Research on the Effect of Ultrasonic Combined with Low-temperature Brining Two-stage Thermal Processing on ChickenQuality and Flavor

-

摘要: 为探究超声预处理及低温卤煮两段加工对鸡肉品质和风味的影响,本研究以鸡胸肉为研究对象,通过单因素和正交试验研究预煮时间、卤煮时间、预煮温度、卤煮温度对低温清卤鸡肉品质的影响,以剪切力和感官评价为目标值,获得优化鸡胸肉低温清卤的工艺参数。其次,以高温卤煮组(high temperature,HT)和未超声组(without-ultrasonic pretreatment,WUP)为对照,在超声预处理及低温卤煮组(ultrasonic pretreatment and low temperature brine group,UP)的最佳工艺基础上,测定了全质构(texture profile analysis,TPA)、水分含量、颜色、脂质氧化(thiobarbituric acid reactive substances,TBARS)、肌原纤维小片化指数(myofibril fragmentation index,MFI)、蛋白质溶解度和挥发性风味物质水平。结果表明,UP组的最佳工艺为预煮时间10 min,卤煮时间3 h,预煮温度45 ℃,卤煮温度69 ℃。与HT组相比,UP组质地参数(硬度,内聚性,弹性,回复性)显著降低(P<0.05),水分含量显著升高(P<0.05),鸡肉颜色属性得以改善,亮度L*值和红度a*值显著升高(P<0.05),脂质氧化水平显著降低(P<0.05)。MFI和蛋白溶解度结果显示超声结合低温卤煮两段加工更大程度地降低了肌原纤维的完整程度,增加了总蛋白的溶解度。感官分析结果表明,低温卤制鸡胸肉虽然气味得分低于高温卤制鸡胸肉,但口感更加鲜嫩可口。气相色谱-质谱法(gas chromatography-mass spectrometry,GC-MS)结果进一步说明超声结合卤煮两段加工能够增加鸡肉挥发性风味物质的种类及含量,但在高温卤煮中鸡肉挥发性醛类物质的含量更多。综上,与其它清卤工艺相比,超声结合低温清卤两段加工提升了鸡肉产品的品质和风味。Abstract: This study aimed to investigate the effects of ultrasonic pre-treatment and low-temperature brining two-stage processing on the quality and flavor of chicken meat. The chicken breast meat was chosen as the research subject. Single-factor and orthogonal experiments were conducted to examine the influence of pre-cooking time, brining time, pre-cooking temperature, and brining temperature on the quality of low-temperature brined chicken meat. Shear force and sensory evaluation were used as target values to obtain optimized process parameters for low-temperature brining of chicken breast meat. Furthermore, using a high-temperature brining group (HT) and without-ultrasonic pretreatment group (WUP) as controls, measurements were taken for texture profile analysis (TPA), moisture content, color, lipid oxidation (thiobarbituric acid reactive substances, TBARS), myofibril fragmentation index (MFI), protein solubility, and volatile flavor substance levels in the ultrasonic pretreatment and low-temperature brine group (UP) based on the optimal process. The results showed that the optimal process for the UP group was a pre-cooking time of 10 minutes, a brining time of 3 hours, a pre-cooking temperature of 45 ℃, and a brining temperature of 69 ℃. Compared to the HT group, the UP group exhibited significantly reduced texture parameters (hardness, cohesiveness, springiness and resilience) (P<0.05), significantly increased moisture content (P<0.05), improved chicken meat color properties with significantly increased lightness (L*) and redness (a*) values (P<0.05), and significantly reduced lipid oxidation levels (P<0.05). The MFI and protein solubility results indicated that the combination of ultrasound and low-temperature brining effectively reduced the integrity of myofibrils and increased the solubility of total protein. According to the results of sensory analysis, low-temperature marinated chicken breast was found to have a more tender and delicious taste, although it received a lower score for odor compared to high-temperature marinated chicken breast. Gas chromatography-mass spectrometry (GC-MS) results further demonstrated that the two-stage processing of ultrasound and brining increased the variety and content of volatile flavor substances in chicken meat, but the content of volatile aldehydes was higher in high-temperature brining. In conclusion, compared to other brining processes, the combination of ultrasound and low-temperature brining in a two-stage process improved the quality and flavor of chicken meat products.

-

Keywords:

- low-temperature brine production /

- ultrasonic pretreatment /

- process optimization /

- quality /

- flavor

-

近些年来,世界禽类消费量一直在稳步增长。由于禽肉含有较高水平的蛋白质、较完整的氨基酸组成和较低的脂肪含量[1],因此越来越多的消费者认为禽肉有助于改善他们的膳食结构,促进健康饮食。相比于鸡腿肉和其他部位,鸡胸肉通常具有更高的口感韧性和易碎性[2]。而在鸡肉加工过程中,易造成肉蛋白质量下降,适口性差,质地较硬[3]。因此,能够生产出口感嫩化、营养丰富、易于烹饪、保质期长的鸡胸肉,对于肉类加工业具有重要意义。

柔软度和多汁性是对消费者而言最重要的品质特征,这些特性受温度和时间等烹饪参数的影响。低温慢煮技术,是一种长时间低温烹饪的过程,对于食品加工过程能够达到更高水平和更均匀的口感嫩化效果,赋予食物更高的营养价值,被人们广泛接受[4]。经过低温烹饪后的肉制品产品的组织质地、口感滋味、营养成分等均有明显提升,加工温度一般控制在50 ℃至80 ℃。相较于传统高温烹饪的肉大量失水、质地差、风味受损,低温处理的肉会有更好的嫩度和外观形态[5]。Hasani等[6]研究认为经过两步温度(50 ℃和60 ℃)处理的鸡胸肉较一步加热显示出良好的质地参数、较低的烹饪损失、可接受的红度值和较低的脂质氧化水平。孙红霞等[7]研究表明55~65 ℃是牛肉加热过程中的一个关键控制温度范围,为牛肉类菜肴低温加热技术提供理论依据。王正雯等[8]研究发现70 ℃加热下,麻鸭胸脯肉肌原纤维蛋白形成结构紧密细腻的凝胶,保水效果最好。消费者对食品加工业和餐饮业的需求将逐渐向营养高、风味佳、品质高发展,低温肉制品市场需求也会随之不断上升。Haghighi等[9]研究不同温度(60、70和80 ℃)和时间组合下的低温烹制鸡胸肉,在4 ℃下储存21 d期间,未检测到总嗜温需氧菌、嗜冷菌和肠杆菌科细菌。低温肉制品已成为人们追求安全与健康的首选。尽管低温肉制品在满足消费者需求方面具有巨大潜力,但优化其品质和风味仍然是一个挑战。

超声波技术作为绿色的非热物理加工技术,具有广阔的发展潜力和应用前景[10]。近年来,超声波技术在肉品加工领域应用前景广阔,可以评估或改善肉品品质、提高加工效率,并涵盖了改善肉类的综合品质、嫩化效果以及促进腌制等多个方面。目前越来越多肉类科学家将其视为研究热点[11−12]。Zou等[13]研究表明,超声波联合低浓度碳酸氢钠腌制可加速肌动球蛋白变性,这被认为是一种有前途且有效的肉类加工技术。本文旨在优化鸡胸肉的清卤工艺,并开发适用于低温慢卤的关键技术。其中,低温是作为第一步温度的选择,可以改善肉的嫩度和其它品质特性[6],因此,本文以超声真空低温加热作为预处理技术,以研究其对鸡肉清卤工艺的影响,并对比低温慢卤与传统高温加工条件下的品质差异。为鸡肉清卤工艺的开发提供理论基础。

1. 材料与方法

1.1 材料与仪器

鸡胸肉 经屠宰后的黄羽鸡(日龄约180 d),取鸡大胸肉,−18 ℃保存,由中国特产·滨州助农馆提供;葱、老姜、料酒、糖、味精、生姜汁、(含碘)中性盐 购于合肥翡翠湖大润发超市;2,4,6-三甲基吡啶(2,4,6-Trimethylpyridine) 纯度99%,上海麦克林生化科技股份有限公司;其它所有化学试剂均为分析级。

AL-204分析天平 德国Mettler Toledo公司;XT-Plus质构仪 英国 XT 公司;HEM酶标仪 美国伯乐公司;T10高速均质机 德国IKA公司;CT14RD高速离心机 上海天美生化仪器设备工程有限公司;EsciTM-2010冷冻摇床 安徽尚科质仪器有限公司;DZQ-420C真空包装机 安盛科包装机械有限公司;XMTX2112数显恒温水浴锅 常州国宇仪器制造有限公司;F8X280真空腌制机 美国Ramm Master公司;ZE7700电色色差仪 日本电色;THC-1000SF超声煎煮锅 济宁天华超声电子仪器有限公司;8890-5977B安捷伦气质联用 美国Agilent公司;萃取头和配套固相微萃取手动进样手柄(75 μm/CAR/PDMS) 德国Supelco公司。

1.2 实验方法

1.2.1 清卤工艺

1.2.1.1 超声结合低温清卤两段加工工艺(UP)

解冻→整形→腌制→(超声)预煮→冷却→低温清卤→冷却→切块

原料处理:将冷冻的鸡胸肉放置在4 ℃冷库,缓慢低温解冻24 h,去除筋膜,脂肪组织,修剪成大小形状相同(60 mm×40 mm×20 mm),重量约为90±0.5 g的肉块。

腌制液:按照样品重量(20%蒸馏水,4%盐,1.5%生姜汁),与肉样放入真空滚揉机中,真空滚揉腌制30 min。

超声预煮:将腌制完成后的肉样表面擦尽,分别装入真空包装袋中,抽真空后,放入调整好参数的超声煎煮锅中(设定超声功率500 W、超声频率20 kHz)。

清卤汤:加入30 g盐、22.5 g白砂糖、20 g老姜、10 g葱、4.5 g味精、15 g料酒,加入清水(3 L),100 ℃至煮沸,80 ℃加热保持20 min。

低温清卤:超声预煮后,放入4 ℃冷水中5 min,加入清卤汤(料液比为1:2),将水浴锅的水升温至25 ℃,设置好时间、温度参数进行低温慢卤。

1.2.1.2 低温清卤工艺(WUP)

解冻→整形→腌制→低温清卤→冷却→切块

低温清卤:将腌制后的肉样加入清卤汤(料液比为1:2),将水浴锅的水升温至25 ℃,设置卤煮温度69 ℃,卤煮时间3 h进行低温慢卤。

1.2.1.3 高温卤制工艺(HT)

解冻→整形→腌制→高温卤制→冷却→切块

高温卤制:将经过腌制后的肉样,表面擦尽后,在水浴锅中定时卤制50 min(起始水温为25 ℃),卤煮温度为95 ℃,料液比为1:2。

所有肉样成品冷却后,放入4 ℃冰箱12 h,根据实验方案测定各指标。

1.2.2 超声结合低温清卤两段加工工艺单因素实验

选择预煮时间、卤煮时间、预煮温度、卤煮温度4个因素作为单因素实验的考察因素。

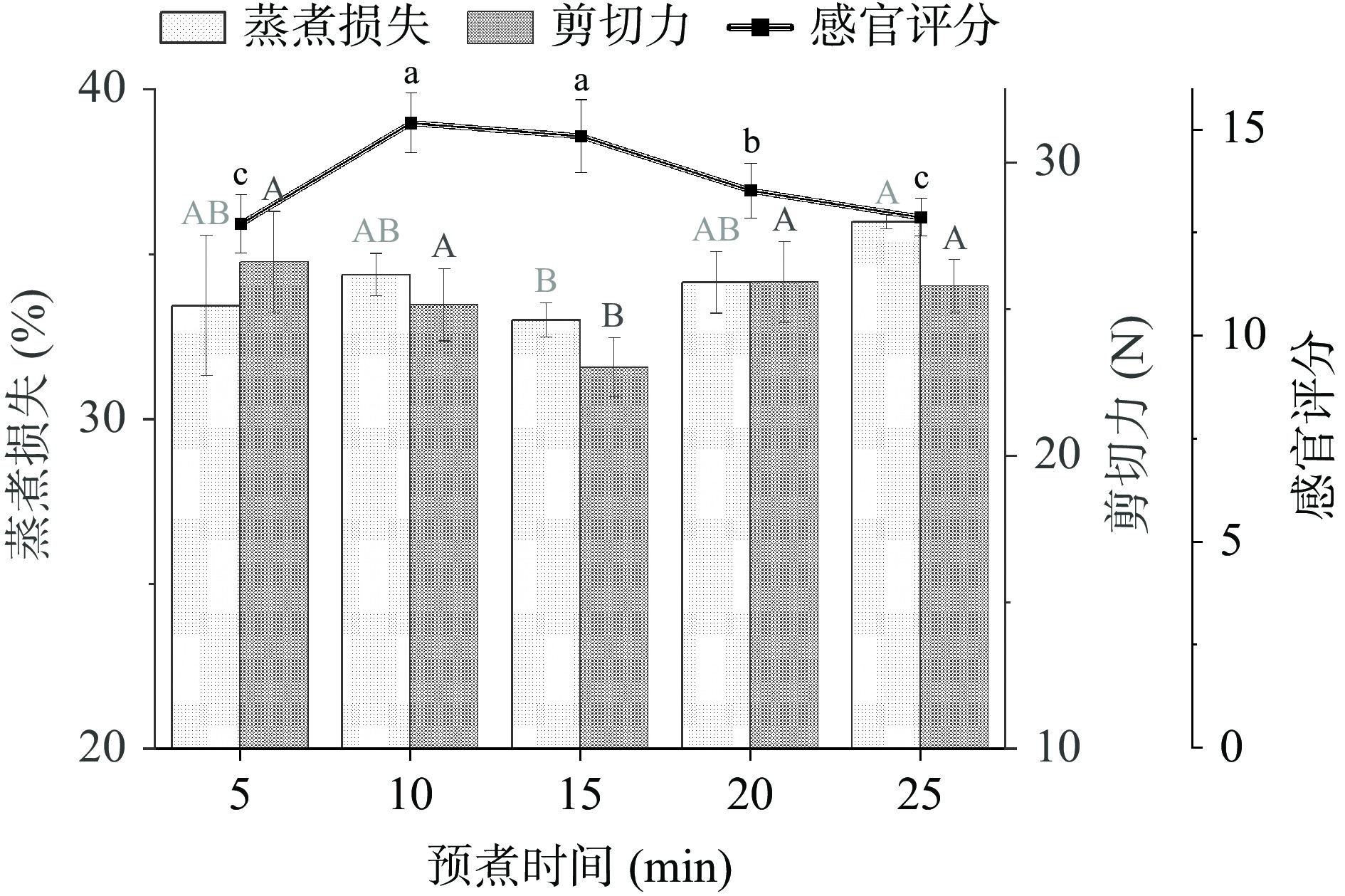

控制卤煮时间为3 h,预煮温度为55 ℃,卤煮温度为73 ℃。研究预煮时间分别为5、10、15、20、25 min对低温清卤鸡肉蒸煮损失、剪切力和感官评价的影响。

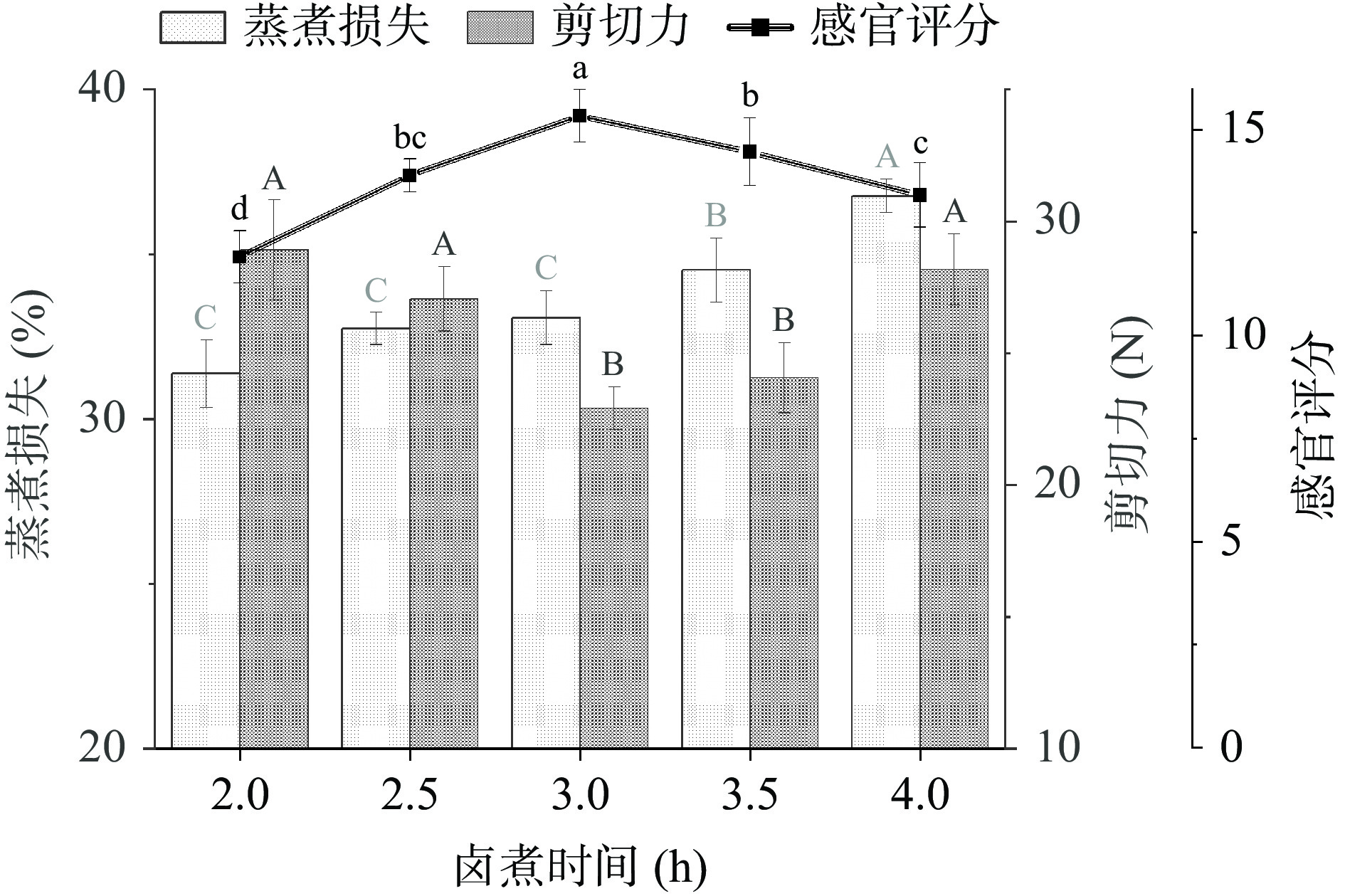

控制预煮时间为15 min,预煮温度为55 ℃,卤煮温度为73 ℃。研究卤煮时间分别为2、2.5、3、3.5、4 h对低温清卤鸡肉蒸煮损失、剪切力和感官评价的影响。

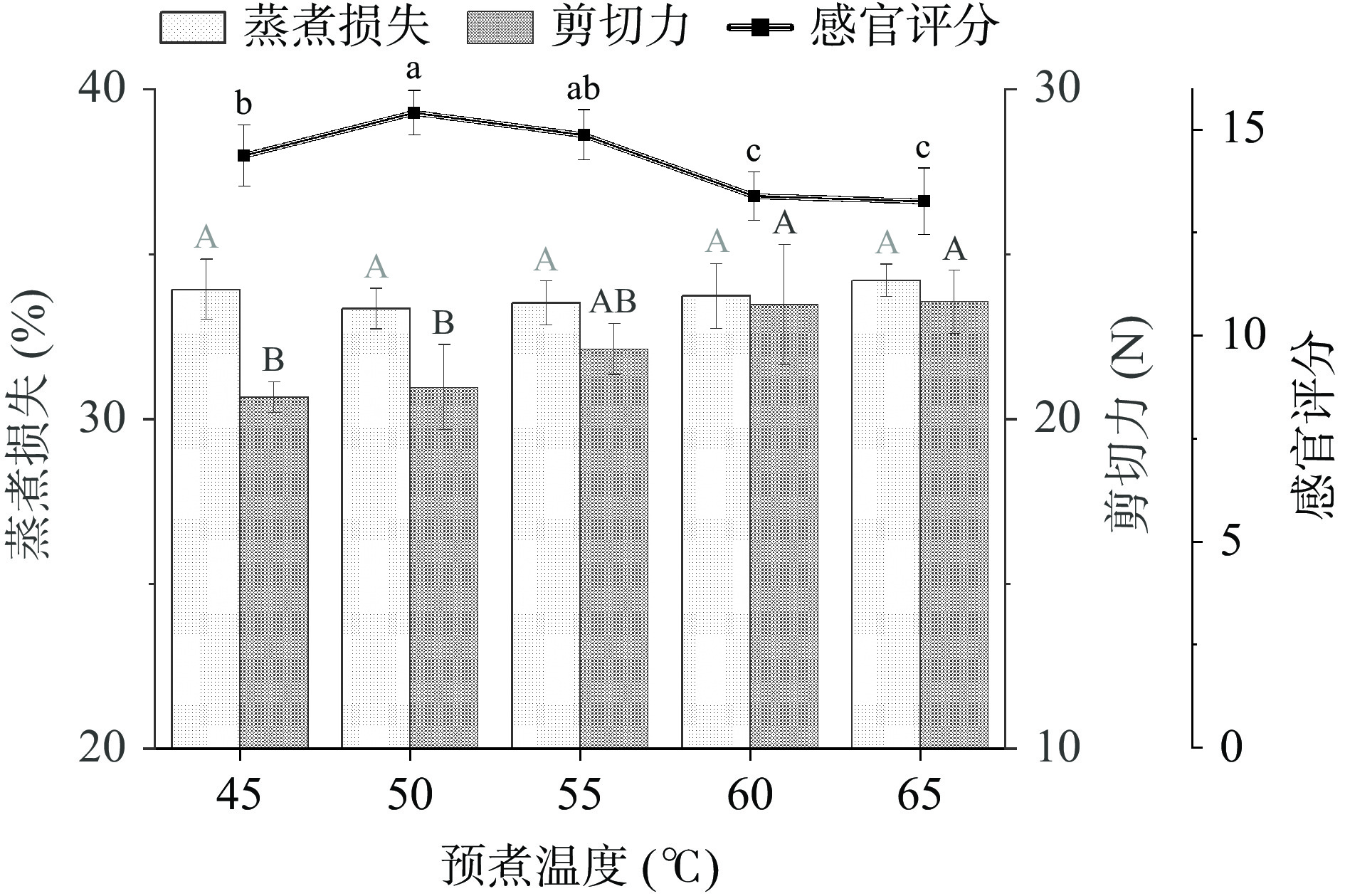

控制预煮时间为15 min,卤煮时间为3 h,卤煮温度为73 ℃。研究预煮温度分别为45、50、55、60、65 ℃对低温清卤鸡肉蒸煮损失、剪切力和感官评价的影响。

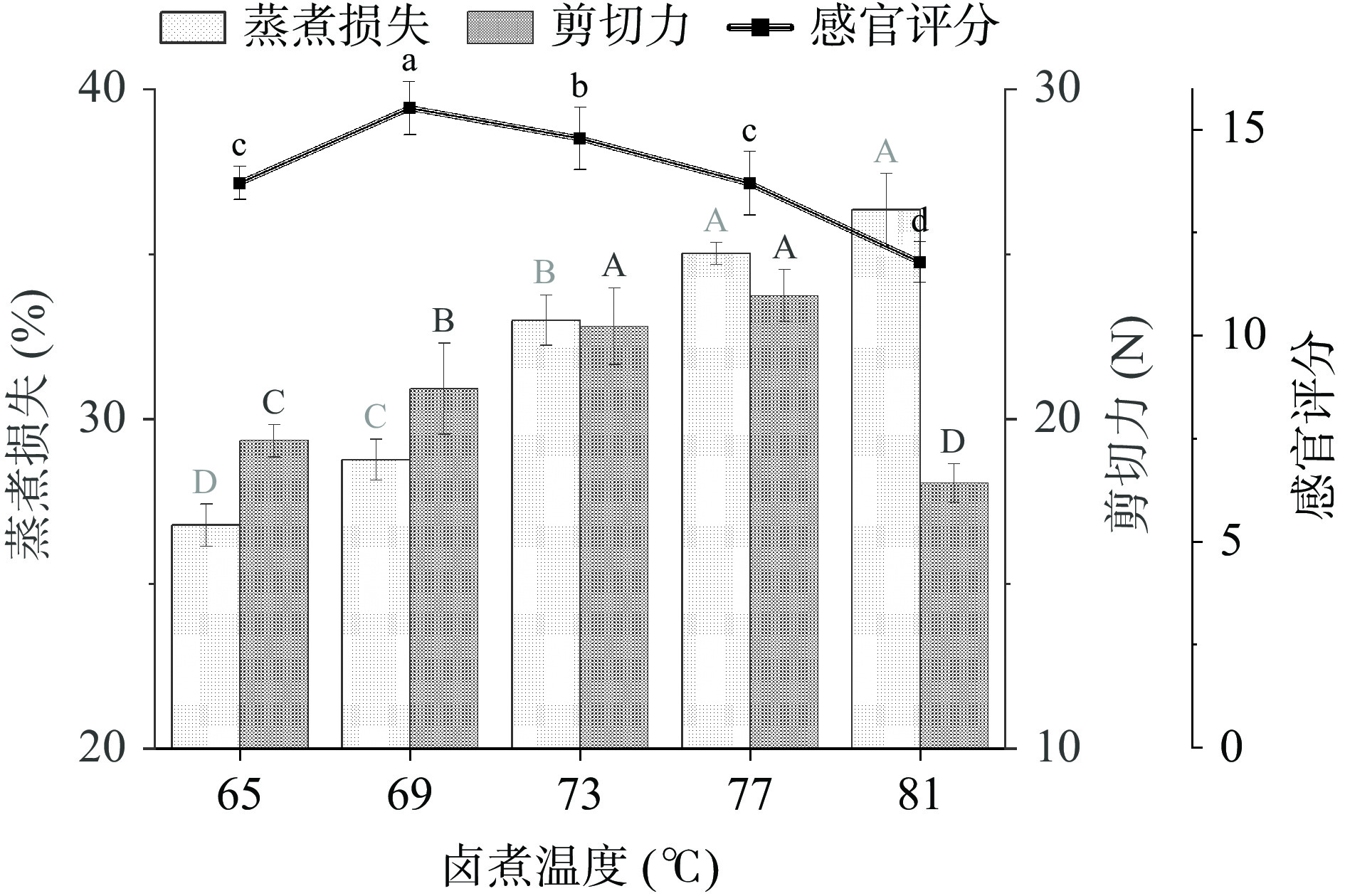

控制预煮时间为15 min,卤煮时间为3 h,预煮温度为55 ℃。研究卤煮温度分别为65、69、73、77、81 ℃对低温清卤鸡肉蒸煮损失、剪切力和感官评价的影响。

1.2.3 正交试验设计

为了更好地保证清卤鸡肉的嫩度和味道,在单因素实验水平基础上及考虑实际生产情况,以剪切力和感官评分为目标值,选择L9(34)进行正交试验,正交试验因素和水平见表1。

表 1 正交试验因素和水平Table 1. Orthogonal experimental factors and levels水平 试验因素 卤煮时间(h) 预煮时间(min) 预煮温度(℃) 卤煮温度(℃) 1 2.5 10 45 65 2 3 15 50 69 3 3.5 20 55 73 1.2.4 蒸煮损失的测定

根据刘颜等[14]的方法并略做修改。将腌制后的鸡胸肉用滤纸吸干表面水分,记重量m1(g);将卤煮后的鸡胸肉冷却后沥干水分,记重量m2(g)。蒸煮损失按式(1)计算。

蒸煮损失(%)=m1−m2m1×100 (1) 1.2.5 质构特性和剪切力的测定

肉样品在测试前在4 ℃条件下放置12 h。沿肌原纤维方向将鸡胸肉样切成1 cm×1 cm×1 cm的正方形状,在使用带有探头(P/36R)的TA-XT plus型质构仪中进行测定,探头以2 mm/s的速度向下移动,设置形变量50%,触发力参数5 g,以评估TPA属性。

对于剪切力的测定,将样品切成3 cm×1 cm×1 cm的长条状,使用刀片沿着样品肌肉纤维的垂直方向以2 mm/s的速度向下切割。将获得的峰值力(N)记录为剪切力值。

1.2.6 感官评价

参照孟凡冰等[15]的方法并略做修改。选择10名食品专业的研究生,经过感官培训后对鸡肉样品进行感官评价,并从目标产品需求出发,商定各评分标准加权系数,用加权法计算总分,总评分=质地×0.3+色泽×0.1+口感×0.2+气味×0.2+滋味×0.1+整体接受×0.1。评价标准如表2所示。

表 2 清卤鸡胸肉感官评定标准Table 2. Standard for assessing the sensibility of clear brine chicken breast等级 评分标准 评分 质地 色泽 口感 气味 滋味 整体接受 优秀 组织紧密,硬度合适,有较强的弹性,咀嚼性较好 色泽均匀,有光泽 口感嫩滑、多汁、

不腻口,肉质鲜嫩清卤汁香气浓郁,

芬芳馥郁肉味浓郁,有卤煮香味,口感丰富 极易接受

卤制鸡肉16~20 良好 组织较为紧密,硬度适中,有弹性,咀嚼性合适 表面颜色稍深,光泽

欠佳,色泽较为均匀口感较嫩滑、较多汁、不腻口 卤汁香气一般,

无异味肉味较浓郁,卤煮香味一般,无其他异味 可以接受

卤制鸡肉11~15 一般 组织较为松散,硬度基本合适,有一定的弹性和咀嚼性 色泽一般,

不均匀,无光泽口感较柴、汁水较少 卤汁香气较淡,

有少量异味肉味一般,卤煮 香味较淡,稍有腥味或其他不良味道 接受程度

一般6~10 较差 组织松散,肉较硬,无弹性,咀嚼性较差 色泽不均匀,

无光泽,暗淡口感过于干柴、腻口 无香气,有异味 香味较淡,有腥味和或其他不良味道 不能接受 0~5 权重 0.3 0.1 0.2 0.2 0.1 0.1 1.2.7 水分含量的测定

根据Haghighi等[9]的方法并略做修改,称取约5 g煮熟的鸡胸肉(Mi),并在105 ℃空气强制烘箱中干燥后重量损失至恒重Md。水分含量按式(2)计算。

水分含量(%)=Mi−MdMi×100 (2) 1.2.8 色差的测定

根据牛百慧等[16]的方法并略做修改,颜色参数(L*、a*和b*)使用ZE7700色差仪进行测定。测试模式:反射模式。测试前通过零点校正和白板校正,将肉样切成3 cm×3 cm×3 cm的正方块状,选择不同的部位重复测定3次(n=3)。

1.2.9 脂质氧化水平测定

参照GB 5009.181-2016《食品安全国家标准食品中丙二醛的测定》中的分光光度法测定脂质氧化水平。

1.2.10 肌原纤维小片化指数测定(MFI)

根据Wang等[17]的方法并略做修改,将2 g切碎的鸡胸肉样品与20 mL预冷的MFI缓冲液(100 mmol/L KCl,20 mmol/L K2HPO4,1 mmol/L EDTA,1 mmol/L MgCl2·6H2O,pH7.0)进行混合。混合物在冰浴中均质3次(12000 r/min,30 s),然后用冷冻离心机在3000 g条件下离心15 min。上述操作重复两次。离心后,去除上清液,加入5倍体积的MFI缓冲液,振荡混匀。最后将混合物通过两层纱布过滤去除结缔组织,收集滤液。用双缩脲法测定滤液中的蛋白浓度,用MFI缓冲液将蛋白浓度调至0.5 mg/mL,在540 nm处测定吸光度。每个样品重复3次(n=3)。MFI 值是根据 540 nm处的吸光度乘以200计算得出的。

1.2.11 蛋白溶解度的测定

根据郭丽萍[18]的方法并略做修改。称取1 g切碎的鸡胸肉样,加入20 mL 4 ℃预冷的碘化钾溶液(1.1 mol/L溶解于0.1 mol/L 磷酸钾缓冲溶液(71.7 mL 1 mol/L K2HPO4和28.3 mL 1 mol/L KH2PO4定容至1 L),pH7.2)。混合物在冰浴中均质3次(5000 r/min,20 s)。将匀浆液4 ℃振荡抽提12 h(150 r/min)。1500 g离心20 min,取上清液,用双缩脲法测定蛋白浓度,每个样品重复测定3次(n=3),溶解度表示为mg/g。

1.2.12 GC-MS分析挥发性成分

样品前处理:称取3 g搅碎的鸡胸肉样于顶空萃取瓶中,加入10 μL稀释一万倍的2,4,6-三甲基吡啶(内标),萃取针头老化后插入顶空瓶内,放入60 ℃水浴锅中加热30 min,富集萃取。萃取完成后取出,进样,250 ℃解吸10 min。GC条件:采用HP-5MS UI色谱柱(30 m×250 μm×250 μm),分流比5:1。升温程序:起始柱箱40 ℃保持3 min,以5 ℃/min的速率升至250 ℃,保持12 min,总运行时间57 min。MS条件:调谐类型:EI,离子源230 ℃,MS四级杆 150 ℃,溶剂延迟时间 1 min,扫描质量范围为35~400 u。根据谱库NIST20.L进行化合物的检索匹配。定量计算公式如下(3)。每组5个平行样品。

物质浓度(μg/100g)=(Area样品Area内标)×0.917g/mL1000×10μL10000×106×1003g (3) 式中:Area样品为样品的气质图谱的峰面积,Area内标为内标物质在气质图谱中所占的面积。

1.3 数据处理

使用IBM SPSS Statistics 22 中的ANOVA方差分析和Duncan多重检验(P<0.05)进行比较分析,图形绘制采用Origin 2022软件。

2. 结果与分析

2.1 单因素实验

2.1.1 预煮时间和卤煮时间对清卤鸡胸肉蒸煮损失、剪切力、感官评分的影响

预煮时间和卤煮时间对清卤鸡胸肉蒸煮损失、剪切力、感官评分的影响如图1、图2所示。预煮时间15 min时相较于预煮25 min时的鸡胸肉蒸煮损失显著降低(P<0.05)。较低的蒸煮损失与较高的多汁性相关,在适当的预煮时间下,鸡胸肉表层可能凝固并形成一层较为稳定的蛋白质凝胶,从而降低了蒸煮损失。随着卤煮时间从2 h增加至4 h时,肉的蒸煮损失显著升高(P<0.05)。加热时间影响样品的蒸煮损失,随着时间的推移,蒸煮损失增加[19]。该结果与Roldán等[20]结果相似。

预煮时间15 min时剪切力显著小于其它组(P<0.05),其它时间的卤煮鸡胸肉剪切力均差异不显著(P>0.05)。卤煮过程中,鸡胸肉剪切力总体呈先下降后增大的趋势,在卤煮时间3 h时剪切力达到最低,与2、2.5和4 h时鸡胸肉的剪切力大小差异显著(P<0.05)。烹饪过程中,肉嫩度的变化与肌原纤维蛋白和结缔组织的热诱导变化密切相关。在热作用下,结缔组织会溶解并导致肉变嫩,而肌原纤维蛋白的变性则会使肉质变得更加坚硬[21]。此外,剪切力下降的原因可能是胶原蛋白增溶更多,而在此之后,剪切力上升的原因则可能是卤煮样品中的胶原蛋白没有足够的时间完全溶解,未能抵消由肌原纤维蛋白收缩引起的硬度增加[20]。

在感官评价中,食物的多汁感不仅取决于咀嚼过程中释放的肉汁量和肉的嫩度,还与其味道和香气等多个因素密切相关[22]。感官评分在预煮时间10 min和15 min最高,差异不显著(P>0.05),可见鸡肉的卤制效果和口感在合适的预煮时间有较好的效果。感官评分在卤煮时间3 h处取得最高分15.37,在3 h后呈下降趋势,原因可能是随着煮制时间进一步延长,鸡胸肉内部水分开始流失,肌肉纤维开始变粗糙,同时加热时肌肉组织的水分流失也有助于肉变硬,口感干柴[23]。因此从清卤鸡肉的蒸煮损失、剪切力、感官评分综合分析,预煮时间在10~20 min,卤煮时间在2.5~3.5 h为宜。

2.1.2 预煮温度和卤煮温度对清卤鸡胸肉蒸煮损失、剪切力、感官评分的影响

预煮温度和卤煮温度对清卤鸡胸肉蒸煮损失、剪切力、感官评分的影响如图3、图4所示。鸡胸肉的蒸煮损失率在预煮温度之间差异不显著(P>0.05)。而在卤煮过程中,蒸煮损失随着卤煮温度的升高而增加,且81 ℃卤煮温度下的蒸煮损失相较于65 ℃时增加了35.7%,这与高帮君[24]研究结果相似。卤煮过程中较高的温度会导致肌原纤维收缩,蛋白质与水之间的结合力降低,进而导致肌原纤维的持水能力降低[25−26]。

剪切力在预煮温度45、50 ℃以及60、65 ℃之间差异不显著(P>0.05),而随着预煮温度的升高,剪切力逐渐上升。这可能是因为过高的预煮温度促使蛋白质分子发生交联和凝聚,进而改变鸡肉组织结构,增加了其紧密程度,从而提高了剪切力。因此,加入低温作为第一步温度有助于改善肉的嫩度和其它质量特性。卤煮温度为65 ℃时,剪切力达到19.34 N,显著低于77 ℃(P<0.05),随着温度的升高,鸡胸肉的剪切力不断上升。这与Tornberg[27]的研究相一致,在65 ℃下较少肌原纤维收缩和变性导致肉较嫩。随着在65 ℃至77 ℃之间肉弹性模量增加并且需要更大的拉伸应力才能使肉组织破裂,烹制的肉变得坚韧。而当卤煮温度为81 ℃时,剪切力相对于77 ℃显著下降(P<0.05),可能原因是胶原蛋白在57.8 ℃至62.6 ℃的温度范围内开始收缩,然后胶原蛋白在80 ℃的鸡肌肉中转化为凝胶化[28],同时随着温度增加发生更大的肌纤维结构的破坏,剪切力下降。

感官评分在预煮温度为50 ℃时达到最大,并总体呈现先增大后降低的趋势,说明在较低的预煮温度下,卤制鸡肉的效果和品质改善较好,肉质较嫩滑。卤煮温度的感官评分在69 ℃时达到最大,并随着温度的升高不断降低(P<0.05)。鸡胸肉肉质变老、口感粗糙、弹性下降,这可能是由于在更高的温度下长时间卤煮,胶原蛋白逐渐流失造成的[29]。因此从清卤鸡肉的蒸煮损失、剪切力、感官评分综合分析,预煮温度在45~55 ℃,卤煮温度在65~73 ℃为宜。

2.2 正交试验

正交试验结果及方差分析如表3~表5所示,除预煮时间外,其它因素对清卤鸡肉感官评价和剪切力的影响均有统计学意义(P<0.05)。由正交试验K均值结果看,以鸡胸肉的嫩度来考虑得到的剪切力指标最佳组合是A3B1C1D1,感官评分指标的最佳组合是A2B1C1D2。而对于水平A3和D1,感官评分K均值结果均取得最低,综合两个评价指标以及结合单因素实验得到鸡胸肉的最佳清卤工艺为预煮时间10 min,卤煮时间3 h,预煮温度45 ℃,卤煮温度69 ℃。

表 3 正交试验结果Table 3. Orthogonal test results试验号 A 卤煮时间 B 预煮时间 C 预煮温度 D 卤煮温度 剪切力(N) 感官评分 1 A1 B1 C1 D1 19.13±0.68 13.98±1.17 2 A1 B2 C2 D2 24.81±1.72 15.12±1.28 3 A1 B3 C3 D3 26.70±1.41 13.25±0.52 4 A2 B1 C2 D3 22.55±1.67 15.02±1.11 5 A2 B2 C3 D1 19.40±0.55 14.16±1.48 6 A2 B3 C1 D2 21.15±0.53 15.98±0.73 7 A3 B1 C3 D2 21.92±0.77 14.13±0.98 8 A3 B2 C1 D3 21.48±1.91 13.72±0.74 9 A3 B3 C2 D1 18.11±0.47 13.23±1.08 剪切力K1 70.64 63.59 61.75 56.64 剪切力K2 63.10 65.70 65.46 67.87 剪切力K3 61.50 65.96 68.03 70.73 剪切力R 9.13 2.36 6.27 14.09 最优组合 A3 B1 C1 D1 主次因素 D>A>C>B 感官评分K1 42.35 43.13 43.68 41.37 感官评分K2 45.16 43 43.37 45.23 感官评分K3 41.08 42.46 41.54 41.99 感官评分R 4.08 0.67 2.14 3.86 最优组合 A2 B1 C1 D2 主次因素 A>D>C>B 表 5 感官评价结果方差分析Table 5. Analysis of variance of sensory evaluation results变异来源 平方和 自由度 均方 F 值 显著性 A 29.062 2 14.531 13.250 * B 0.842 2 0.421 0.384 C 8.916 2 4.458 4.065 * D 28.646 2 14.323 13.060 ** 误差 88.831 81 1.097 总和 18528.950 90 表 4 剪切力结果方差分析Table 4. Analysis of variance of shear force results变异来源 平方和 自由度 均方 F 值 显著性 A 95.226 2 47.613 32.367 ** B 6.710 2 3.355 2.281 C 39.788 2 19.894 13.524 ** D 222.036 2 111.018 75.469 ** 误差 66.197 45 1.471 总和 25843.257 54 注:*表示差异显著(P<0.05);**表示差异极显著(P<0.01);表5同。 2.3 清卤鸡胸肉的品质及风味探究

2.3.1 三种加工方式对清卤鸡胸肉质地参数和水分含量的影响

质地属性是清卤鸡胸肉产品的一个重要因素,与消费者的选择和偏好有关。 硬度的变化与肌肉食物中肌原纤维的退化和收缩以及结缔组织的溶解有关[30]。如表6所示,与WUP组和HT组相比,UP处理显著降低了卤煮鸡胸肉的硬度(P<0.05),这可能因为低温卤煮鸡胸肉的肌原纤维蛋白交联程度减小,肌肉可溶性蛋白增加[24],且超声处理引起的机械效应,引起了肌原纤维蛋白结构的物理破坏,其空化作用在预煮过程可能促进肌肉蛋白的解离。通过超声及卤煮两步处理与未超声处理在内聚性和回复性以及弹性方面没有显著差异 (P>0.05),而对比于高温组显著降低(P<0.05)。

表 6 不同处理组质地参数和水分含量的比较Table 6. Comparison of texture parameters and moisture content in different treatment groups处理组 硬度(N) 回复性 内聚性 弹性 水分含量(%) HT 33.22±0.63a 0.33±0.03a 0.55±0.03a 0.58±0.02a 64.08±0.78c WUP 26.63±0.89b 0.27±0.02b 0.50±0.02b 0.48±0.02b 67.48±0.34b UP 23.63±0.64c 0.26±0.02b 0.48±0.02b 0.49±0.02b 69.36±0.28a 注:同一列上标不同字母者为差异显著(P<0.05); HT:高温组,WUP:未超声组,UP:超声预处理及低温卤煮组;表7同。 低温长时间卤煮使鸡肉产品具有很好的多汁性,高温组的水分含量最低,因为卤煮过程中较高的温度,会增加热蛋白变性的程度,导致肌肉纤维收缩,体积减小,因此在高温烹饪温度下水分含量降低[26]。加热过程中组织的水分流失也会影响肉的韧性,这与质构属性结果相对应。据Ismail等[31]报道高水分含量可能与更高的蛋白溶解度有关,大多数肌浆蛋白在40 ℃和60 ℃之间聚集,形成凝胶,从而影响肉的保水性。UP组较于WUP组显著提高了水分含量(P<0.05),超声处理既使肉品表面盐溶性蛋白含量增加,从而防止卤煮中肉品表面水分向外扩散,又促进了卤汤渗入鸡肉内部,提高水分含量[13]。

2.3.2 三种加工方式对清卤鸡胸肉色差的影响

三种加工方式的清卤鸡胸肉色差的比较如表7所示。颜色是消费者对肉类质量和安全感知的主要指标之一[32],与高温卤煮相比,超声及卤煮两步处理的鸡胸肉获得更高的L*值(亮度)和a*值(红度)(P<0.05),更低的b*值(黄度)(P<0.05)。肌红蛋白热变性随着温度升高而迅速发生,可以直接与脂质氧化的副产物相互作用,导致a*值降低[33]。热处理使肌红蛋白变性并导致肉中形成高铁肌红蛋白,高铁肌红蛋白会进一步变性,这会导致肉变黄[34]。UP组与WUP组相比,L*值和b*值没有显著差异(P>0.05),a*值显著增大(P<0.05),可能是因为超声空化作用使水分子裂解产生具有强氧化能力的自由基,促进了清卤鸡肉中肌红蛋白的氧化,形成氧合肌红蛋白,从而提高a*值。

表 7 不同处理组色差的比较Table 7. Comparison of color differences in different treatment groups处理组 L* a* b* HT 77.38±0.14b 0.25±0.01c 15.45±0.23a WUP 80.61±0.11a 1.38±0.05b 12.89±0.06b UP 80.49±0.21a 1.60±0.04a 12.82±0.05b 2.3.3 三种加工方式对清卤鸡胸肉脂质氧化的影响

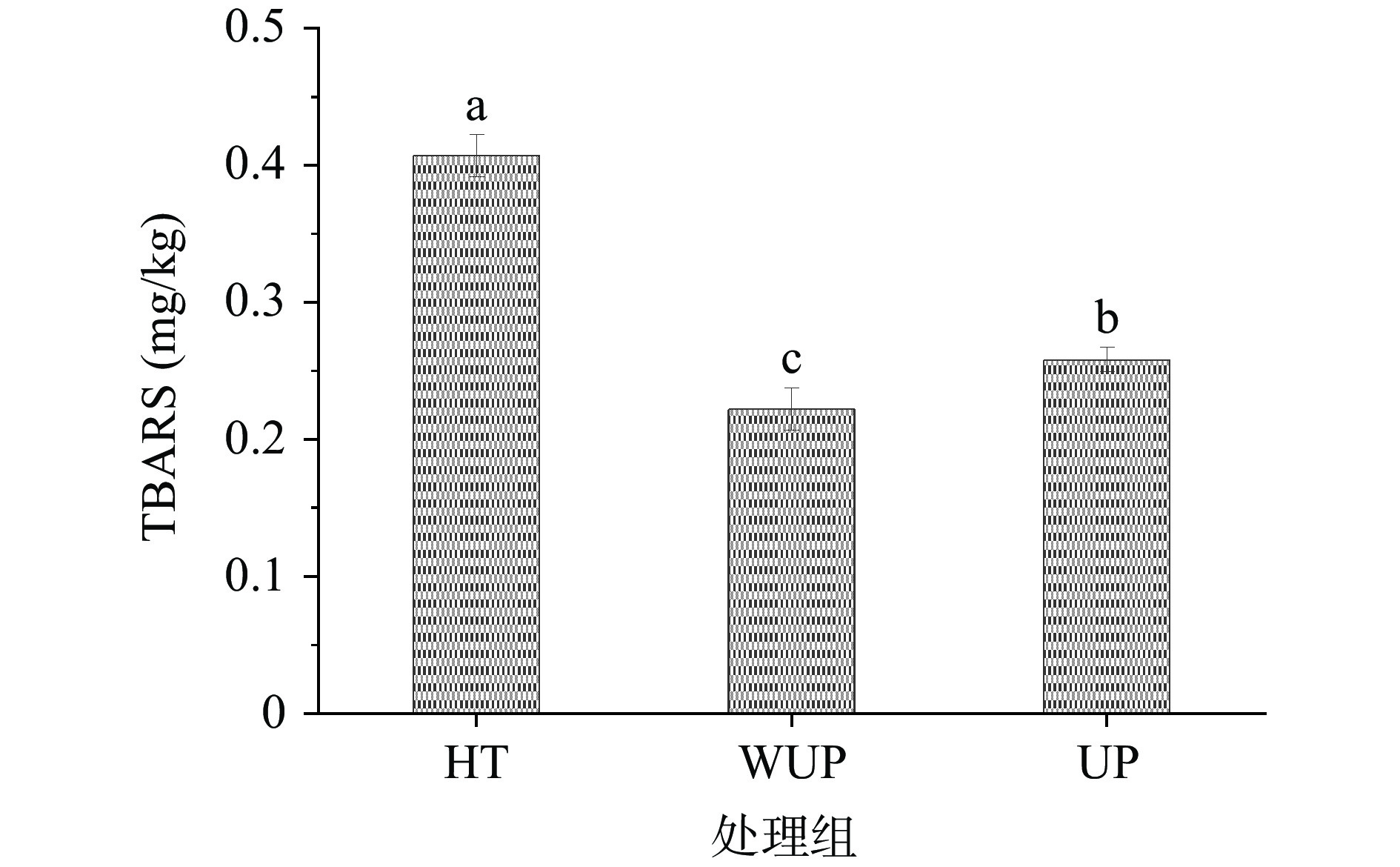

TBARS 值是食品中脂质氧化的指标,它反映了二级脂质氧化产物的存在,主要是初级脂质氧化分解产生的丙二醛,影响芳香特性风味化合物的生成,从而产生独特的风味[35]。鸡胸肉中的多不饱和脂肪酸含量高,容易发生脂质氧化。三种加工方式的清卤鸡胸脂质氧化水平的比较如图5所示,可以看出,HT组相比于UP组和WUP组具有更高的TBARS值(P<0.05),因为鸡胸肉卤煮过程中在高温的刺激下,脂肪氧化程度更深,产生了更多的丙二醛等二级氧化产物。在超声的预煮过程中,可能由于超声引起的热效应和空化效应进一步促进了氧化,其TBARS值相对于未超声处理显著升高(P<0.05)。

2.3.4 三种加工方式对清卤鸡胸肉MFI和蛋白溶解度的影响

肉的MFI值是衡量热加工处理后鸡胸肉肌原纤维完整性的参数,是判断肉嫩度的重要指标[36]。如图6所示,与HT组相比,UP组的MFI值提高了54.7%,UP组的MFI值显著高于其他组(P<0.05)。一般来说,MFI值越高,分解的肌原纤维蛋白越多,嫩化的改善与MFI值的增加密切相关[37]。蛋白溶解度反映了肌浆蛋白和肌原纤维蛋白的热变性程度,其对热凝胶的形成具有重要影响。蛋白溶解度既是肌肉蛋白质重要的功能性质,也是肌肉品质评价的关键标志之一[38]。低温长时间卤煮条件能够最大限度地减少热敏蛋白质的凝结,更大程度地增加了蛋白的溶解度,如图6所示,UP组的蛋白溶解度相比于HT组显著增加(P<0.05),加热会导致蛋白质发生变化,包括蛋白质变性和纤维收缩。肌浆蛋白和肌原纤维蛋白的热变性随着温度的升高而发生,这些变化有助于增加肉的韧性,这与MFI和TPA的结果相一致。UP组的蛋白溶解度比WUP组提高了12.4%(P<0.05),这表明超声预煮过程适当的空化效应会提高蛋白质分子的溶解度,对鸡胸肉的品质具有提升作用,这与高子武[39]的研究结果相一致。

2.3.5 三种加工方式对清卤鸡胸肉感官评分的影响

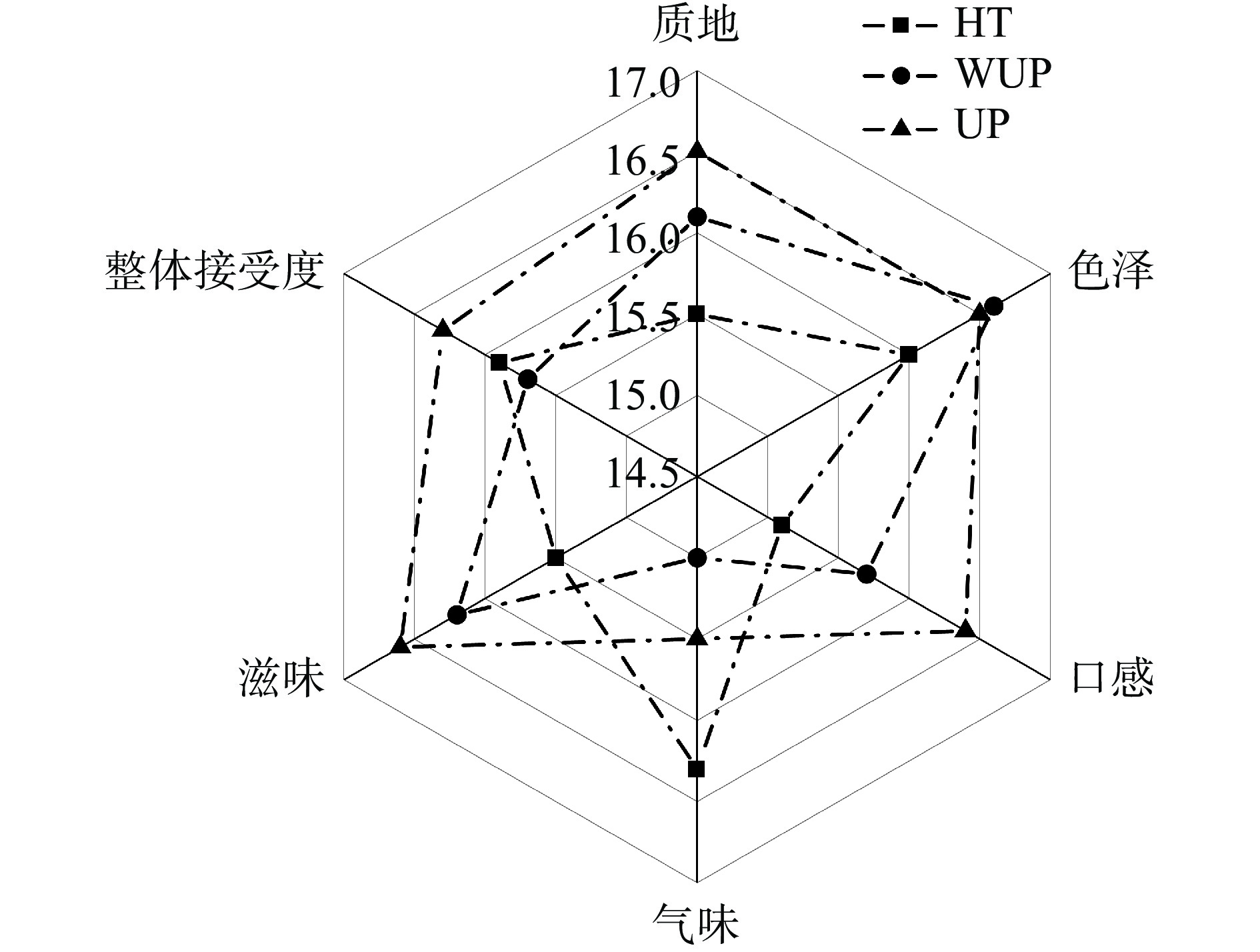

由感官评分图所示(图7),UP和WUP组的质地、色泽、口感、滋味评分均高于HT组,UP组的综合感官评分最高。一般来说,烹饪温度和时间都会影响肉的嫩度,增加烹饪温度比增加烹饪时间对纤维收缩的影响更大[40]。同时,高温卤制鸡胸肉在烹调过程中容易流失水分和营养物质,而低温则可以保留更多的营养成分和天然味道。因此低温清卤鸡胸肉口感更为嫩滑和鲜美。在气味方面,HT组气味评分高于UP和WUP组,主要归因于挥发性芳香化合物的熟肉风味通常在70 ℃以上的温度下产生,因此在较低温度下烹制的肉比在较高温度下烹制的肉表现出更差的风味。有研究表明[41],随着烹饪温度在50 ℃至90 ℃范围内的增加,鸡胸肉的风味得到增强。

2.3.6 三种加工方式对清卤鸡胸肉挥发性风味物质的影响

热处理引发糖和氨基酸之间的相互作用,诱导硫胺素的脂质氧化和热降解,碳水化合物降解,美拉德反应、Strecker反应,导致鸡肉中风味化合物的释放,这些是造成清卤鸡胸肉特有味道和香气的原因[42]。三种热加工方式对于清卤鸡胸肉挥发性化合物的GC-MS检测结果如表8所示,结果共鉴定出71种挥发性化合物。从清卤鸡胸肉中检出的挥发性化合物分为醛类、酮类、酸类、醇类、烃类、酯类、硫醚类、芳香化合物类和胺类。HT、WUP和UP组分别检测出56、54和55种风味物质。由图8、图9 可以看出三种处理组鸡胸肉之间检测到的挥发性风味物质种类相近,但是含量有明显差异(P<0.05)。超声及卤煮两步处理的挥发性化合物浓度相比于未超声处理明显升高,这可能是由于超声及卤煮两步处理引起的脂质氧化水平增加,因为形成不同风味的肉的化合物主要来自脂质氧化,尽管只有一小部分脂质被氧化,但它们足以显著改变风味[43]。

表 8 不同处理组的挥发性风味物质含量Table 8. Content of volatile flavor substances in different treatment groups化合物 保留时间

(min)风味物质含量(μg/100 g) 化合物 保留时间

(min)风味物质含量(μg/100 g) HT WUP UP HT WUP UP 醛类 正己醇 10.55 0.51±0.15 苯甲醛 14.91 12.56±1.73a 7.81±1.49b 11.41±0.86a 正戊醇 5.60 1.55±0.17 壬醛 19.15 11.97±1.93a 7.92±0.66c 10.04±1.14b 4-甲基-1-己醇 15.10 0.4±0.12a 0.42±0.14a 己醛 9.67 87.29±4.60a 51.8±8.88c 69.32±13.55b 烃类 正庚醛 12.94 3.98±0.76a 2.86±0.39b 3.63±0.59ab 环氧丙烷 3.69 7.45±0.91a 4.82±1.16b 6.73±0.81a 正辛醛 16.13 3.89±0.69a 2.72±0.24a 4.03±1.53a 3,8-二甲基十一烷 29.32 0.64±0.07 正戊醛 6.74 15.34±0.66a 8.14±1.72c 11.94±2.63b 苯己烷 23.54 1.43±0.41b 5.08±0.78a 6.06±1.13a 肉豆蔻醛 31.9 0.64±0.16a 0.62±0.10a 0.7±0.10a 戊基环丙烷 18.15 0.9±0.15a 0.72±0.16b 十六醛 36.15 0.89±0.33b 0.98±0.19b 1.63±0.40a 十二烷 21.80 1.19±0.43a 1.21±0.31a 2-十一烯醛 26.13 1.7±0.40a 1.17±0.18a 1.6±0.34a 十四烷 26.95 0.6±0.17a 0.7±0.07a 癸醛 21.99 1.08±0.19a 0.64±0.08c 0.85±0.12b 1-苯基辛烷 28.68 3.26±0.42a 3.07±0.63a 十五醛 34.07 0.56±0.07a 0.37±0.06b 0.64±0.14a 十三烷 24.41 0.34±0.09b 0.48±0.06a E-2-辛烯醛 17.82 1.39±0.25a 1.01±0.60a 1.07±0.30a 3,5-二甲基辛烷 15.54 0.43±0.19a 0.44±0.05a 十一醛 24.68 0.26±0.04a 0.18±0.02b 0.29±0.09a 八硫杂环辛烷 40.82 0.81±0.14a 0.67±0.18a 反式-2-癸烯醛 23.52 2.34±0.35a 1.52±0.24b 1.97±0.38ab 1-苯基-1-庚烯 27.93 0.26±0.06a 0.27±0.08a 反式-2,4-癸二烯醛 24.97 1.92±0.51a 0.96±0.24b 1.13±0.18b 4,7-二甲基十一烷 24.45 0.38±0.07 (E)-2-庚烯醛 14.71 0.57±0.08a 0.41±0.07b 0.46±0.07ab 3,5-二甲基十一烷 31.59 0.45±0.09 十三醛 29.62 0.43±0.05a 0.29±0.05b 0.48±0.11a 十五烷 29.32 0.83±0.18a 0.52±0.08b 0.68±0.06ab 十二醛 27.21 0.35±0.08a 0.41±0.07a 苯乙烯 12.67 1.66±1.01a 0.62±0.32b 酮类 酯类 2-庚酮 12.60 1.03±0.22a 0.53±0.05c 0.82±0.09b 棕榈酸缩水甘油酯 45.89 9.07±1.46a 2.61±0.85c 5.96±0.95b 苯己酮 28.59 1.85±0.41a 0.47±0.10c 0.9±0.19b 己酸乙烯基酯 15.46 13.8±1.49a 6.57±1.68c 10.59±2.47b 2-丁酮 4.78 4.76±0.76a 2.58±0.61b 3.92±0.54a 6-己内酯 20.38 0.81±0.15a 0.28±0.10c 0.55±0.09b 辛基苯基酮 35.44 0.78±0.08ab 0.57±0.16b 1±0.26a 硬脂酸缩水甘油基酯 53.39 2.8±0.9 苯辛酮 33.27 0.85±0.10b 0.99±0.09a 硫醚类 5-甲基-1-苯基己

烷-1-酮30.99 0.4±0.24a 0.62±0.35a 0.3±0.08a 二甲基三硫 15.14 1.01±0.20a 1.45±0.42a 1.51±0.43a 酸类 二甲醚 2.69 21.07±13.30a 20.91±4.84a 24.19±9.26a 棕榈酸 38.92 21.34±1.87a 11.45±2.88b 19.52±2.86a 二甲基二硫 7.62 0.97±0.30a 1±0.29a 1.33±0.37a 十八烷酸 42.64 5.31±0.64a 3.08±0.66b 5.57±0.81a 芳香化合物 肉豆蔻酸 34.96 1.42±0.32a 0.49±0.19c 0.9±0.18b 甲苯 8.52 2.85±1.02a 2.57±1.08a 顺式-13-十八碳烯酸 42.29 4.41±2.17a 2.7±0.54a 4.82±2.06a 丁基苯 17.82 1.92±0.43b 4±0.82a 4.57±1.14a 反式-13-十八碳烯酸 42.19 6.43±2.72a 2.18±0.58a 5.59±3.50a 癸苯 33.31 1.13±0.17 缩水甘油(Z)-9-庚烯酸 52.19 2.89±0.54 间二甲苯 11.97 0.72±0.17 正辛酸 20.99 3.33±0.65 正壬基苯 31.06 2.14±0.25a 1.99±0.46a 十二酸 30.68 0.72±0.25 戊基苯 20.76 5.58±1.11a 5.93±1.33a 丙烯酸-2,3-环氧丙酯

十八烯酸41.30 4.59±1.49 正庚基苯 26.18 4.38±0.61a 4.24±1.26a 壬酸 23.56 5.05±1.07 己基-1-苯 25.39 0.24±0.05a 0.26±0.07a 醇类 异戊基苯 20.63 2.25±0.47 1-辛烯-3-醇 15.40 4.84±0.31a 2.94±0.38c 3.74±0.74b 胺类 正庚醇 15.01 0.59±0.13 N-(2-甲基丙基)-1-苯基甲磺酰胺 14.70 3.32±1.10a 2.46±1.00a 注:同一行上标不同字母者为差异显著(P<0.05); HT:高温组,WUP:未超声组,UP:超声预处理及低温卤煮组。 醛类是肉类中最丰富的风味化合物,醛类和酮类由于其低气味阈值和脂肪香味,对肉制品的香气有很大的影响[44]。在所有处理组样品中检测到的醛类和酮类共24种。三种处理中醛类物质的比重最大,HT、WUP和UP组醛类的相对含量分别50.74%、47.12%和47.27%,这表明清卤鸡胸肉中主要风味物质是醛类。己醛含量最高,其次为苯甲醛、戊醛和壬醛,相对含量都在10%以上。一般来说,己醛是由n-6 PUFA的氧化产生的[45],具有草香。壬醛是由n-9 PUFA的氧化产生[46],具花香。苯甲醛是亚油酸分解的产物,和戊醛同具有独特的甜味、芳香味和杏仁气味,是合成香精香料的一种重要中间体。相对于UP和WUP组,HT组醛的浓度整体提高,这可能与较高的温度和较短的烹饪时间有关。升高温度会促进Strecker降解产生挥发性化合物,从而激发出理想的风味,长时间的烹饪可能导致醛类物质挥发或流失到卤汤中,含量降低[47]。

胺类、芳香类化合物是熟肉的重要特征香气成分,具有较低的气味阈值。从图中可知,UP和WUP组中芳香化合物类风味物质含量比HT组更多,是低温鸡肉产品重要贡献的风味物质,且仅在低温处理的鸡胸肉中检出胺类化合物。醇类具有较高的气味阈值,这被认为对肉类样品的香气贡献较小[48],但对总体气味有协同效应。三种处理组共检测出5种醇类,与UP和WUP组相比,HT组醇类种类和总体含量更为丰富,可能因为醇类来源于高温下更多脂质的降解。1-辛烯-3-醇在三种处理组中都被检出,其阈值较低,具有蘑菇味和油味,对风味有重要作用。

在三种处理组,共检出10种酸类,且高温处理相比较于低温处理中酸类物质的种类和相对含量较高,主要为棕榈酸。烃通常由脂质氧化形成,低温长时间卤煮的过程发现了更多烃类物质,但由于其高气味阈值而对肉类风味影响不大。酯类来源于肉制品中的醇和羧酸的酯化反应,多带有芳香味,阈值较低,其挥发性较高,在高温环境中酯类风味物质更易挥发,含量相对较高。与未超声组相比,超声结合卤煮两段加工能够增加清卤鸡胸肉中酯类物质的含量。

3. 结论

本研究以鸡胸肉制品的剪切力、蒸煮损失和感官评价为考察指标,通过单因素和正交试验分析,优化了低温清卤工艺参数,研究了超声结合卤煮两段加工方式在鸡肉制品中最佳应用条件,以开发低温慢卤关键技术。实验结果表明最佳工艺为预煮时间10 min,卤煮时间3 h,预煮温度45 ℃,卤煮温度69 ℃。超声结合卤煮两段加工方式相比较于高温短时加工改善了肉制品的主要质地参数,更有效地保持红度值和含水量,降低了脂质氧化水平,获得更高的感官评价分数,是一种有价值的烹饪选择。同时,两步加工相比较于一步加工方式(未超声预处理)增加了总蛋白的溶解度,降低了肌原纤维的完整程度,提升了鸡肉挥发性风味物质的种类及含量。综上所述,超声结合卤煮两段加工方式提升了清卤鸡肉产品的品质,为鸡肉现代化加工提供理论指导。

-

表 1 正交试验因素和水平

Table 1 Orthogonal experimental factors and levels

水平 试验因素 卤煮时间(h) 预煮时间(min) 预煮温度(℃) 卤煮温度(℃) 1 2.5 10 45 65 2 3 15 50 69 3 3.5 20 55 73 表 2 清卤鸡胸肉感官评定标准

Table 2 Standard for assessing the sensibility of clear brine chicken breast

等级 评分标准 评分 质地 色泽 口感 气味 滋味 整体接受 优秀 组织紧密,硬度合适,有较强的弹性,咀嚼性较好 色泽均匀,有光泽 口感嫩滑、多汁、

不腻口,肉质鲜嫩清卤汁香气浓郁,

芬芳馥郁肉味浓郁,有卤煮香味,口感丰富 极易接受

卤制鸡肉16~20 良好 组织较为紧密,硬度适中,有弹性,咀嚼性合适 表面颜色稍深,光泽

欠佳,色泽较为均匀口感较嫩滑、较多汁、不腻口 卤汁香气一般,

无异味肉味较浓郁,卤煮香味一般,无其他异味 可以接受

卤制鸡肉11~15 一般 组织较为松散,硬度基本合适,有一定的弹性和咀嚼性 色泽一般,

不均匀,无光泽口感较柴、汁水较少 卤汁香气较淡,

有少量异味肉味一般,卤煮 香味较淡,稍有腥味或其他不良味道 接受程度

一般6~10 较差 组织松散,肉较硬,无弹性,咀嚼性较差 色泽不均匀,

无光泽,暗淡口感过于干柴、腻口 无香气,有异味 香味较淡,有腥味和或其他不良味道 不能接受 0~5 权重 0.3 0.1 0.2 0.2 0.1 0.1 表 3 正交试验结果

Table 3 Orthogonal test results

试验号 A 卤煮时间 B 预煮时间 C 预煮温度 D 卤煮温度 剪切力(N) 感官评分 1 A1 B1 C1 D1 19.13±0.68 13.98±1.17 2 A1 B2 C2 D2 24.81±1.72 15.12±1.28 3 A1 B3 C3 D3 26.70±1.41 13.25±0.52 4 A2 B1 C2 D3 22.55±1.67 15.02±1.11 5 A2 B2 C3 D1 19.40±0.55 14.16±1.48 6 A2 B3 C1 D2 21.15±0.53 15.98±0.73 7 A3 B1 C3 D2 21.92±0.77 14.13±0.98 8 A3 B2 C1 D3 21.48±1.91 13.72±0.74 9 A3 B3 C2 D1 18.11±0.47 13.23±1.08 剪切力K1 70.64 63.59 61.75 56.64 剪切力K2 63.10 65.70 65.46 67.87 剪切力K3 61.50 65.96 68.03 70.73 剪切力R 9.13 2.36 6.27 14.09 最优组合 A3 B1 C1 D1 主次因素 D>A>C>B 感官评分K1 42.35 43.13 43.68 41.37 感官评分K2 45.16 43 43.37 45.23 感官评分K3 41.08 42.46 41.54 41.99 感官评分R 4.08 0.67 2.14 3.86 最优组合 A2 B1 C1 D2 主次因素 A>D>C>B 表 5 感官评价结果方差分析

Table 5 Analysis of variance of sensory evaluation results

变异来源 平方和 自由度 均方 F 值 显著性 A 29.062 2 14.531 13.250 * B 0.842 2 0.421 0.384 C 8.916 2 4.458 4.065 * D 28.646 2 14.323 13.060 ** 误差 88.831 81 1.097 总和 18528.950 90 表 4 剪切力结果方差分析

Table 4 Analysis of variance of shear force results

变异来源 平方和 自由度 均方 F 值 显著性 A 95.226 2 47.613 32.367 ** B 6.710 2 3.355 2.281 C 39.788 2 19.894 13.524 ** D 222.036 2 111.018 75.469 ** 误差 66.197 45 1.471 总和 25843.257 54 注:*表示差异显著(P<0.05);**表示差异极显著(P<0.01);表5同。 表 6 不同处理组质地参数和水分含量的比较

Table 6 Comparison of texture parameters and moisture content in different treatment groups

处理组 硬度(N) 回复性 内聚性 弹性 水分含量(%) HT 33.22±0.63a 0.33±0.03a 0.55±0.03a 0.58±0.02a 64.08±0.78c WUP 26.63±0.89b 0.27±0.02b 0.50±0.02b 0.48±0.02b 67.48±0.34b UP 23.63±0.64c 0.26±0.02b 0.48±0.02b 0.49±0.02b 69.36±0.28a 注:同一列上标不同字母者为差异显著(P<0.05); HT:高温组,WUP:未超声组,UP:超声预处理及低温卤煮组;表7同。 表 7 不同处理组色差的比较

Table 7 Comparison of color differences in different treatment groups

处理组 L* a* b* HT 77.38±0.14b 0.25±0.01c 15.45±0.23a WUP 80.61±0.11a 1.38±0.05b 12.89±0.06b UP 80.49±0.21a 1.60±0.04a 12.82±0.05b 表 8 不同处理组的挥发性风味物质含量

Table 8 Content of volatile flavor substances in different treatment groups

化合物 保留时间

(min)风味物质含量(μg/100 g) 化合物 保留时间

(min)风味物质含量(μg/100 g) HT WUP UP HT WUP UP 醛类 正己醇 10.55 0.51±0.15 苯甲醛 14.91 12.56±1.73a 7.81±1.49b 11.41±0.86a 正戊醇 5.60 1.55±0.17 壬醛 19.15 11.97±1.93a 7.92±0.66c 10.04±1.14b 4-甲基-1-己醇 15.10 0.4±0.12a 0.42±0.14a 己醛 9.67 87.29±4.60a 51.8±8.88c 69.32±13.55b 烃类 正庚醛 12.94 3.98±0.76a 2.86±0.39b 3.63±0.59ab 环氧丙烷 3.69 7.45±0.91a 4.82±1.16b 6.73±0.81a 正辛醛 16.13 3.89±0.69a 2.72±0.24a 4.03±1.53a 3,8-二甲基十一烷 29.32 0.64±0.07 正戊醛 6.74 15.34±0.66a 8.14±1.72c 11.94±2.63b 苯己烷 23.54 1.43±0.41b 5.08±0.78a 6.06±1.13a 肉豆蔻醛 31.9 0.64±0.16a 0.62±0.10a 0.7±0.10a 戊基环丙烷 18.15 0.9±0.15a 0.72±0.16b 十六醛 36.15 0.89±0.33b 0.98±0.19b 1.63±0.40a 十二烷 21.80 1.19±0.43a 1.21±0.31a 2-十一烯醛 26.13 1.7±0.40a 1.17±0.18a 1.6±0.34a 十四烷 26.95 0.6±0.17a 0.7±0.07a 癸醛 21.99 1.08±0.19a 0.64±0.08c 0.85±0.12b 1-苯基辛烷 28.68 3.26±0.42a 3.07±0.63a 十五醛 34.07 0.56±0.07a 0.37±0.06b 0.64±0.14a 十三烷 24.41 0.34±0.09b 0.48±0.06a E-2-辛烯醛 17.82 1.39±0.25a 1.01±0.60a 1.07±0.30a 3,5-二甲基辛烷 15.54 0.43±0.19a 0.44±0.05a 十一醛 24.68 0.26±0.04a 0.18±0.02b 0.29±0.09a 八硫杂环辛烷 40.82 0.81±0.14a 0.67±0.18a 反式-2-癸烯醛 23.52 2.34±0.35a 1.52±0.24b 1.97±0.38ab 1-苯基-1-庚烯 27.93 0.26±0.06a 0.27±0.08a 反式-2,4-癸二烯醛 24.97 1.92±0.51a 0.96±0.24b 1.13±0.18b 4,7-二甲基十一烷 24.45 0.38±0.07 (E)-2-庚烯醛 14.71 0.57±0.08a 0.41±0.07b 0.46±0.07ab 3,5-二甲基十一烷 31.59 0.45±0.09 十三醛 29.62 0.43±0.05a 0.29±0.05b 0.48±0.11a 十五烷 29.32 0.83±0.18a 0.52±0.08b 0.68±0.06ab 十二醛 27.21 0.35±0.08a 0.41±0.07a 苯乙烯 12.67 1.66±1.01a 0.62±0.32b 酮类 酯类 2-庚酮 12.60 1.03±0.22a 0.53±0.05c 0.82±0.09b 棕榈酸缩水甘油酯 45.89 9.07±1.46a 2.61±0.85c 5.96±0.95b 苯己酮 28.59 1.85±0.41a 0.47±0.10c 0.9±0.19b 己酸乙烯基酯 15.46 13.8±1.49a 6.57±1.68c 10.59±2.47b 2-丁酮 4.78 4.76±0.76a 2.58±0.61b 3.92±0.54a 6-己内酯 20.38 0.81±0.15a 0.28±0.10c 0.55±0.09b 辛基苯基酮 35.44 0.78±0.08ab 0.57±0.16b 1±0.26a 硬脂酸缩水甘油基酯 53.39 2.8±0.9 苯辛酮 33.27 0.85±0.10b 0.99±0.09a 硫醚类 5-甲基-1-苯基己

烷-1-酮30.99 0.4±0.24a 0.62±0.35a 0.3±0.08a 二甲基三硫 15.14 1.01±0.20a 1.45±0.42a 1.51±0.43a 酸类 二甲醚 2.69 21.07±13.30a 20.91±4.84a 24.19±9.26a 棕榈酸 38.92 21.34±1.87a 11.45±2.88b 19.52±2.86a 二甲基二硫 7.62 0.97±0.30a 1±0.29a 1.33±0.37a 十八烷酸 42.64 5.31±0.64a 3.08±0.66b 5.57±0.81a 芳香化合物 肉豆蔻酸 34.96 1.42±0.32a 0.49±0.19c 0.9±0.18b 甲苯 8.52 2.85±1.02a 2.57±1.08a 顺式-13-十八碳烯酸 42.29 4.41±2.17a 2.7±0.54a 4.82±2.06a 丁基苯 17.82 1.92±0.43b 4±0.82a 4.57±1.14a 反式-13-十八碳烯酸 42.19 6.43±2.72a 2.18±0.58a 5.59±3.50a 癸苯 33.31 1.13±0.17 缩水甘油(Z)-9-庚烯酸 52.19 2.89±0.54 间二甲苯 11.97 0.72±0.17 正辛酸 20.99 3.33±0.65 正壬基苯 31.06 2.14±0.25a 1.99±0.46a 十二酸 30.68 0.72±0.25 戊基苯 20.76 5.58±1.11a 5.93±1.33a 丙烯酸-2,3-环氧丙酯

十八烯酸41.30 4.59±1.49 正庚基苯 26.18 4.38±0.61a 4.24±1.26a 壬酸 23.56 5.05±1.07 己基-1-苯 25.39 0.24±0.05a 0.26±0.07a 醇类 异戊基苯 20.63 2.25±0.47 1-辛烯-3-醇 15.40 4.84±0.31a 2.94±0.38c 3.74±0.74b 胺类 正庚醇 15.01 0.59±0.13 N-(2-甲基丙基)-1-苯基甲磺酰胺 14.70 3.32±1.10a 2.46±1.00a 注:同一行上标不同字母者为差异显著(P<0.05); HT:高温组,WUP:未超声组,UP:超声预处理及低温卤煮组。 -

[1] MARANGONI F, CORSELLO G, CRICELLI C, et al. Role of poultry meat in a balanced diet aimed at maintaining health and wellbeing:An Italian consensus document[J]. Food & Nutrition Research,2015,59:27606.

[2] ZHANG J, BOWKER B, YANG Y, et al. Effects of deboning time and thawing method interaction on sensory descriptive profiles of cooked chicken breast and thigh meat[J]. LWT-Food Science and Technology,2020,120:108939. doi: 10.1016/j.lwt.2019.108939

[3] ZHAO X, CHEN X, HAN M Y, et al. Application of isoelectric solubilization/precipitation processing to improve gelation properties of protein isolated from pale, soft, exudative (PSE)-like chicken breast meat[J]. LWT-Food Science and Technology,2016,72:141−148. doi: 10.1016/j.lwt.2016.04.045

[4] BOTINESTEAN C, KEENAN D F, KERRY J P, et al. The effect of thermal treatments including sous-vide, blast freezing and their combinations on beef tenderness of M. semitendinosus steaks targeted at elderly consumers[J]. LWT-Food Science and Technology,2016,74:154−159. doi: 10.1016/j.lwt.2016.07.026

[5] THATHSARANI A P K, ALAHAKOON A U, LIYANAGE R. Current status and future trends of sous vide processing in meat industry; A review[J]. Trends in Food Science & Technology,2022,129:353−363.

[6] HASANI E, CSEHI B, DARNAY L, et al. Effect of combination of time and temperature on quality characteristics of sous vide chicken breast[J]. Foods,2022,11(4):521. doi: 10.3390/foods11040521

[7] 孙红霞, 黄峰, 丁振江, 等. 不同加热条件下牛肉嫩度和保水性的变化及机理[J]. 食品科学,2018,39(1):84−90. [SUN H X, HUANG F, DING Z J, et al. Changes in tenderness and water-holding capacity and underlying mechanism during beef stewing[J]. Food Science,2018,39(1):84−90. doi: 10.7506/spkx1002-6630-201801013 SUN H X, HUANG F, DING Z J, et al . Changes in tenderness and water-holding capacity and underlying mechanism during beef stewing[J]. Food Science,2018 ,39 (1 ):84 −90 . doi: 10.7506/spkx1002-6630-201801013[8] 王正雯, 田宏伟, 周富裕, 等. 加热温度对麻鸭肌原纤维蛋白结构与凝胶特性的影响[J]. 食品科学,2020,41(13):61−68. [WANG Z W, TIAN H W, ZHOU F Y, et al. Effect of heating temperature on myofibrillar protein structure and gel properties of sheldrake breast muscle[J]. Food Science,2020,41(13):61−68. doi: 10.7506/spkx1002-6630-20191128-280 WANG Z W, TIAN H W, ZHOU F Y, et al . Effect of heating temperature on myofibrillar protein structure and gel properties of sheldrake breast muscle[J]. Food Science,2020 ,41 (13 ):61 −68 . doi: 10.7506/spkx1002-6630-20191128-280[9] HAGHIGHI H, BELMONTE A M, MASINO F, et al. Effect of time and temperature on physicochemical and microbiological properties of sous vide chicken breast fillets[J]. Applied Sciences,2021,11(7):3189. doi: 10.3390/app11073189

[10] BHARGAVA N, MOR R S, KUMAR K, et al. Advances in application of ultrasound in food processing:A review[J]. Ultrasonics Sonochemistry,2021,70:105293. doi: 10.1016/j.ultsonch.2020.105293

[11] INGUGLIA E S, ZHANG Z, TIWARI B K, et al. Salt reduction strategies in processed meat products-A review[J]. Trends in Food Science & Technology,2017,59:70−78.

[12] TURANTAS F, KILIC G B, KILIC B. Ultrasound in the meat industry:General applications and decontamination efficiency[J]. International Journal of Food Microbiology,2015,198:59−69. doi: 10.1016/j.ijfoodmicro.2014.12.026

[13] ZOU Y, SHI H, XU P, et al. Combined effect of ultrasound and sodium bicarbonate marination on chicken breast tenderness and its molecular mechanism[J]. Ultrasonics Sonochemistry,2019,59:104735. doi: 10.1016/j.ultsonch.2019.104735

[14] 刘颜, 周颖, 贾永京, 等. 安徽白山羊肉品质及其低温加工特性[J]. 食品与发酵工业,2021,47(16):211−218. [LIU Y, ZHOU Y, JIA Y J, et al. Low-temperature processing characteristics and quality of Anhui white goat meat[J]. Food and Fermentation Industries,2021,47(16):211−218. doi: 10.13995/j.cnki.11-1802/ts.026374 LIU Y, ZHOU Y, JIA Y J, et al . Low-temperature processing characteristics and quality of Anhui white goat meat[J]. Food and Fermentation Industries,2021 ,47 (16 ):211 −218 . doi: 10.13995/j.cnki.11-1802/ts.026374[15] 孟凡冰, 刘达玉, 向茂德, 等. 不同卤制方法对白鹅腿肉品质及挥发性风味成分的影响[J]. 食品工业科技,2018,39(5):272−279. [MENG F B, LIU D Y, XIANG M D, et al. Effects of different bittern process on volatile flavor compounds of white goose thigh[J]. Science and Technology of Food Industry,2018,39(5):272−279. doi: 10.13386/j.issn1002-0306.2018.05.051 MENG F B, LIU D Y, XIANG M D, et al . Effects of different bittern process on volatile flavor compounds of white goose thigh[J]. Science and Technology of Food Industry,2018 ,39 (5 ):272 −279 . doi: 10.13386/j.issn1002-0306.2018.05.051[16] 牛百慧, 陈洪生, 孙迪, 等. 休闲即食低温酱卤猪手的开发及加工工艺的优化[J]. 食品研究与开发,2018,39(23):122−128. [NIU B H, CHEN H S, SUN D, et al. Development and optimization of processing technology of snack low-temperature sauced trotters[J]. Food Research and Development,2018,39(23):122−128. doi: 10.3969/j.issn.1005-6521.2018.23.022 NIU B H, CHEN H S, SUN D, et al . Development and optimization of processing technology of snack low-temperature sauced trotters[J]. Food Research and Development,2018 ,39 (23 ):122 −128 . doi: 10.3969/j.issn.1005-6521.2018.23.022[17] WANG D, ZHANG M, DENG S, et al. Postmortem changes in actomyosin dissociation, myofibril fragmentation and endogenous enzyme activities of grass carp (Ctenopharyngodon idellus) muscle [J]. Food Chemistry, 2016, 197(Pt A):340−344.

[18] 郭丽萍. 超高压结合热处理对猪肉蛋白质氧化、结构及特性的影响[D]. 绵阳:西南科技大学, 2016. [GUO L P. Effects of combined ultra-high pressure and thermal treatment on oxidation, structure and properties of pork proteins[D]. Mianyang:Southwest University of Science and Technology, 2016. GUO L P. Effects of combined ultra-high pressure and thermal treatment on oxidation, structure and properties of pork proteins[D]. Mianyang: Southwest University of Science and Technology, 2016.

[19] ZHANG M, CHEN M, FANG F, et al. Effect of sous vide cooking treatment on the quality, structural properties and flavor profile of duck meat[J]. International Journal of Gastronomy and Food Science,2022,29:100565. doi: 10.1016/j.ijgfs.2022.100565

[20] ROLDAN M, ANTEQUERA T, MARTIN A, et al. Effect of different temperature-time combinations on physicochemical, microbiological, textural and structural features of sous-vide cooked lamb loins[J]. Meat Science,2013,93(3):572−578. doi: 10.1016/j.meatsci.2012.11.014

[21] LAAKKONEN E, WELLINGTON G H, SHERBON J N. Low-temperature, long-time heating of bovine muscle 1. Changes in tenderness, water-binding capacity, pH and amount of water-soluble components[J]. Journal of Food Science,1970,35(2):175−177. doi: 10.1111/j.1365-2621.1970.tb12131.x

[22] AASLYNG M D, OKSAMA M, OLSEN E V, et al. The impact of sensory quality of pork on consumer preference[J]. Meat Science,2007,76(1):61−73. doi: 10.1016/j.meatsci.2006.10.014

[23] 刘树萍, 苏晓文, 方伟佳. 基于感官评价结合理化指标分析低温慢煮过程中鸡胸肉品质变化[J]. 中国调味品,2021,46(2):40−45. [LIU S P, SU X W, FANG W J. Analysis of the changes of chicken breast quality during the process of low temperature and slow cooking based on sensory evaluation and physicochemical indexes[J]. China Condiment,2021,46(2):40−45. doi: 10.3969/j.issn.1000-9973.2021.02.008 LIU S P, SU X W, FANG W J . Analysis of the changes of chicken breast quality during the process of low temperature and slow cooking based on sensory evaluation and physicochemical indexes[J]. China Condiment,2021 ,46 (2 ):40 −45 . doi: 10.3969/j.issn.1000-9973.2021.02.008[24] 高帮君. 酱卤鸭腿真空低温卤制工艺优化及品质研究[D]. 武汉:武汉轻工大学, 2021. [GAO B J. Study on the optimization of vacuum cryogenic and low-temperature marinating technology and quality of braised duck leg[D]. Wuhan:Wuhan Polytechnic University, 2021. GAO B J. Study on the optimization of vacuum cryogenic and low-temperature marinating technology and quality of braised duck leg[D]. Wuhan: Wuhan Polytechnic University, 2021.

[25] WAN J, CAO A, CAI L. Effects of vacuum or sous-vide cooking methods on the quality of largemouth bass ( Micropterus salmoides)[J]. International Journal of Gastronomy and Food Science,2019,18:100181. doi: 10.1016/j.ijgfs.2019.100181

[26] SÁNCHEZ DEL PULGAR J, GÁZQUEZ A, RUIZ-CARRASCAL J. Physico-chemical, textural and structural characteristics of sous-vide cooked pork cheeks as affected by vacuum, cooking temperature, and cooking time[J]. Meat Science,2012,90(3):828−835. doi: 10.1016/j.meatsci.2011.11.024

[27] TORNBERG E. Effects of heat on meat proteins-Implications on structure and quality of meat products[J]. Meat Science,2005,70(3):493−508. doi: 10.1016/j.meatsci.2004.11.021

[28] WATTANACHANT S, BENJAKUL S, LEDWARD D A. Effect of heat treatment on changes in texture, structure and properties of Thai indigenous chicken muscle[J]. Food Chemistry,2005,93(2):337−348. doi: 10.1016/j.foodchem.2004.09.032

[29] 王心诗, 刘琨, 郑万琴, 等. 超声波低温烹煮卤牛肉工艺优化[J]. 食品工业,2022,43(7):17−21. [WANG X S, LIU K, ZHENG W Q, et al. Optimization of ultrasonic low-temperature cooking process for braised beef[J]. The Food Industry,2022,43(7):17−21. WANG X S, LIU K, ZHENG W Q, et al . Optimization of ultrasonic low-temperature cooking process for braised beef[J]. The Food Industry,2022 ,43 (7 ):17 −21 .[30] KONG F, TANG J, RASCO B, et al. Kinetics of salmon quality changes during thermal processing[J]. Journal of Food Engineering,2007,83(4):510−520. doi: 10.1016/j.jfoodeng.2007.04.002

[31] ISMAIL I, HWANG Y-H, BAKHSH A, et al. The alternative approach of low temperature-long time cooking on bovine semitendinosus meat quality[J]. Asian-Australasian Journal of Animal Sciences,2019,32(2):282−289. doi: 10.5713/ajas.18.0347

[32] LEE S K, CHON J W, YUN Y K, et al. Properties of broiler breast meat with pale color and a new approach for evaluating meat freshness in poultry processing plants[J]. Poultry Science,2022,101(3):101627. doi: 10.1016/j.psj.2021.101627

[33] KHAN A, ALLEN K, WANG X. Effect of type I and type II antioxidants on oxidative stability, microbial growth, pH, and color in raw poultry meat[J]. Food and Nutrition Sciences,2015,6(16):1541−1551. doi: 10.4236/fns.2015.616159

[34] ZHANG L, WANG S. Effects of cooking on thermal-induced changes of Qingyuan partridge chicken breast[J]. Food Science and Biotechnology,2012,21(6):1525−1531. doi: 10.1007/s10068-012-0203-1

[35] ISMAIL I, HWANG Y H, JOO S T. Low-temperature and long-time heating regimes on non-volatile compound and taste traits of beef assessed by the electronic tongue system[J]. Food Chemistry,2020,320:126656. doi: 10.1016/j.foodchem.2020.126656

[36] SILVA-BUZANELLO R A D, SCHUCH A F, NUNES NOGUES D R, et al. Physicochemical and biochemical parameters of chicken breast meat influenced by stunning methods[J]. Poultry Science,2018,97(11):3786−3792. doi: 10.3382/ps/pey281

[37] GEESINK G H, TAYLOR R G, BEKHIT A E D, et al. Evidence against the non-enzymatic calcium theory of tenderization[J]. Meat Science,2001,59(4):417−422. doi: 10.1016/S0309-1740(01)00097-3

[38] CHAN J T Y, OMANA D A, BETTI M. Effect of ultimate pH and freezing on the biochemical properties of proteins in turkey breast meat[J]. Food Chemistry,2011,127(1):109−117. doi: 10.1016/j.foodchem.2010.12.095

[39] 高子武. 超声波协同低温卤煮对牛肉品质特性的影响及蛋白质氧化作用研究[D]. 扬州:扬州大学, 2022. [GAO Z W. Study on the effect of ultrasound-assisted sous-vide cooking on the quality characteristics and protein oxidation of spiced beef[D]. Yangzhou:Yangzhou University, 2022. GAO Z W. Study on the effect of ultrasound-assisted sous-vide cooking on the quality characteristics and protein oxidation of spiced beef[D]. Yangzhou: Yangzhou University, 2022.

[40] DOMINGUEZ-HERNANDEZ E, SALASEVICIENE A, ERTBJERG P. Low-temperature long-time cooking of meat:Eating quality and underlying mechanisms[J]. Meat Science,2018,143:104−113. doi: 10.1016/j.meatsci.2018.04.032

[41] CHUMNGOEN W, CHEN C F, CHEN H Y, et al. Influences of end-point heating temperature on the quality attributes of chicken meat[J]. British Poultry Science,2016,57(6):740−750. doi: 10.1080/00071668.2016.1216942

[42] AFZAL A, SAEED F, AFZAAL M, et al. The chemistry of flavor formation in meat and meat products in response to different thermal and non-thermal processing techniques:An overview[J]. Journal of Food Processing and Preservation,2022,46(10):e16847.

[43] ZOU Y, KANG D, LIU R, et al. Effects of ultrasonic assisted cooking on the chemical profiles of taste and flavor of spiced beef[J]. Ultrasonics Sonochemistry,2018,46:36−45. doi: 10.1016/j.ultsonch.2018.04.005

[44] ROLDAN M, RUIZ J, DEL PULGAR J S, et al. Volatile compound profile of sous-vide cooked lamb loins at different temperature-time combinations[J]. Meat Science,2015,100:52−57. doi: 10.1016/j.meatsci.2014.09.010

[45] WATANABE A, KAMADA G, IMANARI M, et al. Effect of aging on volatile compounds in cooked beef[J]. Meat Science,2015,107:12−19. doi: 10.1016/j.meatsci.2015.04.004

[46] WANG Y, JIANG Y T, CAO J X, et al. Study on lipolysis-oxidation and volatile flavour compounds of dry-cured goose with different curing salt content during production[J]. Food Chemistry,2016,190:33−40. doi: 10.1016/j.foodchem.2015.05.048

[47] ISMAIL I, HWANG Y H, BAKHSH A, et al. Control of sous-vide physicochemical, sensory, and microbial properties through the manipulation of cooking temperatures and times[J]. Meat Science,2022,188:108787. doi: 10.1016/j.meatsci.2022.108787

[48] VENTANAS S, MUSTONEN S, PUOLANNE E, et al. Odour and flavour perception in flavoured model systems:Influence of sodium chloride, umami compounds and serving temperature[J]. Food Quality and Preference,2010,21(5):453−462. doi: 10.1016/j.foodqual.2009.11.003

-

期刊类型引用(1)

1. 代莹,刘双能,刘晋琦,邢莉那,朱童,周素梅,芦晶. 多重酶解协同制备绿豆基植物乳及其品质分析. 食品科技. 2024(09): 175-183 .  百度学术

百度学术

其他类型引用(0)

下载:

下载:

下载:

下载: