Changes of Volatile Flavor Substances of Beeves in Spoilage Process Based on Gas Chromatography–Ion Mobility Spectrometry and Electronic Nose

-

摘要: 为探究牛肉腐败进程中挥发性风味物质的变化规律,本研究以不同保藏时间的牛肉为研究对象,通过气相色谱-离子迁移谱(GC-IMS)技术和电子鼻分析其挥发性风味物质。结果表明,通过GC-IMS共检出55种挥发性风味物质,主要包括12种酮类物质、10种醇类物质、9种酯类物质、8种醛类物质和4种烃类物质。GC-IMS和电子鼻分析表明,牛肉腐败过程中挥发性风味物质含量呈显著上升趋势,其中醇类、醛类、酯类、酸类、呋喃、吡咯、噻唑、胺类、吡嗪和醚类物质持续增加;酮类、烃类和含硫化合物逐渐增加,在第7 d时达到峰值,而后逐渐下降。PCA和PLS-DA分析表明,牛肉腐败过程中挥发性风味物质发生了显著性变化。通过VIP值共筛选出16个差异性风味物质,随着保藏时间的延长,正己醛-D、正己醛-M、丁醛-M、丁醛-D、四氢吡咯-M、异戊醇-D、异戊醇-M、正丙醇-D、2,3-丁二酮等刺激性、不愉快风味物质的含量逐渐增加,可作为区分牛肉腐败进程的潜在生物标志物。本研究为牛肉腐败进程的监测提供一定的理论依据。

-

关键词:

- 牛肉 /

- 腐败 /

- 挥发性风味物质 /

- 气相色谱-离子迁移谱

Abstract: In order to investigate the changes of volatile flavor substances in the process of beeves spoilage, beeves with different storage time were employed. The volatile flavor substances of beeves in spoilage process were analyzed by using gas chromatography ion transfer spectroscopy (GC-IMS) and electronic nose. The results showed that a total of 55 volatile flavor substances were detected through GC-IMS, mainly including 12 ketones, 10 alcohols, 9 esters, 8 aldehydes and 4 hydrocarbons. GC-IMS and electronic nose analysis indicated that the types and contents of volatile flavor substances significantly increased during the spoilage process. The alcohols, aldehydes, esters, acids, furans, pyrroles, thiophenes, amines, pyridines and ethers continuously increased during the spoilage process. However, ketones, hydrocarbons, and sulfur compounds gradually increased and reached peak at the seventh day, and then gradually decreased. PCA and PLS-DA analysis suggested that there were significant differences in volatile flavor substances of beeves in spoilage process. Sixteen different volatile flavor substances were identified by variable importance for the projection (VIP) value, with the extension of storage, the contents of irritating and unpleasant flavor substances such as n-hexanal-D, n-hexanal-M, butyraldehyde-M, butyraldehyde-D, tetrahydropyrrole-M, isoamyl-D, isoamyl-M, n-propanol-D, 2,3-butanedione gradually increased, which could be used as potential biomarkers to distinguish beeves with different degrees of spoilage. This work provides a theoretical basis for monitoring beef spoilage process. -

牛肉产业是我国畜牧业和肉类产业的重要组成部分,随着中国经济的快速发展,牛肉产业得以快速发展[1]。中国已成为世界第三大牛肉生产国,2022年牛肉年产量达767万吨,牛肉产值约6780亿元[2]。由于鲜牛肉富含蛋白质、脂肪,在贮藏运输过程中极易受到微生物污染而发生腐败变质[3−4]。肉品腐败变质导致每年20%的肉品浪费,造成了严重的经济损失,并显著增加了食物中毒的发生率,极大地制约了我国牛肉产业的发展。牛肉腐败变质通常表现为异味、发黏、变色和变软等,其中由微生物产生的挥发性化合物是肉品腐败异味的主要来源[5]。挥发性盐基氮、菌落总数等是反映牛肉等肉品腐败的重要指标。牛肉等肉品腐败周期一般为7~10 d[6]。

肉品腐败气味是微生物生长代谢的结果,微生物及其代谢途径的不同将直接决定肉制品腐败气味[7]。新鲜牛肉中常见的初始挥发性风味成分主要有己醛、2-丁酮、1-辛烯-3-醇等[8],微生物产生的挥发性代谢物包括有机酸、挥发性脂肪酸、乙酯、硫化物、酮、醛、醇、氨等[9],所有挥发性代谢物共同作用构成了牛肉腐败气味。以莓实假单胞菌(Pseudomonas fragi)和恶臭假单胞菌(Pseudomonas putida)为主的假单胞菌是牛肉中的优势腐败菌,在生长过程中会释放大量的乙酸乙酯、辛酸乙酯、二硫化碳、壬醛、庚醛和己醇等挥发性化合物[10−11]。此外,热死环丝菌是牛肉中的优势腐败菌。2-甲基丁酸和3-甲基丁酸是热死环丝菌在有氧条件下的特殊代谢物[12],具有浓烈的汗臭和腐臭味[13],对肉制品风味有不良影响。腐败气味是消费者评判鲜肉腐败的重要指标,Argyri等[8]研究发现2-戊酮、2-壬酮、2-甲基-1-丁醇、3-甲基-1-丁醇、己酸乙酯、丙酸乙酯、乳酸乙酯、乙酸乙酯、乙醇、2-庚酮、3-辛酮、双乙酰和乙偶姻是牛肉腐败过程中可能的腐败标志物。

腐败牛肉的风味大多通过GC-MS定性和定量检测。近年来,气相色谱-离子迁移谱(GC-IMS)越来越多地用于食品工业中的风味表征,它结合了GC优异的分离能力与IMS的高灵敏度和快速响应,具有高灵敏性、高分辨率和快速分析的特点[14−15],可以有效和直观地区分产品之间的风味差异并且提高了定性分析的准确性。目前,尚未发现利用GC-IMS分析牛肉腐败进程的研究报道。本研究利用GC-IMS分析牛肉腐败进程的挥发性风味组成,以期精准揭示牛肉腐败过程中不良风味的变化规律,为牛肉腐败进程的监测提供一定的理论依据。

1. 材料与方法

1.1 材料与仪器

新鲜牛上脑肉 购自成都市龙泉驿区平安批发市场,屠宰后2 h内低温运送至实验室。

Flavour Spec®气相-离子迁移谱仪 德国G.A.S公司;PEN3电子鼻系统 德国Airsense公司;GL224I-1SCN型电子天平 赛多利斯科学仪器(北京)有限公司。

1.2 实验方法

1.2.1 试样制备方法

选用12月龄西门塔尔牛后颈部位牛上脑瘦肉作为实验材料,将牛肉切分为约400 g/块的肉块,进行托盘包装,将肉样置于普通塑料托盘,用透明高阻隔塑料袋包裹。后于4 ℃分别保存0、3、7和10 d,分别命名为D0、D3、D7和D10。

1.2.2 GC-IMS检测

将牛肉粉碎后真空保存于铝箔袋中,−40 ℃保存备用。精确称取3 g样品于20 mL顶空进样瓶中,密封,自动进样器参数设置为:顶空瓶孵化温度60 ℃,孵化时间15 min,孵化速度500 r/min,进样针温度85 ℃,进样体积500 μL,每个样品设3个重复。

气相色谱相关参数为:色谱柱MXT-WAX(30 m×0.53 mm),色谱柱温度:60 ℃,载气:N2(纯度>99.999%),运行时间:30 min,载气起始流速2 mL/min,保持2 min,2~5 min流速为10 mL/min,5~15 min流速为15 mL/min,15~20 min流速为50 mL/min,20~25 min流速为100 mL/min。

离子迁移谱参数:电离源为氚,载气:N2(纯度>99.999%),漂移管长度:10 cm,管内电压:400 V/cm,漂移气流速:150 mL/min,IMS探测器温度:45 ℃。

定性:利用GC-IMS系统自带软件VOCal根据保留时间、漂移时间进行挥发性化合物的定性分析。

定量:通过GC-IMS物质峰峰体积进行定量。

1.2.3 电子鼻检测

精确称取3 g粉碎后的牛肉试样于20 mL顶空瓶中,密封,室温平衡30 min,取顶空气体进行检测。样品检测时间120 s,清洗时间60 s,自动调零5 s,进样流量600 mL/min,每个样品平行测定5次。PEN3电子鼻传感器信息如表1所示。

表 1 PEN3电子鼻传感器名称及其性能描述Table 1. PEN3 sensors name and performance description序号 传感器名称 性能 1 S1 对芳香族化合物敏感 2 S2 对氮氧化物敏感 3 S3 对氨和芳香族化合物敏感 4 S4 对氢气(氢化物)敏感 5 S5 对碳氢化合物和芳香族化合物敏感 6 S6 对甲基类化合物敏感 7 S7 对硫化物和萜烯敏感 8 S8 对醇类和醛酮类化合物敏感 9 S9 对芳香族成分和有机硫化合物敏感 10 S10 对碳氢化合物敏感 1.3 数据处理

利用Microsoft office 2021进行数据处理;PCA和OPLS-DA分析通过SIMCA(14.1)完成;挥发性风味物质峰体积柱状图和电子鼻雷达图由Origin 2021绘制。聚类分析通过R(v4.2.3)完成。

2. 结果与分析

2.1 牛肉腐败进程中挥发性成分谱图分析

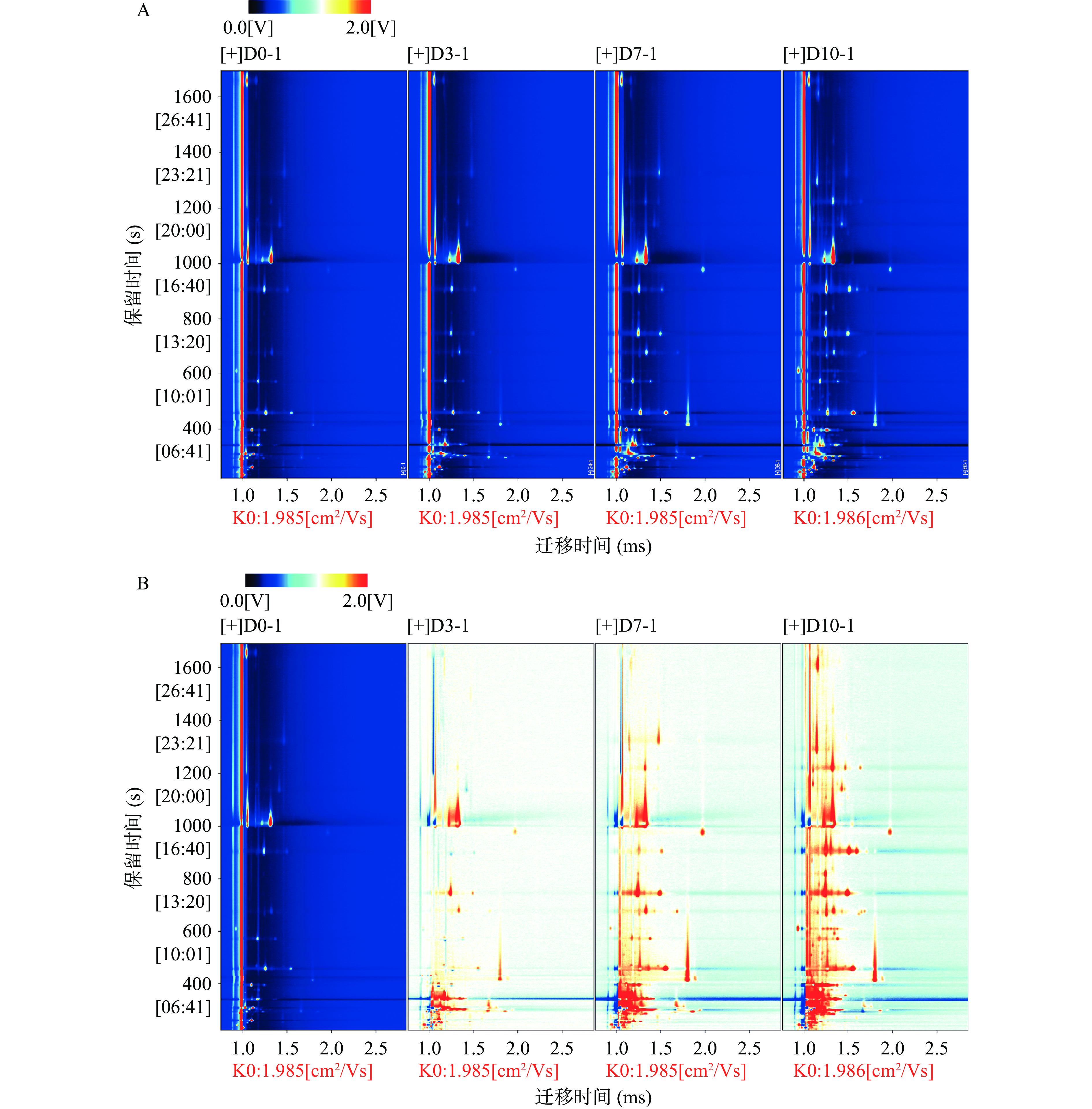

通过GC-IMS技术测定了牛肉腐败进程的挥发性风味成分,挥发性风味谱图如图1A所示,横坐标为化合物的离子迁移时间,纵坐标为挥发性化合物的保留时间,横坐标1.0处的红色竖线为归一化后的反应离子峰(RIP峰)[16]。图中每个点代表一种化合物,红色代表该物质的含量较高,蓝色代表该物质的含量较低。图中各点间分离明显,无交叉重合,说明GC-IMS能较好地分离牛肉腐败进程的挥发性风味成分。随着时间的延长,谱图中的亮点数目和大小不断增加,说明在腐败过程中牛肉的挥发性风味成分种类和含量逐渐增加,为更直观地分析腐败过程中牛肉风味的变化情况,以D0-1为对照,各组样品扣除对照,若挥发性风味成分含量相近则扣除背景后为白色,若挥发性风味成分含量高于或低于对照,则扣除背景后为红色或蓝色,如图1B所示。各组样品挥发性风味组成存在显著差异,随着时间的延长,图中红色区域面积不断增加,说明腐败过程中,风味物质含量显著增加。

2.2 挥发性化合物指纹图谱分析

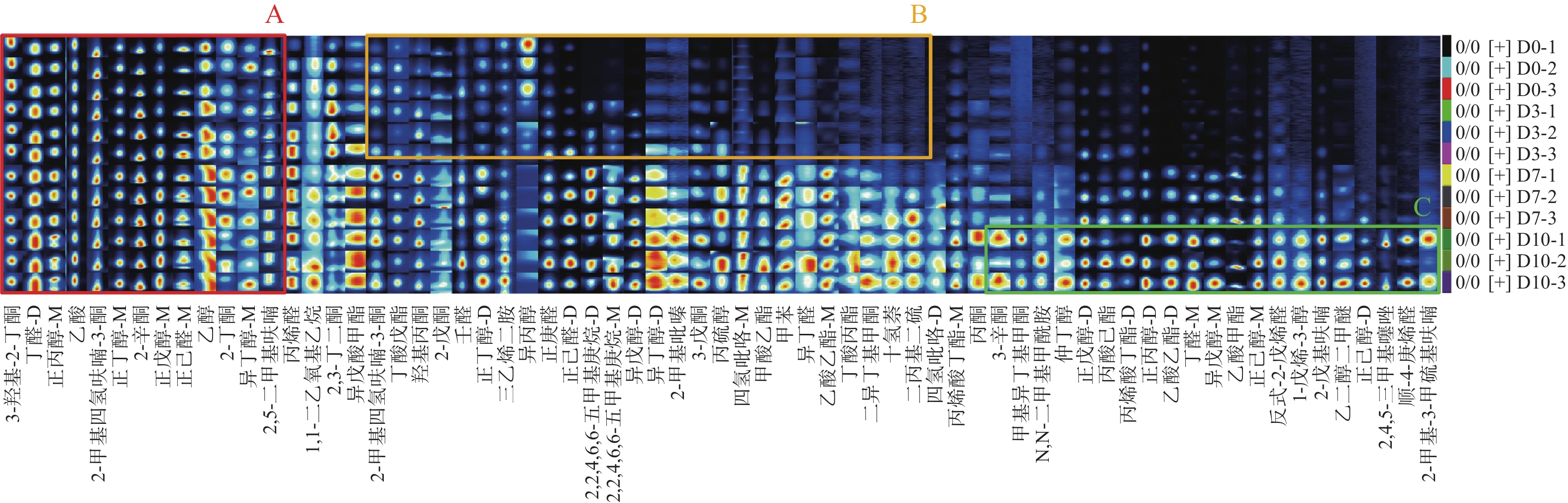

选取所有定性峰,利用GC-IMS系统内置的Gallery Plot插件绘制牛肉腐败进程的挥发性风味物质指纹图谱,如图2所示。通过指纹图谱,可以直观地对比4组牛肉在风味物质组成和含量上的共性和差异。图中同一行为一个样品检出的挥发性成分组成情况,同一列为同一挥发性风味成分在不同样品中的信号峰情况,信号峰颜色的明亮程度代表了对应风味化合物含量的高低。图中A区域是4种共有且差异相对较小的挥发性风味成分,主要包括3-羟基-2丁酮、丁醛-D、2-甲基四氢呋喃-3-酮和乙酸等;B区域是D0和D3样品中含量较低,D7和D10样品中含量较高的挥发性化合物,主要包括异丁醇-D、异丁醛、乙酸乙酯-M和甲苯等;C区域为D10样品含量相对较高的挥发性化合物,主要包括2-甲基-3-甲硫基呋喃、乙二醇二甲醚、丁醛-M和正丙醇-D等。

2.3 挥发性化合物定性及定量分析

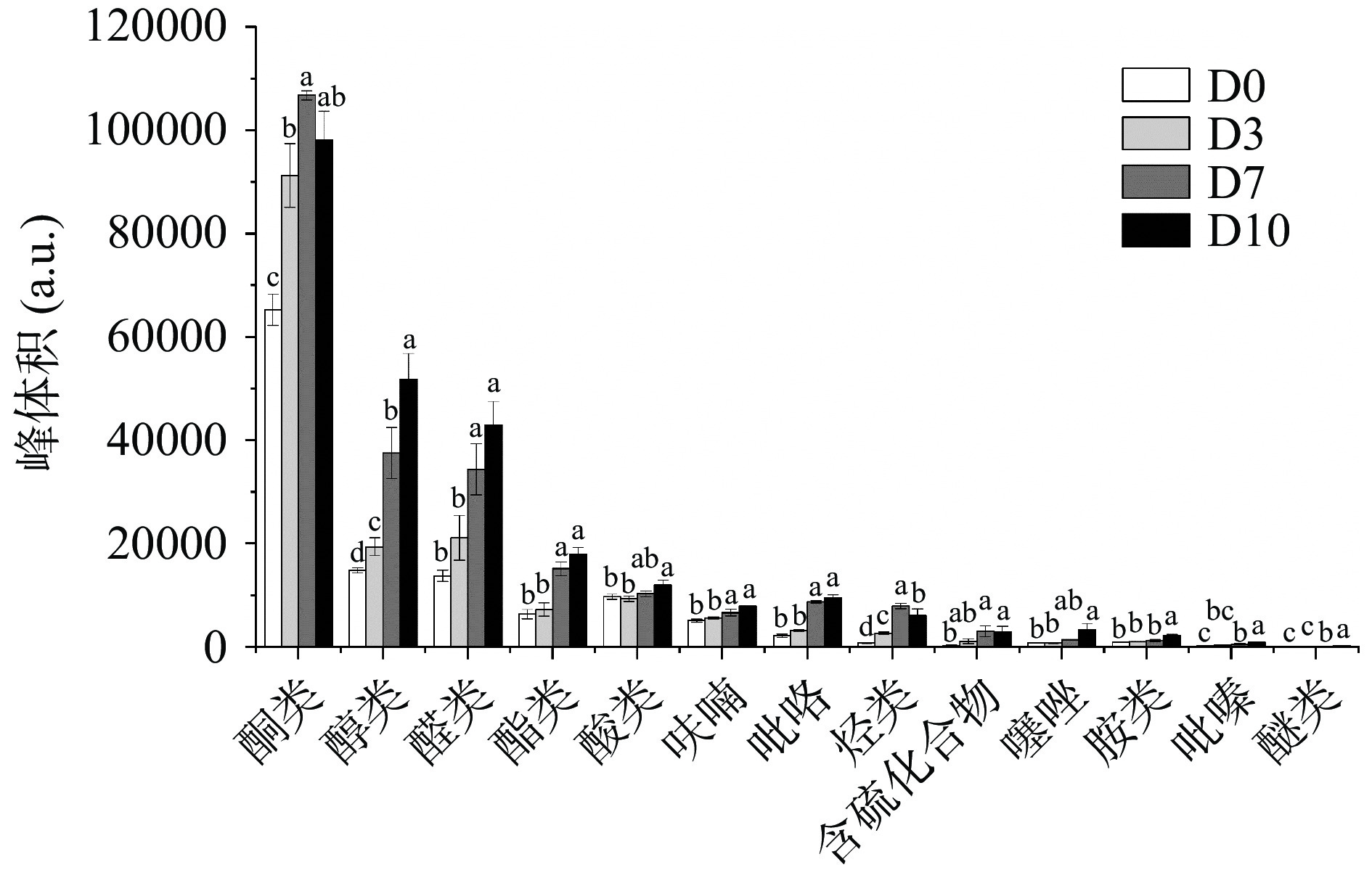

采用保留时间和离子迁移时间对挥发性化合物进行定性分析,利用IMS系统峰体积进行定量分析,结果如表2所示。利用GC-IMS技术从4个牛肉样品中共检出67个物质峰,一些化合物可以以二聚体或三聚体的形式存在,从而产生部分信号峰[17]。通过GC-IMS系统内置的NIST 2014和IMS数据库对检出的67个峰进行鉴定,检出55种挥发性风味化合物,其中12种挥发性化合物存在单倍体和二聚体(正己醇、异戊醇、正丙醇、正丁醇、正戊醇、异丁醇、丙烯酸丁酯、乙酸乙酯、丁醛、正己醛、四氢吡咯和2,2,4,6,6-五甲基庚烷)。酮类物质12种、醇类物质10种、酯类物质9种、醛类物质8种、烃类物质4种、呋喃化合物3种、含硫化合物和胺类物质各2种、吡咯、醚类、噻唑、酸类和吡嗪类物质各1种。如图3所示,各类风味物质在腐败过程中均有显著增加。

表 2 牛肉腐败进程中挥发性风味物质Table 2. VOCs of beeves spoilage process序号 化合物种类及名称 CAS RI RT

(min)DT

(ms)峰体积(a.u) D0 D3 D7 D10 A1 醇类 异丙醇 67-63-0 931.7 306.941 1.08831 520.35±97.27a 215.83±36.89b 79.19±37.91c 152.84±30.70bc A2 乙醇 64-17-5 942.1 312.924 1.12888 2636.34±170.78c 4379.72±424.92b 5313.26±152.40a 5036.93±164.20a A3 仲丁醇 78-92-2 1028.7 381.419 1.14981 72.10±6.27c 93.66±13.15c 252.50±6.98b 568.69±67.65a A4 正丙醇-D 71-23-8 1044.7 399.803 1.24883 646.98±103.50c 565.89±20.00c 1835.43±30.24b 5819.81±940.28a A5 正丙醇-M 71-23-8 1044.7 399.803 1.11204 2655.54±251.01c 2462.51±100.54c 3763.96±81.39b 4524.69±72.58a A6 异丁醇-D 78-83-1 1097.6 461.304 1.36762 122.06±22.74b 256.52±121.20b 682.95±167.50a 863.90±141.58a A7 异丁醇-M 78-83-1 1101.8 470.853 1.17240 400.44±126.61b 467.19±28.30bc 585.43±31.39a 475.45±102.88bc A8 正丁醇-D 71-36-3 1147.5 574.081 1.38348 265.08±58.75b 223.50±2.63b 489.36±85.29a 627.78±126.92a A9 正丁醇-M 71-36-3 1147.5 574.081 1.18332 2192.66±125.63b 1974.50±33.31b 2785.49±124.12a 2934.42±279.92a A10 1-戊烯-3-醇 616-25-1 1157.3 596.104 1.35001 48.80±8.57c 56.07±7.39bc 79.27±15.73b 249.56±26.97a A11 异戊醇-M 123-51-3 1214.3 748.874 1.49567 183.41±14.95b 277.44±45.68b 2358.99±461.41a 3726.41±1971.03a A12 异戊醇-D 123-51-3 1214.7 750.432 1.24934 451.52±36.59b 1888.82±335.87b 6682.02±583.79a 7749.64±1705.49a A13 正戊醇-D 71-41-0 1262.1 908.547 1.51394 708.00±151.71c 1154.81±732.43c 2772.38±1490.23b 4816.31±379.89a A14 正戊醇-M 71-41-0 1262.6 910.056 1.25493 3062.55±465.05b 4239.92±1643.61b 6668.44±1886.33a 8665.77±200.58a A15 正己醇-D 111-27-3 1363.7 1224.347 1.64693 324.62±40.99b 315.28±19.17b 471.34±177.22b 947.37±268.69a A16 正己醇-M 111-27-3 1363.7 1224.347 1.33069 560.07±37.84c 846.28±194.58c 2724.47±1302.31b 4735.02±808.51a B1 酮类 丙酮 67-64-1 825.8 246.220 1.12123 9.92±2.69c 29.03±1.13bc 43.88±6.92b 94.80±29.42a B2 2-丁酮 78-93-3 917.4 298.752 1.05977 623.55±74.30b 588.93±33.10b 822.75±100.65a 498.49±136.57b B3 2,3-丁二酮 431-03-8 996.9 344.817 1.17998 2934.18±1091.89b 5598.47±933.03a 5490.03±728.46a 4037.02±820.00ab B4 2-戊酮 107-87-9 997.1 345.087 1.12164 1016.96±197.11c 1611.60±77.74b 1876.25±238.16ab 2126.76±52.18a B5 3-戊酮 96-22-0 997.2 345.219 1.35880 258.71±131.51d 791.14±245.08c 1299.75±398.34b 1959.10±277.55a B6 甲基异丁基

甲酮108-10-1 1009.5 359.320 1.47891 69.14±1.90b 77.93±10.35b 121.94±36.85b 246.11±55.10a B7 二异丁基甲酮 108-83-8 1214.4 749.377 1.32300 159.02±13.11b 198.07±17.49b 541.77±74.40a 728.11±231.34a B8 3-辛酮 106-68-3 1264 914.879 1.30920 309.20±23.54b 368.37±133.93b 562.29±167.57b 1316.39±413.30a B9 3-羟基-2-丁酮 513-86-0 1289.8 1000.890 1.06948 3301.62±77.31a 2905.06±131.56b 2674.94±25.16c 2840.25±126.85bc B10 羟基丙酮 116-09-6 1294.4 1016.226 1.23288 5699.53±279.40c 8982.49±1052.62b 11003.09±506.78a 9571.10±879.20b B11 2-辛酮 111-13-7 1295.1 1018.546 1.3294 26014.51±1920.04c 41501.87±4630.23b 50207.38±827.20a 44571.63±3530.74b B12 2-甲基四氢呋喃-

3-酮3188-00-9 1304.5 1046.930 1.06879 24924.32±268.13c 28602.11±1485.26b 32165.60±733.07a 30110.38±1867.32ab C1 酯类 甲酸乙酯 109-94-4 825.5 246.033 1.08638 83.57±30.10b 297.14±30.13b 1192.77±218.89a 1352.45±542.41a C2 乙酸甲酯 79-20-9 849.5 259.803 1.19855 116.15±3.48c 171.14±17.46c 779.54±128.03a 509.56±240.47a C3 乙酸乙酯-D 141-78-6 899 288.208 1.33453 44.39±2.95c 51.38±7.45c 950.49±147.22b 2028.50±244.46a C4 乙酸乙酯-M 141-78-6 900 288.778 1.09765 118.73±42.51b 243.85±13.78b 1292.15±81.87a 1333.72±144.70a C5 异戊酸甲酯 556-24-1 1027.9 380.543 1.19072 200.88±27.79b 338.79±120.37b 615.55±142.36a 726.12±138.87a C6 异丁酸异

丁酯97-85-8 1062.4 420.154 1.80405 1170.72±548.03b 983.37±469.80ab 2257.79±717.83ab 2226.11±673.34a C7 丁酸丙酯 105-66-8 1148.2 575.662 1.26304 105.09±14.21b 130.27±49.64b 340.90±97.26a 444.04±138.03a C8 丙烯酸丁酯-M 141-32-2 1189.4 668.656 1.26216 489.74±81.92c 669.57±186.32c 1237.26±356.11b 1857.04±58.72a C9 丙烯酸丁酯-D 141-32-2 1193.5 679.560 1.69325 140.08±12.47d 301.38±164.75c 722.30±103.54b 937.59±179.80a C10 丁酸戊酯 540-18-1 1283.4 979.581 1.97539 3346.16±448.65a 3319.81±464.08a 4171.68±459.75a 3865.73±428.80a C11 丙酸己酯 2445-76-3 1336.5 1142.707 1.42805 564.88±123.67b 727.45±482.45b 1590.88±797.28ab 2639.81±932.10a D1 醛类 异丁醛 78-84-2 811.2 237.813 1.09711 39.40±3.31b 55.00±17.70b 153.82±21.32a 178.73±88.50a D2 丙烯醛 107-02-8 843 256.046 1.06091 792.28±218.23b 1514.68±310.46a 1766.58±35.51a 1571.35±145.72a D3 丁醛-D 123-72-8 864.8 268.569 1.11426 5441.62±157.39c 7129.34±603.03b 7515.13±129.33b 10026.21±1506.57a D4 丁醛-M 123-72-8 915 297.350 1.25327 470.35±95.05c 844.21±152.96c 3080.32±837.26b 8224.03±1765.30a D5 正己醛-D 66-25-1 1097.8 461.736 1.56130 1034.07±228.52b 3404.65±2709.91ab 9248.99±3692.75a 9586.41±4765.92a D6 正己醛-M 66-25-1 1098.7 463.807 1.27008 2919.85±384.72b 4425.37±1239.99ab 6070.34±944.19a 6079.29±1261.01a D7 反式-2-戊

烯醛1576-87-0 1136.6 549.392 1.10700 78.10±6.86c 105.11±16.43bc 144.92±35.91b 288.84±51.63a D8 正庚醛 111-71-7 1193.3 678.781 1.34043 1026.79±273.54b 1958.69±682.93ab 3183.55±602.00a 3296.19±1222.25a D9 顺-4-庚烯醛 6728-31-0 1262 908.163 1.60127 344.32±6.07b 350.53±29.54b 437.42±115.36b 1334.91±569.15a D10 壬醛 124-19-6 1398.9 1329.801 1.47986 1637.24±602.92a 1341.92±303.46a 2798.61±76.03a 2413.55±1424.49a E1 烃类 1,1-二乙氧基乙烷 105-57-7 889.1 282.516 1.04394 214.11±36.13a 197.20±17.35a 210.85±31.75a 227.81±36.77a E2 2,2,4,6,6-五甲基

庚烷-M13475-82-6 927.2 304.353 1.32478 94.37±26.67c 662.42±96.37b 1805.92±236.12a 2009.57±244.44a E3 2,2,4,6,6-五甲基

庚烷-D13475-82-6 927.7 304.643 1.40232 142.48±41.71d 1403.34±189.00c 4605.53±297.26b 2618.14±1233.68a E4 甲苯 108-88-3 1052.3 408.558 1.04598 305.16±44.92b 394.28±38.83b 1128.70±161.30a 978.60±103.27a E5 十氢萘 91-17-8 1164.4 612.114 1.26939 41.02±8.84b 57.30±28.50b 166.36±84.35a 254.71±50.19a F1 呋喃 2,5-二甲基呋喃 625-86-5 947.7 316.113 1.04120 4861.95±385.88c 5314.77±295.19bc 5763.98±522.24ab 6095.40±334.42a F2 2-戊基呋喃 3777-69-3 1236 821.304 1.25062 215.85±12.63c 298.71±119.02c 778.87±293.45b 1593.80±280.80a F3 2-甲基-3-甲硫基

呋喃63012-97-5 1342.3 1160.071 1.10794 45.04±6.41b 57.76±9.62b 94.77±7.83b 223.76±107.16a G1 含硫

化合物丙硫醇 107-03-9 843.1 256.103 1.14261 162.59±106.01b 1030.26±604.80ab 2756.88±1128.83a 2487.64±1305.72a G2 二丙基二硫 629-19-6 1363.7 1224.347 1.47588 89.72±9.46b 91.01±14.06b 313.42±166.54a 460.01±12.72a H1 胺类 N,N-二甲基甲酰胺 68-12-2 1325.2 1108.857 1.25602 81.32±8.37c 104.70±14.68bc 182.54±32.42b 320.92±88.03a H2 三乙烯二胺 280-57-9 1509.4 1661.185 1.16265 848.25±19.64b 875.93±40.81b 1069.55±224.27b 1831.65±347.76a I1 吡咯 四氢吡咯-D 123-75-1 1010.2 360.184 1.28101 28.99±4.80b 41.86±13.92b 208.58±68.53a 283.65±68.91a I2 四氢吡咯-M 123-75-1 1021.5 373.102 1.04116 2179.67±404.59c 3126.32±207.51b 8534.37±212.28a 9204.86±714.87a J1 吡嗪 2-甲基吡嗪 109-08-0 1261.2 905.624 1.40956 224.50±26.41c 301.65±107.21c 542.53±191.90b 903.61±91.25a K1 醚类 乙二醇二甲醚 110-71-4 906.7 292.582 1.29012 19.18±5.85c 21.84±6.35c 92.41±19.73b 256.23±42.83a L1 噻唑 2,4,5-三甲基噻唑 13623-11-5 1387.5 1295.756 1.15503 820.04±81.77b 786.82±98.13b 1383.54±24.08b 3323.61±1565.01a M1 酸类 乙酸 64-19-7 1510.2 1663.479 1.05634 9747.76±597b 9361.83±626.33b 10312.96±660.74b 12065.69±1067.15a 注:同行不同小写字母表示存在显著性差异(P<0.05)。 酮类物质是四个时间段最高的挥发性风味物质,主要由来自脂肪酸的自动氧化和革兰氏阴性菌对脂质的水解作用,是肉类腐败过程中的主要挥发性风味之一[18]。本研究中共检出12种酮类物质,其含量在腐败过程中上升,在第7 d达到峰值106809.68 a.u,而后逐渐下降至98100.15 a.u,可能是由于假单胞菌等腐败菌在腐败过程中快速生长繁殖,引起脂质氧化所致[7]。丙酮[19]、2-戊酮[20]等被认为是肉制品腐败气味的重要贡献者,在腐败过程中含量持续上升,其中丙酮在腐败过程中从9.92 a.u上升至94.80 a.u,2-戊酮由1016.96 a.u增加至2126.76 a.u,可能是由热死环丝菌在有氧条件下大量生长繁殖产生[21]。

醇类物质是腐败牛肉中种类最丰富的挥发性化合物,醇类物质主要来源于碳水化合物发酵、甲基酮还原、氨基酸代谢和脂质氧化等多种途径[22]。本研究共从4组检出10种醇类物质,除异丙醇外其它醇类物质在腐败过程中均有不同程度的显著上升,醇类物质总量从14850.50 a.u显著上升至51894.59 a.u(P<0.05),可能是由于腐败微生物在腐败过程中快速生长发酵产生[7]。乙醇具有辛辣的刺激性气味[23],是牛肉腐败过程中的重要标记物[24]。本研究中,随着腐败时间的延长,乙醇含量从2636.34 a.u显著上升至5036.93 a.u(P<0.05),与Zareian等[25]研究结果一致。1-戊烯-3-醇主要来源于脂肪氧化,能显著增加肉品腥味[26],本研究中1-戊烯-3-醇在腐败过程中从48.80 a.u显著增加至249.56 a.u(P<0.05),对牛肉风味有不良影响。

醛类物质通常阈值较低且气味具有叠加作用,对肉品风味有重要影响[27],主要来源于脂质氧化和不饱和脂肪酸的氧化裂解[28]。本研究中,共检出8种醛类物质,其含量均在腐败过程中逐渐增加,醛类物质总含量从13784.02 a.u显著上升至42999.50 a.u(P<0.05),说明在腐败过程中,牛肉脂质氧化程度加深。己醛和壬醛是肉制品中最常见的醛类物质,主要通过亚油酸等不饱和脂肪酸的氧化产生[29],被认为是脂肪氧化的重要指标,其含量在腐败过程中分别从显著上升,说明腐败过程中不饱和脂肪酸氧化加剧。

酯类物质阈值较低且气味浓郁,是肉制品重要的挥发性风味来源,主要来源于醇和酸在非酶催化下的酯化反应以及微生物作用下的酶催化酯化反应[30]。本研究中酯类物质含量在腐败过程中呈显著的上升趋势,酯类物质总含量从6380.40 a.u显著上升至17920.68 a.u(P<0.05),可能是由于在腐败过程中,牛肉在微生物的作用下产生醇类和酸类物质,进一步经酯化反应后生成酯类物质[31]。乙酸乙酯是自然腐败肉中的主要酯类物质[32],具有刺激性气味[33],本研究中乙酸乙酯含量随着保藏时间的增加而增加,与郭依萍等[34]的研究结果一致。此外,从腐败牛肉中检出了具有刺激性气味的丙烯酸丁酯,在腐败过程中含量增加。

含硫化合物主要来源于含硫氨基酸的降解,如甲硫氨酸和半胱氨酸[35]。本研究中共检出了2种含硫化合物,分别为丙硫醇和二丙基二硫,其中二丙基二硫在腐败初期变化不大,随着腐败的加深其含量分别从 1030.26 a.u 和 91.01 a.u 上升至 2487.64 a.u 和 460.01 a.u,与张凡等[36]研究结果一致。此外,乙酸是四组牛肉中唯一的酸类物质,乙酸主要来源于微生物作用下的碳水化合物代谢[37],具有强烈的刺激性酸味[38],是腐败肉酸臭味的重要来源。在腐败前期,乙酸含量较为稳定,但在腐败中后期,乙酸含量从10312.96 a.u显著上升至12065.69 a.u(P<0.05),可能是由于腐败前期乙酸被用于乙酯类物质的合成,而醋酸菌在腐败中后期大量利用碳水化合物代谢产生的乙醇产生乙酸所致[39]。

2.4 多元统计分析

2.4.1 主成分分析

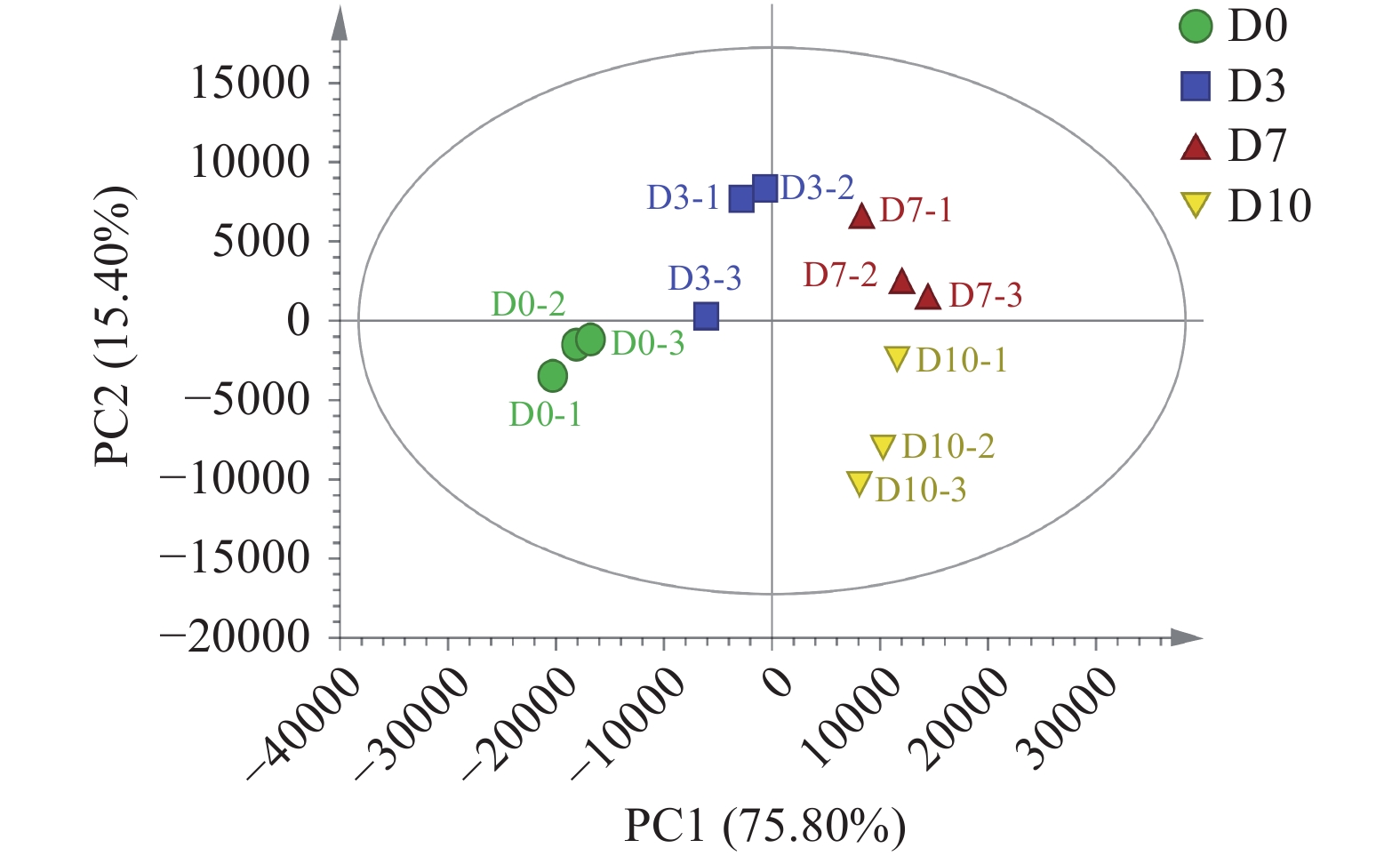

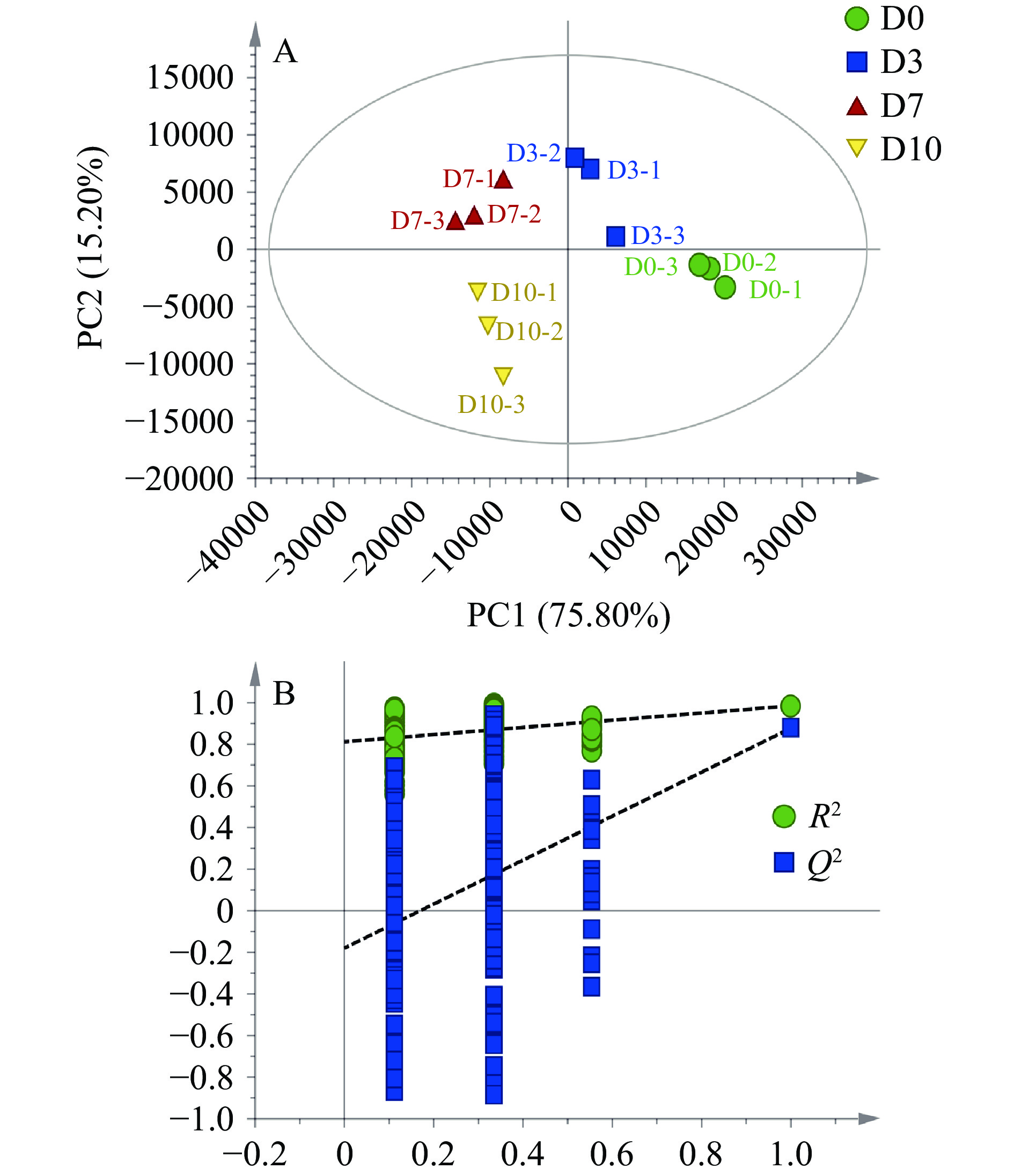

为进一步明确牛肉腐败进程中挥发性风味成分的差异,以挥发性风味物质峰体积为数据源,进行PCA分析。结果如图4所示,所建立的主成分模型将风味分为2个主成分,其中主成分1贡献率为75.80%,主成分2贡献率为15.40%,累计贡献率达91.20%,表明所建立的PCA模型能较好地反映不同样品间的风味差异。4个样本的12个样本点分别位于坐标系的不同位置,各组间分离明显,无交叉重合,说明牛肉腐败进程的风味差异显著,与指纹图谱分析结果相互印证。在主成分1上D0和D3分布较为接近,D7和D10分布较为接近,表明D0和D3风味较为接近,D7和D10风味较接近。

2.4.2 PLS-DA分析

为进一步分析牛肉腐败进程的挥发性风味差异,通过PLS-DA对牛肉腐败进程的风味进行分析,结果如图5A所示,所建立的PLS-DA模型累计累积可以解释91.00%的原始变量,说明该模型很好地反映了样品的整体情况[40]。4个样本的12个样本点均位于95%的置信区间内,组间分离明显,无交叉重合,说明牛肉腐败进程的风味差异显著,所建立的PLS-DA模型能较好地区分4种进程。

为了进一步验证模型是否出现过拟合现象,采用200次循环迭代置换检验,结果如图5B所示。Q2的回归线与Y轴的焦点都在负半轴,表明PLS-DA模型稳定可靠,不存在过拟合现象。

2.4.3 差异风味物质筛选

通过PLS-DA的变量投影重要度(variable importance for the projection,VIP)对牛肉腐败进程中的差异风味物质进行筛选,结果如表3所示。以VIP>1为筛选标准[41],共筛选出16种差异风味物质,可作为区分牛肉腐败进程的潜在生物标志物,分别为2-辛酮、正己醛-D、丁醛-M、四氢吡咯-M、异戊醇-D、正丙醇-D、2-甲基四氢呋喃-3-酮、丁醛-D、正戊醇-M、异戊醇-M、2,2,4,6,6-五甲基庚烷-D、正戊醇-D、2,4,5-三甲基噻唑、正己醛-M、正己醇-M和2,3-丁二酮。随着保藏时间的延长,正己醛-D、正己醛-M、丁醛-M、丁醛-D、四氢吡咯-M、异戊醇-D、异戊醇-M、正丙醇-D、2,3-丁二酮等刺激性、不愉快风味物质的含量逐渐增加。其中2,3-丁二酮、丁醛、正己醛等物质阈值较低,对腐败牛肉刺激性气味的形成有重要作用。

表 3 差异风味物质及其气味描述Table 3. Description of differential flavor substances and their odor序号 化合物名称 CAS VIP 阈值

(mg/kg)[42]气味描述 1 2-辛酮 111-13-7 4.09091 0.04 花草香 2 正己醛-D 66-25-1 2.79090 0.21 酸败、刺激性

气味[43]3 丁醛-M 123-72-8 2.29986 0.05 刺激性气味[44] 4 四氢吡咯-M 123-75-1 2.01654 刺激性气味 5 异戊醇-D 123-51-3 1.99894 0.25 不愉快气味 6 正丙醇-D 71-23-8 1.78065 7.00 刺激性气味 7 2-甲基四氢

呋喃-3-酮3188-00-9 1.62901 8 丁醛-D 123-72-8 1.57109 0.05 刺激性气味 9 正戊醇-M 71-41-0 1.48215 5.00 果香 10 异戊醇-M 123-51-3 1.36635 0.25 不愉快气味 11 2,2,4,6,6-五甲

基庚烷-D13475-82-6 1.34167 12 正戊醇-D 71-41-0 1.10760 5.00 果香 13 2,4,5-三甲基

噻唑13623-11-5 1.09442 0.05 坚果香气 14 正己醛-M 66-25-1 1.05012 0.21 酸败、刺激性

气味[43]15 正己醇-M 111-27-3 1.03851 0.70 果香 16 2,3-丁二酮 431-03-8 1.01774 0.016 刺激性气味 2.5 电子鼻分析

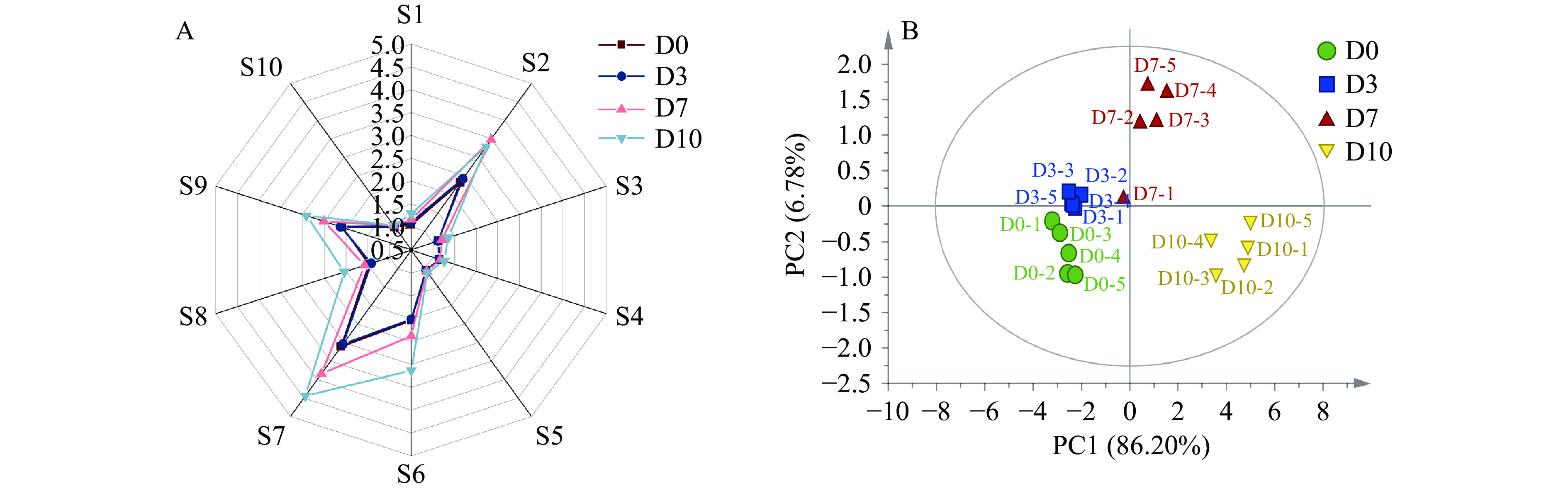

电子鼻传感器对牛肉腐败进程的挥发性风味成分响应值如图6A所示,传感器S2、S3、S6、S7、S8、S9差异明显,随着腐败时间的延长其响应值逐渐增加,表明腐败过程中氮氧化物、芳香族化合物、甲基类化合物、硫化物、醇类和醛酮类物质不断增加,与GC-IMS结果一致。对电子鼻相应数据进行分析,结果如图6B所示,PCA模型累积贡献率达92.98%,说明所建立的模型能较好地反映样品的整体信息[45]。图中不同样本分布于坐标系不同区域,分离明显无重合,说明牛肉腐败进程中风味存在显著差异,与GC-IMS结果一致。

3. 结论

本研究对牛肉腐败进程中挥发性化合物进行了测定分析。利用GC-IMS建立了4种腐败牛肉的挥发性风味指纹图谱,共提取了67个物质峰,鉴定出55种挥发性化合物。GC-IMS和电子鼻分析结果表明,牛肉腐败进程的风味存在显著差异,在腐败过程中,牛肉挥发性风味的含量显著增加,其中醇类、醛类、酯类、酸类、呋喃、吡咯、噻唑、胺类、吡嗪和醚类物质在腐败过程中持续增加,酮类烃类和含硫化合物在腐败过程中逐渐增加,在第7 d时达到峰值,而后逐渐下降。PCA和PLS-DA分析表明不同腐败牛肉样品风味存在显著差异。通过VIP值共筛选出16种差异性风味物质,其中正己醛-D、正己醛-M、丁醛-M、丁醛-D、四氢吡咯-M、异戊醇-D、异戊醇-M、正丙醇-D、2,3-丁二酮等刺激性、不愉快风味物质的含量逐渐增加。可作为区分牛肉腐败进程的潜在生物标志物。

本研究建立了牛肉腐败进程挥发性风味的可视化指纹图谱,阐明了牛肉腐败过程中挥发性风味的变化规律,为牛肉腐败进程的精准监测提供一定的理论依据。

-

表 1 PEN3电子鼻传感器名称及其性能描述

Table 1 PEN3 sensors name and performance description

序号 传感器名称 性能 1 S1 对芳香族化合物敏感 2 S2 对氮氧化物敏感 3 S3 对氨和芳香族化合物敏感 4 S4 对氢气(氢化物)敏感 5 S5 对碳氢化合物和芳香族化合物敏感 6 S6 对甲基类化合物敏感 7 S7 对硫化物和萜烯敏感 8 S8 对醇类和醛酮类化合物敏感 9 S9 对芳香族成分和有机硫化合物敏感 10 S10 对碳氢化合物敏感 表 2 牛肉腐败进程中挥发性风味物质

Table 2 VOCs of beeves spoilage process

序号 化合物种类及名称 CAS RI RT

(min)DT

(ms)峰体积(a.u) D0 D3 D7 D10 A1 醇类 异丙醇 67-63-0 931.7 306.941 1.08831 520.35±97.27a 215.83±36.89b 79.19±37.91c 152.84±30.70bc A2 乙醇 64-17-5 942.1 312.924 1.12888 2636.34±170.78c 4379.72±424.92b 5313.26±152.40a 5036.93±164.20a A3 仲丁醇 78-92-2 1028.7 381.419 1.14981 72.10±6.27c 93.66±13.15c 252.50±6.98b 568.69±67.65a A4 正丙醇-D 71-23-8 1044.7 399.803 1.24883 646.98±103.50c 565.89±20.00c 1835.43±30.24b 5819.81±940.28a A5 正丙醇-M 71-23-8 1044.7 399.803 1.11204 2655.54±251.01c 2462.51±100.54c 3763.96±81.39b 4524.69±72.58a A6 异丁醇-D 78-83-1 1097.6 461.304 1.36762 122.06±22.74b 256.52±121.20b 682.95±167.50a 863.90±141.58a A7 异丁醇-M 78-83-1 1101.8 470.853 1.17240 400.44±126.61b 467.19±28.30bc 585.43±31.39a 475.45±102.88bc A8 正丁醇-D 71-36-3 1147.5 574.081 1.38348 265.08±58.75b 223.50±2.63b 489.36±85.29a 627.78±126.92a A9 正丁醇-M 71-36-3 1147.5 574.081 1.18332 2192.66±125.63b 1974.50±33.31b 2785.49±124.12a 2934.42±279.92a A10 1-戊烯-3-醇 616-25-1 1157.3 596.104 1.35001 48.80±8.57c 56.07±7.39bc 79.27±15.73b 249.56±26.97a A11 异戊醇-M 123-51-3 1214.3 748.874 1.49567 183.41±14.95b 277.44±45.68b 2358.99±461.41a 3726.41±1971.03a A12 异戊醇-D 123-51-3 1214.7 750.432 1.24934 451.52±36.59b 1888.82±335.87b 6682.02±583.79a 7749.64±1705.49a A13 正戊醇-D 71-41-0 1262.1 908.547 1.51394 708.00±151.71c 1154.81±732.43c 2772.38±1490.23b 4816.31±379.89a A14 正戊醇-M 71-41-0 1262.6 910.056 1.25493 3062.55±465.05b 4239.92±1643.61b 6668.44±1886.33a 8665.77±200.58a A15 正己醇-D 111-27-3 1363.7 1224.347 1.64693 324.62±40.99b 315.28±19.17b 471.34±177.22b 947.37±268.69a A16 正己醇-M 111-27-3 1363.7 1224.347 1.33069 560.07±37.84c 846.28±194.58c 2724.47±1302.31b 4735.02±808.51a B1 酮类 丙酮 67-64-1 825.8 246.220 1.12123 9.92±2.69c 29.03±1.13bc 43.88±6.92b 94.80±29.42a B2 2-丁酮 78-93-3 917.4 298.752 1.05977 623.55±74.30b 588.93±33.10b 822.75±100.65a 498.49±136.57b B3 2,3-丁二酮 431-03-8 996.9 344.817 1.17998 2934.18±1091.89b 5598.47±933.03a 5490.03±728.46a 4037.02±820.00ab B4 2-戊酮 107-87-9 997.1 345.087 1.12164 1016.96±197.11c 1611.60±77.74b 1876.25±238.16ab 2126.76±52.18a B5 3-戊酮 96-22-0 997.2 345.219 1.35880 258.71±131.51d 791.14±245.08c 1299.75±398.34b 1959.10±277.55a B6 甲基异丁基

甲酮108-10-1 1009.5 359.320 1.47891 69.14±1.90b 77.93±10.35b 121.94±36.85b 246.11±55.10a B7 二异丁基甲酮 108-83-8 1214.4 749.377 1.32300 159.02±13.11b 198.07±17.49b 541.77±74.40a 728.11±231.34a B8 3-辛酮 106-68-3 1264 914.879 1.30920 309.20±23.54b 368.37±133.93b 562.29±167.57b 1316.39±413.30a B9 3-羟基-2-丁酮 513-86-0 1289.8 1000.890 1.06948 3301.62±77.31a 2905.06±131.56b 2674.94±25.16c 2840.25±126.85bc B10 羟基丙酮 116-09-6 1294.4 1016.226 1.23288 5699.53±279.40c 8982.49±1052.62b 11003.09±506.78a 9571.10±879.20b B11 2-辛酮 111-13-7 1295.1 1018.546 1.3294 26014.51±1920.04c 41501.87±4630.23b 50207.38±827.20a 44571.63±3530.74b B12 2-甲基四氢呋喃-

3-酮3188-00-9 1304.5 1046.930 1.06879 24924.32±268.13c 28602.11±1485.26b 32165.60±733.07a 30110.38±1867.32ab C1 酯类 甲酸乙酯 109-94-4 825.5 246.033 1.08638 83.57±30.10b 297.14±30.13b 1192.77±218.89a 1352.45±542.41a C2 乙酸甲酯 79-20-9 849.5 259.803 1.19855 116.15±3.48c 171.14±17.46c 779.54±128.03a 509.56±240.47a C3 乙酸乙酯-D 141-78-6 899 288.208 1.33453 44.39±2.95c 51.38±7.45c 950.49±147.22b 2028.50±244.46a C4 乙酸乙酯-M 141-78-6 900 288.778 1.09765 118.73±42.51b 243.85±13.78b 1292.15±81.87a 1333.72±144.70a C5 异戊酸甲酯 556-24-1 1027.9 380.543 1.19072 200.88±27.79b 338.79±120.37b 615.55±142.36a 726.12±138.87a C6 异丁酸异

丁酯97-85-8 1062.4 420.154 1.80405 1170.72±548.03b 983.37±469.80ab 2257.79±717.83ab 2226.11±673.34a C7 丁酸丙酯 105-66-8 1148.2 575.662 1.26304 105.09±14.21b 130.27±49.64b 340.90±97.26a 444.04±138.03a C8 丙烯酸丁酯-M 141-32-2 1189.4 668.656 1.26216 489.74±81.92c 669.57±186.32c 1237.26±356.11b 1857.04±58.72a C9 丙烯酸丁酯-D 141-32-2 1193.5 679.560 1.69325 140.08±12.47d 301.38±164.75c 722.30±103.54b 937.59±179.80a C10 丁酸戊酯 540-18-1 1283.4 979.581 1.97539 3346.16±448.65a 3319.81±464.08a 4171.68±459.75a 3865.73±428.80a C11 丙酸己酯 2445-76-3 1336.5 1142.707 1.42805 564.88±123.67b 727.45±482.45b 1590.88±797.28ab 2639.81±932.10a D1 醛类 异丁醛 78-84-2 811.2 237.813 1.09711 39.40±3.31b 55.00±17.70b 153.82±21.32a 178.73±88.50a D2 丙烯醛 107-02-8 843 256.046 1.06091 792.28±218.23b 1514.68±310.46a 1766.58±35.51a 1571.35±145.72a D3 丁醛-D 123-72-8 864.8 268.569 1.11426 5441.62±157.39c 7129.34±603.03b 7515.13±129.33b 10026.21±1506.57a D4 丁醛-M 123-72-8 915 297.350 1.25327 470.35±95.05c 844.21±152.96c 3080.32±837.26b 8224.03±1765.30a D5 正己醛-D 66-25-1 1097.8 461.736 1.56130 1034.07±228.52b 3404.65±2709.91ab 9248.99±3692.75a 9586.41±4765.92a D6 正己醛-M 66-25-1 1098.7 463.807 1.27008 2919.85±384.72b 4425.37±1239.99ab 6070.34±944.19a 6079.29±1261.01a D7 反式-2-戊

烯醛1576-87-0 1136.6 549.392 1.10700 78.10±6.86c 105.11±16.43bc 144.92±35.91b 288.84±51.63a D8 正庚醛 111-71-7 1193.3 678.781 1.34043 1026.79±273.54b 1958.69±682.93ab 3183.55±602.00a 3296.19±1222.25a D9 顺-4-庚烯醛 6728-31-0 1262 908.163 1.60127 344.32±6.07b 350.53±29.54b 437.42±115.36b 1334.91±569.15a D10 壬醛 124-19-6 1398.9 1329.801 1.47986 1637.24±602.92a 1341.92±303.46a 2798.61±76.03a 2413.55±1424.49a E1 烃类 1,1-二乙氧基乙烷 105-57-7 889.1 282.516 1.04394 214.11±36.13a 197.20±17.35a 210.85±31.75a 227.81±36.77a E2 2,2,4,6,6-五甲基

庚烷-M13475-82-6 927.2 304.353 1.32478 94.37±26.67c 662.42±96.37b 1805.92±236.12a 2009.57±244.44a E3 2,2,4,6,6-五甲基

庚烷-D13475-82-6 927.7 304.643 1.40232 142.48±41.71d 1403.34±189.00c 4605.53±297.26b 2618.14±1233.68a E4 甲苯 108-88-3 1052.3 408.558 1.04598 305.16±44.92b 394.28±38.83b 1128.70±161.30a 978.60±103.27a E5 十氢萘 91-17-8 1164.4 612.114 1.26939 41.02±8.84b 57.30±28.50b 166.36±84.35a 254.71±50.19a F1 呋喃 2,5-二甲基呋喃 625-86-5 947.7 316.113 1.04120 4861.95±385.88c 5314.77±295.19bc 5763.98±522.24ab 6095.40±334.42a F2 2-戊基呋喃 3777-69-3 1236 821.304 1.25062 215.85±12.63c 298.71±119.02c 778.87±293.45b 1593.80±280.80a F3 2-甲基-3-甲硫基

呋喃63012-97-5 1342.3 1160.071 1.10794 45.04±6.41b 57.76±9.62b 94.77±7.83b 223.76±107.16a G1 含硫

化合物丙硫醇 107-03-9 843.1 256.103 1.14261 162.59±106.01b 1030.26±604.80ab 2756.88±1128.83a 2487.64±1305.72a G2 二丙基二硫 629-19-6 1363.7 1224.347 1.47588 89.72±9.46b 91.01±14.06b 313.42±166.54a 460.01±12.72a H1 胺类 N,N-二甲基甲酰胺 68-12-2 1325.2 1108.857 1.25602 81.32±8.37c 104.70±14.68bc 182.54±32.42b 320.92±88.03a H2 三乙烯二胺 280-57-9 1509.4 1661.185 1.16265 848.25±19.64b 875.93±40.81b 1069.55±224.27b 1831.65±347.76a I1 吡咯 四氢吡咯-D 123-75-1 1010.2 360.184 1.28101 28.99±4.80b 41.86±13.92b 208.58±68.53a 283.65±68.91a I2 四氢吡咯-M 123-75-1 1021.5 373.102 1.04116 2179.67±404.59c 3126.32±207.51b 8534.37±212.28a 9204.86±714.87a J1 吡嗪 2-甲基吡嗪 109-08-0 1261.2 905.624 1.40956 224.50±26.41c 301.65±107.21c 542.53±191.90b 903.61±91.25a K1 醚类 乙二醇二甲醚 110-71-4 906.7 292.582 1.29012 19.18±5.85c 21.84±6.35c 92.41±19.73b 256.23±42.83a L1 噻唑 2,4,5-三甲基噻唑 13623-11-5 1387.5 1295.756 1.15503 820.04±81.77b 786.82±98.13b 1383.54±24.08b 3323.61±1565.01a M1 酸类 乙酸 64-19-7 1510.2 1663.479 1.05634 9747.76±597b 9361.83±626.33b 10312.96±660.74b 12065.69±1067.15a 注:同行不同小写字母表示存在显著性差异(P<0.05)。 表 3 差异风味物质及其气味描述

Table 3 Description of differential flavor substances and their odor

序号 化合物名称 CAS VIP 阈值

(mg/kg)[42]气味描述 1 2-辛酮 111-13-7 4.09091 0.04 花草香 2 正己醛-D 66-25-1 2.79090 0.21 酸败、刺激性

气味[43]3 丁醛-M 123-72-8 2.29986 0.05 刺激性气味[44] 4 四氢吡咯-M 123-75-1 2.01654 刺激性气味 5 异戊醇-D 123-51-3 1.99894 0.25 不愉快气味 6 正丙醇-D 71-23-8 1.78065 7.00 刺激性气味 7 2-甲基四氢

呋喃-3-酮3188-00-9 1.62901 8 丁醛-D 123-72-8 1.57109 0.05 刺激性气味 9 正戊醇-M 71-41-0 1.48215 5.00 果香 10 异戊醇-M 123-51-3 1.36635 0.25 不愉快气味 11 2,2,4,6,6-五甲

基庚烷-D13475-82-6 1.34167 12 正戊醇-D 71-41-0 1.10760 5.00 果香 13 2,4,5-三甲基

噻唑13623-11-5 1.09442 0.05 坚果香气 14 正己醛-M 66-25-1 1.05012 0.21 酸败、刺激性

气味[43]15 正己醇-M 111-27-3 1.03851 0.70 果香 16 2,3-丁二酮 431-03-8 1.01774 0.016 刺激性气味 -

[1] LI X Z, YAN C G, ZAN L S. Current situation and future prospects for beef production in China-a review[J]. Asian-Australasian Journal of Animal Sciences,2018,31(7):984−991. doi: 10.5713/ajas.18.0212

[2] 曹兵海, 李俊雅, 王之盛, 等. 2022年度肉牛牦牛产业技术发展报告[J]. 中国畜牧杂志,2023,59(3):330−335. [CAO Binghai, LI Junya, WANG Zhisheng, et al. Report on the technological development of the beef yak industry in 2022[J]. Chinese Journal of Animal Science,2023,59(3):330−335.] CAO Binghai, LI Junya, WANG Zhisheng, et al. Report on the technological development of the beef yak industry in 2022[J]. Chinese Journal of Animal Science, 2023, 59(3): 330−335.

[3] ALIREZALU K, MOVLAN H S, YAGHOUBI M, et al. ɛ-Plylysine coating with stinging nettle extract for fresh beef preservation[J]. Meat Science,2021,176:108474. doi: 10.1016/j.meatsci.2021.108474

[4] DURAN A, KAHVE H I. The effect of chitosan coating and vacuum packaging on the microbiological and chemical properties of beef[J]. Meat Science,2020,162:107961. doi: 10.1016/j.meatsci.2019.107961

[5] STUTZ H K, SILVERMAN G J, ANGELINI P, et al. Bacteria and volatile compounds associated with ground-beef spoilage[J]. Journal of Food Science,1991,56(5):1147−1153. doi: 10.1111/j.1365-2621.1991.tb04721.x

[6] 张秀凤, 申晓琳, 赵金辉. 冷鲜牛肉腐败临界期及特定腐败菌研究[J]. 黑龙江畜牧兽医,2018(24):66−69,260. [ZHANG Xiufeng, SHEN Xiaolin, ZHAO Jinhui. Study on critical spoilage period and specific spoilage bacteria of chilled beef[J]. Heilongjiang Animal Science and Veterinary Medicine,2018(24):66−69,260.] ZHANG Xiufeng, SHEN Xiaolin, ZHAO Jinhui. Study on critical spoilage period and specific spoilage bacteria of chilled beef[J]. Heilongjiang Animal Science and Veterinary Medicine, 2018(24): 66−69,260.

[7] 杨啸吟, 张一敏, 梁荣蓉, 等. 包装冷却肉中微生物腐败及其挥发性气味的研究进展[J]. 食品科学,2021,42(1):285−293. [YANG Xiaoyin, ZHANG Yimin, LIANG Rongrong, et al. Microbial spoilage and formation and detection of volatile odor compounds in packaged chilled meat:A review[J]. Food Science,2021,42(1):285−293.] YANG Xiaoyin, ZHANG Yimin, LIANG Rongrong, et al. Microbial spoilage and formation and detection of volatile odor compounds in packaged chilled meat: A review[J]. Food Science, 2021, 42(1): 285−293.

[8] ARGYRI A A, MALLOUCHOS A, PANAGOU E Z, et al. The dynamics of the HS/SPME–GC/MS as a tool to assess the spoilage of minced beef stored under different packaging and temperature conditions[J]. International Journal of Food Microbiology,2015,193:51−58. doi: 10.1016/j.ijfoodmicro.2014.09.020

[9] CASABURI A, PIOMBINO P, NYCHAS G J, et al. Bacterial populations and the volatilome associated to meat spoilage[J]. Food Microbiology,2015,45:83−102. doi: 10.1016/j.fm.2014.02.002

[10] EDWARDS R A, DAINTY R H, HIBBARD C M. Volatile compounds produced by meat pseudomonads and relate reference strains during growth on beef stored in air at chill temperatures[J]. The Journal of Applied Bacteriology,1987,62(5):403−412. doi: 10.1111/j.1365-2672.1987.tb02669.x

[11] ERCOLINI D, CASABURI A, NASI A, et al. Different molecular types of Pseudomonas fragi have the same overall behaviour as meat spoilers[J]. International Journal of Food Microbiology,2010,142(1−2):120−131. doi: 10.1016/j.ijfoodmicro.2010.06.012

[12] CASABURI A, DE FILIPPIS F, VILLANI F, et al. Activities of strains of Brochothrix thermosphacta in vitro and in meat[J]. Food Research International,2014,62:366−374. doi: 10.1016/j.foodres.2014.03.019

[13] THIERRY A, MAILLARD M B, RICHOUX R, et al. Propionibacterium freudenreichii strains quantitatively affect production of volatile compounds in swiss cheese[J]. Lait,2005,85(1−2):57−74. doi: 10.1051/lait:2004036

[14] YANG X, ZHU K, GUO H, et al. Characterization of volatile compounds in differently coloured Chenopodium quinoa seeds before and after cooking by headspace-gas chromatography-ion mobility spectrometry[J]. Food Chemistry,2021,348:129086. doi: 10.1016/j.foodchem.2021.129086

[15] WANG S, CHEN H, SUN B. Recent progress in food flavor analysis using gas chromatography-ion mobility spectrometry (GC-IMS)[J]. Food Chemistry,2020,315:126158. doi: 10.1016/j.foodchem.2019.126158

[16] YANG Y, WANG B, FU Y, et al. HS-GC-IMS with PCA to analyze volatile flavor compounds across different production stages of fermented soybean whey tofu[J]. Food Chemistry,2021,346:128880. doi: 10.1016/j.foodchem.2020.128880

[17] 张培茵, 孟宁, 刘明, 等. 低温等离子体处理对糙米原料及糙米饭风味特性的影响[J]. 食品科学,2021,42(15):74−80. [ZHANG Peiyin, MENG Ning, LIU Ming, et al. Effects of low temperature plasma treatment on flavor characteristics of raw and cooked brown rice[J]. Food Science,2021,42(15):74−80.] ZHANG Peiyin, MENG Ning, LIU Ming, et al. Effects of low temperature plasma treatment on flavor characteristics of raw and cooked brown rice[J]. Food Science, 2021, 42(15): 74−80.

[18] 周煦成. 基于蚕丝丝素纤维的气敏传感器开发及检测猪肉新鲜度研究[D]. 镇江:江苏大学, 2017. [ZHOU Xucheng. Development of gas sensors based on silk fibroin fiber and their application in pork freshness detection[D]. Zhenjiang:Jiangsu University, 2017.] ZHOU Xucheng. Development of gas sensors based on silk fibroin fiber and their application in pork freshness detection[D]. Zhenjiang: Jiangsu University, 2017.

[19] 余舒婷, 林淑芳, 黄姝玲, 等. 腐败食品快速检测技术的应用及研究进展[J]. 食品科技,2022,47(9):297−303. [YU Shuting, LIN Shufang, HUANG Shuling, et al. Application and research progress of rapid detection technology for spoilage food[J]. Food Science and Technology,2022,47(9):297−303.] YU Shuting, LIN Shufang, HUANG Shuling, et al. Application and research progress of rapid detection technology for spoilage food[J]. Food Science and Technology, 2022, 47(9): 297−303.

[20] 马姗, 于文龙, 焦英帅, 等. 不同减菌处理对凡纳对虾贮藏期间品质的影响[J]. 食品科技,2022,47(3):116−124. [MA Shan, YU Wenlong, JIAO Yingshuai, et al. Effects of different bacteria reducing treatments on the quality of Penaeus vannamei during storage[J]. Food Science and Technology,2022,47(3):116−124.] MA Shan, YU Wenlong, JIAO Yingshuai, et al. Effects of different bacteria reducing treatments on the quality of Penaeus vannamei during storage[J]. Food Science and Technology, 2022, 47(3): 116−124.

[21] PATANGE A, BOEHM D, BUENO-FERRER C, et al. Controlling Brochothrix thermosphacta as a spoilage risk using in-package atmospheric cold plasma[J]. Food Microbiology,2017,66:48−54. doi: 10.1016/j.fm.2017.04.002

[22] SIDIRA M, KANDYLIS P, KANELLAKI M, et al. Effect of immobilized Lactobacillus casei on the evolution of flavor compounds in probiotic dry-fermented sausages during ripening[J]. Meat Science,2015,100:41−51. doi: 10.1016/j.meatsci.2014.09.011

[23] 刘俊霞, 赵萍, 金晶, 等. 基于气相色谱-离子迁移谱结合化学计量学分析大鲵肉冷藏期间挥发性成分[J]. 食品与发酵工业,2022,48(22):269−278. [LIU Junxia, ZHAO Ping, JIN Jing, et al. Analysis of volatile components in giant salamander meat during cold storage based on gas chromatography-ion mobility spectrometer and chemometrics[J]. Food and Fermentation Industries,2022,48(22):269−278.] LIU Junxia, ZHAO Ping, JIN Jing, et al. Analysis of volatile components in giant salamander meat during cold storage based on gas chromatography-ion mobility spectrometer and chemometrics[J]. Food and Fermentation Industries, 2022, 48(22): 269−278.

[24] MANSUR A R, SEO D H, SONG E J, et al. Identifying potential spoilage markers in beef stored in chilled air or vacuum packaging by HS-SPME-GC-TOF/MS coupled with multivariate analysis[J]. LWT,2019,112:108256. doi: 10.1016/j.lwt.2019.108256

[25] ZAREIAN M, BÖHNER N, LOOS H M, et al. Evaluation of volatile organic compound release in modified atmosphere-packaged minced raw pork in relation to shelf-life[J]. Food Packaging and Shelf Life,2018,18:51−61. doi: 10.1016/j.fpsl.2018.08.001

[26] 吴静, 黄卉, 李来好, 等. 鱼制品腥味产生机制及调控措施研究进展[J]. 食品与发酵工业,2019,45(24):254−261. [WU Jing, HUANG Hui, LI Laihao, et al. Review on the formation and regulation of the fishy odor in fish products[J]. Food and Fermentation Industries,2019,45(24):254−261.] WU Jing, HUANG Hui, LI Laihao, et al. Review on the formation and regulation of the fishy odor in fish products[J]. Food and Fermentation Industries, 2019, 45(24): 254−261.

[27] 陈泓帆, 聂鑫, 宋川, 等. 不同种类白酒对广式香肠质构和风味的影响分析[J]. 食品科技,2022,47(12):104−112. [CHEN Hongfan, NIE Xin, SONG Chuan, et al. Analysis of the effect of different kinds of Baijiu on the texture and flavor of Cantonese sausage[J]. Food Science and Technology,2022,47(12):104−112.] CHEN Hongfan, NIE Xin, SONG Chuan, et al. Analysis of the effect of different kinds of Baijiu on the texture and flavor of Cantonese sausage[J]. Food Science and Technology, 2022, 47(12): 104−112.

[28] WANG Y, TING J Y, CAN J X, et al. Study on lipolysis-oxidation and volatile flavour compounds of dry-cured goose with different curing salt content during production[J]. Food Chemistry,2016,190:33−40. doi: 10.1016/j.foodchem.2015.05.048

[29] JÄÄSKELÄINEN E, HULTMAN J, PARSHINTSEV J, et al. Development of spoilage bacterial community and volatile compounds in chilled beef under vacuum or high oxygen atmospheres[J]. International Journal of Food Microbiology,2016,223:25−32. doi: 10.1016/j.ijfoodmicro.2016.01.022

[30] SOLOMANDO J C, ANTEQUERA T, MARTÍN A, et al. Fish oil microcapsules as omega-3 enrichment strategy:Changes in volatile compounds of meat products during storage and cooking[J]. Foods,2021,10(4):745. doi: 10.3390/foods10040745

[31] 潘晓倩, 周慧敏, 李素, 等. 卤牛肉贮藏过程中气味活性化合物变化及异味分析[J]. 食品科学,2021,42(22):240−248. [PAN Xiaoqian, ZHOU Huiming, LI Su, et al. Changes in odor-active compounds during storage and analysis of off-flavor substances in stewed marinated beef[J]. Food Science,2021,42(22):240−248.] PAN Xiaoqian, ZHOU Huiming, LI Su, et al. Changes in odor-active compounds during storage and analysis of off-flavor substances in stewed marinated beef[J]. Food Science, 2021, 42(22): 240−248.

[32] 方金玉. 冷鲜牛肉中假单胞菌和热死环丝菌致腐机制及其光动力杀菌控制研究[D]. 杭州:浙江工商大学, 2022. [FANG Jinyu. Spoilage mechanisms of Pseudomonas and Brochothrix thermosphacta in chilled beef and photodynamic inactivation control[D]. Hangzhou:Zhejiang Gongshang University, 2022.] FANG Jinyu. Spoilage mechanisms of Pseudomonas and Brochothrix thermosphacta in chilled beef and photodynamic inactivation control[D]. Hangzhou: Zhejiang Gongshang University, 2022.

[33] 顾雅昕, 乔柱, 郭行, 等. 发酵乳杆菌LBM97所产细菌素提取方法的优化及比较[J]. 食品与发酵工业,2020,46(19):111−116. [GU Yaxin, QIAO Zhu, GUO Xing, et al. Optimization and comparison of extraction methods of bacteriocin produced by Lactobacillus fermentum LBM97[J]. Food and Fermentation Industries,2020,46(19):111−116.] GU Yaxin, QIAO Zhu, GUO Xing, et al. Optimization and comparison of extraction methods of bacteriocin produced by Lactobacillus fermentum LBM97[J]. Food and Fermentation Industries, 2020, 46(19): 111−116.

[34] 郭依萍, 栗婧文, 窦晗, 等. 精准温控对冰温贮藏生鲜猪肉保鲜效果的影响[J]. 南京农业大学学报,2023,46(1):150−158. [GUO Yiping, LI Jingwen, DOU Han, et al. Effect of precise temperature control on the preservation effect of fresh pork during ice-temperature storage[J]. Journal of Nanjing Agricultural University,2023,46(1):150−158.] GUO Yiping, LI Jingwen, DOU Han, et al. Effect of precise temperature control on the preservation effect of fresh pork during ice-temperature storage[J]. Journal of Nanjing Agricultural University, 2023, 46(1): 150−158.

[35] 吴鸣, 吴浚滢, 范琦琦, 等. 食品风味物质的合成机理及检测方法的研究进展[J/OL]. 食品科学, 1−14[2024-03-15]. http://kns.cnki.net/kcms/detail/11.2206.TS.20231010.0933.044.html. [WU Ming, WU Junying, Fan Qiqi, et al. Research progress on synthesis mechanism and detection methods of food flavor substances[J]. Food Science, 1−14[2024-03-15]. http://kns.cnki.net/kcms/detail/11.2206.TS.20231010.0933.044.html.] WU Ming, WU Junying, Fan Qiqi, et al. Research progress on synthesis mechanism and detection methods of food flavor substances[J]. Food Science, 1−14[2024-03-15]. http://kns.cnki.net/kcms/detail/11.2206.TS.20231010.0933.044.html.

[36] 张凡, 张宇帆, 苏心悦, 等. 基于顶空气相离子迁移谱的干腐病马铃薯挥发性成分分析[J]. 食品科学,2022,43(6):317−323. [ZHANG Fan, ZHANG Yufan, SU Xinyue, et al. Analysis of volatile components in potatoes with dry rot by headspace-gas chromatography-ion mobility spectrometry[J]. Food Science,2022,43(6):317−323.] ZHANG Fan, ZHANG Yufan, SU Xinyue, et al. Analysis of volatile components in potatoes with dry rot by headspace-gas chromatography-ion mobility spectrometry[J]. Food Science, 2022, 43(6): 317−323.

[37] 朱嘉敏, 么紫瑶, 李梦彤, 等. 不同接种量的清酒乳杆菌对低钠盐风干肠品质的改善作用研究[J]. 食品工业科技, 2023, 44(7):133-142. ZHU Jiamin, MO Ziyao, LI Mengtong, et al. Study on different inoculation levels of Lactobacillus sakei on the improvement of quality characteristics of low-sodium dry sausages[J]. Science and Technology of Food Industry, 2023, 44(7):133−142. [38] 黄晓霞, 游云, 刘巧瑜, 等. 不同剂量~(60)Co-γ射线辐照对烟鸡胸肉贮藏过程中滋味的影响[J]. 食品安全质量检测学报,2023,14(7):56−64. [HUANG Xiaoxia, YOU Yun, LIU Qiaoyu, et al. Effects of different doses of 60Co-γ irradiation on the taste of smoked chicken breast during storage[J]. Journal of Food Safety and Quality,2023,14(7):56−64.] HUANG Xiaoxia, YOU Yun, LIU Qiaoyu, et al. Effects of different doses of 60Co-γ irradiation on the taste of smoked chicken breast during storage[J]. Journal of Food Safety and Quality, 2023, 14(7): 56−64.

[39] HUTCHINSON U F, JOLLY N P, CHIDI B S, et al. Vinegar engineering:A bioprocess perspective[J]. Food Engineering Reviews,2019,11(4):290−305. doi: 10.1007/s12393-019-09196-x

[40] 周慧敏, 张顺亮, 郝艳芳, 等. HS-SPME-GC-MS-O结合电子鼻对坨坨猪肉主体风味评价分析[J]. 食品科学,2021,42(2):218−226. [ZHOU Huimin, ZHANG Shunliang, HAO Yanfang, et al. Analysis of major flavor components of Tuotuo Pork, a traditional meat product in Liangshan, Southwest China's Sichuan, by HS-SPME-GC-MS-O combined with electronic nose[J]. Food Science,2021,42(2):218−226.] ZHOU Huimin, ZHANG Shunliang, HAO Yanfang, et al. Analysis of major flavor components of Tuotuo Pork, a traditional meat product in Liangshan, Southwest China's Sichuan, by HS-SPME-GC-MS-O combined with electronic nose[J]. Food Science, 2021, 42(2): 218−226.

[41] WANG J, LI X, WU Y, et al. HS-SPME/GC-MS reveals the season effects on volatile compounds of green tea in high-latitude region[J]. Foods,2022,11(19):3016. doi: 10.3390/foods11193016

[42] VAN GEMERT L. Compilations of flavour threshold values in water and other media[M]. Boelens Aroma Chemical Information Service, 2003.

[43] 罗杰琼, 张淼, 贾洪锋, 等. 不同部位原切牛排品质对比分析[J]. 食品工业科技, 2023, 44(10):270-279. LUO Jieqiong, ZHANG Miao, JIA Hongfeng, et al. Comparative analysis of quality of raw cut steak in different parts[J]. Science and Technology of Food Industry, 2023, 44(10):270−279. [44] 赵改名, 王森, 祝超智, 等. 基于顶空气相离子迁移色谱对鸭肉腥味特征物质的鉴定[J]. 食品科学,2023,44(4):247−255. [ZHAO Gaiming, WANG Sen, ZHU Chaozhi, et al. Identification of characteristic odorants in duck meat by headspace-gas chromatography-ion mobility spectrometry[J]. Food Science,2023,44(4):247−255.] ZHAO Gaiming, WANG Sen, ZHU Chaozhi, et al. Identification of characteristic odorants in duck meat by headspace-gas chromatography-ion mobility spectrometry[J]. Food Science, 2023, 44(4): 247−255.

[45] 白洁, 蒋华彬, 陶国琴, 等. 基于SPME-GC-MS和PCA分析气流膨化处理对马铃薯方便粥香气成分的影响[J]. 食品科学,2020,41(14):217−224. [BAI Jie, JIANG Huabin, TAO Guoqin, et al. Analysis of the aromatic components of potato flour incorporated instant congee processed by explosion puffing by combined use of SPME-GC-MS and PCA[J]. Food Science,2020,41(14):217−224.] BAI Jie, JIANG Huabin, TAO Guoqin, et al. Analysis of the aromatic components of potato flour incorporated instant congee processed by explosion puffing by combined use of SPME-GC-MS and PCA[J]. Food Science, 2020, 41(14): 217−224.

-

期刊类型引用(4)

1. 刘明珠,华玲,张秀萍,丁燃容,刘媛媛. 微波花椒鸡丁预制菜的工艺优化及其挥发性风味物质分析. 四川旅游学院学报. 2025(01): 30-35 .  百度学术

百度学术

2. 王美仁,王柏辉,杨帆,刘学勤,苏春霞,段晓蓉. 不同加工方式对牛肉干产品风味物质的影响. 食品安全质量检测学报. 2025(02): 127-137 .  百度学术

百度学术

3. 玛尔哈巴·帕尔哈提,宋占腾,杨睿娜,李静,安静,刘敏,徐贞贞,朱靖蓉. 不同品种恰玛古风味品质分析. 食品工业科技. 2025(04): 306-315 .  本站查看

本站查看

4. 郑佳琦,宫雅姝,牛梦迪,王军. 鲫鱼冷藏期间新鲜度与挥发性物质相关性分析. 食品与发酵工业. 2024(23): 226-233 .  百度学术

百度学术

其他类型引用(1)

下载:

下载:

下载:

下载: