Application of Extrusion Technology in Starch and Starch-based Food

-

摘要: 食品挤压在过去几十年中不断发展,现已成为一个独特的研究领域。淀粉是许多食物中的重要组成成分,也是人类饮食中能量的主要来源。在食品工业中,淀粉通常通过各种热处理操作进行加工,然后才能转化为适合人类消费的产品。挤压是淀粉类食品加工中常用的一种传统热处理方法。在挤压过程中,淀粉经历结构转变。近几年的研究表明了解挤压过程中淀粉的结构、性质变化对于淀粉类食品在实际生产中品质的调控与改进具有至关重要的作用。为了解挤压过程中淀粉结构、性质变化,本文从挤压对淀粉结构影响、挤压对淀粉性质影响、挤压技术在淀粉及淀粉基食品中应用三个方面进行综述,以期为挤压影响淀粉结构特性的作用机理和淀粉类食品的深度加工提供参考和建议。Abstract: Food extrusion has been developing in the past decades and has become a unique research field. Starch is an important component of many foods and the main source of energy in human diet. In the food industry, starch is usually processed through various heat treatment operations before it can be transformed into products suitable for human consumption. Extrusion is a traditional heat treatment method commonly used in starch food processing. During extrusion, starch undergoes structural transformation. In recent years, studies have shown that understanding the changes in the structure and properties of starch during extrusion plays a crucial role in regulating and improving the quality of starch food in actual production. In order to understand the changes of starch structure and properties in the extrusion process, this paper summarizes the impact of extrusion on starch structure, the impact of extrusion on starch properties, and the application of extrusion technology in starch and starch-based foods, with a view to providing reference and suggestions for the mechanism of extrusion affecting starch structure and properties and the further processing of starch based foods.

-

Keywords:

- extrusion technology /

- starch structure /

- starch properties /

- food /

- application

-

挤压技术是一种集混合、加热、杀菌和成型于一体的食品加工技术[1]。与其他食品加工技术相比,挤压技术具有营养成分损失少、生产时间短、微生物污染机会少、产品多样、原料适应性强、耗能低、操作简单、生产效率高等诸多优点,具有良好的利用价值[2]。挤压在谷物加工领域应用广泛,淀粉作为谷物中最主要的成分,挤压对淀粉颗粒结构、结晶结构、精细结构的影响不仅决定了淀粉在原料生产中的用途,也决定了淀粉基食品的食用品质[3]。

近年来对淀粉需求的增加使食品中淀粉的消费持续提高。挤压作为一种常见的食品加工方式,已在谷类、薯类、豆类等淀粉原料的改性以及淀粉基食品加工中得到广泛应用。挤压是一个连续的高温高压短时的机械过程[4],挤压过程中的高温高压高剪切力会对淀粉的结构、性质产生一定的影响[5]。在过去的几十年里,许多研究人员致力于研究挤压加工过程中淀粉结构性质的变化[6-8]。然而,由于挤压机是一个复杂的系统,挤压过程中淀粉的理化性质和结构特征的确切变化尚未解开[9]。了解淀粉在挤压过程中结构和性质的变化,有利于淀粉类食品在实际生产中品质的调控与改进。因此,本文主要综述了淀粉在挤压前后其结构和性质的变化情况,以及挤压技术在淀粉及淀粉基食品中的应用,以期为未来食品工业发展过程中挤压技术的应用与发展提供参考。

1. 挤压技术

1.1 挤压技术原理

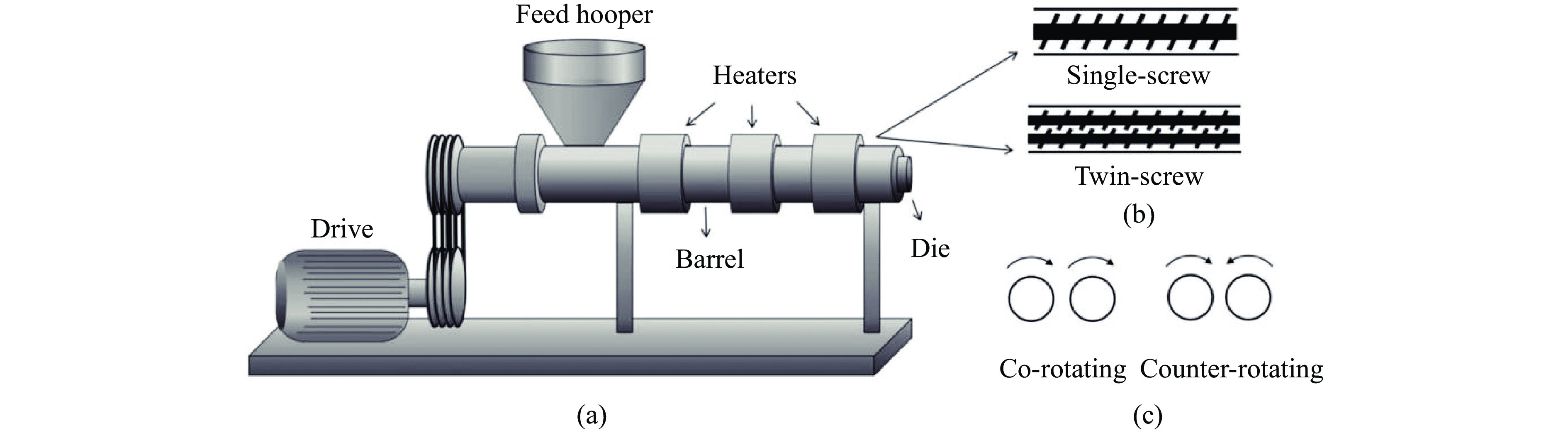

挤压作为一种连续混合和成型工艺,是一种通用、低成本、高温短时和非常高效的食品加工技术[10]。挤压机通常由料斗、机筒、螺杆、模具、切割装置、温度控制装置、端口、测量仪器和驱动器组成[11](见图1)。挤压过程可以概括如下:物料从料斗进入料筒,然后在高温高压下进行压缩和剪切,最终由桶末端的模孔成型。通过调整进料水分、料筒温度、螺杆转速、压力、螺杆直径等挤压参数,可以实现所需的产品特性。挤压技术的优势包括速度快、生产率高、通用性强和能耗低,它还可以混合多种成分,这有助于新产品的开发。

1.2 挤压机分类

挤压机是一种基于螺杆系统的连续加工生产设备,一般可分为单螺杆、双螺杆和多螺杆挤压机,具体取决于所使用的螺杆数量[12]。多螺杆挤压机制造加工比较复杂,而且对传动系统的要求比较高,因此在食品工业中很少使用。单螺杆挤压机在金属机筒中只有一个螺杆,并且通常在内表面上具有螺旋或轴向凹槽,整个挤出机包括三个部分:进料段、过渡段和计量段[13]。物料在进料段没有改变,但在过渡段被压缩和加热,当输送到模具时,压力突然释放,产品中的一些水分迅速蒸发,导致产品膨胀。单螺杆挤压机的结构参数比较简单,但成品的控制及其特性则比较复杂。双螺杆挤压机通常由两个沿相同方向或相反方向旋转的螺杆组成。与单螺杆挤压机相比,双螺杆挤压机具有以下优点:易于进料;混合效果好;效率高,停留时间短[14]。与双螺杆挤压机相比,单螺杆挤压机的能耗高出约30%,双螺杆挤压机为混合物提供了良好的混合性能[15]。

2. 挤压对淀粉结构的影响

2.1 淀粉颗粒结构的变化

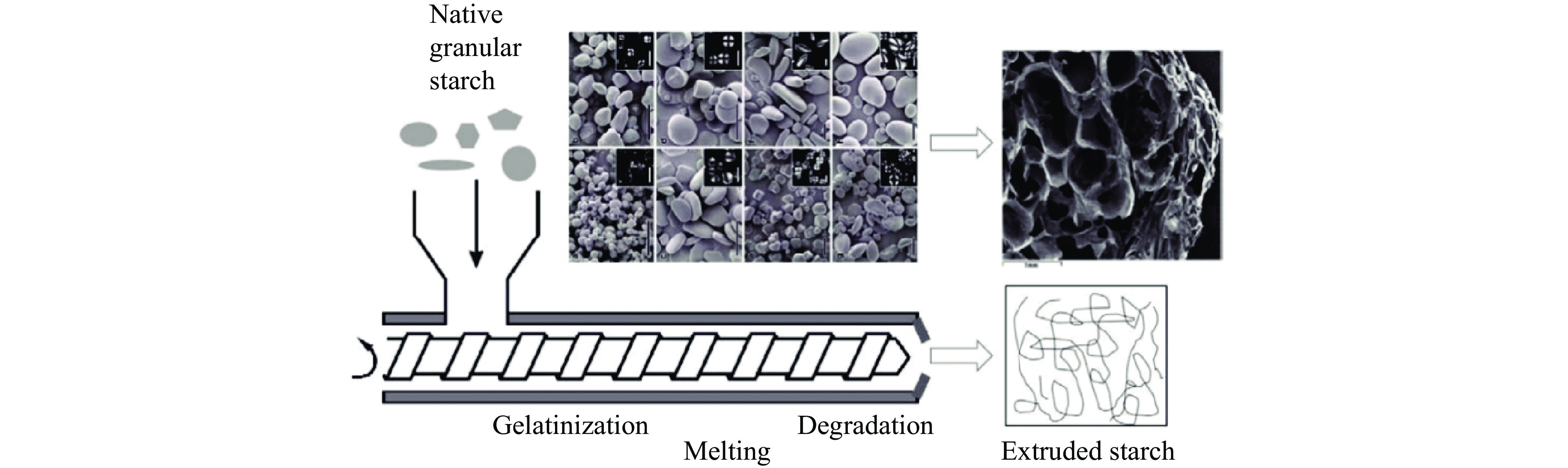

扫描电镜(SEM)是观察淀粉微观结构的重要仪器。不同植物来源的淀粉颗粒的粒径在1~100 μm之间,淀粉颗粒可以是球形、椭圆形、多边形结构。在挤压过程中,高温、高压和高剪切加工彻底破坏了淀粉颗粒结构,几乎所有的颗粒都会失去完整性[16]。挤压过程中淀粉颗粒形态的变化示意图如图2所示。玉米淀粉颗粒呈多边形,边缘相对光滑,挤压后淀粉结构完全被破坏,颗粒严重受损,表面失去其光滑性,出现不规则碎片和裂缝[17]。王立东等[18]研究发现,鹰嘴豆淀粉颗粒在挤压前表面光滑,主要呈椭圆形,挤压后颗粒表面变得粗糙,大部分呈不规则多边形。淀粉经挤压后其颗粒结构的破损程度与挤压工艺参数相关。Ali等[19]研究了水分含量对马铃薯淀粉颗粒形貌的影响,结果表明,随着水分含量的增加,淀粉破损程度降低。在较高的水分条件下,淀粉颗粒与挤压机内部摩擦降低,从而减少了淀粉颗粒的破损。随着挤压温度的升高,马铃薯淀粉表面的裂纹数量明显增加,表面变得不均匀有褶皱产生[20]。Zhang等[21]在挤压高直链淀粉时也观察到了类似的效果。总的来说,挤压过程中的温度、机械剪切作用会使不同来源和品种的淀粉颗粒结构发生变化,其变化程度因淀粉的特性以及挤压参数的不同呈现出不同特点。

2.2 淀粉结晶结构的变化

X射线衍射(XRD)仪可用于研究淀粉颗粒的结晶结构。淀粉常见的晶型有A型、B型、C型(A和B的组合)和V型(直链淀粉-脂质复合物)。不同来源的淀粉有不同的晶体结构。大米淀粉呈A型晶型,经过挤压处理,淀粉发生糊化,其晶体结构被完全破坏,形成了新的结构[22]。马铃薯淀粉呈B型晶型,挤压会破坏马铃薯淀粉的结晶区和无定形区,导致B型晶型结构发生变化,相对结晶度消失[23]。木薯淀粉呈C型晶型,其相对结晶度为21.2%,经挤压后,结晶度能降低70%[24]。这可能是由于挤压过程中的糊化和剪切导致淀粉的双螺旋结构被破坏,相对结晶度显著降低。许多学者[25-27]研究发现淀粉或者淀粉基食品经过挤压后,X射线衍射图谱都呈现出V型结晶特征,这是由于直链淀粉和脂质形成复合物。在强机械力和高温的作用下,油脂水解程度增大、淀粉颗粒结构破坏增强,使得更多的游离脂肪酸与直链淀粉反应形成V型结晶复合物[28]。挤压后淀粉的结晶度受直链淀粉与支链淀粉比例的影响。研究发现,高直链淀粉在挤压后保持其结晶度,而低直链淀粉在相同条件下挤压后变为无定形状态[29]。挤压后淀粉的结晶度也由加工参数决定。Waramboi等[30]发现,甘薯淀粉的结晶度随着螺杆转速的增加而降低。由此可见,在挤压淀粉及淀粉基食品的过程中,淀粉的晶体结构会发生变化,同时其结晶度也会发生一定程度的变化。

2.3 淀粉分子结构的变化

在挤压过程中,淀粉分子结构会遭到破坏。挤压处理会使糖苷键断裂,淀粉分子发生降解。在此过程中,支链淀粉特别是α-1,6糖苷键的位置优先降解,即淀粉部分去支化。挤压首先发生在支链淀粉分子中,这是由于支链淀粉分子尺寸较大,柔韧性不佳,受机械剪切作用容易降解[31]。研究发现,挤压后淀粉的平均分子量和支链淀粉含量降低,而表观直链淀粉含量增加[32]。支链淀粉可能比直链淀粉对挤压更敏感,其许多分支点很容易断裂,这导致形成类似于直链淀粉的线性片段。挤压参数显著影响淀粉的分子结构。随着螺杆转速的提高,挤压越强,淀粉的分子链断裂越严重。挤压时物料水分含量和挤压温度增加会显著降低淀粉的重均分子量和数均分子量。当挤压温度从110 °C增加到130 °C并且物料水分含量和挤压机螺杆速度分别保持在18%和90 r/min时,糯玉米淀粉的重均分子量从336×106降低至40×106 g/mol[33]。挤压处理不能改变支链淀粉的链长分布及其支链长度。这可能是由于支链淀粉链长大,高剪切力将支链淀粉分子分解为相对较少的较小片段,破坏的为可忽略不计的单键部分[34]。综上,淀粉在挤压过程中所发生的分子结构的变化,主要是由于分子降解所导致的,而分子降解则归因于剪切应力的存在。

3. 挤压对淀粉性质的影响

3.1 挤压对淀粉糊化性质的影响

淀粉的糊化特性在淀粉及淀粉基食品的加工利用中具有重要意义。淀粉糊化是生淀粉和水受热导致淀粉颗粒由于其结构变化而膨胀的过程[35]。淀粉在挤压过程中通常被糊化,糊化程度随着模头温度和进料速度的增加而增加,随着物料水分的增加而降低[36]。产生糊化特性的差异主要归因于淀粉颗粒结构的破碎及直链淀粉的浸出。挤压导致淀粉发生预糊化,破坏淀粉颗粒,氢键弱化,且随着螺杆转速的增加,残留淀粉颗粒数越来越少,进而导致黏度值随转速的增加而降低[37]。Guha等[38]研究发现,在温度100 °C和螺杆转速400 r/min下,米粉挤出物的糊化(99.0%)达到最大值。Gomez等[39]在研究水分含量对挤压后玉米淀粉糊化特性的影响时发现,当水分含量从12%增加到32%时,玉米淀粉的糊化度从63%下降到16%,糊化度随着水分含量的增加而降低。当水分含量增加时,物料流动性增加,机筒内外压力差较小,不易膨胀,导致糊化度较低。Liu等[40]研究了水分含量(30%~70%)对挤压后大米淀粉糊化的影响,发现淀粉峰值黏度随着水分含量的增加而降低,峰值黏度与淀粉颗粒的膨胀有关,在挤压过程中,淀粉发生糊化,残留的颗粒状淀粉减少,膨胀程度降低,导致峰值黏度显著降低。

3.2 挤压对淀粉质构性质的影响

淀粉及淀粉基食品的质构性质可以使用质构分析仪进行测定。挤压会显著影响淀粉类挤压产品的质构特性。Kantrong等[41]研究发现物料含水量越高,挤出物越致密,产品硬度越高。物料水分含量较低时,增加进料速度可显著增加挤出产品的硬度。Pardhi等[42]研究发现,螺杆转速和模头温度越高,淀粉类挤压产品的硬度越低。王超[43]在研究模头温度对豌豆淀粉质构特性的影响时发现,随着模头温度的升高,豌豆淀粉凝胶的硬度、弹性、粘聚性均呈现先降低后升高的趋势。当温度为150 ℃时,淀粉凝胶最软;温度为200 ℃时,各特征值最高,这可能是由于高温使水分蒸发加快,淀粉降解后,内部分子间重新发生聚合重排,形成新的稳定的分子间网络结构,表现为重新形成强凝胶。挤压条件也会影响挤出物的咀嚼性。咀嚼性随着螺杆转速的降低而降低,在较低的螺杆转速下,由于高挤出压力,淀粉网络的连续性被破坏,最终导致咀嚼度降低。挤压涉及挤压温度、螺杆转速等许多参数设置,通过调整这些参数,可以对淀粉及淀粉基食品的质构性质进行调整,从而获得感官得分较好的产品。

3.3 挤压对淀粉老化性质的影响

当糊化淀粉冷却时,系统的热能降低,这导致分散的直链淀粉和支链淀粉分子之间的氢键重整,淀粉分子形成交联和局部结晶区域,导致沉淀或凝胶形成,这个过程称为老化[44]。许多研究表明,挤压延缓了淀粉的老化。淀粉经挤压改性后其分子链与水分子相互作用,从而延缓了淀粉老化[45]。Sarawong等[46]研究发现香蕉淀粉在低水分高转速条件下经过挤压后,淀粉分子降解,淀粉糊回生值较低,表明挤压可以抑制香蕉淀粉的短期老化作用。徐晓茹等[47]发现挤压后大米淀粉的回生值显著降低,表明挤压对大米淀粉的老化有抑制作用。淀粉在挤压过程中降解,而短期老化与糊化过程中直链淀粉的溶出量呈正相关,表明挤压促进了糊化过程中直链淀粉的溶出。根据这一特性,通过挤压获得的淀粉不仅可以添加到速食米饭中,使其在烹饪后几个小时仍保持较好的口感,还可以用于制备具有缓慢消化特点的淀粉类食品。

3.4 挤压对淀粉流变学性质的影响

淀粉及淀粉基食品的流变学特性是决定其应用的主要理化性质之一。Wani等[48]研究表明,与未处理的淀粉相比,挤压后淀粉的储能模量(G′)和损耗模量(G'')在施加的频率范围内均显著降低。这可能与糊化时多糖链的降解有关。Zeng等[49]在研究挤压对板栗淀粉糊流变特性的影响时得到了类似的结果。挤压降低了淀粉糊的弹性模量和淀粉凝胶网络结构,从而改变了淀粉分子链的聚集行为,形成了弱化的凝胶系统。挤压影响淀粉和淀粉基食品的流变特性,进而影响产品的运输、贮存和感官品质,可以根据这一特性来改善产品品质[50]。

3.5 挤压对淀粉消化性质的影响

淀粉在经过挤压处理后,它的消化特性会发生一定的变化。谢岩黎等[51]比较了原料、传统挂面工艺颗粒面条和挤压膨化颗粒面条的消化率,发现它们的消化率有所不同,其中挤压膨化颗粒面条的消化率最高。这可能是因为在挤压过程中,由于高温高压的作用,一些淀粉降解生成糊精和还原糖,同时相邻淀粉之间的主次价键和氢键被破坏,产品疏松多孔,增加了与淀粉酶的接触机会,使得挤压后淀粉的消化率显著提高[52]。Omosebi等[53]发现挤压处理显著提高了淀粉的消化率,这可能是因为挤压处理使得淀粉链从有序结构趋于无序化,淀粉对酶的敏感性增加所导致的。相反地,在挤压过程中,淀粉-脂质复合物、淀粉-蛋白质复合物或抗性淀粉可能会形成,从而降低淀粉的消化率。在上述研究中,淀粉消化率仅指体外消化率,即模拟淀粉对体内相关酶的敏感程度,但实际上,淀粉在体内的消化过程极其复杂,与很多因素有关。

4. 挤压技术在淀粉及淀粉基食品中的应用

4.1 挤压技术在淀粉改性中的应用

4.1.1 抗性淀粉

抗性淀粉(RS)被认为是膳食纤维之一,可以产生广泛的有益影响,它对调节血糖代谢和胰岛素水平有着显著影响,并对肠道具有保护作用[54]。因此,近年来人们对抗性淀粉的生产和利用越来越感兴趣。RS的制备方法主要包括物理改性、化学改性和其他改性技术。挤压法是一种新型抗性淀粉热加工技术,在挤压过程中,支链淀粉部分降解,短直链淀粉重新排列形成抗性淀粉[55]。挤压法已被广泛用于大米、玉米、鹰嘴豆、小麦等淀粉基原料生产RS。在使用挤压法生产RS时,物料水分含量、螺杆转速、挤压温度、储藏温度、储藏时间和进料速度对RS的产率有显著的影响,其中物料水分含量影响最大[56]。在一定的水分含量范围内,RS的含量随着物料水分含量的增加而增加。水分含量越高,淀粉颗粒膨胀越充分,糊化程度也越高,有利于淀粉黏度的下降、直链淀粉分子相互接近,进而有利于双螺旋结构的形成[57]。

4.1.2 预糊化淀粉

天然淀粉固有的半结晶结构抑制了其溶解度和膨胀能力。预糊化淀粉(PGS)是一种物理改性淀粉,具有吸收水分并在冷水中膨胀的能力,可以提高体系的黏度,并具有适当的增稠性能[58]。预糊化淀粉冷水成糊、吸水性较高的特性使其经常作为辅料用来提升食品的加工性能及感官品质[59]。挤压是一种热加工工艺,可以用来生产预糊化淀粉。但是通过挤压得到的预糊化淀粉结构被严重破坏,冷水溶解度和冷糊黏度显著增加,热糊黏度相对较低[60]。挤压将产品变成圆柱形,因此需要额外的工艺(例如粉碎和筛分)才能获得粉末产品。

4.1.3 复合改性淀粉

多孔淀粉是一种具有蜂窝状多孔结构的变性淀粉,是淀粉颗粒经适度水解后得到的[61],在食品、制药等工业中具有广泛的应用。多孔淀粉可以通过物理、化学、酶促作用及其组合获得。近几十年来,随着食品中对“清洁标签”成分的需求不断增加,通过一些物理方法(挤压、微波、超声波、球磨和脉冲电场)制备多孔淀粉逐渐受到广泛关注。吴文琪等[62]对挤压法和酶法复合制备多孔淀粉的工艺条件进行了优化,与天然淀粉酶解法相比,该方法有效提高了多孔淀粉的制备效率,且所制得的多孔淀粉在孔径和分布均匀性等方面具有明显优势。通过挤压与酶水解相结合制备多孔淀粉,效率更高,方法更简单,并且制备过程不涉及有机试剂,是一种对环境友好的多孔淀粉制备新方法[63]。

4.2 挤压技术在淀粉基食品中的应用

4.2.1 早餐谷物食品

早餐谷物食品主要由小麦、玉米、大麦、大米和燕麦等淀粉类原料制成,可以通过挤压工艺获得[64]。早餐谷物食品是全球早餐的重要组成部分。通常,在发达国家,大约一半的人口食用早餐谷物食品。目前,挤压技术已成功应用于片状谷物食品、膨化早餐谷物食品、烘焙膨化早餐谷物食品、喷射膨化早餐谷物食品和纤维状早餐谷物食品的生产中。淀粉的结构和性质在挤压过程中会发生复杂的变化,这会影响谷物早餐的品质[65]。此外,在挤压过程中添加糖和盐等调味品也会影响谷物早餐的品质[66]。因此,在挤压制备谷物早餐的过程中,要合理调整原料的组成配比,以便生产出口感和质地易于消费者接受的产品。

4.2.2 方便食品

方便食品由于其便利性在现代生活中越来越受欢迎。市场上的方便食品种类繁多,给人们的生活带来了很多便利。挤压是一种高温短时间工艺和高效的食品加工技术,现已广泛应用于以谷物为原料的方便食品的生产。王晨等[67]以碎米为主要原料生产挤压膨化方便粥,通过D-最优混料实验对原料配比进行优化,开发研制了高蛋白、高膳食纤维的方便粥。蔡乔宇等[68]开发了以碎米和马铃薯粉为原料的挤压马铃薯方便米饭,通过感官评定发现,在沸水中浸泡9 min后,该方便米饭的食用品质接近市售米饭。贺也[69]以黑米、燕麦、红豆为原料,以杏仁粉、蔗糖和奶粉为辅料,研究了三种原料的最佳配比和三种辅料添加的最佳配方,通过改良配方和工艺从而开发出一种无添加防腐剂、无添加化学色素的新型方便杂粮粉。

4.2.3 休闲食品

挤压技术在休闲食品中主要用于生产膨化食品。挤压技术生产的膨化食品分为三类:直接膨化型休闲食品、共挤压型休闲食品、间接膨化型休闲食品[70]。直接膨化型休闲食品通常需要高剪切力才能使其适当膨胀,当水分含量在5%到8%之间时,产品在模头处膨胀,除了干燥之外,通常不需要进一步加工[71]。这类产品包括膨化虾条、洋葱圈、玉米果等。共挤压型休闲食品是一种将两种材料(通常性质不同)在挤压模板处结合的技术。这两种材料可以来自两台挤压机或一台挤压机和一台泵。间接膨化型休闲食品属于第三代休闲食品,为半成品,因为产品需要后续通过油炸、热空气或微波加热来进行膨胀[72]。

4.2.4 营养强化食品

挤压技术作为一种食品加工技术,正逐渐应用于食品工业中,尤其是营养强化食品的生产。其中挤压重组米是将混合均匀的物料,经高温、高压作用,从模孔挤出,得到类似米粒形态的挤压产品。可以根据不同人群的营养需求,选择相应食品原料组合,不仅能使重组米和天然大米具有相似的外观形态、食用口感以及蒸煮特性,还能拥有比天然大米更高的营养价值和功能特性,可以辅助解决因饮食结构失衡和膳食结构不科学导致的慢性病[73]。Moretti等[74]将大米粉作为主要原料,通过添加高生物利用率的硫酸亚铁和焦磷酸盐作为铁元素强化剂,采用螺杆挤压机生产出感官品质与天然大米相接近的铁强化营养重组米。与市售大米相比,该产品铁含量明显要高,能满足人们的日常需求,可有效减少铁缺乏症的发生率。

5. 结论与展望

在各种技术中,挤压在淀粉及淀粉基食品的生产中极具前景。淀粉在挤压过程中受到温度、湿度、压力和机械剪切的共同作用,其结构和性质发生变化,直接影响淀粉基食品的最终品质。因此,明确挤压过程对淀粉产生的影响,对控制和改进淀粉基食品的生产工艺及品质具有重要意义。目前,对淀粉类食品挤压加工的研究大多局限于对单一组分淀粉的处理,不足以反映实际加工过程对由碳水化合物、蛋白质、脂质和其他成分组成的复杂食品基质中淀粉的结构和性质的影响。因此,在实际加工应用中探索不同食品成分之间的相互作用将非常重要。此外,目前大多数研究集中在工艺参数和配方的优化上,但对淀粉性质变化与食品质量之间的关系仍缺乏深入研究。在未来,需要建立加工技术、淀粉结构、食品质量和消化率之间的联系,从而生产出质量更好、更健康的产品。

-

[1] LI B, ZHANG Y, XU F, et al. Supramolecular structure of Artocarpus heterophyllus Lam seed starch prepared by improved extrusion cooking technology and its relationship with in vitro digestibility[J]. Food Chemistry,2021,336:127716. doi: 10.1016/j.foodchem.2020.127716

[2] 付晓航, 李赫, 曹金诺, 等. 挤压加工对植物组织蛋白功能性影响的研究进展[J]. 食品研究与开发,2021,42(6):179−183. [FU X H, LI H, CAO J N, et al. Research progress on the effect of extrusion processing on the function of plant tissue protein[J]. Food Research and Development,2021,42(6):179−183. FU X H, LI H, CAO J N, et al. Research progress on the effect of extrusion processing on the function of plant tissue protein[J]. Food Research and Development, 2021, 42(6): 179-183.

[3] MORTEZA J, ARASH K, ELANZ M. Effect of extrusion cooking on chemical structure, morphology, crystallinity and thermal properties of sorghum flour extrudates[J]. Journal of Cereal Science,2017,75:324−331. doi: 10.1016/j.jcs.2017.05.005

[4] DALBHAGAT C G, MAHATO D K, MISHRA H N. Effect of extrusion processing on physicochemical, functional and nutritional characteristics of rice and rice-based products: A review[J]. Trends in Food Science & Technology,2019,85:226−240.

[5] 朱浩然, 秦贵信, 刘博, 等. 挤压对能量饲料中淀粉结构及可消化性影响的研究进展[J]. 中国畜牧杂志,2021,57(8):37−41. [ZHU H R, QIN G X, LIU B, et al. Research progress on the effect of extrusion on starch structure and digestibility in energy feed[J]. Chinese Journal of Animal Husbandry,2021,57(8):37−41. ZHU H R, QIN G X, LIU B, et al. Research progress on the effect of extrusion on starch structure and digestibility in energy feed[J]. Chinese Journal of Animal Husbandry, 2021, 57(8): 37-41.

[6] YU X, ZHANG J, WANG L, et al. Changes in physicochemical properties and structural characteristics of rice starch during extrusion processing: The role of glutelin and different extrusion zones[J]. Innovative Food Science & Emerging Technologies, 2022: 103163.

[7] ROMAN L, GOMEZ M, HAMAKER B R, et al. Shear scission through extrusion diminishes inter-molecular interactions of starch molecules during storage[J]. Journal of Food Engineering,2018,238:134−140. doi: 10.1016/j.jfoodeng.2018.06.019

[8] MCCLURE J, AHN J, WILDE P, et al. The effects of extrusion processing on the digestibility and functionality of pulse starches[J]. Journal of the Academy of Nutrition and Dietetics,2020,120(9):A55.

[9] MOAD G. Chemical modification of starch by reactive extrusion[J]. Progress in Polymer Science,2011,36(2):218−237. doi: 10.1016/j.progpolymsci.2010.11.002

[10] CHENG W, GAO L, WU D, et al. Effect of improved extrusion cooking technology on structure, physiochemical and nutritional characteristics of physically modified buckwheat flour: Its potential use as food ingredients[J]. LWT-Food Science and Technology,2020,133:109872. doi: 10.1016/j.lwt.2020.109872

[11] YI C P, QIANG N N, ZHU H, et al. Extrusion processing: A strategy for improving the functional components, physicochemical properties, and health benefits of whole grains[J]. Food Research International,2022,160:111681. doi: 10.1016/j.foodres.2022.111681

[12] 陈龙, 王谊, 程昊, 等. 水相高温处理对淀粉结构与性质的影响[J]. 食品与生物技术学报,2021,40(11):1−11. [CHEN L, WANG Y, CHENG H, et al. Effect of water phase high temperature treatment on starch structure and properties[J]. Journal of Food and Biotechnology,2021,40(11):1−11. CHEN L, WANG Y, CHENG H, et al. Effect of water phase high temperature treatment on starch structure and properties[J]. Journal of Food and Biotechnology, 2021, 40(11): 1-11.

[13] 肖洪, 李楠楠, 闫龙涛, 等. 挤压加工技术对食品理化性质, 营养成分影响的研究进展[J]. 食品研究与开发,2022,43(2):214−219. [XIAO H, LI N N, YAN L T, et al. Research progress on the influence of extrusion processing technology on the physical and chemical properties and nutritional components of food[J]. Food Research and Development,2022,43(2):214−219. XIAO H, LI N N, YAN L T, et al. Research progress on the influence of extrusion processing technology on the physical and chemical properties and nutritional components of food[J]. Food Research and Development, 2022, 43(2): 214-219.

[14] BWA B, YDA B, YF C, et al. Effects of different moisture contents on the structure and properties of corn starch during extrusion[J]. Food Chemistry,2022,368:130804. doi: 10.1016/j.foodchem.2021.130804

[15] EVELIEN U, PHILIPPE E. Twin-screw extrusion technology for vegetable oil extraction: A review[J]. Journal of Food Engineering,2017,212:190−200. doi: 10.1016/j.jfoodeng.2017.06.006

[16] PEREZ S, BERTOFT E. The molecular structures of starch components and their contribution to the architecture of starch granules: A comprehensive review[J]. Starch-Stärke,2010,62(8):389−420.

[17] XIANG Y, ZZW B, MYLA C, et al. The combined effects of extrusion and heat-moisture treatment on the physicochemical properties and digestibility of corn starch[J]. International Journal of Biological Macromolecules,2019,134:1108−1112. doi: 10.1016/j.ijbiomac.2019.05.112

[18] 王立东, 沈丹. 不同挤压参数对鹰嘴豆淀粉颗粒形貌的影响[J]. 农产品加工,2017,16:1−3,7. [WANG L D, SHEN D. Effect of different extrusion parameters on the morphology of chickpea starch granules[J]. Processing of Agricultural Products,2017,16:1−3,7. WANG L D, SHEN D. Effect of different extrusion parameters on the morphology of chickpea starch granules[J]. Processing of Agricultural Products, 2017, 16: 1-3, 7.

[19] ALI S, SINGH B, SHARMA S. Impact of feed moisture on microstructure, crystallinity, pasting, physico-functional properties and in vitro digestibility of twin-screw extruded corn and potato starches[J]. Plant Foods for Human Nutrition,2019,74(4):474−480. doi: 10.1007/s11130-019-00762-6

[20] ALI S, SINGH B, SHARMA S. Effect of processing temperature on morphology, crystallinity, functional properties, and in vitro digestibility of extruded corn and potato starches[J]. Journal of Food Processing and Preservation,2020,44(7):e14531.

[21] ZHANG Y, WEI L, LIU C, et al. Retrogradation behaviour of high-amylose rice starch prepared by improved extrusion cooking technology[J]. Food Chemistry,2014,158(1):255−261.

[22] NAN W, LW C, FZA B, et al. Modifying the rheological properties, in vitro digestion, and structure of rice starch by extrusion assisted addition with bamboo shoot dietary fiber[J]. Food Chemistry,2022,375:131900. doi: 10.1016/j.foodchem.2021.131900

[23] SUN X X, SUN Z Z, GUO Y, et al. Effect of twin-xuscrew extrusion combined with cold plasma on multi-scale structure, physicochemical properties, and digestibility of potato starches[J]. Innovative Food Science & Emerging Technologies,2021,74:102855.

[24] DOFA B, RADO B, EPSB B, et al. Dry extrusion pretreatment of cassava starch aided by sugarcane bagasse for improved starch saccharification[J]. Carbohydrate Polymers,2022,285:119256. doi: 10.1016/j.carbpol.2022.119256

[25] LIMA D C, MANIGLIA B C, JUNIOR M, et al. Dual-process of starch modification: Combining ozone and dry heating treatments to modify cassava starch structure and functionality[J]. International Journal of Biological Macromolecules,2021,167:894−905. doi: 10.1016/j.ijbiomac.2020.11.046

[26] WANG Q, LI L, LIU C, et al. Heat-moisture modified blue wheat starch: Physicochemical properties modulated by its multi-scale structure[J]. Food Chemistry,2022,386:132771. doi: 10.1016/j.foodchem.2022.132771

[27] ZHONG H, RUI S, DWSABC D. Effects of novel physical processing techniques on the multi-structures of starch[J]. Trends in Food Science & Technology,2020,97:126−135.

[28] XMHA B, JJXA B, XNGA B, et al. Effects of extruded endogenous starch on the gel-entrapped network formation in gluten-free Tartary buckwheat noodles during sheeting[J]. LWT-Food Science and Technology,2022,160:113226. doi: 10.1016/j.lwt.2022.113226

[29] SHRESTHA A K, NG C S, LOPEZ A, et al. Enzyme resistance and structural organization in extruded high amylose maize starch[J]. Carbohydrate Polymers,2010,80(3):699−710. doi: 10.1016/j.carbpol.2009.12.001

[30] WARAMBOI J G, GIDLEY M J, SOPADE P A. Influence of extrusion on expansion, functional and digestibility properties of whole sweet potato flour[J]. LWT-Food Science and Technology,2014,59(2):1136−1145. doi: 10.1016/j.lwt.2014.06.016

[31] 刘云飞. 改良挤压技术对大米淀粉结构和性质的影响及其在淀粉基食品中的应用[D]. 南昌: 南昌大学, 2019. LIU Y F. Effect of modified extrusion technology on the structure and properties of rice starch and its application in starch-based food[D]. Nanchang: Nanchang University, 2019.

[32] DONG Y Q, WANG B, FANG Y X, et al. Effect of different rotational speeds of the extruder on the structure of corn starch[J]. Starch-Stärke,2022,74(3-4):2100234.

[33] WILLETT J L, MILLARD M M, JASBERG B K. Extrusion of waxy maize starch: melt rheology and molecular weight degradation of amylopectin[J]. Polymer,1997,38(24):5983−5989. doi: 10.1016/S0032-3861(97)00155-9

[34] LIU Y F, CHEN J, WU J, et al. Modification of retrogradation property of rice starch by improved extrusion cooking technology[J]. Carbohydrate Polymers,2019,213:192−198. doi: 10.1016/j.carbpol.2019.02.089

[35] DONMEZ D, PINHO L, PATEL B, et al. Characterization of starch-water interactions and their effects on two key functional properties: Starch gelatinization and retrogradation[J]. Current Opinion in Food Science,2021,39:103−109. doi: 10.1016/j.cofs.2020.12.018

[36] WANG P, FU Y, WANG L, et al. Effect of enrichment with stabilized rice bran and extrusion process on gelatinization and retrogradation properties of rice starch[J]. Starch-Stärke,2017,69(7−8):1600201.

[37] XU E, WU Z, JIAO A, et al. Dynamics of rapid starch gelatinization and total phenolic thermomechanical destruction moderated via rice bio-extrusion with alpha-amylase activation[J]. Rsc Advances,2017,7(32):19464−19478. doi: 10.1039/C7RA00477J

[38] GUHA M, ALI S Z, BHATTACHARYA S. Effect of barrel temperature and screw speed on rapid viscoanalyser pasting behaviour of rice extrudate[J]. International Journal of Food Science and Technology,1998,33(3):259−266. doi: 10.1046/j.1365-2621.1998.00189.x

[39] GOMEZ M, AGUILERA J. A physicochemical model for extrusion of corn starch[J]. Journal of Food Science,1984,49(1):40−43. doi: 10.1111/j.1365-2621.1984.tb13664.x

[40] LIU Y, CHEN J, LUO S, et al. Physicochemical and structural properties of pregelatinized starch prepared by improved extrusion cooking technology[J]. Carbohydrate Polymers,2017,175:265−272. doi: 10.1016/j.carbpol.2017.07.084

[41] KANTRONG H, CHARUNUCH C, LIMSANGOUAN N, et al. Influence of process parameters on physical properties and specific mechanical energy of healthy mushroom-rice snacks and optimization of extrusion process parameters using response surface methodology[J]. Journal of Food Science and Technology,2018,55(9):3462−3472. doi: 10.1007/s13197-018-3271-2

[42] PARDHI S D, SINGH B, NAYIK G A, et al. Evaluation of functional properties of extruded snacks developed from brown rice grits by using response surface methodology[J]. Journal of the Saudi Society of Agricultural Sciences,2019,18(1):7−16. doi: 10.1016/j.jssas.2016.11.006

[43] 王超. 挤压条件对豌豆粉及其主要组分加工特性的影响研究[D]. 天津: 天津商业大学, 2019. WANG C. Effect of extrusion conditions on processing characteristics of pea powder and its main components[D]. Tianjin: Tianjin University of Commerce, 2019.

[44] WU P, LI C, BAI Y, et al. A starch molecular basis for aging-induced changes in pasting and textural properties of waxy rice[J]. Food Chemistry,2019,284:270−278. doi: 10.1016/j.foodchem.2019.01.065

[45] 杜春婷, 党斌, 杨希娟, 等. 不同加工方式对藜麦淀粉结构与功能特性的影响[J]. 中国粮油学报,2022,37(4):54−61. [DU C T, DANG B, YANG X J, et al. Effects of different processing methods on the structure and functional characteristics of quinoa starch[J]. Chinese Journal of Cereals and Oils,2022,37(4):54−61. DU C T, DANG B, YANG X J, et al. Effects of different processing methods on the structure and functional characteristics of quinoa starch[J]. Chinese Journal of Cereals and Oils, 2022, 37(4): 54-61.

[46] SARAWONG C, SCHOENLECHNER R, SEKIGUCHI K, et al. Effect of extrusion cooking on the physicochemical properties, resistant starch, phenolic content and antioxidant capacities of green banana flour[J]. Food Chemistry,2014,143:33−39. doi: 10.1016/j.foodchem.2013.07.081

[47] 徐晓茹, 周坚, 吕庆云, 等. 挤压前后大米淀粉理化性质的变化[J]. 中国食品学报,2019,19(12):187−194. [XU X R, ZHOU J, LV Q Y, et al. Changes of physical and chemical properties of rice starch before and after extrusion[J]. Chinese Journal of Food Science,2019,19(12):187−194. XU X R, ZHOU J, LV Q Y, et al. Changes of physical and chemical properties of rice starch before and after extrusion[J]. Chinese Journal of Food Science, 2019, 19(12): 187-194.

[48] WANI I A, FAROOQ G, QADIR N, et al. Physico-chemical and rheological properties of Bengal gram (Cicer arietinum L.) starch as affected by high temperature short time extrusion[J]. International Journal of Biological Macromolecules,2019,131:850−857. doi: 10.1016/j.ijbiomac.2019.03.135

[49] ZENG X, ZHENG B, XIAO G, et al. Synergistic effect of extrusion and polyphenol molecular interaction on the short/long-term retrogradation properties of chestnut starch[J]. Carbohydrate Polymers,2022,276:118731. doi: 10.1016/j.carbpol.2021.118731

[50] GANDHI N, SINGH B, SINGH P, et al. Functional, rheological, morphological, and micro-structural properties of extrusion-processed corn and potato starches[J]. Starch-Stärke,2021,73(1−2):2000140.

[51] 谢岩黎, 张春雨, 王小丽. 挤压膨化对婴幼儿颗粒面条中淀粉结构及消化特性的影响[J]. 中国粮油学报,2018,33(7):38−42,50. [XIE Y L, ZHANG C Y, WANG X L. Effect of extrusion on starch structure and digestive characteristics of granular noodles for infants and young children[J]. Chinese Journal of Cereals and Oils,2018,33(7):38−42,50. XIE Y L, ZHANG C Y, WANG X L. Effect of extrusion on starch structure and digestive characteristics of granular noodles for infants and young children[J]. Chinese Journal of Cereals and Oils, 2018, 33(7): 38-42, 50.

[52] 雷泽田, 王金荣, 许继隆, 等. 饲料加工工艺对淀粉消化特性影响的研究进展[J]. 动物营养学报,2022,34(9):1−8. [LEI Z T, WANG J R, XU J L, et al. Research progress on the influence of feed processing technology on starch digestibility[J]. Journal of Animal Nutrition,2022,34(9):1−8. LEI Z T, WANG J R, XU J L, et al. Research progress on the influence of feed processing technology on starch digestibility[J]. Journal of Animal Nutrition, 2022, 34(9): 1-8.

[53] OMOSEBI M O, OSUNDAHUNSI O F, FAGBEMI T N. Effect of extrusion on protein quality, antinutritional factors, and digestibility of complementary diet from quality protein maize and soybean protein concentrate[J]. Journal of Food Biochemistry,2018,42(4):e12508. doi: 10.1111/jfbc.12508

[54] SUN H, FAN J, TIAN Z, et al. Effects of treatment methods on the formation of resistant starch in purple sweet potato[J]. Food Chemistry,2022,367:130580. doi: 10.1016/j.foodchem.2021.130580

[55] 张婧婷. 抗性淀粉的类型及其制备技术研究进展[J]. 现代面粉工业,2021,35(6):26−33. [ZHANG J T. Research progress on types of resistant starch and its preparation technology[J]. Modern Flour Industry,2021,35(6):26−33. ZHANG J T. Research progress on types of resistant starch and its preparation technology[J]. Modern Flour Industry, 2021, 35(6): 26-33.

[56] MASATCIOGLU T M, SUMER Z, KOKSEL H. An innovative approach for significantly increasing enzyme resistant starch type 3 content in high amylose starches by using extrusion cooking[J]. Journal of Cereal Science,2017,74:95−102. doi: 10.1016/j.jcs.2017.01.015

[57] 李俊伟, 唐书泽, 张志森, 等. 挤压法制备大米抗性淀粉中系统参数控制与目标参数的关系[J]. 食品科学,2008,29(12):381−384. [LI J W, TANG S Z, ZHANG Z S, et al. The relationship between system parameter control and target parameter in extruding rice resistant starch[J]. Food Science,2008,29(12):381−384. LI J W, TANG S Z, ZHANG Z S, et al. The relationship between system parameter control and target parameter in extruding rice resistant starch[J]. Food Science, 2008, 29(12): 381-384.

[58] NAKORN K N, TONGDANG T, SIRIVONGPAISAL P. Crystallinity and rheological properties of pregelatinized rice starches differing in amylose content[J]. Starch-Stärke,2010,61(2):101−108.

[59] 李小林, 李建勋, 张文娟, 等. 挤压预糊化淀粉的性能及其添加对糙米发糕品质的影响[J]. 食品工业科技,2022,43(15):66−72. [LI X L, LI J X, ZHANG W J, et al. Properties of extruded pregelatinized starch and its effect on the quality of brown rice cake[J]. Science and Technology of Food Industry,2022,43(15):66−72. LI X L, LI J X, ZHANG W J, et al. Properties of extruded pregelatinized starch and its effect on the quality of brown rice cake[J]. Science and Technology of Food Industry, 2022, 43(15): 66-72.

[60] ZHANG X, CHEN Y, ZHANG R, et al. Effects of extrusion treatment on physicochemical properties and in vitro digestion of pregelatinized high amylose maize flour[J]. Journal of Cereal Science,2016,68:108−115. doi: 10.1016/j.jcs.2016.01.005

[61] 冯朵, 丁振, 曹盼盼, 等. 预处理辅助酶解制备多孔淀粉及其在食品领域中的应用[J]. 美食研究,2022,39(2):87−94. [FENG D, DING Z, CAO P P, et al. Preparation of porous starch by pretreatment assisted enzymatic hydrolysis and its application in food field[J]. Gastronomic Research,2022,39(2):87−94. doi: 10.19913/j.cnki.2095-8730msyj.2022.02.14 FENG D, DING Z, CAO P P, et al. Preparation of porous starch by pretreatment assisted enzymatic hydrolysis and its application in food field[J]. Gastronomic Research, 2022, 39(2): 87-94. doi: 10.19913/j.cnki.2095-8730msyj.2022.02.14

[62] 吴文琪, 焦爱权, 杨月月, 等. 反应挤出与酶法联合制备多孔淀粉工艺的优化[J]. 食品工业科技,2020,41(14):114−119,128. [WU W Q, JIAO A Q, YANG Y Y, et al. Optimization of the process of preparing porous starch by reactive extrusion and enzymatic method[J]. Science and Technology of Food Industry,2020,41(14):114−119,128. WU W Q, JIAO A Q, YANG Y Y, et al. Optimization of the process of preparing porous starch by reactive extrusion and enzymatic method[J]. Food Industry Science and Technology, 2020, 41(14): 114-119, 128.

[63] CHEN J, WANG Y, LIU J, et al. Preparation, characterization, physicochemical property and potential application of porous starch: A review[J]. International Journal of Biological Macromolecules,2020,148:1169−1181. doi: 10.1016/j.ijbiomac.2020.02.055

[64] FARHANA M A, AZAD Z, DAR B N, et al. Breakfast cereals from whole grain and Indian horse chestnut flours obtained through extrusion: physical, mechanical and functional characteristics[J]. Applied Food Research,2022,2(2):100137. doi: 10.1016/j.afres.2022.100137

[65] SANTOS D, PINTADO M, DASILVA J A L. Potential nutritional and functional improvement of extruded breakfast cereals based on incorporation of fruit and vegetable by-products-a review[J]. Trends in Food Science & Technology,2022,125:136−153.

[66] WOJTOWICZ A, MITRUS M, ONISZCZUK T, et al. Selected physical properties, texture and sensory characteristics of extruded breakfast cereals based on wholegrain wheat flour[J]. Agriculture and Agricultural Science Procedia,2015,7:301−308. doi: 10.1016/j.aaspro.2015.12.051

[67] 王晨, 王燕, 吴卫国, 等. 双螺杆挤压复合方便粥配方优化及品质分析[J]. 食品工业科技,2022,43(5):245−254. [WANG C, WANG Y, WU W G, et al. Formulation optimization and quality analysis of double screw extrusion composite instant porridge[J]. Science and Technology of Food Industry,2022,43(5):245−254. WANG C, WANG Y, WU W G, et al. Formulation optimization and quality analysis of double screw extrusion composite instant porridge[J]. Food Industry Science and Technology, 2022, 43(5): 245-254.

[68] 蔡乔宇, 陈轩, 周梦舟, 等. 双螺杆挤压法制备马铃薯方便米饭的研究[J]. 粮食与饲料工业,2018,6:15−22. [CAI Q Y, CHEN X, ZHOU M Z, et al. Study on the preparation of potato instant rice by twin screw extrusion[J]. Grain and Feed Industry,2018,6:15−22. CAI Q Y, CHEN X, ZHOU M Z, et al. Study on the preparation of potato instant rice by twin screw extrusion[J]. Grain and Feed Industry, 2018, 6: 15-22.

[69] 贺也. 挤压膨化制备方便杂粮粉的工艺研究[D]. 长沙: 湖南农业大学, 2016. HE Y. Study on the preparation of instant cereals powder by extrusion[D]. Changsha: Hunan Agricultural University, 2016.

[70] 颜梦婷, 刘施琳, 朱丰, 等. 休闲食品加工技术研究进展[J]. 食品安全质量检测学报,2015,6(10):4013−4018. [YAN M T, LIU S L, ZHU F, et al. Research progress of snack food processing technology[J]. Journal of Food Safety and Quality Inspection,2015,6(10):4013−4018. YAN M T, LIU S L, ZHU F, et al. Research progress of snack food processing technology[J]. Journal of Food Safety and Quality Inspection, 2015, 6(10): 4013-4018.

[71] FM A, MVA B, RMA B, et al. Second-generation snacks with high nutritional and antioxidant value produced by an optimized extrusion process from corn/common bean flours mixtures[J]. LWT-Food Science and Technology,2020,124:109172. doi: 10.1016/j.lwt.2020.109172

[72] AAT A, AUS B. The replacement of cereals by legumes in extruded snack foods: Science, technology and challenges[J]. Trends in Food Science & Technology,2021,116:701−711.

[73] VISHWAKARMA S, DALBHAGAT C G, MANDLIYA S, et al. Investigation of natural food fortificants for improving various properties of fortified foods: A review[J]. Food Research International, 2022: 111186.

[74] MORETTI D, LEE T C, ZIMMERMANN M B, et al. Development and evaluation of iron-fortified extruded rice grains[J]. Journal of Food Science,2005,70(5):S330−S336. doi: 10.1111/j.1365-2621.2005.tb09987.x

-

期刊类型引用(5)

1. 张田,黄雨洋,刘琳琳,吕铭守,朱颖,孙冰玉,朱秀清. 多糖对高水分挤压植物蛋白肉结构及品质影响的研究进展. 食品科学. 2024(22): 341-350 .  百度学术

百度学术

2. 李清清,刘淑一,李秋雨,戴志勇. 影响婴幼儿面条中维生素A稳定性的因素. 食品与机械. 2024(11): 160-165 .  百度学术

百度学术

3. 周文达,伏静轩,马恺扬,李莹. 酶法复合挤压工艺制备绿豆面条及其对血糖生成指数的影响. 中国粮油学报. 2024(11): 79-86 .  百度学术

百度学术

4. 李婉冰,蒋晓宇,刘颖,卢玥,邹爱军,常超. 淀粉糊化新技术对即食冲调粉冲调特性的改善. 武汉轻工大学学报. 2023(04): 10-16 .  百度学术

百度学术

5. 张光,李俣霏,马春敏,许馨予,杨杨,边鑫,王冰,张娜. 小麦淀粉改性技术及应用研究进展. 食品安全质量检测学报. 2023(22): 39-47 .  百度学术

百度学术

其他类型引用(2)

下载:

下载:

下载:

下载: