Effects of Tea Residue Extracts with Different Molecular Weight on the Pasting Characteristics of Potato Starch

-

摘要: 茶渣是茶叶经加工利用后的剩余残渣,富含多种活性成分。为了探究不同种类及分子量的茶渣提取物对马铃薯淀粉(PS)糊化特性的影响,采用连续提取法分别获得茶渣乙醇提取物(TRE)、水提取物(TRW)和碱提取物(TRA),进而利用膜分离制备了不同分子量的乙醇提取物(TRE-1,<30 kDa;TRE-2,>30 kDa)、水提取物(TRW-1,<100 kDa;TRW-2,>100 kDa)。将0.5%、1%、2%、5%、10%(w/w淀粉干基)的茶渣提取物添加到马铃薯淀粉中,考察了不同茶渣提取物对马铃薯淀粉黏度特性的影响,并用扫描电子显微镜观察了添加茶渣提取物的马铃薯淀粉微观结构。结果表明,不同种类及分子量的茶渣提取物均能显著降低马铃薯淀粉的峰值黏度和膨润率(P<0.05),抑制马铃薯淀粉的糊化,抑制顺序依次为:TRA>TRW-2>TRE-2>TRW-1>TRE-1。随着茶渣提取物添加量的增加,马铃薯淀粉的峰值黏度均逐渐降低。添加10%的TRA、TRW-2、TRE-2、TRW-1、TRE-1后,马铃薯淀粉的峰值黏度分别为4624、5013、5431、5911、6195 cP。与TRE-1和TRW-1相比,TRE-2、TRW-2和TRA能更好的促进马铃薯淀粉碎片的连接,使片状结构更加完整光滑。综上,添加不同种类及分子量的茶渣提取物均能有效抑制马铃薯淀粉的糊化,其中10%的碱提取物的抑制效果最佳。Abstract: Tea residues are the remaining residue of tea after processing and utilization, which are rich in multiple active components. To investigate the effects of different types and molecular weights of tea residue extracts on the pasting characteristics of potato starch (PS), the ethanol extract (TRE), water extract (TRW) and alkali extract (TRA) of tea residue were obtained by continuous extraction method. On this basis, the different molecular weights of ethanol extract (TRE-1, <30 kDa. TRE-2, >30 kDa) and water extract (TRW-1, <100 kDa. TRW-2, >100 kDa) were prepared by a membrane separation. The effects of different tea residue extracts on the viscosity properties were investigated, and the microstructure of potato starch added with tea residue extract was observed by scanning electron microscopy (SEM). The results showed that different types and molecular weights of tea residue extracts could significantly (P<0.05) reduce the peak viscosity and swelling power of potato starch and inhibit the pasting behaviors of potato starch. The inhibition order was as follows: TRA>TRW-2>TRE-2>TRW-1>TRE-1. The peak viscosity of potato starch was gradually decreased with the increase of different extracts. After adding 10% TRA, TRW-2, TRE-2, TRW-1 and TRE-1, the peak viscosity of potato starch was 4624, 5013, 5431, 5911 and 6195 cP, respectively. TRE-2, TRW-2 and TRA could better promote the link between potato starch fragments and result in a more complete and smooth lamellar structure, compared with TRE-1, TRW-1. In summary, the addition of different types and molecular weights of tea residue extracts could effectively inhibit the gelatinization of potato starch, and the inhibitory effect of 10% alkali extract was the best.

-

Keywords:

- tea residue /

- ethanol extract /

- water extract /

- alkali extract /

- potato starch /

- pasting characteristics

-

目前全球每年茶叶消耗量约为600万吨。在茶叶种植、生产、加工及消费环节中会产生大量的茶渣剩余物,单中国每年可产生500万吨以上的茶渣剩余物[1]。由于传统的泡茶、现代饮料加工工艺等只能溶出茶叶中部分生物活性成分,这些茶渣中仍然含有多种有效成分,包括4.2%~10.1%的茶多酚、13.0%~19.0%的粗纤维,26.0%~35.0%的茶蛋白等[2]。其中,茶多酚[3−4]、茶多糖[5]、茶蛋白[6]具有很好的抗氧化活性,已被广泛应用于食品、化学品、医药等领域。因此,深入研究茶渣中活性成分的应用价值,可减少副产物的污染,实现现代食品工业的绿色可持续发展。

马铃薯淀粉具有颗粒大,吸水膨胀快,糊化温度低,黏度高等特性,但马铃薯淀粉糊因机械强度过低极大的限制了其加工贮藏[7]。为改善淀粉品质,往往在淀粉中加入多酚、多糖和蛋白质等几类外源物。淀粉基食品的营养特性受淀粉理化性质及与其它成分相互作用的影响[8−10]。Du等[11]研究了茶多酚对高压糊化大米淀粉结构和理化性质的影响,发现在室温下,茶多酚可以加速高静水压(≥ 400 MPa)诱导的大米淀粉糊化,并改变其结构和理化性质。Yin等[12]研究了RG-І果胶对马铃薯淀粉理化性质的影响。结果表明,RG-1果胶的添加显著降低了马铃薯淀粉的峰值黏度和崩解值,提高了马铃薯淀粉的糊化温度,增加了马铃薯淀粉的回生值,抑制了淀粉颗粒的膨润率。刘佳松等[13]研究了乳清蛋白及其水解物对马铃薯淀粉体外消化性和理化性质的影响。结果表明,添加乳清蛋白及其水解物提高了马铃薯淀粉的糊化温度。Chen等[14]研究了湿热条件下大豆肽对马铃薯淀粉理化性质的影响。结果表明,大豆蛋白肽能够降低马铃薯淀粉黏度和膨润率,提高马铃薯淀粉的糊化温度。曾铭等[15]系统总结了多酚对淀粉理化性质的影响,包括多酚来源、种类、添加量和淀粉来源及结构等影响因素。Li[16]总结了淀粉分子结构、水分含量、盐类、糖类、蛋白质、脂类和非淀粉多糖对淀粉糊化特性的影响。

本研究采用连续提取法,分别用50%乙醇、80 ℃水溶液、氢氧化钠溶液提取茶渣中的活性成分,并对乙醇提取物和水提取物进行膜分离,通过快速黏度分析仪(RVA)和扫描电子显微镜(SEM)研究了不同分子量茶渣提取物对马铃薯淀粉糊化特性的影响,为茶渣资源在食品加工中的应用提供科学基础和理论支撑。

1. 材料与方法

1.1 材料与仪器

茶渣 福建省仙洋洋食品科技有限公司提供,绿茶在80 ℃下浸提30 min后所获得的加工余渣;马铃薯淀粉(含水量17.14%,脂肪含量0.47%) 浙江省田灿食品科技有限公司提供;氢氧化钠、盐酸、乙醇等试剂 均为分析纯,国药集团化学试剂有限公司。

Eppendorf Centrifuge 5424 R型高速离心机 北京宏达恒业科技有限公司;N1210型旋转蒸发仪 杭州嘉维创新科技有限公司;RO-NF-UF-4010型实验用膜分离装置 上海摩塑科学器材有限公司;FD-SERIES型冷冻干燥机 上海田枫实业有限公司;DHG-9243BS-Ⅲ型烘箱 上海坤权生物科技有限公司;RVA-Super 4型快速黏度分析仪 瑞典波通仪器公司;Phenom-World BV型扫描电镜 复钠科学仪器有限公司。

1.2 实验方法

1.2.1 茶渣提取物制备

1.2.1.1 乙醇提取物(TRE)

采用文献[17−18]的方法,并稍作修改。将绿茶渣粉碎过20目筛,与50%乙醇按料液比1:25(w/v)混合搅拌,于50 ℃下提取80 min,离心(4000 r/min,10 min,4 ℃)后收集上清液,通过旋转蒸发仪浓缩后再经超滤膜分离,收集分子量为<30 kDa和>30 kDa的两个组分,浓缩后冷冻干燥得乙醇提取物,分别命名为TRE-1和TRE-2。

1.2.1.2 水提取物(TRW)

采用Wang等[19]的方法,并稍作修改。将乙醇提取后的茶渣烘干(65 ℃,48 h),与蒸馏水按料液比1:20(w/v)混合搅拌,在80 ℃下提取90 min,离心后收集上清液,并通过旋转蒸发仪浓缩。将浓缩液添加4倍无水乙醇于4 ℃过夜沉淀,离心(4000 r/min,10 min,4 ℃)后收集沉淀,沉淀加蒸馏水复溶,再离心去除水不溶组分,上清液过膜处理,收集分子量<100 kDa和>100 kDa的两个组分,浓缩后冷冻干燥得水提取物,分别命名为TRW-1和TRW-2。

1.2.1.3 碱提取物(TRA)

采用文静等[20]的方法,并稍作修改。将水提取后的茶渣继续干燥(65 ℃,48 h),与0.8 mol/L的氢氧化钠溶液按料液比1:15(w/v)混合搅拌,在80 ℃下提取30 min,离心后收集上清液,上清液采用等电点沉淀法,调节pH至4.5沉淀茶蛋白,离心后将沉淀加蒸馏水并调节pH至7.0后透析,透析液经旋转蒸发仪浓缩,冷冻干燥后得碱提取物,命名为TRA。

1.2.2 糊化性能测定

为了研究茶渣提取物对马铃薯淀粉糊化的影响,采用Yin等[12]的方法,并稍作修改。将3 g马铃薯淀粉分别添加0.5%、1%、2%、5%和10%的茶渣提取物(w/w淀粉干基),然后移至快速黏度分析仪的铝筒中,固定水分25 g,程序条件为:混合物于50 ℃,保持1 min;加热至95 ℃(速率9 ℃/min),保持5 min;再降温至50 ℃(速率9 ℃/min),保持1 min。

1.2.3 微观结构观察

将10%的茶渣提取物(w/w淀粉干基)和马铃薯淀粉于95 ℃糊化后,真空冷冻干燥,研磨过100目筛,通过扫描电子显微镜观察其微观结构变化。

1.2.4 膨润率测定

将0.6 g马铃薯淀粉(绝干)分别添加0.5%、1%、2%、5%和10%茶渣提取物(w/w淀粉干基),再溶于30 mL蒸馏水中,分别加热至50、60、70、80和90 °C,加热30 min,冷却至室温后离心(4000 r/min,10 min,4 °C),膨润率由沉淀质量与淀粉质量的比值表示[12]。

1.3 数据处理

所有测试中每组样品平行测定三次,结果以平均值±标准偏差表示,实验结果利用 SPSS 26.0 软件进行独立样本 t 检验,p<0.05表示差异显著,数据绘图使用Origin 8.5 pro。

2. 结果与分析

2.1 茶渣提取物对马铃薯淀粉糊化特性的影响

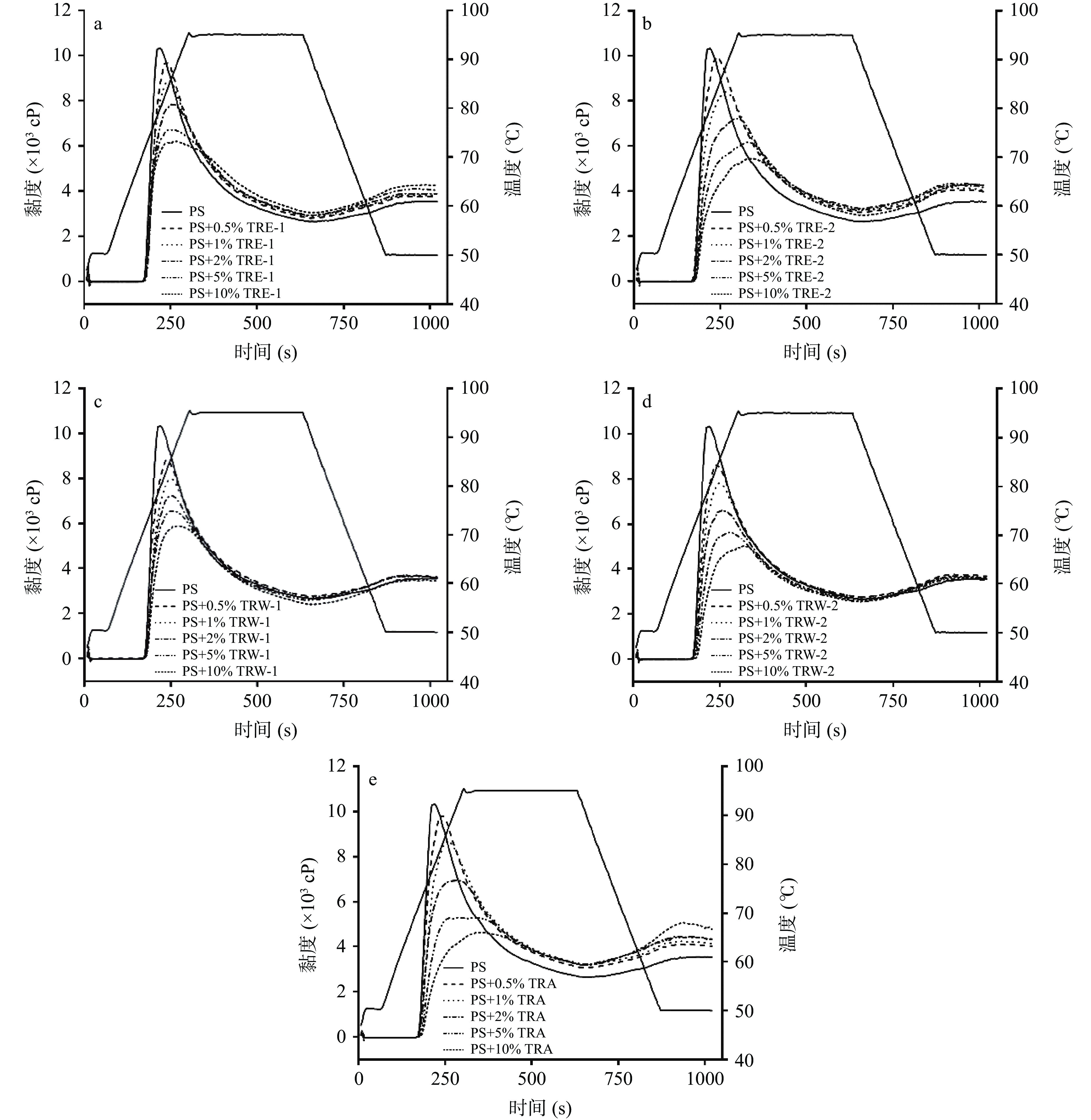

三种茶渣提取物(TRE、TRW和TRA)对马铃薯淀粉糊化特性的影响,如图1所示。茶渣提取物对马铃薯淀粉糊化特征参数(峰值黏度、谷值黏度、崩解值、终值黏度、回生值和糊化温度)的影响见表1。

表 1 茶渣提取物对马铃薯淀粉糊化特征参数的影响Table 1. Effects of tea residue extracts on the characteristic parameters of potato starch pasting样品 峰值黏度(cP) 谷值黏度(cP) 崩解值(cP) 终值黏度(cP) 回生值(cP) 糊化温度(℃) PS 10321±43a 2640±7l 7681±50a 3524±8m 884±1lm 71±0.05c PS+0.5% TRE-1 9709±25d 2804±13i 6905±12b 3758±13hi 954±0ijkl 70.2±0.06d PS+1% TRE-1 8893±29e 2866±10h 6027±19d 3826±16fgh 960±7hijkl 70.95±0.06c PS+2% TRE-1 7829±29j 2933±12g 4896±17i 3869±13efg 936±1jkl 71.8±0.15b PS+5% TRE-1 6724±28m 2925±4g 3799±24l 4041±25c 1116±21def 70.9±0.15c PS+10% TRE-1 6195±40p 3046±22f 3149±18n 4248±79b 1202±57bc 70.95±0.35c PS+0.5% TRE-2 9963±21b 3045±13f 6918±8b 3866±41efg 821±28mn 70.2±0.05d PS+1% TRE-2 8396±41h 3120±19e 5276±22g 3929±35de 809±16mno 70.15±0.15d PS+2% TRE-2 7215±50k 3219±17abc 3996±33k 4000±84cd 781±68fghi 70.9±0.05c PS+5% TRE-2 6158±33p 3233±21a 2925±43p 4225±118b 993±130ghijk 70.9±0.05c PS+10% TRE-2 5431±33s 3224±19ab 2207±36r 4263±67b 1039±68fghi 71.8±0.05b PS+0.5% TRW-1 8813±17f 2759±23j 6054±6d 3718±53ijk 959±30hijkl 70.2±0.04d PS+1% TRW-1 8010±28i 2722±10k 5288±18g 3647±20jkl 925±26kl 70.95±0.05c PS+2% TRW-1 7254±18k 2649±14l 4605±4j 3641±20kl 992±18ghijk 70.9±0.05c PS+5% TRW-1 6578±37o 2568±32m 4010±5k 3611±9lm 1043±30fgh 70.9±0.05c PS+10% TRW-1 5911±18q 2395±27o 3516±9m 3414±49n 1019±22ghij 70.9±0.04c PS+0.5% TRW-2 8638±36g 2727±24k 5911±12e 3855±86efg 1128±62cde 70.25±0.05d PS+1% TRW-2 7805±10j 2723±14k 5082±4h 3775±77ghi 1052±63efg 71±0.5c PS+2% TRW-2 6641±43n 2630±18l 4011±25k 3741±27hij 1111±9def 70.95±0.1c PS+5% TRW-2 5632±30r 2529±26n 3103±4o 3708±23ijk 1179±3bcd 71.7±0.2b PS+10% TRW-2 5013±27u 2528±7n 2485±23q 3745±60hij 1217±56b 72.45±0.05a PS+0.5% TRA 9833±31c 3056±12f 6777±19c 3856±55efg 800±43no 70.2±0.05d PS+1% TRA 8668±43g 3196±30bcd 5472±13f 3924±59def 728±29o 71.47±0.62b PS+2% TRA 6977±25i 3192±13bcd 3785±12l 3954±58cde 762±45no 70.95±0.05c PS+5% TRA 5290±12t 3189±12cd 2101±16s 4320±24b 1131±26cde 71.65±0.05b PS+10% TRA 4624±24v 3183±11d 1441±13t 4767±69a 1584±58a 71.7±0.05b 注:同行不同小写字母表示同列的数据差异显著,P<0.05;表2同。 由图1可知,添加茶渣提取物均能降低马铃薯淀粉的峰值黏度,且随着不同提取物添加量的增加,峰值黏度持续下降。当TRE-1、TRE-2、TRW-1、TRW-2和TRA的添加量分别从0%增加到10%时(w/w淀粉干基),马铃薯淀粉的峰值黏度由10321 cP分别降至6195、5431、5911、5013、4624 cP,峰值黏度降低程度依次为:TRA>TRW-2>TRE-2>TRW-1>TRE-1(P<0.05)。结果表明:相较于小分子量提取物,大分子量提取物,特别是碱提物(TRA)对降低马铃薯淀粉峰值黏度作用更强。淀粉糊的黏度下降主要是由于淀粉体系中淀粉与水的相分离,茶渣提取物中的羟基具有很强的亲水性,而淀粉分子与水分子的结合能力相对较弱,导致淀粉颗粒外可用水分含量减少[21−22],并且茶渣提取物的添加均能抑制淀粉糊化,且随着添加量的增加,抑制效果更加明显,这与文献[23−26]的研究结果一致。

由图1可知,乙醇提取物和碱提取物的添加可以使马铃薯淀粉谷值黏度和终值黏度增加,随着TRE-1、TRE-2、TRA添加量从0%增加到10%,马铃薯淀粉的谷值黏度由2640 cP分别增加至3046、3224和3183 cP,终值黏度由3524 cP分别增加至4248、4263、4767 cP。这可能是因为乙醇提取物和碱提取物与马铃薯淀粉分子之间产生氢键相互作用,形成缠结,导致黏度增加[27]。而添加水提取物使马铃薯淀粉谷值黏度和终值黏度均降低,例如,随着TRW-1、TRW-2添加量从0%增加到10%,马铃薯淀粉的谷值黏度由2640 cP分别降至2395、2528 cP,终值黏度由3524 cP分别降至3414、3745 cP。可能是由于水提物中茶多糖组分与淀粉发生相互作用,阻碍了直链淀粉分子之间的相互作用,减少了直链淀粉双螺旋区域的缠绕和形成,导致黏度降低[28]。

然而,茶渣提取物的添加对马铃薯淀粉糊化温度的影响并不显著,这与陈南等[29]的结果一致。经测定马铃薯淀粉样品糊化温度为71 ℃,添加2% TRE-1、10% TRE-2、5% TRW-2、10% TRW-2、1% TRA、5% TRA和10% TRA(w/w淀粉干基)后,马铃薯淀粉的糊化温度提高了0.47~1.45 ℃。可能是因为茶渣提取物中的茶多糖呈弱酸性,在酸性环境下糊化温度高于碱性环境[30],而且茶渣提取物与水之间形成的氢键阻碍了水分子的运动,只有更高的温度才能破坏这种结合力[31−32]。而添加0.5%的茶渣提取物(w/w,淀粉干基)后马铃薯淀粉糊化温度降低,是由于适当的添加量导致膨胀的淀粉颗粒相互碰撞的频率最大[33]。

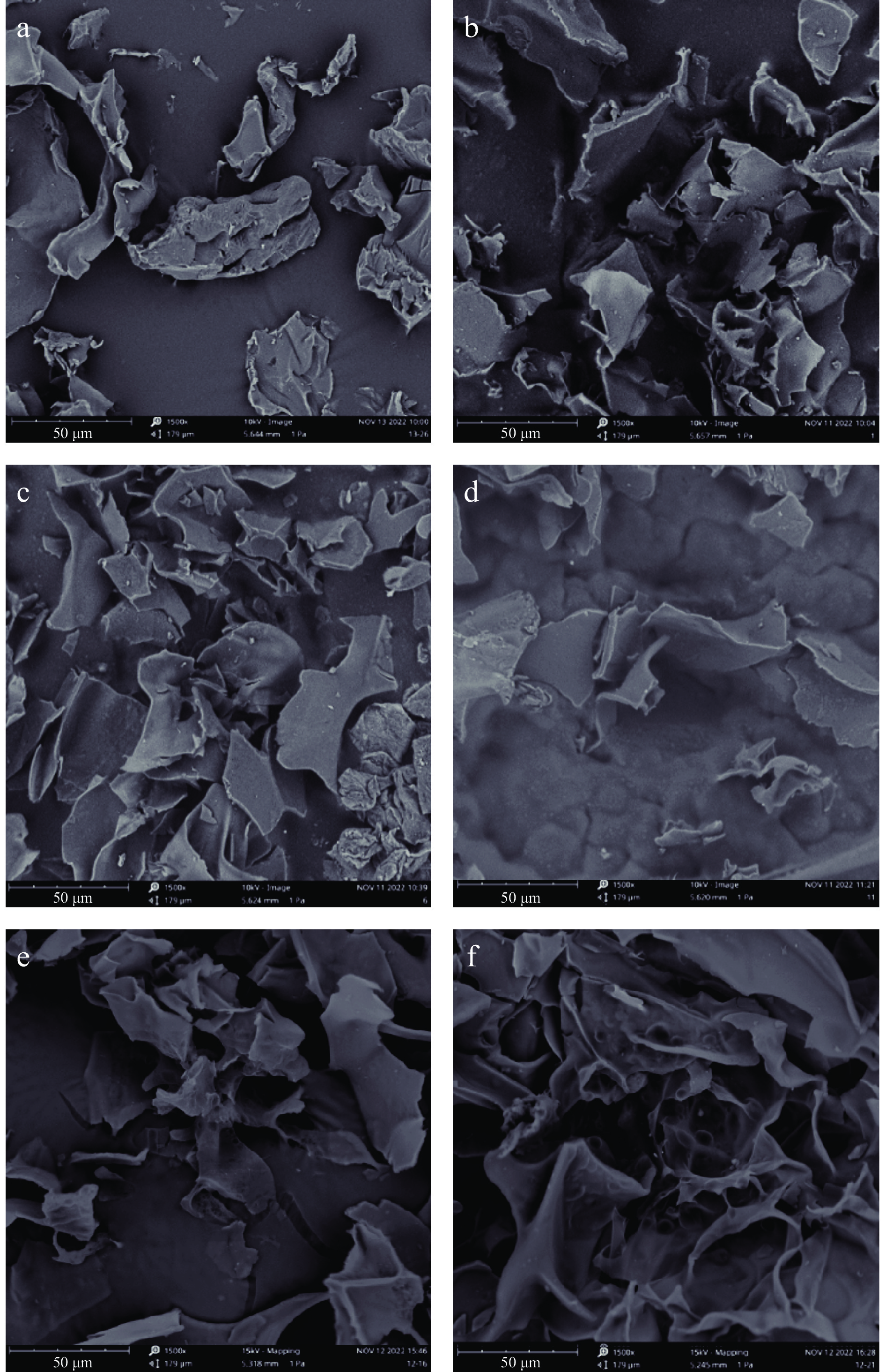

2.2 茶渣提取物对马铃薯淀粉微观结构的影响

由图2可以看出,马铃薯淀粉糊化后颗粒的原始结构被完全破坏,表面较为粗糙且有较多裂痕。添加茶渣提取物后,马铃薯淀粉呈现明显的片状结构。添加TRE-1和TRE-2后,破碎的淀粉颗粒重新聚集,形成大量表面光滑的片状结构,其中添加TRE-2后,淀粉颗粒更完整光滑;添加TRW-1后,破碎的淀粉颗粒减少,但仍有较多裂痕;添加TRW-2后,淀粉颗粒结构更加完整;添加TRA后,淀粉凝胶中出现孔状结构,淀粉颗粒聚集程度更高。淀粉微观结构呈现片状的原因可能是在冻干的过程中,水从凝胶网中逸出,形成不规则片状结构;茶渣提取物与直链淀粉分子以及支链淀粉分子侧链之间发生交互作用,形成更加致密的片层结构。不同分子量的茶渣提取物含有不同活性成分(茶多糖、茶多酚和茶蛋白),性质具有较大差异,从而影响与淀粉分子之间的分子相互作用强度,对淀粉及其凝胶的微观结构会产生不同的影响[34]。茶多酚的酚羟基数目越多分子量越大,通过氢键聚集周围淀粉分子的能力就越强[35]。茶蛋白通过自身形成凝胶网络,或与淀粉形成互穿网络来影响淀粉凝胶的结构及稳定性[31,36]。总体而言,茶渣提取物对马铃薯淀粉糊化过程有一定的抑制作用,且膜分离的高分子量茶渣提取物抑制效果更佳,这与黏度测定结果以及膨润率测定结果一致。

2.3 茶渣提取物对马铃薯淀粉膨润率的影响

如表2所示,不同的茶渣提取物对马铃薯淀粉膨润率影响不同。茶渣提取物的添加在大多数情况下可以降低马铃薯淀粉的膨润率。这可能是由于茶渣提取物与淀粉分子竞争水分子,淀粉可用水分子的降低,导致较低的膨润率[37];茶渣提取物限制了马铃薯淀粉溶液在加热过程中的膨胀,减小了淀粉颗粒的比表面积,从而减小了马铃薯淀粉膨润率[38]。这个现象和Pang等[39]的研究结果一致,他们发现淀粉/大豆蛋白糊的特性受到两种成分比例的极大影响,大豆蛋白比例越高,混合物就越像液体,膨润率降低。然而,在50 ℃时以及添加0.5% TRE-2(70 ℃)、0.5% TRW-2(80 ℃)的情况下,与对照组相比马铃薯淀粉表现出更高的膨润率,这是因为淀粉颗粒的吸水能力在茶渣提取物适当的添加量下有所增加[40]。

表 2 茶渣提取物对马铃薯淀粉膨润率的影响Table 2. Effects of tea residue extracts on the swelling rate of potato starch样品 膨润率(g/g) 50 ℃ 60 ℃ 70 ℃ 80 ℃ 90 ℃ PS 2.22±0.04l 6.85±0.18a 14.11±0.10b 19.26±0.13b 22.53±0.05a PS+0.5% TRE-1 2.24±0.06kl 6.83±0.01a 13.95±0.01d 19.14±0.01c 22.41±0.01b PS+1% TRE-1 2.25±0.06k 6.54±0.01c 13.53±0.01g 18.94±0.01e 22.11±0.01c PS+2% TRE-1 2.31±0.01j 6.39±0.35d 13.23±0.01j 17.62±0.01h 21.95±0.01d PS+5% TRE-1 2.37±0.01efg 5.82±0.03h 12.74±0.01m 17.62±0.01h 21.74±0.01e PS+10% TRE-1 2.40±0.01de 5.55±0.01jk 11.82±0.01r 16.90±0.01j 19.65±0.01k PS+0.5% TRE-2 2.22±0.01kl 6.21±0.01e 14.21±0.01a 19.01±0.01d 19.94±0.01j PS+1% TRE-2 2.35±0.01fghi 6.11±0.01efg 13.07±0.01l 18.55±0.01g 19.47±0.01m PS+2% TRE-2 2.38±0.01ef 6.01±0.01g 12.76±0.01m 17.63±0.01h 18.30±0.01n PS+5% TRE-2 2.42±0.01cd 5.21±0.01l 12.26±0.01p 14.64±0.01q 16.19±0.01s PS+10% TRE-2 2.53±0.00b 4.96±0.01m 11.58±0.01u 12.77±0.01u 13.24±0.01y PS+0.5% TRW-1 2.33±0.01hij 5.62±0.01ijk 13.65±0.01f 19.27±0.00b 16.60±0.01l PS+1% TRW-1 2.35±0.01fghi 5.63±0.01ij 13.49±0.01h 18.73±0.01f 17.94±0.01o PS+2% TRW-1 2.35±0.00fghi 5.50±0.01jk 12.52±0.01n 17.32±0.01i 17.12±0.01p PS+5% TRW-1 2.36±0.01efgh 5.49±0.01k 11.86±0.01q 16.82±0.01k 16.01±0.01t PS+10% TRW-1 2.35±0.01fghij 5.30±0.01l 11.62±0.01t 16.00±0.01n 13.38±0.01x PS+0.5% TRW-2 2.25±0.01k 6.20±0.01ef 14.10±0.01b 20.59±0.01a 21.20±0.01g PS+1% TRW-2 2.34±0.01ghij 6.10±0.01efg 13.92±0.01d 16.40±0.01m 21.68±0.01f PS+2% TRW-2 2.32±0.01ij 5.88±0.01h 13.81±0.01e 15.34±0.01p 16.93±0.01q PS+5% TRW-2 2.34±0.01ghij 5.75±0.01hi 12.33±0.01o 14.24±0.01r 13.62±0.01v PS+10% TRW-2 2.43±0.01c 5.51±0.01jk 11.73±0.01s 13.02±0.01t 13.49±0.01w PS+0.5% TRA 2.34±0.01ghij 6.85±0.01a 14.05±0.01c 19.25±0.01b 20.35±0.01h PS+1% TRA 2.36±0.01efgh 6.78±0.01ab 13.92±0.01d 16.90±0.01j 20.24±0.06i PS+2% TRA 2.38±0.01ef 6.67±0.01b 13.66±0.01f 16.52±0.01l 16.66±0.01r PS+5% TRA 2.38±0.01ef 6.06±0.01fg 13.29±0.01i 15.57±0.01o 15.99±0.01t PS+10% TRA 2.63±0.01ab 5.80±0.01h 13.13±0.01k 13.80±0.01s 13.84±0.01u 3. 结论

本文采用连续提取法结合膜分离技术分别制备不同种类和不同分子量茶渣的乙醇提取物TRE-1(<30 kDa)、TRE-2(>30 kDa),水提取物TRW-1(<100 kDa)、TRW-2(>100 kDa)和碱提取物TRA,并将制备的五种提取物分别加入马铃薯淀粉中,研究茶渣提取物对马铃薯淀粉糊化特性的影响。添加醇提取物和碱提取物后,淀粉峰值黏度和崩解值降低,谷值黏度、终值黏度和回生值略有增加。添加水提取物后,淀粉峰值黏度、谷值黏度、崩解值、终值黏度降低,回生值略有增加。添加茶渣提取物可以抑制马铃薯淀粉的糊化,茶渣提取物的添加也提高了淀粉颗粒的糊化温度和完整性,以及降低淀粉膨润率。其中,碱提取物对马铃薯淀粉糊化的抑制效果显著(P<0.05)高于水提取物和乙醇提取物,且添加10%的TRA对马铃薯淀粉糊化的抑制效果最佳。此外,茶渣提取物的添加均可以改变马铃薯淀粉微观结构,促进马铃薯淀粉破碎颗粒的连接,其中TRA、TRW-2和TRE-2的促进效果优于TRW-1和TRE-1,形成更加完整光滑的片状结构。本研究可为茶渣提取物对淀粉基食品特性改善及其茶叶加工副产物高值化开发利用提供科学依据与理论指导。

-

表 1 茶渣提取物对马铃薯淀粉糊化特征参数的影响

Table 1 Effects of tea residue extracts on the characteristic parameters of potato starch pasting

样品 峰值黏度(cP) 谷值黏度(cP) 崩解值(cP) 终值黏度(cP) 回生值(cP) 糊化温度(℃) PS 10321±43a 2640±7l 7681±50a 3524±8m 884±1lm 71±0.05c PS+0.5% TRE-1 9709±25d 2804±13i 6905±12b 3758±13hi 954±0ijkl 70.2±0.06d PS+1% TRE-1 8893±29e 2866±10h 6027±19d 3826±16fgh 960±7hijkl 70.95±0.06c PS+2% TRE-1 7829±29j 2933±12g 4896±17i 3869±13efg 936±1jkl 71.8±0.15b PS+5% TRE-1 6724±28m 2925±4g 3799±24l 4041±25c 1116±21def 70.9±0.15c PS+10% TRE-1 6195±40p 3046±22f 3149±18n 4248±79b 1202±57bc 70.95±0.35c PS+0.5% TRE-2 9963±21b 3045±13f 6918±8b 3866±41efg 821±28mn 70.2±0.05d PS+1% TRE-2 8396±41h 3120±19e 5276±22g 3929±35de 809±16mno 70.15±0.15d PS+2% TRE-2 7215±50k 3219±17abc 3996±33k 4000±84cd 781±68fghi 70.9±0.05c PS+5% TRE-2 6158±33p 3233±21a 2925±43p 4225±118b 993±130ghijk 70.9±0.05c PS+10% TRE-2 5431±33s 3224±19ab 2207±36r 4263±67b 1039±68fghi 71.8±0.05b PS+0.5% TRW-1 8813±17f 2759±23j 6054±6d 3718±53ijk 959±30hijkl 70.2±0.04d PS+1% TRW-1 8010±28i 2722±10k 5288±18g 3647±20jkl 925±26kl 70.95±0.05c PS+2% TRW-1 7254±18k 2649±14l 4605±4j 3641±20kl 992±18ghijk 70.9±0.05c PS+5% TRW-1 6578±37o 2568±32m 4010±5k 3611±9lm 1043±30fgh 70.9±0.05c PS+10% TRW-1 5911±18q 2395±27o 3516±9m 3414±49n 1019±22ghij 70.9±0.04c PS+0.5% TRW-2 8638±36g 2727±24k 5911±12e 3855±86efg 1128±62cde 70.25±0.05d PS+1% TRW-2 7805±10j 2723±14k 5082±4h 3775±77ghi 1052±63efg 71±0.5c PS+2% TRW-2 6641±43n 2630±18l 4011±25k 3741±27hij 1111±9def 70.95±0.1c PS+5% TRW-2 5632±30r 2529±26n 3103±4o 3708±23ijk 1179±3bcd 71.7±0.2b PS+10% TRW-2 5013±27u 2528±7n 2485±23q 3745±60hij 1217±56b 72.45±0.05a PS+0.5% TRA 9833±31c 3056±12f 6777±19c 3856±55efg 800±43no 70.2±0.05d PS+1% TRA 8668±43g 3196±30bcd 5472±13f 3924±59def 728±29o 71.47±0.62b PS+2% TRA 6977±25i 3192±13bcd 3785±12l 3954±58cde 762±45no 70.95±0.05c PS+5% TRA 5290±12t 3189±12cd 2101±16s 4320±24b 1131±26cde 71.65±0.05b PS+10% TRA 4624±24v 3183±11d 1441±13t 4767±69a 1584±58a 71.7±0.05b 注:同行不同小写字母表示同列的数据差异显著,P<0.05;表2同。 表 2 茶渣提取物对马铃薯淀粉膨润率的影响

Table 2 Effects of tea residue extracts on the swelling rate of potato starch

样品 膨润率(g/g) 50 ℃ 60 ℃ 70 ℃ 80 ℃ 90 ℃ PS 2.22±0.04l 6.85±0.18a 14.11±0.10b 19.26±0.13b 22.53±0.05a PS+0.5% TRE-1 2.24±0.06kl 6.83±0.01a 13.95±0.01d 19.14±0.01c 22.41±0.01b PS+1% TRE-1 2.25±0.06k 6.54±0.01c 13.53±0.01g 18.94±0.01e 22.11±0.01c PS+2% TRE-1 2.31±0.01j 6.39±0.35d 13.23±0.01j 17.62±0.01h 21.95±0.01d PS+5% TRE-1 2.37±0.01efg 5.82±0.03h 12.74±0.01m 17.62±0.01h 21.74±0.01e PS+10% TRE-1 2.40±0.01de 5.55±0.01jk 11.82±0.01r 16.90±0.01j 19.65±0.01k PS+0.5% TRE-2 2.22±0.01kl 6.21±0.01e 14.21±0.01a 19.01±0.01d 19.94±0.01j PS+1% TRE-2 2.35±0.01fghi 6.11±0.01efg 13.07±0.01l 18.55±0.01g 19.47±0.01m PS+2% TRE-2 2.38±0.01ef 6.01±0.01g 12.76±0.01m 17.63±0.01h 18.30±0.01n PS+5% TRE-2 2.42±0.01cd 5.21±0.01l 12.26±0.01p 14.64±0.01q 16.19±0.01s PS+10% TRE-2 2.53±0.00b 4.96±0.01m 11.58±0.01u 12.77±0.01u 13.24±0.01y PS+0.5% TRW-1 2.33±0.01hij 5.62±0.01ijk 13.65±0.01f 19.27±0.00b 16.60±0.01l PS+1% TRW-1 2.35±0.01fghi 5.63±0.01ij 13.49±0.01h 18.73±0.01f 17.94±0.01o PS+2% TRW-1 2.35±0.00fghi 5.50±0.01jk 12.52±0.01n 17.32±0.01i 17.12±0.01p PS+5% TRW-1 2.36±0.01efgh 5.49±0.01k 11.86±0.01q 16.82±0.01k 16.01±0.01t PS+10% TRW-1 2.35±0.01fghij 5.30±0.01l 11.62±0.01t 16.00±0.01n 13.38±0.01x PS+0.5% TRW-2 2.25±0.01k 6.20±0.01ef 14.10±0.01b 20.59±0.01a 21.20±0.01g PS+1% TRW-2 2.34±0.01ghij 6.10±0.01efg 13.92±0.01d 16.40±0.01m 21.68±0.01f PS+2% TRW-2 2.32±0.01ij 5.88±0.01h 13.81±0.01e 15.34±0.01p 16.93±0.01q PS+5% TRW-2 2.34±0.01ghij 5.75±0.01hi 12.33±0.01o 14.24±0.01r 13.62±0.01v PS+10% TRW-2 2.43±0.01c 5.51±0.01jk 11.73±0.01s 13.02±0.01t 13.49±0.01w PS+0.5% TRA 2.34±0.01ghij 6.85±0.01a 14.05±0.01c 19.25±0.01b 20.35±0.01h PS+1% TRA 2.36±0.01efgh 6.78±0.01ab 13.92±0.01d 16.90±0.01j 20.24±0.06i PS+2% TRA 2.38±0.01ef 6.67±0.01b 13.66±0.01f 16.52±0.01l 16.66±0.01r PS+5% TRA 2.38±0.01ef 6.06±0.01fg 13.29±0.01i 15.57±0.01o 15.99±0.01t PS+10% TRA 2.63±0.01ab 5.80±0.01h 13.13±0.01k 13.80±0.01s 13.84±0.01u -

[1] 龚新怀, 李明春, 辛梅华, 等. 茶生物质填充高分子复合材料的研究进展[J]. 农业工程学报,2020,36(18):283−291 doi: 10.11975/j.issn.1002-6819.2020.18.033 GONG X H, LI M C, XIN M H, et al. Research progress of polymer composites filled with tea biomass[J]. Transactions of the Chinese Society of Agricultural Engineering,2020,36(18):283−291. doi: 10.11975/j.issn.1002-6819.2020.18.033

[2] 郑清梅, 陈昆平, 钟艳梅, 等. 4类茶叶及其茶渣主要成分的测定与分析[J]. 广东农业科学,2015,42(6):14−20 doi: 10.3969/j.issn.1004-874X.2015.06.003 ZHENG Q M, CHEN K P, ZHONG Y M, et al. Determination and analysis of main components of four kinds of tea and their tea wastes[J]. Guangdong Agricultural Sciences,2015,42(6):14−20. doi: 10.3969/j.issn.1004-874X.2015.06.003

[3] LÜ Y J, LI M, PAN J X, et al. Interactions between tea products and wheat starch during retrogradation[J]. Food Bioscience,2020,34:100523. doi: 10.1016/j.fbio.2019.100523

[4] WU Y, NIU M, XU H. Pasting behaviors, gel rheological properties, and freeze-thaw stability of rice flour and starch modified by green tea polyphenols[J]. LWT,2020,118:108796. doi: 10.1016/j.lwt.2019.108796

[5] XU A, LAI W, CHEN P, et al. A comprehensive review on polysaccharide conjugates derived from tea leaves:Composition, structure, function and application[J]. Trends in Food Science & Technology,2021,114:83−99.

[6] MIAO S, WEI Y, CHEN J, et al. Extraction methods, physiological activities and high value applications of tea residue and its active components:A review[J]. Critical Reviews in Food Science and Nutrition, 2022, 1-19.

[7] 汪薇. 马铃薯淀粉/玉米淀粉共混体系理化性质、互作机理研究及其应用[D]. 武汉:华中农业大学, 2017 WANG W. Physicochemical properties, interaction mechanism of potato starch/maize starches systems and its applications[D]. Wuhan:Huazhong Agricultural University, 2017.

[8] NIU L, WU L, XIAO J. Inhibition of gelatinized rice starch retrogradation by rice bran protein hydrolysates[J]. Carbohydrate Polymers,2017,175:311−319. doi: 10.1016/j.carbpol.2017.07.070

[9] CHENG H, HANSEN J H. Extrudate expansion model in a twin-screw extrusion cooking process considering melt rheological property[J]. Food and Bioprocess Technology,2016,9(4):604−611. doi: 10.1007/s11947-015-1655-0

[10] JIN N, KONG D, WANG H. Effects of temperature and time on gelatinization of corn starch employing gradient isothermal heating program of rapid visco analyzer[J]. Journal of Food Process Engineering,2019,42(7):e13264. doi: 10.1111/jfpe.13264

[11] DU J J, YANG Z K, XU X N, et al. Effects of tea polyphenols on the structural and physicochemical properties of high-hydrostatic-pressure-gelatinized rice starch[J]. Food Hydrocolloids,2019,91:256−262. doi: 10.1016/j.foodhyd.2019.01.035

[12] YIN X, ZHENG Y, KONG X, et al. RG-І pectin affects the physicochemical properties and digestibility of potato starch[J]. Food Hydrocolloids,2021,117:106687. doi: 10.1016/j.foodhyd.2021.106687

[13] 刘佳松, 刘青, 杨月月, 等. 乳清蛋白及其水解物对马铃薯淀粉体外消化性和理化性质的影响[J]. 食品工业科技,2023,44(5):74−81 LIU J S, LIU Q, YANG Y Y, et al. Effects of whey protein and its hydrolysates on in vitro digestibility and physicochemical properties of potato starch[J]. Science and Technology of Food Industry,2023,44(5):74−81.

[14] CHEN X, ZHANG Y, ZHAO H, et al. Effects of heat moisture treatment on the structural, physicochemical, and digestibility properties of potato starch-soybean peptide complexes[J]. International Journal of Food Science & Technology,2022,57(4):1975−1987.

[15] 曾铭, 李蟠莹, 胡鹏, 等. 多酚对淀粉理化性质影响的研究进展[J]. 食品工业科技,2018,39(22):334−340 ZENG M, LI P Y, HU P, et al. Research progress on the effects of polyphenols on the physicochemical properties of starch[J]. Science and Technology of Food Industry,2018,39(22):334−340.

[16] LI C. Recent progress in understanding starch gelatinization-An important property determining food quality[J]. Carbohydrate Polymers, 2022:119735.

[17] 许晨新, 杨海东, 张思访, 等. 响应面法优化雨花茶茶多酚提取工艺及其化学模式识别研究[J]. 中国食品添加剂,2023,34(3):33−41 doi: 10.19804/j.issn1006-2513.2023.03.005 XU C X, YANG H D, ZHANG S F, et al. Optimization of extraction process of tea polyphenols from Yuhua tea by response surface methodology and its chemical pattern recognition[J]. China Food Additives,2023,34(3):33−41. doi: 10.19804/j.issn1006-2513.2023.03.005

[18] DOS S L F, VARGAS B K, BERTOL C D, et al. Clarification and concentration of yerba mate extract by membrane technology to increase shelf life[J]. Food and Bioproducts Processing,2020,122:22−30. doi: 10.1016/j.fbp.2020.04.002

[19] WANG Y, YANG Z, WEI X. Antioxidant activities potential of tea polysaccharide fractions obtained by ultra filtration[J]. International Journal of Biological Macromolecules,2012,50(3):558−564. doi: 10.1016/j.ijbiomac.2011.12.028

[20] 文静, 解新安, 李雁, 等. 微波辅助碱法提取茶渣蛋白工艺及抗氧化活性研究[J]. 粮食与油脂,2017,30(5):41−44 doi: 10.3969/j.issn.1008-9578.2017.05.012 WEN J, XIE X A, LI Y, et al. Technology and antioxidant activity of tea-residue protein using microwave-assisted alkaline extraction[J]. Cereals & Oils,2017,30(5):41−44. doi: 10.3969/j.issn.1008-9578.2017.05.012

[21] 金娃, 陈威, 李松原, 等. 海藻糖对三种淀粉理化性质的影响[J]. 中国调味品,2021,46(2):152−155 doi: 10.3969/j.issn.1000-9973.2021.02.033 JIN W, CHEN W, LI S Y, et al. Effects of trehalose on physical and chemical properties of three starches[J]. China Condiment,2021,46(2):152−155. doi: 10.3969/j.issn.1000-9973.2021.02.033

[22] MA S P, ZHU P L, WANG M C. Effects of konjac glucomannan on pasting and rheological properties of corn starch[J]. Food Hydrocolloids,2019,89:234−240. doi: 10.1016/j.foodhyd.2018.10.045

[23] 符珍, 贾燕君, 林莹, 等. 玉米醇溶蛋白对木薯淀粉理化性质的影响[J]. 粮食与饲料工业,2018(10):26−29 FU Z, JIA Y J, LIN Y, et al. Influence of zein on physicochemical properties of tapioca starch[J]. Cereal & Feed Industry,2018(10):26−29.

[24] 许柠, 王远辉, 张国治, 等. 米糠不溶性膳食纤维和阿魏酸共同作用对籼米淀粉糊化过程的影响[J]. 河南工业大学学报(自然科学版),2021,42(4):30−37 XU N, WANG Y H, ZHANG G Z, et al. The effect of rice bran insoluble dietary fiber and ferulic acid on the gelatinization process of indica rice starch[J]. Journal of Henan University of Technology (Natural Science Edition),2021,42(4):30−37.

[25] LI Z, WANG L, CHEN Z, et al. Impact of protein content on processing and texture properties of waxy rice flour and glutinous dumpling[J]. Journal of Cereal Science,2018,81:30−36. doi: 10.1016/j.jcs.2018.03.005

[26] JEONG S, KIM H W, LEE S. Rheological and secondary structural characterization of rice flour-zein composites for noodles slit from gluten-free sheeted dough[J]. Food Chemistry,2017,221:1539−1545. doi: 10.1016/j.foodchem.2016.10.139

[27] 莫呈鹏, 余奔, 王鲁峰. 添加黄原胶和脂肪酸后玉米淀粉理化性质的变化[J]. 现代食品科技,2020,36(8):102−109 MO C P, YU B, WANG L F. Changes in physicochemical properties of maize starch supplemented with xanthan gum and fatty acids[J]. Modern Food Science and Technology,2020,36(8):102−109.

[28] 王晨, 谢岩黎, 南永远. 阿魏酸对小麦淀粉理化特性的影响[J]. 食品工业科技,2018,39(18):12−16,21 doi: 10.13386/j.issn1002-0306.2018.18.003 WANG C, XIE Y L, NAN Y Y. Effect of ferulic acid on physicochemical properties of wheat starch[J]. Science and Technology of Food Industry,2018,39(18):12−16,21. doi: 10.13386/j.issn1002-0306.2018.18.003

[29] 陈南, 高浩祥, 何强, 等. 植物多酚与淀粉的分子相互作用研究进展[J]. 食品工业科技,2023,44(2):497−505 doi: 10.13386/j.issn1002-0306.2022040140 CHEN N, GAO H X, HE Q, et al. A review of the molecular interaction between plant polyphenols and starch[J]. Science and Technology of Food Industry,2023,44(2):497−505. doi: 10.13386/j.issn1002-0306.2022040140

[30] 章丽琳, 付晶晶, 张喻. 应用RVA仪分析凉薯淀粉的糊化特性[J]. 粮食与油脂,2017,30(4):38−41 doi: 10.3969/j.issn.1008-9578.2017.04.011 ZHANG L L, FU J J, ZHANG Y. Analysis on pasting properties of yam bean starch by RVA[J]. Cereals & Oils,2017,30(4):38−41. doi: 10.3969/j.issn.1008-9578.2017.04.011

[31] 任顺成, 张丹丹. 黑豆蛋白和扁豆蛋白对小麦淀粉理化性质的影响[J]. 河南工业大学学报(自然科学版),2022,43(5):22−28 REN S C, ZHANG D D. Effects of black bean protein and lentil bean protein on physicochemical properties of wheat starch[J]. Journal of Henan University of Technology (Natural Science Edition),2022,43(5):22−28.

[32] YU Z, WANG Y S, CHEN H H, et al. The gelatinization and retrogradation properties of wheat starch with the addition of stearic acid and sodium alginate[J]. Food Hydrocolloids,2018,81:77−86. doi: 10.1016/j.foodhyd.2018.02.041

[33] 刘成龙, 史彩燕, 武乔乔, 等. 蛋白质对玉米淀粉理化特性的影响[J]. 齐鲁工业大学学报,2018,32(6):29−33 doi: 10.16442/j.cnki.qlgydxxb.2018.06.006 LIU C L, SHI C Y, WU Q Q, et al. Effect of protein on physicochemical properties of corn starch[J]. Journal of Qilu University of Technology,2018,32(6):29−33. doi: 10.16442/j.cnki.qlgydxxb.2018.06.006

[34] 张敏, 徐燕, 周裔彬, 等. 大米蛋白对小麦淀粉理化特性的影响[J]. 食品工业科技,2019,40(12):101−104,111 doi: 10.13386/j.issn1002-0306.2019.12.017 ZHANG M, XU Y, ZHOU Y B, et al. Effects of rice protein on the physicochemical properties of wheat starch[J]. Science and Technology of Food Industry,2019,40(12):101−104,111. doi: 10.13386/j.issn1002-0306.2019.12.017

[35] 崔欣阳, 邢佳浩, 王睿思, 等. 枸杞叶黄酮对多种淀粉理化性质的影响[J]. 食品安全导刊,2022(6):42−45,49 doi: 10.3969/j.issn.1674-0270.2022.6.spaqdk202206018 CUI X Y, XING J H, WANG R S, et al. Effects of flavonoids from lycium barbarum leaves on physicochemical properties of various starch[J]. China Food Safety Magazine,2022(6):42−45,49. doi: 10.3969/j.issn.1674-0270.2022.6.spaqdk202206018

[36] 张宏远, 木泰华, 马梦梅. 马铃薯淀粉凝胶形成及其品质影响因素研究进展[J]. 食品工业科技,2022,43(23):450−456 doi: 10.13386/j.issn1002-0306.2022010181 ZHANG H Y, MU T H, MA M M. Formation of potato starch gel and influencing factors of its quality-a review[J]. Science and Technology of Food Industry,2022,43(23):450−456. doi: 10.13386/j.issn1002-0306.2022010181

[37] KAUSHIK M, YADAV B S, YADAV R B, et al. Assessing the influence of lentil protein concentrate on pasting and rheological properties of barley starch[J]. Journal of Food Measurement and Characterization,2020,14(3):1623−1633. doi: 10.1007/s11694-020-00410-7

[38] 任顺成, 肖遥. 几种食源多酚对玉米淀粉理化特性的影响[J]. 河南工业大学学报(自然科学版),2018,39(4):8−13 doi: 10.3969/j.issn.1673-2383.2018.04.002 REN S C, XIAO Y. Effect of several kinds of dietary polyphenols on physicochemical properties of corn starch[J]. Journal of Henan University of Technology (Natural Science Edition),2018,39(4):8−13. doi: 10.3969/j.issn.1673-2383.2018.04.002

[39] PANG Z, BOUROUIS I, SUN M, et al. Physicochemical properties and microstructural behaviors of rice starch/soy proteins mixtures at different proportions[J]. International Journal of Biological Macromolecules,2022,209:2061−2069. doi: 10.1016/j.ijbiomac.2022.04.187

[40] JIA S, TAO H, ZHAO H, et al. Effects of lycium barbarum polysaccharide on pasting, rheology, and in vitro digestibility of starch[J]. Starch-Stärke,2023,75(1−2):2200185.

下载:

下载:

下载:

下载: