Bacteriozyme Cooperated with Solid-fermented Walnut Glutenin to Prepare Bacteriostatic Peptides

-

摘要: 核桃粕作为榨油副产物常被用作饲料或丢弃,造成大量优质蛋白资源的浪费。本文为高值化利用核桃粕资源,以其中含量最高的谷蛋白为原料,采用枯草芽孢杆菌和碱性蛋白酶协同固态发酵法制备核桃谷蛋白抑菌肽。以多肽含量和抑菌圈直径作为评价指标,进行单因素实验和响应面试验优化最佳菌酶协同固态发酵工艺参数。对制备的谷蛋白抑菌肽热稳定性进行探究。结果显示,单因素实验表明谷蛋白抑菌肽对大肠杆菌和金黄色葡萄球菌均有一定的抑制作用。响应面试验下最佳发酵工艺参数为:接种量5%,料液比1:1.5,发酵温度43 ℃,发酵时间3 d,加酶量400 U/g。最佳工艺条件下多肽含量达到26.35±1.29 mg/g,对金黄色葡萄球菌抑菌圈直径为15.50±1.53 mm。通过差示扫描量热仪(Differential Scanning Calorimeter,DSC)分析可得,谷蛋白抑菌肽比谷蛋白具有更高的热稳定性。研究表明通过菌酶协同固态发酵核桃谷蛋白制备的抑菌肽具有良好的抑菌效果且结构相对稳定。Abstract: As a by-product of oil extraction, walnut meal was often used as feed or discarded, resulting in a waste of a large amount of high-quality protein resources. In this paper, for the high-value utilization of walnut meal resources, the highest content of glutelin was used as raw material to prepare walnut glutelin bacteriostatic peptide by solid-state fermentation with Bacillus subtilis and alkaline protease. The polypeptide content and the diameter of the inhibition zone of Staphylococcus aureus were used as the response values to optimize the optimal bacterial enzyme synergistic solid-state fermentation process parameters by single factor test. and response surface test. The thermal stability of the prepared glutelin bacteriostatic peptide was investigated. The results showed that the single factor test showed that the glutelin bacteriostatic peptide had a certain inhibitory effect on Escherichia coli and Staphylococcus aureus. The optimal fermentation process parameters under the response surface test were as follows: Inoculation amount 5%, solid-liquid ratio 1:1.5, fermentation temperature 43 ℃, fermentation time 3 d, and enzyme dosage 400 U/g. Under the optimal process conditions, the peptide content reached 26.35±1.29 mg/g, and the diameter of the inhibition zone against Staphylococcus aureus was 15.50±1.53 mm. Differential scanning calorimetry (DSC) analysis showed that glutelin antimicrobial peptides had higher thermal stability than glutelin. This study showed that the bacteriostatic peptide prepared by solid-state fermentation of walnut glutelin with enzyme has a good bacteriostatic effect and relatively stable structure.

-

核桃(Juglans regia L.)属于胡桃科胡桃属。是世界著名的“四大干果”之一[1],在全球分布广泛。中国是当今世界上最大的核桃生产国[2]。核桃粕是核桃榨油后的副产物,蛋白含量可达43.8%[3],且氨基酸种类丰富,是一种可为人体提供丰富氨基酸的植物源蛋白原料[4]。但目前核桃粕整体利用率较低,常被用于动物饲料或直接丢弃,导致蛋白资源的浪费[5]。核桃粕蛋白主要由谷蛋白、球蛋白、清蛋白和醇溶谷蛋白构成[6−7]。其中,清蛋白和球蛋白的溶解性最佳,目前相关研究也最多[8−9]。而含量最多的谷蛋白(70%以上)的溶解性最差,针对谷蛋白的功能性质与生理活性的研究也相对较少[10]。因此,利用菌酶协同固态发酵核桃粕谷蛋白制备生物活性肽进行研究,不仅能提高核桃粕的综合利用价值,对核桃谷蛋白的开发利用也具有重大意义。

目前,对核桃粕蛋白的研究主要集中在表征其生物活性方面,包括抗氧化能力[11],ACE抑制[12]和神经调节活性[13]等。而对核桃粕蛋白制备抑菌肽的研究相对较少[14],随着食品防腐领域对无毒、绿色和天然防腐剂的需求日益增加,抑菌性核桃肽的筛选和特性研究可为新型抗生素的替代品以及食品级抗菌剂研发提供新思路[15]。生产核桃粕蛋白抑菌肽的主要方法为酶解法[16]和发酵法[17],实际生产中,通常将这两种方法协同使用制备生物活性肽。菌酶协同发酵技术综合了微生物发酵和酶解技术两大优势,通过酶解可以为微生物的发酵过程供给氮源和碳源等基本营养素,同时发酵技术还能够克服单纯酶解所带来的功能元素缺失等问题。将二者有机融合不仅可以降低活性肽的生产成本,也可在生产中起到原料解毒和脱苦的作用[18]。

因此,为充分利用核桃加工副产物—核桃粕,提高其资源利用率,本研究以核桃粕谷蛋白为原料,采用菌酶协同固态发酵的方式制备抑菌肽,对协同工艺进行优化,测定产物的抑菌活性,分析发酵前后的热稳定性变化。以期筛选出一种具有良好抑菌性能且结构相对稳定的核桃谷蛋白抑菌肽,为核桃蛋白质的高值化利用提供新的研究思路,增加核桃副产物的综合利用价值。

1. 材料与方法

1.1 材料与仪器

脱脂核桃粕(温185) 实验室自制;核桃谷蛋白 由脱脂核桃粕制得;枯草芽胞杆菌CICC10732、金黄色葡萄球菌CICC10384、大肠埃希氏菌CICC10899 广东微生物研究所;麦氏比浊管 温州康泰生物有限公司;还原型谷胱甘肽试剂盒 北京索莱宝科技有限公司;LB肉汤培养基、营养琼脂 青岛高科技工业园海博生物技术有限公司;碱性蛋白酶(200 U/mg)、酸性蛋白酶(200 U/mg)、中性蛋白酶(100 U/mg)、复合蛋白酶(120 U/mg) 上海源叶生物科技有限公司;三氯乙酸、石油醚(60~90 ℃)、无水乙醇 天津市北联精细化学品有限公司。

CHRIST真空冷冻干燥机 北京五洲东方科技发展有限公司;BUCHI Rotavapor R-100旋转蒸发仪 瑞士步琦有限公司;TU-1810PC紫外可见分光光度计 北京普析通用仪器有限责任公司;AL204精度千分之一电子天平 梅特勒-托利多仪器有限公司;LHS-100CH恒温恒湿培养箱 上海一恒科学仪器有限公司;HH-S4数显恒温水浴锅 江苏金怡仪器科技有限公司;LXJ-IIB台式离心机、DZ-DSC300C差示扫描量热仪、HMDC-2006低温恒温槽 南京大展检测仪器有限公司;5817R低温离心机 德国艾本德公司;SZCL数显智能控温磁力搅拌器 上海力辰邦西仪器科技有限公司;ALPCL-40L高温高压灭菌锅 上海思默生物科技有限公司;VD-850超净工作台 苏州净化设备有限公司DHG-9070A电热恒温鼓风干燥箱 上海齐欣科学仪器有限公司。

1.2 实验方法

1.2.1 脱脂核桃粕的制备

核桃粕→粉碎过0.425 mm(40目)筛→烘箱50 ℃条件下干燥24 h→按1:2料液比加入石油醚(60~90 ℃)→磁力搅拌3 h→离心(4500 r/min,15 min)→弃掉上清液→重复脱脂3次→脱脂核桃粕→晾干装PE袋,−20 ℃冷冻备用[19]。

1.2.2 核桃谷蛋白的制备

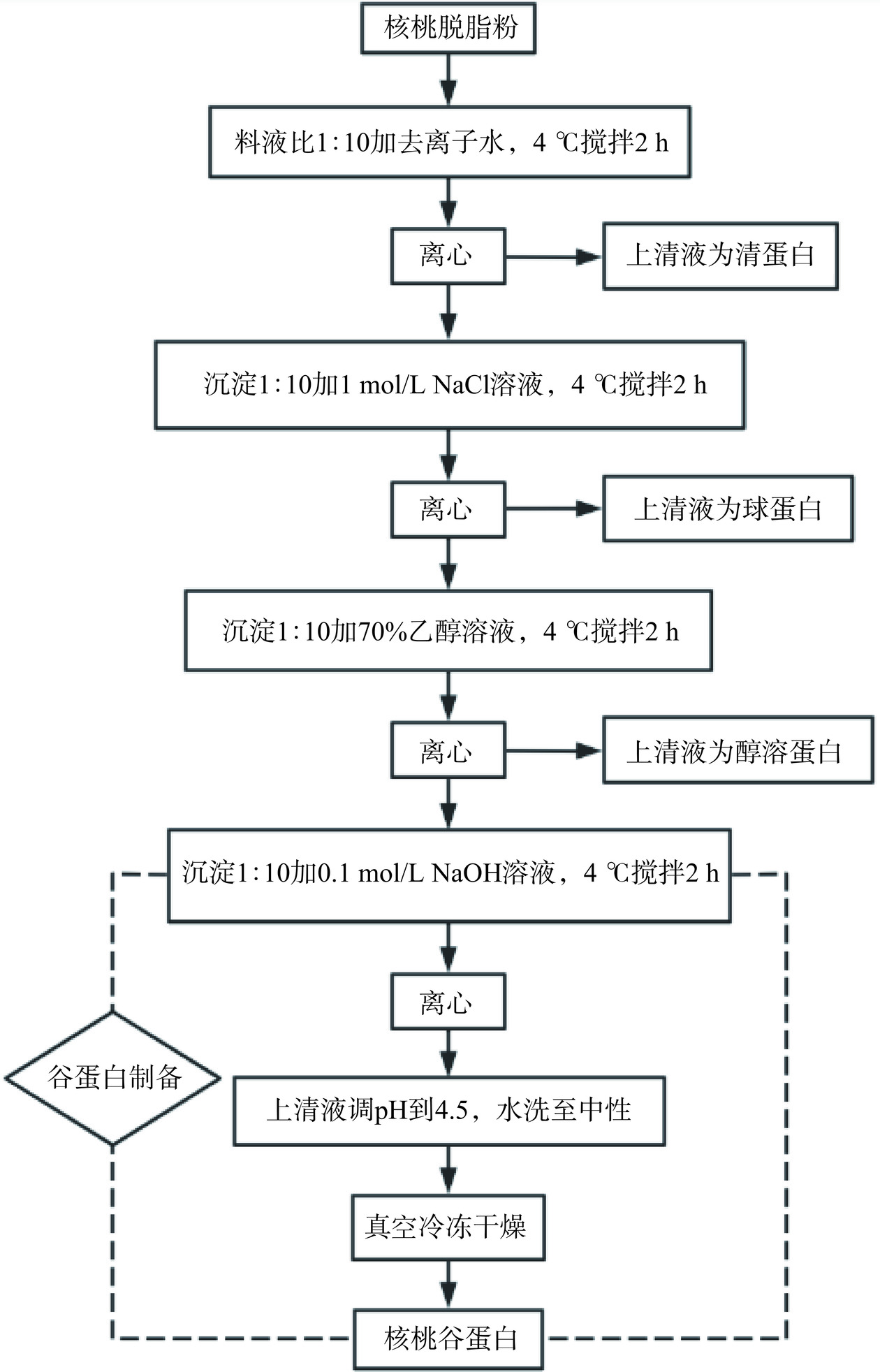

参考Sze-Tao等[20]和毛晓英[21]关于核桃蛋白组分分离提取谷蛋白的方法进行略微修改。以脱脂核桃粕为原料,依次使用去离子水、1 mol/L NaCl、70%乙醇(v/v)、0.1 mol/L NaOH溶液提取清蛋白、球蛋白、醇溶谷蛋白和谷蛋白。然后将每种组分蛋白分别以1:10的料液比在4 ℃下混合搅拌2 h,以10000 r/min离心20 min,弃去沉淀,收集上清液。为确保各个蛋白组分的充分提取,每项步骤重复3次,将制备的谷蛋白真空冷冻干燥后于−20 ℃冰箱冷冻保存。

核桃组分蛋白质的提取流程如图1所示。

1.2.3 菌种活化及种子液制备

枯草芽孢杆菌划线接种于LB固体培养基,37 ℃恒温培养箱中活化24 h,用接种环挑取2环菌体接入100 mL已灭菌的液体培养基中摇床培养,温度37 ℃、转速180 r/min,培养12 h。之后取活化完成的液体培养基1 mL接入100 mL LB液体培养基内进行扩大培养,得到发酵种子液,使用麦氏比浊法调节菌液浓度至107 CFU/mL[22]。

1.2.4 菌酶协同固态发酵核桃谷蛋白

核桃谷蛋白经粉碎后过0.425 mm(40目)筛,在50 mL烧杯中准确称取5 g(精确至0.01 g)于高压蒸汽灭菌锅中121 ℃灭菌20 min。按加酶量称取碱性蛋白酶加入无菌水溶解,于50 ℃水浴30 min,制成酶液[23]。在超净工作台无菌操作,按照不同的条件分别加入菌种种子液、无菌生理盐水和碱性蛋白酶酶液,无菌玻璃棒搅拌均匀,用封口膜封口,在不同试验条件下进行菌酶协同发酵。发酵完毕后95 ℃条件下灭酶15 min,于55 ℃烘箱干燥48 h,粉碎过筛备用。

1.2.5 多肽含量的测定

多肽含量的测定参考刘潇[24]采用双缩脲法绘制标准曲线的方法进行测量。得到标准曲线的回归方程为:y=0.0809x+0.0275,决定系数R2=0.9918。

1.2.6 抑菌性的测定

菌悬液的制备:用大肠埃希氏菌和金黄色葡萄球菌作为抑菌性试验的指示菌。将两种菌分别经液体培养基活化后,划线培养于LB固体培养基上,继续挑取单菌落至液体培养基中摇床培养(温度37 ℃、转速180 r/min)12 h后,用比浊法制成含菌数为107 CFU/mL的菌液,用于抑菌试验[25]。

样品处理:无菌条件取发酵的样品,按照2.5倍体积加入无菌水稀释,在4000 r/min下离心15 min。向培养皿中倒入LB固体培养基15 mL,待其凝固后,分别取150 μL不同菌液,用涂布器在LB固体培养基表面均匀涂布,在每个培养皿上放置3个牛津杯(内径6 mm),分别向其中加入发酵样液100 μL,同时加入同等体积无菌生理盐水作空白对照,于37 ℃培养箱中培养12~18 h,培养结束后用游标卡尺测量抑菌圈直径,取平均值。

1.2.7 单因素实验

固定料液比1:1.5(g/mL)、发酵温度42 ℃、发酵时间3 d、加酶量400 U/g,以接种量(5%、10%、15%、20%、25%)为单一研究参数[26];固定接种量为5%、发酵温度42 ℃、发酵时间3 d、加酶量400 U/g,以料液比(1:1、1:1.25、1:1.5、1:1.75、1:2)为单一研究参数;固定接种量为5%、料液比1:1.5、发酵时间3 d、加酶量400 U/g,以不同发酵温度(27、32、37、42、47 ℃)为单一研究参数;固定接种量为5%、料液比1:1.5、发酵温度42 ℃、加酶量400 U/g,以不同发酵时间(1、2、3、4、5 d)为单一研究参数;固定接种量为5%、料液比1:1.5、发酵温度42 ℃、发酵时间3 d,以不同加酶量(100、200、300、400、500 U/g)为单一研究参数。研究不同条件对核桃谷蛋白菌酶协同固态发酵的影响,以多肽含量和抑菌圈直径为指标进行实验。

1.2.8 响应面试验

根据Box-Behnken设计原理,结合单因素实验结果,固定接种量为5%,选择料液比(A)、发酵时间(B)、发酵温度(C)、加酶量(D)4个因素设计四因素三水平试验。以多肽含量(Y1)和对金黄色葡萄球菌抑菌圈直径(Y2)大小为响应值。应用Design-Expert 8.0.6进行优化试验,各因素水平见表1。

表 1 响应面试验因素及水平Table 1. Factors and levels of response surface tests水平 A料液比(g/mL) B发酵温度(℃) C发酵时间(d) D加酶量(U/g) −1 1:1.25 37 2 300 0 1:1.5 42 3 400 1 1:1.75 47 4 500 1.2.9 热稳定性分析

称取10 mg谷蛋白抑菌肽样品于铝坩埚中,以10 ℃/min升温速率从30 ℃加热到160 ℃。空坩埚作对照。使用分析程序ThermalAnalys计算样品的热焓值(J/g)[27]。

1.3 数据处理

采用Origin 2021软件进行制图及Design-Expert 8.0.6软件和Box-Behnken试验方法设计响应面优化分析。利用IBM SPSS statistics 20软件进行ANOVA显著性分析,P<0.05表示具有显著性差异。每个样品均做3个平行,结果以平均值±标准误差表示。

2. 结果与分析

2.1 单因素实验结果

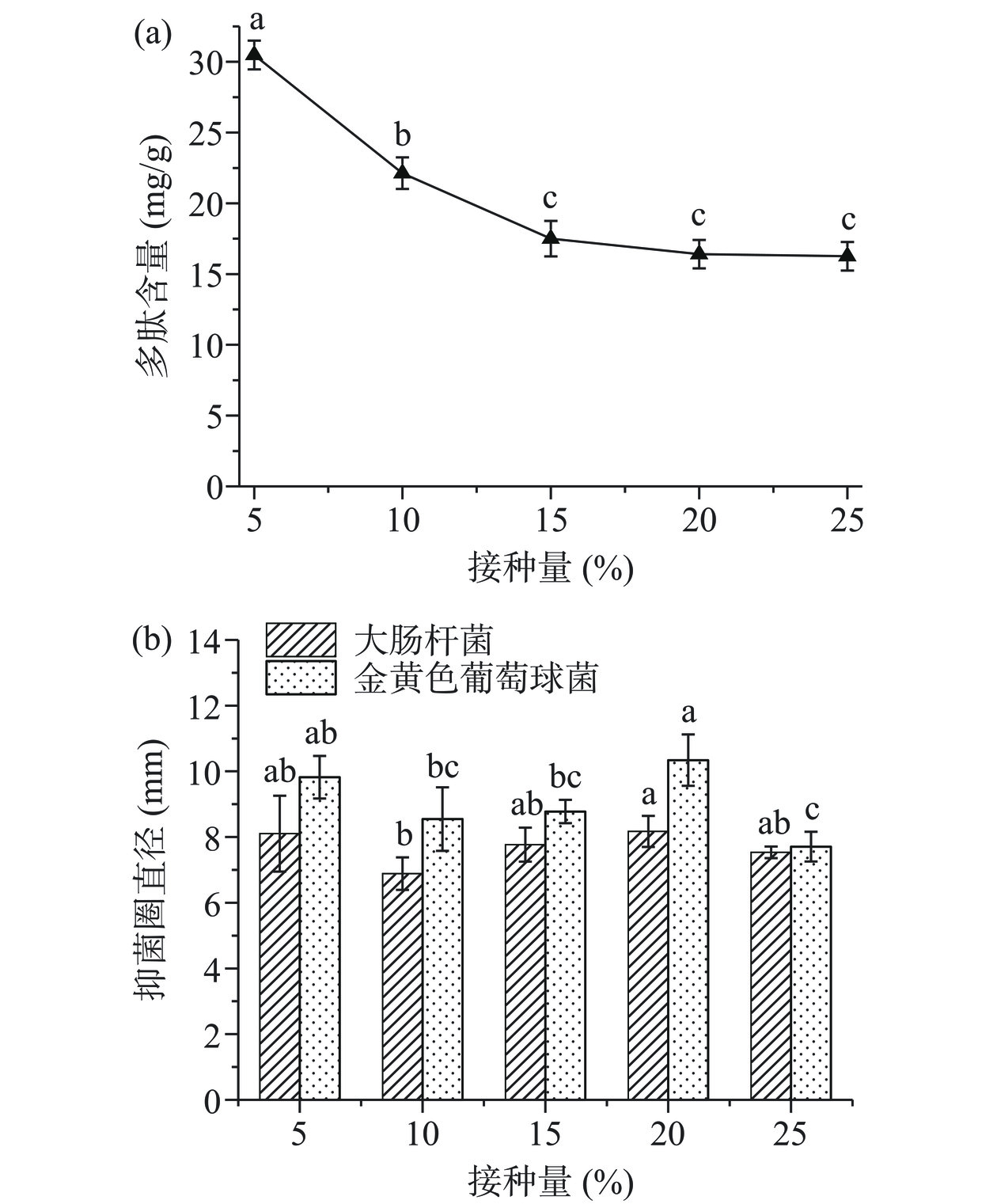

2.1.1 接种量对菌酶协同制备核桃谷蛋白抑菌肽的影响

不同接种量对菌酶协同固态发酵制备核桃谷蛋白抑菌肽的多肽含量和抑菌圈直径影响如图2所示。由图2a可以看出,当枯草芽孢杆菌接种量在5%(v/v)时,多肽含量达到最大值30.48 mg/g。此后,随着接种量的增加,核桃谷蛋白抑菌肽含量逐渐下降并最终趋于稳定。可能是发酵微生物的增多加大了发酵体系中蛋白质的消耗,从而造成多肽含量的降低。继续增加接种量,发酵体系中蛋白质消耗完全,多肽含量最终趋于稳定。

图2b为接种量对核桃谷蛋白抑菌肽抑菌圈直径的影响,通过抑菌圈直径大小可判断谷蛋白抑菌肽抑菌活性的强弱。由图可知,接种量为5%时,谷蛋白抑菌肽对大肠杆菌和金黄色葡萄球菌的抑菌圈直径与接种量为20%时的抑菌圈直径接近,从节约资源及多肽含量考虑,确定菌酶协同固态发酵核桃谷蛋白的最佳接种量为5%。

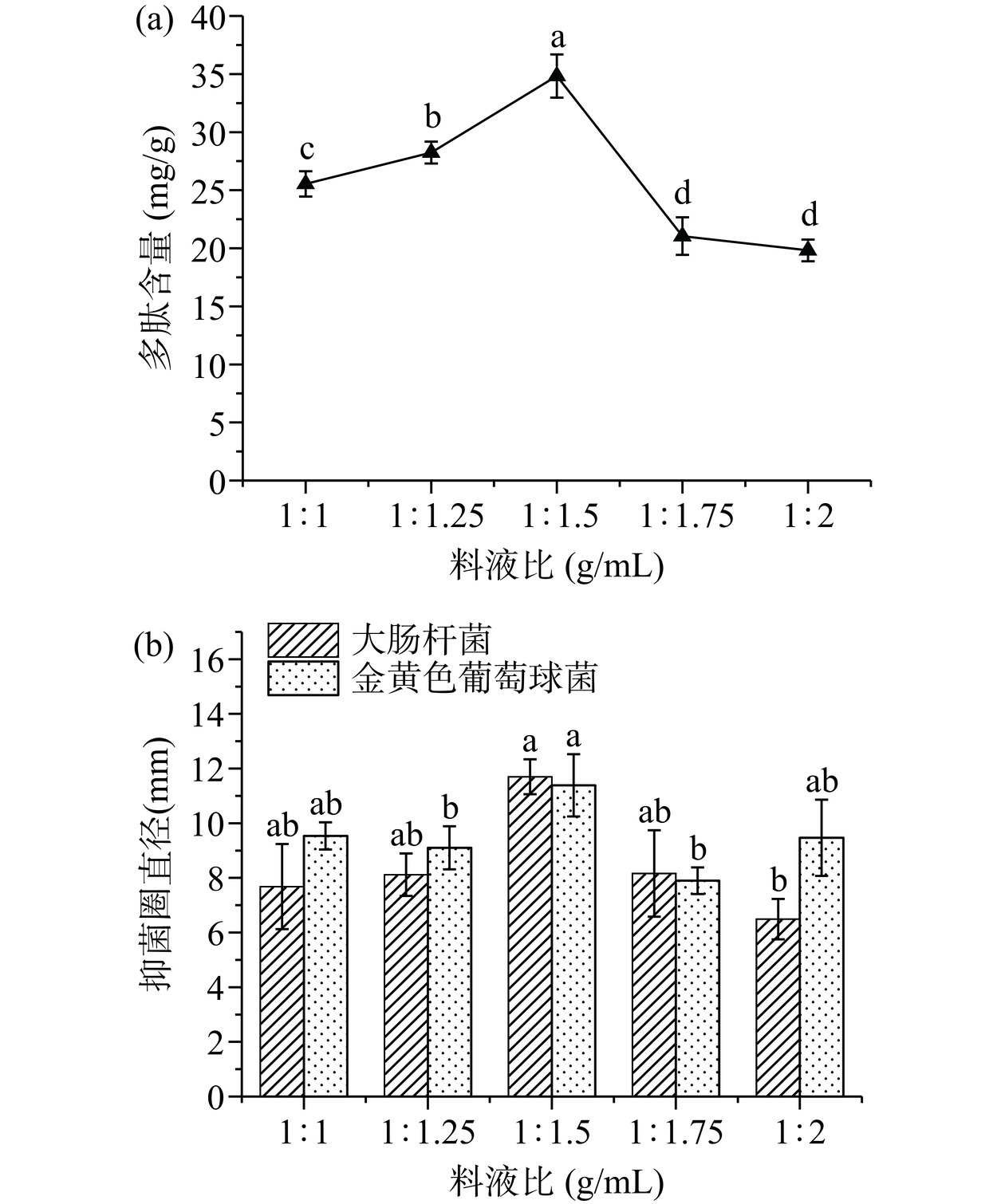

2.1.2 料液比对菌酶协同制备核桃谷蛋白抑菌肽的影响

不同料液比对菌酶协同固态发酵制备核桃谷蛋白抑菌肽的多肽含量和抑菌圈直径影响如图3所示。

由图3a可以看出,随着料液比的增加,多肽含量也在相应增加,这是由于一定量的水使得蛋白酶与原料充分接触,从而具有更好的菌酶协同发酵产多肽效果。当料液比达到1:1.5时,多肽含量达到最大值,且效果显著(P<0.05)。此后随着料液比的增加,多肽含量逐渐下降,这是由于过多的水分阻止了原料与菌和酶的接触。由此表明水分含量会直接影响菌体生长,从而影响多肽含量[28]。

图3b为料液比对核桃谷蛋白抑菌肽抑菌圈直径的影响,由图可知,当料液比为1:1.5时,谷蛋白抑菌肽对大肠杆菌和金黄色葡萄球菌的抑菌圈直径均达到最大,这说明此条件下抑菌效果最好。因此,选择菌酶协同固态发酵核桃谷蛋白的最佳料液比为1:1.5进行后续响应面试验。

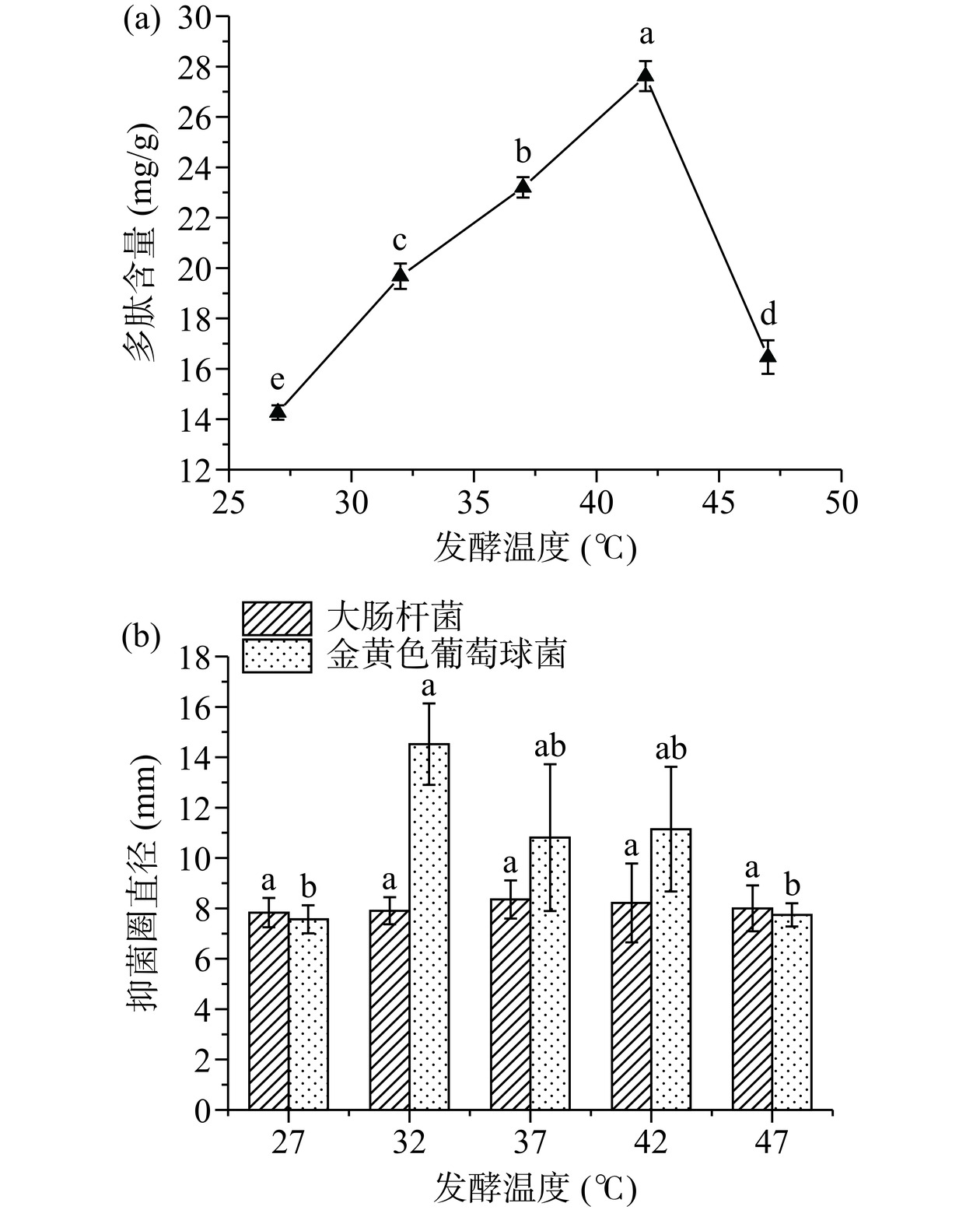

2.1.3 发酵温度对菌酶协同制备核桃谷蛋白抑菌肽的影响

不同发酵温度对菌酶协同固态发酵制备核桃谷蛋白抑菌肽的多肽含量和抑菌圈直径影响如图4所示。

由图4a可得,随着发酵温度的升高,多肽含量呈现先增加后下降的趋势。当发酵温度为42 ℃时,多肽含量最高,达到27.62 mg/g。随后,随着温度的升高,多肽含量呈现下降趋势。且各组发酵温度之间多肽含量差异均显著(P<0.05)。这是由于在菌酶协同固态发酵核桃谷蛋白制备多肽的过程中,适度的高温有利于蛋白酶的酶解反应,但是高温会影响菌体的生长,因此,综合考察碱性蛋白酶与枯草芽孢杆菌的相互作用,选择42 ℃作为两者之间较为合适的发酵温度。

图4b为发酵温度对核桃谷蛋白抑菌肽抑菌圈直径的影响,由图4b可得,当发酵温度为32 ℃时,谷蛋白抑菌肽对金黄色葡萄球菌的抑菌效果最好,27 ℃和47 ℃下对两种菌的抑菌效果都偏低。再次说明低温或者高温都不利于菌酶协同发挥作用。综合多肽含量的变化,最终选择42 ℃作为菌酶协同固态发酵核桃谷蛋白的最佳发酵温度。

2.1.4 发酵时间对菌酶协同制备核桃谷蛋白抑菌肽的影响

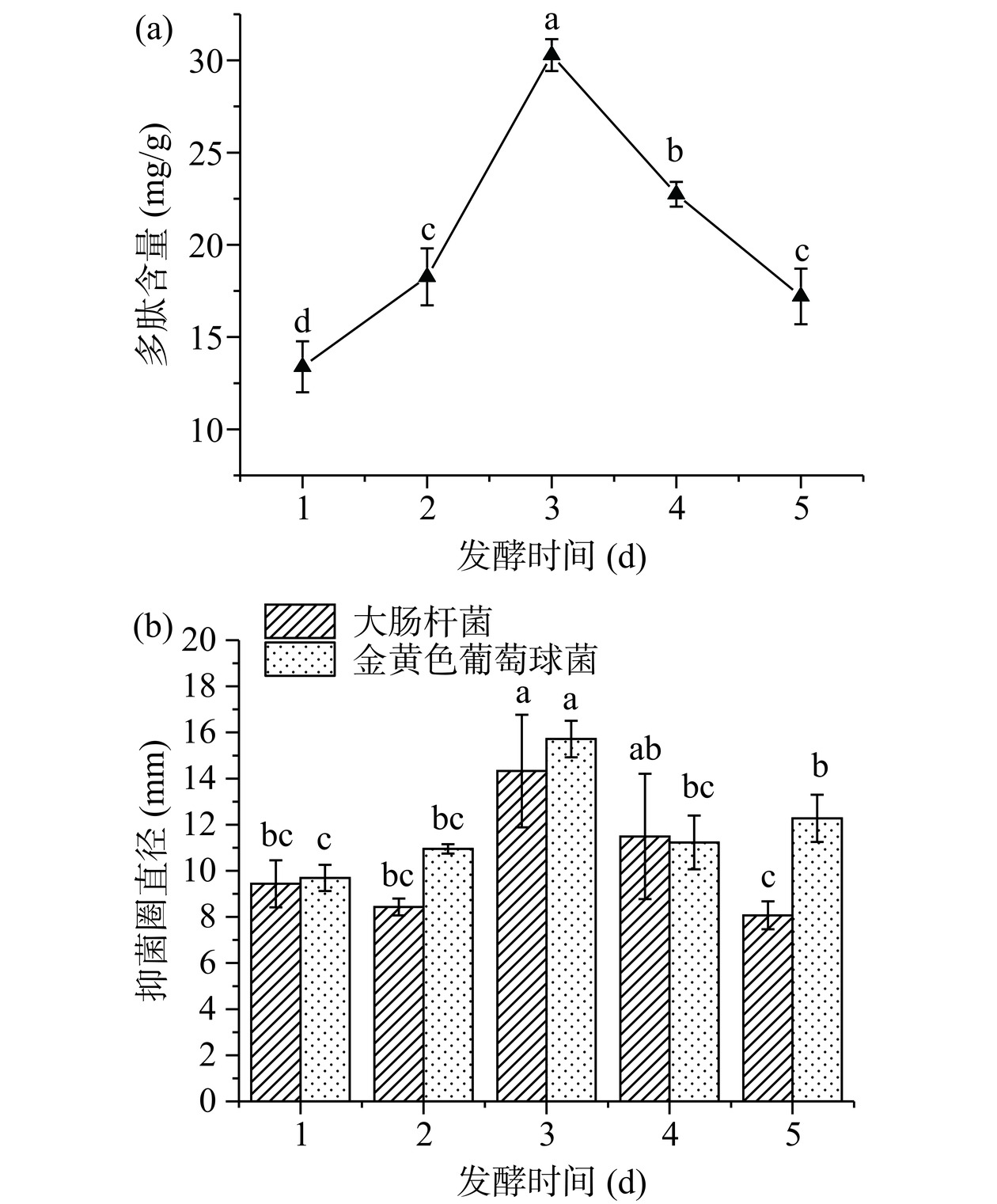

不同发酵时间对菌酶协同固态发酵制备核桃谷蛋白抑菌肽的多肽含量和抑菌圈直径影响如图5所示。

由图5a可知,伴随着发酵时间的增加,在菌和酶的双重作用下,多肽含量在1~3 d内呈现上升趋势,且在第三天达到峰值29.32 mg/g,变化趋势显著(P<0.05),3 d后逐渐下降。说明发酵时间的延长无益于多肽含量的增加,还可能会使多肽被水解成游离氨基酸[29],造成多肽含量的下降。

图5b为发酵时间对核桃谷蛋白抑菌肽抑菌圈直径的影响,由图5b可看出,当菌酶协同固态发酵到第3 d时,谷蛋白抑菌肽对两种菌的抑菌效果最好。所以选择发酵时间为3 d作为菌酶协同固态发酵核桃谷蛋白的最佳条件。

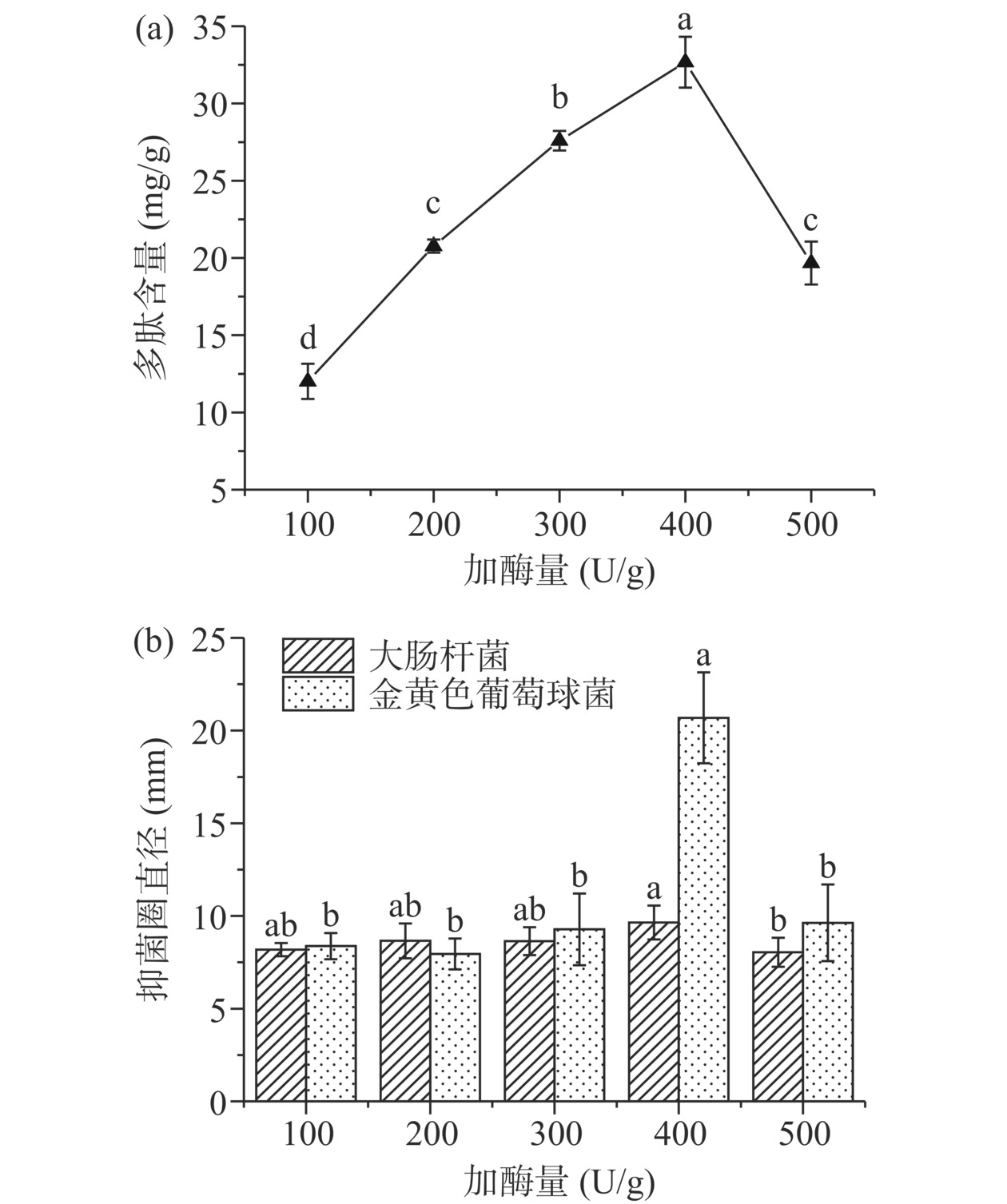

2.1.5 加酶量对枯草芽孢杆菌发酵制备核桃谷蛋白抑菌肽的影响

不同加酶量对菌酶协同固态发酵制备核桃谷蛋白肽的多肽含量和抑菌圈直径影响如图6所示。

由图6a可知,当加酶量在100~400 U/g时,多肽含量随着酶添加量的增加而升高,当酶添加量超过400 U/g时,多肽含量逐渐下降。主要是由于在反应初期底物含量较多,蛋白酶的结合位点也相应较多。而酶和底物之间结合位点过多,也会使酶分子发生竞争抑制[30],从而造成多肽含量的下降。

图6b为加酶量对核桃谷蛋白抑菌肽抑菌圈直径的影响,图6b显示,加酶量为400 U/g时,谷蛋白抑菌肽对金黄色葡萄球菌的抑菌圈直径达到最大20.68 mm,抑菌效果显著(P<0.05)。综合多肽含量结果最终选择加酶量400 U/g作为最佳条件。

2.2 响应面试验结果

用Design Expert 8.0.6软件对表2多肽含量(Y1)和对金黄色葡萄球菌的抑菌圈直径(Y2)的试验数据进行表3的回归与方差分析后,得到菌酶协同固态发酵核桃谷蛋白抑菌肽的多肽含量和抑菌圈直径,对料液比(A)、发酵温度(B)、发酵时间(C)、加酶量(D)各因素变量的二次多元回归方程分别为:

表 2 响应面试验方案与结果Table 2. Design and results of response surface experimental试验号 A料液比 B发酵

温度C发酵

时间D加酶量 Y1多肽含量

(mg/g)Y2抑菌圈

直径(mm)1 0 1 1 0 11.67±1.17 7.22±0.76 2 1 1 0 0 13.72±1.09 9.56±1.34 3 0 1 0 1 11.08±1.04 7.69±0.74 4 −1 1 0 0 14.55±1.04 7.57±0.72 5 0 1 −1 0 15.70±1.39 7.81±0.70 6 0 1 0 −1 12.76±1.71 8.68±1.07 7 −1 0 0 1 17.51±1.77 9.46±1.01 8 0 0 0 0 20.36±1.47 13.25±0.85 9 −1 0 0 −1 21.32±1.19 9.43±1.44 10 0 0 0 0 23.98±1.54 15.92±1.16 11 1 0 1 0 23.19±1.04 7.09±0.47 12 1 0 0 −1 17.88±1.02 9.52±1.53 13 0 0 1 −1 16.95±1.05 7.56±0.80 14 −1 0 −1 0 22.59±1.34 8.89±1.01 15 0 0 0 0 25.44±1.51 13.53±1.78 16 0 0 0 0 26.32±1.62 14.65±0.72 17 0 0 −1 1 20.5±1.08 8.26±1.02 18 1 0 0 1 22.27±1.45 8.67±0.67 19 0 0 −1 −1 19.55±1.17 11.06±1.26 20 −1 0 1 0 17.51±1.01 9.34±1.20 21 0 0 0 0 27.54±1.22 14.27±1.52 22 0 0 1 1 19.65±1.17 8.76±1.26 23 1 0 −1 0 23.36±1.34 10.75±1.85 24 −1 −1 0 0 13.63±1.11 12.01±0.83 25 0 −1 −1 0 15.37±1.98 13.98±0.75 26 0 −1 0 1 15.28±1.23 10.23±1.64 27 0 −1 0 −1 17.89±1.10 9.79±1.76 28 1 −1 0 0 22.98±1.02 9.13±0.80 29 0 −1 1 0 18.32±1.83 8.27±0.93 表 3 回归与方差结果分析Table 3. Analysis of regression and variance results变异来源 平方和 自由度 均方 F值 P值 显著性 Y1 Y2 Y1 Y2 Y1 Y2 Y1 Y2 Y1 Y2 模型 510.57 163.61 14 36.47 11.69 10.28 19.24 <0.0001 <0.0001 ** ** A-液料比 22.11 0.33 1 22.11 0.33 6.23 0.54 0.0256 0.4755 * B-发酵温度 47.96 18.45 1 47.96 18.45 13.52 30.37 0.0025 <0.0001 * ** C-发酵时间 7.97 13.04 1 7.97 13.04 2.25 21.47 0.1561 0.0004 * D-加酶量 3×10−4 0.74 1 3×10−4 0.74 8.5×10−5 1.21 0.9928 0.2899 AB 25.91 5.93 1 25.91 5.93 7.3 9.76 0.0172 0.0075 * * AC 6.03 4.22 1 6.03 4.22 1.7 6.95 0.2135 0.0195 * AD 16.81 0.19 1 16.81 0.19 4.74 0.32 0.0471 0.5813 * BC 12.18 6.55 1 12.18 6.55 3.43 10.79 0.0851 0.0054 * BD 0.22 0.51 1 0.22 0.51 0.061 0.84 0.8086 0.3745 CD 0.77 4 1 0.77 4 0.22 6.58 0.6494 0.0224 * A2 10.43 38.35 1 10.43 38.35 2.94 63.13 0.1084 <0.0001 ** B2 337.49 36.33 1 337.49 36.33 95.14 59.8 <0.0001 <0.0001 ** ** C2 26.91 48.53 1 26.91 48.53 7.59 79.88 0.0155 <0.0001 * ** D2 79.55 48 1 79.55 48 22.42 79.01 0.0003 <0.0001 * ** 残差 49.66 8.51 14 3.55 0.61 失拟项 19.08 4.07 10 1.91 0.41 0.25 0.37 0.9659 0.91 不显著 不显著 纯误差 30.59 4.44 4 7.65 1.11 总离差 560.23 172.12 28 注:**差异极显著,P<0.0001;*差异显著,P<0.05。 Y1=24.73−1.36A+2B+0.81C+(5.000E−003)D−2.54AB+1.23AC+2.05AD−1.74BC+0.23BD+0.44CD−1.27A2−7.21B2−2.04C2−3.50D2;

Y2=14.32−0.16A+1.24B+1.04C+0.25D+1.22AB−1.03AC−0.22AD+1.28BC−0.36BD+1.00CD−2.43A2−2.37B2−2.74C2−2.72D2。

从表3可知,对于多肽含量Y1来说,模型F值为10.28(P<0.0001),说明该模型极显著。失拟项P=0.9659>0.05不显著,说明模型比较稳定,拟合度良好。其中,R2=0.9113,说明试验值和拟合值相关性较好,模型校正系数R2adj=0.8227,说明该模型能够解释82.27%试验数据响应值的变化。因此,该二次回归方程可以客观预测菌酶协同固态发酵后,多肽含量随各因素变化的规律。由表可知,B2达到极显著水平,A、B、AB、AD、C2、D2达到显著水平,而C、D、AC、BC、BD、CD、A2对核桃谷蛋白抑菌肽的多肽含量没有显著影响,综上分析各因素对核桃谷蛋白抑菌肽的多肽含量影响顺序为B>A>C>D。可知该模型与实际情况拟合良好,可用于核桃谷蛋白抑菌肽的多肽含量的优化。

对于抑菌圈直径来说,模型F值为19.24(P<0.0001),说明该模型极显著。失拟项P=0.91>0.05不显著,说明模型比较稳定,拟合度良好。其中,R2=0.9506,说明试验值和拟合值相关性较好,模型校正系数R2adj=0.9012,说明该模型能够解释90.12%的试验数据响应值变化。因此,该二次回归方程可以客观预测菌酶协同固态发酵后抑菌圈直径随各因素变化的规律。由表可知,B、A2、B2、C2、D2达到极显著水平(P<0.01),C、AB、AC、BC、CD达到显著水平(P<0.05),而A、D、AD和BD对核桃谷蛋白抑菌肽的抑菌圈直径没有显著影响,综上分析各因素对核桃谷蛋白抑菌肽的抑菌圈直径影响顺序为B>C>D>A。可知该模型与实际情况拟合良好,可用于核桃谷蛋白抑菌肽抑菌圈直径的优化。

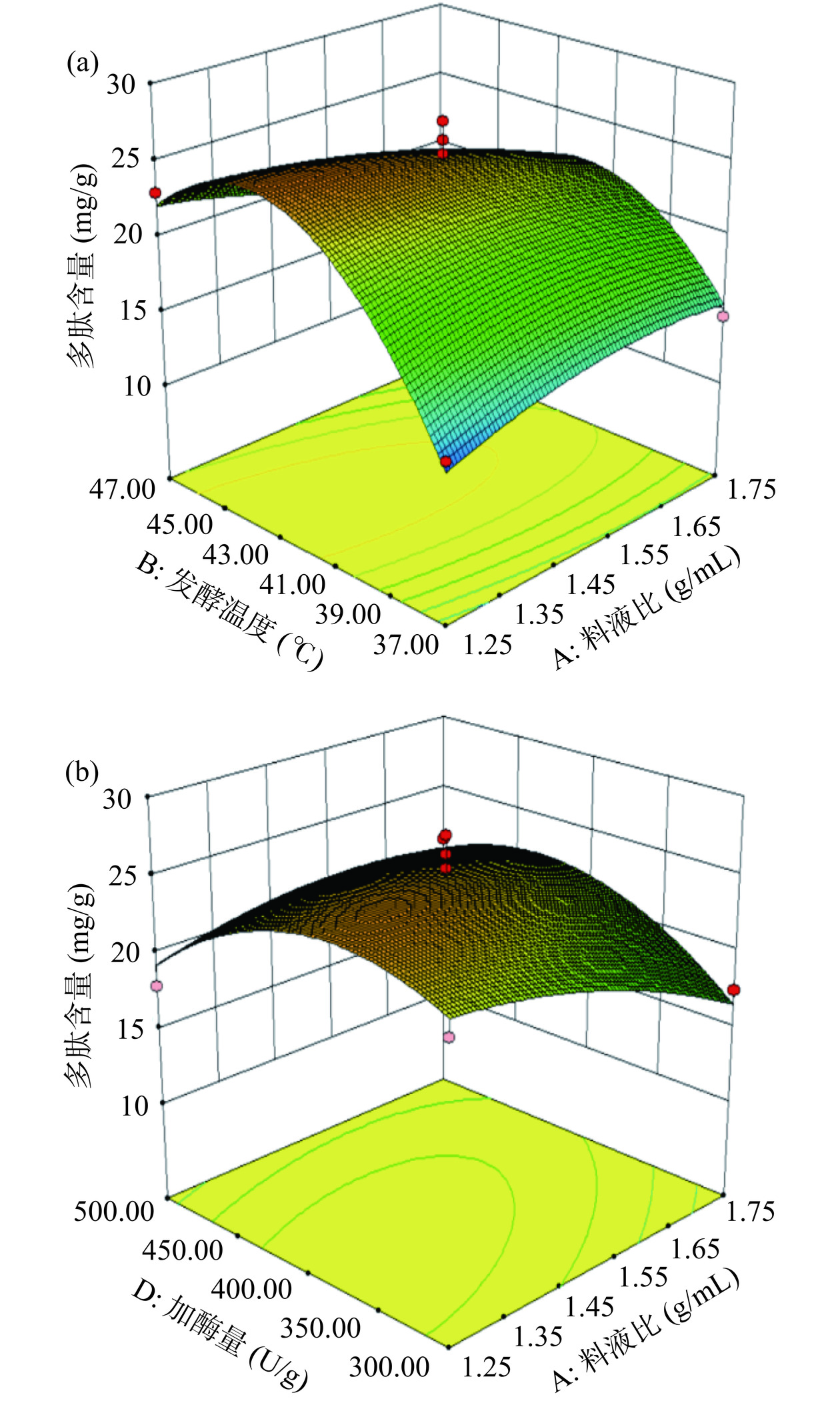

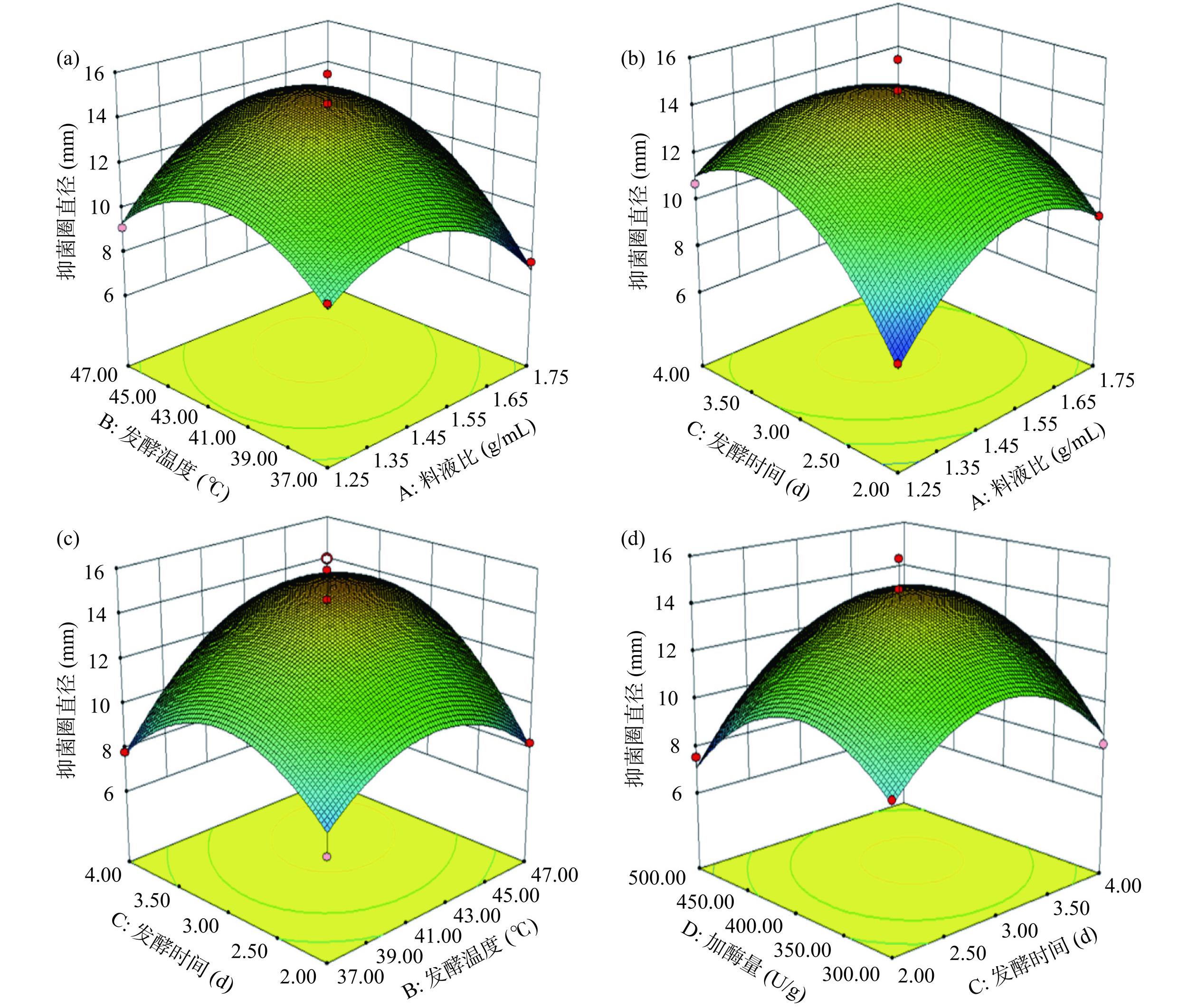

2.3 响应面交互作用分析

菌酶协同发酵制备核桃谷蛋白抑菌肽各个因素之间交互作用对多肽含量的影响如图7所示,对抑菌圈直径的影响如图8所示。从图7可看出,液料比与发酵温度、料液比与加酶量之间的交互作用等高线均呈现椭圆形,响应面较为陡峭,说明这两组分别对多肽含量具有显著性的影响(P<0.05)。图8所呈现的两两之间的交互作用等高线也都呈现椭圆形,且响应面曲线不平缓,由此可知液料比与发酵温度、液料比与发酵时间、发酵时间与发酵温度、发酵时间与加酶量之间的交互作用对抑菌圈直径均有显著性的影响(P<0.05),与方差分析结果一致。

采用Design-Expert 8.0.6对试验进行优化分析,得到谷蛋白抑菌肽最佳制备工艺为:料液比1:1.47(g/mL)、发酵温度42.96 ℃、发酵时间3.21 d、加酶量404.01 U/g,此时多肽含量为24.99 mg/g,抑菌圈直径达到14.59 mm。从实际操作性及节约资源方面,将菌酶协同固态发酵条件调整为料液比1:1.5(g/mL),发酵温度43 ℃、发酵时间3 d、加酶量400 U/g。在此条件下经过验证试验,得到多肽含量为26.35±1.29 mg/g,对金黄色葡萄球菌抑菌圈直径为15.50±1.53 mm。

2.4 热稳定性分析

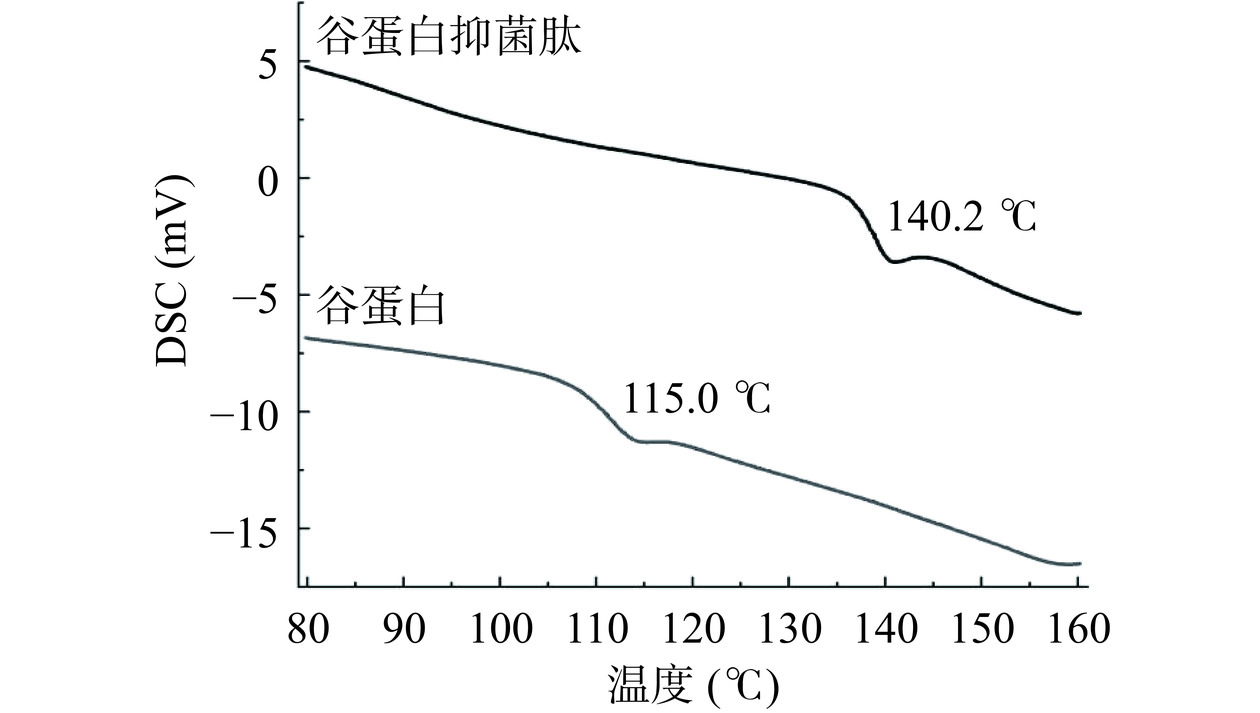

图9为谷蛋白和谷蛋白抑菌肽的差示扫描量热 (Differential Scanning Calorimeter,DSC)图谱,热学特性见表4。

表 4 谷蛋白和谷蛋白抑菌肽的热学特性Table 4. Thermal properties of glutelin and glutelin antimicrobial peptides样品 起始温度(℃) 峰值温度(℃) 终止温度(℃) 热焓值(J/g) 谷蛋白 110.1 115.0 118.9 2.3449 谷蛋白抑菌肽 136.7 140.2 142.6 3.5950 峰值温度与热焓值反映蛋白质的热稳定性[31]。从图9可知,核桃谷蛋白和谷蛋白抑菌肽DSC扫描图谱都只有一个平滑的吸热峰,无杂质峰,这说明本试验所用样品的蛋白质含量比较高。由表1可知,谷蛋白和谷蛋白抑菌肽峰值温度分别为115.0 ℃和140.2 ℃,热焓值分别为2.3449和3.5950 J/g。说明经过菌酶协同发酵制备的核桃谷蛋白抑菌肽比原料谷蛋白组分更稳定,对热相对不敏感,具有更高的热稳定性。

3. 结论

试验采用菌酶协同固态发酵法制备核桃谷蛋白抑菌肽,通过对菌酶协同发酵处理核桃谷蛋白的影响因素进行探究,确定最佳工艺条件:接种量5%(v/v)、料液比1:1.5(g/mL)、发酵温度42 ℃、发酵时间3 d、加酶量400 U/g。在此条件下,谷蛋白抑菌肽多肽含量达到26.35±1.29 mg/g;对金黄色葡萄球菌具有明显的抑菌效果,抑菌圈直径达到15.50±1.53 mm。且谷蛋白抑菌肽比谷蛋白具有更高的热稳定性。

菌酶协同处理目前在生物活性肽制备方面主要集中在抗氧化、ACE抑制肽等方面,在抑菌肽的制备领域研究较少。使用菌酶协同技术制备核桃谷蛋白抑菌肽不仅解决了简单的酶解和单纯的微生物发酵过程中存在的不足,且提高了抑菌肽的稳定性,这为核桃粕的高值化利用提供了新的研究思路,也为新型抗生素的替代品以及食品级抗菌剂研发奠定了基础。但本试验只是进行了菌酶协同制备抑菌肽及其热稳定性的研究,并未明确其抑菌机制,有待进一步深入研究。

-

表 1 响应面试验因素及水平

Table 1 Factors and levels of response surface tests

水平 A料液比(g/mL) B发酵温度(℃) C发酵时间(d) D加酶量(U/g) −1 1:1.25 37 2 300 0 1:1.5 42 3 400 1 1:1.75 47 4 500 表 2 响应面试验方案与结果

Table 2 Design and results of response surface experimental

试验号 A料液比 B发酵

温度C发酵

时间D加酶量 Y1多肽含量

(mg/g)Y2抑菌圈

直径(mm)1 0 1 1 0 11.67±1.17 7.22±0.76 2 1 1 0 0 13.72±1.09 9.56±1.34 3 0 1 0 1 11.08±1.04 7.69±0.74 4 −1 1 0 0 14.55±1.04 7.57±0.72 5 0 1 −1 0 15.70±1.39 7.81±0.70 6 0 1 0 −1 12.76±1.71 8.68±1.07 7 −1 0 0 1 17.51±1.77 9.46±1.01 8 0 0 0 0 20.36±1.47 13.25±0.85 9 −1 0 0 −1 21.32±1.19 9.43±1.44 10 0 0 0 0 23.98±1.54 15.92±1.16 11 1 0 1 0 23.19±1.04 7.09±0.47 12 1 0 0 −1 17.88±1.02 9.52±1.53 13 0 0 1 −1 16.95±1.05 7.56±0.80 14 −1 0 −1 0 22.59±1.34 8.89±1.01 15 0 0 0 0 25.44±1.51 13.53±1.78 16 0 0 0 0 26.32±1.62 14.65±0.72 17 0 0 −1 1 20.5±1.08 8.26±1.02 18 1 0 0 1 22.27±1.45 8.67±0.67 19 0 0 −1 −1 19.55±1.17 11.06±1.26 20 −1 0 1 0 17.51±1.01 9.34±1.20 21 0 0 0 0 27.54±1.22 14.27±1.52 22 0 0 1 1 19.65±1.17 8.76±1.26 23 1 0 −1 0 23.36±1.34 10.75±1.85 24 −1 −1 0 0 13.63±1.11 12.01±0.83 25 0 −1 −1 0 15.37±1.98 13.98±0.75 26 0 −1 0 1 15.28±1.23 10.23±1.64 27 0 −1 0 −1 17.89±1.10 9.79±1.76 28 1 −1 0 0 22.98±1.02 9.13±0.80 29 0 −1 1 0 18.32±1.83 8.27±0.93 表 3 回归与方差结果分析

Table 3 Analysis of regression and variance results

变异来源 平方和 自由度 均方 F值 P值 显著性 Y1 Y2 Y1 Y2 Y1 Y2 Y1 Y2 Y1 Y2 模型 510.57 163.61 14 36.47 11.69 10.28 19.24 <0.0001 <0.0001 ** ** A-液料比 22.11 0.33 1 22.11 0.33 6.23 0.54 0.0256 0.4755 * B-发酵温度 47.96 18.45 1 47.96 18.45 13.52 30.37 0.0025 <0.0001 * ** C-发酵时间 7.97 13.04 1 7.97 13.04 2.25 21.47 0.1561 0.0004 * D-加酶量 3×10−4 0.74 1 3×10−4 0.74 8.5×10−5 1.21 0.9928 0.2899 AB 25.91 5.93 1 25.91 5.93 7.3 9.76 0.0172 0.0075 * * AC 6.03 4.22 1 6.03 4.22 1.7 6.95 0.2135 0.0195 * AD 16.81 0.19 1 16.81 0.19 4.74 0.32 0.0471 0.5813 * BC 12.18 6.55 1 12.18 6.55 3.43 10.79 0.0851 0.0054 * BD 0.22 0.51 1 0.22 0.51 0.061 0.84 0.8086 0.3745 CD 0.77 4 1 0.77 4 0.22 6.58 0.6494 0.0224 * A2 10.43 38.35 1 10.43 38.35 2.94 63.13 0.1084 <0.0001 ** B2 337.49 36.33 1 337.49 36.33 95.14 59.8 <0.0001 <0.0001 ** ** C2 26.91 48.53 1 26.91 48.53 7.59 79.88 0.0155 <0.0001 * ** D2 79.55 48 1 79.55 48 22.42 79.01 0.0003 <0.0001 * ** 残差 49.66 8.51 14 3.55 0.61 失拟项 19.08 4.07 10 1.91 0.41 0.25 0.37 0.9659 0.91 不显著 不显著 纯误差 30.59 4.44 4 7.65 1.11 总离差 560.23 172.12 28 注:**差异极显著,P<0.0001;*差异显著,P<0.05。 表 4 谷蛋白和谷蛋白抑菌肽的热学特性

Table 4 Thermal properties of glutelin and glutelin antimicrobial peptides

样品 起始温度(℃) 峰值温度(℃) 终止温度(℃) 热焓值(J/g) 谷蛋白 110.1 115.0 118.9 2.3449 谷蛋白抑菌肽 136.7 140.2 142.6 3.5950 -

[1] ZHOU Xingjian, PENG Xingyu, PEI Huan, et al. An overview of walnuts application as a plant-based[J]. Frontiers in Endocrinology,2022,13(10):1−5.

[2] ZHANG Wen, LI Hua. Research progress on the preparation and functional activity of walnut peptides[J]. Food Industry,2020,41:257−259.

[3] 邸红艳, 马海乐, 王洋, 等. 超声辅助提取核桃粕蛋白的工艺研究[J]. 现代食品科技,2019,35(7):164−170. [DI H Y, MA H L, WANG Y, et al. Study on ultrasound-assisted extraction of walnut meal protein[J]. Modern Food Technology,2019,35(7):164−170.] DI H Y, MA H L, WANG Y, et al. Study on ultrasound-assisted extraction of walnut meal protein[J]. Modern Food Technology, 2019, 35(7): 164−170.

[4] GOLLY M K, MA H L, DUAN Y Q, et al. Enzymolysis of walnut (Juglans regia L.) meal protein:Ultrasonication-assisted alkaline pretreatment impact on kinetics and thermodynamics[J]. Journal of Food Biochemistry,2019,43(8):e12948.

[5] 门德盈, 代佳和, 汤木果, 等. 核桃肽制备及生物活性的研究进展[J]. 食品科学,2022,43(23):367−376. [MEN D Y, DAI J H, TANG M G, et al. Research progress on preparation and biological activity of walnut peptides[J]. Food Science,2022,43(23):367−376.] MEN D Y, DAI J H, TANG M G, et al. Research progress on preparation and biological activity of walnut peptides[J]. Food Science, 2022, 43(23): 367−376.

[6] WANG Jing, WANG Guoliang, CHEN Ning, et al. Characterization of structural, functional and antioxidant properties and amino acid composition of pepsin-derived glutelin-1 hydrolysate from walnut processing by-products[J]. Rsc Advances,2021,11(31):19158−19168. doi: 10.1039/D1RA00657F

[7] YAN Chunjun, ZHOU Zheng. Walnut pellicle phenolics greatly influence the extraction and structural properties of walnut protein isolates[J]. Food Research International,2021,141:110163−110165. doi: 10.1016/j.foodres.2021.110163

[8] 徐倩, 陈洲, 王青华, 等. 核桃球蛋白的分离纯化、鉴定及抗氧化性分析[J]. 食品工业科技,2022,43(18):105−113. [XU Q, CHEN Z, WANG Q H, et al. Isolation, purification, identification and antioxidant analysis of walnut globulin[J]. Food Industry Technology,2022,43(18):105−113.] XU Q, CHEN Z, WANG Q H, et al. Isolation, purification, identification and antioxidant analysis of walnut globulin[J]. Food Industry Technology, 2022, 43(18): 105−113.

[9] 邱娟. 核桃清蛋白抗氧化肽对力竭运动小鼠抗疲劳和抗氧化能力的影响[J]. 基因组学与应用生物学,2020,39(5):2222−2229. [QIU J. Effects of walnut albumin antioxidant peptides on fatigue and antioxidant capacity in exhausted exercise mice[J]. Genomics and Applied Biology,2020,39(5):2222−2229.] QIU J. Effects of walnut albumin antioxidant peptides on fatigue and antioxidant capacity in exhausted exercise mice[J]. Genomics and Applied Biology, 2020, 39(5): 2222−2229.

[10] QIAN Sun, ZHENG Feima, ZHANG Hongxia, et al. Structural characteristics and functional properties of walnut glutelin as hydrolyzed:effect of enzymatic modification[J]. International Journal of Food Properties,2019,22(1):265−279. doi: 10.1080/10942912.2019.1579738

[11] LI Feng, PENG Fei, WANG Xiaojing, et al. Identification and characterization of antioxidative peptides derived from simulatedin vitro gastrointestinal digestion of walnut meal proteins[J]. Food Research International,2018,116:518−526.

[12] WANG Cong, TU Maolin, WU Di, et al. Identification of an ACE-Inhibitory peptide from walnut protein and its evaluation of the inhibitory mechanism[J]. International Journal of Molecular Sciences,2018,19(4):1156. doi: 10.3390/ijms19041156

[13] WANG Shuguang, SU Guowan, ZHANG Xun, et al. Characterization and exploration of potential neuroprotective peptides in walnut (Juglans regia) protein hydrolysate against cholinergic system damage and oxidative stress in scopolamine-induced cognitive and memory impairment mice and zebrafish[J]. Journal of Agricultural and Food Chemistry,2021,69(9):2773−2783. doi: 10.1021/acs.jafc.0c07798

[14] JENNIFER C, THOMAS J M, INGOLF F. et al. Chikindas bacteriocins:Safe, natural antimicrobials for food preservation[J]. International Journal of Food Microbiology,2001,71(1):1−20. doi: 10.1016/S0168-1605(01)00560-8

[15] LIU Dongwei, LIU Mei, MENG Dehao, et al. Harsh sensitivity and mechanism exploration of an bacteriostatic peptide extracted from walnut oil residue derived from agro-industrial waste[J]. Journal of Agricultural and Food Chemistry,2022,70(24):7460−7470. doi: 10.1021/acs.jafc.2c02699

[16] 卢蔼纯, 苏嘉毅, 杨迅, 等. 富硒核桃粕蛋白降血压肽的酶解制备、超滤分离及硒含量分析[J]. 现代食品科技,2023,5(12):1−10. [LU A C, SU J Y, YANG X, et al. Enzymatic hydrolysis preparation, ultrafiltration separation and selenium content analysis of selenium-rich walnut meal protein antihypertensive peptide[J]. Modern Food Science and Technology,2023,5(12):1−10.] LU A C, SU J Y, YANG X, et al. Enzymatic hydrolysis preparation, ultrafiltration separation and selenium content analysis of selenium-rich walnut meal protein antihypertensive peptide[J]. Modern Food Science and Technology, 2023, 5(12): 1−10.

[17] ZHENG Xiao, LI Dongsheng, DING Ke, et al. Purification and identification of angiotensin I-converting enzyme inhibitory peptides from fermented walnut residues[J]. International Journal of Food Properties,2018,20(3):S3326−S3333.

[18] RIVERO-PINO F. Bioactive food-derived peptides for functional nutrition:Effect of fortification, processing and storage on peptide stabilityand bioactivity within food matrices[J]. Food Chemistry,2023,406:135046. doi: 10.1016/j.foodchem.2022.135046

[19] 张娅妮, 阮晓惠, 陈浩, 等. 核桃蛋白的酶解工艺优化及产物特性研究[J]. 中国油脂,2021,46(10):18−23. [ZHANG Y N, RUAN X H, CHEN H, et al. Enzymatic hydrolysis process optimization and product characteristics of walnut protein[J]. China Oils and Fats,2021,46(10):18−23.] ZHANG Y N, RUAN X H, CHEN H, et al. Enzymatic hydrolysis process optimization and product characteristics of walnut protein[J]. China Oils and Fats, 2021, 46(10): 18−23.

[20] SZE-TAO K W C, SATHE S K. Walnut (Juglans regia L.):Proximate composition, proteinsolubility, protein amino acid composition and protein in vitro digestibility[J]. Journal of the Science of Food and Agriculture,2000(80):1393−1401.

[21] 毛晓英. 核桃蛋白质的结构表征及其制品的改性研究[D]. 无锡:江南大学, 2012. [MAO X Y. Structural characterization of walnut protein and modification of its products[D]. Wuxi:Jiangnan University, 2012.] MAO X Y. Structural characterization of walnut protein and modification of its products[D]. Wuxi: Jiangnan University, 2012.

[22] 刘潇, 郭丽娜, 马海乐, 等. 枯草芽孢杆菌和黑曲霉固态发酵制备核桃多肽的工艺条件优化[J]. 现代食品科技,2018,34(8):130−137. [LIU X, GUO L N, MA H L. et al. Optimization of process conditions for preparation of walnut polypeptides by solid fermentation of bacillus subtilis and Aspergillus niger[J]. Modern Food Science and Technology,2018,34(8):130−137.] LIU X, GUO L N, MA H L. et al. Optimization of process conditions for preparation of walnut polypeptides by solid fermentation of bacillus subtilis and Aspergillus niger[J]. Modern Food Science and Technology, 2018, 34(8): 130−137.

[23] 齐晓芬, 齐良君, 孙立斌, 等. 枯草芽孢杆菌和中性蛋白酶协同发酵豆粕方法的研究[J]. 食品工业,2016,37(9):163−168. [QI X F, QI L J, SUN L B, et al. Study on synergistic fermentation of soybean meal by Bacillus subtilis and neutral protease[J]. Food Industry,2016,37(9):163−168.] QI X F, QI L J, SUN L B, et al. Study on synergistic fermentation of soybean meal by Bacillus subtilis and neutral protease[J]. Food Industry, 2016, 37(9): 163−168.

[24] 刘潇. 基于磁场强化与原位监测的核桃多肽固态发酵-蛋白酶解联合制备技术研究[D]. 镇江:江苏大学, 2019. [LIU X. Research on combined preparation technology of walnut polypeptide solid-state fermentation-protease based on magnetic field strengthening and in situ monitoring[D]. Zhenjiang:Jiangsu University, 2019.] LIU X. Research on combined preparation technology of walnut polypeptide solid-state fermentation-protease based on magnetic field strengthening and in situ monitoring[D]. Zhenjiang: Jiangsu University, 2019.

[25] 魏嘉雯, 王海宽, 张惠玲. 副干酪乳杆菌固态发酵对红枣碎活性成分和抑菌性影响[J]. 食品工业科技,2020,41(21):133−138. [WEI Jiawen, WANG Haikuan, ZHANG Huiling. Effect of solid-state fermentation of Lactobacillus paracasei on active ingredients and antibacterial activity of jujube chips[J]. Food Industry Technology,2020,41(21):133−138.] WEI Jiawen, WANG Haikuan, ZHANG Huiling. Effect of solid-state fermentation of Lactobacillus paracasei on active ingredients and antibacterial activity of jujube chips[J]. Food Industry Technology, 2020, 41(21): 133−138.

[26] 武万兴. 固态发酵核桃粕制备抗氧化活性肽的研究[D]. 昆明:昆明理工大学, 2015. [WU W X. Study on preparation of antioxidant active peptides from solid-fermented walnut meal[D]. Kunming:Kunming University of Science and Technology, 2015.] WU W X. Study on preparation of antioxidant active peptides from solid-fermented walnut meal[D]. Kunming: Kunming University of Science and Technology, 2015.

[27] 张佳宁, 李俊, 郝艳宾, 等. 超微粉碎处理对核桃蛋白结构及功能性质的影响[J]. 食品研究与开发,2023,44(8):23−29,130. [ZHANG J N, LI J, HAO Y B, et al. Effects of ultrafine pulverization on the structure and functional properties of walnut protein[J]. Food Research and Development,2023,44(8):23−29,130.] ZHANG J N, LI J, HAO Y B, et al. Effects of ultrafine pulverization on the structure and functional properties of walnut protein[J]. Food Research and Development, 2023, 44(8): 23−29,130.

[28] HARMON D D, PHIPPS K P. Invited review:Rise of craft breweries in the southeastern USA increases supplement availability for beef cattle[J]. Applied Animal Science,2022,38(6):540−550. doi: 10.15232/aas.2022-02315

[29] PURBANINGRUM K, HIDAYAT C, WITASARILUCIA D, et al. Flavor precursors and volatile compounds improvement of unfermented cocoa beans by hydrolysis using bromelain[J]. Foods,2023,12(4):820−820. doi: 10.3390/foods12040820

[30] 阙凤, 夏雨婷, 高天麒, 等. β-葡聚糖酶降解魔芋葡甘聚糖产物的制备及结构表征[J]. 食品科学,2023,44(8):9−15. [QUE F, XIA Y T, GAO T Q, et al. Preparation and structural characterization of glucomannan products degraded by β-glucanase from konjac glucomannan[J]. Food Science,2023,44(8):9−15.] QUE F, XIA Y T, GAO T Q, et al. Preparation and structural characterization of glucomannan products degraded by β-glucanase from konjac glucomannan[J]. Food Science, 2023, 44(8): 9−15.

[31] DI MATTEO P, LUZIATELLI F, BORTOLAMI M, et al. Differential scanning calorimetry (DSC) as a tool for studying thermal properties of a crude cellulase cocktail[J]. Chemical Papers,2023,77(5):2689−2696. doi: 10.1007/s11696-022-02658-3

-

期刊类型引用(11)

1. 姜坤,李玉国,张道志,徐恒伟,冯丹萍,孟小茜,郑春英. 微生物发酵对刺五加叶黄酮类成分生物合成的影响. 中国农学通报. 2024(03): 145-151 .  百度学术

百度学术

2. 陆少君,蔡肇栩,郭瑞雪,谢群巧,罗力,唐春萍,陈文健,江涛. 基于TLR-4/NF-κB信号通路探究金花茶提取物对非酒精性脂肪肝的作用. 食品工业科技. 2024(20): 349-360 .  本站查看

本站查看

3. 周月,王一珈,臧健,高英旭,潘丰,郭志富,李胤之. 刺五加活性成分及药用价值研究进展. 辽宁林业科技. 2024(06): 48-50+71 .  百度学术

百度学术

4. 何嘉伟,江汉美,黄振阳,曾格格,戴全武,刘天琪,韩蔓. HS-SPME-GC-MS结合化学计量法分析刺五加不同部位的挥发性成分. 南京中医药大学学报. 2023(02): 146-156 .  百度学术

百度学术

5. 李强,袁勇,李玉,于建海. 刺五加多糖对奶牛生产性能、抗氧化指标及免疫功能的影响. 中国饲料. 2023(12): 28-31 .  百度学术

百度学术

6. 丁思宇,张道涵,韩丽琴. 星点-响应面法优化刺五加根黄酮闪式提取工艺研究. 吉林医药学院学报. 2023(04): 269-271 .  百度学术

百度学术

7. 孙琳,井长欣,邹睿,辛宇,张晓旭,邱智东,王伟楠. 刺五加-灵芝双向固体发酵工艺优化及抗氧化活性评价. 科学技术与工程. 2023(21): 9004-9014 .  百度学术

百度学术

8. 李强,张若冰,杨玉赫,田冰,李文兰,李陈雪. 刺五加叶化学成分及药理作用研究进展. 药学研究. 2023(07): 495-501 .  百度学术

百度学术

9. 石玉璞,牛思思,韩璐瑶,李莞颖,余君伟,武冰辉,徐波,张艳萍,曹艳,乔长晟. 枸杞刺梨复合饮料的工艺优化及其降血糖性能. 食品研究与开发. 2023(18): 149-157 .  百度学术

百度学术

10. 茆鑫,郑剑斌,李广耀,曲敏,郑心琪. 响应曲面法优化刺五加-五味子混菌发酵工艺的研究. 食品科技. 2023(09): 57-64 .  百度学术

百度学术

11. 戴丛书,柴晶美,林长青. 金银花黄酮提取物的降血糖作用. 食品工业科技. 2022(24): 386-393 .  本站查看

本站查看

其他类型引用(5)

下载:

下载:

下载:

下载: