Processing Technology Optimization and Quality Analysis of Chimonobambusa quadrangularis Shoot Powder Crisp Biscuits

-

摘要: 为研制一款具有高膳食纤维含量的饼干制品,提高竹笋综合利用率,本文将金佛山方竹笋全粉添加至饼干中,以色度值、质构特性、感官评价为指标对饼干进行品质分析,探究竹笋粉添加量、黄油添加量、白砂糖添加量、烘焙温度、烘焙时间对饼干品质的影响,通过单因素实验优化方竹笋全粉酥性饼干的工艺配方。结果表明,随着CQSP添加量的增加,饼干a*值和b*值均增大,添加量为0%~3%时,L*值变化不显著(P>0.05),添加量为4%~5%时,饼干亮度明显降低,饼干硬度、脆度、咀嚼性均逐渐增大。随黄油添加量的增加,饼干的硬度、脆度、咀嚼性减小,黄油添加量为24%时饼干品质较佳。饼干的硬度随白砂糖添加量的增加而增大,当白砂糖添加量为13%~15%时,饼干硬度最为适宜。饼干的L*值随着烘焙温度的升高而逐渐减小,当烘焙温度为160~180 ℃时,饼干明显变暗。随着烘焙时间的延长,饼干a*值和b*值增大,L*值逐渐减小,硬度、脆度、咀嚼性均逐渐增大。经单因素优化后得到方竹笋全粉酥性饼干的较优工艺配方为CQSP添加量3%、黄油添加量24%、白砂糖添加量13%、烘焙温度150 ℃、烘焙时间25 min,在此工艺条件下,饼干L*值为71.1,a*值为2.05,b*值为27.43,硬度为2466.16 g,脆度为2050.02 g,咀嚼性为541.29,感官评分达到83.1分。研究结果可为方竹笋加工副产物的高值化利用提供一定的理论参考。Abstract: To develop a biscuit product with high dietary fiber content and improve the comprehensive utilization rate of bamboo shoots, Chimonobambusa quadrangularis shoot powder (CQSP) was added to biscuits. Inspected by the effect of CQSP addition, butter addition, sugar addition, baking temperature and baking time on the quality of biscuits, using chroma value, texture properties and sensory evaluation as the index, studied by single factor experiment to optimize the Chimonobambusa quadrangularis shoot biscuits craft formula. The results showed that with the increase of CQSP addition, the a* and b * of biscuits increased. The L* did not change significantly when the content of CQSP was added from 0% to 3%, the brightness of biscuits decreased significantly (P>0.05) when the content of CQSP was added from 4% to 5%, and the hardness, crispness and chewiness of biscuits increased gradually. The hardness, crispness and chewiness of the biscuits decreased with the increase of butter content. The biscuit quality was better, when the content of butter added was 24%. The hardness of the biscuit increased with the increase of sugar content. When the sugar content was 13%~15%, the biscuit hardness was the best. The L* of biscuits gradually decreases with the increase of baking temperature. When the baking temperature was 160~180 ℃, the biscuits become dark obviously. With the increase of baking time, the a* and b * of biscuits increased, the L* gradually decreased, and the hardness, crispness and chewiness of biscuits increased gradually. After single factor optimization, the best formula of CQSP crisp biscuit was CQSP 3%, butter 24%, sugar 13%, baking at 150 ℃ for 25 minutes. Under the technological conditions, the L* of was 71.1, the a* was 2.05, the b* was 27.43, the hardness was 2466.16 g, the crispness was 2050.02 g, the chewiness was 541.29, the sensory score could reach 83.1. The results can provide a theoretical reference for high value utilization of by-products of bamboo shoot processing.

-

方竹笋(Chimonobambusa quadrangularis shoot)为禾本科竹亚科寒竹属植物,因竹竿呈方形而得名。被喻为“笋中之冠”[1]的金佛山方竹是我国西南地区特有竹种,集中分布于重庆市南川区、万盛经济开发区、贵州省桐梓县近邻的金佛山林区以及云南省镇雄县[2]。方竹笋营养丰富,口感清脆香甜,含有膳食纤维、氨基酸、蛋白质、矿物质元素等多种成分,是一种高蛋白、高纤维、低脂肪的绿色健康食品[3]。目前,方竹笋加工方法主要有清水竹笋、腌制竹笋、干制竹笋等[4],加工过程中会产生大量笋渣、笋头、笋壳等副产物,综合利用率较低,造成大量资源浪费和环境污染,因此亟需研制开发竹笋高值化产品以期提高全笋利用率,扩展其在食品领域的应用。

饼干因其质感特性和独特风味深受消费者喜爱,且近年来为满足大众需求,饼干研究方向朝着功能化和营养化发展。研究表明,添加膳食纤维后,面团特性发生显著变化,面团吸水性、混合耐受性、韧性均增强,延展性减弱[5]。古明亮等[6]将雷竹笋膳食纤维加入酥性饼干,制作出了膳食纤维饼干;吴映雪[7]以笋渣为实验材料,采用响应面法优化复合酶法提取笋渣膳食纤维,研制出了笋渣膳食纤维饼干;Sakac等[8]通过在饼干配方中将甜菜膳食纤维作为小麦粉的替代品研制出了甜菜膳食纤维饼干;Marilisa等[9]将富含膳食纤维的苹果渣粉末部分取代小麦粉研制饼干。方竹笋全粉(Chimonobambusa quadrangularis shoot powder,CQSP)作为一种高蛋白、高膳食纤维的粉体[10],可广泛来源于竹笋加工副产物,并作为主食改良剂、膳食纤维补充剂及食品原料应用于食品行业中,但目前将CQSP应用于高膳食纤维饼干开发的报道较少。因此,本实验以CQSP、低筋面粉、黄油、鸡蛋液、白砂糖为主要原料,进行单因素实验,通过饼干色泽、质构及感官评价对饼干进行品质分析,从而优化方竹笋饼干制作工艺,以期为方竹笋源食品的开发和方竹笋资源利用率的提高提供有益参考。

1. 材料与方法

1.1 材料与仪器

CQSP(来自金佛山方竹笋加工废弃笋头,水分7.55%,蛋白质37.20%,膳食纤维30.25%,灰分7.82%) 重庆特珍农业开发有限公司提供;低筋面粉 中粮面业(海宁)有限公司;黄油 恒天然集团;白砂糖 太古糖业(中国)有限公司;鸡蛋 重庆市北碚区永辉超市。

FA1004A电子分析天平 上海精天电子仪器有限公司;FKB-2分层烘炉 佛山市顺德区陈村镇华兴实业有限公司;Ultra Scan PRO测色仪 美国Hunter Lab公司;TA. XT. Plus质构仪 英国SMS公司。

1.2 实验方法

1.2.1 工艺流程

原辅料预处理→面团调制→压模成型→烘烤→冷却→包装→成品。

1.2.2 操作要点

1.2.2.1 原辅料预处理

将购置的CQSP称量好,存放密封袋中备用。将黄油软化加入白砂糖,搅拌均匀,将鸡蛋液分三次加入其中,搅拌均匀,备用。

1.2.2.2 面团调制

将水、CQSP、黄油、白砂糖、鸡蛋液加入低筋面粉中,搅拌均匀,和成颜色均匀、表面光滑细腻的面团。用保鲜膜将调制好的面团包裹后,置于室温下静置10~20 min。

1.2.2.3 压模成型

用擀面杖将面团擀至厚度约为10 mm,再用印花模具(50 mm×30 mm)压印成型。

1.2.2.4 烘烤冷却及包装

设置烤箱烘焙温度和烘焙时间,将烤箱提前预热10~15 min。 将饼干坯放入烤箱中烘烤。烘烤完成后,取出冷却至室温再包装,以防水汽被封在包装内影响品质,经检验合格后即得CQSP酥性饼干成品。

1.2.3 单因素实验设计

1.2.3.1 CQSP添加量对饼干品质的影响

以低筋面粉、CQSP、黄油、白砂糖、鸡蛋液总重量100%计,下同。固定黄油25%、白砂糖13%、低筋面粉54%、鸡蛋液8%,烘焙温度为上下火150 ℃,烘焙时间25 min,考察CQSP添加量分别为0%、1%、2%、3%、4%、5%对成品品质的影响。

1.2.3.2 黄油添加量对饼干品质的影响

固定白砂糖13%、低筋面粉54%、鸡蛋液8%、CQSP 3%,烘焙温度为上下火150 ℃,烘焙时间25 min,考察黄油添加量分别为20%、22%、24%、26%、28%、30%对成品品质的影响。

1.2.3.3 白砂糖添加量对饼干品质的影响

固定黄油25%、低筋面粉54%、鸡蛋液8%、CQSP 3%,烘焙温度为上下火150 ℃,烘焙时间25 min,考察白砂糖添加量分别为9%、11%、13%、15%、17%、19%对成品品质的影响。

1.2.3.4 烘焙温度对饼干品质的影响

固定黄油25%、白砂糖13%、低筋面粉54%、鸡蛋液8%、CQSP3%,烘焙时间25 min,考察烘焙温度分别为130、140、150、160、170、180 ℃对成品品质的影响。

1.2.3.5 烘焙时间对饼干品质的影响

固定黄油25%、白砂糖13%、低筋面粉54%、鸡蛋液8%、CQSP 3%,烘焙温度为上下火150 ℃,考察烘焙时间分别为15、20、25、30、35、40 min对成品品质的影响。

1.2.4 饼干品质指标测定

1.2.4.1 色度值测定

利用色差仪对测试样品的色泽进行测定,色差仪开机后进行黑白校正,校正结束后测量样品的L*、a*、b*值。L*值表示明亮度(0=黑色,100=白色),a*值表示红绿色度(−a*为绿色,+a*为红色),b*值表示黄蓝色度(−b*为蓝色,+b*为黄色),每个样品重复测3次,取平均值。

1.2.4.2 质构特性测定

用质构仪对方竹笋饼干的硬度、脆度、咀嚼性进行测定,饼干厚度为(5.5±0.3)mm。测定条件:TPA(Texture profile analysis)模式,选用P5探头,测前速率1.0 mm/s,测中和测后速率2.0 mm/s,压缩量30%,触发力5 g。每个样品重复4次,取平均值。

1.2.4.3 方竹笋饼干感官评价

方竹笋饼干制作完成并冷却后,由10人(5男5女)组成的感官评价小组进行感官评价,参照《GB 7100-2015食品安全国家标准 饼干》感官要求,结合方竹笋饼干自身特性,制定了感官评分表,对方竹笋饼干进行感官评分,取其平均值,具体评分标准见表1。

表 1 金佛山方竹笋饼干感官评定标准Table 1. The sensory evaluation criteria of Chimonobambusa quadrangularis shoot biscuits评价项目 评分标准 分数(分) 形态 外形完整,大小厚薄均匀,无变形,表面光滑 15~20 外形完整,大小厚薄较均匀,少许变形,表面光滑 10~14 外形不完整,大小厚薄不均匀,变形,表面粗糙 0~9 色泽 表面棕黄色,色泽均匀,无焦边 15~20 色泽基本均匀,有少许焦边 10~14 色泽不均匀,过白过焦 0~9 质地 内部组织细腻,断面细致均匀,多孔状 15~20 内部组织较为粗糙,断面无层次,孔隙大 10~14 内部组织粗糙,质地松垮 0~9 口感 酥脆细腻,不粘牙,甜度适宜,有适宜的方竹笋味 15~20 略酥脆,稍有粘牙,甜度较适宜,

方竹笋味过浓或过淡10~14 较硬,不酥不脆,粘牙,过甜或甜味不足,

方竹笋味过浓或过淡0~9 气味 有方竹笋的清香味,香味纯正,

奶香味浓郁,无异味15~20 方竹笋的清香味略淡,奶香味较淡 10~14 方竹笋的清香味淡,无奶香味,有异味 0~9 1.3 数据处理

每个样品重复三次平行,采用SPSS18.0对数据进行单因素方差分析(Tukey's test),P<0.05被认为具有统计学显著性,结果以“平均值±标准差”方式表示。采用Origin 2021和Microsoft Excel进行绘图与数据分析。

2. 结果与分析

2.1 CQSP添加量对饼干品质的影响

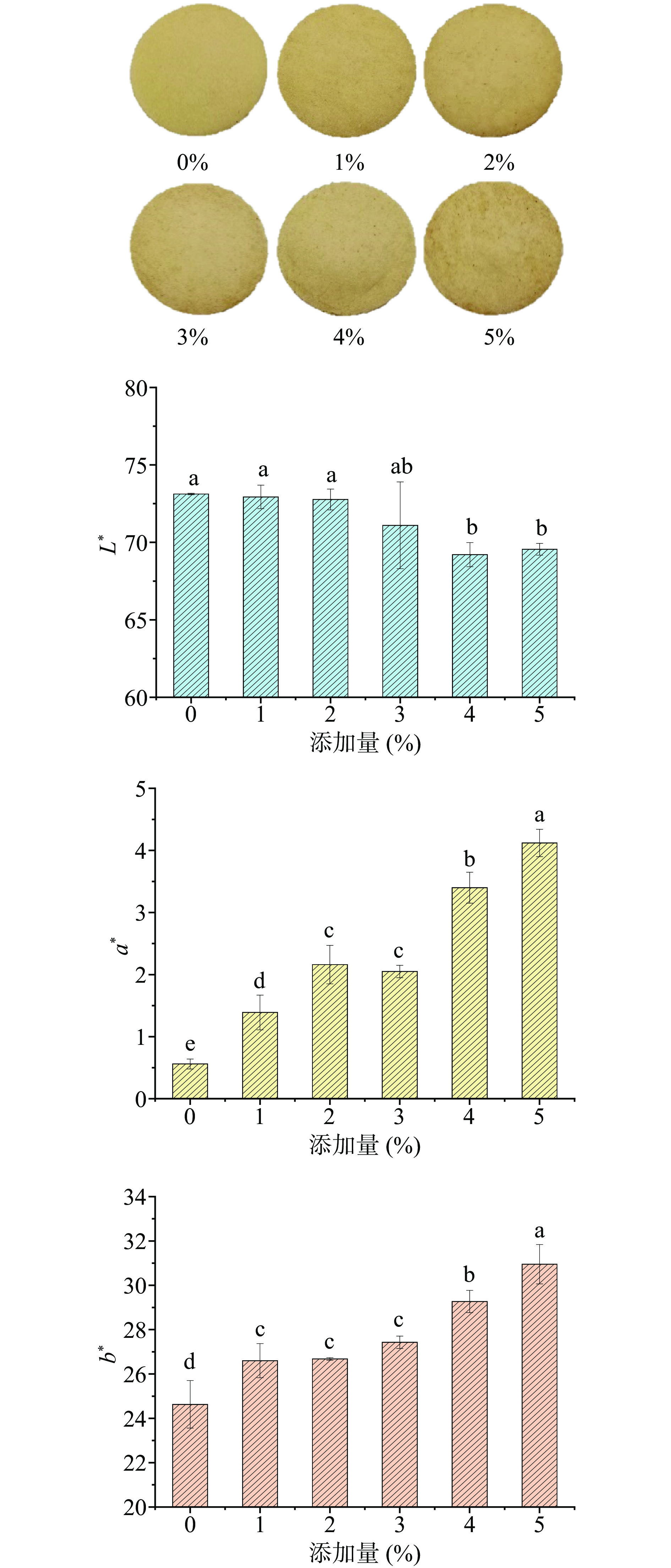

2.1.1 CQSP添加量饼干色泽的影响

饼干的色泽是其重要的评价指标,拥有良好的色泽可吸引消费者。图1为CQSP添加量对饼干色泽的影响结果。随着CQSP的增加,饼干的黄色明显加深。这可能是由于CQSP偏黄,添加后使得饼干颜色加深、明亮度降低。相比于未添加CQSP的饼干,添加CQSP的饼干L*值减小,这表明CQSP的添加使得饼干的亮度降低。CQSP添加量在0%~3%时,L*值变化不显著(P>0.05),添加量在4%~5%时,饼干亮度明显降低。饼干的a*值和b*值均随CQSP添加量的增加而增大,且均为正值,这表明CQSP的添加使得饼干偏向红色和黄色的程度更大。综上,添加CQSP对饼干亮度的影响最小,对饼干黄蓝色度影响最大,CQSP添加量为0%~3%时,饼干的色泽较为适宜。

2.1.2 CQSP添加量对饼干质构的影响

质构是消费者衡量产品品质的主要指标之一[11],通过质构仪获得的饼干质构参数不仅有助于饼干品质的客观评价,而且能够从侧面反映出饼干的内部组织状态和适口性[12]。表2为CQSP添加量对饼干质构的影响结果。饼干的硬度、脆度、咀嚼性都随着CQSP的增加而呈现规律性的变化。随着CQSP添加量的增加,饼干的硬度逐渐增大,这是因为CQSP作为填充物存在于面筋网络中,CQSP中的膳食纤维具有较好的吸水性和持水性,抑制面筋的吸水率,从而影响面筋蛋白的形成,导致饼干硬度增大[13],同时CQSP中的蛋白质可能与面筋蛋白结合,影响面筋网络的形成。当CQSP添加量为5%时,饼干的硬度超过3000 g,咬合口感超过普通消费者所能接受的范围。一般硬度为2000~3000 g之间的饼干较适宜[14],对应CQSP添加量为3%~4%。与硬度的变化趋势相似,饼干的脆度和咀嚼性都随CQSP添加量的增加而增大。综上,当CQSP添加量为3%~4%时饼干的硬度、脆度、咀嚼性均较适宜。

表 2 CQSP添加量对饼干质构的影响Table 2. Effect of CQSP on texture properties of biscuitsCQSP添加量(%) 硬度(g) 脆度(g) 咀嚼性 0 1336.09±113.43b 1172.77±169.35c 365.65±6.71e 1 1564.84±469.89b 1392.52±545.07bc 409.12±33.24e 2 1721.96±577.02b 1546.35±577.57bc 468.23±40.20d 3 2466.16±185.91a 2050.02±185.92ab 541.29±18.58c 4 2615.55±384.77a 2319.83±167.60a 601.96±27.76b 5 3115.74±110.28a 2454.82±278.39a 678.53±48.00a 注:同列不同小写字母表示具有显著性差异(P<0.05),表3~表6同。 2.1.3 CQSP添加量对饼干感官品质的影响

图2为CQSP添加量对饼干感官品质的影响结果。由图可知,CQSP的添加对饼干的影响主要体现在形态、质地、色泽以及口感上,对气味的影响并不显著(P>0.05)。添加了CQSP的饼干形态得分逐渐减小,当CQSP添加量为0%~3%时,饼干形态得分变化不显著(P>0.05),添加量为4%~5%时,饼干形态得分差异显著(P<0.05)。这可能是因为CQSP的添加量增加,使得面团粗糙程度增大,同时饼干内部组织不够细腻,产生较大孔隙[15],因此饼干的质地得分也逐渐减小。饼干的色泽得分逐渐减小,这与前文饼干色泽分析结果一致。当CQSP添加量为0%~3%时,口感得分无显著变化(P>0.05),添加量为4%~5%时,口感得分显著减小(P<0.05)。因此,CQSP添加量在0%~3%时,饼干的感官品质较佳。

2.2 黄油添加量对饼干品质的影响

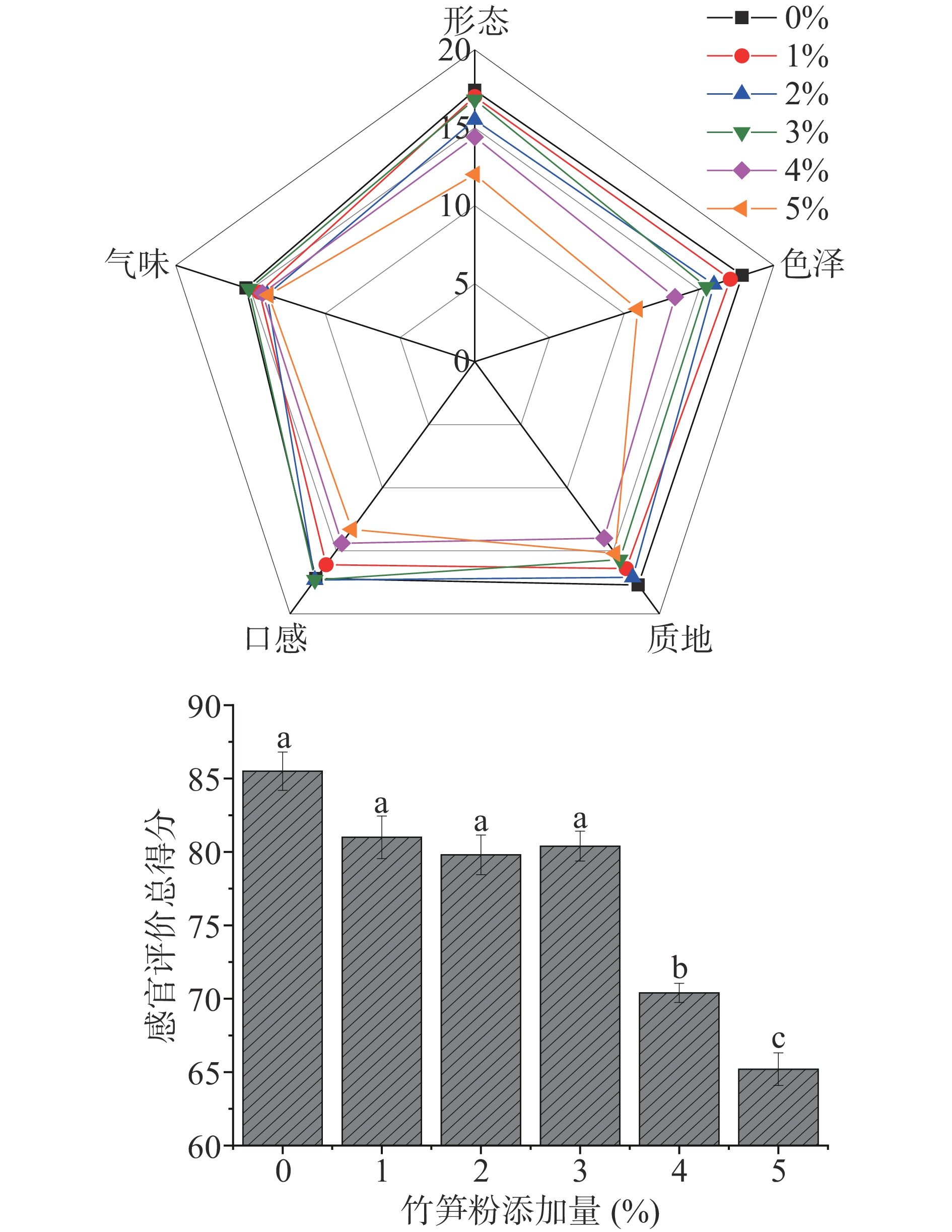

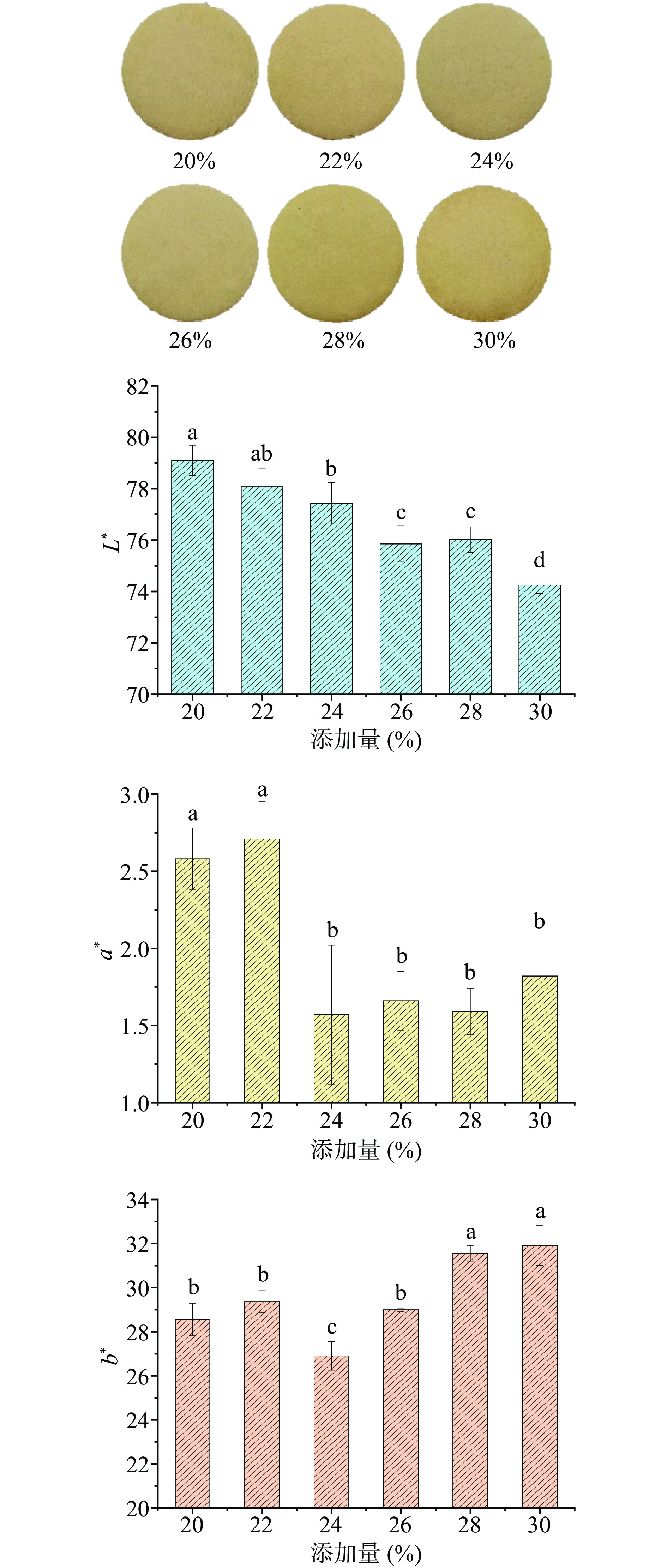

2.2.1 黄油添加量对饼干色泽的影响

图3为黄油添加量对饼干色泽的影响结果。由图可知,饼干整体颜色变化较小,饼干的L*值随着黄油添加量的增加而逐渐减小,表明随着黄油添加量的增加,饼干的亮度减小。饼干的a*值随黄油添加量的增加而减小,b*值随黄油添加量的增加而增大,且均为正值,表明黄油添加量的增加使饼干偏向红色的程度减小,偏向黄色的程度增大。但当黄油添加量为24%时,饼干的b*值显著减小(P<0.05),一方面可能受黄油本身颜色影响;另一方面可能与加入黄油后面筋蛋白不易吸水而控制面筋网络有关。综上,黄油添加量对饼干的红绿色度影响最小,对饼干的亮度和黄蓝色度影响较大,黄油添加量为24%时,饼干色泽较适宜。

2.2.2 黄油添加量对饼干质构的影响

表3为黄油添加量对饼干质构的影响结果。由表可知,饼干的硬度、脆度、咀嚼性都随着黄油添加量的增加而呈现规律性的变化。黄油与面粉混合时,油脂将蛋白质与淀粉包裹,形成油膜,油膜含疏水基团,阻止了水分子的进入,抑制了面筋网络的形成[16],但黄油添加量过多时,面团的黏弹性减小,使饼干抗干裂能力差,容易松散、破裂[17]。饼干的脆度和咀嚼性随着黄油添加量的增加而减小,与硬度的变化趋势一致。黄油添加量为24%时,饼干的硬度、脆度、咀嚼性最为适宜。

表 3 黄油添加量对饼干质构的影响Table 3. Effect of butter addition on on texture properties of biscuits黄油添加量(%) 硬度(g) 脆度(g) 咀嚼性 20 3920.80±512.20a 4135.76±683.86a 761.54±105.11a 22 3354.60±1341.00a 2629.27±338.30b 589.9±78.93b 24 2760.74±589.51a 2349.62±381.94b 522.47±30.74bc 26 1821.63±460.86ab 2524.96±212.68b 517.3±23.04bc 28 1483.15±536.38ab 2234.85±293.94b 412.68±58.61cd 30 1427.36±268.80b 1461.11±73.93c 364.1±49.52d 2.2.3 黄油添加量对饼干感官品质的影响

图4为黄油添加量对饼干感官品质的影响结果。饼干的形态得分随着黄油添加量的增加而增大,这可能是由于当黄油添加量较小时,黄油打发空气的进入量较小,饼干的蓬松度不够、表面干燥[18]。饼干的质地得分随着黄油添加量的增加先增大后减小,黄油添加量为24%时,饼干质地得分最高。随着黄油添加量的增加,饼干的口感得分先增大后减小,当黄油添加量为24%~26%时,口感较佳。饼干的气味得分随着黄油添加量的增加先增大后减小,黄油可以为饼干提供乳香味,但当添加量过多时,饼干油脂味过浓[19]。饼干的感官评价得分随着黄油添加量的增加先增大后减小,当黄油添加量为24%时,饼干感官评价总得分最高。

2.3 白砂糖添加量对饼干品质的影响

2.3.1 白砂糖添加量对饼干色泽的影响

图5为白砂糖添加量对饼干色泽的影响结果。由图可知,白砂糖添加量对饼干的整体颜色影响较小,烘焙过程中发生的焦糖化反应程度较小。饼干的L*值随着白砂糖添加量的增加而逐渐增大,表明白砂糖添加量的增加使得饼干的亮度增大。饼干的a*值和b*值均随白砂糖添加量的增加而减小,且均为正值,表明白砂糖添加量的增加使得饼干偏向红色和黄色的程度减小。综上,白砂糖添加量对饼干的红绿色度、黄蓝色度和亮度的影响都较为明显,白砂糖添加量为13%~15%时,饼干色泽较适宜。

2.3.2 白砂糖添加量对饼干质构的影响

表4为白砂糖添加量对饼干质构的影响结果。由表可知,饼干的硬度、脆度、咀嚼性都随着白砂糖添加量的增加而呈现规律性的变化。随着白砂糖添加量的增加,饼干的硬度逐渐增大,这是由于白砂糖的反水化作用,白砂糖吸收蛋白质胶体粒子之间的游离水,使胶体粒子内部的水分产生渗透压,降低胶体粒子的胀润度,抑制面筋网络的形成,使面团黏弹性减小,硬度增大[20]。饼干的脆度随白砂糖添加量的增加而增加,这是可能与白砂糖的焦糖化反应有关[21]。饼干的咀嚼性随着白砂糖添加量的增加而增加,与硬度的变化趋势一致。白砂糖添加量为13%~15%时,饼干的硬度、脆度、咀嚼性最为适宜。

表 4 白砂糖添加量对饼干质构的影响Table 4. Effect of powdered sugar on texture properties of biscuits白砂糖添加量(%) 硬度(g) 脆度(g) 咀嚼性 9 1363.70±191.43d 1247.20±88.44d 405.26±28.51e 11 1675.87±220.98d 1418.70±182.50d 480.45±33.74d 13 2436.95±202.89c 2016.74±149.41c 537.80±14.02c 15 2722.77±154.76c 2666.79±136.42b 568.26±25.59c 17 3217.04±111.33b 2871.74±53.29b 636.38±32.86b 19 3858.20±307.26a 3500.18±260.46a 770.88±40.38a 2.3.3 白砂糖添加量对饼干感官品质的影响

图6为白砂糖对饼干感官品质的影响结果。由图可知,白砂糖添加量对饼干的影响主要体现在形态、质地、色泽以及口感上,对气味的影响并不明显。饼干的形态和质地得分随着白砂糖添加量的增加先增大后减小,添加量为13%时,饼干形态和质地得分最高。糖添加量的增加可防止蛋白质过度膨胀,减少饼干表面起泡、凹低或凸面、收缩变形等现象,但糖添加量过高时焦糖化反应导致饼干失水过多,饼干硬度增加,表面干燥、孔隙少[22]。随着糖添加量增加,饼干的亮度增大,饼干的色泽得分增大。饼干的口感得分随着白砂糖添加量的增加先增大后减小,这与饼干的质构和甜度相关,当白砂糖添加量为13%~15%时,饼干口感和甜度较为适宜。饼干的感官评价总得分随着白砂糖添加量的增加而先增大后减小,当白砂糖添加量为13%时,饼干感官评价总得分最高,食用品质较佳。

2.4 烘焙温度对饼干品质的影响

2.4.1 烘焙温度对饼干色泽的影响

图7为烘焙温度对饼干色泽的影响结果。由图可知,饼干颜色随烘焙温度升高而加深,当烘焙温度为180 ℃时,饼干表面颜色由内向外加深,外圈呈现焦褐色。这可能是由于随着烘焙温度升高,美拉德反应和焦糖化反应剧烈[23],使饼干颜色变深、明亮度降低,温度过高时甚至造成饼干表面炭化。饼干的L*值随着烘焙温度的升高而逐渐减小,当烘焙温度为160~180 ℃时,饼干明显变暗。饼干的a*值和b*值均随烘焙温度的增加而增大,且均为正值,这表明烘焙温度的增加使得饼干偏向红色和黄色的程度增大。综上,烘焙温度对饼干的红绿色度、黄蓝色度和亮度的影响都较为明显,烘焙温度为140~150 ℃时,饼干色泽较适宜。

2.4.2 烘焙温度对饼干质构的影响

表5为烘焙温度对饼干质构的影响结果。由表可知,饼干的硬度、脆度、咀嚼性都随着烘焙温度的升高而呈现规律性的变化。随着烘焙温度的升高,饼干的硬度和脆度逐渐增大,温度过低时,饼干内部水分没有完全挥发,饼干质地柔软,硬度和脆度较小;温度过高时,饼干表面会发生炭化反应,内部水分不能挥发,内外水分含量存在较大差异,导致饼干硬度和脆度较大,易断裂[24]。饼干的咀嚼性随着烘焙温度的增加而增大。烘焙温度为140~150 ℃时,饼干的硬度、脆度、咀嚼性最为适宜。

表 5 烘焙温度对饼干质构的影响Table 5. Effect of baking temperature on texture properties of biscuits烘焙温度(℃) 硬度(g) 脆度(g) 咀嚼性 130 1223.93±181.51c 1499.41±282.28f 400.02±14.51e 140 2374.44±159.47b 2376.10±419.80e 503.46±11.83d 150 2385.71±617.37b 3030.74±35.80c 554.72±7.63cd 160 3643.40±679.08ab 3082.31±14.16c 608.91±31.67c 170 3095.43±636.14a 3487.52±83.40b 713.47±41.79b 180 4060.04±590.68a 4113.15±182.94a 861.09±73.14a 2.4.3 烘焙温度对饼干感官品质的影响

图8为烘焙温度对饼干感官品质的影响结果。由图可知,烘焙温度对饼干的影响主要体现在色泽、口感以及气味上,对形态和质地的影响并不明显。饼干的色泽得分随着烘焙温度的升高先增大后减小,当烘焙温度为150 ℃时,饼干的色泽得分最高,这与饼干的美拉德反应和焦糖化反应发生程度有关[25]。饼干的口感得分随着烘焙温度的升高呈现先增大后减小,当烘焙温度过低时,饼干蓬松度低,含水量高,口感较差;当烘焙温度过高时,饼干有较淡的炭化产生的苦涩味,当烘焙温度为150 ℃时,口感得分最高。饼干的气味得分随着烘焙温度的升高先增大后减小,当烘焙温度过低时,饼干美拉德反应不完全,烘焙香味较淡;当烘焙温度过高时,饼干有淡淡的焦糊味,当烘焙温度为140~150 ℃时,饼干的气味较为适宜。饼干的感官评价得分随着烘焙温度的增加而先增大后降低,当烘焙温度为150 ℃时,饼干感官评价总得分最高,食用品质较佳。

2.5 烘焙时间对饼干品质的影响

2.5.1 烘焙时间对饼干色泽的影响

图9为烘焙时间对饼干色泽的影响。由图可知,随着烘焙时间延长饼干的颜色加深,这可能是由于随着烘焙时间增加,美拉德反应和焦糖化反应剧烈,使饼干颜色变深、明亮度降低,烘焙时间过长时甚至造成饼干水分挥发完全,表面炭化。饼干的L*值随着烘焙时间的增加而逐渐减小,且减小幅度逐渐增大,表明饼干亮度降低。饼干a*值和b*值均随烘焙时间的增加而增大,且均为正值,表明烘焙时间的增加使得饼干偏向红色和黄色的程度增大。综上,烘焙时间对饼干亮度影响最大,对饼干红绿色度和黄蓝色度的影响较小,烘焙时间为25~30 min时,饼干色泽较适宜。

2.5.2 烘焙时间对饼干质构的影响

表6为烘焙时间对饼干质构的影响结果。随着烘焙时间的增加,饼干的硬度和脆度逐渐增大。烘焙时间过短时,饼干水分含量高,质地柔软,硬度和脆度小;烘焙时间过长时,饼干水分挥发完全,发生炭化反应,饼干的硬度和脆度大。与硬度的变化趋势一致,饼干的咀嚼性随着烘焙时间的增加而增加。烘焙时间为20~30 min时,饼干的硬度、脆度、咀嚼性最为适宜。

表 6 烘焙时间对饼干质构的影响Table 6. Effect of baking time on texture properties of biscuits烘焙时间(min) 硬度(g) 脆度(g) 咀嚼性 15 1347.39±118.43c 1209.61±181.44c 428.06±48.07e 20 2308.46±168.33bc 1553.15±102.00c 491.13±25.15de 25 2397.99±87.99bc 2608.13±261.45b 535.87±27.68cd 30 2731.24±427.40b 2645.56±76.56b 607.31±24.11c 35 4189.11±235.01a 2916.91±80.40b 789.16±73.05b 40 5157.35±139.46a 4347.92±443.17a 913.64±29.01a 2.5.3 烘焙时间对饼干感官品质的影响

图10为烘焙时间对饼干感官品质的影响结果。由图可知,烘焙时间对饼干的影响主要体现在形态、色泽、口感以及气味上,对质地的影响并不明显。饼干的形态得分随着烘焙时间的增加先不变后减小,这可能由于烘焙时间过长时饼干的水分流失过多,饼干表面干燥甚至开裂。饼干的色泽、口感、气味得分均随着烘焙时间的增加先增大后减小。当烘焙时间过短时,美拉德反应不完全,烘焙特有的香味较淡;当烘焙时间过长时,饼干有淡淡的焦糊味。饼干的感官评价得分随着烘焙时间的增加而先增大后减小,当烘焙时间为25 min时,饼干感官评价总得分最高。

3. 结论

本文通过色差、质构分析、感官评定等指标分析方竹笋全粉酥性饼干的品质,对CQSP添加量、黄油添加量、白砂糖添加量、烘焙时间和烘焙温度等制作工艺进行单因素实验优化。结果表明,添加CQSP后,饼干a*值和b*值均增大,L*值在添加量为0%~3%变化不显著(P>0.05),添加量为4%~5%时,饼干亮度明显降低,饼干硬度、脆度、咀嚼性均逐渐增大。随黄油添加量的增加,饼干L*值和a*值逐渐减小,b*值增大,硬度、脆度、咀嚼性均逐渐减小。随白砂糖添加量的增加,饼干L*值逐渐增大,a*值和b*值均减小,硬度、脆度、咀嚼性均增大。随烘焙温度的升高和烘焙时间的延长,饼干L*值逐渐减小,a*值和b*值增大,硬度、脆度、咀嚼性均逐渐增大。综上,经单因素优化后得出CQSP酥性饼干的较优工艺配方为CQSP添加量3%、黄油添加量24%、白砂糖添加量13%、烘焙温度150 ℃、烘焙时间25 min,在此工艺条件下,饼干L*值为71.1,a*值为2.05,b*值为27.43,硬度为2466.16 g,脆度为2050.02 g,咀嚼性为541.29,感官评分达到83.1分。以上实验结果为方竹笋资源的综合利用和高值化产品的开发提供了理论依据。

-

表 1 金佛山方竹笋饼干感官评定标准

Table 1 The sensory evaluation criteria of Chimonobambusa quadrangularis shoot biscuits

评价项目 评分标准 分数(分) 形态 外形完整,大小厚薄均匀,无变形,表面光滑 15~20 外形完整,大小厚薄较均匀,少许变形,表面光滑 10~14 外形不完整,大小厚薄不均匀,变形,表面粗糙 0~9 色泽 表面棕黄色,色泽均匀,无焦边 15~20 色泽基本均匀,有少许焦边 10~14 色泽不均匀,过白过焦 0~9 质地 内部组织细腻,断面细致均匀,多孔状 15~20 内部组织较为粗糙,断面无层次,孔隙大 10~14 内部组织粗糙,质地松垮 0~9 口感 酥脆细腻,不粘牙,甜度适宜,有适宜的方竹笋味 15~20 略酥脆,稍有粘牙,甜度较适宜,

方竹笋味过浓或过淡10~14 较硬,不酥不脆,粘牙,过甜或甜味不足,

方竹笋味过浓或过淡0~9 气味 有方竹笋的清香味,香味纯正,

奶香味浓郁,无异味15~20 方竹笋的清香味略淡,奶香味较淡 10~14 方竹笋的清香味淡,无奶香味,有异味 0~9 表 2 CQSP添加量对饼干质构的影响

Table 2 Effect of CQSP on texture properties of biscuits

CQSP添加量(%) 硬度(g) 脆度(g) 咀嚼性 0 1336.09±113.43b 1172.77±169.35c 365.65±6.71e 1 1564.84±469.89b 1392.52±545.07bc 409.12±33.24e 2 1721.96±577.02b 1546.35±577.57bc 468.23±40.20d 3 2466.16±185.91a 2050.02±185.92ab 541.29±18.58c 4 2615.55±384.77a 2319.83±167.60a 601.96±27.76b 5 3115.74±110.28a 2454.82±278.39a 678.53±48.00a 注:同列不同小写字母表示具有显著性差异(P<0.05),表3~表6同。 表 3 黄油添加量对饼干质构的影响

Table 3 Effect of butter addition on on texture properties of biscuits

黄油添加量(%) 硬度(g) 脆度(g) 咀嚼性 20 3920.80±512.20a 4135.76±683.86a 761.54±105.11a 22 3354.60±1341.00a 2629.27±338.30b 589.9±78.93b 24 2760.74±589.51a 2349.62±381.94b 522.47±30.74bc 26 1821.63±460.86ab 2524.96±212.68b 517.3±23.04bc 28 1483.15±536.38ab 2234.85±293.94b 412.68±58.61cd 30 1427.36±268.80b 1461.11±73.93c 364.1±49.52d 表 4 白砂糖添加量对饼干质构的影响

Table 4 Effect of powdered sugar on texture properties of biscuits

白砂糖添加量(%) 硬度(g) 脆度(g) 咀嚼性 9 1363.70±191.43d 1247.20±88.44d 405.26±28.51e 11 1675.87±220.98d 1418.70±182.50d 480.45±33.74d 13 2436.95±202.89c 2016.74±149.41c 537.80±14.02c 15 2722.77±154.76c 2666.79±136.42b 568.26±25.59c 17 3217.04±111.33b 2871.74±53.29b 636.38±32.86b 19 3858.20±307.26a 3500.18±260.46a 770.88±40.38a 表 5 烘焙温度对饼干质构的影响

Table 5 Effect of baking temperature on texture properties of biscuits

烘焙温度(℃) 硬度(g) 脆度(g) 咀嚼性 130 1223.93±181.51c 1499.41±282.28f 400.02±14.51e 140 2374.44±159.47b 2376.10±419.80e 503.46±11.83d 150 2385.71±617.37b 3030.74±35.80c 554.72±7.63cd 160 3643.40±679.08ab 3082.31±14.16c 608.91±31.67c 170 3095.43±636.14a 3487.52±83.40b 713.47±41.79b 180 4060.04±590.68a 4113.15±182.94a 861.09±73.14a 表 6 烘焙时间对饼干质构的影响

Table 6 Effect of baking time on texture properties of biscuits

烘焙时间(min) 硬度(g) 脆度(g) 咀嚼性 15 1347.39±118.43c 1209.61±181.44c 428.06±48.07e 20 2308.46±168.33bc 1553.15±102.00c 491.13±25.15de 25 2397.99±87.99bc 2608.13±261.45b 535.87±27.68cd 30 2731.24±427.40b 2645.56±76.56b 607.31±24.11c 35 4189.11±235.01a 2916.91±80.40b 789.16±73.05b 40 5157.35±139.46a 4347.92±443.17a 913.64±29.01a -

[1] CHEN G, FANG C, RAN C X, et al. Comparison of different extraction methods for polysaccharides from bamboo shoots (Chimonobambusa quadrangularis) processing by-products[J]. International Journal of Biological Macromolecules,2019,130:903−914. doi: 10.1016/j.ijbiomac.2019.03.038

[2] 任春春, 贾玉龙, 娄义龙, 等. 贵州金佛山方竹笋营养及功能成分剖析[J]. 食品与发酵工业,2021,47(10):214−221. [REN C C, JIA Y L, LOU Y L, et al. Analysis of nutritional and functional components of bamboo shoots in Chimonobambusa utilis, Guizhou[J]. Food and Fermentation Industry,2021,47(10):214−221. REN C C, JIA Y L, LOU Y L, et al. Analysis of nutritional and functional components of bamboo shoots in Chimonobambusa utilis, Guizhou [J]. Food and Fermentation Industry, 2021, 47(10): 214-221.

[3] SANTOSH S, BAL L M, POONAM S, et al. Bamboo shoot processing: food quality and safety aspect (A review)[J]. Trends in Food Science & Technology,2010,21(4):181−189.

[4] LIN Z, CHEN J, ZHANG J Z, et al. Potential for value-added utilization of bamboo shoot processing waste-recommendations for a biorefinery approach[J]. Food and Bioprocess Technology,2018,11(5):901−912. doi: 10.1007/s11947-018-2088-3

[5] MANUEL G, FELICIDAD R, CARLOS A B, et al. Effect of dietary fibre on dough rheology and bread quality[J]. European Food Research and Technology,2003,216(1):51−56. doi: 10.1007/s00217-002-0632-9

[6] 古明亮, 温科, 魏远隆, 等. 竹笋膳食纤维在酥性饼干中的应用[J]. 粮食加工,2019,44(4):38−41. [GU M L, WEN K, WEI Y L, et al. Application of dietary fiber from bamboo shoot in short biscuit[J]. Food Processing,2019,44(4):38−41. GU M L, WEN K, WEI Y L, et al. Application of dietary fiber from bamboo shoot in short biscuit[J]. Food Processing, 2019, 44(4): 38-41.

[7] 吴映雪. 笋渣膳食纤维提取及其饼干加工工艺参数优化[D]. 雅安: 四川农业大学, 2020. WU Y X. Extraction of dietary fiber from bamboo shoot residue and optimization of processing parameters of its biscuit[D]. Ya'an: Sichuan Agricultural University, 2020.

[8] SAKAC M B, GYURA J F, MISAN A C, et al. Antioxidant activity of cookies supplemented with sugarbeet dietary fibre[J]. Zuckerindustrie,2011,136(3):151−157.

[9] MARILISA A, SOFIA M, MONICA A. Reducing the glycemic index of short dough biscuits by using apple pomace as a functional ingredient[J]. LWT,2018,100:300−305.

[10] 史早, 张甫生, 杨金来, 等. 超微粉碎对方竹笋全粉理化特性及微观结构的影响[J]. 食品工业科技,2021,42(24):40−47. [SHI Z, ZHANG F S, YANG J L, et al. Effect of superfine grinding on physicochemical properties and microstructure of Chimonobambusa quadrangularis shoot powder[J]. Science and Technology of Food Industry,2021,42(24):40−47. SHI Z, ZHANG F S, YANG J L, et al. Effect of superfine grinding on physicochemical properties and microstructure of Chimonobambusa quadrangularis shoot powder[J]. Science and Technology of Food Industry, 201, 42(24): 40-47.

[11] MA S, WANG X X, ZHENG X L, et al. Improvement of the quality of steamed bread by supplementation of wheat germ from milling process[J]. Journal of Cereal Science,2014,60(3):589−594. doi: 10.1016/j.jcs.2014.07.010

[12] HUANG S, QUAIL K, MOSS R, et al. Objective methods for the quality assessment of northern-style Chinese steamed bread[J]. Journal of Cereal Science,1995,21(1):49−55. doi: 10.1016/S0733-5210(95)80007-7

[13] HUANG W N, LI Z N, OKKYUNG K C. Effects of acrylamide inhibition by asparaginase and sugar substitution on cookie dough rheology and baking attributes[J]. Food Science,2011,32(5):157−166.

[14] 高小娜. 红枣不溶性膳食纤维的提取与铅离子吸附性能研究及在饼干中的应用[D]. 邯郸: 河北工程大学, 2021. GAO X N. Study on red dates extraction and adsorption of insoluble dietary fiber and application in biscuits[D]. Handan: Hebei University of Engineering, 2021.

[15] 赵金梅, 邢灵英, 苑广静, 等. 马铃薯全粉对酥性饼干品质风味及消化特性的影响[J]. 食品与发酵工业,2022,48(1):218−226. [ZHAO J M, XING L Y, YUAN G J, et al. Effects of adding potato granules on the quality and digestibility of crisp biscuits[J]. Food and Fermentation Industry,2022,48(1):218−226. ZHAO J M, XING L Y, YUAN G J, et al. Effects of adding potato granules on the quality and digestibility of crisp biscuits [J]. Food and Fermentation Industry, 202, 48(1): 218-226.

[16] 沈忱, 蒋予箭, 林家莲. 油脂对面团物理特性的影响[J]. 食品与机械,2007(3):45−47. [SHEN C, JIANG Y J, LIN J L. Effect of oil on physical properties of dough[J]. Food & Machinery,2007(3):45−47. SHEN C, JIANG Y J, LIN J L. Effect of oil on physical properties of dough [J]. Food & Machinery, 2007(3): 45-47.

[17] 陈凤莲, 贾冰心. 小麦麸皮膳食纤维饼干的单因素研究[J]. 食品科技,2011,36(12):147−149. [CHEN F L, JIA B X. Preparation of wheat fibre biscuit by single factor[J]. Science and Technology,2011,36(12):147−149. CHEN F L, JIA B X. Preparation of wheat fibre biscuit by single factor[J]. Science and Technology, 2011, 36(12): 147-149.

[18] DEVI A, KHATKAR B S. Physicochemical, rheological, and functional properties of fats and oils in relation to cookie quality: A review[J]. Journal of Food Science and Technology,2016,53(10):3633−3641. doi: 10.1007/s13197-016-2355-0

[19] 刘传富, 董海洲, 侯汉学. 影响饼干质量的关键因素分析[J]. 食品工业科技,2002,23(8):87−89. [LIU C F, DONG H Z, HOU H X. Analysis of key factors affecting biscuit quality[J]. Science and Technology of Food Industry,2002,23(8):87−89. LIU C F, DONG H Z, HOU H X. Analysis of key factors affecting biscuit quality [J]. Science and Technology of Food Industry, 2002, 23(8): 87-89.

[20] 刘宗浩, 张嫣妮, 于重伟, 等. 挤压薏米粉饼干研制及品质分析[J]. 食品工业,2021,42(1):32−36. [LIU Z H, ZHANG Y N, YU C W, et al. Development and quality of mixed extruded coix biscuit[J]. Food Industry,2021,42(1):32−36. LIU Z H, ZHANG Y N, YU C W, et al. Development and quality of mixed extruded coix biscuit[J]. Food Industry, 2021, 42(1): 32-36.

[21] QUINTAS M A C, FUNDO J F, SILVA C L M. Sucrose in the concentrated solution or the supercooled 'state': A review of caramelization reactions and physical behaviour[J]. Food Engineering Reviews,2010,2(3):204−215. doi: 10.1007/s12393-010-9022-4

[22] 金万浩, 马兴胜. 奶油、白糖、鸡蛋混合比对饼干物性的影响[J]. 哈尔滨商业大学学报:自然科学版,1990(3):19−24. [JIN W H, MA X S. Effect of mixture ratio of cream, sugar and egg on physical properties of biscuit[J]. Journal of Harbin University of Commerce: Natural Science Edition,1990(3):19−24. JIN W H, MA X S. Effect of mixture ratio of cream, sugar and egg on physical properties of biscuit [J]. Journal of Harbin University of Commerce: Natural Science Edition, 1990(3): 19-24.

[23] MARIELA P, GUSTAVO J R, CECILIA E L. In vivo effects of Maillard reaction products derived from biscuits[J]. Food Chemistry,2016,196:201−210.

[24] 孙莹, 李欣, 刘艳香, 等. 全谷物发芽糙米韧性饼干制作工艺优化[J]. 食品工业科技,2022,43(5):182−190. [SUN Y, LI X, LIU Y X, et al. Optimization of processing technology of whole germinated brown rice tough biscuit[J]. Science and Technology of Food Industry,2022,43(5):182−190. doi: 10.13386/j.issn1002-0306.2021060029 SUN Y, LI X, LIU Y X, et al. Optimization of processing technology of whole germinated brown rice tough biscuit[J]. Science and Technology of Food Industry, 2022, 43(5): 182-190. doi: 10.13386/j.issn1002-0306.2021060029

[25] 吴慧. 螺旋藻曲奇饼干制作工艺的研究[J]. 食品安全导刊,2022(4):128−131. [WU H. Study on processing technology of Spirulina cookies[J]. Food Safety Guide,2022(4):128−131. WU H. Study on processing technology of Spirulina cookies [J]. Food Safety Guide, 2022(4): 128-131.

-

期刊类型引用(5)

1. 金鑫,段续,任广跃,陈俊亮,李琳琳,曹伟伟,刘文超. 不同干燥方式对无花果干燥特性及品质的影响. 食品与发酵工业. 2024(10): 69-75 .  百度学术

百度学术

2. 孙兆岳,崔文玉,程安玮. 油用牡丹籽种皮多酚的提取及抗氧化和体外发酵特性. 现代食品科技. 2024(05): 162-170 .  百度学术

百度学术

3. 宋娟,张海燕,曾朝珍,袁晶,慕钰文,康三江,文鹏程. 干燥方式对苹果干品质特性及风味的影响. 食品工业科技. 2024(17): 221-231 .  本站查看

本站查看

4. 李楠,杨婷. 不同干燥方式对萌芽苦荞功能成分及抗氧化活性的影响. 运城学院学报. 2023(03): 41-45 .  百度学术

百度学术

5. 汤天瑾,王晓彤,齐杰,吕玥霖,朱文立,朱俊向,吴昊. 包装膜透气性对双孢蘑菇保鲜效果及呼吸代谢的影响. 食品科学. 2023(21): 249-257 .  百度学术

百度学术

其他类型引用(2)

下载:

下载:

下载:

下载: