Effects of Curing Time on the Edible Quality and Oxidation Characteristics of Complex Low-sodium Yak Meat

-

摘要: 为明确腌制时间对复合低钠酱牦牛肉制品食用品质及氧化特性的影响。本试验以低钠配方腌制不同时间(12、18、24、30、36 h)的酱牦牛肉制品为试验对象,测定分析其食用品质及氧化特性的变化。结果表明:延长腌制时间显著降低了低钠配方酱牦牛肉制品蒸煮损失(P<0.05),影响了腌制牦牛肉流变特性,改善了产品质构特性,提高了感官评分,但对pH、色泽并无明显影响;牦牛肉在腌制期间总肌红蛋白(Total myoglobin,TMb)、氧合肌红蛋白(Oxymyoglobin,OMb)整体呈下降趋势,高铁肌红蛋白(Methemoglobin,MMb)呈上升趋势;同时,相关性分析显示酱牦牛肉制品蒸煮损失与腌制时间呈显著负相关,而脂肪氧化和蛋白氧化与其呈显著正相关(P<0.05)。随着腌制时间的延长,脂肪氧化和蛋白氧化不断加重,表现为硫代巴比妥酸(Thiobarbituric acid reactive substances,TBARS)值、羰基含量、二聚酪氨酸含量显著增加,巯基含量显著减少(P<0.05)。综合各项指标数据可知,腌制时间为24 h时,产品感官评分最高(7.411)且质构特性较好,氧化程度较小,整体品质特性最佳。Abstract: In order to investigate the effect of curing time on the edible quality and oxidative characteristics of compound low-sodium yak meat products, in this experiment, complex low-sodium yak meat was selected to investigate the effects of curing time (12, 18, 24, 30 and 36 h) on the edible quality and oxidative characteristics. The results showed that prolonging the curing time significantly reduced the cooking loss (P<0.05), affected the energy storage modulus (G′) and loss modulus (G′′), and improved the textural characteristics of the products, but had no significant effect on the yield pH and color of the products; total myoglobin (TMb) and oxymyoglobin (OMb) showed an overall decreasing trend, and methemoglobin (MMb) showed an increasing trend during the curing period. Meanwhile, correlation analysis showed that the cooking loss of yak meat products in sauce was significantly negatively correlated with the curing time, and the fat oxidation and protein oxidation were significantly positively correlated with the curing time (P<0.05). With the extension of curing time, the oxidation of fat and protein were increased, which was manifested by a significant increase in the value of thiobarbituric acid reactive substances (TBARS), carbonyl content, dimerized tyrosine content, and a significant decrease in sulfhydryl content (P<0.05). In conclusion, the highest sensory score (7.411) and the best overall quality characteristics were obtained at 24 h of curing time with better textural characteristics and less oxidation.

-

Keywords:

- yak meat /

- complex low-sodium /

- curing time /

- edible quality /

- oxidation characteristics

-

牦牛肉营养丰富,高蛋白低脂肪,还富含人体必需的氨基酸和多不饱和脂肪酸[1],近年来逐渐受到消费者的青睐。酱牛肉是我国传统酱卤肉制品,其成品具有酱香浓郁、色泽诱人、口感爽弹等特点,深受消费者喜爱。

腌制是酱牛肉加工制作过程中极其重要的一环,经过腌制,牛肉变得柔嫩多汁,滋味鲜美。食盐是腌制液中最重要的成分,除了调味,还有助于提高肌肉中盐溶蛋白溶解度,增强蛋白质水合作用,从而改善肉制品嫩度和保水能力[2]。但现有研究认为,高钠盐会增加健康风险,如增加中风、高血压和心血管等疾病的患病率[3]。目前主要的减盐方式有:直接减少食盐添加量、添加风味改良剂、使用新型加工技术和使用钠盐替代物等[4]。其中,前三者都具有一定局限性,直接减少钠盐会对产品的风味和口感造成不利影响,风味改良剂无法弥补质构和口感的损失,而新型加工技术则存在成本高、处理量小等缺点。钠盐替代物便宜易得,既具有相当的咸味,也可起到改善质构,增加肉品嫩度和持水性的作用,因此部分替代钠盐被认为是最有潜力的减钠策略[5]。常用的钠盐替代物有金属氯盐(KCl、MgCl2等)、磷酸盐(焦磷酸钠、磷酸二钠、六偏磷酸钠、三聚磷酸钠等)、乳酸盐等[6]。除腌制液以外,腌制时间也是影响腌制效果的重要因素。腌制的本质是盐以及其他腌制液成分在肌肉中渗透和扩散的传质过程。长时间的腌制赋予了产品良好的风味和口感,但同时也增加了氧化变质的可能性。因此,寻找合适的腌制时间以达到风味和氧化水平的平衡对于产品至关重要。但由于原料肉、最终产品的种类以及腌制液配方不同,其最适腌制时间也不同。目前关于低钠腌制时间的研究多集中在猪肉、禽肉、海产品等肉类,涉及的产品多为腊肉、牛肉干、鱼片等干制品,品种较少,涉猎范围较窄[7−8],关于牦牛肉制品的研究鲜见报道,其最适腌制时间是未知的,且现有的关于低钠腌制的文献大多集中于优化低钠复合盐的比例,关于低钠腌制过程中肌肉氧化程度的报道较少,腌制过程中肌肉的品质变化和氧化程度以及二者的关系尚不明确。

本文采用复合低钠配方腌制,以腌制不同时间的牦牛肉为研究对象,通过测定其食用品质、脂质氧化和蛋白氧化等指标,并对酱牦牛肉制品进行感官评价,探究腌制时间对低钠牦牛肉食用品质和氧化特性的影响,以期为低钠酱牦牛肉制品的开发提供数据参考和理论支持。

1. 材料与方法

1.1 材料与仪器

牦牛前腿肉 采自四川广汉向阳江南屠宰场,选择饲养条件一致,2~4岁龄雄性牦牛3头,屠宰后1 h内取前腿肉,切分成块装入自封袋,每块约500 g,干冰覆盖带回实验室后置于−80 ℃;烧卤香辛料(含八角、小茴香、桂皮、草果、辣椒、香叶等) 购自四川成都双流邻里优选生鲜超市;氯化钠、氯化钾、焦磷酸钠 食品级,河南万邦实业有限公司;磷酸二氢钠、磷酸氢二钠、三氯乙酸、2-硫代巴比妥酸、盐酸胍 分析纯,成都市科隆化学品有限公司。

CL22Q1-405J多功能电磁炉 广东美的生活电器制造有限公司;雷磁PHS-3C型pH计 上海仪电科学仪器有限公司;CM-700D色差仪 柯尼卡美能达股份有限公司;XHF-D高速分散器 宁波新芝生物科技股份有限公司;Centrifuge 5804 R高速冷冻离心机 德国Eppendorf公司;V-1000紫外分光光度计 翱艺仪器上海有限公司;F-4700荧光分光光度计 日本株式会所日立高新技术科学那珂事业所。

1.2 实验方法

1.2.1 原料肉预处理

牦牛肉4 ℃解冻后,切分成5块6 cm×6 cm×2 cm的肉块,每块约100 g。根据预实验确定的腌制配方对牦牛肉进行注射,4 ℃分别腌制12、18、24、30、36 h。腌制液配方:牦牛肉100 g、复合盐3.2 g(60%NaCl、30%KCl、10%焦磷酸钠)、水30 g。

1.2.2 酱牦牛肉制作方法

锅中加入500 g牦牛肉、40 g酱油、20 g料酒、12 g糖、100 g甜面酱和50 g香辛料加水没过肉块,煮沸后再以小火煮制60 min,煮制完成后将肉块捞出沥干冷却用保鲜膜包装避光冷藏保存,24 h内测定。

1.2.3 食用品质指标

1.2.3.1 pH

参照GB 5009.237—2016《食品pH值的测定》[9],取3 g牦牛肉切碎,加入10倍体积的KCl溶液(0.1 mol/L)匀浆,静置30 min后测定pH。

1.2.3.2 色泽

将肉样表面的水分用滤纸擦干,采用手持色差仪测定样品表面的L*值、a*值和b*值,每份样品测定6次,结果取平均值。

1.2.3.3 肉色稳定性

参考柳艳霞等[10]的方法,略作修改。取 5.0 g 切碎的牦牛肉加入 25 mL 0.04 mol/L pH6.8 磷酸缓冲液(Phosphate buffer,PBS),5000 r/min 匀浆 20 s,4 ℃ 静置 1 h 后离心(3300 r/min,30 min,15 ℃),用滤纸过滤上清液,用上述 PBS 定容至25 mL,测定 525、545、565、572 nm 处波长吸光度。总肌红蛋白(Total myoglobin,TMb)、氧合肌红蛋白(Oxymyoglobin,OMb)、高铁肌红蛋白(Methemoglobin,MMb)含量分别按式(1)、(2)、(3)计算。

TMb(mg/g)=−0.166A572+0.086A565+0.088A545+0.099A525 (1) OMb(%)=(0.882R1−1.267R2+0.809R3−0.361)×100 (2) MMb(%)=(−2.514R1+0.777R2+0.800R3+1.098)×100 (3) 式中:R1为A572/A525、R2为A565/A525、R3为A545/A525。

1.2.3.4 蒸煮损失

拭去肉块表面水分并称重记为w1,90 ℃水浴加热。肉样中心温度达到70 ℃时取出冷却至室温后用滤纸吸去表面水分,称重记为w2。蒸煮损失率按式(4)计算。

蒸煮损失(%)=w1−w2w1×100 (4) 式中:w1为蒸煮前质量(g);w2为蒸煮后质量(g)。

1.2.3.5 质构特性

参照唐月利等[11]的方法稍作修改,将酱牦牛肉切分成2 cm×2 cm×4 cm的肉块,使用P/50探头,测前速度1.0 mm/s,测定速度5.0 mm/s,测后速度为5.0 mm/s,Strain模式,压缩50%,触发力为5.0 g。测定硬度、弹性、内聚性、黏性和咀嚼性5个指标。

1.2.3.6 流变特性

参考Li等[12]的方法,略有修改。狭缝设置为1 mm,起始温度为20 ℃,以2.0 ℃/min速率升温至85 ℃,平衡时间为60 s,应变0.25%,频率1 Hz,测定G′值和Gʹʹ值。

1.2.3.7 感官评价

感官评分参考赵子瑞[13]的测定方法。10名感官评定人员分别对酱牦牛肉制品的色泽及外观、气味、质地口感、滋味风味四个方面进行感官评价。

1.2.4 脂质氧化指标

硫代巴比妥酸(Thiobarbituric acid reactive substances,TBARS)值测定参照梅议文等[14]的方法略作修改。取5.0 g切碎的牦牛肉,加入25 mL 7.5%三氯乙酸溶液(含0.1%EDTA),3000 r/min匀浆1 min后离心(5000 r/min,5 min,4 ℃),取上清液过滤,取5 mL滤液加入5 mL 0.02 mol/L硫代巴比妥酸溶液并混合均匀,100 ℃水浴加热40 min,冷却后测量532 nm和600 nm波长处的吸光值。TBARS值按式(6)计算:

TBARS值(mg/kg)=4.65×(A532−A600) (5) 式中:A532、A600分别为样品在532和600 nm处的吸光值。

1.2.5 蛋白氧化指标

1.2.5.1 肌原纤维蛋白(Myofibrillar protein,MP)提取

参考Park等[15]的方法并稍作修改。取5 g牦牛肉糜加入4倍体积的PBS(pH7.0,20 mmol/L,含0.1 mol/L NaCl,2 mmol/L MgCl2,1 mmol/L EGTA)冰浴匀浆(8000 r/min,1 min)后离心15 min (2000×g,4 ℃),所得沉淀加入PBS重复操作3次。最后一次离心所得沉淀与4倍体积的0.1 mol/L NaCl溶液匀浆,用4层纱布过滤后再次离心(参数同上),所得沉淀即为MP(4 ℃下冷藏),采用双缩脲法测定蛋白浓度,并在48 h内完成蛋白质氧化指标的测定。

1.2.5.2 羰基含量

参考文献方法[16],将1 mL 2 mg/mL的蛋白溶液和1 mL 2 mol/L HCl溶液(含0.02 mol/L 2,4-二硝基苯肼)混匀后避光静置60 min,加入4 mL 20%三氯乙酸溶液,摇匀后离心5 min(10000×g,4 ℃)。弃上清,用2 mL乙酸乙酯-乙醇溶液洗涤沉淀3次,之后加入6 mL 6 mol/L盐酸胍溶液并置于37 ℃水浴30 min,冷却后在波长370 nm处测定溶液的吸光值。

羰基含量(nmol/mg)=A370C×D×22000×106×n (6) 式中:A370为样品在波长370 nm处的吸光值;C为蛋白溶液浓度(mg/mL);D为比色直径,1 cm;22000为摩尔吸光系数(L/(mol·cm));n为稀释倍数,6。

1.2.5.3 总巯基含量

按照芦慧勤等[16]方法,取1 mL 2 mg/mL的蛋白溶液加入4 mL尿素-SDS溶液(含8 mol/L尿素,30 g/L SDS,0.1 mol/L PBS,pH7.4)和1 mL 10 mmol/L DTNB溶液(溶于0.1 mol/L PBS中,pH7.4),避光反应15 min,测定溶液在波长412 nm处的吸光值。

总巯基含量(nmol/mg)=A412×n13600×C (7) 式中:A412为样品在波长412 nm处的吸光值;n为稀释倍数,5;13600为摩尔吸光系数(L/(mol·cm));C为蛋白浓度(mg/mL)。

1.2.5.4 表面疏水性

参考Zhou等[17]的方法,取离心管加入2 mL 2 mg/mL蛋白溶液和400 µL 1 mg/mL的溴酚蓝,涡旋混匀后在4 ℃ 6000 r/min条件下离心15 min。取1 mL上清液稀释10倍,在波长595 nm处测定其吸光值。以PBS代替蛋白溶液进行相同操作。表面疏水性以溴酚蓝结合量表示,按式(8)计算。

溴酚蓝结合量(μg)=A0−A1A0×200 (8) 式中:A0为PBS吸光值;A1为蛋白溶液吸光值。

1.2.5.5 二聚酪氨酸含量

参考Li等[18]的方法稍加修改。MP溶液稀释至2 mg/mL,采用荧光分光光度计测定蛋白溶液在激发波长325 nm、发射波长420 nm条件下的荧光强度,狭缝为5 nm,电压400 V。待测样品的二聚酪氨酸含量以相对荧光值表示。

相对荧光值(AU)=A样品C (9) 式中:A样品为测定的蛋白溶液的吸光度;C为蛋白溶液浓度(mg/mL)。

1.3 数据处理

各组试验重复测定3次,取平均值,数据用平均值±标准差表示;数据处理使用Microsoft 2016 Excel;显著性分析使用SPSS 26.0,以P<0.05表示差异显著;图表绘图使用Origin 2022。

2. 结果与分析

2.1 食用品质分析

2.1.1 腌制时间对复合低钠牦牛肉pH影响

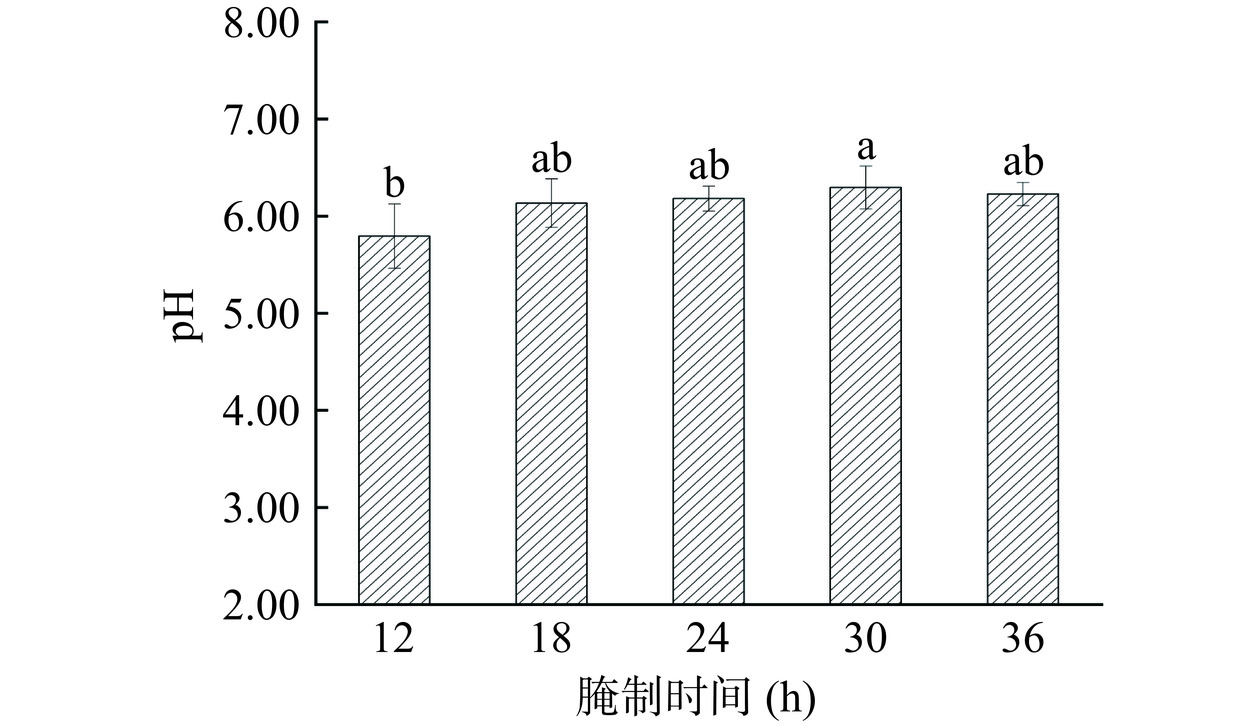

通常新鲜肉和次鲜肉的pH为5.7~6.6[19]。由图1可得,随着腌制时间增加,牦牛肉的pH变化不大,在5.79~6.29之间,基本处在新鲜肉及次鲜肉pH范围内,说明腌制时间对复合低钠配方腌制的牦牛肉pH影响较小,这与José等[20]的研究结果一致。在腌制过程内,肉样的pH整体呈增大趋势,30 h与12 h的pH存在显著差异(P<0.05),这可能是由于配方中焦磷酸钠呈弱碱性,在腌制过程中逐渐作用于肉块,腌制液在肌肉中的扩散使肉样pH增大。36 h时,肌肉的无氧糖酵解占据主要地位,糖酵解产生的乳酸使pH开始下降。

2.1.2 腌制时间对复合低钠酱牦牛肉制品色度、肉色稳定性的影响

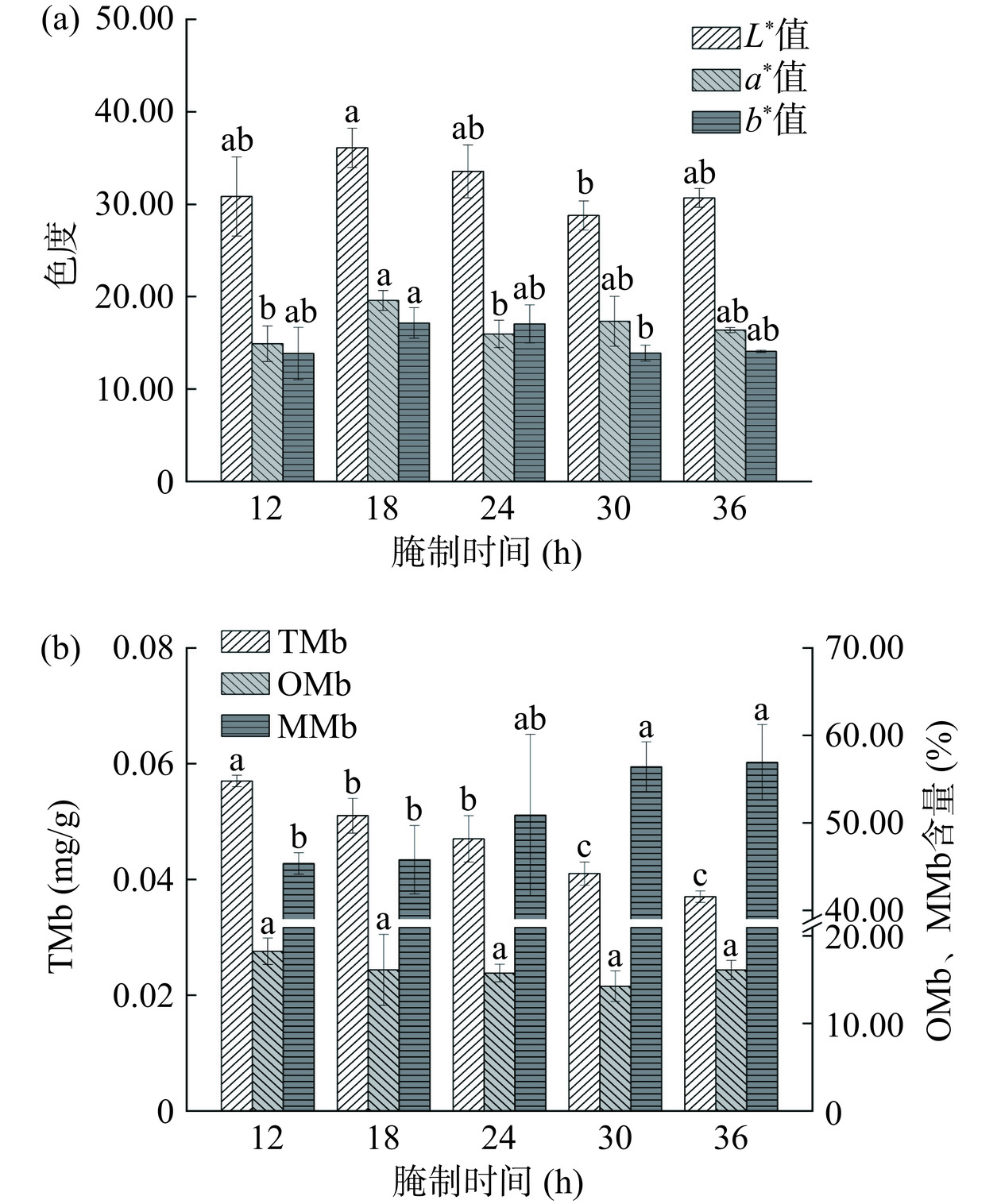

肉品的颜色是影响消费者选择商品的重要标准,好的肉色可以提高肉品的综合评价。根据图2(a)可得出,酱牦牛肉产品的L*值、a*值随着腌制时间延长有所波动,L*值在28.80~36.11之间,a*值在14.89~19.56之间,18 h和30 h的b*值具有显著差异(P<0.05)。a*值与肌肉中肌红蛋白(Myoglobin,Mb)氧化状态、相对比例有关。由图2(b)可知,随着腌制时间增加,肉样的TMb含量和OMb百分比含量呈下降趋势,MMb百分比含量呈上升趋势。随着腌制时间的延长,肉中的Mb逐渐流失进入腌制液,导致肉样中的TMb含量持续显著减少(P<0.05),由12 h的0.057 mg/g降低至24 h的0.047 mg/g,36 h降低至0.037 mg/g;OMb百分比含量逐渐下降但并无显著差异(P>0.05);MMb百分比含量由12 h的45.36%显著增加至36 h的56.91%(P<0.05)。由于腌制过程中未隔绝空气,Mb与O2快速结合形成亮红色OMb,OMb又进一步与被氧化成红褐色MMb[21]。另外,脂肪氧化是Mb促氧化因素之一,脂肪氧化产生的大量自由基和次级氧化产物,会使Mb的血红素基团暴露而容易被氧化,所产生的自由基使MMb进一步积累[22]。Mb的状态和相对比例往往是影响肉色的主要因素,但在本研究中,a*值、b*值与Mb变化趋势并不完全一致,说明酱牦牛肉色泽还可能受到血红素等其他因素的影响,另外,牦牛肉煮制过程中加入的酱油、甜面酱等有色调料可能掩盖了腌制肉本身的色泽,导致成品所测出的L*值、a*值略有波动。

2.1.3 腌制时间对复合低钠酱牦牛肉制品蒸煮损失的影响

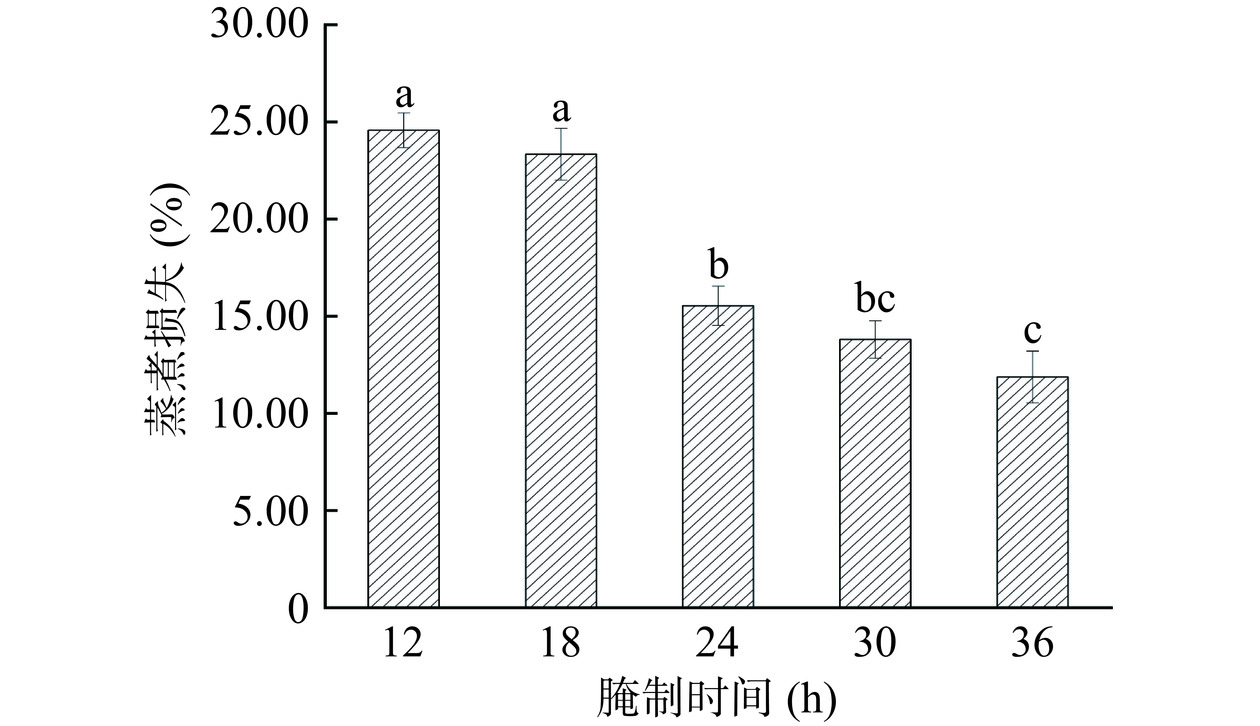

蒸煮损失反映了肌肉蛋白质的持水能力,决定着肉制品加工过程中产品的出品率以及最终的感官品质,对于加工企业和消费者至关重要。由图3可得出,随着腌制时间的增加,牦牛肉块的蒸煮损失率逐渐显著减小(P<0.05)。崔璐璐等[23]发现烧烤鱼块在腌制4 h时水分含量已经达到峰值。本研究中,蒸煮损失率则在腌制36 h时降至最低,低至11.87%,较12 h显著下降了51.69%(P<0.05),本研究与崔璐璐研究结果相差较大可能是原料肉的种类不同造成的。随着腌制时间的增加,NaCl在渗透压的作用下逐渐进入肌肉内部,MP出现盐溶现象,牦牛肉溶胀吸收大量水分[24],同时本复合低钠配方中的焦磷酸钠具有增加保水性,提高肉制品出品率的作用,二者协同作用降低了酱牦牛肉的蒸煮损失率。

2.1.4 腌制时间对复合低钠酱牦牛肉制品质构特性的影响

质构特性能够反映出食品的口感,与感官特性关系密切。由表1可得,随着腌制时间增加,复合低钠配方改善了酱牦牛肉的质构特性,具体表现为硬度、黏性、咀嚼性显著增大(P<0.05)。酱牦牛肉的硬度值和黏性值均在36 h时达到最大,分别为2651.87 g和1710.81 g·sec,这可能是因为适度的氧化使蛋白发生交联,形成较为紧密的三维结构[25],这种结构在截留水分减少蒸煮损失的同时,也增大了肌原纤维蛋白凝胶强度,使酱牦牛肉的硬度和咀嚼性变大,然而过大的硬度和咀嚼性并不被消费者接受,也不利于产品的咀嚼和消化。在加工过程中部分蛋白质被降解交联形成大分子不溶物,导致其黏性增大[26]。随着复合低钠配方腌制时间的延长,肉样的弹性值和内聚性数值上下波动,但差异不显著(P>0.05),说明腌制时间对酱牦牛肉的弹性、内聚性的影响不大。

表 1 腌制时间对复合低钠酱牦牛肉制品质构特性的影响Table 1. Effects of curing time on texture characteristics of complex low-sodium yak meat腌制时间(h) 硬度(g) 弹性 内聚性 黏性(g·sec) 咀嚼性 12 1872.84±115.68c 0.79±0.05a 0.64±0.06a 1197.02±159.50c 946.56±146.31c 18 2292.78±110.57b 0.83±0.04a 0.69±0.02a 1591.61±99.31ab 1322.90±131.64a 24 1903.73±195.67c 0.78±0.04a 0.71±0.02a 1348.02±125.53bc 1046.91±48.37bc 30 2405.07±129.70ab 0.82±0.05a 0.71±0.05a 1694.98±150.63a 1386.80±161.30a 36 2651.87±216.82a 0.75±0.01a 0.65±0.03a 1710.81±53.56a 1277.57±44.88ab 注:同列不同字母表示差异显著(P<0.05)。 2.1.5 腌制时间对复合低钠牦牛肉流变特性的影响

储能模量G′又被称为弹性模量,可以衡量蛋白质的凝胶能力,通过测定升温过程中G′值,可以推测热诱导肉糜凝胶结构的稳定性,G′越高说明样品凝胶能力越强。损耗模量G′′又被称为黏性模量,反映了样品的黏性特征。由图4(a)、(b)可得,不同时间的G′值变化曲线相似,均在50 ℃左右开始上升,肌球蛋白头部变性聚集,初步形成松散的凝胶结构,随后肌球蛋白尾部解旋,蛋白网络被暂时性地破坏[27],G'略有下降,最后在60~85 ℃温度升高导致肌球蛋白结构大量展开暴露活性基团,蛋白间交联加强,形成稳定且富有弹性的有序三维凝胶结构[28],G′值快速升高。G′′值的总体变化趋势先下降再升高最后稍有下降,且G′′值在整个升温过程中始终小于G′值,说明在加热过程中,肉糜体系形成的凝胶以弹性为主。在本试验中各组肉糜最终G′值随腌制时间整体呈下降趋势,这可能是焦磷酸钠诱导肌球蛋白解离和蛋白氧化稳定性改变导致的[29]。

2.1.6 腌制时间对复合低钠酱牦牛肉制品感官品质的影响

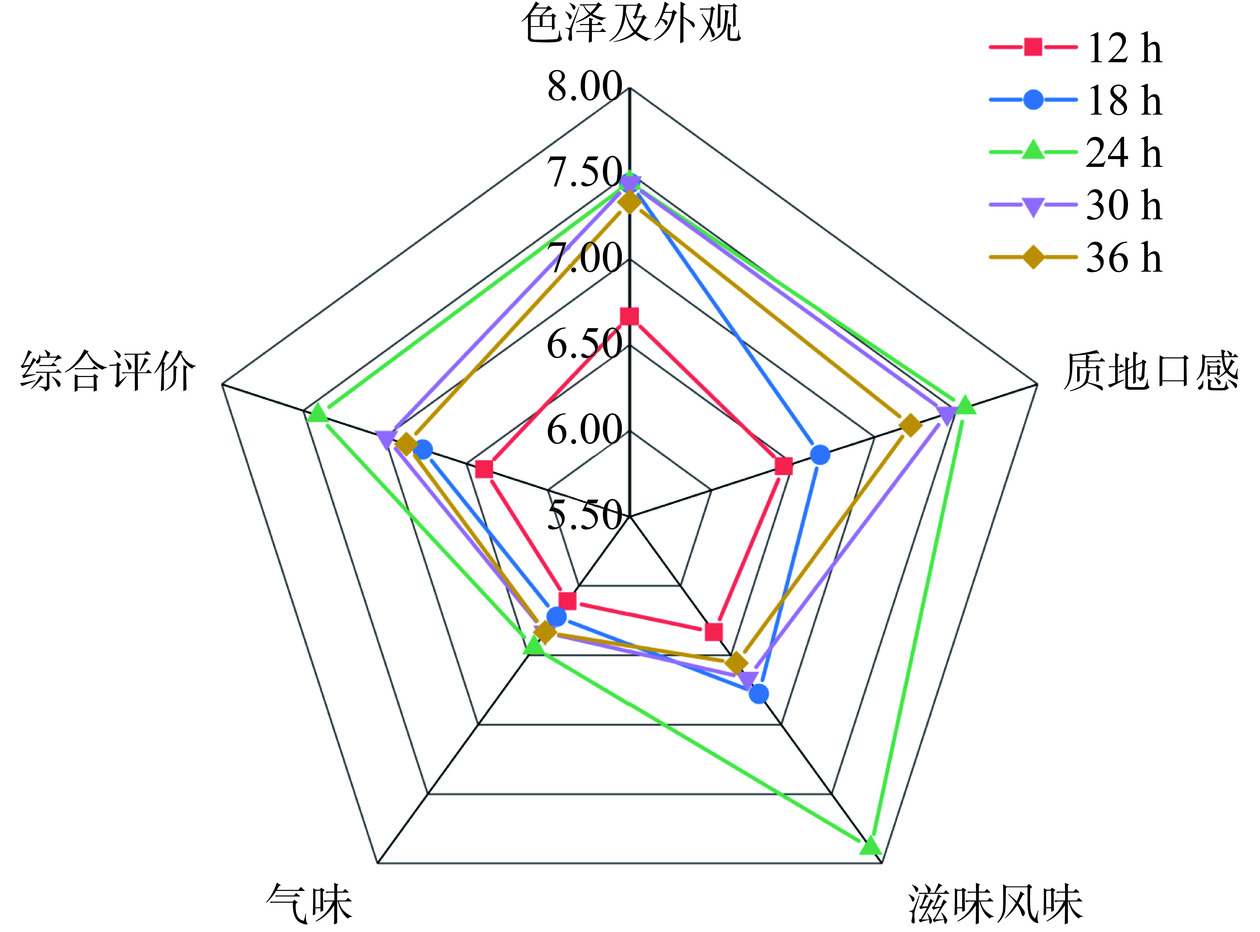

由图5可知,通过各感官指标权重计算得出的综合评分和多变量分析可得出在腌制的12~24 h内,感官综合评分随腌制时间增加而不断升高,24 h后开始下降。其中,腌制24 h的酱牦牛肉综合评分最高,为7.411,与12 h(6.389)的综合评分存在显著差异(P<0.05),但其他各组之间无显著性差异(P>0.05)。当腌制时间为24 h时,产品肉色红润,组织紧凑,纹理清晰,质地软硬适中、口感有嚼劲、咸淡适口,滋味鲜美且气味浓郁,最符合大众口味。腌制时间过短则酱牦牛肉风味不足,质地较软,过长则口味过咸,肉质变柴,感官品质又有所下降。余健等[30]发现对于低钠干腌咸肉腌制72 h时其感官评分最高,而对于苗岭腊肉,最佳低盐腌制时间则为63 h[31]。可见,低钠配方肉制品由于最终产品种类不同,其最适腌制时间也有所不同。从感官评价结果来看,本试验所采用的低钠配方腌制牦牛肉24 h较为合适,此腌制时长制作出的酱牦牛肉最受欢迎。

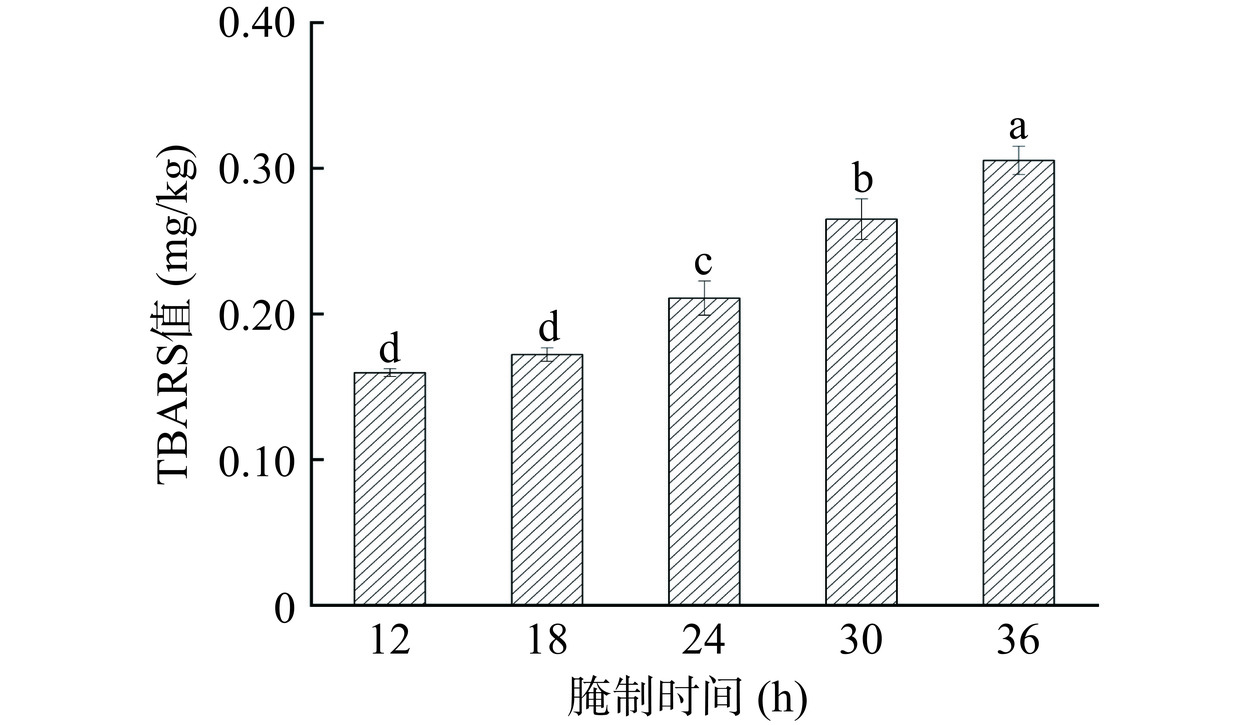

2.2 脂质氧化分析

TBARS值代表样品中脂肪次级氧化产物丙二醛的含量,是衡量脂肪氧化的常用指标之一。由图6可以看出,由于腌制时间的延长,样品TBARS值不断显著增大(P<0.05),脂质氧化程度不断加重,这与先前的报道[32]一致。但在前18 h内,体系中的TBARS值并无明显变化,一方面,这可能是由于腌制时间较短,脂肪氧化程度较低;另一方面,低钠配方中的焦磷酸钠可以螯合促氧化的金属离子,这有助于延缓脂肪氧化的发生[29]。但焦磷酸钠对脂肪氧化的抑制作用是有限的,在18 h后肉品的氧化程度大于腌制液抑制作用,导致丙二醛含量显著增多。

2.3 蛋白氧化分析

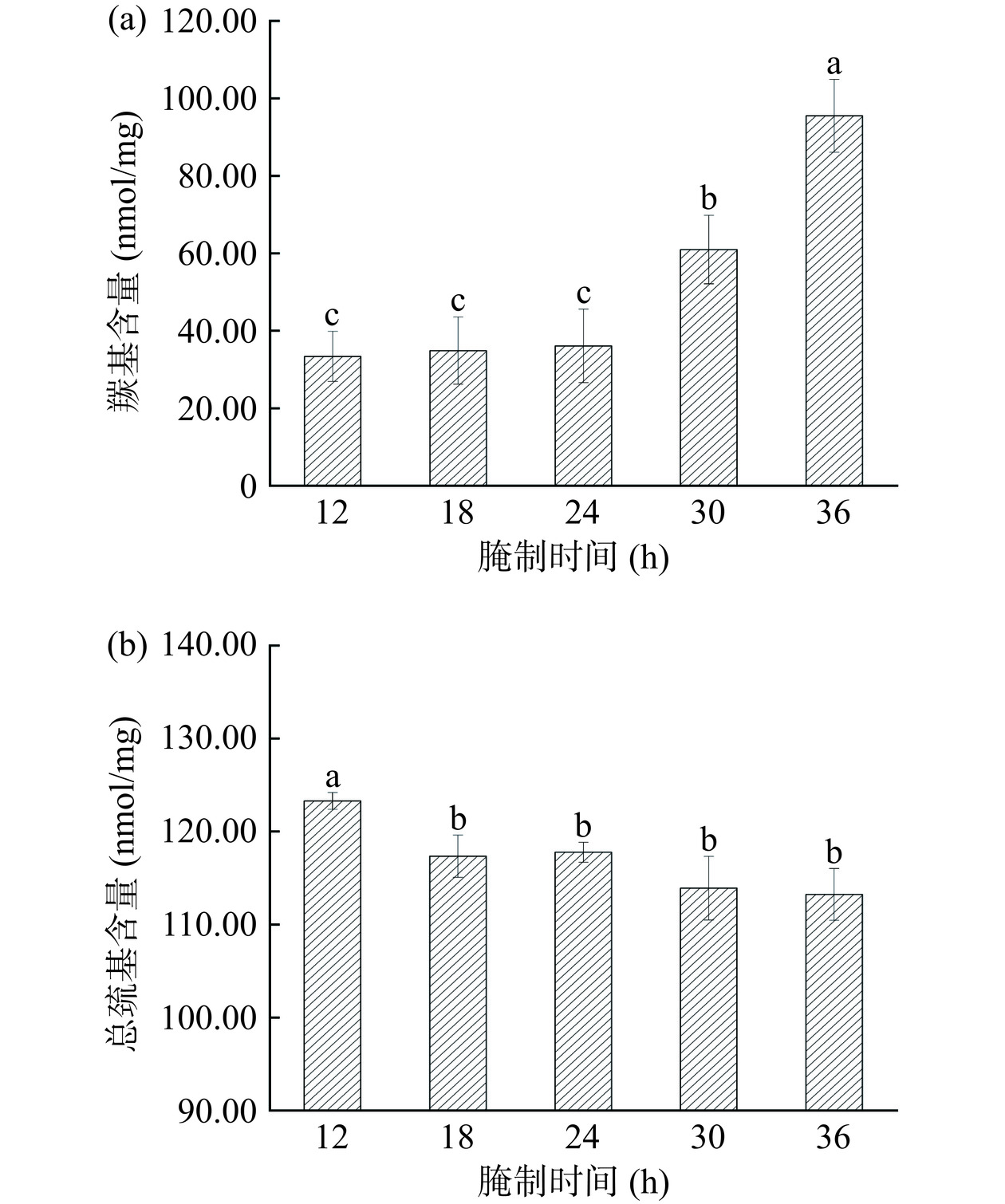

2.3.1 腌制时间对复合低钠牦牛肉羰基、巯基含量的影响

蛋白受到氧化攻击后,氨基酸侧链基团经过氧化修饰形成羰基化合物,巯基则转化为二硫键,因此,常用羰基化水平和巯基含量反映蛋白质氧化程度。由图7(a)可得,随着腌制时间的增加,肉样的羰基含量呈上升趋势,这与张进伟等[33]的研究相符。腌制时间在24 h以内肌肉蛋白氧化程度较低,无明显变化,韩馨蕊等[29]发现焦磷酸钠可有效抑制蛋白羰基化。继续延长腌制时间,肌肉中蛋白氧化加剧,到达腌制终点时羰基含量最大,达到95.5 nmol/mg,显著高于其他组(P<0.05)。

由图7(b)可得,随着腌制的进行,肉样的总巯基含量呈下降趋势,12 h时总巯基含量为123.28 nmol/mg,之后开始显著减少(P<0.05)。总巯基含量的降低是由于腌制提高了牦牛肉中的离子强度,破坏了蛋白质的静电平衡,使原本被掩盖在分子内部的巯基暴露出来成为氧化攻击的靶点,而导致巯基氧化损失变成二硫键[34]。因此推测腌制24 h时发生的蛋白低水平氧化是有利的,蛋白可能通过二硫键轻度交联,帮助形成凝胶截留水分。同时,MP氧化交联形成的MP聚合体会覆盖一些巯基,使游离巯基减少,导致总巯基含量下降。羰基和巯基含量的变化均证明腌制时间的延长加剧了蛋白氧化,但复合低钠配方在腌制前期延缓了氧化的发生,有利于提高成品品质和产量。

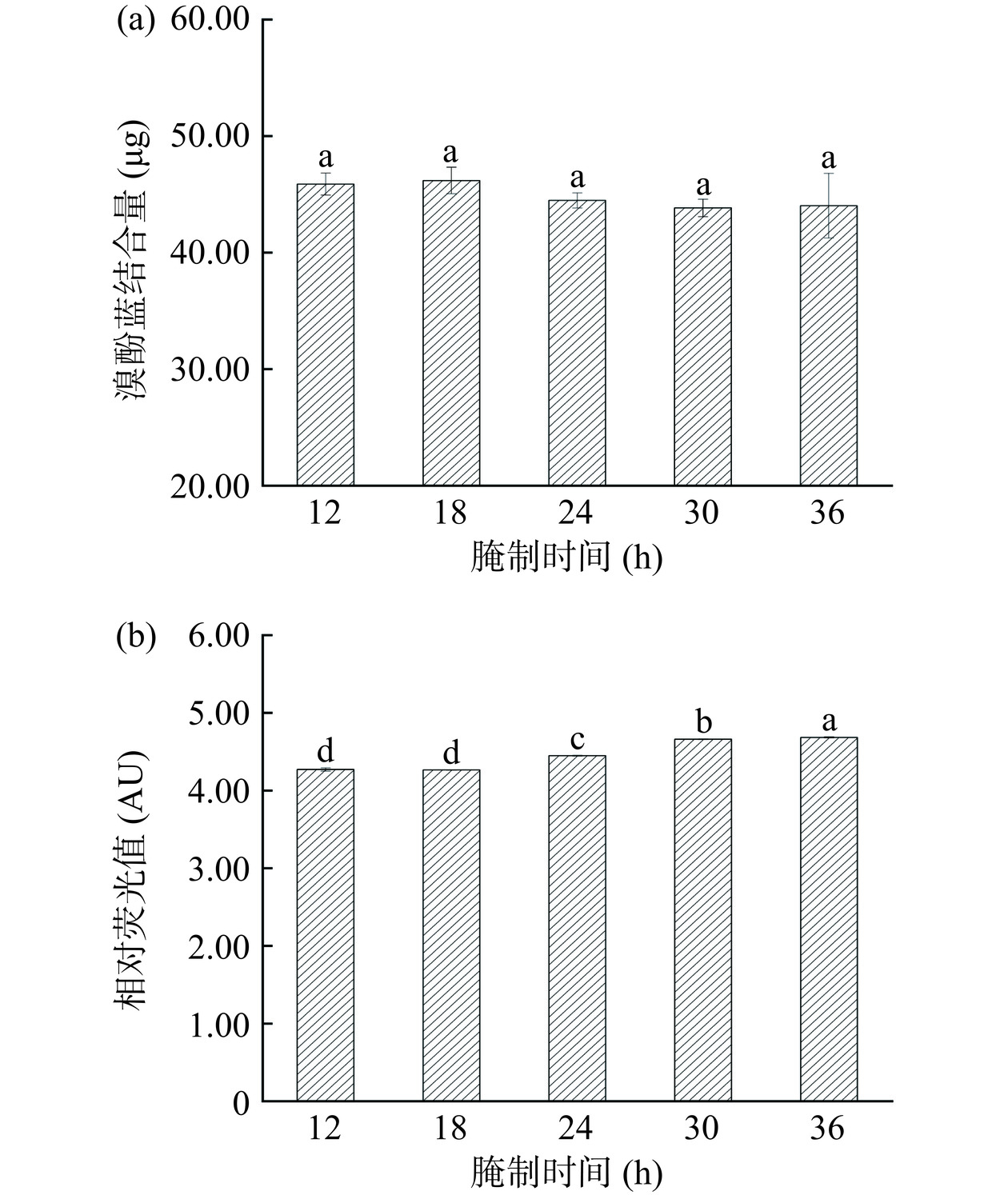

2.3.2 腌制时间对复合低钠牦牛肉制品表面疏水性、二聚酪氨酸含量的影响

表面疏水性反映了蛋白质构象变化情况,与蛋白内部疏水区域的暴露程度有关。当蛋白发生氧化变性,分子结构展开后,原本被包埋在分子内部的疏水氨基酸暴露出来,表面疏水性增加[35]。由图8(a)可得,五个试验组的表面疏水性变化不大,并无显著性差异(P>0.05)。说明本试验条件下,腌制时间对蛋白质结构影响较小,牦牛肉MP结构并未大量展开,疏水氨基酸仍被包裹在内部。蛋白分子结构的解折叠会促进交联聚集的发生,过度交联聚集将使蛋白形成粒径较大的聚合体,从而对蛋白功能特性造成严重影响,不利于蛋白的凝胶行为[35]。

酪氨酸残基在氧化条件下,容易转化成二聚酪氨酸,并通过共价和非共价键形成蛋白质聚集体[36]。酪氨酸二聚体增加表明蛋白发生氧化。由图8(b)可得,随着腌制时间的延长,肉样的二聚酪氨酸含量持续增大,腌制终点36 h时达到4.684 AU,显著高于其他组(P<0.05),说明更多的盐分渗入肉中,改变了蛋白表面静电荷分布,导致蛋白质稳定性降低,使蛋白氧化程度加重。另外,与羰基结果类似,在腌制前24 h内,二聚酪氨酸含量变化不显著(P>0.05),可能是焦磷酸钠起到了一定的抗氧化作用。

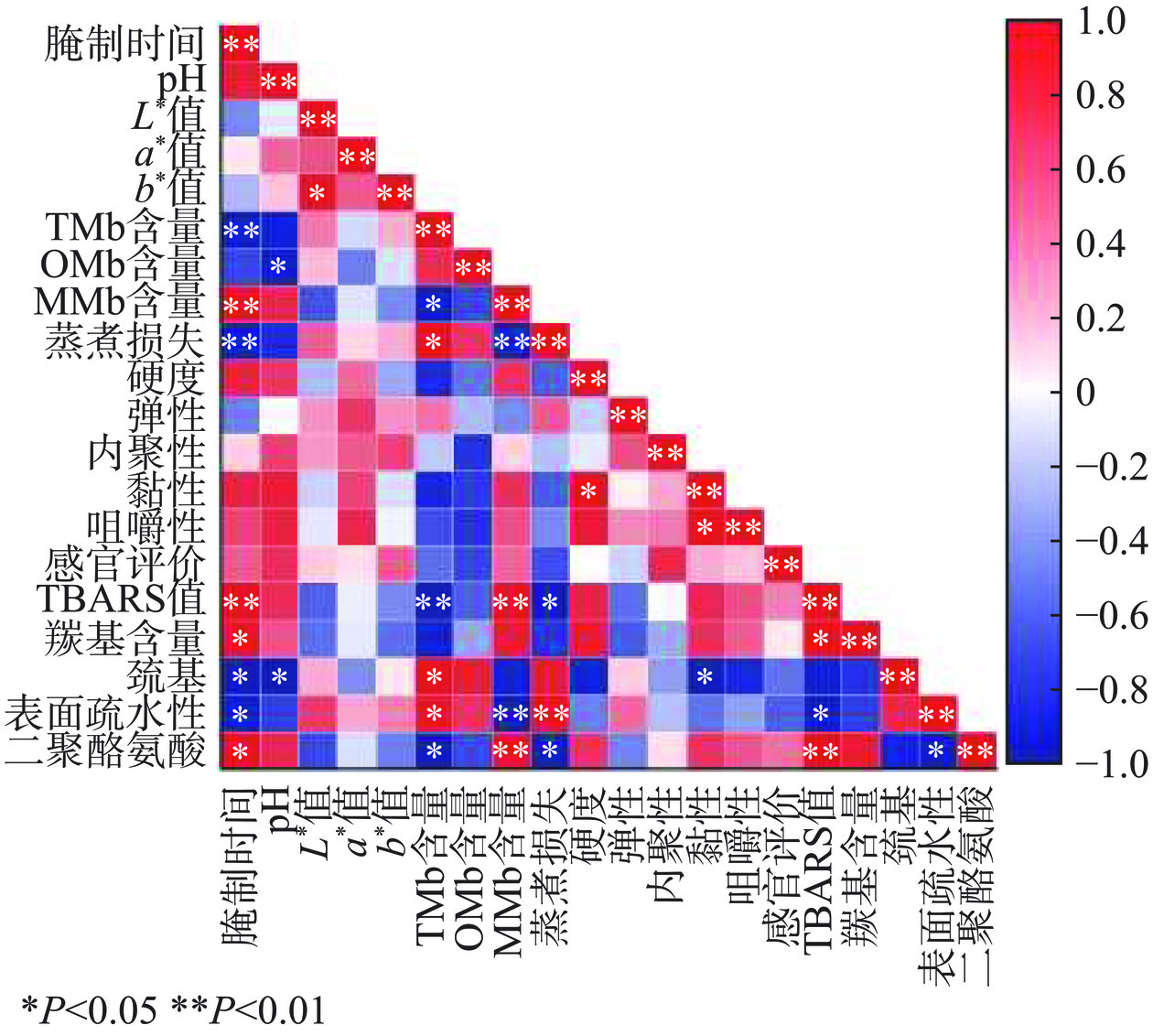

2.4 相关性分析

对腌制时间及其他指标进行Person相关性分析,结果如图9所示,腌制时间与巯基、表面疏水性呈显著负相关(P<0.05),与TMb含量、蒸煮损失呈极显著负相关(P<0.01),与羰基含量和二聚酪氨酸含量呈显著正相关(P<0.05),与MMb含量、TBARS值呈极显著正相关(P<0.01)。说明随着腌制时间的延长,腌制液中的NaCl、KCl和焦磷酸钠逐渐扩散渗入肉样,增强了蛋白的水合作用,降低了蒸煮损失,但随着时间推移,更多的盐分渗入肉中,离子强度过大,降低了蛋白质稳定性,组织中的脂肪和蛋白氧化变性,TMb转化成MMb。并且TMb含量、MMb含量、蒸煮损失与TBARS值、表面疏水性、二聚酪氨酸含量或羰基含量具有显著相关性。说明Mb的状态以及产品的保水性受到脂肪和蛋白氧化的显著影响。

3. 结论

本研究发现腌制时间对复合低钠配方腌制的酱牦牛肉的品质特性具有重要影响。随着腌制时间的延长,腌制液扩散渗入肌肉,改变了肌肉的功能特性,显著降低肉制品蒸煮损失(P<0.05),同时造成酱牦牛肉质构特性发生显著变化,改善了肉制品的食用品质。但随着腌制时间延长,肉制品脂肪、蛋白质不断氧化,具体表现为羰基含量、二聚酪氨酸含量以及TBARS值逐渐上升,同时总巯基含量下降,肌肉的适度氧化有利于蛋白凝胶和风味物质的形成,提高肉制品的持水能力,但过度氧化将对酱牦牛肉制品的品质产生消极影响。因此,适当的腌制时间(24 h)不仅可以降低蒸煮损失,提高产量,也能控制脂质、蛋白质的氧化水平,赋予产品良好的口感和独特的风味。综合来看,复合盐添加量为肉重的3.2 %(NaCl: KCl:焦磷酸钠为6:3:1),4 ℃腌制24 h时,复合低钠配方牦牛肉制品氧化程度较低,感官品质较好。

-

表 1 腌制时间对复合低钠酱牦牛肉制品质构特性的影响

Table 1 Effects of curing time on texture characteristics of complex low-sodium yak meat

腌制时间(h) 硬度(g) 弹性 内聚性 黏性(g·sec) 咀嚼性 12 1872.84±115.68c 0.79±0.05a 0.64±0.06a 1197.02±159.50c 946.56±146.31c 18 2292.78±110.57b 0.83±0.04a 0.69±0.02a 1591.61±99.31ab 1322.90±131.64a 24 1903.73±195.67c 0.78±0.04a 0.71±0.02a 1348.02±125.53bc 1046.91±48.37bc 30 2405.07±129.70ab 0.82±0.05a 0.71±0.05a 1694.98±150.63a 1386.80±161.30a 36 2651.87±216.82a 0.75±0.01a 0.65±0.03a 1710.81±53.56a 1277.57±44.88ab 注:同列不同字母表示差异显著(P<0.05)。 -

[1] 李彩云, 孙恒元, 华红新, 等. 超高压联合乳酸钙处理对牦牛肉品质及肌红蛋白消化特性的影响[J]. 食品与发酵工业,2023,49(19):257−264. [LI C Y, SUN H Y, HUA H X, et al. Effects of ultra-high pressure combined with calcium lactate treatment on yak quality and myoglobin digestion characteristics[J]. Food and Fermentation Industries,2023,49(19):257−264.] LI C Y, SUN H Y, HUA H X, et al. Effects of ultra-high pressure combined with calcium lactate treatment on yak quality and myoglobin digestion characteristics[J]. Food and Fermentation Industries, 2023, 49(19): 257−264.

[2] 陈瑞霞. 淘汰蛋鸡蛋白咸味增强肽的制备及其在广式腊肠中的应用研究[D]. 烟台:烟台大学, 2020. [CHEN R X. Preparation of salt-enhanced peptide by spent hen protein and its application in cantonese sausage[D]. Yantai:Yantai University, 2020.] CHEN R X. Preparation of salt-enhanced peptide by spent hen protein and its application in cantonese sausage[D]. Yantai: Yantai University, 2020.

[3] ELLIN-DOYLE M, KATHLEEN A G. Sodium reduction and its effect on food safety, food quality, and human health[J]. Comprehensive Reviews in Food Science and Food Safety,2010,9(1):44−56. doi: 10.1111/j.1541-4337.2009.00096.x

[4] 林静, 刘斌, 李松林. 氯化钾、氯化钙和氯化镁部分替代食盐腌制对风鸡品质影响的研究[J]. 食品工业科技,2016,37(3):105−109. [LIN J, LIU B, LI S L. Study on the influence of potassium, calcium and magnesium chloride as partial substitute for salt on the quality of air-dried chicken[J]. Science and Technology of Food Industry,2016,37(3):105−109.] LIN J, LIU B, LI S L. Study on the influence of potassium, calcium and magnesium chloride as partial substitute for salt on the quality of air-dried chicken[J]. Science and Technology of Food Industry, 2016, 37(3): 105−109.

[5] GULLÓN P, GONZALO A, BEATRIZ G, et al. Inclusion of seaweeds as healthy approach to formulate new low-salt meat products[J]. Current Opinion in Food Science,2021,40(prepublish):20−25.

[6] 王栋, 张琦, 陈玉峰, 等. 干腌肉制品低盐加工技术及其减盐机制研究进展[J]. 食品科学,2022,43(7):222−231. [WANG D, ZHANG Q, CHEN Y F, et al. Progress in processing technologies for low-salt dry-cured meat products and understanding their principles[J]. Food Science,2022,43(7):222−231.] doi: 10.7506/spkx1002-6630-20210123-256 WANG D, ZHANG Q, CHEN Y F, et al. Progress in processing technologies for low-salt dry-cured meat products and understanding their principles[J]. Food Science, 2022, 43(7): 222−231. doi: 10.7506/spkx1002-6630-20210123-256

[7] SHA G, ZHU Q J, ZHOU Y, et al. Effect of ultrasound combined with glycerol-mediated low-sodium curing on the quality and protein structure of pork tenderloin[J]. Foods,2022,11(23):3798. doi: 10.3390/foods11233798

[8] JUTHAWUT U C, MALILA Y, GOZZI G, et al. Influence of non-phosphate and low-sodium salt marination in combination with tumbling process on properties of chicken breast meat affected by white striping abnormality[J]. Journal of Food Science,2021,86(2):3798.

[9] 国家卫生和计划生育委员会. GB 5009.237-2016 食品安全国家标准 食品pH值的测定[S]. 中华人民共和国国家卫生和计划生育委员会, 2016. [National Health and Family Planning Commission. GB 5009.237-2016 National standard for food safety Determination of food pH[S]. National Health and Family Planning Commission of the People's Republic of China, 2016.] National Health and Family Planning Commission. GB 5009.237-2016 National standard for food safety Determination of food pH[S]. National Health and Family Planning Commission of the People's Republic of China, 2016.

[10] 柳艳霞, 刘纯, 李苗云, 等. 煮制过程中卤煮鸡肉色泽变化的动力学模型构建[J]. 食品与发酵工业,2023,49(19):249−256. [LIU Y X, LIU C, LI M Y, et al. Kinetic model construction of color change of braised chicken during cooking[J]. Food and Fermentation Industries,2023,49(19):249−256.] LIU Y X, LIU C, LI M Y, et al. Kinetic model construction of color change of braised chicken during cooking[J]. Food and Fermentation Industries, 2023, 49(19): 249−256.

[11] 唐月利, 贾娜, 杨松涛, 等. 亚麻籽胶-亚麻籽油乳液替代脂肪对乳化肠品质特性的影响[J]. 食品科学,2023,44(10):64−72. [TANG Y L, JIA N, YANG S T, et al. Effect of flaxseed gum-linseed oil emulsion as a fat substitute on the quality characteristics of emulsified sausage[J]. Food Science,2023,44(10):64−72.] doi: 10.7506/spkx1002-6630-20220818-207 TANG Y L, JIA N, YANG S T, et al. Effect of flaxseed gum-linseed oil emulsion as a fat substitute on the quality characteristics of emulsified sausage[J]. Food Science, 2023, 44(10): 64−72. doi: 10.7506/spkx1002-6630-20220818-207

[12] LI J G, CHEN Y H, DONG X P, et al. Effect of chickpea (Cicer arietinum L.) protein isolate on the heat-induced gelation properties of pork myofibrillar protein[J]. Journal of the Science of Food and Agriculture,2020,101(5):2108−2166.

[13] 赵子瑞. 低钠酱牛肉制备配方优化与品质改良及贮藏特性研究[D]. 长春:吉林大学, 2019. [ZHAO Z R. Study on the preparation formula optimization, quality improvement and storage characteristics of low sodium spiced beef[D]. Changchun:Jilin University, 2019.] ZHAO Z R. Study on the preparation formula optimization, quality improvement and storage characteristics of low sodium spiced beef[D]. Changchun: Jilin University, 2019.

[14] 梅议文, 李婕, 杜荣胜, 等. 精氨酸协同壳聚糖对宰后牦牛肉成熟过程中品质的影响[J]. 食品工业科技,2023,44(11):350−360. [MEI Y W, LI J, DU R S, et al. Effect of arginine combined with chitosan on quality of postmortem yak meat during maturing[J]. Science and Technology of Food Industry,2023,44(11):350−360.] MEI Y W, LI J, DU R S, et al. Effect of arginine combined with chitosan on quality of postmortem yak meat during maturing[J]. Science and Technology of Food Industry, 2023, 44(11): 350−360.

[15] PARK D, XIONG Y L. Oxidative modification of amino acids in porcine myofibrillar protein isolates exposed to three oxidizing systems[J]. Food Chemistry,2006,103(2):607−616.

[16] 芦慧勤, 梅议文, 谢琦蓝, 等. L-赖氨酸对丙二醛诱导氧化下牦牛肉品质特性及氧化程度的影响[J]. 食品工业科技,2023,44(16):90−98. [LU H Q, MEI Y W, XIE Q L, et al. Effect of L-Lys on the quality characteristics and oxidation degree of yak meat under MDA induced oxidation[J]. Science and Technology of Food Industry,2023,44(16):90−98.] LU H Q, MEI Y W, XIE Q L, et al. Effect of L-Lys on the quality characteristics and oxidation degree of yak meat under MDA induced oxidation[J]. Science and Technology of Food Industry, 2023, 44(16): 90−98.

[17] ZHOU Y J, HU M Q, WANG L. Effects of different curing methods on edible quality and myofibrillar protein characteristics of pork[J]. Food Chemistry,2022,387:132872. doi: 10.1016/j.foodchem.2022.132872

[18] LI X P, LIU C K, WANG J X, et al. Tea polyphenols affect oxidative modification and solution stability of myofibrillar protein from grass carp (Ctenopharyngodon idellus)[J]. Food Biophysics,2020,15(4):1−12.

[19] 王志琴, 孙磊, 姚刚, 等. 不同保存温度下牛肉新鲜度变化规律的研究[J]. 新疆农业科学,2011,48(6):1120−1124. [WANG Z Q, SUN L, YAO G, et al. The changes of beef freshness at different storage temperatures[J]. Xinjiang Agricultural Sciences,2011,48(6):1120−1124.] doi: 10.6048/j.issn.1001-4330.2011.06.025 WANG Z Q, SUN L, YAO G, et al. The changes of beef freshness at different storage temperatures[J]. Xinjiang Agricultural Sciences, 2011, 48(6): 1120−1124. doi: 10.6048/j.issn.1001-4330.2011.06.025

[20] JOSÉ M L, SONIA F, MARÍA G, et al. Influence of the salting time on physico-chemical parameters, lipolysis and proteolysis of dry-cured foal "cecina"[J]. LWT - Food Science and Technology,2015,60(1):332−338. doi: 10.1016/j.lwt.2014.07.023

[21] 王琳琳, 陈炼红, 张岩. 不同部位牦牛肉宰后成熟过程中肉色稳定性研究[J]. 食品与发酵工业,2022,48(20):29−35. [WANG L L, CHEN L H, ZHANG Y. Study on the flesh color stability of different parts of yak meat during postmortem aging[J]. Food and Fermentation Industries,2022,48(20):29−35.] WANG L L, CHEN L H, ZHANG Y. Study on the flesh color stability of different parts of yak meat during postmortem aging[J]. Food and Fermentation Industries, 2022, 48(20): 29−35.

[22] RAMANATHAN R, SUMAN S P, FAUSTMAN C. Biomolecular interactions governing fresh meat color in post-mortem skeletal muscle:A review[J]. J Agric Food Chemistry,2020,68(46):12779−12787. doi: 10.1021/acs.jafc.9b08098

[23] 崔璐璐, 陈季旺, 莫加利, 等. 加盐量和腌制时间对烧烤草鱼块品质的影响[J]. 水产学报,2023,47(8):166−174. [CUI L L, CHEN J W, MO J L, et al. Effect of salt addition and curing time on the quality of grilled grass carp pieces[J]. Journal of Fisheries of China,2023,47(8):166−174.] CUI L L, CHEN J W, MO J L, et al. Effect of salt addition and curing time on the quality of grilled grass carp pieces[J]. Journal of Fisheries of China, 2023, 47(8): 166−174.

[24] 崔莹莹, 杨铭铎, 李想, 等. 食盐浓度和腌制时间对猪肉渗透动力学及品质的影响[J]. 美食研究,2020,37(2):41−47. [CUI Y Y, YANG M Z, LI X, et al. Effects of salt concentration and time on curing osmotic kinetics and quality of pork[J]. Journal of Researches on Dietetic Science and Culture,2020,37(2):41−47.] doi: 10.3969/j.issn.1009-4717.2020.02.007 CUI Y Y, YANG M Z, LI X, et al. Effects of salt concentration and time on curing osmotic kinetics and quality of pork[J]. Journal of Researches on Dietetic Science and Culture, 2020, 37(2): 41−47. doi: 10.3969/j.issn.1009-4717.2020.02.007

[25] DOMÍNGUEZ R, PATEIRO M, MUNEKATA P, et al. Protein oxidation in muscle foods:A comprehensive review[J]. Antioxidants,2021,11(1):60. doi: 10.3390/antiox11010060

[26] 刘龙龙, 张华, 梁成云. 腌制时间对辣白菜风味牛肉干质构特性及色泽的影响[J]. 延边大学农学学报,2019,41(2):80−85. [LIU L L, ZHANG H, LIANG C Y, et al. Effect of curing time on texture andcolor of spicycabage flavored beef jerky[J]. Agricultural Science Journal of Yanbian University,2019,41(2):80−85.] LIU L L, ZHANG H, LIANG C Y, et al. Effect of curing time on texture andcolor of spicycabage flavored beef jerky[J]. Agricultural Science Journal of Yanbian University, 2019, 41(2): 80−85.

[27] 马文慧, 邝吉卫, 李保玲, 等. 氧化条件下精氨酸对肌原纤维蛋白结构及凝胶性能的调控[J]. 食品科学,2021,42(24):24−31. [MA W H, KUANG J W, LI B L, et al. Effect of L-Arg concentration on structural and gelling properties of myofibrillar protein under oxidative conditions[J]. Food Science,2021,42(24):24−31.] doi: 10.7506/spkx1002-6630-20200903-028 MA W H, KUANG J W, LI B L, et al. Effect of L-Arg concentration on structural and gelling properties of myofibrillar protein under oxidative conditions[J]. Food Science, 2021, 42(24): 24−31. doi: 10.7506/spkx1002-6630-20200903-028

[28] LI H, DING B, ZHANG H, et al. Textural and sensorial quality protection in frozen dumplings through the inhibition of lipid and protein oxidation with clove and rosemary extracts[J]. Journal of the Science of Food and Agriculture,2019,99(10):4739−4747. doi: 10.1002/jsfa.9716

[29] 韩馨蕊, 李颖, 刘苗苗, 等. 安石榴苷与焦磷酸钠对肌原纤维蛋白氧化稳定性及凝胶性能的影响[J]. 食品科学,2022,43(8):15−21. [HAN X R, LI Y, LIU M M, et al. Effect of punicalagin combined with sodium pyrophosphate on the oxidative stability and gel properties of myofibrillar protein[J]. Food Science,2022,43(8):15−21.] HAN X R, LI Y, LIU M M, et al. Effect of punicalagin combined with sodium pyrophosphate on the oxidative stability and gel properties of myofibrillar protein[J]. Food Science, 2022, 43(8): 15−21.

[30] 余健, 郇延军. 低钠复合腌制剂对干腌咸肉品质的影响[J]. 食品工业科技,2018,39(7):197−201,236. [YU J, HUAN Y J. Effects of low sodium composite marinade on the quality of dry cured Bacon[J]. Science and Technology of Food Industry,2018,39(7):197−201,236.] YU J, HUAN Y J. Effects of low sodium composite marinade on the quality of dry cured Bacon[J]. Science and Technology of Food Industry, 2018, 39(7): 197−201,236.

[31] 聂黔丽, 王修俊, 周雯等. 低钠复合盐腌制对苗岭腊肉品质的影响[J]. 包装工程,2021,42(19):114−121. [NIE Q L, WANG X J, ZHOU W, et al. Effect of low-sodium compound salt curing on the quality of Miaoling bacon[J]. Packaging Engineering,2021,42(19):114−121.] NIE Q L, WANG X J, ZHOU W, et al. Effect of low-sodium compound salt curing on the quality of Miaoling bacon[J]. Packaging Engineering, 2021, 42(19): 114−121.

[32] 杨世虎, 刘贵珊, 张远绿, 等. 贮藏期间亚硝酸钠对滩羊肉品质特性的影响[J]. 食品与发酵工业,2024,50(11):209−215. [YANG S H, LIU G S, ZHANG Y L, et al. Influence of sodium nitrite on quality characteristics of cured Tan mutton during storage[J]. Food and Fermentation Industries,2024,50(11):209−215.] YANG S H, LIU G S, ZHANG Y L, et al. Influence of sodium nitrite on quality characteristics of cured Tan mutton during storage[J]. Food and Fermentation Industries, 2024, 50(11): 209−215.

[33] 张进伟, 胡晓, 陈胜军, 等. 腌制风干过程中卵形鲳鲹鱼肉性质、蛋白质氧化及游离氨基酸的变化[J]. 食品科学,2022,43(18):272−278. [ZHANG J W, HU X, CHEN S J, et al. Changes in physicochemical properties, protein oxidation and free amino acids of Trachinotus ovatus during curing and air-drying[J]. Food Science,2022,43(18):272−278.] doi: 10.7506/spkx1002-6630-20211104-044 ZHANG J W, HU X, CHEN S J, et al. Changes in physicochemical properties, protein oxidation and free amino acids of Trachinotus ovatus during curing and air-drying[J]. Food Science, 2022, 43(18): 272−278. doi: 10.7506/spkx1002-6630-20211104-044

[34] BENJAKUL S, WONNOP V, CHUTIMA T, et al. Comparative study on physicochemical changes of muscle proteins from some tropical fish during frozen storage[J]. Food Research International,2003,36(8):787−795. doi: 10.1016/S0963-9969(03)00073-5

[35] 熊杰, 伯朝英, 常海军. 甘草提取物对冷藏鸡肉糜脂肪和蛋白质氧化及品质特性的影响[J]. 食品工业科技,2021,42(1):75−81,88. [XIONG J, BO Z Y, CHANG H J. Effects of licorice extract on oxidation and quality characteristics of fat and protein in refrigerated chicken meat batter[J]. Science and Technology of Food Industry,2021,42(1):75−81,88.] XIONG J, BO Z Y, CHANG H J. Effects of licorice extract on oxidation and quality characteristics of fat and protein in refrigerated chicken meat batter[J]. Science and Technology of Food Industry, 2021, 42(1): 75−81,88.

[36] LI B W, YANG H H, DING Y Y, et al. Dityrosine in food:A review of its occurrence, health effects, detection methods, and mitigation strategies[J]. Comprehensive Reviews in Food Science and Food Safety,2022,22(1):355−379.

-

期刊类型引用(2)

1. 张黎梅,汪云飞,陈艳,董天秋,马文思,陈娴. HPLC-DAD法测定养生茶中的双氯芬酸钠. 食品与发酵科技. 2025(01): 169-172 .  百度学术

百度学术

2. 李肖斐. 超高效液相色谱-串联质谱法测定酵素梅中12种酚汀(酚丁)、酚酞及其酯类衍生物或类似物. 食品安全导刊. 2025(07): 105-109 .  百度学术

百度学术

其他类型引用(1)

下载:

下载:

下载:

下载: