Effects of Drying Methods on Physicochemical Properties and Structure of Phyllostachys pubescens Shoot Powder

-

摘要: 为探究干燥方式对毛竹笋全粉(Phyllostachys pubescens shoot powder,PPSP)理化特性及结构的影响,该实验以毛竹笋为原料,采用喷雾干燥(Spray drying,SD)、热风干燥(Hot air drying,HAD)和低温真空干燥(Low-temperature vacuum drying,LVD)3种方式制备PPSP,比较3种PPSP的营养成分、持水力、持油力、膨胀力、色泽等理化特性,并通过红外光谱、X-射线衍射、扫描电镜分析其结构。结果表明,不同干燥方式制备的PPSP营养成分差异显著(P<0.05),LVD组的蛋白质、不溶性膳食纤维、灰分、总糖含量均显著高于其他2组(P<0.05),而水分、可溶性膳食纤维含量最低;HAD组中可溶性膳食纤维含量最高,达5.79%;HAD组样品的持水力和持油力分别为4.10、1.91 g/g,显著高于SD组和LVD组(P<0.05);SD样品的膨胀力最高,达到3.85 mL/g;3组PPSP的滑角和休止角差异显著(P<0.05),其中,SD>LVD>HAD;3组PPSP的L*值、a*值、b*值均有显著差异(P<0.05),LVD样品的L*值为77.32,显著高于SD和HAD样品(P<0.05),且其a*值和b*值最低,分别为3.74、14.50;SD和LVD显著降低了样品的热稳定性(P<0.05)。干燥方式未改变PPSP的基本结构和官能团以及晶体结构。扫描电镜观察到SD制备的PPSP颗粒尺寸明显减小,分布更为均匀。综上所述,LVD制备的毛竹笋干制品营养、理化特性及结构整体最佳,其次是SD。研究结果可为高品质PPSP的制备提供理论参考。Abstract: In order to explore the effects of drying methods on the physicochemical properties and structure of Phyllostachys pubescens shoot powder (PPSP), this research used bamboo shoots as raw materials, and used spray drying (SD), hot air drying (HAD) and low-temperature vacuum drying (LVD) to get 3 kinds of PPSP. The nutrient content, water holding capacity, oil holding capacity, swelling capacity, color, and other physicochemical properties of samples were compared, and their structures were analyzed by infrared spectroscopy, X-ray diffraction and scanning electron microscopy. The results showed that the nutritional characteristics of PPSP prepared by different drying methods were significantly different(P<0.05). The contents of protein, insoluble dietary fiber, ash, and total sugar in LVD samples were significantly higher than those in the other two groups (P<0.05), while the contents of water and soluble dietary fiber were the lowest. The content of soluble dietary fiber in HAD samples was the highest (5.79%). The water holding capacity and oil holding capacity of HAD powder were 4.10 and 1.91 g/g, respectively, which were significantly higher than those of SD group and LVD group. The swelling capacity of SD powder was the best, reaching 3.85 mL/g. The angle of repose and slip angle of PPSP in 3 groups were significantly different (P<0.05), which was SD>LVD>HAD. The L*, a* and b* value of PPSP in the three groups were significantly different in color. The L* value of LVD sample was 77.32, which was significantly higher than that of SD and HAD samples (P<0.05), and the a* and b* value were the lowest, which were 3.74 and 14.50, respectively. SD and LVD significantly reduced the thermal stability of the sample (P<0.05). The drying method did not change the basic structure, functional group, and crystal structure of PPSP. The particle size of PPSP prepared by SD decreased significantly and the distribution was more uniform. In summary, the nutrition, physicochemical properties, and structure of dried bamboo shoots prepared by LVD were the best, followed by SD. The results can provide experimental basis for the preparation of high quality PPSP.

-

竹笋又称竹芽、鞭笋,因其高膳食纤维、高蛋白、低脂肪以及富含多种生物活性物质被认为是一种健康营养蔬菜[1−2]。然而竹笋采摘后水分含量高,呼吸作用较强,大量水分和营养物质被消耗,从而引起组织木质化和笋肉褐变,导致其食用品质和商品价值大大降低[3]。干燥制粉是一种比较常见的竹笋加工方式,通过脱水处理,可以有效地抑制果蔬中微生物的生长和繁殖,防止果蔬腐败和变质,延长其货架期,同时减小果蔬的体积,从而降低运输和贮藏成本[4−5]。研究表明,竹笋粉能够改善老化纤维的粗糙口感,改良其理化性质和功能特性,从而扩大竹笋原料的应用范围,可作为主食改良剂、膳食纤维补充剂等广泛应用于食品工业中[6]。

喷雾干燥(Spray drying,SD)、热风干燥(Hot air drying,HAD)和低温真空干燥(Low-temperature vacuum drying,LVD)作为3种常见的干燥技术,在果蔬制粉等应用中有着不同的工艺特点。岳天义等[7]分别对茄子进行热风干燥、微波干燥、真空微波干燥及真空冷冻干燥处理,发现真空冷冻干燥处理后的茄子总酚和总黄酮含量最高、抗氧化能力最强,微观结构保留较好。葛邦国等[8]研究热风干燥、喷雾干燥、真空冷冻干燥及真空带式干燥对南瓜粉品质的影响,发现真空冷冻干燥制得的南瓜粉总糖、还原糖含量最高,溶解性、持水力最大,流动性、容重最小,品质最好。为进一步明确不同干燥方式处理后毛竹笋全粉(Phyllostachys pubescens shoot powder,PPSP)的理化特性及微观结构变化,本研究以毛竹笋为原料,采用喷雾干燥(Spray drying,SD)、热风干燥(Hot air drying,HAD)和低温真空干燥(Low-temperature vacuum drying,LVD)3种不同的干燥方式制备PPSP,比较分析其营养成分、持水力、持油力等理化特性,对不同干燥方式的PPSP进行红外光谱分析和X-射线衍射分析,并用扫描电子显微镜观察其微观结构,以期为高品质PPSP的制备提供有益参考。

1. 材料与方法

1.1 材料与仪器

毛竹笋 福建省建瓯市美森竹业有限公司提供;硫酸钾、无水硫酸铜、硼酸、石油醚、硫脲 分析纯,成都市科隆化学品有限公司;氢氧化钠、浓硫酸、乙醇、葡萄糖 分析纯,重庆万盛川东化工有限公司;蒽酮、KBr 分析纯,天津市科密欧化学试剂有限公司;红蜻蜓一级菜籽油 重庆红蜻蜓油脂有限责任公司。

FW135型中草药粉碎机 天津市泰斯特仪器有限公司;JMP-80胶体磨 广州市祥明机械设备有限公司;NT-H6均质机 南京市纳通机电制造有限公司;ADL311喷雾干燥机 日本雅马拓科学株式会社;DHG-9140电热恒温鼓风干燥箱 上海齐欣科学仪器有限公司;K9840自动凯氏定氮仪 济南海能仪器股份有限公司;G210滤袋式全自动脂肪测定仪 上海晟声自动化分析仪器有限公司;马弗炉 河南奥菲达仪器设备有限公司;UV2800A紫外可见分光光度计 江苏迅迪仪器科技有限公司;Mastersizer 3000马尔文帕纳科激光粒度仪 马尔文帕纳科公司;Ultra Scan PRO分光测色仪 美国Hunter Lab公司;Spectrum100傅里叶红外光谱仪 美国PerkinElmer公司;TGA55热重分析仪 美国TA公司;XRD-7000 X 射线衍射分析仪 日本岛津公司;Phenom Pro扫描电镜 荷兰Phenom World公司。

1.2 实验方法

1.2.1 样品制备

将新鲜毛竹笋剥壳洗净并切片,分为3组,在质量分数为0.2%的柠檬酸护色液中浸泡20 min,料液比1:5,然后用蒸馏水将笋片清洗3~4次,并沥干表面水分。具体样品制备过程如下:

SD组:将一定质量笋片置于胶体磨中打浆,然后在30 MPa下均质2次得到质量分数为10%的进料溶液,将进料溶液用喷雾干燥机进行喷雾干燥,条件为进风温度200 ℃、出风温度80 ℃、入料流量50 mL/min,干燥结束后收集样品。

HAD组:将盛有一定质量笋片的托盘放入电热恒温鼓风干燥箱中,70 ℃条件下干燥10 h,将干燥后的样品粉碎后过200目筛。

LVD组:将一定质量的笋片放入电热真空干燥箱中,在真空度600 Pa,温度55 ℃条件下干燥10 h,干燥结束后粉碎,过200目筛。

1.2.2 PPSP理化特性的测定

1.2.2.1 营养成分的测定

水分含量测定:参照GB 5009.3-2016《食品中水分的测定》;蛋白质含量测定:参照GB 5009.5-2016《食品中蛋白质的测定》;膳食纤维含量测定:参照GB 5009.88-2014《食品中膳食纤维的测定》;脂肪含量的测定:参照GB/T 5009.6-2003《食品中脂肪的测定》;总灰分含量的测定:参照GB 5009.4-2016《食品中灰分的测定》;总糖含量的测定:采用蒽酮比色法测定[9]。

1.2.2.2 持水力、持油力和膨胀力的测定

参考汤彩碟等[10]的方法。持水力(Water holding capacity,WHC):分别称取3种PPSP 0.5 g(m1)在质量为m2的离心管中后进行振荡,加入30 mL蒸馏水,混合均匀后在室温下静置6 h,然后在4000 r/min离心10 min,倒去上层水分后进行称重(m3),根据公式(1)进行计算。

WHC(g⋅g−1)=m3−(m1+m2)m1 (1) 持油力(Oil holding capacity,OHC):分别称取3种PPSP 0.5 g(m1)在质量为m2的离心管中,加入30 mL菜籽油后进行振荡,混合均匀后在室温下静置6 h,然后在4000 r/min离心10 min,倒去上层油后进行称重(m3),根据公式(2)进行计算。

OHC(g⋅g−1)=m3−(m1+m2)m1 (2) 膨胀力(Swelling force,SC):分别称取1.0 g(m)3种PPSP于10 mL量筒中,读取此时的体积(V1),再加入8 mL蒸馏水后进行振荡,混合均匀后在室温下静置24 h后读取体积(V2)。根据下列公式计算SC:

SC(mL⋅g−1)=V2−V1m (3) 1.2.2.3 滑角和休止角测定

滑角:参考史早等[11]的方法并加以改动,在放置在水平桌面上的玻璃板上放称取好的3.0 g样品,缓慢倾斜玻璃板,粉体表面开始滑动时停止,记录此时玻璃板与水平面所成的角度。

休止角:参考王阳等[12]的方法,将玻璃漏斗固定于铁架台上,保持垂直,漏斗下端距离坐标纸的高度(H)为3.0 cm。将不同干燥方式处理的PPSP缓慢倒入漏斗中,粉末自然下落,当粉末锥体顶端刚好接触到漏斗下端时停止倒入,读取锥体直径2R(cm),根据下列公式计算休止角:

休止角(°)=arctanHR (4) 1.2.2.4 色度测定

用色差仪测定PPSP的色度,开机进行黑白校正,校正后分别测定3组样品的L*、a*和b*值,其中L*表示明亮度;a*表示红绿色度;b*表示黄蓝色度。以HAD样品作为标准对照品,按下式计算样品的色差(∆E)。∆E<1.5表示颜色与未处理组差异小;1.5≤∆E≤3.0表示差异明显;∆E >3.0表示差异极显著。

ΔE=√(L∗−L∗0)2+(a∗−a∗0)2+(b∗−b∗0)2 (5) 式中:∆E表示不同干燥方式处理所得PPSP的色差;L0*、a0*、b0*表示标准对照组值;L*、a*、b*表示不同干燥方式处理组值。

1.2.2.5 热重分析

使用同步热分析仪分别对4~6 mg不同干燥方式处理制备的PPSP进行热重分析,采用热重法(TG)和微分热重分析法(DTG)测定样品的热力学性质。测量条件:充N2,升温速率:10 ℃/min,测定范围:室温至600 ℃。

1.2.3 PPSP结构的测定

1.2.3.1 红外光谱分析

分别取2 mg不同干燥方式处理的PPSP在玛瑙研钵中,然后加入200 mg充分干燥的KBr粉末,研磨均匀并压片,将制备好的薄片在400~4000 cm−1范围内扫描,分辨率为4 cm−1。扫描次数为32次。

1.2.3.2 X-射线衍射分析

在样品槽中分别放入适量不同干燥方式下的样品,压实后将样品槽插入仪器测定。测定参数为:Cu-Kα靶,角度步长0.02°,工作电压40 kV,电流40 mA,扫描范围5~60°,扫描频率6°/min。

1.2.3.3 微观结构观察

固定不同干燥方式处理的PPSP后进行镀金,然后在扫描电镜下观察。电压:15 kV,放大倍数:1000倍。

1.3 数据处理

每组试验至少重复3次;数据用Excel 2019进行处理,结果采用x±s表示;用Origin 8.1进行绘图;用SPSS 20.0进行差异显著性分析,P<0.05为差异显著。

2. 结果与分析

2.1 不同干燥方式对PPSP理化性质的影响

2.1.1 营养成分

营养成分是评价食品营养价值和应用前景的重要指标[13]。由表1可知,HAD和SD的PPSP样品水分含量无显著性差异(P>0.05),而LVD样品水分含量最低,仅为5.95%,与其他2种干燥方法相比差异显著(P<0.05)。LVD样品的蛋白质、不溶性膳食纤维以及灰分含量均显著高于其他2种干燥方式(P<0.05),分别达25.11%、37.06%和9.08%。3种毛竹笋干制品中可溶性膳食纤维含量为4.09%~5.79%,HAD可溶性膳食纤维含量最高,其次为SD,含量最低的为LVD。3组PPSP样品中脂肪含量都较低,为2.14%~3.32%,说明PPSP是一种低脂产品。3组样品中总糖含量为9.27%~10.36%,从大到小依次为LVD>HAD>SD,可能是因为LVD过程处于低温真空环境下,美拉德反应程度小,总糖损失最少,而HAD与SD相比,干燥温度较低,降低了美拉德反应程度,故HAD所得PPSP总糖含量高于SD样品。综上,经不同干燥方式处理所得的PPSP营养成分存在一定差异,在本研究的3种干燥方式中,LVD相对其余2种干燥方式而言脱水效果更优,在营养成分的保持上也表现出明显优势。刘贵阁等[14]研究发现经LVD处理的黄桃果粉的营养物质含量保留较多,与本研究结果一致。

表 1 不同干燥方式对PPSP营养成分的影响Table 1. Effects of different drying methods on nutrient composition of PPSP样品 水分(%) 蛋白质(%) 不溶性膳食纤维(%) 可溶性膳食纤维(%) 灰分(%) 脂肪(%) 总糖(%) HAD 8.13±0.06a 23.18±0.34c 35.42±0.21b 5.79±0.05a 8.86±0.07b 2.14±0.03c 9.50±0.17b LVD 5.95±0.06b 25.11±0.23a 37.06±0.37a 4.09±0.10c 9.08±0.10a 3.03±0.07b 10.36±0.20a SD 8.03±0.06a 24.41±0.18b 34.56±0.14c 4.90±0.07b 8.77±0.05b 3.32±0.05a 9.23±0.04c 注:同列不同小写字母表示差异显著(P<0.05),表2~表3同。 2.1.2 持水力、持油力和膨胀力

持水力和膨胀力是衡量粉体促进肠道蠕动,预防便秘、肠癌等生理功能的重要物理指标[15−16],较高的持油力对油脂吸附能力较强,具有降血脂的功效[17],表2为不同干燥方式对PPSP持水力、持油力和膨胀力的影响。由表可知,经不同干燥方式处理后,各样品组的持水力和持油力有显著差异(P<0.05),HAD组样品的持水力和持油力显著大于其余2种干燥方式(P<0.05),分别达到4.10 g/g和1.91 g/g,其次为LVD样品,SD制备的PPSP最小。这可能是因为HAD样品膳食纤维总量较高,尤其是可溶性膳食纤维含量显著高于其他2组样品(P<0.05),其纤维网状结构提升了粉体对水和油的束缚力[18]。SD制备的PPSP膨胀力显著大于其余2种干燥方式,这可能是因为SD干燥处理后粒子间的静电排斥作用和位阻效应增大,组织结构较为疏松,膨胀力增大[19]。

表 2 不同干燥方式对PPSP持水力、持油力和膨胀力的影响Table 2. Effects of different drying methods on water holding, oil holding and expansion of PPSP样品 持水力(g/g) 持油力(g/g) 膨胀力(mL/g) HAD 4.10±0.07a 1.91±0.04a 3.07±0.09c LVD 3.47±0.05b 1.65±0.02b 3.40±0.05b SD 3.19±0.04c 1.54±0.03c 3.85±0.12a 2.1.3 滑角和休止角

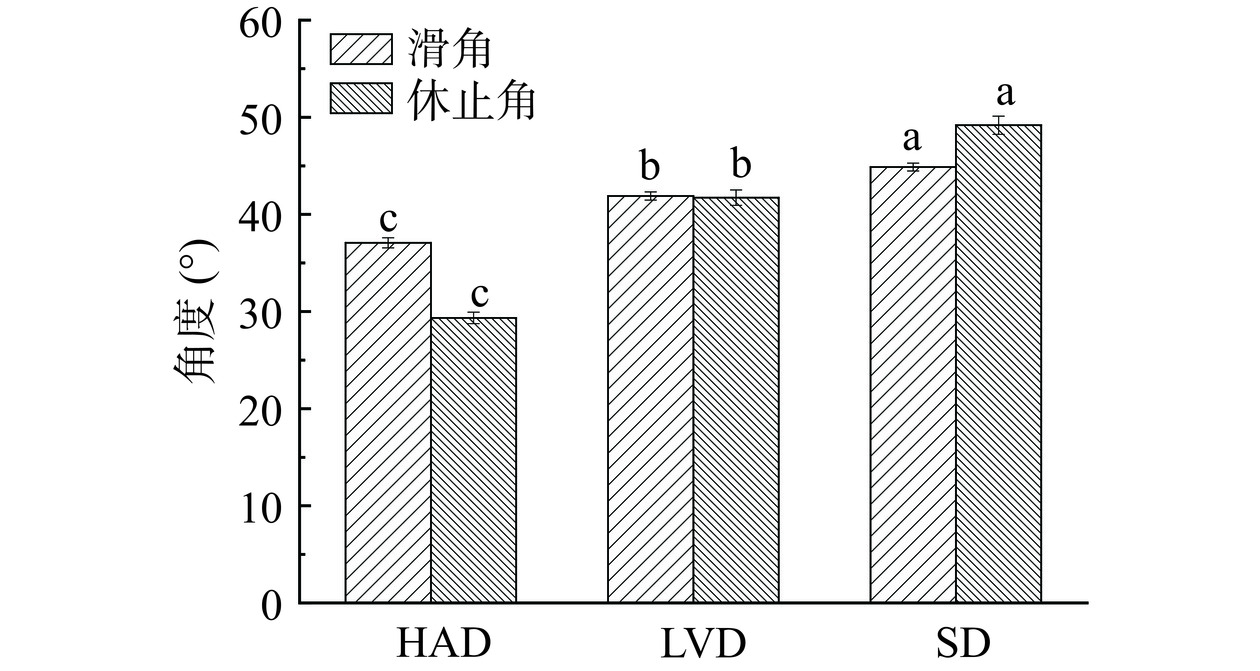

滑角和休止角是两项用来表征粉体流动性能的重要指标[20]。不同干燥方式对PPSP滑角和休止角的影响如图1所示,不同干燥方式的PPSP的滑角和休止角均存在显著性差异(P<0.05)。其中,SD样品的滑角和休止角最大,其次为LVD样品,HAD制备的PPSP滑角和休止角最小,分别为37.07°、29.35°,流动性最好。这可能是由于经SD处理后,PPSP粒径较小,比表面积大,营养物质溶出程度较高,使得粉体与玻璃板之间的粘着力增强,休角和滑止角增大[21]。

2.1.4 色度

色度是衡量竹笋品质的重要指标。图2是不同干燥方式处理后PPSP的外观颜色图,由图2可知,不同干燥方式处理的PPSP存在肉眼可辨的色差,HAD样品呈棕黄色,LVD的粉体则较为明亮,呈淡黄色,SD制备的PPSP呈金黄色。3组样品的色度值如表3所示。由表3可知,L*值由小到大依次是:HAD、SD、LVD,各组之间存在显著差异(P<0.05);3种干燥方式的a*值均为正数,其中HAD组最大,为5.96,LVD组最小,为3.74;b*值越大,样品的颜色越黄,b*值从大到小依次为SD>HAD>LVD,分别为21.71、19.26、14.50,各组间差异显著。HAD组的亮度L*值、绿色a*值均最高,其色度表现较佳,但黄色b*值位于第二,颜色偏黄,这与图2结果一致,可能是由于其干燥温度高,且加工时间较长,与热空气接触充分,进而褐变程度严重[22]。色差ΔE表示与HAD组的颜色差距程度,ΔE越小表明颜色差距越小。LVD粉和SD粉的样品色差值均大于3.0,表明这2种干燥方式所得PPSP与HAD组颜色差异显著(P<0.05),且LVD>SD。综上,不同干燥方式对PPSP的色度具有显著影响,适宜的干燥方式可以在一定程度上改善PPSP偏黄偏暗、颜色不均等问题。

表 3 不同干燥方式对PPSP色度的影响Table 3. Effects of different drying methods on chromance of PPSP样品 L* a* b* ΔE HAD 73.14±0.11c 5.96±0.08a 19.26±0.10b − LVD 77.32±0.09a 3.74±0.05c 14.50±0.07c 8.25±0.17a SD 75.26±0.09b 5.11±0.06b 21.71±0.03a 3.33±0.06b 2.1.5 热重分析

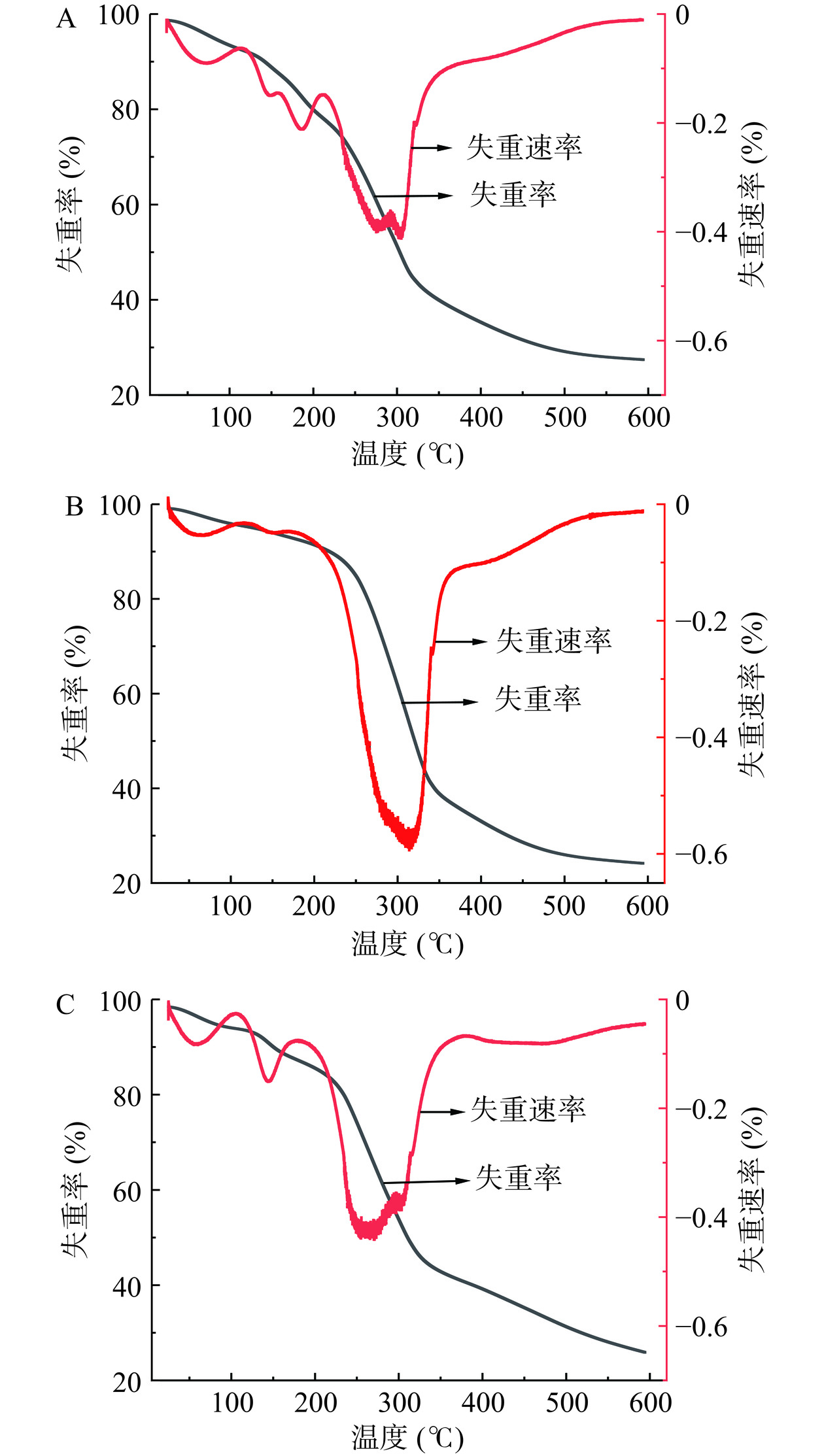

热重分析是衡量粉体热稳定性的重要方法,在升温过程中,粉体由于温度升高而发生物理或化学变化,从而使质量发生变化。图3是不同干燥方式PPSP热重分析图。由图3可知,3组PPSP的热分解过程均包括3个阶段。第1阶段温度为100~170 ℃,该阶段PPSP主要失去自由水、结晶水以及小分子碳氢化合物[23−24],150 ℃达到最大失重速率。在此阶段,HAD和SD样品的失重速率均出现两个明显的峰,而LVD制备的PPSP则较为平缓,这可能与样品含水量有关,LVD样品含水量为5.95%,显著低于HAD和SD组样品,而后两者含水量未见明显差异。第2个失重阶段,即热分解的主要阶段,温度范围在200~400 ℃。在这个阶段,PPSP的失重率和失重速率显著上升,这是因为毛竹笋全粉的主要组成成分,如纤维素、半纤维素和木质素开始分解,同时蛋白质也在高温下分解。在290 ℃左右,各组样品都出现了一个明显的峰值,这可能是因为干燥后PPSP颗粒尺寸减小,表面积增大,分解速率加快。在400 ℃后热分解较为平缓,少量木质素和热解残余物在此阶段缓慢分解,产生碳和灰分。

2.2 不同干燥方式对PPSP结构的影响

2.2.1 红外光谱分析

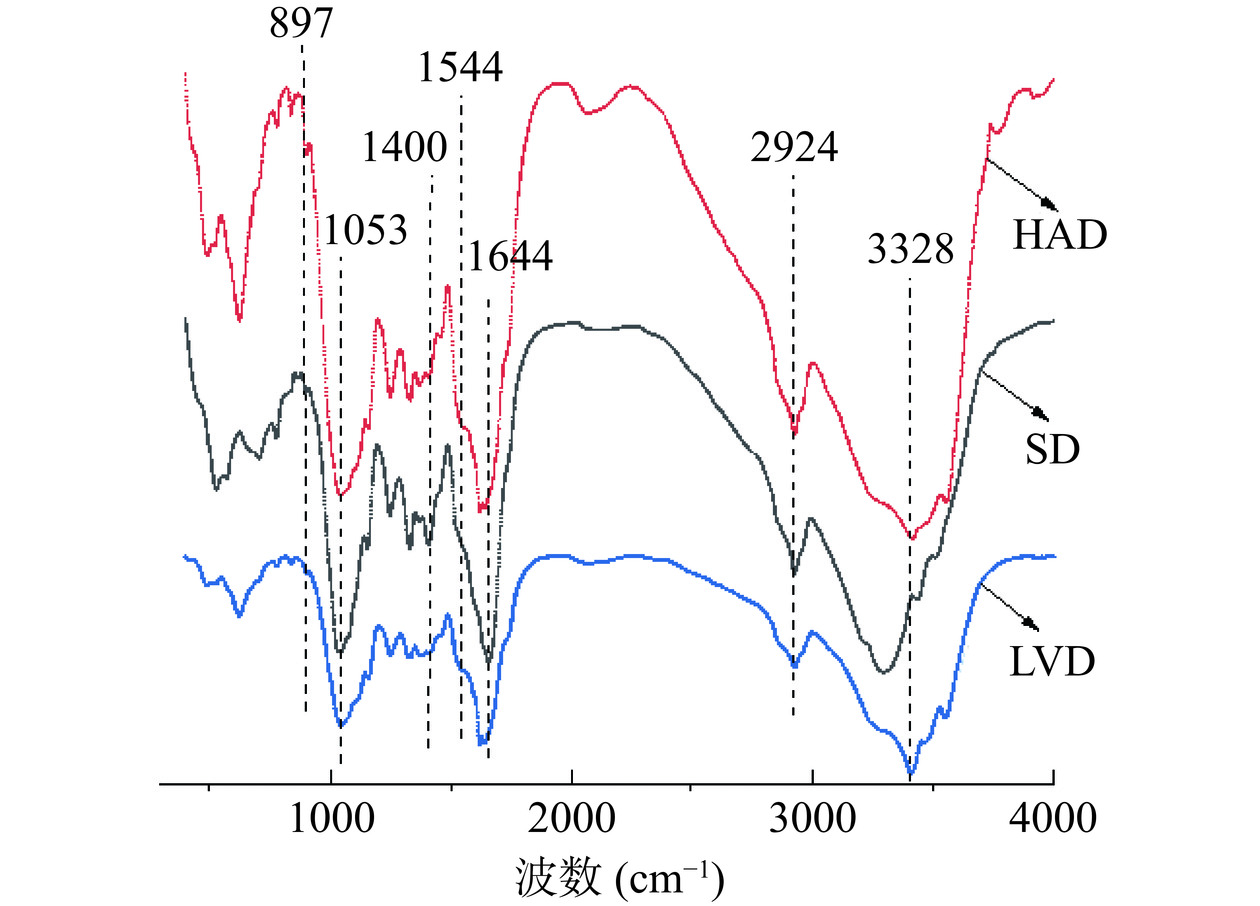

红外光谱中吸收峰位置及强度的变化与原子振动频率及其化学组成、化学键类型有着密切的关系[25]。不同干燥方式PPSP红外光谱如图4所示。经不同干燥方式处理后,PPSP的峰位置和形状基本一致,只是强度出现差异,说明不同干燥方式对PPSP的官能团并无显著影响。在波长3100~3330 cm−1处,各组样品都表现一个明显的吸收峰,这是纤维素或半纤维素的O-H的伸缩振动产生的[26]。其中,LVD组样品吸收峰最为尖锐,峰强度最强,这与部分糖苷键的断裂及氢键之间作用力的增强有关。2924 cm−1处的吸收峰是由糖类亚甲基上的C-H的收缩振动引起的[20];1644 cm−1处的吸收峰来源于酯化的C=O的非对称伸缩振动[24,27],说明PPSP中含有醛基或羧基;1544 cm−1是仲酰胺基的酰胺Ⅱ吸收带[20];在1400 cm−1处的吸收峰是由N-H的弯曲振动引发的,可能与木质素中的苯环拉伸或特征弯曲相关[24,28];1053 cm−1处的强吸收峰源于纤维素、半纤维素中的C-O的伸缩振动,以及O-H的变角振动形成糖环C-O-C和C-O-H [29];在897 cm−1处,存在β-吡喃糖C-H变角的振动吸收峰,说明不同干燥方式处理的PPSP中均含有β-吡喃糖[30]。

2.2.2 X-射线衍射分析

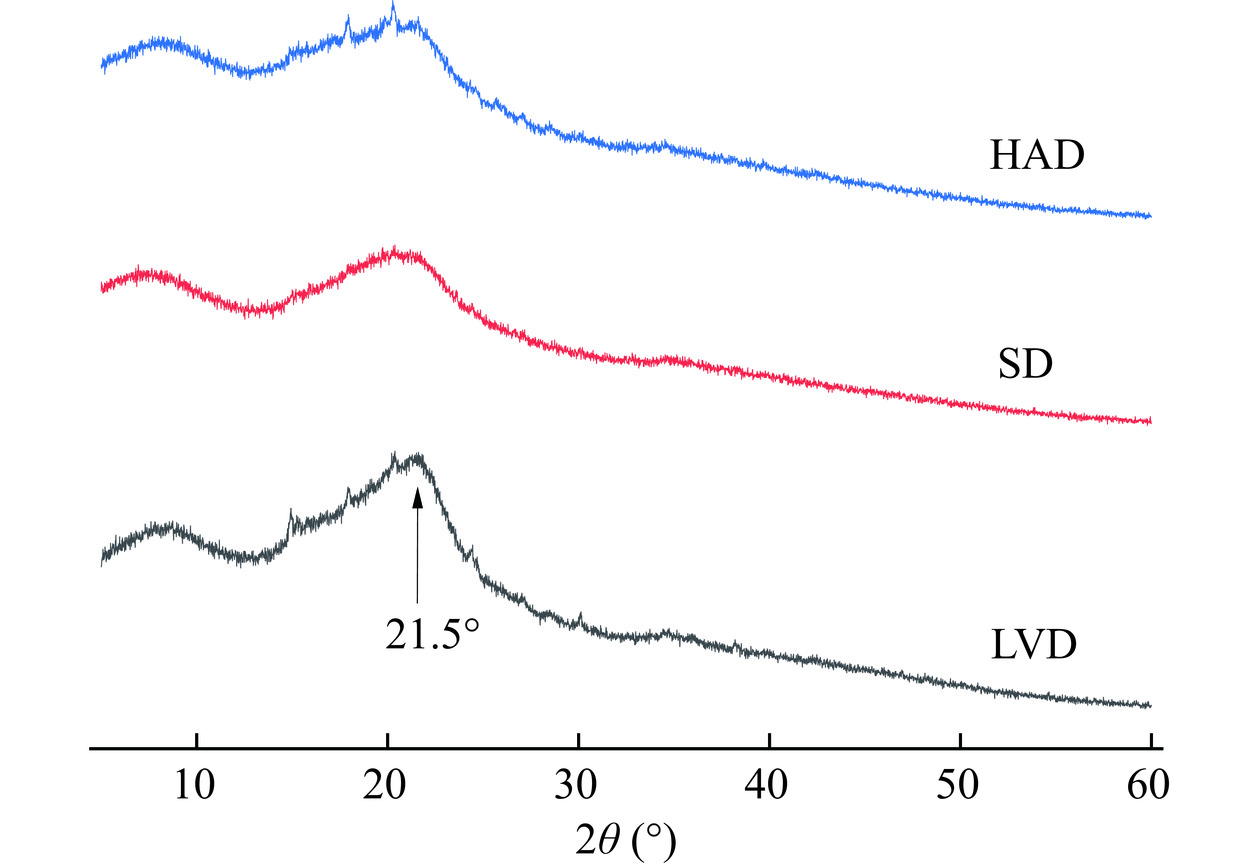

X-射线衍射分析可以用来分析粉体的晶体结构特性,不同干燥方式下的PPSP的X-射线衍射如图5所示。由图可知,3种PPSP的X射线衍射图形状及衍射峰的位置相似,PPSP的晶体结构未发生改变。各组均在21.5°有显著的衍射峰,表明PPSP呈典型的纤维素和半纤维素晶体结构,且HAD和SD样品的峰强度低于LVD组,说明HAD和SD的PPSP结晶度较小。纤维类样品中存在结晶区和非结晶区,结晶区结构紧密,分子取向较好,非结晶区氢键结合量少,分子排列杂乱无序。HAD和SD干燥过程中可能使连接纤维素分子的氢键断裂,内部结构被破坏而变得松散,部分结晶区发生转化,最终成为无序的非结晶区,从而导致PPSP结晶度减小,晶体有序度下降[30]。

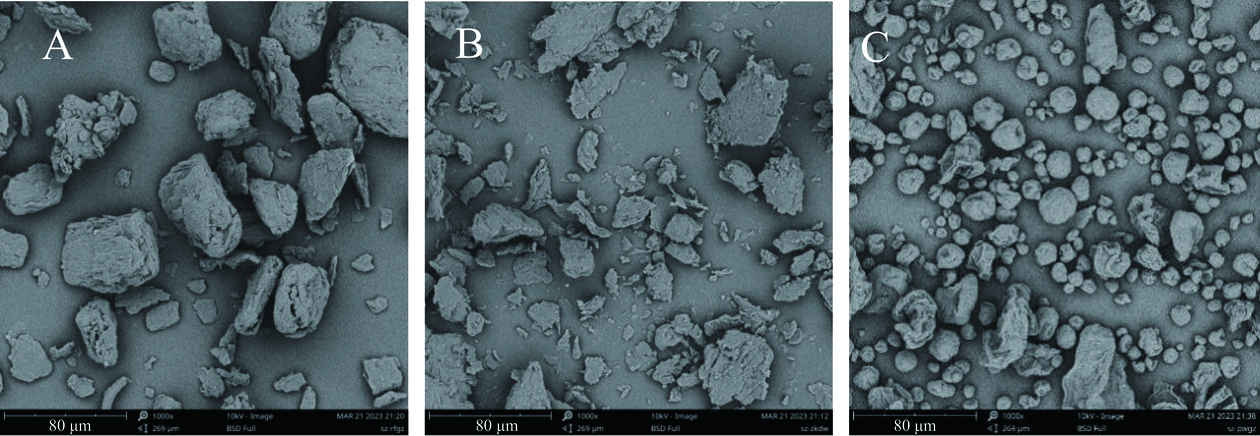

2.2.3 扫描电子显微镜形态观察

扫描电子显微镜观察能够反映粉体微观结构和形态。图6是不同干燥方式PPSP扫描电子显微镜形态观察图(放大1000倍)。由图可知,经不同干燥方式处理后样品表面微观结构差异显著,HAD的颗粒较大且形状不一,呈现出部分椭球形结构,且表面较为粗糙、有少量裂隙,主要是因为长时间热风的影响使得物料表面发生皱变。LVD较HAD样品颗粒有所减小,并且能观察到拥有较多较小的颗粒碎片。SD样品颗粒为球体状,尺寸较小且分布均匀,颗粒之间空隙大小适中,这与大多数SD物料结构相似,这是因为喷雾干燥雾化器喷出细小的液滴在热风作用下,失水形成均匀球形粉体,使得物料呈现出较为规则的小颗粒结构[31]。扫描电镜结果进一步证实了干燥方式对PPSP微观形态具有显著影响,对于粉体表面结构的破坏程度也具有显著差异。

3. 结论

干燥方式对PPSP的营养成分、持水力、持油力、膨胀力、色度等理化性质均有显著影响。其中,LVD样品的蛋白质、不溶性膳食纤维、灰分、总糖含量均显著高于其他两组,在营养成分的保持上表现出明显优势;SD和LVD制备的PPSP膨胀力表现良好,分别达到3.85和3.40 mL/g,但其持水力和持油力表现较差,滑角与休止角显著高于HAD样品(P<0.05);LVD的PPSP色泽更为明亮,L*值为77.32,显著高于SD和HAD样品(P<0.05),且其a*值和b*值最低;SD和LVD显著降低了样品的热稳定性。干燥方式未改变PPSP的基本结构、官能团及晶体结构,SD制备的PPSP颗粒尺寸显著减小,分布更为均匀。综合分析而言,LVD可以使毛竹笋保持较好的营养、色泽、膨胀力等理化特性,其次表现较好的SD。因此,LVD和SD是制备高品质PPSP的有效方式。研究结果可为毛竹笋适宜干燥方式的选择及高品质PPSP的制备提供理论依据。

-

表 1 不同干燥方式对PPSP营养成分的影响

Table 1 Effects of different drying methods on nutrient composition of PPSP

样品 水分(%) 蛋白质(%) 不溶性膳食纤维(%) 可溶性膳食纤维(%) 灰分(%) 脂肪(%) 总糖(%) HAD 8.13±0.06a 23.18±0.34c 35.42±0.21b 5.79±0.05a 8.86±0.07b 2.14±0.03c 9.50±0.17b LVD 5.95±0.06b 25.11±0.23a 37.06±0.37a 4.09±0.10c 9.08±0.10a 3.03±0.07b 10.36±0.20a SD 8.03±0.06a 24.41±0.18b 34.56±0.14c 4.90±0.07b 8.77±0.05b 3.32±0.05a 9.23±0.04c 注:同列不同小写字母表示差异显著(P<0.05),表2~表3同。 表 2 不同干燥方式对PPSP持水力、持油力和膨胀力的影响

Table 2 Effects of different drying methods on water holding, oil holding and expansion of PPSP

样品 持水力(g/g) 持油力(g/g) 膨胀力(mL/g) HAD 4.10±0.07a 1.91±0.04a 3.07±0.09c LVD 3.47±0.05b 1.65±0.02b 3.40±0.05b SD 3.19±0.04c 1.54±0.03c 3.85±0.12a 表 3 不同干燥方式对PPSP色度的影响

Table 3 Effects of different drying methods on chromance of PPSP

样品 L* a* b* ΔE HAD 73.14±0.11c 5.96±0.08a 19.26±0.10b − LVD 77.32±0.09a 3.74±0.05c 14.50±0.07c 8.25±0.17a SD 75.26±0.09b 5.11±0.06b 21.71±0.03a 3.33±0.06b -

[1] 汪楠, 张甫生, 阚建全, 等. 不同解冻方式对速冻方竹笋品质的影响[J]. 食品科学,2022,43(11):180−185. [WANG N, ZHANG F S, KAN J Q, et al. Effects of different thawing methods on the quality of quick-frozen square bamboo shoots[J]. Food Science,2022,43(11):180−185.] doi: 10.7506/spkx1002-6630-20210602-030 WANG N, ZHANG F S, KAN J Q, et al. Effects of different thawing methods on the quality of quick-frozen square bamboo shoots[J]. Food Science, 2022, 43(11): 180−185. doi: 10.7506/spkx1002-6630-20210602-030

[2] SANTOSH S, BAL L M, POONAM S, et al. Bamboo shoot processing:food quality and safety aspect[J]. Trends in Food Science & Technology,2010,21(4):181−189.

[3] 耿想. 干燥方式对毛竹笋品质的影响研究[D]. 北京:中国林业科学研究院, 2021. [GENG X. Effect of drying method on quality of hairy bamboo shoots[D]. Beijing:Chinese Academy of Forestry, 2021.] GENG X. Effect of drying method on quality of hairy bamboo shoots[D]. Beijing: Chinese Academy of Forestry, 2021.

[4] 蒋小雅, 郑炯. 竹笋干燥技术及其对竹笋品质的影响[J]. 食品与发酵工业,2016,42(6):260−264. [JIANG X Y, ZHENG J. Research advances in drying technology and its impact on the quality of bamboo shoots[J]. Food and Fermentation Industries,2016,42(6):260−264.] JIANG X Y, ZHENG J. Research advances in drying technology and its impact on the quality of bamboo shoots[J]. Food and Fermentation Industries, 2016, 42(6): 260−264.

[5] SAGAR V R, SURESH K P. Recent advances in drying and dehydration of fruits and vegetable[J]. Journal of Food Science and Technology,2010,47(1):15−26. doi: 10.1007/s13197-010-0010-8

[6] 李艳艳, 廖雪勤, 程诗涵, 等. 方竹笋全粉酥性饼干制作工艺优化及品质分析[J]. 食品工业科技,2023,44(15):238−247. [LI Y Y, LIAO X Q, CHENG S H, et al. Processing technology optimization and quality analysis of Chimonobambusa quadrangularis shoot powder crisp biscuits[J]. Science and Technology of Food Industry,2023,44(15):238−247.] LI Y Y, LIAO X Q, CHENG S H, et al. Processing technology optimization and quality analysis of Chimonobambusa quadrangularis shoot powder crisp biscuits[J]. Science and Technology of Food Industry, 2023, 44(15): 238−247.

[7] 岳天义, 杨萍, 许青莲, 等. 不同干燥方式对茄子理化性质的影响[J]. 食品研究与开发,2022,43(23):48−54. [YUE T Y, YANG P, XU Q L, et al. Effects of different drying methods on physicochemical properties of eggplant[J]. Food Research and Development,2022,43(23):48−54.] doi: 10.12161/j.issn.1005-6521.2022.23.007 YUE T Y, YANG P, XU Q L, et al. Effects of different drying methods on physicochemical properties of eggplant[J]. Food Research and Development, 2022, 43(23): 48−54. doi: 10.12161/j.issn.1005-6521.2022.23.007

[8] 葛邦国, 高玲. 不同干燥方式对南瓜粉品质的影响[J]. 中国果菜,2019,39(6):1−6. [GE B G, GAO L. Effects of different drying methods on the quality of pumpkin powder[J]. Chinese fruit and vegetable,2019,39(6):1−6.] GE B G, GAO L. Effects of different drying methods on the quality of pumpkin powder[J]. Chinese fruit and vegetable, 2019, 39(6): 1−6.

[9] 张耀雷, 黄立新, 张彩虹, 等. 不同干燥方式对壶瓶枣粉品质的影响[J]. 食品工业科技,2016,37(1):76−79,85. [ZHANG Y L, HUANG L X, ZHANG C H, et al. Effects of different drying methods on the quality of Ziziphus jujube Mill. cv. Hupingzao[J]. Science and Technology of Food Industry,2016,37(1):76−79,85.] doi: 10.1590/1678-457x.07716 ZHANG Y L, HUANG L X, ZHANG C H, et al. Effects of different drying methods on the quality of Ziziphus jujube Mill. cv. Hupingzao[J]. Science and Technology of Food Industry, 2016, 37(1): 76−79,85. doi: 10.1590/1678-457x.07716

[10] 汤彩碟, 张甫生, 杨金来, 等. 机械球磨处理对方竹笋全粉理化特性及微观结构的影响[J]. 食品与发酵工业,2022,48(12):175−182. [TANG C D, ZHANG F S, YANG J L, et al. Effects of mechanical ball milling on physicochemical properties and microstructure of bamboo shoot powder[J]. Food and Fermentation Industry,2022,48(12):175−182.] TANG C D, ZHANG F S, YANG J L, et al. Effects of mechanical ball milling on physicochemical properties and microstructure of bamboo shoot powder[J]. Food and Fermentation Industry, 2022, 48(12): 175−182.

[11] 史早, 张甫生, 杨金来, 等. 超微粉碎对方竹笋全粉理化特性及微观结构的影响[J]. 食品工业科技,2021,42(24):40−47. [SHI Z, ZHANG F S, YANG J L, et al. Effects of ultrafine grinding on physicochemical properties and microstructure of bamboo shoot powder[J]. Science and Technology of Food Industry,2021,42(24):40−47.] SHI Z, ZHANG F S, YANG J L, et al. Effects of ultrafine grinding on physicochemical properties and microstructure of bamboo shoot powder[J]. Science and Technology of Food Industry, 2021, 42(24): 40−47.

[12] 王阳, 颜才植, 叶发银, 等. 膳食纤维粉体流动性与其颗粒结构的关系[J]. 食品科学,2018,39(10):84−88. [WANG Y, YAN C Z, YE F Y, et al. Relationship between flowability and particle structure of dietary fiber powders[J]. Food Science,2018,39(10):84−88.] doi: 10.7506/spkx1002-6630-201810014 WANG Y, YAN C Z, YE F Y, et al. Relationship between flowability and particle structure of dietary fiber powders[J]. Food Science, 2018, 39(10): 84−88. doi: 10.7506/spkx1002-6630-201810014

[13] 汤彩云. 富集γ-氨基丁酸桑叶粉制备与产品开发研究[D]. 镇江:江苏科技大学, 2020. [TANG C Y. Preparation and product development of γ-aminobutyric acid enriched Mulberry leaf powder[D]. Zhenjiang:Jiangsu University of Science and Technology, 2020.] TANG C Y. Preparation and product development of γ-aminobutyric acid enriched Mulberry leaf powder[D]. Zhenjiang: Jiangsu University of Science and Technology, 2020.

[14] 刘贵阁, 乔勇进, 陈冰洁, 等. 不同干燥方式对黄桃果粉品质的影响[J]. 浙江农业学报,2023,35(10):2456−2464. [LIU G G, QIAO Y J, CHEN B J, et al. Effect of drying methods on quality of yellow peach powder[J]. Acta Agriculturae Zhejiangensis,2023,35(10):2456−2464.] LIU G G, QIAO Y J, CHEN B J, et al. Effect of drying methods on quality of yellow peach powder[J]. Acta Agriculturae Zhejiangensis, 2023, 35(10): 2456−2464.

[15] WU Bengang, QIU Chengcheng, GUO Yiting, et al. Comparative evaluation of physicochemical properties, microstructure, and antioxidant activity of jujube polysaccharides subjected to hot air, infrared, radio frequency, and freeze drying[J]. Agriculture,2022,12(10):1606. doi: 10.3390/agriculture12101606

[16] 蒋丽娜, 张秀清, 裴海生, 等. 超微粉碎对花椒籽粉品质特性的影响[J/OL]. 食品工业科技: 1−13[2023-11-23]. DOI:10.13386/j.issn1002-0306.2023040017. [JIANG L N, ZHANG X Q, PEI H S, et al. The effect of superfine grinding technology on the quality characteristics of Zanthoxylum bungeanum seed powder [J/OL]. Science and Technology of Food Industry: 1−13[2023-11-23]. DOI:10.13386/j.issn1002-0306.2023040017.] JIANG L N, ZHANG X Q, PEI H S, et al. The effect of superfine grinding technology on the quality characteristics of Zanthoxylum bungeanum seed powder [J/OL]. Science and Technology of Food Industry: 1−13[2023-11-23]. DOI: 10.13386/j.issn1002-0306.2023040017.

[17] 易建华, 张志婕, 朱振宝, 等. 不同粒径对黑米粉理化性质的影响[J]. 陕西科技大学学报, 2021, 39(1):39−44. [YI J H, ZHANG Z J, ZHU Z B, et al. Impact of different grain sizes on physicochemical properties of black rice powder[J]. Journal of Shaanxi University of Science & Technology, 2021, 39(1):39−44.] YI J H, ZHANG Z J, ZHU Z B, et al. Impact of different grain sizes on physicochemical properties of black rice powder[J]. Journal of Shaanxi University of Science & Technology, 2021, 39(1): 39−44.

[18] 张益嘉, 张甫生, 李彬, 等. 单甘酯对高压均质处理竹笋膳食纤维理化及结构特性的影响[J]. 食品与发酵工业,2023,49(15):180−186. [ZHANG Y J, ZHANG F S, LI B, et al. Effect of glyceryl monostearate on physicochemical and structural properties of dietary fiber from bamboo shoots treated with high-pressure homogenization[J]. Food and Fermentation Industries,2023,49(15):180−186.] ZHANG Y J, ZHANG F S, LI B, et al. Effect of glyceryl monostearate on physicochemical and structural properties of dietary fiber from bamboo shoots treated with high-pressure homogenization[J]. Food and Fermentation Industries, 2023, 49(15): 180−186.

[19] 赵萌萌, 党斌, 张文刚, 等. 超微粉碎对青稞麸皮粉微观结构及功能特性的影响[J]. 农业工程学报,2020,36(8):278−286. [ZHAO M M, DANG B, ZHANG W G, et al. Effects of ultrafine crushing on microstructure and functional properties of highland barley bran powder[J]. Transactions of the Chinese Society of Agricultural Engineering,2020,36(8):278−286.] doi: 10.11975/j.issn.1002-6819.2020.08.034 ZHAO M M, DANG B, ZHANG W G, et al. Effects of ultrafine crushing on microstructure and functional properties of highland barley bran powder[J]. Transactions of the Chinese Society of Agricultural Engineering, 2020, 36(8): 278−286. doi: 10.11975/j.issn.1002-6819.2020.08.034

[20] 寇福兵. 超微粉碎板栗粉理化性质及其对面条加工特性的影响[D]. 重庆:西南大学, 2022. [KOU F B. Study on Physicochemical properties of superfine grinding chestnut powder and its effect on noodle processing characteristics[D]. Chongqing:Southwest University, 2022.] KOU F B. Study on Physicochemical properties of superfine grinding chestnut powder and its effect on noodle processing characteristics[D]. Chongqing: Southwest University, 2022.

[21] ANTONIO G, KARINA D S, KATIA R, et al. Effect of air-drying temperature on physico-chemical properties, antioxidant capacity, colour and total phenolic content of red pepper[J]. Food Chemistry,2009,117(4):647−653. doi: 10.1016/j.foodchem.2009.04.066

[22] 董文成. 柑橘果实膳食纤维物化特性及其性能表征研究[D]. 杭州:浙江大学, 2015. [DONG W C. Study on the physicochemical properties and characteristics of citrus fruit dietary fiber[D]. Hangzhou:Zhejiang University, 2015.] DONG W C. Study on the physicochemical properties and characteristics of citrus fruit dietary fiber[D]. Hangzhou: Zhejiang University, 2015.

[23] 李璐, 黄亮, 苏玉, 等. 超微化雷竹笋膳食纤维的结构表征及其功能特性[J]. 食品科学,2019,40(7):74−81. [LI L, HUANG L, SU Y, et al. Structural characterization and functional properties of ultrafine dietary fiber from Phyllostachys praecox[J]. Food Science,2019,40(7):74−81.] doi: 10.7506/spkx1002-6630-20180306-069 LI L, HUANG L, SU Y, et al. Structural characterization and functional properties of ultrafine dietary fiber from Phyllostachys praecox[J]. Food Science, 2019, 40(7): 74−81. doi: 10.7506/spkx1002-6630-20180306-069

[24] YAN Xiaoguang, YE Ran, CHEN Ye. Blasting extrusion processing:The increase of soluble dietary fiber content and extraction of soluble-fiber polysaccharides from wheat bran[J]. Food Chemistry,2015,180:106−115. doi: 10.1016/j.foodchem.2015.01.127

[25] 汤彩碟, 张甫生, 杨金来, 等. 动态高压微射流处理对方竹笋膳食纤维理化及结构特性的影响[J]. 食品与机械,2021,37(6):24−29. [TANG C D, ZHANG F S, YANG J L, et al. Effects of dynamic high-pressure micro-fluidization treatment on physicochemical and structural properties of square bamboo shoots dietary fiber[J]. Food & Machinery,2021,37(6):24−29.] TANG C D, ZHANG F S, YANG J L, et al. Effects of dynamic high-pressure micro-fluidization treatment on physicochemical and structural properties of square bamboo shoots dietary fiber[J]. Food & Machinery, 2021, 37(6): 24−29.

[26] CHANG S C, HSU B Y, CHEN B H. Structural characterization of polysaccharides from Zizyphusjujuba and evaluation of antioxidant activity[J]. International Journal of Biological Macromolecules,2010,47(4):445−453. doi: 10.1016/j.ijbiomac.2010.06.010

[27] SONI B, HASSAN E B, MAHMOUD B. Chemical isolation and characterization of different cellulose nanofibers from cotton stalks[J]. Carbohydrate Polymers,2015,134(10):581−589.

[28] 汪楠, 黄山, 张月, 等. 高温蒸煮协同纤维素酶改性竹笋膳食纤维[J]. 食品与发酵工业,2020,46(4):13−18. [WANG N, HUANG S, ZHANG Y, et al. Modification of bamboo shoot dietary fiber by high temperature cooking combined with cellulase[J]. Food and Fermentation Industries,2020,46(4):13−18.] WANG N, HUANG S, ZHANG Y, et al. Modification of bamboo shoot dietary fiber by high temperature cooking combined with cellulase[J]. Food and Fermentation Industries, 2020, 46(4): 13−18.

[29] FAUSTINO M, PEREIRA C F, DURÃO J, et al. Effect of drying technology in Saccharomyces cerevisiae mannans:Structural, physicochemical, and functional properties[J]. Food Chemistry, 2023, 135545.

[30] 张慧娟, 靳程茗, 吕世豪, 等. 黑麦麸膳食纤维的结构和功能特性研究[J]. 中国食品学报,2023,23(8):84−93. [ZHANG H J, JIN C M, LÜ S H, et al. Studies on structure and functional characteristics of dietary fiber from rye bran[J]. Journal of Chinese Institute of Food Science and Technology,2023,23(8):84−93.] ZHANG H J, JIN C M, LÜ S H, et al. Studies on structure and functional characteristics of dietary fiber from rye bran[J]. Journal of Chinese Institute of Food Science and Technology, 2023, 23(8): 84−93.

[31] 马尧. 不同干燥方式对黄花菜粉品质影响及喷雾干燥工艺优化[D]. 银川:宁夏大学, 2022. [MA Y. Effect of different drying methods on quality of daylily powder and optimization of spray drying process[D]. Yinchuan:Ningxia University, 2022.] MA Y. Effect of different drying methods on quality of daylily powder and optimization of spray drying process[D]. Yinchuan: Ningxia University, 2022.

-

期刊类型引用(1)

1. 白俊露,曾军杰,何鹏飞,李佩佩. QuEChERS-超高效液相色谱串联质谱法同时检测水产品中11种四环素类药物. 浙江海洋大学学报(自然科学版). 2024(04): 335-345 .  百度学术

百度学术

其他类型引用(2)

下载:

下载:

下载:

下载: