Optimization of Vacuum Flavoring Technology and Quality Analysis of Pepper-flavored Peanut Kernel

-

摘要: 花生传统加工方式存在能耗大、入味慢、加工周期长等缺点,为了得到风味更佳的花椒味花生仁休闲食品,本研究采用真空技术与传统技术相结合的加工方式,通过负压时间、负压次数、真空度三个单因素实验筛选真空入味工艺参数条件,以花椒酰胺含量和感官评分为考察指标,在单因素实验的基础上通过响应面试验优化真空入味花椒味花生仁的工艺条件。结果表明,各因素对花椒味花生仁的影响顺序为负压时间>负压次数>真空度,最佳工艺参数为负压时间100 s、负压次数6 次、真空参数0.80 MPa。该最佳工艺制作的花椒花生仁蛋白质含量为27%,脂肪含量为57%,过氧化值和酸价均符合国家的标准,感官评分为93.1分。本研究以推动标准化加工的坚果休闲食品全产业链提供参考,促进坚果休闲食品产业的可持续发展。Abstract: The traditional processing method of peanuts has drawbacks such as high energy consumption, slow flavor absorption, and long processing cycles, to get better flavor of pepper-flavored peanut kernel snack food, this study used the vacuum technology combining with traditional technology to optimize by examining the effect of negative pressure time, negative pressure times and vacuum degree on the content of zanthoxylamide and sensory score using a combination of single factor method and response surface design. The results showed that the order of influence of various factors on pepper-flavored peanut kernels was negative pressure time>negative pressure frequency>vacuum degree. The optimal process parameters were negative pressure time of 100 seconds, negative pressure frequency of 6 times, and vacuum parameter of 0.80 MPa. The protein and fat content of pepper-flavored peanut kernels produced by this optimal process were 27% and 57%, respectively. The peroxide value and acid value meet national standards, and the sensory score was 93.1 points. This study would provide a reference for promoting the standardized processing of the entire nut snack food industry chain, and promoted the sustainable development of the nut snack food industry.

-

Keywords:

- peanut kernel /

- processing method /

- response surface optimization /

- quality analysis

-

花生(Arachis hypogaea Linn.)别名长生果,原产于热带、亚热带的南美洲地区,是全世界第四大油料农作物,同时也是食用油脂和植物蛋白的重要来源[1−2]。经常食用花生对人的健康有利,因花生富含将近55%的脂肪[3−4]、30%左右的蛋白质[5−7]和20%左右的碳水化合物[8],并且含有丰富的小分子营养物质,如维生素、生育酚、黄酮甾醇、卵磷脂和白藜芦醇,因此具有延缓衰老、促进细胞发育、增强记忆、降低胆固醇和减少心脑血管疾病等作用[9−11]。中医认为,花椒性温味辛,有芳香健胃、温中散寒的功效[12−13],其中,花椒中的麻味物质(花椒酰胺)是其独特风味的重要组成成分,直接决定了花椒的辛麻程度并且是影响花椒品质的重要因素[14]。

调味花生是一种深受消费者青睐的休闲食品,传统的花生生产是经过挑选、清洗、煮制入味、干燥、烘烤或炒制,其中入味是关键的工艺。花生长时熬煮或常温常压浸渍方式与烘焙相结合的传统加工方式存在能耗大、入味慢、加工周期长、调味不稳定、可控性差、机械化程度低等缺点,负压入味原理就是用真空负压抽真空,将料水压入花生仁内,不用加热煮制,节约能源,采用真空入味的花椒味花生仁具有入味快、得率高、口感好、成本低等优点,优于传统工艺加工[15]。王柏华等[16]通过真空渗透技术缩短传统醉鱼加工周期,减少生产成本,提高其风味稳定性和安全性。何家林等[17]采用有机酸预处理结合真空入味腌制咸蛋,缩短了生产周期,提高了成品率,保持着咸蛋的最佳品质。姜顾倩妮等[18]真空入味西瓜子,可以有效改善嗑咬西瓜子的开口性状,改善口感,降低生产成本。

本实验为了得到风味更佳的花椒味花生仁休闲食品,对花椒味花生仁的加工工艺进行了优化,以花生仁为原料,花椒、草果、茴香、八角、盐、白砂糖为辅料,将负压时间、负压次数和真空参数作为变量,以单因素实验为基础,进行响应面优化设计试验,通过花椒酰胺含量和感官评分确定花椒味花生仁的最佳工艺。获得工艺最优的花椒花生仁并分析其基本指标的测定和与煮制入味之间的质构的对比,为真空入味调味花生提供科学依据和生产指导,以推动标准化加工的坚果休闲食品全产业链提供参考,促进坚果休闲食品产业的可持续发展。

1. 材料与方法

1.1 材料与仪器

四粒红花生 辽宁省铁岭市昌图县傅家镇;白砂糖 太古糖业(中国)有限公司(分装);盐 湖南省湘衡盐化有限公司;香辛料(红花椒、茴香、八角、草果) 江苏味博园生物科技有限公司;异丙醇、乙醚、酚酞指示剂、石油醚、无水硫酸钠、氢氧化钠、三氯甲烷、冰乙酸、碘化钾、硫代硫酸钠、可溶性淀粉、硫酸铜、硫酸钾、硫酸、硼酸、盐酸、甲基红、95%的乙醇、溴甲酚绿、甲醇 均为国产分析纯,国药集团化学试剂有限公司。

LQ-C10002电子天平 深圳市飞亚衡器有限公司;AE2204电子分析天平 湘仪天平仪器设备有限公司;220V电子万用炉 泸兴电热电器厂;101-2AB型电热鼓风干燥箱、DK-98-II电热恒温水浴锅、SX-4-10马弗炉 天津市泰斯特仪器有限公司;不锈钢筛子 深圳市瑞丰电器有限公司;DZF-6030A真空干燥箱 上海一恒科学仪器有限公司;2XZ(S)-2型旋片式真空泵 上海德英真空照明设备有限公司;DE-100g多功能粉碎机 浙江红景天工贸有限公司;SHZ-D(Ⅲ)旋转蒸发仪 巩义市予华仪器有限责任公司;K9840自动凯氏定氮仪、SOX406脂肪测定仪 山东海能科学仪器有限公司;TA-XT2i Plus质构仪 英国Stable Micro Systems公司;UV-1200型紫外可见分光光度计 翱艺仪器(上海)有限公司;CR-400型色差仪 杭州彩谱科技有限公司。

1.2 实验方法

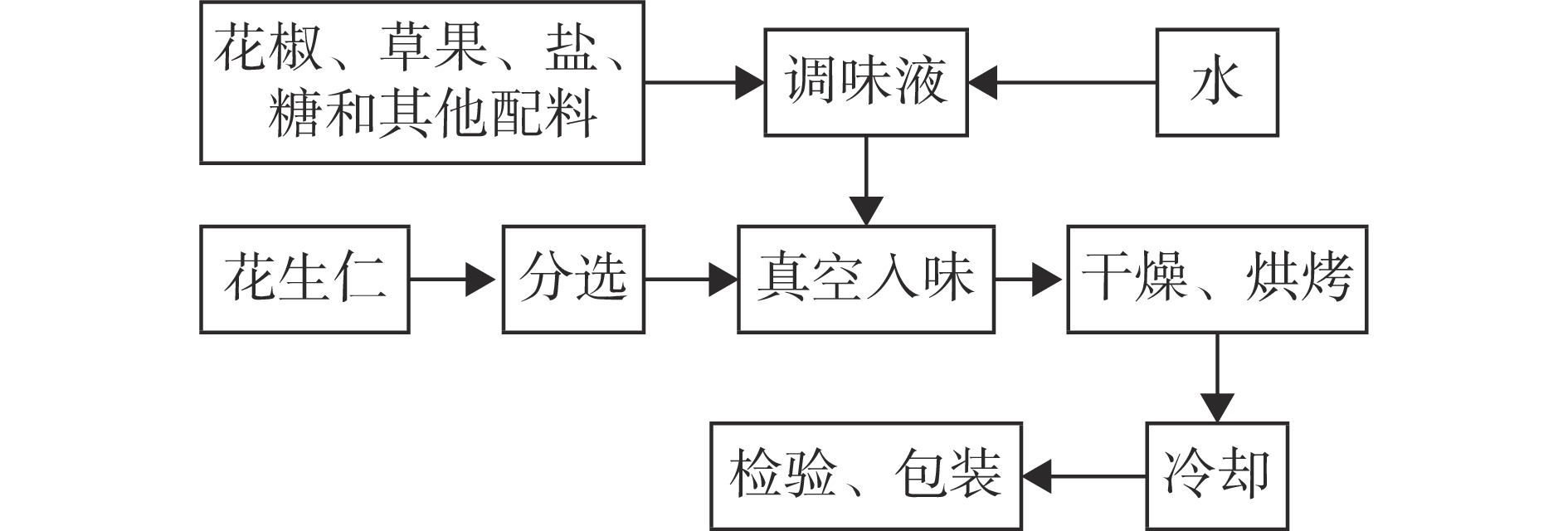

1.2.1 工艺流程

花椒味花生仁的制备工艺流程如图1所示。

1.2.2 操作要点

1.2.2.1 分选

挑选新鲜、饱满的,形态完整,大小均一,没有发霉,没有虫蚀,色泽均匀一致的花生仁颗粒;每次称量100 g花生仁进行试验。

1.2.2.2 调味液配制

按实验所需称取花椒和其他天然香辛料(花椒17 g、八角3 g、小茴香2 g,草果4 g)加入1000 g的沸水中,预煮20 min后过滤得到滤液,制成固定调味液,冷却至55 ℃左右,加入白砂糖与盐(白砂糖33 g、盐24 g),搅拌均匀得到调味液。

1.2.2.3 真空入味与煮制入味

真空入味:将花生仁浸入调味液后抽取真空,保持一定时间,放气后,再重复抽真空,最后常温常压浸泡30 min。

煮制入味:将花生仁浸入调味液后煮制10 min,最后常温常压浸泡30 min。

1.2.2.4 干燥烘烤

入味的花生仁均匀的平铺在不锈钢烘盘上。烘烤工艺分为4个阶段,烘烤第1段:将花生仁放入75 ℃电热鼓风干燥箱中,烘烤2.5 h;烘烤第2段:将电热鼓风干燥箱的温度提高至95 ℃烘烤2 h;烘烤第3段:将电热鼓风干燥箱的温度提高至105 ℃烘烤2 h;烘烤第4段:将电热鼓风干燥箱升温至118 ℃烘烤,最后使花生充分烘熟,取出冷却,然后包装。

1.2.3 花椒味花生仁制作的单因素实验

按照1.2.1工艺流程和1.2.2操作要点,以吸水率、盐度、花椒酰胺含量和模糊数学感官评分为指标,分别考察负压时间、负压次数、真空度对花椒味花生仁品质的影响。

固定负压次数为6次,真空度为0.08 MPa,考察不同负压时间(30、60、90、120、150 s)对花椒味花生仁品质的影响。固定负压时间为90 s,真空度为0.08 MPa,考察不同负压次数(4、5、6、7、8 次)对花椒味花生仁品质的影响。固定负压时间为90 s,负压次数为6次,考察不同真空度(0.06、0.07、0.08、0.09、0.10 MPa)对花椒味花生仁品质的影响。

1.2.4 花椒味花生仁的响应面试验

在单因素实验基础上,以花椒酰胺含量、模糊数学感官评分为响应值,负压时间、负压次数、真空度为自变量,探究花椒味花生仁真空入味的最佳工艺,因素水平设计见表1。采用Design-Expert 13软件进行响应面优化试验选取最优方案。

表 1 Box-Behnken 试验设计因素与水平Table 1. Factors and levels of response surface experiment水平 因素 负压时间(s) 负压次数(次) 真空度(MPa) −1 60 5 0.08 0 90 6 0.09 1 120 7 0.10 1.2.5 指标测定方法

1.2.5.1 花椒味花生仁的感官评价

选10名有感官评定经验的食品研究生,依据GB 19300-2014《食品安全国家标准 坚果与籽类食品》分别对花椒味花生仁的色泽、气味、滋味和口感进行感官评价,每组样品测三次,取平均值。感官评价标准见表2。

表 2 花椒味花生仁感官评价标准Table 2. Sensory evaluation standard of pepper-flavored peanut kernels指标 评分标准(分) 优(100分) 良(75分) 中(50分) 差(25分) 色泽 均匀一致,无异色 较均匀一致,无明显的异色 不均匀一致,有异色 不均匀一致,有明显的异色 气味 香辛料香味适中,

有浓郁的花生仁香味香气不足,香辛料气味较淡,无异味 香气不足,香辛料气味较淡,

有异味基本无香味,有焦糊味或其他异味 滋味 咸味、甜味、香料味适中,

咀嚼时有浓郁的花生仁香味咸味、甜味、香料味较好,

咀嚼时有淡淡的花生仁香味有一定的适口性,咸味、

甜味、香料味较好带有异味,咸味、甜味过重,

咀嚼无香味口感 酥脆,不粘牙,软硬适中 较酥脆,些许粘牙 不酥脆,些许粘牙 不酥脆,粘牙,过软或过硬 1.2.5.2 建立模糊数学评价模型

a.评语等级集V的确定。设评语等级集V,见式(1):

V=(V1,V2,V3,V4)=(100,75,50,25) (1) 式中,V1、V2、V3、V4分别表示优、良、中、差,所对应的分数分别为100、75、50、25 分,最终每个花生仁的总感官评分是花椒花生仁模糊数学感官因素综合评判的结果向量与各等级分值的总和。

b.权重的确定。实验采用用户调查法[19]及二次对比决定法[20]来确定色泽、气味、滋味、口感4项指标的权重。要求10名评定员对4个评价因素作一对一比较,重要的可以记为1分,相对次要的只记为0分,自身比较的按1分记。各项评价因素得分与总分100的比重即为权重。通过计算即得到花椒味花生仁的色泽、气味、滋味、口感4个指标的权重,权重的集合为U,U={U1,U2,U3,U4}。

根据10名评价员的权重结果得:色泽0.15、气味0.23、滋味0.35、口感0.27,即权重集U,U={0.15,0.23,0.35,0.27}。

1.2.5.3 模糊评价

由10位评价员对每个样品品尝后打分,统计出各因素评价等级得到评语人数,形成评价矩阵T,则花椒味花生仁的模糊数学感官综合评判的结果向量为Y=U×T。

1.2.6 花生的吸水率、盐度测定

1.2.6.1 吸水率的测定

参照艾静汶等[21]的方法,称取花生仁重量为干料质量,花生仁真空入味后,称取花生仁质量为吸料液后的质量。所有样品测3次取平均值。吸水率(%)按下式(2)计算:

吸水率(%)=m−MM×100 (2) 式中:m为吸料液后的质量,M为干料质量。

1.2.6.2 盐度的测定

真空入味后,用盐度计测定该调味液的盐度。所有样品测3次取平均值。

1.2.7 花生的花椒酰胺含量测定

根据GH/T 1290-2020《花椒及花椒加工产品 花椒酰胺总含量的测定 紫外分光光度法》,所有样品测3次取平均值。

1.2.8 基本成分测定

水分含量测定根据GB 5009.3-2016《食品安全国家标准 食品中水分的测定》-直接干燥法;蛋白含量测定根据GB 5009.5-2016《食品安全国家标准 食品中蛋白质的测定》-凯氏定氮法;灰分含量测定根据GB 5009.4-2016《食品安全国家标准 食品中灰分的测定》-灼烧法;脂肪含量测定根据GB 5009.6-2016《食品安全国家标准 食品中脂肪的测定》-索氏抽提法;酸价含量测定根据GB 5009.229-2016《食品安全国家标准 食品中酸价的测定》-冷溶剂指示剂滴定法;过氧化值含量测定根据GB 5009.227-2016《食品安全国家标准 食品中过氧化值的测定》-滴定法。

1.2.9 花生仁质构特性的测定

原料处理:选择大小均匀的花生仁,然后把花生仁去皮,用手剥开两瓣将种胚去掉,选择花生瓣大小一致[22]。

采用质构仪对花椒味花生仁的硬度、脆度、咀嚼性指标进行分析,参照汤鹏宇等[23]的质构测定方法稍有调整,操作模式为TPA运行程序(P/36R探头),具体测定的设定参数:测试前、中、后速度分别为2、3、3 mm/s,压缩形变比40%,触发力为5 g,两次压缩间隔时间2 s。测定指标为硬度、脆度、咀嚼度,每个样品重复测定6次,去掉最大值、最小值、异常值,取平均值。

1.2.10 花生仁色差的测定

花椒味花生仁进行去红皮处理,并粉碎过20目筛,得到色泽均匀的花生仁粉末,取样置于测定皿中并铺满测定皿底面,使用色差仪测定花椒味花生仁的亮度值(L*)、红绿度值(a*)、黄蓝度值(b*)。每个样品测三次,取平均值。

ΔE=√(ΔL∗)2+(Δa∗)2+(Δb∗)2 (3) 1.3 数据处理

采用Design Expert 13.0软件进行D-最优混料设计实验及数据分析、Excel 2021对混料试验数据进行统计和SPSS 26.0软件进行数据分析,各组间差异比较用单因素方差分析(One-Way ANOVA)进行组间两两多重比较,P<0.05表示差异有统计学意义,所有数值均用“均数±标准误差”。

2. 结果与分析

2.1 不同负压时间对花椒味花生仁品质的影响

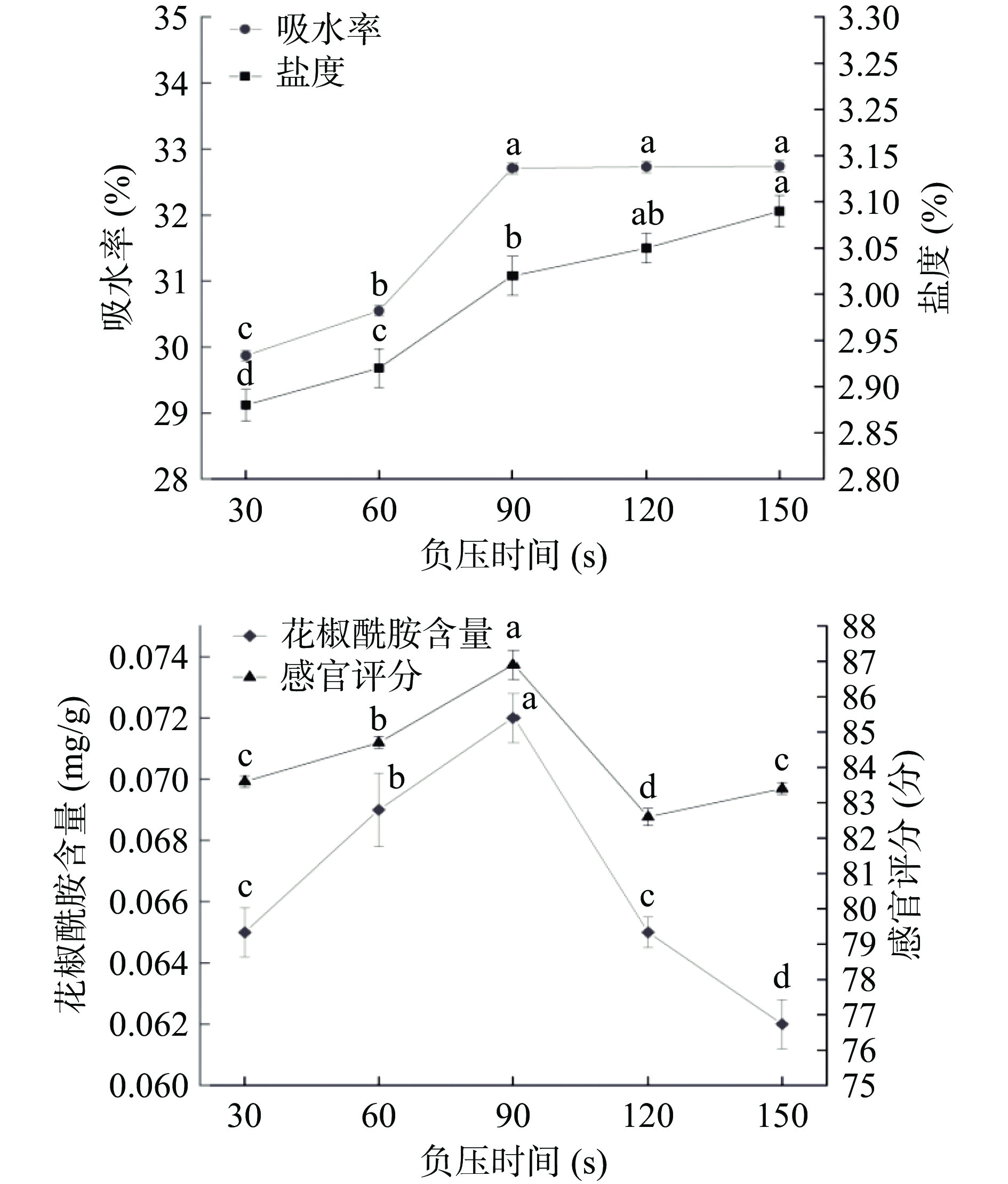

随着负压时间的增加,吸水率、盐度逐渐上升,花椒酰胺含量、感官评分先上升再下降,其中负压时间在前90 s内,吸水率和盐度曲线斜率较大,90 s后吸水率和盐度上升速度缓慢,入味速率减慢,花椒酰胺含量和感官评价在前90 s逐渐上升,负压时间为90 s时花椒酰胺含量和感官评分达到最高,90 s后花椒酰胺含量和感官评价分数在逐渐下降(图2)。这主要原因是随着负压时间的增加,调味液在真空浓度差及重力作用下浸入花椒花生仁,使得水分和盐快速进入花生仁内部,花椒酰胺的含量也上升,随着负压时间的继续增加,吸水率缓慢上升已趋于平缓,盐度还在上升,渗入花生的咸味会增加,花椒的味道会被咸味盖住,咸味过重,花椒酰胺的含量和感官评分在下降。综合考虑,选择负压时间为60、90、120 s进行响应面试验。

2.2 不同负压次数对花椒味花生仁品质的影响

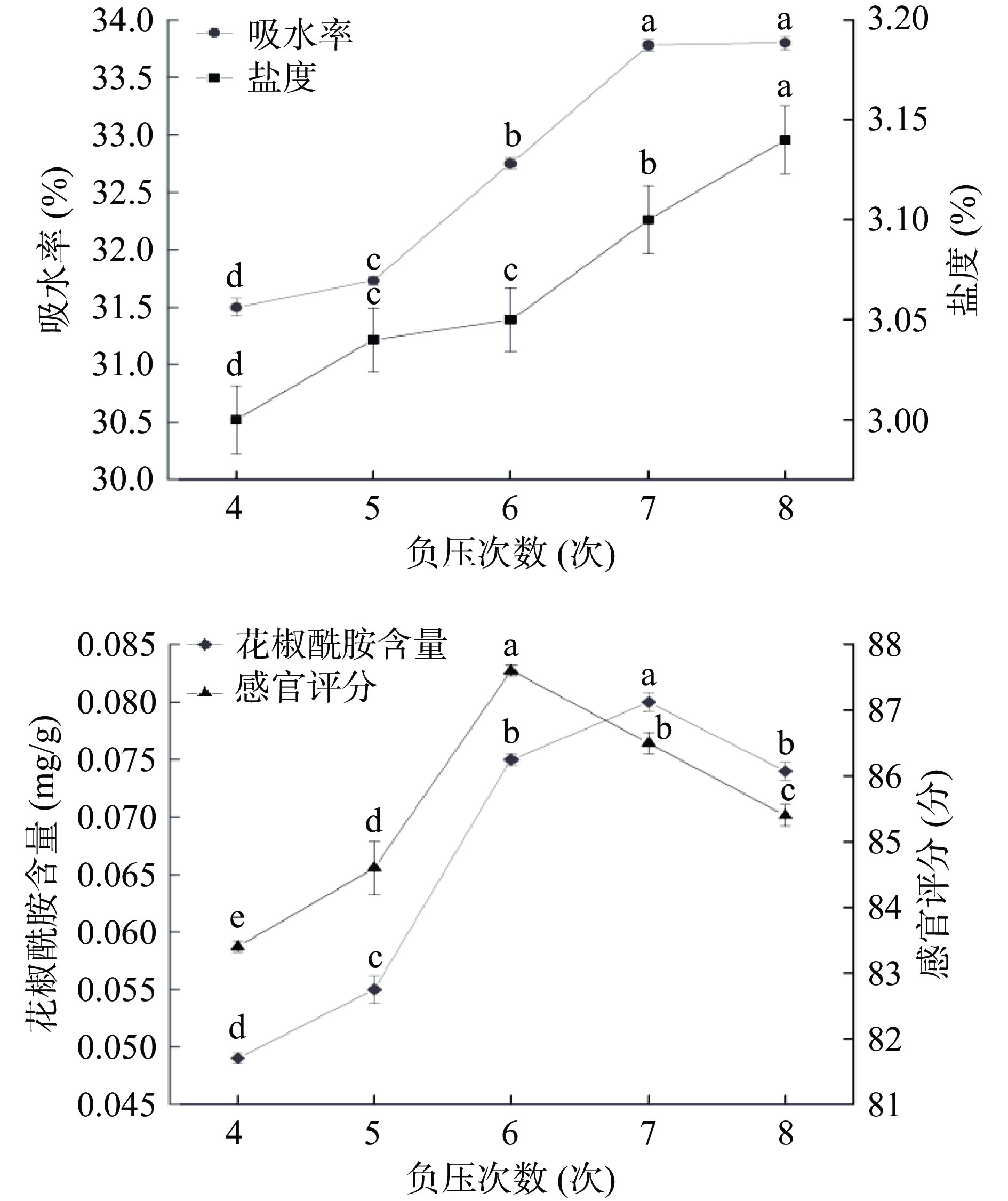

随着负压次数的增加,吸水率逐渐上升再趋于稳定,盐度逐渐上升,花椒酰胺含量先上升后下降,感官评分逐渐上升再下降,其中负压次数为6次时花椒花生仁感官评分达到最高(图3)。这主要原因是抽真空时,压强的变化,使得调味液渗透到花生仁内部,负压次数的增加,不断的负压、放气,使其产生压强差,更好地把调味液渗透进去[18]。当负压次数超过6次,吸水率在上升趋于稳定,盐度在上升,盐度过重,会影响花生仁的口感,感官评分在下降。当负压次数为7次时,花椒酰胺的含量最多,但花椒的麻味会影响感官评分。综合考虑,选择负压次数为5、6、7次进行响应面试验。

2.3 不同真空度对花椒味花生仁品质的影响

随着真空度的增加,吸水率、盐度逐渐上升再趋于稳定,花椒酰胺含量逐渐上升,感官评分逐渐上升再下降,其中真空度为0.09 MPa时花椒花生仁感官评分达到最高(图4)。这主要是由于花生仁在真空作用下产生一定程度的膨胀,组织细胞间距增大。真空度越大,细胞间距越大,调味液更易进入花生仁内部,提高入味速率。在抽真空时花生仁内部空气被抽出,调味液迅速进入花生仁内,吸水率、盐度上升,花椒酰胺含量增加[24−25]。当真空度超过0.09 MPa,吸水率和盐度趋于稳定,花椒酰胺含量上升缓慢,花椒的麻味过重,会使得感官评分下降。综合考虑,选择真空度为0.08、0.09、0.10 MPa进行响应面试验。

2.4 花椒花生仁模糊数学感官评价结果

由10名评价员对响应面试验得出的17种花椒味花生仁的4项指标包括色泽、气味、滋味、口感进行评价,统计人数后,结果如表3所示。

表 3 花椒味花生仁感官评价指标票数统计结果Table 3. Statistical results of sensory evaluation index votes for pepper-flavored peanut kernels样品 色泽(15%) 气味(23%) 滋味(35%) 口感(27%) 优 良 中 差 优 良 中 差 优 良 中 差 优 良 中 差 1 6 2 2 0 6 0 4 0 5 2 3 0 4 3 3 0 2 6 1 3 0 6 1 3 0 6 1 3 0 5 3 2 0 3 5 0 5 0 6 0 4 0 6 1 3 0 5 3 2 0 4 6 3 1 0 4 4 2 0 7 2 1 0 7 2 1 0 5 7 2 1 0 8 0 2 0 6 2 2 0 6 2 2 0 6 7 3 0 0 8 2 0 0 6 3 1 0 7 3 0 0 7 7 2 1 0 6 3 1 0 7 0 3 0 5 3 2 0 8 8 0 2 0 8 1 1 0 6 3 1 0 6 3 1 0 9 6 2 2 0 6 3 1 0 6 2 2 0 5 3 2 0 10 7 1 2 0 7 2 1 0 6 3 1 0 6 3 1 0 11 7 2 1 0 6 1 3 0 7 0 3 0 5 3 2 0 12 5 2 2 1 5 3 2 0 6 3 1 0 7 3 0 0 13 8 2 0 0 8 2 0 0 8 0 2 0 7 1 2 0 14 8 1 1 0 8 1 1 0 9 0 1 0 8 0 2 0 15 8 1 1 0 8 1 1 0 9 0 1 0 8 0 2 0 16 8 2 0 0 8 2 0 0 8 0 2 0 8 1 1 0 17 8 2 0 0 7 2 1 0 8 0 2 0 8 2 0 0 实验结果可知,10位评定员中有6位评定员认为样品1的花椒花生仁色泽优,2位评定员认为色泽良,只有2位评定员认为色泽中。花椒味花生仁的4个因素的各评价等级评价人数除以总评价人数,所以T色泽=(0.6,0.2,0.2,0.0),同理可得T气味=(0.6,0.0,0.4,0.0),T滋味=(0.5,0.2,0.3,0.0),T口感=(0.4,0.3,0.3,0.0)。最终得到1个Tg的模糊评价矩阵即:

T1=(0.60.20.20.00.60.00.40.00.50.20.30.00.40.30.30.0) 已知4个权重集为U={0.15,0.23,0.35,0.27},按照Y=U×T得到试验号1的花生仁的评价结果:

Y1=U×T1=(0.150.230.350.27)×(0.60.20.20.00.60.00.40.00.50.20.30.00.40.30.30.0)=(0.5110.1810.3080) 根据“1.2.5”中描述的评定结果,则1号花椒味花生仁的感官评分为:

Y1=0.511×100+0.181×75+0.308×50=80.1 1号花椒味花生仁的感官评价分数为80.1分,同理可得用其方法对本实验17个样品进行计算,结果如表4所示。

表 4 花椒味花生仁响应面试验设计及结果Table 4. Design and results od pepper-flavored peanut kernel response surface experimental实验号 A:负压

时间B:负压

次数C:真空度 Y1:花椒酰胺

含量(mg/g)Y2:感官评分

(分)1 −1 −1 0 0.064 80.1 2 1 −1 0 0.070 82.5 3 −1 1 0 0.065 80.8 4 1 1 0 0.075 87.3 5 −1 0 −1 0.072 86.9 6 1 0 −1 0.080 91.3 7 −1 0 1 0.071 85.7 8 1 0 1 0.078 89.0 9 0 −1 −1 0.070 84.9 10 0 1 −1 0.075 88.1 11 0 −1 1 0.069 84.5 12 0 1 1 0.072 86.2 13 0 0 0 0.079 91.2 14 0 0 0 0.080 92.7 15 0 0 0 0.081 92.7 16 0 0 0 0.078 92.6 17 0 0 0 0.080 92.1 2.5 花椒味花生仁真空入味工艺优化参数

2.5.1 响应面试验结果

采用Box-Behnken响应面试验原理,以花椒酰胺含量(Y1)、花椒味花生仁的模糊数学感官评价(Y2)为响应值,考查负压时间(A)、负压次数(B)和真空度(C)3个因素对花椒花生仁品质的影响,结果如表4所示。

花椒味花生仁的花椒酰胺含量(Y1)的回归方程:

Y1=0.0796+0.0039A+0.0018B−0.0009C+0.0010AB−0.0002AC−0.0005BC−0.0037A2−0.0074B2−0.0007C2;

花椒味花生仁的感官评分(Y2)的回归方程为:

Y2=92.26+2.08A+1.30B−0.7250C+1.02AB−0.2750AC−0.3750BC−3.64A2−5.94B2−0.3925C2。

方差分析(表5~表6)表明,响应面Y1花椒酰胺含量的P<0.0001,模型极其显著,决定系数R²为0.9874,失拟度P=0.8966>0.05不存在显著性,说明该回归方程拟合度好,花椒味花生仁真空入味条件不同的情况下,花椒味花生仁的花椒酰胺含量存在高度显著差异。响应值Y2感官评分的P<0.0001,模型极其显著,决定系数R²为0.9926,失拟度P=0.8074>0.05不存在显著性,说明该回归方程拟合度好,花椒味花生仁真空入味条件不同的情况下,花椒味花生仁的感官评分存在高度显著差异。一般Y2越接近1,拟合的经验模型越好。数据可信可靠,具有统计学意义,能够较准确预测花椒味花生仁的感官评分。表5花椒酰胺含量的方差分析中,一次项的负压时间、负压次数对花椒酰胺含量影响极显著(P<0.01),真空度对花椒酰胺含量影响显著(P<0.05),负压时间对花椒酰胺含量的影响最大,其次为负压次数,最后为真空度。表6感官评价的方差分析中,其中A、B、A2、B2影响极显著(P<0.01);C、AB影响显著(P<0.05);其他因素影响不显著。根据F值的大小,试验范围内各因素的影响大小依次为A(负压时间)>B(负压次数)>C(真空度)。

表 5 花椒酰胺含量的方差分析Table 5. Analysis of variance for pepper amide content变异源 平方和 自由度 均方 F值 P值 显著性 模型 0.0005 9 0.0001 60.78 <0.0001 ** A 0.0001 1 0.0001 141.32 <0.0001 ** B 0.0000 1 0.0000 28.82 0.0010 ** C 6.125E-06 1 6.125E-06 7.21 0.0313 * AB 4.000E-06 1 4.000E-06 4.71 0.0667 AC 2.500E-07 1 2.500E-07 0.2941 0.6044 BC 1.000E-06 1 1.000E-06 1.18 0.3140 A2 0.0001 1 0.0001 66.90 <0.0001 ** B2 0.0002 1 0.0002 273.09 <0.0001 ** C2 1.918E-06 1 1.918E-06 2.26 0.1767 残差 5.950E-06 7 8.500E-07 失拟项 7.500E-07 3 2.500E-07 0.1923 0.8966 纯误差 5.200E-06 4 1.300E-06 总变异 0.0005 16 注:*表示P<0.05为显著差异,**表示P<0.01为极显著差异;R2=0.9874,R2Adj=0.9711。 表 6 感官评价的方差分析Table 6. Analysis of variance for sensory evaluation变异源 平方和 自由度 均方 F值 P值 显著性 模型 275.60 9 30.62 104.21 <0.0001 ** A 34.45 1 34.45 117.22 <0.0001 ** B 13.52 1 13.52 46.01 0.0003 ** C 4.21 1 4.21 14.31 0.0069 * AB 4.20 1 4.20 14.30 0.0069 * AC 0.3025 1 0.3025 1.03 0.3441 BC 0.5625 1 0.5625 1.91 0.2090 A2 55.86 1 55.86 190.11 <0.0001 ** B2 148.69 1 148.69 505.99 <0.0001 ** C2 0.6487 1 0.6487 2.21 0.1809 残差 2.06 7 0.2939 失拟项 0.4050 3 0.1350 0.3269 0.8074 纯误差 1.65 4 0.4130 总变异 277.66 16 注:*表示P<0.05为显著差异,**表示P<0.01为极显著差异;R2=0.9926,R2Adj=0.9831。 2.5.2 响应曲面分析

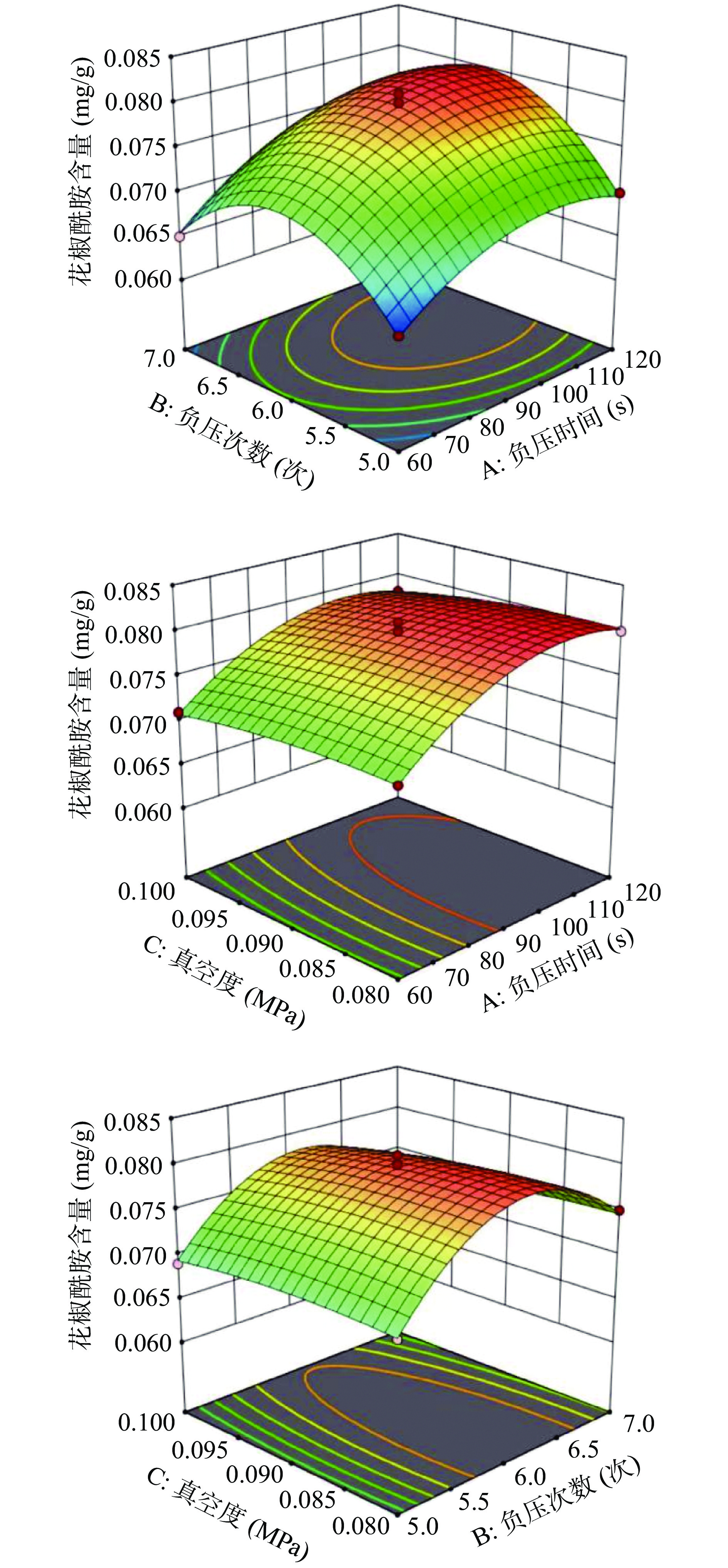

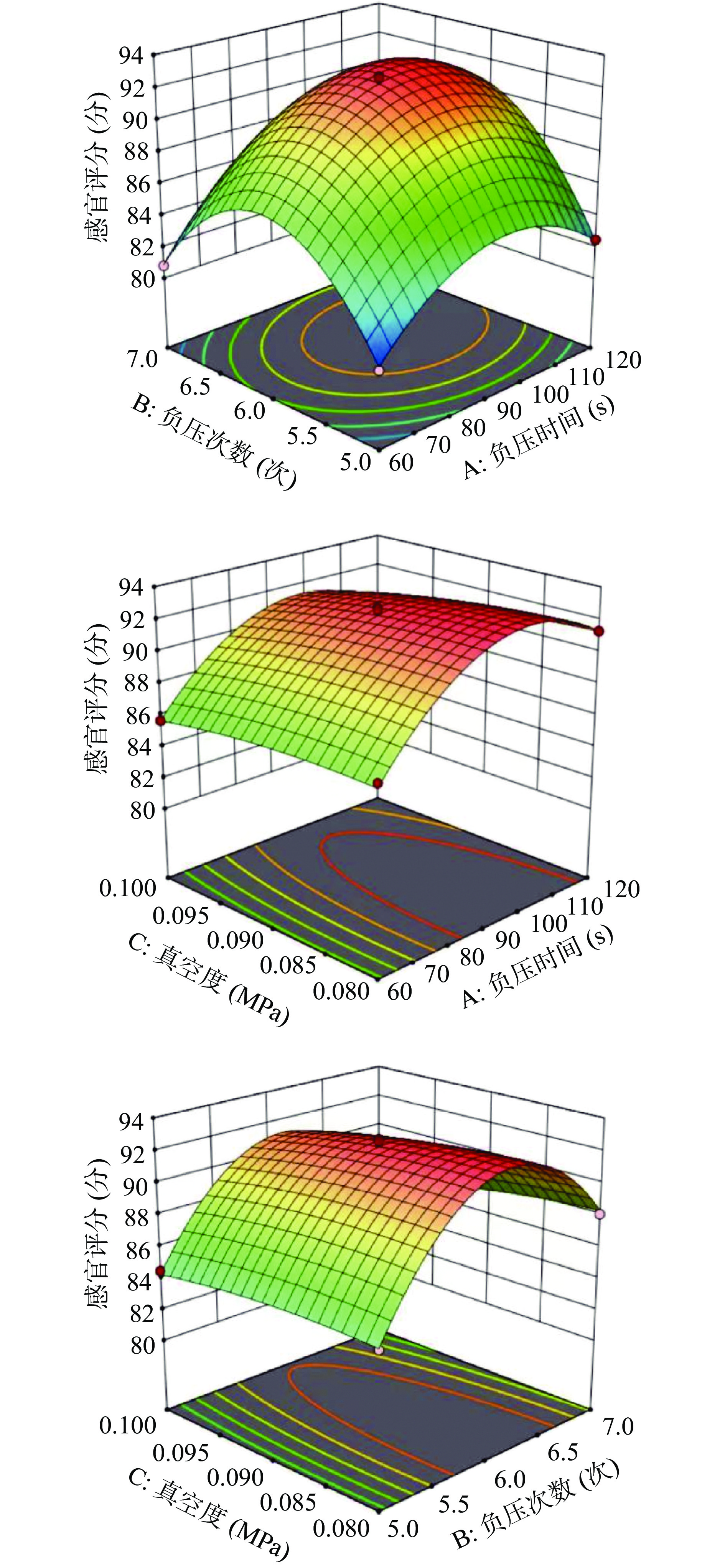

负压时间、负压次数、真空度的相互作用对花椒味花生仁的花椒酰胺含量和感官评分的曲面图(图5~图6)。结合花椒酰胺含量、感官评分方差分析表和曲面图可知,各个单因素对花椒味花生仁的花椒酰胺含量和感官评分影响显著。响应面曲面的陡峭程度能反映花椒味花生仁花椒酰胺含量和感官评价影响,曲面陡度越大,说明两因素交互作用越显著[26−27];等高线的形状可反映出交互作用的强弱,椭圆的等高线表示两个因素之间有显著交互作用,圆形的等高线表示相反[28]。响应面均开口向下,响应值均出现先增加后减少的趋势,即在试验范围内存在稳定点。花椒酰胺含量的响应曲面坡度趋势平缓,等高线呈圆形,表明负压时间(A)、负压次数(B)和真空度(C)各因素的交互作用相对较弱,与方差分析结果一致。花椒味花生仁的感官评分,随各因素的增大呈先升高后降低趋势,其中AB响应曲面比较陡峭,等高线是椭圆形,表明各因素之间有明显的交互作用。AC、BC响应曲面陡度适中,等高线偏圆,说明负压时间(A)和真空度(C)、负压次数(B)和真空度(C)之间各因素之间的交互作用很小,与方差分析结果一致。

根据响应面试验结果,综合花椒酰胺含量数据、感官评分的要求及回归方程的计算,得到最优条件为:负压时间100.381 s、负压次数6.17次、真空度0.08 MPa。为验证响应面实验的预测结果的可靠性,考虑设备及实验环境条件,修正真空入味工艺条件:负压时间100 s、负压次数6次、真空度0.08 MPa。

2.6 花椒味花生仁验证试验结果

通过Design Expert 13软件对该模型进行分析,花椒味花生仁的工艺优化应选择花椒酰胺含量在合理范围内,感官评分高的条件作为最优组,从而预测真空入味工艺为:负压时间100.381 s、负压次数6.17次、真空度0.08 MPa,在该实验下得到最大理论花椒酰胺含量为0.0810 mg/g,感官分数为93.143分。进行最优的花椒味花生仁的三组平行试验,最终得出花椒酰胺含量为0.078 mg/g,感官评分为94.2分,该实验结果与软件所得的理论最大花椒酰胺含量的偏差为3.7%,感官评价得分的偏差为1.1%,三组平行试验花椒酰胺含量和感官评价结果稳定可重复性高。这说明响应面实验对花椒味花生仁工艺优化实验结果的分析和预测是有效和可靠的。最优的花椒味花生仁色泽均匀、协调,香气浓郁、协调,酥脆。

2.7 花椒味花生仁基本理化指标

由表7可知,煮制入味和真空入味的花生仁蛋白质、脂肪的含量都为27.5%、57.9%,没有显著性的差异;真空入味的和煮制入味的花生仁的水分含量分别为6.45%、6.38%,没有显著性差异,花生仁在烘烤中水分不断蒸发,花生仁逐渐变得酥脆,花椒花生仁均符合NY/T 1889-2021绿色食品 烘炒食品和GB 22165-2008坚果炒货食品通则对烘烤食品的要求:水分含量≤15 g/100 g。花椒味花生仁的酸价和过氧化值是检验产品品质的一项重要指标,酸价代表的是花生油脂中游离脂肪酸的含量,过氧化值表示油脂被氧化的程度。真空入味的花生仁的酸价、过氧化值、灰分都小于煮制入味的花生仁,真空入味使花生仁滋味更加浓郁。花椒味花生仁均符合NY/T 1889-2021绿色食品 烘炒食品和GB 19300-2014坚果与籽类食品国家标准对烘烤花生仁的要求:酸价0.25≤3 mg/g、过氧化值0.01≤0.5 g/100 g,符合消费者的味觉要求。

表 7 花椒味花生仁的基本理化指标Table 7. Basic physical and chemical indexes of pepper-flavored peanut kernel指标 花椒味花生仁

(煮制入味)花椒味花生仁

(真空入味)水分含量(g/100 g) 6.38±0.25a 6.45±0.11a 蛋白质(g/100 g) 27.49±0.04a 27.53±0.03a 脂肪(g/100 g) 57.91±0.11a 57.81±0.26a 灰分(g/100 g) 3.55±0.14a 3.44±0.15a 酸价(mg/g) 0.28±0.01a 0.25±0.01b 过氧化值(g/100 g) 0.015±0.003a 0.008±0.002b 注:同一行肩标小写字母表示基本理化指标差异显著(P<0.05),表9同。 2.8 花椒味花生仁工艺优化的质构分析

真空入味的花生仁的感官评分显著高于煮制入味的花生仁。质构可以在一定程度上反映产品的感官品质,本研究利用质构仪分析了煮制入味的和真空入味的花椒味花生仁质构的变化,结果如表8所示[29]。花椒味花生仁真空工艺参数经过试验优化后,煮制入味和真空入味的花椒味花生仁的硬度和咀嚼性在P<0.05水平上有显著差异,真空入味的口感比煮制入味的口感要好。

表 8 花椒味花生仁质构的变化Table 8. Changes of texture of pepper-flavored peanut kernels指标 花椒味花生仁(煮制入味) 花椒味花生仁(真空入味) 硬度(g) 7535.89±113.34 6958.16±106.35* 脆度(g) 5581.61±147.75 5338.29±123.84 咀嚼性 658.32±32.20 756.21±30.17* 注:*表示差异显著,P<0.05。 2.9 花椒味花生仁工艺优化的色泽变化

坚果类的食品的色泽非常重要,会影响到消费者的购买和品尝的欲望,坚果类休闲食品由于原料本身脂肪含量高,特别是较高含量的不饱和脂肪酸,高温加工以及储藏时会导致坚果类产品中不饱和脂肪酸氧化酸败,花生仁在高温加工的时候会发生美拉德反应,产生褐变使产品颜色加深[30]。由表9可知,与生花生仁相比,煮制入味和真空入味的L*值在降低,煮制入味和真空入味的a*、b*在增加,两种入味的花生仁总的颜色变化∆E值增加,两者的颜色变化显著。说明加工花生仁的亮度降低,煮制入味的颜色更偏向红色,真空入味的颜色偏向黄色[31-33]。真空入味的花生仁色泽均匀,总体偏向淡黄色,更加被消费者接受[34-35]。

表 9 花椒味花生仁色差的变化Table 9. Chromatism variations of pepper-flavored peanut kernels色度指数 生花生仁 花椒味花生仁

(煮制入味)花椒味花生仁

(真空入味)L* 74.46±0.11a 52.94±0.50c 68.10±0.36b a* 1.97±0.08c 12.46±0.43a 8.31±0.10b b* 16.96±0.10c 24.56±0.62b 29.02±0.35a ∆E 27.43±0.22c 50.84±0.69a 40.21±0.50b 3. 结论

本试验以花椒、白砂糖、盐、其他香辛料为主要原料,经真空入味加工制得花椒味花生仁产品,通过单因素实验和响应面试验,优化了真空入味花椒味花生仁的工艺条件。花椒味花生仁的最优真空工艺为:负压时间100 s、负压次数6次、真空度0.08 MPa。最优的花椒味花生仁色泽均匀、协调,香气浓郁、协调,酥脆,并且各项理化指标均符合GB 19300-2014坚果与籽类食品国家标准要求。相比于煮制入味,真空入味有更佳的入味效果,提高入味效率。

-

表 1 Box-Behnken 试验设计因素与水平

Table 1 Factors and levels of response surface experiment

水平 因素 负压时间(s) 负压次数(次) 真空度(MPa) −1 60 5 0.08 0 90 6 0.09 1 120 7 0.10 表 2 花椒味花生仁感官评价标准

Table 2 Sensory evaluation standard of pepper-flavored peanut kernels

指标 评分标准(分) 优(100分) 良(75分) 中(50分) 差(25分) 色泽 均匀一致,无异色 较均匀一致,无明显的异色 不均匀一致,有异色 不均匀一致,有明显的异色 气味 香辛料香味适中,

有浓郁的花生仁香味香气不足,香辛料气味较淡,无异味 香气不足,香辛料气味较淡,

有异味基本无香味,有焦糊味或其他异味 滋味 咸味、甜味、香料味适中,

咀嚼时有浓郁的花生仁香味咸味、甜味、香料味较好,

咀嚼时有淡淡的花生仁香味有一定的适口性,咸味、

甜味、香料味较好带有异味,咸味、甜味过重,

咀嚼无香味口感 酥脆,不粘牙,软硬适中 较酥脆,些许粘牙 不酥脆,些许粘牙 不酥脆,粘牙,过软或过硬 表 3 花椒味花生仁感官评价指标票数统计结果

Table 3 Statistical results of sensory evaluation index votes for pepper-flavored peanut kernels

样品 色泽(15%) 气味(23%) 滋味(35%) 口感(27%) 优 良 中 差 优 良 中 差 优 良 中 差 优 良 中 差 1 6 2 2 0 6 0 4 0 5 2 3 0 4 3 3 0 2 6 1 3 0 6 1 3 0 6 1 3 0 5 3 2 0 3 5 0 5 0 6 0 4 0 6 1 3 0 5 3 2 0 4 6 3 1 0 4 4 2 0 7 2 1 0 7 2 1 0 5 7 2 1 0 8 0 2 0 6 2 2 0 6 2 2 0 6 7 3 0 0 8 2 0 0 6 3 1 0 7 3 0 0 7 7 2 1 0 6 3 1 0 7 0 3 0 5 3 2 0 8 8 0 2 0 8 1 1 0 6 3 1 0 6 3 1 0 9 6 2 2 0 6 3 1 0 6 2 2 0 5 3 2 0 10 7 1 2 0 7 2 1 0 6 3 1 0 6 3 1 0 11 7 2 1 0 6 1 3 0 7 0 3 0 5 3 2 0 12 5 2 2 1 5 3 2 0 6 3 1 0 7 3 0 0 13 8 2 0 0 8 2 0 0 8 0 2 0 7 1 2 0 14 8 1 1 0 8 1 1 0 9 0 1 0 8 0 2 0 15 8 1 1 0 8 1 1 0 9 0 1 0 8 0 2 0 16 8 2 0 0 8 2 0 0 8 0 2 0 8 1 1 0 17 8 2 0 0 7 2 1 0 8 0 2 0 8 2 0 0 表 4 花椒味花生仁响应面试验设计及结果

Table 4 Design and results od pepper-flavored peanut kernel response surface experimental

实验号 A:负压

时间B:负压

次数C:真空度 Y1:花椒酰胺

含量(mg/g)Y2:感官评分

(分)1 −1 −1 0 0.064 80.1 2 1 −1 0 0.070 82.5 3 −1 1 0 0.065 80.8 4 1 1 0 0.075 87.3 5 −1 0 −1 0.072 86.9 6 1 0 −1 0.080 91.3 7 −1 0 1 0.071 85.7 8 1 0 1 0.078 89.0 9 0 −1 −1 0.070 84.9 10 0 1 −1 0.075 88.1 11 0 −1 1 0.069 84.5 12 0 1 1 0.072 86.2 13 0 0 0 0.079 91.2 14 0 0 0 0.080 92.7 15 0 0 0 0.081 92.7 16 0 0 0 0.078 92.6 17 0 0 0 0.080 92.1 表 5 花椒酰胺含量的方差分析

Table 5 Analysis of variance for pepper amide content

变异源 平方和 自由度 均方 F值 P值 显著性 模型 0.0005 9 0.0001 60.78 <0.0001 ** A 0.0001 1 0.0001 141.32 <0.0001 ** B 0.0000 1 0.0000 28.82 0.0010 ** C 6.125E-06 1 6.125E-06 7.21 0.0313 * AB 4.000E-06 1 4.000E-06 4.71 0.0667 AC 2.500E-07 1 2.500E-07 0.2941 0.6044 BC 1.000E-06 1 1.000E-06 1.18 0.3140 A2 0.0001 1 0.0001 66.90 <0.0001 ** B2 0.0002 1 0.0002 273.09 <0.0001 ** C2 1.918E-06 1 1.918E-06 2.26 0.1767 残差 5.950E-06 7 8.500E-07 失拟项 7.500E-07 3 2.500E-07 0.1923 0.8966 纯误差 5.200E-06 4 1.300E-06 总变异 0.0005 16 注:*表示P<0.05为显著差异,**表示P<0.01为极显著差异;R2=0.9874,R2Adj=0.9711。 表 6 感官评价的方差分析

Table 6 Analysis of variance for sensory evaluation

变异源 平方和 自由度 均方 F值 P值 显著性 模型 275.60 9 30.62 104.21 <0.0001 ** A 34.45 1 34.45 117.22 <0.0001 ** B 13.52 1 13.52 46.01 0.0003 ** C 4.21 1 4.21 14.31 0.0069 * AB 4.20 1 4.20 14.30 0.0069 * AC 0.3025 1 0.3025 1.03 0.3441 BC 0.5625 1 0.5625 1.91 0.2090 A2 55.86 1 55.86 190.11 <0.0001 ** B2 148.69 1 148.69 505.99 <0.0001 ** C2 0.6487 1 0.6487 2.21 0.1809 残差 2.06 7 0.2939 失拟项 0.4050 3 0.1350 0.3269 0.8074 纯误差 1.65 4 0.4130 总变异 277.66 16 注:*表示P<0.05为显著差异,**表示P<0.01为极显著差异;R2=0.9926,R2Adj=0.9831。 表 7 花椒味花生仁的基本理化指标

Table 7 Basic physical and chemical indexes of pepper-flavored peanut kernel

指标 花椒味花生仁

(煮制入味)花椒味花生仁

(真空入味)水分含量(g/100 g) 6.38±0.25a 6.45±0.11a 蛋白质(g/100 g) 27.49±0.04a 27.53±0.03a 脂肪(g/100 g) 57.91±0.11a 57.81±0.26a 灰分(g/100 g) 3.55±0.14a 3.44±0.15a 酸价(mg/g) 0.28±0.01a 0.25±0.01b 过氧化值(g/100 g) 0.015±0.003a 0.008±0.002b 注:同一行肩标小写字母表示基本理化指标差异显著(P<0.05),表9同。 表 8 花椒味花生仁质构的变化

Table 8 Changes of texture of pepper-flavored peanut kernels

指标 花椒味花生仁(煮制入味) 花椒味花生仁(真空入味) 硬度(g) 7535.89±113.34 6958.16±106.35* 脆度(g) 5581.61±147.75 5338.29±123.84 咀嚼性 658.32±32.20 756.21±30.17* 注:*表示差异显著,P<0.05。 表 9 花椒味花生仁色差的变化

Table 9 Chromatism variations of pepper-flavored peanut kernels

色度指数 生花生仁 花椒味花生仁

(煮制入味)花椒味花生仁

(真空入味)L* 74.46±0.11a 52.94±0.50c 68.10±0.36b a* 1.97±0.08c 12.46±0.43a 8.31±0.10b b* 16.96±0.10c 24.56±0.62b 29.02±0.35a ∆E 27.43±0.22c 50.84±0.69a 40.21±0.50b -

[1] ARYA S S, SALVE A R, CHAUHAN S. Peanuts as functional food:A review[J]. Journal of Food Science and Technology,2016,53(1):31−41. doi: 10.1007/s13197-015-2007-9

[2] 张照华, 王志慧, 淮东欣, 等. 利用回交和标记辅助选择快速培育高油酸花生品种及其评价[J]. 中国农业科学,2018,51(9):1641−1652. [ZHANG Zhaohua, WANG Zhihui, HUAI Dongxin, et al. Fast development of high oleate peanut cultivars by using marker-assisted backcrossing and their evaluation[J]. Scientia Agricultura Sinica,2018,51(9):1641−1652.] ZHANG Zhaohua, WANG Zhihui, HUAI Dongxin, et al . Fast development of high oleate peanut cultivars by using marker-assisted backcrossing and their evaluation[J]. Scientia Agricultura Sinica,2018 ,51 (9 ):1641 −1652 .[3] 刘连红, 陈飞, 张丽, 等. 花生的药用成分及其提取分离技术的研究进展[J]. 生物加工过程,2018,16(4):40−48. [LIU Lianhong, CHEN Fei, ZHANG Li, et al. Advance of medicinal ingredients in peanuts and their extraction technology[J]. Chinese Journal of Bioprocess Engineering,2018,16(4):40−48.] LIU Lianhong, CHEN Fei, ZHANG Li, et al . Advance of medicinal ingredients in peanuts and their extraction technology[J]. Chinese Journal of Bioprocess Engineering,2018 ,16 (4 ):40 −48 .[4] 郭聪. 焙烤花生的营养成分、体外消化特性及培烤花生酸奶的加工工艺研究[D]. 南昌:南昌大学, 2019. [GUO Cong. Study on nutritional components, in vitro digestive characteristics of roasted peanut and processing technology of roasting peanut yoghurt[D]. Nanchang:Nanchang University, 2019.] GUO Cong. Study on nutritional components, in vitro digestive characteristics of roasted peanut and processing technology of roasting peanut yoghurt[D]. Nanchang: Nanchang University, 2019.

[5] FRANCISCO M L D L, RESURRECCION A V A. Functional components in peanuts[J]. Critical Reviews in Food Science and Nutrition,2008,48(8):715−746. doi: 10.1080/10408390701640718

[6] HWANG J Y, SHUE Y S, CHANG H M. Antioxidative activity of roasted and defatted peanut kernels[J]. Food Research International,2001,34(7):639−647. doi: 10.1016/S0963-9969(01)00083-7

[7] MAZHAR H, BASHA S M. Effects of desiccation on peanut ( Arachis hypogaea L.) seed protein composition[J]. Environment and Experimental Botany,2002,47(1):67−75. doi: 10.1016/S0098-8472(01)00110-1

[8] ROS E. Health benefits of nut consumption[J]. Nutrients,2010,2(7):652−682. doi: 10.3390/nu2070652

[9] 张翔, 刘锦宜, 黄雪松. 坚果的主要生物活性成分及其保健作用[J]. 食品安全质量检测学报,2017,8(7):2606−2614. [ZHANG Xiang, LIU Jinyi, HUANG Xuesong. Bioactive components of nuts and their health effects[J]. Journal of Food Safety and Quality,2017,8(7):2606−2614.] ZHANG Xiang, LIU Jinyi, HUANG Xuesong . Bioactive components of nuts and their health effects[J]. Journal of Food Safety and Quality,2017 ,8 (7 ):2606 −2614 .[10] GUASCH-FERRÉ M, LIU X, MALIK V S, et al. Nut consumption and risk of cardiovascular disease[J]. Journal of the American College of Cardiology,2017,70(20):2519−2532. doi: 10.1016/j.jacc.2017.09.035

[11] 赵梅, 王晶珊, 李文香. 不同品种花生抗氧化能力的研究[J]. 中国粮油学报,2011,26(9):70−73. [ZHAO Mei, WANG Jingshan, LI Wenxiang. Study on oxidation resistance of different peanut varieties[J]. Journal of the Chinese Cereals and Oils Association,2011,26(9):70−73.] ZHAO Mei, WANG Jingshan, LI Wenxiang . Study on oxidation resistance of different peanut varieties[J]. Journal of the Chinese Cereals and Oils Association,2011 ,26 (9 ):70 −73 .[12] 李锦. 花椒及花椒籽风味油的制取及品质研究[D]. 郑州:河南工业大学, 2020. [LI Jin. Study on preparation and quality of zanthoxylum bungeanum and zanthoxylum bungeanum seed flavor oil[D]. Zhengzhou:Henan University of Technology, 2020.] LI Jin. Study on preparation and quality of zanthoxylum bungeanum and zanthoxylum bungeanum seed flavor oil[D]. Zhengzhou: Henan University of Technology, 2020.

[13] 柴丽琴. 花椒油树脂提取、成分分析、抗氧化性及抑菌性研究[D]. 西安:陕西师范大学, 2018. [CHAI Liqin. Study on extraction of Zanthoxylum oleoresin, component analysis, antioxidative activity and antibacterial activity[D]. Xi'an:Shaanxi Normal University, 2018.] CHAI Liqin. Study on extraction of Zanthoxylum oleoresin, component analysis, antioxidative activity and antibacterial activity[D]. Xi'an: Shaanxi Normal University, 2018.

[14] 潘姝璇, 蒲彪, 付本宁, 等. 花椒麻味物质感官分级及其检测研究进展[J]. 食品工业科技,2017,38(18):347−351. [PAN Shuxuan, PU Biao, FU benning, et al. Research progress in the sensory classification and detection of numb-taste components of zanthoxylum[J]. Science and Technology of Food Industry,2017,38(18):347−351.] PAN Shuxuan, PU Biao, FU benning, et al . Research progress in the sensory classification and detection of numb-taste components of zanthoxylum[J]. Science and Technology of Food Industry,2017 ,38 (18 ):347 −351 .[15] 方铁路, 王景源, 李玉岩, 等. 盐焗南瓜子负压入味加工工艺研究[J]. 现代食品,2020(8):82−84,89. [FANG Tielu, WANG Jingyuan, LI Yuyan, et al. Study on the processing technology of vacuum flavoring of baked pumpkin seeds with salt[J]. Modern Food,2020(8):82−84,89.] FANG Tielu, WANG Jingyuan, LI Yuyan, et al . Study on the processing technology of vacuum flavoring of baked pumpkin seeds with salt[J]. Modern Food,2020 (8 ):82 −84,89 .[16] 王伯华, 谢思敏, 香雪娇, 等. 醉鱼快速醉制工艺的优化[J]. 食品科技,2021,46(8):111−117. [WANG Bohua, XIE Simin, XIANG Xuejiao, et al. Optimization of rapid curing process for vinasse fish[J]. Food Science and Technology,2021,46(8):111−117.] WANG Bohua, XIE Simin, XIANG Xuejiao, et al . Optimization of rapid curing process for vinasse fish[J]. Food Science and Technology,2021 ,46 (8 ):111 −117 .[17] 何家林, 朱雪晶, 欧阳玲花, 等. 用响应面法优化咸蛋腌制工艺[J]. 江西农业学报,2017,29(4):85−88. [HE Jialin, ZHU Xuejing, OUYANG Linghua, et al. Optimization of pickling technology of salted duck eggs by response surface methodology[J]. Acta Agriculturae Jiangxi,2017,29(4):85−88.] HE Jialin, ZHU Xuejing, OUYANG Linghua, et al . Optimization of pickling technology of salted duck eggs by response surface methodology[J]. Acta Agriculturae Jiangxi,2017 ,29 (4 ):85 −88 .[18] 姜顾倩妮, 屠生辉, 刘镇, 等. 西瓜子真空负压锅入味加工工艺研究[J]. 食品安全导刊,2023(6):129−132. [JIANG Guqianni, TU Shenghui, LIU Zhen, et al. Study on the processing technology of vacuum flavoring of watermelon seeds[J]. China Food Safety Magazine,2023(6):129−132.] JIANG Guqianni, TU Shenghui, LIU Zhen, et al . Study on the processing technology of vacuum flavoring of watermelon seeds[J]. China Food Safety Magazine,2023 (6 ):129 −132 .[19] 王瑞花, 张文娟, 陈健初, 等. 基于模糊数学综合评价法优化红烧肉制作工艺[J]. 食品工业科技,2015,36(6):274−278. [WANG Ruihua, ZHANG Wenjuan, CHEN Jianchu, et al. Optimization of braised pork processing based on fuzzy mathematic evaluation[J]. Science and Technology of Food Industry,2015,36(6):274−278.] WANG Ruihua, ZHANG Wenjuan, CHEN Jianchu, et al . Optimization of braised pork processing based on fuzzy mathematic evaluation[J]. Science and Technology of Food Industry,2015 ,36 (6 ):274 −278 .[20] 刘静波, 吴丽英, 宫新统, 等. 基于模糊数学综合感官评价的红松针茶饮料的制作[J]. 食品科学,2013(7):308−311. [LIU Jingbo, WU Liying, GONG Xintong, et al. Manufacture of korean pine needle tea drink based on fuzzy mathematic sensory evaluation[J]. Food Science,2013(7):308−311.] LIU Jingbo, WU Liying, GONG Xintong, et al . Manufacture of korean pine needle tea drink based on fuzzy mathematic sensory evaluation[J]. Food Science,2013 (7 ):308 −311 .[21] 艾静汶, 李建强, 苏艳兰, 等. 原味带壳咸脆花生加工工艺研究[J]. 食品研究与开发,2019,40(10):125−130. [AI Jingwen, LI Jianqiang, SU Yanlan, et al. Study on the production process of natural salty and crispy peanut[J]. Food Research and Development,2019,40(10):125−130.] AI Jingwen, LI Jianqiang, SU Yanlan, et al . Study on the production process of natural salty and crispy peanut[J]. Food Research and Development,2019 ,40 (10 ):125 −130 .[22] 邱展英, 袁书鑫, 吴怡颖, 等. 原料特性对咸干花生加工品质的影响[J]. 农业工程学报,2022,38(S1):321−330. [QIU Zhanying, YUAN Shuxin, WU Yiying, et al. Effects of peanut material characteristics on the processing qualities of salty peanuts[J]. Transactions of the Chinese Society of Agricultural Engineering,2022,38(S1):321−330.] QIU Zhanying, YUAN Shuxin, WU Yiying, et al . Effects of peanut material characteristics on the processing qualities of salty peanuts[J]. Transactions of the Chinese Society of Agricultural Engineering,2022 ,38 (S1 ):321 −330 .[23] 汤鹏宇, 孟繁博, 黄道梅, 等. 质构参数与花生物性测定的相关性[J]. 现代食品科技,2021,37(7):294−301. [TANG Pengyu, MENG Fanbo, HUANG Daomei, et al. Correlation between texture-analyzer parameters and physical properties measurement of peanut[J]. Modern Food Science and Technology,2021,37(7):294−301.] TANG Pengyu, MENG Fanbo, HUANG Daomei, et al . Correlation between texture-analyzer parameters and physical properties measurement of peanut[J]. Modern Food Science and Technology,2021 ,37 (7 ):294 −301 .[24] 米顺利, 高程海, 姜舒, 等. 榄钱牡蛎软罐头的工艺研究[J]. 现代食品科技,2018,34(1):203−208. [MI Shunli, GAO Chenghai, JIANG Shu, et al. Study on the process of Avicennia marina fruit oysters soft cans[J]. Modern Food Science and Technology,2018,34(1):203−208.] MI Shunli, GAO Chenghai, JIANG Shu, et al . Study on the process of Avicennia marina fruit oysters soft cans[J]. Modern Food Science and Technology,2018 ,34 (1 ):203 −208 .[25] LIMLEY H A, CROSBIE G B, LIM K K, et al. Wheat quality requirements for char siew bao made from Australian soft wheat[J]. Cereal Chemistry,2013,90(3):231−239. doi: 10.1094/CCHEM-11-12-0152-R

[26] 张嘉琪, 杨东松, 李锐. 蚝油沙茶汁配方优化研究[J]. 中国调味品,2022,47(7):151−156. [ZHANG Jiaqi, YANG Dongsong, LI Rui. Study on formula optimization of satay sauce with oyster sauce[J]. China Condiment,2022,47(7):151−156.] ZHANG Jiaqi, YANG Dongsong, LI Rui . Study on formula optimization of satay sauce with oyster sauce[J]. China Condiment,2022 ,47 (7 ):151 −156 .[27] 严康玲, 于立梅, 白卫东, 等. 响应面法优化猴头菇戚风蛋糕配方工艺研究[J]. 食品工业科技,2023,44(21):234−242. [YAN Kangling, YU Limei, BAI Weidong, et al. Optimization of recipe of hericium erinaceus chiffon cake by response surface methodology[J]. Science and Technology of Food Industry,2023,44(21):234−242.] YAN Kangling, YU Limei, BAI Weidong, et al . Optimization of recipe of hericium erinaceus chiffon cake by response surface methodology[J]. Science and Technology of Food Industry,2023 ,44 (21 ):234 −242 .[28] 栾琳琳, 卢红梅, 陈莉, 等. 微波辅助低共熔溶剂提取桑葚果渣花青素的工艺研究[J]. 中国调味品,2020,45(5):191−196. [LUAN Linlin, LU Hongmei, CHEN Li, et al. Research on process of microwave-assisted low-eutectic solvent extraction of anthocyanins from mulberry residues[J]. China Condiment,2020,45(5):191−196.] LUAN Linlin, LU Hongmei, CHEN Li, et al . Research on process of microwave-assisted low-eutectic solvent extraction of anthocyanins from mulberry residues[J]. China Condiment,2020 ,45 (5 ):191 −196 .[29] 王琪, 刘琨毅, 郭云霞, 等. D-最优混料设计优化糯米蛋用料配比及质构分析[J]. 食品安全质量检测学报,2022,13(7):2168−2175. [WANG Qi, LIU Kunyi, GUO Yunxia, et al. Optimization of the ingredient ratio for glutinous rice egg by D-optimal mixture design and texture analysis[J]. Journal of Food Safety and Quality,2022,13(7):2168−2175.] WANG Qi, LIU Kunyi, GUO Yunxia, et al . Optimization of the ingredient ratio for glutinous rice egg by D-optimal mixture design and texture analysis[J]. Journal of Food Safety and Quality,2022 ,13 (7 ):2168 −2175 .[30] 赵俊杰, 王燕. 烘烤葵瓜子工艺优化及品质分析[J]. 食品与发酵工业,2023,49(10):237−244. [ZHAO Junjie, WANG Yan. Optimization and quality analysis of roasted sunflower seeds[J]. Food and Fermentation Industries,2023,49(10):237−244.] ZHAO Junjie, WANG Yan . Optimization and quality analysis of roasted sunflower seeds[J]. Food and Fermentation Industries,2023 ,49 (10 ):237 −244 .[31] LYKOMITROS D, FOGLIANO V, CAPUANO E. Flavor of roasted peanuts ( Arachis hypogaea)-Part I:Effect of raw material and processing technology on flavor, color and fatty acid composition of peanuts[J]. Food Research International,2016,89:860−869. doi: 10.1016/j.foodres.2016.09.024

[32] 罗环, 夏文水, 许艳顺, 等. 醉鱼间歇式真空浸渍快速入味工艺优化[J]. 食品与机械,2012,28(5):197−201,219. [LUO Huan, XIA Wenshui, XU Yanshun, et al. Optimization of flavor impregnation bases on vacuum osmotic technology of marinating drunk fish[J]. Food and Machinery,2012,28(5):197−201,219.] LUO Huan, XIA Wenshui, XU Yanshun, et al . Optimization of flavor impregnation bases on vacuum osmotic technology of marinating drunk fish[J]. Food and Machinery,2012 ,28 (5 ):197 −201,219 .[33] 许志诚, 吴鹏, 徐艳, 等. D-最优混料设计优化水油面团基础配方[J]. 美食研究,2017,34(3):42−44. [XU Zhicheng, WU Peng, XU Yan, et al. Optimization of basic formula for water-oiled dough by D-optimal mixture design[J]. Journal of Researches on Dietetic Science and Culture,2017,34(3):42−44.] XU Zhicheng, WU Peng, XU Yan, et al . Optimization of basic formula for water-oiled dough by D-optimal mixture design[J]. Journal of Researches on Dietetic Science and Culture,2017 ,34 (3 ):42 −44 .[34] STEPHEN D N, DAVID T N. Nuts as part of a healthy cardiovascular diet[J]. Current Atherosclerosis Reports,2008,10(6):529−535. doi: 10.1007/s11883-008-0082-3

[35] LYKOMITROS D, FOGLIANO V, CAPUANO E. Flavor of roasted peanuts ( Arachis hypogaea)-Part II:Correlation of volatile compounds to sensory characteristics[J]. Food Research International,2016,89:870−881. doi: 10.1016/j.foodres.2016.08.017

-

期刊类型引用(6)

1. 王寿峰,兰茜,雍登金,杨惠妮,胡敏. 利用核磁氢谱定量白酒中的酸酯总量. 食品与发酵工业. 2025(06): 306-310 .  百度学术

百度学术

2. 陶兰德,车富红,郭建慧,林有兰,王生库,孙海浪,冯声宝. 天佑德青稞酒中酸酯总量的测定及比对分析. 酿酒. 2023(04): 88-91 .  百度学术

百度学术

3. 陈茂飞,焦富,袁进,李巧玉,聂叶,李代鑫. 酱香型白酒酒醅中近红外快速检测乳酸的模型构建. 酿酒科技. 2023(09): 75-80 .  百度学术

百度学术

4. 宗绪岩,彭厚博,吴键航,盛旭峰,李丽. 化学计量学结合NIR对浓香型白酒年份、等级的研究. 包装与食品机械. 2022(02): 87-94 .  百度学术

百度学术

5. 翟双,张贵宇,庹先国,朱雪梅,罗林. 近红外光谱结合二维卷积在白酒基酒判别中的应用. 食品科技. 2022(09): 250-256 .  百度学术

百度学术

6. 宋艳,杨洋,张学平,许驰,王毓,蔡亮,李子文. 中红外光谱技术结合竞争性自适应重加权算法快速分析白酒风味组分. 中国酿造. 2022(12): 230-234 .  百度学术

百度学术

其他类型引用(4)

下载:

下载:

下载:

下载: