Effect of Superfine Grinding Technology on the Quality Characteristics of Zanthoxylum bungeanum Seed Powder

-

摘要: 为探究超微粉碎技术对花椒籽品质特性的影响,本文采用超微粉碎技术制备花椒籽粉,利用粒度仪、分光测色仪、扫描电子显微镜等手段和持水/油力、膨胀力和振实密度等指标,考察了超微粉碎技术及粉体粒径大小对花椒籽粉的基本成分、理化特性和微观形貌的影响。结果表明:超微粉碎技术有助于提高花椒籽粉中可溶性膳食纤维的含量;与普通粉碎相比,超微粉碎处理20 min得到的花椒籽粉粒径可减小至7.69 μm(D90)、比表面积更大、粉体均一性更强;随着粉体粒径的减小,花椒籽粉的L*、a*、b*值逐步增加;同时,粒径的减小使得花椒籽粉的持水/油力明显增加至1.65 g/g和1.16 g/g,膨胀力增加至2.35 mL/g,休止角和滑角增加、振实密度降低;扫描电镜结果显示,随着粉碎时间的延长,粉体纤维束粉碎得更彻底。综上,利用超微粉碎技术可提高花椒籽粉中可溶性膳食纤维的含量,改善花椒籽粉的水合性质和吸水膨胀性,获得粒径更小、粉体均匀度更高的原料,但一定程度上会使花椒籽粉的致密性和流动性变差。Abstract: In order to investigate the functional effects of superfine grinding technology on Zanthoxylum bungeanum seed, in this study, superfine grinding technology was used to prepare Zanthoxylum bungeanum superfine powder. The basic components, particle size, color, surface morphology, and the water/oil holding capacity, expansion force, compaction density were investigated and recorded using particle size analyzer, spectrophotometer, and scanning electron microscope (SEM). The results showed that the soluble dietary fiber content of Zanthoxylum bungeanum seed powder gradually increased with the decrease of particle size. In comparison with the conventionally produced powder, the size of superfine powder could decrease to 7.69 μm, along with a larger specific surface area and stronger powder uniformity. As the particle size decreased, the color of the superfine powder gradually increased in L*, a*, and b* values. After superfine grinding, the water-holing capacity, oil-holding capacity, and swelling capacity would increase to 1.65 g/g, 1.16 g/g, and 2.35 mL/g, respectively. In addition, angles of repose and slide increased butthe tap density exhibited the opposite tendency. SEM images revealed that fiber bundle could be more thoroughly crushed with grinding time. In summary, the uniform Zanthoxylum bungeanum seed powder with a smaller particle size, higher powder uniformity, more soluble dietary fiber and better hydration capacity can be prepared through superfine grinding. However, to some extent, superfine grinding will also decrease the density and fluidity of Zanthoxylum bungeanum seed powder.

-

花椒(Zanthoxylum bungeanum Maxim.)属芸香科(Rutaceae),广泛分布于亚洲、美洲、非洲及大洋洲的热带和亚热带地区[1]。我国的花椒资源丰富,主要分布在四川、河南、陕西、山西、甘肃、重庆以及云南等地[2],2022年花椒年产量达53.84万吨,种植规模大并以每年20%~30%的速度增加[3]。花椒籽是花椒的主要副产物,约占花椒总重的60%。研究发现,花椒籽中富含的膳食纤维、脂肪酸和黑色素等活性物质往往具备抗氧化、抑菌、降血压、预防心脑血管疾病等功能[4−5]。如张宇[6]采用超声辅助法提取的花椒籽油具有一定体外抗氧化性,并对血脂代谢异常具有调节作用。Pang等[7]研究发现花椒籽油对恶性黑色素瘤具有抗癌活性,经花椒籽油处理的A375细胞表现出了典型的凋亡形态学特征。但花椒籽在实际应用中仍然存在一些问题,比如花椒籽近70%的高纤维含量导致其加工特性差、适口性差、营养成分溶出效果差等。除此之外,目前对于花椒籽本身的品质特性鲜有报道。为拓宽花椒籽的应用方向、促进花椒籽新产品的开发,利用外源加工技术改善花椒籽品质特性很有必要。

超微粉碎技术作为一种新兴的食品加工技术,可利用高剪切力、空穴作用等机械作用获得微米级甚至纳米级的食品物料粉末[8],从而改善物料粉体的理化特性及功能活性。Zhang等[9]研究发现薏苡仁经超微粉碎后粒径明显减小、比表面积增大、粉体质地更均匀,同时薏苡仁产品糊化特性和热特性明显得到改善。Archana等[10]发现高能球体磨处理可改变生姜粉的晶体结构、内部凝聚力和晶面间距,且生姜粉的抗氧化活性随粒径的减小而增强。Yan等[11]发现高静压超微粉碎处理不仅能够显著增加梨渣中可溶性膳食纤维含量,并可改变可溶性膳食纤维的化学结构和单糖组成,所得梨渣表现出了良好的持水持油能力、溶胀能力和胆固醇结合能力。

本文通过超微粉碎技术制备获得不同粒径分布的花椒籽超微粉,并与普通粉碎技术得到的花椒籽粗粉进行比较,研究分析其基本成分、粒径、色泽、持水/油力等理化特性和微观形貌的变化,以期为花椒籽资源的加工利用提供理论参考。

1. 材料与方法

1.1 材料与仪器

青花椒籽 由重庆骄王农业开发有限公司提供;耐高温α-淀粉酶液(≥300 U/g)、糖化酶(10万U/mL) 购自阿拉丁化学试剂网;压榨一级花生油 烟台龙源油食品有限公司;其他试剂均为分析纯。

HE53/02水分测定仪 梅特勒-托利多仪器(上海)有限公司;KND-08C消化炉 上海力辰邦西仪器科技有限公司;K9860 全自动凯氏定氮仪 山东海能科学仪器有限公司;HWS-26电热恒温水浴锅 上海-恒科学仪器有限公司;RE-2000A旋转蒸发器 西安禾普生物科技有限公司;YS3010分光测色仪 深圳市三恩时科技有限公司;SHZ-D循环水式多用真空泵 上海科兴仪器有限公司;WZJ-6B 振动式药物超微粉碎机 济南倍力粉体工程技术有限公司;SU8020场发射扫描电子显微 日本日立公司;Mastersizer 2000激光粒度仪 英国马尔文公司。

1.2 实验方法

1.2.1 粉体制备

将花椒籽置于50 ℃的烘箱内干燥5 h,控制原料水分含量在10%±0.5%,干燥后密封备用。

粗粉:取适量的干燥青花椒籽置于万能粉碎机中,直到物料填满粉碎机容积的2/3,粉碎1 min后收集粗粉,花椒籽粗粉作为实验对照组(CK)。

超微粉:将约240 g干燥青花椒籽放入超微粉碎机容器中,设定温度6 ℃(上调10 ℃;下调−5 ℃),待温度到达区间对青花椒籽分别粉碎处理1、3、5、10和20 min,得到不同粒径的花椒籽超微粉(Superfine grinding on Zanthoxylum bungeanum seed meal,ZBSM-SG),分别命名为ZBSM-SG1、ZBSM-SG3、ZBSM-SG5、ZBSM-SG10和ZBSM-SG20。

1.2.2 基本成分测定

粗蛋白的测定参照GB 5009.5-2016《食品中蛋白质的测定》;粗脂肪的测定参照GB 5009.6-2016《食品中脂肪的测定》;灰分的测定参照GB 5009.4-2016《食品中灰分的测定》;膳食纤维的测定参照GB 5009.88-2014《食品中膳食纤维的测定》。

1.2.3 理化特性分析

1.2.3.1 粒径测定

采用Mastersizer 2000激光粒度仪,使用湿法粒径测试系统进行粒径测定,粒径分布选择水相,样品测定前进行超声辅助分散。

1.2.3.2 色泽分析

采用YS3010分光测色仪测定花椒籽粉体的L*、a*、b*值,测色仪基础参数:D65光源、直径8 mm测量区、10°观测角。测色仪使用前进行白板校正和黑板校正后,设定标样参数为白色标准板的色度值[12]:(L*=95.26,a*=−0.89,b*=1.18)。取适量样品粉末平铺在桌面上,将粉末压紧实后置于测色仪测量口下端,保持稳定后进行测定。花椒籽粉与白色标准版的色差按式(1)计算:

ΔE=(ΔL∗2+Δa∗2+Δb∗2)1/2 (1) 1.2.3.3 持水力测定

花椒籽粉的持水力测定参照Mcconnell等[13]的方法:称取1.00 g花椒籽粉置于离心管中,加入20 mL去离子水后振荡混匀并于60 ℃恒温水浴40 min,冷却至室温后在4000 r/min条件下离心20 min,弃去上清液并用滤纸吸干残液,记录其质量。花椒籽粉的持水力按式(2)计算:

持水力(g/g)=吸水后花椒籽粉质量−吸水前花椒籽粉质量吸水前花椒籽粉质量 (2) 1.2.3.4 持油力测定

花椒籽粉的持油力的测定参照Caprez等[14]的方法:称取0.5 g花椒籽粉置于离心管中,加入4 mL花生油后振荡混匀后于37 ℃恒温水浴1 h,冷却至室温后在4000 r/min条件下离心20 min,弃去上层花生油并用滤纸吸干残油,记录其质量。花椒籽粉的持油力按式(3)计算:

持油力(g/g)=吸油后花椒籽粉质量−吸油前花椒籽粉质量吸油前花椒籽粉质量 (3) 1.2.3.5 膨胀力测定

花椒籽粉的吸水膨胀力测定参照Kuniak等[15]的方法并稍作修改:称取0.5 g花椒籽粉置于15 mL量筒中,轻微敲击量筒壁5~8次使粉末表面平整内部无空隙,读取初始体积;移取10 mL去离子水加入样品中,混匀并静置24 h后,读取吸水膨胀后样品的体积。花椒籽的吸水膨胀力按式(4)计算:

膨胀力(mL/g)=吸水膨胀后花椒籽粉的体积−花椒籽粉初始体积花椒籽粉质量 (4) 1.2.3.6 振实密度测定

花椒籽粉振实密度的测定参照陈璁等[16]的方法并稍作修改:称取花椒籽粉10 g于50 mL量筒中,刚开始轻微振荡样品,以防因粉体内部空气排出使蓬松样品外溢,待样品振荡紧实后将量筒竖直从3~4 cm高处反复振落至实验平台上,直至量筒内的粉体体积不再降低为止,读取最终体积。花椒籽粉的振实密度按式(5)计算:

振实密度(g/mL)=花椒籽粉质量花椒籽粉最终体积 (5) 1.2.3.7 休止角测定

花椒籽粉休止角的测定参照Huang等[17]的方法并稍作修改:将漏斗垂直固定在漏斗底端距水平桌面3 cm高度的铁架台上,并在桌面上放置一块透明玻璃板,将3 g花椒籽粉经玻璃漏斗匀速滑落至玻璃板上堆积成物料圆锥体,借助游标卡尺记录圆锥体的半径和高度。花椒籽的休止角按式(6)计算:

α=arctan(HR) (6) 式中:H为花椒籽粉堆成的圆锥体的高度(mm);R为圆锥体底面圆的半径(mm)。

1.2.3.8 滑角测定

花椒籽粉滑角的测定参照Huang等[17]的方法并稍作修改:将10 g花椒籽粉倒入玻璃板固定的一端上,保持每次物料的初始位置不变,缓慢倾斜玻璃板直到花椒籽粉开始滑动,借助游标卡尺记录平面长度和顶部距桌面的垂直距离。花椒籽粉的滑角按式(7)计算:

α=arcsin(hL) (7) 式中:h为样品初始位置距离桌面的垂直距离(mm);L为玻璃平板的长度(mm)。

1.2.4 微观形貌分析

采用SU8020场发射扫描电子显微镜观察花椒籽粉的微观形态。取适量花椒籽粉固定于载物台上,真空喷金处理后进行扫描电子显微镜观察。仪器工作具体参数:加速电压为3 kV;放大倍数为5000倍。

1.3 数据处理

所有实验均进行3次平行,结果表示为平均值±标准差,采用SPSS 26.0软件对数据进行处理,并用ANOVA和Duncan检验(P<0.05)进行统计分析,用Origin 9.0软件进行数据统计与处理。

2. 结果与分析

2.1 花椒籽基本成分

由表1可知,青花椒籽的基本成分中含量最高的是膳食纤维,约占干基总重的69.50%,其中可溶性膳食纤维占2.49%、不可溶膳食纤维占67.00%;蛋白质含量约为9.95%,这与瞿瑗等[18]报道的青花椒籽9.77%的蛋白质含量相近,且可能与花椒籽的品种与产地相关。除此之外,青花椒籽的粗脂肪含量约为1.92%、灰分含量约为15.50%。

表 1 花椒籽基本成分(以干基计)Table 1. Basic components of Zanthoxylum bungeanum seeds (dry basis)品种 粗蛋白(%) 粗脂肪(%) 灰分(%) 膳食纤维(%) IDF SDF TDF 青花椒籽 9.95±0.01 1.92±0.15 15.50±0.01 67.00±0.31 2.49±0.24 69.50±0.55 2.2 超微粉碎对花椒籽膳食纤维的影响

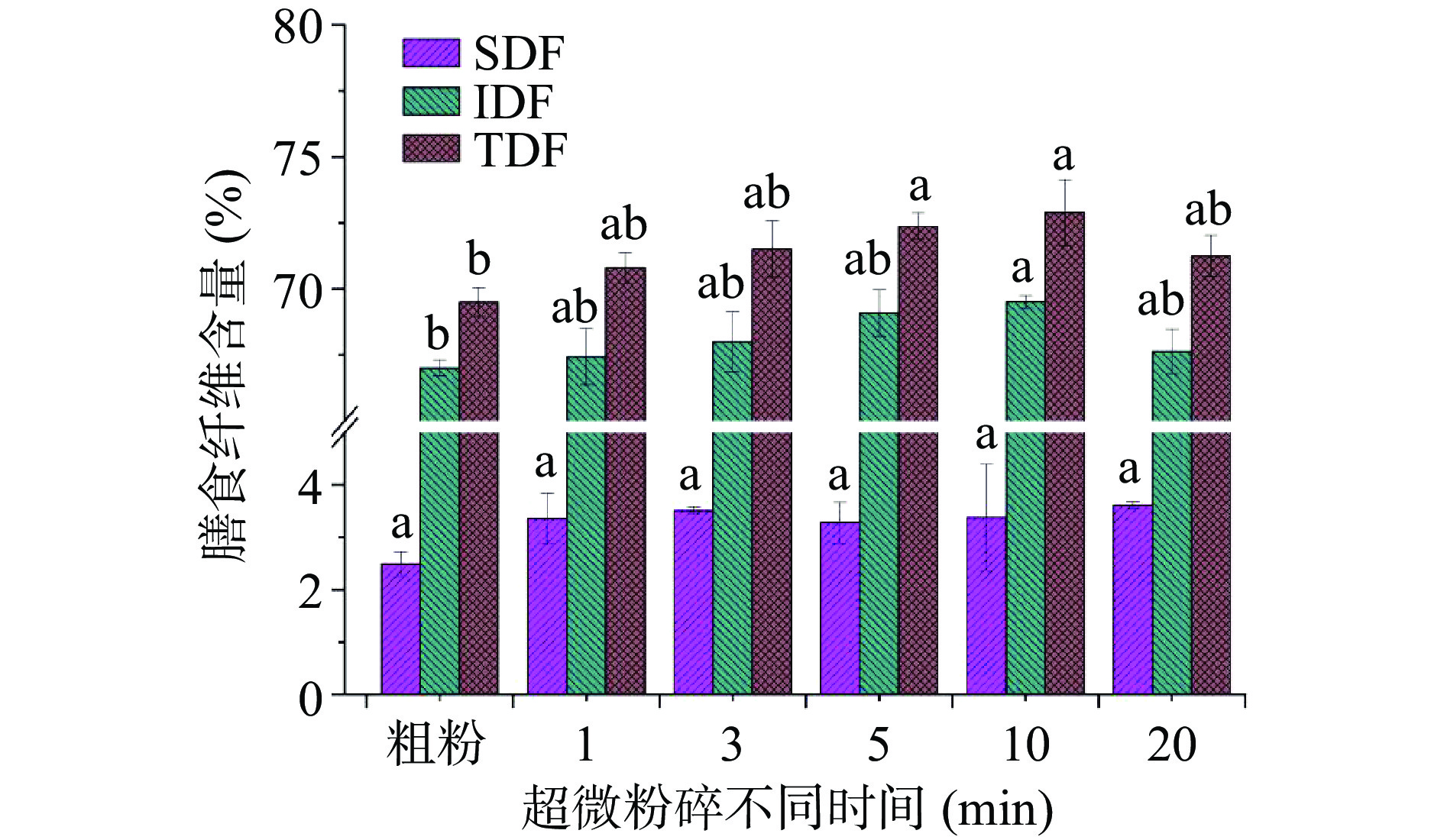

图1展示了不同粒径花椒籽粉的可溶性膳食纤维(SDF)、不可溶膳食纤维(IDF)、总膳食纤维(TDF)含量。如图1所示,与花椒籽粗粉相比,花椒籽经超微粉碎后,其SDF含量可从2.49%增加到3.36%,但并无显著性差异(P>0.05),说明超微粉碎一定程度上有助于提高膳食纤维中SDF的比例。此外,超微粉碎处理的花椒籽粉其SDF含量升高可能与粉体粒径变小、表面积增大、从而更有利于测定过程中SDF的溶出有关[19]。从TDF的含量变化来看,ZBSM-SG5中TDF的含量显著高于粗粉(P<0.05),这可能与粉碎时间延长后颗粒发生团聚导致粉体蛋白质和油脂等成分的去除率降低有关,从而导致测得TDF的测定值变大。

2.3 超微粉碎对花椒籽粉粒径的影响

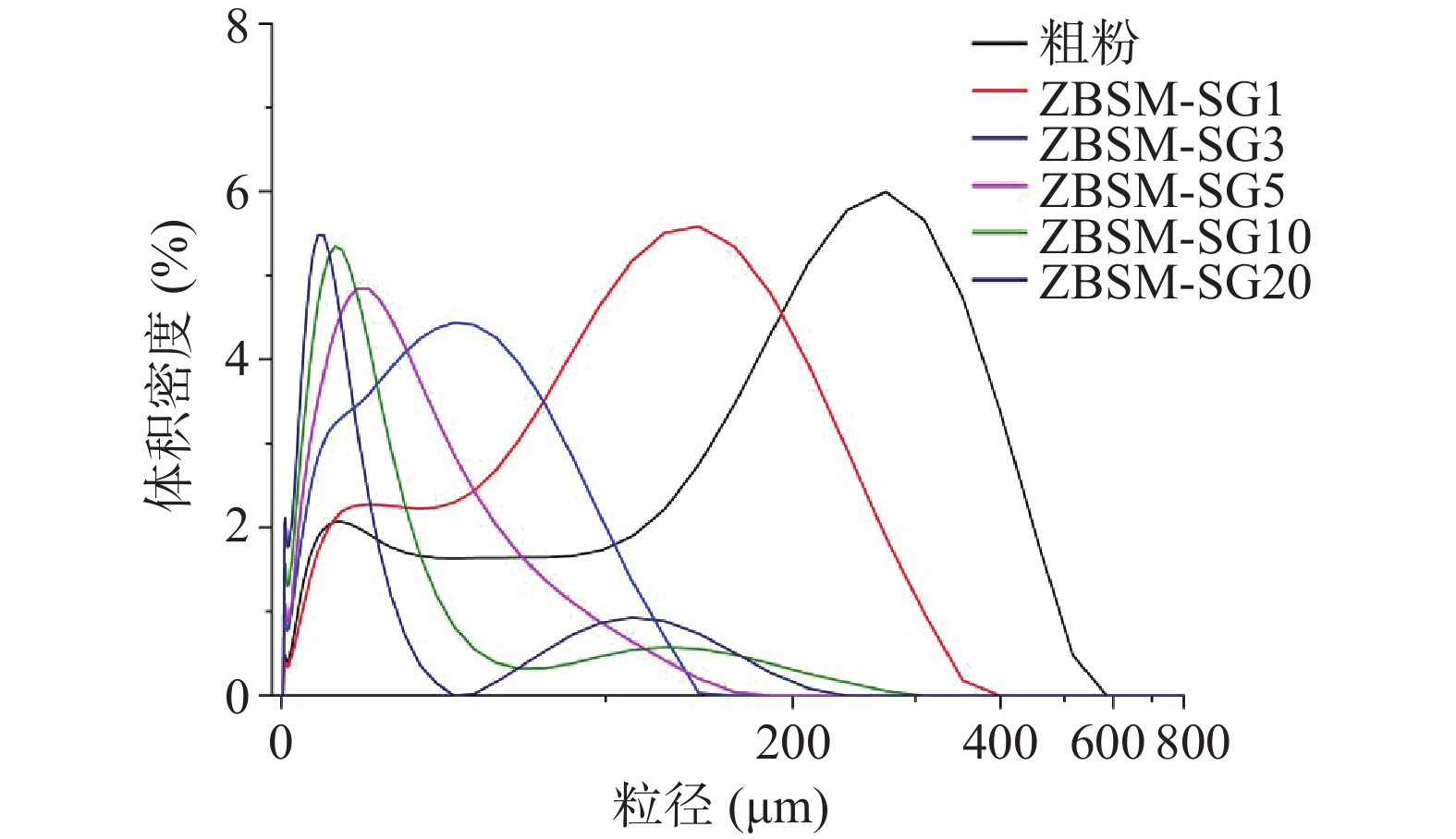

粉体粒径是衡量超微粉碎对物料处理效果的直接指标[20]。由表2可知,花椒籽粉的平均粒径D50从大到小分别为粗粉CK>ZBSM-SG1>ZBSM-SG3>ZBSM-SG5>ZBSM-SG10>ZBSM-SG20。与粗粉D50(94.06 μm)相比,ZBSM-SG1的D50即可减小至71.63 μm,说明超微粉碎技术可显著降低花椒籽粉的粒径(P<0.05),且随着超微粉碎时间的延长,花椒籽粉的粉体粒径不断减小并呈现显著差异(P<0.05),具体表现为ZBSM-SG1与ZBSM-SG20相比,其D50由71.63 μm减小到7.69 μm、D90由210.46 μm减小到24.51 μm,其中花椒籽经超微粉碎处理3 min后所得粉体的平均粒度可达超微粉级别(D50<10~25 μm)[21]。同时,随着花椒籽粉D50的降低,其D[4,3]与D[3,2]的差值逐渐减小,从154.38减小到11.99,Span值从3.73减小到3.02,说明花椒籽粉粒度分布越集中、均一性逐步增强[22],这一点也从图2(峰变窄)可得到验证。另外,由图2可知,随着粉碎时间的延长,ZBSM-SG10与ZBSM-SG20出现了一定程度的颗粒团聚,这可能是因为在超微粉碎的过程中,粉体比表面积的增大引起了分离自由能的增加,从而导致粉末发生聚集(ZBSM-SG20的Asf值(1611.67±7.00)m2/g显著大于ZBSM-SG10的(955.71±2.37)m2/g( P<0.05))。陈如[23]的实验也发现苹果粉在超微粉碎超过10 min后即会出现团聚现象,且时间延长其团聚现象更甚。

表 2 不同粉碎时间对花椒籽超微粉粒径的影响Table 2. Effect of different grinding time on particle size of Zanthoxylum bungeanum seed superfine powder样品 D[3,4] D[3,2] D10(μm) D50(μm) D90(μm) Span Asf(m2/g) 粗粉CK 144.98±10.37a 12.60±0.51b 5.34±0.22b 94.06±12.64a 356.20±20.93a 3.73±0.30a 476.60±19.57e ZBSM-SG1 91.38±3.03b 14.25±0.30a 6.65±0.16a 71.63±3.07b 210.46±6.61b 2.85±0.03d 421.18±8.70f ZBSM-SG3 32.34±0.12c 7.36±0.02c 2.94±0.01c 22.39±0.06c 77.48±0.33c 3.33±0.01b 815.09±2.12d ZBSM-SG5 23.40±0.11d 6.28±0.02d 2.51±0.01d 15.78±0.04cd 54.08±0.65d 3.27±0.03bc 955.71±2.37c ZBSM-SG10 18.62±0.44d 4.70±0.02e 1.65±0.01e 10.60±0.07d 33.68±0.56e 3.02±0.03cd 1277.21±5.75b ZBSM-SG20 15.71±0.21d 3.72±0.02f 1.27±0.00f 7.69±0.05d 24.51±0.41e 3.02±0.03cd 1611.67±7.00a 注:不同小写字母表示同一指标数据差异显著(P<0.05);表3同。 2.4 超微粉碎对花椒籽色泽的影响

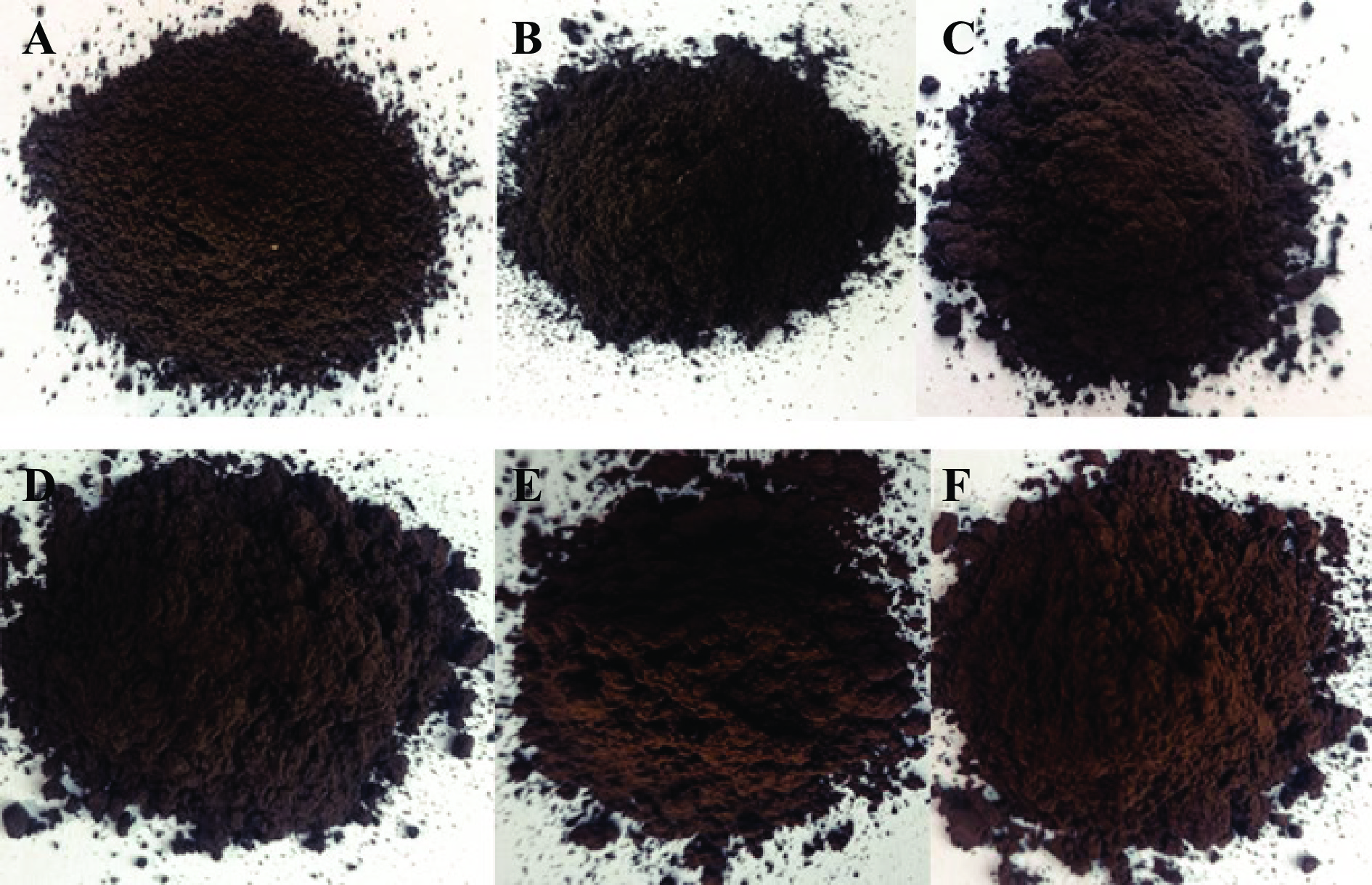

色泽是表征粉体感官品质的一项重要指标[24]。图3为不同粒径花椒籽粉的直观形态,由图3可知利用超微粉碎与普通粉碎得到的花椒籽粉差异较大,其中花椒籽粗粉(图3A)颗粒较为粗糙而花椒籽超微粉(图3B~图3F)的粉质更均匀细腻、蓬松度更高。且随着超微粉碎时间的延长,可发现花椒籽粉的颜色逐渐由黑褐色变成黄褐色,即超微粉碎技术一定程度上会影响花椒籽粉的色泽。进一步地,对花椒籽粉进行色度测定(表3),随着粉碎时间的延长,L*值从40.41增加到44.15,涨幅6.59%;同时,a*值从2.43增加到5.07,涨幅54.10%,超微粉色泽趋向红色;b*值也从4.54增加到7.79,涨幅43.20%,即色泽趋向黄色,与肉眼观察的超微粉颜色变化一致。整体来说,随着超微粉碎时间的延长,花椒籽粉与标准白板间的总色差△E逐渐减小,花椒籽粉的色泽呈现出明显的改观。

表 3 不同粉碎时间对花椒籽超微粉色泽的影响Table 3. Effect of different grinding time on the color of Zanthoxylum bungeanum seed ultrafine powder样品 亮度L* 红绿值a* 黄蓝值b* 色差△E 粗粉CK 41.42±0.13b 3.29±0.12d 5.44±0.16c 54.21±0.11b ZBSM-SG1 40.41±0.24c 2.43±0.22f 4.54±0.30d 55.06±0.26a ZBSM-SG3 41.44±0.03b 2.72±0.02e 4.97±0.64cd 54.46±0.20b ZBSM-SG5 41.53±0.76b 3.70±0.13c 5.58±0.34c 54.50±0.25b ZBSM-SG10 41.60±0.06b 4.30±0.04b 6.53±0.15b 54.36±0.30b ZBSM-SG20 44.15±0.00a 5.07±0.04a 7.79±0.30a 51.82±0.07c 2.5 超微粉碎对花椒籽粉持水/油力的影响

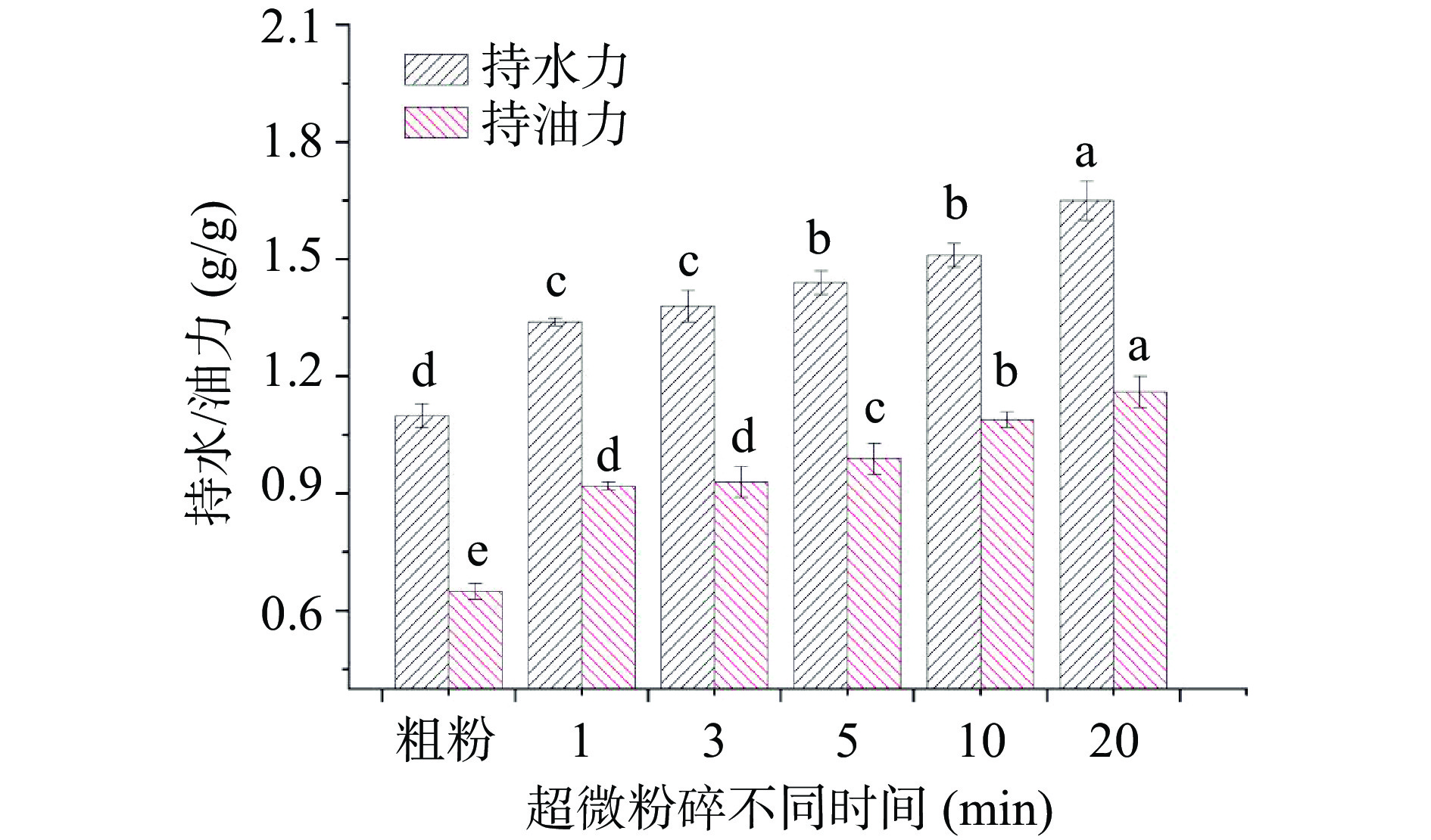

水合性质作为衡量膳食纤维功能性强弱的一个重要指标,持水力和持油力是表征水合性质的两个重要指标,持水/油力越大,水合性越好。由图4可知,与普通粉碎相比,超微粉碎能够显著提高花椒籽粉的持水持油能力(P<0.05),其中持水力从1.1 g/g增加到1.65 g/g,持油力从0.65 g/g增加到1.16 g/g。一方面,这可能与花椒籽超微粉的比表面积较大、结构相对松散,更易与水/油分子接触有关;另一方面,超微粉碎会促进物料中SDF的溶出和亲水基团的外露,从而提高粉体与水分子间的相互作用;再者,膳食纤维的分子微晶结构在超微粉碎过程中也会发生一定程度的断裂,进而增强其持水/油能力[25]。

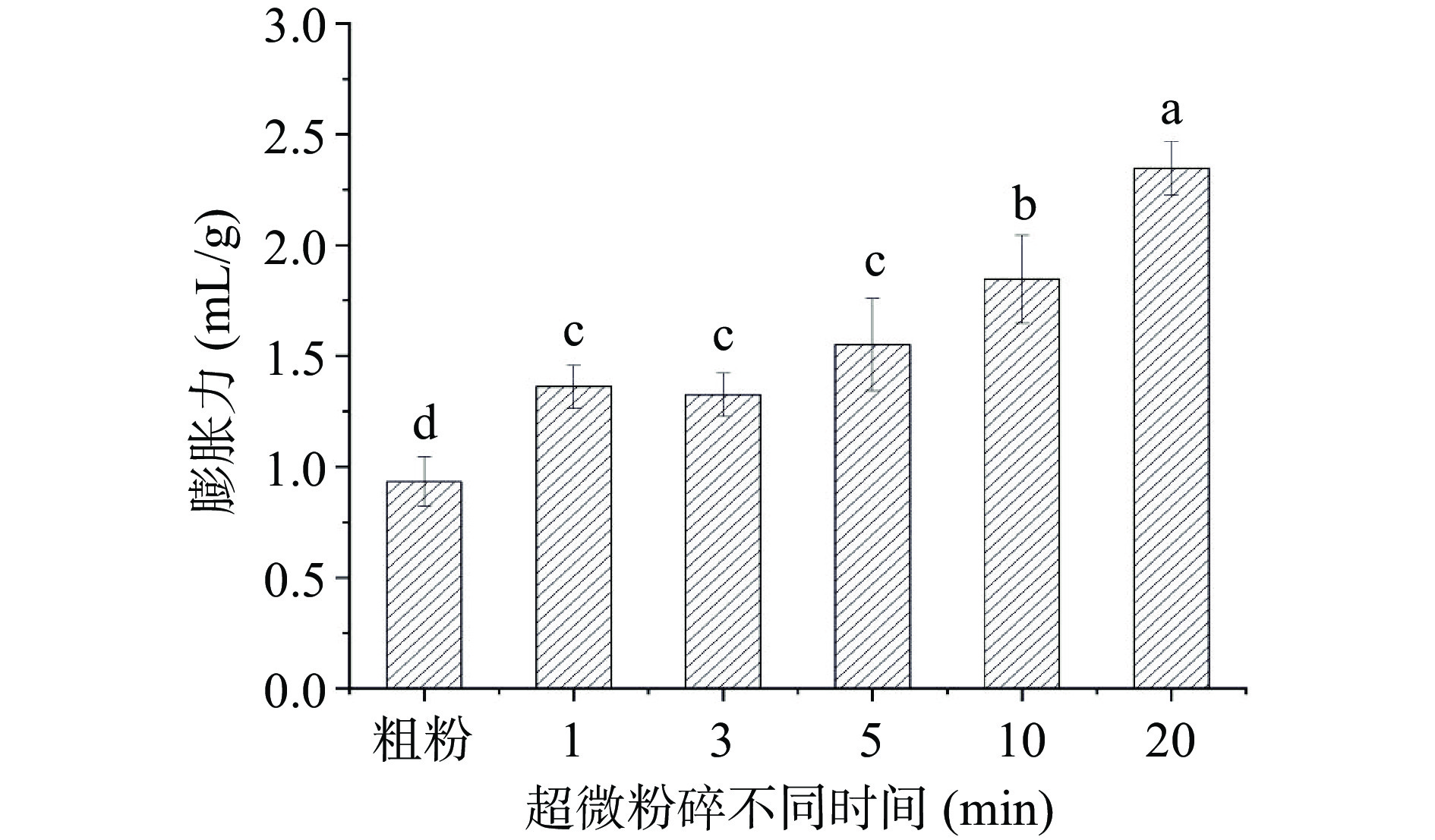

2.6 超微粉碎对花椒籽粉膨胀力的影响

膨胀力是膳食纤维预防便秘、肠癌等生理功能的重要物理指标[26]。由图5可知,与普通粉碎相比,超微粉碎能够显著提高花椒籽粉的膨胀力至ZBSM-SG20的2.35 mL/g(P<0.05)。随着超微粉碎时间的延长,粉体膨胀力越大,当超微粉碎时间较短时,ZBSM-SG1、ZBSM-SG3、ZBSM-SG5粉体间的膨胀力无显著差异(P>0.05),进一步延长粉碎时间,粉体的膨胀力显著增大(P<0.05),其中ZBSM-SG20的膨胀力是ZBSM-SG1的1.53倍;这可能与花椒籽粉中膳食纤维网络结构在较高粉碎强度下被破坏、亲水基团更多的暴露出来有关[27]。推测超微粉碎可辅助花椒籽粉开发防便秘产品。

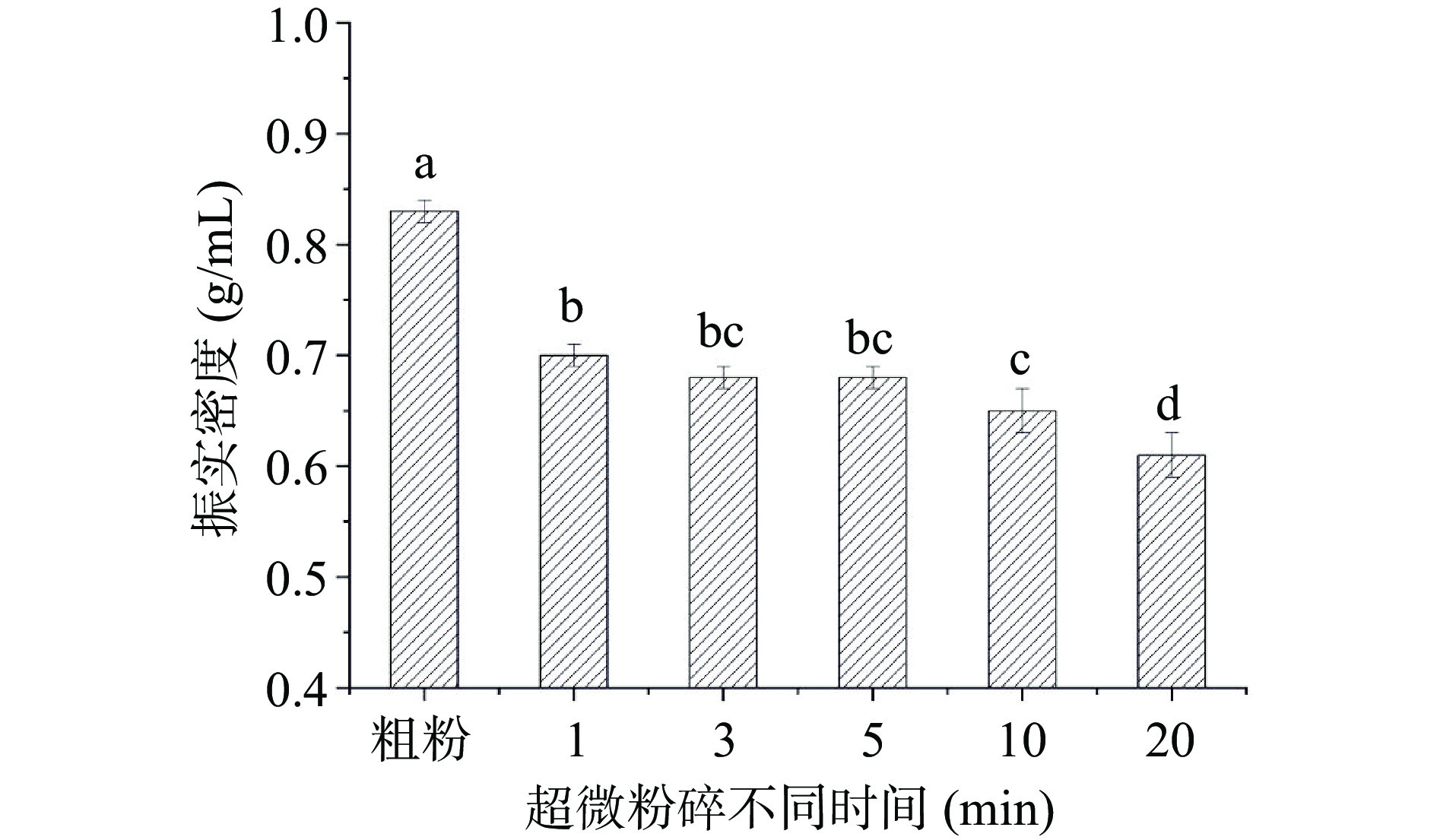

2.7 超微粉碎对花椒籽粉振实密度的影响

振实密度是反映粉体堆砌致密性的重要指标,振实密度越大,粉体的致密性越好,颗粒间的空隙越小越容易压片成型[28]。由图6可知,超微粉碎技术会明显降低花椒籽粉的振实密度(P<0.05),可由粗粉的0.83 g/mL下降到ZBSM-SG20的0.61 g/mL;并随着粉碎时间的延长,花椒籽粉的振实密度逐渐下降,并在处理10 min后呈现出显著性降低(P<0.05),这可能是由于颗粒发生团聚而导致粒间空隙增大,进而使得振实密度减小,即超微粉碎制备的花椒籽粉相对不易压缩、成形性较差。

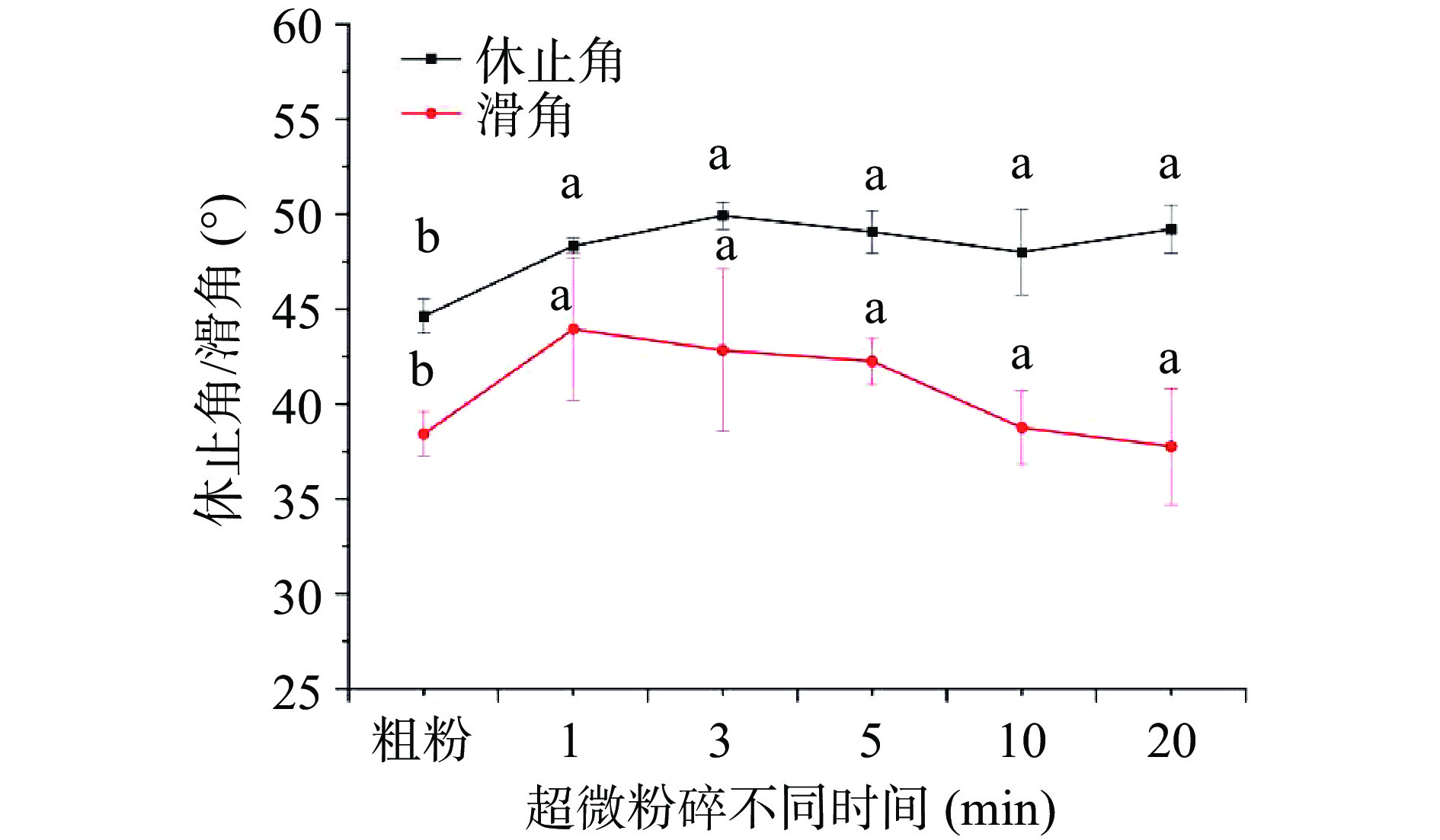

2.8 超微粉碎对花椒籽粉休止角和滑角的影响

休止角和滑角是评价粉体流动性的重要指标,其大小与粉体的粒径、湿度、电荷等因素有关,休止角和滑角越小,表明粉体的流动性越好[29]。由图7可知,本研究中所制备的花椒籽粉休止角均大于45°,即流动性较差[30];且与粗粉相比,超微粉碎处理还会显著增大花椒籽粉的休止角,降低粉体的流动性,其中ZBSM-SG1的休止角为48.33°,显著高于粗粉的44.63°(P<0.05),但超微粉碎的处理程度不会显著影响花椒籽粉的休止角。就花椒籽粉的滑角而言,与普通粉碎粗粉相比,超微粉碎得到的花椒籽粉其滑角显著增大(P<0.05),同样地,处理时间不会显著影响花椒籽粉的休止角(P>0.05)。综上所述,超微粉碎技术相比于普通粉碎技术,会明显降低花椒籽粉的流动性,且粉体粒径的大小也会对花椒籽粉的流动性有一定影响。

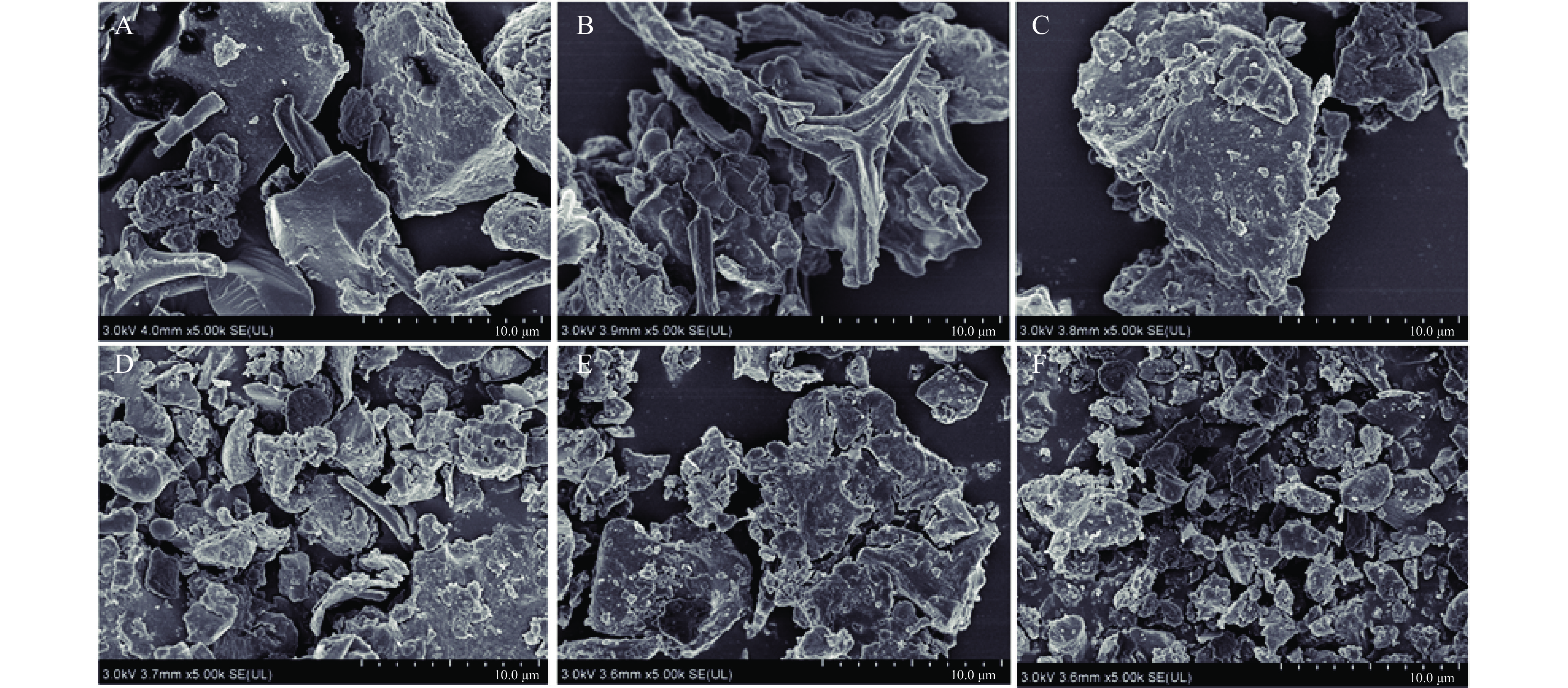

2.9 超微粉碎对花椒籽微观形貌的影响

花椒籽粗粉和5种不同花椒籽超微粉的扫描电镜形貌如图8所示。花椒籽粗粉(图8A)呈现为较为完整的块状及相对平滑的表面,经超微粉碎处理1 min后的花椒籽粉颗粒表面有明显的纤维束脉络结构(图8B),且随着粉碎时间的延长,粉体呈现出不完整的碎片状,且颗粒粒径越来越小均一性增强,并可观察到纤维断裂的现象,表明纤维束也被粉碎得更彻底。

3. 结论

超微粉碎技术能够显著改善花椒籽粉的品质特性,一方面,其可通过破坏纤维束提高花椒籽粉SDF的含量,从2.49%增加到3.36%。经超微粉碎技术处理,能够得到粉体均一、比表面积大的花椒籽超微粉(D50=7.69 μm);另一方面,超微粉碎技术可显著改善花椒籽粉的色泽及其理化性质,显著提高其持水/油力、膨胀力、休止角和滑角(P<0.05),并降低其振实密度(P<0.05);再者,超微粉碎强度,即处理时间也会影响花椒籽粉的理化性质,过度超微粉碎会导致颗粒团聚从而对营养物质溶出、粉体的流动性产生负面影响。综上,超微粉碎技术在花椒籽粉的品质改性中具有较强的可行性,花椒籽微粉作为潜在的食品原辅料具有广泛的开发应用前景;未来需依据其开发方向合理选择超微粉碎处理强度。

-

表 1 花椒籽基本成分(以干基计)

Table 1 Basic components of Zanthoxylum bungeanum seeds (dry basis)

品种 粗蛋白(%) 粗脂肪(%) 灰分(%) 膳食纤维(%) IDF SDF TDF 青花椒籽 9.95±0.01 1.92±0.15 15.50±0.01 67.00±0.31 2.49±0.24 69.50±0.55 表 2 不同粉碎时间对花椒籽超微粉粒径的影响

Table 2 Effect of different grinding time on particle size of Zanthoxylum bungeanum seed superfine powder

样品 D[3,4] D[3,2] D10(μm) D50(μm) D90(μm) Span Asf(m2/g) 粗粉CK 144.98±10.37a 12.60±0.51b 5.34±0.22b 94.06±12.64a 356.20±20.93a 3.73±0.30a 476.60±19.57e ZBSM-SG1 91.38±3.03b 14.25±0.30a 6.65±0.16a 71.63±3.07b 210.46±6.61b 2.85±0.03d 421.18±8.70f ZBSM-SG3 32.34±0.12c 7.36±0.02c 2.94±0.01c 22.39±0.06c 77.48±0.33c 3.33±0.01b 815.09±2.12d ZBSM-SG5 23.40±0.11d 6.28±0.02d 2.51±0.01d 15.78±0.04cd 54.08±0.65d 3.27±0.03bc 955.71±2.37c ZBSM-SG10 18.62±0.44d 4.70±0.02e 1.65±0.01e 10.60±0.07d 33.68±0.56e 3.02±0.03cd 1277.21±5.75b ZBSM-SG20 15.71±0.21d 3.72±0.02f 1.27±0.00f 7.69±0.05d 24.51±0.41e 3.02±0.03cd 1611.67±7.00a 注:不同小写字母表示同一指标数据差异显著(P<0.05);表3同。 表 3 不同粉碎时间对花椒籽超微粉色泽的影响

Table 3 Effect of different grinding time on the color of Zanthoxylum bungeanum seed ultrafine powder

样品 亮度L* 红绿值a* 黄蓝值b* 色差△E 粗粉CK 41.42±0.13b 3.29±0.12d 5.44±0.16c 54.21±0.11b ZBSM-SG1 40.41±0.24c 2.43±0.22f 4.54±0.30d 55.06±0.26a ZBSM-SG3 41.44±0.03b 2.72±0.02e 4.97±0.64cd 54.46±0.20b ZBSM-SG5 41.53±0.76b 3.70±0.13c 5.58±0.34c 54.50±0.25b ZBSM-SG10 41.60±0.06b 4.30±0.04b 6.53±0.15b 54.36±0.30b ZBSM-SG20 44.15±0.00a 5.07±0.04a 7.79±0.30a 51.82±0.07c -

[1] 孙小文, 段志兴. 花椒属药用植物研究进展[J]. 药学学报,1996,31(3):231−40. [SUN X W, DUAN Z X. Research progress on medicinal plants of Zanthoxylum genus[J]. Acta Pharmaceutica Sinica,1996,31(3):231−40.] SUN X W, DUAN Z X . Research progress on medicinal plants of Zanthoxylum genus[J]. Acta Pharmaceutica Sinica,1996 ,31 (3 ):231 −40 .[2] 李亚南. 不同省份花椒的化学成分差异分析及其产地判别 [D]. 合肥:安徽农业大学, 2022. [LI Y N. Analysis of chemical composition differenceand origin discrimination of Zanthoxylum bungeanum from different provinces[D]. Hefei:Anhui Agriculrural University, 2022.] LI Y N. Analysis of chemical composition differenceand origin discrimination of Zanthoxylum bungeanum from different provinces[D]. Hefei: Anhui Agriculrural University, 2022.

[3] 史劲松, 顾龚平, 吴素玲, 等. 花椒资源与开发利用现状调查[J]. 中国野生植物资源,2003(5):6−8. [SHI J S, GU G P, WU S L, et al. Investigation of the Zanthoxylum bungeanum Maxim. resource and status in quo of its utilizaation[J]. Chinese Wild Plant Resources,2003(5):6−8.] SHI J S, GU G P, WU S L, et al . Investigation of the Zanthoxylum bungeanum Maxim. resource and status in quo of its utilizaation[J]. Chinese Wild Plant Resources,2003 (5 ):6 −8 .[4] HE F T, LUO S H, LIU S J, et al. Zanthoxylum bungeanum seed oil inhibits RANKL-induced osteoclastogenesis by suppressing ERK/c-JUN/NFATc1 pathway and regulating cell cycle arrest in RAW264.7 cells[J]. J Ethnopharmacol,2022,289:115094. doi: 10.1016/j.jep.2022.115094

[5] JING N N, WANG M Y, GAO M L, et al. Color sensory characteristics, nutritional components and antioxidant capacity of Zanthoxylum bungeanum Maxim. as affected by different drying methods[J]. Industrial Crops and Products,2021,160:113167. doi: 10.1016/j.indcrop.2020.113167

[6] 张宇. 汉源花椒籽油提取及其调节血脂功能的研究[D]. 成都:四川农业大学, 2020. [ZHANG Y. Study on extraction and the regulating effecton blood lipid of Han Yuan Zanthoxylum bungeanum Maxim seed oil[D]. Chengdu:Sichuan Agricultural University, 2020.] ZHANG Y. Study on extraction and the regulating effecton blood lipid of Han Yuan Zanthoxylum bungeanum Maxim seed oil[D]. Chengdu: Sichuan Agricultural University, 2020.

[7] PANG W W, LIU S, HE F T, et al. Anticancer activities of Zanthoxylum bungeanum seed oil on malignant melanoma[J]. J Ethnopharmacol,2019,229:180−189. doi: 10.1016/j.jep.2018.10.012

[8] 卫子颜, 谢勇, 王朦朦, 等. 超微粉碎对米糠多酚的组成及抗氧化活性的影响[J]. 食品与发酵工业,2022,48(14):138−144. [WEI Z Y, XIE Y, WANG M M, et al. Effect of ultrafine grinding on the composition and antioxidnt activity of phenolic compounds in rice[J]. Food and Fermentation Industries,2022,48(14):138−144.] WEI Z Y, XIE Y, WANG M M, et al . Effect of ultrafine grinding on the composition and antioxidnt activity of phenolic compounds in rice[J]. Food and Fermentation Industries,2022 ,48 (14 ):138 −144 .[9] ZHANG T, XIAO S Y, DING Z H, et al. Effects of superfine grinding on physicochemical properties and morphological structure of coix seed powders[J]. Journal of Cereal Science,2021,102:62−73.

[10] ARCHANA K R. AMAN A K R, SINGH R, et al. Effect of superfine grinding on structural, morphological and antioxidant properties of ginger ( Zingiber officinale) nano crystalline food powder[J]. Materials Today: Proceedings,2021,43:3397−3403. doi: 10.1016/j.matpr.2020.09.028

[11] YAN L, LI T, LIU C H, et al. Effects of high hydrostatic pressure and superfine grinding treatment on physicochemical/ functional properties of pear pomace and chemical composition of its soluble dietary fibre[J]. LWT,2019,107:171−177. doi: 10.1016/j.lwt.2019.03.019

[12] 任晓婵, 张风雪, 常婧瑶, 等. 不同粒径对超微粉碎大麦全粉品质特性的影响[J]. 食品与发酵工业,2023,49(3):227−233. [REN X C, ZHANG F X, CHANG J Y, et al. Effect of different particle sizes on the quality characteristics of superfine barley whole flour[J]. Food and Fermentation Industries,2023,49(3):227−233.] REN X C, ZHANG F X, CHANG J Y, et al . Effect of different particle sizes on the quality characteristics of superfine barley whole flour[J]. Food and Fermentation Industries,2023 ,49 (3 ):227 −233 .[13] MCCONNELL A A, EASTWOOD M A, MITCHELL W D. Physical characteristics of vegetable foodstuffs that could influence bowel function[J]. J Sci Food Agric,1974,25(12):1457−1464. doi: 10.1002/jsfa.2740251205

[14] CAPREZ A, ARRIGONI E, AMADò R, et al. Influence of different types of thermal treatment on the chemical composition and physical properties of wheat bran[J]. Journal of Cereal Science,1986,4(3):233−239. doi: 10.1016/S0733-5210(86)80025-X

[15] KUNIAK L, MARCHESSAULT R H. Study of the crosslinking reaction between epichlorohydrin and starch[J]. Starch-Stärke,1972,24(4):110−116.

[16] 陈璁, 叶爽, 王桂华, 等. 不同干燥方式和粉碎程度对双孢蘑菇理化、营养和功能特性的影响[J]. 食品科学,2023,44(1):88−97. [CHEN C, YE S, WANG G H, et al. Effect of different drying method and crushing degrees on the physicochemical, nutritional and function properties of agaricus bisporus[J]. Food Science,2023,44(1):88−97.] CHEN C, YE S, WANG G H, et al . Effect of different drying method and crushing degrees on the physicochemical, nutritional and function properties of agaricus bisporus[J]. Food Science,2023 ,44 (1 ):88 −97 .[17] HUANG X, LIANG K H, LIU Q, et al. Superfine grinding affects physicochemical, thermal and structural properties of Morin ga oleifera leaf powders[J]. Industrial Crops and Products,2020,151:112472. doi: 10.1016/j.indcrop.2020.112472

[18] 瞿瑗, 余国贤, 黎杉珊, 等. Osborne法分级提取青花椒籽蛋白质及其理化性质研究[J]. 核农学报,2018,32(12):2373−2379. [QU Y, YU G X, LI S S, et al. Physicochemical properties of proteins isolated from Zanthxylum armatum DC. seed using osborne extract method[J]. Journal of Nuclear Agricultural Sciences,2018,32(12):2373−2379.] QU Y, YU G X, LI S S, et al . Physicochemical properties of proteins isolated from Zanthxylum armatum DC. seed using osborne extract method[J]. Journal of Nuclear Agricultural Sciences,2018 ,32 (12 ):2373 −2379 .[19] 赵秋艳, 许淇, 郭星星, 等. 粉碎粒径对豆渣化学组成和物理特性的影响[J]. 山东化工,2022,51(7):61−64. [ZHAO Q Y, XU Q, GUO X X, et al. Effect of particle size on chemical components and physical characteristics of okara[J]. Shandong Chemical Industry,2022,51(7):61−64.] ZHAO Q Y, XU Q, GUO X X, et al . Effect of particle size on chemical components and physical characteristics of okara[J]. Shandong Chemical Industry,2022 ,51 (7 ):61 −64 .[20] ZHANG J T, DONG Y S, NISAR T, et al. Effect of superfine-grinding on the physicochemical and antioxidant properties of Lycium ruthenicum Murray powders[J]. Powder Technology,2020,372:68−75. doi: 10.1016/j.powtec.2020.05.097

[21] 区子弁, 王琴. 超微粉碎技术及其设备在粮油加工中的应用[J]. 广东农业科学,2010,37(7):192−194. [QU Z B, WANG Q. Applications on grain and oil processing in micronized technology and its machinery[J]. Guangdong Agricultural Sciences,2010,37(7):192−194.] QU Z B, WANG Q . Applications on grain and oil processing in micronized technology and its machinery[J]. Guangdong Agricultural Sciences,2010 ,37 (7 ):192 −194 .[22] 寇福兵, 夏晓霞, 薛艾莲, 等. 超微粉碎对板栗粉理化特性及结构特征的影响[J]. 食品与发酵工业,2022,48(13):155−162. [KOU F B, XIA X X, XUE A L, et al. Effect of superfine griding on physicochemical properties and structural characteristics of Chinese chestnut powder[J]. Food and Fermentation Industries,2022,48(13):155−162.] KOU F B, XIA X X, XUE A L, et al . Effect of superfine griding on physicochemical properties and structural characteristics of Chinese chestnut powder[J]. Food and Fermentation Industries,2022 ,48 (13 ):155 −162 .[23] 陈如. 超微粉碎对苹果全粉及其膳食纤维物化性质的影响 [D]. 咸阳:西北农林科技大学, 2017. [CHEN R. Effect of ultrafine grinding on the physicochemical properties of apple powder and its dietary fiber[D]. Xianyang:Northwest A&F University, 2017.] CHEN R. Effect of ultrafine grinding on the physicochemical properties of apple powder and its dietary fiber[D]. Xianyang: Northwest A&F University, 2017.

[24] 邓凯波, 黄雅萍, 代亚萍, 等. 超微粉碎对南瓜粉物化及其粉糊流变性质的影响[J]. 东北农业大学学报,2018,49(11):42−49. [DENG K B, HUANG Y P, DAI Y P, et al. Effect of ultrafine grinding on physicochemical and paste rheological properties of pumpkin powder[J]. Journal of Northeast Agricultural University,2018,49(11):42−49.] DENG K B, HUANG Y P, DAI Y P, et al . Effect of ultrafine grinding on physicochemical and paste rheological properties of pumpkin powder[J]. Journal of Northeast Agricultural University,2018 ,49 (11 ):42 −49 .[25] 赵仕婷, 木泰华, 郭亚姿, 等. 两种超微粉碎方法对甘薯膳食纤维物化功能特性影响的比较研究[J]. 食品工业科技,2014,35(15):101−106. [ZHAO S T, MU T H, GUO Y Z, et al. The effect of two different ultrafine grinding methods on physicochemical and functional properties of sweet potato dietary diber[J]. Science and Technology of Food Industry,2014,35(15):101−106.] ZHAO S T, MU T H, GUO Y Z, et al . The effect of two different ultrafine grinding methods on physicochemical and functional properties of sweet potato dietary diber[J]. Science and Technology of Food Industry,2014 ,35 (15 ):101 −106 .[26] 王娜, 柯轶, 魏瑜. 超微粉碎-纤维素酶法改性竹笋膳食纤维的工艺评价[J]. 福建农业科技,2021,52(5):6−10. [WANG N, KE Y, WEI Y. Process evaluation of the modification of dietary fiber in bamboo shoots by ultra-fine pulverization-cellulse method[J]. Fujian Agricultural Science and Technology,2021,52(5):6−10.] WANG N, KE Y, WEI Y . Process evaluation of the modification of dietary fiber in bamboo shoots by ultra-fine pulverization-cellulse method[J]. Fujian Agricultural Science and Technology,2021 ,52 (5 ):6 −10 .[27] 施建斌, 隋勇, 蔡沙, 等. 麦麸及麦麸膳食纤维常规粉碎和超微粉碎物化特性比较[J]. 现代食品科技,2021,37(1):150−6,49. [SHI J B, SUI Y, CAI S, et al. Comparison of physicochemical properties between conventional and ultrafine crushing of wheat bran and wheat bran dietary fiber[J]. Modern Food Science and Technology,2021,37(1):150−6,49.] SHI J B, SUI Y, CAI S, et al . Comparison of physicochemical properties between conventional and ultrafine crushing of wheat bran and wheat bran dietary fiber[J]. Modern Food Science and Technology,2021 ,37 (1 ):150 −6,49 .[28] ZHAO X Y, ZHU H T, ZHANG G X, et al. Effect of superfine grinding on the physicochemical properties and antioxidant activity of red grape pomace powders[J]. Powder Technology,2015,286:838−844. doi: 10.1016/j.powtec.2015.09.025

[29] HUANG X, DOU J Y, LI D, et al. Effects of superfine grinding on properties of sugar beet pulp powders[J]. LWT,2018,87:203−209. doi: 10.1016/j.lwt.2017.08.067

[30] 赵萌萌, 党斌, 张文刚, 等. 超微粉碎对青稞麸皮粉微观结构及功能特性的影响[J]. 农业工程学报,2020,36(8):278−286. [ZHAO M M, DANG B, ZHANG W G, et al. Effect of ultrafine grinding on the microstructure and functional characteristics of highland barley bran powder[J]. Journal of Agricultural Engineering,2020,36(8):278−286.] ZHAO M M, DANG B, ZHANG W G, et al . Effect of ultrafine grinding on the microstructure and functional characteristics of highland barley bran powder[J]. Journal of Agricultural Engineering,2020 ,36 (8 ):278 −286 . -

期刊类型引用(1)

1. 刀梅,宫树森,韦祖粉,王青芬,杨自云,吴田. 诱导剂对海巴戟莨菪亭累积的影响. 西北农林科技大学学报(自然科学版). 2024(08): 133-142 .  百度学术

百度学术

其他类型引用(0)

下载:

下载:

下载:

下载: