Research Progress on Premade Meat and Poultry Dishes Off-flavors and Their Inhibiting and Masking Technology

-

摘要: 畜禽类预制菜是以畜禽肉为主要原料,经预加工后在室温或冷链条件下贮存、运输及销售的熟制或未完全熟制的成品或半成品菜肴。预制菜风味品质是影响消费者购买意愿的重要因素,畜禽类预制菜食用前可能因原料特性、微生物代谢、营养成分氧化降解、复热方式不当等产生异味,严重影响其感官品质,限制预制菜产业进一步发展。畜禽类预制菜常见的异味物质主要包括具有酸臭味的己醛;蜡味和油脂味的壬醛、癸醛、辛醛、(E,E)-2,4-癸二烯醛;油腻脂肪氧化味的(E)-2-癸烯醛;霉味的3-甲基丁醛和2-甲基丁醛;浓烈奶酪味的丁酸;汗臭味的3-甲基丁酸;硫磺味的二甲基硫醚、二甲基三硫醚;泥土味的1-辛烯-3-醇等。本文梳理了畜禽类预制菜主要的异味来源,总结了预制菜加工过程中涉及的主要异味抑制或掩蔽技术,为预制菜行业的风味品控创新和发展提供实践指导和参考。Abstract: Premade meat and poultry dishes refer to the finished or semi-finished products that use meat and poultry materials as the main ingredients, which undergo pretreatments and stored, transported and sold under room temperature or cold chain conditions. Flavor is an important factor that determines consumers' willing for premade dish purchase. However, due to raw material characteristics, microbial metabolism, nutrients oxidation or degradation, inappropriate reheating, the premade meat and poultry dishes might generate some unpleasant off-flavors. The off-flavors might have strong negative impact on the sensory quality of premade dishes, which restricts the further development of the whole industry. The commonly seen off-flavor substances in premade meat and poultry dishes include hexanal with sour note, nonanal, octanal, decanal and (E,E)-2,4-decadienal with waxy and oily note, (E)-2-decenal with greasy fatty note, 3-methylbutyraldehyde and 2-methylbutyraldehyde with musty note, butyric acid with a strong cheesy note, 3-methylbutyric acid with sweaty note, dimethyl trisulfide, dimethyl sulphide with sulphurous note, and 1-octen-3-ol with earthy note etc. This paper reviews the main sources of premade meat and poultry dishes off-flavors, summarizes the off-flavors inhibiting and masking techniques applied in premade dish preparation. This study would provide practical guidance and reference for the innovation and development of the flavor quality control in premade dish industry.

-

Keywords:

- raw meat and poultry for processing /

- off-flavor /

- reheating /

- inhibiting /

- masking

-

预制菜也称预制菜肴,是以一种或多种食用农产品及其制品为原料,使用或不使用调味料等辅料,不添加防腐剂,经工业化预加工(如搅拌、腌制、滚揉、成型、炒、炸、烤、煮、蒸等)制成,配以或不配以调味料包,符合产品标签标明的贮存、运输及销售条件,加热或熟制后方可食用的预包装菜肴,不包括主食类食品,如速冻面米食品、方便食品、盒饭、盖浇饭、馒头、糕点、肉夹馍、面包、汉堡、三明治、披萨等[1]。随着2023年中央一号文件涉及“培育发展预制菜产业”内容的提出[2],市场对预制菜的关注进一步升级。中国预制菜市场2022年规模达4196亿元,预计2026年达10720亿元[3]。畜禽类是预制菜的重要组成部分,2022年市场规模达到1224亿元,预计2026年市场规模增至3289亿元,发展潜力巨大[4]。畜禽类预制菜以深受市场喜爱的小酥肉、红烧肉、鱼香肉丝、宫保鸡丁为代表,市场格局与我国猪、禽肉品消费量大于牛、羊肉品的结构基本一致[5]。

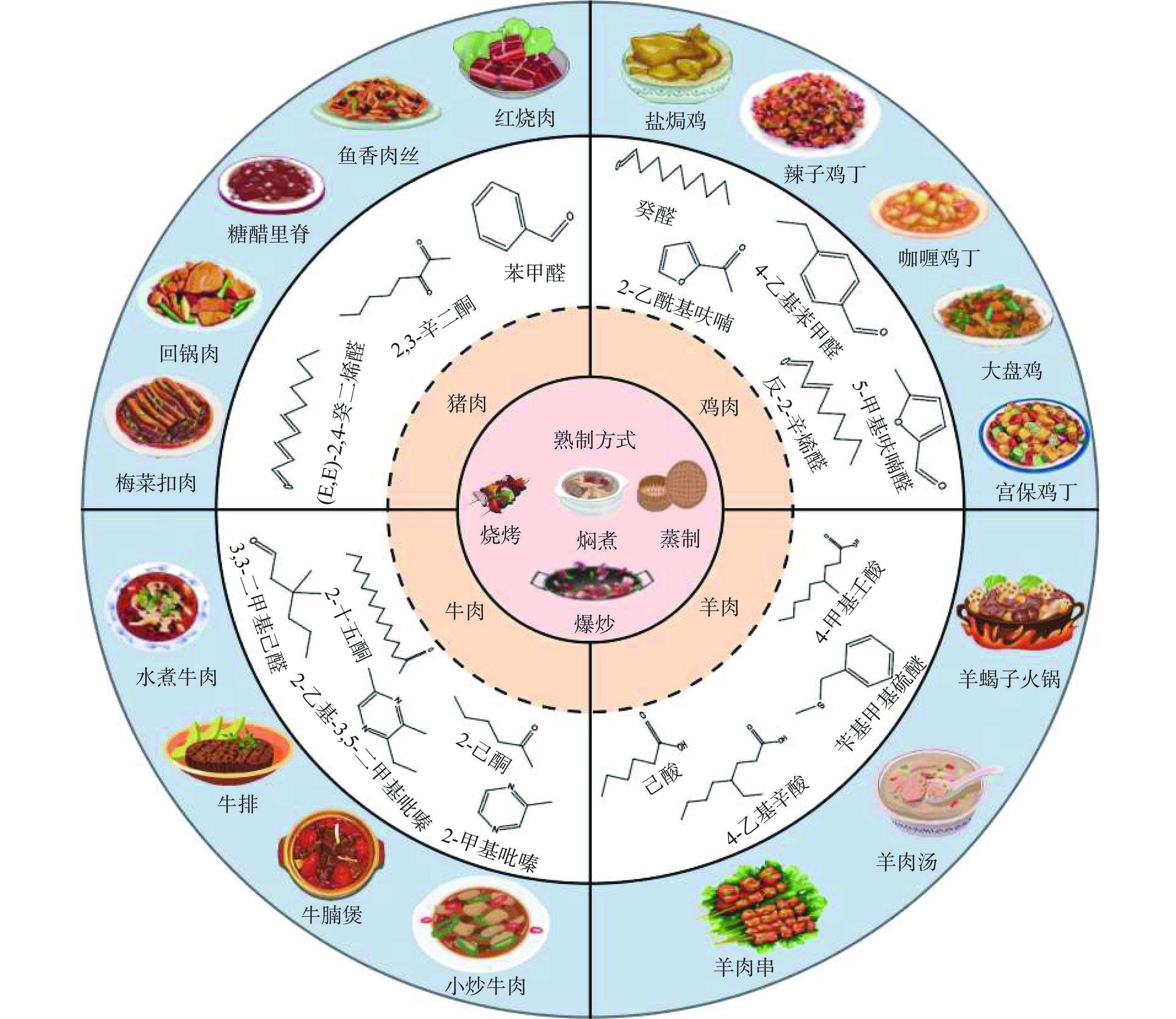

预制菜风味品质是影响消费者购买意愿的重要因素。畜禽类预制菜的特征风味主要来自肉品熟化过程中脂肪、蛋白质、氨基酸、硫化物等前体物质通过降解或美拉德反应产生脂肪烃、醛、酮、醇、羧酸、酯类、杂环化合物烷基呋喃和烷基硫等[6]。图1汇总了典型畜禽肉原料及其爆款预制菜肴的特征性风味物质[7−10]。近年来预制菜的研究多关注不良风味的消除以及特征风味的还原,在此基础上再进行便捷、营养、功能性探索。畜禽类预制菜的原料异味抑制和掩蔽、复热异味抑制都是相关研究的重点、热点和难点。畜禽原料异味主要包括屠宰后至烹饪前过程中脂肪、蛋白质因氧化降解产生挥发性异味,或致腐败微生物代谢上述营养物质产生异味。由于畜禽类预制菜食用前或经过复热处理,该过程涉及的多种物理化学变化可能导致菜品特征风味的损失和复热异味的产生。复热异味主要包括成品或半成品菜肴冷却贮藏后再加热过程中磷脂等不饱和脂肪酸因氧化产生挥发性异味及蛋白质中含硫氨基酸降解产生部分含硫化合物产生异味[11]。

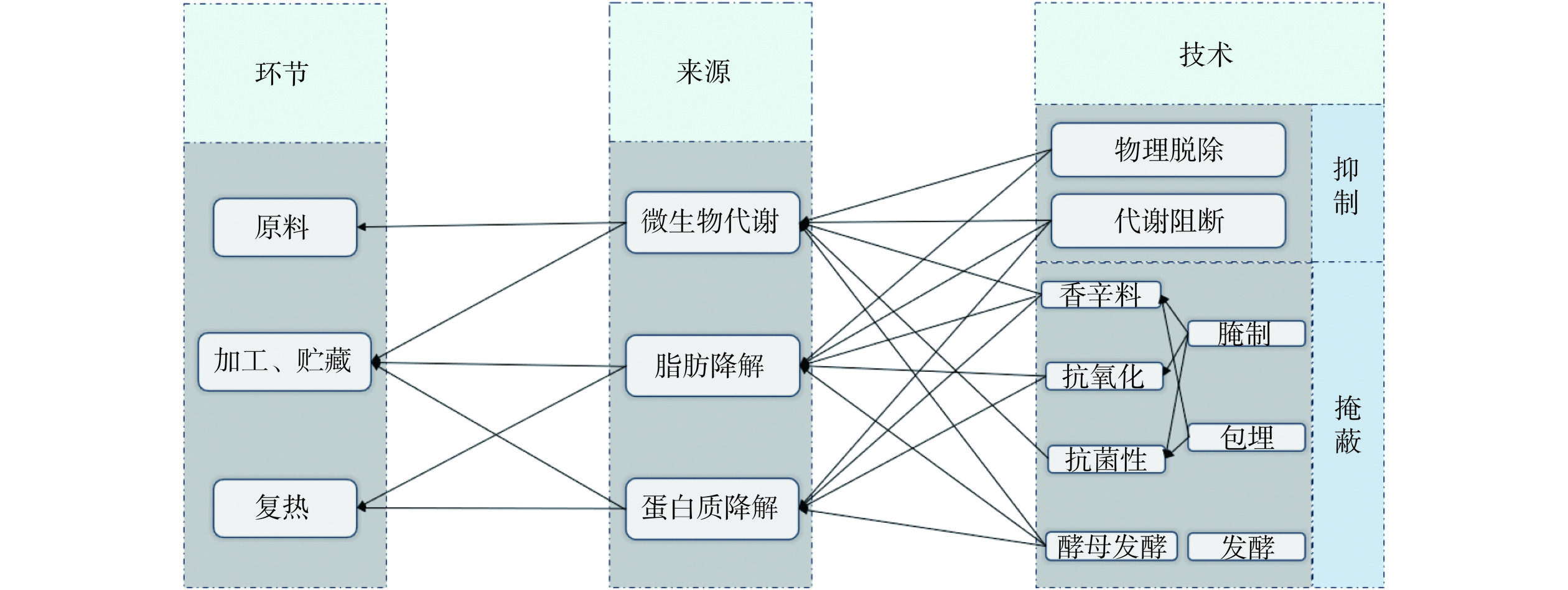

本文围绕畜禽类预制菜原料异味的来源、预制菜品复热异味的产生、相关异味的抑制和掩蔽展开综述(图2),系统梳理了畜禽类预制菜加工异味调控技术相关进展,期望能够以风味为着力点赋能中国畜禽类预制菜产业发展。

1. 畜禽类预制菜异味来源

1.1 原料异味

1.1.1 原料特性

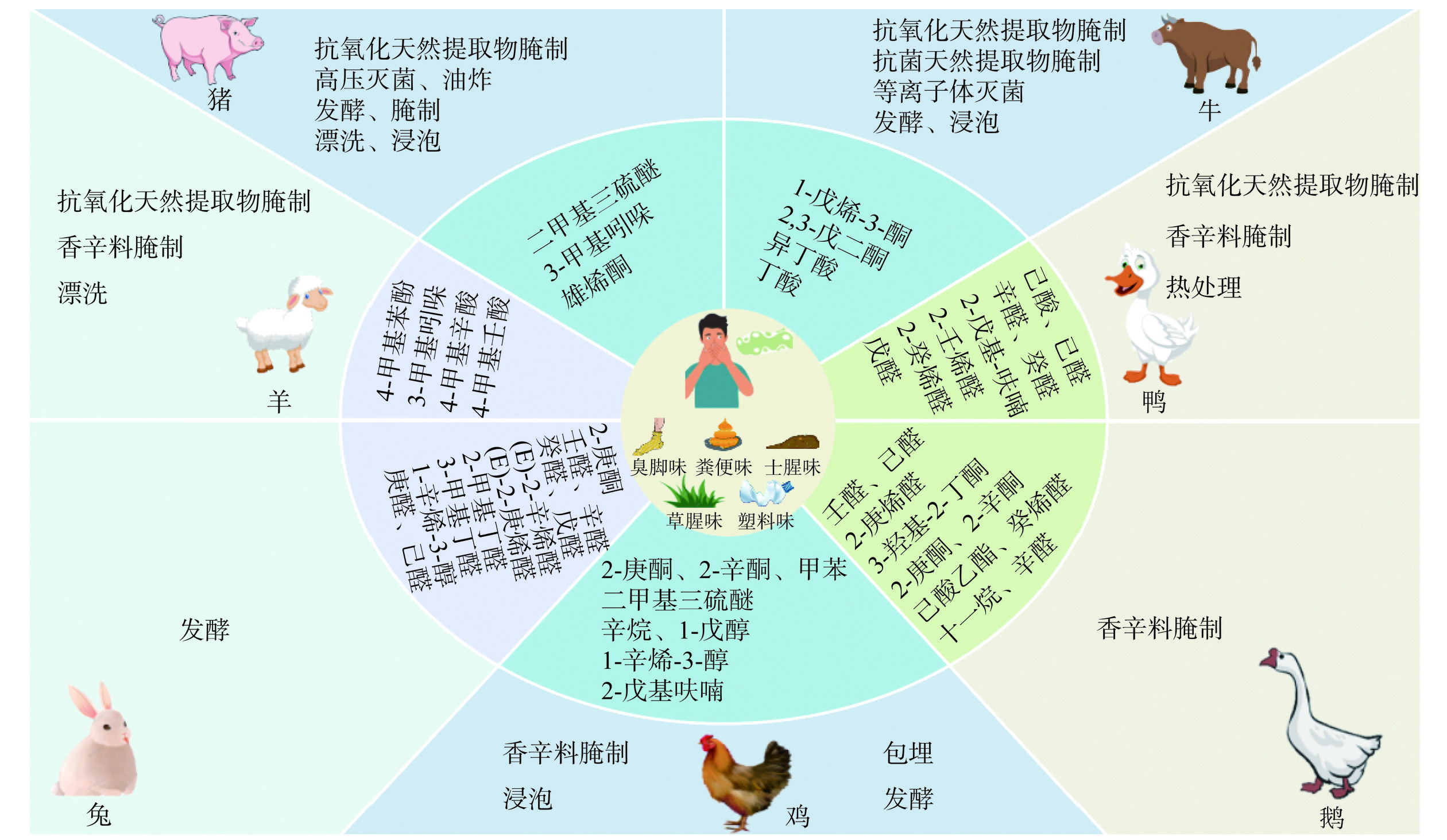

畜禽类预制菜原料肉品因基因、环境、饲料等原因宰杀前即存在某些令人不悦的气味[12−13]。猪肉自身存在的异味主要是有尿骚味和粪便臭味的雄烯酮、粪臭素和部分吲哚类物质[12−13],且粪臭素和吲哚类对猪肉异味的影响大于雄烯酮[14]。羊肉异味一般指羊肉膻味,以山羊为甚,膻味主要来源于C8~C10的支链脂肪酸,还有4-甲基苯酚、3-甲基吲哚、4-甲基辛酸和4-甲基壬酸等化合物[15−16]。绵羊的特殊风味亦与2-异丙基酚、3,4-二甲基酚、百里酚、甲基异丙基酚及3-异丙基酚等酚类物质有关[17]。膻味物质一般脂溶性好,故羊肉皮下脂肪、羊尾脂肪和肌肉间隙等脂肪富集的部位膻味较大[18]。兔肉异味主要来源于胺类、戊醛、2-戊基呋喃、己醛和己酸,养殖过程对其异味生成有显著影响[19−20]。鸡肉异味的主体物质为2-庚酮、2-辛酮、甲苯、辛烷、1-戊醇、1-辛烯-3-醇、2-戊基呋喃、二甲基三硫醚[21]。鹅肉异味主体物质为3-羟基-2-丁酮、2-庚酮、2-辛酮、壬醛、己醛、辛醛、2-庚烯醛、癸烯醛、己酸乙酯、十一烷[21]。

典型畜禽肉品原料异味成分及其主流异味掩蔽技术总结如图3。

1.1.2 微生物代谢

屠宰后肉品本身微生物繁殖能够促进醇类、醛类、酮类、脂肪酸类、酯类、含硫化合物等异味代谢物产生[20]。肉制品中含有丰富的蛋白质、必需矿物质、B-复合维生素,适于肉类腐败微生物和常见的食源性病原体生长繁殖。常见的肉品致腐微生物包括肠杆菌科、乳酸杆菌属、明串珠菌属、热杀索丝菌、假单胞菌、金黄色葡萄球菌、梭状芽孢杆菌属[22−23]。一般来说,肉制品的腐败速度取决于其葡萄糖、乳糖、含氮化合物和游离氨基酸的浓度,腐败微生物根据其种类不同和对以上化合物氧亲和力不同代谢产生不同物质[24]。典型的异味物质如表1所示,这些化合物之间的掩蔽和协同效应可能会导致畜禽类原料屠宰后异味的产生。对腐败畜禽肉的挥发性成分组学研究显示,醇类挥发性代谢物主要与假单胞菌属和肌细菌属有关[25];醛类挥发性代谢物和酮类挥发性代谢物主要与假单胞菌属、肌细胞菌属、肠杆菌科有关[25];酯类挥发性代谢物主要与莓实假单胞菌有关等[25];酸类挥发性代谢物主要与热杀索丝菌[26]、乳酸菌[27]有关;硫类挥发性代谢物等硫化物与假单胞菌有关[28]。

表 1 微生物作用下典型畜禽肉品的异味物质Table 1. Typical unfavorable odor compounds of meat and poultry materials with organism种类 异味物质 风味描述词 参考文献 醛类 己醛 青草味、酸败味 [28−29] 壬醛 脂肪味 [25,29] 庚醛 青草味 [29] 苯甲醛 尖锐苦杏仁味 [29] 3-甲基丁醛 脂肪味、坚果味 [29] 醇类 1-己醇 辛辣味 [29] 2,3-丁二醇 油脂味 [25] 3-甲基-1-丁醇 发酵味、辛辣味 [29] 1-辛烯-3-醇 泥土味 [30] 酯类 乙酸乙酯 刺激性气味 [25] 酸类 乙酸 辛辣酸味 [25] 丁酸 浓烈酸奶味 [29] 己酸 汗味、油脂味 [30] 2-甲基丁酸 刺鼻酸味 [31] 3-甲基丁酸 汗臭味、臭脚味 [29,31] 酮类 乙偶姻 奶油味 [32] 2,3-丁二酮 刺激性气味 [29] 硫化物 二甲基硫醚 硫磺味 [29] 二甲基二硫醚 硫磺味 [29] 二甲基三硫醚 熟制肉味、硫磺味 [29] 硫代乙酸甲酯 奶酪味、硫磺味 [33] 1.1.3 营养成分降解

屠宰后肉品蛋白质、脂质氧化降解也会进一步加速异味物质产生[33]。在畜禽类预制菜中,蛋白质和脂肪氧化常发生在加工后与复热前的贮运过程中。脂肪氧化降解的醛类、酮类、醇类是畜禽肉典型异味的主要来源之一,如羊肉脂肪氧化产生大量具有酸败味、辛辣味、刺激性气味的辛醛、戊醛、2-戊酮等[34],鸭肉脂肪氧化产生具有油脂味、蜡味、肥皂味的壬醛、辛醛、庚醛、癸醛、戊醛、己醛、(E)-2-辛烯醛、(E)-2-庚烯醛和3-甲基丁醛及1-辛烯-3-醇[35]。部分典型具有油脂味、口水味、肥皂味的醛类物质,常作为指标成分用于初步判断肉品变质的定性判断。

此外,蛋白质氧化产生的谷胱甘肽及含硫维生素也可在微生物酶促反应或热降解过程中生成二甲基二硫醚或三甲胺(腐臭味、鱼腥味)等异味成分;蛋白质氧化产生的亮氨酸、异亮氨酸和苯丙氨酸则可降解生成3-甲基丁醛(脂肪味、坚果味)、2-甲基丁醛(霉味、脂肪味)、苯甲醛(苦杏仁味)等具有特征异味的醛类物质[36]。蛋白质氧化与脂肪氧化产生的羰基化合物会转化衍生成部分多肽或氨基酸等中间产物[37−38],进而在微生物代谢产生的蛋白酶及酯酶的作用下发生脱氨和脱羧反应,生成半胱氨酸和蛋氨酸,进一步代谢可生成挥发性硫化异味成分。蛋白质降解及脂肪与脂质降解产物的互作产物大多具有显著的异味,例如牛肉中,蛋白质降解产物半胱氨酸与脂质降解产物磷脂互作生成了具有刺激性味道的4-甲基噻唑[39]。类似成分还包括具有硫磺味、腐败味的硫化物。这些营养成分代谢产物常具有典型的酸臭味、腐臭味或霉味,常用作判断畜禽肉品及其加工品新鲜程度的参考。

1.2 复热异味

预制菜复热不当可能导致菜品品质特别是风味品质出现不同程度的劣变,畜禽肉预制菜冷藏后复热可能出现“过熟味(warmed-over flavor,WOF)”,这种异味的描述词包括但不限于“硫化味”“亚麻籽油味”“硬纸板味”“金属味”“酸败味”“陈腐味”等[40]。脂肪过度氧化和蛋白质降解,菜肴贮藏时间、复热条件等均可能影响WOF形成。

1.2.1 脂质过度氧化

脂质氧化是WOF形成的主要途径。WOF主要在预先煮熟的肉制品短时间冷却冷藏后再加热期间产生,与磷脂在冷却冷藏过程氧化和烹饪过程经血红素铁和非血红素铁催化而过度氧化产生醛类物质有关[41−42]。WOF主要与棕榈油酸C16:1、油酸C18:1和亚油酸C18:2的氧化呈正相关,棕榈油酸和油酸主要氧化产物包括辛醛和壬醛[43],亚油酸主要氧化产物包括己醛和(E,E)-2,4-癸二烯醛。WOF依据肉品原料种类存在差异性,各类肉品WOF关键风味物质如表2,以己醛为代表的醛类和2,3-辛二酮是大多肉品的典型WOF。

由于WOF具有挥发性,适当延长复热时间和提高复热温度一定程度上能减少食用时感受到的WOF,但菜肴的特征风味成分也同时挥发导致菜肴感官体验不佳。张凯华等[44]探究水浴复热时间对猪肉糜制品挥发性物质含量影响,以WOF中典型醛类物质(戊醛、己醛、辛醛和(E,E)-2,4-癸二烯醛)含量为熟猪肉产品WOF的评价指标,沸水水浴复热前期(5~20 min)醛类物质含量较高,复热后期(35~65 min)酸类物质含量大幅升高,推测熟猪肉糜脂肪氧化生成WOF的醛类物质随复热时间延长而持续氧化降解为酸类物质。同时,在复热过程中,70~80 ℃的温度下,温和烹饪肉类会导致肌肉膜结构的破坏,并促进脂质氧化催化剂与不饱和脂肪酸的相互作用,导致自由基的产生和WOF的逸散,当复热温度达到100 ℃时,WOF风味物质形成受到抑制[45]。复热肉类菜品时,适当延长复热时间或能通过转化典型WOF成分减少食用时的异味,也可通过提高复热温度抑制脂肪氧化产生特定种类的WOF;但复热时间过长、复热温度过高易致蛋白质变性,使肉类菜品感官品质下降。

1.2.2 蛋白质降解

蛋白质降解产生的硫化物,特别是环状含硫化合物,是WOF的重要贡献成分。这类化合物在低浓度下具有肉香,高浓度下可能有“橡胶味”“硫化味”等气味[11]。冷藏过程中蛋白质中的含硫氨基酸或降解产生大量自由基,进一步生成有臭鸡蛋气味的硫化氢;烹饪过程中蛋白质中的烷基硫化物异构化和歧化也可能产生甲硫醇或硫化氢,它们与脂肪降解产生的不饱和醛反应也是生成含硫WOF的主要生成路径[48−49]。畜禽类预制菜的贮藏时间对WOF形成也有影响,将完成烹饪后的水煮猪肉和红烧肉在锅里放至自然冷却1 h,再放入冰箱,探究贮藏0、3、6、8、10 d的菜品风味变化,发现水煮猪肉在贮藏过程中戊醛、己醛、庚醛、2-戊基呋喃等主要WOF物质呈上升趋势,其含量在第6 d达到最大;红烧肉形成的WOF物质较少,可能是因为酱油的加入有助于延缓红烧肉的脂质氧化劣变[50]。含硫WOF含量随贮藏时间可能呈先增加达峰值后再降低的趋势[45]。究其原因,烹饪过程中经美拉德反应产生的硫醇可通过氧化还原反应生成含硫WOF,使其含量上升;贮藏过程中,脂肪氧化的消耗导致包装内氧含量下降,含硫WOF可能被还原为硫醇;且硫醇和含硫WOF都可能与其他自由基反应生成新的WOF。为减少含硫WOF生成,建议畜禽肉菜品熟制后需特别关注贮藏时间和贮藏温度,以最小化不同WOF组合对畜禽类预制菜品风味品质的不良影响。

2. 畜禽类预制菜的异味抑制与掩蔽

2.1 脱除原料异味

对于部分来源于畜禽原料本身的异味物质,清洗、浸泡、加热等物理方法能够达到一定的异味脱除效果。清洗畜禽原料是经典且经济的异味脱除方法,对羊肉膻味等原料本身异味较重的原料有良好的去膻效果。有报道发现用7倍于肉质量的温度40 ℃、pH8.2的水对羊肉进行5次漂洗后,经此条件处理的羊肉感官得分为8.8(总分10),膻味基本上难以察觉[51]。浸泡也是经典的减弱生肉腥味的方法之一。对烹饪前的猪肉进行温度50 ℃、20~40 min的温水浸泡,经感官评价发现生猪肉在此条件下气味评分最高,颜色呈淡黄色,脂肪细胞结构完整[52],有助于提升生猪肉后续烹饪时的风味品质。部分内脏菜肴可使用盐溶液浸泡辅助腥臭味物质溶出实现异味减弱的目的,可能引起牛肝异味的E-2-戊烯醛二聚体、E-3-戊烯-2-酮、乙酸乙酯、乙酸乙酯二聚体以及甲硫醇经1.0% NaCl 溶液浸泡60 min后含量显著降低[53]。热处理是较高效率除去异味物质的方法,加热后蛋白质结构变化,醛类风味物质(己醛、庚醛、辛醛、壬醛异味物质)与其结合能力改变[54];加热还可直接去除甲硫醇、乙醛、丙烯醛等低沸点异味物质[55]。用高压灭菌能降解猪肉原料中15%的具有粪便臭味的3-甲基吲哚,油炸能降解8.58%的3-甲基吲哚,而紫外线照射、超高压处理对3-甲基吲哚的降解效果不佳[56]。另有研究用90、100、105 ℃煮制鸭肉30 min,发现热处理后的鸭肉腥味程度感官评分降低,且105 ℃处理的鸭肉腥味评分最低[57]。清洗、浸泡、加热等是降低畜禽肉腥味简易可行、经济有效的方式。但清洗和浸泡仅能除去特定类型的异味成分,且异味脱除效果相对有限;热处理可能会改变畜禽肉菜品的感官品质,且适用范围聚焦熟食半成品或成品,有一定的局限性。

2.2 阻断异味代谢

对于部分来源于屠宰后肉品本身微生物繁殖或蛋白质、脂质氧化降解产生的异味物质,杀菌、灭酶等方法以及适宜的熟制方式能够达到一定的延缓或阻断其生成效果。等离子体技术通过产生活性氧抑制微生物生长和脂肪氧化,在有效灭菌的同时减少预制菜品特征风味的损失。将等离子体技术应用于高温蒸汽(SR)烘烤牛肉的处理,处理后肉品的亚硝酸盐产生的一氧化氮可与牛肉脂质氧化生成的过氧自由基反应,阻断SR牛肉脂肪氧化,较仅经SR处理的烘烤牛肉,其牛肉脂肪氧化产生的羰基类异味物质显著减少[58]。但目前类似的异味代谢阻断技术研究聚焦在鲜食果蔬、初级加工水产品等异味抑制,应用于熟制程度较高的畜禽类预制菜的异味抑制研究报道相对较少。

2.3 掩蔽异味成分

对于无法通过清洗、浸泡脱除或减菌抑霉方式有效抑制的其他异味成分,或难以通过有效的代谢阻断技术抑制的异味成分,则主要通过腌制、包埋、发酵等异味掩蔽技术,利用特殊风味或特殊结构掩蔽异味物质,实现弱化异味对菜品风味干扰的目的。

2.3.1 腌制掩蔽

具有特殊风味的植物提取物因兼具异味掩盖、抑菌和抗氧化的多重作用能较好地掩盖畜禽类预制菜的肉品异味。常见的植物提取物腌制剂主要包括香辛料、中草药和果蔬提取物等,部分天然提取物在畜禽类肉制品的脱腥应用及其作用机制总结于表3。

表 3 部分天然提取物在畜禽类肉制品的异味掩蔽应用及其作用机制Table 3. Application and its working mechanism of phytochemicals on deodorization of premade meat and poultry dishes序号 植物来源 作用活性成分 作用机制 应用 参考文献 1 百里香 百里香酚、壳聚糖 抑菌、抗氧化 猪肉、羊肉 [74,79] 2 紫苏 迷迭香酸、紫苏花色苷 抑菌、抗氧化 兔肉 [80−84] 3 木姜子 柠檬烯、芳樟醇和柠檬醛 抑菌、抗氧化 鸭肉 [70,85−86] 4 牛至 香芹酚、百里酚、γ-萜品烯、对萜烯 抑菌、抗氧化 猪肉 [87] 5 小叶薄荷 类黄酮(咖啡酸、迷迭香酸)、多酚(叶黄素、亚麻仁素、薯蓣皂苷和百里香素) 抑菌、抗氧化 禽类 [88] 6 丁香 丁香酚、乙酸丁香酯 抗氧化 牛肉 [89] 7 肉桂 (E)-肉桂醛、乙酸肉桂酯 抑菌 猪肉 [87] 8 迷迭香 迷迭香酸、鼠尾草酸、鼠尾草酚 抑菌、抗氧化 畜类、禽类 [90−92] 9 金丝莲 多酚、原小檗碱生物碱、罂粟碱、二氢小檗碱 抑菌、抗氧化 牛肉 [89,93] 10 菟子丝 菟子丝多糖 抑菌、抗氧化 猪肉 [94] 11 松针 多酚类、黄酮类 抑菌、抗氧化 猪肉 [95] 12 葡萄籽 原花青素、类黄酮儿茶素、表儿茶素 抗氧化 畜类、鸡肉 [96−97] 13 葡萄果皮 类黄酮(黄酮醇) 抗氧化 鸡肉 [98] 14 辣椒 辣椒素、二氢辣椒素 抗氧化 牛肉 [99] 15 淡竹叶 黄酮、内酯、酚酸类 抗氧化 马鹿肉 [100] 16 绿茶、红茶 茶多酚(儿茶素)、萜烯类、黄酮类 抗氧化 鸭肉 [101−102] 风味浓郁的生姜、葱、大蒜、茶叶、辣椒等植物能有效掩盖肉类异味。大蒜中的蒜氨酸、生姜中的姜精油和姜辣素都被常用于肉菜烹饪的压腥去膻处理,姜中多酚化合物(6-姜酚及衍生物)还能够抑制鸭肉中脂肪氧化,减少脂肪氧化特征异味物质的生成[59−60]。郭卫芸等[61]以新鲜鸭肉为原料,研究酱油、食醋的添加量、腌制温度和时间对鸭肉饺子馅料的腌制去腥效果,发现腌制温度为16 ℃,腌制时间为70 min时去腥效果评分最优。

以抑菌功能为主的植物提取物是抑制微生物代谢异味生成的有效方法。由肉豆蔻精油与鼠尾草种子粘液制备的一种新型食用涂层,能显著减少牛肉切片预制菜产品中的大肠杆菌、金黄色葡萄球菌、嗜冷菌和真菌等活菌数量,并降低牛肉切片的硫代巴比妥酸值,改善牛肉及牛肉制品颜色稳定性和感官特性[62]。经300 ppm百里酚和香芹酚腌制联合气调包装(MAP)处理的鸵鸟肉饼、鸡肉饼于18 ℃贮藏时,典型腐败和酸臭异味可延缓到第5 d出现,未经处理组异味第1 d即出现[63]。罗进等[64]采用壳聚糖腌制协同超声处理牛肝中的腥味物质正己醛、(E,E)-2,4-壬二烯醛、(E)-2-辛烯醛、壬醛、癸醛、十二醛、壬醇等,其抑腥效果强于葱-姜提取液掩盖法、面包酵母发酵法和活性干酵母+β环糊精复合法:因为壳聚糖具有抑菌作用,能够较好地抑制腥味的生成;超声的空化效应亦会破坏腥味物质与肉的结合,可加速腥味物质的去除。

具有抗氧化活性的植物提取物的异味掩蔽作用机制主要是与异味物质前体的活性形式反应形成相对稳定的非活性产物,通过阻断或抑制异味物质合成途径达到异味掩蔽的目的[65]。这些植物提取物可以直接与脂质自由基反应,转化为相对稳定的产物;或通过提供氢(H)、络合金属离子(Fe2+和Fe3+及铜离子)、清除氧气、吸收紫外辐射、抑制酶来降低氧化速率,或分解氢过氧化物来延缓氧化过程[33]。常见的香辛料如大蒜、香菜等具有一定的抗氧化活性。大蒜中的有机硫化物(二烯丙基二硫醚、二烯丙基硫醚)可显著延缓牛肉中氧合肌红蛋白和脂质的氧化[66];香菜水提液具有还原活性,可通过螯合铁离子、清除自由基抑制脂质氧化[67]。此外,用橡木提取物处理肉饼能延缓肉饼脂肪氧化,使具有草味和酸败味的己醛和庚醛异味物质含量减少[68]。在炖煮的鸭肉汤中加入木姜子后,鸭肉汤中的关键腥味物质壬醛、辛醛、庚醛、癸醛、戊醛、己醛、(E)-2-辛烯醛、(E)-2-庚烯醛、2-甲基丁醛、3-甲基丁醛、2-庚酮、1-辛烯-3-醇、反式-4,5-环氧-(E)-癸烯醛、对甲酚和4-甲基辛酸等含量显著减少[69−70]。将特定食材、香料、中草药与羊肉共煮可达到减轻羊肉膻味的效果,一方面加热能够促进部分异味物质挥发去除,另一方面胡萝卜、白萝卜、板栗、绿豆等食材,大蒜、辣椒、醋等香料以及白芷、砂仁、山楂、核桃、杏仁等中草药的特殊风味能够对羊肉膻味进行掩蔽,但产品冷藏后,膻味掩蔽作用减弱[71−72]。

天然植物提取物种类丰富,香辛料植物及提取物、抗菌类植物提取物、抗氧化功能性植物提取物腌制方法能安全、高效地去除和抑制异味。复合型天然植物提取物腌制极有可能是去除畜禽类预制菜腥味方式的发展方向。

2.3.2 其他异味掩蔽方法

包埋法是将需要包覆的物质细化成为粒径极其微小的固体颗粒或液滴,利用特殊工艺将其包裹在聚合物薄膜中。这种技术既能掩盖异味,又能起到抗氧化的作用[73]。通过包埋技术,基于百里香精油和百里香酚的具有抑菌特性的壳聚糖纳米乳,能够有效抑制猪肉中铜绿假单胞菌和大肠杆菌生长代谢,抑制具有恶臭味的硫化物产生[74]。但该方法有部分壁材对食品风味成分的特异性包埋效果不佳的风险[21],采用β-环糊精包埋鸡肝腥味的研究中发现,β-环糊精在包埋异味同时还会包埋鸡肝固有风味,造成成品菜肴特征风味的损失[75]。

部分酵母菌、乳酸菌、植物乳杆菌的代谢作用使小分子的异味物质转化为无异味的物质,或者在微生物酶的作用下发生分子结构修饰转化为无异味物质,发酵生成的部分代谢产物也会起到一定程度的异味掩蔽效果[76]。兔肉经酵母发酵后,典型兔肉腥味物质醛类减少,呈海产腥味的卤代烷烃类1-碘代十八烷、氯代十四烷和1-氯-7-十七烯在脱腥后也显著减少[77]。对豪猪猪肝进行酵母发酵脱腥,发现己醛、(Z)-2-庚烯醛(鱼腥味)、(E)-2-辛烯醛(纸板味)、1-辛烯-3-酮(金属味)、1-辛烯-3-醇等异味物质的种类和含量显著下降,能够有效去除豪猪肝异味[78]。鸡肝经姜酒浸泡和酵母发酵后,鸡肝中醛类物质含量均显著降低,多种致腥物质含量均明显下降,能较好改善鸡肝风味[75]。

包埋技术常与天然植物提取物协同用于特定异味的掩蔽,但有时会因包埋技术的识别机制有限,会非选择性地包埋畜禽类预制菜的固有特征风味。发酵工艺在大多数传统畜禽肉预制菜中的应用可能受限于消费者接受意愿,未能大规模推广应用。

2.4 改善复热异味

复热方式不仅影响预制菜品产生本身特征风味,且对WOF生成有显著影响。水浴复热、微波复热、蒸汽复热是目前畜禽类预制菜最常见的复热方式,它们对糖醋排骨的典型风味成分影响略有差异。三种主体风味D-柠檬烯、2-戊基呋喃、糠醛在微波复热后损失最多,损失率达44%、43%、17%;蒸汽复热损失最少,损失率为34%、25%、0%[103]。张凯华等[40]探究巴氏复热、水蒸复热、微波复热和高温复热与猪耳朵WOF相关性,己醛、庚醛、辛醛、壬醛、癸醛、(E)-2-癸烯醛、(E,E)-2,4-癸二烯醛和1-辛烯-3-醇为猪耳朵WOF关键风味成分,巴氏复热显著增加WOF关键风味成分含量和硫代巴比妥酸值,微波复热能够较好减少WOF的形成。

目前对预制菜复热工艺及WOF抑制的研究主要集中在菜品贮藏时间、贮藏温度、烹饪温度、烹饪方式、烹饪时间、烹饪最终温度,围绕抑制脂肪氧化、蛋白质氧化或促使已生成WOF转化为其他非异味成分开展研究。

3. 总结与展望

预制菜风味品质是影响消费者购买意愿的重要因素。本文从预制菜异味的产生和相关异味的抑制和掩蔽技术两个方面对当前畜禽类预制菜的风味调控技术开展讨论,总结了脱除原料异味、阻断异味代谢、掩蔽异味成分等目前降低预制菜原料异味的主要方法。由于畜禽类预制菜风味一旦发生劣变特别是异味产生后难以逆转,兼具异味掩盖和抗氧化双重作用的天然植物提取物腌制技术是现行畜禽类预制菜异味抑制的研究热点和发展方向。抑制预制菜复热异味的产生也是提升预制菜风味品质的重要方面,菜品贮藏时间、复热时间及复热方式对复热异味的生成有重要影响。我国预制菜正进入高速发展的阶段,畜禽类预制菜的异味抑制和掩蔽仍是限制产业升级的瓶颈问题。拥有清洁标签优势的天然植物提取物在预制菜风味调控方向的应用前景非常广阔,未来应进一步开展有关天然植物提取物、复热方式对畜禽类预制菜风味调控的研究,重点关注天然植物提取物在畜禽类预制菜原料异味掩蔽及复热异味抑制的理论和应用研究。异味掩蔽和抑制技术的合理应用有助于满足消费者对预制菜品质提升的期待,是未来预制菜产业持续关注和重点发展的方向。

-

表 1 微生物作用下典型畜禽肉品的异味物质

Table 1 Typical unfavorable odor compounds of meat and poultry materials with organism

种类 异味物质 风味描述词 参考文献 醛类 己醛 青草味、酸败味 [28−29] 壬醛 脂肪味 [25,29] 庚醛 青草味 [29] 苯甲醛 尖锐苦杏仁味 [29] 3-甲基丁醛 脂肪味、坚果味 [29] 醇类 1-己醇 辛辣味 [29] 2,3-丁二醇 油脂味 [25] 3-甲基-1-丁醇 发酵味、辛辣味 [29] 1-辛烯-3-醇 泥土味 [30] 酯类 乙酸乙酯 刺激性气味 [25] 酸类 乙酸 辛辣酸味 [25] 丁酸 浓烈酸奶味 [29] 己酸 汗味、油脂味 [30] 2-甲基丁酸 刺鼻酸味 [31] 3-甲基丁酸 汗臭味、臭脚味 [29,31] 酮类 乙偶姻 奶油味 [32] 2,3-丁二酮 刺激性气味 [29] 硫化物 二甲基硫醚 硫磺味 [29] 二甲基二硫醚 硫磺味 [29] 二甲基三硫醚 熟制肉味、硫磺味 [29] 硫代乙酸甲酯 奶酪味、硫磺味 [33] 表 2 典型畜禽肉品的复热异味成分

Table 2 Warmed-over flavor compounds of typical meat and poultry materials

表 3 部分天然提取物在畜禽类肉制品的异味掩蔽应用及其作用机制

Table 3 Application and its working mechanism of phytochemicals on deodorization of premade meat and poultry dishes

序号 植物来源 作用活性成分 作用机制 应用 参考文献 1 百里香 百里香酚、壳聚糖 抑菌、抗氧化 猪肉、羊肉 [74,79] 2 紫苏 迷迭香酸、紫苏花色苷 抑菌、抗氧化 兔肉 [80−84] 3 木姜子 柠檬烯、芳樟醇和柠檬醛 抑菌、抗氧化 鸭肉 [70,85−86] 4 牛至 香芹酚、百里酚、γ-萜品烯、对萜烯 抑菌、抗氧化 猪肉 [87] 5 小叶薄荷 类黄酮(咖啡酸、迷迭香酸)、多酚(叶黄素、亚麻仁素、薯蓣皂苷和百里香素) 抑菌、抗氧化 禽类 [88] 6 丁香 丁香酚、乙酸丁香酯 抗氧化 牛肉 [89] 7 肉桂 (E)-肉桂醛、乙酸肉桂酯 抑菌 猪肉 [87] 8 迷迭香 迷迭香酸、鼠尾草酸、鼠尾草酚 抑菌、抗氧化 畜类、禽类 [90−92] 9 金丝莲 多酚、原小檗碱生物碱、罂粟碱、二氢小檗碱 抑菌、抗氧化 牛肉 [89,93] 10 菟子丝 菟子丝多糖 抑菌、抗氧化 猪肉 [94] 11 松针 多酚类、黄酮类 抑菌、抗氧化 猪肉 [95] 12 葡萄籽 原花青素、类黄酮儿茶素、表儿茶素 抗氧化 畜类、鸡肉 [96−97] 13 葡萄果皮 类黄酮(黄酮醇) 抗氧化 鸡肉 [98] 14 辣椒 辣椒素、二氢辣椒素 抗氧化 牛肉 [99] 15 淡竹叶 黄酮、内酯、酚酸类 抗氧化 马鹿肉 [100] 16 绿茶、红茶 茶多酚(儿茶素)、萜烯类、黄酮类 抗氧化 鸭肉 [101−102] -

[1] 国家市场监督管理总局, 教育部, 工业和信息化部, 农业农村部, 商务部, 国家卫生健康委. 关于加强预制菜食品安全监管促进产业高质量发展的通知[EB/OL]. (2024-03-18)[2024-05-15]. https://www.gov.cn/zhengce/zhengceku/202403/content_6940808.htm. [State Administration for Market Regulation, Ministry of Education of the People's Republic of China, Ministry of Industry and Information Technology of the People's Republic of China, Ministry of Agriculture and Rural Affairs of the People's Republic of China, Ministry of Commerce, National Health Commission of the People's Republic of China. Notice on strengthening food safety supervision of prepared dishes and promoting high-quality development of the industry[EB/OL]. (2024-03-18) [2024-05-15]. https://www.gov.cn/zhengce/zhengceku/202403/content_6940808.htm.] State Administration for Market Regulation, Ministry of Education of the People's Republic of China, Ministry of Industry and Information Technology of the People's Republic of China, Ministry of Agriculture and Rural Affairs of the People's Republic of China, Ministry of Commerce, National Health Commission of the People's Republic of China. Notice on strengthening food safety supervision of prepared dishes and promoting high-quality development of the industry[EB/OL]. (2024-03-18) [2024-05-15]. https://www.gov.cn/zhengce/zhengceku/202403/content_6940808.htm.

[2] 国家粮食和物资储备局. 2023年中央一号文件[EB/OL]. (2023–01–02). http://www.lswz.gov.cn/html/xinwen/2023-02/13/content_273655.shtml. [State Bureau of Grain and Material Reserves. Central document No. 1 of 2023[EB/OL]. (2023-01-02)[2024-05-15]. http://www.lswz.gov.cn/html/xinwen/2023-02/13/content_273655.shtml.] State Bureau of Grain and Material Reserves. Central document No. 1 of 2023[EB/OL]. (2023-01-02)[2024-05-15]. http://www.lswz.gov.cn/html/xinwen/2023-02/13/content_273655.shtml.

[3] 人民网研究院. 预制菜行业发展报告[EB/OL]. (2023–07–11) [2024-05-15]. http://yjy.people.com.cn/n1/2023/0710/c440911-40031856.html. [People's Daily Online Research Institute. Prefabricated dish industry development report [EB/OL]. (2023-07-11) [2024-05-15]. http://yjy.people.com.cn/n1/2023/0710/c440911-40031856.html.] People's Daily Online Research Institute. Prefabricated dish industry development report [EB/OL]. (2023-07-11) [2024-05-15]. http://yjy.people.com.cn/n1/2023/0710/c440911-40031856.html.

[4] 艾媒餐饮研究院. 艾媒咨询|2022年中国预制菜产业发展白皮书[EB/OL]. (2023–03–03) [2024-05-15]. https://www.iimedia.cn/c400/92015.html. [iMedia Restaurant Research Institute. Ai Media Consulting|White paper on the development of China's prepared dishes industry in 2022[EB/OL]. (2023-03-03) [2024-05-15]. https://www.iimedia.cn/c400/92015.html.] iMedia Restaurant Research Institute. Ai Media Consulting|White paper on the development of China's prepared dishes industry in 2022[EB/OL]. (2023-03-03) [2024-05-15]. https://www.iimedia.cn/c400/92015.html.

[5] 薛梦帆, 刘亚钊. 我国城镇居民猪肉消费影响因素研究[J]. 现代畜牧兽医,2022(8):62−66. [XUE M F, LIU Y Z. Research on influencing factors of pork consumption of urban residents in China[J]. Modern Animal Husbandry and Veterinary Medicine,2022(8):62−66.] XUE M F, LIU Y Z. Research on influencing factors of pork consumption of urban residents in China[J]. Modern Animal Husbandry and Veterinary Medicine, 2022(8): 62−66.

[6] BLEICHER J, EBNER E E, BAK K H. Formation and analysis of volatile and odor compounds in meat—A review[J]. Molecules,2022,27(19):6703. doi: 10.3390/molecules27196703

[7] CERNY C, GROSCH W. Precursors of ethyldimethylpyrazine isomers and 2,3-diethyl-5-methylpyrazine formed in roasted beef[J]. Zeitschrift Für Lebensmittel-Untersuchung and -Forschung,1994,198(3):210−214.

[8] 薛雁, 周芳伊, 黄峰, 等. 毛氏红烧肉特征风味成分分析[J]. 食品研究与开发, 2019, 40(11):153–158. [XUE Y, ZHOU F Y, HUANG F, et al. Analysis of characteristic flavor components of Mao's braised meat[J]. Food Research and Development, 2019, 40(11):153–158.] XUE Y, ZHOU F Y, HUANG F, et al. Analysis of characteristic flavor components of Mao's braised meat[J]. Food Research and Development, 2019, 40(11): 153–158.

[9] 詹萍, 田洪磊, 李卫国, 等. 羊肉特征风味指纹图谱的构建[J]. 现代食品科技,2013,29(10):2522−2527. [ZHAN P, TIAN H L, LI W G, et al. Establishment of mutton characteristic flavor fingerprint[J]. Modern Food Science and Technology,2013,29(10):2522−2527.] ZHAN P, TIAN H L, LI W G, et al. Establishment of mutton characteristic flavor fingerprint[J]. Modern Food Science and Technology, 2013, 29(10): 2522−2527.

[10] 肖智超, 葛长荣, 周光宏, 等. 肉的风味物质及其检测技术研究进展[J]. 食品工业科技,2019,40(4):325−330. [XIAO Z C, GE C R, ZHOU G H, et al. Research progress on meat flavor substance and detect technique[J]. Science and Technology of Food Industry,2019,40(4):325−330.] XIAO Z C, GE C R, ZHOU G H, et al. Research progress on meat flavor substance and detect technique[J]. Science and Technology of Food Industry, 2019, 40(4): 325−330.

[11] BYRNE D V, BREDIE W L P, BAK L S, et al. Sensory and chemical analysis of cooked porcine meat patties in relation to warmed-over flavour and pre-slaughter Stress[J]. Meat Science,2001,59(3):229−249. doi: 10.1016/S0309-1740(01)00072-9

[12] KOCK H L, HEINZE P H, POTGIETER C M , et al. Temporal aspects related to the perception of skatole and androstenone, the major boar odour compounds[J]. Meat Science, 2001, 57(1):61–70.

[13] 孟晓, 贺稚非, 李洪军. 全公猪肉膻味物质研究进展[J]. 食品工业科技,2013,34(12):392−395. [MENG X, HE Z F, LI H J. Research progress in boar taint of intact male pig meat[J]. Science and Technology of Food Industry,2013,34(12):392−395.] MENG X, HE Z F, LI H J. Research progress in boar taint of intact male pig meat[J]. Science and Technology of Food Industry, 2013, 34(12): 392−395.

[14] ANNOR-FREMPONG I E, NUTE G R, WHITTINGTON F W, et al. The problem of taint in pork—III. Odour profile of pork fat and the interrelationships between androstenone, skatole and indole concentrations[J]. Meat Science,1997,47(1-2):63−76. doi: 10.1016/S0309-1740(97)00043-0

[15] 张志超, 王小琪, 包琦, 等. 澳洲白羊与小尾寒羊杂交F1代背最长肌肉品质与皮下脂肪组织膻味物质分析[J]. 食品工业科技,2021,42(14):272−277. [ZHANG Z C, WANG X Q, BAO Q, et al. Analysis of the longissimus dorsi meat quality and the content of mutton flavor substances of F1 hybrid sheep between Australian white sheep and native small-tail Han sheep[J]. Science and Technology of Food Industry,2021,42(14):272−277.] ZHANG Z C, WANG X Q, BAO Q, et al. Analysis of the longissimus dorsi meat quality and the content of mutton flavor substances of F1 hybrid sheep between Australian white sheep and native small-tail Han sheep[J]. Science and Technology of Food Industry, 2021, 42(14): 272−277.

[16] 丁艳艳, 王亮亮, 韩卫杰, 等. 不同绵羊品种膻味物质分离、鉴定和比较分析[J]. 西北农业学报,2011,20(11):17−21. [DING Y Y, WANG L L, HAN W J, et al. Extraction, identification and comparison of mutton flavor materials from different sheep breeds[J]. Acta Agriculturae Boreali-occidentalis Sinica,2011,20(11):17−21.] doi: 10.3969/j.issn.1004-1389.2011.11.004 DING Y Y, WANG L L, HAN W J, et al. Extraction, identification and comparison of mutton flavor materials from different sheep breeds[J]. Acta Agriculturae Boreali-occidentalis Sinica, 2011, 20(11): 17−21. doi: 10.3969/j.issn.1004-1389.2011.11.004

[17] 张巧娥, 敖长金. 羊肉风味的研究进展[J]. 动物营养学报,2006(S1):367−371. [ZHANG Q E, AO C J. Research progress on the study of lamb flavour[J]. Chinese Journal of Animal Nutrition,2006(S1):367−371.] ZHANG Q E, AO C J. Research progress on the study of lamb flavour[J]. Chinese Journal of Animal Nutrition, 2006(S1): 367−371.

[18] 黄梅丽. 禽、畜肉的异味与加工处理[J]. 中国食品,1999(23):29. [HUANG M L. Odour and processing of meat and poultry meat[J]. China Food,1999(23):29.] HUANG M L. Odour and processing of meat and poultry meat[J]. China Food, 1999(23): 29.

[19] 谢跃杰, 贺稚非, 李洪军. 超临界CO2流体萃取兔肉腥味物质[J]. 中国农业科学,2016,49(16):3208−3218. [XIE Y J, HE Z F, LI H J. The odor of rabbit meat extracted by supercritical carbon dioxide fluid extraction[J]. Scientia Agricultura Sinica,2016,49(16):3208−3218.] doi: 10.3864/j.issn.0578-1752.2016.16.014 XIE Y J, HE Z F, LI H J. The odor of rabbit meat extracted by supercritical carbon dioxide fluid extraction[J]. Scientia Agricultura Sinica, 2016, 49(16): 3208−3218. doi: 10.3864/j.issn.0578-1752.2016.16.014

[20] 朱成林, 李诚, 付刚, 等. 兔肉腥味物质的研究进展[J]. 食品安全质量检测学报, 2015, 6(1):165–169. [ZHU C L, LI C, FU G, et al. Research progress on rabbit meat flavor substances[J]. Journal of Food Safety and Quality, 2015, 6(1):165–169.] ZHU C L, LI C, FU G, et al. Research progress on rabbit meat flavor substances[J]. Journal of Food Safety and Quality, 2015, 6(1): 165–169.

[21] 刘春节, 张涛, 曾治国, 等. 畜禽肉类腥味物质检测与去除方法研究进展[J]. 食品与发酵工业,2022,49(14):338−345. [LIU C J, ZHANG T, ZENG Z G, et al. Research progress on detection and removal methods of fishy substances in livestock and poultry meat[J]. Food and Fermentation Industries,2022,49(14):338−345.] LIU C J, ZHANG T, ZENG Z G, et al. Research progress on detection and removal methods of fishy substances in livestock and poultry meat[J]. Food and Fermentation Industries, 2022, 49(14): 338−345.

[22] ELISABETH B, MARIE L K M, YLVA B. Bacterial spoilage of meat and cured meat products[J]. International Journal of Food Microbiology,1996,33(1):103−120. doi: 10.1016/0168-1605(96)01135-X

[23] DOULGERAKI A I, ERCOLINI D, VILLANI F, et al. Spoilage microbiota associated to the storage of raw meat in different conditions[J]. International Journal of Food Microbiology,2012,157(2):130−141. doi: 10.1016/j.ijfoodmicro.2012.05.020

[24] GEORGE-JOHN E N, PANOS N S, CHRYSOULA C T, et al. Meat spoilage during distribution[J]. Meat Science,2008,78(1−2):77−89. doi: 10.1016/j.meatsci.2007.06.020

[25] 赵志平, 张盛源, 陈泓帆, 等. 基于GC-IMS和电子鼻分析牛肉腐败进程中挥发性风味物质的变化[J/OL]. 食品工业科技, 1−15. [2024-05-14]. https://doi.org/10.13386/j.issn1002-0306.2023070121. [ZHAO Z P, ZHANG S Y, CHEN H F, et al. Changes of volatile flavor substances of beeves in spoilage process based on gas chromatographyion mobility spectrometry and electronic nose[J/OL]. Science and Technology of Food Industry, 1−15. [2024-05-14]. https://doi.org/10.13386/j.issn1002-0306.2023070121.] ZHAO Z P, ZHANG S Y, CHEN H F, et al. Changes of volatile flavor substances of beeves in spoilage process based on gas chromatographyion mobility spectrometry and electronic nose[J/OL]. Science and Technology of Food Industry, 1−15. [2024-05-14]. https://doi.org/10.13386/j.issn1002-0306.2023070121.

[26] ANNALISA C, FRANCESCA D F, FRANCESCO V, et al. Activities of strains of Brochothrix thermosphacta in vitro and in meat[J]. Food Research International,2014,62:366−374. doi: 10.1016/j.foodres.2014.03.019

[27] BRODA D M, SAUL D J, LAWSON P A, et al. Clostridium gasigenes sp. nov., a psychrophile causing spoilage of vacuum-packed meat[J]. International Journal of Systematic and Evolutionary Microbiology, 2000, 50(1):107–118.

[28] SAMELIS J. Managing microbial spoilage in the meat industry[M]. Greece:Food Spoilage Microorganisms & Woodhead Publishing, 2006:213–286.

[29] ANNALISA C, PAOLA P, GEORGE-JOHN N, et al. Bacterial populations and the volatilome associated to meat spoilage[J]. Food Microbiology,2015,45:83−102. doi: 10.1016/j.fm.2014.02.002

[30] CASABURI A, NASI A, FERROCINO I, et al. Spoilage-related activity of Carnobacterium maltaromaticum strains in air-stored and vacuum-packed meat[J]. Applied and Environmental Microbiology,2011,77(20):7382−7393. doi: 10.1128/AEM.05304-11

[31] DAINTY R H, EDWARDS R A, HIBBARD C M. Time course of volatile compound formation during refrigerated storage of naturally contaminated beef in air[J]. Journal of Applied Bacteriology,1985,59(4):303−309. doi: 10.1111/j.1365-2672.1985.tb03324.x

[32] 方金玉. 冷鲜牛肉中假单胞菌和热死环丝菌致腐机制及其光动力杀菌控制研究[D]. 杭州:浙江工商大学, 2023. [FANG J Y. Spoilage mechannisms of Pseudomonas and Brochothrix thermosphacta in chilled beef and photodynamic inactivation control[D]. Hangzhou:Zhejiang Gongshang University, 2023.] FANG J Y. Spoilage mechannisms of Pseudomonas and Brochothrix thermosphacta in chilled beef and photodynamic inactivation control[D]. Hangzhou: Zhejiang Gongshang University, 2023.

[33] KUMAR Y, YADAV D N, AHMAD T, et al. Recent trends in the use of natural antioxidants for meat and meat products[J]. Comprehensive Reviews in Food Science and Food Safety,2015,14(6):796−812. doi: 10.1111/1541-4337.12156

[34] 董阳阳. 水煮羊肉在贮藏期风味物质变化及工艺优化[D]. 乌鲁木齐:新疆农业大学, 2022. [DONG Y Y. Changes of flavor substances and process optimization of boiled mutton during storage[D]. Urumqi:Xinjiang Agricultural University, 2022.] DONG Y Y. Changes of flavor substances and process optimization of boiled mutton during storage[D]. Urumqi: Xinjiang Agricultural University, 2022.

[35] SUN H L, ZHAO Y Q, ZHAO J, et al. Ultrasound thawing for improving the eating quality and off-flavor of frozen duck meat and its possible mechanisms[J]. LWT,2023,187:115314. doi: 10.1016/j.lwt.2023.115314

[36] 石林凡, 李周茹, 任中阳, 等. 贝类腥味物质及形成机理研究进展[J]. 中国食品学报,2023,23(3):406−415. [SHI L F, LI Z R, REN Z Y, et al. Research progress on the study of fishy flavour substances and formation mechanism of shellfish[J]. Journal of Chinese Institute of Food Science and Technology,2023,23(3):406−415.] SHI L F, LI Z R, REN Z Y, et al. Research progress on the study of fishy flavour substances and formation mechanism of shellfish[J]. Journal of Chinese Institute of Food Science and Technology, 2023, 23(3): 406−415.

[37] ZHANG W, XIAO S, AHN D U. Protein oxidation:Basic principles and implications for meat quality[J]. Critical Reviews in Food Science and Nutrition,2013,53(11):1191−1201. doi: 10.1080/10408398.2011.577540

[38] DAVIES M J. Protein oxidation and peroxidation[J]. Biochemical Journal,2016,473(7):805−825. doi: 10.1042/BJ20151227

[39] WANG Q, DONG K, WU Y Y. Exploring the formation mechanism of off-flavor of irradiated yak meat based on metabolomics[J]. Food Chemistry:X,2022,16:100494.

[40] 张凯华, 臧明伍, 张哲奇, 等. 不同复热方式对猪耳朵制品挥发性风味和脂肪氧化的影响[J]. 食品科学,2018,39(14):242−248. [ZHANG K H, ZHANG M W, ZHANG Z Q, et al. Effect of reheating methods on volatile flavor constituents and lipid oxidation in cooked pig ear[J]. Food Science,2018,39(14):242−248.] doi: 10.7506/spkx1002-6630-201814036 ZHANG K H, ZHANG M W, ZHANG Z Q, et al. Effect of reheating methods on volatile flavor constituents and lipid oxidation in cooked pig ear[J]. Food Science, 2018, 39(14): 242−248. doi: 10.7506/spkx1002-6630-201814036

[41] CHARLOTTE U C, JENS K S, LEIF H S, et al. Heme-iron in lipid oxidation[J]. Coordination Chemistry Reviews,2005,249(3-4):485−498. doi: 10.1016/j.ccr.2004.08.028

[42] 任志伟. 鸭肉熟制品WOF异味抑制研究[D]. 合肥:合肥工业大学, 2012. [REN Z W. Study on the inhibtion of warmed-over flavor in cooked duck meat[D]. Hefei:Hefei Technology University, 2012.] REN Z W. Study on the inhibtion of warmed-over flavor in cooked duck meat[D]. Hefei: Hefei Technology University, 2012.

[43] ZHANG K, LI D, ZANG M W. Comparative characterization of fatty acids, reheating volatile compounds, and warmed-over flavor (WOF) of Chinese indigenous pork and hybrid pork[J]. LWT,2022,155:112981. doi: 10.1016/j.lwt.2021.112981

[44] 张凯华, 臧明伍, 张哲奇, 等. 水浴复热时间对猪肉糜制品挥发性风味的影响[J]. 食品科学,2019,40(2):186−191. [ZHANG K H, ZHANG M W, ZHANG Z Q, et al. Effects of water-bath reheating time on volatile compounds in cooked minced pork[J]. Food Science,2019,40(2):186−191.] doi: 10.7506/spkx1002-6630-20180727-325 ZHANG K H, ZHANG M W, ZHANG Z Q, et al. Effects of water-bath reheating time on volatile compounds in cooked minced pork[J]. Food Science, 2019, 40(2): 186−191. doi: 10.7506/spkx1002-6630-20180727-325

[45] BYRNE D V, BREDIE W L P, MOTTRAM D S, et al. Sensory and chemical investigations on the effect of oven cooking on warmed-over flavour development in chicken meat[J]. Meat Science,2002,61(2):127−139. doi: 10.1016/S0309-1740(01)00171-1

[46] SULLIVAN M G, BYRNE D V, JENSEN M T, et al. A comparison of warmed-over flavour in pork by sensory analysis, GC/MS and the electronic nose[J]. Meat Science,2003,65(3):1125−1138. doi: 10.1016/S0309-1740(02)00342-X

[47] 王子凌, 王海滨, 周晓荣, 等. 水产品、畜禽肉异味物质及其脱除技术的研究进展[J]. 肉类工业,2022(9):41−47. [WANG Z L, WANG H B, ZHOU X R, et al. Research progress on the odorours substances in aquaic products and livestock and poultry meat and their removal technology[J]. Meat Industry,2022(9):41−47.] doi: 10.3969/j.issn.1008-5467.2022.09.008 WANG Z L, WANG H B, ZHOU X R, et al. Research progress on the odorours substances in aquaic products and livestock and poultry meat and their removal technology[J]. Meat Industry, 2022(9): 41−47. doi: 10.3969/j.issn.1008-5467.2022.09.008

[48] DRUMM T D, SPANIER A M. Changes in the content of lipid autoxidation and sulfur-containing compounds in cooked beef during storage[J]. Journal of Agriculture and Food Chemistry,1991,39:336−343. doi: 10.1021/jf00002a023

[49] BOELENS M, VAN L M, DE V P J, et al. Organic sulfur compounds from fatty aldehydes, hydrogen sulfide, thiols, and ammonia as flavor constituents[J]. Journal of Agricultural and Food Chemistry,1974,22(6):1071−1076. doi: 10.1021/jf60196a036

[50] LIU T T, YANG T S, WU C M. Changes of volatiles in soy sauce-stewed pork during cold storage and reheating[J]. Journal of the Science of Food and Agriculture,2001,81(15):1547−1552. doi: 10.1002/jsfa.978

[51] 顾仁勇, 银永忠, 傅伟昌. 羊肉的漂洗脱膻及风味羊肉丝的研制[J]. 食品工业科技,2008(3):213−215. [GU R Y, YIN Y Z, FU W C. Preparatoin of flavor mutton silk and de-odoring of mutton with wash[J]. Science and Technology of Food Industry,2008(3):213−215.] GU R Y, YIN Y Z, FU W C. Preparatoin of flavor mutton silk and de-odoring of mutton with wash[J]. Science and Technology of Food Industry, 2008(3): 213−215.

[52] 朱氏黎花, 谢佳, 何松贵, 等. 温水浸泡消除生猪肉腥味及肉质损失评价[J]. 食品工业科技,2016,37(23):328−332,337. [ZHU S L H, XIE J, HE S G, et al. Evaluation of immersion using warm water on the removal of off-flavor from raw pork and its weight loss[J]. Science and Technology of Food Industry,2016,37(23):328−332,337.] ZHU S L H, XIE J, HE S G, et al. Evaluation of immersion using warm water on the removal of off-flavor from raw pork and its weight loss[J]. Science and Technology of Food Industry, 2016, 37(23): 328−332,337.

[53] 刘子琪, 董丽琴, 杨大维, 等. NaCl浸泡处理对牛肝风味的影响[J]. 食品与发酵工业,2022,48(24):147−156. [LIU Z Q, DONG L Q, YANG D W, et al. Effect of NaCl immersion on flavor of beef liver[J]. Food and Fermentation Industries,2022,48(24):147−156.] LIU Z Q, DONG L Q, YANG D W, et al. Effect of NaCl immersion on flavor of beef liver[J]. Food and Fermentation Industries, 2022, 48(24): 147−156.

[54] 徐永霞, 王瑞, 李学鹏, 等. 热处理对鱼肌原纤维蛋白结构及腥味物质结合能力的影响[J]. 中国食品学报,2020,20(9):131−138. [XU Y X, WANG R, LI X P, et al. Effects of heat treatment on the structure of myofibrillar protein and binding ability with fishy odor compounds[J]. Journal of Chinese Institute of Food Science and Technology,2020,20(9):131−138.] XU Y X, WANG R, LI X P, et al. Effects of heat treatment on the structure of myofibrillar protein and binding ability with fishy odor compounds[J]. Journal of Chinese Institute of Food Science and Technology, 2020, 20(9): 131−138.

[55] 张志红. 烹饪中腥味去除的化学机理[J]. 化学教学,1996(6):26. [ZHANG Z H. Chemical mechanisms of fishy odour removal in cooking[J]. Chemistry Teaching,1996(6):26.] ZHANG Z H. Chemical mechanisms of fishy odour removal in cooking[J]. Chemistry Teaching, 1996(6): 26.

[56] 王红萍. 猪肉膻味物质粪臭素的加工降解研究[D]. 重庆:西南大学, 2012. [WANG H P. Research on processing degradation of skatole that caused boar taint[D]. Chongqi:Southwest University, 2012.] WANG H P. Research on processing degradation of skatole that caused boar taint[D]. Chongqi: Southwest University, 2012.

[57] 王森. 鸭肉腥味特征物质及脱腥技术研究[D]. 郑州:河南农业大学, 2023. [WANG S. Study on characteristic substances of duck odorous smell and deodorization technology[D]. Zhengzhou: Henan Agriculture University, 2023.] WANG S. Study on characteristic substances of duck odorous smell and deodorization technology[D]. Zhengzhou: Henan Agriculture University, 2023.

[58] TENG H, FANG Z F, MA Q L, et al. Effect of cold atmospheric plasma-assisted curing process on the color, odor, volatile composition, and heterocyclic amines in beef meat roasted by charcoal and superheated steam[J]. Meat Science,2023,196:109046. doi: 10.1016/j.meatsci.2022.109046

[59] 姚磊, 胡盛本, 范亚苇, 等. 生姜对草鱼腥味的影响[J]. 南昌大学学报(理科版),2016,40(2):177−181,187. [YAO L, HU S B, FAN Y W, et al. The effects of ginger on grass carp fishy smell[J]. Journal of Nanchang University (Natural Science),2016,40(2):177−181,187.] doi: 10.3969/j.issn.1006-0464.2016.02.014 YAO L, HU S B, FAN Y W, et al. The effects of ginger on grass carp fishy smell[J]. Journal of Nanchang University (Natural Science), 2016, 40(2): 177−181,187. doi: 10.3969/j.issn.1006-0464.2016.02.014

[60] SURYANTI U, BINTORO V P, ATMOMARSONO U, et al. Antioxidant activity of indonesian endogenous duck meat marinated in ginger (Zingiber officinale Roscoe) extract[J]. International Journal of Poultry Science,2014,13(2):102−107. doi: 10.3923/ijps.2014.102.107

[61] 郭卫芸, 肖付刚, 刘学功. 腌制法脱除鸭肉水饺馅料腥味的研究[J]. 食品研究与开发,2015,36(2):102−105. [GUO W Y, XIAO F G, LIU X G. Firing off the odorous smell of duck dumplings by pickling[J]. Food Research and Development,2015,36(2):102−105.] doi: 10.3969/j.issn.1005-6521.2015.02.025 GUO W Y, XIAO F G, LIU X G. Firing off the odorous smell of duck dumplings by pickling[J]. Food Research and Development, 2015, 36(2): 102−105. doi: 10.3969/j.issn.1005-6521.2015.02.025

[62] KIARSI Z, HOJJATI M, BEHBAHANI B A, et al. In vitro antimicrobial effects of Myristica fragrans essential oil on foodborne pathogens and its influence on beef quality during refrigerated storage[J]. Journal of Food Safety,2020,40(3):e12782. doi: 10.1111/jfs.12782

[63] MARIANNA M, ANNALISA L, MILENA S, et al. Combined effects of thymol, carvacrol and temperature on the quality of non conventional poultry patties[J]. Meat Science,2009,83(2):246−254. doi: 10.1016/j.meatsci.2009.05.007

[64] 罗进, 马玉琴, 余群力, 等. 牛肝不同脱腥方法比较及腥味物质分析[J]. 食品与发酵工业,2023,49(22):78−85. [LUO J, MA Y Q, YU Q L, et al. Comparison of different deodorization methods for bovine liver and analysis of off-flavor substances[J]. Food and Fermentation Industries,2023,49(22):78−85.] LUO J, MA Y Q, YU Q L, et al. Comparison of different deodorization methods for bovine liver and analysis of off-flavor substances[J]. Food and Fermentation Industries, 2023, 49(22): 78−85.

[65] YOGESH K, ALI J. Antioxidant potential of thuja (Thuja occidentalis) cones and peach (Prunus persia) seeds in raw chicken ground meat during refrigerated (4±1 °C) storage[J]. Journal of Food Science and Technology,2014,51(8):1547−1553. doi: 10.1007/s13197-012-0672-5

[66] YIN M C, CHENG W S. Antioxidant and antimicrobial effects of four garlic-derived organosulfur compounds in ground beef[J]. Meat Science,2003,63(1):23−28. doi: 10.1016/S0309-1740(02)00047-5

[67] PETER Y Y W, DAVID D K. Studies on the dual antioxidant and antibacterial properties of parsley (Petroselinum crispum) and cilantro (Coriandrum sativum) extracts[J]. Food Chemistry,2006,97(3):505−515. doi: 10.1016/j.foodchem.2005.05.031

[68] SORIANO A, ALANON M E, ALARCÓN M, et al. Oak wood extracts as natural antioxidants to increase shelf life of raw pork patties in modified atmosphere packaging[J]. Food Research International,2018,111:524−533. doi: 10.1016/j.foodres.2018.05.055

[69] 赵改名, 王森, 祝超智, 等. 基于顶空气相离子迁移色谱对鸭肉腥味特征物质的鉴定[J]. 食品科学,2023,44(4):247−255. [ZHAO G M, WANG S, ZHU C Z, et al. Identification of characteristic odorants in duck meat by headspace-gas chromatography-ion mobility spectrometry[J]. Food Science,2023,44(4):247−255.] doi: 10.7506/spkx1002-6630-20220420-257 ZHAO G M, WANG S, ZHU C Z, et al. Identification of characteristic odorants in duck meat by headspace-gas chromatography-ion mobility spectrometry[J]. Food Science, 2023, 44(4): 247−255. doi: 10.7506/spkx1002-6630-20220420-257

[70] PU D D, SHAN Y M, ZHANG L L, et al. Identification and inhibition of the key off-odorants in duck broth by means of the sensomics approach and binary odor mixture[J]. Journal of Agricultural and Food Chemistry,2022,70(41):13367−13378. doi: 10.1021/acs.jafc.2c02687

[71] 王振东. 羊肉膻味强度评价模型构建及四种食材除膻作用效果研究[D]. 扬州:扬州大学, 2017. [WANG Z D. Evaluation modeling of lamb dankness intensity and the effect of four ingredients on dankness elimination[D]. Yangzhou:Yangzhou University, 2017.] WANG Z D. Evaluation modeling of lamb dankness intensity and the effect of four ingredients on dankness elimination[D]. Yangzhou: Yangzhou University, 2017.

[72] 肖岚, 辛松林. 羊肉脱膻技术研究现状[J]. 四川烹饪高等专科学校学报,2009(6):25−27. [XIAO L, XIN S L. Research progress on lamb deodorisation technology[J]. Journal of Sichuan Cuisine College,2009(6):25−27.] XIAO L, XIN S L. Research progress on lamb deodorisation technology[J]. Journal of Sichuan Cuisine College, 2009(6): 25−27.

[73] 伍瑞祥, 吴涛. 淡水鱼土腥味物质及脱腥技术研究进展[J]. 长江大学学报(自然科学版),2011,8(10):253–256. [WU R X, WU T, Progress of research on earthy odour substances and deodorisation technology of freshwater fish[J]. Journal of Changjiang University (Natural Science Edition),2011,8(10):253–256.] WU R X, WU T, Progress of research on earthy odour substances and deodorisation technology of freshwater fish[J]. Journal of Changjiang University (Natural Science Edition), 2011, 8(10): 253–256.

[74] 刘婷. 基于百里香精油抗菌特性的自组装纳米乳对冷鲜猪肉保鲜作用的研究[D]. 西安:陕西师范大学, 2021. [LIU T. Self-assembled nano-emulsions based on the antimicrobial properties of thyme essential oil for preservation of cold pork meat[D]. Xi'an:Shaanxi Normal University, 2021.] LIU T. Self-assembled nano-emulsions based on the antimicrobial properties of thyme essential oil for preservation of cold pork meat[D]. Xi'an: Shaanxi Normal University, 2021.

[75] 刘泽祺, 江伟烽, 邓湙曈, 等. 不同脱腥方法对鸡肝风味物质的影响[J]. 食品工业科技,2022,43(13):258−266. [LIU Z Q, JIANG F W, DENG Y T, et al. Effects of different deodorization methods on volatile flavor compounds in chincken liver[J]. Science and Technology of Food Industry,2022,43(13):258−266.] LIU Z Q, JIANG F W, DENG Y T, et al. Effects of different deodorization methods on volatile flavor compounds in chincken liver[J]. Science and Technology of Food Industry, 2022, 43(13): 258−266.

[76] 陈增鑫, 刘咏霖, 潘芸芸, 等. 不同脱腥方法对海参肠卵酶解液脱腥效果的比较[J]. 食品与发酵工业,2022,48(5):187−194. [CHEN Z X, LIU Y L, PAN Y Y, et al. Effect of different deodorization methods on enzymatic hydrolysate of sea cucumber (Stichopus japonicas) intestines and gonads[J]. Food and Fermentation Industries,2022,48(5):187−194.] CHEN Z X, LIU Y L, PAN Y Y, et al. Effect of different deodorization methods on enzymatic hydrolysate of sea cucumber (Stichopus japonicas) intestines and gonads[J]. Food and Fermentation Industries, 2022, 48(5): 187−194.

[77] 王晓君, 夏杨毅, 张丹, 等. 不同脱腥方法对兔肉脱腥效果的比较[J]. 现代食品科技,2016,32(5):205−212,179. [WANG X J, XIA Y Y, ZHANG D, et al. Comparison of different deodorization methods for deodorizing rabbit meat[J]. Modern Food Science and Technology,2016,32(5):205−212,179.] WANG X J, XIA Y Y, ZHANG D, et al. Comparison of different deodorization methods for deodorizing rabbit meat[J]. Modern Food Science and Technology, 2016, 32(5): 205−212,179.

[78] YU X, CHEN L, SHENG L, et al. Volatile compounds analysis and off-flavors removing of porcupine liver[J]. Food Science and Technology Research,2016,22(2):283−289. doi: 10.3136/fstr.22.283

[79] QI S, ZHAN P, TIAN H, et al. Effects of thyme (Thymus vulgaris L.) addition on the volatile compounds of mutton broth during boiling[J]. Food Science and Human Wellness,2022,11(2):305−315. doi: 10.1016/j.fshw.2021.11.025

[80] 吴天乐, 詹萍, 王鹏. 基于GC-O-MS结合化学计量学探究紫苏对鱼腥味的抑制作用[J]. 食品研究与开发,2022,43(18):9−18. [WU T L, ZHAN P, WANG P. Inhibitory effect of Perilla frutescens leaves on fishy smell based on GC-O-MS and chemometrics[J]. Food Research and Development,2022,43(18):9−18.] doi: 10.12161/j.issn.1005-6521.2022.18.002 WU T L, ZHAN P, WANG P. Inhibitory effect of Perilla frutescens leaves on fishy smell based on GC-O-MS and chemometrics[J]. Food Research and Development, 2022, 43(18): 9−18. doi: 10.12161/j.issn.1005-6521.2022.18.002

[81] 雷跃磊, 郑小宁, 卢素芳, 等. 养殖鳜鱼肉紫苏汁脱腥工艺的优化研究[J]. 食品工业科技,2015,36(7):228−231. [LEI Y L, ZHENG X N, LU S F, et al. Optimization of deodorization process on mandarin fish meat with perilla juice[J]. Science and Technology of Food Industry,2015,36(7):228−231.] LEI Y L, ZHENG X N, LU S F, et al. Optimization of deodorization process on mandarin fish meat with perilla juice[J]. Science and Technology of Food Industry, 2015, 36(7): 228−231.

[82] 王若瑜. 紫苏多酚除腥功效评价及紫苏除腥剂制备[D]. 长春:吉林农业大学, 2022. [WANG R Y. Evaluation of the efficacy of perilla polyphenols and preparation of perilla fishing agents[D]. Changchun:Jilin Agriculture University, 2022.] WANG R Y. Evaluation of the efficacy of perilla polyphenols and preparation of perilla fishing agents[D]. Changchun: Jilin Agriculture University, 2022.

[83] 姚正颖, 孙力军, 侯北伟, 等. 紫苏精油对白鲢鱼丸的脱腥工艺研究[J]. 中国调味品,2022,47(7):94−98. [YAO Z Y, SUN L J, HOU B W, et al. Study on deodorization process of silver carp balls with perilla essential oil[J]. China Condiment,2022,47(7):94−98.] doi: 10.3969/j.issn.1000-9973.2022.07.017 YAO Z Y, SUN L J, HOU B W, et al. Study on deodorization process of silver carp balls with perilla essential oil[J]. China Condiment, 2022, 47(7): 94−98. doi: 10.3969/j.issn.1000-9973.2022.07.017

[84] 杨展铭, 孔瑞, 焉斐然, 等. 响应面法优化兔肉紫苏脱腥工艺[J]. 粮食与油脂,2023,36(2):129−132. [YANG Z M, KONG R, YAN F R, et al. Optimization of deodorization process of rabbit meat with Perilla frutescens (L.) Britt. by response surface methodology[J]. Grain and Oils,2023,36(2):129−132.] doi: 10.3969/j.issn.1008-9578.2023.02.027 YANG Z M, KONG R, YAN F R, et al. Optimization of deodorization process of rabbit meat with Perilla frutescens (L.) Britt. by response surface methodology[J]. Grain and Oils, 2023, 36(2): 129−132. doi: 10.3969/j.issn.1008-9578.2023.02.027

[85] 陈彦宏, 张鑫瑶, 陈旺, 等. 木姜子挥发油成分分析及抑菌活性研究[J]. 四川林业科技,2022,43(4):124−128. [CHEN Y H, ZHANG X Y, CHEN W, et al. Analysis of volatile oil composition and bacteriostatic activity of Litsea pungens[J]. Sichuan Forestry Science and Technology,2022,43(4):124−128.] doi: 10.12172/202109090001 CHEN Y H, ZHANG X Y, CHEN W, et al. Analysis of volatile oil composition and bacteriostatic activity of Litsea pungens[J]. Sichuan Forestry Science and Technology, 2022, 43(4): 124−128. doi: 10.12172/202109090001

[86] 张建, 黄艳, 刘秋妍, 等. 木姜子新鲜果实挥发油成分分析及抗氧化活性研究[J]. 中国食品添加剂,2023,34(4):269−275. [ZHANG J, HUANG Y, LIU Q Y, et al. Analysis of volatile oil constituents in fresh fruit of Litsea pungens Hemsl and its antioxidant activity[J]. China Food Additives,2023,34(4):269−275.] ZHANG J, HUANG Y, LIU Q Y, et al. Analysis of volatile oil constituents in fresh fruit of Litsea pungens Hemsl and its antioxidant activity[J]. China Food Additives, 2023, 34(4): 269−275.

[87] VAN H S, RAES K, VAN D M P, et al. The effect of cinnamon, oregano and thyme essential oils in marinade on the microbial shelf life of fish and meat products[J]. Food Control,2016,68:30−39. doi: 10.1016/j.foodcont.2016.03.025

[88] SHAHBAZI Y, KARAMI N, SHAVISI N. Effect of Ziziphora clinopodioides essential oil on shelf life and fate of Listeria monocytogenes and Staphylococcus aureus in refrigerated chicken meatballs[J]. Journal of Food Safety,2018,38(1):e12394. doi: 10.1111/jfs.12394

[89] ZAHID A, SEO J K, PARK J Y, et al. The effects of natural antioxidants on protein oxidation, lipid oxidation, color, and sensory attributes of beef patties during cold storage at 4 ℃[J]. Food Science of Animal Resources,2018,38(5):1029−1042. doi: 10.5851/kosfa.2018.e36

[90] HAĆ-SZYMAŃCZUK E, CEGIEŁKA A, CHMIEL M, et al. Addition of different rosemary preparations (Rosmarinus officinalis L.) to chicken meatballs improves their quality profile[J]. International Journal of Food Science & Technology,2021,56(12):6236−6245.

[91] AL-HIJAZEEN M, AL-RAWASHDEH M. Preservative effects of rosemary extract (Rosmarinus officinalis L.) on quality and storage stability of chicken meat patties[J]. Food Science and Technology,2017,39:27−34.

[92] 顾苑婷, 牟琴, 黄燕, 等. 迷迭香和百里香提取物对冷藏猪肉丸品质的影响[J]. 食品科技,2021,46(4):103−109. [GU Y T, MOU Q, HUANG Y, et al. Effects of rosemary and thyme extracts on the quality of chilled pork balls[J]. Food Science and Technology,2021,46(4):103−109.] GU Y T, MOU Q, HUANG Y, et al. Effects of rosemary and thyme extracts on the quality of chilled pork balls[J]. Food Science and Technology, 2021, 46(4): 103−109.

[93] 许梦洁. 金线莲质量评价及其抗氧化活性分析[D]. 杭州:浙江农林大学, 2018. [XU M J. Quality evaluation of Anoectochilus roxburghii and it's antioxidant activity[D]. Hangzhou:Zhejiang Agriculture and Forestry University, 2018.] XU M J. Quality evaluation of Anoectochilus roxburghii and it's antioxidant activity[D]. Hangzhou: Zhejiang Agriculture and Forestry University, 2018.

[94] 陈尚戊, 杨玉琴, 王雪梅, 等. 菟丝子多糖对生鲜猪肉保鲜效果的工艺优化[J]. 成都大学学报(自然科学版),2022,41(1):19−24. [CHEN S W, YANG Y Q, WANG X M, et al. Process optimisation of the preservation effect of Cuscuta sinensis polysaccharides on raw pork preservation[J]. Journal of Chengdu University (Natural Science Edition),2022,41(1):19−24.] doi: 10.3969/j.issn.1004-5422.2022.01.004 CHEN S W, YANG Y Q, WANG X M, et al. Process optimisation of the preservation effect of Cuscuta sinensis polysaccharides on raw pork preservation[J]. Journal of Chengdu University (Natural Science Edition), 2022, 41(1): 19−24. doi: 10.3969/j.issn.1004-5422.2022.01.004

[95] XU Q D, ZHOU Z Q, JING Z, et al. Pine needle extract from Cedrus deodara:Potential applications on hazardous chemicals and quality of smoked bacon and its mechanism[J]. Food Control,2021,130:108368. doi: 10.1016/j.foodcont.2021.108368

[96] 许宝琛, 张一敏, 罗欣, 等. 葡萄籽提取物和茶多酚抑制高氧气调包装牛肉饼的提前褐变现象[J]. 现代食品科技,2022,38(1):181−187,344. [XU B C, ZHANG Y M, LUO X, et al. Inhibition of grape seed extract and tea polyphenols on the premature[J]. Modern Food Science and Technology,2022,38(1):181−187,344.] XU B C, ZHANG Y M, LUO X, et al. Inhibition of grape seed extract and tea polyphenols on the premature[J]. Modern Food Science and Technology, 2022, 38(1): 181−187,344.

[97] BRANNAN R G. Effect of grape seed extract on descriptive sensory analysis of ground chicken during refrigerated storage[J]. Meat Science,2009,81(4):589−595. doi: 10.1016/j.meatsci.2008.10.014

[98] SELANI M M, CONTRERAS-CASTILLO C J, SHIRAHIGUE L D, et al. Wine industry residues extracts as natural antioxidants in raw and cooked chicken meat during frozen storage[J]. Meat Science,2011,88(3):397−403. doi: 10.1016/j.meatsci.2011.01.017

[99] SÁNCHEZ-ESCALANTE A, TORRESCANO G, DJENANE D, et al. Stabilisation of colour and odour of beef patties by using lycopene-rich tomato and peppers as a source of antioxidants[J]. Journal of the Science of Food and Agriculture,2003,83(3):187−194. doi: 10.1002/jsfa.1298

[100] 尚志远. 超高压处理与天然抗氧化剂对马鹿肉品质影响的研究[D]. 长春:吉林农业大学, 2011. [SHANG Z Y. Effects of ultra pressure processing and natural antioxidation on the research of the quality of vension[D]. Changchun:Jilin Agriculture University, 2011.] SHANG Z Y. Effects of ultra pressure processing and natural antioxidation on the research of the quality of vension[D]. Changchun: Jilin Agriculture University, 2011.

[101] 白玉荣, 魏玲, 李婷婷, 等. 绿茶腌制液对鸭肉脱脂过程中挥发性风味物质的影响[J]. 农产品加工,2023(2):14−17,21. [BAI Y R, WEI L, LI T T, et al. Effects of green tea marinating liquid on volatile flavor substances of duck during degreasing[J]. Farm Products Processing,2023(2):14−17,21.] BAI Y R, WEI L, LI T T, et al. Effects of green tea marinating liquid on volatile flavor substances of duck during degreasing[J]. Farm Products Processing, 2023(2): 14−17,21.

[102] 姜鹏飞, 陈瑶, 金文刚, 等. 罗非鱼脱腥方法研究[J]. 中国食品学报,2023,23(2):202−212. [JIANG P F, CHEN Y, JIN W G, et al. Studies on the deodorization methods of tilapia[J]. Journal of Chinese Institute of Food Science and Technology,2023,23(2):202−212.] JIANG P F, CHEN Y, JIN W G, et al. Studies on the deodorization methods of tilapia[J]. Journal of Chinese Institute of Food Science and Technology, 2023, 23(2): 202−212.

[103] 赵颖颖, 李三影, 闫路辉, 等. 不同复热方式对糖醋排骨品质的影响[J]. 中国调味品,2021,46(7):52−59. [ZHAO Y Y, LI S Y, YAN L H, et al. Effects of different reheating methods on the quality of sweet and sour pork ribs[J]. China Condiment,2021,46(7):52−59.] doi: 10.3969/j.issn.1000-9973.2021.07.011 ZHAO Y Y, LI S Y, YAN L H, et al. Effects of different reheating methods on the quality of sweet and sour pork ribs[J]. China Condiment, 2021, 46(7): 52−59. doi: 10.3969/j.issn.1000-9973.2021.07.011

下载:

下载:

下载:

下载: