Effects of Natural Spices on Shelf Life Quality of Roasted Peanut Kernels

-

摘要: 为探究天然香辛料对烘炒花生仁货架期品质的影响,以姜黄、茴香、花椒水提物浸泡处理的花生仁为研究对象,采用Schaal烘箱法对花生仁进行加速氧化,分析花生仁在烘箱贮藏期间的酸价、过氧化值、丙二醛、色度色差、质构、水分含量、水分活度及风味感官,结合动力学和Arrhenius 方程,建立20~63 ℃贮藏温度下烘炒花生货架期预测模型,并对其进行验证和应用。结果表明,与空白组相比,姜黄、茴香、花椒水提物处理组可有效抑制油脂水解与脂肪酸氧化;抑制过氧化值与丙二醛的上升;更好维持花生色度与质构品质;提高烘炒花生的风味评分。香辛料组的水分含量和空白组无显著性差异;水分活度均小于0.60,黄曲霉难以生长。所得的货架期模型相对误差不大于8.93%,可快速预测20~63 ℃贮藏温度下烘炒花生货架期。当贮藏温度为25 ℃时,姜黄味的货架期为170.6 d;茴香味的货架期为150.5 d;花椒味的货架期为169.4 d;空白组的货架期为97.7 d。因此,加入姜黄、茴香、花椒能更好地保持烘炒花生品质及延长货架期。Abstract: To investigate the effect of natural spices on the shelf life quality of roasted peanut kernels, peanut kernels treated with aqueous extracts of turmeric, fennel, and peppercorns were subjected to accelerated oxidation using the Schaal oven method and were analyzed for acidity, peroxide, malondialdehyde, chroma colourimetry, textural composition, moisture content, water activity, and flavour sensory indexes during the period of storage in the oven, combined with the kinetics and the Arrhenius equation, the shelf life prediction model was completed at 20~63 ℃, validated and applied. The results showed that compared with the control group, the turmeric, fennel and peppercorn aqueous extract treatment groups could effectively inhibit the hydrolysis of oil and fatty acid oxidation, inhibit the increase of peroxide value and malondialdehyde, maintain the chromaticity and texture of peanuts better, and improve the flavour score of roasted peanuts. There was no significant difference between the moisture content of the spices groups and the control group. The water activity was less than 0.60, Aspergillus flavus struggled to thrive. The relative error of the resulting shelf life model was not more than 8.93%, which was used to quickly predict the shelf life of roasted peanuts stored at 20~63 ℃. When the storage temperature was 25 ℃, the shelf life was 170.6 days for turmeric-flavored peanuts, 150.5 days for fennel-flavored peanuts, 169.4 days for pepper-flavored peanuts, and 97.7 days for the control group. Therefore, adding turmeric, fennel and pepper can maintain the quality of the roasted peanuts and prolong their shelf life.

-

Keywords:

- turmeric /

- fennel /

- pepper /

- roasted peanut /

- shelf life /

- chemical kinetics /

- sensory evaluation

-

我国花生休闲食品种类繁多,如烘炒花生、油炸花生、裹衣花生、花生糖等[1],其中烘炒花生具有独特的风味和香气,备受市场的欢迎。花生的油脂含量约45%~50%,其中80%由不饱和脂肪酸组成[2]。在烘炒结束后,烘炒花生中的磷脂酰乙醇胺等磷脂由于热不稳定性而降解为游离脂肪酸,同时氧化脂肪酸增加,导致烘炒花生在贮藏过程中极易发生脂质氧化[3]。因此在实际生产中,烘炒花生在常温保存五个月后就会出现哈败现象,已成为产业中的技术瓶颈。

目前GB 2760-2014《食品安全国家标准 食品添加剂使用标准》[4]中规定,能使用在熟制坚果及籽类的抗氧化剂仅有特丁基对苯二酚(TBHQ),但由于其具有油溶性,更适合添加在油炸花生中。目前,Gaikwad等[5]使用含有反式聚异戊二烯的低密度聚乙烯(LDPE/PSN)活性薄膜作为烘炒花生的包装袋,可以有效除氧以达到抑制烘炒花生变质的目的;Kazemian-Bazkiaee等[2]使用β-葡聚糖/壳聚糖作为烘炒花生的食用涂层,结果表明其可控制花生的油稳定性,并且水分含量、真菌数量和平均总黄曲霉毒素低于对照组;Paula等[6]将脱脂花生粉包裹烘炒花生,结果表明其可抑制贮藏期烘炒花生的脂质氧化;Olmedo等[7]在烘炒花生中添加月桂树、牛至和迷迭香精油这类天然抗氧化剂,结果显示添加这些精油可以延长花生货架期,并且对花生有调味作用。但是这些方法产品成本大幅度增加,并且有些技术难以实现工业化,此外目前烘炒花生仅有原味、盐味、麻辣味、五香味等,需要拓展新口味。而香辛料富含酚类、黄酮类、萜类和烯烃类等化学物质,可调香、调味、抗氧化,在食品中被广泛应用。杨轶浠等[8]将香辛料提取物添加到肉制品中,有效防腐保鲜;周强等[9]发现香辛料的香气成分可很好地浸入到葵瓜子仁中,并且对瓜子仁呈香组分有较大的影响;侯春宇等[10]发现对大黄鱼使用香辛料保鲜剂能较好维持大黄鱼的感官效果、延长其货架期,但目前利用香辛料延长烘炒花生货架期的研究较少。

本实验选用3种天然香辛料(姜黄、茴香、花椒)制成调味液来研究其对烘炒花生仁品质的影响,以期延长烘炒花生货架期,增加烘炒花生风味,提供更为简单、低成本,便于工业化的技术,为保持烘炒花生仁货架期品质稳定提供新的思路。并且通过零级反应动力学结合Arrhenius方程,建立货架期预测模型,以期为烘炒花生的贮藏提供理论指导。

1. 材料与方法

1.1 材料与仪器

花生 品种为鲁花10号,乳山市金果食品股份有限公司提供;姜黄粉、茴香粉、花椒粉 购自川麻麻淘宝店铺;石油醚(沸程30~60 ℃)、冰乙酸、三氯甲烷、乙醚、三氯乙酸、乙二胺四乙酸二钠、硫代巴比妥酸、丙二醛乙缩醛、碘化钾、硫代硫酸钠、无水硫酸钠、可溶性淀粉、异丙醇、酚酞、氢氧化钠 分析纯,泰坦科技探索平台。

LC-RE-5299旋转蒸发器 上海力辰邦西仪器科技有限公司;SHZ-D(Ⅲ)循环水式多用真空泵 河南省予华仪器有限公司;UV-1100紫外可见分光光度计 上海美谱达仪器有限公司;DNP-9162隔水式恒温培养箱 上海精宏实验设备有限公司;MB23快速水分测定仪 奥豪斯国际贸易(上海)有限公司;CM-3700A 色度色差仪 Konica Minolta;LabMaster-aw neo水分活度仪 瑞士Novasina公司;TA.XT Plus质构仪 英国Stable Micro System公司。

1.2 实验方法

1.2.1 烘炒花生仁的制备及货架期测定

在沸水中加入香辛料粉、盐,文火煮30 min(香辛料粉:盐:水的质量分数=1:2:40),过滤得到香辛料水提物。水提物冷却至室温后,在花生仁上均匀喷淋(调味液:花生仁的质量分数=1:1),再把花生仁装入周转框中,静置、匀湿,200 ℃烘炒75 min,烘炒结束后冷却至室温,使用铝塑复合袋包装,每袋净含量为108 g。

采用Schaal烘箱法进行烘炒花生加速实验[11],将包装好的花生仁放置于(63±0.5) ℃的恒温箱,每隔2 d取样进行测定。

1.2.2 测定指标及方法

1.2.2.1 酸价的测定

采用GB 5009.229-2016[12]的冷溶剂指示剂滴定法测定。

1.2.2.2 过氧化值的测定

采用GB 5009.227-2016[13]的滴定法测定。

1.2.2.3 丙二醛的测定

采用GB 5009.181-2016[14]的分光光度法测定。

1.2.2.4 色度、色差的测定

随机挑选10粒花生仁,去除红衣,采用色度色差仪测定花生仁的亮度(L*)、红绿值(a*)及黄蓝值(b*)。具体测定参数[15]:测量类型:反射率;镜面光成分:SCI;测定区域:SAV(3×5 mm);UV设置:100%完全。

1.2.2.5 质构特性的测定

采用质构仪进行测定,选用P/36R探头,采用TPA模式。测定具体参数[16]:测前速度:2 mm/sec;测中速度:2 mm/sec;测后速度:2 mm/sec;应变:40%;时间:3 sec;触发力:15g。

1.2.2.6 水分含量的测定

采用GB 5009.3-2016的直接干燥法测定。

1.2.2.7 水分活度的测定

采用水分活度仪测定。

1.2.2.8 风味感官评价方法

挑选10名身体健康、感觉正常的人员,对其进行训练后进行感官评价,同时对放于20 ℃中的烘炒花生每隔2个月进行风味评价,持续9个月。根据Peter等[17]完善的花生风味词典确定烘炒花生风味感官评价评分标准,如表1所示。

表 1 感官评价标准Table 1. Sensory evaluation criteria得分(分) 风味 10 焙烤花生风味浓郁,且无其他变质异味 9~7 烤花生味较浓郁 6 轻微酸败味或烤花生味稀薄 5~0 酸败味明显或无烤花生味 1.2.3 烘炒花生货架期预测模型的建立

1.2.3.1 动力学模型的建立

在食品贮藏过程中,大多数食品的品质变化遵循零级或一级反应的动力学规律[18]。

零级反应动力学方程:

$$\rm A = {A_0}+kt $$ (1) 一级反应动力学方程:

$$\rm \ln [A] = kt+\ln [{A_0}] $$ (2) 式(1)和式(2)中:A为贮藏t时的氧化指标;A0为氧化初始值;t为贮藏时间,d;k为反应速率常数。

根据零级和一级反应动力学方程不同温度下回归系数R2的总和(∑R2),选择更适合本实验的动力学模型。

1.2.3.2 Arrhenius方程的建立

Arrhenius方程可用来描述温度对食品品质指标变化的影响,根据Arrhenius 公式[19],即:

$$\rm k = {k_0}{e^{ - Ea/RT}} $$ (3) 式子两边取对数得:

$$\rm \ln k = - \frac{{Ea}}{{RT}}+\ln {k_o} $$ (4) 式中:k为反应速率常数;k0为指前因子;Ea为活化能,J/mol;R为气体常数,8.3144 J/(mol·K);T为绝对温度(K);将63 ℃、20 ℃的k、T带入式(4)求解,求得Ea、k0。

1.2.3.3 货架期预测模型的建立

根据烘炒花生储藏品质指标的限值,结合动力学方程和Arrhenius方程,可得到烘炒花生不同储藏温度下的理论预测货架期,其零级和一级动力学预测模型见式(5)和式(6)。

$$\rm SL = \frac{{\left| {A - {A_0}} \right|}}{{{k_0}\exp \left( { - \dfrac{{Ea}}{{RT}}} \right)}} $$ (5) $$\rm SL = \frac{{\left| {\ln A - \ln {A_0}} \right|}}{{{k_0}\exp \left( { - \dfrac{{Ea}}{{RT}}} \right)}} $$ (6) 式中,SL为货架期(d)。

1.3 数据处理

所有实验至少重复3次,实验结果以“平均值±标准偏差”表示。采用Origin 2023、SPSS 26软件对实验数据进行统计。由SIDAK检测来确定显著性水平(P<0.05),并在图中用字母标注表示显著性差异,其中大写字母表示组间差异,小写字母表示组内差异。

2. 结果与分析

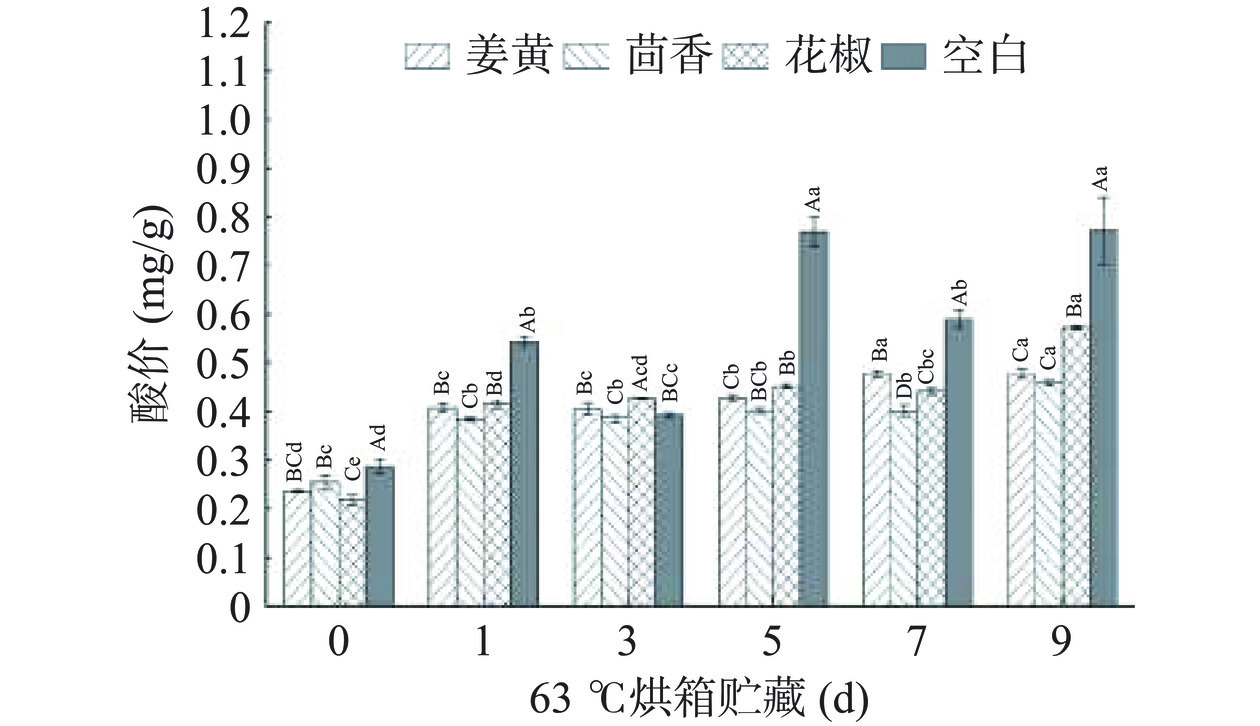

2.1 天然香辛料对花生仁酸价的影响

花生的油脂含量可达45%~50%,酸价是衡量油脂中游离脂肪酸的量,游离脂肪酸的降低可在一定程度上反应油脂氧化裂解的程度,是评价烘炒花生品质的重要指标[20]。对添加天然香辛料的烘炒花生的酸价进行测定,结果如图1所示。

在烘炒花生贮藏前,空白组与香辛料组的酸价有显著差异(P<0.05),这可能是因为花生仁在烘炒过程中就会有脂肪酸的积累[3],而姜黄和茴香水提物主要成分为酚类,花椒水提物主要成分为烯烃类[21−23],酚类和烯烃类都具有较好的抑制脂质过氧化能力[24]。随着贮藏时间的延长,空白组出现先上升再下降的趋势,而香辛料组一直呈上升趋势。空白组与张喻等[25]研究的咸干花生的酸价变化趋势一致,可能是由于在贮藏过程中,烘炒花生的油脂发生水解反应,生成游离脂肪酸和甘油,其中游离脂肪酸的大量堆积会进一步氧化,造成烘炒花生中油脂酸败,因而酸价降低。空白组的酸价在贮藏期第3 d出现显著(P<0.05)下降,可说明空白组最先出现游离脂肪酸的进一步氧化,且空白组的酸价几乎在整个高温破坏性实验期间都高于香辛料组,具有显著性差异(P<0.05),可见3种香辛料的水提物能显著抑制烘炒花生油脂氧化及水解,从而延缓烘炒花生品质下降。

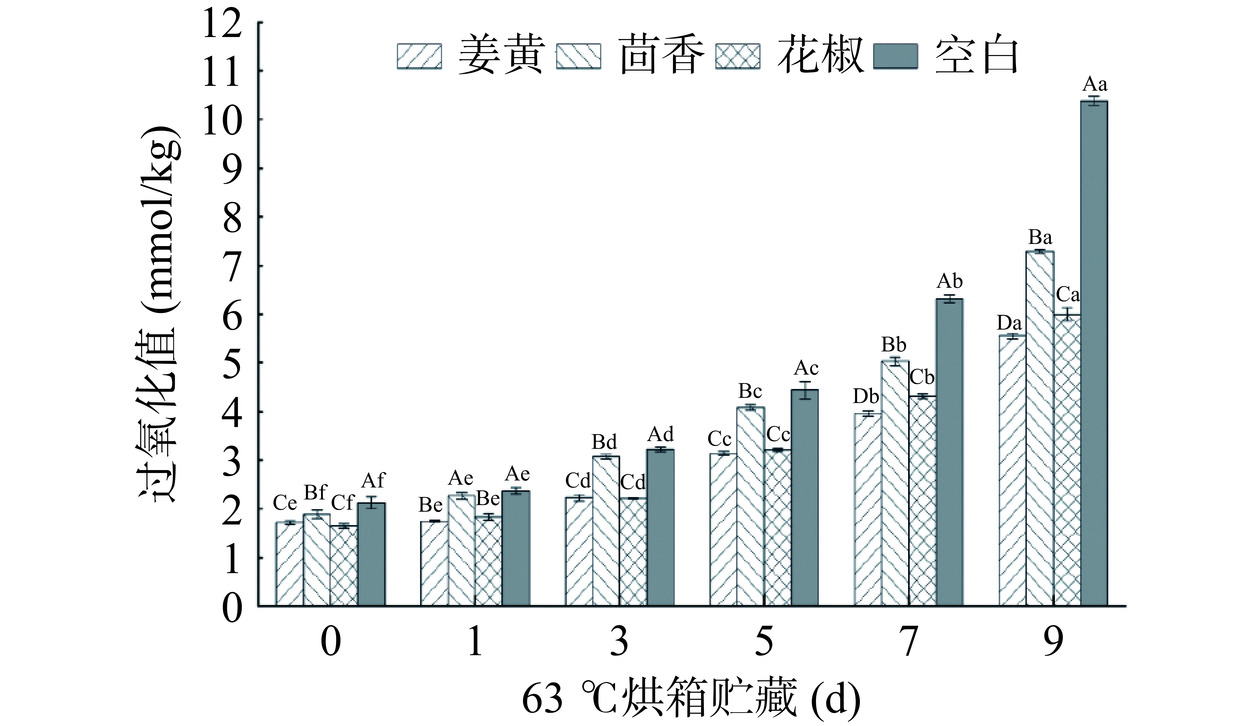

2.2 天然香辛料对花生仁过氧化值的影响

烘炒花生中的油脂氧化初期会生成氢过氧化合物,氢过氧化合物是烘炒花生出现酸败臭的前提,而过氧化值可用来表示氢过氧化合物的量,因此过氧化值可衡量油脂氧化初期的氧化程度[26]。对添加天然香辛料的烘炒花生的过氧化值进行测定,结果如图2所示。

从图2可看出,在烘炒花生贮藏前,空白组与另外3组的过氧化值有显著性差异(P<0.05),其中空白组最高,茴香组其次,姜黄组与花椒组没有显著性差异,这可能是由于在烘炒过程中自由基攻击不饱和脂肪酸导致氢过氧化合物的积累[27],而三种香辛料的水提物都有较好的自由基清除能力[22,28]。随着贮藏时间的延长,每组的过氧化值都呈显著(P<0.05)上升趋势,在贮藏的第9 d,空白组达到最高(10.382 mmol/kg),茴香组第二(6.753 mmol/kg),花椒组第三(5.992 mmol/kg),姜黄组最低(5.550 mmol/kg),香辛料组与空白组相比具有显著性差异(P<0.05)。说明在贮藏过程中烘炒花生的油脂氧化造成氢过氧化物不断累积,与空白组相比,3种香辛料的水提物能有效延缓烘炒花生氧化速率,其中姜黄的效果最佳。

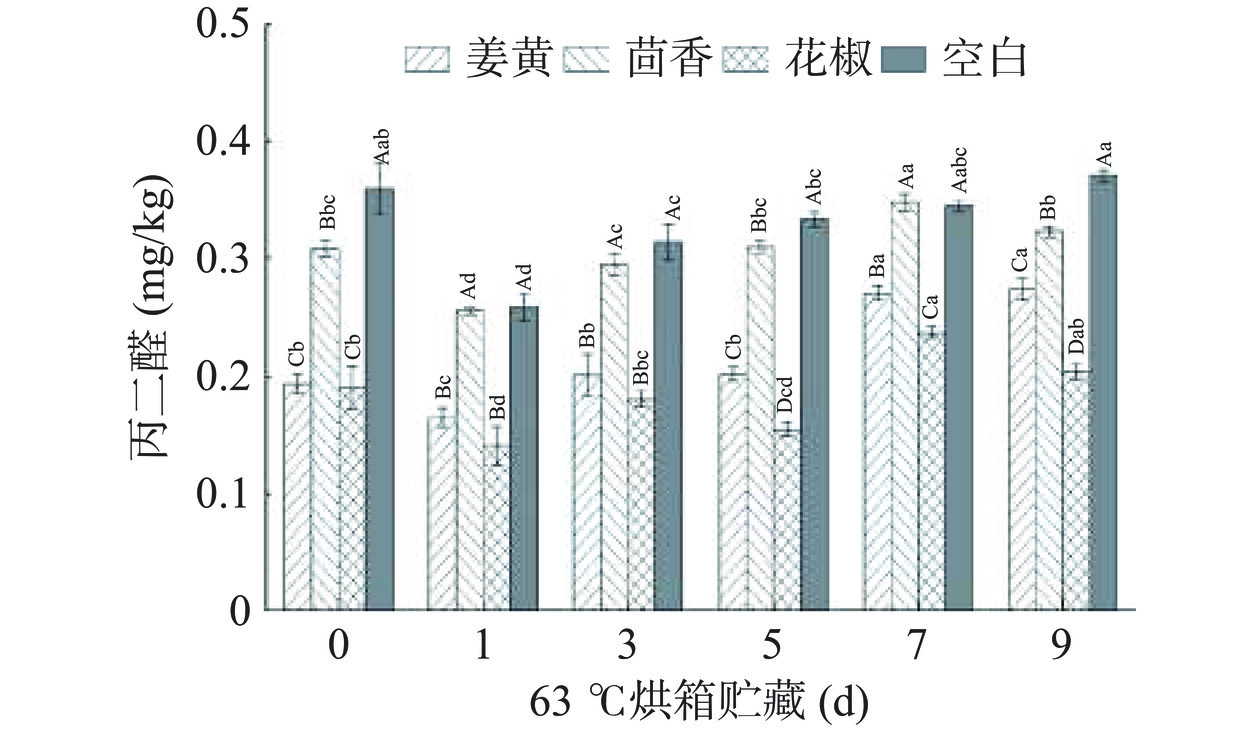

2.3 天然香辛料对花生仁丙二醛的影响

在油脂氧化后期,氢过氧化合物分解会形成小分子醛、酮、醇、酸,并且大部分具有刺激性气味,形成油脂氧化的酸败臭[11],其中醛类最主要的物质为丙二醛[29],因此丙二醛的含量可以反应油脂后期的氧化程度[30]。对添加天然香辛料的烘炒花生的丙二醛进行测定,结果如图3所示。

从图3可看出,在烘炒花生贮藏前,空白组与香辛料组的丙二醛有显著差异(P<0.05),其中空白组最高,茴香组其次,姜黄组与花椒组没有显著性差异,这可能是由于在烘炒花生过程中丙二醛增加[31],而三种香辛料的水提物可抑制油脂氧化劣变[32]。随着贮藏时间的延长,每组丙二醛的含量都处于波动状态,这可能是因为氧化体系中的丙二醛会与蛋白质反应[11]。在整个高温破坏性实验期间,空白组的丙二醛几乎都高于其他组,这说明三种天然香辛料的水提物能有效延缓花生丙二醛的生成,其中花椒和姜黄的效果更佳。

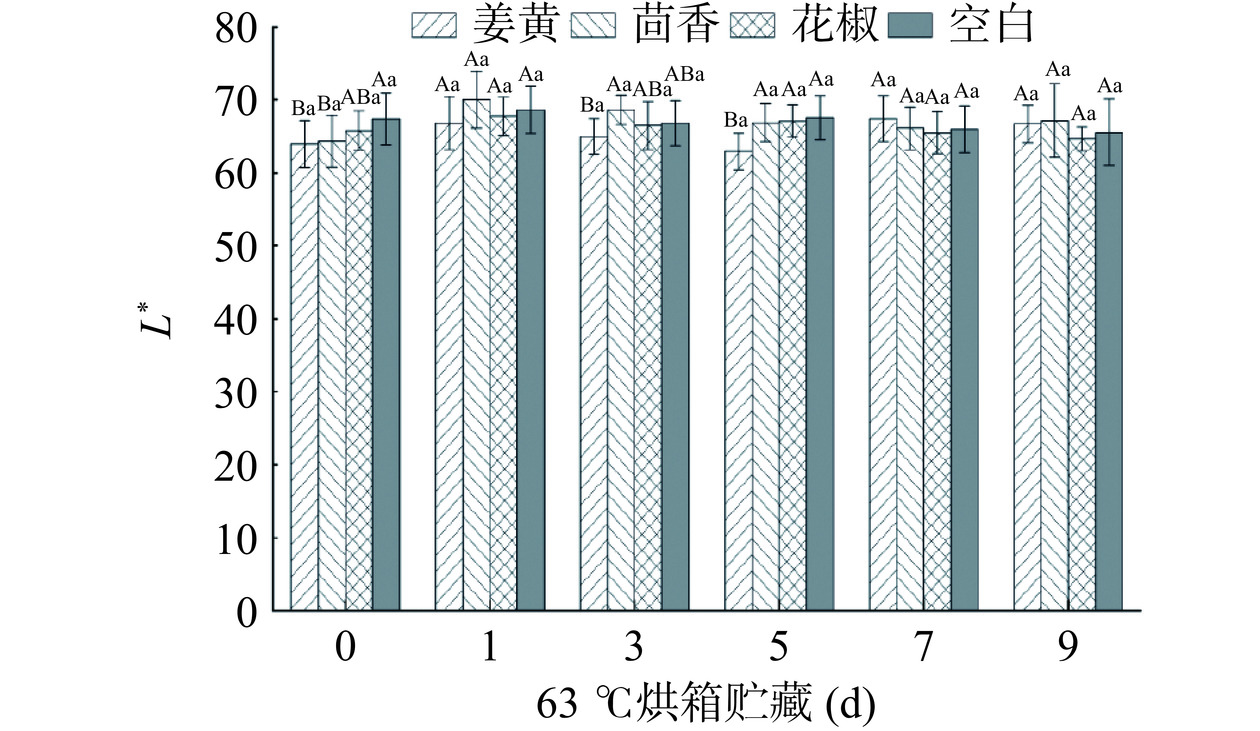

2.4 天然香辛料对花生仁色度色差的影响

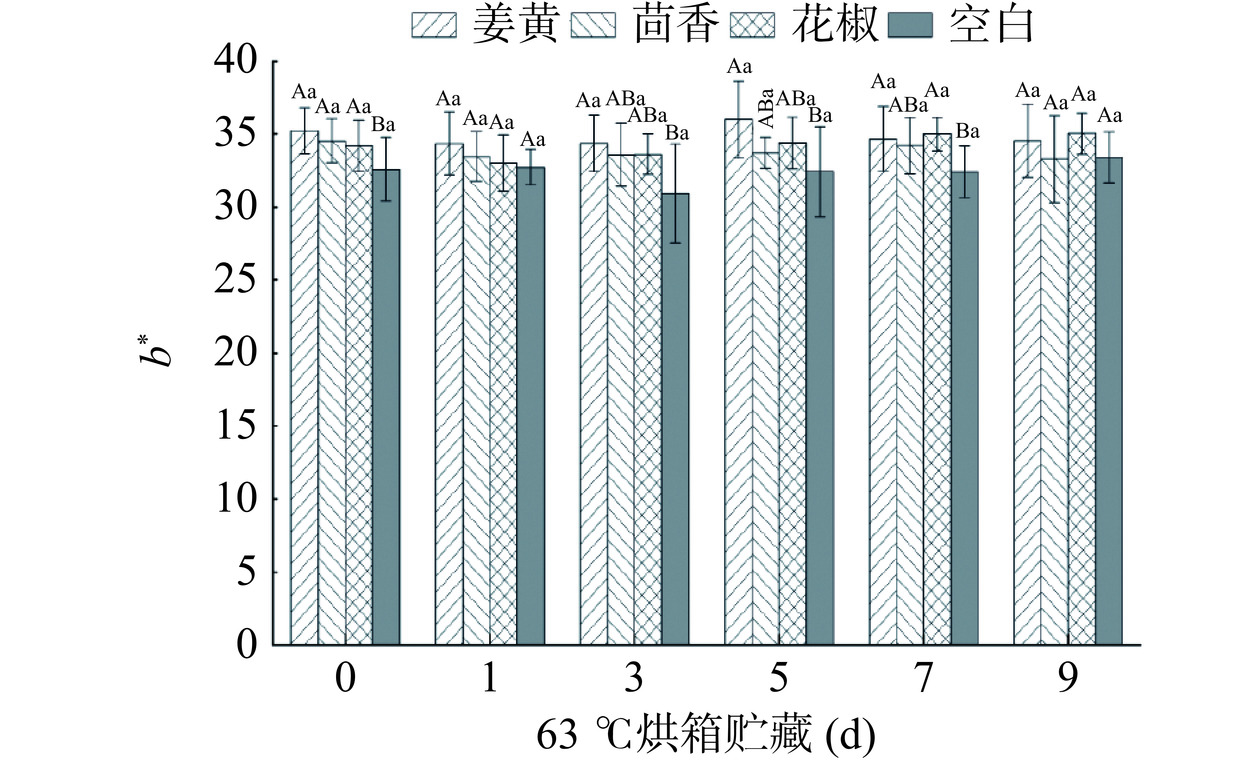

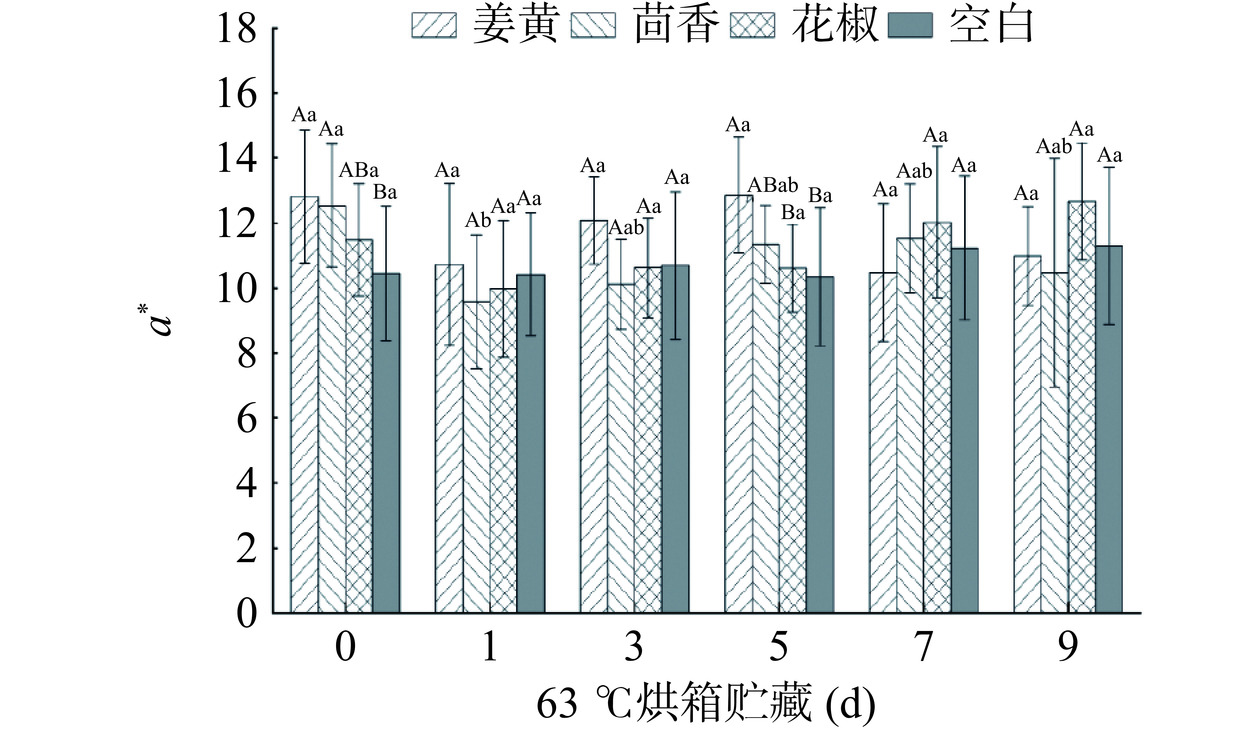

烘炒花生色泽对于感官品质有重要影响。图4~图6显示了花生仁贮藏过程中花生色度亮度(L*)、红绿值(a*)及黄蓝值(b*)的变化。

从图4可看出,随着贮藏时间的延长,每组均未出现显著性变化(P>0.05)。其中空白组的L*下降最快,从最初67.406下降至65.519,花椒组略有下降,其余组L*均呈上升趋势,这可能是在烘炒花生仁时发生的美拉德反应导致类黑素产生,但美拉德产物会与茴香和姜黄水提物发生逆反应,导致花生仁褪色,从而亮度上升[25]。从图5和图6可看出,随着贮藏时间的延长,姜黄和茴香组的a*和b*整体都呈现下降趋势,空白和花椒组的a*和b*整体都呈现上升趋势,说明姜黄和茴香组的红度与黄度减弱,而空白和花椒组的红度与黄度增强。

综上,烘炒花生在储藏过程中会出现L*的下降和a*、b*的上升,而姜黄和茴香的水提物都能抑制L*的下降和a*、b*的上升,花椒组的变化趋势虽与空白组一致,但总体变化小于空白组。因此,与空白组相比,3种香辛料的水提物都可更好地维持花生在贮藏过程中的色泽,与赵钜阳等[33]在油炸肉丝中添加香辛料提取物,研究发现香辛料具有较好的护色作用一致。

2.5 天然香辛料对花生仁质构的影响

质构是烘炒花生仁重要的品质指标之一,其中硬度、脆度、咀嚼度都会对感官评价有较大影响,但由于烘炒花生受热不完全均匀,花生大小、形状不一,测定所得的花生质构参数差异较大[34],因此烘炒花生质构特性的标准差较大。表2~表4分别列出烘炒花生在贮藏过程的硬度、脆度与咀嚼度。

表 2 天然香辛料对烘炒花生仁硬度的影响(kg)Table 2. Effects of natural spices on hardness in roasted peanut kernels (kg)组别 烘箱贮藏(d) 0 1 3 5 7 9 姜黄组 3.618±0.758ab 2.886±1.530b 5.045±1.047ab 3.067±1.421b 4.963±3.125ab 5.836±1.166a 茴香组 3.384±2.151ab 2.541±1.042ab 4.444±2.470a 1.687±0.950b 4.415±2.732a 2.468±1.386ab 花椒组 3.699±1.101ab 3.669±0.743ab 5.215±2.716a 2.553±1.221b 5.395±2.265a 3.026±1.582ab 空白组 6.305±2.880a 6.676±1.601a 3.728±1.539b 6.772±3.136a 3.138±1.181b 3.783±2.182b 注:小写字母表示组内不同贮藏时间差异显著(P<0.05);表3~表4同。 表 4 天然香辛料对烘炒花生仁咀嚼度的影响Table 4. Effects of natural spices on chewiness in roasted peanut kernels组别 烘箱贮藏(d) 0 1 3 5 7 9 姜黄组 34.881±3.170bc 48.923±11.554b 44.724±5.179bc 54.933±1.299b 65.102±21.773b 317.065±45.361a 茴香组 46.649±11.046b 65.310±7.197b 96.385±25.701ab 91.486±3.275ab 112.309±18.812ab 146.029±58.647a 花椒组 48.561±10.686cd 89.700±7.699bc 101.271±15.532bc 17.566±2.12d 120.619±22.041b 328.433±60.458a 空白组 97.433±1.923b 114.419±13.420b 155.551±36.209a 105.863±15.172b 44.595±12.468c 50.744±16.990c 其中空白组的硬度、脆度及咀嚼度的显著性(P<0.05)变化均早于香辛料组,因此香辛料都能比空白组更好地维持质构品质。这可能与脂质氧化产物-蛋白质相互作用机制[35]有关,在贮藏过程中脂质氧化时产生的初级氧化产物会裂解生成自由基,自由基发生链式反应导致蛋白质粒径随着贮藏时间而展开和聚集。当花生仁的脂质发生氧化反应时,花生分离蛋白表面微观结构也会遭到氧化破坏,导致花生蛋白质的稳定性发生变化。蛋白质稳定性对质构影响明显,从而花生仁质构受脂质氧化影响。因此3种香辛料的水提物可抑制油脂氧化也会抑制蛋白质品质变化,从而维持产品质构品质。

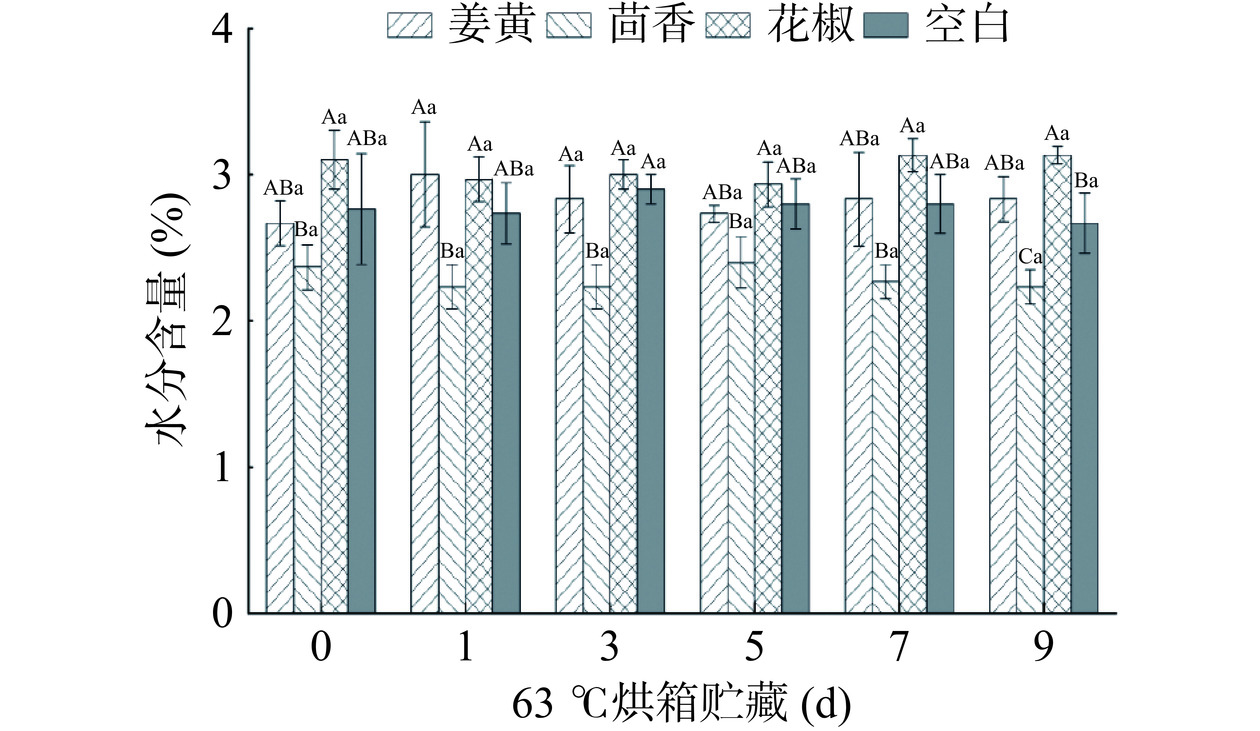

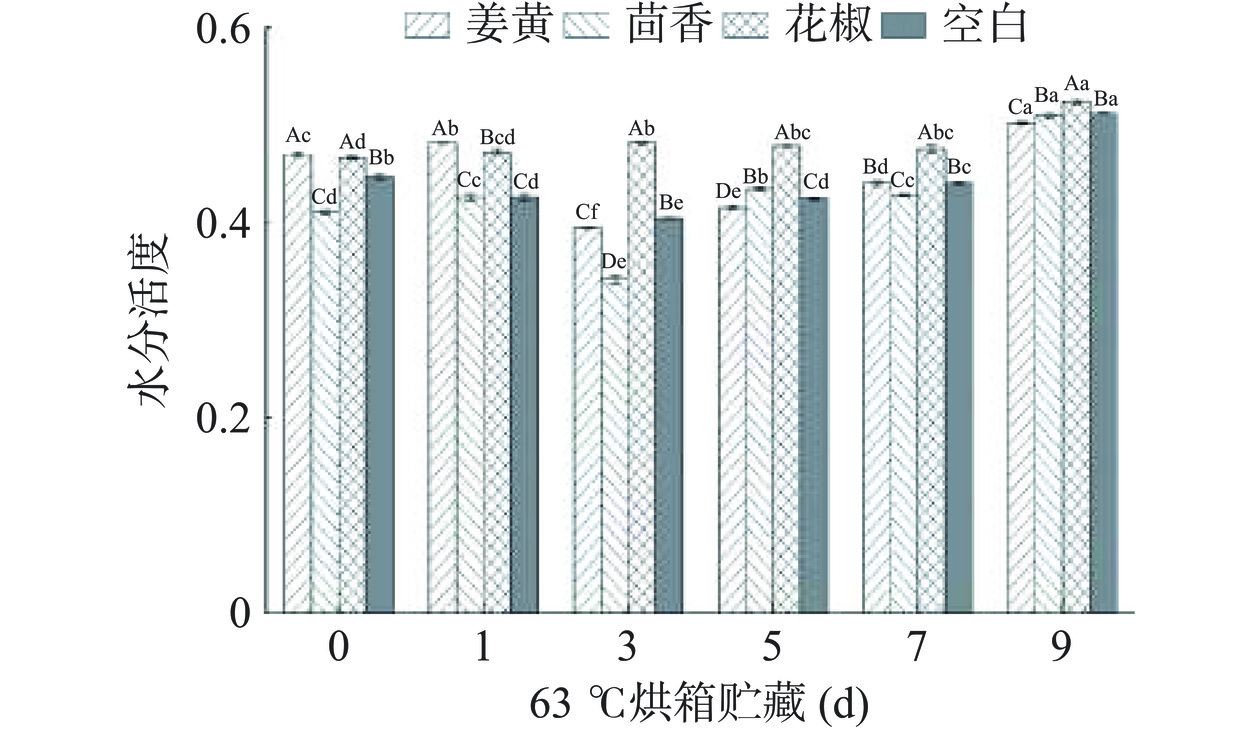

表 3 天然香辛料对烘炒花生仁脆度的影响(kg)Table 3. Effects of natural spices on fracturability in roasted peanut kernels (kg)组别 烘箱贮藏(d) 0 1 3 5 7 9 姜黄组 3.319±0.881ab 2.203±1.349ab 3.070±1.495ab 1.557±0.707b 4.029±2.216a 3.396±1.378ab 茴香组 3.977±2.237a 2.585±1.451ab 4.010±1.645a 2.475±1.459ab 3.398±1.589ab 2.146±1.007b 花椒组 4.65±0.632a 3.726±1.932a 3.738±2.191a 2.921±1.200a 4.528±1.803a 3.619±1.556a 空白组 2.925±1.644c 3.158±1.053c 1.949±1.273c 5.818±1.327a 1.978±1.287c 5.044±1.755ab 2.6 天然香辛料对花生仁水分含量和水分活度的影响

烘炒花生仁的水分含量也与烘炒花生的硬度、脆度、口感、风味等有极大的影响。从贮藏过程中水分含量的变化(图7)可得,所有组在烘箱贮藏的9 d中的水分含量都处于小幅度波动,变化并不显著(P>0.05),这可能因为使用铝塑复合袋能有效阻隔水分的逸出或进入,这与马颖颖[36]认为铝箔袋能够有效将氧气、水分以及光线阻隔的研究结论一致。

花生极易被黄曲霉侵染,黄曲霉会产生有剧毒致癌性的黄曲霉毒素,严重影响食品安全质量,而水分活度小于0.60时,绝大多数微生物都难以生长[11],且通常黄曲霉生长要求的最低水分活度为0.78~0.8[37],因此水分活度是烘炒花生仁安全品质的重要影响因素。从贮藏过程中水分活度的变化(图8)可得,4个组的烘炒花生在贮藏过程中的最大水分活度为0.524,因此花生仁在贮藏过程中受黄曲霉的危害风险较小。

2.7 烘炒花生仁风味的感官评价

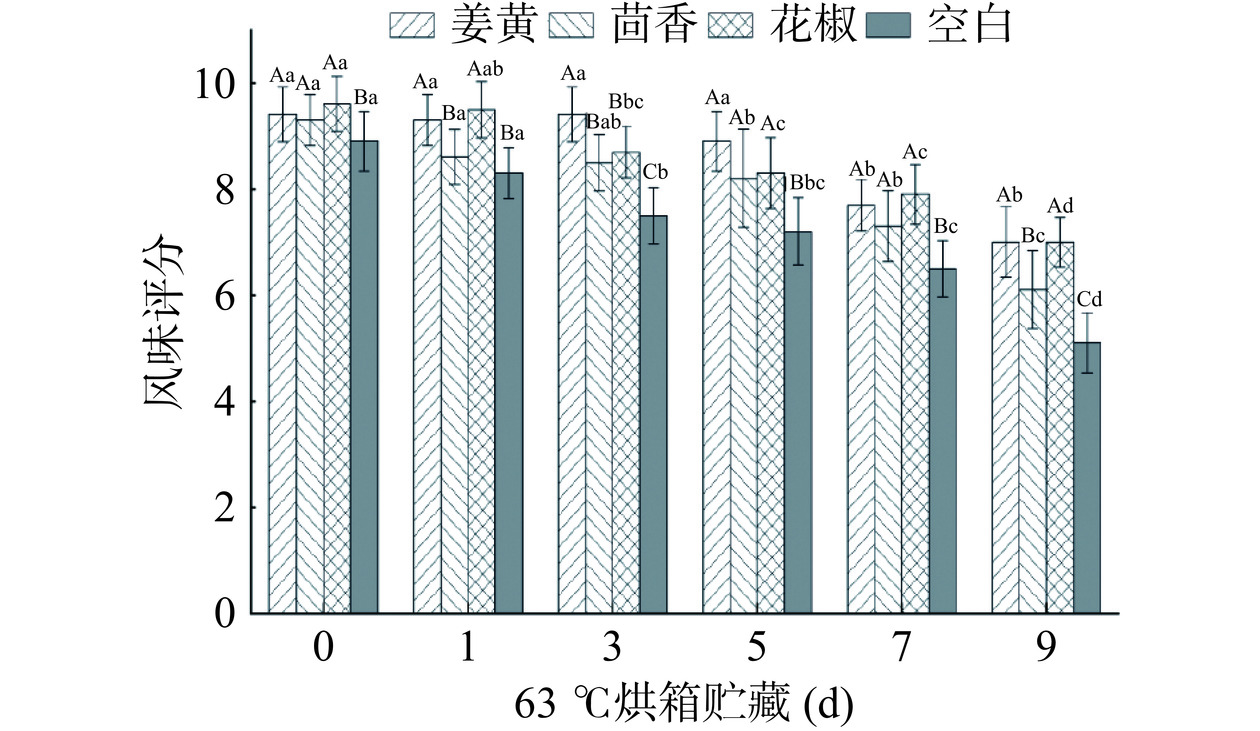

根据GB 19300-2014《食品安全国家标准 坚果与籽类食品》[38]规定,烘炒花生酸价应不大于3 mg/g,过氧化值应不大于0.5 g/100 g(19.70 mmol/kg),而在烘箱贮藏的9 d里,每组过氧化值、酸价都未超出国家标准,但烘炒花生的风味有出现明显变化,因此对烘炒花生的风味进行感官评价,结果如图9所示。

从图9可知,香辛料组的风味感官评分始终比空白组的评分高。随着贮藏时间的延长,每组的风味值都出现显著降低(P<0.05)。空白组花生在第7 d时风味评分为6.7分,出现轻微酸败味,第9 d酸败味更明显,其风味评分出现显著(P<0.05)下降。在贮藏第9 d时,姜黄组和花椒组花生评分都为7分,其风味仅变淡,茴香组仅有6.1分,其风味稀薄或出现轻微酸败味。可见,香辛料的加入可以提高烘炒花生的风味,并且延缓烘炒花生纸板味的出现。

2.8 烘炒花生货架期预测模型的建立

2.8.1 烘炒花生动力学模型的建立

烘炒花生可用感官评价、过氧化值、酸价及醛类挥发物含量作为油脂氧化程度指标[25,39],由于空白组烘炒花生的风味超出接受度。因此,选用零级和一级反应动力学模型对63、20 ℃的烘炒花生风味评分进行回归分析,得到烘炒花生风味评分的动力学模型参数,如表5所示。

表 5 烘炒花生仁在不同贮藏温度下风味变化的动力学模型参数Table 5. Kinetic model parameters for flavour changes in roasted peanut kernels at different storage temperatures烘炒花生口味 温度(℃) 零级 一级 回归方程 速率常数 回归系数R2 ∑R2 回归方程 速率常数 回归系数R2 ∑R2 姜黄 63 y=−0.2715x+9.4 −0.2715 0.8577 1.7714 y=−0.033x+2.2407 −0.033 0.8488 1.7409 20 y=−0.009x+9.4 −0.0090 0.9137 y=−0.001x+2.2407 −0.001 0.8921 茴香 63 y=−0.3107x+9.3 −0.3107 0.9118 1.8811 y=−0.041x+2.2300 −0.041 0.8875 1.8415 20 y=−0.0097x+9.3 −0.0093 0.9693 y=−0.001x+2.2300 −0.001 0.9540 花椒 63 y=−0.2811x+9.6 −0.2811 0.9810 1.9247 y=−0.034x+2.2618 −0.034 0.9731 1.8950 20 y=−0.0099x+9.6 −0.0099 0.9437 y=−0.001x+2.2618 −0.001 0.9219 空白 63 y=−0.3458x+8.9 −0.3458 0.9603 1.9227 y=−0.049x+2.1861 −0.049 0.9417 1.8772 20 y=−0.0126x+8.9 −0.0126 0.9624 y=−0.002x+2.1861 −0.002 0.9355 从表5可知,各方程的都具有较高的回归系数R2,在0.8488~0.9810之间,说明拟合程度好。零级反应动力学方程的回归系数∑R2>一级反应动力学方程的回归系数∑R2,表明零级反应动力学模型的拟合趋势更符合烘炒花生的储藏过程中风味变化。因此,选用零级动力学模型结合Arrhenius方程,推导烘炒花生的理论预测货架期。

2.8.2 Arrhenius方程的建立

结合零级动力学方程和Arrhenius方程,带入63、20 ℃的反应速率常数及贮藏温度,解得Ea和k0,得到货架期模型如表6所示。

表 6 烘炒花生仁的货架期模型Table 6. Shelf life modelling of roasted peanut kernels烘炒花

生口味Ea[kJ/mol] k0 货架期模型 姜黄 64.912 3.314×109 $\rm SL = \dfrac{{\left| {A - {A_0}} \right|}}{{3.314 \times {{10}^9}\exp \left( { - \dfrac{{64.912 \times {{10}^3}}}{{RT}}} \right)}} $ 茴香 66.054 5.708×109 $\rm SL = \dfrac{{\left| {A - {A_0}} \right|}}{{5.708 \times {{10}^9}\exp \left( { - \dfrac{{66.054 \times {{10}^3}}}{{RT}}} \right)}} $ 花椒 63.758 2.271×109 $\rm SL = \dfrac{{\left| {A - {A_0}} \right|}}{{2.271 \times {{10}^9}\exp \left( { - \dfrac{{63.758 \times {{10}^3}}}{{RT}}} \right)}} $ 空白 63.109 2.215×109 $\rm SL = \dfrac{{\left| {A - {A_0}} \right|}}{{2.215 \times {{10}^9}\exp \left( { - \dfrac{{63.109 \times {{10}^3}}}{{RT}}} \right)}} $ 2.8.3 货架期模型的验证与应用

感官评分低于7.0分,即烘炒花生出现轻微酸败味或烤花生味稀薄,因此以感官评价表中烘炒花生风味7.0分作为消费者可接受最低限值。通过表6货架期模型计算可得63 ℃贮藏温度下烘炒花生的货架期预测值,将其与实测值进行相对误差计算,来验证货架期模型的可行性,结果如表7所示。

表 7 烘炒花生仁货架期模型的验证Table 7. Validation of a shelf life model for roasted peanut kernels烘炒花生口味 贮藏温度(℃) 货架期预测值(d) 货架期实测值(d) 相对误差(%) 姜黄 63 8.3 8 3.75 茴香 63 6.7 7 -4.29 花椒 63 9.2 9 2.22 空白 63 5.0 5.49 8.93 注:相对误差(%)=(预测值-实测值)×100/实测值。 从表7可得,使用本实验所得的货架期模型,其相对误差不大于8.93%,说明准确性好,可快速预测20~63 ℃贮藏温度下的烘炒花生货架期。烘炒花生在售卖时一般贮藏温度为0~25 ℃,当温度为25 ℃时,带入表6中的货架期模型可知,姜黄味的货架期为170.6 d;茴香味的货架期为150.5 d;花椒味的货架期为169.4 d;空白组的货架期为97.7 d。

3. 讨论与结论

通过选用姜黄、茴香、花椒制成调味液来研究其对烘炒花生仁品质的影响。结果发现,与空白组相比,香辛料组均能更好抑制游离脂肪酸、氢过氧化合物、丙二醛的生成,在色差、质构方面的维持效果也更好,并且风味评价值有明显提高,说明香辛料的加入能更好地维持烘炒花生的品质,且增加烘炒花生风味。

在烘箱贮藏第7d,空白组花生出现轻微酸败味,但此时其酸价、过氧化值均未超过国家标准,这可能是由于国标中酸价和过氧化值的限值过高,因此选用风味评价值作为货架期模型指标。这与Nghiem等[40]通过延长植物油贮藏时间,研究发现油品质有明显下降,而其过氧化值和酸价仍在允许范围内结论一致。

经零级和一级反应动力学拟合度比较,发现零级反应动力学更符合本实验,这与刘志明等[19]采用的花生货架期模型的动力学方程不同,可能由于指标选取的不同,本实验以风味感官评价为指标,烘炒花生的风味不仅与其油脂有关,也会有蛋白质的影响,不能单一考虑油脂氧化。通过零级反应动力学结合Arrhenius方程,建立的货架期预测模型相对误差不大于8.93%,说明货架期预测模型的准确性高,可以快速预测出20~63 ℃贮藏温度下的烘炒花生货架期,为烘炒花生贮藏提供理论指导。当贮藏温度为25 ℃时,通过货架期模型计算可得,姜黄味、茴香味、花椒味及空白组的货架期分别为170.6、150.5、169.4、97.7 d,可知香辛料的加入能够显著延长烘炒花生的货架期。

本实验的风味评价仅使用感官,后续还可以通过气相色谱-质谱与电子鼻联用对烘炒花生挥发性气味分析,将其挥发性气味量化,建立更准确的货架期预测模型。此外,本实验建立的货架期模型仅适用于推算20~63 ℃贮藏温度下的货架期,可扩大实验温度范围,为预测更多贮藏温度下的货架期提供可能性。

-

表 1 感官评价标准

Table 1 Sensory evaluation criteria

得分(分) 风味 10 焙烤花生风味浓郁,且无其他变质异味 9~7 烤花生味较浓郁 6 轻微酸败味或烤花生味稀薄 5~0 酸败味明显或无烤花生味 表 2 天然香辛料对烘炒花生仁硬度的影响(kg)

Table 2 Effects of natural spices on hardness in roasted peanut kernels (kg)

组别 烘箱贮藏(d) 0 1 3 5 7 9 姜黄组 3.618±0.758ab 2.886±1.530b 5.045±1.047ab 3.067±1.421b 4.963±3.125ab 5.836±1.166a 茴香组 3.384±2.151ab 2.541±1.042ab 4.444±2.470a 1.687±0.950b 4.415±2.732a 2.468±1.386ab 花椒组 3.699±1.101ab 3.669±0.743ab 5.215±2.716a 2.553±1.221b 5.395±2.265a 3.026±1.582ab 空白组 6.305±2.880a 6.676±1.601a 3.728±1.539b 6.772±3.136a 3.138±1.181b 3.783±2.182b 注:小写字母表示组内不同贮藏时间差异显著(P<0.05);表3~表4同。 表 4 天然香辛料对烘炒花生仁咀嚼度的影响

Table 4 Effects of natural spices on chewiness in roasted peanut kernels

组别 烘箱贮藏(d) 0 1 3 5 7 9 姜黄组 34.881±3.170bc 48.923±11.554b 44.724±5.179bc 54.933±1.299b 65.102±21.773b 317.065±45.361a 茴香组 46.649±11.046b 65.310±7.197b 96.385±25.701ab 91.486±3.275ab 112.309±18.812ab 146.029±58.647a 花椒组 48.561±10.686cd 89.700±7.699bc 101.271±15.532bc 17.566±2.12d 120.619±22.041b 328.433±60.458a 空白组 97.433±1.923b 114.419±13.420b 155.551±36.209a 105.863±15.172b 44.595±12.468c 50.744±16.990c 表 3 天然香辛料对烘炒花生仁脆度的影响(kg)

Table 3 Effects of natural spices on fracturability in roasted peanut kernels (kg)

组别 烘箱贮藏(d) 0 1 3 5 7 9 姜黄组 3.319±0.881ab 2.203±1.349ab 3.070±1.495ab 1.557±0.707b 4.029±2.216a 3.396±1.378ab 茴香组 3.977±2.237a 2.585±1.451ab 4.010±1.645a 2.475±1.459ab 3.398±1.589ab 2.146±1.007b 花椒组 4.65±0.632a 3.726±1.932a 3.738±2.191a 2.921±1.200a 4.528±1.803a 3.619±1.556a 空白组 2.925±1.644c 3.158±1.053c 1.949±1.273c 5.818±1.327a 1.978±1.287c 5.044±1.755ab 表 5 烘炒花生仁在不同贮藏温度下风味变化的动力学模型参数

Table 5 Kinetic model parameters for flavour changes in roasted peanut kernels at different storage temperatures

烘炒花生口味 温度(℃) 零级 一级 回归方程 速率常数 回归系数R2 ∑R2 回归方程 速率常数 回归系数R2 ∑R2 姜黄 63 y=−0.2715x+9.4 −0.2715 0.8577 1.7714 y=−0.033x+2.2407 −0.033 0.8488 1.7409 20 y=−0.009x+9.4 −0.0090 0.9137 y=−0.001x+2.2407 −0.001 0.8921 茴香 63 y=−0.3107x+9.3 −0.3107 0.9118 1.8811 y=−0.041x+2.2300 −0.041 0.8875 1.8415 20 y=−0.0097x+9.3 −0.0093 0.9693 y=−0.001x+2.2300 −0.001 0.9540 花椒 63 y=−0.2811x+9.6 −0.2811 0.9810 1.9247 y=−0.034x+2.2618 −0.034 0.9731 1.8950 20 y=−0.0099x+9.6 −0.0099 0.9437 y=−0.001x+2.2618 −0.001 0.9219 空白 63 y=−0.3458x+8.9 −0.3458 0.9603 1.9227 y=−0.049x+2.1861 −0.049 0.9417 1.8772 20 y=−0.0126x+8.9 −0.0126 0.9624 y=−0.002x+2.1861 −0.002 0.9355 表 6 烘炒花生仁的货架期模型

Table 6 Shelf life modelling of roasted peanut kernels

烘炒花

生口味Ea[kJ/mol] k0 货架期模型 姜黄 64.912 3.314×109 SL=|A−A0|3.314×109exp(−64.912×103RT) 茴香 66.054 5.708×109 SL=|A−A0|5.708×109exp(−66.054×103RT) 花椒 63.758 2.271×109 SL=|A−A0|2.271×109exp(−63.758×103RT) 空白 63.109 2.215×109 SL=|A−A0|2.215×109exp(−63.109×103RT) 表 7 烘炒花生仁货架期模型的验证

Table 7 Validation of a shelf life model for roasted peanut kernels

烘炒花生口味 贮藏温度(℃) 货架期预测值(d) 货架期实测值(d) 相对误差(%) 姜黄 63 8.3 8 3.75 茴香 63 6.7 7 -4.29 花椒 63 9.2 9 2.22 空白 63 5.0 5.49 8.93 注:相对误差(%)=(预测值-实测值)×100/实测值。 -

[1] 陈奕颖. 半脱脂花生加工工艺与贮藏特性研究[D]. 洛阳:河南科技大学, 2022. [CHEN Y Y. Study on processing technology and storage characteristics of semi-defatted peanut[D]. Luoyang:Henan University of Science and Technology, 2022.] CHEN Y Y. Study on processing technology and storage characteristics of semi-defatted peanut[D]. Luoyang: Henan University of Science and Technology, 2022.

[2] KAZEMIAN-BAZKIAEE F, EBRAHIMI A, HOSSEINI S M, et al. Evaluating the protective effect of edible coatings on lipid oxidation, fatty acid composition, aflatoxins levels of roasted peanut kernels[J]. Journal of Food Measurement and Characterization,2020,14(1):1025−1038.

[3] ZHANG D, GUO X, WANG Q, et al. Investigation on lipid profile of peanut oil and changes during roasting by lipidomic approach[J]. LWT-Food Science and Technology, 2022, 154.

[4] 中华人民共和国国家卫生和计划生育委员会GB 2760-2014 食品添加剂使用标准[S]. 北京:中国标准出版社, 2014:220. [National Health and Family Planning Commission, People's Republic of China. GB 2760-2014 Standard for Use of Food Additives[S]. Beijing:Standards Press of China, 2014:220.] National Health and Family Planning Commission, People's Republic of China. GB 2760-2014 Standard for Use of Food Additives[S]. Beijing: Standards Press of China, 2014: 220.

[5] GAIKWAD K K, SINGH S, NEGI Y S, et al. The effect of trans-polyisoprene/LDPE based active films on oxidative stability in roasted peanuts[J]. Journal of Food Measurement and Characterization,2020,14(4):1857−1864.

[6] PAULA M M, GABRIELA R C, JAVIER P A, et al. A natural peanut edible coating enhances the chemical and sensory stability of roasted peanuts[J]. Journal of Food Science,2019,84(6):1529−1537. doi: 10.1111/1750-3841.14644

[7] OLMEDO R H, GROSSO N R. Oxidative stability, affective and descriptive sensory properties of roasted peanut flavored with oregano, laurel, and rosemary essential oils as natural preservatives of food lipids[J]. European Journal of Lipid Science and Technology,2019,121(5):1800428. doi: 10.1002/ejlt.201800428

[8] 杨轶浠, 崔钊伟, 王卫, 等. 香辛料提取物及其在肉制品抑菌防腐中的应用进展[J]. 现代食品科技,2022,38(3):314−327. [YANG Yixi, CUI Zhaowei, WANG Wei, et al. Spice extracts and their application of antimicrobial and preservation activities in meat products[J]. Modern Food Science and Technology,2022,38(3):314−327.] YANG Yixi, CUI Zhaowei, WANG Wei, et al. Spice extracts and their application of antimicrobial and preservation activities in meat products[J]. Modern Food Science and Technology, 2022, 38(3): 314−327.

[9] 周强, 沈旭, 付梦, 等. 炒制与烤制工艺对洽洽香瓜子呈香组分的影响[J]. 食品工业,2017,38(1):53−57. [ZHOU Qiang, SHEN Xu, FU Meng, et al. Effect of frying and roasting processing technologies on aroma components in chacheer aromatic sunflower seeds[J]. The Food Industry,2017,38(1):53−57.] ZHOU Qiang, SHEN Xu, FU Meng, et al. Effect of frying and roasting processing technologies on aroma components in chacheer aromatic sunflower seeds[J]. The Food Industry, 2017, 38(1): 53−57.

[10] 侯春宇, 买尔孜亚·买买提, 周纷, 等. 复配香辛料保鲜剂对大黄鱼贮藏期间品质的影响[J]. 食品工业科技,2019,40(13):221−225,230. [HOU Chunyu, MAIMAITI Maierziya, ZHOU Fen, et al. Effect of compound essential oil preservative on the quality of pseudosciaena crocea during storage[J]. Science and Technology of Food Industry,2019,40(13):221−225,230.] HOU Chunyu, MAIMAITI Maierziya, ZHOU Fen, et al. Effect of compound essential oil preservative on the quality of pseudosciaena crocea during storage[J]. Science and Technology of Food Industry, 2019, 40(13): 221−225,230.

[11] 江波, 杨瑞金. 食品化学[M]. 第二版. 北京:中国轻工业出版社, 2018:120. [JIANG Bo, YANG Ruijin. Food Chemistry[M]. 2nd Edition. Beijing:China Light Industry Press, 2018:120.] JIANG Bo, YANG Ruijin. Food Chemistry[M]. 2nd Edition. Beijing: China Light Industry Press, 2018: 120.

[12] 中华人民共和国国家卫生和计划生育委员会. GB 5009.229-2016 食品中酸价的测定[S]. 北京:中国标准出版社 2016:20. [National Health and Family Planning Commission, People's Republic of China. GB 5009.229-2016 Determination of acid value in food[S]. Beijing:Standards Press of China, 2016:20.] National Health and Family Planning Commission, People's Republic of China. GB 5009.229-2016 Determination of acid value in food[S]. Beijing: Standards Press of China, 2016: 20.

[13] 中华人民共和国国家卫生健康委员会. GB 5009.227-2016 食品中过氧化值的测定[S]. 北京:中国标准出版社,2016. [National Health Commission of the People's Republic of China. GB 5009.227-2016 Determination of peroxide value in food[S]. Beijing:Standards Press of China,2016.] National Health Commission of the People's Republic of China. GB 5009.227-2016 Determination of peroxide value in food[S]. Beijing: Standards Press of China, 2016.

[14] 中华人民共和国国家卫生和计划生育委员会. GB 5009.181-2016 食品中丙二醛的测定[S]. 北京:中国标准出版社, 2016:12. [National Health and Family Planning Commission, People's Republic of China. GB 5009.181-2016 Determination of malondialdehyde in food[S]. Beijing:Standards Press of China. 2016:12.] National Health and Family Planning Commission, People's Republic of China. GB 5009.181-2016 Determination of malondialdehyde in food[S]. Beijing: Standards Press of China. 2016: 12.

[15] 艾静汶, 李建强, 程三红, 等. 护色剂及包装工艺对水煮花生贮藏效果的研究[J]. 粮食与油脂,2021,34(7):70−73,81. [AI Jingwen, LI Jianqiang, CHENG Sanhong, et al. Study on the effect of color protectants and packaging technology on the storage of boiled peanut[J]. Cereals & Oils,2021,34(7):70−73,81.] doi: 10.3969/j.issn.1008-9578.2021.07.018 AI Jingwen, LI Jianqiang, CHENG Sanhong, et al. Study on the effect of color protectants and packaging technology on the storage of boiled peanut[J]. Cereals & Oils, 2021, 34(7): 70−73,81. doi: 10.3969/j.issn.1008-9578.2021.07.018

[16] 曹晓雨, 赵赓九, 张慧丽, 等. 油炸工艺对高油酸花生品质与微观结构的影响[J]. 中国食品学报,2022,22(8):200−206. [CAO Xiaoyu, ZHAO Gengjiu, ZHANG Huili, et al. Effects of frying process on quality and microstructure of high oleic acid peanut[J]. Journal of Chinese Institute of Food Science and Technology,2022,22(8):200−206.] CAO Xiaoyu, ZHAO Gengjiu, ZHANG Huili, et al. Effects of frying process on quality and microstructure of high oleic acid peanut[J]. Journal of Chinese Institute of Food Science and Technology, 2022, 22(8): 200−206.

[17] PETER B JOHNSEN, GAIL VANCE CIVILLE, JOHN R VERCELLOTTI, et al. Development of a lexicon for the description of peanut flavor[J]. Journal of Sensory Studies,1988,3(1):9−17. doi: 10.1111/j.1745-459X.1988.tb00426.x

[18] 姚宇晨, 毋思敏, 苏晓霞, 等. 蓝柑风味糖浆货架期预测模型的建立与评价[J]. 食品工业科技,2022,43(2):255−262. [YAO Yuchen, WU Simin, SU Xiaoxia, et al. Establishment and evaluation of the shelf life prediction model of blue mandarin flavor syrup[J]. Science and Technology of Food Industry,2022,43(2):255−262.] YAO Yuchen, WU Simin, SU Xiaoxia, et al. Establishment and evaluation of the shelf life prediction model of blue mandarin flavor syrup[J]. Science and Technology of Food Industry, 2022, 43(2): 255−262.

[19] 刘志明, 赵婉舒, 冯玉超, 等. 化学动力学法预测炒制花生仁货架期[J]. 食品研究与开发,2016,37(19):212−215. [LIU Zhiming, ZHAO Wanshu, FENG Yuchao, et al. Predict shelf life of fried peanut kernel by chemical dynamics method[J]. Food Research and Development,2016,37(19):212−215.] doi: 10.3969/j.issn.1005-6521.2016.19.048 LIU Zhiming, ZHAO Wanshu, FENG Yuchao, et al. Predict shelf life of fried peanut kernel by chemical dynamics method[J]. Food Research and Development, 2016, 37(19): 212−215. doi: 10.3969/j.issn.1005-6521.2016.19.048

[20] 雷露, 周景瑞, 张琴, 等. 贵州省不同地区牡丹子油营养成分的差异分析[J]. 湖北农业科学,2023,62(5):148−152. [LEI Lu, ZHOU Jingrui, ZHANG Qin, et al. Differences in nutritional composition of peony seed oil in different regions of Guizhou Province[J]. Hubei Agricultural Science,2023,62(5):148−152.] LEI Lu, ZHOU Jingrui, ZHANG Qin, et al. Differences in nutritional composition of peony seed oil in different regions of Guizhou Province[J]. Hubei Agricultural Science, 2023, 62(5): 148−152.

[21] PARK C Y, LEE K Y, GUL K, et al. Phenolics and antioxidant activity of aqueous turmeric extracts as affected by heating temperature and time[J]. LWT-Food Science and Technology,2019,105:149−155. doi: 10.1016/j.lwt.2019.02.014

[22] 王丽梅, 雷秋琪, 钟珍, 等. 不同处理方式对花椒提取液及卤鸭脖挥发性风味成分的影响[J]. 食品工业科技,2023,44(3):67−75. [WANG Limei, LEI Qiuqi, ZHONG Zhen, et al. Effects of different processing methods on volatile flavor components of zanthoxylum bungeanum maxim. extract and braised duck neck[J]. Science and Technology of Food Industry,2023,44(3):67−75.] WANG Limei, LEI Qiuqi, ZHONG Zhen, et al. Effects of different processing methods on volatile flavor components of zanthoxylum bungeanum maxim. extract and braised duck neck[J]. Science and Technology of Food Industry, 2023, 44(3): 67−75.

[23] DALLI M, AZIZI S E, KANDSI F, et al. Evaluation of the in vitro antioxidant activity of different extracts of Nigella sativa L. seeds, and the quantification of their bioactive compounds[C]//Netherlands:Proceedings of the 4th International Conference on Materials and Environmental Science (ICMES), 2021:7259−7263.

[24] 吴妙鸿, 方灵, 司瑞茹, 等. 5种市售姜黄素产品功能成分含量及抗氧化活性分析[J]. 福建农业科技,2022,53(8):61−67. [WU Miaohong, FANG Ling, SI Ruiru, et al. Analysis of functional components and antioxidant activity of five commercially available curcumin products[J]. Fujian Agricultural Science and Technology,2022,53(8):61−67.] WU Miaohong, FANG Ling, SI Ruiru, et al. Analysis of functional components and antioxidant activity of five commercially available curcumin products[J]. Fujian Agricultural Science and Technology, 2022, 53(8): 61−67.

[25] 张喻, 邱展英, 许秋桐. 不同包装方式对咸干花生储藏品质的影响[J]. 中国粮油学报[J]. 中国粮油学报,2023,38(10):15−21. [ZHANG Y, QIU Z Y, XU Q T. Effect of packaging method on storage quality of salty peanut during storage[J]. Journal of the Chinese Cereals and Oils Association,2023,38(10):15−21.] ZHANG Y, QIU Z Y, XU Q T. Effect of packaging method on storage quality of salty peanut during storage[J]. Journal of the Chinese Cereals and Oils Association, 2023, 38(10): 15−21.

[26] 马宇晨, 王光宜, 刘乐乐, 等. 植物油中内源性成分的抗氧化作用[J]. 食品工业科技,2023,44(24):119−130. [MA Yuchen, WANG Guangyi, LIU Lele, et al. Antioxidant effects of endogenous components in vegetable oils[J]. Food Industry Science and Technology,2023,44(24):119−130.] MA Yuchen, WANG Guangyi, LIU Lele, et al. Antioxidant effects of endogenous components in vegetable oils[J]. Food Industry Science and Technology, 2023, 44(24): 119−130.

[27] SURI K, SINGH B, KAUR A, et al. Impact of roasting and extraction methods on chemical properties, oxidative stability and Maillard reaction products of peanut oils[J]. Journal of Food Science and Technology Mysore,2019,56(5):2436−2445. doi: 10.1007/s13197-019-03719-4

[28] 王溢, 黄润生, 程俊森, 等. 基于UPLC-MS/MS的油茶种仁成分差异分析及其油脂抗氧化活性研究[J]. 中国食品学报,2023,23(8):329−341. [WANG Yi, HUANG Runsheng, CHENG Junsen et al. Differential composition analysis of seed kernels between two camellia species by UPLC-MS/MS-based metabolomics and the antioxidant activity research of seed kernels oil[J]. Journal of Chinese Institute of Food Science and Technology,2023,23(8):329−341.] WANG Yi, HUANG Runsheng, CHENG Junsen et al. Differential composition analysis of seed kernels between two camellia species by UPLC-MS/MS-based metabolomics and the antioxidant activity research of seed kernels oil[J]. Journal of Chinese Institute of Food Science and Technology, 2023, 23(8): 329−341.

[29] 寇含笑. 高油大豆储藏期间的品质变化研究[D]. 郑州:河南工业大学, 2021. [KOU Hanxiao. Quality changes of high-oil soybeans during storage[D]. Zhengzhou:Henan University of Technology, 2021.] KOU Hanxiao. Quality changes of high-oil soybeans during storage[D]. Zhengzhou: Henan University of Technology, 2021.

[30] 尚秀国, 刘孝春, 尚超越, 等. 不同形式铁离子对存储期间油脂酸败的影响[J]. 饲料工业,2020,41(16):31−35. [SHANG Xiuguo, LIU Xiaochun, SHANG Chaoyue, et al. Effects of different iron ions on oxidation rancidity of soybean oil during storage[J]. Feed Industry,2020,41(16):31−35.] SHANG Xiuguo, LIU Xiaochun, SHANG Chaoyue, et al. Effects of different iron ions on oxidation rancidity of soybean oil during storage[J]. Feed Industry, 2020, 41(16): 31−35.

[31] STOERMER L, GLOBISCH M, HENLE T. Glycerol-bound oxidized fatty acids:Formation and occurrence in peanuts[J]. European Food Research and Technology,2022,248(8):2053−2066. doi: 10.1007/s00217-022-04030-x

[32] 陈鑫沛. 茴香、砂仁精油对葵花籽油煎炸麻叶过程的影响[D]. 郑州:河南工业大学, 2022. [CHEN Xinpei. Influence of the essential oil of foeniculumvulgare mill. and amomum villosum lour. onsunflower oil during the deep-frying of chinese maye[D]. Zhengzhou:Henan University of Technology, 2022.] CHEN Xinpei. Influence of the essential oil of foeniculumvulgare mill. and amomum villosum lour. onsunflower oil during the deep-frying of chinese maye[D]. Zhengzhou: Henan University of Technology, 2022.

[33] 赵钜阳, 石长波, 左嵩. 香辛料提取物对低温油炸肉丝软罐头的抗氧化效应研究[J]. 食品安全质量检测学报,2017,8(9):3334−3340. [ZHAO Juyang, SHI Changbo, ZUO Song. Effects of spice extracts on antioxidative ability of soft canning of deep-fried shredded meat[J]. Journal of Food Safety & Quality,2017,8(9):3334−3340.] ZHAO Juyang, SHI Changbo, ZUO Song. Effects of spice extracts on antioxidative ability of soft canning of deep-fried shredded meat[J]. Journal of Food Safety & Quality, 2017, 8(9): 3334−3340.

[34] 邱展英, 袁书鑫, 吴怡颖, 等. 原料特性对咸干花生加工品质的影响[J]. 农业工程学报,2022,38(S1):321−330. [QIU Z Y, YUAN S X, WU Y Y, et al. Effects of peanut material characteristics on the processing qualities of salty peanuts[J]. Transactions of the Chinese Society of Agricultural Engineering,2022,38(S1):321−330.] QIU Z Y, YUAN S X, WU Y Y, et al. Effects of peanut material characteristics on the processing qualities of salty peanuts[J]. Transactions of the Chinese Society of Agricultural Engineering, 2022, 38(S1): 321−330.

[35] 郭亚晶. 花生储藏期油脂氧化产物-蛋白质相互作用及其对储藏品质的影响机理[D]. 郑州:河南工业大学, 2022. [GUO Yajing. Their effects on storage quality in peanuts products and proteins during storage and Interactions between lipid oxidation [D]. Zhengzhou:Henan University of Technology, 2022.] GUO Yajing. Their effects on storage quality in peanuts products and proteins during storage and Interactions between lipid oxidation [D]. Zhengzhou: Henan University of Technology, 2022.

[36] 马颖颖. 包材和保藏条件对花生仁品质变化的影响[D]. 大连:大连工业大学, 2018. [Ma Yingying. Changes of peanuts chemical component under different packing materials and storage condition[D]. Dalian:Dalian University of Technology, 2018.] Ma Yingying. Changes of peanuts chemical component under different packing materials and storage condition[D]. Dalian: Dalian University of Technology, 2018.

[37] 王殿轩, 刘磊, 黄依林, 等. 影响花生果安全储藏的环境因素研究进展[J]. 植物保护,2022,48(3):31−38. [WANG Dianxuan, LIU Lei, HUANG Yilin, et al. Advances in the environmental factors influencing safe storage of peanut pods[J]. Plant Protection,2022,48(3):31−38.] WANG Dianxuan, LIU Lei, HUANG Yilin, et al. Advances in the environmental factors influencing safe storage of peanut pods[J]. Plant Protection, 2022, 48(3): 31−38.

[38] 中华人民共和国国家卫生和计划生育委员会. GB 19300-2014 坚果与籽类食品[S]. 北京:中国标准出版社,2014:12. [National Health and Family Planning Commission, People's Republic of China. GB 19300-2014 Nuts and seeds[S]. Beijing:Standards Press of China, 2014:12.] National Health and Family Planning Commission, People's Republic of China. GB 19300-2014 Nuts and seeds[S]. Beijing: Standards Press of China, 2014: 12.

[39] 傅静. 花生粉中油脂氧化及其货架期预测试验的研究[D]. 郑州:河南工业大学, 2016. [FU J. Peanut flour:Lipid oxidation mechanism and its modeling of shelf life[D]. Zhengzhou:Henan University of Technology, 2016.] FU J. Peanut flour: Lipid oxidation mechanism and its modeling of shelf life[D]. Zhengzhou: Henan University of Technology, 2016.

[40] NGHIEM D T, NHAN N P T, TRUONG L D, et al. Effect of storage time and temperature on the quality of Sacha Inchi Oil (Plukenetia volubilis) during processing[C]// Pahang:3rd Symposium on Industrial Science and Technology (SISTEC2021), 2023:9.

-

期刊类型引用(0)

其他类型引用(1)

下载:

下载:

下载:

下载: