Effect of Carnosic Acid on Quality Characteristics of Rapeseed Oil during Thermal Processing

-

摘要: 本研究以菜籽油为原料,通过添加不同浓度的(0、200、400、700 mg/kg)鼠尾草酸和200 mg/kg特丁基对苯二酚对比分析,系统研究菜籽油热加工过程中(180 ℃,0、8、16、24、32 h)的色度、酸价、过氧化值、生育酚、黏度、脂肪酸组成与极性组分等的变化规律,以揭示鼠尾草酸对热加工菜籽油品质特性的影响规律。结果显示,鼠尾草酸添加量为700 mg/kg时表现出最优作用:延缓了菜籽油色度的劣变和抑制了油脂黏度的增大;热加工32 h后,酸价增幅最小,由0.280±0.030 mg/g升至0.757±0.020 mg/g,过氧化值较其余添加量低,为0.138 g/100 g;在热加工过程中α-生育酚损耗率与γ-生育酚损耗率均最低,分别为95.51%±0.96%与83.37%±0.39%;在热加工32 h时的极性组分含量为26.62%±0.03%,使菜籽油的热加工寿命得到延长。鼠尾草酸在热加工菜籽油中的使用可更好地实现对风险因子的控制,减少油脂浪费。Abstract: In order to reveal the influence of carnosic acid on the quality characteristics of thermal processed rapeseed oil, the changes of color, acid value, peroxide value, tocopherol, viscosity, fatty acid composition and total polar compound were investigated during thermal processing (180 ℃, 0, 8, 16, 24, 32 h) by adding different concentrations of carnosic acid (0, 200, 400, 700 mg/kg) and 200 mg/kg tert-butylhydroquinone as antioxidants. The results indicated that the addition of 700 mg/kg carnosic acid showed a better performance in the thermal processed rapeseed oil: The color deterioration was delayed and the increase of viscosity was inhibited; the increased value of acid value was the smallest which was from 0.280±0.030 mg/g to 0.757±0.020 mg/g, as well as the minimum peroxide value (0.138 g/100 g) was obtained at 32 h; the loss rate of α-tocopherol and γ-tocopherol were 95.51%±0.96% and 83.37%±0.39%, respectively; the content of polar components was 26.62%±0.03%, prolonging the thermal processing life of rapeseed oil by delaying the increase of total polar compound. It was found that the use of carnosic acid could better control the risk factors in rapeseed oil during thermal processing and reduce the waste of oils.

-

Keywords:

- carnosic acid /

- rapeseed oil /

- thermal processing /

- quality characteristics

-

菜籽油是世界第三大植物油,2020~2021年度我国菜籽油的消费量占总植物油消费量的23.6%,位列我国食用油消费的第二位[1−2]。菜籽油的不饱和脂肪酸含量超过85%,富含油酸和亚油酸,人体对其消化吸收率达99%,还含有生育酚、甾醇、多酚、角鲨烯等丰富的生物活性成分[3−4],具有抗菌、降低胆固醇、软化血管和延缓衰老等功效[5]。高温烹饪热加工(以下简称:热加工)是我国的传统烹饪方式,经油脂高温热加工后的食品不仅具有诱人的风味,还能提升食物本身的口感(酥脆等)。油脂高温热加工虽只是一个简单的食品加工过程,但在热加工过程中发生的物理和化学变化却十分复杂[6]。油脂的热加工增加了油脂中大分子聚合物的含量,油脂黏度也随之增大,热加工过程中氧化的聚合物、化合物也会加速油的氧化。聚合物的形成促进油脂进一步氧化,增加油的黏度,减少热量传递,在热加工过程中产生泡沫,并使食物产生不良的颜色,随着油脂热加工时间的延长,油脂的色泽也逐渐加深[7]。油脂在热加工过程中内源生育酚含量的降低与自由基和单线态氧的数量增加,降低了对植物油多不饱和脂肪酸氧化变质的保护作用[8]。已有研究指出,不饱和脂肪酸的种类和数量对油脂的营养成分和品质影响显著,且具有多种生理活性功能[9]。通过热加工的方式可导致不饱和脂肪酸含量降低和损耗,同时可产生极性化合物等危害物[10]。近年来,研究发现热加工油脂产生的总极性组分危害风险极大,极性化合物可损害机体的免疫功能,使血管舒张剂和血管收缩剂之间失衡,导致高血压的发生[11−13]。如今,油脂在热加工过程中品质的劣变已逐渐成为人们关注的重点,合成抗氧化剂在高温条件下的分解产物及其潜在毒性一直是人们关注的问题。因此,需要寻求安全、高效、耐高温的天然抗氧化剂延缓热加工过程中油脂氧化产生的品质劣变。

迷迭香是一种天然原料资源,在我国已广泛种植,迷迭香提取物具有天然无毒、高效且耐高温等特点[14],我国食品安全国家标准GB 2760-2014规定了迷迭香提取物作为食品添加剂、抗氧化剂的使用范围及用量。其中鼠尾草酸(Carnosic acid,CA)是迷迭香提取物的主要抗氧化成分,也是发挥抗氧化功效的主要成分(GB 1886.172-2016)。鼠尾草酸具有两个相邻酚羟基,是一种酚类双萜,在高温环境中具有良好的稳定性,最高可耐受240 ℃,克服了大多数天然抗氧化剂遇高温不稳定的弱点,目前欧盟和日本等发达国家和地区在植物油中添加使用[15−16]。研究表明,鼠尾草酸可以提高棕榈油的氧化稳定性,提高油脂品质,在花生油中的抗氧化效果也优于化学合成抗氧化剂[17]。鼠尾草酸的加入可减缓油脂品质劣变,但未系统研究鼠尾草酸对油脂热加工过程中多维指标变化的影响规律[18−19],因此,本文将探讨天然抗氧化剂鼠尾草酸在菜籽油热加工过程中对其品质特性的影响。本研究通过向菜籽油中加入鼠尾草酸,模拟真实的油脂热加工条件,研究鼠尾草酸在高温条件下对菜籽油品质特性的影响。通过对热加工菜籽油的色度、酸价、过氧化值、生育酚含量、黏度、脂肪酸组成与极性组分含量的分析来评价鼠尾草酸的作用效果,旨在更好地实现热加工油脂的品质控制,从而减少油脂浪费,促进节粮减损。

1. 材料与方法

1.1 材料与仪器

菜籽油 精炼一级油,购自商超,未添加抗氧化剂;鼠尾草酸(含量≥85%) 购自北京润泽康生物科技有限公司;特丁基对苯二酚(Tert-butylhydroquinone,TBHQ) 食品级,市售;乙醚、异丙醇、三氯甲烷、冰乙酸、石油醚等 分析纯,北京润泽康生物科技有限公司;异辛烷、正庚烷、四氢呋喃等 色谱纯,北京润泽康生物科技有限公司;氢氧化钾标准滴定水溶液(0.10 mol/L)、硫代硫酸钠标准溶液(0.01 mol/L)、无水硫酸钠、碘化钾、海砂、饱和氯化钠水溶液、柱层析硅胶、淀粉指示剂、酚酞指示剂 北京润泽康生物科技有限公司;α-生育酚标准品、γ-生育酚标准品和37种脂肪酸标品 Sigma-Aldrich公司。

DGG-9140AD型电热恒温鼓风干燥箱 上海森信实验仪器有限公司;WR-10型精密色度色差仪 深圳市威福光电科技有限公司;AB204-S型电子天平 METTLER TOLEDO公司;AR2000ex型流变仪 TA Instruments公司;7890B型气相色谱仪 安捷伦科技(中国)有限公司;DZF-6050A型真空干燥箱 邦西仪器科技(上海)有限公司;e 2695型液相色谱仪 美国Waters公司;BUCHI R-215型旋转蒸发仪 步琦实验室设备(上海)贸易有限公司。

1.2 实验方法

1.2.1 热加工菜籽油样品的制备

参照Chen等[20]的方法加以改进,将不同质量的CA(0、200、400、700 mg/kg)分别添加到100 g菜籽油中,制成不同CA浓度的菜籽油(0、200、400、700 mg/kg)。置于180 ℃的恒温烘箱中加热0、8、16、24、32 h,并将含TBHQ(200 mg/kg)的菜籽油做同样处理,每个样品做三个平行试验,所制样品于−4 ℃密封保存。用量设置方面:CA 200 mg/kg是为了与TBHQ国标中规定的最大添加量做对比;由于鼠尾草酸在国标中规定的最大添加量为700 mg/kg,故选取400 mg/kg作为中间量,700 mg/kg作为最大添加量。鼠尾草酸与特丁基对苯二酚最大添加量均为GB 2760-2014要求的最大添加量。

将添加200 mg/kg鼠尾草酸180 ℃下热处理的菜籽油命名为CA-2;将添加400 mg/kg鼠尾草酸180 ℃下热处理的菜籽油命名为CA-4;将添加700 mg/kg鼠尾草酸180 ℃下热处理的菜籽油命名为CA-7;将添加200 mg/kg TBHQ 180 ℃下热处理的菜籽油命名为TB-2;将未添加抗氧化剂180 ℃下热处理的菜籽油命名为CA-0。

1.2.2 色度测定

采用WR-10型精密色度色差仪测定菜籽油在热加工过程中颜色的变化。首先使用白板进行颜色校正,将油脂样品置于比色皿进行测定。油脂的颜色根据L*值、a*值、 b*值三个参数值表示,L*值(100=白色;0=黑色),a*值(+,红色;−,绿色),b*值(+,黄色;−,蓝色)。实验重复三次,对结果取平均值。

1.2.3 理化性质的测定

酸价的测定参考 GB 5009.229-2016第一法[21]。取2.50 g油样与50 mL乙醚-异丙醇(1:1,V/V)溶液混合,加入3 滴酚酞溶液。用0.10 mol/L氢氧化钠溶液对混合液进行滴定,呈现稳定微红色为滴定终点。按式(1)计算油脂的酸价:

酸价 (mg/g)=(V−V0)×c×Mm (1) 式中:V为样品消耗氢氧化钠溶液的体积,mL;V0为空白消耗氢氧化钠溶液的体积,mL;c为氢氧化钠溶液浓度,mol/L;M为氢氧化钠的摩尔质量,g/mol;m为油脂样品的质量,g。

过氧化值的测定参考GB 5009.227-2016第一法[22]。称取油样2.00~3.00 g于250 mL碘量瓶中,加入30 mL三氯甲烷-冰乙酸混合液(2:3,V/V),后加入1 mL饱和碘化钾溶液,摇晃后放置暗处3 min。取出加100 mL去离子水,用硫代硫酸钠标准溶液滴定,溶液至淡黄色加1 mL淀粉指示剂,滴定至溶液蓝色消失为终点。

POV(g/100g)=(V−V0)×c×0.1269m×100 (2) 式中:V为样品消耗硫代硫酸钠溶液的体积,mL; V0为空白组消耗硫代硫酸钠溶液的体积,mL;c为硫代硫酸钠标准溶液浓度,mol/L;0.1269为与1.00 mL硫代硫酸钠标准滴定溶液相当的碘的质量;m为样品的质量,g;100为换算系数。

1.2.4 生育酚测定

生育酚的测定参考 GB 26635-2011[23]。称量25 mg油脂样品与生育酚标准品分别于25 mL容量瓶加入正庚烷将样品溶解,用正庚烷稀释至刻度,配制成梯度浓度的生育酚标准溶液。

ω(mg/kg)=ρ×ˉAt×VˉA8×m (3) 式中:ω为生育酚的含量,mg/kg;ρ为标准溶液中α-生育酚的浓度,mg/mL;Āt为标准物质α-生育酚峰面积的均值;Ās为样品的α-生育酚峰面积的均值;m为样品的质量,g;V为测试溶液的体积,25 mL。

生育酚标准曲线的回归方程如下,α-生育酚:y=30000000x,R2=0.996;γ-生育酚:y=40000000x,R2=0.998,根据标准曲线计算生育酚含量。

1.2.5 黏度测定

使用动态流变仪(AR2000ex),选取稳态剪切测试,采用钢质平板夹具(40 mm),Peltier温度控制,分别测试样品在60 ℃和100 ℃条件下油脂黏度随剪切速率的变化。

1.2.6 脂肪酸组成测定

脂肪酸的测定参考GB 5009.128-2016第一法[24]。称取60 mg油脂样品溶于4 mL异辛烷中,加入0.2 mL氢氧化钾溶液混合,加入1 g硫酸氢钠混合,混合物经离心过滤后用于气相色谱检测。脂肪酸种类由37种脂肪酸标品定性得出,脂肪酸含量结果采用面积归一化法处理。

1.2.7 极性组分测定

食用油中极性组分的测定参考 GB 5009.202-2016第二法[25]。配制非极性洗脱液:石油醚-乙醚(87:13,V/V)溶液混合,极性组分洗脱液:乙醚。向玻璃层析柱加入25 g硅胶与80 mL的非极性洗脱液及4 g海砂,立刻称取1 g油脂样品加入50 mL的非极性洗脱液,洗脱后向玻璃层析柱内加入200 mL的非极性洗脱液,收集于干燥250 mL烧瓶。极性物质洗脱完成后,立刻用150 mL的乙醚洗脱极性组分,后将非极性组分洗脱液蒸发近干,放入40 ℃的真空恒温干燥箱负压条件下烘30 min冷却至室温,其残留物即为非极性组分,称重。

X(%)=100−m1−m0m×100 (4) 式中:X为油脂样品极性组分含量,%;m0为空白250 mL烧瓶的质量,g;m1为溶剂蒸干后,250 mL烧瓶和非极性组分的总质量,g;m为上样检测油脂的质量,g。

1.3 数据处理

采用Microsoft Excel 2019软件进行数据的整理与计算;数据的显著性分析均采用SPSS 25.0软件进行处理和分析,并采用Origin 2021软件作图。所有实验均进行3次重复实验,结果以平均值±标准偏差(¯x±s)表示。

2. 结果与分析

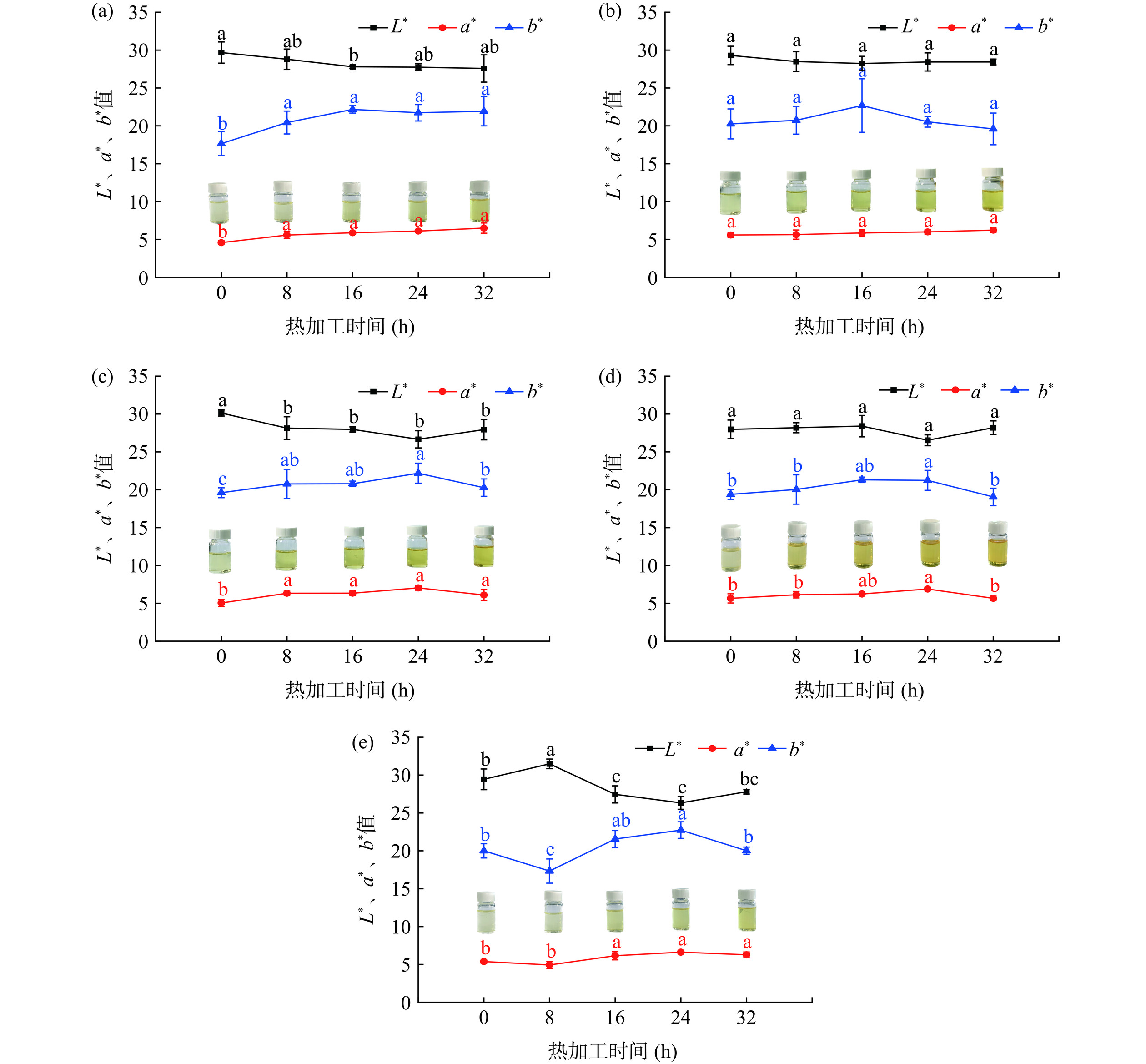

2.1 鼠尾草酸对热加工菜籽油色度的影响

菜籽油在180 ℃下热加工过程中色度随时间变化如图1所示。结果显示CA-0的菜籽油L*值随加热时间的延长而降低,a*值与b*值随加热时间的延长而升高,由此可见,菜籽油的色度随加热时间的延长而加深,亮度降低,颜色向红色和黄色变化;这与董会娟[26]的研究结果一致,其表示菜籽油在煎炸薯条过程中,颜色由淡黄色变为棕黄色最后变为棕红色。这种结果可能是由于脂肪酸的氧化和热分解过程中色素累积[27]。对比发现,添加鼠尾草酸与添加TBHQ的菜籽油L*值、a*值与b*值都呈波动变化趋势。CA-2的a*与L*值基本无变化,b*值呈波动变化趋势;CA-4与CA-7的L*值先下降后上升,a*值与b*值先上升后下降,可能由于在热加工24 h时鼠尾草酸发挥了作用;且CA-7颜色随加热时间变化最明显,可能由于鼠尾草酸浓度的升高导致本身的颜色的升高,影响了菜籽油加热后颜色的改变[28]。研究表明,油脂在氧化过程中会产生羰基类化合物,能够增加油脂对可见光的吸收,导致油脂颜色变深[29]。CA-7热加工32 h与CA-0热加工32 h的菜籽油相比,有着更高的L*值,更低的a*值与b*值,可能与鼠尾草酸抑制了羰基类化合物的生成有关;而TBHQ的添加导致菜籽油色度呈波动变化趋势,表明菜籽油在热加工过程中色度的变化得不到有效控制。CA-7热加工32 h与CA-4热加工32 h的菜籽油相比,L*值升高0.25,a*值降低0.44,b*值降低1.22,表明鼠尾草酸的添加可以延缓热加工菜籽油色度的改变,700 mg/kg的鼠尾草酸添加量较200 mg/kg与400 mg/kg添加量的效果好。

2.2 鼠尾草酸对热加工菜籽油理化性质的影响

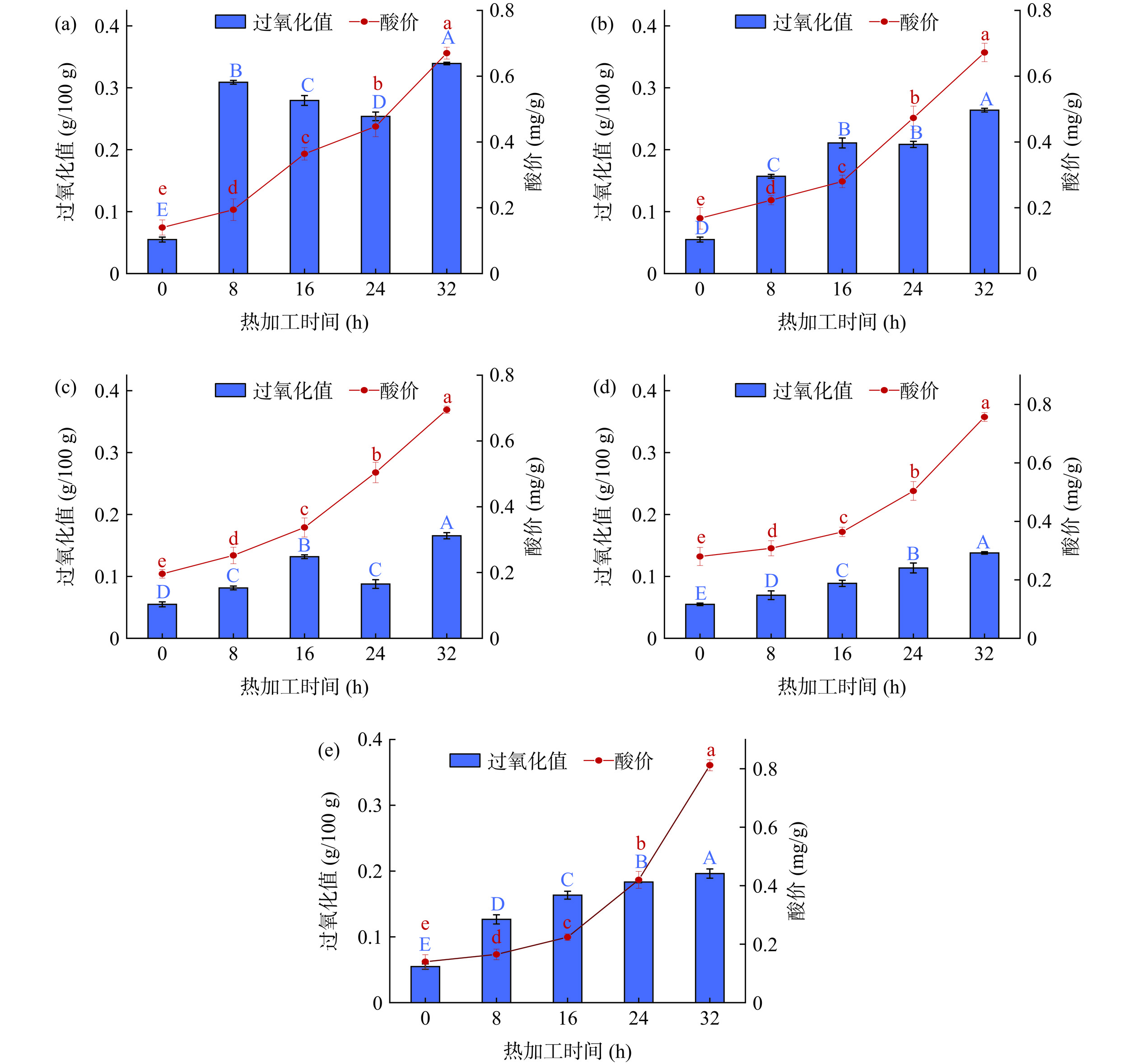

酸价是评价植物油品质的重要理化指标,可用来判断油脂在氧化初级阶段的变质程度[30]。由图2可知,随着热加工时间的延长,CA-0、CA-2、CA-4、CA-7与TB-2的菜籽油酸价都呈持续上升趋势,与姚梦莹等[31]的研究结果一致,加入鼠尾草酸的椰子油热加工过程中酸价随加热时间延长呈上升趋势。在热加工过程中,甘油三酯的水解和不饱和脂肪酸的氧化分解,产生游离脂肪酸,可导致菜籽油中酸价持续增加[32]。经过对比发现,CA-0热加工32 h酸价由0.140±0.020 mg/g升至0.670±0.020 mg/g;CA-2热加工32 h酸价由0.168±0.030 mg/g升至0.672±0.030 mg/g;CA-4热加工32 h酸价由0.196±0.010 mg/g升至0.695±0.010 mg/g;CA-7热加工32 h酸价由0.280±0.030 mg/g升至0.757±0.020 mg/g,TB-2热加工32 h酸价由0.140±0.020 mg/g升至0.812±0.02 mg/g,酸价增加量分别为0.530、0.504、0.499、0.477和0.672 mg/g,其中,CA-7的酸价增加最少,表明添加量为700 mg/kg的鼠尾草酸的加入有利于延缓热加工菜籽油酸价的升高,这种结果可能是由于鼠尾草酸抑制了油脂热加工过程中的氧化分解反应[31]。

过氧化值是表示油脂初期氧化程度的重要指标,在油脂氧化过程中的氢过氧化物形成和分解是一个动态平衡过程[33]。由图2可知,CA-0、CA-2和CA-4的过氧化值变化趋势总体上呈波动性,即先升高再降低再升高,油脂氧化生成的不稳定的氢过氧化物,在高温下进一步氧化成小分子的羰基化合物和挥发性物质,过氧化值的降低可能是热加工时间过长氢过氧化物发生了分解,且分解速度大于其生成速度[32]。而CA-7与TB-2的过氧化值变化趋势一直呈上升趋势,且在热加工终点32 h时二者的过氧化值均小于CA-0,表明添加浓度为700 mg/kg CA 和添加浓度为200 mg/kg TBHQ 样品可有效抑制过氧化值的增长。且CA-7的菜籽油过氧化值增长量较TB-2的菜籽油更低,当热加工32 h时,CA-7的菜籽油过氧化值与TB-2的菜籽油过氧化值的差值为0.058 g/100 g,说明鼠尾草酸表现出比TBHQ更好的抑制过氧化值的能力,可能是由于鼠尾草酸中生物活性成分可抑制热加工油脂中过氧化物的生成[34]。由图2可知,相同抗氧化剂添加量下,热加工0、8、16、24、32 h的菜籽油的酸价与过氧化值均差异显著(P<0.05),鼠尾草酸添加量为200、400、700 mg/kg均可显著抑制热加工过程中酸价与过氧化值的升高。

2.3 鼠尾草酸对热加工菜籽油生育酚含量的影响

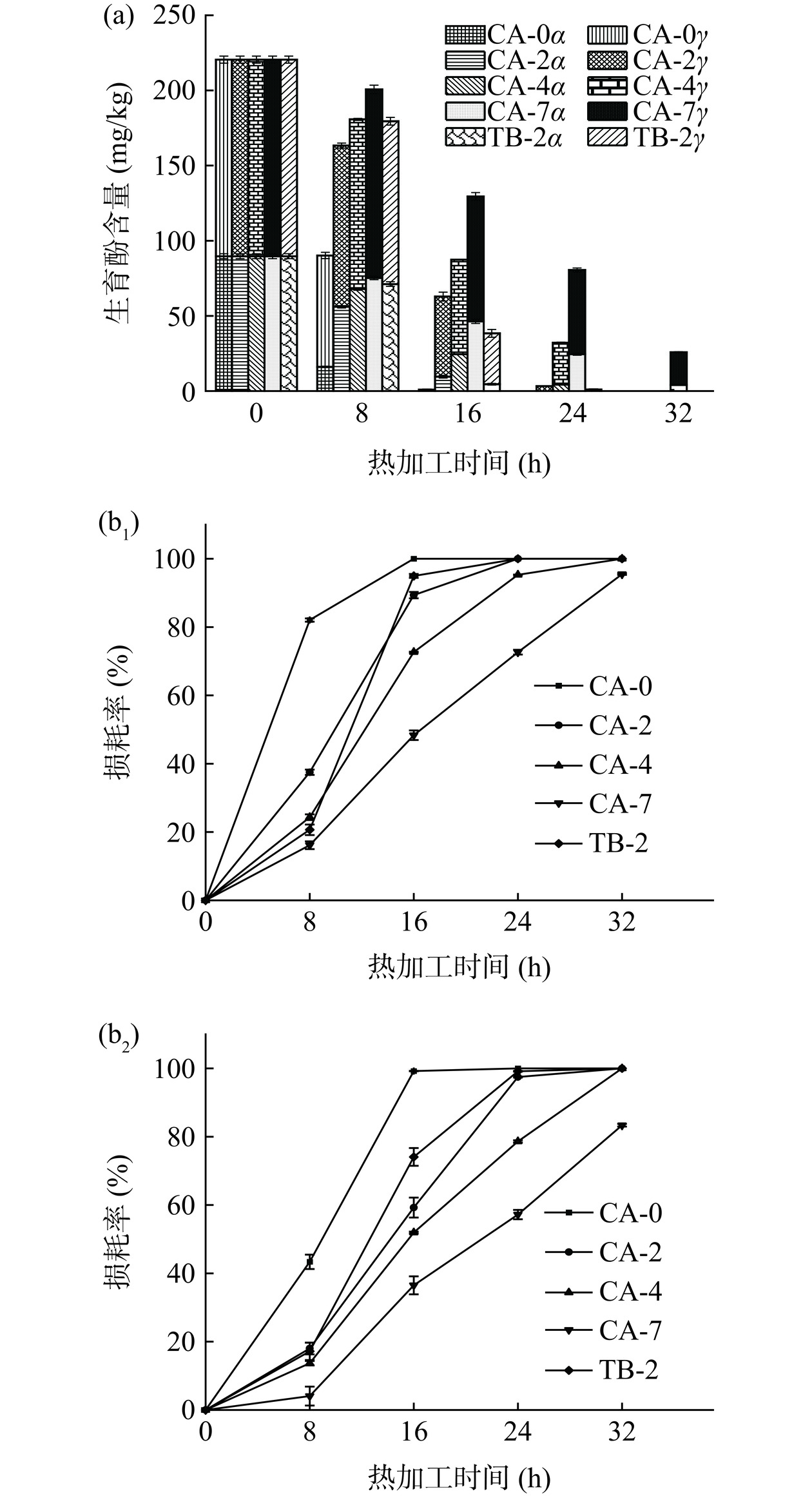

生育酚是植物油中天然的抗氧化剂,但在加热过程中会发生严重损耗,菜籽油中含量最高的是γ-生育酚,其次是α-生育酚[35]。通过图3可以看出,CA-0在0~32 h中α-生育酚与γ-生育酚的含量都随着热加工时间的延长而迅速降低。其中,α-生育酚在热加工16 h时全部损耗,γ-生育酚则是在24 h时全部损耗。这是由于不同生育酚异构体脱氢能力不同,α-生育酚脱氢能力强于γ-生育酚,在氧化过程中更容易被氧化分解,故其损耗速度更快[36],这与尹浩等[37]在大豆油煎炸过程中的研究结果类似。

由图3(a)可知,CA-7的菜籽油的α-生育酚和γ-生育酚的含量始终高于相同热加工时间下CA-0、CA-2、CA-4与TB-2, 由图3(b1)与图3(b2)可知,α-生育酚和γ-生育酚在热加工中的损耗率随时间的延长而增大,在热加工达到32 h时,CA-0、CA-2、CA-4与TB-2的α-生育酚损耗率与γ-生育酚损耗率均达到100%,而CA-7的α-生育酚损耗率为95.51%±0.96%,γ-生育酚损耗率为 83.37%±0.39%,均小于其他抗氧化剂添加量的热加工菜籽油生育酚的损耗。通过斜率得知,CA-0、CA-2、CA-4与TB-2的α-生育酚与γ-生育酚损耗率斜率一直大于CA-7,表明其他组别的生育酚损耗速度一直大于CA-7,进一步说明700 mg/kg可能为最佳添加量。这可能是由于鼠尾草酸在C11和C12的邻位有两个羟基,这些羟基提供它们的氢原子来中断氧化链式反应,可有效清除活性氧和脂质自由基。油脂热氧化过程中,鼠尾草酸可阻止氧化反应的进行,对菜籽油起到保护作用[38]。综上,鼠尾草酸添加量为700 mg/kg时对菜籽油在热加工中生育酚的保护效果最好。

2.4 鼠尾草酸对热加工菜籽油黏度的影响

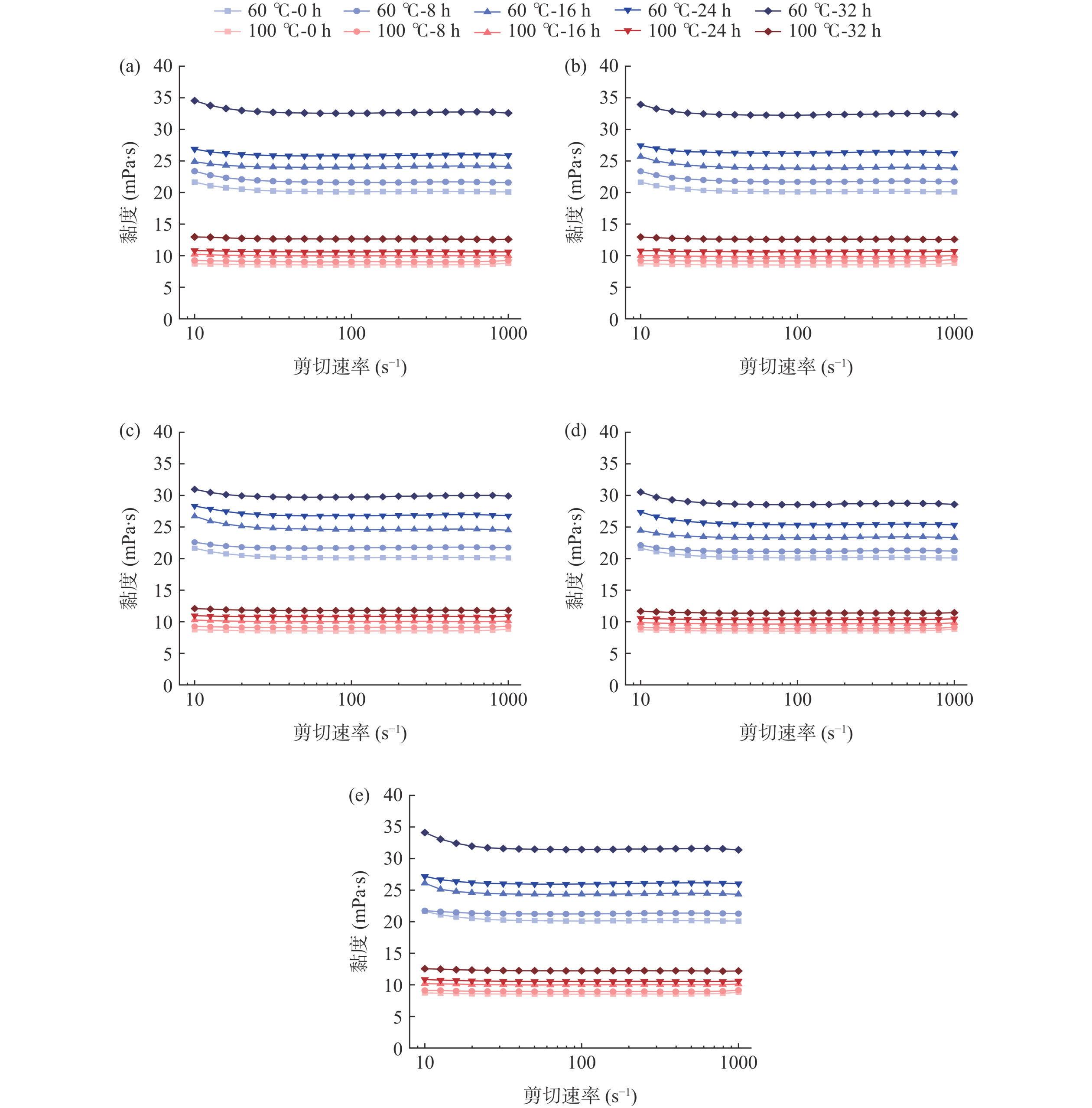

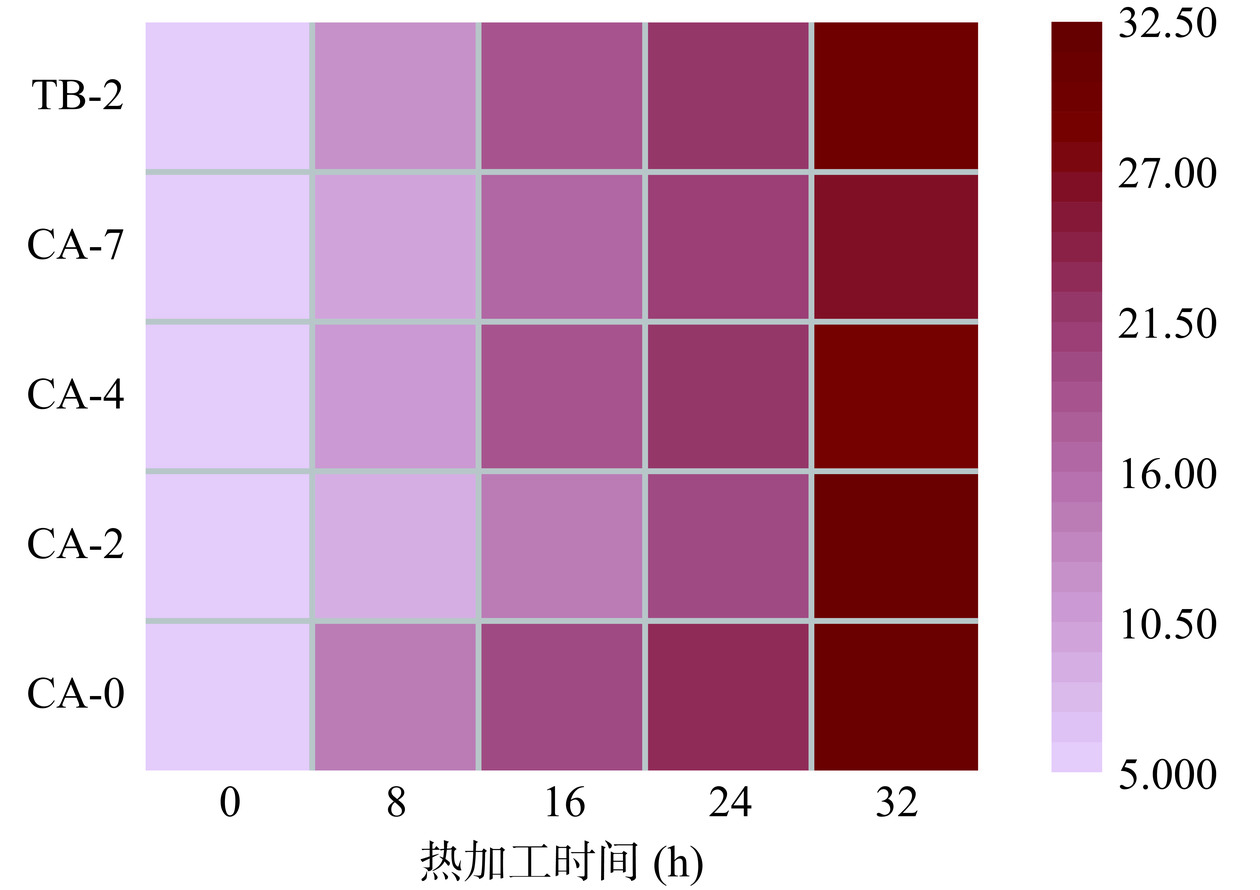

黏度作为液体流变性的参数之一,体现出液体分子在运动时相互作用强弱,黏度越大,分子相互作用越强[39]。如图4所示,测定了60 ℃与100 ℃下不同抗氧化剂添加量的菜籽油热加工过程中的黏度变化。相同的抗氧化剂添加量下,60 ℃菜籽油的黏度高于100 ℃菜籽油的黏度,表明菜籽油的热加工温度与其黏度呈反比。热加工时间逐渐增加,菜籽油黏度逐渐增大。在经过0、8、16、24和32 h的氧化后,添加了鼠尾草酸与添加了TBHQ的菜籽油的黏度都增加;随着鼠尾草酸浓度的增加,菜籽油的黏度降低,且在CA-7时黏度达到最低,表明鼠尾草酸的加入延缓了菜籽油的黏度的增加。在热加工32 h时,CA-0、CA-2、CA-4、CA-7与TB-2在60 ℃下的黏度分别为32.84±0.48、32.52±0.40、29.94±0.29、28.84±0.48与31.77±0.67 mPa·s;在100 ℃下的黏度分别为12.68±0.10、12.64±0.10、11.83±0.08、11.41±0.08与12.27±0.10 mPa·s。可见CA-7在两个检测温度下的黏度均小于CA-0、CA-2、CA-4与TB-2,表明700 mg/kg的鼠尾草酸添加量更适合延缓菜籽油黏度的升高,鼠尾草酸抑制油脂黏度的增大可能与其抑制了油脂在油炸过程中的聚合反应有关[40]。此外,菜籽油的黏度随着剪切速率的增加而波动变化很小,这与Daniel等[41]的研究结果一致。

2.5 鼠尾草酸对热加工菜籽油脂肪酸组成的影响

油脂的脂肪酸组成是评价油脂品质的重要指标,本研究采用气相色谱法测定了不同抗氧化剂添加量的菜籽油热加工后脂肪酸组成,结果如表1所示。在热加工菜籽油中共检测出主要脂肪酸8种:棕榈酸(C16:0)、硬脂酸(C18:0)、油酸(C18:1)、亚油酸(C18:2)、花生酸(C20:0)、亚麻酸甲酯(C18:3n6)、二十一烷酸(C21:0)、α-亚麻酸(C18:3n3)。其中,空白菜籽油样品(未添加抗氧化剂未进行热加工)的主要脂肪酸组成有4种,共占比6.89%±0.06%;多不饱和脂肪酸有2种,共占比28.12%±0.03%;单不饱和脂肪酸有3种,共占比64.90%±0.08%。结果显示,菜籽油的脂肪酸以油酸为主,CA-0在热加工过程中的油酸含量呈上升趋势,由63.25%±0.08%升至68.49%±0.03%,上升5.24%;CA-2在热加工过程中的油酸含量上升4.25%;CA-4在热加工过程中的油酸含量上升3.11%;CA-7在热加工过程中的油酸含量上升2.72%;TB-2在热加工过程中的油酸含量上升3.72%。表明菜籽油中的多不饱和脂肪酸在长时间的热加工下急剧氧化[42],且氧化速度更高,导致菜籽油中以油酸为主的单不饱和脂肪酸相对含量的增加。而鼠尾草酸的加入有利于延缓菜籽油在热加工过程中油酸含量的升高,且700 mg/kg的添加量最适,效果优于TBHQ最高添加量。

表 1 菜籽油热加工后脂肪酸组成与相对含量(%)Table 1. Fatty acid compositions and contents of rapeseed oil during thermal processing (%)样品名称 脂肪酸 0 h 8 h 16 h 24 h 32 h CA-0 C16:0 4.75±0.06e 4.90±0.01d 4.97±0.01c 5.39±0.07b 5.63±0.02a C18:0 1.66±0.06c 1.64±0.01c 1.78±0.02b 1.97±0.02a 1.99±0.02a C18:1 63.25±0.08d 64.81±0.07c 64.74±0.05c 66.97±0.04b 68.49±0.03a C18:2 20.40±0.15a 19.79±0.05b 19.39±0.02c 18.11±0.06d 17.40±0.05e C20:0 0.48±0.02b 0.38±0.02c 0.55±0.03a ND. ND. C18:3n6 0.51±0.01 ND. ND. ND. ND. C20:1 1.75±0.03b 1.73±0.04b 1.80±0.03a 1.70±0.02b 1.81±0.01a C18:3n3 7.20±0.05a 6.75±0.3b 6.15±0.03c 5.38±0.03d 4.68±0.02e ∑SFA 6.89±0.06c 6.92±0.03c 7.29±0.06b 7.35±0.05b 7.62±0.05a ∑MUFA 64.90±0.08c 66.54±0.06b 66.54±0.03b 66.67±0.04b 70.32±0.02a ∑PUFA 28.12±0.03a 26.54±0.02b 25.54±0.03c 23.50±0.09d 22.08±0.06e CA-2 C16:0 4.75±0.06e 4.82±0.01d 4.87±0.03c 5.15±0.02b 5.51±0.02a C18:0 1.66±0.06c 1.66±0.03d 1.74±0.02c 1.81±0.02b 1.88±0.01a C18:1 63.25±0.08d 63.98±0.04d 64.24±0.05c 65.38±0.03b 67.50±0.04a C18:2 20.40±0.15a 19.93±0.02b 19.73±0.02c 18.86±0.03d 17.41±0.03e C20:0 0.48±0.02d 0.47±0.01e 0.55±0.01b 0.54±0.01c 0.59±0.01a C18:3n6 0.51±0.01d 0.52±0.04c 0.66±0.005a 0.62±0.003b 0.52±0.003c C20:1 1.74±0.03b 1.70±0.07b 1.80±0.04a 1.82±0.007a 1.85±0.008a C18:3n3 7.20±0.05a 6.92±0.03b 6.42±0.05c 5.81±0.05d 4.74±0.05e ∑SFA 6.89±0.06e 6.96±0.05d 7.16±0.07c 7.51±0.09b 7.98±0.10a ∑MUFA 64.90±0.08e 65.68±0.06d 66.03±0.05c 67.21±0.08b 69.35±0.08a ∑PUFA 28.12±0.03a 27.37±0.05b 26.81±0.05c 25.29±0.05d 22.67±0.04e CA-4 C16:0 4.75±0.06e 4.77±0.07d 4.90±0.05c 5.03±0.05b 5.19±0.05a C18:0 1.66±0.06c 1.68±0.04b 1.75±0.04b 1.80±0.04b 1.86±0.05a C18:1 63.25±0.08d 63.24±0.06d 64.39±0.05c 65.23±0.06b 66.36±0.01a C18:2 20.40±0.15a 20.29±0.06b 19.58±0.04c 19.04±0.04d 18.22±0.03e C20:0 0.48±0.02b 0.53±0.01b 0.54±0.03b 0.57±0.02a 0.59±0.01a C18:3n6 0.51±0.01d 0.68±0.01b 0.67±0.01b 0.69±0.01a 0.63±0.01c C20:1 1.74±0.03b 1.82±0.01a 1.79±0.01b 1.82±0.01a 1.82±0.01a C18:3n3 7.20±0.05a 7.01±0.07b 6.37±0.02c 5.84±0.05d 5.32±0.07e ∑SFA 6.89±0.06e 6.97±0.11d 7.19±0.12c 7.39±0.05b 7.65±0.05a ∑MUFA 64.90±0.08e 65.05±0.06d 66.18±0.05c 67.05±0.06b 68.18±0.04a ∑PUFA 28.12±0.03a 27.97±0.06b 26.63±0.06c 25.56±0.05d 24.18±0.05e CA-7 C16:0 4.75±0.06e 4.79±0.03d 4.84±0.01c 4.93±0.03b 5.11±0.07a C18:0 1.66±0.06e 1.70±0.01d 1.73±0.01c 1.75±0.01b 1.85±0.01a C18:1 63.25±0.08d 63.75±0.01d 64.21±0.06c 64.94±0.04b 65.97±0.16a C18:2 20.40±0.15a 20.31±0.05b 19.73±0.03c 19.27±0.05d 18.62±0.04e C20:0 0.48±0.02b 0.59±0.02a 0.55±0.01b 0.55±0.01b 0.58±0.01a C18:3n6 0.51±0.01e 0.63±0.01c 0.66±0.01a 0.65±0.01b 0.61±0.01d C20:1 1.74±0.03b 1.89±0.01a 1.80±0.10ab 1.80±0.06a 1.79±0.01b C18:3n3 7.20±0.05a 6.33±0.07c 6.47±0.04b 6.11±0.06d 5.46±0.06e ∑SFA 6.89±0.06e 7.08±0.02d 7.13±0.02c 7.23±0.06b 7.54±0.06a ∑MUFA 64.90±0.08e 65.64±0.01d 66.01±0.01c 66.74±0.02b 67.77±0.03a ∑PUFA 28.12±0.03a 27.28±0.03b 26.86±0.05c 26.03±0.07d 24.69±0.08e TB-2 C16:0 4.75±0.06d 4.73±0.01e 4.92±0.03c 5.00±0.06b 5.21±0.05a C18:0 1.66±0.06c 1.70±0.04b 1.77±0.01b 1.79±0.01b 1.89±0.07a C18:1 63.25±0.08d 63.15±0.02d 64.49±0.13c 65.33±0.15b 66.97±0.36a C18:2 20.40±0.15a 20.35±0.04a 19.49±0.07b 18.98±0.21c 18.01±0.10d C20:0 0.48±0.02d 0.54±0.01c 0.56±0.01b 0.57±0.01b 0.60±0.01a C18:3n6 0.51±0.01c 0.68±0.01a 0.65±0.01a 0.66±0.01a 0.59±0.01b C20:1 1.74±0.03b 1.79±0.01a 1.80±0.02a 1.81±0.01a 1.76±0.01b C18:3n3 7.20±0.05a 7.06±0.02a 6.31±0.06b 5.86±0.01c 4.97±0.03d ∑SFA 6.89±0.06e 6.97±0.06d 7.25±0.05c 7.36±0.03b 7.70±0.07a ∑MUFA 64.90±0.08e 64.95±0.03d 66.29±0.11c 67.14±0.16b 68.73±0.27a ∑PUFA 28.12±0.03a 28.08±0.07a 26.46±0.02b 25.50±0.03c 23.57±0.03d 注:同行不同字母表示差异显著性(P<0.05);ND.未检出;SFA:饱和脂肪酸;MUFA:单不饱和脂肪酸;PUFA:多不饱和脂肪酸。 在菜籽油热加工过程中,饱和脂肪酸含量与单不饱和脂肪酸含量随热加工时间的延长而增加,多不饱和脂肪酸含量则与其相反。这与徐子扬[33]的研究结果类似,表明多不饱和脂肪酸比其他脂肪酸在热加工过程中更容易被氧化。而添加了鼠尾草酸的菜籽油在进行相同时间的热加工后,加热32 h的菜籽油饱和脂肪酸含量与单不饱和脂肪酸含量明显低于CA-0的菜籽油,多不饱和脂肪酸含量则高于CA-0的菜籽油,表明鼠尾草酸的添加有利于延缓多不饱和脂肪酸的热氧化,抑制饱和脂肪酸的增加[43]。且在热加工达到32 h时,CA-7的菜籽油与CA-0、CA-2、CA-4、TB-2相比,具有更低的饱和脂肪酸值与更高的多不饱和脂肪酸含量,其中饱和脂肪酸含量为7.54%±0.06%,多不饱和脂肪酸含量为24.69%±0.08%,表明鼠尾草酸添加量为700 mg/kg的菜籽油在热加工过程中延缓油脂热氧化的效果是最好的。

2.6 鼠尾草酸对热加工菜籽油极性组分的影响

极性组分通常被用来衡量煎炸油的变质程度,许多欧洲国家已经建立了废弃过度使用油的规定,以极性组分总量为基准,超过24%~27%的煎炸油应该被丢弃。我国GB 2716-2018规定油炸油中极性组分的限值必须低于27%[44]。图5为菜籽油添加抗氧化剂后热加工过程中的极性组分含量变化图,随着热加工时间的延长,极性组分含量逐渐增多,当热加工时间达到32 h时CA-0的菜籽油中极性组分含量最高(31.27%±0.07%);TBHQ的添加使极性组分含量得到降低(29.41%±0.04%);而鼠尾草酸的加入使极性组分含量得到明显降低,CA-2、CA-4、CA-7在热加工32 h时的极性组分含量分别为30.31%±0.05%、28.78%±0.07%、26.62%±0.03%,表明鼠尾草酸的加入有效抑制了极性组分的生成,且添加量较大时效果优于TBHQ,这与李鹏娟[45]的研究结果一致,经过迷迭香提取物处理的油脂极性组分的含量生成较慢。且鼠尾草酸添加量为700 mg/kg的菜籽油在热加工32 h时极性组分含量未超过国家限制值(27%),表明此鼠尾草酸浓度为最优添加量,700 mg/kg的鼠尾草酸的添加使菜籽油的热加工寿命得到延长。

2.7 相关性分析

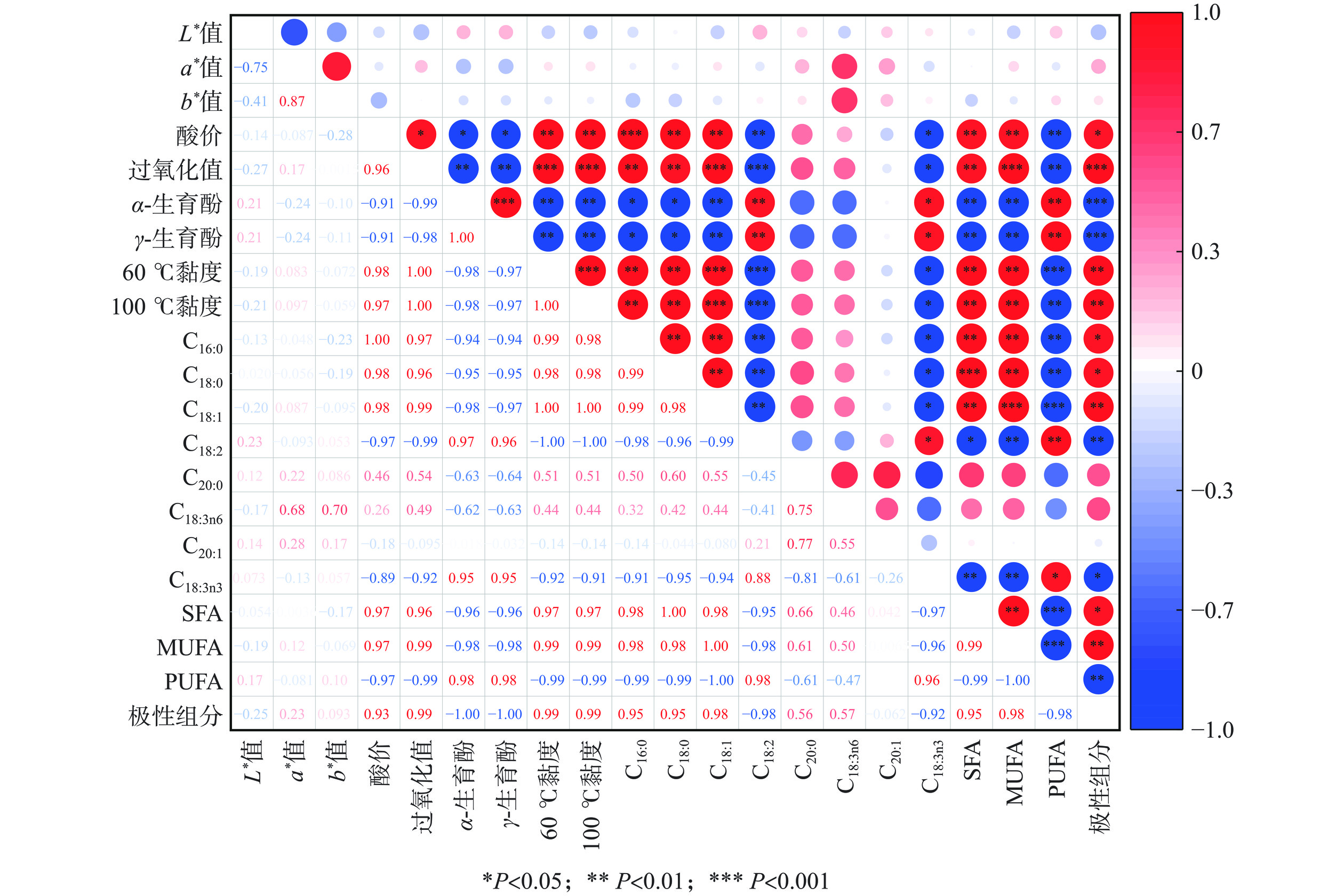

结合上述油脂品质特性分析,当鼠尾草酸添加量为700 mg/kg时,热加工菜籽油的色度、酸价、过氧化值、生育酚含量、黏度、脂肪酸含量与极性组分均表现出最优品质,故选用CA-7菜籽油的上述指标进行Pearson相关性分析。如图6结果显示,菜籽油氧化程度(实验中过氧化值)与酸价、黏度、C16:0、C18:0、C18:1、SFA、MUFA、极性组分之间呈显著正相关(P<0.05),这些指标都随着热加工时间的延长而增加;菜籽油氧化程度与α-生育酚、γ-生育酚、C18:2、C18:3n3、PUFA之间呈显著负相关(P<0.05),这些指标都随着热加工时间的延长而降低。结果说明,菜籽油随着热加工时间的延长,氧化程度增强,使其黏度、饱和脂肪酸含量、单不饱和脂肪酸含量与极性组分含量增大,生育酚含量和多不饱和脂肪酸含量降低,表明在菜籽油热加工过程中氧化反应程度的加强会使聚合反应的程度也提升。Li等[46]进行大豆油煎炸实验发现,油脂黏度升高、生育酚含量降低,表明煎炸时间与油脂氧化反应及聚合反应程度呈正相关。L*值、a*值、b*值与多个指标无相关性,表明热加工时间对其结果影响不大。可见,菜籽油品质的变化与热加工时间密切相关,各指标的变化有明显的对应关系。

3. 结论

在菜籽油热加工过程中,鼠尾草酸添加量为700 mg/kg时表现出最优作用:延缓了菜籽油色度的劣变和抑制了油脂黏度的增大;热加工32 h后,酸价增加量最少为0.477 mg/g,过氧化值较其余添加量低为0.138 g/100 g;在热加工过程中生育酚含量均高于其余添加量,α-生育酚损耗率与γ-生育酚损耗率均最低,分别为95.51%±0.96%与83.37%±0.39%;热加工32 h时其饱和脂肪酸含量为7.54%±0.06%,多不饱和脂肪酸含量为24.69%±0.08%,表现了良好的延缓油脂热氧化效果;对于有害物质极性组分来说,CA-7在热加工32 h时的极性组分含量为26.62%±0.03%,表现了其抑制有害物质生成的作用。与合成抗氧化剂TBHQ相比,鼠尾草酸作为天然抗氧化剂在油脂热加工中表现出更好的热稳定性和抗氧化活性,增强了油脂在热加工中的性能,延缓了油脂在热加工过程中品质的下降,使菜籽油的热加工寿命得到延长,表明鼠尾草酸在食品行业具有保护和提高热加工油脂品质的应用前景。本研究可为天然抗氧化剂在热加工油脂中的使用与对油脂品质影响研究提供理论参考,有助于更好地实现对油脂热加工中风险因子的调控,从而减少油脂损耗浪费。

-

表 1 菜籽油热加工后脂肪酸组成与相对含量(%)

Table 1 Fatty acid compositions and contents of rapeseed oil during thermal processing (%)

样品名称 脂肪酸 0 h 8 h 16 h 24 h 32 h CA-0 C16:0 4.75±0.06e 4.90±0.01d 4.97±0.01c 5.39±0.07b 5.63±0.02a C18:0 1.66±0.06c 1.64±0.01c 1.78±0.02b 1.97±0.02a 1.99±0.02a C18:1 63.25±0.08d 64.81±0.07c 64.74±0.05c 66.97±0.04b 68.49±0.03a C18:2 20.40±0.15a 19.79±0.05b 19.39±0.02c 18.11±0.06d 17.40±0.05e C20:0 0.48±0.02b 0.38±0.02c 0.55±0.03a ND. ND. C18:3n6 0.51±0.01 ND. ND. ND. ND. C20:1 1.75±0.03b 1.73±0.04b 1.80±0.03a 1.70±0.02b 1.81±0.01a C18:3n3 7.20±0.05a 6.75±0.3b 6.15±0.03c 5.38±0.03d 4.68±0.02e ∑SFA 6.89±0.06c 6.92±0.03c 7.29±0.06b 7.35±0.05b 7.62±0.05a ∑MUFA 64.90±0.08c 66.54±0.06b 66.54±0.03b 66.67±0.04b 70.32±0.02a ∑PUFA 28.12±0.03a 26.54±0.02b 25.54±0.03c 23.50±0.09d 22.08±0.06e CA-2 C16:0 4.75±0.06e 4.82±0.01d 4.87±0.03c 5.15±0.02b 5.51±0.02a C18:0 1.66±0.06c 1.66±0.03d 1.74±0.02c 1.81±0.02b 1.88±0.01a C18:1 63.25±0.08d 63.98±0.04d 64.24±0.05c 65.38±0.03b 67.50±0.04a C18:2 20.40±0.15a 19.93±0.02b 19.73±0.02c 18.86±0.03d 17.41±0.03e C20:0 0.48±0.02d 0.47±0.01e 0.55±0.01b 0.54±0.01c 0.59±0.01a C18:3n6 0.51±0.01d 0.52±0.04c 0.66±0.005a 0.62±0.003b 0.52±0.003c C20:1 1.74±0.03b 1.70±0.07b 1.80±0.04a 1.82±0.007a 1.85±0.008a C18:3n3 7.20±0.05a 6.92±0.03b 6.42±0.05c 5.81±0.05d 4.74±0.05e ∑SFA 6.89±0.06e 6.96±0.05d 7.16±0.07c 7.51±0.09b 7.98±0.10a ∑MUFA 64.90±0.08e 65.68±0.06d 66.03±0.05c 67.21±0.08b 69.35±0.08a ∑PUFA 28.12±0.03a 27.37±0.05b 26.81±0.05c 25.29±0.05d 22.67±0.04e CA-4 C16:0 4.75±0.06e 4.77±0.07d 4.90±0.05c 5.03±0.05b 5.19±0.05a C18:0 1.66±0.06c 1.68±0.04b 1.75±0.04b 1.80±0.04b 1.86±0.05a C18:1 63.25±0.08d 63.24±0.06d 64.39±0.05c 65.23±0.06b 66.36±0.01a C18:2 20.40±0.15a 20.29±0.06b 19.58±0.04c 19.04±0.04d 18.22±0.03e C20:0 0.48±0.02b 0.53±0.01b 0.54±0.03b 0.57±0.02a 0.59±0.01a C18:3n6 0.51±0.01d 0.68±0.01b 0.67±0.01b 0.69±0.01a 0.63±0.01c C20:1 1.74±0.03b 1.82±0.01a 1.79±0.01b 1.82±0.01a 1.82±0.01a C18:3n3 7.20±0.05a 7.01±0.07b 6.37±0.02c 5.84±0.05d 5.32±0.07e ∑SFA 6.89±0.06e 6.97±0.11d 7.19±0.12c 7.39±0.05b 7.65±0.05a ∑MUFA 64.90±0.08e 65.05±0.06d 66.18±0.05c 67.05±0.06b 68.18±0.04a ∑PUFA 28.12±0.03a 27.97±0.06b 26.63±0.06c 25.56±0.05d 24.18±0.05e CA-7 C16:0 4.75±0.06e 4.79±0.03d 4.84±0.01c 4.93±0.03b 5.11±0.07a C18:0 1.66±0.06e 1.70±0.01d 1.73±0.01c 1.75±0.01b 1.85±0.01a C18:1 63.25±0.08d 63.75±0.01d 64.21±0.06c 64.94±0.04b 65.97±0.16a C18:2 20.40±0.15a 20.31±0.05b 19.73±0.03c 19.27±0.05d 18.62±0.04e C20:0 0.48±0.02b 0.59±0.02a 0.55±0.01b 0.55±0.01b 0.58±0.01a C18:3n6 0.51±0.01e 0.63±0.01c 0.66±0.01a 0.65±0.01b 0.61±0.01d C20:1 1.74±0.03b 1.89±0.01a 1.80±0.10ab 1.80±0.06a 1.79±0.01b C18:3n3 7.20±0.05a 6.33±0.07c 6.47±0.04b 6.11±0.06d 5.46±0.06e ∑SFA 6.89±0.06e 7.08±0.02d 7.13±0.02c 7.23±0.06b 7.54±0.06a ∑MUFA 64.90±0.08e 65.64±0.01d 66.01±0.01c 66.74±0.02b 67.77±0.03a ∑PUFA 28.12±0.03a 27.28±0.03b 26.86±0.05c 26.03±0.07d 24.69±0.08e TB-2 C16:0 4.75±0.06d 4.73±0.01e 4.92±0.03c 5.00±0.06b 5.21±0.05a C18:0 1.66±0.06c 1.70±0.04b 1.77±0.01b 1.79±0.01b 1.89±0.07a C18:1 63.25±0.08d 63.15±0.02d 64.49±0.13c 65.33±0.15b 66.97±0.36a C18:2 20.40±0.15a 20.35±0.04a 19.49±0.07b 18.98±0.21c 18.01±0.10d C20:0 0.48±0.02d 0.54±0.01c 0.56±0.01b 0.57±0.01b 0.60±0.01a C18:3n6 0.51±0.01c 0.68±0.01a 0.65±0.01a 0.66±0.01a 0.59±0.01b C20:1 1.74±0.03b 1.79±0.01a 1.80±0.02a 1.81±0.01a 1.76±0.01b C18:3n3 7.20±0.05a 7.06±0.02a 6.31±0.06b 5.86±0.01c 4.97±0.03d ∑SFA 6.89±0.06e 6.97±0.06d 7.25±0.05c 7.36±0.03b 7.70±0.07a ∑MUFA 64.90±0.08e 64.95±0.03d 66.29±0.11c 67.14±0.16b 68.73±0.27a ∑PUFA 28.12±0.03a 28.08±0.07a 26.46±0.02b 25.50±0.03c 23.57±0.03d 注:同行不同字母表示差异显著性(P<0.05);ND.未检出;SFA:饱和脂肪酸;MUFA:单不饱和脂肪酸;PUFA:多不饱和脂肪酸。 -

[1] 王瑞元. 2021年我国粮油产销和进出口情况[J]. 中国油脂,2022,47(6):1−7. [WANG R Y. State of grain and oil production sales import and export in 2021[J]. China Oil and Fats,2022,47(6):1−7.] WANG R Y. State of grain and oil production sales import and export in 2021[J]. China Oil and Fats, 2022, 47(6): 1−7.

[2] 张冉, 曹娟娟, 濮超, 等. 中国油菜籽和菜籽油的生产、进出口及供需分析[J]. 中国油脂,2022,47(6):8−14,52. [ZHANG R, CAO J J, PU C, et al. Supply and demand analysis and development suggestions of rapeseed and rapeseed oil in China[J]. China Oils and Fats,2022,47(6):8−14,52.] ZHANG R, CAO J J, PU C, et al. Supply and demand analysis and development suggestions of rapeseed and rapeseed oil in China[J]. China Oils and Fats, 2022, 47(6): 8−14,52.

[3] CHW S H. Cold-pressed rapeseed (Brassica napus) oil:Chemistry and functionality[J]. Food Research International,2020,131(C):108997.

[4] 邓龙. 菜籽油特征香气成分和营养物质组成的研究[D]. 南昌:南昌大学, 2017. [DENG L. Study on characteristic aroma components and nutrient composition of rapeseed oil[D]. Nanchang:Nanchang University, 2017.] DENG L. Study on characteristic aroma components and nutrient composition of rapeseed oil[D]. Nanchang: Nanchang University, 2017.

[5] YE Z, LIU Y F. Polyphenolic compounds from rapeseeds (Brassica napus L.):The major types, biofunctional roles, bioavailability, and the influences of rapeseed oil processing technologies on the content[J]. Food Research International,2023,163:112282. doi: 10.1016/j.foodres.2022.112282

[6] 刘玉兰, 刘海兰, 黄会娜, 等. 煎炸方式和煎炸食材对花生煎炸油中3-氯丙醇酯和缩水甘油酯含量的影响[J]. 食品科学,2019,40(11):42−48. [LIU Y L, LIU H L, HUANG H N, et al. Effects of frying method and frying ingredients on contents of 3-chloropropanol ester and glycidyl ester in frying oil of peanut[J]. Food Science,2019,40(11):42−48.] doi: 10.7506/spkx1002-6630-20180504-042 LIU Y L, LIU H L, HUANG H N, et al. Effects of frying method and frying ingredients on contents of 3-chloropropanol ester and glycidyl ester in frying oil of peanut[J]. Food Science, 2019, 40(11): 42−48. doi: 10.7506/spkx1002-6630-20180504-042

[7] 高浩祥, 陈南, 徐乾达, 等. 油炸过程中茶多酚对油脂品质的影响[J]. 食品科学,2021,42(4):1−7. [GAO H X, CHEN N, XU G D, et al. Effects of tea polyphenols on oil quality during frying[J]. Food Science,2021,42(4):1−7.] doi: 10.7506/spkx1002-6630-20191010-075 GAO H X, CHEN N, XU G D, et al. Effects of tea polyphenols on oil quality during frying[J]. Food Science, 2021, 42(4): 1−7. doi: 10.7506/spkx1002-6630-20191010-075

[8] LIU Y, TAN J J, DUAN Z H, et al. Effect of oil surface activity on oil absorption behavior of potato strips during frying process[J]. Food Chemistry,2021,365:130427−130427. doi: 10.1016/j.foodchem.2021.130427

[9] KERRIHARD A L, NAGY K, CRAFT B D, et al. Oxidative stability of commodity fats and oils:Modeling based on fatty acid composition[J]. JAOCS, Journal of the American Oil Chemists' Society,2015,92(8):1153−1163. doi: 10.1007/s11746-015-2686-4

[10] YUAN L Y, XU Z Y, TAN C P, et al. Biohazard and dynamic features of different polar compounds in vegetable oil during thermal oxidation[J]. LWT,2021,146:111450. doi: 10.1016/j.lwt.2021.111450

[11] SITI H N, KAMISAH Y, ILIYANI M I N, et al. Citrus leaf extract reduces blood pressure and vascular damage in repeatedly heated palm oil diet-induced hypertensive rats[J]. Biomedicine & Pharmacotherapy,2017,87:451−460.

[12] LIN Y S, LU S Y, WU H P, et al. Is frying oil a dietary source of an endocrine disruptor? Anti-estrogenic effects of polar compounds from frying oil in rats[J]. Ecotoxicology and Environmental Safety,2019,169:18−27. doi: 10.1016/j.ecoenv.2018.10.111

[13] JU J J, ZHENG Z J, XU Y J, et al. Influence of total polar compounds on lipid metabolism, oxidative stress and cytotoxicity in HepG2 cells[J]. Lipids in Health and Disease,2019,18(1):37. doi: 10.1186/s12944-019-0980-0

[14] SAVANI P, PUTHIYEDATH A, RAMESH C K, et al. Evaluation of the sensory properties and antioxidant activity of clean rosemary extracts for an effective replacement of EDTA in mayonnaise[J]. Applied Food Research,2023,3(1):100302. doi: 10.1016/j.afres.2023.100302

[15] MUTSCHLECHNER B, SCHWAIGER S, SCHNEIDER P, et al. Degradation study of carnosic acid[J]. Planta Medica, 2016, 81(S01):1−381.

[16] 王莹, 仝飞飞, 薛刚, 等. 迷迭香脂溶性提取物在花生油中抗氧化性能研究[J]. 中国粮油学报, 2021, 36(12):72-77. [WANG Y, TONG F F, XUE G, et al. Antioxidant activity of soluble extract of rosemary in peanut oil [J]. Journal of Cereals and Oils, 2019, 36(12):72−77.] WANG Y, TONG F F, XUE G, et al. Antioxidant activity of soluble extract of rosemary in peanut oil [J]. Journal of Cereals and Oils, 2019, 36(12): 72−77.

[17] 赵昕. 鼠尾草酸对棕榈油氧化稳定性的影响研究[J]. 食品科技,2019,44(11):222−226. [ZHAO X. Effects of carnosic acid on oxidation stability of palm oil[J]. Food Science and Technology,2019,44(11):222−226.] ZHAO X. Effects of carnosic acid on oxidation stability of palm oil[J]. Food Science and Technology, 2019, 44(11): 222−226.

[18] 匡婷. 鼠尾草酸对椰子油热氧化稳定性影响研究[D]. 海口:海南大学, 2019. [KUANG T. Effect of carnosic acid on thermal oxidation stability of coconut oil[D]. Haikou:Hainan University, 2019.] KUANG T. Effect of carnosic acid on thermal oxidation stability of coconut oil[D]. Haikou: Hainan University, 2019.

[19] HOUSSEM B. Modeling the peroxyl radical scavenging behavior of carnosic acid:Mechanism, kinetics, and effects of physiological environments[J]. Phytochemistry,2021,192:112950. doi: 10.1016/j.phytochem.2021.112950

[20] CHEN J N, WANG Y, LIU W, et al. Effects of free fatty acids and peroxide on thermal loss of sesamol and formation of its transformation products in soybean oil[J]. LWT,2022,159:113136. doi: 10.1016/j.lwt.2022.113136

[21] 卫生部. 食品中酸价的测定:GB 5009.229-2016[S]. 北京:中国标准出版社, 2016. [Ministry of Health. Determination of acid value in food:GB 5009.229-2016[S]. Beijing:Standards Press of China, 2016.] Ministry of Health. Determination of acid value in food: GB 5009.229-2016[S]. Beijing: Standards Press of China, 2016.

[22] 卫生部. 食品中过氧化值的测定:GB 5009.227-2016[S]. 北京:中国标准出版社, 2016. [Ministry of Health. Determination of peroxide value in food:GB 5009.227-2016[S]. Beijing:Standards Press of China, 2016.] Ministry of Health. Determination of peroxide value in food: GB 5009.227-2016[S]. Beijing: Standards Press of China, 2016.

[23] 卫生部. 动植物油脂 生育酚及生育三烯酚含量测定 高效液相色谱法:GB 26635-2011[S]. 北京:中国标准出版社, 2011. [Ministry of Health. Determination of tocopherol and tocotrienol in animal and vegetable oils by high performance liquid chromatography:GB 26635-2011[S]. Beijing:Standards Press of China, 2011.] Ministry of Health. Determination of tocopherol and tocotrienol in animal and vegetable oils by high performance liquid chromatography: GB 26635-2011[S]. Beijing: Standards Press of China, 2011.

[24] 卫生部. 食品中脂肪酸的测定:GB 5009.168-2016[S]. 北京:中国标准出版社, 2016. [Ministry of Health. Determination of fatty acids in food:GB 5009.168-2016[S]. Beijing:Standards Press of China, 2016.] Ministry of Health. Determination of fatty acids in food: GB 5009.168-2016[S]. Beijing: Standards Press of China, 2016.

[25] 卫生部. 食用油中极性组分的测定:GB 5009.202-2016[S]. 北京:中国标准出版社, 2016. [Ministry of Health. Determination of polar components in edible oil:GB 5009.202-2016[S]. Beijing:Standards Press of China, 2016.] Ministry of Health. Determination of polar components in edible oil: GB 5009.202-2016[S]. Beijing: Standards Press of China, 2016.

[26] 董会娟. 菜籽油煎炸过程中品质变化及氧化稳定性研究[D]. 天津:天津科技大学, 2018. [DONG H J. Study on quality change and oxidation stability of rapeseed oil during frying[D]. Tianjin:Tianjin University of Science and Technology, 2018.] DONG H J. Study on quality change and oxidation stability of rapeseed oil during frying[D]. Tianjin: Tianjin University of Science and Technology, 2018.

[27] KETAONA D, CLERGE T. Quality of Ricinodendron heudelotii (Bail.) Pierre ex Pax seedsoil as affected by heating[J]. Int J Eng Res Sci Technol,2013,2:94−100.

[28] CAO J, JIANG X, CHEN Q, et al. Oxidative stabilities of olive and camellia oils:Possible mechanism of aldehydes formation in oleic acid triglyceride at high temperature[J]. LWT,2020,118(C):108858.

[29] SHAZIYA M, MASOODI F A, RUBIYA R, et al. Effect of apple pomace-based antioxidants on the stability of mustard oil during deep frying of French fries[J]. LWT,2022,163:113576. doi: 10.1016/j.lwt.2022.113576

[30] 李荣蕊, 袁媛. 复合抗氧化剂对油炸鲜切薯片中丙烯酰胺和氯丙醇酯的抑制作用[J]. 食品安全质量检测学报,2023,14(17):241−251. [LI R R, YUAN Y. Inhibition effect of compound antioxidant on acrylamide and chloropropanol ester in fried fresh cut potato chips[J]. Journal of Food Safety and Quality Inspection,2023,14(17):241−251.] LI R R, YUAN Y. Inhibition effect of compound antioxidant on acrylamide and chloropropanol ester in fried fresh cut potato chips[J]. Journal of Food Safety and Quality Inspection, 2023, 14(17): 241−251.

[31] 姚梦莹, 匡婷, 云永欢, 等. 鼠尾草酸对椰子油热加工过程中主要理化性质、脂肪酸组成与自由基的影响研究[J]. 中国油脂,2020,45(8):39−44. [YAO M Y, KUANG T, YUN Y H, et al. Effects of carnosic acid on main physicochemical properties, fatty acid composition and free radicals of coconut oil during hot processing[J]. China Oil and Fats,2020,45(8):39−44.] doi: 10.12166/j.zgyz.1003-7969/2020.08.009 YAO M Y, KUANG T, YUN Y H, et al. Effects of carnosic acid on main physicochemical properties, fatty acid composition and free radicals of coconut oil during hot processing[J]. China Oil and Fats, 2020, 45(8): 39−44. doi: 10.12166/j.zgyz.1003-7969/2020.08.009

[32] JIANG Y F, SU M K, YU T, et al. Quantitative determination of peroxide value of edible oil by algorithm-assisted liquid interfacial surface enhanced Raman spectroscopy[J]. Food Chemistry,2021,344:128709. doi: 10.1016/j.foodchem.2020.128709

[33] 徐子扬. 高油酸植物油在加热过程中的组分变化与评价[D]. 无锡:江南大学, 2020. [XU Z Y. Composition change and evaluation of high oleic acid vegetable oil during heating[D]. Wuxi:Jiangnan University, 2020.] XU Z Y. Composition change and evaluation of high oleic acid vegetable oil during heating[D]. Wuxi: Jiangnan University, 2020.

[34] UJONG A E, EMELIKE N, OWUNO F, et al. Effect of frying cycles on the physical, chemical and antioxidant properties of selected plant oils during deep-fat frying of potato chips[J]. Food Chemistry Advances,2023,3:100338. doi: 10.1016/j.focha.2023.100338

[35] SIMONA B, PIERRE D, FRANCOIS X P, et al. Carnosic acid[J]. Phytochemistry,2015,115:9−19. doi: 10.1016/j.phytochem.2014.12.026

[36] PAGANI M A, BALTANAS M A. Production of natural antioxidants from vegetable oil deodorizer distillates:Effect of catalytic hydrogenation[J]. Bioresource Technology,2010,101(4):1369−1376. doi: 10.1016/j.biortech.2009.09.068

[37] 尹浩, 姜碧若, 曾裕, 等. 迷迭香提取物对一级大豆油煎炸品质的影响[J]. 食品工业,2022,43(2):153−156. [YIN H, JIANG B R, ZENG Y, et al. Effects of rosemary extract on frying quality of primary soybean oil[J]. Food Industry,2022,43(2):153−156.] YIN H, JIANG B R, ZENG Y, et al. Effects of rosemary extract on frying quality of primary soybean oil[J]. Food Industry, 2022, 43(2): 153−156.

[38] 李徐. 加热和煎炸过程油脂极性物质组成的变化规律及应用研究[D]. 无锡:江南大学, 2021. [LI X. Study on variation and application of polar substance composition of oil in heating and frying process[D]. Wuxi:Jiangnan University, 2021.] LI X. Study on variation and application of polar substance composition of oil in heating and frying process[D]. Wuxi: Jiangnan University, 2021.

[39] DAVID A, DAVID M, LESNIAREK P, et al. Oleogelation of rapeseed oil with cellulose fibers as an innovative strategy for palm oil substitution in chocolate spreads[J]. Journal of Food Engineering,2021,292:110315. doi: 10.1016/j.jfoodeng.2020.110315

[40] ZHAO L L, ZHANG M, WANG H X, et al. Effects of carbon dots in combination with rosemary-inspired carnosic acid on oxidative stability of deep frying oils[J]. Food Control,2021,125:107968. doi: 10.1016/j.foodcont.2021.107968

[41] DANIEL P G, JOHN W G. Rheology of vegetable oil analogs and triglycerides[J]. Journal of the American Oil Chemists' Society,2000,77(2):111−114. doi: 10.1007/s11746-000-0018-4

[42] 杨雪莲, 张翔宇, 谢建春, 等. 部分食品煎炸用油的反式脂肪酸比较[J]. 中国食品学报,2021,21(1):327−333. [YANG X L, ZHANG X Y, XIE J C, et al. Comparison of trans fatty acids in frying oil of some foods[J]. Chinese Journal of Food Science,2021,21(1):327−333.] YANG X L, ZHANG X Y, XIE J C, et al. Comparison of trans fatty acids in frying oil of some foods[J]. Chinese Journal of Food Science, 2021, 21(1): 327−333.

[43] MADIHA D, ZAHRA A, MNARI B A, et al. Comparative study of the phenolic profile and antioxidant activities of Moringa (Moringa oleifera Lam.) and Jujube (Ziziphus lotus Linn.) leaf extracts and their protective effects in frying stability of corn oil[J]. Measurement:Food, 2022, 7:3665−3672.

[44] 卫星华, 董曼曼, 李涛, 等. 影响煎炸油中极性组分含量的研究[J]. 食品安全质量检测学报,2018,9(7):1660−1664. [WEI X H, DONG M M, LI T, et al. Study on the influence of polar components content in frying oil[J]. Journal of Food Safety and Quality Inspection,2018,9(7):1660−1664.] doi: 10.3969/j.issn.2095-0381.2018.07.033 WEI X H, DONG M M, LI T, et al. Study on the influence of polar components content in frying oil[J]. Journal of Food Safety and Quality Inspection, 2018, 9(7): 1660−1664. doi: 10.3969/j.issn.2095-0381.2018.07.033

[45] 李鹏娟. 迷迭香源抗氧化物对薯条煎炸油品质的影响研究[D]. 广州:暨南大学, 2021. [LI P J. Effect of rosemary source antioxidants on the quality of fries oil[D]. Guangzhou:Jinan University, 2021.] LI P J. Effect of rosemary source antioxidants on the quality of fries oil[D]. Guangzhou: Jinan University, 2021.

[46] LI P, YANG X, LEE J W, et al. Comparison between synthetic and rosemary-based antioxidants for the deep frying of French fries in refined soybean oils evaluated by chemical and non-destructive rapid methods[J]. Food Chemistry,2021,335:127638. doi: 10.1016/j.foodchem.2020.127638

-

期刊类型引用(1)

1. 赵益菲,袁瑞,尚红岩,贾新超,李永阳. 鼠尾草酸中多环芳烃去除工艺及抗氧化特性. 食品与机械. 2024(11): 187-193 .  百度学术

百度学术

其他类型引用(1)

下载:

下载:

下载:

下载: