Volatile Organic Compounds in Malt Based on GC-MS and GC-IMS Technology

-

摘要: 为探究不同种类麦芽中挥发性有机物(Volatile Organic Compounds,VOCs)的差异,本研究以焦香麦芽和饼干麦芽为研究对象,采用气相色谱-质谱联用(Gas Chromatography-Mass Spectrometry,GC-MS)和气相离子迁移谱(Gas Chromatography-ion Mobility Spectrometry,GC-IMS)技术对两种麦芽的VOCs进行检测分析。结果表明:GC-MS技术在焦香和饼干麦芽中共检测出90余种挥发性物质,其中相对含量大于0.01%的化合物有48种,主要包括9种酮类、14种醛类、4种酯类、4种醇类、2种酸类、10种吡嗪类和5种杂环类物质;两种麦芽中醛类和酸类物质含量均远高于其他物质,主要包括2-甲基丁醛、异戊醛和乙酸等;饼干麦芽中吡嗪类物质更丰富,尤其2-甲基吡嗪、2,5-二甲基吡和2-乙基-3,5-二甲基吡嗪。GC-IMS技术在两种麦芽中共检测出135种化合物,定性鉴别出80种,以小分子的醇类、酮类、醛类和酯类为主,吡嗪类和杂环类物质种类较少。两种技术检测结果均表明两种麦芽中的VOCs种类接近,但含量存在明显差异。焦香麦芽中酯类、醇类和醛类物质含量相对较高,饼干麦芽中吡嗪类和酮类物质含量较丰富。主成分分析(Principal Component Analysis,PCA)结合指纹图谱相似度表明GC-MS和GC-IMS技术均能够有效区分焦香麦芽和饼干麦芽。综上,GC-MS与GC-IMS两种技术结合可以更全面地解析麦芽样品中的挥发性物质组成,为麦芽的VOCs研究提供有力的检测技术支持。Abstract: In order to explore the differences of volatile organic compounds (VOCs) in different malts, roasted malt and biscuit malt were detected by gas chromatography-mass spectrometry (GC-MS) and gas chromatography-ion mobility spectrometry (GC-IMS) respectively. The results showed that more than 90 kinds of VOCs in both roasted and biscuit malt were identified by GC-MS, and 48 kinds of VOCs had relative amounts greater than 0.01%, which mainly included 9 ketones, 14 aldehydes, 4 esters, 4 alcohols, 2 acids, 10 pyrazines and 5 heterocyclic substances. The relative content of aldehydes and acids in roasted malt and biscuit malt were much higher than other compounds, including 2-mmethylbutanal, iso-valeraldehyde and acetic acid. The pyrazines in biscuit malt were richer than roasted malt, especially 2-methylpyrazine, 2,5-dimethylpyrazine, and 2-ethyl-3,5-dimethylpyrazine. 135 kinds of VOCs in malt were detected by GC-IMS, and 80 kinds of compound were identified, which concentrated on alcohols, ketones, aldehydes and esters with smaller molecule. The types of pyrazine and heterocyclic substances in malt were not abundant. The results from GC-MS and GC-IMS showed that types of VOCs in roasted malt and biscuit malt were similar, while the contents had significant differences. The esters, alcohols and aldehydes were richer in roasted malt, while the biscuit malt had higher contents of pyrazines and ketones. The principal component analysis (PCA) and fingerprint similarity analysis showed that both GC-MS and GC-IMS technique could distinguish between roasted and biscuit malt effectively. In conclusion, the combination of GC-MS and GC-IMS techniques could provide a comprehensive approach to analyze the composition of VOCs, and offers strong technical support for VOCs researches in malt.

-

啤酒作为世界第三大饮品,是一种富含CO2且略带苦味的低酒精饮料。由于啤酒酿造所用的原辅料种类、用料比例、酵母类型等选择性较多,导致酿造工艺也千差万别,最终形成了啤酒独特的感官品质,其中挥发性风味物质是评价啤酒质量好坏的重要指标之一[1−3]。麦芽作为啤酒酿造的主要原料,对啤酒整体风味特征具有重要的影响,目前已有报道麦芽中共检测出250多种挥发性风味物质[4]。经过高温焙焦工艺,麦芽中的有机物质成分经历复杂的化学反应,可产生各类风味物质,主要包括美拉德反应产物吡嗪类物质、Strecker醛类、酚类物质、硫化物以及脂类氧化产物等,其中前两类是麦芽关键风味的主要贡献者[5]。

麦芽中VOCs检测主要采用现代分析仪器,如液相色谱、气相色谱(gas chromatography,GC)、液质联用(liquid chromatography-mass spectrometry,LC-MS)、气相色谱-质谱联用(Gas Chromatography-Mass Spectrometry,GC-MS)、电子鼻、气相色谱嗅闻仪联用(gas chromatographic-olfactory-mass spectrometry,GC-O-MS)等[6−9]。目前,麦芽中挥发性有机物(Volatile Organic Compounds,VOCs)方面的研究已有诸多报道,王晓会等[10]采用GC-MS技术跟踪检测啤酒酿造过程中16种麦芽香气组分的含量变化,发现吡嗪类物质在酿造阶段含量变化不明显,麦芽酚和2-乙酰吡咯在煮沸过程含量显著增加,菠萝酮在煮沸过程中有所损失。于淼等[11]采用GC-O-MS对六款特种麦芽的风味物质和感官特性进行分析,研究发现随着特种麦芽颜色的加深,其甜香果香逐渐降低,咖啡味和烟熏味逐渐增加。赵川艳等[12]通过GC-MS技术研究制麦工艺对麦芽中风味物质的影响,得到麦芽风味物质在制麦过程中的变化规律。近年来,气相离子迁移谱(Gas Chromatography-ion Mobility Spectrometry,GC-IMS)作为一种新的联用技术在风味研究领域应用广泛,该技术根据气相离子在电场中迁移速率的不同而进行识别,使得气相色谱分离后得到的化学信息更加丰富,已在黄酒品牌和酒龄鉴别[13−16]、陈酿时间对白酒香气影响[17−18]以及果酒[19−22]、葡萄酒[23−25]和白兰地[26−29]等酒精饮料的风味组成研究方面被广泛应用。然而,目前GC-IMS技术在麦芽VOCs方面的研究少有报道。

本文以焦香麦芽和饼干麦芽为研究对象,同时采用GC-MS和GC-IMS技术,对麦芽中的VOCs进行检测分析,明确不同种类麦芽的VOCs种类及含量差异,为麦芽在啤酒酿造中的应用增添理论依据。

1. 材料和方法

1.1 材料与仪器

麦芽 由澳大利亚大麦制成的特种麦芽,包括焦香麦芽和饼干麦芽,购于中粮大连麦芽厂。

7890-5975C型GC-MS联用仪、FFAP色谱柱60 m×0.32 mm×0.25 μm(配备于GC-MS) 美国Agilent公司;FlavourSpec® GC-IMS 德国G.A.S.公司;MXT-WAX 30 m×0.53 mm×1.0 μm(配备于GC-IMS) 美国RESTEK公司;CAR/PDMS萃取头、自动进样装置 瑞士PAL System公司;麦芽粉碎机 德国Buhler公司。

1.2 实验方法

1.2.1 样品前处理

取适量麦芽样品倒入粉碎机中粉成细粉,每个样品分别称取5.00、1.00 g麦芽细粉至20 mL顶空瓶中,分别用于GC-MS和GC-IMS检测。

1.2.2 GC-MS检测条件

1.2.2.1 进样方式

自动固相微萃取(solid phase microextraction,SPME)进样;萃取温度:60 ℃;萃取时间:30 min;进样口解析时间:5 min。

1.2.2.2 GC条件

载气:氦气,恒流模式;进样口温度250 ℃;分流比:10:1;程序升温:初始温度35 ℃,保持3min;以5 ℃/min升温至85 ℃,保持2 min;4 ℃/min升温至200 ℃,保持5 min;6 ℃/min升温至240 ℃,保持3 min。

1.2.2.3 MS条件

EI电离源;电离电压:70 eV;传输线温度:280 ℃;离子源温度:230 ℃;四级杆温度:150 ℃;溶剂延迟时间:1 min;扫描范围:40~500 m/z。

1.2.3 GC-IMS条件

1.2.3.1 进样条件

进样方式:自动顶空进样;孵育温度:40 ℃;孵育时间:15 min;加热方式:振荡加热;孵化转速:500 r/min;进样体积:500 μL;进样针温度:85 ℃。

1.2.3.2 GC条件

谱柱温:60 ℃;载气:高纯氮气;初始流速2.0 mL/min保持2 min,在2~10 min内线性增至10 mL/min,10~30 min内线性增至100 mL/min,保持10 min。

1.2.3.3 IMS条件

检测器温度:45 ℃;漂移管长度:9.8 cm;管内线性电压:400 V/cm;漂移管温度:45 ℃;漂移气:高纯氮气;漂移气流速:150 mL/min。

1.3 数据处理

所有样品平行测定3次,采用GC-MS数据处理软件中内置的NIST库对麦芽样品的谱图进行VOCs定性检索,使用GC-IMS Library Search软件(内置的NIST和IMS数据库)对麦芽样品的GC-IMS谱图进行VOCs定性检索。采用SPSS Statistics 26.0 软件进行Duncan法多重比较检验进行差异显著性分析(P<0.05),定量结果以平均值±标准差形式。采用GC-IMS仪器配套分析软件中的Reporter插件绘制二维谱图、Gallery Plot插件绘制指纹图谱、Matching matrix插件进行指纹图谱相似度分析。采用Origin 2022软件进行PCA分析。

2. 结果与分析

2.1 GC-MS分析麦芽的VOCs

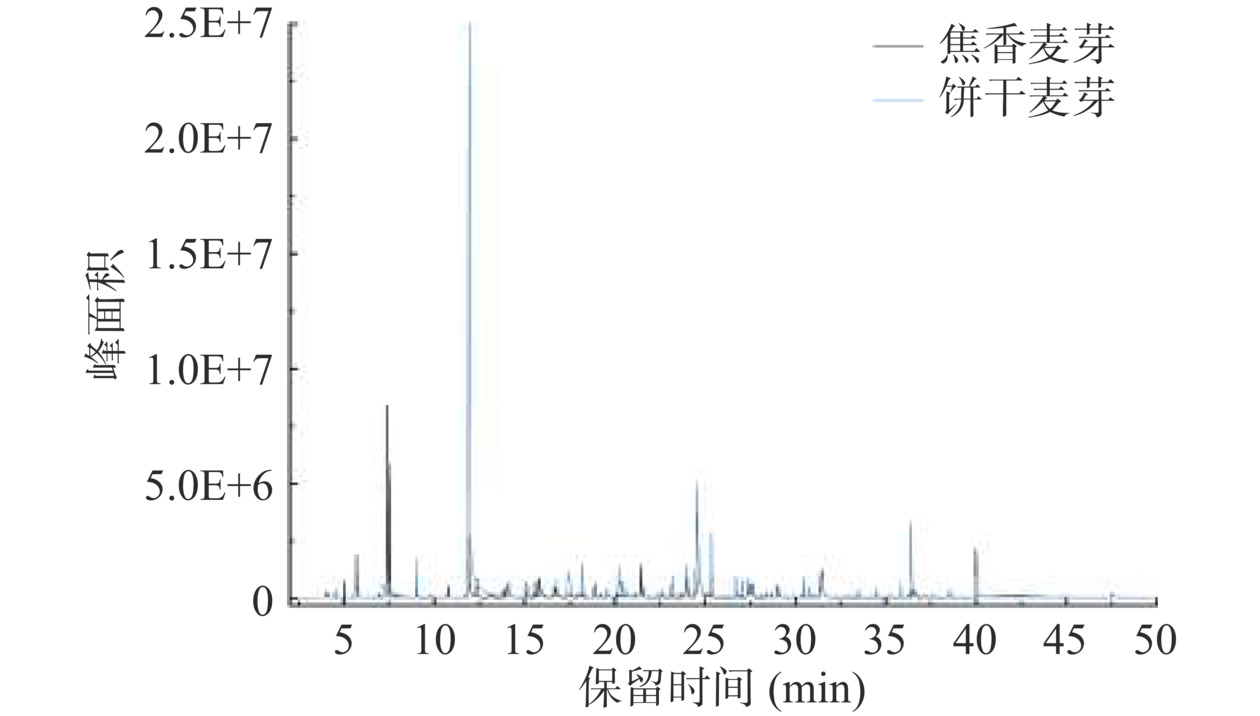

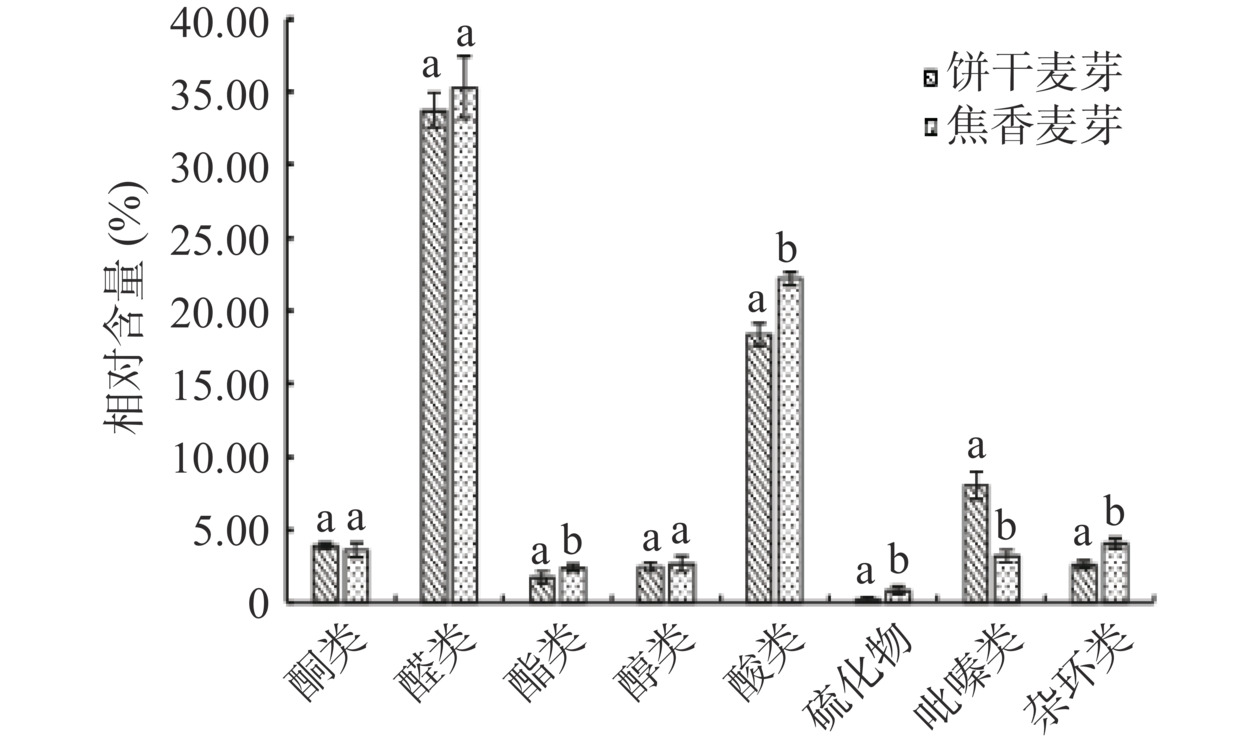

图1为焦香麦芽和饼干麦芽的GC-MS总离子流(total ion chromatogram,TIC)图,由图可知两种麦芽中VOCs种类很接近,但各物质对应的峰高值存在明显差异,即各物质含量不同。两种麦芽共分离检测出90余种挥发性有机物,表1为峰面积占比大于0.01%的化合物信息,主要包括9种酮类、14种醛类、4种酯类、4种醇类、2种酸类、10种吡嗪类和5种杂环类物质等48种物质成分,其中32种物质相对含量有显著(P<0.05)差异。将定性出的所有物质分类后比较其相对含量差异,结果如图2,可知麦芽中的醛类和酸类含量远高于其他物质,其中饼干麦芽中醛类含量占比33.75%,酸类含量占比18.35%;焦香麦芽中醛类含量占比35.31%,酸类含量占比22.18%。麦芽中醛类物质主要包括:2-甲基丁醛、异戊醛、正己醛、正戊醛、反-2-辛烯醛、糠醛等,前三种醛类含量尤其丰富。酸类物质主要包括乙酸和正己酸等,焦香麦芽中乙酸含量高达15.76%,饼干麦芽中乙酸含量达9.57%,正己酸在麦芽中含量相对略低,饼干麦芽中正己酸含量显著高于焦香麦芽。两种麦芽中吡嗪类和杂环类物质含量也较丰富,饼干麦芽中吡嗪类物质含量显著高于焦香麦芽(P<0.05),焦香麦芽中杂环类物质显著高于饼干麦芽(P<0.05)。吡嗪类和杂环类物质也是焦香麦芽和饼干麦芽特征风味的主要呈香物质[2−3]。吡嗪类物质中2-甲基吡嗪、2,5-二甲基吡嗪和2-乙基-3,5-二甲基吡嗪、2-丁基-3-甲基吡嗪和2-乙基-6-甲基吡嗪含量相对较高。饼干麦芽中吡嗪类物质含量占比8.07%,而在焦香麦芽中占比仅有3.23%,这也是饼干麦芽香气更丰富的原因所在。麦芽中杂环类物质占比较低,不足5.00%,其中焦香麦芽中杂环类物质含量相对更高。饼干麦芽中吡嗪类和酮类含量高于焦香麦芽,而醛类、酯类、硫化物和酸类含量相对较低,两种麦芽中的醇类化合物含量相差不大。

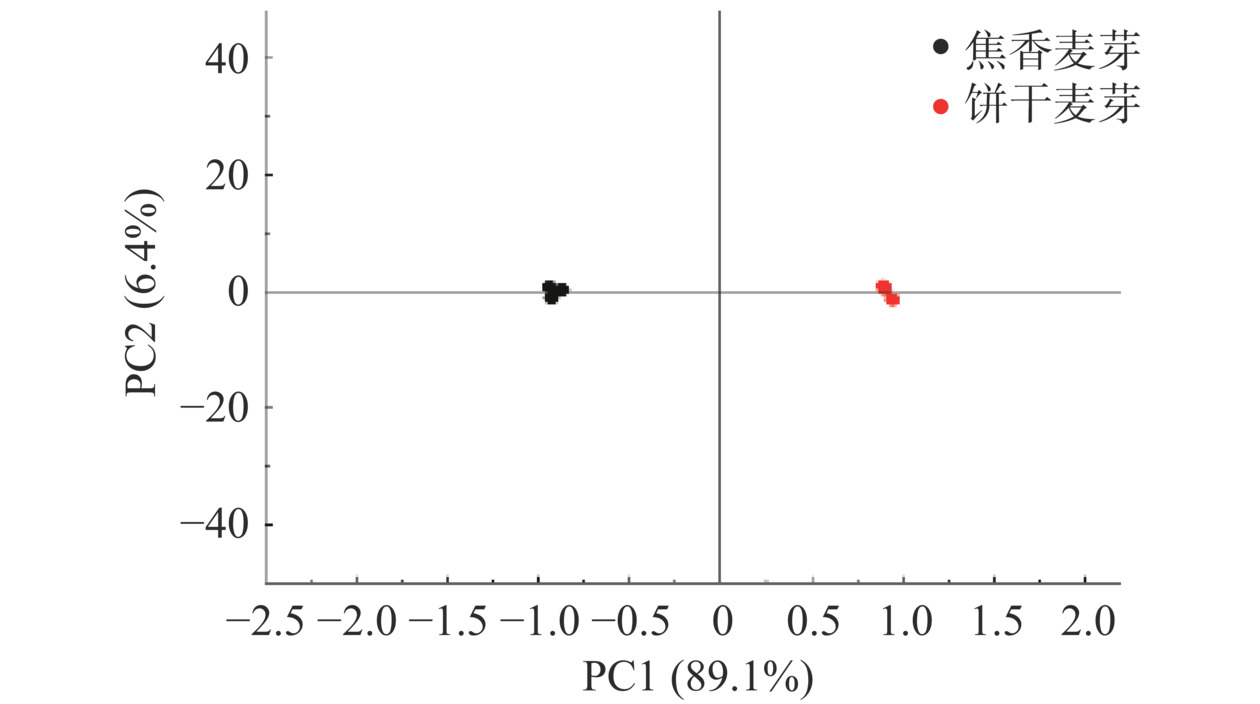

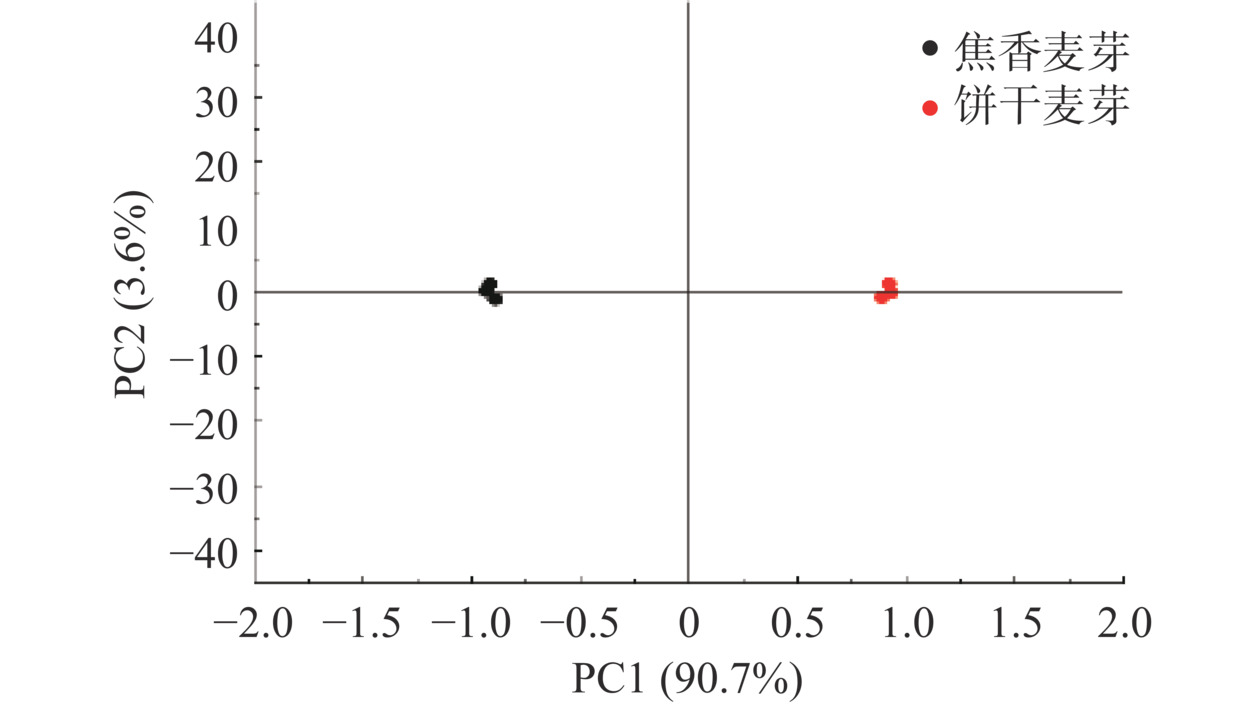

表 1 GC-MS检测麦芽中挥发性物质的峰面积百分含量Table 1. Peak area percentage of volatile organic compounds in malt detected by GC-MS序号 化合物名称 CAS号 分子式 峰面积(%) 匹配度(%) 焦香 饼干 酮类 1 丙酮 67-64-1 C3H6O 0.59±0.06a 0.27±0.03b 75.41 2 丁酮 78-93-3 C4H8O 0.73±0.03a 0.37±0.11b 86.43 3 2,3-戊二酮 600-14-6 C5H8O2 0.09±0.00a 0.06±0.00b 60.80 4 2-庚酮 110-43-0 C7H14O 0.47±0.11a 0.63±0.12b 48.54 5 2-甲基四氢呋喃-3-酮 3188-00-9 C5H8O2 0.43±0.09a 0.48±0.08a 67.08 6 羟基丙酮 116-09-6 C3H6O2 0.47±0.07a 0.47±0.04a 73.40 7 3-辛烯-2-酮 18402-82-9 C8H14O 0.29±0.00a 1.14±0.24b 40.00 8 乙酸基丙酮 592-20-1 C5H8O3 0.31±0.00a 0.28±0.00a 61.06 9 2-吡咯烷酮 616-45-5 C4H7NO 0.17±0.00a 0.17±0.00a 40.63 醛类 10 乙醛 75-07-0 C2H4O 0.13±0.00a 0.08±0.00b 42.61 11 异丁醛 78-84-2 C4H8O 1.90±0.36a 0.18±0.00b 74.90 12 2-甲基丁醛 96-17-3 C5H10O 9.56±0.31a 6.69±0.37b 72.14 13 异戊醛 590-86-3 C5H10O 7.72±0.37a 6.41±0.28a 77.76 14 正戊醛 110-62-3 C5H10O 0.80±0.07a 1.34±0.21b 84.38 15 正己醛 66-25-1 C6H12O 4.94±0.16a 5.88±0.40a 61.32 16 庚醛 111-71-7 C7H14O 0.23±0.00a 0.52±0.05b 60.05 17 正辛醛 124-13-0 C8H16O 1.33±0.04a 0.23±0.01b 42.30 18 反-2-辛烯醛 2548-87-0 C8H14O 2.33±0.26a 2.14±0.03a 44.51 19 (E,E)-2,4-庚二烯醛 4313-03-5 C7H10O 0.11±0.00a 0.14±0.00a 54.35 20 可可醛 35158-25-9 C10H18O 2.18±0.12a 0.20±0.00b 48.26 21 糠醛 98-01-1 C5H4O2 2.07±0.34a 2.44±0.06a 77.40 22 苯甲醛 100-52-7 C7H6O 0.72±0.06a 0.75±0.16a 75.29 23 5-甲基呋喃醛 620-02-0 C6H6O2 0.23±0.04a 0.30±0.05b 86.23 酯类 24 癸酸乙酯 110-38-3 C12H24O2 0.92±0.06a 0.79±0.04b 82.34 25 γ-丁内酯 96-48-0 C4H6O2 0.76±0.01a 0.38±0.00b 76.25 26 γ-己内酯 695-06-7 C6H10O2 0.11±0.00a 0.12±0.00a 61.96 27 乙酸苯乙酯 103-45-7 C10H12O2 0.62±0.00a 0.45±0.04a 59.06 醇类 28 正戊醇 71-41-0 C5H12O 0.75±0.03a 0.89±0.23a 72.53 29 顺-2-戊烯醇 1576-95-0 C5H10O 0.05±0.00a 0.15±0.00b 49.56 30 5-甲基-2-呋喃甲醇 3857-25-8 C6H8O2 0.11±0.00a 0.05±0.00b 43.61 31 苯乙醇 60-12-8 C8H10O 0.59±0.05a 0.27±0.00b 72.14 酸类 32 乙酸 64-19-7 C2H4O2 15.76±0.57a 9.57±0.45b 98.26 33 正己酸 142-62-1 C6H12O2 1.21±0.05a 4.50±0.26b 91.22 吡嗪类 34 2-甲基吡嗪 109-08-0 C5H6N2 0.33±0.08a 1.60±0.11b 69.40 35 2,5-二甲基吡嗪 123-32-0 C6H8N2 0.20±0.00a 1.19±0.06b 78.13 36 2-丁基-3-甲基吡嗪 108-50-9 C6H8N2 0.26±0.00a 0.84±0.03b 67.45 37 2-乙基吡嗪 13925-00-3 C6H8N2 0.28±0.00a 0.69±0.03b 59.96 38 2,3-二甲基吡嗪 5910-89-4 C6H8N2 0.57±0.06a 0.54±0.04a 75.03 39 2,6-二甲基吡嗪 13925-03-6 C7H10N2 0.22±0.00a 0.36±0.07b 69.86 40 2-乙基-6-甲基吡嗪 13925-03-6 C7H10N2 0.34±0.05a 0.73±0.13b 46.12 41 3-乙基-2-甲基吡嗪 15707-23-0 C7H10N2 0.18±0.00a 0.53±0.12b 49.50 42 2-乙基-3,5-二甲基吡嗪 13925-07-0 C8H12N2 0.44±0.13a 1.24±0.26b 65.64 43 2-异戊基吡嗪 13925-07-0 C8H12N2 0.41±0.06a 0.35±0.00b 46.43 杂环化合物 44 2-甲基呋喃 534-22-5 C5H6O 0.06±0.00a 0.04±0.00a 43.68 45 2-戊基呋喃 3777-69-3 C9H14O 0.67±0.08a 0.99±0.09a 88.82 46 2-乙酰基呋喃 1192-62-7 C6H6O2 0.59±0.01a 0.84±0.03b 82.84 47 2-乙酰吡咯 109-97-7 C4H5N 0.09±0.00a 0.13±0.00b 45.55 48 1-甲酰吡咯烷 3760-54-1 C5H9NO 0.18±0.04a 0.36±0.01b 67.53 注:表中仅列出峰面积占比大于0.01%的化合物,结果为均值±标准差,同行不同字母表示不同样品之间存在显著性差异(P<0.05)。 PCA分析是一种无监督的降维分析方法,能够在新的坐标空间反映了数据的聚集状态,利于从整体上发现离散样本[30]。对GC-MS鉴定出的VOCs进行PCA分析,结果如图3所示,可知两个主成分贡献率之和为95.5%,能够代表两种麦芽的原始信息。饼干麦芽和焦香麦芽在PC1水平上被明显区分开,分别位于PC1轴两侧,说明GC-MS技术能够对不同种类麦芽进行较好地分类鉴别。

2.2 GC-IMS分析麦芽的VOCs

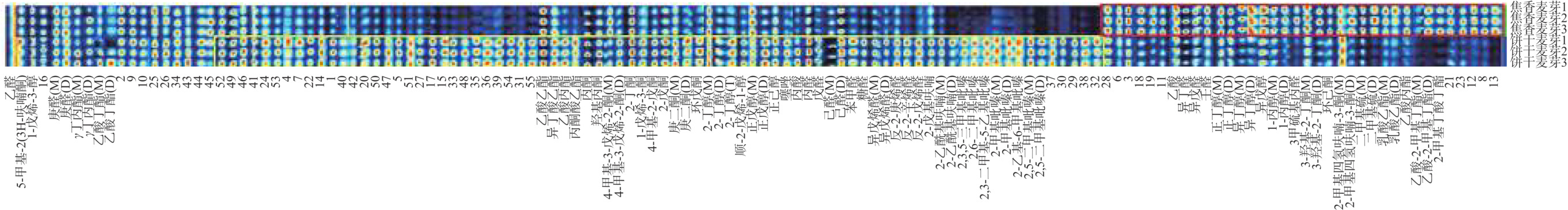

为直观对比两种麦芽中VOCs的差异,选取焦香麦芽为参比样品,饼干麦芽的谱图则在扣减参比样品信号的基础上进行显示。如果两种麦芽中的VOCs含量一致,则扣减后饼干麦芽的背景为白色;若VOCs的浓度高于参比样品,背景则为红色;若VOCs的浓度低于参比样品,背景则为蓝色。二者浓度差异越大,红色或蓝色越明显。采用差异对比模式后的结果如图4所示,可以明显看出图4中红色方框区域白色背景较少,红色和蓝色背景较多且明显,说明保留时间在200~1600 s,迁移时间在1.0~2.0 ms区域内的麦芽VOCs信号较强,含量差异较大。

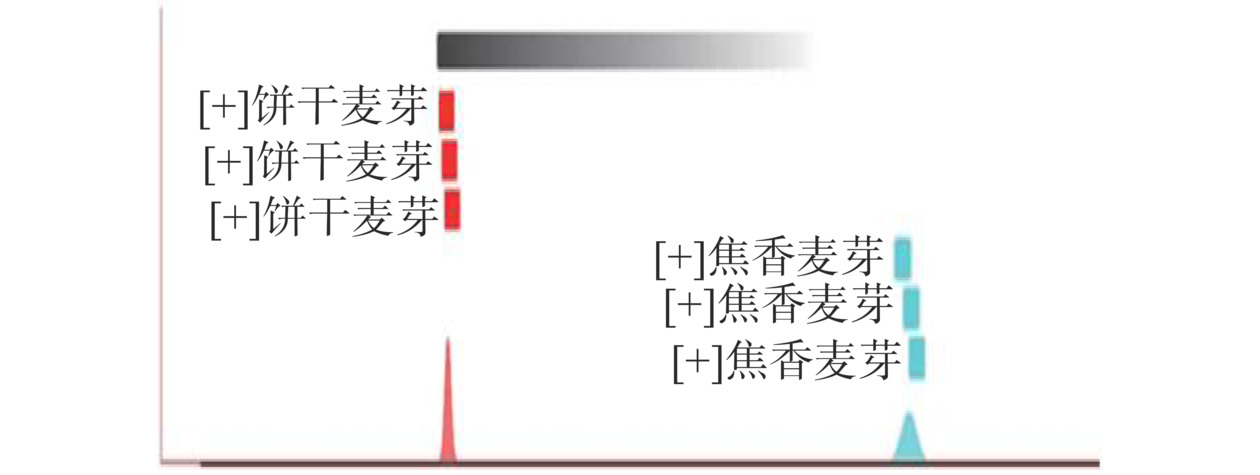

两种不同麦芽中共检测到135种化合物,其中定性出80种(见表2),VOCs以醇类、酮类、醛类和酯类等小分子化合物为主,部分化合物存在单聚体、二聚体,甚至三聚体形式,主要包括3-羟基-2-丁酮、庚二酮、异戊烯醛、2,5-二甲基吡嗪、2-甲基吡嗪和2-丁醇等20种物质。通过Gallery Plot插件对其分析得到麦芽的指纹图谱(图4),图中每一行中的每个点代表样品中检测到的挥发性物质,每一列中每个点代表同一挥发性物质在不同样品中含量,颜色越深表示峰强度越大,含量越高,以数字标记化合物名称代表该物质未被定性。从已识别的化合物可以直观看出,两种麦芽挥发性物质种类接近但含量上存在明显差异。

表 2 GC-IMS检测麦芽中挥发性物质的峰体积百分比Table 2. Peak volume percentage of volatile organic compounds in malt detected by GC-IMS序号 化合物名称 CAS号 分子式 保留时间(s) 迁移时间(ms) 备注 峰体积(%) 焦香麦芽 饼干麦芽 1 苯甲醛 100-52-7 C7H6O 1306.967 1.1502 0.55±0.08a 0.88±0.04b 2 乙酸 64-19-7 C2H4O2 1178.190 1.1590 7.76±0.21a 5.29±0.43b 3 顺-2-戊烯-1-醇 1576-95-0 C5H10O 847.567 0.9522 0.34±0.02a 0.49±0.03b 4 3-羟基-2-丁酮 513-86-0 C4H8O2 785.272 1.0611 M 1.29±0.11a 0.83±0.05b 5 3-羟基-2-丁酮 513-86-0 C4H8O2 784.113 1.3303 D 2.83±0.09a 1.35±0.08b 6 正己醇 111-27-3 C6H14O 906.540 1.3307 0.25±0.07a 0.25±0.00a 7 异戊烯醛 107-86-8 C5H8O 669.192 1.0952 M 0.19±0.00a 0.28±0.00b 8 异戊烯醛 107-86-8 C5H8O 667.674 1.3622 D 0.12±0.00a 0.12±0.00a 9 庚二酮 110-43-0 C7H14O 637.949 1.2627 M 0.38±0.12a 0.40±0.06a 10 庚二酮 110-43-0 C7H14O 638.982 1.6312 D 0.82±0.06a 1.23±0.10b 11 4-甲基-3-戊烯-2-酮 141-79-7 C6H10O 558.259 1.1225 M 0.72±0.04a 0.47±0.03b 12 4-甲基-3-戊烯-2-酮 141-79-7 C6H10O 556.468 1.4459 D 0.20±0.00a 0.26±0.00a 13 4-甲基-2-戊酮 108-10-1 C6H12O 389.538 1.4860 0.50±0.10a 0.64±0.01b 14 2-戊酮 107-87-9 C5H10O 361.406 1.3693 2.05±0.03a 2.44±0.10a 15 戊醛 110-62-3 C5H10O 363.875 1.4307 0.57±0.04a 0.97±0.18b 16 异丁酸乙酯 97-62-1 C6H12O2 348.816 1.5639 0.15±0.00a 0.14±0.00a 17 2-丁酮 78-93-3 C4H8O 306.123 1.2490 3.84±0.15a 3.71±0.09a 18 乙酸乙酯 141-78-6 C4H8O2 295.956 1.3394 4.37±0.32a 3.86±0.20b 19 丙醛 123-38-6 C3H6O 253.564 1.1449 2.00±0.09a 2.37±0.09a 20 丙酮 67-64-1 C3H6O 262.741 1.1103 5.78±0.34a 6.32±0.37a 21 乙酸-2-甲基丁酯 624-41-9 C7H14O2 532.425 1.3016 M 0.33±0.01a 0.07±0.00b 22 乙酸-2-甲基丁酯 624-41-9 C7H14O2 533.436 1.7373 D 0.11±0.00a 0.01±0.00b 23 正丁醇 71-36-3 C4H10O 568.558 1.1802 M 0.79±0.012a 0.60±0.02b 24 正丁醇 71-36-3 C4H10O 567.357 1.3828 D 0.42±0.07a 0.35±0.02a 25 乙醛 75-07-0 C2H4O 231.911 0.9846 1.73±0.06a 1.31±0.14b 26 3-甲硫基丙醛 3268-49-3 C4H8OS 1126.053 1.0908 0.64±0.10a 0.20±0.00b 27 2-乙酰基呋喃 1192-62-7 C6H6O2 1279.510 1.4418 M 0.19±0.00a 0.20±0.00a 28 2-乙酰基呋喃 1192-62-7 C6H6O2 1276.789 1.1176 D 0.64±0.04a 1.39±0.46b 29 5-甲基-2(3H)-呋喃酮 591-12-8 C5H6O2 1057.839 1.1258 0.35±0.01a 0.21±0.03b 30 壬醛 124-19-6 C9H18O 978.375 1.4761 0.59±0.03a 0.51±0.10a 31 环己酮 108-94-1 C6H10O 782.623 1.4563 0.26±0.01a 0.14±0.00b 32 己酸丙酯 626-77-7 C9H18O2 833.825 1.4008 0.20±0.00a 0.24±0.00a 33 反-2-庚烯醛 18829-55-5 C7H12O 843.543 1.2566 0.33±0.02a 0.05±0.00b 34 2-甲基丁酸丁酯 15706-73-7 C9H18O2 699.122 1.8996 1.88±0.06a 2.12±0.03b 35 羟基丙酮 116-09-6 C3H6O2 810.737 1.2276 2.16±0.22a 1.22±0.02b 36 异戊醇 123-51-3 C5H12O 675.117 1.4896 0.58±0.11a 0.54±0.04a 37 2-戊基呋喃 3777-69-3 C9H14O 707.593 1.2507 1.04±0.08a 1.12±0.02a 38 1-戊烯-3-醇 616-25-1 C5H10O 598.906 0.9410 0.73±0.13a 0.49±0.01b 39 1-丙醇 71-23-8 C3H8O 418.985 1.1079 M 0.48±0.09a 0.22±0.01b 40 1-丙醇 71-23-8 C3H8O 417.521 1.2555 D 0.41±0.03a 0.43±0.00a 41 2-丁醇 78-92-2 C4H10O 401.174 1.1512 M 0.97±0.13a 1.19±0.05b 42 2-丁醇 78-92-2 C4H10O 399.710 1.3252 D 0.24±0.03a 0.29±0.00a 43 2-丁醇 78-92-2 C4H10O 398.002 1.3902 T 2.56±0.26a 1.30±0.04b 44 二甲基硫 75-18-3 C2H6S 245.737 0.9633 M 0.86±0.33a 0.14±0.00b 45 二甲基硫 75-18-3 C2H6S 242.704 1.1198 D 0.68±0.15a 0.29±0.02b 46 异丁醛 78-84-2 C4H8O 259.927 1.2790 1.63±0.05 1.11±0.13 47 异戊醛 590-86-3 C5H10O 313.157 1.4005 0.09±0.00a 0.46±0.05b 48 反-2-辛烯醛 2548-87-0 C8H14O 1049.205 1.3358 0.13±0.00a 0.35±0.01b 49 2,3,5-三甲基吡嗪 14667-55-1 C7H10N2 985.485 1.1652 0.10±0.00a 0.43±0.02b 50 2,6-二甲基吡嗪 108-50-9 C6H8N2 845.389 1.1411 0.04±0.00a 0.18±0.00b 51 2,3-二甲基-5-乙基吡嗪 15707-34-3 C8H12N2 1082.875 1.2332 0.04±0.00a 0.21±0.00b 52 噻唑 288-47-1 C3H3NS 733.566 1.0268 0.06±0.00a 0.08±0.00a 53 反式-2-戊烯醛 1576-87-0 C5H8O 515.634 1.1122 0.03±0.00a 0.05±0.00b 54 环戊酮 120-92-3 C5H8O 551.884 1.0998 0.14±0.00a 0.21±0.03b 55 乙酸丙酯 109-60-4 C5H10O2 355.513 1.4790 0.04±0.00a 0.07±0.00b 56 乳酸乙酯 97-64-3 C5H10O3 888.840 1.1405 M 0.54±0.14a 0.22±0.00b 57 乳酸乙酯 97-64-3 C5H10O3 888.840 1.5380 D 0.07±0.00a 0.03±0.00b 58 正戊醇 71-41-0 C5H12O 737.170 1.2564 M 1.06±0.36a 0.89±0.07b 59 正戊醇 71-41-0 C5H12O 737.170 1.5184 D 0.55±0.06a 0.93±0.06b 60 庚醛 111-71-7 C7H14O 645.431 1.3302 M 0.36±0.00a 0.27±0.00b 61 庚醛 111-71-7 C7H14O 646.618 1.6993 D 0.06±0.00a 0.06±0.00a 62 异丁醇 78-83-1 C4H10O 488.656 1.1717 M 0.53±0.12a 0.23±0.05b 63 异丁醇 78-83-1 C4H10O 485.011 1.3740 D 1.19±0.27a 0.48±0.06b 64 己醛 66-25-1 C6H12O 470.098 1.2654 M 0.46±0.10a 0.23±0.00b 65 己醛 66-25-1 C6H12O 469.435 1.5684 D 2.70±0.28a 3.91±0.25b 66 1-戊烯-3-酮 1629-58-9 C5H8O 373.328 1.0829 0.03±0.00a 0.04±0.00a 67 2,5-二甲基吡嗪 123-32-0 C6H8N2 833.388 1.1144 M 0.14±0.00a 0.77±0.05b 68 2,5-二甲基吡嗪 123-32-0 C6H8N2 836.488 1.5027 D 0.02±0.00a 0.26±0.02b 69 2-甲基四氢呋喃-3-酮 3188-00-9 C5H8O2 760.519 1.0748 M 0.48±0.06a 0.49±0.03a 70 2-甲基四氢呋喃-3-酮 3188-00-9 C5H8O2 755.868 1.4293 D 0.83±0.14a 0.34±0.07b 71 γ-丁内酯 96-48-0 C4H6O2 1791.197 1.0831 M 3.54±0.29a 3.57±0.12a 72 γ-丁内酯 96-48-0 C4H6O2 1779.599 1.3028 D 1.73±0.25a 1.41±0.08b 73 丙酸 79-09-4 C3H6O2 1540.193 1.1120 1.90±0.07a 3.09±0.04b 74 糠醛 98-01-1 C5H4O2 1166.138 1.3392 1.46±0.01a 2.97±0.09b 75 2-乙基-6-甲基吡嗪 13925-03-6 C7H10N2 957.371 1.1723 0.05±0.00a 0.18±0.00b 76 2-甲基吡嗪 109-08-0 C5H6N2 759.977 1.0939 M 0.31±0.01a 0.59±0.06b 77 2-甲基吡嗪 109-08-0 C5H6N2 754.520 1.3885 D 0.14±0.00a 0.44±0.08b 78 丙酮酸乙酯 617-35-6 C5H8O3 725.345 1.1531 0.02±0.00a 0.04±0.00b 79 乙酸丁酯 123-86-4 C6H12O2 456.438 1.2378 M 0.23±0.01a 0.25±0.07a 80 乙酸丁酯 123-86-4 C6H12O2 457.033 1.6153 D 0.03±0.00a 0.03±0.00a 注:M代表单体;D代表二聚体;T代表三聚体;同行不同字母表示不同样品之间存在显著性差异(P<0.05)。 图5红框中的化合物在焦香麦芽中的含量要明显高于饼干麦芽,包括2-甲基丁酸丁酯、乙酸-2-甲基丁酯、己酸丙酯、乳酸乙酯、二甲基硫、2-甲基四氢呋喃-3-酮、环己酮、3-羟基-2-丁酮、3-甲硫基丙醛、1-丙醇、异戊醇、异丁醇、正丁醇、壬醛、异戊醛、异丁醛和乙酸等17种物质。GC-MS检测结果也显示异丁醛、异戊醛和乙酸在焦香麦芽中含量较高。黄框中的化合物在饼干麦芽中的含量则相对更高,主要是吡嗪类、醛类、酯类和酮类物质,包括2,5-二甲基吡嗪、2-乙基-6-甲基吡嗪、2-甲基吡嗪、2,3-二甲基-5-乙基-吡嗪、2,6-二甲基吡嗪、2,3,5-三甲基吡嗪、2-乙酰基呋喃、2-戊基呋喃、反-2-戊烯醛、反-2-辛烯醛、反-2-庚烯醛、异戊烯醛、糠醛、苯甲醛、己醛、戊醛、丙醛、丙酸、噻唑、正己醇、正戊醇、顺-2-戊烯-1-醇、2-丁醇、环戊酮、庚二酮、2-戊酮、4-甲基-2-戊酮、1-戊烯-3-酮、2-丁酮、4-甲基-3-戊烯-2酮、羟基丙酮、丙酮、丙酮酸乙酯、乙酸丙酯、异丁酸乙酯和乙酸乙酯等36种物质。GC-IMS检测结果也同样表明吡嗪类、呋喃类等物质在饼干麦芽中含量较高,这可能与饼干麦芽制备时焙烤温度较焦香麦芽高且时间较长有关[31]。麦芽制备过程伴随着焦糖化和美拉德反应等非酶褐变反应,焙烤温度较低时,还原糖和氨基酸生成的化合物只含有碳、氢和氧的化合物,以酮、缩醛和呋喃为主,随着焙烤温度的逐渐升高,美拉德反应经过一系列复杂的途径,形成许多中间反应产物,如乙酰基、呋喃、吡咯和吡嗪等[32−33],GC-MS检测结果也印证了这一结论。

对GC-IMS定性出的麦芽VOCs进行PCA分析(见图6),数据经降维后,主成分1贡献率达到90.7%,主成分2贡献率为3.6%,两个主成分贡献率之和为94.3%,整体上能够代表原始样本的绝大部分数据信息。两种麦芽样品分别位于PCA图中相对独立的区域,并且重复性较好,说明焦香麦芽和饼干麦芽挥发性物质差异明显,这也与于淼等[11]的研究结果吻合。同时采用最近邻算法,结合欧氏距离对指纹图谱相似度进行分析,结果见图7,焦香麦芽和饼干麦芽所在区域距离较远,说明指纹图谱相似度较低,挥发性物质含量差异大,与PCA分析结果吻合。

3. 结论

本文利用GC-MS和GC-IMS技术对焦香麦芽和饼干麦芽中VOCs进行检测,GC-MS技术共检测定性出90余种挥发性物质,其中峰面积占比大于0.01%化合物有48种,主要包括9种酮类、14种醛类、4种酯类、4种醇类、2种酸类、10种吡嗪类和5种杂环类物质。两种麦芽中醛类和酸类物质含量均明显较高,醛类含量高达30%以上,酸类含量在20%左右,主要包括2-甲基丁醛、异戊醛和乙酸等。焦香麦芽中酯类、醇类、醛类、酸类和杂环类物质含量相对较高,而饼干麦芽中吡嗪类物质含量更丰富,尤其2-甲基吡嗪、2,5-二甲基吡和2-乙基-3,5-二甲基吡嗪三种成分,酮类物质在两种麦芽中含量差异不明显。GC-IMS技术在麦芽中检测出135种化合物,其中定性出80种,以醇类、酮类、醛类和酯类等小分子化合物为主,吡嗪类和杂环类等大分子物质种类较少。GC-IMS检测结果也同样表明焦香麦芽中酯类、醇类和醛类物质含量相对较高,饼干麦芽中吡嗪类和酮类物质含量更丰富,与GC-MS结果一致。PCA分析结果表明GC-MS和GC-IMS两种技术均能够对焦香麦芽和饼干麦芽进行有效分类鉴别,指纹图谱相似度分析结果进一步证明GC-IMS技术可以应用于麦芽VOCs方面的研究。

GC-MS与GC-IMS技术对不同VOCs检出的灵敏度有所差异,GC-MS对分子量较大的化合物仪器响应更高,而GC-IMS技术产生信号响应的多为小分子量化合物,其可视化的指纹图谱可更快速地筛选出特异性物质。两种技术结合,能够扩大样品中挥发性物质的检测范围,更加全面解析麦芽中VOCs,为麦芽的VOCs研究提供有力的检测技术支持。

-

表 1 GC-MS检测麦芽中挥发性物质的峰面积百分含量

Table 1 Peak area percentage of volatile organic compounds in malt detected by GC-MS

序号 化合物名称 CAS号 分子式 峰面积(%) 匹配度(%) 焦香 饼干 酮类 1 丙酮 67-64-1 C3H6O 0.59±0.06a 0.27±0.03b 75.41 2 丁酮 78-93-3 C4H8O 0.73±0.03a 0.37±0.11b 86.43 3 2,3-戊二酮 600-14-6 C5H8O2 0.09±0.00a 0.06±0.00b 60.80 4 2-庚酮 110-43-0 C7H14O 0.47±0.11a 0.63±0.12b 48.54 5 2-甲基四氢呋喃-3-酮 3188-00-9 C5H8O2 0.43±0.09a 0.48±0.08a 67.08 6 羟基丙酮 116-09-6 C3H6O2 0.47±0.07a 0.47±0.04a 73.40 7 3-辛烯-2-酮 18402-82-9 C8H14O 0.29±0.00a 1.14±0.24b 40.00 8 乙酸基丙酮 592-20-1 C5H8O3 0.31±0.00a 0.28±0.00a 61.06 9 2-吡咯烷酮 616-45-5 C4H7NO 0.17±0.00a 0.17±0.00a 40.63 醛类 10 乙醛 75-07-0 C2H4O 0.13±0.00a 0.08±0.00b 42.61 11 异丁醛 78-84-2 C4H8O 1.90±0.36a 0.18±0.00b 74.90 12 2-甲基丁醛 96-17-3 C5H10O 9.56±0.31a 6.69±0.37b 72.14 13 异戊醛 590-86-3 C5H10O 7.72±0.37a 6.41±0.28a 77.76 14 正戊醛 110-62-3 C5H10O 0.80±0.07a 1.34±0.21b 84.38 15 正己醛 66-25-1 C6H12O 4.94±0.16a 5.88±0.40a 61.32 16 庚醛 111-71-7 C7H14O 0.23±0.00a 0.52±0.05b 60.05 17 正辛醛 124-13-0 C8H16O 1.33±0.04a 0.23±0.01b 42.30 18 反-2-辛烯醛 2548-87-0 C8H14O 2.33±0.26a 2.14±0.03a 44.51 19 (E,E)-2,4-庚二烯醛 4313-03-5 C7H10O 0.11±0.00a 0.14±0.00a 54.35 20 可可醛 35158-25-9 C10H18O 2.18±0.12a 0.20±0.00b 48.26 21 糠醛 98-01-1 C5H4O2 2.07±0.34a 2.44±0.06a 77.40 22 苯甲醛 100-52-7 C7H6O 0.72±0.06a 0.75±0.16a 75.29 23 5-甲基呋喃醛 620-02-0 C6H6O2 0.23±0.04a 0.30±0.05b 86.23 酯类 24 癸酸乙酯 110-38-3 C12H24O2 0.92±0.06a 0.79±0.04b 82.34 25 γ-丁内酯 96-48-0 C4H6O2 0.76±0.01a 0.38±0.00b 76.25 26 γ-己内酯 695-06-7 C6H10O2 0.11±0.00a 0.12±0.00a 61.96 27 乙酸苯乙酯 103-45-7 C10H12O2 0.62±0.00a 0.45±0.04a 59.06 醇类 28 正戊醇 71-41-0 C5H12O 0.75±0.03a 0.89±0.23a 72.53 29 顺-2-戊烯醇 1576-95-0 C5H10O 0.05±0.00a 0.15±0.00b 49.56 30 5-甲基-2-呋喃甲醇 3857-25-8 C6H8O2 0.11±0.00a 0.05±0.00b 43.61 31 苯乙醇 60-12-8 C8H10O 0.59±0.05a 0.27±0.00b 72.14 酸类 32 乙酸 64-19-7 C2H4O2 15.76±0.57a 9.57±0.45b 98.26 33 正己酸 142-62-1 C6H12O2 1.21±0.05a 4.50±0.26b 91.22 吡嗪类 34 2-甲基吡嗪 109-08-0 C5H6N2 0.33±0.08a 1.60±0.11b 69.40 35 2,5-二甲基吡嗪 123-32-0 C6H8N2 0.20±0.00a 1.19±0.06b 78.13 36 2-丁基-3-甲基吡嗪 108-50-9 C6H8N2 0.26±0.00a 0.84±0.03b 67.45 37 2-乙基吡嗪 13925-00-3 C6H8N2 0.28±0.00a 0.69±0.03b 59.96 38 2,3-二甲基吡嗪 5910-89-4 C6H8N2 0.57±0.06a 0.54±0.04a 75.03 39 2,6-二甲基吡嗪 13925-03-6 C7H10N2 0.22±0.00a 0.36±0.07b 69.86 40 2-乙基-6-甲基吡嗪 13925-03-6 C7H10N2 0.34±0.05a 0.73±0.13b 46.12 41 3-乙基-2-甲基吡嗪 15707-23-0 C7H10N2 0.18±0.00a 0.53±0.12b 49.50 42 2-乙基-3,5-二甲基吡嗪 13925-07-0 C8H12N2 0.44±0.13a 1.24±0.26b 65.64 43 2-异戊基吡嗪 13925-07-0 C8H12N2 0.41±0.06a 0.35±0.00b 46.43 杂环化合物 44 2-甲基呋喃 534-22-5 C5H6O 0.06±0.00a 0.04±0.00a 43.68 45 2-戊基呋喃 3777-69-3 C9H14O 0.67±0.08a 0.99±0.09a 88.82 46 2-乙酰基呋喃 1192-62-7 C6H6O2 0.59±0.01a 0.84±0.03b 82.84 47 2-乙酰吡咯 109-97-7 C4H5N 0.09±0.00a 0.13±0.00b 45.55 48 1-甲酰吡咯烷 3760-54-1 C5H9NO 0.18±0.04a 0.36±0.01b 67.53 注:表中仅列出峰面积占比大于0.01%的化合物,结果为均值±标准差,同行不同字母表示不同样品之间存在显著性差异(P<0.05)。 表 2 GC-IMS检测麦芽中挥发性物质的峰体积百分比

Table 2 Peak volume percentage of volatile organic compounds in malt detected by GC-IMS

序号 化合物名称 CAS号 分子式 保留时间(s) 迁移时间(ms) 备注 峰体积(%) 焦香麦芽 饼干麦芽 1 苯甲醛 100-52-7 C7H6O 1306.967 1.1502 0.55±0.08a 0.88±0.04b 2 乙酸 64-19-7 C2H4O2 1178.190 1.1590 7.76±0.21a 5.29±0.43b 3 顺-2-戊烯-1-醇 1576-95-0 C5H10O 847.567 0.9522 0.34±0.02a 0.49±0.03b 4 3-羟基-2-丁酮 513-86-0 C4H8O2 785.272 1.0611 M 1.29±0.11a 0.83±0.05b 5 3-羟基-2-丁酮 513-86-0 C4H8O2 784.113 1.3303 D 2.83±0.09a 1.35±0.08b 6 正己醇 111-27-3 C6H14O 906.540 1.3307 0.25±0.07a 0.25±0.00a 7 异戊烯醛 107-86-8 C5H8O 669.192 1.0952 M 0.19±0.00a 0.28±0.00b 8 异戊烯醛 107-86-8 C5H8O 667.674 1.3622 D 0.12±0.00a 0.12±0.00a 9 庚二酮 110-43-0 C7H14O 637.949 1.2627 M 0.38±0.12a 0.40±0.06a 10 庚二酮 110-43-0 C7H14O 638.982 1.6312 D 0.82±0.06a 1.23±0.10b 11 4-甲基-3-戊烯-2-酮 141-79-7 C6H10O 558.259 1.1225 M 0.72±0.04a 0.47±0.03b 12 4-甲基-3-戊烯-2-酮 141-79-7 C6H10O 556.468 1.4459 D 0.20±0.00a 0.26±0.00a 13 4-甲基-2-戊酮 108-10-1 C6H12O 389.538 1.4860 0.50±0.10a 0.64±0.01b 14 2-戊酮 107-87-9 C5H10O 361.406 1.3693 2.05±0.03a 2.44±0.10a 15 戊醛 110-62-3 C5H10O 363.875 1.4307 0.57±0.04a 0.97±0.18b 16 异丁酸乙酯 97-62-1 C6H12O2 348.816 1.5639 0.15±0.00a 0.14±0.00a 17 2-丁酮 78-93-3 C4H8O 306.123 1.2490 3.84±0.15a 3.71±0.09a 18 乙酸乙酯 141-78-6 C4H8O2 295.956 1.3394 4.37±0.32a 3.86±0.20b 19 丙醛 123-38-6 C3H6O 253.564 1.1449 2.00±0.09a 2.37±0.09a 20 丙酮 67-64-1 C3H6O 262.741 1.1103 5.78±0.34a 6.32±0.37a 21 乙酸-2-甲基丁酯 624-41-9 C7H14O2 532.425 1.3016 M 0.33±0.01a 0.07±0.00b 22 乙酸-2-甲基丁酯 624-41-9 C7H14O2 533.436 1.7373 D 0.11±0.00a 0.01±0.00b 23 正丁醇 71-36-3 C4H10O 568.558 1.1802 M 0.79±0.012a 0.60±0.02b 24 正丁醇 71-36-3 C4H10O 567.357 1.3828 D 0.42±0.07a 0.35±0.02a 25 乙醛 75-07-0 C2H4O 231.911 0.9846 1.73±0.06a 1.31±0.14b 26 3-甲硫基丙醛 3268-49-3 C4H8OS 1126.053 1.0908 0.64±0.10a 0.20±0.00b 27 2-乙酰基呋喃 1192-62-7 C6H6O2 1279.510 1.4418 M 0.19±0.00a 0.20±0.00a 28 2-乙酰基呋喃 1192-62-7 C6H6O2 1276.789 1.1176 D 0.64±0.04a 1.39±0.46b 29 5-甲基-2(3H)-呋喃酮 591-12-8 C5H6O2 1057.839 1.1258 0.35±0.01a 0.21±0.03b 30 壬醛 124-19-6 C9H18O 978.375 1.4761 0.59±0.03a 0.51±0.10a 31 环己酮 108-94-1 C6H10O 782.623 1.4563 0.26±0.01a 0.14±0.00b 32 己酸丙酯 626-77-7 C9H18O2 833.825 1.4008 0.20±0.00a 0.24±0.00a 33 反-2-庚烯醛 18829-55-5 C7H12O 843.543 1.2566 0.33±0.02a 0.05±0.00b 34 2-甲基丁酸丁酯 15706-73-7 C9H18O2 699.122 1.8996 1.88±0.06a 2.12±0.03b 35 羟基丙酮 116-09-6 C3H6O2 810.737 1.2276 2.16±0.22a 1.22±0.02b 36 异戊醇 123-51-3 C5H12O 675.117 1.4896 0.58±0.11a 0.54±0.04a 37 2-戊基呋喃 3777-69-3 C9H14O 707.593 1.2507 1.04±0.08a 1.12±0.02a 38 1-戊烯-3-醇 616-25-1 C5H10O 598.906 0.9410 0.73±0.13a 0.49±0.01b 39 1-丙醇 71-23-8 C3H8O 418.985 1.1079 M 0.48±0.09a 0.22±0.01b 40 1-丙醇 71-23-8 C3H8O 417.521 1.2555 D 0.41±0.03a 0.43±0.00a 41 2-丁醇 78-92-2 C4H10O 401.174 1.1512 M 0.97±0.13a 1.19±0.05b 42 2-丁醇 78-92-2 C4H10O 399.710 1.3252 D 0.24±0.03a 0.29±0.00a 43 2-丁醇 78-92-2 C4H10O 398.002 1.3902 T 2.56±0.26a 1.30±0.04b 44 二甲基硫 75-18-3 C2H6S 245.737 0.9633 M 0.86±0.33a 0.14±0.00b 45 二甲基硫 75-18-3 C2H6S 242.704 1.1198 D 0.68±0.15a 0.29±0.02b 46 异丁醛 78-84-2 C4H8O 259.927 1.2790 1.63±0.05 1.11±0.13 47 异戊醛 590-86-3 C5H10O 313.157 1.4005 0.09±0.00a 0.46±0.05b 48 反-2-辛烯醛 2548-87-0 C8H14O 1049.205 1.3358 0.13±0.00a 0.35±0.01b 49 2,3,5-三甲基吡嗪 14667-55-1 C7H10N2 985.485 1.1652 0.10±0.00a 0.43±0.02b 50 2,6-二甲基吡嗪 108-50-9 C6H8N2 845.389 1.1411 0.04±0.00a 0.18±0.00b 51 2,3-二甲基-5-乙基吡嗪 15707-34-3 C8H12N2 1082.875 1.2332 0.04±0.00a 0.21±0.00b 52 噻唑 288-47-1 C3H3NS 733.566 1.0268 0.06±0.00a 0.08±0.00a 53 反式-2-戊烯醛 1576-87-0 C5H8O 515.634 1.1122 0.03±0.00a 0.05±0.00b 54 环戊酮 120-92-3 C5H8O 551.884 1.0998 0.14±0.00a 0.21±0.03b 55 乙酸丙酯 109-60-4 C5H10O2 355.513 1.4790 0.04±0.00a 0.07±0.00b 56 乳酸乙酯 97-64-3 C5H10O3 888.840 1.1405 M 0.54±0.14a 0.22±0.00b 57 乳酸乙酯 97-64-3 C5H10O3 888.840 1.5380 D 0.07±0.00a 0.03±0.00b 58 正戊醇 71-41-0 C5H12O 737.170 1.2564 M 1.06±0.36a 0.89±0.07b 59 正戊醇 71-41-0 C5H12O 737.170 1.5184 D 0.55±0.06a 0.93±0.06b 60 庚醛 111-71-7 C7H14O 645.431 1.3302 M 0.36±0.00a 0.27±0.00b 61 庚醛 111-71-7 C7H14O 646.618 1.6993 D 0.06±0.00a 0.06±0.00a 62 异丁醇 78-83-1 C4H10O 488.656 1.1717 M 0.53±0.12a 0.23±0.05b 63 异丁醇 78-83-1 C4H10O 485.011 1.3740 D 1.19±0.27a 0.48±0.06b 64 己醛 66-25-1 C6H12O 470.098 1.2654 M 0.46±0.10a 0.23±0.00b 65 己醛 66-25-1 C6H12O 469.435 1.5684 D 2.70±0.28a 3.91±0.25b 66 1-戊烯-3-酮 1629-58-9 C5H8O 373.328 1.0829 0.03±0.00a 0.04±0.00a 67 2,5-二甲基吡嗪 123-32-0 C6H8N2 833.388 1.1144 M 0.14±0.00a 0.77±0.05b 68 2,5-二甲基吡嗪 123-32-0 C6H8N2 836.488 1.5027 D 0.02±0.00a 0.26±0.02b 69 2-甲基四氢呋喃-3-酮 3188-00-9 C5H8O2 760.519 1.0748 M 0.48±0.06a 0.49±0.03a 70 2-甲基四氢呋喃-3-酮 3188-00-9 C5H8O2 755.868 1.4293 D 0.83±0.14a 0.34±0.07b 71 γ-丁内酯 96-48-0 C4H6O2 1791.197 1.0831 M 3.54±0.29a 3.57±0.12a 72 γ-丁内酯 96-48-0 C4H6O2 1779.599 1.3028 D 1.73±0.25a 1.41±0.08b 73 丙酸 79-09-4 C3H6O2 1540.193 1.1120 1.90±0.07a 3.09±0.04b 74 糠醛 98-01-1 C5H4O2 1166.138 1.3392 1.46±0.01a 2.97±0.09b 75 2-乙基-6-甲基吡嗪 13925-03-6 C7H10N2 957.371 1.1723 0.05±0.00a 0.18±0.00b 76 2-甲基吡嗪 109-08-0 C5H6N2 759.977 1.0939 M 0.31±0.01a 0.59±0.06b 77 2-甲基吡嗪 109-08-0 C5H6N2 754.520 1.3885 D 0.14±0.00a 0.44±0.08b 78 丙酮酸乙酯 617-35-6 C5H8O3 725.345 1.1531 0.02±0.00a 0.04±0.00b 79 乙酸丁酯 123-86-4 C6H12O2 456.438 1.2378 M 0.23±0.01a 0.25±0.07a 80 乙酸丁酯 123-86-4 C6H12O2 457.033 1.6153 D 0.03±0.00a 0.03±0.00a 注:M代表单体;D代表二聚体;T代表三聚体;同行不同字母表示不同样品之间存在显著性差异(P<0.05)。 -

[1] 杨珍, 贺立东. 反吹-气相色谱法快速检测啤酒中的主要风味物质[J]. 中国酿造,2019,38(10):171−174. [YANG Z, HE L D. Quick determination of main volatile flavor compounds in beer by GC using back-flush technique[J]. China Brewing,2019,38(10):171−174.] doi: 10.11882/j.issn.0254-5071.2019.10.035 YANG Z, HE L D. Quick determination of main volatile flavor compounds in beer by GC using back-flush technique[J]. China Brewing, 2019, 38(10): 171−174. doi: 10.11882/j.issn.0254-5071.2019.10.035

[2] 陈华磊, 黄克兴, 郑敏, 等. 基于非靶向风味组学分析3种品牌啤酒的风味差异[J]. 食品科学,2021,42(6):223−228. [CHEN H L, HUANG K X, ZHENG M, et al. Analysis of flavor differences among three brands of lager beer based on untargeted flavoromics[J]. Food Science,2021,42(6):223−228.] doi: 10.7506/spkx1002-6630-20200319-294 CHEN H L, HUANG K X, ZHENG M, et al. Analysis of flavor differences among three brands of lager beer based on untargeted flavoromics[J]. Food Science, 2021, 42(6): 223−228. doi: 10.7506/spkx1002-6630-20200319-294

[3] 钟成, 刘伶普, 李清亮, 等. 采用代谢组学分析技术分析工业啤酒发酵过程中风味物质生成规律[J]. 中国生物工程杂志,2016,36(12):49−58. [ZHONG C, LIU L P, LI Q L, et al. Analyze the mechanism of flavor compounds formation using metabonomics method during industrial beer fermentation[J]. China Biotechnology,2016,36(12):49−58.] ZHONG C, LIU L P, LI Q L, et al. Analyze the mechanism of flavor compounds formation using metabonomics method during industrial beer fermentation[J]. China Biotechnology, 2016, 36(12): 49−58.

[4] 吴幼茹, 江伟, 刘翔, 等. 气相色谱-嗅闻-质谱分析浅色麦芽、焦香麦芽及黑麦芽中香气成分[J]. 食品与发酵工业,2016,42(7):193−201. [WU Y R, JIANG W, LIU X, et al. Identification of aroma-active compounds in pale malt, caramel malt and black malt by GC-O-MS[J]. Food and Fermentation Industries,2016,42(7):193−201.] WU Y R, JIANG W, LIU X, et al. Identification of aroma-active compounds in pale malt, caramel malt and black malt by GC-O-MS[J]. Food and Fermentation Industries, 2016, 42(7): 193−201.

[5] COGHE S, GHEERAERT B, MICHIELS A, et al. Development of Maillard reaction related characteristics during malt roasting[J]. Journal of the Institute of Brewing,2006,112(2):148−156. doi: 10.1002/j.2050-0416.2006.tb00244.x

[6] 范文来, 徐岩. 酒类风味化学[M]. 北京:中国轻工业出版社, 2019:25-27. [FAN W L, XU Y. Flavor chemistry of alcoholic beverage[M]. Beijing:China Light Industry Press, 2019:25-27.] FAN W L, XU Y. Flavor chemistry of alcoholic beverage[M]. Beijing: China Light Industry Press, 2019: 25-27.

[7] QIN O Y, ZHAO J W. Classification of rice wine according to different marked ages using a novel artificial olfactory technique based on colorimetric sensor array[J]. Food Chemistry,2013,138(23):1320−1324.

[8] 陶鑫凉, 闫鹏, 郝俊光, 等. 气相色谱-质谱法分析啤酒中酒花香气成分[J]. 分析实验室,2012,31(6):24−29. [TAO X L, YAN P, HAO J G, et al. Determination of hop aroma compounds in beer by gas chromatography-mass spectrometry couple with headspace solid-phase micro-extraction[J]. Chinese Journal of Analysis Laboratory,2012,31(6):24−29.] TAO X L, YAN P, HAO J G, et al. Determination of hop aroma compounds in beer by gas chromatography-mass spectrometry couple with headspace solid-phase micro-extraction[J]. Chinese Journal of Analysis Laboratory, 2012, 31(6): 24−29.

[9] BERTUZZI T, MULAZZI A, RASTELLI S, et al. Targeted healthy compounds in small and large-scale brewed beers[J]. Food Chemistry,2019,153(6):1−19.

[10] 王晓会, 韩璐璐, 邢宝立, 等. 啤酒酿造过程中麦芽香气变化规律的研究[J]. 啤酒科技,2022(13):5−10. [WANG X H, HAN L L, XING B L, et al. Study on the change law of malt aroma during beer brewing[J]. Beer Science and Technology,2022(13):5−10.] WANG X H, HAN L L, XING B L, et al. Study on the change law of malt aroma during beer brewing[J]. Beer Science and Technology, 2022(13): 5−10.

[11] 于淼, 马明娟, 毋思敏, 等. 六款特种麦芽风味物质和感官特性分析[J]. 食品工业科技,2020,41(20):246−250. [YU M, MA M J, WU S M, et al. Sensory and volatile compounds analysis of six kinds of specialty malts[J]. Science of Technology of Food Industry,2020,41(20):246−250.] YU M, MA M J, WU S M, et al. Sensory and volatile compounds analysis of six kinds of specialty malts[J]. Science of Technology of Food Industry, 2020, 41(20): 246−250.

[12] 赵川艳, 尹永祺, 杨正飞, 等. 制麦工艺对特种麦芽品质的影响[J]. 食品科学, 2020, 41(10):21-28. [ZAHO C Y, YIN Y Q, YANG Z F, et al. Effect of malting conditions on the quality of specialty malt[J]. Food Science 2020, 41(10):21-28.] ZAHO C Y, YIN Y Q, YANG Z F, et al. Effect of malting conditions on the quality of specialty malt[J]. Food Science 2020, 41(10): 21-28.

[13] 顾双, 任芳, 韦真博, 等. 基于气相-离子迁移谱技术快速鉴定黄酒酒龄及品牌[J]. 中国食品学报,2020,20(9):248−255. [GU S, REN F, WEI Z B, et al. Rapid identification of age and brand of yellow rice wine based on gas-ion mobility spectrometry[J]. Journal of Chinese Institute of Food Science and Technology,2020,20(9):248−255.] GU S, REN F, WEI Z B, et al. Rapid identification of age and brand of yellow rice wine based on gas-ion mobility spectrometry[J]. Journal of Chinese Institute of Food Science and Technology, 2020, 20(9): 248−255.

[14] 祁兴普, 陈通, 刘萍, 等. 基于气相离子迁移谱黄酒产地识别的研究[J]. 食品工业科技,2019,40(22):273−276,281. [QI X P, CHEN T, LIU P, et al. Origin identification of yellow wine based on gas chromatography-ion mobility spectrometry[J]. Science of Technology of Food Industry,2019,40(22):273−276,281.] QI X P, CHEN T, LIU P, et al. Origin identification of yellow wine based on gas chromatography-ion mobility spectrometry[J]. Science of Technology of Food Industry, 2019, 40(22): 273−276,281.

[15] 黄兴奕, 吴梦紫, 马梅, 等. 采用气相色谱-离子迁移谱技术检测黄酒风味物质[J]. 现代食品科技,2019,35(9):271−276,226. [HUANG X Y, WU M Z, MA M, et al. Determination of flavor substances of Chinese rice wine by gas chromatography-ion mobility spectrometry[J]. Modern Food Science and Technology,2019,35(9):271−276,226.] HUANG X Y, WU M Z, MA M, et al. Determination of flavor substances of Chinese rice wine by gas chromatography-ion mobility spectrometry[J]. Modern Food Science and Technology, 2019, 35(9): 271−276,226.

[16] CHEN T, QI X P, CHEN M J, et al. Discrimination of Chinese yellow wine from different origins based on flavor fingerprint[J]. Chemicals & Chemistry,2020,32(2):139−144.

[17] 朱玲, 蔡尽忠, 刘奔. 气相-离子迁移谱法对三种不同香型白酒的风味分析[J]. 广东化工, 2020, 47(5):53−55. [ZHU L, CAI J Z, LIU B. Flavor analysis of three different flavor types of liquors using gas chromatography-ion mobility spectrometry[J]. Guangdong Chemical Industry, 2020, 47(5):53−55.] ZHU L, CAI J Z, LIU B. Flavor analysis of three different flavor types of liquors using gas chromatography-ion mobility spectrometry[J]. Guangdong Chemical Industry, 2020, 47(5): 53−55.

[18] 刘丽丽, 杨辉, 荆雄, 等. 基于GC-MS 和GC-IMS 技术分析凤香型年份基酒挥发性成分[J]. 食品科学,2022,43(23):318−327. [LIU L L, YANG H, JING X, et al. Analysis of volatile compounds in aged Fengxiang crude Baijiu based on GC-MS and GC-IMS[J]. Food Science,2022,43(23):318−327.] LIU L L, YANG H, JING X, et al. Analysis of volatile compounds in aged Fengxiang crude Baijiu based on GC-MS and GC-IMS[J]. Food Science, 2022, 43(23): 318−327.

[19] TANG Z S, ZENG X A, ZHONG H, et al. Characterization of aroma profile and characteristic aromas during lychee wine fermentation[J]. Journal of Food Process and Preservation,2019,43(8):1236−1243.

[20] 龚霄, 周伟, 李积华, 等. 基于静态顶空气相离子迁移谱技术的果啤种类判别[J]. 食品工业科技,2021,42(7):296−301. [GONG X, ZHOU W, LI Z H, et al. Identification of fruit beers based on static headspace-gas chromatography-ion mobility spectroscopy (SH-GC-IMS)[J]. Science of Technology of Food Industry,2021,42(7):296−301.] GONG X, ZHOU W, LI Z H, et al. Identification of fruit beers based on static headspace-gas chromatography-ion mobility spectroscopy (SH-GC-IMS)[J]. Science of Technology of Food Industry, 2021, 42(7): 296−301.

[21] 范威威, 林熙, 龚霄, 等. 基于顶空气相-离子迁移谱技术对不同酵母发酵的百香果果啤香气比较[J]. 食品工业科技,2022,43(7):325−332. [FAN W W, LIN X, GONG X, et al. Aroma comparison of passion beer fermented by different yeasts based on headspace phase-ion mobility spectroscopy technology[J]. Science of Technology of Food Industry,2022,43(7):325−332.] FAN W W, LIN X, GONG X, et al. Aroma comparison of passion beer fermented by different yeasts based on headspace phase-ion mobility spectroscopy technology[J]. Science of Technology of Food Industry, 2022, 43(7): 325−332.

[22] 鲜灵芝, 刘金阳, 鲁金花, 等. 基于气相色谱-离子迁移谱分析杨梅酒和糯米杨梅酒的风味特征[J]. 食品与机械,2021,37(2):14−18. [XAIN L Z, LIU J Y, LU J H, et al. The flavor characteristics of bayberry wine and glutinous rice bayberry wine were analyzed based on gas chromatography-ion migration spectrum[J]. Food and Machinery,2021,37(2):14−18.] XAIN L Z, LIU J Y, LU J H, et al. The flavor characteristics of bayberry wine and glutinous rice bayberry wine were analyzed based on gas chromatography-ion migration spectrum[J]. Food and Machinery, 2021, 37(2): 14−18.

[23] 吴强. 海底陈酿对葡萄酒香气品质的影响[J]. 中外葡萄与葡萄酒,2021(5):49−54. [WU Q. Effect of seafloor storage on aroma quality of wine[J]. Sino-overseas Grapevine and Wine,2021(5):49−54.] WU Q. Effect of seafloor storage on aroma quality of wine[J]. Sino-overseas Grapevine and Wine, 2021(5): 49−54.

[24] LIU W L, JIANG D Q, ZHANG Y, et al. Effect of Saccharomyces cerevisiae, Torulaspora delbrueckii and malolactic fermentation on fermentation kinetics and sensory property of black raspberry wines[J]. Food Microbiology,2020,91:103551. doi: 10.1016/j.fm.2020.103551

[25] 周洪江, 姜文广, 阮仕立, 等. 三种非酿酒酵母对贵人香白葡萄酒发酵进程及挥发性组分的影响[J]. 食品工业科技,2022,43(20):163−172. [ZHOU H J, JIANG W G, RUAN S L, et al. Influence of three non-saccharomyces yeasts on fermentation and volatile components of italian riesling white wines[J]. Science of Technology of Food Industry,2022,43(20):163−172.] ZHOU H J, JIANG W G, RUAN S L, et al. Influence of three non-saccharomyces yeasts on fermentation and volatile components of italian riesling white wines[J]. Science of Technology of Food Industry, 2022, 43(20): 163−172.

[26] LI H M, JIANG D Q, LIU W L, et al. Comparison of fermentation behaviors and properties of raspberry wines by spontaneous and controlled alcoholic fermentations[J]. Food Research International,2020,128(C):108801−108801.

[27] REBECCA B, SEBASTIAN S, SASCHA R, et al. Gas-phase volatilomic approaches for quality control of brewing hops based on simultaneous GC-MS-IMS and machine learning[J]. Analytical and Bionanlytical Chemistry,2020,412(26):7085−7097. doi: 10.1007/s00216-020-02842-y

[28] LI S Y, YANG H F, TIAN H H, et al. Correlation analysis of the age of brandy and volatiles in brandy by gas chromatography-mass spectrometry and gas chromatography-ion mobility spectrometry[J]. Microchemical Journal,2020,157(18):489−492.

[29] CHEN K, LI S Y, YANG H F, et al. Feasibility of using gas chromatography-ion mobility spectrometry to identify characteristic volatile compounds related to brandy aging[J]. Journal of Food Composition and Analysis,2021,98(24):103812−103812.

[30] 皇甫洁. 焦香特种麦芽的鉴别[J]. 啤酒科技,2019(95):58−62. [HUANG P J. Identification of special malt with scorched aroma[J]. Beer Science and Technology,2019(95):58−62.] HUANG P J. Identification of special malt with scorched aroma[J]. Beer Science and Technology, 2019(95): 58−62.

[31] 蒋孝峰, 谢辉, 陆兔林, 等. 基于Heracles Neo 超快速气相电子鼻技术的麦芽炒制过程气味变化物质基础研究[J]. 中草药,2022,53(1):42−50. [JIANG X F, XIE H, LU T L, et al. Study on material basis of odor changes in stir-frying process of Hordei Fructus germinatus based on Heracles Neo ultra-fast gas phase electronic nose technology[J]. Chinese Traditional and Herbal Drugs,2022,53(1):42−50.] JIANG X F, XIE H, LU T L, et al. Study on material basis of odor changes in stir-frying process of Hordei Fructus germinatus based on Heracles Neo ultra-fast gas phase electronic nose technology[J]. Chinese Traditional and Herbal Drugs, 2022, 53(1): 42−50.

[32] 海绪成. 焦香麦芽特征风味及其在焙焦过程中变化规律研究[D]. 扬州:扬州大学, 2019. [HAI X C. Study on the characteristic flavor of coke malt and its variation in the process of roasting[D]. Yangzhou:Yangzhou University, 2019.] HAI X C. Study on the characteristic flavor of coke malt and its variation in the process of roasting[D]. Yangzhou: Yangzhou University, 2019.

[33] 金文刚, 赵萍, 金晶, 等. 基于气相-离子迁移谱分析大鲵不同可食部位挥发性成分指纹差异[J]. 食品科学,2022,43(2):303−309. [JIN W G, ZHAO P, JIN J, et al. Characterization of volatile organic compounds of giant salamander (Andrias davidianus) oil adulterated with different amount of peanut oil by gas chromatography-ion mobility spectrometry combined with chemometrics[J]. Food Science,2022,43(2):303−309.] doi: 10.7506/spkx1002-6630-20201102-010 JIN W G, ZHAO P, JIN J, et al. Characterization of volatile organic compounds of giant salamander (Andrias davidianus) oil adulterated with different amount of peanut oil by gas chromatography-ion mobility spectrometry combined with chemometrics[J]. Food Science, 2022, 43(2): 303−309. doi: 10.7506/spkx1002-6630-20201102-010

-

期刊类型引用(1)

1. 邓思琪. 啤酒中挥发性有机化合物的分析存在的问题与应对策略. 食品安全导刊. 2024(24): 141-143 .  百度学术

百度学术

其他类型引用(2)

下载:

下载:

下载:

下载: