Emulsifying Property and Emulsifying Stability of Alkali Extracted Tea Residue Protein

-

摘要: 碱提茶渣蛋白质(Alkali-extracted tea residue protein,ATRP)作为新型蛋白资源,具有成为食品级乳化剂的潜力。本研究以ATRP为原料,测定其形成的乳液类型及亲水疏水平衡值,分析室温条件下(20 ℃)不同乳化因素(油水比、乳化剂浓度、pH、存储温度)对其乳化性(静置10 min)及乳化稳定性(静置15 d)的影响,并在优化条件下将ATRP、大豆分离蛋白和乳清蛋白的乳化性和乳化稳定性进行对比分析。结果表明,ATRP乳液为水包油(O/W)类型,其亲水疏水平衡值为13。在油水比7:3、浓度4 mg/mL、pH7和储藏温度为20 ℃的条件下,ATRP乳化能力较好。在该条件下,ATRP乳液静置10 min时,乳化活性指数(EAI值)为43.3 m2/g,乳化指数(CI值)为97%。静置15 d后,ATRP乳液的EAI值和CI值保留了82.9%和88.5%,显示出较强的稳定性。相比于大豆分离蛋白和乳清蛋白,ATRP乳液在储藏15 d的过程中其粒径变化较小,且其在储存过程中的ζ-电位约为大豆分离蛋白的2倍、乳清蛋白的2.5倍,显示出更好的乳化性。Abstract: The alkali-extracted tea residue protein (ATRP) is a novel protein resource with the potential to become a food-grade emulsifier. This study assessed ATRP's emulsion type and hydrophilic-lipophilic balance value, analyzed the effects of various emulsification factors (oil-water ratio, emulsifier concentration, pH, storage temperature) at room temperature (20 ℃) on emulsifying performance (10-minute settling) and stability (15-day settling), followed by a comparison of emulsifying performance and stability of soybean isolate protein and whey protein emulsions. The results showed that the ATRP emulsion was of the water-in-oil (O/W) type, with a hydrophilic-lipophilic balance of 13. Under conditions of a 7:3 oil-water ratio, 4 mg/mL concentration, pH of 7, and storage temperature of 20 ℃, ATRP exhibited good emulsification properties. Under these conditions, the ATRP emulsion showed an EAI of 43.3 m²/g and a CI of 97% after 10 minutes of settling. After 15 days, the EAI and CI values remained strong at 82.9% and 88.5% respectively, indicating excellent stability. Compared with the emulsion of soy protein isolate or whey protein, the ATRP emulsion had little change in particle size during storage and the ζ-potential was double and 2.5 times, showing better emulsifying properties.

-

Keywords:

- tea residue /

- protein /

- emulsification performance /

- whey protein /

- soybean protein isolate

-

随着社会节奏的加快,人们对快消茶饮料的需求越来越旺盛,茶叶的消费模式从家庭式消费逐渐向大型茶饮料企业的采买转变[1]。以福建省两家速溶茶加工企业为例,每年茶叶消费量高达15万吨,产生的茶渣量近10万吨[2−3],蛋白含量约为2.5万吨[4]。这些茶渣大多采用堆肥或焚烧的方式处理,生物质利用率低且容易造成环境污染[5]。因此,若将其蛋白质进行提取并应用于食品工业,不仅可以有效地提高茶渣的利用价值,还可以为食品工业提供新型的乳化剂。

当前茶渣蛋白的提取方法研究较多,如碱法[4,6]、酶法[7]、超声辅助碱法[8]。其中,碱法是从茶渣中提取蛋白质的高效方法,提取率可达96%[4]。经过酸沉纯化后,茶渣蛋白质的回收率为85%、纯度为52%。此外,碱提茶渣蛋白质(Alkali-extracted tea residue protein,ATRP)还含有18%的糖类物质(9%的半乳糖醛酸)、3%的多酚类物质、11%的灰分、16%的其他物质[4]。前期研究表明,ATRP展现出良好的加工特性[9−12],具有作为新型食品剂乳化剂的潜力[13]。

食品工业中常见的蛋白质乳化剂一般为大豆分离蛋白和乳清蛋白。大豆分离蛋白在油水比1:6~1:10、蛋白质浓度>2%、pH>6、温度>50 ℃的条件下乳化能力较好[14−15];而乳清蛋白在pH>6、90 ℃保温处理10 min的条件下乳化能力较好[16]。相比之下,ATRP蛋白可能在室温条件(20 ℃)下具有较好的乳化性和稳定性[17]。在室温条件下,不仅可以降低能耗,而且还有助于保持食品成分的完整性,避免被破坏。然而,ATRP乳化剂的开发还处于较为初级的阶段,其乳化剂类型、油水平衡值,以及使用范围均未确定,影响了其在食品工业中的具体使用方法和应用价值。

因此,为了探究ATRP的应用范围,本文首先测定ATRP的乳液类型和亲水疏水平衡值(Hydrophile-Lipophile balance,HLB),确定其乳化剂特性。然后,通过测定不同条件下(油水比、物质浓度、pH、温度)ATRP乳液分别在静置10 min(用于分析乳化性)和15 d(用于分析乳化稳定性)后的乳化活性指数EAI值(Emulsifying activity index)、乳化指数CI值(Creaming index),分析常温下ATRP乳化剂在不同环境下的乳化应用范围及储藏稳定性。最后在优化的条件下,比较ATRP与大豆分离蛋白、乳清蛋白的乳化性、乳化稳定性、粒径分布状态和ζ-电位,分析其商业价值,为茶蛋白质乳化剂的开发与应用提供了理论依据。

1. 材料与方法

1.1 材料与仪器

茶渣 福建大闽食品有限公司提供;金龙鱼大豆油 益海嘉里金龙鱼粮油食品股份有限公司;大豆分离蛋白(纯度>90%)、乳清蛋白(纯度>80%)、液体生物防腐剂(Proclin300) 上海源叶生物科技有限公司;其他试剂均为国产分析纯。

LXJ-IIB型低速离心机 上海安亭科学仪器厂;UV2000型紫外可见分光光度计 上海一恒科学仪器有限公司;OMNI型Zeta电位和粒径分析仪 美国Brookhaven仪器公司;F6/10型号均质机 上海沪析实业有限公司;Mastersizer 3000型马尔文粒度仪 英国Malvern Panalytical;MF43-N型荧光显微镜 广州市明美光电技术有限公司。

1.2 实验方法

1.2.1 样品的制备

1.2.1.1 ATRP的制备

参考ZHANG等[4]的方法,将茶渣与氢氧化钠溶液(1 mol/L)在料液比1:20,温度95 ℃,时间4 h条件下反应。反应结束后离心(4800×g,10 min)获得上清液。使用盐酸溶液(l mol/L)酸沉上清液蛋白质,将pH调至3.5,静置10 min,离心获得蛋白质沉淀。在蛋白质沉淀中加入200 mL蒸馏水,使用氢氧化钠溶液(1 mol/L)将pH调至7复溶蛋白质。复溶后的蛋白质通过冷冻干燥(真空度100 Pa、−60 ℃、48 h)处理后获得ATRP。

1.2.1.2 ATRP乳液的制备

ATRP乳液由大豆油和ATRP蛋白溶液在特定油水比、乳化剂浓度、pH和温度的条件下加入Proclin300(0.02%,v/v)均质(10000 r/min,2 min)获得。

1.2.2 ATRP乳液性质的测定

1.2.2.1 ATRP乳液油水类型的判别

取体积50 μL、油水比5:5、乳化剂浓度1 mg/mL、pH7的ATRP乳液与体积50 μL、浓度1 mg/mL的亚甲基蓝进行混合染色,混合液通过光学显微镜(100×)观察、拍照。

1.2.2.2 ATRP乳液复合类型的判别

取体积50 μL、油水比5:5、乳化剂浓度1 mg/mL、pH7的ATRP乳液置于光学显微镜下,以500×倍数观察,分析乳液复合类型。

1.2.2.3 HLB平衡值的测定

ATRP乳液的HLB值通过乳化法测定[18],具体操作如下:使用棉籽油(HLB值6)和松节油(HLB值16)复配出HLB值为8、9、10、11、12、13、14、15、16的油相;将ATRP溶液与不同HLB值的油相混合均质配制成油水比5:5、乳化剂浓度为1 mg/mL的ATRP乳液;在常温(20 ℃)下静置1 d后,ATRP乳液的CI值通过其乳液体积计算。CI值最高状态下,乳液所使用的油相HLB值即为ATRP的HLB值。油相HLB的计算见公式(1)。

HLBAB=HLBA×WA+HLBB×WBWA+WB (1) 式中:HLBAB:油相HLB值;HLBA:16,松节油的HLB值;HLBB:6,棉籽油的HLB值;WA:松节油体积,mL;WB:棉籽油体积,mL。

1.2.3 乳化性的测定

1.2.3.1 乳化活性指数的测定

乳液的EAI值通过分光光度法测定,具体操作如下:将油水比5:5、乳化剂浓度1 mg/mL、体积20 μL的ATRP乳液分散到2 mL十二烷基硫酸钠(0.1%,w/v)溶液中,振荡混匀得待测样品。在波长500 nm下,测定样品吸光度,记为A0。EAI值的计算参考AZIZ等[19]的方法,见公式(2)。

EAI(m2/g)=2×2.303×A0×N×10−4θ×C (2) 式中:N:稀释倍数;θ:油相在溶液中占比;C:乳化剂浓度,mg/mL。

1.2.3.2 乳化指数的测定

测定乳液体积Hs和样品总体积Ht后,CI值的计算参考SHI等[20]的方法,见公式(3)。

CI(%))=HsHt×100 (3) 1.2.4 ATRP乳化剂应用范围的探究

1.2.4.1 油水比对ATRP乳化性及稳定性的影响

ATRP乳液在乳化剂浓度1 mg/mL,pH7,温度20 ℃,10000 r/min,油水比分别为3:7、5:5、7:3、9:1条件下均质获得,并测定ATRP乳液10 min和15 d的EAI值和CI值。

1.2.4.2 乳化剂浓度对ATRP乳化性及稳定性的影响

ATRP乳液在油水比7:3,pH7,温度20 ℃,10000 r/min,乳化剂浓度分别为1、2、3、4、5 mg/mL条件下均质获得,并测定ATRP乳液10 min和15 d的EAI值和CI值。

1.2.4.3 pH对ATRP乳化性及稳定性的影响

ATRP乳液在油水比7:3,乳化剂浓度4 mg/mL,温度20 ℃,10000 r/min,pH分别为3.0、4.0、5.0、7.0、9.0、10.0、11.0条件下均质获得,并测定ATRP乳液10 min和15 d的EAI值和CI值。

1.2.4.4 储存温度对ATRP乳化性及稳定性的影响

ATRP乳液在油水比7:3,乳化剂浓度4 mg/mL,pH7,温度20 ℃,10000 r/min的条件下均质获得。均质后的ATRP乳液分别放入于冰箱(4 ℃)、常温(20 ℃)、恒温培养箱(35 ℃)中保存并在10 min和15 d后测定ATRP乳液的EAI值和CI值。

1.2.5 ATRP乳液、大豆分离蛋白乳液、乳清蛋白乳液的乳化性及稳定性分析

1.2.5.1 ATRP乳液、大豆分离蛋白乳液和乳清蛋白乳液的制备

ATRP乳液、大豆分离蛋白乳液、乳清蛋白乳液在乳化剂浓度4 mg/mL、油水比7:3、pH7、20 ℃、10000 r/min条件下均质2 min后获得,并分别测定各乳液10 min、1 d、15 d的EAI值和CI值。

1.2.5.2 粒径分布状态的测定

乳液中的粒度分布和体积平均直径通过Mastersizer 3000马尔文粒度仪测定,具体参数如下:样品颗粒折射率1.460,吸收率0.001,分散剂水,分散剂折射率1.330,样品浓度0.25% (v/v),转速1200 r/min,测定温度25 ℃。体积加权平均直径(D4,3)的计算参考BAI等[21]的方法,见公式(4)。

D4,3=∑nid4i∑nid3i (4) 式中:di:液滴直径,μm;ni:液滴数量。

1.2.5.3 ζ-电位的测定

设置样品浓度2.0%(v/v)、测定温度25 ℃,乳液的ζ-电位通过高灵敏Zeta电位分析仪测定[22]。

1.3 数据处理

采用Microsoft excel 2016软件进行数据统计与分析,若无特别说明,每个样品重复测定3次,其结果表示为“平均值±标准差(Means±SD)”。采用单因素方差分析(one-way ANOVA)和Duncan’s法多重比较分析各组的差异显著性,显著性水平为P<0.05。

2. 结果与分析

2.1 ATRP乳液类型和HLB值

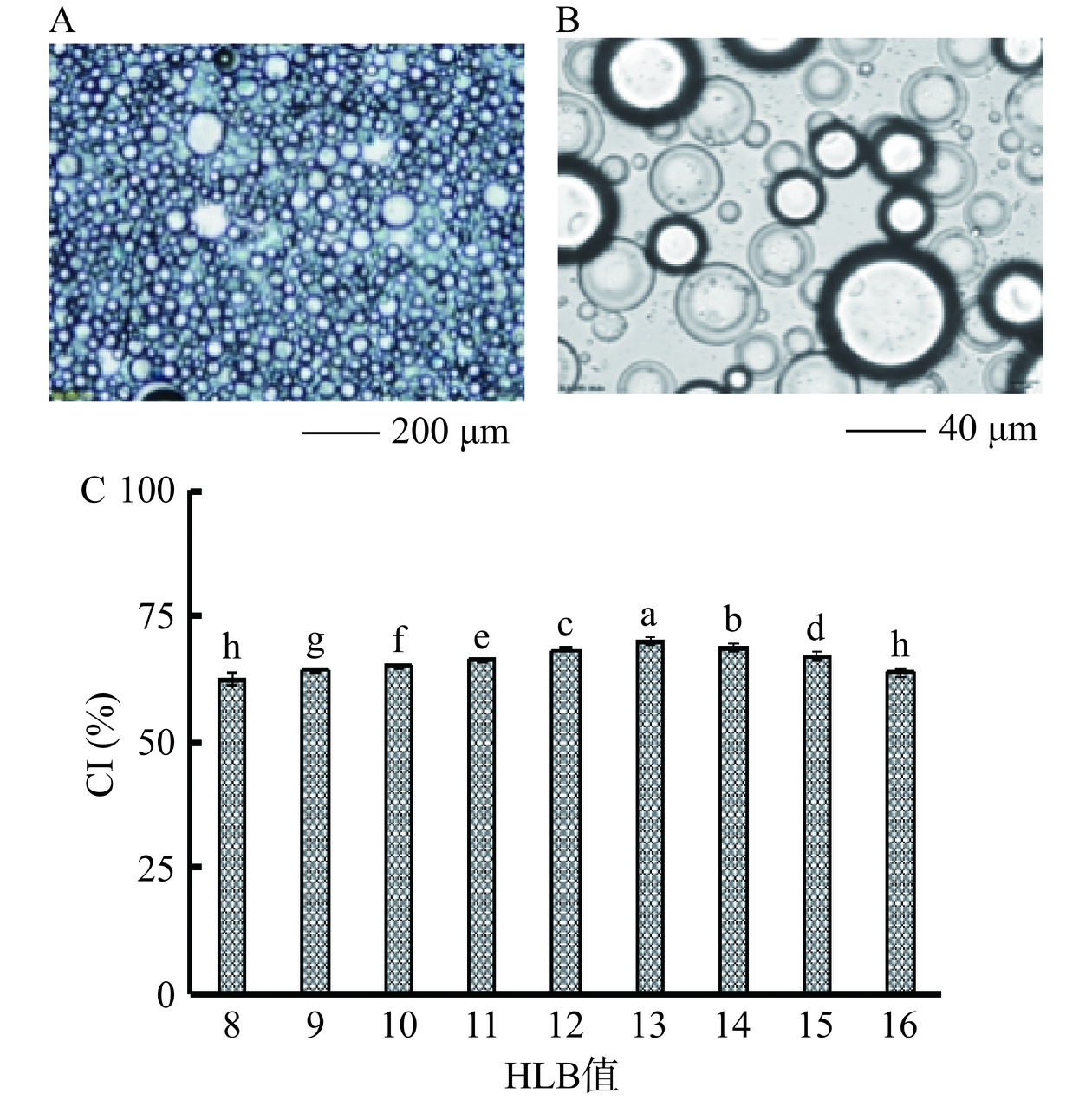

通过光学显微镜拍摄不同倍数下ATRP乳液的图片,并测定HLB值对乳液的乳化性影响,结果如图1所示。亚甲基蓝在液滴的外圈显色,可见ATRP能够在油水界面起到乳化作用且ATRP乳液为水包油(O/W)类型(见图1A)。ATRP乳液的油液滴中并未出现大量的细小液滴,可见该乳液为非多重乳液(见图1B)。

当HLB值为13时,ATRP乳液的CI值最高(70%),亲水性较强(见图1C),这与报道中所述茶渣中非水溶性蛋白质约占94%[23],具有较大的差异。这可能是经碱和高温处理后,茶渣蛋白质结构发生变性,导致其亲水基团的暴露程度增加[24]。此外,其疏水性氨基酸残基在碱性条件下可能发生氧化反应,如甲基、乙基或丙基氧化成相应的醇或酮[25−26],进而增强ATRP的亲水性。

2.2 制备条件对ATRP乳化性及稳定性的影响

2.2.1 油水比对ATRP乳化性及稳定性的影响

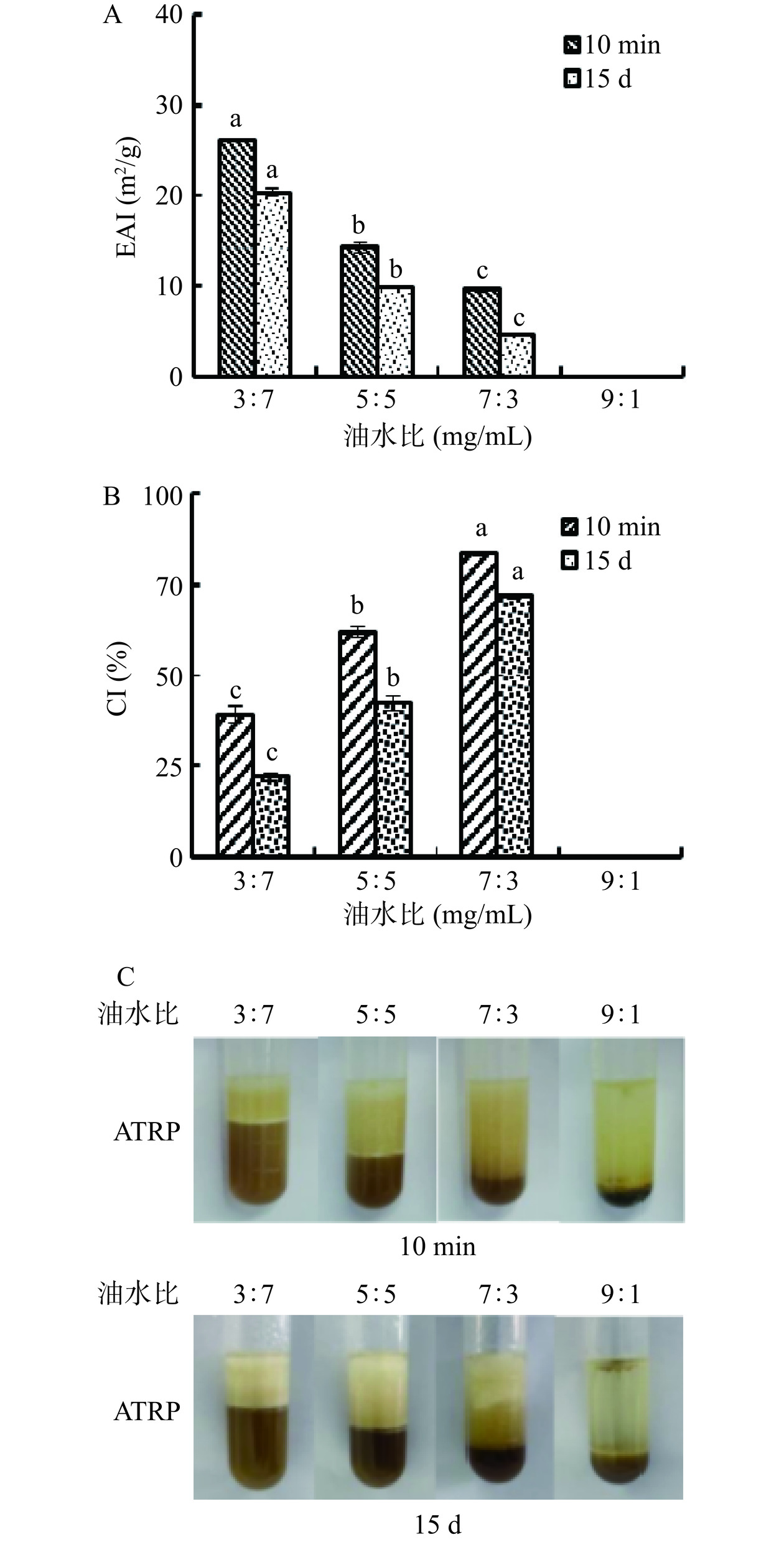

在静置时间为10 min和15 d时,测定油水比对ATRP乳液EAI值和CI值的影响,结果如图2所示。

随着油水比的升高,ATRP乳液的乳化活性指数下降,乳化指数增加。静置10 min时,油水比为3:7的ATRP乳液EAI值最高(26.3 m2/g),但其CI值最低(38.9%)。油水比为7:3的ATRP乳液EAI值仅为9.6 m2/g,而CI值增加至84.0%。当油水比达到9:1时,未观察到乳化层形成(见图2C)。造成这种现象的原因可能是油相的增加不仅会增加乳液的黏度,降低ATRP结合油的能力,使EAI值下降[27],还会增大液滴尺寸,缩短液滴之间的距离,使CI值上升[28]。但是当油水比超过一定界限时,乳液无法形成稳定的乳化体系[29]。

油水比的变化对ATRP乳化稳定性的影响也呈现相同的趋势。静置15 d时,油水比为3:7的ATRP乳液EAI值仍保留77.4%,而其CI值仅保留56.2%。油水比为7:3的ATRP乳液EAI值仅保留48.4%,而其CI值的保留量则高达86.1%。为探究ATRP的应用范围,综合考虑后续实验选择油水比7:3。

2.2.2 乳化剂浓度对ATRP乳化性及稳定性的影响

在静置时间为10 min和15 d时,测定乳化剂浓度对ATRP乳液EAI值和CI值的影响,结果如图3所示。

增加乳化剂浓度可提高ATRP乳液的乳化活性指数和乳化指数(见图3A、图3B)。当静置时间为10 min时,ATRP乳液的EAI值随着乳化剂浓度的增加而提高。而当乳化剂浓度为5 mg/mL时,ATRP乳液的EAI值为54.9 m2/g,约为浓度1 mg/mL的ATRP乳液的4倍。乳液的CI值尽管也随着乳化剂的增加而提高,但当乳化剂浓度达到2 mg/mL时,乳液的CI值较大(97.0%),继续增加乳化剂浓度对乳液的CI值没有显著性影响(P>0.05)。乳化剂浓度的变化对ATRP乳化稳定性的影响也呈现相同的趋势。静置15 d时,乳化剂浓度为4 mg/mL的ATRP乳液乳化稳定性较高,其EAI值和CI值保留86.2%和87.5%。继续增加乳化剂的浓度乳液的稳定性影响较小。

增加乳化剂浓度,不仅增加蛋白质在油水界面的吸附量,使EAI值和CI值上升[30−31]。而且还增加了乳化液滴界面膜的厚度,提高了乳液的稳定性[32]。为更好探究ATRP的应用条件,后续实验ATRP乳液的制备乳化剂浓度将选择4 mg/mL。

2.2.3 pH对ATRP乳化性及稳定性的影响

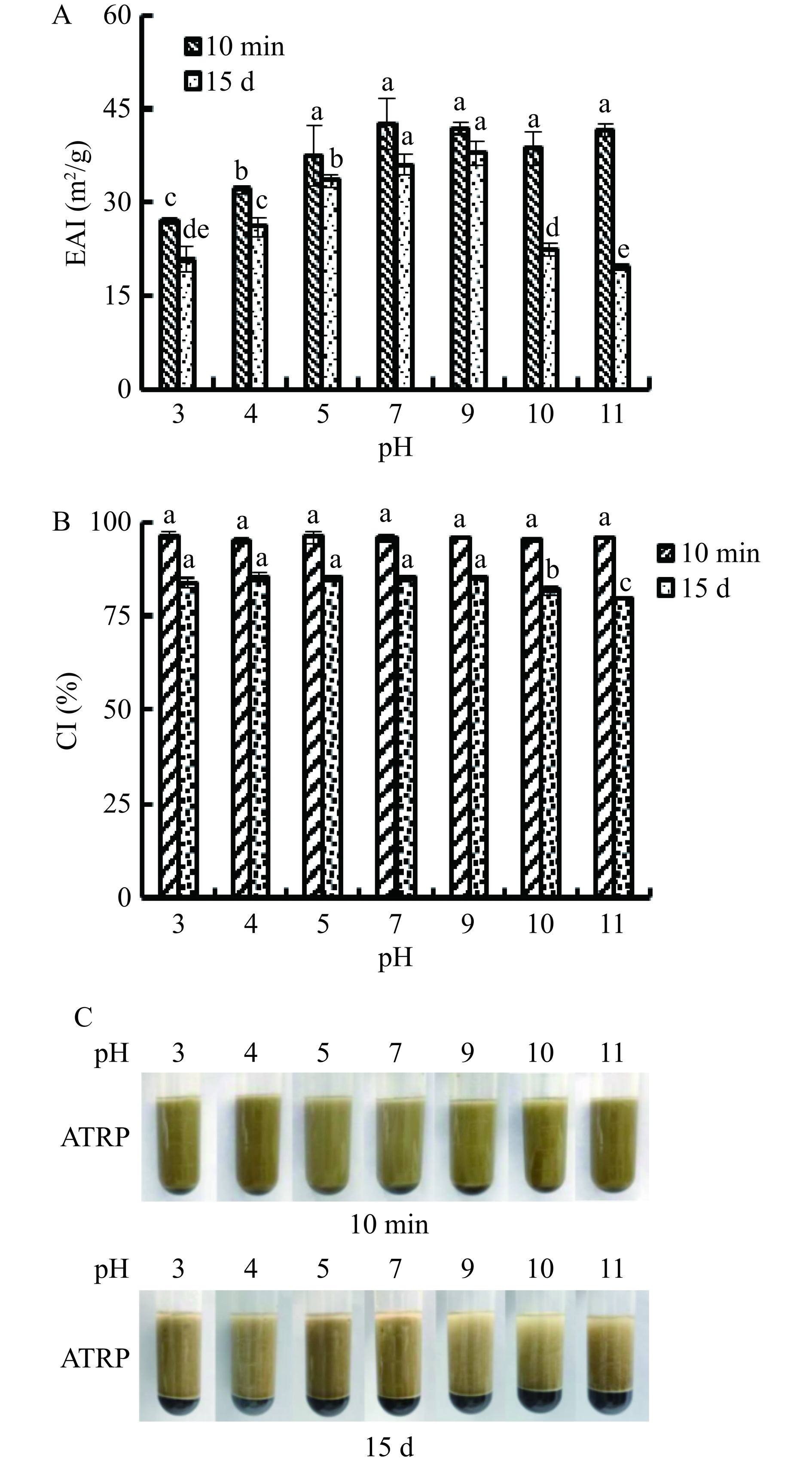

在静置时间为10 min和15 d时,测定pH对ATRP乳液EAI值和CI值的影响,结果如图4所示。

随着pH升高,ATRP乳液的乳化活性指数呈现先上升后平稳的趋势,而乳化指数没有显著变化(见图4A、图4B)。当静置时间为10 min,pH7.0的ATRP乳液EAI值高达42.6 m2/g,约为pH3.0的ATRP乳液的1.8倍。同时,乳液接近全乳化状态,CI值为97%。静置15 d后,pH9.0条件下的ATRP乳液的EAI值和CI值仍保留了90.3%和90.0%;但是当pH>9时,乳液的稳定性开始降低。在pH10时,ATRP的EAI值保留量降低至57.9%,CI值的保留量降至85.8%;当pH11时,ATRP乳液的EAI值和CI值保留量更低。

pH影响蛋白质乳化剂乳化性和乳化稳定性的方式是通过静电作用改变蛋白质溶解性,进而影响其乳化性和乳化稳定性[33]。与大豆分离蛋白等电点(pH5.0)相比,ATRP具有更低的等电点(pH3.5)。这可能是ATRP中碱性氨基酸的含量较低所致。ATRP中赖氨酸、精氨酸和组氨酸的含量为2.8%、3.4%、1.9%,约为大豆分离蛋白中相应氨基酸含量的一半[4,34]。因此,ATRP可在pH4以上的溶液中表现出良好的乳化性和乳化稳定性。从最佳的乳化效果考虑,后续实验ATRP乳液的制备pH选择7.0。

2.2.4 储存温度对ATRP乳化性及稳定性的影响

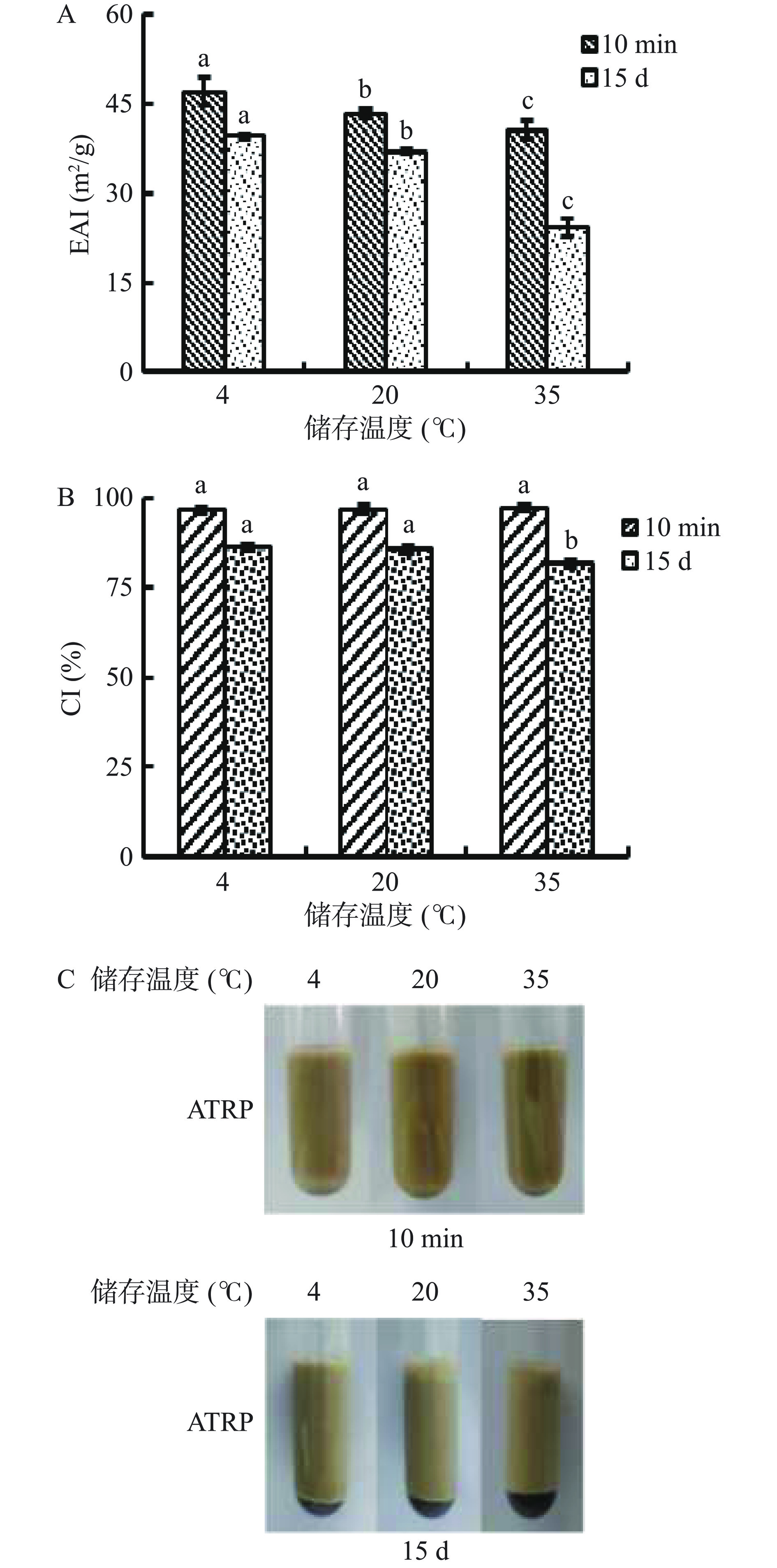

在静置时间为10 min和15 d时,测定储存温度对ATRP乳液EAI值和CI值的影响,结果如图5所示。

储存温度的变化对ATRP乳化性影响较小(见图5A、图5B、图5C)。在乳液静置时间10 min时,4、20、35 ℃储存的ATRP乳液的EAI值分别为47.1、43.3、40.5 m2/g。三种温度存储下的乳液CI值没有显著差异(P>0.05),均达到97%。相比之下,储存温度的变化对ATRP乳化稳定性的影响较为明显。静置15 d时,储存温度在4 ℃和20 ℃条件下的ATRP乳液的稳定性较高,其EAI值和CI值的保留值均超过85%,两者并无显著差异(P>0.05)。然而,当储存温度为35 ℃时,ATRP乳液EAI值仅保留60.2%,其CI值保留84.1%。表明在较高温度的环境下ATRP乳液稳定性降低,不易于保存。这可能是由于当温度高于35 ℃时乳液液滴中的油相体积膨胀,加剧了油水两相的密度差,导致油水分离[35]。同时,较高的温度也会使得蛋白质的结构容易发生改变,从而降低蛋白质乳化剂乳化性和乳化稳定性[36]。考虑到实际的应用场景多为室温条件,故后续实验ATRP乳液的储存温度选择20 ℃。

在单因素实验过程中,ATRP展现出了应用范围广的优势和较好的乳化能力和乳化稳定性。在油水比为7:3、乳化剂浓度为4 mg/mL、pH为7、温度为20 ℃的条件下,ATRP乳液静置10 min时,EAI值为43.3 m2/g,CI值为97%,且静置15 d后ATRP乳液EAI值和CI值的保留量高达82.9%和88.5%。在此条件下,ATRP乳液在10 min和15 d的CI值分别是反相微乳法在最优条件下制备茶蛋白乳液的CI值(60.27%)的1.6倍和1.4倍[9],说明与同类乳化剂相比,ATRP展现出更优秀的乳化性和乳化稳定性。综上所述,后续实验中的ATRP乳液将在此条件下进行制备和研究。

2.3 ATRP与大豆蛋白和乳清蛋白的对比分析

2.3.1 乳化性及乳化稳定性

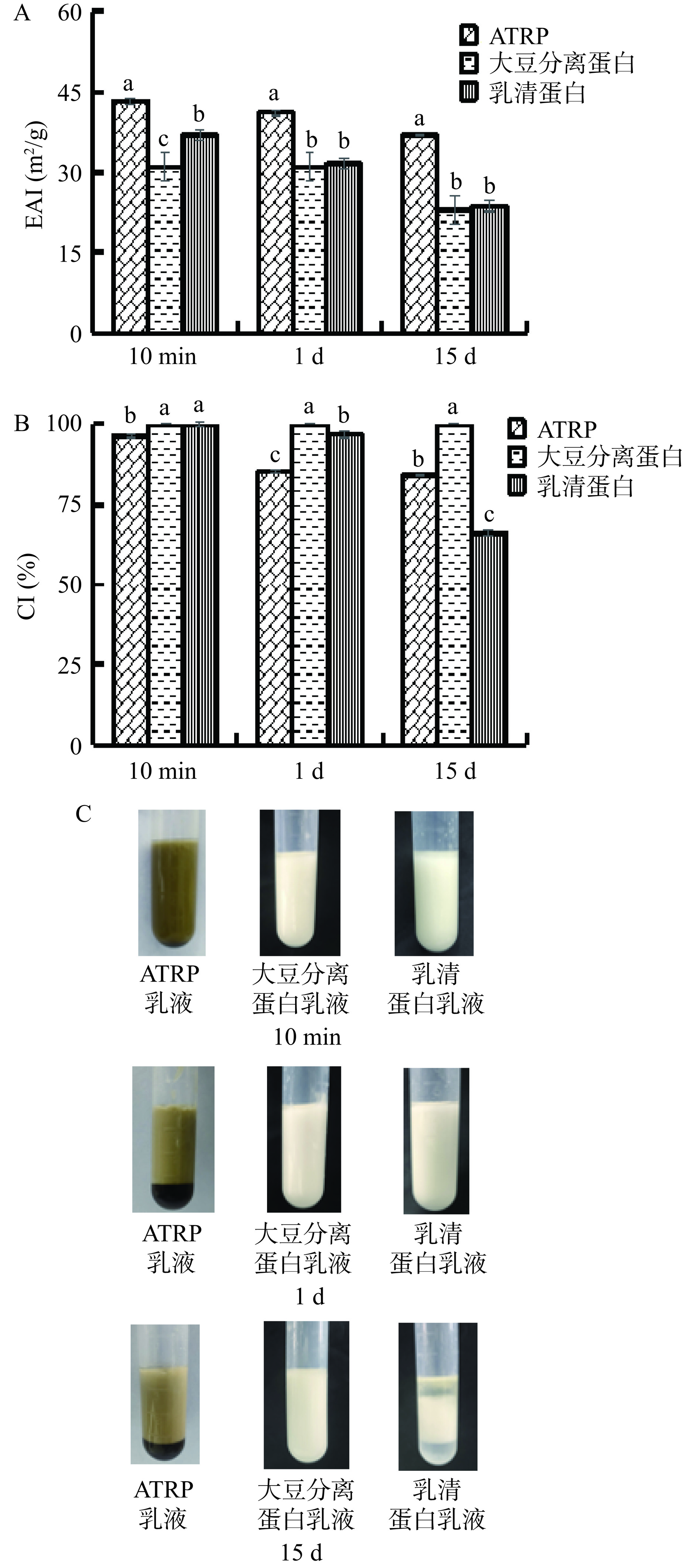

测定10 min、1 d、15 d下ATRP、大豆分离蛋白和乳清蛋白的乳化能力,结果如图6所示。ATRP的乳化性优于大豆分离蛋白和乳清蛋白。在静置时间为10 min时,ATRP乳液的EAI值最高(43.3 m2/g),约为大豆分离蛋白和乳清蛋白的1.4倍和1.2倍,而三种乳液的CI值均在95%以上。与大豆分离蛋白和乳清蛋白的蛋白质含量相比,ATRP的蛋白质含量相对较低(仅为52%),然而ATRP却显示出了更为优越的乳化性。这可能是茶渣蛋白质在提取过程中与茶多糖发生了美拉德反应或与茶多酚发生了非酶促反应[37−38]。一般来说,等电点沉降后可去除游离态的多糖和多酚。然而,ATRP仍含有18%多糖和3%多酚[4],说明ATRP主要为糖-蛋白质或多酚-蛋白质的复合物,这类复合物具有较好的乳化性[37−38],从而提高了ATRP整体的乳化性。

![]() 图 6 静置10 min、1 d或15 d后 ATRP、大豆分离蛋白和乳清蛋白的乳化能力对比注:A:10 min、1 d和15 d下ATRP、大豆分离蛋白和乳清蛋白乳液的EAI值;B:10 min、1 d和15 d下ATRP、大豆分离蛋白和乳清蛋白乳液的CI值;C:10 min、1 d和15 d下ATRP、大豆分离蛋白和乳清蛋白乳液的直观状态。Figure 6. Emulsifying capacity comparison of ATRP, soy protein isolate, and whey protein after a storage of 10 min, 1 d or 15 d

图 6 静置10 min、1 d或15 d后 ATRP、大豆分离蛋白和乳清蛋白的乳化能力对比注:A:10 min、1 d和15 d下ATRP、大豆分离蛋白和乳清蛋白乳液的EAI值;B:10 min、1 d和15 d下ATRP、大豆分离蛋白和乳清蛋白乳液的CI值;C:10 min、1 d和15 d下ATRP、大豆分离蛋白和乳清蛋白乳液的直观状态。Figure 6. Emulsifying capacity comparison of ATRP, soy protein isolate, and whey protein after a storage of 10 min, 1 d or 15 d经过15 d的静置,ATRP乳液的EAI值和CI值保留82.9%和88.5%;大豆分离蛋白乳液的EAI值和CI值分别保留了74.4%和100%;乳清蛋白乳液的EAI值和CI值仅保留63.8%和66.2%。可见在室温条件下,ATRP乳化性及乳化稳定性优于乳清蛋白,并且与大豆分离蛋白相似。

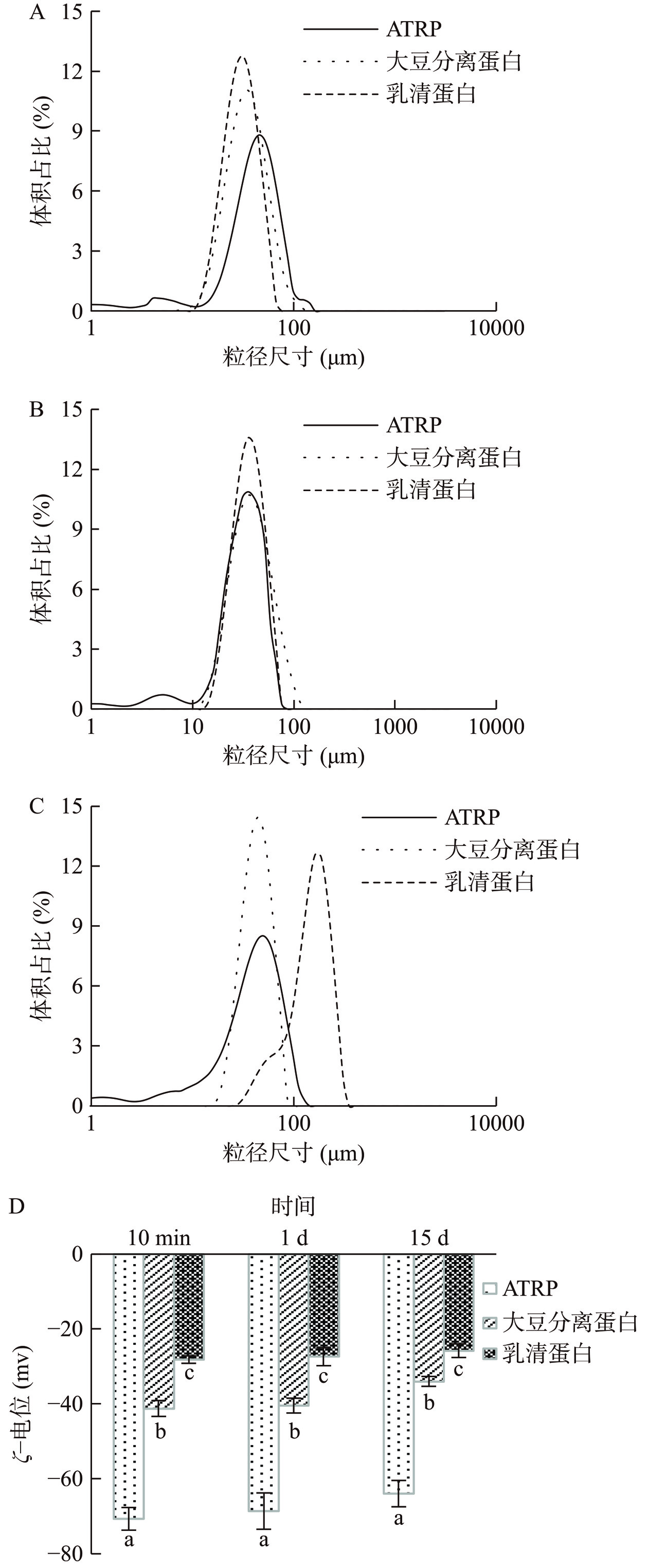

2.3.2 粒径分布状态变化和ζ-电位

测定10 min、1 d、15 d下ATRP乳液、大豆分离蛋白乳液和乳清蛋白乳液的粒度分布和ζ-电位,结果如图7所示。随着静置时间的增加,ATRP乳液的平均粒径几乎没有变化,保持在51.8 μm附近。相比之下,大豆分离蛋白乳液和乳清蛋白乳液的粒径均有增大的趋势。静置时间从10 min到15 d,大豆分离蛋白乳液的平均粒径从31.1 μm上升至40.1 μm,而乳清蛋白乳液的平均粒径则从35.3 μm上升至186.0 μm。这可能是由于ATRP中的多糖-蛋白质复合物或多酚-蛋白质复合物更为稳定,具有更好的乳化稳定性[39−40]。

如图7D所示,ATRP乳液的ζ-电位约为大豆分离蛋白乳液的2倍、乳清蛋白乳液的2.5倍。静置时间为15 d时,ATRP乳液ζ-电位为-63.9 mV,大豆分离蛋白乳液电位为-34.0 mV,而乳清蛋白乳液ζ-电位为-25.8 mV。这可能是由于茶渣中可降解的多糖主要是HG型果胶[6],而HG型果胶含有较多的羧基[41],这使得ATRP乳液中主要呈现出较低的ζ-电位值。综上,在乳液存储过程中,ATRP乳液的粒径变化较小且其ζ-电位较低,说明其具有较优的乳化性和乳化稳定性。

3. 结论

ATRP形成的乳液为水包油(O/W)类型,其HLB值为13。在油水比7:3、浓度4 mg/mL、pH7和储藏温度为20 ℃的条件下,ATRP乳化能力较好。在该条件下,ATRP乳液静置10 min时,乳化活性指数(EAI值)为43.3 m2/g,乳化指数(CI值)为97%。静置15 d后,ATRP乳液的EAI值和CI值保留了82.9%和88.5%,显示出较强的稳定性。同时,在该条件下相比于大豆分离蛋白和乳清蛋白,ATRP乳液在静置15 d的过程中粒径变化较小,且其在储存过程中的ζ-电位约为大豆分离蛋白2倍、乳清蛋白的2.5倍,说明其具有更好的乳化性和乳化稳定性,具有较高的应用价值。

-

图 6 静置10 min、1 d或15 d后 ATRP、大豆分离蛋白和乳清蛋白的乳化能力对比

注:A:10 min、1 d和15 d下ATRP、大豆分离蛋白和乳清蛋白乳液的EAI值;B:10 min、1 d和15 d下ATRP、大豆分离蛋白和乳清蛋白乳液的CI值;C:10 min、1 d和15 d下ATRP、大豆分离蛋白和乳清蛋白乳液的直观状态。

Figure 6. Emulsifying capacity comparison of ATRP, soy protein isolate, and whey protein after a storage of 10 min, 1 d or 15 d

-

[1] 彭靖里. 论茶叶深加工的研究动向及其发展前景[J]. 民营科技,2001(5):11−13. [PENG Jingli. Research trends and development prospects of tea deep processing[J]. Private Science and Technology,2001(5):11−13.] PENG Jingli. Research trends and development prospects of tea deep processing[J]. Private Science and Technology, 2001(5): 11−13.

[2] 翁蔚. 2020年及2021年上半年中国茶叶市场概况[J]. 中国茶叶,2021,43(9):74−76. [WENG Wei. Overview of China's tea market in 2020 and the first half of 2021[J]. China Tea,2021,43(9):74−76.] doi: 10.3969/j.issn.1000-3150.2021.09.011 WENG Wei. Overview of China's tea market in 2020 and the first half of 2021[J]. China Tea, 2021, 43(9): 74−76. doi: 10.3969/j.issn.1000-3150.2021.09.011

[3] 肖智, 黄贤金, 孟浩, 等. 2009-2014年中国茶叶生产空间演变格局及变化特征[J]. 地理研究,2017,36(1):109−120. [XIAO Zhi, HUANG Xianjin, MENG Hao, et al. 2009-2014 China's tea production spatial evolution pattern and change characteristics[J]. Geographic Research,2017,36(1):109−120.] XIAO Zhi, HUANG Xianjin, MENG Hao, et al. 2009-2014 China's tea production spatial evolution pattern and change characteristics[J]. Geographic Research, 2017, 36(1): 109−120.

[4] ZHANG C, SANDERS J P M, BRUINS M E. Critical parameters in cost-effective alkaline extraction for high protein yield from leaves[J]. Biomass and Bioenergy,2014,67:466−472. doi: 10.1016/j.biombioe.2014.05.020

[5] 李丽, 朱彬, 王馨悦. 废弃茶渣资源化应用及作污染物处理介质的研究进展[J]. 遵义师范学院学报,2016,18(3):88−92. [LI Li, ZHU Bin, WANG Xinyue. Research progress on the resource utilization of waste tea residue and its use as a pollutant treatment medium[J]. Journal of Zunyi Normal University,2016,18(3):88−92.] LI Li, ZHU Bin, WANG Xinyue. Research progress on the resource utilization of waste tea residue and its use as a pollutant treatment medium[J]. Journal of Zunyi Normal University, 2016, 18(3): 88−92.

[6] ZHANG C, SANDERS J P, XIAO T T, et al. How does alkali aid protein extraction in green tea leaf residue:A basis for integrated biorefinery of leaves[J]. PLoS One,2015,10(7):e0133046. doi: 10.1371/journal.pone.0133046

[7] 李圆圆. 茶渣蛋白的酶法提取及功能性质研究[D]. 无锡:江南大学, 2013. [LI Yuanyuan. Enzymatic extraction and functional properties of tea residue protein[D]. Wuxi:Jiangnan University, 2013.] LI Yuanyuan. Enzymatic extraction and functional properties of tea residue protein[D]. Wuxi: Jiangnan University, 2013.

[8] 陆晨. 茶渣中蛋白质的提取、脱色及改性研究[D]. 无锡:江南大学, 2012. [LU Chen. Extraction, decolorization, and modification of proteins from tea residue[D]. Wuxi:Jiangnan University, 2012.] LU Chen. Extraction, decolorization, and modification of proteins from tea residue[D]. Wuxi: Jiangnan University, 2012.

[9] 文静, 万紫媛, 解新安, 等. 反相微乳法与碱法、酶法制备的茶蛋白功能性质比较研究[J]. 食品工业科技,2016,37(7):97−100,332. [WEN Jing, WAN Ziyuan, JIE Xin'an, et al. Comparative study on the functional properties of tea protein prepared by reverse microemulsion method, alkaline method, and enzymatic method[J]. Food Industry Technology,2016,37(7):97−100,332.] WEN Jing, WAN Ziyuan, JIE Xin'an, et al. Comparative study on the functional properties of tea protein prepared by reverse microemulsion method, alkaline method, and enzymatic method[J]. Food Industry Technology, 2016, 37(7): 97−100,332.

[10] 王威威, 昝丽霞, 张文夷, 等. 茶蛋白的提取方法及生物活性研究进展[J]. 农业技术与装备,2022(1):102−104. [WANG Weiwei, ZAN Lixia, ZHANG Wenyi, et al. Progress in extraction methods and biological activities of tea protein[J]. Agricultural Technology and Equipment,2022(1):102−104.] doi: 10.3969/j.issn.1673-887X.2022.01.038 WANG Weiwei, ZAN Lixia, ZHANG Wenyi, et al. Progress in extraction methods and biological activities of tea protein[J]. Agricultural Technology and Equipment, 2022(1): 102−104. doi: 10.3969/j.issn.1673-887X.2022.01.038

[11] 罗发美, 谭文翰, 刀仕强, 等. 茶渣中蛋白质提取方法研究进展[J]. 食品安全质量检测学报,2020,11(13):4291−4297. [LUO Famei, TAN Wenhan, DAO Shiqiang, et al. Research progress on protein extraction methods in tea residue[J]. Journal of Food Safety and Quality Testing,2020,11(13):4291−4297.] LUO Famei, TAN Wenhan, DAO Shiqiang, et al. Research progress on protein extraction methods in tea residue[J]. Journal of Food Safety and Quality Testing, 2020, 11(13): 4291−4297.

[12] LIN Z, WEI H, ZHANG Y, et al. Improving emulsification properties of alkaline protein extract from green tea residue by enzymatic methods[J]. Current Research in Food Science,2022,5:1235−1242. doi: 10.1016/j.crfs.2022.07.016

[13] 魏汉, 张钰婷, 李伟强, 等. 茶渣蛋白提取物对吉富罗非鱼生长性能和生化指标的影响[J]. 福州大学学报(自然科学版),2023,51(3):425−430,438. [WEI Han, ZHANG Yuting, LI Weiqiang, et al. Effects of tea residue protein extract on growth performance and biochemical indicators of tilapia Jifu[J]. Journal of Fuzhou University (Natural Science Edition),2023,51(3):425−430,438.] WEI Han, ZHANG Yuting, LI Weiqiang, et al. Effects of tea residue protein extract on growth performance and biochemical indicators of tilapia Jifu[J]. Journal of Fuzhou University (Natural Science Edition), 2023, 51(3): 425−430,438.

[14] 张根生, 岳晓霞, 李继光, 等. 大豆分离蛋白乳化性影响因素的研究[J]. 食品科学,2006(7):48−51. [ZHANG Gensheng, YUE Xiaoxia, LI Jiguang, et al. Study on factors affecting the emulsifying properties of soy protein isolate[J]. Food Science,2006(7):48−51.] ZHANG Gensheng, YUE Xiaoxia, LI Jiguang, et al. Study on factors affecting the emulsifying properties of soy protein isolate[J]. Food Science, 2006(7): 48−51.

[15] 曹璐, 王瑞, 陈芳莉, 等. 不饱和脂肪酸单甘油酯对大豆蛋白饮料稳定性的影响[J]. 中国油脂,2019,44(11):34−40. [CAO Lu, WANG Rui, CHEN Fangli, et al. The effect of unsaturated fatty acid monoglycerides on the stability of soy protein beverages[J]. Chinese Journal of Fats and Fats,2019,44(11):34−40.] CAO Lu, WANG Rui, CHEN Fangli, et al. The effect of unsaturated fatty acid monoglycerides on the stability of soy protein beverages[J]. Chinese Journal of Fats and Fats, 2019, 44(11): 34−40.

[16] 孙炜炜. 乳清分离蛋白—葡聚糖接枝改性及功能性质研究[D]. 广州:华南理工大学, 2012. [SUN Weiwei. Graft modification and functional properties of whey protein isolate-glucan[D]. Guangzhou:South China University of Technology, 2012.] SUN Weiwei. Graft modification and functional properties of whey protein isolate-glucan[D]. Guangzhou: South China University of Technology, 2012.

[17] 李永富. 茶渣蛋白和茶渣多肽的制备及性质的初步研究[D]. 上海:上海师范大学, 2015. [LI Yongfu. Preliminary study on the preparation and properties of tea residue protein and tea residue peptides[D]. Shanghai:Shanghai Normal University, 2015.] LI Yongfu. Preliminary study on the preparation and properties of tea residue protein and tea residue peptides[D]. Shanghai: Shanghai Normal University, 2015.

[18] 申莉莉. 百里香微胶囊制备及抑菌效果和机理研究[D]. 武汉:华中农业大学, 2015. [SHEN Lili. Study on preparation of thyme microcapsules and antimicrobial effect and mechanism[D]. Wuhan:Huazhong Agricultural University, 2015.] SHEN Lili. Study on preparation of thyme microcapsules and antimicrobial effect and mechanism[D]. Wuhan: Huazhong Agricultural University, 2015.

[19] AZIZ A, KHAN N M, ALI F, et al. Effect of protein and oil volume concentrations on emulsifying properties of acorn protein isolate[J]. Food Chemistry,2020,324:126894. doi: 10.1016/j.foodchem.2020.126894

[20] SHI J J, ZHANG J G, SUN Y H, et al. Physicochemical properties and antioxidant activities of polysaccharides sequentially extracted from peony seed dreg[J]. Int J Biol Macromol,2016,91:23−30. doi: 10.1016/j.ijbiomac.2016.05.082

[21] BAI L, HUAN S, LI Z, et al. Comparison of emulsifying properties of food-grade polysaccharides in oil-in-water emulsions:Gum arabic, beet pectin, and corn fiber gum[J]. Food Hydrocolloids,2017,66:144−153. doi: 10.1016/j.foodhyd.2016.12.019

[22] GUAN Y, WU J, ZHONG Q. Eugenol improves physical and chemical stabilities of nanoemulsions loaded with beta-carotene[J]. Food Chemistry,2016,194:787−796. doi: 10.1016/j.foodchem.2015.08.097

[23] ROHN S. Possibilities and limitations in the analysis of covalent interactions between phenolic compounds and proteins[J]. Food Research International,2014,65:13−19. doi: 10.1016/j.foodres.2014.05.042

[24] 于娇娇. 高温花生蛋白的低温等离子体结构修饰及物性研究[D]. 天津:天津科技大学, 2022. [YU Jiaojiao. Low temperature plasma structural modification and physical properties study of high-temperature peanut protein[D]. Tianjin:Tianjin University of Science and Technology, 2022.] YU Jiaojiao. Low temperature plasma structural modification and physical properties study of high-temperature peanut protein[D]. Tianjin: Tianjin University of Science and Technology, 2022.

[25] 刘宗鹏, 胡少剑, 张宇宁, 等. 复合型多元醇酯合成反应的热力学分析及动力学研究[J]. 化工学报,2023,74(11):4475−4486. [LIU Zongpeng, HU Shaojian, ZHANG Yuning, et al. Thermodynamic analysis and kinetic study of composite polyol ester synthesis reaction[J]. Journal of Chemical Engineering,2023,74(11):4475−4486.] doi: 10.11949/0438-1157.20230902 LIU Zongpeng, HU Shaojian, ZHANG Yuning, et al. Thermodynamic analysis and kinetic study of composite polyol ester synthesis reaction[J]. Journal of Chemical Engineering, 2023, 74(11): 4475−4486. doi: 10.11949/0438-1157.20230902

[26] LI T, GUO X N, ZHU K X, et al. Effects of alkali on protein polymerization and textural characteristics of textured wheat protein[J]. Food Chem,2018,239:579−587. doi: 10.1016/j.foodchem.2017.06.155

[27] 陈玉明, 李小玲, 张梦轲, 等. 水包油型乳状液乳化和破乳的影响因素实验研究[J]. 当代化工,2023,52(5):1103−1107,1120. [CHEN Yuming, LI Xiaoling, ZHANG Mengke, et al. Experimental study on the influencing factors of emulsification and demulsification of water in oil emulsions[J]. Contemporary Chemical Industry,2023,52(5):1103−1107,1120.] CHEN Yuming, LI Xiaoling, ZHANG Mengke, et al. Experimental study on the influencing factors of emulsification and demulsification of water in oil emulsions[J]. Contemporary Chemical Industry, 2023, 52(5): 1103−1107,1120.

[28] 黄红玺, 张峰, 许明标, 等. 油包水乳状液稳定性影响因素分析[J]. 断块油气田,2009,16(6):99−101. [HUANG Hongxi, ZHANG Feng, XU Mingbiao, et al. Analysis of factors influencing the stability of oil in water emulsion[J]. Fault Block Oil and Gas Field,2009,16(6):99−101.] HUANG Hongxi, ZHANG Feng, XU Mingbiao, et al. Analysis of factors influencing the stability of oil in water emulsion[J]. Fault Block Oil and Gas Field, 2009, 16(6): 99−101.

[29] MUNK M B, UTOFT A, LARSEN F H, et al. Oleogelating properties of ethylcellulose in oil-in-water emulsions:The impact of emulsification methods studied by 13C MAS NMR, surface tension and micropipette manipulation studies[J]. Food Hydrocolloids,2019,89:700−706. doi: 10.1016/j.foodhyd.2018.11.019

[30] 冯屏, 徐玉佩. 功能性大豆蛋白及其应用[J]. 中国油脂,2001(6):70−74. [FENG Ping, XU Yupei. Functional soy protein and its application[J]. Chinese Journal of Oils and Fats,2001(6):70−74.] doi: 10.3321/j.issn:1003-7969.2001.06.024 FENG Ping, XU Yupei. Functional soy protein and its application[J]. Chinese Journal of Oils and Fats, 2001(6): 70−74. doi: 10.3321/j.issn:1003-7969.2001.06.024

[31] 胡坤, 赵谋明, 彭志英. 乳化剂和多糖对蛋白质乳浊液的稳定性的影响[J]. 食品与发酵工业,2002(6):61−65. [HU Kun, ZHAO Muming, PENG Zhiying. Effects of emulsifiers and polysaccharides on the stability of protein emulsion[J]. Food and Fermentation Industry,2002(6):61−65.] doi: 10.3321/j.issn:0253-990X.2002.06.015 HU Kun, ZHAO Muming, PENG Zhiying. Effects of emulsifiers and polysaccharides on the stability of protein emulsion[J]. Food and Fermentation Industry, 2002(6): 61−65. doi: 10.3321/j.issn:0253-990X.2002.06.015

[32] 杨小莉, 陆婉珍. 有关原油乳状液稳定性的研究[J]. 油田化学,1998(1):88−97. [YANG Xiaoli, LU Wanzhen. Research on the stability of crude oil emulsions[J]. Oilfield Chemistry,1998(1):88−97.] YANG Xiaoli, LU Wanzhen. Research on the stability of crude oil emulsions[J]. Oilfield Chemistry, 1998(1): 88−97.

[33] 卢亚东, 梁亚萍, 王愈, 等. 糖基化改性大豆蛋白溶解特性[J]. 食品工业,2021,42(5):37−40. [LU Yadong, LIANG Yaping, WANG Yu, et al. Solubility characteristics of glycation modified soy protein[J]. Food Industry,2021,42(5):37−40.] LU Yadong, LIANG Yaping, WANG Yu, et al. Solubility characteristics of glycation modified soy protein[J]. Food Industry, 2021, 42(5): 37−40.

[34] 田其英, 华欲飞. 大豆蛋白溶解性研究[J]. 粮食与油脂,2006(6):6−8. [TIAN Qiying, HUA Yufei. Research on the solubility of soybean protein[J]. Grain and Oil,2006(6):6−8.] doi: 10.3969/j.issn.1008-9578.2006.06.002 TIAN Qiying, HUA Yufei. Research on the solubility of soybean protein[J]. Grain and Oil, 2006(6): 6−8. doi: 10.3969/j.issn.1008-9578.2006.06.002

[35] 何亚其, 冯爱煊, 孙超, 等. 浅析海上原油乳状液破乳影响因素[J]. 山东化工,2021,50(5):160−161. [HE Yaqi, FENG Aixuan, SUN Chao, et al. Analysis of factors affecting demulsification of offshore crude oil emulsions[J]. Shandong Chemical Industry,2021,50(5):160−161.] doi: 10.3969/j.issn.1008-021X.2021.05.059 HE Yaqi, FENG Aixuan, SUN Chao, et al. Analysis of factors affecting demulsification of offshore crude oil emulsions[J]. Shandong Chemical Industry, 2021, 50(5): 160−161. doi: 10.3969/j.issn.1008-021X.2021.05.059

[36] 杨希娟, 党斌, 吴昆仑, 等. 青稞蛋白的超声波辅助提取工艺及其功能特性研究[J]. 中国食品学报,2013,13(6):48−56. [YANG Xijuan, DANG Bin, WU Kunlun, et al. Study on ultrasonic assisted extraction process and functional properties of highland barley protein[J]. Chinese Journal of Food Science,2013,13(6):48−56.] YANG Xijuan, DANG Bin, WU Kunlun, et al. Study on ultrasonic assisted extraction process and functional properties of highland barley protein[J]. Chinese Journal of Food Science, 2013, 13(6): 48−56.

[37] TANG W, ZHANG Q, RITZOULIS C, et al. Food protein glycation:A review focusing on stability and in vitro digestive characteristics of oil/water emulsions[J]. Comprehensive Reviews in Food Science and Food Safety,2023,22(3):1986−2016. doi: 10.1111/1541-4337.13138

[38] 陈颖, 万海峰, 陈小强, 等. 蛋白质-多酚相互作用及在食品开发中的应用进展[J]. 食品科技,2023,48(1):90−97. [CHEN Ying, WAN Haifeng, CHEN Xiaoqiang, et al. Protein polyphenol interactions and their application progress in food development[J]. Food Science and Technology,2023,48(1):90−97.] CHEN Ying, WAN Haifeng, CHEN Xiaoqiang, et al. Protein polyphenol interactions and their application progress in food development[J]. Food Science and Technology, 2023, 48(1): 90−97.

[39] DING Y, CHEN L, SHI Y, et al. Emulsifying and emulsion stabilizing properties of soy protein hydrolysates, covalently bonded to polysaccharides:The impact of enzyme choice and the degree of hydrolysis[J]. Food Hydrocolloids,2021,113:106519. doi: 10.1016/j.foodhyd.2020.106519

[40] TAHA A, AHMED E, ISMAIEL A, et al. Ultrasonic emulsification:An overview on the preparation of different emulsifiers-stabilized emulsions[J]. Trends in Food Science & Technology,2020,105:363−377.

[41] ZHANG C, ZHU X, ZHANG F, et al. Improving viscosity and gelling properties of leaf pectin by comparing five pectin extraction methods using green tea leaf as a model material[J]. Food Hydrocolloids,2020,98:105246. doi: 10.1016/j.foodhyd.2019.105246

下载:

下载:

下载:

下载: