Effect of Bagging on Wax Components and Storage Quality of ‘Yali’ Pear

-

摘要: 为了探究套袋对鸭梨果实蜡质和贮藏品质的影响,本研究设定两组处理:聚乙烯(Polyethylene,PE)塑膜袋、三层纸袋,均在盛花后60 d完成套袋,采后摘袋,以未套袋为对照,于25 ℃±1 ℃贮藏14 d并分析不同处理果实蜡质组分含量和分布规律、营养和品质指标、抗氧化性的差异及相关性。结果表明:贮藏14 d内,PE塑膜袋处理的果实失重率最高,且对照和处理三者之间果实硬度、脆度和紧实度均无差异。两组处理均明显延缓蜡质组分烯烃、脂肪醛、脂肪醇、酯质、和总蜡质含量的增加。两组处理中烷烃C27和C29、烯烃C24-C26、脂肪酸C18:1、脂肪醛C26和C34、偶数脂肪醇C22-C28、七种酯质、及三萜类α-法尼烯、β-香树酯醇、羽扇豆醇和β-香树酯酮等主要组分的含量均低于对照组。另外相比PE塑膜袋,三层纸袋处理延缓烯烃C26、脂肪酸C16和C18:1、偶数脂肪醛C28-C32、两种酯质C22:1醇-C18:1酸和C24:1醇-C18:1酸、三萜类Urs-12-en-28-al,3-(acetyloxy)-,(3á)-和Urs-12-en-28-al等蜡质组分含量的下降,且三层纸袋处理后果皮黄酮、果皮总酚(14 d时)、果实可滴定酸和果实VC(14 d时)的含量以及果皮DPPH清除率均高于PE塑膜袋处理。蜡质组分PCA分析将对照组和三层纸袋处理归为一类,而PE塑膜袋处理为另一类。相关分析发现不同处理中烷烃、脂肪醛、三萜类等组分和总蜡质含量与果皮黄酮含量正相关(P<0.05),而脂肪醇、酯质组分和总蜡质含量与果实VC含量正相关(P<0.05或P<0.01)。综上说明三层纸袋通过延缓果实蜡质一些组分含量的下降,使果皮保持较高抗氧化能力,进而提高鸭梨果实的品质。Abstract: In order to explore the effect of bagging on the wax compositions and storage quality of ‘Yali’ pear fruit, the differences and correlations of wax content and distribution, nutrition and quality indicators, and antioxidant properties of the two different treatments (polyethylene, (PE) plastic film bags and three-layer paper bags) stored at 25 ℃±1 ℃ were analyzed. The fruits were bagged at day 60 after blooming, then the bags were removed at harvest, and no-bagged fruit acted as the control. The results showed that the highest rate of fruit weight loss was found in PE plastic film bags-treated fruit, while there was no difference in fruit hardness, brittleness and compactness between the control and the two treatments within 14 days of storage. The increases in contents of wax compositions alkenes, fatty aldehydes, fatty alcohols, esters, and total wax were significantly delayed in the two treatments. The contents of alkanes C27 and C29, alkenes C24-C26, fatty acid C18:1, fatty aldehydes C26 and C34, even number fatty alcohols C22-C28, seven esters, and triterpenoids (such as α-farnesene, β-amyrin, lupeol, and β-amyrenone) in the two treatments were lower than the control. In addition, compared to the PE plastic film bags treatment, the decline in contents of wax compositions alkene C26, fatty acids C16 and C18:1, even number fatty aldehydes C28-C32, two esters (C22:1 alcohol-C18:1 acid and C24:1 alcohol-C18:1 acid), triterpenoids (Urs-12-en-28-al,3-(acetyloxy)-,(3á)-and Urs-12-en-28-al) were delayed by the three-layer paper bags treatment. Furthermore, in comparison with PE plastic film bags treatment, higher contents of peel flavonoids, peel total phenols (at day 14), fruit titratable acid and Vc (at day 14), and higher DPPH clearance rate were found in three-layer paper bags-treated fruit. According to PCA analysis of wax components, the control and the three-layer paper bags treatment were belonged to one group, while PE plastic film bags treatment was divided into the other group. The correlation analysis showed that wax components alkanes, fatty aldehydes, triterpenes and total wax in different treatments were positively correlated with the content of peel flavonoids (P<0.05), while fatty alcohols, esters and total wax were positively correlated with the content of fruit VC (P<0.05 or P<0.01). This study indicated that the three-layer paper bags treatment could delay the decline in accumulation of some fruit wax components, maintain the higher peel antioxidant capacity, and thus enhance fruit quality of ‘Yali’ pear.

-

Keywords:

- bagging /

- ‘Yali’ pear /

- wax /

- storage quality /

- oxidation resistance /

- polyethylene plastic film bags /

- three-layer paper bags

-

果实采后贮运过程中易发生失水、营养物质转化、外观颜色变化、病原菌侵害腐烂等现象,而蜡质的存在可有效延缓其进程。遗传背景不同、生物和非生物等环境胁迫的影响使果实蜡质组分分布和含量差异明显。研究者将35个品种梨鉴定出的146种蜡质组分聚类分析后发现白梨、沙梨和秋子梨聚为一类,而香梨单独为一类[1]。研究发现发育和成熟期‘苹果梨’果实蜡质烷烃、三萜和脂肪酸等组分可以有效抑制链格孢菌菌丝生长和孢子萌发[2−3]。另外低温贮藏‘雪花梨’、‘玉露香梨’、‘库尔勒香梨’时,它们蜡质组分的变化趋势与提高果实病原菌耐受力、延缓采后品质下降等作用相关[4]。作为枸杞和苹果果实蜡质晶体和其它蜡质结构的主要组成成分,脂肪酸、烷烃和初级醇对保持采后品质特性具有重要作用[5−6]。据报道水杨酸处理可以延缓蓝莓表面积累的酯质、甾醇、脂肪酸、脂肪醇和烷烃等蜡质组分含量减少,并加速三萜类物质的积累,从而延缓果实软化和变质[7]。亦有研究证明气调、低温和高湿度处理均能延缓‘库尔勒香梨’蜡质组分积累和果实硬度的下降,同时延迟果实软化进程、减少果实失重率和抑制呼吸速率升高[8-9]。以上研究表明蜡质在果实发育、采后和贮藏阶段对其抵御各种胁迫、品质形成和保持方面具有重要作用,因此,探究果实蜡质和其品质的关系尤其重要。

套袋是改善果实外观和内在品质的常见技术,它增加了果实的光敏感性,促进摘果袋后果实中酚类、类黄酮、叶绿素、类胡萝卜素和花青苷等抗氧化和色素物质的合成[10−11]。绿色纸袋使‘翠冠梨’表面角质积累增加,同时降低果皮木栓质的积累及其合成酶活性和合成基因的表达,最终降低果实表面褐皮的发生率[12−13]。相比未套袋和聚乙烯塑膜袋,无纺布有效降低‘莱阳慈梨’虎皮病的发病率[14]。另外,红色纤维素袋降低了石榴白叶枯病和开裂的发生率,使果肉组织中抗坏血酸和总花青素的积累增加[15]。但研究发现套袋处理会降低‘鸭梨’果实总抗坏血酸含量,这与套袋后谷胱甘肽还原酶(GR)、抗坏血酸过氧化物酶(APX)、单脱氢抗坏血酸过氧化物酶(MDHAR)、L-半乳糖酮-1,4-内酯脱氢酶(GalLDH)等活性的降低,和抗坏血酸氧化酶(AO)活性及其合成基因表达的升高有关[16]。蜡质存在于果实表面,受套袋形成的微环境影响,其组分分布和含量会发生改变,进而影响果实品质形成和后期贮藏品质劣变进程,而全面分析套袋后果实蜡质变化及其与果实营养品质关系的研究还未见详细报道。因此本研究模拟鲜食鸭梨采后常温贮藏进程,设置两组处理:PE塑膜袋、三层纸袋,以未套袋为对照,分析25 ℃±1 ℃ 贮藏14 d内,对照和处理组蜡质组分含量及分布、品质营养指标及果实抗氧化性的变化和差异,以及三者的相关性,为研发提高果实品质的新型套袋技术提供理论依据。

1. 材料与方法

1.1 材料与仪器

鸭梨果树 于2021年6月5日(盛花后60 d)在河北省魏县东南温村果园(36°37′N,114°93′E)选择生长状态良好、树龄10年的鸭梨果树;氯仿(分析纯) 天津永大化学试剂公司;正二十四烷标准品 美国AccuStandard公司;N-O三甲基硅烷基三氟乙酰胺、1,1-二苯基-2-苦肼基 日本东京化成株式会社(TCI);吡啶(分析纯)、2,6-二氯酚碘酚、抗坏血酸标准品、芦丁、没食子酸标准品 北京索莱宝科技有限公司;福林酚 北京酷来搏科技有限公司;草酸 天津博迪化工股份有限公司。

TA.XT Plus C物性测试仪 英国Stable Micro Systems公司;Thermo DSQⅡ气相色谱-质谱分析仪(配有Xcalibur处理系统)、ThermoHeraeus Multifuge X1R离心机 美国赛默飞世尔科技有限公司;RE-3000B型旋转蒸发仪 上海亚荣生化仪器有限公司;RZK-S24水浴氮吹仪 北京亿阳润泽科技有限公司;BSA124S精密电子天平 德国赛多利斯科技有限公司;T6紫外可见光分光光度计 北京普析通用仪器有限公司。

1.2 实验方法

1.2.1 样品处理

套袋处理:选择的鸭梨果树分别进行聚乙烯(PE)塑膜袋(厚度0.006 mm)和三层纸袋(黑-灰-白)的套袋处理,每组三棵。于9月18日采收不同处理的果实(沿树冠顶部-中部-底部东、西、南、北四个方向随机采摘),外套网袋装箱,当天运回实验室,去除果袋,室温(25 ℃±1 ℃)过夜,隔天从每种处理中分别挑选果形端正、无机械损伤、成熟度和大小基本一致的150个果实,以30个/箱装入瓦楞纸箱,置于25 ℃±1 ℃,湿度45%~50%环境条件下贮藏,其中3箱固定用于失重率测定,在采后0 d和贮藏14 d,测定对照和处理组果实蜡质含量及化学组分变化、及品质营养指标(可滴定酸、维生素C、总黄酮和总酚含量、果实硬度、脆度和紧实度)、抗氧化性和果实失重率。

1.2.2 果实表皮总蜡质提取和组分测定

总蜡质提取和前处理参考Wang等[17]的方法,鸭梨果实经过两次氯仿溶液浸泡,每次1min,在提取液中加入200 µg正二十四烷作为内标,经旋转蒸发仪浓缩后由氮气流吹干。测定前样品中加入400 µL N-O三甲基硅烷基三氟乙酰胺(BSTFA)在60 ℃条件下充分硅烷化40 min,吹干样品,加氯仿重新溶解,使用微孔滤膜将其过滤至顶空进样瓶中待测。每种处理蜡质提取均包含3次重复。

气相色谱质谱(Gas chromatography-mass spectrometry,GC-MS)条件参考Wang等[17]方法:DB-1毛细管柱(30 m×0.25 mm×0.25 µm);氦气流速为1 mL min−1。升温程序:初始温度70 ℃保持1 min,以10 ℃·min−1升至200 ℃并保持2 min,以2 ℃·min−1升至285 ℃,再以1 ℃·min−1升至290 ℃,2 ℃·min−1升至300 ℃并保持10 min,3 ℃·min−1升至320 ℃,分流比10:1,进样量1.5 µL。质谱条件:进样口温度250 ℃,传输线温度300 ℃,离子源温度230 ℃,EI离子源70 eV,质荷比范围为50~650。蜡质组分鉴定参考NIST 2013库,含量计算参考内标法,单位为µg·cm−2。

1.2.3 果实质地和失重率测定

质地测定参考马庆华等[18] 的方法并做修改,采用P2探头(直径2 mm),沿完整鸭梨果实最大横径处选择对称位置测定质地(取平均值),每个重复15个果子(3次重复)。测试方案如下:测前速度5 mm s−1,测中速度1 mm·s−1,测后速度5 mm·s−1,最小感知力为5 g,穿刺距离10 mm,测得果实硬度(g)、脆度(g)和紧实度(g·sec)等参数。

失重率测定:采用差重法。每种处理固定3箱(3次重复),其中一箱总重量为m0,14 d时测定同一箱总重量为m1,果实失重率(%)=(m0¬m1)/m0×100。

1.2.4 果实营养品质和抗氧化性指标测定

随机沿果实长轴对称位置取果皮和果肉,冻于液氮后存放于超低温冰箱,每个重复15个果子(3次重复)。取果皮0.3 g、果肉0.5 g加入5 mL 60%乙醇提取液,室温超声浸提30 min,10000 g min−1离心10 min,收集粗提液。其中总酚测定参考福林酚法[19]、总黄酮测定参考硝酸铝显色法[20]和DPPH清除率测定参考Locatelli等[21]的方法。

1.2.5 果实可滴定酸和维生素C含量测定

果实可滴定酸测定参考酸碱滴定法[22],折算系数按苹果酸计算。果实维生素C(VC)测定参考2,6-二氯酚靛酚滴定法 [23]。

1.3 数据处理

试验所有指标测定均包含3组重复,数据表示为平均值±标准误差。使用IBM SPSS Statistics 24.0进行单因素方差分析,多重比较采用Duncan和LSD。主成分分析(PCA)和相关系数热图使用软件 Origin2021,绘图使用软件 Graphpad prism 7。

2. 结果与分析

2.1 套袋处理对果实质地和失重率的影响

25 ℃±1 ℃贮藏14 d内,对照和处理组的果实脆度均呈下降趋势,而它们的果实紧实度呈增长趋势,但对照和处理组的果实硬度、脆度和紧实度均无差异(表1)。另外PE塑膜袋处理的果实失重率明显最高(表1)。此外,也有报道发现套袋处理对货架期‘早金酥’梨和三种‘烟富’苹果的硬度无影响[24−25],与这里的结果类似。

表 1 25 ℃±1 ℃贮藏14 d 对照和处理组果实质地和失重率比较Table 1. Comparison in fruit texture and weightlessness rate of the control and the treatments within 14 days of storage at 25 ℃±1 ℃贮藏期(d) 处理 硬度(g) 脆度(g) 紧实度(g·sec) 失重率(%) 0 未套袋 253.92±90.46a 259.05±40.58a 223.66±68.44ab − PE袋 237.54±87.73a 236.16±41.46ab 209.49±82.45b − 三层纸袋 213.33±68.6a 257.77±30.15a 208.86±71.24b − 14 未套袋 226.98±66.42a 225.74±33.58b 290.48±147.75a 2.32±0.47b PE袋 208.18±60.94a 227.08±39.1b 246.02±85.7ab 3.24±0.56a 三层纸袋 209.36±57.91a 227.32±43.02b 230.51±75.11ab 2.03±0.28b 注:数据表示为平均值±标准误差,同一列不同字母代表数据间差异显著(P<0.05);表2、表4~表5同。 2.2 套袋处理对果实蜡质组分含量和分布的影响

对照和处理组中均发现烷烃、烯烃、脂肪酸、酯质、脂肪醛、脂肪醇、和三萜类等7种类型蜡质组分(表2)。贮藏14 d内,对照和处理组中烯烃、脂肪酸、和酯质的含量均上升,而两种套袋处理却延缓它们含量的上升(表2);另外对照组中脂肪醛、脂肪醇和总蜡质含量均升高,而两种套袋处理中它们无变化或者下降;两种套袋处理中烷烃和三萜类含量始终低于对照组(表2)。相似研究发现双层纸袋处理使‘苹果梨’表面烷酸和烷酸酯等蜡质组分的含量降低,而处理组三萜类和脂肪醛的含量与对照无差异[26],这与课题组结果部分相似,差异可能来源于纸袋层数和材质不同引起蜡质组分变化的差异。

表 2 25 ℃±1 ℃贮藏14 d 对照和处理组果实蜡质各组分含量比较Table 2. Comparison in contents of fruit wax components in the control and treatments within 14 days of storage at 25 ℃±1 ℃贮藏期(d) 处理 蜡质组分含量(µg/cm2) 烷烃 烯烃 脂肪醛 脂肪酸 脂肪醇 酯类 三萜类 总蜡质 0 未套袋 15.45±3.4ab 3.1±0.55c 44.39±7.6b 1.1±0.39c 10.13±2.7b 14.14±3.44c 40.25±4.78a 143.53±23.57b PE袋 10.24±1.01cd 3.75±1c 39.59±4.74b 0.21±0.11c 5.94±0.63c 7.55±2.36d 27.77±3.48b 105.32±10.85c 三层纸袋 12.53±1.4bc 3.76±0.23c 49.7±7.41b 0.12±0.03c 4.78±0.73cd 4.12±0.2d 36.21±6.04a 128.36±18.42bc 14 未套袋 16.9±1.95a 9.85±0.27a 60.4±4.3a 8.76±1.6a 13.56±1.24a 42.86±3.04a 41.32±5.88a 211.51±19.65a PE袋 8.52±1.75d 6.74±0.88b 44.3±4.95b 7.82±1.2a 3.34±0.5d 17.87±3.67bc 25.29±4.23b 120.2±17.8bc 三层纸袋 9.86±0.36cd 6.81±0.49b 46.33±0.5b 6.25±0.36b 5.56±0.47cd 19.86±1.83b 26.58±0.97b 131.85±3.21bc 烷烃C21-C29、烯烃C24-C30、4种脂肪酸、脂肪醛C22-C34、偶数脂肪醇C18-C28、12种酯质和12种三萜类为不同处理的蜡质分布(表3)。其中烷烃C27和C29,烯烃C24、C26和C30,脂肪酸C16和C18:1,脂肪醛C26、C30、C32和C34,偶数脂肪醇C22-C28,7种酯质(C22:1醇-C16酸、C22醇-C16酸、C22:1醇-C18:1酸、C22醇-C18:1酸、C24:1醇-C18:1酸、C24醇-C18:1酸和C26醇-C18:1酸),7种三萜类物质α-法尼烯、β-香树酯醇、羽扇豆醇、Stigmastan-3,5-diene、β-香树酯酮、Urs-12-en-28-al,3-(acetyloxy)-,(3á)-和Urs-12-en-28-al为主要成分(表3)。

表 3 25 ℃±1 ℃贮藏14 d对照和处理组鉴定的全部果实蜡质组分含量(µg/cm2)Table 3. Contents of each fruit wax components detected in the control and treatments within 14 days of storage at 25 ℃±1 ℃ (µg/cm2)蜡质组分 贮藏时间(d) 0 14 未套袋 PE袋 三层纸袋 未套袋 PE袋 三层纸袋 C16酸 0.39±0.12 0.05±0.02 0.09±0.03 0.73±0.35 0.3±0.03 0.68±0.17 C18:1酸 0.4±0.27 0.15±0.08 0.02±0 5.54±2.13 3.04±0.47 4.88±0.35 C20酸 0.31±0.13 Nd Nd 0.62±0.45 Nd Nd C22酸 Nd Nd Nd 0.32±0.29 Nd Nd C21烷烃 0.07±0.05 0.02±0 0.01±0 0.06±0.03 0.03±0.01 0.09±0.05 C23烷烃 0.1±0.03 0.05±0.02 0.32±0.03 0.06±0.02 0.03±0.01 0.24±0.02 C24烷烃 Nd 0.63±0.12 1.77±0.17 Nd 0.58±0.01 0.99±0.12 C25烷烃 0.47±0.16 0.13±0.02 0.76±0.09 0.35±0.17 0.12±0.03 0.54±0.02 C27烷烃 2.42±0.61 1.01±0.2 0.88±0.08 1.85±0.98 0.86±0.19 0.71±0.01 C28烷烃 0.71±0.16 0.46±0.09 0.2±0.03 0.6±0.38 0.31±0.12 0.15±0.02 C29烷烃 10.65±2.32 7.94±0.82 8.59±1.04 10.33±3.69 6.58±1.42 7.14±0.42 C24烯烃 0.2±0.04 0.17±0.05 0.07±0.01 2.1±0.84 1±0.15 1.15±0.2 C25烯烃 0.86±0.21 0.53±0.25 0.36±0.03 0.84±0.44 0.36±0.11 0.24±0.03 C26烯烃 0.35±0.08 0.41±0.14 0.39±0.06 1.75±0.61 1.22±0.2 1.54±0.27 C27烯烃 0.31±0.03 0.32±0.18 0.5±0.12 0.68±0.18 0.7±0.15 0.74±0.02 C28烯烃 0.17±0.05 0.43±0.08 0.46±0.05 0.36±0.14 0.42±0.12 0.44±0.07 C29烯烃 0.57±0.11 0.4±0.15 0.37±0.04 0.38±0.11 0.41±0.11 0.32±0.02 C30烯烃 0.64±0.08 1.48±0.56 1.61±0.07 2.01±0.76 2.64±0.09 2.38±0.28 C22醛 0.06±0.01 Nd Nd 0.2±0.1 0.05±0.01 0.05±0 C24醛 0.19±0.09 0.05±0.01 Nd 0.49±0.16 0.17±0.02 0.12±0.01 C26醛 2.09±0.49 1.28±0.31 1.05±0.12 3.62±0.9 2.3±0.34 1.75±0.09 C28醛 2.53±0.68 1.34±0.18 1.86±0.51 2.37±0.61 1.73±0.31 2.79±0.75 C30醛 6.69±1.04 4.96±0.86 8.81±1.2 6.47±1.07 5.56±1.19 7.27±0.05 C31醛 0.76±0.16 0.43±0.05 0.32±0.05 1±0.32 0.46±0.05 0.3±0.02 C32醛 18.91±2.61 17.77±2.71 22.87±3.45 22.32±4.09 17.95±1.89 20.79±0.92 C33醛 0.9±0.18 0.68±0.11 0.64±0.09 1.01±0.29 0.66±0.05 0.57±0.02 C34醛 12.27±2.65 13.07±1.38 14.16±2.25 16.52±4.46 15.43±1.24 12.7±0.59 C18醇 Nd Nd Nd 0.03±0.01 Nd Nd C20醇 0.29±0.1 0.14±0.04 0.07±0.01 0.29±0.09 0.21±0.05 0.1±0.02 C22醇 6.98±1.92 4.15±0.53 2.92±0.45 8.47±2.55 5.78±0.89 4.36±0.34 C24醇 1.21±0.26 0.74±0.06 0.75±0.15 1.15±0.27 0.91±0.2 0.8±0.06 C26醇 0.64±0.15 0.37±0.04 0.5±0.08 0.82±0.27 0.38±0.07 0.43±0.02 C28醇 1.02±0.28 0.54±0.02 0.54±0.08 0.94±0.28 0.54±0.04 0.55±0.02 C18:1酸-甘油酯 0.27±0.09 0.14±0.04 Nd 0.42±0.28 0.25±0.08 0.17±0.04 C20醇-C16烷酸酯 0.25±0.1 0.15±0.07 0.15±0.01 0.8±0.32 0.44±0.16 0.27±0.03 C22:1醇-C16烷酸酯 0.74±0.17 0.29±0.05 0.15±0.01 3.38±0.48 1.38±0.32 1.75±0.31 C22醇-C16烷酸酯 3.29±0.95 1.27±0.6 0.95±0.13 8.33±1.65 3.7±0.72 3.9±0.03 C22:1醇-C18:1酸酯 0.41±0.13 0.33±0.16 0.25±0 4.68±0.49 1.84±0.23 3.14±0.42 C22醇-C18:1酸酯 5.77±1.5 2.31±0.77 1.76±0.17 11.73±1.05 5.2±0.89 6.87±0.75 C24醇-C16烷酸酯 0.54±0.15 0.48±0.07 Nd 0.88±0.25 0.52±0.07 0.41±0.06 C16:1酸-甘油三酯 Nd Nd Nd 0.9±0.44 0.43±0.02 Nd C24:1醇-C18:1酸酯 0.46±0.09 1.52±0.49 Nd 2.99±0.07 1.59±0.36 2.12±0.35 C24醇-C18:1酸酯 0.76±0.16 0.32±0.01 0.24±0.05 1.49±0.34 0.69±0.29 0.44±0.02 C26醇-C18:1酸酯 1.65±0.31 0.55±0.28 0.34±0.04 4.14±0.73 1.57±0.68 0.8±0.03 13-Benzenedicarboxylic acid bis(2-ethylhexyl) ester/

13-苯二甲酸双(2-乙基己基)酯Nd 0.18±0.01 Nd 1.78±2.46 0.26±0.07 Nd α-法尼烯 Nd Nd Nd 1.52±0.31 0.93±0.31 1.09±0.07 法尼烯环氧化物- Nd Nd Nd 0.24±0.09 0.14±0.05 Nd δ-生育酚 0.44±0.06 0.57±0.1 Nd 0.65±0.18 0.38±0.1 Nd β-生育酚 0.17±0.13 0.2±0.07 Nd 0.27±0.06 0.12±0.02 Nd β-香树酯醇 7.7±1.02 2.57±0.83 2.86±0.67 5.73±1 2.93±0.63 2.01±0.1 羽扇豆醇 7.41±1.39 4.12±0.73 5.15±1.51 6.11±0.79 2.64±0.82 2.48±0.11 Stigmastan-3,5-diene 5.03±0.32 5.06±1.29 6.97±1.04 4.15±0.38 4.73±0.23 5.6±0.11 α-香树酯醇 1.5±0.66 0.99±0.21 0.99±0.07 1.42±0.73 0.99±0.13 Nd Urs-12-en-24-oic acid 3-oxo- methyl ester (+)-/

Urs-12-en-24-酸3-氧代-甲酯(+)-1.11±0.25 1.51±0.18 1.28±0.13 1.32±0.45 1.39±0.19 1.11±0.2 β-香树酯酮 5.35±1.02 4.44±0.47 3.81±0.45 6.47±1 3.48±0.38 2.64±0.17 Urs-12-en-28-al,3-(acetyloxy)-,(3á)-/Urs-12-en-28-al,3-

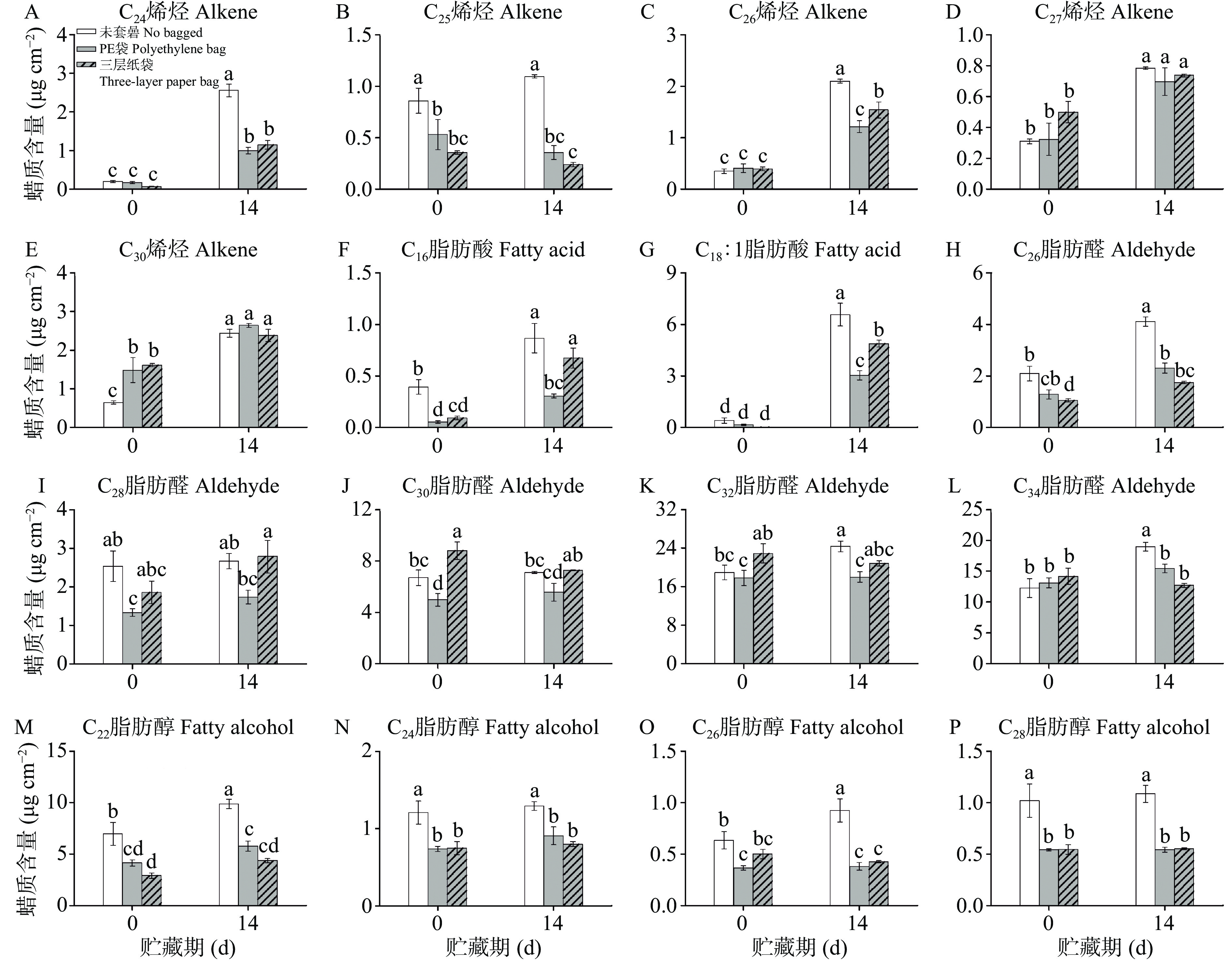

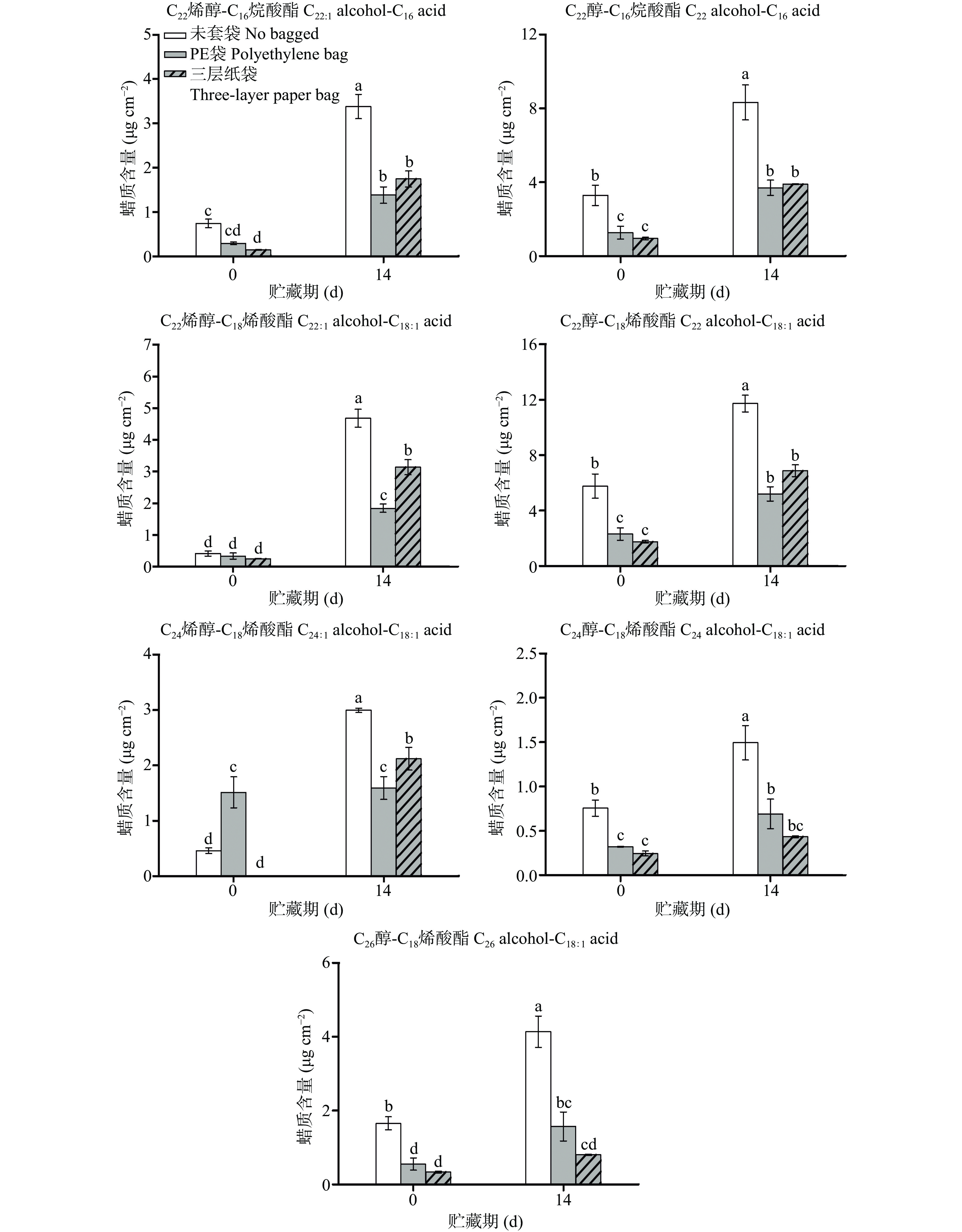

(乙酰氧基)-,(3á)-2.5±0.26 1.81±0.25 3.1±0.39 2.56±0.22 1.55±0.37 2.19±0.09 Urs-12-en-28-al 9.05±1.32 6.5±1.01 12.05±1.98 10.13±1.53 6.01±1.16 9.45±0.47 注:数据表示为平均值±标准误差;Nd表示未检测到。 贮藏14 d内,两种套袋处理中烷烃C27和C29、烯烃C24-C26、脂肪酸C18:1、脂肪醛C26和C34、偶数脂肪醇C22-C28、7种酯质、α-法尼烯、β-香树酯醇、羽扇豆醇、和β-香树酯酮等组分的含量低于对照(图1~图3)。相比PE塑膜袋处理,对照和三层纸袋处理保持更高含量的偶数脂肪醛C28-C32,以及萜类Stigmastan-3,5-diene、Urs-12-en-28-al,3-(acetyloxy)-,(3á)-和Urs-12-en-28-al(图1和图3)。另外两种套袋处理均明显延缓酯质C22:1醇-C18:1酸和C24:1醇-C18:1酸、烯烃C26、脂肪酸C16和C18:1含量的上升,但三层纸袋中它们的含量要高于PE塑膜袋(图1~图2)。

曾有研究发现双层纸袋处理降低‘苹果梨’果实蜡质中主要组分亚油酸甲酯、反式-油酸甲酯、C16烷酸,C26(或者C28)烷酸甲酯、C30烷酸甲酯等酯质成分,以及α-香树脂醇、3-β-羟基-奥利-18-烯-28-酸(甲酯)等萜类的含量[26],这与本研究中三层纸袋降低鸭梨蜡质酯质和萜类组分积累的结论相似,同时受到梨品种、生长环境和纸袋结构差异的影响,套袋对两种梨果面蜡质组分的影响也存在一些差异。

套袋改变果实周围环境如温度、湿度和光照等,进而影响果实表面蜡质变化。与本研究相似的是,我们前期发现低温结合1-MCP(乙烯抑制剂)也降低了‘红香酥’梨蜡质中奇数烷烃C25和C29、脂肪酸C16、酯质C22醇-C16酸和C22醇-C18酸、偶数脂肪醛C32和C34、和萜类β-香树酯醇等物质的积累[27]。本研究结果表明相比PE塑膜袋,三层纸袋延缓一些主要组分含量的下降,因此它的蜡质特征更趋近于对照。有学者发现,与湿度70%~75%相比,湿度90%~95%延缓主要蜡质组分烷烃C29含量的下降,从而保持更高的总蜡质和烷烃含量,进而提高‘库尔勒香梨’果实品质[9]。

2.3 套袋处理对果实品质营养指标及抗氧化性的影响

贮藏14 d内,对照组果实可滴定酸和VC的含量均上升,而PE塑膜袋处理果实VC的含量下降,三层纸袋处理的两种品质指标无明显变化(表4)。14 d内,对照和三层纸袋处理的果皮黄酮、果皮总酚(14 d时)、果实可滴定酸和VC的含量(14 d时)以及果皮DPPH值均高于PE塑膜袋处理中的对应值(表4~表5)。据报道三层纸袋处理提高‘考密斯’梨果皮酚类物质含量(儿茶素和咖啡酸)[28]亦有研究发现黄色织袋使‘delicious’苹果具有和未套袋果实同样较高含量的总酚,甚至高于未套袋的SSC和可滴定酸含量[29]。棕色和白色纸袋提高了芒果总可溶性固形物、抗坏血酸、还原糖和柠檬酸含量,但PE塑膜袋并未明显改善芒果的以上品质指标[30]。单层纸袋处理提高石榴采后果实的抗氧化性[31]。课题组研究也发现,与PE塑膜袋相比,对照和三层纸袋处理具有更高含量的抗氧化组分和抗氧化活性。

表 4 25 ℃±1 ℃贮藏14 d 对照和处理组果实品质指标的差异Table 4. Difference of fruit quality in the control and treatments within 14 days of 25 ℃±1 ℃ storage品质指标 贮藏时间(d) 0 14 未套袋 PE袋 三层纸袋 未套袋 PE袋 三层纸袋 可滴定酸含量(%) 0.13±0.02bc 0.12±0.01c 0.15±0.01ab 0.16±0.01a 0.12±0.02c 0.16±0.05a VC含量(mg/100 g) 0.018±0.001cd 0.021±0.009bc 0.02±0.004bc 0.035±0.006a 0.014±0.003d 0.025±0.006b 表 5 25 ℃±1 ℃贮藏14 d对照和处理组果实营养指标及抗氧化性的差异Table 5. Difference of fruit nutritional index and antioxidant activity in the control and treatments within14 days of 25 ℃±1 ℃ storage贮藏时间(d) 处理 部位 营养指标 总酚含量(mg/g) 黄酮含量(mg/g) DPPH自由基清除率(%) 未套袋 果皮 1.39±0.03ab 3.89±0.25a 90.06±0.64a 0 PE袋 果皮 1.15±0.02c 2.17±0.06b 54.42±3.99d 三层纸袋 果皮 1.25±0.04bc 3.98±0.41a 80.61±1.57a 未套袋 果皮 1.41±0.06a 4.09±0.13a 84.63±2.90a 14 PE袋 果皮 1.16±0.05c 2.74±0.57b 61.55±3.6c 三层纸袋 果皮 1.50±0.13a 3.88±0.26a 92±0.33a 未套袋 果肉 0.17±0.01a 0.33±0.02a 16.14±0.70a 0 PE袋 果肉 0.17±0.02ab 0.31±0.02a 14.24±1.09ab 三层纸袋 果肉 0.14±0.02ab 0.25±0.02b 11.98±0.52b 未套袋 果肉 0.17±0.02a 0.32±0.04a 12.38±0.53b 14 PE袋 果肉 0.16±0.01ab 0.32±0.05a 11.75±2.79b 三层纸袋 果肉 0.13±0.01b 0.24±0.04b 12.45±1.24b 2.4 对照和处理组果实蜡质组分的主成分分析(PCA)以及蜡质与果实品质营养指标、和抗氧化性的相关分析

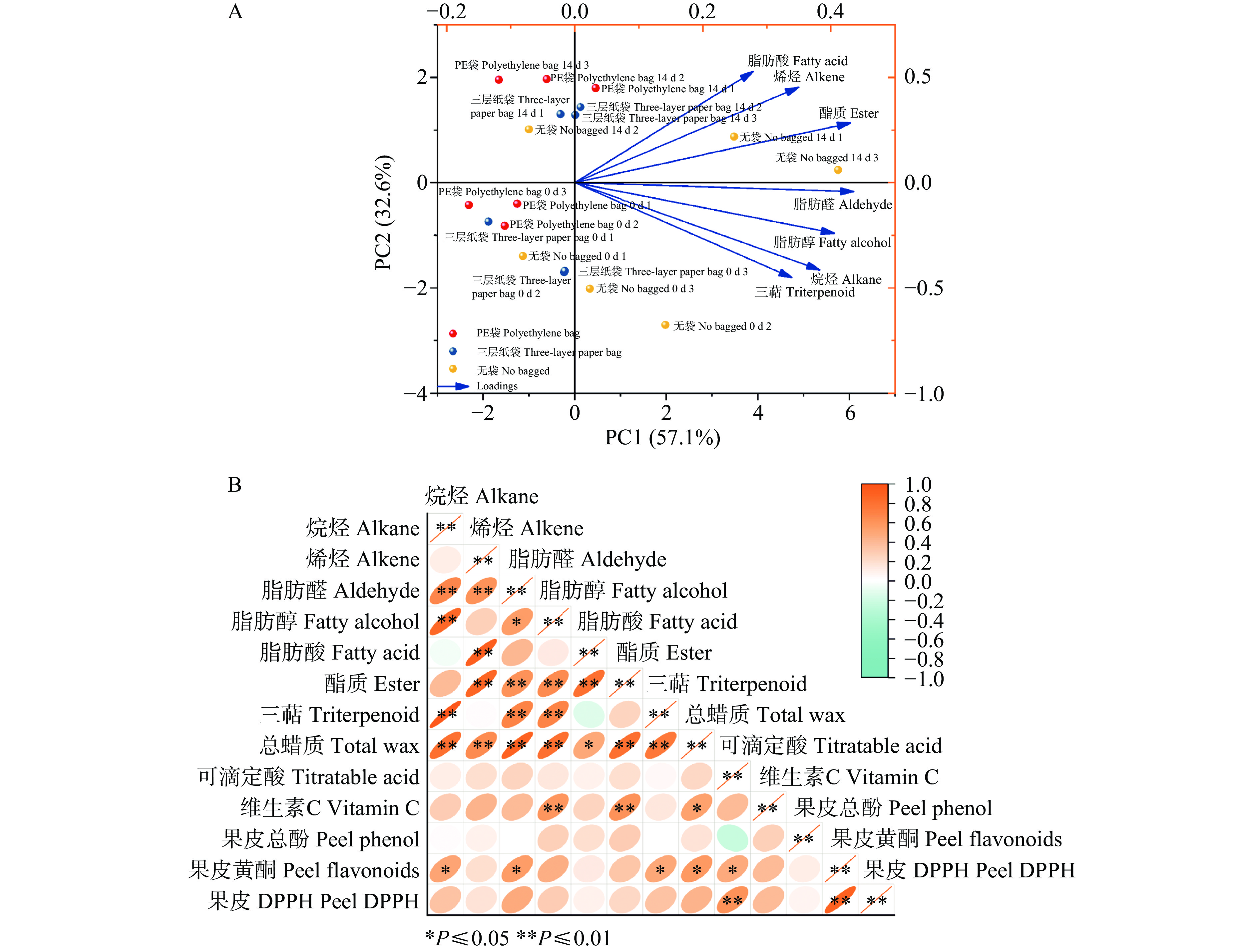

图4A载荷图中2个主成分,PC1和PC2的方差贡献率之和大于70%,且特征值均大于1,可以代表7种蜡质组分分析不同处理对‘鸭梨’果实蜡质组分的影响,其中脂肪酸、烯烃、和酯质均分布在PC1和PC2的正半轴上;脂肪醛、脂肪醇、烷烃、和三萜类分布在PC1的正半轴和PC2的负半轴上。图4得分图中除PE袋14 d 1分布在PC1正半轴上,其余5种组合均分布在PC1负半轴上,且与原点相距较远。未套袋14 d 2、未套袋0 d 1分布在PC1负半轴上,而其余4种组合均分布在PC1正半轴上。三层纸袋14d 1、三层纸袋0 d 1分布在PC1负半轴上,其余4种组合分布在PC1正半轴上或者接近原点。据此分析未套袋(对照)和三层纸袋处理具有相似蜡质特征。

![]() 图 4 25 ℃±1 ℃贮藏14 d对照和处理果实蜡质组分的PCA分析(A)果实蜡质组分与营养品质指标和果皮抗氧化指标的相关系数热图(B)Figure 4. PCA analysis of wax components (A) and heat map of correlation coefficient between fruit wax components and indexes of nutritional quality and peel antioxidant (B) in the control and treatments within 14 days of 25 ℃±1 ℃ storage

图 4 25 ℃±1 ℃贮藏14 d对照和处理果实蜡质组分的PCA分析(A)果实蜡质组分与营养品质指标和果皮抗氧化指标的相关系数热图(B)Figure 4. PCA analysis of wax components (A) and heat map of correlation coefficient between fruit wax components and indexes of nutritional quality and peel antioxidant (B) in the control and treatments within 14 days of 25 ℃±1 ℃ storage图4B显示蜡质组分烷烃、脂肪醛、三萜类、总蜡质与果皮黄酮含量正相关(P<0.05);脂肪醇、酯质、总蜡质与果实VC含量正相关(P<0.05或P<0.01);果实可滴定酸含量分别与果皮黄酮和果皮DPPH正相关(P<0.05或P<0.01);果皮总酚和果皮黄酮含量均与果皮DPPH正相关(P<0.01);果皮总酚与果皮黄酮含量正相关(P<0.01)。有相似的研究表明低温和气调延缓库尔勒香梨蜡质总量和贮藏品质下降,其中蜡质组分烷烃与果实总酚含量正相关,脂肪醇和脂肪醛与果实可滴定酸含量正相关[32];另外与纤维素、可溶性果胶、纤维素酶活性和果胶酶活性等果皮相关生理指标正相关[8]。另外去除蜡质后,活性氧诱导三种哈密瓜果实总酚、总黄酮、Vc等抗氧化组分的积累和APX、POD和CAT抗氧化酶活性下降,从而使果实可滴定酸和SSC降低,这与三层纸袋延缓部分鸭梨主要蜡质组分积累的下降,从而呈现高于PE塑膜袋处理的抗氧化组分含量的结果相似[33]。

3. 结论

两种套袋处理均降低鸭梨采后总蜡质和各蜡质组分(烷烃和三萜类除外)的积累。相比PE塑膜袋,三层纸袋处理延缓了果皮总酚、果皮黄酮等抗氧化物质和果皮DPPH清除率的下降,从而使果实保持更高的可滴定酸和维生素C含量等品质,同时降低果实失重率,这归因于三层纸袋中延缓下降的烯烃C26、脂肪酸C18:1、2种酯质C22:1醇-C18:1酸和C24:1醇-C18:1酸、偶数脂肪醛C28-C32、Stigmastan-3, 5-diene、Urs-12-en-28-al,3-(acetyloxy)-,(3á)-、和Urs-12-en-28-al等蜡质组分的积累。另外三层纸袋处理呈现与对照相似的蜡质和果实贮藏品质特征,且一些蜡质组分与果皮抗氧化物质和果实品质指标相关。因此,表皮蜡质对套袋果实采后品质的保持起着重要作用。本研究阐述了套袋引起的表皮蜡质变化与鸭梨贮藏品质的关系。

-

图 1 25 ℃±1 ℃贮藏14 d 对照和处理组果实蜡质烯烃、脂肪酸、脂肪醛和脂肪醇主要组分的含量变化

注:烯烃主要组分(A~E);脂肪酸主要组分(F~G);脂肪醛主要组分(H~L);脂肪醇主要组分(M~P);数据表示为平均值±标准误差,不同字母代表数据间差异显著(P<0.05);图2~图3同。

Figure 1. Changes in the main compositions of fruit wax alkenes, fatty acids, fatty aldehydes and fatty alcohols in the control and treatments within 14 days of 25 ℃±1 ℃ storage

图 4 25 ℃±1 ℃贮藏14 d对照和处理果实蜡质组分的PCA分析(A)果实蜡质组分与营养品质指标和果皮抗氧化指标的相关系数热图(B)

Figure 4. PCA analysis of wax components (A) and heat map of correlation coefficient between fruit wax components and indexes of nutritional quality and peel antioxidant (B) in the control and treatments within 14 days of 25 ℃±1 ℃ storage

表 1 25 ℃±1 ℃贮藏14 d 对照和处理组果实质地和失重率比较

Table 1 Comparison in fruit texture and weightlessness rate of the control and the treatments within 14 days of storage at 25 ℃±1 ℃

贮藏期(d) 处理 硬度(g) 脆度(g) 紧实度(g·sec) 失重率(%) 0 未套袋 253.92±90.46a 259.05±40.58a 223.66±68.44ab − PE袋 237.54±87.73a 236.16±41.46ab 209.49±82.45b − 三层纸袋 213.33±68.6a 257.77±30.15a 208.86±71.24b − 14 未套袋 226.98±66.42a 225.74±33.58b 290.48±147.75a 2.32±0.47b PE袋 208.18±60.94a 227.08±39.1b 246.02±85.7ab 3.24±0.56a 三层纸袋 209.36±57.91a 227.32±43.02b 230.51±75.11ab 2.03±0.28b 注:数据表示为平均值±标准误差,同一列不同字母代表数据间差异显著(P<0.05);表2、表4~表5同。 表 2 25 ℃±1 ℃贮藏14 d 对照和处理组果实蜡质各组分含量比较

Table 2 Comparison in contents of fruit wax components in the control and treatments within 14 days of storage at 25 ℃±1 ℃

贮藏期(d) 处理 蜡质组分含量(µg/cm2) 烷烃 烯烃 脂肪醛 脂肪酸 脂肪醇 酯类 三萜类 总蜡质 0 未套袋 15.45±3.4ab 3.1±0.55c 44.39±7.6b 1.1±0.39c 10.13±2.7b 14.14±3.44c 40.25±4.78a 143.53±23.57b PE袋 10.24±1.01cd 3.75±1c 39.59±4.74b 0.21±0.11c 5.94±0.63c 7.55±2.36d 27.77±3.48b 105.32±10.85c 三层纸袋 12.53±1.4bc 3.76±0.23c 49.7±7.41b 0.12±0.03c 4.78±0.73cd 4.12±0.2d 36.21±6.04a 128.36±18.42bc 14 未套袋 16.9±1.95a 9.85±0.27a 60.4±4.3a 8.76±1.6a 13.56±1.24a 42.86±3.04a 41.32±5.88a 211.51±19.65a PE袋 8.52±1.75d 6.74±0.88b 44.3±4.95b 7.82±1.2a 3.34±0.5d 17.87±3.67bc 25.29±4.23b 120.2±17.8bc 三层纸袋 9.86±0.36cd 6.81±0.49b 46.33±0.5b 6.25±0.36b 5.56±0.47cd 19.86±1.83b 26.58±0.97b 131.85±3.21bc 表 3 25 ℃±1 ℃贮藏14 d对照和处理组鉴定的全部果实蜡质组分含量(µg/cm2)

Table 3 Contents of each fruit wax components detected in the control and treatments within 14 days of storage at 25 ℃±1 ℃ (µg/cm2)

蜡质组分 贮藏时间(d) 0 14 未套袋 PE袋 三层纸袋 未套袋 PE袋 三层纸袋 C16酸 0.39±0.12 0.05±0.02 0.09±0.03 0.73±0.35 0.3±0.03 0.68±0.17 C18:1酸 0.4±0.27 0.15±0.08 0.02±0 5.54±2.13 3.04±0.47 4.88±0.35 C20酸 0.31±0.13 Nd Nd 0.62±0.45 Nd Nd C22酸 Nd Nd Nd 0.32±0.29 Nd Nd C21烷烃 0.07±0.05 0.02±0 0.01±0 0.06±0.03 0.03±0.01 0.09±0.05 C23烷烃 0.1±0.03 0.05±0.02 0.32±0.03 0.06±0.02 0.03±0.01 0.24±0.02 C24烷烃 Nd 0.63±0.12 1.77±0.17 Nd 0.58±0.01 0.99±0.12 C25烷烃 0.47±0.16 0.13±0.02 0.76±0.09 0.35±0.17 0.12±0.03 0.54±0.02 C27烷烃 2.42±0.61 1.01±0.2 0.88±0.08 1.85±0.98 0.86±0.19 0.71±0.01 C28烷烃 0.71±0.16 0.46±0.09 0.2±0.03 0.6±0.38 0.31±0.12 0.15±0.02 C29烷烃 10.65±2.32 7.94±0.82 8.59±1.04 10.33±3.69 6.58±1.42 7.14±0.42 C24烯烃 0.2±0.04 0.17±0.05 0.07±0.01 2.1±0.84 1±0.15 1.15±0.2 C25烯烃 0.86±0.21 0.53±0.25 0.36±0.03 0.84±0.44 0.36±0.11 0.24±0.03 C26烯烃 0.35±0.08 0.41±0.14 0.39±0.06 1.75±0.61 1.22±0.2 1.54±0.27 C27烯烃 0.31±0.03 0.32±0.18 0.5±0.12 0.68±0.18 0.7±0.15 0.74±0.02 C28烯烃 0.17±0.05 0.43±0.08 0.46±0.05 0.36±0.14 0.42±0.12 0.44±0.07 C29烯烃 0.57±0.11 0.4±0.15 0.37±0.04 0.38±0.11 0.41±0.11 0.32±0.02 C30烯烃 0.64±0.08 1.48±0.56 1.61±0.07 2.01±0.76 2.64±0.09 2.38±0.28 C22醛 0.06±0.01 Nd Nd 0.2±0.1 0.05±0.01 0.05±0 C24醛 0.19±0.09 0.05±0.01 Nd 0.49±0.16 0.17±0.02 0.12±0.01 C26醛 2.09±0.49 1.28±0.31 1.05±0.12 3.62±0.9 2.3±0.34 1.75±0.09 C28醛 2.53±0.68 1.34±0.18 1.86±0.51 2.37±0.61 1.73±0.31 2.79±0.75 C30醛 6.69±1.04 4.96±0.86 8.81±1.2 6.47±1.07 5.56±1.19 7.27±0.05 C31醛 0.76±0.16 0.43±0.05 0.32±0.05 1±0.32 0.46±0.05 0.3±0.02 C32醛 18.91±2.61 17.77±2.71 22.87±3.45 22.32±4.09 17.95±1.89 20.79±0.92 C33醛 0.9±0.18 0.68±0.11 0.64±0.09 1.01±0.29 0.66±0.05 0.57±0.02 C34醛 12.27±2.65 13.07±1.38 14.16±2.25 16.52±4.46 15.43±1.24 12.7±0.59 C18醇 Nd Nd Nd 0.03±0.01 Nd Nd C20醇 0.29±0.1 0.14±0.04 0.07±0.01 0.29±0.09 0.21±0.05 0.1±0.02 C22醇 6.98±1.92 4.15±0.53 2.92±0.45 8.47±2.55 5.78±0.89 4.36±0.34 C24醇 1.21±0.26 0.74±0.06 0.75±0.15 1.15±0.27 0.91±0.2 0.8±0.06 C26醇 0.64±0.15 0.37±0.04 0.5±0.08 0.82±0.27 0.38±0.07 0.43±0.02 C28醇 1.02±0.28 0.54±0.02 0.54±0.08 0.94±0.28 0.54±0.04 0.55±0.02 C18:1酸-甘油酯 0.27±0.09 0.14±0.04 Nd 0.42±0.28 0.25±0.08 0.17±0.04 C20醇-C16烷酸酯 0.25±0.1 0.15±0.07 0.15±0.01 0.8±0.32 0.44±0.16 0.27±0.03 C22:1醇-C16烷酸酯 0.74±0.17 0.29±0.05 0.15±0.01 3.38±0.48 1.38±0.32 1.75±0.31 C22醇-C16烷酸酯 3.29±0.95 1.27±0.6 0.95±0.13 8.33±1.65 3.7±0.72 3.9±0.03 C22:1醇-C18:1酸酯 0.41±0.13 0.33±0.16 0.25±0 4.68±0.49 1.84±0.23 3.14±0.42 C22醇-C18:1酸酯 5.77±1.5 2.31±0.77 1.76±0.17 11.73±1.05 5.2±0.89 6.87±0.75 C24醇-C16烷酸酯 0.54±0.15 0.48±0.07 Nd 0.88±0.25 0.52±0.07 0.41±0.06 C16:1酸-甘油三酯 Nd Nd Nd 0.9±0.44 0.43±0.02 Nd C24:1醇-C18:1酸酯 0.46±0.09 1.52±0.49 Nd 2.99±0.07 1.59±0.36 2.12±0.35 C24醇-C18:1酸酯 0.76±0.16 0.32±0.01 0.24±0.05 1.49±0.34 0.69±0.29 0.44±0.02 C26醇-C18:1酸酯 1.65±0.31 0.55±0.28 0.34±0.04 4.14±0.73 1.57±0.68 0.8±0.03 13-Benzenedicarboxylic acid bis(2-ethylhexyl) ester/

13-苯二甲酸双(2-乙基己基)酯Nd 0.18±0.01 Nd 1.78±2.46 0.26±0.07 Nd α-法尼烯 Nd Nd Nd 1.52±0.31 0.93±0.31 1.09±0.07 法尼烯环氧化物- Nd Nd Nd 0.24±0.09 0.14±0.05 Nd δ-生育酚 0.44±0.06 0.57±0.1 Nd 0.65±0.18 0.38±0.1 Nd β-生育酚 0.17±0.13 0.2±0.07 Nd 0.27±0.06 0.12±0.02 Nd β-香树酯醇 7.7±1.02 2.57±0.83 2.86±0.67 5.73±1 2.93±0.63 2.01±0.1 羽扇豆醇 7.41±1.39 4.12±0.73 5.15±1.51 6.11±0.79 2.64±0.82 2.48±0.11 Stigmastan-3,5-diene 5.03±0.32 5.06±1.29 6.97±1.04 4.15±0.38 4.73±0.23 5.6±0.11 α-香树酯醇 1.5±0.66 0.99±0.21 0.99±0.07 1.42±0.73 0.99±0.13 Nd Urs-12-en-24-oic acid 3-oxo- methyl ester (+)-/

Urs-12-en-24-酸3-氧代-甲酯(+)-1.11±0.25 1.51±0.18 1.28±0.13 1.32±0.45 1.39±0.19 1.11±0.2 β-香树酯酮 5.35±1.02 4.44±0.47 3.81±0.45 6.47±1 3.48±0.38 2.64±0.17 Urs-12-en-28-al,3-(acetyloxy)-,(3á)-/Urs-12-en-28-al,3-

(乙酰氧基)-,(3á)-2.5±0.26 1.81±0.25 3.1±0.39 2.56±0.22 1.55±0.37 2.19±0.09 Urs-12-en-28-al 9.05±1.32 6.5±1.01 12.05±1.98 10.13±1.53 6.01±1.16 9.45±0.47 注:数据表示为平均值±标准误差;Nd表示未检测到。 表 4 25 ℃±1 ℃贮藏14 d 对照和处理组果实品质指标的差异

Table 4 Difference of fruit quality in the control and treatments within 14 days of 25 ℃±1 ℃ storage

品质指标 贮藏时间(d) 0 14 未套袋 PE袋 三层纸袋 未套袋 PE袋 三层纸袋 可滴定酸含量(%) 0.13±0.02bc 0.12±0.01c 0.15±0.01ab 0.16±0.01a 0.12±0.02c 0.16±0.05a VC含量(mg/100 g) 0.018±0.001cd 0.021±0.009bc 0.02±0.004bc 0.035±0.006a 0.014±0.003d 0.025±0.006b 表 5 25 ℃±1 ℃贮藏14 d对照和处理组果实营养指标及抗氧化性的差异

Table 5 Difference of fruit nutritional index and antioxidant activity in the control and treatments within14 days of 25 ℃±1 ℃ storage

贮藏时间(d) 处理 部位 营养指标 总酚含量(mg/g) 黄酮含量(mg/g) DPPH自由基清除率(%) 未套袋 果皮 1.39±0.03ab 3.89±0.25a 90.06±0.64a 0 PE袋 果皮 1.15±0.02c 2.17±0.06b 54.42±3.99d 三层纸袋 果皮 1.25±0.04bc 3.98±0.41a 80.61±1.57a 未套袋 果皮 1.41±0.06a 4.09±0.13a 84.63±2.90a 14 PE袋 果皮 1.16±0.05c 2.74±0.57b 61.55±3.6c 三层纸袋 果皮 1.50±0.13a 3.88±0.26a 92±0.33a 未套袋 果肉 0.17±0.01a 0.33±0.02a 16.14±0.70a 0 PE袋 果肉 0.17±0.02ab 0.31±0.02a 14.24±1.09ab 三层纸袋 果肉 0.14±0.02ab 0.25±0.02b 11.98±0.52b 未套袋 果肉 0.17±0.02a 0.32±0.04a 12.38±0.53b 14 PE袋 果肉 0.16±0.01ab 0.32±0.05a 11.75±2.79b 三层纸袋 果肉 0.13±0.01b 0.24±0.04b 12.45±1.24b -

[1] WU X, YIN H, SHI Z B, et al. Chemical composition and crystal morphology of epicuticular wax in mature fruits of 35 pear ( Pyrus spp.) cultivars[J]. Frontiers in Plant Science,2018,9:679. doi: 10.3389/fpls.2018.00679

[2] LI Y C, YIN Y, CHEN S J, et al. Chemical composition of cuticular waxes during fruit development of Pingguoli pear and their potential role on early events of Alternaria alternata infection[J]. Functional Plant Biology,2013,41(3):313−320.

[3] WU X, YIN H, CHEN Y Y, et al. Chemical composition, crystal morphology and key gene expression of cuticular waxes of Asian pears at harvest and after storage [J]. Postharvest Biology and Technology, 2017, 132: 71-80.

[4] YIN Y, BI Y, CHEN S J, et al. Chemical composition and antifungal activity of cuticular wax isolated from Asian pear fruit (cv. Pingguoli)[J]. Scientia Horticulturae,2011,129(4):577−582. doi: 10.1016/j.scienta.2011.04.028

[5] WANG P, WANG J J, ZHANG H Y, et al. Chemical composition, crystal morphology, and key gene expression of the cuticular waxes of Goji ( Lycium barbarum L.) Berries[J]. Journal of Agricultural and Food Chemistry,2021,69(28):7874−7883. doi: 10.1021/acs.jafc.1c02009

[6] CHAI Y F, LI A, WAI S C, et al. Cuticular wax composition changes of 10 apple cultivars during postharvest storage[J]. Food Chemistry,2020,324:126903. doi: 10.1016/j.foodchem.2020.126903

[7] LEIDE J, DE SOUZA A X, PAPP I, et al. Specific characteristics of the apple fruit cuticle:investigation of early and late season cultivars ‘Prima’ and ‘Florina’( Malus domestica Borkh.)[J]. Scientia Horticulturae,2018,229(9):137−147. doi: 10.1016/j.scienta.2017.10.042

[8] MAO H J, LÜ Y H, CHEN G G, et al. Effects of cuticular wax on the postharvest physiology in fragrant pear at different storages[J]. Journal of the Science of Food and Agriculture,2022,102(11):4425−4434. doi: 10.1002/jsfa.11796

[9] WANG Y, MAO H J, LÜ Y H, et al. Comparative analysis of total wax content, chemical composition and crystal morphology of cuticular wax in Korla pear under different relative humidity of storage[J]. Food Chemistry,2021,339:128097. doi: 10.1016/j.foodchem.2020.128097

[10] ALI M M, ANWAR R, YOUSEF A F, et al. Influence of bagging on the development and quality of fruits[J]. Plants,2021,10(2):358. doi: 10.3390/plants10020358

[11] BUTHELEZI N M D, MAFEO T P, MATHABA N. Preharvest bagging as an alternative technique for enhancing fruit quality:A review[J]. Hort Technology,2021,31(1):4−13.

[12] ZHANG J, ZHANG Y F, ZHANG P F, et al. An integrated metabolic and transcriptomic analysis reveals the mechanism through which fruit bagging alleviates exocarp semi-russeting in pear fruit[J]. Tree Physiology,2021,41(7):1306−1318. doi: 10.1093/treephys/tpaa172

[13] SHI C H, WANG X Q, ZHANG X Y, et al. Response of fruit bagging to lignin biosynthesis and expression of related genes in fruit peel of sand pear ( Pyrus pyrifolia Nakai) cv. Cuiguan[J]. Hortscience,2019,54(11):1989−1997. doi: 10.21273/HORTSCI14382-19

[14] LI Q, CHENG C X, ZHANG X F, et al. Preharvest bagging and postharvest calcium treatment affects superficial scald incidence and calcium nutrition during storage of ‘Chili’pear ( Pyrus bretschneideri) fruit[J]. Postharvest Biology and Technology,2020,163:111149. doi: 10.1016/j.postharvbio.2020.111149

[15] ASREY R, KUMAR K, SHARMA R R, et al. Fruit bagging and bag color affects physico-chemical, nutraceutical quality and consumer acceptability of pomegranate ( Punica granatum L.) arils[J]. Journal of Food Science and Technology,2020,57(4):1469−1476. doi: 10.1007/s13197-019-04182-x

[16] WANG L B, MA M, ZHANG S L, et al. Characterization of genes involved in pear ascorbic acid metabolism and their response to bagging treatment during ‘Yali’ fruit development[J]. Scientia Horticulturae,2021,285:110178. doi: 10.1016/j.scienta.2021.110178

[17] WANG J Q, HAO H H, LIU R S, et al. Comparative analysis of surface wax in mature fruits between Satsuma mandarin ( Citrus unshiu) and ‘Newhall’navel orange ( Citrus sinensis) from the perspective of crystal morphology, chemical composition and key gene expression[J]. Food Chemistry,2014,153:177−185. doi: 10.1016/j.foodchem.2013.12.021

[18] 马庆华, 王贵禧, 梁丽松, 等. 质构仪穿刺试验检测冬枣质地品质方法的建立[J]. 中国农业科学,2011,44(6):1210−1217 doi: 10.3864/j.issn.0578-1752.2011.06.016 MA Q H, WANG G X, LIANG L S, et al. Establishment of the detecting methods on the fruit texture of Dongzao by puncture test[J]. Scientia Agricultura Sinica,2011,44(6):1210−1217. doi: 10.3864/j.issn.0578-1752.2011.06.016

[19] BONILLA E P, AKOH C C, SELLAPPAN S, et al. Phenolics content and antioxidant capacity of Muscadine grapes[J]. Journal of Agricultural Food Chemistry,2003,51(18):5497−5503. doi: 10.1021/jf030113c

[20] JIA Z S, TANG M C, WU J M. The determination of flavonoid contents in mulberry and their scavenging effects on superoxide Radicals[J]. Food Chemistry,1999,64(4):555−559. doi: 10.1016/S0308-8146(98)00102-2

[21] LOCATELLI M, GINDRO R, TRAVAGLIA F, et al. Study of the DPPH-scavenging activity:Development of a free software for the correct interpretation of data[J]. Food Chemistry,2009,114(3):889−897. doi: 10.1016/j.foodchem.2008.10.035

[22] 冯云霄, 何近刚, 程玉豆, 等. 成熟度对‘红香酥’梨冷藏及货架期品质的影响[J]. 食品安全质量检测学报,2021,12(11):4513−4519 FENG Y X, HE J G, CHENG Y D, et al. Effect of different harvest maturity on quality of ‘Hongxiangsu’ pear during cold storage and subsequent shelf life[J]. Journal of Food Safety& Quality,2021,12(11):4513−4519.

[23] 郝艳娟, 谢立波, 陈秀玲, 等. 辣椒不同品种果实维生素C含量与果实相关性状的分析[J]. 江苏农业科学,2017,45(14):100−103. [HAO Y J, XIE L B, CHENG X L, et al. Analysis of vitamin C content and fruit related characters in different pepper varieties[J]. Jiangsu Agricultural Sciences,2017,45(14):100−103. doi: 10.15889/j.issn.1002-1302.2017.14.028 HAO Y J, XIE L B, CHENG X L, et al . Analysis of vitamin C content and fruit related characters in different pepper varieties[J]. Jiangsu Agricultural Sciences,2017 ,45 (14 ):100 −103 . doi: 10.15889/j.issn.1002-1302.2017.14.028[24] 姜晓艳, 李俊才, 王家珍, 等. 套袋对'早金酥'梨果实品质的影响[J]. 中国果树,2021(5):44−47 JIANG X Y, LI J C, WANG J Z, et al. Effect of bagging on fruit quality of ‘Zaojinsu’ pear[J]. China Fruits,2021(5):44−47.

[25] 何江, 程晓廷, 高宇, 等. 3个苹果品种套袋果与不套袋果品质及耐贮性的比较[J]. 中国果树,2022(6):6−9 HE J, CHENG X T, GAO Y, et al. Comparison of quality aand storability among bagged and non-bagged fruits of three apple varieties[J]. China Fruits,2022(6):6−9.

[26] 李永才, 尹燕, 陈松江, 等. 采前套袋对苹果梨表皮蜡质结构和化学组分的影响[J]. 中国农业科学,2012,45(17):3661−3668 LI Y C, YIN Y, CHEN S J, et al. Effects of preharvest bagging treatment on the micro-structure and chemical composition of cuticular wax in Pingguoli pear fruit[J]. Scientia Agricultura Sinica,2012,45(17):3661−3668.

[27] LI D, CHENG Y D, GUAN J F, et al. Effects of 1‐methylcyclopropene on surface wax and related gene expression in cold‐stored ‘Hongxiangsu’pears[J]. Journal of the Science of Food and Agriculture,2019,99(5):2438−2446. doi: 10.1002/jsfa.9452

[28] HUDINA M, STAMPAR F. Effect of fruit bagging on quality of ‘Conference’Pear ( Pyrus communis L.)[J]. European Journal of Horticultural Science,2011,76(5):176−181.

[29] SHARMA R R, PAL R K, ASREY R, et al. Pre-harvest fruit bagging influences fruit color and quality of apple cv. Delicious[J]. Agricultural Sciences,2013,4(9):443. doi: 10.4236/as.2013.49059

[30] ISLAM M T, RAHMAN M S, AKTER M M, et al. Influence of pre-harvest bagging on fruit quality of mango ( Mangifera indica L. ) cv. Langra[J]. Asian Journal of Agricultural and Horticultural Research,2019,4(4):1−10.

[31] GRINAN I, MORALES D, GALINDO A, et al. Effect of preharvest fruit bagging on fruit quality characteristics and incidence of fruit physiopathies in fully irrigated and water stressed pomegranate trees[J]. Journal of the Science of Food and Agriculture,2019,99(3):1425−1433. doi: 10.1002/jsfa.9324

[32] WANG Y, SU S N, CHEN G G, et al. Relationship between cuticular waxes and storage quality parameters of Korla pear under different storage methods[J]. Journal of Plant Growth Regulation,2021,40(3):1152−1165. doi: 10.1007/s00344-020-10176-3

[33] ZHANG W D, WANG Y, GUO H J, et al. Cuticular wax removal on reactive oxygen species-related mechanisms and on the quality of Hami melon cultivars[J]. Postharvest Biology and Technology,2022,193:112060. doi: 10.1016/j.postharvbio.2022.112060

下载:

下载:

下载:

下载: