Comparative Analysis on Cleaning Effect of Different Surface Treatment Equipments on Wheat

-

摘要: 为深入探究不同清理设备对小麦籽粒表面的清理程度,选用FBPY-S-1 30小麦剥皮机和FDMW30×60打麦机(转子、定子结构不同),通过原粮直接清理、一清润麦后二清、原料先润麦后清理三种工艺来清理原粮小麦。以增碎率、剥皮率、灰分降等指标作为表征清理效率的可视化参数,对比两种设备对小麦的清理效果;以小麦籽粒的阿拉伯木聚糖、烷基间苯二酚含量并结合扫描电镜(SEM)观察微观结构综合分析两种设备对小麦皮层的去除情况;通过测定处理前后小麦籽粒的真菌毒素和微生物含量确定两种设备对小麦籽粒的卫生改变情况。实验结果表明,剥皮机的清理效率是打麦机的3~4倍,增碎率不及打麦机的二分之一。剥皮机可将0.45%~0.63%的小麦表皮轻微剥落,而打麦机对小麦皮层厚度无影响。剥皮机对毒素微生物的去除率高于打麦机近2倍,同时轻度剥皮处理对小麦的总淀粉和粗蛋白含量无显著影响(P>0.05)。在不同工艺中,工艺一单次剥皮处理可以达到较好的干法清理效果。但以工艺二润麦前后分别进行剥皮处理对小麦的清理效果最佳,与一清前的原粮相比,此工艺的整机出杂率达1.93%,可使小麦籽粒的脱氧雪腐镰刀菌烯醇含量降低62%、菌落总数含量减少49%,大肠杆菌减少78%。综上可知,FBPY-S-1 30小麦剥皮机的剥皮处理和工艺二相结合可以达到对原粮小麦清理的最佳效果。Abstract: In order to deeply explore the cleaning degree of wheat grain surface by different cleaning equipments, FBPY-S-1 30 debranner and FDMW30×60 scourer were selected in this paper (with different rotor and stator structures). Three processes were used to treat raw wheat, including direct cleaning of the raw grain, first cleaning and tempering followed by second cleaning, and first tempering and then cleaning of the raw grain. The degree of wheat cleaning by the two kinds of equipments was compared by taking such indicators as increase of broken wheat grains, debranning rate and ash reduction as visual parameters to characterize the cleaning efficiency. The removal of wheat cortex by the two kinds of equipments was comprehensively analyzed based on the content of arabinoxylan and alkylresorcinol in wheat grain and the microstructure observed by scanning electron microscopy (SEM). The hygienic changes of the two kinds of equipment to wheat grains were determined by determining the mycotoxins and microorganisms contents of wheat grains before and after treatment. The experimental results showed that the cleaning efficiency of the debranner was 3~4 times of that of the scourer, and the increase rate of broken wheat grains was less than half of that of the scourer. The debranner could slightly peel off 0.45%~0.63% of wheat bran, while the scourer had no effect on the thickness of wheat bran. The removal rate of mycotoxins and microorganisms by the debranner was nearly twice higher than that of the scourer, and the slight peeling treatment had no significant effect on the total starch and crude protein content of wheat (P>0.05). In different processes, the single peeling treatment of process I could achieve good dry cleaning results. However, the best cleaning effect of wheat was achieved by peeling before and after wheat moistening in process II. Compared with the raw grain before first cleaning, the impurity removal rate of this process was 1.93%, which could reduce the content of deoxynivalenol in wheat grains by 62%, the total aerobic plate content by 49%, and the number of coliforms content by 78%. In summary, the combination of peeling treatment of FBPY-S-1 30 Debranner and process II can achieve the best effect on cleaning raw grain wheat.

-

Keywords:

- surface cleaning /

- debranner /

- scourer /

- hygiene indicators /

- process optimization

-

小麦的潜在污染物大多来源于环境,包括空气、土壤、水等。大多数污染是微生物性质的,但也包含重金属和化学污染物。在小麦表面生长的真菌产生的次级代谢产物属于多种污染中最具毒性的污染物[1]。小麦皮层质量仅占粒重的15%左右[2],但麦皮表面附着的微生物污染占整粒小麦的87%以上[3]。表面微生物如果进入小麦籽粒内部或在后续制粉工艺混入小麦粉中将导致食物中毒[4−5]。清理设备和工艺决定了小麦深加工或小麦制粉产品的品质与安全[6]。小麦收获后依据粒径质量、颜色形状、内部强度等物理性质的差异来清理不完善粒和小麦表面,据此原理设计的清理设备包括高方筛、重力分级机、色选机、精选机、打麦机等,清理工序包括筛选、比重分级、色选、打麦、刷麦等[7−9]。

其中打、剥、刷等表面处理类工序是影响小麦清理程度的基础工序和关键步骤。Magyar等[10]通过对比四种不同设备组合的小麦制粉流程,发现色选机和打麦机的组合可以最有效地降低小麦粉中的毒素浓度。在俄罗斯联邦的工业面粉厂,主要使用打麦机和擦刷机(如R3-BMO或A1-BSHM)清理小麦表面的污染,但经此处理后碎粒含量显著增加[11]。英国Henry Simon公司生产的HSKKSI型强力打麦机通过摩擦和打击清理小麦外皮和杂质,分解和去除瘪麦、虫蚀粒。我国目前广泛使用的FDMW型卧式打麦机,是“七五”国家重点科技计划的产品,存在体积大、碎麦多、故障率高的缺陷[12]。考虑到外源污染物主要存在于小麦表面,同时为改善传统打麦的缺陷,粮食加工行业提出谷物轻剥皮或柔性脱皮处理[13−15]。该处理不仅需要在较短的碾磨工艺中提高小麦粉的品质[16],同时需要减少粮粒破碎,达到节粮减损的效果[17]。基于此提议开发出清理原理(转子结构)相似的清理设备有Bühler公司的MHXM-W轻度剥皮机、汉中三益公司的FBGY系列小麦剥皮机等[18]。

目前有大量的研究工作侧重于小麦粉或制品的卫生特性和品质差异[19−21],然而涉及原粮小麦卫生特性方面的研究较少,并且大多集中在剥皮率4%以上的处理[22]。如何在减少破碎、保证小麦皮层完整、保留整粒小麦营养成分的情况下,通过加工处理有效地清理小麦并将污染物控制在国家标准安全限量内是十分迫切的。为了探究柔性清理技术或剥皮率小于1%的轻剥皮加工技术对小麦清理效果的影响,本文采用新型FBPY小麦剥皮机和传统FDMW打麦机作为研究对象,模拟面粉厂实际生产情况,设计出三种清理工艺对小麦进行表面清理,旨在研究轻度剥皮与打麦处理对小麦表面清理效果的差异性表现,以期为后续制粉工艺或全麦制品加工提供符合卫生标准和麸皮结构完整的小麦产品,为面粉厂在实际生产中进行设备选型和工艺优化提供理论基础。

1. 材料与方法

1.1 材料与仪器

中筋硬质冬小麦 于2022年6月收获自山东省青岛市平度地区,经晾晒后贮藏于某粮库;无水乙醇、乙酸乙酯、重氮盐、甲醇、盐酸、间苯三酚、冰乙酸、葡萄糖、亚铁氰化钾、氢氧化钠、硫酸锌等 分析纯,天津市科密欧化学试剂有限公司;结晶紫中性红胆盐琼脂、平板计数琼脂、酶标工作液 生物试剂,北京奥博星生物技术有限责任公司。

FBPY-S-1 30小麦剥皮机 工作腔内的转子是表面带螺纹的锲形金刚砂板,定子是金刚砂筒[23](图1),汉中三益科技有限责任公司;FDMW30×60打麦机 工作腔内的转子是铸铁打板,定子是钢丝编制筛筒[24](图2),河北苹乐面粉机械集团有限公司;101-2EBS电热鼓风干燥箱 北京市永光明医疗仪器有限公司;SX4-10马弗炉 上海树立仪器仪表有限公司;JYDB100×40小麦硬度指数测定仪 布勒粮食检验仪器无锡有限公司;UV-2000紫外-可见分光光度计 尤尼柯(上海)仪器有限公司;WZZ-2S自动旋光仪 上海申光仪器仪表有限公司;Co.S-3400N II型扫描电镜 日本HITACHI 公司;DC-12氮吹仪 上海安谱实验科技股份有限公司;SPX-250生化培养箱 北京市永光明医疗仪器有限公司;Scientz-II D超声波细胞粉碎机 宁波新芝生物科技股份有限公司;SSBC-RE微孔板酶标仪 洛阳中科生物芯片技术有限公司;HJ-6A恒温磁力搅拌器 金坛市华峰仪器有限公司;5810R高速离心机 德国Eppendorf仪器有限公司。

1.2 实验方法

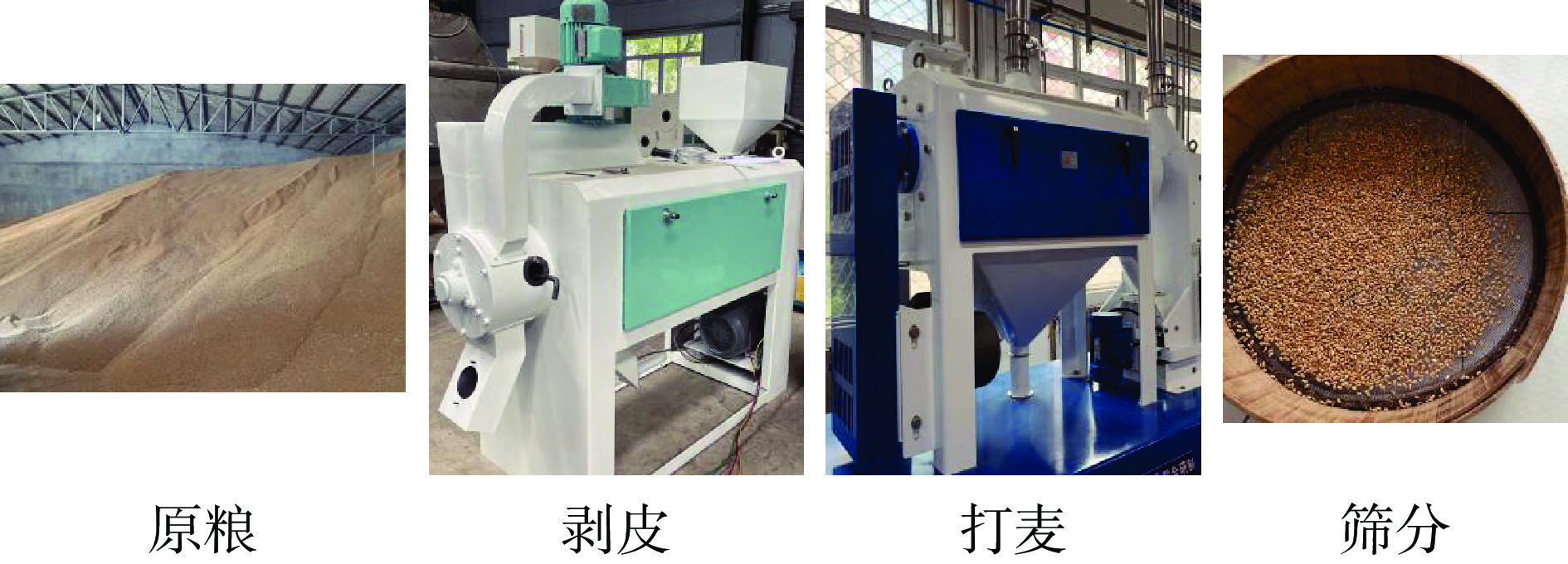

1.2.1 清理工艺流程

工艺一为原料直接清理:原粮→剥皮→筛分、原粮→打麦→筛分;

工艺二为原粮一清润麦后二清(即在工艺一之后增加润麦工序和一次清理工序):原粮→剥皮→筛分→润麦→剥皮→筛分、原粮→打麦→筛分→润麦→打麦→筛分;

工艺三为原粮先润麦后清理:原粮→润麦→剥皮→筛分、原粮→润麦→打麦→筛分。

各步骤的具体操作要点及最佳运行参数如下:

原粮:根据GB/T 5491-1985《粮食、油料检验 扦样、分样法》取样;

剥皮:使用FBPY-S-1 30小麦剥皮机,保持进机原粮20 kg、电压409 V、负载电流8.1 A、转子转速350 r/min、进料口开度40%;

打麦:使用FDMW30×60打麦机,保持进机原粮20 kg、电压390 V、负载电流14.9 A、转子转速660 r/min、进料口开度40%;

润麦:根据NY/T 1094.1-2006《小麦实验制粉 第1部分:设备、样品制备和润麦》,使润后小麦水分达到15%;

筛分:方法见1.2.2、1.2.3。

各步骤的实验现场如图3所示。

1.2.2 增碎率的测定

小麦样品的碎麦率参考GB/T 5494-2019并加以修改:取小麦样品m1约1 kg,精确至0.01 g,放入筛孔直径为2.5 mm的选筛上。然后将选筛放在玻璃板或光滑的桌面上,用双手以110~120次/min的速度,按顺时针方向和逆时针方向各筛动1 min。筛动的范围掌握在选筛直径扩大8~10 cm。筛后静止片刻,将上层筛的筛上物和下层筛的筛下物分别倒入分析盘内。卡在筛孔中间的颗粒属于筛上物。收集筛下碎麦粒并称量m2,精确至0.01 g,计其中碎麦粒(每粒小麦不完整性达到80%以上)含量的质量分数w0,按式(1)计算:

(1) 式中:w0为样品的碎麦率,%;m1为取样的质量,g;m2为样品中碎麦的质量,g。

设备的增碎率w按式(2)计算:

(2) 式中:w为设备的增碎率,%;w1为进机小麦的碎麦率,%;w2为出机小麦的碎麦率,%。

1.2.3 整机出杂率、去糠率、剥皮率和出灰率的测定

取设备集尘斗中的所有出机杂质m1,精确至0.01 g,计整机出杂率为β,按式(3)计算;

(3) 式中:β为整机出杂率,%;m1为出机杂质的质量,g;20×103为进机原粮的质量,g。

剥皮机的出机杂质包含剥下的麦糠和麦皮,麦皮又包含附着在麦皮上一同被剥下的麦灰,因此剥皮机集尘斗中除去麦糠的其它杂质记为麦皮杂质,比例记为剥皮率。打麦机的出机杂质包含打下的麦糠和麦灰,因此打麦机集尘斗中除去麦糠的其它杂质记为麦灰杂质,比例记为出灰率。将所有出机杂质放入筛孔直径为2.0 mm的选筛上。筛分操作同1.2.2,继而得到筛上物麦糠m2、筛下物麦皮或麦灰m3,精确至0.01 g,计去糠率为,按式(4)计算。剥皮机的剥皮率或打麦机的出灰率为,按式(5)计算:

(4) (5) 式中:为去糠率,%;为剥皮率或出灰率,%;m2为筛上物的质量,g;m3为筛下物的质量,g;20×103为进机原粮的质量,g。

1.2.4 皮层微观结构的观察

分别取不同处理后小麦籽粒的横截面进行观察,其中上表面为自然断面,下表面为平整面。将样品进行喷金处理后,置于扫描电镜下观察并拍照。

1.2.5 阿拉伯木聚糖(Arabinoxylan,AX)含量的测定

参考Douglas[25]的方法进行测定,称取4.5~5.5 mg样品于具塞试管中,依次加入2 mL蒸馏水和10 mL显色剂(由110 mL冰乙酸,2 mL浓盐酸,5 mL 20%的间苯三酚醇溶液和1 mL 1.75%葡萄糖水溶液混合配制而成),置于沸水浴中反应25 min后迅速用冷水冷却,分别在552 nm和510 nm处测定吸光度,根据标准曲线计算阿拉伯木聚糖含量。该实验标准曲线回归方程是y=7.0137x−2.0704(R2=0.9993)。

1.2.6 烷基间苯二酚(Alkylresorcinol,ARs)含量的测定

参考彭田园等[26]的方法稍作修改,称取全麦粉样品0.5 g(精确至0.1 mg),置于50 mL 离心管中,加入40 mL乙酸乙酯,使用超声波细胞粉碎机进行超声提取2 min(开1 s,关1 s),设定功率285 W。然后将提取液在3000 r/min条件下离心10 min,取1 mL上清液至离心管中,用氮气吹干。然后加入2 mL重氮盐工作溶液,混匀后室温避光孵育60 min。用紫外分光光度计在520 mm处进行检测。该实验标准曲线回归方程是y=0.2427x−0.0036(R2=0.9998)。

1.2.7 理化成分的测定

水分含量的测定参照GB 5009.3-2016《食品安全国家标准 食品中水分的测定》;灰分含量的测定参照GB 5009.4-2016《食品安全国家标准 食品中灰分的测定》;容重的测定参照GB/T 5498-2013《粮油检验 容重测定》;硬度指数(Hardness index,HI)的测定参照GB/T 21304-2007《小麦硬度测定 硬度指数法》;总淀粉(Total starch,TS)含量的测定参照GB/T 20378-2006《原淀粉 淀粉含量的测定》;粗蛋白(Crude protein,PRO)含量的测定参照GB/T 24899-2010《粮油检验 小麦粗蛋白质含量测定》。

1.2.8 卫生指标的测定

脱氧雪腐镰刀菌烯醇(Deoxynivalenol,DON)的测定参照GB 5009.111-2016《食品安全国家标准 食品中脱氧雪腐镰刀菌烯醇及其乙酰化衍生物的测定》;菌落总数(Aerobic plate count)参照GB 4789.2-2016《食品安全国家标准 食品微生物学检验 菌落总数测定》;大肠菌群(Coliforms)参照GB 4789.3-2016《食品安全国家标准 食品微生物学检验 大肠菌群计数》。

1.3 数据处理

采用Excel及SPSS 22进行数据统计和数据分析,用Wilcoxon、Duncan法进行差异性检验,并用Origin 2018作图。

2. 结果与分析

2.1 剥皮与打麦处理对物料组分出率的影响

经过不同设备处理后的杂质出率是表征设备清理效果最直观的指标。如表1所示,工艺一至工艺三,FBPY-S-1 30小麦剥皮机的整机出杂率均显著高于FDMW30×60打麦机(P<0.05),剥皮机的去糠率均显著高于打麦机(P<0.05),剥皮机的剥皮率均大于打麦机的出灰率,表明剥皮机对小麦的清杂程度高于打麦机。同时发现工艺一中单次剥皮处理的清杂效率最佳,整机出杂率为1.13%、去糠率为0.5%、剥皮率为0.63%,可能的原因是润麦增加了小麦皮层的韧性,而工艺一的干法清理使麦糠和麦皮保持干燥时的脆性,所以在剥皮机的碾削机械力下麦糠和麦皮更易与小麦籽粒分离。工艺二润后单次剥皮处理的清杂效率不及工艺一,但连续两次剥皮处理的效率之和最高,其整机出杂率为1.93%、去糠率为0.85%、剥皮率为1.08%。对出机小麦进行筛分得到筛上物主流小麦、筛下物碎麦。工艺一至工艺三中剥皮机的增碎率差别不大,分别为0.13%、0.11%、0.1%,但均显著低于打麦机的0.24%、0.29%、0.38%(P<0.05)。因为剥皮机依靠金刚砂板转子对小麦表面进行低速磨削处理,作用力为摩擦力,打麦机依靠铸铁打板转子对小麦籽粒进行高速打击处理,作用力为打击力。对同一小麦籽粒而言,打麦机所施加的机械力大于剥皮机,因此打麦机的增碎率远高于剥皮机。同时剥皮机通过转子的反复搓磨将更多的麦糠和部分麦皮剥落,这对于降低小麦加工过程中的增碎率和提升清理效率具有重要意义。从工作原理和效率角度分析,小麦剥皮机优于打麦机更适合于清理原粮小麦。

表 1 不同设备处理后各组分的质量占比结果Table 1. Mass proportion results of components treated with different equipments处理方式 处理设备 整机出杂率

(%)增碎率

(%)去糠率

(%)剥皮率

(%)出灰率

(%)工艺一 剥皮机 1.13±0.01a 0.13±0.00b 0.50±0.00a 0.63±0.01 / 打麦机 0.27±0.01b 0.24±0.01a 0.09±0.00b / 0.16±0.01 工艺二 剥皮机 0.80±0.00a 0.11±0.00b 0.35±0.00a 0.45±0.01 / 打麦机 0.20±0.01b 0.29±0.01a 0.06±0.01b / 0.14±0.00 工艺三 剥皮机 0.92±0.00a 0.10±0.01b 0.32±0.00a 0.60±0.01 / 打麦机 0.35±0.01b 0.38±0.01a 0.18±0.01b / 0.17±0.00 注:同列不同字母表示同一工艺下不同设备间的差异显著性(P<0.05),表2同。 2.2 剥皮与打麦处理后小麦的籽粒表现

2.2.1 剥皮与打麦处理后小麦的形貌变化

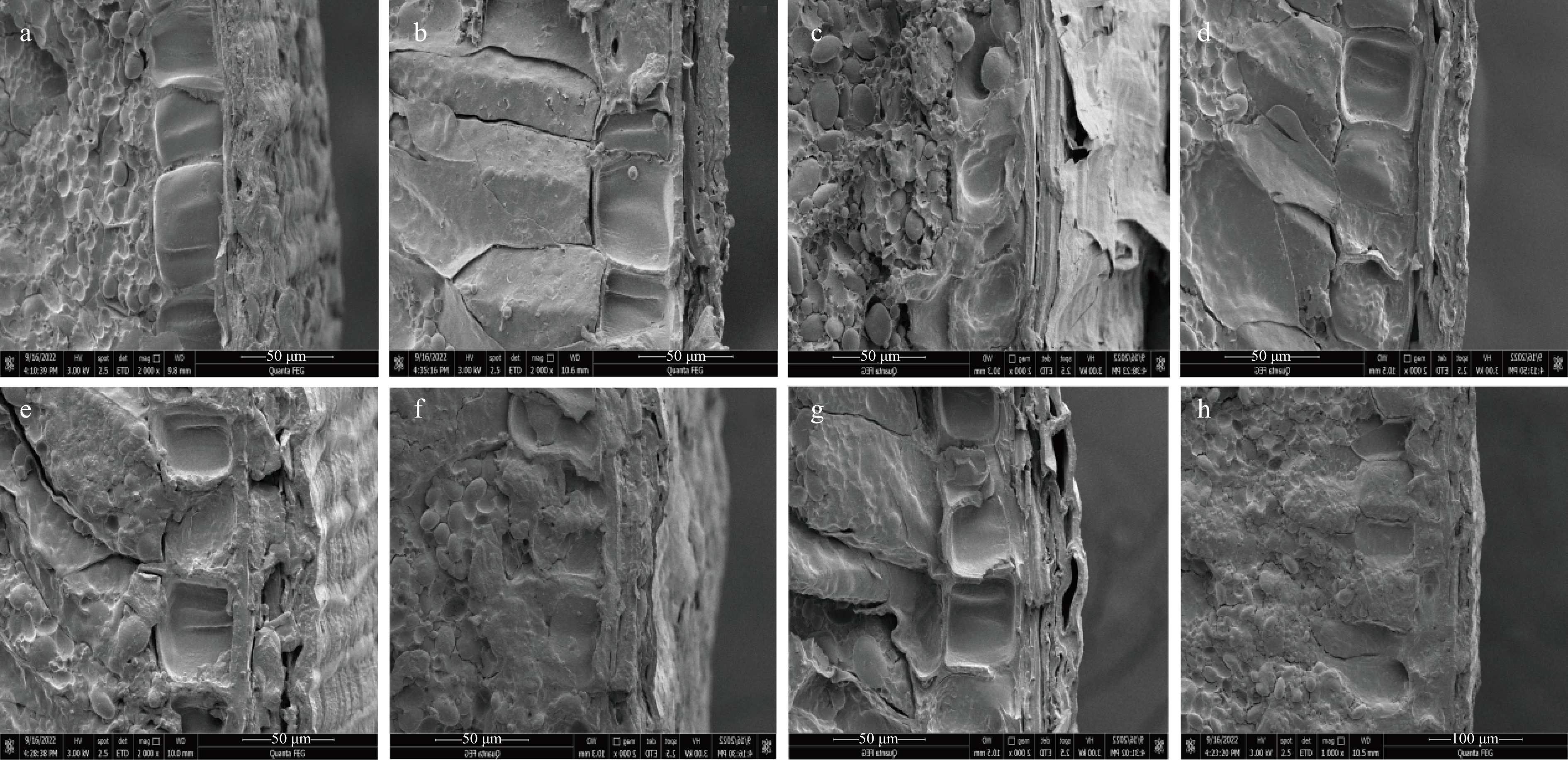

采用扫描电子显微镜在放大倍数2000倍下分别观察了不同工艺流程下,剥皮机和打麦机处理后小麦皮层的微观结构变化。如图4所示,两个设备的进机小麦皮层结构完整(图4a、e),表皮角质化细胞、糊粉层细胞、胚乳细胞清晰可见。当小麦经过工艺一的剥皮处理后(图4b),鳞状角质化表皮被轻微磨平,内果皮及糊粉层完整,说明在此处理下外果皮被轻微地剥落。当小麦经过工艺二的剥皮处理后(图4c),表皮被摩擦破裂外翻,内果皮及糊粉层完整,外果皮进一步被剥落。当小麦经过工艺三的剥皮处理后(图4d),鳞状角质化表皮被磨平,内果皮及糊粉层完整,外果皮的剥落程度与工艺一相近。以上结果表明,剥皮机对小麦籽粒的处理效果体现在表皮层,属于轻剥皮处理,当连同表面杂质剥落下部分表皮后,既能起到对小麦的清理作用又能保证麸皮结构的完整性,使后续的制粉工艺可以碾磨下完整的麸皮。当小麦经过工艺一的打麦处理后(图4f),小麦表皮和整体结构几乎无变化。当小麦经过工艺二的打麦处理后(图4g),皮层变得疏松,表皮、下表皮及内果皮之间有不同程度的分离但皮层结构完整。当小麦经过工艺三的打麦处理后(图4h),小麦表皮角质化结构依然存在,整体结构完整。以上结果表明,打麦机对小麦籽粒的处理效果不涉及小麦皮层,对皮层厚度无影响,但多次打麦处理后小麦皮层结构松散。整体结果表明,工艺一和工艺三中单次剥皮处理可以将小麦外果皮轻微地剥落。单次打麦处理后小麦籽粒的整体结构仍然完整,对皮层厚度无影响。工艺二经过两次剥皮处理后小麦表面杂质连同外果皮被剥落,经过两次打麦处理后小麦皮层结构松散但完整。

2.2.2 剥皮与打麦处理后小麦皮层成分的变化

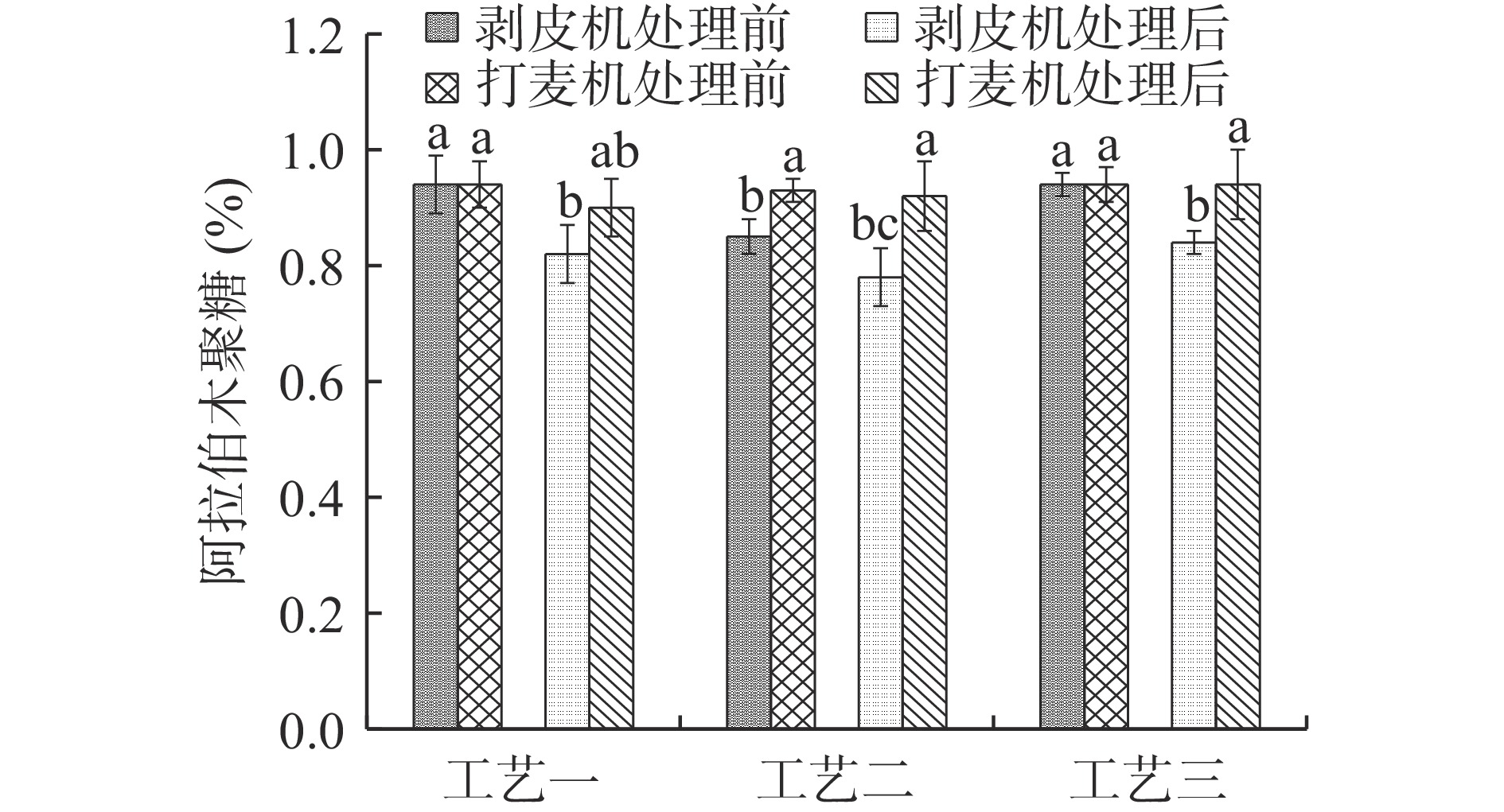

利用扫描电镜观察小麦皮层的微观结构可以大致确定不同设备对小麦皮层的处理情况,但要更加客观地分析外果皮乃至内果皮的存在情况,还需要通过测定小麦皮层所含的营养组分来进行分析。有文献表明,外果皮和内果皮中所含有的化学组分各不相同,尤其是AX和ARs的含量相差较大[27−28]。AX是一种非淀粉多糖,富集于粗膳食纤维中,小麦中的AX主要存在于外果皮[29],而内果皮及外种皮中则富含一种酚类物质——ARs,其含量随剥皮时间的增加而减小[30]。从图5可以看出工艺一至工艺三每项工艺中,经剥皮机处理后小麦的AX含量均呈下降趋势,降低率分别为13%、8%、11%。对比打麦机处理后小麦的AX含量无显著变化(P>0.05),说明小麦在干燥状态或是润后的湿润状态,剥皮机的碾削处理都会剥落下一定量的小麦果皮,使小麦籽粒的AX含量减少。不同设备处理后小麦的AX含量变化与扫描电镜的皮层留存情况吻合,即打麦机对小麦表皮无影响或影响很小,而剥皮机对小麦表皮有一定剥落效果,可以轻度剥皮。在工艺二中,处理前的小麦样品取润麦后待进机的小麦,即工艺一的出机小麦再经过润麦处理,因此小麦籽粒的AX含量与工艺一处理后小麦的AX含量相似。且工艺二中润后再经剥皮处理的小麦AX含量降低率低于工艺一和工艺三,原因是润麦使麦皮的韧度增强,同时小麦已经过一清处理,剥皮机对其剥皮效果降低,此变化趋势与表1中不同工艺下剥皮机的剥皮率变化情况一致。但如图6所示,使用不同设备处理小麦时,小麦的ARs含量基本不变或者变化很小,表明两种设备在三种工艺下对小麦皮层的处理均未深入至种皮或内果皮。综上,润麦工序会使剥皮机剥落外果皮的效果减弱,但减弱幅度较小。同时表面处理设备可以保证小麦外果皮不会被完全去除,麸皮整体结构完整,这将有利于后续制粉工艺中磨粉机从完整的小麦麸皮上剥刮下胚乳粉。

2.3 剥皮与打麦处理对小麦理化成分的影响

两种设备处理后小麦的理化成分变化如表2所示。灰分含量是小麦经高温灼烧后残留的无机物含量,其主要分布在皮层[31],是鉴别小麦加工精度或确定等级的依据,在表面清理阶段,灰分含量的变化也可体现清理程度[32]。工艺一至工艺三经剥皮机处理后小麦籽粒的灰分含量显著降低(P<0.05),其中剥皮机在工艺一中的灰分下降0.06%、工艺二的灰分下降0.05%、工艺三的灰分下降0.09%,打麦机对应的灰分分别下降0.05%、0.03%、004%。可见,剥皮机对小麦的清理程度高于打麦机,进一步可以得出工艺三的清理程度最高,这是因为润麦时,水介质促使混在物料中无机物杂质强烈地粘附在麦皮表面,剥皮机剥落小麦果皮的同时可以将大部分灰杂去除。对于同一批次小麦来说,在形状大小、成熟度、胚乳质地等条件相同的情况下,容重增加意味着谷物被清理[33]。打麦机在工艺一中对小麦容重影响较大,处理后小麦容重升高42 g/L,这是因为打麦机将虫蚀粒等不完善粒击碎后产生的碎麦量多,随着打击产生的碎不完善粒和碎麦粒被筛去,主流小麦容重大幅升高。而剥皮机在工艺二中显现容重优势,处理后小麦容重升高54 g/L,说明经过两次剥皮和筛分处理,皮杂被有效地清理和筛除,清理效果更佳。两种设备处理后均对小麦的HI影响不大,说明施加的机械力不至于改变小麦的硬度。同时主要存在于小麦胚乳中的TS和PRO含量在不同设备处理后变化不大,说明基于物理原理清理小麦的剥皮机和打麦机不会对小麦胚乳成分产生影响[34]。在实际生产中如果原粮表面较脏,可以考虑在润麦前后均设置剥皮机进行连续地清理,通过累加一清和二清工艺的结果,得出经过两次清理后小麦的灰分累计降低0.11%,容重累计提升84 g/L,为三种工艺中提升小麦理化品质的最佳选择。

表 2 不同设备处理后小麦理化成分的变化Table 2. Changes of physical and chemical components in wheat after treatment with different equipments工艺流程 样品处理 水分含量

(%)灰分含量干基

(%)容重

(g/L)HI TS干基

(%)PRO基

(%)工艺一 进机小麦 11.73±0.07ab 1.92±0.02a 736±1c 63.5±0.6a 62.62±0.30bc 14.55±0.15a 剥皮机 11.82±0.02a 1.86±0.03b 766±1b 62.9±0.3ab 62.88±0.32bc 14.47±0.08a 打麦机 11.72±0.04bc 1.87±0.04b 778±1a 63.1±0.4a 64.64±0.41a 13.92±0.11b 工艺二 进机小麦 15.04±0.06ab 1.94±0.02a 720±1c 62.6±0.2a 63.90±0.21ab 13.85±0.05a 剥皮机 15.18±0.04a 1.89±0.00b 774±3a 62.8±0.4a 63.46±0.74ab 13.85±0.15a 打麦机 14.77±0.00c 1.91±0.01a 737±0b 62.5±0.2a 64.16±0.92a 13.87±0.02a 工艺三 进机小麦 15.01±0.05b 1.99±0.01a 727±2c 63.1±0.0a 63.08±0.16ab 14.05±0.05a 剥皮机 15.15±0.03a 1.90±0.04b 769±3a 62.8±0.5ab 63.78±0.05a 13.90±0.10ab 打麦机 14.45±0.07c 1.95±0.02ab 755±0b 63.7±0.5a 61.64±0.28bc 13.95±0.05ab 2.4 剥皮与打麦处理对小麦卫生指标的影响

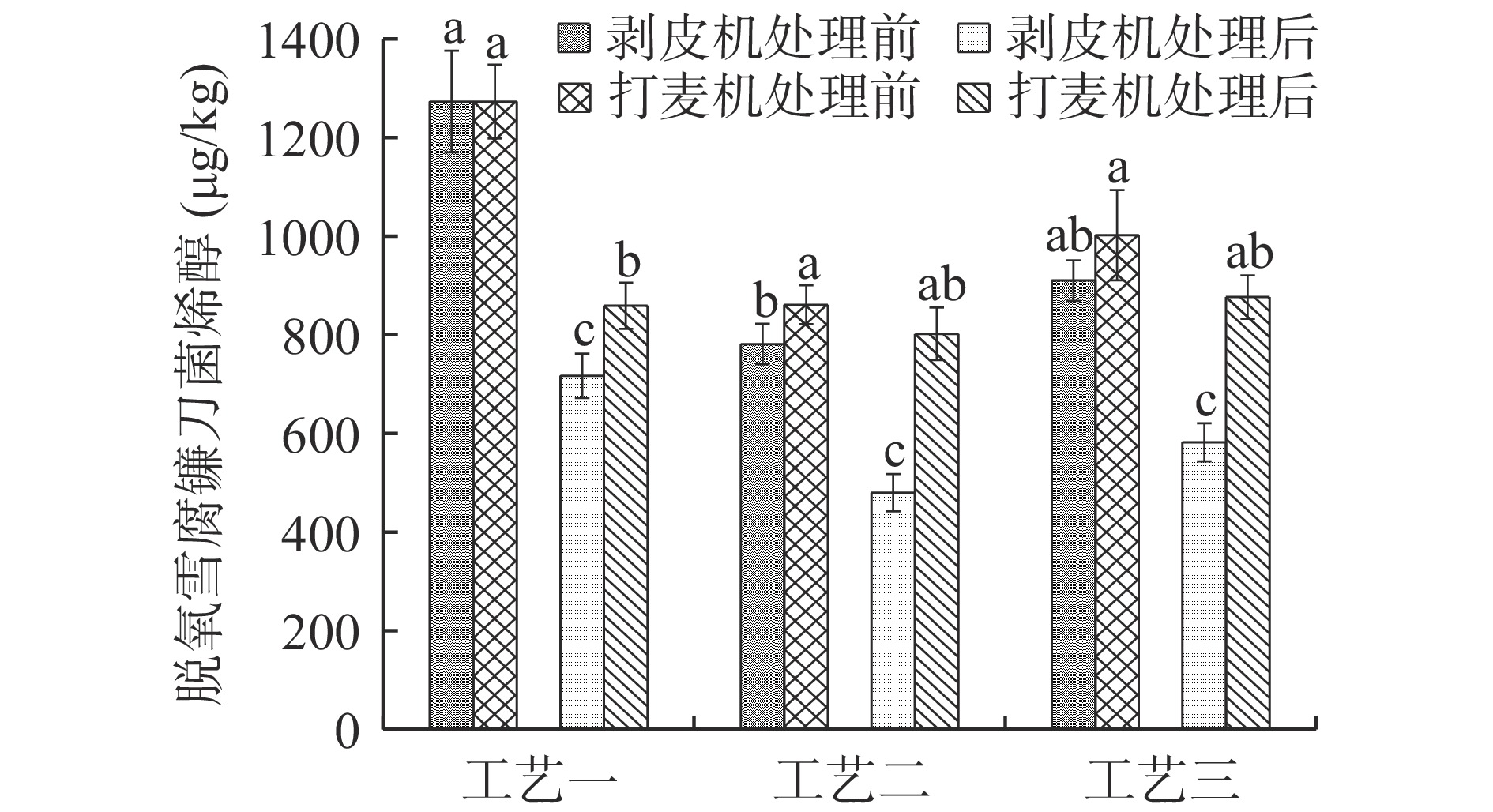

2.4.1 剥皮与打麦处理对DON含量的影响

DON是小麦感染镰刀菌属真菌后产生的次级代谢产物[35],俗称“呕吐毒素”。生长成熟的小麦在高温高湿条件下易受镰刀菌感染,此真菌汲取麦粒中营养物质并造成麦粒表面形成霉状物。我国小麦DON的限量标准为1000 μg/kg。由图7得出,工艺一原粮小麦经过一次剥皮处理后小麦籽粒的DON含量显著降低(P<0.05),降低率为44%。在工艺二中,处理前的小麦样品取润麦后待进机的小麦,即工艺一的出机小麦再经过润麦处理,因此小麦籽粒的DON含量与工艺一处理后小麦的DON含量相似,同时经过润麦工序小麦DON含量有所升高。工艺二润后小麦再经过一次剥皮处理的DON含量降低39%。工艺三原粮直接经过润麦后进行一次剥皮处理的DON降低36%。工艺一的单次剥皮处理使DON含量降低幅度最大,说明干法磨削更有利于去除小麦表面毒素。对比打麦机仅打除浮杂未进行剥皮,工艺一DON降低率为31%,工艺二DON降低率为7%,工艺三DON降低率为12%。在工艺一的干法清理中毒素与麦皮粘连性低,易被打麦机的打击机械力去除,而工艺二和工艺三小麦经过调质处理后,打麦机对DON的去除效果明显降低,但剥皮机对DON的清理效果受调质处理的影响较小。对比得出三种工艺下,剥皮机对DON的去除率均显著高于打麦机(P<0.05),打麦机对DON的去除效果较差,表明磨削表皮的清理方式对降低小麦中的毒素含量方面具有很大优势。

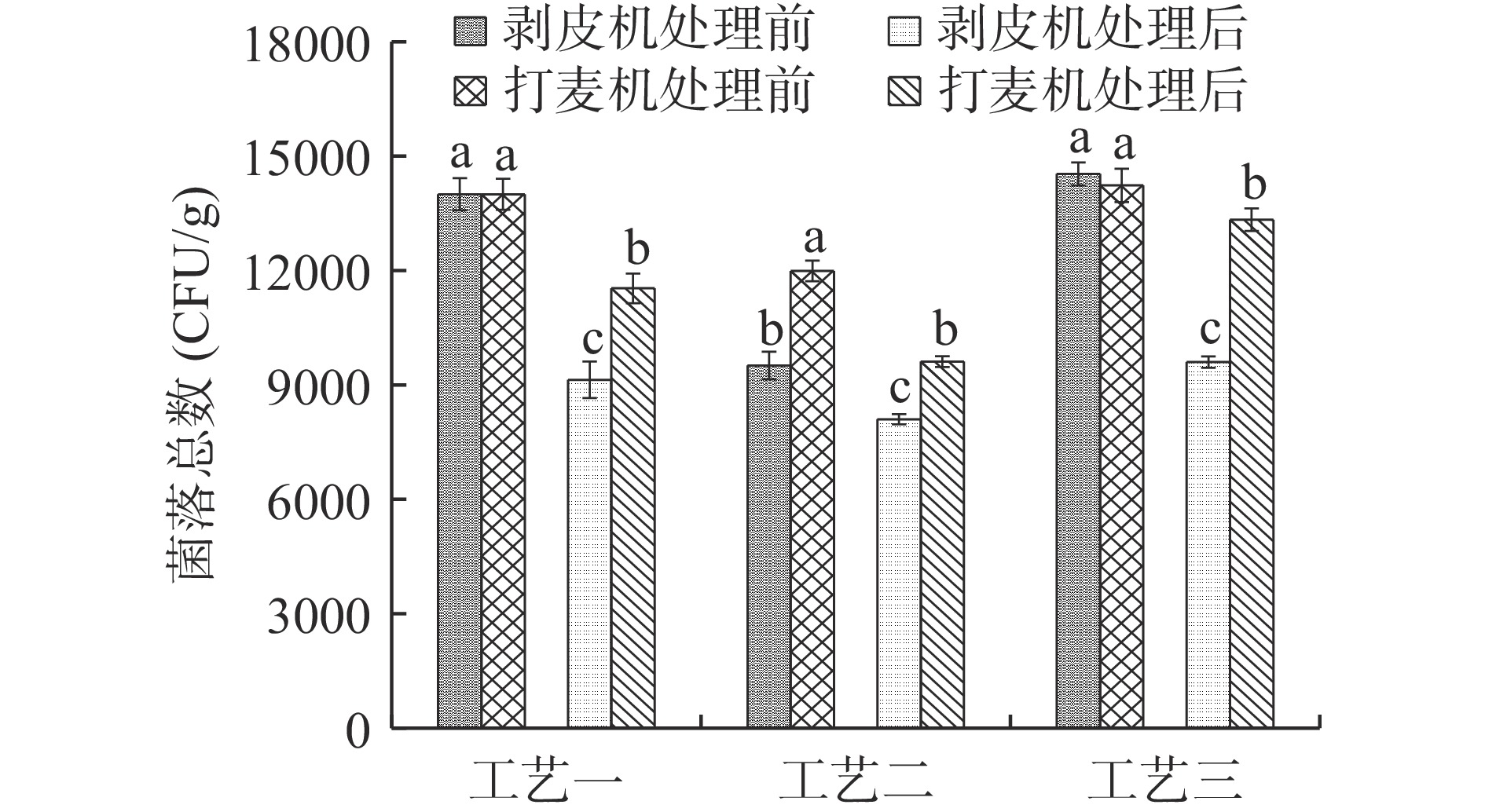

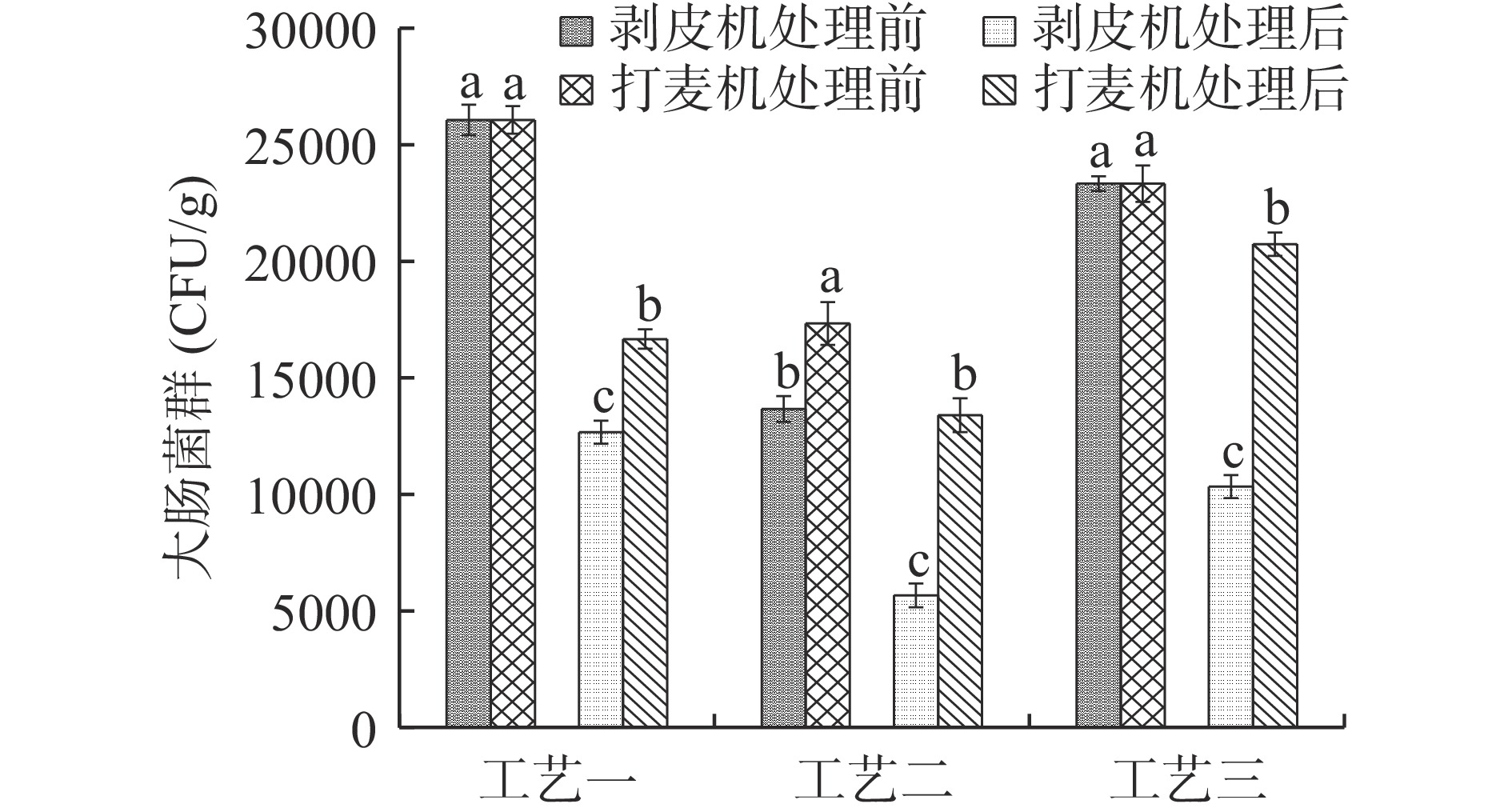

2.4.2 剥皮与打麦处理对微生物含量的影响

我国在LS/T 3248-2017中限制小麦粉的真菌毒素、污染物和农药残留的安全指数0.7,但我国还未形成对小麦或小麦粉微生物含量的限制标准。从图8和图9可以得出,工艺一剥皮处理后,菌落总数和大肠菌群数量显著降低(P<0.05),菌落总数降低率为35%,大肠菌群降低率为51%;工艺二润后小麦再经过一次剥皮处理,此时,设备进机小麦的微生物数量较工艺一处理后有所上升,原因是湿润的润麦条件适宜微生物生长,也有研究表明小麦籽粒的微生物数量在调质过程中会有所增加[36]。随着基数增加,工艺二剥皮处理后菌落总数降低率为27%,大肠菌群降低率为58%。工艺三剥皮处理后,菌落总数降低率为34%,大肠菌群降低率为56%。可以看出剥皮机对大肠菌群的清理效果较佳。对比打麦机在工艺一中使菌落总数和大肠菌群数量有所降低,菌落总数降低率为17%,大肠菌群降低率为26%;工艺二菌落总数降低率为19%,大肠菌群降低率为18%。工艺三菌落总数降低率为13%,大肠菌群降低率为17%,但打麦机对两类微生物的降低率均显著小于剥皮机(P<0.05)。卫生指标实验表明小麦果皮是有害微生物的主要富集部位,当小麦经过剥皮机处理后外果皮被部分剥去,小麦籽粒的真菌微生物含量大幅降低。当小麦经过打麦机处理后,微生物含量降低率较小。如果在实际生产中使用打麦机,可以参照工艺一将打麦机设置在润麦前的清理阶段,其对毒素和微生物的降低效率高于润麦后。虽然打麦机对小麦表面微生物有一定清理效果,但去除效果较剥皮机差。如果在实际生产中使用剥皮机,可以参照工艺二将剥皮机设置在润麦前和润麦后的清理阶段,这将有效改善小麦的卫生品质。

3. 结论

本研究以未清理的原粮小麦为原料进行表面清理试验,采用原粮直接清理、一清润麦后二清、原料先润麦后清理这三种工艺进行处理,探究了FBPY-S-1 30小麦剥皮机和FDMW30×60打麦机在三种清理工艺中对小麦清理效果的影响,为小麦清理设备选型和工艺优化提供一定参考。在设备选型方面,基于不同工作原理(转子结构)的剥皮机的清理效率高于打麦机。整机出杂率是打麦机的3~4倍,增碎率平均较打麦机低0.19%,以规模为500 t/d的面粉厂为例,预计日均可节约粮食960 kg。剥皮机金刚砂板转子的磨削作用使小麦表皮的微观形貌发生变化,在工艺二中表面杂质连同部分外果皮被剥落,种皮及以下组织完整。0.45%~0.63%的轻剥皮处理既保证小麦表面大部分污染物被去除,又最大限度降低杂质进入小麦胚乳的可能性。同时,在卫生指标方面,剥皮机对真菌毒素和微生物的清除效率高于打麦机近2倍,未来面粉厂在清理工段的设备配置可以考虑将传统打麦机替换成剥皮机。在工艺优化方面,若面粉厂仅设置一道表面清理流程,可以参照工艺一进行直接地剥皮处理,单次剥皮处理后的整机出杂率为1.13%、小麦籽粒灰分降低0.06%、DON含量可降低44%,菌落总数减少35%、大肠杆菌减少51%。若原粮污染程度较高的情况下可以参照工艺二在润麦前后分别设置剥皮机,经过两次剥皮处理后的整机出杂率可达1.93%,灰分下降0.11%、DON含量降低62%,菌落总数减少49%、大肠杆菌减少78%。以此实验结论为理论基础来提升小麦清理工序的效率,从而实现小麦的节粮、高效生产。

-

表 1 不同设备处理后各组分的质量占比结果

Table 1 Mass proportion results of components treated with different equipments

处理方式 处理设备 整机出杂率

(%)增碎率

(%)去糠率

(%)剥皮率

(%)出灰率

(%)工艺一 剥皮机 1.13±0.01a 0.13±0.00b 0.50±0.00a 0.63±0.01 / 打麦机 0.27±0.01b 0.24±0.01a 0.09±0.00b / 0.16±0.01 工艺二 剥皮机 0.80±0.00a 0.11±0.00b 0.35±0.00a 0.45±0.01 / 打麦机 0.20±0.01b 0.29±0.01a 0.06±0.01b / 0.14±0.00 工艺三 剥皮机 0.92±0.00a 0.10±0.01b 0.32±0.00a 0.60±0.01 / 打麦机 0.35±0.01b 0.38±0.01a 0.18±0.01b / 0.17±0.00 注:同列不同字母表示同一工艺下不同设备间的差异显著性(P<0.05),表2同。 表 2 不同设备处理后小麦理化成分的变化

Table 2 Changes of physical and chemical components in wheat after treatment with different equipments

工艺流程 样品处理 水分含量

(%)灰分含量干基

(%)容重

(g/L)HI TS干基

(%)PRO基

(%)工艺一 进机小麦 11.73±0.07ab 1.92±0.02a 736±1c 63.5±0.6a 62.62±0.30bc 14.55±0.15a 剥皮机 11.82±0.02a 1.86±0.03b 766±1b 62.9±0.3ab 62.88±0.32bc 14.47±0.08a 打麦机 11.72±0.04bc 1.87±0.04b 778±1a 63.1±0.4a 64.64±0.41a 13.92±0.11b 工艺二 进机小麦 15.04±0.06ab 1.94±0.02a 720±1c 62.6±0.2a 63.90±0.21ab 13.85±0.05a 剥皮机 15.18±0.04a 1.89±0.00b 774±3a 62.8±0.4a 63.46±0.74ab 13.85±0.15a 打麦机 14.77±0.00c 1.91±0.01a 737±0b 62.5±0.2a 64.16±0.92a 13.87±0.02a 工艺三 进机小麦 15.01±0.05b 1.99±0.01a 727±2c 63.1±0.0a 63.08±0.16ab 14.05±0.05a 剥皮机 15.15±0.03a 1.90±0.04b 769±3a 62.8±0.5ab 63.78±0.05a 13.90±0.10ab 打麦机 14.45±0.07c 1.95±0.02ab 755±0b 63.7±0.5a 61.64±0.28bc 13.95±0.05ab -

[1] KLICH M A, CARY J W, BELTZ S B, et al. Phylogenetic and morphological analysis of Aspergillus ochraceoroseus[J]. Mycologia,2003,95(6):1252−1260. doi: 10.1080/15572536.2004.11833033

[2] POSNER E, HIBBS A. Wheat flour milling[M]. American Association of Cereal Chemists, 2006:141−163.

[3] LACA A, MOUSIA Z, DÍAZ M, et al. Distribution of microbial contamination within cereal grains[J]. Journal of Food Engineering,2006,72(4):332−338. doi: 10.1016/j.jfoodeng.2004.12.012

[4] BARROSO L R, SALMAN P E, ALBERTI A, et al. Pre milling debranning of wheat with a commercial system to improve flour quality[J]. Journal of Food Science and Technology,2022,59(10):3881−3887. doi: 10.1007/s13197-022-05411-6

[5] BERGHOFER L K, HOCKING A D, MISKELLY D, et al. Microbiology of wheat and flour milling in Australia[J]. International Journal of Food Microbiology,2003,85:137−149. doi: 10.1016/S0168-1605(02)00507-X

[6] TIBOLA C S, FERNANDES M C, GUARIENTI E M. Effect of cleaning, sorting and milling processes in wheat mycotoxin content[J]. Food Control,2016,60:174−179. doi: 10.1016/j.foodcont.2015.07.031

[7] 叶维林, 叶威, 苏勇, 等. 高效无尘清理筛在粮食清理环节中抑尘效果分析[J]. 粮油食品科技,2021,29(4):226−233 YE W L, YE W, SU Y, et al. Effect analysis of high-efficiency dust-free cleaning screen in grain cleaning[J]. Science and Technology of Cereals,2021,29(4):226−233.

[8] 吴军永, 李浩, 刘素山. 小麦清理设备技术现状及发展方向[J]. 现代面粉工业,2020,34(1):15−16 WU J Y, LI H, LIU S S. Technical status and development direction of wheat cleaning equipments[J]. Modern Flour Milling Industry,2020,34(1):15−16.

[9] KRZYSIAK Z, SAMOCIUK W, SKIC A, et al. Effect of sieve drum inclination angle on wheat grain cleaning in a novel rotary cleaning device[J]. Transactions of the ASABE,2017,60(5):1751−1758. doi: 10.13031/trans.12110

[10] MAGYAR Z, VÉHA A, PEPÓ P, et al. Wheat cleaning and milling technologies to reduce DON toxin contamination[J]. Acta Agraria Debreceniensis,2019(2):89−95. doi: 10.34101/actaagrar/2/3684

[11] ANISIMOV A V, RUDIK F Y. The experimental determination of optimum parameters of the equipments for processing grain in preparation for grinding[J]. Engineering Technologies and Systems,2019,29(4):594−613. doi: 10.15507/2658-4123.029.201904.594-613

[12] 曹武军, 原富林, 聂运强, 等. FDMWA卧式摩擦打麦机的设计与应用[J]. 粮食加工,2011,36(6):53−55 doi: 10.3969/j.issn.1007-6395.2011.06.019 CAO W J, YUAN F L, NIE Y Q, et al. Design and application of FDMWA horizontal friction scourer[J]. Grain Processing,2011,36(6):53−55. doi: 10.3969/j.issn.1007-6395.2011.06.019

[13] LIN Q, LIU L N, BI Y, et al. Effects of different debranning degrees on the qualities of wheat flour and Chinese steamed bread[J]. Food & Bioprocess Technology,2012,5(2):648−656.

[14] CHELI F, PINOTTI L, ROSSI L, et al. Effect of milling procedures on mycotoxin distribution in wheat fractions: A review[J]. LWT- Food Science and Technology,2013,54(2):307−314. doi: 10.1016/j.lwt.2013.05.040

[15] 赵吉凯, 王凤成, 付文军, 等. 轻碾脱皮对全麦粉及其馒头品质的影响[J]. 食品科学,2017,38(21):158−164 ZHAO J K, WANG F C, FU W J, et al. Effect of different debranning degrees on the qualities of whole wheat flour and Chinese steamed bread[J]. Food Science,2017,38(21):158−164.

[16] FICCO D B M, BORRELLI G M, MIEDICO O, et al. Effects of grain debranning on bioactive compounds, antioxidant capacity and essential and toxic trace elements in purple durum wheats[J]. LWT-Food Science and Technology,2019,118:108734.

[17] 武拉平. 我国粮食损失浪费现状与节粮减损潜力研究[J]. 农业经济问题,2022,515(11):34−41 WU L P. Grain loss and waste in China: Current situation, reduction potential and counter-measures[J]. Issues in Agricultural Economy,2022,515(11):34−41.

[18] 张振辉, 郭祯祥. 小麦加工中一些新技术和新设备对小麦粉安全生产的影响[J]. 粮食与饲料工业,2015,343(11):8−11 ZHANG Z H, GUO Z X. The influence on wheat flour safety caused by the new technologies and equipments in wheat processing[J]. Cereal & Feed Industry,2015,343(11):8−11.

[19] 蔡文雅, 孙冰华, 田潇凌, 等. 脱皮制粉及其对小麦粉品质影响的研究进展[J]. 食品研究与开发,2021,42(17):204−210 doi: 10.12161/j.issn.1005-6521.2021.17.032 CAI W Y, SUN B H, TIAN X L, et al. Research progress of debranning milling and its effect on wheat flour quality[J]. Food Research and Development,2021,42(17):204−210. doi: 10.12161/j.issn.1005-6521.2021.17.032

[20] RIOS G, PINSON-GADAIS L, ABÉCASSIS J, et al. Assessment of dehulling efficiency to reduce deoxynivalenol and Fusarium level in durum wheat grains[J]. Journal of Cereal Science,2009,49(3):387−392. doi: 10.1016/j.jcs.2009.01.003

[21] CICCORITTI R, TADDEI F, NICOLETTI I, et al. Use of bran fractions and debranned kernels for the development of pasta with high nutritional and healthy potential[J]. Food Chemistry,2017,225:77−86. doi: 10.1016/j.foodchem.2017.01.005

[22] SINGH S, SINGH N. Effect of debranning on the physico-chemical, cooking, pasting and textural properties of common and durum wheat varieties[J]. Food Research International,2010,43(9):2277−2283. doi: 10.1016/j.foodres.2010.07.016

[23] MARCHINI D, MONTANARI R, BOTTANI E, et al. Lifecycle modelling of an innovative durum wheat debranner[C]. International Multidisciplinary Modeling & Simulation Multiconference, 2016, I3M.

[24] 陈忠. 卧式打麦机改进和使用[J]. 粮食与油脂, 2009, 164(12):38 CHEN Z. Improvement and use of the horizontal wheat scourer[J]. Cereals & Oils, 2009, 164(12):38.

[25] DOUGLAS S G. A rapid method for the determination of pentosans in wheat flour[J]. Food Chemistry,1981,7(2):139−145. doi: 10.1016/0308-8146(81)90059-5

[26] 彭田园, 赵仁勇, 王香玉. 超声波辅助提取全麦粉中烷基间苯二酚的工艺优化[J]. 河南工业大学学报(自然科学版),2017,38(4):14−19 doi: 10.3969/j.issn.1673-2383.2017.04.003 PENG T Y, ZHAO R Y, WANG X Y. Optimization of ultrasonic-assisted extraction of alkylresorcinols from whole wheat meal[J]. Journal of Henan University of Technology(Natural Science Edition),2017,38(4):14−19. doi: 10.3969/j.issn.1673-2383.2017.04.003

[27] BARRON C, SAMSON M F, LULLIEN-PELLERIN V, et al. Wheat grain tissue proportions in milling fractions using biochemical marker measurements: Application to different wheat cultivars[J]. Journal of Cereal Science,2011,53(3):306−311. doi: 10.1016/j.jcs.2011.01.013

[28] HEMEDANCE S, JACOBS P J, DORNEZ E, et al. Wheat ( Triticum aestivum L.) bran in bread making: A critical review[J]. Comprehensive Reviews in Food Science and Food Safety,2016,15(1):28−42. doi: 10.1111/1541-4337.12176

[29] 周素梅, 王强, 张晓娜. 小麦中功能性多糖-阿拉伯木聚糖研究进展[J]. 核农学报,2009,23(2):297−301 ZHOU S M, WANG Q, ZHANG X N. Research advances in functional polysaccharide-wheat arabinoxylan[J]. Journal of Nuclear Agricultural Sciences,2009,23(2):297−301.

[30] 于爽, 夏玉琳, 朱恩俊. 不同剥皮程度对小麦粉烷基间苯二酚和B族维生素含量的影响[J]. 食品科技,2017,42(6):162−166 YU S, XIA Y L, ZHU N J. Effect of different peeling degree on ARs and vitamins B contents in wheat nutrition powder[J]. Food Science and Technology,2017,42(6):162−166.

[31] 邹恩坤, 王晓曦, 翟秀超, 等. 剥皮对小麦面粉中矿物质、植酸含量的影响[J]. 粮食与食品工业,2015,22(3):57−62 doi: 10.3969/j.issn.1672-5026.2015.03.015 ZOU N K, WANG X X, ZHAI X C, et al. Effect of debranning on minerals and phytic acid content wheat flour[J]. Cereal and Food Industry,2015,22(3):57−62. doi: 10.3969/j.issn.1672-5026.2015.03.015

[32] 田建珍, 温纪平. 小麦加工工艺与设备[M]. 科学出版社, 2011:31−32 TIAN J Z, WEN J P. Wheat processing technologies and equipments[M]. Science Press, 2011:31−32.

[33] CRÉPON K, DUYME F. Efficiency of grain cleaner to increase test weight in wheat ( Triticum aestivum)[J]. Cereal Chemistry,2020(97):1263−1269.

[34] KATYAL M, SINGH N, VIRDI A S, et al. Effect of debranning on grains and meal characteristics of different Indian and exotic wheat varieties[J]. Food Research International,2019,123:327−339. doi: 10.1016/j.foodres.2019.04.036

[35] TITTLEMIER S A, SOBERING D, BOWLER K, et al. By-products of grain cleaning: An opportunity for rapid sampling and screening of wheat for mycotoxins[J]. World Mycotoxin Journal,2015,8(1):45−53. doi: 10.3920/WMJ2014.1760

[36] NEAGU C, MAFTEI N A, BANU I, et al. The effect of industrial cleaning on wheat microbial burden and deoxynivalenol levels[J]. Environmental Engineering & Management Journal,2012,11(10):1857−1863.

-

期刊类型引用(1)

1. 赵克东,阮长青,李志江,汤华成,王长远. 超声辅助制备抗性淀粉研究进展. 食品工业科技. 2025(05): 8-16 .  本站查看

本站查看

其他类型引用(0)

下载:

下载:

下载:

下载: