Process Optimization of Enzyme-Assisted Extraction of Polysaccharides from Artificially-Cultivated Cordyceps cicadae and Its Kinetic, Thermodynamic and Antioxidant Activities Analysis

-

摘要: 目的:优化酶法辅助提取人工培育蝉花多糖的工艺,考察料液比、酶添加量、酶解温度、提取时间等单因素对多糖得率的影响。方法:借助Box-Behnken设计的四因素三水平法建立了该多糖提取工艺的理论模型,并研究多糖对三种自由基的清除效果,根据Fick第二定律建立了人工培育蝉花提取的动力学模型,并根据速率常数、相对萃余率、活化能等参数,研究其动力学和热力学性质。结果:经响应面分析得到该多糖最佳提取工艺为:料液比1:30 g/mL、酶添加量1.6%、酶解温度67 ℃、提取时间90 min,在此条件下蝉花多糖的得率可达7.91%,与理论值接近。在该工艺下的人工蝉花粗多糖的DPPH自由基和羟自由基的IC50值分别为0.54和0.60 mg/mL,ORAC值是45.62 Trolox μmol/g,具有良好的体外抗氧化活性。结论:利用酶法辅助提取人工培育蝉花多糖,为该类已商业化的蝉花资源的多糖组分开发提供了理论基础。Abstract: Objective: To optimize the enzyme-assisted extraction process of polysaccharides from artificially-cultivated Cordyceps cicadae was conducted in this study. Four different parameters were considered to evaluate the yield of polysaccharides including liquid to solid ratio, enzyme dosage, enzymatic temperature and extraction time. Methods: A four-factor-three-level experimental design was employed to establish a mathematical model by Box-Behnken method, and the scavenging capacity of polysaccharides against three radicals was examined. Afterward, Fick's second law was used to build the kinetic model for the extraction of polysaccharide from artificially-cultivated Cordyceps cicadae. The parameters including rate constants, relative extraction rate, and activation energy were employed to analyze the kinetic and thermodynamic features. Results: Based on the response surface analysis, the optimal extraction process was presented to be as following: Liquid to solid ratio 1:30 g/mL, enzyme dosage 1.6%, enzymatic digestion temperature 67 ℃ and extraction time 90 min. The polysaccharide yield under the above condition was 7.91%, which was close to the predicted value. Moreover, the results of antioxidant capacities indicated that the obtained crude polysaccharides under optimal conditions showed strong DPPH radical scavenging and hydroxyl radical scavenging with IC50 values for 0.60 and 0.54 mg/mL, respectively, and its ORAC value was 45.62 Trolox μmol/g, suggesting potent antioxidant activity in vitro. Conclusion: The study of enzyme-assisted extraction of artificially-cultivated Cordyceps cicadae flower polysaccharides provide theoretical support for the production of polysaccharide fractions from this kind of commercialized Cordyceps cicadae resources.

-

蝉花(Cordyceps cicadae)属于虫草科,分布于我国长江以南,是与冬虫夏草相类似的虫草,其是蝉的幼虫在羽化前被虫草菌感染、寄生、吸收营养,最终被菌丝体完全占据后的躯壳[1]。早在明代《本草纲目》就已记载包括冬虫夏草、蝉花、黑木耳在内的40多种食用菌,这类食用菌受到学者的广泛关注。但因野生资源较少,严重限制了蝉花商业化的应用。蝉拟青霉(Paecilomyces cicadae Miq. Samson)又名雌蝉花,是从天然蝉花子实体中有丝分裂出的孢子真菌[2−3],可通过人工培育的方法进行大规模生产,有效解决资源短缺的问题。2021年底,利用该食用菌培育出的虫草被卫健委批准列入“新资源食品”目录(2021年第9号公告),因此,吸引了大量学者围绕该真菌进行人工培育。

越来越多的文献报道,人工培育的蝉花含有多糖、核苷、腺苷、麦角甾醇、虫草酸等多种活性成分[4]。其中多糖组分能够改善机体自身的免疫功能,提升机体的抗病、抗风险能力,减少各种常见病的发生,毒副作用较小,不容易造成药物的残留,可以放心食用。研究表明,天然蝉花多糖具有抗氧化[5]、抗肿瘤[6]、保护肾脏[7]、增强免疫活性[8]等药理作用。目前,报道的提取人工培育蝉花多糖的方法主要为微波法[9]。而多糖提取方法有热水浸泡、酸、碱提法、酶法辅助提取等[10]。单纯的热水浸提法耗时且得率不高;酸、碱提法多糖对设备要求较高,且容易破坏多糖的内部结构;酶法提取是将酶作为一种生物催化剂来破坏植物细胞壁结构,有效去除蛋白质等成分干扰,加快细胞中活性物质溶出,该方法操作安全,易于控制,提取效率高[11],所以本次实验采用木瓜蛋白酶法提取人工培育蝉花多糖。

本文拟采取酶法提取人工培育蝉花多糖,结合响应面法对其提取工艺进行优化,重点考察料液比、酶添加量、酶解温度、提取时间等单因素对多糖得率的影响,建立该多糖提取工艺的数学模型,获得其最佳提取工艺,并探究其动力学和热力学性质,再根据DPPH·、·OH及ORAC等指标,测定该虫草多糖的体外抗氧化活性,为进一步深度开发人工培育蝉花资源及其活性多糖组分提供可能。

1. 材料与方法

1.1 材料与仪器

人工培育蝉花菌粉 浙江泛亚医药有限公司;酚类、单糖标品、无水葡萄糖、水杨酸、过氧化氢、硫酸亚铁、浓硫酸 徐州淞誉化工科技有限公司;维生素C、2,2-联苯基-1-大苦基肼基(DPPH)、荧光素、水溶性VE衍生物(Trolox)、2,2-偶氮二(2-甲基丙基咪)二盐酸盐(AAPH)、木瓜蛋白酶(3 units/mg) 上海阿拉丁生物科技股份有限公司;所用试剂均为分析纯。

RE-201D旋转蒸发仪 常州亚旺仪器有限公司;SB25-YZ-120DB超声波清洗机 上海越众仪器设备有限公司;IEC-CL31R多功能高速离心机 美国Thermo公司;荧光微孔板细胞分析仪 美国Thermo公司;LT-DBX60N精密可编程烘干箱 上海博迅设备有限公司;DL-3020低温冷却液循环泵 宁波新芝有限公司;电子天平 北京正联兴业称重科技有限公司;电热恒温水浴锅 苏州正基仪器有限公司。

1.2 实验方法

1.2.1 人工培育蝉花的预处理及提取

将原料用95%乙醇按料液比1:10(g/L)除脂,水浴90 ℃回流,每次3 h,放在55 ℃ 的烘箱之中烘干,过40目筛,放置备用。

取一定量的人工培育蝉花,用蒸馏水做溶剂,调节pH为6.5,放入65 ℃水浴锅中搅拌30 min,调节pH至7.0。90 ℃回流提取,每次2 h,过滤,将滤渣复提一次。将2次所得滤液混合,按溶液体积的1%加入木瓜蛋白酶,放入70 ℃烘箱2 h,进行多次搅拌,5000 r/min离心5 min,取上清液。60 ℃下进行减压浓缩,浓缩液与95%乙醇体积比例为1:4,醇沉(4 ℃,12 h),5000 r/min离心8 min,收集沉淀,冷冻干燥后,得到即为蝉花粗多糖。

1.2.2 粗多糖得率的测定

采用苯酚-硫酸法测定多糖含量[12]。利用葡萄糖溶液绘制标准曲线,用紫外分光光度计在490 nm处测定其吸光值,得到葡萄糖标准曲线y=15.94x−0.0622,R2=0.9581,说明该标准曲线具有线性关系。将10 mg样品称取到烧杯中进行溶解,转移至10 mL容量瓶定容,按照制定标准曲线的同样方法测定样品吸光度值,计算蝉花菌粉多糖得率:

粗多糖得率(%)=C×V×nm×100 (1) 式中:m为人工培育蝉花菌粉质量,g;C为样品多糖质量浓度,mg/mL;V为样品溶液总体积,mL;n为稀释倍数。

1.2.3 单因素实验

考虑料液比、酶添加量、酶解温度、提取时间不同因素对蝉花虫草多糖得率的影响。将酶添加量控制为1.5%,酶解温度控制为65 ℃,提取时间为90 min,考察料液比(1:10、1:20、1:30、1:40、1:50 g/mL)对多糖得率的影响;将料液比控制在1:30 g/mL,酶解温度控制为65 ℃,提取时间为90 min,考察酶添加量(0.5%、1.0%、1.5%、2.0%、2.5%)对多糖得率的影响;将料液比控制在1:30 g/mL,酶添加量控制为1.5%,提取时间为90 min,考察酶解温度(45、55、65、75、85 ℃)对多糖得率的影响;将料液比控制在1:30 g/mL,酶添加量控制为1.5%,酶解温度为65 ℃,考察提取时间(70、80、90、100、110 min)对多糖得率的影响。

1.2.4 人工培育蝉花多糖提取工艺响应面试验优化

根据单因素实验,将料液比、酶添加量、酶解温度、提取时间为4个因素,每个因素选取3个水平,进行Box-Behnken原理设计响应面试验见表1,将蝉花多糖得率作为响应值,对其提取工艺进行优化。

表 1 响应面试验因素与水平Table 1. Factors and levels of response surface test

水平因素 A料液比

(g/mL)B酶添加量

(%)C酶解温度

(℃)D提取时间

(min)−1 1:20 1.0 55 80 0 1:30 1.5 65 90 1 1:40 2.0 75 100 1.2.5 人工培育蝉花多糖提取动力学分析

参考文献[13]可知,多糖的提取过程一般分为三个阶段:溶剂向内渗透、有效成分内部扩散到表面中以及有效成分向外扩散到溶剂。假设人工培育蝉花样品为球形,根据Fick第二定律[14]:

∂c∂t=Ds(∂2c∂r2+2r⋅∂c∂r) (2) 设f=r·c,方程可以变成

∂f∂t=Ds∂2f∂r2 (3) 在其边界条件下,即r=0,f=0,r=R,(∂CW∂t)×Va=−DsA(∂C∂t)r=R,其中,CW为溶剂中人工培育蝉花多糖的浓度,mg/mL;C为任意时间的得率,%;Va为提取溶液的体积,cm3;A代表人工培育蝉花样品颗粒与溶剂的接触面积,cm。

根据傅里叶变换求得:

C∞−CC∞−C0=(6π2)∑∞n=1{exp[−(nπ/R2)Dst]} (4) 通常情况下,高次项分布趋近于0,可忽略,式(4)取n=1,则:

∂∞−CC∞−C0=(6π2)[exp(−π2Dst/R2)] (5) 等式左右两边同时取对数得:

ln[C∞C∞−C]=Kt+ln[π2C∞6(C∞−C0)],且K=π2Ds/R2 (6) 式(5)、式(6)为蝉花多糖提取过程的动力学模型,该模型反映了多糖提取过程中提取的酶添加量、料液比、酶解温度、提取时间参数对蝉花多糖浓度的影响。

式中:Ds为扩散系数;C为任意时间的得率,%;C∞为平衡时的得率,%;C0为提取溶液中多糖的初始得率,%;K为速率常数,min−4;t为提取时间,min。

1.2.6 热力学分析

根据文献[15],将Arrhenius公式进行下列推导:

lnK=lnA−Ea/RT (7) lnK=−EaR⋅1T+lnA (8) ΔGm=−RTlnK (9) ΔHm=Ea−RT (10) ΔGm=ΔHm−TΔSm (11) 式中:A为阿伦尼乌斯常数;R为气体常数,8.314 J/mol·K;T为提取温度,K;K为分配系数;Ea为活化能,kJ/mol;∆Gm为吉布斯自由能,kJ/mol;∆Hm为焓自由能,kJ/mol;∆Sm为熵自由能,kJ/mol。

1.2.7 抗氧化活性分析

1.2.7.1 DPPH自由基清除能力的测定

参考文献[16−17]方法,制备不同浓度梯度(0.25,0.5,1.0,1.5,2.0,2.5 mg/mL)的粗多糖溶液,依次添加2 mL DPPH乙醇溶液,混合均匀,避光室温放置30 min,用蒸馏水作空白,VC溶液作对照,在517 nm处测定其吸光度,计算DPPH自由基清除率:

清除率(%)=[1−(A0−A1)/A2]×100 (12) 式中:A0为空白对照品在517 nm处的吸光值;A1为样品溶液的在517 nm处吸光值;A2为以蒸馏水代替DPPH的样品溶液在517 nm处的吸光值。

1.2.7.2 羟自由基清除能力的测定

参考文献[18−19]的方法,制备不同浓度梯度(0.25,0.5,1.0,1.5,2.0,2.5 mg/mL)的粗多糖溶液,取1~5号试管,加入2 mL多糖溶液,再依次加入9.0 mmol/L FeSO4 溶液、9.0 mmol/L 水杨酸乙醇液、8.8 mmol/L H2O2溶液各2.0 mL,摇匀,在室温下放置30 min待其稳定,紫外分光光度计510 nm处测定不同浓度多糖溶液吸光度值,维生素C溶液作对照液,计算羟自由基清除率:

清除率(%)=(A0−A1+A2)/A0×100 (13) 式中:A0为空白对照品在510 nm处的吸光值;A1为样品溶液在510 nm处的吸光值;A2为多糖溶液不加显色剂H2O2在510 nm处的吸光值。

1.2.7.3 氧化自由基清除能力的测定

根据文献[20]的方法,取荧光96孔板,分别做对照组、标准曲线组、样品组。三组同时加入荧光素盐(700 nmol/mL)40 μL,对照组加入20 μL磷酸盐缓冲液,标准曲线组加入20 μL水溶性VE衍生物Trolox(200 μmol/mL),样品组加入20 μL待测样品。37 ℃烘箱孵育15 min,阴性对照组加入140 μL磷酸盐缓冲液,其他待测孔全部加入140 μL AAPH(12 mmol/mL)。迅速用酶标仪进行测量。在485 nm激发条件下,538 nm发射波长处记录荧光发射强度的变化。从0 min开始,每隔2 min测量一次,记录120 min,计算样品荧光变化零阶矩曲线下面积(area under curve,AUC),并绘制Trolox标准曲线,计算样品ORAC值:

AUC=1+f1/f0+f2/f0+f3/f0+⋯+fn/f0 (14) 式中:f1:初始荧光读数;fn:时间为一定时间(min)后荧光读数。

ORAC值=AUC样−AUC+AAPHAUCTrolox−AUC+AAPH×nTroloxnTrolox (15) 1.3 数据处理

所有单因素及响应面试验进行3组重复并取平均值,使用Origin8.0软件对获得的数据进行统计学分析,响应面设计和数据处理采用Design Expert12.0分析。

2. 结果与分析

2.1 单因素实验结果

2.1.1 料液比的确定

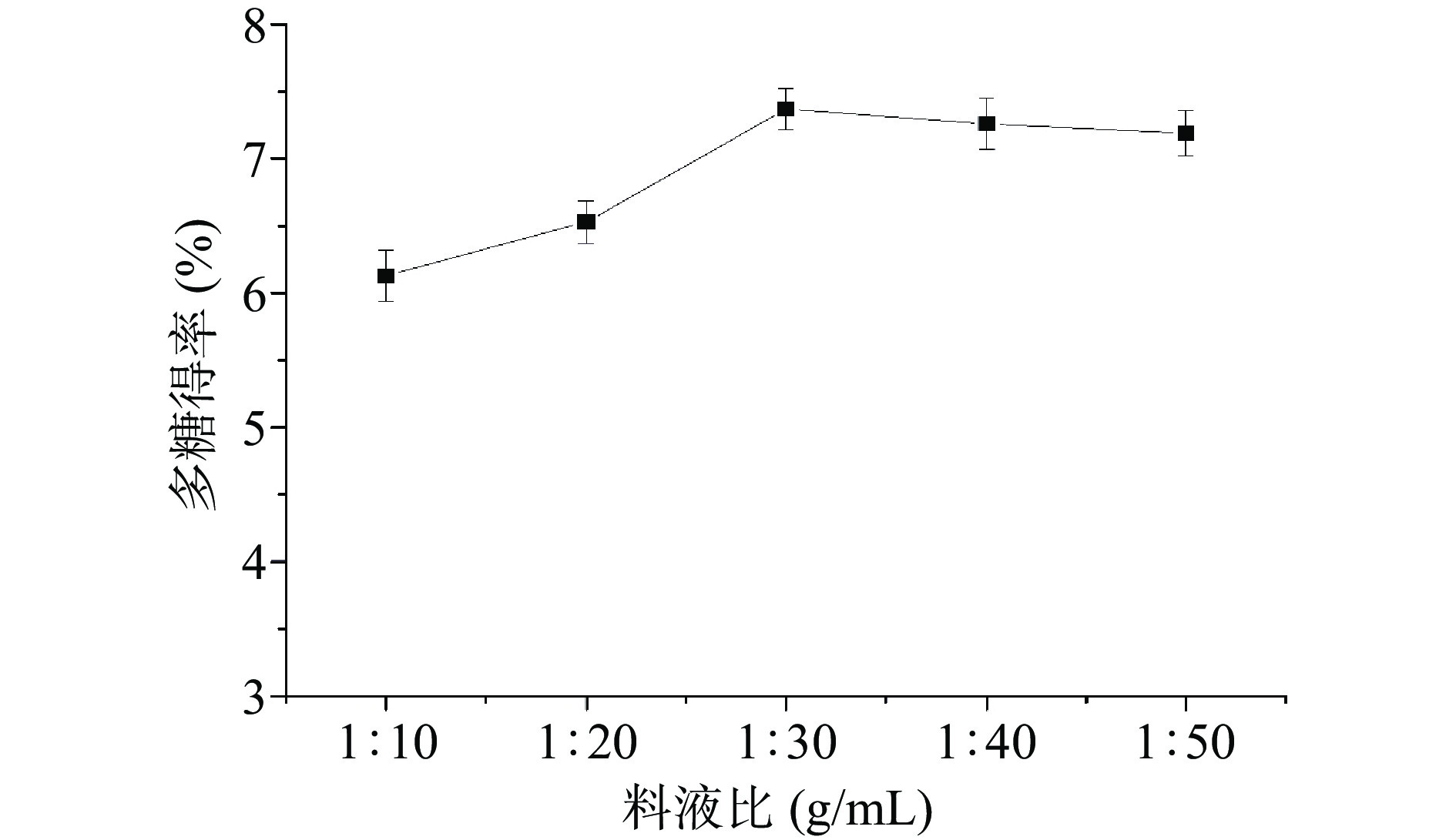

由图1可知,料液比在1:10~1:50 g/mL范围内,多糖得率随功率增大显著(P<0.05)增加。当料液比在1:30 g/mL时,多糖得率达到最大,可能是样品与溶剂的接触达到平衡,多糖不再析出;当料液比大于1:30 g/mL时,多糖得率不再继续升高,因为过多的加溶剂会导致杂质的溶出,从而抑制多糖的溶解[21]。所以,料液比控制在1:30 g/mL时为最佳。

2.1.2 酶添加量的确定

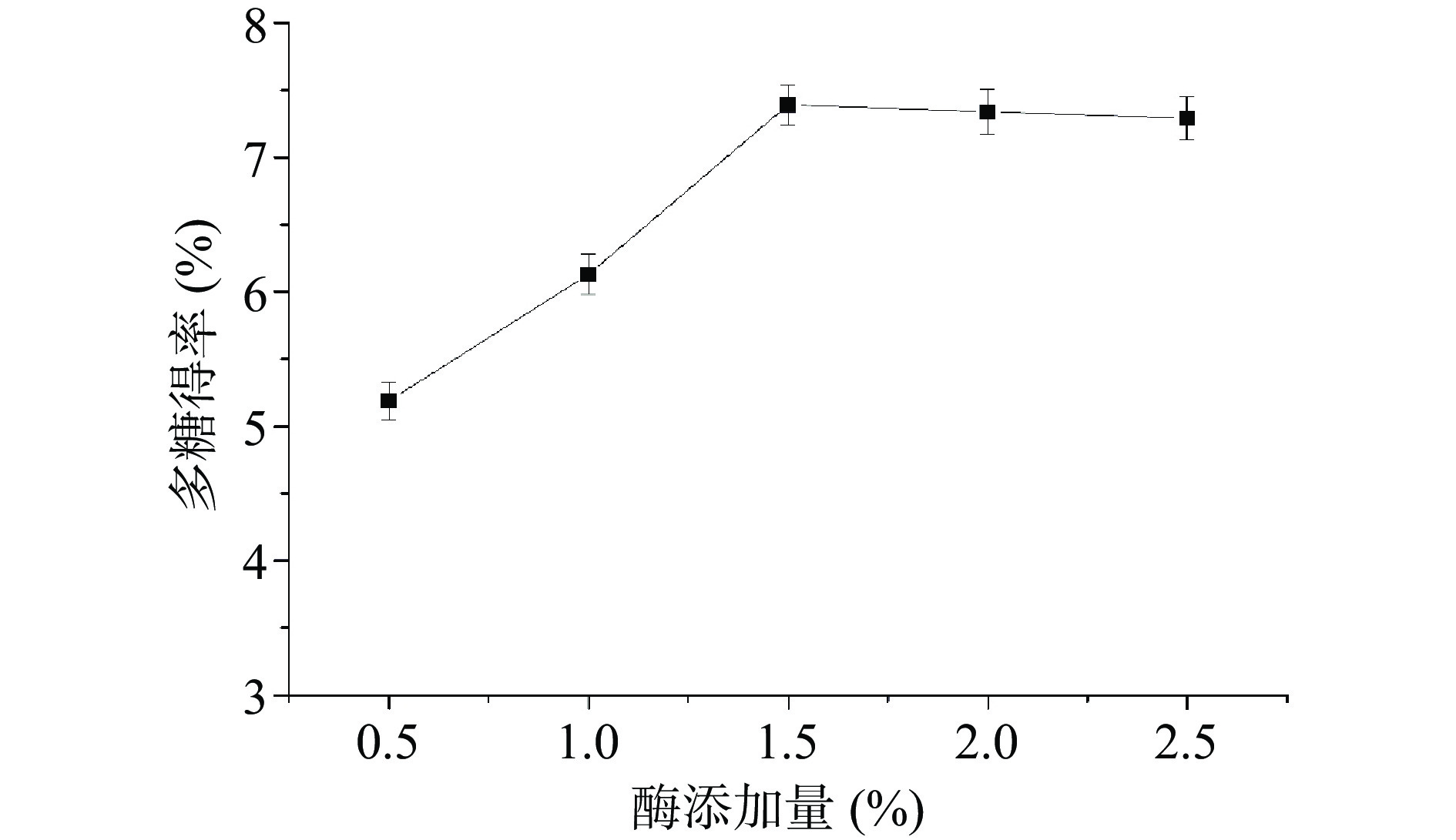

由图2可知,酶添加量在0.5%~1.5%范围内,多糖得率随酶添加量增加显著(P<0.05)增大。当酶添加量在1.5%时,多糖得率达到最大;当酶添加量大于1.5%时,多糖得率不再因为酶添加量增多继续升高,可能是在固定量的原料下,酶添加量已经最大化,对于多糖的溶出不再起作用。所以,酶添加量在1.5%时为最佳。

2.1.3 酶解温度的确定

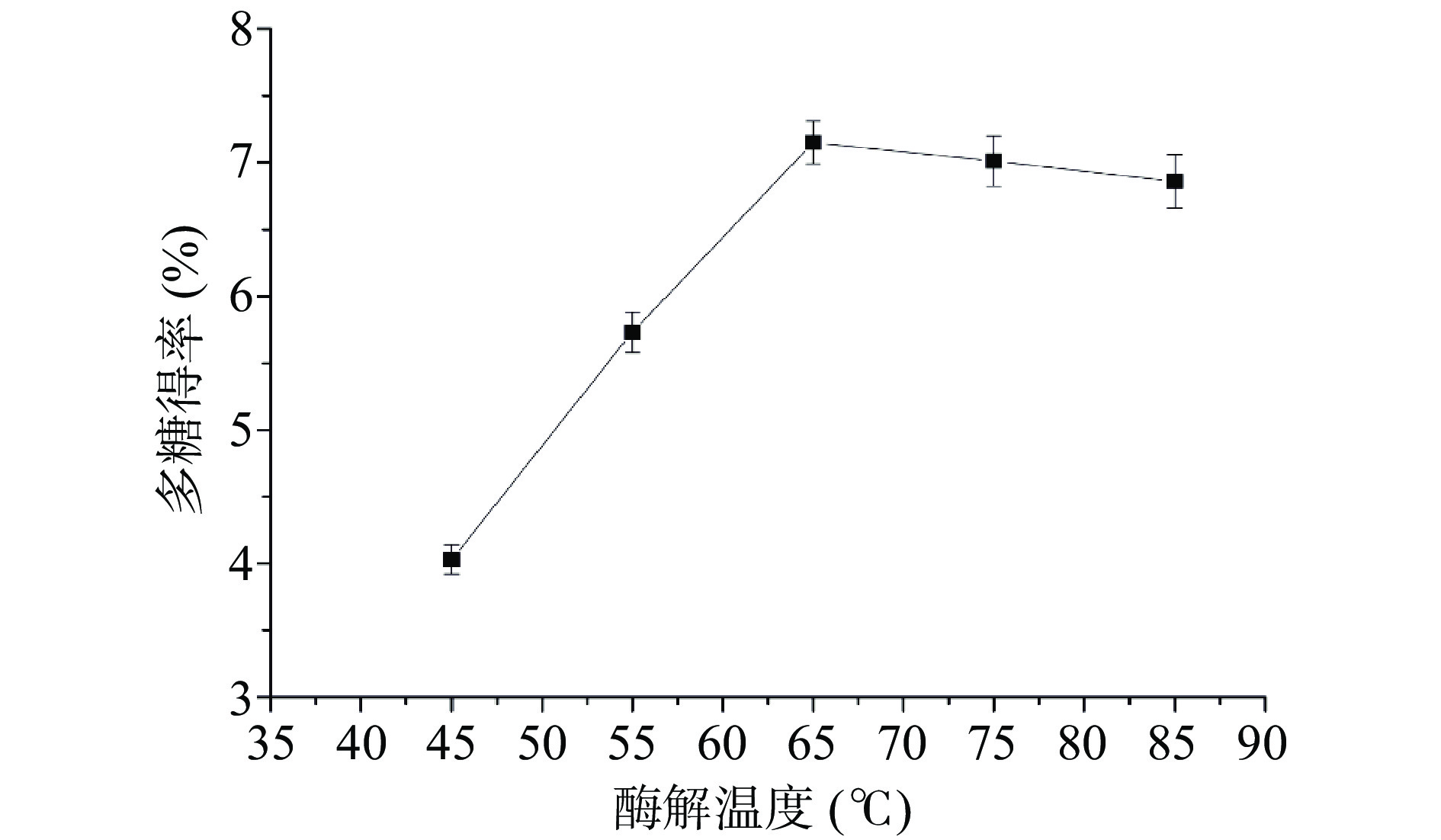

由图3可知,酶解温度在45~65 ℃范围内,多糖得率随酶解温度增加显著(P<0.05)增加。当酶解温度在65 ℃时,多糖得率达到最大;当酶解温度大于65 ℃时,多糖得率不再因为酶解温度增多继续升高,可能是因为温度太高,部分多糖出现降解。所以,酶解温度在65 ℃时为最佳。

2.1.4 提取时间的确定

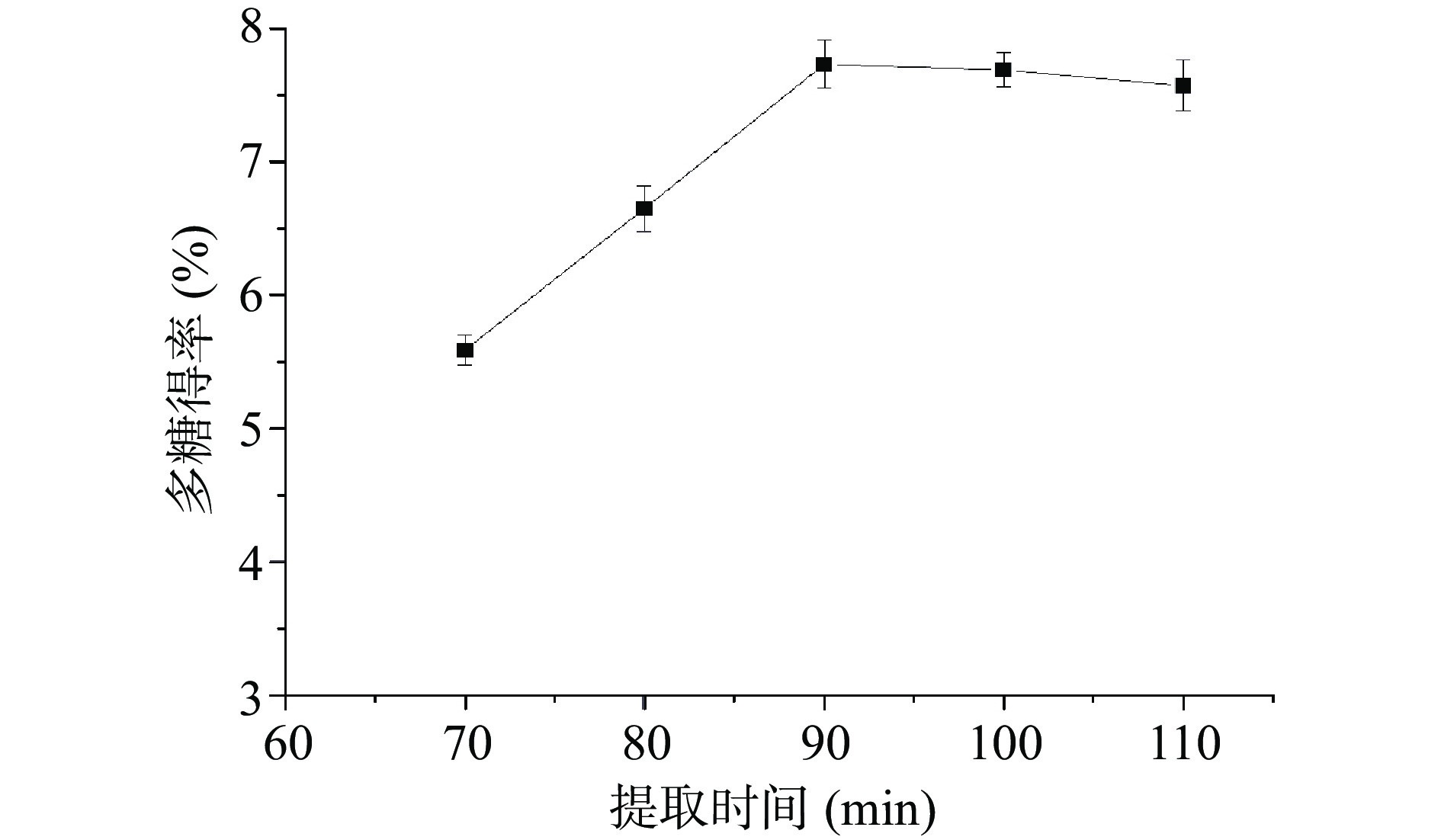

由图4可知,提取时间在70~90 min范围内,多糖得率随提取时间增加显著(P<0.05)上升。当提取时间在90 min时,多糖得率达到最大;当提取时间大于90 min时,多糖得率不再因为提取时间增加继续升高,还出现下降趋势,可能是在90 min内多糖溶解率达到最优。所以,提取时间在90 min时为最佳。

2.2 响应面试验

2.2.1 响应面试验结果分析

根据Design expert软件,设计出四因素三水平响应面试验,共29个试验点,详细方案如下表2,方差分析见表3,根据拟合结果,得到多糖得率Y的回归方程:

表 2 各因素响应面试验设计与结果Table 2. Response surface design and results for each factor实验号 A B C D 多糖得率(%) 1 −1 −1 0 0 6.06 2 1 −1 0 0 6.65 3 −1 1 0 0 6.72 4 1 1 0 0 7.04 5 0 0 −1 −1 6.16 6 0 0 1 −1 6.75 7 0 0 −1 1 6.48 8 0 0 1 1 6.89 9 −1 0 0 −1 6.59 10 1 0 0 −1 6.73 11 −1 0 0 1 6.71 12 1 0 0 1 7.12 13 0 −1 −1 0 6.03 14 0 1 −1 0 6.35 15 0 −1 1 0 6.49 16 0 1 1 0 7.20 17 −1 0 −1 0 6.12 18 1 0 −1 0 6.60 19 −1 0 1 0 6.84 20 1 0 1 0 6.90 21 0 −1 0 −1 6.16 22 0 1 0 −1 6.77 23 0 −1 0 1 6.51 24 0 1 0 1 6.99 25 0 0 0 0 7.98 26 0 0 0 0 7.90 27 0 0 0 0 7.93 28 0 0 0 0 7.88 29 0 0 0 0 7.88 表 3 各因素回归方程的方差分析Table 3. Variance analysis of regression equations of various factors方差来源 平方和 自由度 均方 F值 P值 显著性 模型 9.51 14 0.6794 156.11 <0.0001 ** A-料液比 0.3333 1 0.3333 76.59 <0.0001 ** B-酶添加量 0.8374 1 0.8374 192.42 <0.0001 ** C-酶解温度 0.9241 1 0.9241 212.33 <0.0001 ** D-提取时间 0.1976 1 0.1976 45.41 <0.0001 ** AB 0.0182 1 0.0182 4.19 0.0600 AC 0.0441 1 0.0441 10.13 0.0066 ** AD 0.0182 1 0.0182 4.19 0.0600 BC 0.038 1 0.038 8.74 0.0104 * BD 0.0042 1 0.0042 0.9708 0.3412 CD 0.0081 1 0.0081 1.86 0.1940 A2 2.08 1 2.08 477.76 <0.0001 ** B2 3.22 1 3.22 740.62 <0.0001 ** C2 3.41 1 3.41 783.24 <0.0001 ** D2 2.29 1 2.29 525.3 <0.0001 ** 残差 0.0609 14 0.0044 失拟项 0.0538 10 0.0054 3.02 0.1489 纯误差 0.0071 4 0.0018 总和 9.57 28 注:**表示极显著(P<0.01);*表示显著(P<0.05)。 Y=7.91+0.1667A+0.2642B+0.2775C+0.1283D−0.0675AB−0.1050AC+0.0675AD+0.0975BC−0.0325BD−0.0450CD−0.5662A2−0.7049B2−0.7249C2−0.5937D2

由表3可知:本数据模型P<0.0001,失拟项P(0.1489)>0.05,说明该试验模型成立。A(料液比)、B(酶添加量)、C(酶解温度)、D(酶解时间)四个因素P值均小于0.001,说明本文选定的四个因素对蝉花虫草多糖得率有显著的影响;其中R2=0.9936,R2adj=0.9873,CV=0.96%,说明该实验拟合效果较好,误差小,准确度高,外界因素对多糖得率影响较小,可以用此模型对提取目标多糖工艺参数进行优化。通过F值,可以看出每个单因素对多糖得率的影响为:C>B>A>D,即酶解温度>酶添加量>料液比>提取时间。

2.2.2 交互作用分析

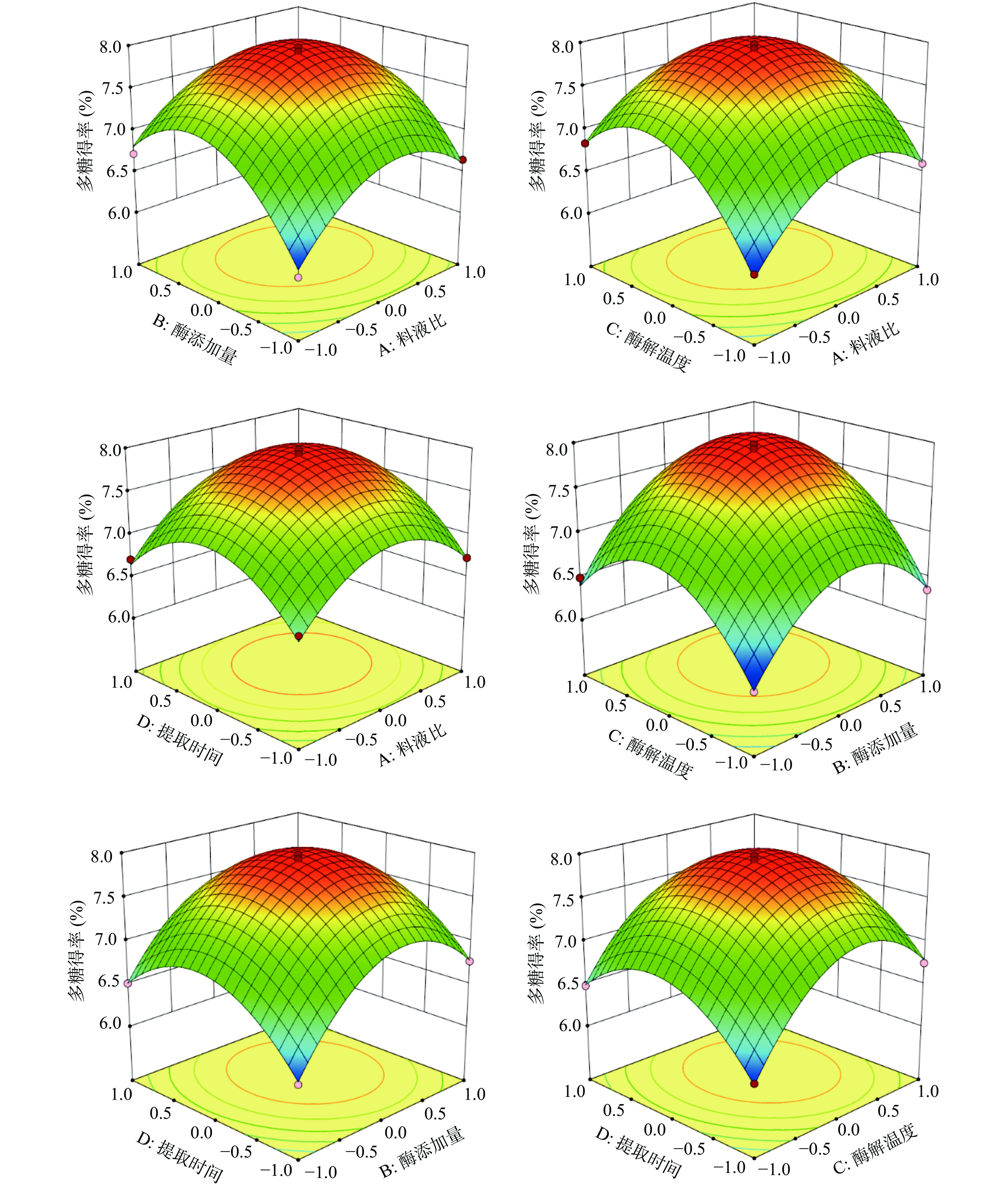

通过响应面软件得到的响应面曲面图见图5,可以看到两因素交互结果对人工培育蝉花多糖的影响。由文献[22−23]得知,响应曲面图和等高线图均可显示不同因素对结果的影响,响应曲面图中曲线越陡,说明该因素对结果影响越大;等高线接近椭圆说明两因素的交互作用显著。由图5可知,A(料液比)与C(酶解温度)、B(酶添加量)与C(酶解温度)这两组响应图曲线陡峭,且等高线成椭圆,表明这两组因素交互作用对目标多糖得率影响显著,与表3方差结果一致,更加证实了该数学模型的准确性。

2.2.3 响应面试验的优化及验证

通过本次研究可知,人工培育蝉花多糖得率是文献[24]报道的天然蝉花得率1.18倍。根据响应面试验模型,得到多糖提取最佳工艺预测值:料液比为1:30 g/mL、酶添加量为1.596%、酶解温度为66.92 ℃、提取时间为91.03 min,人工培育蝉花预测提取得率为7.99%。结合实际生产情况,将试验条件改成料液比1:30 g/mL、酶添加量为1.6%、酶解温度为67 ℃、提取时间为90 min,进行3次以上平行试验,得到多糖得率平均值为7.91%,与理论值相差较小,再次说明本次响应面模型对优化人工培育蝉花多糖的提取工艺具有一定的可行性。

2.3 人工培育蝉花提取多糖的动力学分析

2.3.1 速率常数求解

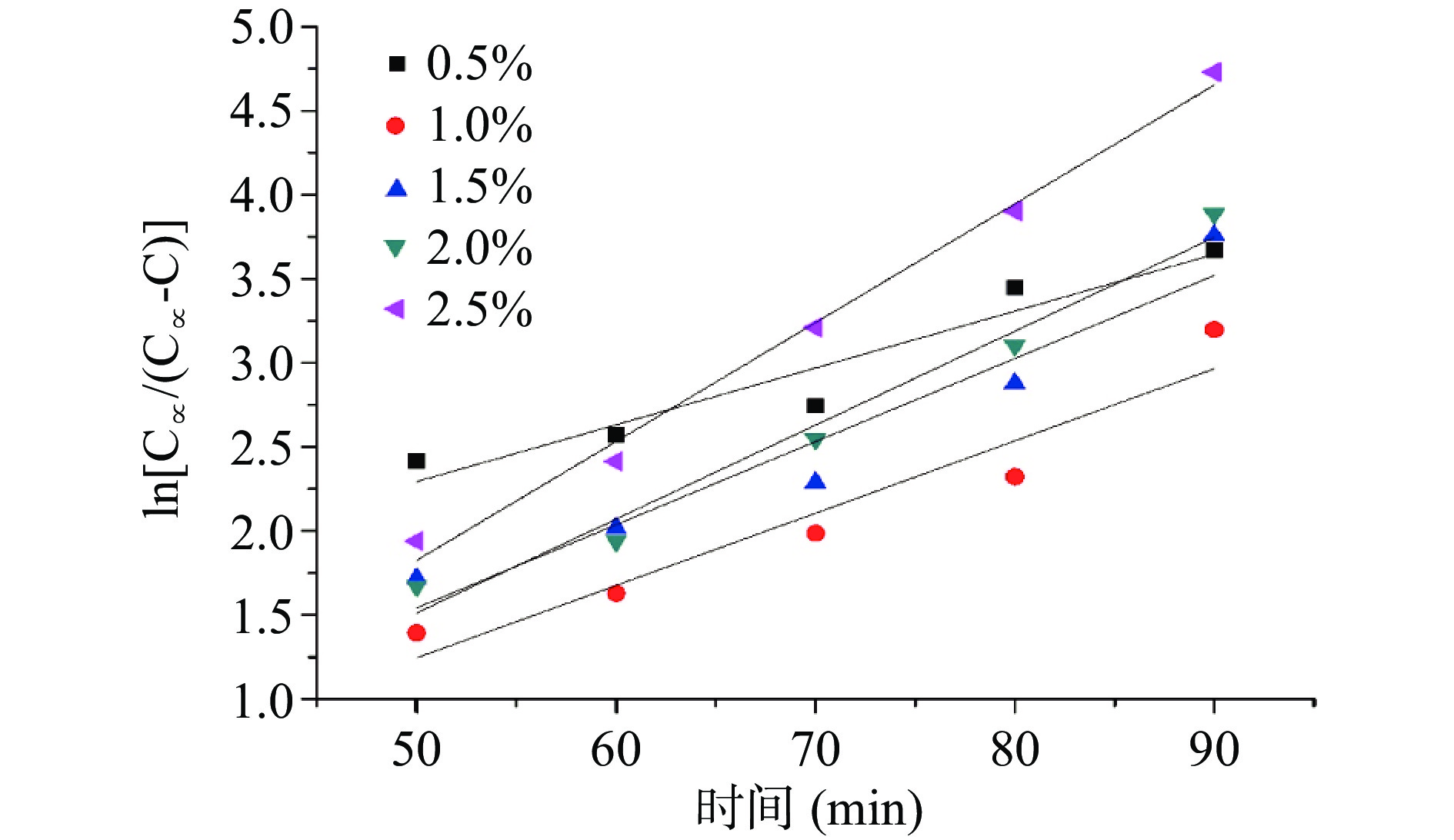

研究了不同酶添加量下,多糖得率随时间的变化。根据表4可知,多糖得率随着时间的增加而增加,100 min时得率已经达到平衡,将100 min时的得率设为平衡得率C∞。取ln[C∞/(C∞−C)]和时间t作图(图6),随着酶添加量增加,得率也在不断提高,说明ln[C∞/(C∞−C)]和t呈线性依赖关系。由此可知,人工培育蝉花多糖的提取过程符合Fick第二定律。通过图6的回归方程可得到表5,根据表5的拟合系数(R2>0.9),说明该模型拟合较好。同时得到了在不同酶添加量下速率常数K值,并随着酶添加量增多而变大,这是因为木瓜蛋白酶的添加有效分解人工培育蝉花菌丝壁上的蛋白以及游离蛋白,更好地使目标多糖溶解[25]。

表 4 不同酶添加量对多糖提取效果的影响Table 4. Polysaccharide extraction rate under different enzyme addition酶添加量(%) 多糖得率(%) 50 min 60 min 70 min 80 min 90 min 100 min 0.5 4.29 4.35 4.407 4.56 4.71 4.81 1.0 4.601 4.92 5.28 5.52 5.87 6.12 1.5 5.98 6.32 6.55 6.88 7.12 7.29 2.0 6.41 6.67 7.18 7.44 7.63 7.79 2.5 6.79 7.22 7.61 7.77 7.86 7.93 表 5 不同酶添加量下ln[C∞/(C∞−C)]与t的回归方程Table 5. Regression equation between ln[C∞/(C∞−C)] and t at different enzyme addition酶添加量(%) 回归方程 R2 C∞ K/10−4/s−1 0.5 y=0.0338x+0.6031 0.9271 4.81 5.63 1.0 y=0.043x−0.9055 0.9307 6.12 7.167 1.5 y=0.0495x−0.9301 0.9355 7.29 8.25 2.0 y=0.0567x−1.3442 0.9803 7.79 9.45 2.5 y=0.0707x+1.7103 0.9929 7.93 11.783 2.3.2 相对萃余率的求解

相对萃余率是多糖在某一条件下的残留值比上平衡时的得率,其数值越小,说明得率越大。基于表4数据,利用(C∞−C)/C∞与时间t作图得到如下图7,从图中拟合曲线显示,拟合方程精度良好(R2≥0.9),说明整个提取过程符合指数方程模型。进一步得知,相对萃余率常数与表5中速率常数的趋势一致,说明在不同酶添加量的条件下,多糖的得率随着时间增加而提高,该萃取过程与建立的动力学模型吻合。

2.3.3 半衰期

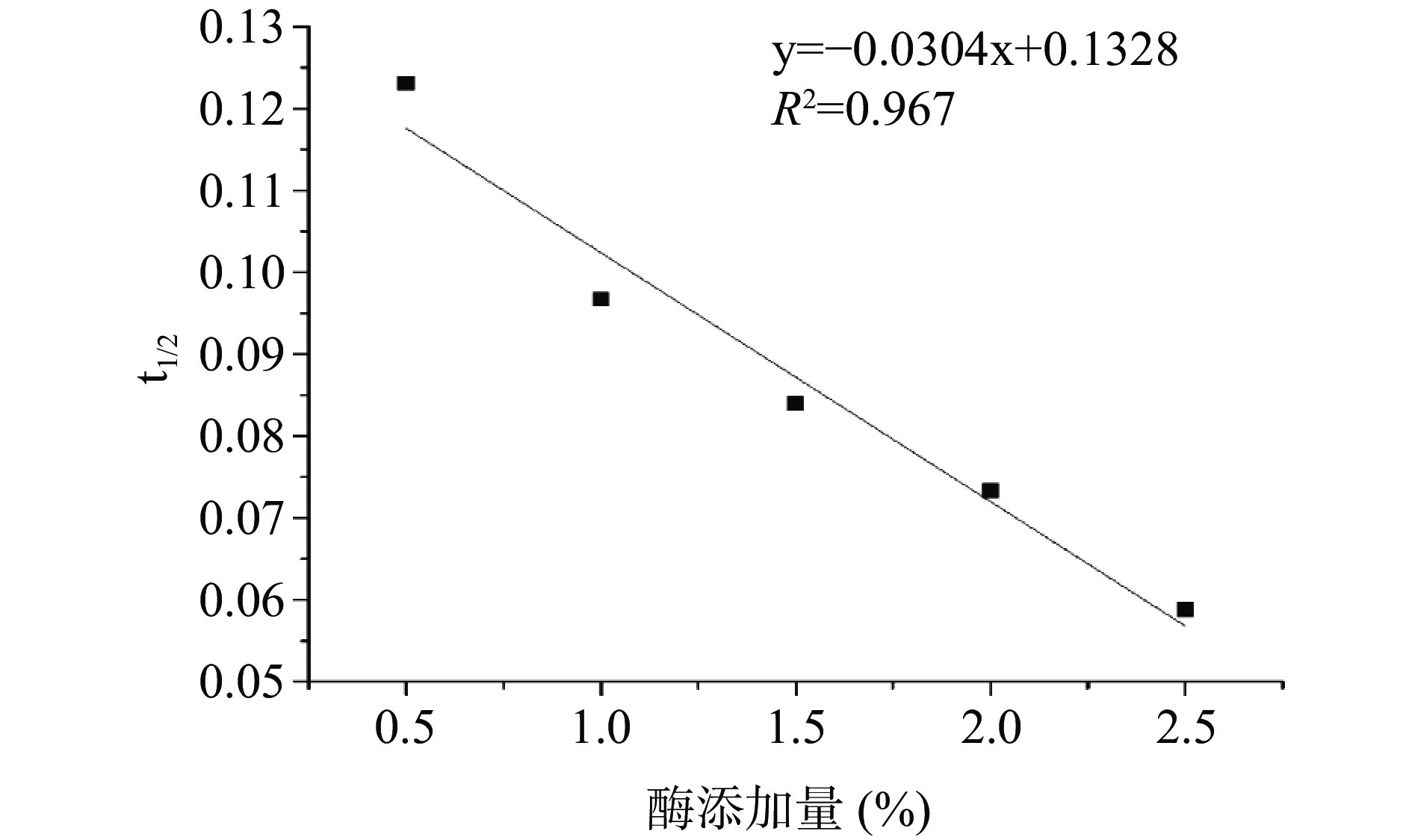

半衰期是指提取一半多糖所需要的时间。由t1/2=ln2/k对酶添加量作图。根据图8可知,半衰期与酶添加量成反比,通过酶的催化和能量的消耗,酶添加量越大,半衰期越小,越有利于人工培育蝉花中的蛋白分解,使多糖的溶出越快,从而t1/2值越低[26]。

2.4 热力学相关性质

根据单因素实验可知,酶添加量在1.5%的条件下,提得率达到最佳,所以,选酶添加量在1.5%的情况下进行热力学分析。如表6,根据热力学公式,求出活化能Ea=10.32 kJ/mol,ΔGm为−0.82~−13.49 kJ/mol,吉布斯能小于零,说明提取多糖的反应是一个不可逆的自发反应;ΔHm大于零,说明人工培育蝉花多糖的提取过程是一个吸热的反应[27]。研究表明,多糖得率与温度升高呈正相关。

表 6 人工培育蝉花多糖分布常数热力学参数Table 6. Thermodynamic parameters of distribution constants of artificially-cultivated Cordyceps cicadaeT(K) K Ea(kJ/mol) ΔGm(kJ/mol) ΔHm(kJ/mol) ΔSm(J/mol) 318.15 0.278 10.32 −13.49 7.681 0.066 328.15 0.359 −12.59 338.15 0.512 −7.81 348.15 0.643 −5.34 358.15 0.785 −0.82 2.5 人工培育蝉花体外抗氧化活性分析

2.5.1 DPPH 自由基清除率

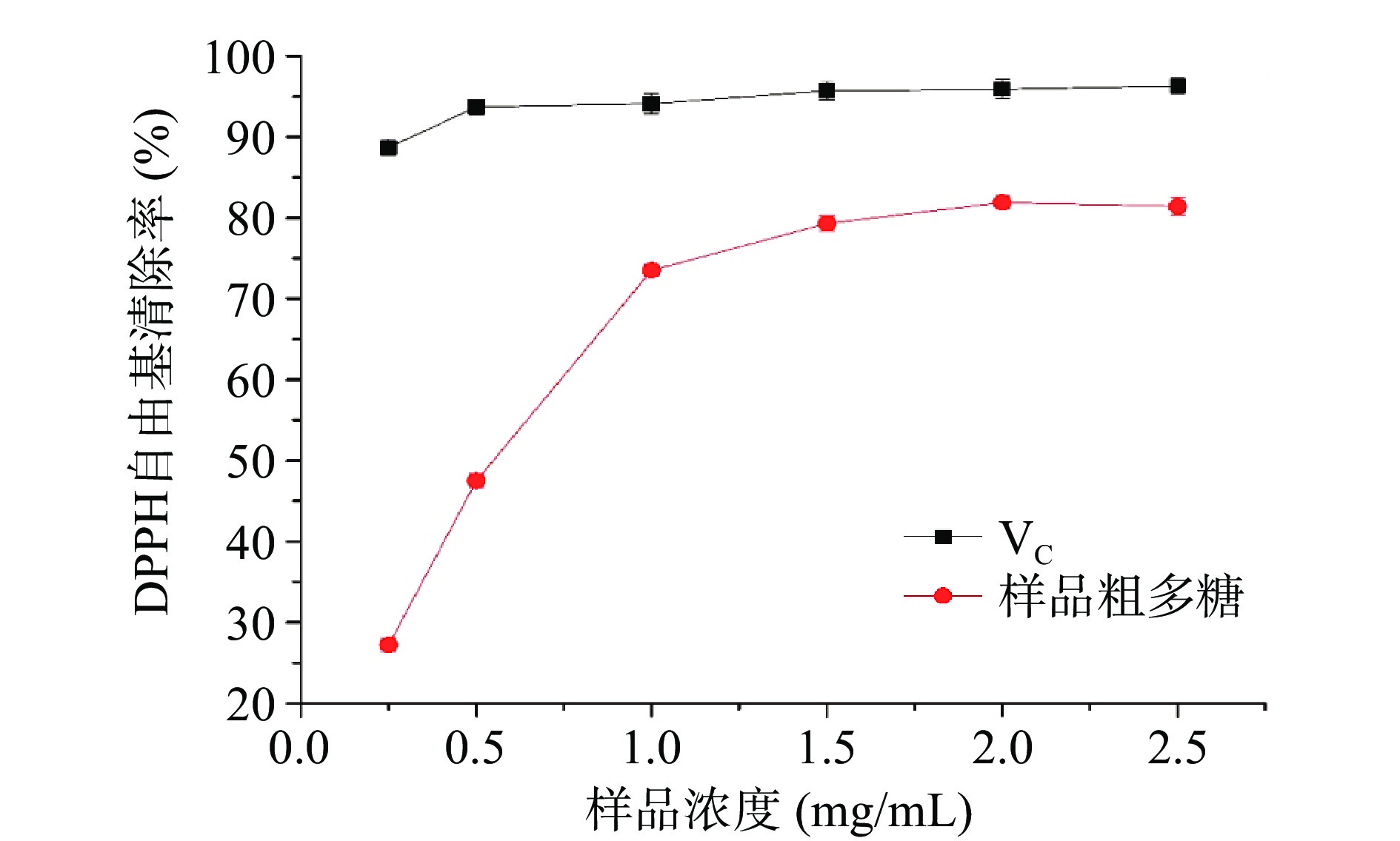

DPPH 是较为常用的考察活性物质的抗氧化能力的药理模型[28−29]。由图9可知,在0.25~2.5 mg/mL范围内,人工培育蝉花粗多糖溶液随着浓度增大,对DPPH自由基清除能力也逐渐升高;当多糖溶液浓度为1.0 mg/mL,对DPPH自由基清除率达到81.9%,通过计算得到其IC50数值:0.54 mg/mL,其抗氧化活性高于浙江金蝉花[30]。结果表明,人工培育蝉花具有良好的抗氧化性。但是相对于维生素C对照液的抗氧化性还是较弱。

2.5.2 羟自由基清除率

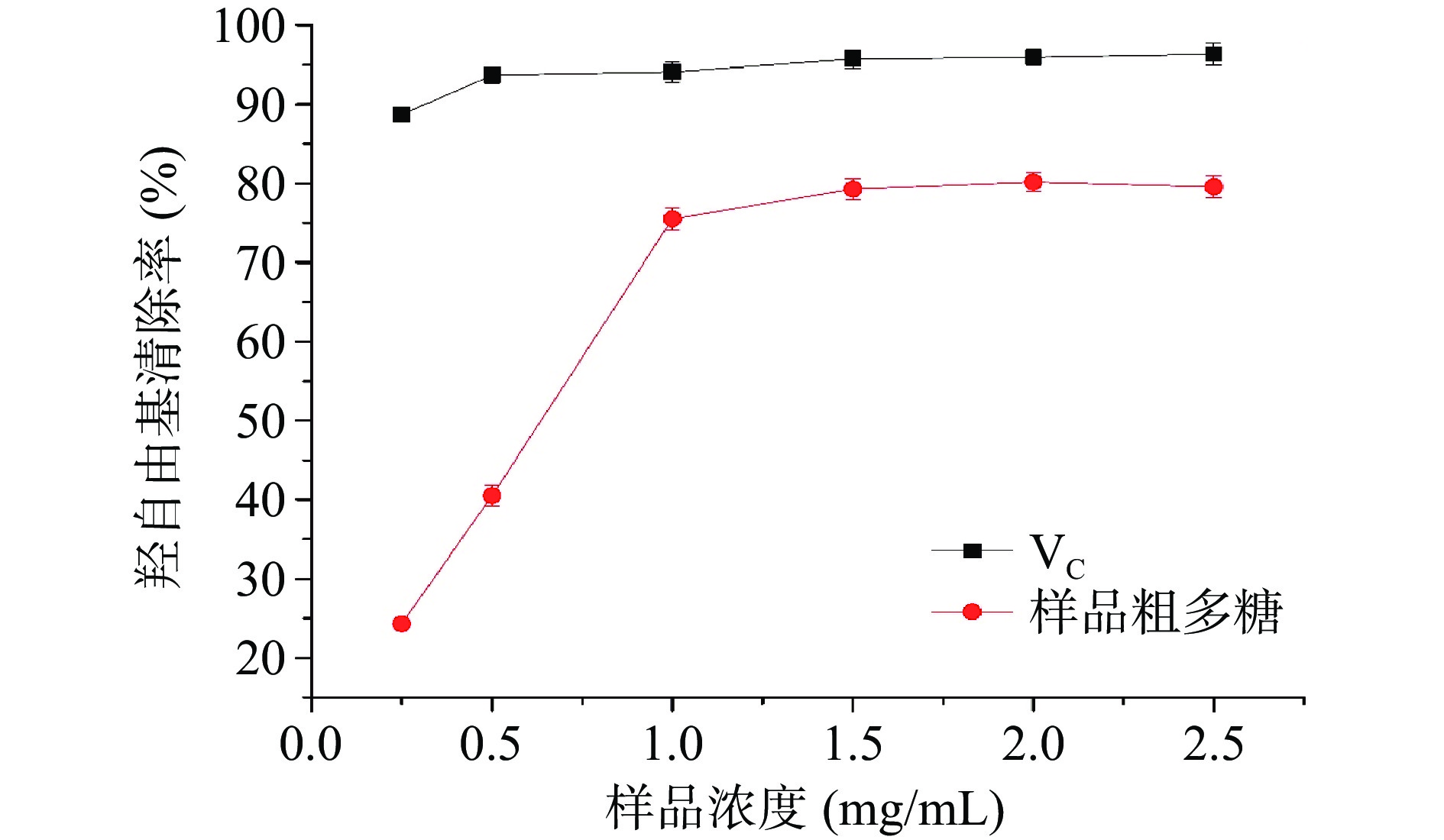

羟自由基和DPPH自由基一样,经常被作为常用的考察物质的抗氧化能力的模型[31]。由图10可知,在0.25~2.5 mg/mL范围内,人工培育蝉花粗多糖溶液随着浓度增大,对羟自由基清除能力也逐渐升高,当多糖溶液浓度为1.0 mg/mL,对羟自由基清除率达到80.2%,得到其IC50为0.60 mg/mL,高于江苏野生金蝉花[32]。结果表明,人工培育蝉花具有良好的抗氧化性。但是相对于维生素C对照组的抗氧化性还是较弱。

2.5.3 氧化自由基的吸收能力

以维生素E(Trolox)浓度为横坐标,以当量的形式代表药物的抗氧化能力,NetAUC为纵坐标,为相对曲线面积,制定标准曲线[33]。如图11,该标准曲线y=0.8981x+2.8097,R2=0.9572,表明该标准曲线有良好的线性关系,将样品的NetAUC值大入标准曲线中,得到对应的Trolox浓度值,计算氧自由基数值。用Trolox(μmol/g)表示样自由基吸收能力,根据标准曲线得到人工培育蝉花粗多糖的ORAC值为45.62 Trolox μmol/g,说明人工培育蝉花具有良好的抗氧化活性。

3. 结论

本实验以商业化的人工培育蝉花为原料,利用酶法辅助提取其活性多糖组分,从单因素实验结果发现,各因素对多糖得率均有显著影响;结合响应面优化法,建立了适合人工培育蝉花多糖的数学模型,该模型具有良好的稳定性和准确性,其中对多糖得率影响最大的是酶解温度,其次是酶添加量、料液比和提取时间。结合实际生产最终获得最佳提取工艺:料液比1:30 g/mL、酶添加量1.6%、酶解温度67 ℃、提取时间90 min,多糖的得率达到7.91%。基于Fick第二定律,本文对其进行动力学研究,通过速率常数、相对萃余率等数据,说明在不同酶添加量的条件下,增加时间有助于多糖的溶出。根据热力学参数:Ea、ΔGm、ΔHm、ΔSm表示此过程是自发吸热的反应。通过体外抗氧化实验,DPPH自由基和羟自由基的IC50值分别是:0.54、0.60 mg/mL,说明人工培育蝉花具有良好的抗氧化性。本实验首次利用酶法提取人工培育蝉花多糖,既解决低得率问题,又结合了酶提法的多效性,为进一步工业化开发人工培育蝉花多糖提供理论依据。

-

表 1 响应面试验因素与水平

Table 1 Factors and levels of response surface test

水平因素 A料液比

(g/mL)B酶添加量

(%)C酶解温度

(℃)D提取时间

(min)−1 1:20 1.0 55 80 0 1:30 1.5 65 90 1 1:40 2.0 75 100 表 2 各因素响应面试验设计与结果

Table 2 Response surface design and results for each factor

实验号 A B C D 多糖得率(%) 1 −1 −1 0 0 6.06 2 1 −1 0 0 6.65 3 −1 1 0 0 6.72 4 1 1 0 0 7.04 5 0 0 −1 −1 6.16 6 0 0 1 −1 6.75 7 0 0 −1 1 6.48 8 0 0 1 1 6.89 9 −1 0 0 −1 6.59 10 1 0 0 −1 6.73 11 −1 0 0 1 6.71 12 1 0 0 1 7.12 13 0 −1 −1 0 6.03 14 0 1 −1 0 6.35 15 0 −1 1 0 6.49 16 0 1 1 0 7.20 17 −1 0 −1 0 6.12 18 1 0 −1 0 6.60 19 −1 0 1 0 6.84 20 1 0 1 0 6.90 21 0 −1 0 −1 6.16 22 0 1 0 −1 6.77 23 0 −1 0 1 6.51 24 0 1 0 1 6.99 25 0 0 0 0 7.98 26 0 0 0 0 7.90 27 0 0 0 0 7.93 28 0 0 0 0 7.88 29 0 0 0 0 7.88 表 3 各因素回归方程的方差分析

Table 3 Variance analysis of regression equations of various factors

方差来源 平方和 自由度 均方 F值 P值 显著性 模型 9.51 14 0.6794 156.11 <0.0001 ** A-料液比 0.3333 1 0.3333 76.59 <0.0001 ** B-酶添加量 0.8374 1 0.8374 192.42 <0.0001 ** C-酶解温度 0.9241 1 0.9241 212.33 <0.0001 ** D-提取时间 0.1976 1 0.1976 45.41 <0.0001 ** AB 0.0182 1 0.0182 4.19 0.0600 AC 0.0441 1 0.0441 10.13 0.0066 ** AD 0.0182 1 0.0182 4.19 0.0600 BC 0.038 1 0.038 8.74 0.0104 * BD 0.0042 1 0.0042 0.9708 0.3412 CD 0.0081 1 0.0081 1.86 0.1940 A2 2.08 1 2.08 477.76 <0.0001 ** B2 3.22 1 3.22 740.62 <0.0001 ** C2 3.41 1 3.41 783.24 <0.0001 ** D2 2.29 1 2.29 525.3 <0.0001 ** 残差 0.0609 14 0.0044 失拟项 0.0538 10 0.0054 3.02 0.1489 纯误差 0.0071 4 0.0018 总和 9.57 28 注:**表示极显著(P<0.01);*表示显著(P<0.05)。 表 4 不同酶添加量对多糖提取效果的影响

Table 4 Polysaccharide extraction rate under different enzyme addition

酶添加量(%) 多糖得率(%) 50 min 60 min 70 min 80 min 90 min 100 min 0.5 4.29 4.35 4.407 4.56 4.71 4.81 1.0 4.601 4.92 5.28 5.52 5.87 6.12 1.5 5.98 6.32 6.55 6.88 7.12 7.29 2.0 6.41 6.67 7.18 7.44 7.63 7.79 2.5 6.79 7.22 7.61 7.77 7.86 7.93 表 5 不同酶添加量下ln[C∞/(C∞−C)]与t的回归方程

Table 5 Regression equation between ln[C∞/(C∞−C)] and t at different enzyme addition

酶添加量(%) 回归方程 R2 C∞ K/10−4/s−1 0.5 y=0.0338x+0.6031 0.9271 4.81 5.63 1.0 y=0.043x−0.9055 0.9307 6.12 7.167 1.5 y=0.0495x−0.9301 0.9355 7.29 8.25 2.0 y=0.0567x−1.3442 0.9803 7.79 9.45 2.5 y=0.0707x+1.7103 0.9929 7.93 11.783 表 6 人工培育蝉花多糖分布常数热力学参数

Table 6 Thermodynamic parameters of distribution constants of artificially-cultivated Cordyceps cicadae

T(K) K Ea(kJ/mol) ΔGm(kJ/mol) ΔHm(kJ/mol) ΔSm(J/mol) 318.15 0.278 10.32 −13.49 7.681 0.066 328.15 0.359 −12.59 338.15 0.512 −7.81 348.15 0.643 −5.34 358.15 0.785 −0.82 -

[1] 李思迪, 盛益华, 张忠亮, 等. 蝉花水提物及蝉花复方对小鼠免疫功能影响的实验研究[J]. 药物评价研究,2020,43(4):636−641. [LI S D, SHENG Y H, ZHANG Z L, et al. Experimental study on effect of Cicada flower water extract and Cicada flower compound on immune function in mice[J]. Drug Evaluation Research,2020,43(4):636−641.] LI S D, SHENG Y H, ZHANG Z L, et al . Experimental study on effect of Cicada flower water extract and Cicada flower compound on immune function in mice[J]. Drug Evaluation Research,2020 ,43 (4 ):636 −641 .[2] 韦朝阳, 贺亮, 李卫旗, 等. 不同中药水提物对蝉拟青霉液体深层发酵和产物活性的影响[J]. 食品工业科技,2015,36(3):168−171,177. [WEI C Y, HE L, LI W Q, et al. Effects of different kinds of aqueous herbal extracts on submerged fermentation and product activity of Paecilomyces cicadae[J]. Science and Technology of Food Industry,2015,36(3):168−171,177.] WEI C Y, HE L, LI W Q, et al . Effects of different kinds of aqueous herbal extracts on submerged fermentation and product activity of Paecilomyces cicadae[J]. Science and Technology of Food Industry,2015 ,36 (3 ):168 −171,177 .[3] 韦朝阳. 蝉拟青霉深层发酵及其胞内多糖的结构研究[D]. 杭州:浙江大学, 2015. [WEI C Y. Study on the submerged fermentation of Pacecilomyces cicadae and structural characterization of intracellular polvsaccharide[D]. Hangzhou:Zhejiang University, 2015.] WEI C Y. Study on the submerged fermentation of Pacecilomyces cicadae and structural characterization of intracellular polvsaccharide[D]. Hangzhou: Zhejiang University, 2015.

[4] 杨文雅, 李长征, 张海晖, 等. 蛹虫草多糖的亚临界水萃取及其抗氧化活性研究[J]. 食品工业科技,2016(5):252−253. [YANG W Y, LI C Z, ZHANG H H, et al. Study on the optimization for the extraction and antioxidant activity of polysaccharide from Cordyceps militaris by subcritical water[J]. Science and Technology of Food Industry,2016(5):252−253.] YANG W Y, LI C Z, ZHANG H H, et al . Study on the optimization for the extraction and antioxidant activity of polysaccharide from Cordyceps militaris by subcritical water[J]. Science and Technology of Food Industry,2016 (5 ):252 −253 .[5] 谢飞, 李伟, 陈美珍, 等. 野生蝉花多糖抗肿瘤活性及其作用机制[J]. 食品科学,2016,37(13):209−213. [XIE F, LI W, CHEN M Z, et al. Antitumor activity and mechanism of action of Wild Cordyceps sobolifera polysaccharide[J]. Food Science,2016,37(13):209−213.] XIE F, LI W, CHEN M Z, et al . Antitumor activity and mechanism of action of Wild Cordyceps sobolifera polysaccharide[J]. Food Science,2016 ,37 (13 ):209 −213 .[6] 解思友, 尹彬, 龙文君, 等. 蝉花及其成分增强免疫、抗肿瘤药理作用研究进展[J]. 药物评价研究,2020,43(4):624−629. [XIE S Y, YIN B, LONG W J, et al. Research progress of Cicada flower and its components in enhancing immunity and anti-tumor pharmacology[J]. Drug Evaluation Research,2020,43(4):624−629.] XIE S Y, YIN B, LONG W J, et al . Research progress of Cicada flower and its components in enhancing immunity and anti-tumor pharmacology[J]. Drug Evaluation Research,2020 ,43 (4 ):624 −629 .[7] 秦文平, 慕程, 殷世鹏. 中药蝉花的化学成分及药理作用研究进展[J]. 中国中医药图书情报杂志,2019,43(4):73−76. [QIN W P, MU C, YIN S P. Research progress of chemical components and pharmacological effects of Isaria cicadae Miquel[J]. Chinese Journal of Library and Information Science for Traditional Chinese Medicine,2019,43(4):73−76.] QIN W P, MU C, YIN S P . Research progress of chemical components and pharmacological effects of Isaria cicadae Miquel[J]. Chinese Journal of Library and Information Science for Traditional Chinese Medicine,2019 ,43 (4 ):73 −76 .[8] 何晓波, 芦柏震, 周俐斐, 等. 蝉花总多糖对细胞免疫和体液免疫反应的促进作用[J]. 中华中医药学刊,2010,28(7):1465−1468. [HE X B, LU B Z, ZHOU L F, et al. The promoti on effects of polysaccharides from Cordyceps cicadae on the cellular and humoral immune responses[J]. Chinese Archives of Traditional Chinese Medicine,2010,28(7):1465−1468.] HE X B, LU B Z, ZHOU L F, et al . The promoti on effects of polysaccharides from Cordyceps cicadae on the cellular and humoral immune responses[J]. Chinese Archives of Traditional Chinese Medicine,2010 ,28 (7 ):1465 −1468 .[9] 刘森琴, 温鲁, 夏敏, 等. 人工培育蝉花的活性成分含量测定[J]. 安徽农业科学,2008,219(2):429−467. [LIU S Q, WEN L, XIA M, et al. Determination of the active ingredient produced in the artificial cultivated Cordyceps sobolifera[J]. Journal of AnHui Agricultural Sciences,2008,219(2):429−467.] LIU S Q, WEN L, XIA M, et al . Determination of the active ingredient produced in the artificial cultivated Cordyceps sobolifera[J]. Journal of AnHui Agricultural Sciences,2008 ,219 (2 ):429 −467 .[10] 刘于, 贺亮, 谢娜, 等. 雷竹笋壳多糖超声辅助酶法提取工艺及其抗氧化活性[J]. 现代食品,2022,28(11):56−62. [LIU Y, HE L, XIE N, et al. Ultrasound-assisted enzymatic extraction of polysaccharide from Bamboo shoots and its antioxidant activity[J]. Modern food,2022,28(11):56−62.] LIU Y, HE L, XIE N, et al . Ultrasound-assisted enzymatic extraction of polysaccharide from Bamboo shoots and its antioxidant activity[J]. Modern food,2022 ,28 (11 ):56 −62 .[11] 王占一, 赵静, 朱天顺, 等. 纤维素酶辅助提取藕节多糖工艺优化及其动力学、热力学研究[J]. 中成药, 2020, 42(4):836−842. [WANG Z Y, ZHAO J, ZHU T S, et al. Cellulase-assisted extraction process optimization, kinetics and thermodynamics of polysaccharides from Nelumbinis hizomatis Nodus[J]. Chinese Traditional Patent Medicine, 2020, 42(4):836−842.] WANG Z Y, ZHAO J, ZHU T S, et al. Cellulase-assisted extraction process optimization, kinetics and thermodynamics of polysaccharides from Nelumbinis hizomatis Nodus[J]. Chinese Traditional Patent Medicine, 2020, 42(4): 836−842.

[12] 刘刚, 梁琪, 宋雪梅, 等. 复合诱变选育高产胞外多糖嗜热链球菌菌株[J]. 食品与发酵科技,2019,55(1):11−18,70. [LIU G, LIANG Q, SONG X M, et al. Compound mutagenesis for the selection of strains of Streptococcus thermophilus with high extracellular polysaccharide production[J]. Food and Fermentation Technology,2019,55(1):11−18,70.] LIU G, LIANG Q, SONG X M, et al . Compound mutagenesis for the selection of strains of Streptococcus thermophilus with high extracellular polysaccharide production[J]. Food and Fermentation Technology,2019 ,55 (1 ):11 −18,70 .[13] GUO X H, LIU S H, WANG Z K, et al. Ultrasonic-assisted extraction of polysaccharide from Dendrobium officinale:Kinetics, thermodynamics and optimization[J]. Biochemical Engineering Journal, 2022(177):108227).

[14] LAZAR L, TALMACIU A I, VOLF I, et al. Kinetic modeling of the ultrasound-assisted extraction of polyphenols from Picea abies bark[J]. Ultrasonics Sonochemistry,2016,32:191−197. doi: 10.1016/j.ultsonch.2016.03.009

[15] RUBAIYI M T, PURANJAN M, SHABANA T, et al. High methoxyl pectin extracts from Hylocereus polyrhizus's peels:Extraction kinetics and thermodynamic studies[J]. International Journal of Biological Macromolecules,2019,141:1147−1157. doi: 10.1016/j.ijbiomac.2019.09.017

[16] 叶兆伟, 叶润, 赫丁轩, 等. 息半夏多糖提取工艺优化及其抗氧化活性研究[J]. 中国食品添加剂,2022,33(1):90−98. [YE Z W, YE R, HE D X, et al. Optimization of polysaccharide extraction from Xi Pinellia ternate by response surface methodology and its antioxidant activity[J]. China Food Additives,2022,33(1):90−98.] YE Z W, YE R, HE D X, et al . Optimization of polysaccharide extraction from Xi Pinellia ternate by response surface methodology and its antioxidant activity[J]. China Food Additives,2022 ,33 (1 ):90 −98 .[17] 郭毓菲, 张诗泉, 王汉迪, 等. 超声波法提取水溶性茯苓多糖工艺优化及其抗氧化活性探究[J]. 中国酿造,2018,37(12):160−164. [GUO Y F, ZHANG S Q, WANG H D, et al. Extraction technology optimization of water soluble Pachyman by ultrasonic method and its antioxidant activity[J]. China Brewing,2018,37(12):160−164.] GUO Y F, ZHANG S Q, WANG H D, et al . Extraction technology optimization of water soluble Pachyman by ultrasonic method and its antioxidant activity[J]. China Brewing,2018 ,37 (12 ):160 −164 .[18] 孟繁磊, 陈瑞战, 张敏, 等. 刺五加多糖的提取工艺及抗氧化活性研究[J]. 食品科学,2010,31(10):168−174. [MENG F L, CHEN R Z, ZHANG M, et al. Extraction and antioxidant activity of polysaccharides from Acanthopanacis senticosi leaves[J]. Food Science,2010,31(10):168−174.] MENG F L, CHEN R Z, ZHANG M, et al . Extraction and antioxidant activity of polysaccharides from Acanthopanacis senticosi leaves[J]. Food Science,2010 ,31 (10 ):168 −174 .[19] CHEN X Y, JI H Y, XU X M, et al. Optimization of polysaccharide extraction process from Grifola frondosa and its antioxidant and anti-tumor research[J]. Journal of Food Measurement and Characterization,2019,13(1):144−153. doi: 10.1007/s11694-018-9927-9

[20] 张颖, 曾艳, 张丽姣, 等. 不同食用菌菌糠多糖的组分分析与抗氧化活性评价[J]. 食品科学,2015,36(5):18−23. [ZHANG Y, ZENG Y, ZHANG L J, et al. Monosaccharide composition and antioxidant activity of polysaccharides from different spent Mushroom substrates[J]. Food Science,2015,36(5):18−23.] ZHANG Y, ZENG Y, ZHANG L J, et al . Monosaccharide composition and antioxidant activity of polysaccharides from different spent Mushroom substrates[J]. Food Science,2015 ,36 (5 ):18 −23 .[21] 王博, 孙润广, 张静. 超声波强化提取对茯苓水溶性多糖结构影响的研究[J]. 应用声学,2009,28(3):195−202. [WANG B, SUN R G, ZHANG J, et al. Effect of ultrasonic extraction on the structure of water-soluble polysaccharide from the sclerotium of Poriacocos[J]. Applied Acoustics,2009,28(3):195−202.] doi: 10.3969/j.issn.1000-310X.2009.03.007 WANG B, SUN R G, ZHANG J, et al . Effect of ultrasonic extraction on the structure of water-soluble polysaccharide from the sclerotium of Poriacocos[J]. Applied Acoustics,2009 ,28 (3 ):195 −202 . doi: 10.3969/j.issn.1000-310X.2009.03.007[22] 黄琼, 何燕萍. 铁皮石斛叶多糖提取工艺优化及其抗氧化活性[J]. 中国食品添加剂,2022,33(9):48−53. [HUANG Q, HE Y P. Optimization of extraction process of polysaccharides from Dendrobium officinale leaves and its antioxidant activity[J]. China Food Additives,2022,33(9):48−53.] HUANG Q, HE Y P . Optimization of extraction process of polysaccharides from Dendrobium officinale leaves and its antioxidant activity[J]. China Food Additives,2022 ,33 (9 ):48 −53 .[23] MURALIDHAR R V, CHIRUMAMILA R R, MARCHANTR, et al. A response surface approach for the comparison of lipase production by Candida cylindracea using two different carbon sources[J]. Biochemistry Engineering Journal,2001,9(1):17−23. doi: 10.1016/S1369-703X(01)00117-6

[24] 鲁吉珂, 古国峰, 汪瑞, 等. 蝉花多糖提取工艺优化研究[J]. 食品工业科技,2013,34(22):196−199. [LU J K, GU G F, WANG R, et al. Optimization of extraction of polysaccharide from Cordyceps sobolifera[J]. Science and Technology of Food Industry,2013,34(22):196−199.] LU J K, GU G F, WANG R, et al . Optimization of extraction of polysaccharide from Cordyceps sobolifera[J]. Science and Technology of Food Industry,2013 ,34 (22 ):196 −199 .[25] WANG Y, WANG X, ZhANG K, et al. Extraction kinetics, thermodynamics, rheological properties and anti-BVDV activity of Glycyrrhiza polysaccharide by hot water assisted extraction[J]. Food & Function,2020,11(5):4067−4080.

[26] WANG Y G, LIU J C, LIU X F, et al. Kinetic modeling of the ultrasonic-assisted extraction of polysaccharide from Nostoc commune and physicochemical properties analysis[J]. International journal of biological macromolecules,2019,128:421−428. doi: 10.1016/j.ijbiomac.2018.12.247

[27] WANG Y G, ZHANG X, MA X Q, et al. Study on the kinetic model, thermodynamic and physicochemical properties of Glycyrrhiza polysaccharide by ultrasonic assisted extraction[J]. Ultrasonics Sonochemistry,2019,51:249−257. doi: 10.1016/j.ultsonch.2018.10.012

[28] 王娟, 袁绍莉, 王丹. Box-Behnken响应面法优化枇杷叶多糖提取工艺及其抗氧化活性研究[J]. 中国食品添加剂,2021,32(6):47−54. [WANG J, YUAN S L, WANG D. Optimization of extraction process and antioxidant activity of polysaccharides from Eriobotrya japonica leaves by Box-Behnken response surface methodology[J]. China Food Additives,2021,32(6):47−54.] WANG J, YUAN S L, WANG D . Optimization of extraction process and antioxidant activity of polysaccharides from Eriobotrya japonica leaves by Box-Behnken response surface methodology[J]. China Food Additives,2021 ,32 (6 ):47 −54 .[29] BABA S A, MALIK S A. Determination of total phenolic and flavonoid content, antimicrobial and antioxidant activity of a root extract of Arisaema jacquemontii Blume[J]. Journal of Taibah University for Science,2018,9(4):449−454.

[30] 宋佳敏, 王鸿飞, 孙朦, 等. 响应面法优化金蝉花多糖提取工艺及抗氧化活性分析[J]. 食品科学,2018,39(4):275−281. [SONG J M, WANG H F, SUN M, et al. Optimization of extraction and antioxidant activity of polysaccharides from Cordyceps cicadae by response surface methodology[J]. Food Science,2018,39(4):275−281.] SONG J M, WANG H F, SUN M, et al . Optimization of extraction and antioxidant activity of polysaccharides from Cordyceps cicadae by response surface methodology[J]. Food Science,2018 ,39 (4 ):275 −281 .[31] SONG H F, ZHANG Q B, ZHANG Z S, et al. In vitro antioxidant activity of polysaccharides extracted from Bryopsis plumosa[J]. Carbohydrate Polymers,2010,80(4):1057−1061. doi: 10.1016/j.carbpol.2010.01.024

[32] 封燕, 贡小辉, 韦德群, 等. 金蝉花多糖的抗氧化活性及结构分析[J]. 食品科学,2016,37(13):19−24. [FENG Y, GONG X H, WEI D Q, et al. Antioxidant activity and preliminary structure analysis of polysaccharides from Cordyceps cicadas[J]. Food Science,2016,37(13):19−24.] FENG Y, GONG X H, WEI D Q, et al . Antioxidant activity and preliminary structure analysis of polysaccharides from Cordyceps cicadas[J]. Food Science,2016 ,37 (13 ):19 −24 .[33] VAUCGEL P, COLLI C, PRADAL D, et al. Comparative LCA of ultrasound-assisted extraction of polyphenols from chicory grounds under different operational conditions[J]. Journal of Cleaner Production,2018,196(20):1116−1123.

下载:

下载:

下载:

下载: