Effect of Pigskin Collagen Peptides on Quality Characteristics and Microstructure of Pork Stuffing

-

摘要: 为评估猪皮胶原蛋白肽在肉馅类食品中的应用潜力,本试验研究了不同添加量的猪皮胶原蛋白肽(0.5%、1%、2%、4%和6%)对新鲜猪肉馅品质特性、水分分布和微观结构的影响,分别以不添加猪皮胶原蛋白肽的肉馅为空白组以及添加复配改良剂(2%大豆蛋白和0.15%卡拉胶)的肉馅为对照组进行实验。结果表明,当猪皮胶原蛋白肽添加量达到2%以上时,肉馅的蒸煮损失率显著降低(P<0.05),添加量为6%时,与空白组和对照组相比,其蒸煮损失率分别降低了71.1%和43.9%;和空白组相比,当添加量为6%时,其硬度、粘聚性、咀嚼性和弹性分别下降31.0%、19.7%、52.2%和15.3%;添加量为4%时,肉馅鲜嫩多汁,可接受性好。水分分布试验结果表明,猪皮胶原蛋白肽添加量超过4%时,肉馅中不易流动水(T22)的最高出峰时间发生了左移(75.65 ms→65.79 ms),在500倍电镜下观察,添加猪皮胶原蛋白肽的肉馅网络结构更加均匀致密。本试验结果为猪皮胶原蛋白肽在肉馅类食品中的应用提供了科学依据。Abstract: In order to evaluate the potential application of pigskin collagen peptides (PCP) in fresh pork stuffing products, the effects of PCP content (0.5%, 1%, 2%, 4% and 6%) on the quality characteristics, water distribution and microstructure of fresh pork stuffing were investigated in this study. For comparison, the pork stuffing without PCP and the pork stuffing with a compound modifier (2% soybean protein and 0.15% carrageenan) were used as blank and control, respectively. The results showed that when the PCP content was more than 2%, the cooking loss rate of the sample was significantly reduced (P<0.05). When the PCP content was 6%, compared with the blank and the control, the cooking loss rate was reduced by 71.1% and 43.9%, respectively. Compared with the blank, when the PCP content was 6%, the hardness, cohesiveness, chewiness and elasticity of the sample decreased by 31.0%, 19.7%, 52.2% and 15.3%, respectively. The pork stuffing developed at the PCP content of 4% was fresh and juicy and had good acceptability. The results of water distribution test indicated that when the PCP content was more than 4%, the maximum peak signal of immobile water (T22) in pork stuffing shifted from 75.65 ms to 65.79 ms. Observed under 500 times electron microscope, the network structure of pork stuffing with PCP was more uniform and denser. The results would provide a scientific basis for the application of PCP in meat stuffing food.

-

随着人们生活节奏的加快和饮食消费模式的变化,含有肉馅的各种预制调理食品越来越多的走上消费者的餐桌[1]。在实际生产和流通过程中,肉馅会出现持水性下降、脂肪氧化和蛋白质变性等问题,导致其营养和食用品质下降[2-3]。因此,改善和保持肉馅类调理食品的品质一直是该领域的研究重点。常用的方法包括改进加工工艺[2]和添加食品配料等,常用来作为水分保持剂和改良剂的食品配料有大豆蛋白[4]、复合磷酸盐[5]、黄原胶[6]等。

胶原蛋白肽是天然胶原蛋白经水解而成的一种生物活性肽,具有三螺旋结构,其肽链通常由重复序列Gly-X-Y组成,X和Y分别是脯氨酸和4-羟脯氨酸[7]。这种序列赋予了胶原蛋白肽独特的性质,如稳定性、保水性、粘弹性、增稠性以及凝胶化等[8],因此被广泛应用于医药[9]、化妆品[10]、食品[11]等领域。Fan等[12]发现使用燕麦β-葡聚糖-胶原蛋白肽可以更好地将水分固定在肉糜中。除此以外,也有研究表明,胶原蛋白还具有抑制冰晶形成、蛋白质变性和脂质氧化等多种功效,是一种新型的比较有潜力的食品配料[13]。其中猪皮胶原蛋白肽(Pigskin collagen pep-tide,PCP)是一种天然的胶原蛋白酶解物,研究发现,将其以一定量添加到酸奶[14]、冷冻面团[15]和冰激凌[16]中,可以改善产品的质构,提高产品品质和稳定性。

目前关于PCP对传统猪肉馅品质特性的影响研究较少。因此,本试验以猪里脊和猪肥膘为原料制备肉馅,研究不同添加量的猪皮胶原蛋白肽(0.5%、1%、2%、4%和6%)对新鲜猪肉馅品质特性的影响,并进一步研究肉馅水分状态分布与迁移规律、微观结构的变化。系统评估猪皮胶原蛋白肽在肉馅类食品中的作用特点以及应用潜力,为其在肉馅类食品中的应用提供科学依据。

1. 材料与方法

1.1 材料与仪器

新鲜的猪里脊和猪肥膘、食盐、大豆油、纯净水 购自新乡市春天里超市;猪皮胶原蛋白肽(食品级) 武汉天天好生物制品有限公司;大豆分离蛋白(食品级) 临沂山松生物制品有限公司;卡拉胶(食品级) 滕州市香凝生物工程有限公司;磷酸氢二钠十二水合物、磷酸二氢钠二水合物、氯化钠 天津市光复科技发展有限公司;50%戊二醛溶液 郑州派尼化学试剂厂;叔丁醇、无水乙醇 天津新技术产业园区科贸化学试剂有限公司;三氯甲烷 洛阳昊华化学试剂有限公司;所有试剂均为分析纯。

FA124型分析天平 上海舜宇恒平科学仪器有限公司;QSJ-C04V3型绞肉机 小熊电器股份有限公司;JW-1044型低速离心机 安徽嘉文仪器装备有限公司;TA-XT plus型质构仪 英国Stable Micro Systems公司;NMI20-040V-I型低场核磁共振成像分析仪 苏州纽迈分析仪器股份有限公司;DZF型真空干燥箱 上海一恒科学仪器有限公司;HITACHI E-1010型离子溅射仪 日本日立公司;Quanta 200型扫描电子显微镜 美国FEI公司。

1.2 实验方法

1.2.1 样品制备

取新鲜的猪里脊和猪肥膘,按照肥瘦质量比为1:4搅成肉糜,边搅拌边加入1.5%(以肉馅质量计)的食盐、0.5%~6%的猪皮胶原蛋白肽、15%的冰水、1%的油。试验设置两组对照,以不添加猪皮胶原蛋白肽的肉馅为空白组,以添加保水性效果较好的大豆蛋白复配改良剂的肉馅(2%大豆分离蛋白和0.15%卡拉胶)为对照组[4,17-18]。将上述处理好的各组样品,按照各指标测定要求,分别制样,进行指标测定。

1.2.2 蒸煮损失率测定

取1份15 g左右的肉馅样品,准确称量,其质量记为m0。将其装入蒸煮袋内,再次称量,记为m1,然后将其放入沸水中煮,测定肉馅中心温度达到85 ℃时(大约8 min),取出在室温下,将蒸煮袋剪小口控干汁液,2 h左右,等不再有汁液流出后再次称重,记为m2,每组样品平行测定5次,取平均值。根据以下公式计算蒸煮损失率:

蒸煮损失率(%)=m1−m2m0×100 1.2.3 质构特性测定

将处理完的样品称取45 g左右,放入离心管中,以3000 r/min,离心5 min。将离心后样品置于80 ℃恒温水浴锅中煮15 min,取出后冷却至室温,将样品切成2 cm×2 cm ×2 cm的立方体。每组样品平行测定6次,取平均值。参考Pan等[19]的方法,设定质构仪为TPA模式,采用P/36R探头,测试前、中、后速度为2 mm/s,压缩量为40%,测定肉样的硬度、弹性、粘聚性和咀嚼性。

1.2.4 感官评定

选取10名嗅觉和味觉正常的同学(年龄在19~25岁之间)进行感官评价。通过事先培训和预实验,每名评价员对评价对象和感官指标及评分标准有充分理解。具体方法如下:称取经过1.2.1方法处理的肉馅,按照每个肉馅(15±0.1) g制成水饺,放入沸水中煮8 min,捞出后室温冷却至50 ℃左右,进行感官评定。根据实验目的,每位评价员对样品的嫩度、多汁性、整体可接受性3个指标分别进行评价,评价采用9分制评分法[20],每个样品以随机三位数编码,不同样品之间用清水漱口。具体感官评分标准见表1。

表 1 感官评分标准Table 1. Criterion for sensory evaluation指标 评分标准(得分范围) 嫩度 入口爽滑鲜嫩、有嚼劲、具有肉馅本身的口感(7~9分) 肉馅易咀嚼、口感稍差(4~6分) 肉馅嫩但无嚼劲、过于软烂或质地较硬、不易咀嚼(1~3分) 多汁性 入口或咀嚼时肉馅饱满多汁(7~9分) 入口或咀嚼时肉馅湿润,汤汁较少(4~6分) 肉馅汤汁较少、口感干柴(1~3分) 整体可接受性 肉馅鲜嫩多汁、细腻滑润、有嚼劲,可接受性好(7~9分) 肉馅汁水较少、口感一般,可接受性一般(4~6分) 肉馅多汁无嚼劲或又干又柴,可接受性差(1~3分) 1.2.5 水分状态分布测定

参考Zhang等[21]的方法并稍加改动。采用低场核磁共振成像分析仪(NMR)对水分状态分布进行测定。取约5 g样品放置在NMR管(直径10 mm)中,插入磁体探头,调节共振中心的频率,选定CPMG脉冲序列检测样品的弛豫时间(T2),每个样品平行测定3次。CPMG试验参数:采样点数TD=240008,主频=20 MHz,偏移频率=626486.66 Hz,重复扫描次数NS=4,半回波时间τ=6.52 μs,采样间隔时间TW=5000 ms。采用系统自带的反演拟合软件对CPMG曲线进行反演得到弛豫图谱和T2。

1.2.6 微观结构变化测定

采用扫描电子显微镜测量肉馅的微观结构变化,参考黄莉等[22]的方法并略加改动。将按照1.2.1方法制备的肉馅样品速冻10 min后切成厚度为2 mm左右的薄片,用2.5%、pH6.8的戊二醛浸泡48 h固定,然后分别用30%~100%梯度的乙醇溶液依次进行脱水,再用氯仿脱脂1 h后,依次用无水乙醇:叔丁醇(1:1 V/V)、叔丁醇浸泡置换15 min,在25 ℃真空下干燥4 h,取干燥后样品粘在导电胶带上,用E-1010型离子溅射仪进行90 s喷金,最后上机放大500倍进行观察。

1.3 数据处理

使用SPSS 26软件进行数据分析,采用ANOVA单因素方差分析以及Duncan多重比较进行差异显著性分析,P<0.05为差异显著;用Origin 2017进行绘图。试验数据以平均值±标准差表示,每组试验平行3~6次。

2. 结果与分析

2.1 猪皮胶原蛋白肽对新鲜猪肉馅蒸煮损失的影响

蒸煮损失主要用来评价肉馅的持水能力。猪皮胶原蛋白肽对新鲜猪肉馅蒸煮损失率的影响见图1。由图1可知,当猪皮胶原蛋白肽添加量超过2%时,可以显著降低肉馅的蒸煮损失率(P<0.05)。其中6%添加量的蒸煮损失率最低,与空白组和对照组相比,其蒸煮损失率分别降低了71.1%和43.9%。其原因可能是胶原蛋白肽在肉糜搅拌和煮制的过程中,与蛋白质交联,形成凝胶网络,从而增加了保水性,降低了蒸煮损失。WANG等[23]将猪皮胶原蛋白经过不同温度预处理后,应用于哈尔滨红肠,发现改性的胶原蛋白因其良好的凝胶性而发挥保水作用。宋永等[24]发现,添加1%~2%鱼鳞水解胶原蛋白,可显著提高灌肠的出品率和持水力(P<0.05),其认为主要是鱼鳞水解胶原蛋白的乳化性、吸水性、保水性和凝胶性发挥了作用。赵颖等[25]研究了添加猪皮胶原蛋白和TGase对模拟腌肉制品品质的影响,发现添加猪皮胶原蛋白,在提高产品的出品率的同时,还能改善由于出品率增加所造成的质构和口感不佳,同时降低蒸煮损失率。

2.2 猪皮胶原蛋白肽对新鲜猪肉馅质构特征的影响

质构特性是反映肉制品的质地和口感的指标。硬度指的是食品达到一定变形所必需的力,主要用来描述咀嚼食品的难易程度;粘聚性表示样品内部粘合力;弹性表示物体在外力作用下发生形变,当撤去外力后恢复原来状态的能力;咀嚼性为咀嚼固体食品所需的能量[26]。猪皮胶原蛋白肽对新鲜猪肉馅的硬度、弹性、粘聚性和咀嚼性的影响结果见表2。

表 2 猪皮胶原蛋白肽对新鲜猪肉馅质构特性的影响Table 2. Effect of pigskin collagen peptides on texture properties of fresh pork fillings添加量(%) 硬度(g) 弹性(mm) 粘聚性 咀嚼性(g) 空白组 4357.01±164.34b 0.85±0.01a 0.61±0.01a 2229.04±79.77b 0.5 3905.65±146.60c 0.83±0.01ab 0.57±0.01ab 1851.79±80.38c 1 3594.31±31.51cd 0.82±0.01ab 0.55±0.01bc 1625.64±43.42d 2 3293.00±76.25de 0.85±0.01a 0.51±0.01cd 1439.35±45.61d 4 3066.57±43.20e 0.80±0.01b 0.47±0.01e 1164.94±50.44e 6 3005.10±99.71e 0.72±0.03c 0.49±0.02de 1065.93±56.35e 对照组 5229.43±128.26a 0.83±0.01ab 0.58±0.01ab 2547.90±94.55a 注:空白组:未添加猪皮胶原蛋白肽;对照组:2%大豆分离蛋白+0.15%卡拉胶;数据表示为平均值±标准差(n=6),同一列不同小写字母(a~e)表示相互之间有显著差异(P<0.05)。 由表2可知,猪皮胶原蛋白肽对新鲜猪肉馅质构特性有显著影响,随着PCP添加量的增加,新鲜猪肉馅的硬度、粘聚性和咀嚼性呈下降趋势。当添加量为6%时,和空白组相比,肉馅硬度下降31.0%,粘聚性下降19.7%,咀嚼性下降52.2%;在PCP添加量达到4%时,弹性开始显著下降(P<0.05),当添加量为6%时,下降幅度为15.3%。当PCP添加量为6%时,和对照组相比,肉馅硬度、弹性、粘聚性和咀嚼性分别降低42.5%、13.3%、15.5%和58.2%(P<0.05)。

邹烨等[27]用鸡爪胶原蛋白肽溶液处理鸡胸肉,发现鸡胸肉的硬度、胶黏性和咀嚼性显著下降,但弹性增加。Wang等[23]发现,随着猪皮胶原蛋白添加量的增加,哈尔滨红肠的硬度、弹性和咀嚼性都显著增加。毛云等[28]研究发现,当胶原蛋白的添加量为11.5%~14.5%时,牦牛肉肉糜的硬度显著增加,弹性和黏结性显著下降(P<0.01),而咀嚼性指标无显著性差异。

以上结果和分析表明,胶原蛋白肽对肉类产品的质构特性有显著影响,但具体影响效果与产品配方、胶原蛋白分子量和氨基酸组成有较大关系[29]。在本试验中,添加PCP降低了肉馅的硬度、粘聚性、咀嚼性,当添加量低于4%时,对弹性无显著影响。

2.3 猪皮胶原蛋白肽对新鲜猪肉馅感官特性的影响

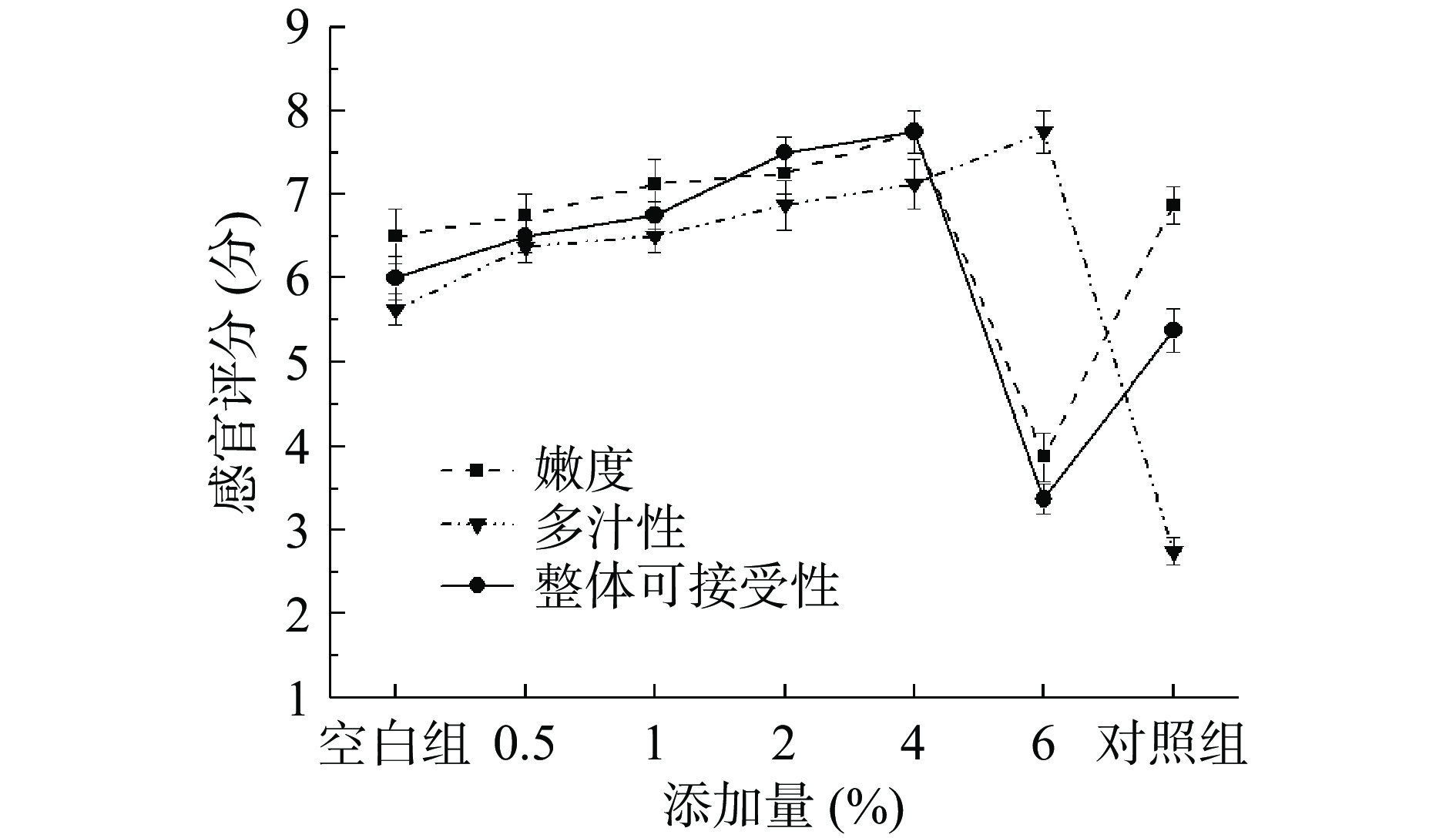

猪皮胶原蛋白肽对新鲜猪肉馅感官特性的影响见图2。由图2可知,猪皮胶原蛋白肽对新鲜猪肉馅的嫩度、多汁性、整体可接受性具有显著影响(P<0.05)。

![]() 图 2 猪皮胶原蛋白肽对新鲜猪肉馅感官指标的影响注:空白组:未添加猪皮胶原蛋白肽;对照组:2%大豆分离蛋白+0.15%卡拉胶;图3同。Figure 2. Effect of pigskin collagen peptides on sensory evaluation of fresh pork stuffing

图 2 猪皮胶原蛋白肽对新鲜猪肉馅感官指标的影响注:空白组:未添加猪皮胶原蛋白肽;对照组:2%大豆分离蛋白+0.15%卡拉胶;图3同。Figure 2. Effect of pigskin collagen peptides on sensory evaluation of fresh pork stuffing与空白组相比:对于嫩度指标,添加量为4%时效果最好;随着PCP添加量的增加,咀嚼变得更加容易,当添加量为6%时,肉馅鲜嫩但无嚼劲;对于多汁性而言,6% PCP添加量效果最好,咬开后汁液感饱满,其次为4%添加量。对于整体可接受性指标,当PCP添加量在0.5%~4%时,其评分与添加量成正比,和空白组相比,肉馅更加鲜嫩多汁,但当添加量达到6%时,肉馅质感变得软烂,导致整体可接受性变差。Wang等[23]将改性的猪皮胶原蛋白应用于哈尔滨红肠的试验表明,在1%~5%浓度范围内,随着添加量的增加,多汁性得分增加,但对其它风味无显著影响。

同时,试验也发现,与空白组以及试验组相比,大豆蛋白复配对照组(2%大豆蛋白+0.15%卡拉胶)的口感完全不同。加入大豆蛋白和卡拉胶后,肉馅弹性十足,硬度增加,有嚼劲和韧劲,有类似肠类制品的口感,结合质构试验的结果,推测可能与它们与水和肉馅中肌原纤维蛋白相互作用形成的凝胶强度有关。胶原蛋白肽是一种亲水性胶体,其具有独特的三股螺旋及纤维结构特征,与水的相互作用和热转变机制会随着含水量的增加发生变化,在胶原蛋白螺旋内每三肽重复单元含有两个结构水分子,分别以氢键与双氢键同多肽链结合,从而形成完整的重复微晶结构,更多的水则以较弱的方式作用于各级纤维结构[30]。Onodera等[29]在研究罗非鱼鱼鳞胶原蛋白肽的浓度和分子量对琼脂凝胶流变和热稳定性的影响时发现,胶原蛋白肽的分子量和氨基酸组成对凝胶强度有较大影响,较大的分子量会阻碍分子间交联,降低凝胶强度。Abdollahi等[31]从鲢鱼中提取胶原蛋白和胶原蛋白水解物,并将其应用于鲢鱼蛋白,结果发现,凝胶行为取决于添加的胶原蛋白水解物的分子量。更高水解度的胶原蛋白提高了鲢鱼凝胶的保水能力,同时降低了破胶力。

2.4 猪皮胶原蛋白肽对新鲜猪肉馅水分分布的影响

肉馅中水分分布和含量可直接影响肉馅的质构和风味特性等[32]。通过低场核磁对横向弛豫(T2)的测定,可以了解样品的水分分布、水分迁移及相互演变规律。猪皮胶原蛋白肽对新鲜猪肉馅水分分布的影响见表3和图3。在样品中识别出了两种形式的水,即结合水(0~10 ms)和不易流动水(10~100 ms),最高出峰时间分别用T21和T22表示,对应的峰面积百分比则用P21和P22表示。T2表示水分的移动能力,数值越小,说明水分与底物结合地越紧密[33]。研究发现,当PCP添加量大于4%时,对不易流动水的最高出峰时间(T22)有显著影响(P<0.05),但对结合水和不易流动水的峰面积百分比(P21)和(P22)没有显著影响(P>0.05)。当PCP添加量达到4%时,样品的T22发生了左移(75.65 ms→65.79 ms),说明随着PCP添加量的增加,肉馅中水分流动性降低,邹烨等[27]的研究结果和本试验一致,其在超声辅助鸡爪胶原蛋白肽处理对鸡胸肉贮藏品质的影响的研究中,也证实了经过胶原蛋白肽溶液浸泡处理后,T22发生了显著左移。本实验中,所有样品的P22所占比例为97%左右,说明肉馅中的水大部分是与生肉糜溶胶基质疏松结合的水,前面蒸煮损失试验也验证了本结果。由表3可以看出,4% PCP添加量对水分分布的影响与对照组一致,相互间没有显著性差异(P>0.05)。

表 3 猪皮胶原蛋白肽对新鲜猪肉馅水分分布的影响Table 3. Effect of pigskin collagen peptides on moisture distribution of fresh pork stuffing添加量(%) T2(ms) P2(%) T21 T22 P21 P22 空白组 3.89±0.53a 75.65±0.00a 3.17±0.03a 96.83±0.03a 0.5 3.51±0.00ab 75.65±0.00a 2.88±0.00a 97.05±0.06a 1 4.03±0.00a 75.65±0.00a 3.89±0.14a 96.11±0.14a 2 4.21±0.31a 75.65±0.00a 3.52±0.79a 96.48±0.79a 4 3.66±0.99a 65.79±0.00b 2.89±0.06a 97.13±0.06a 6 4.97±0.75a 65.79±0.00b 3.93±1.02a 96.05±1.02a 对照组 2.26±0.89b 65.79±0.00b 3.37±0.20a 96.60±0.21a 注:空白组:未添加猪皮胶原蛋白肽;对照组:2%大豆分离蛋白+0.15%卡拉胶;数据表示为平均值±标准差(n=6)。 2.5 猪皮胶原蛋白肽对新鲜猪肉馅微观结构的影响

为了进一步了解猪皮胶原蛋白肽对猪肉馅的影响,本文对其微观结构进行了观察。其500倍电镜扫描结果见图4。由图4可以看出,PCP的添加明显改变了肉馅的微观结构。有研究表明胶原蛋白肽是一种高分子多肽聚合物,这些聚合物很容易交织成不易断裂的链和网状结构,从图4A可以观察到未添加PCP的样品表面空洞较多、不平整;PCP添加量≤2%时(图4B~图4D),脂肪颗粒均匀的分布在整个网络中,肉馅表面有较多小孔洞;4%和6%添加量的肉馅结构更加致密、表面细腻(图4E~图4F)。有研究表明胶原蛋白肽是一种高分子多肽聚合物,这些聚合物很容易交织成不易断裂的链和网状结构,从而提高制品的持水力[34]。观察发现,添加2%大豆分离蛋白和0.15%卡拉胶的对照组,与添加PCP所呈现的微观状态不同。

3. 结论

添加猪皮胶原蛋白肽可以提高肉馅的持水能力,当添加量达到2%以上时,肉馅的蒸煮损失显著降低(P<0.05),添加量为6%时,其蒸煮损失比空白组降低了71.1%。同时,添加猪皮胶原蛋白肽也改善了肉馅的质构和感官特性,和空白组相比,当添加量为6%时,其硬度、粘聚性、咀嚼性和弹性分别下降31.0%、19.7%、52.2%和15.3%;添加量为4%时,肉馅嫩度和整体可接受性评分最高。低场核磁结果显示,当猪皮胶原蛋白肽添加量超过4%时,T22的最高出峰时间从75.65 ms左移到65.79 ms。微观结构观察发现,当添加量超过4%时,肉馅网络结构更加均匀致密、质地细腻。综合考虑,4%添加量效果最好。

本研究为猪皮胶原蛋白肽在肉馅类食品中的应用提供了科学依据。但猪皮胶原蛋白肽在提高肉馅持水能力的同时,为何降低了肉馅的硬度和咀嚼性的机制尚不明确,推测与胶原蛋白肽的分子量、氨基酸组成和凝胶强度有关,在后续的研究工作中,应关注“猪皮胶原蛋白肽-肌原纤维蛋白-水”相互之间的作用机制及凝胶特性,从而为猪皮胶原蛋白肽的应用提供更好的指导。

-

图 2 猪皮胶原蛋白肽对新鲜猪肉馅感官指标的影响

注:空白组:未添加猪皮胶原蛋白肽;对照组:2%大豆分离蛋白+0.15%卡拉胶;图3同。

Figure 2. Effect of pigskin collagen peptides on sensory evaluation of fresh pork stuffing

表 1 感官评分标准

Table 1 Criterion for sensory evaluation

指标 评分标准(得分范围) 嫩度 入口爽滑鲜嫩、有嚼劲、具有肉馅本身的口感(7~9分) 肉馅易咀嚼、口感稍差(4~6分) 肉馅嫩但无嚼劲、过于软烂或质地较硬、不易咀嚼(1~3分) 多汁性 入口或咀嚼时肉馅饱满多汁(7~9分) 入口或咀嚼时肉馅湿润,汤汁较少(4~6分) 肉馅汤汁较少、口感干柴(1~3分) 整体可接受性 肉馅鲜嫩多汁、细腻滑润、有嚼劲,可接受性好(7~9分) 肉馅汁水较少、口感一般,可接受性一般(4~6分) 肉馅多汁无嚼劲或又干又柴,可接受性差(1~3分) 表 2 猪皮胶原蛋白肽对新鲜猪肉馅质构特性的影响

Table 2 Effect of pigskin collagen peptides on texture properties of fresh pork fillings

添加量(%) 硬度(g) 弹性(mm) 粘聚性 咀嚼性(g) 空白组 4357.01±164.34b 0.85±0.01a 0.61±0.01a 2229.04±79.77b 0.5 3905.65±146.60c 0.83±0.01ab 0.57±0.01ab 1851.79±80.38c 1 3594.31±31.51cd 0.82±0.01ab 0.55±0.01bc 1625.64±43.42d 2 3293.00±76.25de 0.85±0.01a 0.51±0.01cd 1439.35±45.61d 4 3066.57±43.20e 0.80±0.01b 0.47±0.01e 1164.94±50.44e 6 3005.10±99.71e 0.72±0.03c 0.49±0.02de 1065.93±56.35e 对照组 5229.43±128.26a 0.83±0.01ab 0.58±0.01ab 2547.90±94.55a 注:空白组:未添加猪皮胶原蛋白肽;对照组:2%大豆分离蛋白+0.15%卡拉胶;数据表示为平均值±标准差(n=6),同一列不同小写字母(a~e)表示相互之间有显著差异(P<0.05)。 表 3 猪皮胶原蛋白肽对新鲜猪肉馅水分分布的影响

Table 3 Effect of pigskin collagen peptides on moisture distribution of fresh pork stuffing

添加量(%) T2(ms) P2(%) T21 T22 P21 P22 空白组 3.89±0.53a 75.65±0.00a 3.17±0.03a 96.83±0.03a 0.5 3.51±0.00ab 75.65±0.00a 2.88±0.00a 97.05±0.06a 1 4.03±0.00a 75.65±0.00a 3.89±0.14a 96.11±0.14a 2 4.21±0.31a 75.65±0.00a 3.52±0.79a 96.48±0.79a 4 3.66±0.99a 65.79±0.00b 2.89±0.06a 97.13±0.06a 6 4.97±0.75a 65.79±0.00b 3.93±1.02a 96.05±1.02a 对照组 2.26±0.89b 65.79±0.00b 3.37±0.20a 96.60±0.21a 注:空白组:未添加猪皮胶原蛋白肽;对照组:2%大豆分离蛋白+0.15%卡拉胶;数据表示为平均值±标准差(n=6)。 -

[1] 杨铭铎, 张瑛, 崔莹莹, 等. 调理食品内涵及其研究进展[J]. 中国调味品,2022,47(3):211−216. [YANG M D, ZHANG Y, CUI Y Y, et al. The connotation and research progress of prepared food[J]. China Condiment,2022,47(3):211−216. [YANG M D, ZHANG Y, CUI Y Y, et al. The connotation and research progress of prepared food[J]. China Condiment, 2022, 47(3): 211-216. ]

[2] 吴宇桐, 张潮, 孔保华. 超声辅助浸渍冷冻对猪肉水饺肉馅品质的影响[J]. 食品科学,2020,41(23):107−113. [WU Y T, ZHANG C, KONG B H. Effect of ultrasonic-assisted immersion freezing on the quality of pork dumpling filling[J]. Food Science,2020,41(23):107−113. doi: 10.7506/spkx1002-6630-20191123-267 WU Y T, ZHANG C, KONG B H. Effect of ultrasonic-assisted immersion freezing on the quality of pork dumpling filling[J]. Food Science, 2020, 41(23): 107-113. doi: 10.7506/spkx1002-6630-20191123-267

[3] 潘男, 董依迪, 邓思杨, 等. 速冻肉馅类制品品质劣变机理及阻断技术的研究进展[J]. 食品工业科技,2019,40(6):323−329. [PAN N, DONG Y D, DENG S Y, et al. Research progress on mechanism and inhibition technology of quality deterioration of quick-frozen meat stuffing product[J]. Food Science,2019,40(6):323−329. doi: 10.13386/j.issn1002-0306.2019.06.056 PAN N, DONG Y D, DENG S Y, et al. Research progress on mechanism and inhibition technology of quality deterioration of quick-frozen meat stuffing product[J]. Food Science, 2019, 40(6): 323-329. doi: 10.13386/j.issn1002-0306.2019.06.056

[4] 赵泽润, 邢通, 赵雪, 等. 大豆分离蛋白添加量对低盐木质化鸡肉糜凝胶特性的影响[J]. 食品科学,2022,43(6):49−56. [ZHAO Z R, XING T, ZHAO X, et al. Effect of addition of soy isolate on the gelation properties of low-salt wooden chicken breast meat batter[J]. Food Science,2022,43(6):49−56. ZHAO Z R, XING T, ZHAO X, et al. Effect of addition of soy isolate on the gelation properties of low-salt wooden chicken breast meat batter[J]. Food Science, 2022, 43(6): 49-56.

[5] 杨子怡, 吴晗, 饶伟丽, 等. 复合磷酸盐对3类肉制品品质的影响研究[J]. 现代食品, 2020(14): 15-17. [YANG Z Y, WU H, RAO W L, et al. Effect of compound phosphate on the quality of three kinds of meat products[J]. Modern Food, 2020(14): 15-17. ] [6] 王莹. 魔芋胶与黄原胶复配对鸡胸肉糜品质的影响[J]. 现代食品, 2021(17): 196-199. [WANG Y. The compound of konjac gum and xanthan gum impact on the quality of chicken breast minced[J]. Modern Food, 2021(17): 196-199. ] [7] 杨晓东, 张杨, 张寿, 等. 胶原蛋白肽的提取及应用研究进展[J]. 食品工业科技,2022,43(9):469−476. [YANG X D, ZHANG Y, ZHANG S, et al. Research progress in extraction and application of collagen peptides[J]. Science and Technology of Food Industry,2022,43(9):469−476. YANG X D, ZHANG Y, ZHANG S, et al. Research progress in extraction and application of collagen peptides[J]. Science and Technology of Food Industry, 2022, 43(9): 469-476.

[8] 梁健华. 胶原蛋白的提取、性质及其应用的研究进展[J]. 现代食品,2021(16):44−49. [LIANG J H. Research progress in extraction, properties and application of collagen[J]. Modern Food,2021(16):44−49. LIANG J H. Research progress in extraction, properties and application of collagen[J]. Modern Food, 2021(16): 44-49.

[9] VAHTSEVANOS K, CHATZIAVRAMIDIS A, PAPADIOCHOS I Y, et al. Prevention of Frey's syndrome with the use of porcine dermal collagen graft: Retrospective analysis of 76 "Formal" parotidectomies for benign pathologies[J]. The Annals of Otology, Rhinology and Laryngology,2021,130(9):1036−1043. doi: 10.1177/0003489421990185

[10] LI C Y, FU Y, DAI H J, et al. Recent progress in preventive effect of collagen peptides on photoaging skin and action mechanism[J]. Food Science and Human Wellness,2022,11(2):218−229. doi: 10.1016/j.fshw.2021.11.003

[11] TANG C, ZHOU K, ZHU Y C, et al. Collagen and its derivatives: From structure and properties to their applications in food industry[J]. Food Hydrocolloids, 2022: 131.

[12] FAN R, ZHOU D, CAO X L. Evaluation of oat β-glucan-marine collagen peptide mixed gel and its application as the fat replacer in the sausage products[J]. PloS One,2020,15(5):e0233447. doi: 10.1371/journal.pone.0233447

[13] TIAN J, WALAYAT N, DING Y T, et al. The role of trifunctional cryoprotectants in the frozen storage of aquatic foods: Recent developments and future recommendations[J]. Comprehensive Reviews in Food Science and Food Safety,2021,21(1):321−339.

[14] WANG W L, CHEN M S, WU J H, et al. Hypothermia protection effect of antifreeze peptides from pigskin collagen on freeze-dried Streptococcus thermophiles and its possible action mechanism[J]. LWT-Food Science and Technology,2015,63(2):878−885. doi: 10.1016/j.lwt.2015.04.007

[15] 余文杰. 猪皮明胶对冷冻面团及其面包品质的影响与机理研究[D]. 无锡: 江南大学, 2020: 30-35 YU W J. Effect of pigskin gelatin on frozen dough and its bread quality and mechanistic study[D]. Wuxi: Jiangnan University, 2020: 30-35.

[16] 赵莹, 曹慧, 徐斐, 等. 猪皮胶原酶解复合物在冰淇淋中的应用[J]. 食品与发酵工业,2014,40(12):94−98. [ZHAO Y, CAO H, XU F, et al. Application of enzymatic hydrolysate from pigskin collagen in ice cream[J]. Food and Fermentation Industries,2014,40(12):94−98. ZHAO Y, CAO H, XU F, et al. Application of enzymatic hydrolysate from pigskin collagen in ice cream[J]. Food and Fermentation Industries, 2014, 40(12): 94-98.

[17] 张艳艳, 王文涛, 张中义, 等. 真空协同大豆分离蛋白复合冷冻保护剂对速冻饺子馅品质的影响[J]. 食品科学,2020,41(19):105−110. [ZHANG Y Y, WANG W T, ZAHNG Z Y, et al. Effect of vacuum treatment combined with soybean protein isolate-based composite cryoprotectant on the quality of quick-frozen dumpling stuffing[J]. Food Science,2020,41(19):105−110. ZHANG Y Y, WANG W T, ZAHNG Z Y, et al. Effect of vacuum treatment combined with soybean protein isolate-based composite cryoprotectant on the quality of quick-frozen dumpling stuffing[J]. Food Science, 2020, 41(19): 105-110.

[18] 高雪琴. 大豆分离蛋白和卡拉胶复配对调理猪肉制品品质的影响及机理研究[D]. 南京: 南京农业大学, 2015: 55−69 GAO X Q. Studies of effects and mechanism of soybean protein isolate and carrageenan on qualities of prepared pork products[D]. Nanjing: Nanjing Agricultural University, 2015: 55−69.

[19] PAN N, DONG C H, DU X, et al. Effect of freeze-thaw cycles on the quality of quick-frozen pork patty with different fat content by consumer assessment and instrument-based detection[J]. Meat Science, 2020: 172.

[20] 徐树来. 食品感官分析与实验[M]. 第三版. 北京: 化学工业出版社, 2020: 39−73 XU S L. Sensory analysis and experiment of foods[M]. Third edition. Beijing: Chemical Industry Press, 2020: 39−73.

[21] ZHANG M C, XIA X F, LIU Q, et al. Changes in microstructure, quality and water distribution of porcine longissimus muscles subjected to ultrasound-assisted immersion freezing during frozen storage[J]. Meat Science, 2019: 151.

[22] 黄莉, 孔保华, 张韩杰, 等. 冻藏温度对冷冻水饺肉馅品质和微观结构的影响[J]. 现代食品科技,2016,32(9):234−473. [HUANG L, KONG B H, ZHANG H J, et al. Influence of frozen storage temperature on quality and microstructure of frozen pork dumpling filling[J]. Modern Food Science and Technology,2016,32(9):234−473. [HUANG L, KONG B H, ZHANG H J, et al. Influence of frozen storage temperature on quality and microstructure of frozen pork dumpling filling[J]. Modern Food Science and Technology, 2016, 32(9): 234-473. ]

[23] WANG W H, WANG X, ZHAO W P, et al. Impact of pork collagen superfine powder on rheological and texture properties of Harbin red sausage[J]. Journal of Texture Studies,2018,49(3):300−308. doi: 10.1111/jtxs.12300

[24] 宋永, 王海燕, 李秀凉, 等. 鱼鳞水解胶原蛋白在蛋糕和灌肠中的应用[J]. 食品科学,2010,31(12):293−296. [SONG Y, WANG H Y, LI X L, et al. Application of fish scales collagen hydrolysate for the production of cake and sausage[J]. Food Science,2010,31(12):293−296. SONG Y, WANG H Y, LI X L, et al. Application of fish scales collagen hydrolysate for the production of cake and sausage[J]. Food Science, 2010, 31(12): 293-296.

[25] 赵颖, 郝立静. 猪皮胶原蛋白在模拟腌肉制品中的应用[J]. 中国食品添加剂,2019,30(5):96−100. [ZHAO Y, HAO L J. Application of pork collagen in simulated cured meat products[J]. China Food Additives,2019,30(5):96−100. ZHAO Y, HAO L J. Application of pork collagen in simulated cured meat products[J]. China Food Additives, 2019, 30(5): 96-100.

[26] 陈俊文, 刘巧瑜, 李湘銮, 等. 解冻方式、反复冻融对猪肉品质的影响[J]. 食品工业,2021,42(4):14−17. [CHEN J W, LIU Q Y, LI X L, et al. Effects of freezing methods and repeated freezing-thawing on pork quality[J]. The Food Industry,2021,42(4):14−17. CHEN J W, LIU Q Y, LI X L, et al. Effects of freezing methods and repeated freezing-thawing on pork quality[J]. The Food Industry, 2021, 42(4): 14-17.

[27] 邹烨, 吴瑀婕, 卢方云, 等. 超声辅助鸡爪胶原蛋白肽处理对鸡胸肉贮藏品质的影响[J]. 肉类研究,2021,35(12):38−45. [ZHOU Y, WU Y J, LU F Y, et al. Effect of ultrasound-assisted chicken feet collagen peptide treatment on the storage quality of chicken breast meat[J]. Meat Research,2021,35(12):38−45. ZHOU Y, WU Y J, LU F Y, et al. Effect of ultrasound-assisted chicken feet collagen peptide treatment on the storage quality of chicken breast meat[J]. Meat Research, 2021, 35(12): 38-45.

[28] 毛云, 周昱宇, 刘静雅, 等. 不同种类脂肪替代物对牦牛肉糜凝胶品质特性影响的研究[J/OL]. 食品与发酵工业: 1−12[2022-10-10]. DOI: 10.13995/j.cnki.11-1802/ts.030443. MAO Y, ZHOU Y Y, LIU J Y, et al. Effects of different kinds of fat substitutes on gel quality characteristics of yak meat surimi[J/OL]. Food and Fermentation Industries:1−12[2022-10-10].

[29] ONODERA M, FUKAE R, EGUCHI S, et al. Rheological properties of mixed agar gels and collagen-peptide from tilapia scales[J]. Journal of the Japanese Society for Food Science and Technology,2012,59(1):22−33. doi: 10.3136/nskkk.59.22

[30] 张极震, 章正廉, 张文定, 等. 胶原蛋白与水的相互作用 Ⅱ. 胶原纤维的水合及其热稳定性[J]. 生理科学,1982(9):28. [ZHANG J Z, ZAHNG Z L, ZHANG W D, et al. The interaction between collagen and water Ⅱ. Hydration and thermal stability of collagen fibers[J]. Basic and Clinical Medicine,1982(9):28. [ZHANG J Z, ZAHNG Z L, ZHANG W D, et al. The interaction between collagen and water Ⅱ. Hydration and thermal stability of collagen fibers[J]. Basic and Clinical Medicine, 1982(9): 28. ]

[31] ABDOLLAHI M, REZAEI M, JAFARPOUR A. et al. Sequential extraction of gel-forming proteins, collagen and collagen hydrolysate from gutted silver carp (Hypophthalmichthys molitrix), a biorefinery approach[J]. Food Chemistry,2018,242:568−578. doi: 10.1016/j.foodchem.2017.09.045

[32] 杨柳, 张一, 王磊, 等. LF-NMR技术在肉及肉制品研究中的应用[J]. 食品工业,2016,37(5):226−228. [YANG L, ZHANG Y, WANG L, et al. Application of LF-NMR technology in meat and products research[J]. The Food Industry,2016,37(5):226−228. YANG L, ZHANG Y, WANG L, et al. Application of LF-NMR technology in meat and products research[J]. The Food Industry, 2016, 37(5): 226-228.

[33] PEARCE K L, ROSENVOLD K, ANDERSEN H J, et al. Water distribution and mobility in meat during the conversion of muscle to meat and ageing and the impacts on fresh meat quality attributes—A review[J]. Meat Science,2011,89(2):111−124. doi: 10.1016/j.meatsci.2011.04.007

[34] 高晶晶. 鳕鱼胶原蛋白在食品加工中的应用[J]. 农产品加工(学刊),2014(20):79−80. [GAO J J. Application of cod fish collagen in food industry[J]. Academic Periodical of Farm Products,2014(20):79−80. GAO J J. Application of cod fish collagen in food industry[J]. Academic Periodical of Farm Products, 2014(20): 79-80.

-

期刊类型引用(4)

1. 张腾腾,高晓光,刘晓畅,雷元华,谢鹏,孙宝忠,晓虎,看卓才仁,尕松扎西,巴永吉,高晓炜,张松山. 动物源副产物胶原蛋白肽的制备及其在食品工业中的应用研究进展. 肉类研究. 2024(01): 67-74 .  百度学术

百度学术

2. 刘琳,胡清雨,郑佳楠,张业辉,焦文娟,佘文海,黄文. 脆肉罗非鱼皮胶原蛋白肽的性质研究. 中国食品添加剂. 2024(06): 70-76 .  百度学术

百度学术

3. 李文娟,徐兰梦,章杰,廖勤丰,李龙娇,张廷焕,郭宗义,何航. 荣昌猪和杜洛克猪猪皮营养组成比较分析. 肉类研究. 2024(05): 21-26 .  百度学术

百度学术

4. 刘泽祺,李明霞,杨琳,郑华,林捷,吴绍宗,郭宗林,雷红涛. 畜禽副产物腥味形成机制及脱腥方法研究进展. 食品安全质量检测学报. 2023(16): 86-93 .  百度学术

百度学术

其他类型引用(1)

下载:

下载:

下载:

下载: