI J X, BI Y, et al. Optimization and comparison of ultrasonic and microwave-assisted extraction of proanthocyanidins from flowers and dregs of Rosa rugosa[J]. Food Science,2018,39(12):268−275.] doi: 10.7506/spkx1002-6630-201812041 XU J, LI J X, BI Y, et al. Optimization and comparison of ultrasonic and microwave-assisted extraction of proanthocyanidins from flowers and dregs of Rosa rugosa[J]. Food Science, 2018, 39(12): 268−275. doi: 10.7506/spkx1002-6630-201812041

[17] ARSHAD R N, ABDUL-MALEK Z, ROOBAB U, et al. Pulsed electric field:A potential alternative towards a sustainable food processing[J]. Trends in Food Science & Technology,2021,111:43−54.

[18] MARTINEZ J M, DELSO C, ALVAREZ I, et al. Pulsed electric field-assisted extraction of valuable compounds from microorganisms[J]. Comprehensive Reviews in Food Science and Food Safety,2020,19(2):530−552. doi: 10.1111/1541-4337.12512

[19] 吕敏明, 杜慧慧, 蔡乐, 等. 脉冲电场预处理在果蔬干燥中的应用研究进展[J]. 食品工业科技,2023,44(12):430−436. [LÜ M M, DU H H, CAI L, et al. Research progress on the application of pulsed electric field pretreatment in fruit and vegetable drying[J]. Food Industry Science and Technology,2023,44(12):430−436.] LÜ M M, DU H H, CAI L, et al. Research progress on the application of pulsed electric field pretreatment in fruit and vegetable drying[J]. Food Industry Science and Technology, 2023, 44(12): 430−436.

[20] 邝金艳, 林颖, 王丽, 等. 高压电场杀菌技术研究进展[J]. 肉类研究,2023,37(9):52−59. [KUANG J Y, LIN Y, WANG L, et al. Progress of high-voltage electric field sterilization technology[J]. Meat Research,2023,37(9):52−59.] KUANG J Y, LIN Y, WANG L, et al. Progress of high-voltage electric field sterilization technology[J]. Meat Research, 2023, 37(9): 52−59.

[21] 杨宇帆, 陈倩, 王浩, 等. 高压电场技术在食品加工中的应用研究进展[J]. 食品工业科技,2019,40(19):316−320. [YANG Y F, CHEN Q, WANG H, et al. Research progress on the application of high-voltage electric field technology in food processing[J]. Food Industry Science and Technology,2019,40(19):316−320.] YANG Y F, CHEN Q, WANG H, et al. Research progress on the application of high-voltage electric field technology in food processing[J]. Food Industry Science and Technology, 2019, 40(19): 316−320.

[22] LOPEZ-GAMEZ G, ELEZ-MARTINEZ P, MARTIN-BELLOSO O, et al. Pulsed electric field treatment strategies to increase bioaccessibility of phenolic and carotenoid compounds in oil-added carrot purees[J]. Food Chemistry,2021,364:130377. doi: 10.1016/j.foodchem.2021.130377

[23] 陈亦璐, 徐梦兰, 邓健善, 等. 化橘红黄酮的高压脉冲电场提取及抗氧化活性检测[J]. 湖南农业大学学报(自然科学版),2021,47(3):305−311. [CHEN Y L, XU M L, DENG J S, et al. High-voltage pulsed electric field extraction and antioxidant activity of flavonoids from Citrus aurantium[J]. Journal of Hunan Agricultural University (Natural Science Edition),2021,47(3):305−311.] CHEN Y L, XU M L, DENG J S, et al. High-voltage pulsed electric field extraction and antioxidant activity of flavonoids from Citrus aurantium[J]. Journal of Hunan Agricultural University (Natural Science Edition), 2021, 47(3): 305−311.

[24] XUE D, FARID M M. Pulsed electric field extraction of valuable compounds from white button mushroom (Agaricus bisporus)[J]. Innovative Food Science & Emerging Technologies,2015,29:178−186.

[25] 吴则东, 胡晓航, 吴玉梅, 等. 甜菜红色素提取工艺研究进展[J]. 中国农学通报,2015,31(36):254−258. [WU Z D, HU X H, WU Y M, et al. Research progress on the extraction process of beet red pigment[J]. Chinese Agronomy Bulletin,2015,31(36):254−258.] doi: 10.11924/j.issn.1000-6850.casb15070143 WU Z D, HU X H, WU Y M, et al. Research progress on the extraction process of beet red pigment[J]. Chinese Agronomy Bulletin, 2015, 31(36): 254−258. doi: 10.11924/j.issn.1000-6850.casb15070143

[26] 王白娟, 崔博俊, 刘艺佳, 等. 不同高压脉冲电场对云南大叶种普洱茶氨基酸含量的影响(英文)[J]. Agricultural Science & Technology,2014,15(5):835−837. [WANG B J, CUI B J, LIU Y J, et al. Effects of different high-voltage pulsed electric fields on amino acid content of Yunnan large-leaf Pu'er tea (In English)[J]. Agricultural Science & Technology,2014,15(5):835−837.] WANG B J, CUI B J, LIU Y J, et al. Effects of different high-voltage pulsed electric fields on amino acid content of Yunnan large-leaf Pu'er tea (In English)[J]. Agricultural Science & Technology, 2014, 15(5): 835−837.

[27] 董铭, 白云, 李月秋, 等. 脉冲电场对食品蛋白质改性作用的研究进展[J]. 食品工业科技,2019,40(2):293−299. [DONG M, BAI Y, LI Y Q, et al. Research progress on the effect of pulsed electric field on food protein modification[J]. Food Industry Science and Technology,2019,40(2):293−299.] DONG M, BAI Y, LI Y Q, et al. Research progress on the effect of pulsed electric field on food protein modification[J]. Food Industry Science and Technology, 2019, 40(2): 293−299.

[28] 李晓娟. 脉冲电场在天然产物提取中的应用研究[J]. 现代食品,2020(17):108−113. [LI X J. Research on the application of pulsed electric field in the extraction of natural products[J]. Modern Food,2020(17):108−113.] LI X J. Research on the application of pulsed electric field in the extraction of natural products[J]. Modern Food, 2020(17): 108−113.

[29] TSONG T Y. Voltage modulation of membrane permeability and energy utilization in cells[J]. Bioscience Reports,1983,3(6):487−505. doi: 10.1007/BF01120693

[30] TSONG T Y. On electroporation of cell membranes and some related phenomena[J]. Journal of Electroanalytical Chemistry and Interfacial Electrochemistry,1990,299(3):271−295. doi: 10.1016/0022-0728(90)87529-S

[31] TSONG T Y. "4-Time sequence of molecular events in electroporation" Guide to Electroporation and Electrofusion[M]. San Diego:Academic Press, 1992:47-61.

[32] 郭雨怡, 石富坤, 王群, 等. 高压纳秒脉冲电场的细胞器生物电效应综述[J]. 物理学报,2022,71(6):266−277. [GUO Y Y, SHI F K, WANG Q, et al. A review of organelle bioelectric effects of high-voltage nanosecond pulsed electric fields[J]. Physics Letters,2022,71(6):266−277.] GUO Y Y, SHI F K, WANG Q, et al. A review of organelle bioelectric effects of high-voltage nanosecond pulsed electric fields[J]. Physics Letters, 2022, 71(6): 266−277.

[33] ZIMMERMANN U, PILWAT G, BRESGEN D. Dielectric breakdown of cell membranes[J]. Biophysics of Structure and Mechanism,1980,6(1):113.

[34] 魏新劳, 李家辉, 延二宝, 等. 脉冲电场灭菌机理分析及细菌失活模型的研究[J]. 电机与控制学报,2011,15(1):6−12. [WEI X L, LI J H, YAN E B, et al. Mechanism analysis of pulsed electric field sterilization and bacterial inactivation model[J]. Journal of Electrical Machines and Control,2011,15(1):6−12.] doi: 10.3969/j.issn.1007-449X.2011.01.002 WEI X L, LI J H, YAN E B, et al. Mechanism analysis of pulsed electric field sterilization and bacterial inactivation model[J]. Journal of Electrical Machines and Control, 2011, 15(1): 6−12. doi: 10.3969/j.issn.1007-449X.2011.01.002

[35] 冯叙桥, 王月华, 徐方旭. 高压脉冲电场技术在食品质量与安全中的应用进展[J]. 食品与生物技术学报,2013,32(4):337−346. [FENG X Q, WANG Y H, XU F X. Progress in the application of high-voltage pulsed electric field technology in food quality and safety[J]. Journal of Food and Biotechnology,2013,32(4):337−346.] doi: 10.3969/j.issn.1673-1689.2013.04.001 FENG X Q, WANG Y H, XU F X. Progress in the application of high-voltage pulsed electric field technology in food quality and safety[J]. Journal of Food and Biotechnology, 2013, 32(4): 337−346. doi: 10.3969/j.issn.1673-1689.2013.04.001

[36] 齐梦圆, 刘卿妍, 石素素, 等. 高压电场技术在食品杀菌中的应用研究进展[J]. 食品科学,2022,43(11):284−292. [QI M Y, LIU Q Y, SHI S S, et al. Progress in the application of high-voltage electric field technology in food sterilization[J]. Food Science,2022,43(11):284−292.] doi: 10.7506/spkx1002-6630-20210313-175 QI M Y, LIU Q Y, SHI S S, et al. Progress in the application of high-voltage electric field technology in food sterilization[J]. Food Science, 2022, 43(11): 284−292. doi: 10.7506/spkx1002-6630-20210313-175

[37] ZIMMERMANN U. Electrical breakdown, electropermeabilization and electrofusion[J]. Reviews of Physiology, Biochemistry and Pharmacology,1986,105:176−256.

[38] MA S, YU S, ZHANG B, et al. Physicochemical properties of sugar beet pulp pectin by pulsed electric field treatment[J]. International Journal of Food Science & Technology,2012,47(12):2538−2544.

[39] RODRIGUES R M, MARTINS A J, RAMOS O L, et al. Influence of moderate electric fields on gelation of whey protein isolate[J]. Food Hydrocolloids,2015,43:329−339. doi: 10.1016/j.foodhyd.2014.06.002

[40] 殷涌光, 樊向东, 刘凤霞, 等. 用高压脉冲电场技术快速提取苹果渣果胶[J]. 吉林大学学报(工学版),2009,39(5):1224−1228. [YIN Y G, FAN X D, LIU F X, et al. Rapid extraction of apple pomace pectin by high voltage pulsed electric field[J]. Journal of Jilin University (Engineering Edition),2009,39(5):1224−1228.] YIN Y G, FAN X D, LIU F X, et al. Rapid extraction of apple pomace pectin by high voltage pulsed electric field[J]. Journal of Jilin University (Engineering Edition), 2009, 39(5): 1224−1228.

[41] RAJHA H N, ABI-KHATTAR A, EL KANTAR S, et al. Comparison of aqueous extraction efficiency and biological activities of polyphenols from pomegranate peels assisted by infrared, ultrasound, pulsed electric fields and high-voltage electrical discharges[J]. Innovative Food Science & Emerging Technologies,2019,58:102212.

[42] SALGADO-RAMOS M, MARTÍ-QUIJAL F J, HUERTAS-ALONSO A J, et al. Sequential extraction of almond hull biomass with pulsed electric fields (PEF) and supercritical CO2 for the recovery of lipids, carbohydrates and antioxidants[J]. Food and Bioproducts Processing,2023,139:216−226. doi: 10.1016/j.fbp.2023.04.003

[43] CHATZIMITAKOS T, ATHANASIADIS V, KALOMPATSIOS D, et al. Pulsed electric field applications for the extraction of bioactive compounds from food waste and by-products:A critical review[J]. Biomass,2023,3(4):367−401. doi: 10.3390/biomass3040022

[44] 赵旭彤. 蓝莓加工废弃物中花青素提取纯化及抗氧化活性研究[D]. 长春:吉林大学, 2015. [ZHAO X T. Research on anthocyanin extraction purification and antioxidant activity from blueberry processing waste[D]. Changchun:Jilin University, 2015.] ZHAO X T. Research on anthocyanin extraction purification and antioxidant activity from blueberry processing waste[D]. Changchun: Jilin University, 2015.

[45] ANDREOU V, DIMOPOULOS G, DERMESONLOUOGLOU E, et al. Application of pulsed electric fields to improve product yield and waste valorization in industrial tomato processing[J]. Journal of Food Engineering,2020,270:109778. doi: 10.1016/j.jfoodeng.2019.109778

[46] KOUBAA M, BARBA F J, GRIMI N, et al. Recovery of colorants from red prickly pear peels and pulps enhanced by pulsed electric field and ultrasound[J]. Innovative Food Science & Emerging Technologies,2016,37:336−344.

[47] 于真真. PEF提取鲍鱼脏器油脂及油脂精炼与抗氧化的研究[D] . 福州:福建农林大学, 2012. [YU Z Z. Study on PEF extraction of abalone viscera oil and lipid refining and antioxidant[D]. Fuzhou:Fujian Agriculture and Forestry University, 2012.] YU Z Z. Study on PEF extraction of abalone viscera oil and lipid refining and antioxidant[D]. Fuzhou: Fujian Agriculture and Forestry University, 2012.

[48] HE G, YIN Y, YAN X, et al. Optimisation extraction of chondroitin sulfate from fish bone by high intensity pulsed electric fields[J]. Food Chemistry,2014,164:205−210. doi: 10.1016/j.foodchem.2014.05.032

[49] 周亚军, 隋思瑶, 黄卉, 等. 高压脉冲电场辅助提取鱼骨钙工艺优化[J]. 农业工程学报,2012,28(23):265−270. [ZHOU Y J, SUI S Y, HUANG H, et al. Optimization of high-voltage pulsed electric field-assisted extraction of calcium from fish bone[J]. Journal of Agricultural Engineering,2012,28(23):265−270.] ZHOU Y J, SUI S Y, HUANG H, et al. Optimization of high-voltage pulsed electric field-assisted extraction of calcium from fish bone[J]. Journal of Agricultural Engineering, 2012, 28(23): 265−270.

[50] HE G, YAN X, WANG X, et al. Extraction and structural characterization of collagen from fishbone by high intensity pulsed electric fields[J]. Journal of Food Process Engineering,2019,42(6):e13214. doi: 10.1111/jfpe.13214

[51] LIU M, MEISHUO Z, SONGYI L, et al. Optimization of extraction parameters for protein from beer waste brewing yeast treated by pulsed electric fields (PEF)[J]. African Journal of Microbiology Research,2012,6(22):4739−4746.

[52] JIN Y, WANG M, LIN S, et al. Optimization of extraction parameters for trehalose from beer waste brewing yeast treated by high-intensity pulsed electric fields (PEF)[J]. African Journal of Biotechnology,2011,10(82):19144−19152.

[53] DIMOPOULOS G, STEFANOU N, ANDREOU V, et al. Effect of pulsed electric fields on the production of yeast extract by autolysis[J]. Innovative Food Science & Emerging Technologies,2018,48:287−295.

[54] 林杰. PEF对鲍鱼内脏蛋白水解及其性质变化影响的研究[D]. 福州:福建农林大学, 2013. [LIN J. Study on the effect of PEF on protein hydrolysis of abalone viscera and its property changes[D]. Fuzhou:Fujian Agriculture and Forestry University, 2013.] LIN J. Study on the effect of PEF on protein hydrolysis of abalone viscera and its property changes[D]. Fuzhou: Fujian Agriculture and Forestry University, 2013.

[55] 贺琴. 高压脉冲电场辅助酶解河蚌蛋白粉的制备及特性研究[D]. 长春:吉林大学, 2016. [HE Q. Preparation and characterization of high-voltage pulsed electric field-assisted enzymatic digestion of mussel protein powder[D]. Changchun:Jilin University, 2016.] HE Q. Preparation and characterization of high-voltage pulsed electric field-assisted enzymatic digestion of mussel protein powder[D]. Changchun: Jilin University, 2016.

[56] JIANG Y, XING M, KANG Q, et al. Pulse electric field assisted process for extraction of Jiuzao glutelin extract and its physicochemical properties and biological activities investigation[J]. Food Chemistry,2022,383:132304. doi: 10.1016/j.foodchem.2022.132304

下载:

下载:

下载:

下载: