Nano-starch and Its Structural Properties Prepared from Enzymolysis-Dynamic High Pressure Micro-fluidization

-

摘要: 为探究蜡质玉米淀粉(WMS)经普鲁兰酶协同动态超高压微射流技术(P-DHPM)制备纳米淀粉后对其结构及性质的变化规律,本文探讨了处理前后淀粉微观结构、结晶结构、分子结构、粒径、分子量及热性能的变化趋势。结果表明,随着酶解时间的增加,淀粉圆球形颗粒变碎片状、结晶结构逐渐消失、淀粉短程有序性增加、分子量显著(P<0.05)减小;同时,淀粉糊化峰值温度由71.23 ℃降低至55.81 ℃,糊化焓值(ΔH)显著 (P<0.05)减小至4.68 J/g;酶解淀粉进一步经微射流处理后,粒径降低至纳米级,淀粉颗粒变成更加无规则的小碎片,糊化峰值温度(Tp)降低至55.37 ℃,糊化焓值(ΔH)增大至14.13 J/g。通过酶解-微射流技术处理WMS淀粉,可制备得到粒径可控且具有短程有序的纳米尺寸淀粉颗粒,提供了一种环境友好、操作简单的制备方法,同时为继续探讨其在淀粉纳米乳液及淀粉基活性包装材料中的应用奠定基础。Abstract: In order to investigate the changes in structure and properties of waxy maize starch (WMS) after its nano-starch was prepared by pullulanase enzymolysis-dynamic high pressure micro-fluidization technology (P-DHPM), this paper explored the trends of changes in starch microstructure, crystalline structure, molecular structure, particle size, molecular weight, and thermal properties before and after the treatment. The results showed that spherical starch particles were turned into fragmentization, and the crystalline structures were transferred into amorphous states, the short-range ordered structure was increased, and the molecular weight of starch was decreased with the increment of enzymatic hydrolysis time. In the meantime, the peak gelatinization temperature (Tp) of treated starch was decreased from 71.23 ℃ to 55.81 ℃, and the enthalpy value of pasting (ΔH) was decreased to 4.68 J/g significantly (P<0.05). Furthermore, with the treatment of DHPM, the particle size of pre-treated starch was significantly (P<0.05) reduced to nano-scale, presenting more random small pieces compared with enzymatic starch. Comparativley, the Tp of nanostarch were reduced to 55.37 °C, while the ΔH of nanostarch was increased to 14.13 J/g further. These results indicated that nano-starch with short-range ordered structure could be prepared from P-DHPM, providing an environmentally friendly and easy-to-operate preparation method, which would provide a foundation for further study of its application in starch nano-emulsion and starch-based active packaging materials.

-

蜡质玉米淀粉(Waxy Maize Starch,WMS)产量丰富、价格低廉,具有较高的膨胀度、透明度、粘度和稳定性,是现代食品工业的重要原料,也是生产变性淀粉的优质原料[1]。纳米淀粉是由原淀粉通过物理、化学、生物等方法制备而成的一种具有粒径小、比表面积大、生物相容性好等优良特性的淀粉颗粒,在食品、生物、包装等领域均有较广泛应用[2−3]。目前制备纳米淀粉的主要化学方法包括酸水解法、化学沉淀法等,此类方法具有良好的可控性,但需要引入化学试剂且反应耗时较长[3−4];物理方法包括超声波法、螺杆挤压法等,此类方法具有耗时短、环境友好等优点,但其制备的样品较难控制粒径及均匀度[5−6]。

动态高压微射流技术(Dynamic High Pressure Microfluidization,DHPM)是一种可连续化作业的新兴均质手段,可在短时间内同步实现料液的输送、混合、超微粉碎、加压、均质等一系列操作[7−9]。在瞬时压力的推动下,流动的混合物料在相互作用腔内受到强烈撞击、高频剪切、高速振荡和气穴爆炸等一系列综合作用力达到剪切破碎、碰撞破碎或聚结的效果[10],基于高压微流射技术处理淀粉,可实现对其结构、理化性质的调控。有研究表明,通过动态超高压微射流技术使淀粉颗粒均匀分散在水中,形成的纳米颗粒可转变为稳定凝胶,与传统的均质方法相比,动态超高压微射流制备的样品细碎度更高,稳定性更好[5,11]。淀粉颗粒在物理破碎下引起大小、形貌和均匀度的改变,淀粉的分子结构也发生变化,从而导致理化性质如分散性、溶解度、糊化性质和化学活性等相应发生变化。然而,利用高压微射流技术直接处理蜡质玉米淀粉制备纳米淀粉颗粒时,易使腔体堵塞,且样品稳定性较差,阻碍其进一步应用[11−12],普鲁兰酶(普鲁兰1,6-葡萄糖水解酶,EC 3.2.1.41),是淀粉加工中一种重要的脱支酶,与异淀粉酶相比,其能切下支链淀粉和其它相关多聚糖的α-1,6糖苷键,形成短直链淀粉,但酶的成本高、且酶解过度会促使淀粉水解,无法得到预期的淀粉纳米粒子。因此,本文利用酶解-高压微射流技术联合制备蜡质玉米纳米淀粉,以期得到均相且粒径可控的淀粉纳米粒子体系,同时探讨淀粉多尺度结构、粒径和热学性能的变化,为蜡质玉米纳米淀粉乳液的制备及其在活性包装材料中的应用提供基础。

1. 材料与方法

1.1 材料与仪器

蜡质玉米淀粉(直链淀粉含量为0.67%±0.07%) 东莞东美食品有限公司;普鲁兰酶(2000 U/g)、溴化锂(分析纯)、二甲基亚砜(色谱纯) 上海阿拉丁生化科技股份有限公司;溴化锂 分析纯,上海麦克林生化科技股份有限公司。

MR Hei-Tec(CN)型磁力搅拌器 德国Heidolph公司;M-110EH-30型高压微射流均质机 美国 MFIC公司;SCIENTZ-18 N 型冷冻干燥机 宁波新芝生物科技股份有限公司;EM-30 PLUS+型扫描电子显微镜 韩国COXEM公司;DX-27mini型X-射线衍射仪 辽宁丹东浩元仪器有限公司;Spectrum Two 型傅立叶红外光谱仪 美国PE公司;LS13 320型激光粒度仪 贝克曼库尔特有限公司;Eclipse DualTec型分子排阻色谱-多角度激光光散射联用仪 美国WYATT公司;DSC3型差示扫描量热仪 梅特勒-托利多仪器有限公司。

1.2 实验方法

1.2.1 酶解淀粉的制备

称取三份50 g蜡质玉米淀粉(WMS),分别置于500 mL去离子水中,于100 ℃下搅拌30 min,使原淀粉糊化完全,搅拌速率为500 r/min。待WMS淀粉糊温度降低至50 ℃,加入添加量均为6 U/g(以淀粉干基计算)的普鲁兰酶,并将其置于50 ℃水浴锅中进行酶解,酶解时间分别为0.5、1、2 h,酶解之后将三种酶解淀粉置于100 ℃水浴锅中进行灭活,灭活时间为30 min,待其降至室温后得到酶解淀粉并将部分样品进行冷冻干燥保存(样品分别记为E-0.5、E-1、E-2)。

1.2.2 纳米淀粉的制备

分别称取2 g不同酶解时间的淀粉置于200 mL去离子水中,充分分散后经动态超高压微射流处理,压力为10000 PSI,循环次数为1次,将处理后的淀粉乳液冷冻干燥后得到纳米淀粉(样品分别记为E-0.5-N、E-1-N、E-2-N)。

1.2.3 微观形貌观察

将原淀粉、冷冻干燥处理后的酶解淀粉和纳米淀粉样品分散在贴有导电双面胶的扫描电子显微镜(Scanning Electron Microscope,SEM)样品台上,并用洗耳球轻吹样品使其单层平铺样品台表面,样品经过离子溅射喷金40 s,电压为5 kV,后于SEM中观察不同放大倍数下的淀粉颗粒形貌。

1.2.4 结晶结构测定

分别取原淀粉、冷冻干燥处理后的酶解淀粉和纳米淀粉置于样品槽内,将样品表面压平放入X-射线衍射仪中,X-射线为Cu-Kα射线(λ=0.15 nm),30 kV×15 m A),测量范围为10°~40°,步长0.02,扫描速度0.1°/s,每个样品测三次,经Jade 6.0软件计算样品的相对结晶度。

1.2.5 分子结构测定

分别将1 mg原淀粉、冷冻干燥处理后的酶解淀粉和纳米淀粉分别与150 mg溴化钾混合,充分研磨使二者混合均匀,取适量进行压片处理并用红外光谱仪进行测定,每个样品平行测定三次,得到傅里叶红外(Fourier Transform Infrared,FT-IR)图谱。

1.2.6 粒径测定

用一次性滴管吸取原淀粉逐滴加入到激光粒度仪的进样口中,待其PIDS检测器值达到40%,开始测量淀粉样品粒径,每个样品平行测定三次。

1.2.7 分子量分布测定

分别称取4 mg原淀粉、冷冻干燥处理后的酶解淀粉和纳米淀粉,将三种淀粉分别用4 mL二甲基亚砜(DMSO,含溴化锂(0.5% w/w))进行混合,后将溶液置于80 ℃的水浴摇床中过夜,使其充分溶解,待溶液冷却至25 ℃,利用0.45 μm过滤膜过滤,备用。使用分子排阻色谱测定淀粉的分子量分布,测定过程中洗脱液为含0.5%(w/w)溴化锂的DMSO,柱温80 ℃,流速为0.5 mL/min,每个样品平行测定三次。

1.2.8 热学性能测定

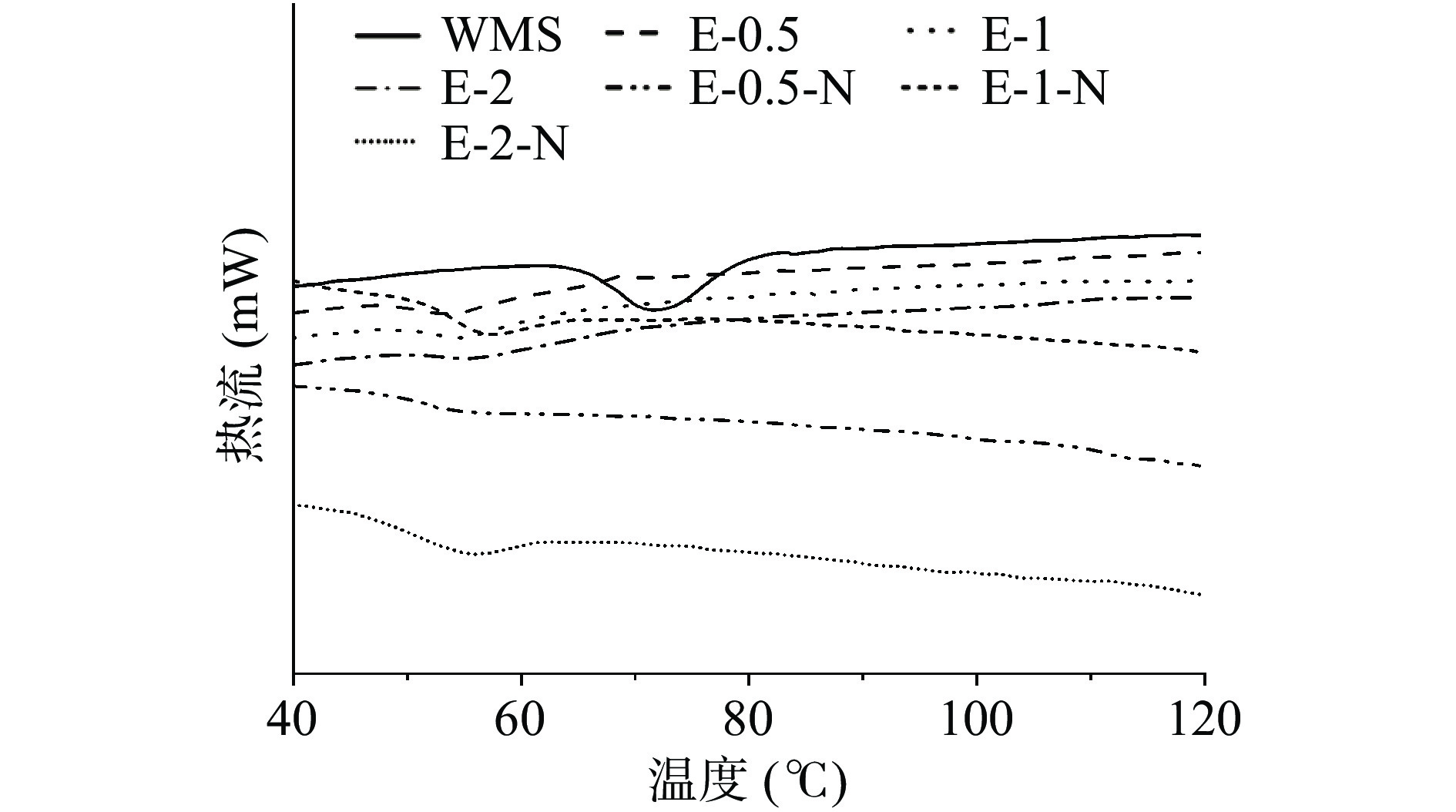

分别准确称取4 mg原淀粉、冷冻干燥处理后的酶解淀粉和纳米淀粉,置于差式扫描量热仪(Differential Scanning Calorimetry,DSC)专用的铝坩埚中,加入12 μL蒸馏水,然后将铝坩埚密封,于室温下平衡12 h,同时以空盘作为空白对照。样品测定温度为30~120 ℃,升温速率为10 ℃/min,氮气流速40 mL/min。利用DSC热谱图计算起始温度、峰值温度、结束温度(分别为To、Tp和Tc)以及焓值(ΔH),每个样品平行测定三次。

1.3 数据处理

实验均进行三次平行测定,所得数据均利用SPSS 软件(24.0版)进行方差分析,通过邓肯多重检验来表示组间显著性差异(P<0.05),结果使用平均值±标准差表示,数据通过Origin 9.0软件进行统计分析及绘图。

2. 结果与分析

2.1 微观形貌观察

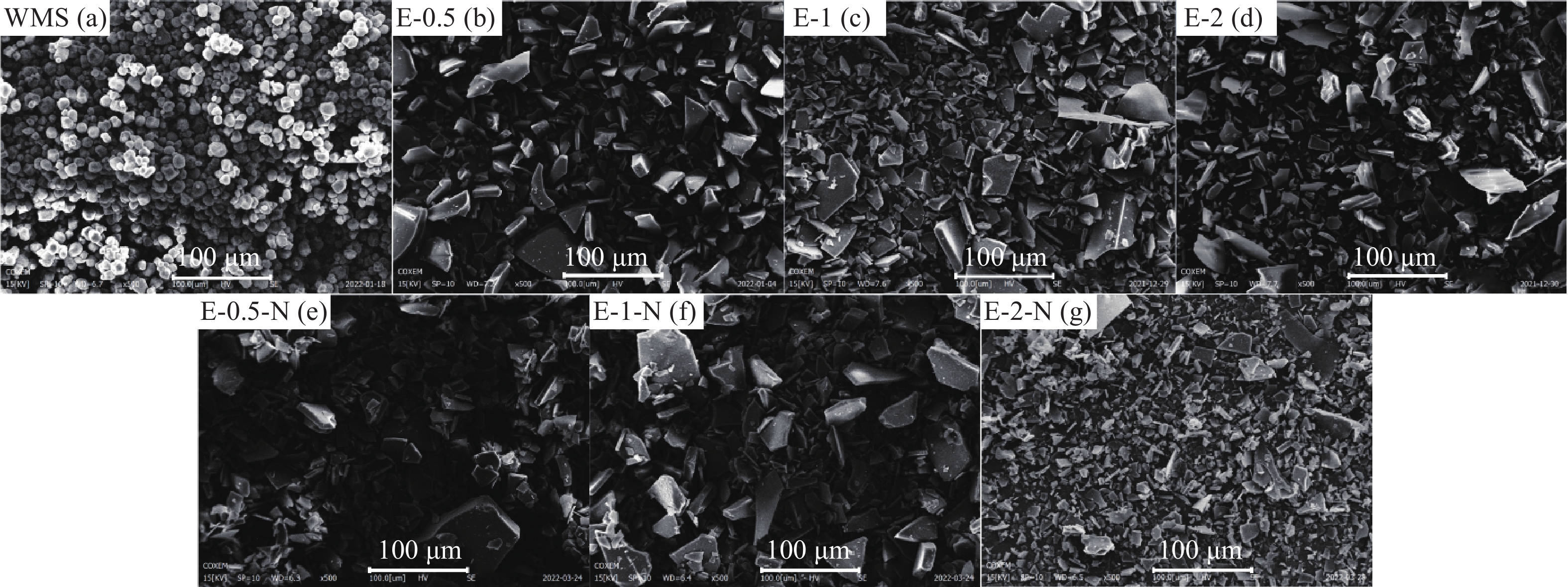

图1为不同酶解时长以及进一步高压微射流处理后淀粉经冷冻干燥处理后的形貌。由图1a所示,原淀粉为圆形或多角形、表面光滑、无气孔[13],酶的加入使淀粉颗粒形貌发生明显变化,变成无规则的碎片颗粒(图1b~图1d),且随着酶解时间的延长,酶解淀粉形态明显变小且出现更多碎片。该现象可能是糊化引起颗粒的膨胀,从而导致颗粒结构的破坏。

酶解淀粉进一步经微射流处理后,微射流剧烈的冲击力使大颗粒破碎成块状颗粒,颗粒的比表面积增大,淀粉的形状发生改变,且淀粉原本光滑的表面变得粗糙,淀粉颗粒进一步被破坏[10,14−15]。纳米淀粉的形貌分析证实了微射流的高压作用使淀粉颗粒变得更加细小,并且出现明显的层状条带(图1e~图1g)。

2.2 结晶结构分析

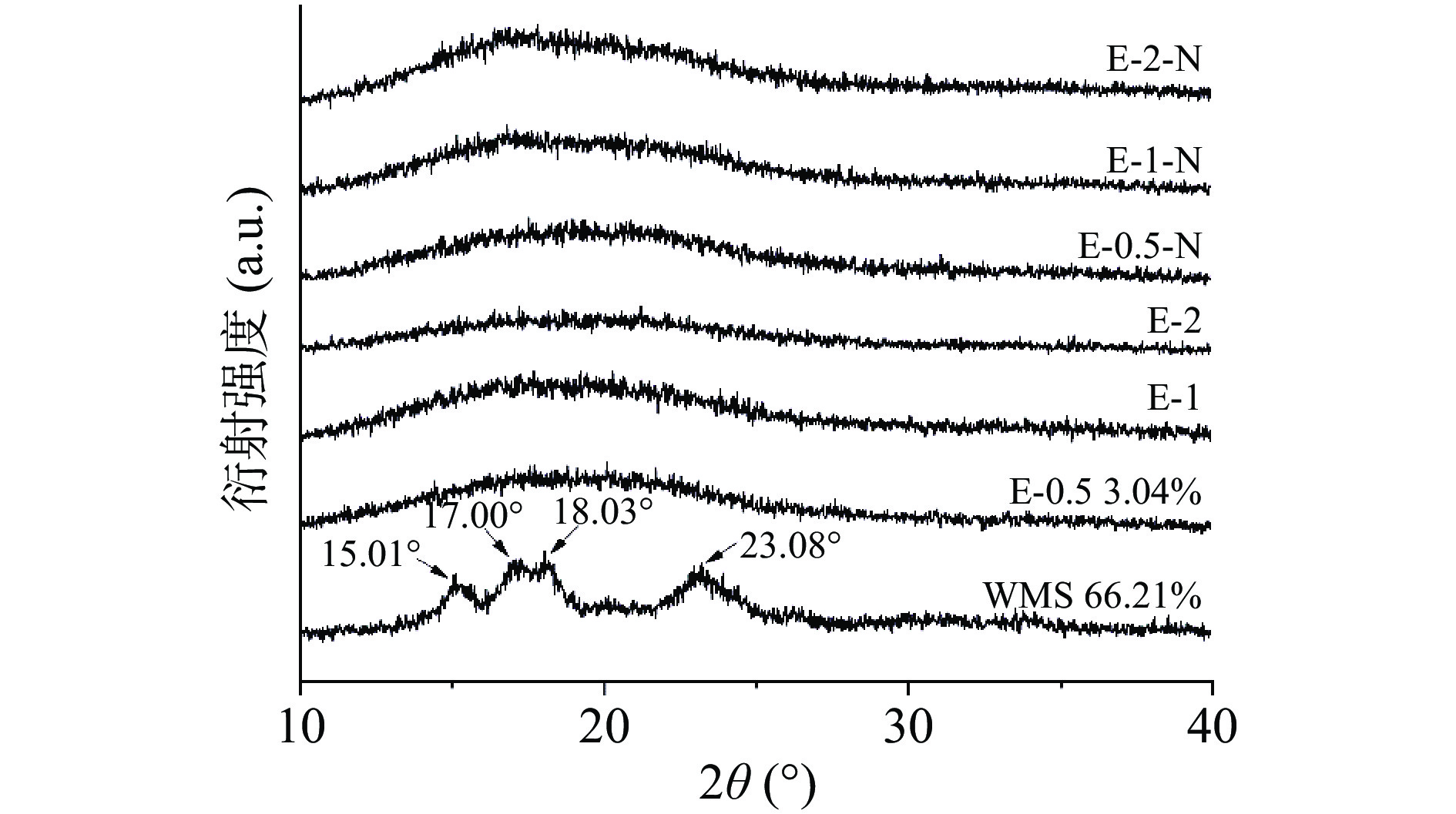

图2为不同酶解时长以及进一步高压微射流处理后淀粉的XRD衍射图谱。如图2所示,原淀粉在2θ为15.01°、17.00°、18.03°、23.08°处有强的衍射峰,为典型的A型结晶。原淀粉经过糊化处理后,当酶解时间为0.5 h时,结晶度从66.21%下降到3.04%,随着酶解时间的进一步增加,淀粉呈弥散衍射特征,表明结晶结构消失[1]。研究表明,当淀粉经普鲁兰酶水解后,淀粉分子中晶态和非晶态结构中氢键作用均被破坏[16−18]。

进一步经微射流处理后,淀粉整体仍呈现弥散衍射峰,未有明显变化,表明酶解淀粉经微射流处理后继续呈现无定型态。经微射流制备得到的纳米淀粉衍射图谱与酶解淀粉相比变化不大。有研究表明,原淀粉经过微射流处理后,X-射线衍射图谱呈现弥散衍射状态,可能是因为淀粉结晶有序程度降低或是淀粉颗粒尺寸减小引起的结晶过小[19]。本实验中酶解使淀粉结晶被显著破坏,且酶解时间越长结晶结构破坏越显著,同时高压微射流处理并没有对淀粉结晶结构进一步产生明显的影响。

2.3 分子结构分析

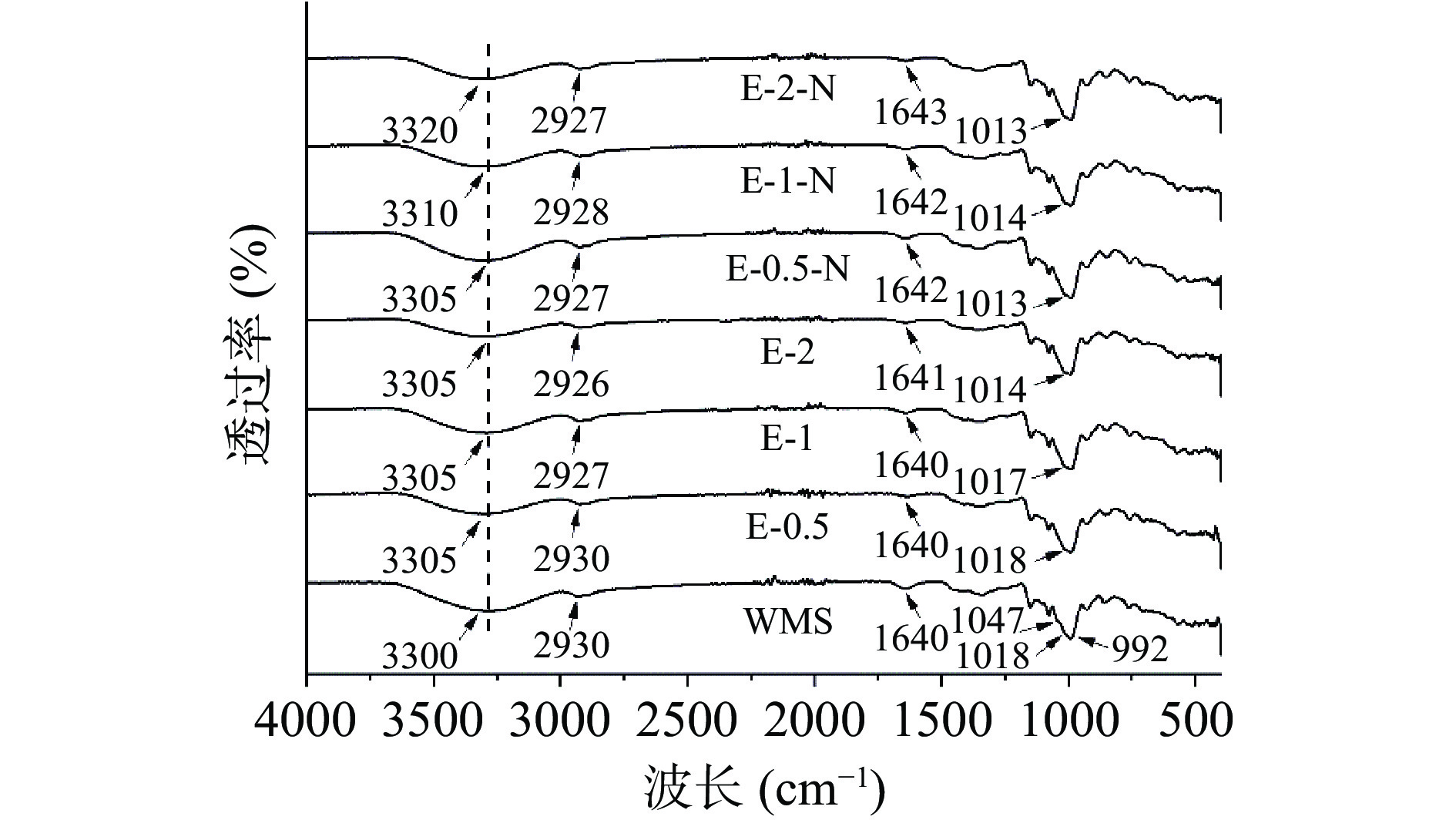

图3为不同酶解时长以及进一步高压微射流处理后淀粉的红外光谱图。如图3所示,3300 cm−1处为O-H伸缩振动和羟基氢键缔合后的特征吸收峰[1,20],2930 cm−1处左右为C-H的伸缩振动,1640 cm−1为C=O伸缩振动,经酶解和微射流处理后,该处波长发生红移,可能是因为微射流处理一定程度上使淀粉的功能基团发生变化;也有报道称1640 cm−1处的峰强和峰位置与淀粉颗粒中结合水的能力有关[21]。由图3可知,经酶解处理后,1047和1018 cm−1处的峰条带变宽甚至消失,这可能与酶解淀粉的长程有序性(结晶度)降低有关[22]。该现象可能是糊化引起颗粒的膨胀,从而导致颗粒结构的破坏。经微射流处理后,1047 cm−1处的峰完全消失,该现象是由微射流过程中高压、高剪切力、湍流力和空化作用导致纳米淀粉从有序变为无序构象[12]。1040 cm−1为无水葡萄糖环C-O拉伸振动特征峰,990 cm−1左右为O-H弯曲振动吸收峰[23]。对比可知,经酶解后,淀粉中的葡萄糖环C-O拉伸振动吸收峰向1020 cm−1进行蓝移,可能是因为在酶解过程中α-1,6-糖苷键被水解并产生羟基,形成氢键。另外,图3中所有样品均没有出现新的红外吸收峰,表明酶解淀粉和纳米颗粒并没有产生新的化学键。

通过去卷积处理后将透射率转换为吸光度,1047和1022 cm−1处的吸光度比值R可表征淀粉的短程有序结构[15,24]。根据表1可知,酶解淀粉和纳米淀粉的R值都高于原淀粉,说明经过处理后,分子短程有序性增强[18],这是由于酶解后淀粉链间氢键数目增加或淀粉中多尺度聚集结构进行了重排所致的[25]。另外,酶解淀粉经微射流处理后R值降低,可能是微射流的高压作用影响淀粉的短程有序结构,使R值略微降低。

表 1 不同处理条件WMS的R值Table 1. R value of WMS under different treatment conditions样品 R值 WMS 1.1028 E-0.5 1.1560 E-1 1.1947 E-2 1.1271 E-0.5-N 1.2190 E-1-N 1.1634 E-2-N 1.1853 注:R值表示淀粉红外光谱波长1047和1022 cm−1处的吸光度比值。 2.4 粒径分布

由表2可知,与原淀粉相比,当酶解时间为0.5 h时,淀粉粒径显著增大(P<0.01),这是由于淀粉在糊化的过程中氢键作用促使淀粉分子与水分子发生强烈的水合作用,使淀粉链不断展开,导致颗粒逐渐膨胀,体积增大[2,26]。当酶解时间为1 h时,粒径显著减小(P<0.05),可能是淀粉颗粒的溶胀促进了普鲁兰酶与淀粉分子间的接触,普鲁兰酶分子与淀粉分子结合后催化糖苷键裂解,促使淀粉粒径降低;随着酶解时间增加到2 h,支链淀粉进一步被裂解,线性直链淀粉分子的缠绕作用促使淀粉粒径增大[17,27]。

表 2 不同处理条件WMS的粒径Table 2. Particle size of WMS under different treatment conditions样品 粒径(nm) WMS 13000±0.57D E-0.5 28360±1.13Aa E-1 21730±1.35Cb E-2 26240±0.58Ba E-0.5-N 36.76±0.85Ea E-1-N 37.24±1.93Ea E-2-N 34.11±0.51Eb 注:每列不同大写字母表示与原淀粉(WMS)具有显著性差异(P<0.05),每列不同小写字母表示不同处理方法组内具有显著性差异(P<0.05)。 与原淀粉和酶解淀粉相比,不同酶解时间的蜡质玉米淀粉经微射流处理后,淀粉粒径均显著减小至纳米级(P<0.01)。当与酶解时间为0.5 h相比,酶解时间为1 h时,纳米淀粉粒径略微增加,可能是因为微射流处理后淀粉颗粒发生了一定聚集[10,12],酶解时间增加到2 h,纳米淀粉粒径明显减小,表明微射流显著降低粒径。

2.5 分子量分布

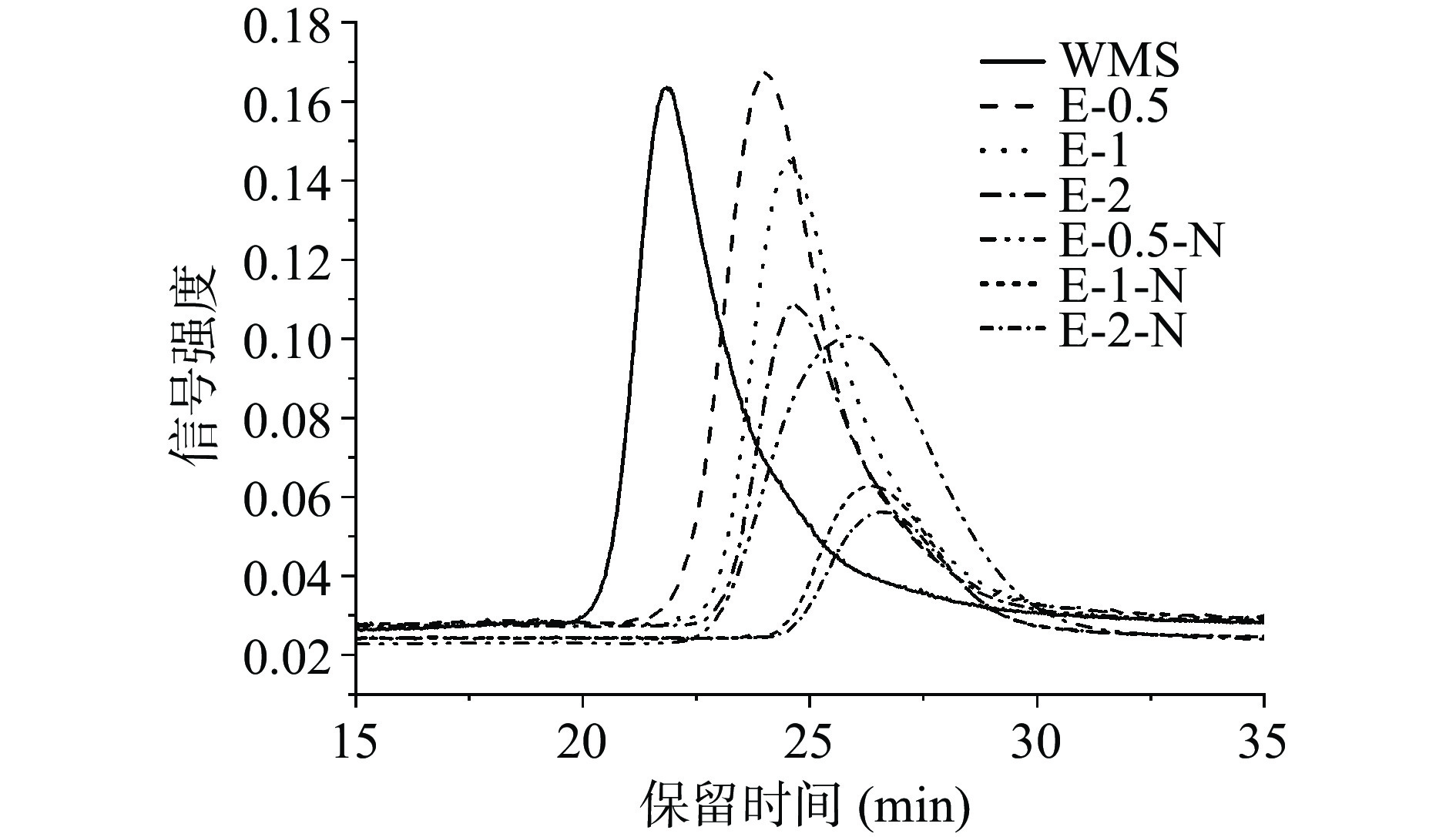

图4为不同酶解时长以及进一步高压微射流处理后淀粉的分子量激光信号,物质分子量越大,保留时间越短。由图4可知,随着酶解时间的增加,淀粉的分子量越小,经微射流处理纳米淀粉的分子量也随酶解时间增加而降低。重均分子量(Mw)如表3所示,酶解淀粉分子量与原淀粉相比显著减小,且随着酶解时间的增加而进一步减小[28],WMS经普鲁兰酶酶解后,淀粉的α-1,6糖苷键断裂,形成了短直链淀粉,这与已有研究结果相似[29−30]。在经微射流处理后,纳米淀粉的分子量较WMS和酶解淀粉均显著降低(P<0.05),且分子量随酶解时间的增加而降低,这主要是因为微射流的高压作用使淀粉分子链发生断裂[19,31]。

表 3 不同处理条件WMS的分子量Table 3. Molecular weight of WMS under different treatment conditions样品 Mw(×107 Da) WMS 14.70±0.14a E-0.5 1.38±0.01b E-1 1.33±0.02c E-2 0.72±0.00d E-0.5-N 0.14±0.00e E-1-N 0.13±0.00e E-2-N 0.10±0.00e 注:同列不同小写字母表示差异显著(P<0.05)。 2.6 热学性能分析

糊化温度作为淀粉的一个重要指标,与淀粉颗粒结晶结构、直链淀粉含量等因素密切相关。由表4可知,与原淀粉的起始糊化温度To(64.76 ℃)和吸热峰值温度Tp(71.23 ℃)相比,酶解淀粉的糊化To(48.04 ℃)和Tp(53.81 ℃)显著降低,但随着酶解时间的增加到2 h,To(49.36 ℃)、Tp(55.81 ℃)略有升高。同时,经过酶解后,淀粉的焓变(ΔH)出现不同程度降低,是因为酶解破坏了淀粉结晶区,导致其糊化温度降低[32]。

表 4 不同处理条件WMS的热学参数Table 4. Thermodynamic parameters of WMS under different treatment conditions样品 ∆H(J/g) To(℃) Tp(℃) Tc(℃) WMS 14.5±2.92a 64.76±0.66a 71.23±0.57a 77.79±1.55a E-0.5 5.85±1.27e 48.04±0.35d 53.81±0.35g 60.93±0.09g E-1 4.68±0.27g 48.67±1.45c 54.06±1.41f 61.71±0.92f E-2 7.14±2.31d 49.36±0.23b 55.81±0.35d 68.34±1.52c E-0.5-N 5.65±1.29f 45.61±4.89f 55.37±0.44e 62.89±2.09e E-1-N 14.13±2.67b 39.72±0.13g 58.78±0.70b 70.06±1.71b E-2-N 13.33±1.02c 46.65±0.76e 55.97±0.51c 66.45±1.02d 注:ΔH为糊化焓值、To为起始温度、Tp为峰值温度和Tc为终止温度。同列不同小写字母表示差异显著(P<0.05)。 经过微射流处理后得到的纳米淀粉(E-1-N)的To进一步降低(39.72 ℃),Tp也明显向低温方向移动(图5),可能是因为淀粉的结晶区被破坏,导致水分子更容易进入淀粉结晶区[12]。由于动态超高压使淀粉链降解,使淀粉短侧链被打断致其结构松散,导致E-0.5-N的ΔH降低(5.65 J/g),但随酶解时间增加到2 h,纳米淀粉的ΔH显著(P<0.05)增大(13.33 J/g),可能和纳米淀粉短程有序性结构增加有关[19]。

3. 结论

蜡质玉米淀粉经酶解处理后其微观结构发生明显变化,结晶结构被破坏,形成短链淀粉分子、分子量显著减小(P<0.05);与原淀粉和酶解淀粉相比,进一步经微射流处理后的淀粉粒径和分子量均显著减小(P<0.05),达到纳米级;同时,淀粉颗粒形态变成更加无规则的碎片状,纳米淀粉具有更低的糊化温度。通过酶解-微射流处理,制备了一种粒径均匀的纳米淀粉,使蜡质玉米淀粉结构和热学性能得到明显改善;提供了一种环境友好、操作简单且稳定性良好的纳米淀粉制备方法,有利于进一步对纳米淀粉进行开发利用,为后续制备淀粉纳米乳液及淀粉基纳米活性材料提供基础。

-

表 1 不同处理条件WMS的R值

Table 1 R value of WMS under different treatment conditions

样品 R值 WMS 1.1028 E-0.5 1.1560 E-1 1.1947 E-2 1.1271 E-0.5-N 1.2190 E-1-N 1.1634 E-2-N 1.1853 注:R值表示淀粉红外光谱波长1047和1022 cm−1处的吸光度比值。 表 2 不同处理条件WMS的粒径

Table 2 Particle size of WMS under different treatment conditions

样品 粒径(nm) WMS 13000±0.57D E-0.5 28360±1.13Aa E-1 21730±1.35Cb E-2 26240±0.58Ba E-0.5-N 36.76±0.85Ea E-1-N 37.24±1.93Ea E-2-N 34.11±0.51Eb 注:每列不同大写字母表示与原淀粉(WMS)具有显著性差异(P<0.05),每列不同小写字母表示不同处理方法组内具有显著性差异(P<0.05)。 表 3 不同处理条件WMS的分子量

Table 3 Molecular weight of WMS under different treatment conditions

样品 Mw(×107 Da) WMS 14.70±0.14a E-0.5 1.38±0.01b E-1 1.33±0.02c E-2 0.72±0.00d E-0.5-N 0.14±0.00e E-1-N 0.13±0.00e E-2-N 0.10±0.00e 注:同列不同小写字母表示差异显著(P<0.05)。 表 4 不同处理条件WMS的热学参数

Table 4 Thermodynamic parameters of WMS under different treatment conditions

样品 ∆H(J/g) To(℃) Tp(℃) Tc(℃) WMS 14.5±2.92a 64.76±0.66a 71.23±0.57a 77.79±1.55a E-0.5 5.85±1.27e 48.04±0.35d 53.81±0.35g 60.93±0.09g E-1 4.68±0.27g 48.67±1.45c 54.06±1.41f 61.71±0.92f E-2 7.14±2.31d 49.36±0.23b 55.81±0.35d 68.34±1.52c E-0.5-N 5.65±1.29f 45.61±4.89f 55.37±0.44e 62.89±2.09e E-1-N 14.13±2.67b 39.72±0.13g 58.78±0.70b 70.06±1.71b E-2-N 13.33±1.02c 46.65±0.76e 55.97±0.51c 66.45±1.02d 注:ΔH为糊化焓值、To为起始温度、Tp为峰值温度和Tc为终止温度。同列不同小写字母表示差异显著(P<0.05)。 -

[1] 张旭鑫, 张书艳, 李琳, 等. 香草醛调控蜡质玉米淀粉-壳聚糖交联薄膜的结构和性能[J]. 现代食品科技,2022,38(4):99−105. [ZHANG X X, ZHANG S Y, LI L, et al. Structure and property of waxy starch-chitosan crosslinking films regulated by vanillin[J]. Modern Food Science & Technology,2022,38(4):99−105.] ZHANG X X, ZHANG S Y, LI L, et al . Structure and property of waxy starch-chitosan crosslinking films regulated by vanillin[J]. Modern Food Science & Technology,2022 ,38 (4 ):99 −105 .[2] FANG C L, HUANG J R, YANG Q, et al. Adsorption capacity and cold-water solubility of honeycomb-like potato starch granule[J]. International Journal of Biological Macromolecules,2020,147:741−749. doi: 10.1016/j.ijbiomac.2020.01.224

[3] 刘璐婕, 黄立新, 张彩虹, 等. 纳米淀粉的制备、性质及应用的研究进展[J]. 材料导报,2020,34(19):19027−19033. [LIU L J, HUANG L X, ZHANG C H, et al. Research progress in preparation, properties and application of nano- starch[J]. Materials Reports,2020,34(19):19027−19033.] doi: 10.11896/cldb.19040230 LIU L J, HUANG L X, ZHANG C H, et al . Research progress in preparation, properties and application of nano- starch[J]. Materials Reports,2020 ,34 (19 ):19027 −19033 . doi: 10.11896/cldb.19040230[4] GUO Y B, QIAO D L, ZHAO S M, et al. Starch-based materials encapsulating food ingredients:Recent advances in fabrication methods and applications[J]. Carbohydrate Polymers,2021,270:118358. doi: 10.1016/j.carbpol.2021.118358

[5] 齐凤敏, 王来忠, 张佳佳, 等. 不同均质方式对红花籽油O/W乳液乳化效果的影响[J]. 食品工业,2020,41(12):8−11. [QI F M, WANG L Z, ZHANG J J, et al. Effects of different homogenization methods on O/W emulsion emulsification of safflower seed oil[J]. The Food Industry,2020,41(12):8−11.] QI F M, WANG L Z, ZHANG J J, et al . Effects of different homogenization methods on O/W emulsion emulsification of safflower seed oil[J]. The Food Industry,2020 ,41 (12 ):8 −11 .[6] LE CORRE D, BRAS J, DUFRESNE A. Starch nanoparticles:A review[J]. Biomacromolecules,2010,11(5):1139−1153. doi: 10.1021/bm901428y

[7] 曹梦梦, 刘一鲲, 陈兴, 等. 动态高压微射流技术制备乳液运载体的研究进展[J]. 食品工业科技,2022,43(18):474−482. [CAO M M, LIU Y K, CHEN X, et al. Research progress on emulsion-based delivery systems produced from dynamic high pressure microfluidization[J]. Science and Technology of Food Industry,2022,43(18):474−482.] CAO M M, LIU Y K, CHEN X, et al . Research progress on emulsion-based delivery systems produced from dynamic high pressure microfluidization[J]. Science and Technology of Food Industry,2022 ,43 (18 ):474 −482 .[8] 涂宗财, 王强, 张博, 等. 动态超高压微射流对蜡质玉米淀粉颗粒结构的影响[J]. 食品与发酵工业,2009,35(11):1−4. [TU Z C, WANG Q, ZHANG B, et al. Effects of dynamic high-pressure microfluidization on granular structure of waxy maize starch[J]. Food and Fermentation Industries,2009,35(11):1−4.] TU Z C, WANG Q, ZHANG B, et al . Effects of dynamic high-pressure microfluidization on granular structure of waxy maize starch[J]. Food and Fermentation Industries,2009 ,35 (11 ):1 −4 .[9] 陈璐璐, 玄晨宇, 代养勇, 等. 高压微射流处理对马铃薯淀粉结构和糊特性的影响[J]. 食品研究与开发,2021,42(11):17−23. [CHEN L L, XUAN C Y, DAI Y Y, et al. Effect of high-pressure microfluidization treatment on the structure and paste properties of potato starch[J]. Food Research and Development,2021,42(11):17−23.] CHEN L L, XUAN C Y, DAI Y Y, et al . Effect of high-pressure microfluidization treatment on the structure and paste properties of potato starch[J]. Food Research and Development,2021 ,42 (11 ):17 −23 .[10] TU Z C, YIN Y B, WANG H, et al. Effect of dynamic high-pressure microfluidization on the morphology characteristics and physicochemical properties of maize amylose[J]. Starch-Stärke,2013,65(5-6):390−397.

[11] LIU D G, WU Q L, CHEN H H, et al. Transitional properties of starch colloid with particle size reduction from micro-to anometer[J]. J Colloid Interface Sci,2009,339(1):117−124. doi: 10.1016/j.jcis.2009.07.035

[12] KASEMWONG K, RUKTANONCHAI U R, SRINUANCHAI W, et al. Effect of high-pressure microfluidization on the structure of cassava starch granule[J]. Starch-Stärke,2011,63(3):160−170.

[13] BAJAJ R, SINGH N, KAUR A, et al. Structural, morphological, functional and digestibility properties of starches from cereals, tubers and legumes:A comparative study[J]. Journal of Food Science and Technology,2018,55(9):3799−3808. doi: 10.1007/s13197-018-3342-4

[14] LI W H, ZHANG F S, LIU P L, et al. Effect of high hydrostatic pressure on physicochemical, thermal and morphological properties of mung bean ( Vigna radiata L.) starch[J]. Journal of Food Engineering,2010,103(4):388−393.

[15] XU J B, MA Z, REN N M, et al. Understanding the multi-scale structural changes in starch and its physicochemical properties during the processing of chickpea, navy bean, and yellow field pea seeds[J]. Food Chemistry,2019,289:582−590. doi: 10.1016/j.foodchem.2019.03.093

[16] SUN Q J, LI G H, DAI L, et al. Green preparation and characterisation of waxy maize starch nanoparticles through enzymolysis and recrystallisation[J]. Food Chemistry,2014,162:223−228. doi: 10.1016/j.foodchem.2014.04.068

[17] 肖云鹏, 余世锋. 酶解处理对糯性玉米淀粉多层次结构特性及热性质的影响[J]. 食品科技,2019,44(8):248−253. [XIAO Y P, YU S F. Effects of enzymolysis treatment on the microstructure and thermal properties of waxy corn starch granule[J]. Food Science and Technology,2019,44(8):248−253.] XIAO Y P, YU S F . Effects of enzymolysis treatment on the microstructure and thermal properties of waxy corn starch granule[J]. Food Science and Technology,2019 ,44 (8 ):248 −253 .[18] NIU W, PU H Y, LIU G M, et al. Effect of repeated heat-moisture treatments on the structural characteristics of nanocrystals from waxy maize starch[J]. International Journal of Biological Macromolecules,2020,158:732−739. doi: 10.1016/j.ijbiomac.2020.04.236

[19] 张博. 动态超高压微射流技术对蜡质淀粉改性的影响及其机理初探[D]. 南昌:南昌大学, 2008. [ZHANG B. Influence of the high pressure microfluidization on the functional properties of waxy starch and its mechanism study[D]. Nanchang:Nanchang University, 2008.] ZHANG B. Influence of the high pressure microfluidization on the functional properties of waxy starch and its mechanism study[D]. Nanchang: Nanchang University, 2008.

[20] 张旭鑫, 张书艳, 赵雷, 等. 纳米淀粉对含香茅醇马铃薯淀粉-壳聚糖复合膜材多尺度结构和热稳定性的影响[J]. 轻工学报,2023,38(1):27−33. [ZHANG X X, ZHANG S Y, ZHAO L, et al. Effects of nano-starch on the multiscale structure and thermal stability of potato starch-chitosan composites containing citronellol[J]. Journal of Light Industry,2023,38(1):27−33.] ZHANG X X, ZHANG S Y, ZHAO L, et al . Effects of nano-starch on the multiscale structure and thermal stability of potato starch-chitosan composites containing citronellol[J]. Journal of Light Industry,2023 ,38 (1 ):27 −33 .[21] RIVERA-CORONA J L, RODRÍGUEZ-GONZÁLEZ F, RENDÓN-VILLALOBOS R, et al. Thermal, structural and rheological properties of sorghum starch with cactus mucilage addition[J]. LWT-Food Science and Technology,2014,59(2):806−812. doi: 10.1016/j.lwt.2014.06.011

[22] RINDLAVA Å, HULLEMAN S H D, GATENHOLMA P. Formation of starch films with varying crystallinity[J]. Carbohydrate Polymers,1997,34(1):25−30.

[23] 李欣欣. 蜡质玉米变性淀粉及其应用研究[D]. 长春:吉林大学, 2013. [LI X X. Research on preparation and application of modified waxy corn starch[D]. Changchun:Jilin Universitysity, 2013.] LI X X. Research on preparation and application of modified waxy corn starch[D]. Changchun: Jilin Universitysity, 2013.

[24] MA Z, BOYE J I. Research advances on structural characterization of resistant starch and its structure-physiological function relationship:A review[J]. Critical Reviews in Food Science and Nutrition,2018,58(7):1059−1083.

[25] HUANG T T, ZHOU D N, JIN Z Y, et al. Effect of repeated heat-moisture treatments on digestibility, physicochemical and structural properties of sweet potato starch[J]. Food Hydrocolloids,2016,54:202−210. doi: 10.1016/j.foodhyd.2015.10.002

[26] ZHANG Y Y, LI G P, WU Y W, et al. Influence of amylose on the pasting and gel texture properties of chestnut starch during thermal processing[J]. Food Chemistry,2019,294:378−383. doi: 10.1016/j.foodchem.2019.05.070

[27] 姜岁岁, 杨洁, 常然然, 等. 短直链淀粉纳米颗粒的制备及其表征[J]. 现代食品科技,2016,32(9):254−259. [JIANG S S, YANG J, CHANG R R, et al. Preparation and characterization of starch nanoparticles prepared using short glucan chains debranched for different times[J]. Modern Food Science & Technology,2016,32(9):254−259.] JIANG S S, YANG J, CHANG R R, et al . Preparation and characterization of starch nanoparticles prepared using short glucan chains debranched for different times[J]. Modern Food Science & Technology,2016 ,32 (9 ):254 −259 .[28] PINKAEW H, WANG Y, NAIVIKUL O. Impact of pre-germination on amylopectin molecular structures, crystallinity, and thermal properties of pre-germinated brown rice starches[J]. Journal of Cereal Science,2017,73:151−157. doi: 10.1016/j.jcs.2016.12.013

[29] 方晨璐. 三种形状无定形淀粉的制备、特征性质及分子结构研究[D]. 西安:陕西科技大学, 2020. [FANG C L. Preparation, characteristic properties and molecular structures of three amorphous starches of different shapes[D]. Xi'an:Shaanxi University of Science & Technology, 2020.] FANG C L. Preparation, characteristic properties and molecular structures of three amorphous starches of different shapes[D]. Xi'an: Shaanxi University of Science & Technology, 2020.

[30] WEI B X, CAI C X, XU B G, et al. Disruption and molecule degradation of waxy maize starch granules during high pressure homogenization process[J]. Food Chemistry,2018,240:165−173. doi: 10.1016/j.foodchem.2017.07.078

[31] HAN J A, LIM S T. Structural changes of corn starches by heating and stirring in DMSO measured by SEC-MALLS-RI system[J]. Carbohydrate Polymers,2003,55(3):265−272.

[32] LIN Q Z, JI N, LI M, et al. Fabrication of debranched starch nanoparticles via reverse emulsification for improvement of functional properties of corn starch films[J]. Food Hydrocolloids,2020,104:105760. doi: 10.1016/j.foodhyd.2020.105760

-

期刊类型引用(2)

1. 郑敦锦,祝顺,敬思群,谭艳仪,张俊艳,郑庆东,丁志昆. 超高压物理改性处理提高甜菜红的热稳定性及应用. 中国食物与营养. 2024(06): 43-50 .  百度学术

百度学术

2. 李黄炜,梁茵瑜,范佳欣,陈旭,张书艳,朱杰. 酶解联合动态高压微射流制备淀粉/百里酚纳米乳液及其结构与性质分析. 食品工业科技. 2024(23): 121-128 .  本站查看

本站查看

其他类型引用(1)

-

其他相关附件

-

其他文件格式

EI收录证明

-

下载:

下载:

下载:

下载: