Effects of Rhodobacter sphaeroides Crude Extracts on Volatile Flavor Substances and Flavor Amino Acids of Sausages During Storage

-

摘要: 为探究类球红细菌粗提物对香肠贮藏期挥发性风味物质及呈味氨基酸的影响,在加工香肠时分别添加高中低浓度的类球红细菌粗提物,以不添加类球红细菌粗提物的香肠作为对照,利用顶空固相微萃取-气相色谱-质谱联用技术(HS-SPME-GC-MS)和氨基酸分析仪分别测定香肠贮藏3个月和6个月时的挥发性风味物质和游离氨基酸。结果表明,GC-MS共检测出36种挥发性风味物质,其中醇类17种、酯类1种、醛类10种、酸类2种、烷烃类3种、其它成分3种,共有8种主体风味物质。多元统计分析表明,贮藏3个月时,添加类球红细菌粗提物香肠的醇类物质含量及种类低于对照组;贮藏6个月时,添加类球红细菌粗提物香肠的醇类物质含量高于对照组,但醛类物质含量低于对照组,且粗提物促进了唯一酯类物质己酸乙烯酯的生成。添加低浓度的类球红细菌粗提物降低了庚醛、辛酸等异味物质的含量。氨基酸分析表明,类球红细菌粗提物提高了香肠鲜味和甜味氨基酸的占比。味觉活性值(taste activity value,TAV)分析表明,组氨酸TAV值最大,对香肠滋味影响最强。本研究为基于类球红细菌代谢物提升传统中式香肠风味品质提供了一定的理论依据和技术支撑。Abstract: In order to test the effects of the crude extracts from Rhodobacter sphaeroides (CCRS) on the volatile flavor substances and flavor amino acids of sausages during storage, the sausages were respectively processed with addition of CCRS at higher, medium and lower concentrations. Sausage processed without addition of CCRS was used as control. The volatile flavor substances and free amino acids were respectively analyzed using headspace solid-phase micro-extraction gas chromatography mass spectrometry (HS-SPME-GC-MS) and amino acid analyzer. The experimental results showed that a total of 36 volatile flavor substances were detected by GC-MS, including 17 alcohols, 1 ester, 10 aldehydes, 2 acids, 3 alkanes and 3 other components, among which 8 substances were considered the main flavor substances. Multivariate statistical analysis showed that the content and types of alcohols in sausages added CCRS were lower than those in control after 3 months storage. After 6 months storage, the alcohol content in the sausages with CCRS was higher than that of the control. However, the aldehyde content of the sausages with CCRS was lower than that of the control. Moreover, the CCRS promoted the production of ethenyl hexanoate, which was the only one ester in the sausages. On the other hand, the addition of low concentration of CCRS reduced the content of heptaldehyde, octanoic acid and other odor substances. Amino acid analysis suggested that the CCRS increased the proportion of delicate and sweet amino acids. The taste activity value (TAV) analysis indicated that the histidine TAV value was the strongest and had the greatest impact on sausage taste. The present study would provide a theoretical basis and technical support for enhancing the flavor quality of Chinese traditional sausages based on the metabolites of Rhodobacter sphaeroides.

-

Keywords:

- Rhodobacter sphaeroides /

- fermented extracts /

- sausages /

- volatile flavor substances /

- amino acids

-

香肠加工及贮藏过程中,脂质氧化产生醛、酮和低级脂肪酸,蛋白质降解为肽和游离氨基酸,从而赋予香肠独特的风味[1]。内源酶和微生物是决定传统中式香肠风味品质的重要因素。冯美琴等[2]研究发现接种模仿葡萄球菌NJ201能提高发酵香肠酮类、酯类的含量,有效促进香肠风味的形成。木糖葡萄球菌YCC3和植物乳杆菌MSZ2可提高香肠挥发性化合物含量[3]。植物乳杆菌X19-2D加入羊肉发酵香肠可促进呈味氨基酸的释放,从而改善发酵香肠的风味[4]。张旭[5]研究发现,中性脂肪酶、酸性脂肪酶等内源酶可促进川式香肠醇类风味物质的生成。此外,香肠加工过程中加入天然提取物也可改善风味特征,如巴尔干式香肠加工过程中加入啤酒花提取物可降低由脂质氧化产生的挥发性化合物含量,生成特定萜类风味化合物[6]。羊肉香肠加工过程中加入沙葱提取物可增加3-羟基-2-丁酮、3-甲基丁醛、己醛、辛醛、壬醛、二甲基二硫等挥发性风味物质的含量[7]。

类球红细菌属光合细菌,代谢产物富含辅酶Q10、类胡萝卜素、超氧化物歧化酶等抗氧化活性物质。辅酶Q10是一种类似于维生素的脂溶性苯醌,也可作为保健食品原料[8]。类胡萝卜素是天然色素,具有清除自由基的能力[9]。超氧化物歧化酶是抗氧化金属酶,在机体氧化与抗氧化平衡中起到至关重要的作用[10]。此外,类球红细菌培养简单、易控,可进行规模化生产[11]。方立超[11]研究发现类球红细菌具有良好的抗氧化作用,并且安全无副作用。研究发现,在白虾和罗非鱼膳食中加入类球红细菌提取物,可提高其存活率[12-13]。

香肠过度氧化会产生酸败味、哈喇味,从而影响香肠的风味,而抗氧化剂的合理使用,也能影响香肠风味与滋味变化,有助于香肠的贮藏[14],如茶多酚可减缓腊肉风味的衰减[15]。类球红细菌粗提物具有良好的抗氧化特性,可开发成抗氧化剂用于稳定香肠风味品质。类球红细菌粗提物可抑制香肠脂肪与蛋白质的氧化[16],但类球红细菌粗提物对香肠挥发性风味和游离氨基酸的影响尚未见报道。本研究将不同浓度类球红细菌粗提物加入香肠中,探究其对贮藏期香肠挥发性风味和游离氨基酸的影响,为基于类球红细菌提取物提升香肠品质提供一定的理论基础和技术支撑。

1. 材料与方法

1.1 材料与仪器

类球红细菌Rhodobacter sphaeroides 2.4.1(分离自海洋) 德国吉森大学Gabriele Klug教授惠赠;猪肉 购自四川高金食品;猪肠衣 购于十陵友谊市场;氯化钠、盐酸、柠檬酸钠、乙酸钠、乙腈 均为分析纯,成都市科隆化学品有限公司。

BCD-452WDPF冰箱 青岛海尔集团;YP302N型电子天平 上海菁海仪器有限公司;5977A-7890B型气相色谱-质谱联用仪(含PAL3自动进样器) 美国安捷伦公司;LC98-I AAA型氨基酸分析仪 北京温分分析仪器技术开发有限公司;HC-2518型台式高速离心机 湘仪设备有限公司;GR60DA型立式自动压力蒸汽灭菌器 致微(厦门)仪器有限公司;SPH-2102C型立式双层全温度恒温培养振荡器 上海程造仪器设备有限公司;Scientz-650E型超声波细胞粉碎机 宁波新芝生物科技股份有限公司。

1.2 实验方法

1.2.1 类球红细菌培养及粗提物制备

类球红细菌Rhodobacter sphaeroides活化后以2%(V/V)接种于RÄ液体培养基中,30 ℃微氧培养48 h[17],共6 L。将6 L培养液在8000×g,4 ℃条件下离心10 min,用生理盐水重悬后超声波破碎(每2 L培养液所含菌体,用35 mL生理盐水重悬)。超声波破碎条件:功率325 W,总时间40 min;超声波破碎后在10000×g,4 ℃条件下离心20 min,上清即为类球红细菌粗提物。粗提物成分主要为蛋白质(酶)、类胡萝卜素和辅酶Q10等成分[18]。

1.2.2 香肠的制备

将10 kg肉切成细丝(肥瘦比为3︰7,肉丝长10 cm、宽0.3 cm、高0.3 cm),加入2.5%食盐(w/w)混匀后分成4份,每份2.5 kg。按每kg分别加入0、0.4、0.8和1.2 L类球红细菌发酵液提取的粗提物,命名为空白A组、D组、C组、B组。每节香肠长15 cm,粗约3.5 cm,灌肠后进行智能仿天然风干(白天12 ℃,晚上8 ℃,相对湿度70%~80%)。风干结束(风干7 d,香肠失水率达到30%)后真空包装常温贮藏3个月和6个月;贮藏3个月样品记为A3、B3、C3和D3,贮藏6个月样品记为A6、B6、C6和D6。

1.2.3 挥发性风味物质的测定

GC-MS检测:将香肠切碎后,精确称取3 g置于15 mL的顶空瓶中密封,每组香肠3个平行。设置CTC自动进样器对香肠的前处理条件如下:加热箱温度60 ℃,加热时间30 min,抽取时间30 min,解析时间5 min。

色谱、质谱条件参考张旭等[19]实验条件。GC条件:HP-5MS UI色谱柱(30 m×0.25 mm,0.25 μm);压力32.0 kPa;流速1.0 mL/min;载气为He气,不分流进样;进样口温度250 ℃;升温程序:起始温度40 ℃,保持1 min,以3 ℃/min升至85 ℃,保持3 min,再以3 ℃/min升至105 ℃,保持2 min,再以12 ℃/min升至165 ℃,再以10 ℃/min升至230 ℃。MS条件:电子电离源(EI);电子能量70 eV;离子源温度230 ℃,四级杆温度150 ℃;检测器电压350 V;质量扫描范围(m/z):40~500。

定性:对化合物进行定性分析,将所得到的数据在仪器中NIST 14.L谱库进行检索和匹配,选择匹配程度高于80%的物质。同时结合参考文献以及相关网络数据库进行定性分析。

定量:使用峰面积对总离子流色谱图归一化定量,最终计算出各组分的相对含量。

1.2.4 游离氨基酸的测定

采用LC98-I AAA型氨基酸分析仪分别测定8组香肠游离氨基酸。

样品处理参考王卫等[20]方法,称取肉样3 g于水解管中,加入15 mL 6 mol/L盐酸溶液,混匀后冷冻5 min,密封后放入110 ℃烘箱中水解22 h,冷却至室温,水解液过滤至50 mL比色管中,定容至50 mL。移取1 mL滤液至25 mL尖底浓缩瓶,45 ℃减压干燥后用1 mL水溶解;再次减压干燥后用1 mL pH2.2的柠檬酸钠缓冲液溶解,经0.22 μm水相滤膜过滤,滤液即为待测液。取200 μL待测液加入衍生试剂于40 ℃衍生1 h,然后加入400 μL正己烷混匀,静置10 min分层后取下层液体测定。LC98-I AAA型氨基酸分析仪测定条件:流动相A为乙酸钠,流动相B为乙腈,氨基酸分析专用ODS柱(Inertsil ods-35 μm,4.6 mm×250 mm),柱温40 ℃,波长254 nm,流速1 mL/min。

1.3 数据处理

表格由Microsoft Office Excel软件完成,采用IMB SPSS Statistics 24进行显著性分析,采用Origin 2017、SIMCA 14.1、TBtools、Canoco 5分析作图。

2. 结果与分析

2.1 贮藏期香肠挥发性风味分析

2.1.1 贮藏期香肠挥发性风味物质组成和含量

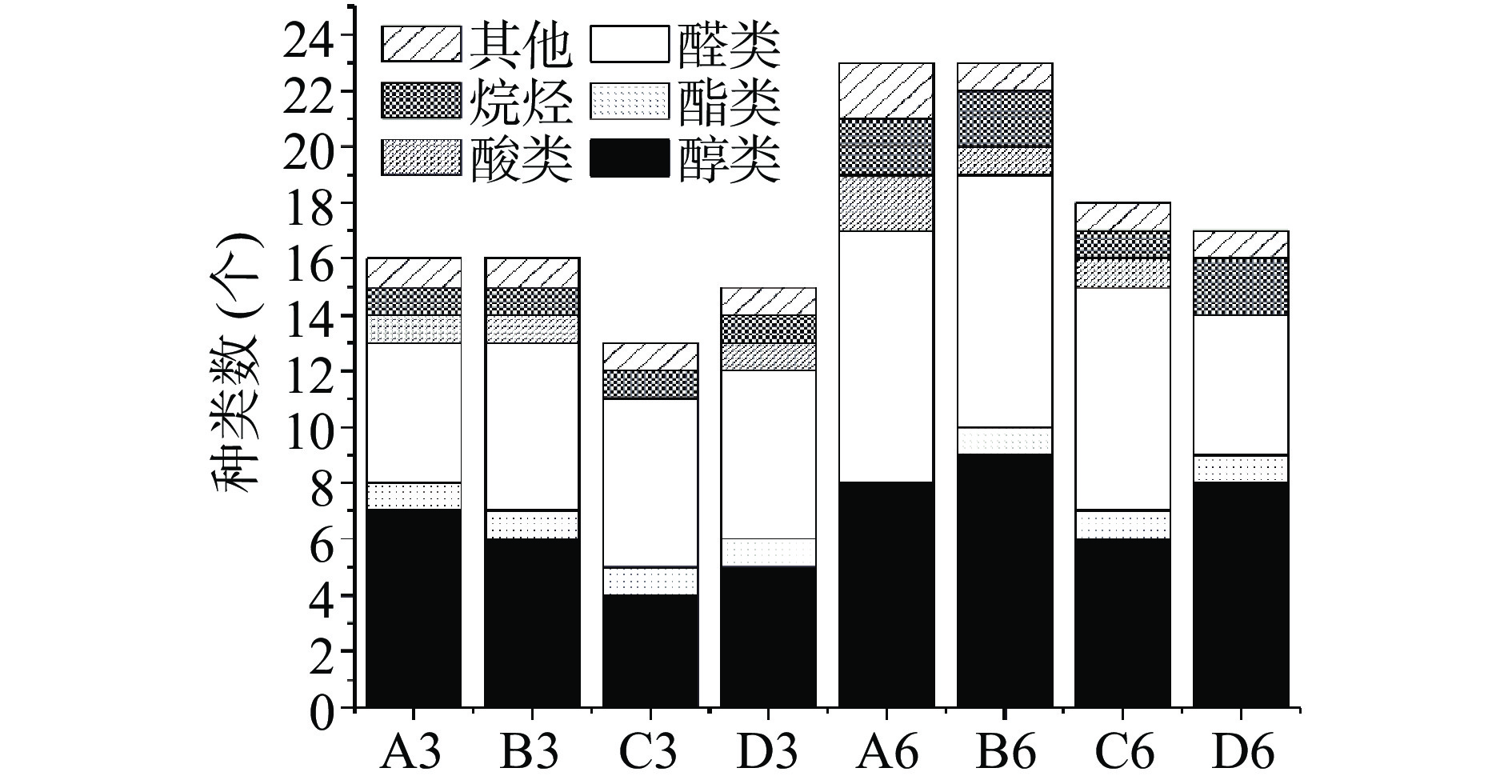

贮藏过程中,香肠挥发性风味物质的数量发生了一定变化,如图1所示。利用GC-MS从香肠中共检测出五类挥发性风味物质,包括醇类、酯类、醛类、酸类、烷烃类,其中醇类、醛类为主要的风味物质。从图1可知,C3挥发性风味物质种类数最少,且无酸类物质。贮藏3个月时,样品间醇类物质种类数差异最大。随贮藏时间的延长,香肠挥发性风味物质的数量呈上升趋势,在贮藏过程中,挥发性化合物不断累积。与贮藏3个月相比,贮藏6个月时,各组香肠的醇类物质的数量均增加,可能是随贮藏时间的延长,脂肪酸氧化降解加剧[21]。D6香肠无酸类挥发性风味物质;A6香肠无酯类挥发性风味物质,可能是A6香肠酸酐与醇反应生成酯的过程受到抑制所致[22]。B6香肠检测出9种醇类物质,高于其它组香肠,可能是贮藏过程中,其它组香肠醇类物质发生酯化、氧化反应,而B组粗提物用量较高,对酯化、氧化反应的抑制作用较强[23]。醛类是传统中式香肠的第二大类挥发性风味物质[24],从图1可知,A、B、C组的醛类风味物质数量随贮藏时间的增加而增加,但D组香肠醛类物质种类减少,可能是D组香肠醛类还原生成了醇[25],D6香肠中醇类种数的增加印证了这一推论。

类球红细菌粗提物对香肠挥发性风味物质的种类和相对含量均产生了显著的影响,结果如表1所示。GC-MS共测出36种挥发性风味物质,其中醇类17种、酯类1种、醛类10种、酸类2种、烷烃类3种、其它成分3种。

表 1 香肠贮藏期挥发性风味组成及含量(%)Table 1. Volatile flavor composition and content of different sausages during storage(%)名称 RT CAS A3 B3 C3 D3 A6 B6 C6 D6 醇类 正己醇 6.35 111-27-3 1.56±0.00c 2.11±0.00c 3.18±0.0 c 0.90±0.00c 4.37±0.01c 18.06±0.02b 18.42±0.05b 24.84±0.04a 1-庚炔-3-醇 9.37 7383-19-9 4.57±0.00 − − − − − − 2.82±0.00 1-辛烯-3-醇 10.38 3391-86-4 8.35±0.00b 8.88±0.00b 10.94±0.01a 8.90±0.01b 4.74±0.00d 5.37±0.00cd 6.26±0.01c 9.37±0.00a 3,5 -辛二烯-2-醇 12.96 69668-82-2 0.75±0.00 0.57±0.00 − 0.71±0.00 0.47±0.00 0.27±0.00 − − 反-2-十一烯醇 14.41 75039-84-8 − − − 1.23±0.01 − − − − 3-甲基-1,6-庚二烯-3-醇 15.41 34780-69-3 3.92±0.00 − 2.92±0.00 − − − − − 正庚醇 10.05 111-70-6 0.59±0.00 0.59±0.00 0.82±0.00 − 0.71±0.00 1.01±0.00 1.04±0.002 1.31±0.00 顺-2-壬烯-1-醇 14.39 41453-56-9 0.87±0.00 1.29±0.01 − − − − − − 4.5-二甲基-2-庚烯-3-醇 15.44 55956-37-1 − 4.18±0.01 − 4.38±0.01 6.56±0.00 5.29±0.01 4.56±0.01 2.77±0.00 环辛醇 14.31 696-71-9 − − − − − − 0.45±0.00 0.41±0.00 2-壬烯-1-醇 14.464 22104-79-6 − − − − − 1.61±0.00 − − 4-乙基-1-辛炔-3-醇 12.77 5877-42-9 − − − − 0.42±0.00 − − − (-)-异松蒎醇 13.25 27779-29-9 − − − − 0.35±0.00 − − − 4-乙基环己醇 12.768 4534-74-1 − − − − − 0.32±0.00 − − 4-甲基-4 -硝基戊醇-1-醇 19.78 5215-92-9 − − − − − 0.58±0.00 − 1.57±0.00 4,4,6-三甲基-环己-2-辛烯-1-醇 28.88 1000144-64-7 − − − − 0.37±0.00 0.40±0.00 0.30±0.00 − 苯乙醇 16.28 60-12-8 − − − − − − − 0.51±0.00 总量 19.06 17.61 17.85 16.13 18.00 32.90 31.02 43.60 酯类 己酸乙烯酯 13.93 3050-69-9 6.42±0.02 8.35±0.00 7.15±0.01 9.56±0.00 − 7.71±0.00 7.68±0.01 6.27±0.01 醛类 正己醛 4.38 66-25-1 50.99±0.01a 47.76±0.05a 50.93±0.03a 49.06±0.02a 33.14±0.02b 27.51±0.03b 27.28±0.03b 15.44±0.01c 庚醛 7.30 111-71-7 2.82±0.00a 2.91±0.00a 2.63±0.00ab 3.01±0.00a 2.31±0.00abc 1.62±0.00cd 2.02±0.01bcd 1.41±0.00d 反-2-辛烯醛 13.75 2548-87-0 5.47±0.02 a 3.65±0.00abc 2.48±0.00c 4.39±0.01ab 3.67±0.00abc 2.78±0.00bc 2.20±0.00c 1.90±0.00c 壬醛 15.87 124-19-6 5.59±0.00a 5.74±0.01a 6.23±0.01a 5.55±0.00a 6.05±0.00a 5.89±0.00a 6.03±0.00a 5.62±0.00a 反式-2-壬醛 18.73 18829-56-6 0.65±0.00 − 0.57±0.00 0.75±0.00 0.91±0.00 0.67±0.00 0.66±0.00 0.54±0.00 (E,E)-2,4-壬二烯醛 10.83 5910-87-2 − 0.98±0.00 − − 0.69±0.00 0.67±0.00 − − (E)-2-庚烯醛 9.38 18829-55-5 − 2.13±0.01 1.32±0.00 2.07±0.001 1.58±0.00 1.32±0.00 1.71±0.00 − 反式-2-癸烯醛 24.59 3913-81-3 − − − − 0.79±0.00 0.66±0.00 0.54±0.00 2-十一烯醛 29.61 2463-77-6 − − − − 0.41±0.00 0.41±0.00 0.37±0.00 桃醛 29.61 104-67-6 − − − − − − − 0.43±0.00 总量 65.52 63.17 64.15 64.82 49.55 41.52 40.810.41 25.34 酸类 己酸 12.11 142-62-1 2.57±0.01 2.97±0.01 2.45±0.01 9.80±0.01 6.34±0.00 4.95±0.01 辛酸 20.40 124-07-2 − − − − 0.39±0.00 - − − 总量 2.57 2.97 0.00 2.45 10.20 6.34 4.95 0.00 烷烃类 1-氯戊烷 3.76 543-59-9 2.90±0.00b 2.69±0.00bc 3.23±0.00ab 3.34±0.01ab 2.16±0.00c 3.25±0.00bc 3.77±0.00a 2.15±0.00 2,3-环氧-4,4-二甲基戊烷 3.20 53897-30-6 − − − − − − − 0.45±0.00 (Z)3-乙基-2-甲基-1,3-己二烯 12.50 74752-97-9 − − − − 0.41±0.00 0.32±0.00 − − 总量 2.90 2.69 3.23 3.34 2.58 3.58 3.770.04 2.60 其他 氯甲基辛基醚 14.44 24566-90-3 − − − − − − 0.73±0.00 1.10±0.00 2,4,6-三甲基吡啶 10.92 108-75-8 1.78±0.01 4.48±0.03 5.13±0.00 1.79±0.01 10.67±0.01 7.76±0.01 10.26±0.01 21.36±0.03 己酸酐 13.94 2051-49-2 − − − − 9.09±0.01 − − − 总量 1.78 4.48 5.13 1.79 19.76 7.76 10.99 22.46 注:表中各组物质均检出时标注显著性,a、b、c字母不同表示显著性差异(P<0.05);−代表未检出。 醇类物质来源广泛,蛋白质水解、乳糖代谢、甲基酮还原、氨基酸代谢、脂质氧化产生的醛,还原后均可生成相应的醇[26]。贮藏3个月时,类球红细菌粗提物降低了香肠中的醇类含量。贮藏6个月时,香肠正己醇含量显著高于对照组(P<0.05) ,且D6香肠中含量最高。2-壬烯-1-醇仅在B6香肠中被检出,4-乙基-1-辛炔-3-醇、(-)-异松蒎醇仅在A6香肠中被检出。苯乙醇具有清香、甜、花香和玫瑰香气,对丰富香肠风味有重要作用[27],仅在D6香肠中被检出。贮藏3个月时,反-2-十一烯醇仅在D3香肠中被检出,其具有霉味和湿润的泥土味[28]。

酯类物质主要由肌肉组织中脂质氧化产生的醇和游离脂肪酸发生酯化反应形成的[25],己酸乙烯酯是唯一被检出的酯类物质,具有令人愉悦的果香;A6中未检出己酸乙烯酯,可能归因于酸酐与醇生成酯的过程受到抑制[22],也可能是生成的酯在脂肪酶的作用下发生酯交换反应,形成了醛[29]。

醛类来源于甘油三酯的水解和脂肪酸氧化,如不饱和脂肪酸的氧化降解和氨基酸的Strecker降解[30]。醛类阈值较低,且风味有叠加作用,是肉类食品风味的重要来源,短链醛倾向于辛辣或酸性[31]。贮藏3个月时,A3香肠中无(E)-2-庚烯醛检出,表明添加粗提物可能促进(E)-2-庚烯醛生成,(E)-2-庚烯醛具有果香、芳香味,能丰富香肠风味[32]。B3香肠中有(E,E)-2,4-壬二烯醛检出。桃醛具有果香、芳香味,仅在D6香肠中被检出。正己醛和庚醛作为亚油酸氧化主要产物,是油脂不良气味和腥味的主要来源[33-36]。D6香肠中庚醛和正己醛含量显著低于对照组(P<0.05),可能是粗提物中的类胡萝卜素使亚油酸氧化受到抑制[37-39]。

己酸和辛酸作为中链酸(C6~C12)主要来自甘油三酯和磷脂的水解。己酸属于脂肪族化合物,来自脂质氧化[40]。己酸作为饱和脂肪酸具有不愉快的椰肉油气味,对香肠风味有消极影响,降低香肠中的己酸含量对香肠风味有积极作用[41]。贮藏6个月时,对照组香肠己酸含量最高,D6香肠中没有检出,可能是粗提物中的类胡萝卜素抑制脂肪氧化,减少己酸含量。辛酸具有不愉快气味和脂肪臭[42],仅在A6香肠中被检出,说明类球红细菌粗提物的添加对稳定香肠风味有重要作用。样品中共检测出3种烷烃,烷烃的感官阈值通常较高,对香肠整体的风味贡献不大。综上所述,D组香肠有效降低了可能造成香肠异味的正己醛、庚醛、辛酸、壬醛的含量。

2.1.2 不同香肠贮藏期挥发性风味物质聚类热图分析

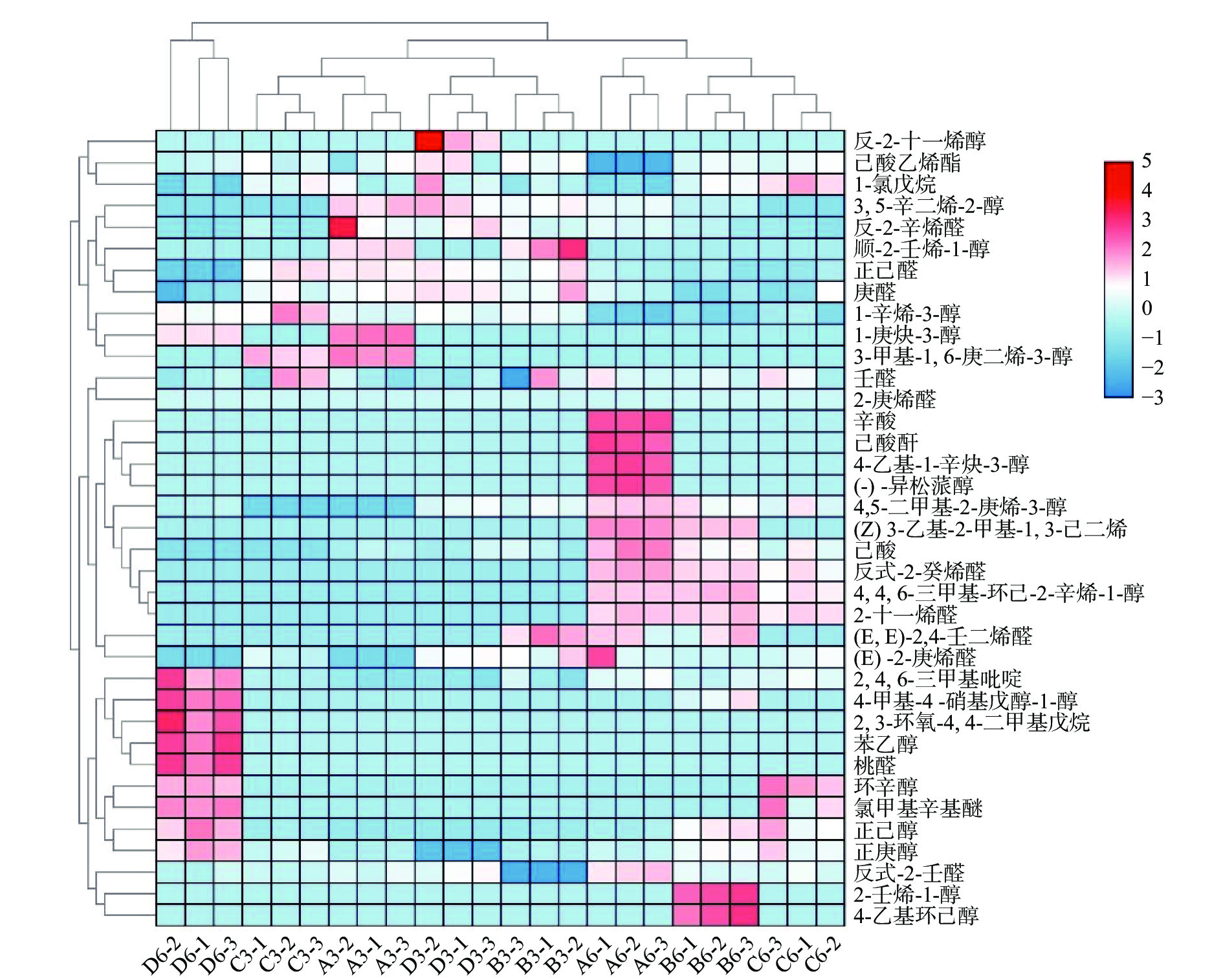

对挥发性风味物质进行聚类分析,以反映所有挥发性风味成分的组间差异,结果如图2所示。从图中可以看出,D6与其它组香肠差异显著,在聚类中单独分为一组。从聚类结果可以看出,贮藏3个月香肠的风味聚为一类,贮藏6个月香肠的风味聚为一类,可知贮藏时间对香肠风味的影响程度大于类球红细菌粗提物添加量影响程度。贮藏3个月时,C组香肠与A组香肠聚为一类,D组香肠与B组香肠聚为一类,表明贮藏3个月提取物添加量对风味影响无线性关系。D6香肠中含量较高的风味物质是苯乙醇、桃醛;而A6香肠中含量较高的风味物质是辛酸、己酸酐。

2.1.3 贮藏香肠主体风味成分

感官阈值直接影响着挥发性成分对产品整体风味的贡献程度。ROAV≥1,说明该组分为香肠中主体风味成分,对香肠风味有直接影响。0.1<ROAV<1说明该组分对香肠风味有修饰作用[43]。经计算共检测出8种主体风味物质,包括正己醇、1-辛烯-3-醇、己酸乙烯酯、正己醛、庚醛、壬醛、反式-2-壬醛、(E,E)-2,4-壬二烯醛,如表2所示。除B3香肠外,反式-2-壬醛对香肠香气贡献最大。1-辛烯-3-醇是贮藏3个月和6个月的主体风味成分,可赋予香肠蘑菇香气[44],正庚醇在所有香肠中均起修饰作用,环辛醇和苯乙醇对香肠风味没有贡献。此外,正己醇仅在D6香肠中作为风味主体成分。除A6香肠外,己酸乙烯酯均作为香肠主体风味成分,且在添加类球红细菌粗提物香肠中的ROAV值远大于对照香肠,说明类球红细菌粗提物有利于己酸乙烯酯香气物质的生成,从而赋予香肠愉悦的果味。庚醛、壬醛是所有香肠的主体风味成分,反-2-辛烯醛在所有香肠中均作为修饰成分,(E,E)-2,4-壬二烯醛是A组香肠的主体风味成分,也是B3、D3香肠的主体风味成分。桃醛为长链醛,具有脂肪香、木香[45],仅在D6香肠中起到修饰作用。

表 2 香肠挥发性物质在水中阈值及ROAV值Table 2. Threshold and ROAV values of sausage volatile substances in water组别 阈值[38]

(mg/kg)A3 B3 C3 D3 A6 B6 C6 D6 正己醇 0.2 0.08 0.13 0.18 0.16 0.88 0.88 0.90 1.50 1-辛烯-3-醇 0.01 8.34 10.65 12.49 3.38 5.24 5.24 6.14 11.35 正庚醇 0.023 0.25 0.31 0.41 0.22 0.43 0.44 0.44 0.69 环辛醇 10 − − − − − 0.00 0.00 0.00 苯乙醇 0.045 − − − − − − − 0.14 己酸乙烯酯 0.001 64.12 100.00 81.64 82.94 − 75.37 75.38 75.96 正己醛 0.21 2.42 2.73 2.77 1.13 1.28 1.27 1.27 0.89 庚醛 0.01 2.82 3.49 3.00 1.64 1.58 1.98 1.98 1.71 反-2-辛烯醛 0.061 0.90 0.72 0.46 0.43 0.45 0.35 0.35 0.38 壬醛 0.035 1.59 1.97 2.03 1.23 1.64 1.69 1.69 1.94 反式-2-壬醛 0.000065 100.00 − 100.00 100.00 100.00 100.00 100.00 100.00 (E,E)-2,4-壬二烯醛 0.0006 2.42 19.61 − 8.17 10.89 − − − (E)-2-庚烯醛 0.75 − 0.03 0.02 0.02 0.02 0.02 − − 反式-2-癸烯醛 0.15 − − − 0.04 0.04 0.04 − − 桃醛 0.025 − − − − − − 0.00 0.21 己酸 81 0.00 0.00 0.00 0.00 0.00 0.00 − − 辛酸 101 − − 0.00 − − − − 注: −代表未检出。 2.1.4 不同香肠挥发性风味主成分分析

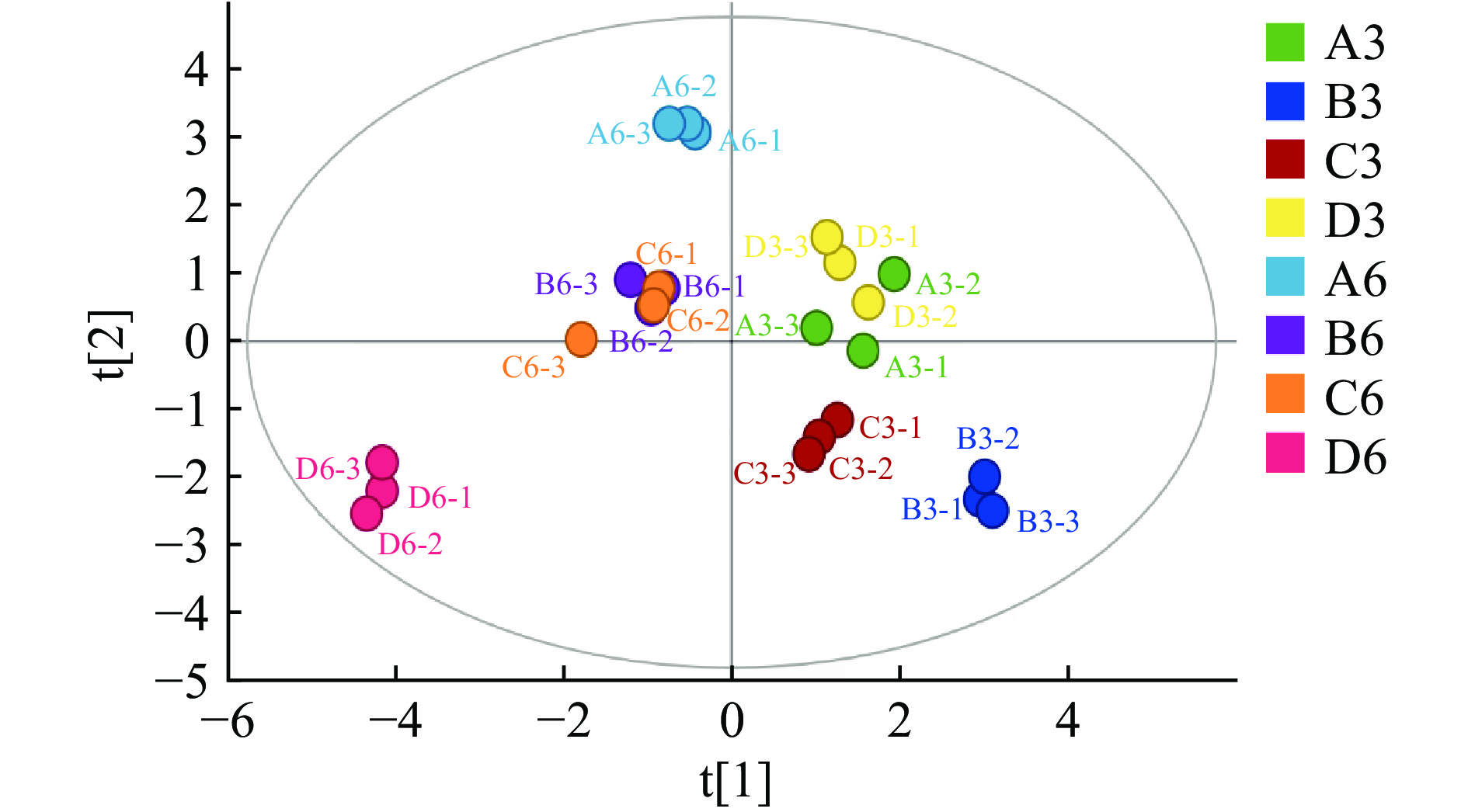

以香肠不同时间段的挥发性风味物质作为数据源,进行主成分分析,结果如图3所示。根据各组香肠挥发性风味间的分布情况,判断不同香肠的挥发性风味物质是否有差异。贮藏3个月与6个月香肠的挥发性风味间距较远,表明随着贮藏时间的延长,香肠挥发性风味物质间有明显差异。贮藏3个月时,A、C和D组香肠距离较近,且A和D组有重叠,说明A、D组香肠挥发性风味差异不显著;B组香肠与其它组香肠挥发性风味物质有显著差异。贮藏6个月时,A组香肠和D组香肠分离明显,距离较远,但B组香肠与C组香肠样本点相互重合,说明添加类球红细菌粗提物后,香肠风味发生了明显变化,但中高添加量的香肠风味差异不大。由图3可知,A6与D6香肠挥发性风味差异最大,且D6组香肠与所有香肠距离较远,与聚类热图结果一致。

2.1.5 贮藏时间和添加量对香肠挥发性风味物质的影响

为研究类球红细菌粗提物添加量和贮藏时间对香肠挥发性风味物质的影响,利用去趋势对应分析(Detrended correspondence analysis,DCA)探究了香肠的挥发性风味物质对香肠整体风味的影响程度,结果显示最长梯度为0.95。因最长梯度小于3,进一步选择Redundancy analysis(RDA)线性模型分析,如图4所示。途中箭头代表不同的影响因素,其长短代表对香肠挥发性物质影响大小。类球红细菌粗提物的添加量与贮藏时间呈现钝角,说明贮藏时间和类球红细菌粗提物添加量与挥发性风味物质呈负相关,可能由于类球红细菌粗提物中含有辅酶Q10、类胡萝卜素等抗氧化活性物质,减缓了香肠的脂质氧化和蛋白质降解[46]。挥发性风味物质与贮藏时间射线的夹角及投影反映了贮藏时间因素对该挥发性风味物质影响的相关性和大小。正己醇、正庚醇、(E,E)-2,4-壬二烯醛、壬醛、己酸乙烯酯、1-辛烯-3-醇、正己醛、庚醛与类球红细菌粗提物的添加量呈锐角,为正相关关系。

2.2 贮藏期香肠氨基酸变化

2.2.1 贮藏期氨基酸含量变化

香肠在贮藏后熟过程中,蛋白质在内源酶和微生物来源酶的作用下被分解为多肽和游离氨基酸[47]。贮藏3个月时,A3香肠总氨基酸含量显著低于B3和C3香肠(P<0.05),但显著高于D3香肠(P<0.05),如表3所示。而贮藏6个月时,A6香肠总氨基酸含量显著低于D6香肠(P<0.05),但显著高于B6和C6香肠。不同贮藏时间,粗提物对总氨基酸含量影响相反。同时,各组香肠必需氨基酸和非必需氨基酸的趋势与总氨基酸趋势一致,表明类球红细菌粗提物的添加促进了蛋白质的水解。谷氨酸和天冬氨酸有利于鲜味滋味的表达[48]。贮藏3个月时,B3和C3香肠谷氨酸和天冬氨酸的含量显著高于A3香肠(P<0.05),说明类球红细菌粗提物促进了谷氨酸和天冬氨酸等鲜味氨基酸的产生,可能是由于类球红细菌粗提物物中含有氨肽酶,促进了游离氨基酸的释放[49]。但贮藏6个月时,A6香肠谷氨酸和天冬氨酸的含量却显著高于B6和C6香肠(P<0.05),但显著低于D6香肠(P<0.05)。

表 3 贮藏期氨基酸含量(mg/100 g)变化Table 3. Changes of amino acid content (mg/100 g) during storage峰名 A3 B3 C3 D3 A6 B6 C6 D6 天冬氨酸 11.410c 17.549b 18.864a 11.973c 56.432B 24.560C 22.340D 71.034A 谷氨酸 14.835c 30.680a 28.890b 13.969d 115.283B 44.295C 41.154D 146.750A 丝氨酸 13.314 55.048 25.284 20.078 97.858 38.274 37.370 123.594 甘氨酸 15.873 16.710 29.122 6.372 134.215 46.528 48.997 151.249 组氨酸 38.256 58.130 67.571 28.752 170.936 82.655 73.690 213.149 精氨酸 21.015 44.956 44.230 16.710 141.625 59.403 58.451 187.688 苏氨酸 26.490 58.757 52.220 22.025 108.013 82.581 78.922 246.031 丙氨酸 4.290 10.083 8.117 3.501 31.421 12.886 12.876 42.619 脯氨酸 49.902 88.019 78.067 38.536 279.652 127.882 126.285 326.562 酪氨酸 32.950 62.290 62.057 25.004 187.595 88.605 84.507 227.311 缬氨酸 23.826 34.256 43.015 14.871 114.686 49.535 44.865 134.881 蛋氨酸 24.819 40.152 37.699 13.824 108.636 48.940 45.035 133.275 异亮氨酸 57.657 22.351 30.238 12.165 117.885 43.413 51.795 132.982 亮氨酸 10.390 55.962 47.947 20.862 194.770 72.293 69.523 228.754 苯丙氨酸 41.860 88.268 84.391 36.568 246.264 123.794 115.770 301.458 赖氨酸 9.340 9.620 13.349 6.679 17.961 13.895 10.888 21.069 总量 396.228c 692.830a 671.060b 291.889d 2123.231B 959.541C 922.469D 2688.407A 注:表中各组物质均检出时标注显著性;a、b、c表示冷藏3个月香肠间的显著性差异(P<0.05);A、B、C表示冷藏6个月香肠间的显著性差异(P<0.05)。 2.2.2 贮藏期香肠游离氨基酸滋味评价

游离氨基酸是主要的呈味物质之一,不同游离氨基酸具有不同呈味特性,主要分为鲜味、甜味、苦味。游离氨基酸之间相互影响作用,对香肠的滋味具有重要的影响。经过氨基酸TAV计算,TAV>1,表明该氨基酸对样品滋味产生影响;TAV值越大,对滋味影响越大。从表4可以看出,天冬氨酸、丝氨酸、苏氨酸、丙氨酸的TAV值较小,对贮藏期香肠滋味影响较小。组氨酸在所有香肠中的TAV值均大于1,说明其对贮藏3个月和6个月的香肠滋味有较大的影响,且随着贮藏时间的延长,对香肠滋味的影响逐渐增大。组氨酸为苦味氨基酸,加入少量提取物能降低组氨酸作用。谷氨酸、精氨酸、缬氨酸、蛋氨酸和苯丙氨酸仅对贮藏6个月的香肠滋味有较大影响,且D6香肠中氨基酸TAV值均高于A6香肠。甘氨酸、酪氨酸、亮氨酸和异亮氨酸仅对D6和A6香肠有影响,并且D6香肠TAV值大于A6香肠。脯氨酸和赖氨酸仅对D6香肠有一定的影响。由表4可知,少量粗提物在贮藏3个月时能显著降低苦味氨基酸作用。由表5可知,贮藏3个月时,添加粗提物能显著增加鲜味和甜味氨基酸占比。

表 4 贮藏期香肠氨基酸TAV值Table 4. The TAV value of sausage amino acids during refrigeration氨基酸名称 A3 B3 C3 D3 A6 B6 C6 D6 滋味阈值[50] 呈味特性[50] 天冬氨酸 0.114 0.175 0.189 0.120 0.564 0.246 0.223 0.710 100 鲜味 谷氨酸 0.494 1.023 0.963 0.466 3.843 1.477 1.372 4.892 30 鲜味 总量 0.608 1.198 1.152 0.586 4.407 1.723 1.595 5.602 丝氨酸 0.089 0.367 0.169 0.134 0.652 0.255 0.249 0.824 150 甜味 甘氨酸 0.122 0.129 0.224 0.049 1.032 0.358 0.377 1.163 130 甜味 苏氨酸 0.102 0.226 0.201 0.085 0.415 0.318 0.304 0.946 260 甜味 丙氨酸 0.072 0.168 0.135 0.058 0.524 0.215 0.215 0.710 60 甜味 脯氨酸 0.166 0.293 0.260 0.128 0.932 0.426 0.421 1.089 300 甜味 总量 0.551 1.183 0.989 0.454 3.555 1.572 1.566 4.732 酪氨酸 0.362 0.685 0.682 0.275 2.061 0.974 0.929 2.498 91 苦味 缬氨酸 0.596 0.856 1.075 0.372 2.867 1.238 1.122 3.372 40 苦味 蛋氨酸 0.827 1.338 1.257 0.461 3.621 1.631 1.501 4.443 30 苦味 异亮氨酸 0.641 0.248 0.336 0.135 1.310 0.482 0.575 1.478 90 苦味 组氨酸 1.913 2.907 3.379 1.438 8.547 4.133 3.685 10.657 20 苦味 精氨酸 0.420 0.899 0.885 0.334 2.832 1.188 1.169 3.754 50 苦味 亮氨酸 0.055 0.295 0.252 0.110 1.025 0.380 0.366 1.204 190 苦味 苯丙氨酸 0.465 0.981 0.938 0.406 2.736 1.375 1.286 3.350 90 苦味 赖氨酸 0.467 0.481 0.667 0.334 0.898 0.695 0.544 1.053 20 苦味 总量 5.746 8.69 9.471 3.865 25.897 12.096 11.177 31.809 表 5 贮藏期香肠不同呈味氨基酸占比(%)Table 5. Proportion of different flavored amino acids in sausages during storage (%)滋味氨基酸类别 A3 B3 C3 D3 A6 B6 C6 D6 甜味氨基酸 8.81 10.82 9.92 11.95 13.02 11.19 11.12 13.29 鲜味氨基酸 7.98 10.69 8.52 9.26 10.50 10.21 10.92 11.23 苦味氨基酸 83.22 78.49 81.56 78.80 76.48 78.59 77.95 75.48 3. 结论

本研究利用顶空固相微萃取-气相色谱-质谱联用技术(HS-SPME-GC-MS)从添加类球红细菌粗提物香肠及对照香肠中共检测出36种挥发性风味物质,包括醇类17种,酯类1种,醛类10种,酸类2种,烷烃类3种及其它类。正己醇、1-辛烯-3-醇、己酸乙烯酯、正己醛、庚醛、壬醛、反式-2-壬醛、(E,E)-2,4-壬二烯醛等为香肠的主体风味物质。贮藏3个月时,添加中浓度的类球红细菌粗提物降低了(E,E)-2,4-壬二烯醛的含量。贮藏6个月时,添加低浓度的类球红细菌粗提物香肠的挥发性风味与其它组差异最为显著。贮藏3个月时,添加类球红细菌粗提物减少了香肠醇类种类及含量。贮藏6个月,类球红细菌粗提物增加了醇类物质含量,但减少了醛类物质含量,促进了唯一酯类物质己酸乙烯酯的生成。添加少量粗提物可降低正己醛、庚醛、辛酸、壬醛的生成,抑制了香肠异味的产生。添加类球红细菌粗提物促进了谷氨酸和天冬氨酸等鲜味氨基酸的产生,提高了鲜味和甜味氨基酸占比,对改善香肠风味有正向作用。

因类球红细菌粗提物中含有蛋白质(酶)、类胡萝卜素、辅酶Q10等物质,基于蛋白质组学、代谢组学等多组学阐明类球红细菌粗提物调控香肠风味品质的机理是未来的研究方向。本研究为传统中式香肠品质改善提供了一定了理论依据。

-

表 1 香肠贮藏期挥发性风味组成及含量(%)

Table 1 Volatile flavor composition and content of different sausages during storage(%)

名称 RT CAS A3 B3 C3 D3 A6 B6 C6 D6 醇类 正己醇 6.35 111-27-3 1.56±0.00c 2.11±0.00c 3.18±0.0 c 0.90±0.00c 4.37±0.01c 18.06±0.02b 18.42±0.05b 24.84±0.04a 1-庚炔-3-醇 9.37 7383-19-9 4.57±0.00 − − − − − − 2.82±0.00 1-辛烯-3-醇 10.38 3391-86-4 8.35±0.00b 8.88±0.00b 10.94±0.01a 8.90±0.01b 4.74±0.00d 5.37±0.00cd 6.26±0.01c 9.37±0.00a 3,5 -辛二烯-2-醇 12.96 69668-82-2 0.75±0.00 0.57±0.00 − 0.71±0.00 0.47±0.00 0.27±0.00 − − 反-2-十一烯醇 14.41 75039-84-8 − − − 1.23±0.01 − − − − 3-甲基-1,6-庚二烯-3-醇 15.41 34780-69-3 3.92±0.00 − 2.92±0.00 − − − − − 正庚醇 10.05 111-70-6 0.59±0.00 0.59±0.00 0.82±0.00 − 0.71±0.00 1.01±0.00 1.04±0.002 1.31±0.00 顺-2-壬烯-1-醇 14.39 41453-56-9 0.87±0.00 1.29±0.01 − − − − − − 4.5-二甲基-2-庚烯-3-醇 15.44 55956-37-1 − 4.18±0.01 − 4.38±0.01 6.56±0.00 5.29±0.01 4.56±0.01 2.77±0.00 环辛醇 14.31 696-71-9 − − − − − − 0.45±0.00 0.41±0.00 2-壬烯-1-醇 14.464 22104-79-6 − − − − − 1.61±0.00 − − 4-乙基-1-辛炔-3-醇 12.77 5877-42-9 − − − − 0.42±0.00 − − − (-)-异松蒎醇 13.25 27779-29-9 − − − − 0.35±0.00 − − − 4-乙基环己醇 12.768 4534-74-1 − − − − − 0.32±0.00 − − 4-甲基-4 -硝基戊醇-1-醇 19.78 5215-92-9 − − − − − 0.58±0.00 − 1.57±0.00 4,4,6-三甲基-环己-2-辛烯-1-醇 28.88 1000144-64-7 − − − − 0.37±0.00 0.40±0.00 0.30±0.00 − 苯乙醇 16.28 60-12-8 − − − − − − − 0.51±0.00 总量 19.06 17.61 17.85 16.13 18.00 32.90 31.02 43.60 酯类 己酸乙烯酯 13.93 3050-69-9 6.42±0.02 8.35±0.00 7.15±0.01 9.56±0.00 − 7.71±0.00 7.68±0.01 6.27±0.01 醛类 正己醛 4.38 66-25-1 50.99±0.01a 47.76±0.05a 50.93±0.03a 49.06±0.02a 33.14±0.02b 27.51±0.03b 27.28±0.03b 15.44±0.01c 庚醛 7.30 111-71-7 2.82±0.00a 2.91±0.00a 2.63±0.00ab 3.01±0.00a 2.31±0.00abc 1.62±0.00cd 2.02±0.01bcd 1.41±0.00d 反-2-辛烯醛 13.75 2548-87-0 5.47±0.02 a 3.65±0.00abc 2.48±0.00c 4.39±0.01ab 3.67±0.00abc 2.78±0.00bc 2.20±0.00c 1.90±0.00c 壬醛 15.87 124-19-6 5.59±0.00a 5.74±0.01a 6.23±0.01a 5.55±0.00a 6.05±0.00a 5.89±0.00a 6.03±0.00a 5.62±0.00a 反式-2-壬醛 18.73 18829-56-6 0.65±0.00 − 0.57±0.00 0.75±0.00 0.91±0.00 0.67±0.00 0.66±0.00 0.54±0.00 (E,E)-2,4-壬二烯醛 10.83 5910-87-2 − 0.98±0.00 − − 0.69±0.00 0.67±0.00 − − (E)-2-庚烯醛 9.38 18829-55-5 − 2.13±0.01 1.32±0.00 2.07±0.001 1.58±0.00 1.32±0.00 1.71±0.00 − 反式-2-癸烯醛 24.59 3913-81-3 − − − − 0.79±0.00 0.66±0.00 0.54±0.00 2-十一烯醛 29.61 2463-77-6 − − − − 0.41±0.00 0.41±0.00 0.37±0.00 桃醛 29.61 104-67-6 − − − − − − − 0.43±0.00 总量 65.52 63.17 64.15 64.82 49.55 41.52 40.810.41 25.34 酸类 己酸 12.11 142-62-1 2.57±0.01 2.97±0.01 2.45±0.01 9.80±0.01 6.34±0.00 4.95±0.01 辛酸 20.40 124-07-2 − − − − 0.39±0.00 - − − 总量 2.57 2.97 0.00 2.45 10.20 6.34 4.95 0.00 烷烃类 1-氯戊烷 3.76 543-59-9 2.90±0.00b 2.69±0.00bc 3.23±0.00ab 3.34±0.01ab 2.16±0.00c 3.25±0.00bc 3.77±0.00a 2.15±0.00 2,3-环氧-4,4-二甲基戊烷 3.20 53897-30-6 − − − − − − − 0.45±0.00 (Z)3-乙基-2-甲基-1,3-己二烯 12.50 74752-97-9 − − − − 0.41±0.00 0.32±0.00 − − 总量 2.90 2.69 3.23 3.34 2.58 3.58 3.770.04 2.60 其他 氯甲基辛基醚 14.44 24566-90-3 − − − − − − 0.73±0.00 1.10±0.00 2,4,6-三甲基吡啶 10.92 108-75-8 1.78±0.01 4.48±0.03 5.13±0.00 1.79±0.01 10.67±0.01 7.76±0.01 10.26±0.01 21.36±0.03 己酸酐 13.94 2051-49-2 − − − − 9.09±0.01 − − − 总量 1.78 4.48 5.13 1.79 19.76 7.76 10.99 22.46 注:表中各组物质均检出时标注显著性,a、b、c字母不同表示显著性差异(P<0.05);−代表未检出。 表 2 香肠挥发性物质在水中阈值及ROAV值

Table 2 Threshold and ROAV values of sausage volatile substances in water

组别 阈值[38]

(mg/kg)A3 B3 C3 D3 A6 B6 C6 D6 正己醇 0.2 0.08 0.13 0.18 0.16 0.88 0.88 0.90 1.50 1-辛烯-3-醇 0.01 8.34 10.65 12.49 3.38 5.24 5.24 6.14 11.35 正庚醇 0.023 0.25 0.31 0.41 0.22 0.43 0.44 0.44 0.69 环辛醇 10 − − − − − 0.00 0.00 0.00 苯乙醇 0.045 − − − − − − − 0.14 己酸乙烯酯 0.001 64.12 100.00 81.64 82.94 − 75.37 75.38 75.96 正己醛 0.21 2.42 2.73 2.77 1.13 1.28 1.27 1.27 0.89 庚醛 0.01 2.82 3.49 3.00 1.64 1.58 1.98 1.98 1.71 反-2-辛烯醛 0.061 0.90 0.72 0.46 0.43 0.45 0.35 0.35 0.38 壬醛 0.035 1.59 1.97 2.03 1.23 1.64 1.69 1.69 1.94 反式-2-壬醛 0.000065 100.00 − 100.00 100.00 100.00 100.00 100.00 100.00 (E,E)-2,4-壬二烯醛 0.0006 2.42 19.61 − 8.17 10.89 − − − (E)-2-庚烯醛 0.75 − 0.03 0.02 0.02 0.02 0.02 − − 反式-2-癸烯醛 0.15 − − − 0.04 0.04 0.04 − − 桃醛 0.025 − − − − − − 0.00 0.21 己酸 81 0.00 0.00 0.00 0.00 0.00 0.00 − − 辛酸 101 − − 0.00 − − − − 注: −代表未检出。 表 3 贮藏期氨基酸含量(mg/100 g)变化

Table 3 Changes of amino acid content (mg/100 g) during storage

峰名 A3 B3 C3 D3 A6 B6 C6 D6 天冬氨酸 11.410c 17.549b 18.864a 11.973c 56.432B 24.560C 22.340D 71.034A 谷氨酸 14.835c 30.680a 28.890b 13.969d 115.283B 44.295C 41.154D 146.750A 丝氨酸 13.314 55.048 25.284 20.078 97.858 38.274 37.370 123.594 甘氨酸 15.873 16.710 29.122 6.372 134.215 46.528 48.997 151.249 组氨酸 38.256 58.130 67.571 28.752 170.936 82.655 73.690 213.149 精氨酸 21.015 44.956 44.230 16.710 141.625 59.403 58.451 187.688 苏氨酸 26.490 58.757 52.220 22.025 108.013 82.581 78.922 246.031 丙氨酸 4.290 10.083 8.117 3.501 31.421 12.886 12.876 42.619 脯氨酸 49.902 88.019 78.067 38.536 279.652 127.882 126.285 326.562 酪氨酸 32.950 62.290 62.057 25.004 187.595 88.605 84.507 227.311 缬氨酸 23.826 34.256 43.015 14.871 114.686 49.535 44.865 134.881 蛋氨酸 24.819 40.152 37.699 13.824 108.636 48.940 45.035 133.275 异亮氨酸 57.657 22.351 30.238 12.165 117.885 43.413 51.795 132.982 亮氨酸 10.390 55.962 47.947 20.862 194.770 72.293 69.523 228.754 苯丙氨酸 41.860 88.268 84.391 36.568 246.264 123.794 115.770 301.458 赖氨酸 9.340 9.620 13.349 6.679 17.961 13.895 10.888 21.069 总量 396.228c 692.830a 671.060b 291.889d 2123.231B 959.541C 922.469D 2688.407A 注:表中各组物质均检出时标注显著性;a、b、c表示冷藏3个月香肠间的显著性差异(P<0.05);A、B、C表示冷藏6个月香肠间的显著性差异(P<0.05)。 表 4 贮藏期香肠氨基酸TAV值

Table 4 The TAV value of sausage amino acids during refrigeration

氨基酸名称 A3 B3 C3 D3 A6 B6 C6 D6 滋味阈值[50] 呈味特性[50] 天冬氨酸 0.114 0.175 0.189 0.120 0.564 0.246 0.223 0.710 100 鲜味 谷氨酸 0.494 1.023 0.963 0.466 3.843 1.477 1.372 4.892 30 鲜味 总量 0.608 1.198 1.152 0.586 4.407 1.723 1.595 5.602 丝氨酸 0.089 0.367 0.169 0.134 0.652 0.255 0.249 0.824 150 甜味 甘氨酸 0.122 0.129 0.224 0.049 1.032 0.358 0.377 1.163 130 甜味 苏氨酸 0.102 0.226 0.201 0.085 0.415 0.318 0.304 0.946 260 甜味 丙氨酸 0.072 0.168 0.135 0.058 0.524 0.215 0.215 0.710 60 甜味 脯氨酸 0.166 0.293 0.260 0.128 0.932 0.426 0.421 1.089 300 甜味 总量 0.551 1.183 0.989 0.454 3.555 1.572 1.566 4.732 酪氨酸 0.362 0.685 0.682 0.275 2.061 0.974 0.929 2.498 91 苦味 缬氨酸 0.596 0.856 1.075 0.372 2.867 1.238 1.122 3.372 40 苦味 蛋氨酸 0.827 1.338 1.257 0.461 3.621 1.631 1.501 4.443 30 苦味 异亮氨酸 0.641 0.248 0.336 0.135 1.310 0.482 0.575 1.478 90 苦味 组氨酸 1.913 2.907 3.379 1.438 8.547 4.133 3.685 10.657 20 苦味 精氨酸 0.420 0.899 0.885 0.334 2.832 1.188 1.169 3.754 50 苦味 亮氨酸 0.055 0.295 0.252 0.110 1.025 0.380 0.366 1.204 190 苦味 苯丙氨酸 0.465 0.981 0.938 0.406 2.736 1.375 1.286 3.350 90 苦味 赖氨酸 0.467 0.481 0.667 0.334 0.898 0.695 0.544 1.053 20 苦味 总量 5.746 8.69 9.471 3.865 25.897 12.096 11.177 31.809 表 5 贮藏期香肠不同呈味氨基酸占比(%)

Table 5 Proportion of different flavored amino acids in sausages during storage (%)

滋味氨基酸类别 A3 B3 C3 D3 A6 B6 C6 D6 甜味氨基酸 8.81 10.82 9.92 11.95 13.02 11.19 11.12 13.29 鲜味氨基酸 7.98 10.69 8.52 9.26 10.50 10.21 10.92 11.23 苦味氨基酸 83.22 78.49 81.56 78.80 76.48 78.59 77.95 75.48 -

[1] 周慧敏, 赵冰, 吴倩蓉, 等. 黑白胡椒腊肠贮藏期中气味活性物质演变及异味分析[J]. 食品科学,2020,41(24):162−171. [ZHOU H, ZHAO B, WU Q R, et al. Change1s of odour activity compounds and analysis of off-flavour substances for black and white pepper-sausage in storage[J]. Food Science,2020,41(24):162−171. ZHOU H, ZHAO B, WU Q R, et al. Change1s of odour activity compounds and analysis of off-flavour substances for black and white pepper-sausage in storage [J]. Food Science, 2020, 41(24): 162-171.

[2] 冯美琴, 张杰, 孙健. 模仿葡萄球菌接种对发酵香肠品质及氧化稳定性的影响[J]. 食品科学,2021,43(4):105−112. [FENG M Q, ZHANG J, SUN J. Effect of staphylococcus simulans NJ201 inoculation on the quality and antioxidant of fermented sausage[J]. Food Science,2021,43(4):105−112. FENG M Q, ZHANG J, SUN J. Effect of staphylococcus simulans NJ201 inoculation on the quality and antioxidant of fermented sausage[J]. Food Science, 2021, 43(4): 105-112.

[3] JI W, JINNA H, XIN Z, et al. Improving the flavor of fermented sausage by increasing its bacterial quality via inoculation with Lactobacillus plantarum MSZ2 and Staphylococcus xylosus YCC3[J]. Foods,2022,11(5):736. doi: 10.3390/foods11050736

[4] 郭文瑞, 韩云飞, 杨扬, 等. 植物乳杆菌对发酵香肠蛋白质分解及游离氨基酸的影响[J]. 中国食品学报,2021,21(4):209−215. [GUO W R, HAN Y F, YANG Y, et al. The effect of Lactobacillus plantarum on the protein decomposition and free amino acids of fermented sausage[J]. Chinese Journal of Food Science,2021,21(4):209−215. GUO W R, HAN Y F, YANG Y, et al. The effect of Lactobacillus plantarum on the protein decomposition and free amino acids of fermented sausage [J]. Chinese Journal of Food Science, 2021, 21(4): 209-215.

[5] 张旭. 川式酱香腊肠加工过程中内源酶对风味形成的影响[D]. 成都: 成都大学, 2021. ZHANG X. Effects of endogenous enzymes on flavor formation during the processing of Sichuan sauce-scented sausage [D]. Chengdu: Chengdu University, 2021.

[6] CARBALLO D E, ANDRÉS S, GIRÁLDEZ F J, et al. The effects of storage and hop extract on aroma and flavour compounds in Balkan-style sausages packed under a CO2-containing anaerobic atmosphere[J]. Heliyon,2020,6(10):e05251. doi: 10.1016/j.heliyon.2020.e05251

[7] ZHAO L, SUN X, WU J, et al. Effects of allium mongolicum regel and its extracts on the quality of fermented mutton sausages[J]. Food Science & Nutrition,2022,10(1):169−178.

[8] 田明, 王玉伟, 李瑞锋, 等. 辅酶Q10等5种原料的保健食品纳入备案制目录管理的情况分析及启示[J]. 食品科学,2022,43(15):320−326. [TIAN M, WANG Y WI, LI R F, et al. Putting five health food of raw materials including coenzyme Q10 under directory management: Analysis and its complications[J]. Food Science,2022,43(15):320−326. TIAN M, WANG Y WI, LI R F, et al. Putting five health food of raw materials including coenzyme Q10 under directory management: Analysis and its complications[J]. Food Science, 2022, 43(15): 320-326.

[9] 段卓, 郭浩昱, 刘也嘉, 等. 油菜籽中类胡萝卜素及其抗氧化研究进展[J/OL]. 中国油脂: 1−8[2023-05-23]. doi: 10.19902/j.cnki.zgyz.1003-7969.210565. DUAN Z, GUO H Y, LIU Y J, et al. Research progress on carotenoids and their antioxidant properties in rapeseed[J/OL]. China Oils and Fats: 1−8[2023-05-23]. doi: 10.19902/j.cnki.zgyz.1003-7969.210565.

[10] 徐靖. 超氧化物歧化酶及其应用的研究进展[J]. 食品工业科技,2013,34(12):387−391. [XU J. Research progress in superoxide dismutase and its application[J]. Science and Technology of Food Industry,2013,34(12):387−391. XU J. Research progress in superoxide dismutase and its application[J]. Science and Technology of Food Industry, 2013, 34(12): 387-391.

[11] 方立超. 光合细菌益生特性的实验研究[D]. 重庆: 第三军医大学, 2005. FANG L C. Study of proboitic properties of photosynthetie bacteria[D]. Chongqing: Third Military Medical University, 2005.

[12] SALWA T, DUANGPORN K, PATTAMARAT R, et al. Dietary supplementation with probiotic Rhodobacter sphaeroides SS15 extract to control acute hepatopancreatic necrosis disease (AHPND)-causing Vibrio parahaemolyticus in cultivated white shrimp[J]. Journal of Invertebrate Pathology,2021,186:107585−107585. doi: 10.1016/j.jip.2021.107585

[13] CHIU K H, LIU W S. Dietary administration of the extract of Rhodobacter sphaeroides WL-APD911 enhances the growth performance and innate immune responses of seawater red tilapia (Oreochromis mossambicus×Oreochromis niloticus)[J]. Aquaculture,2014,418:32−38.

[14] 刘英丽, 于青林, 万真, 等. 发酵剂抗氧化活性对发酵肉制品品质的影响研究进展[J]. 食品科学,2021,42(1):302−312. [LIU Y L, YU Q L, WAN Z, et al. Research progress on effects of antioxidant activity of starter on quality of fermented meat[J]. Food Science,2021,42(1):302−312. LIU Y L, YU Q L, WAN Z, et al. Research progress on effects of antioxidant activity of starter on quality of fermented meat[J]. Food Science, 2021, 42(1): 302-312.

[15] 范代超, 易倩, 刘洋, 等. 抗氧化剂对川式腊肉低温冷藏中挥发性风味物质的影响[J]. 食品科学,2012,33(16):266−273. [FAN D C, YI Q, LIU Y, et al. Effect of antioxidants on volatile flavor components in Sichuan traditional bacon during chilling storage[J]. Food Science,2012,33(16):266−273. FAN D C, YI Q, LIU Y, et al. Effect of Antioxidants on volatile flavor components in Sichuan traditional bacon during chilling storage[J]. Food Science, 2012, 33(16): 266-273.

[16] 聂鑫, 赵志平, 吉莉莉, 等. 类球红细菌粗提物对冷藏期四川腊肠脂肪和蛋白质氧化的影响[J]. 食品与发酵科技,2021,57(1):12−16. [NIE X, ZHAO Z P, JI L L, et al. Effect of crude extract from Rhodobacter sphaeroides on lipid and protein oxidation of cold storage Sichuan sausage[J]. Food and Fermentation Science & Technology,2021,57(1):12−16. doi: 10.3969/j.issn.1674-506X.2021.01.002 NIE X, ZHAO Z P, JI L L, et al. Effect of Crude Extract from Rhodobacter sphaeroides on lipid and protein oxidation of cold storage Sichuan sausage[J]. Food and Fermentation Science & Technology, 2021, 57(1): 12-16. doi: 10.3969/j.issn.1674-506X.2021.01.002

[17] HU Z L, YU P, YUN T, CHEN G P. A powerful hybrid puc operon promoter tightly regulated by both IPTG and low oxygen level[J]. Biochemistry Moscow,2010,75(4):519−525. doi: 10.1134/S0006297910040176

[18] TANG K, ZHAO Z. Advances in the coenzyme Q10 biosynthesis pathway in Rhodobacter sphaeroides and the enhancement of coenzyme Q10 production based on metabolic engineering[J]. Agricultural Biotechnology,2019,8(4):1−6,13.

[19] 张旭, 王卫, 白婷, 等. 四川浅发酵香肠加工进程中挥发性风味物质测定及其主成分分析[J]. 现代食品科技,2020,36(10):274−283. [ZHANG X, WANG W, BAI T, et al. Determination and principal component analysis of the volatile flavor substances during the processing of Sichuan light fermented sausage[J]. Modern Food Science and Technology,2020,36(10):274−283. ZHANG X, WANG W, BAI T, et al. Determination and principal component analysis of the volatile flavor substances during the processing of Sichuan light fermented sausage[J]. Modern Food Science and Technology, 2020, 36(10): 274-283.

[20] 王卫, 张旭, 张佳敏, 等. 四川酱香型风干腊肠加工贮藏特性及其“浅发酵”特征研究[J]. 食品工业科技,2020,42(1):82−88. [WANG W, ZHANG X, ZHANG J M, et al. The processing and storage characteristics of Sichuan sauce-flavored air-dried sausage and its characteristics of "shallow fermentation"[J]. Science and Technology of Food Industry,2020,42(1):82−88. WANG W, ZHANG X, ZHANG J M, et al. The processing and storage characteristics of Sichuan sauce-flavored air-dried sausage and its characteristics of "shallow fermentation"[J]. Science and Technology of Food Industry, 2020, 42(1): 82-88.

[21] 金文刚, 赵萍, 刘俊霞, 等. 基于气相-离子迁移色谱结合化学计量学分析大鲵肉烤制过程中挥发性风味成分[J]. 食品与发酵工业,2021,47(21):231−239. [JIN W G, ZHAO P, LIU J X, et al. Volatile flavor components analysis of giant salamander (Andrias davidiauns) meat during roasting process based on gas chromatography-ion mobility spectroscopy and chemometrics[J]. Food and Fermentation Industries,2021,47(21):231−239. JIN W G, ZHAO P, LIU J X, et al. Volatile flavor components analysis of giant salamander (Andrias davidiauns) meat during roasting process based on gas chromatography-ion mobility spectroscopy and chemometrics[J]. Food and Fermentation Industries, 2021, 47(21): 231-239.

[22] 赖宏刚. 冷鲜鸡与酱卤制品辐照综合保鲜技术研究[D]. 扬州: 扬州大学, 2017. LAI H G. Study on irradiation comprehensive preservation technology of cold fresh chicken and sauce brine products[D]. Yangzhou: Yangzhou University, 2017.

[23] 粟桂蓉, 彭钰媛, 周璐璐, 等. 传统土家腊肉加工过程中风味物质研究[J]. 食品科技,2017,42(3):118−123. [SU G R, PENG Y Y, ZHOU L L, et al. Changes of volatile flavor compounds in the process of traditional Tujia bacon[J]. Food Science and Technology,2017,42(3):118−123. SU G R, PENG Y Y, ZHOU L L, et al. Changes of volatile flavor compounds in the process of traditional Tujia bacon[J]. Food Science and Technology, 2017, 42(3): 118-123.

[24] 封莉, 邓绍林, 黄明, 等. 脂肪酶对中式香肠脂肪降解、氧化和风味的影响[J]. 食品科学,2015,36(1):51−58. [FENG L, DENG S L, HUANG M, et al. Effect of palatase on lipid hydrolysis, lipid oxidation and sensory attributes of Chinese sausage[J]. Food Science,2015,36(1):51−58. FENG L, DENG S L, HUANG M, et al. Effect of palatase on lipid hydrolysis, lipid oxidation and sensory attributes of Chinese sausage[J]. Food Science, 2015, 36(1): 51-58.

[25] 余力, 贺稚非, 王兆明, 等. 不同解冻方式对伊拉兔肉挥发性风味物质的影响[J]. 食品科学,2015,36(22):95−101. [YU L, HE Z F, WANG Z M, et al. Effect of different thawing methods on volatile flavor compounds of hyla rabbit meat[J]. Food Science,2015,36(22):95−101. YU L, HE Z F, WANG Z M, et al. Effect of different thawing methods on volatile flavor compounds of hyla rabbit meat[J]. Food Science, 2015, 36(22): 95-101.

[26] 吴彩云, 张晓荣, 徐怀德, 等. 益生菌发酵果蔬汁生物活性成分及功能特性研究进展[J]. 中国食品学报,2021,21(12):323−334. [WU C Y, ZHANG X R, XU H D, et al. Research progress on bioactive components and functional properties of fruit and vegetable juice fermented by probiotics[J]. Journal of Chinese Institute of Food Science and Technology,2021,21(12):323−334. WU C Y ZHANG X R XU H D, et al. Research progress on bioactive components and functional properties of fruit and vegetable juice fermented by probiotics[J]. Journal of Chinese Institute of Food Science and Technology, 2021, 21(12): 323-334.

[27] ALVAREZ M G, GONZALEZ-BARREIRO C, CANCHO-GRANDE B, et al. Relationships between Godello white wine sensory properties and its aromatic fingerprinting obtained by GC-MS[J]. Food Chemistry,2011,129(3):890−898. doi: 10.1016/j.foodchem.2011.05.040

[28] ANNAN N T, POLL L, PLAHAR W A, et al. Aroma characteristics of spontaneously fermented Ghanaian maize dough for kenkey[J]. European Food Research and Technology,2003,217(1):53−60. doi: 10.1007/s00217-003-0697-0

[29] 陈春梅. 超声波辅助炖煮羊肉汤的工艺优化及风味分析[D]. 扬州: 扬州大学, 2021. CHEN C M. Optimization of the technology and flavor analysis of the stewed sheep meat soup with ultrasonic-assisted [D]. Yangzhou: Yangzhou University, 2021.

[30] 吴倩蓉, 周慧敏, 李素, 等. 风干肠贮藏过程中挥发性风味物质的变化及异味物质分析[J]. 食品科学,2019,40(20):208−216. [WU Q R, ZHOU H M, LI S, et al. Changes in volatile flavour compounds during storage and analysis of off-flavour substances in air-dried sausage[J]. Food Science,2019,40(20):208−216. WU Q R, ZHOU H M, LI S, et al. Changes in volatile flavour compounds during storage and analysis of off-flavour substances in air-dried sausage[J]. Food Science, 2019, 40(20): 208-216.

[31] CASABURI A, PIOMBINO P, NYCHAS G J, et al. Bacterial populations and the volatilome associated to meat spoilage[J]. Food Microbiology,2015,45:83−102. doi: 10.1016/j.fm.2014.02.002

[32] 齐琳, 王帅, 苏晨, 等. 乳酸菌发酵核桃酸乳不良气味的形成与分析[J]. 食品科学,2022,43(14):234−241. [QI L, WANG S, SU C, et al. Formation and analysis of the off-flavor of walnut yoghurt fermented by lactic acid bacteria[J]. Food Science,2022,43(14):234−241. QI L, WANG S, SU C, et al. Formation and analysis of the off-flavor of walnut yoghurt fermented by lactic acid bacteria[J]. Food Science, 2022, 43(14): 234-241.

[33] LUDWIG V, BERGHETTI M R P, RIBEIRO S R, et al. The effects of soybean storage under controlled atmosphere at different temperatures on lipid oxidation and volatile compounds profile[J]. Food Research International,2021,147:110483. doi: 10.1016/j.foodres.2021.110483

[34] ESTéVEZ M, MORCUENDE D, VENTANAS S, et al. Analysis of volatiles in meat from Iberian pigs and lean pigs after refrigeration and cooking by using SPME-GC-MS[J]. Journal of Agricultural & Food Chemistry,2003,51(11):3429−3435.

[35] GUILLEN M D, GOICOECHEA E. Formation of oxygenated α, β-unsaturated aldehydes and other toxic compounds in sunflower oil oxidation at room temperature in closed receptacles[J]. Food Chemistry,2008,111(1):157−164. doi: 10.1016/j.foodchem.2008.03.052

[36] 蔺佳良, 蔡江佳, 何红萍, 等. 两种海洋甲壳动物挥发性物质的研究[J]. 中国食品学报,2015,15(9):240−249. [LIN J L, CAI J J, HE H P, et al. Studies on volatiles substances in two species of marine crustacean[J]. Chinese Journal of Food Science,2015,15(9):240−249. LIN J L, CAI J J, HE H P, et al. Studies on volatiles substances in two species of marine crustacean[J]. Chinese Journal of Food Science, 2015, 15(9): 240-249.

[37] RAJAMANI K, BALASUBRAMANIAN T, THIRUGNANASAMBANDAN S S. Bioassay-guided isolation of triterpene from brown alga Padina boergesenii possess anti-inflammatory and anti-angiogenic potential with kinetic inhibition of β-carotene linoleate system[J]. LWT,2018,93:549−555. doi: 10.1016/j.lwt.2018.04.010

[38] 孙宝国, 陈海涛. 食用调香术[M]. 第3版. 北京: 化学工业出版社, 2016. SUN B G, CHEN H T. Edible perfumery[M]. Third edition. Beijing: Chemical Industry Press, 2016.

[39] GU Z, CHEN D, HAN Y, et al. Optimization of carotenoids extraction from Rhodobacter sphaeroides[J]. LWT-Food Science and Technology,2008,41(6):1082−1088. doi: 10.1016/j.lwt.2007.07.005

[40] 刘春云, 赵鑫琦, 孔令茹, 等. 桑葚白兰地对风干肠挥发性风味成分及品质的影响[J]. 食品科学,2023,44(6):244−253. [LIU C Y, ZHAO X Q, KONG L R, et al. Effects of mulberry brandy on volatile flavor components and quality of air-dried sausage[J]. Food Science,2023,44(6):244−253. LIU C Y, ZHAO X Q, KONG L R, et al. Effects of mulberry brandy on volatile flavor components and quality of air-dried sausage[J]. Food Science, 2023, 44(6): 244-253.

[41] 邓文辉, 赵燕, 李建科, 等. 游离脂肪酸在几种常见食品风味形成中的作用[J]. 食品工业科技,2012,33(11):422−425. [DENG W H, ZHAO Y, LI J K, et al. The role of free fatty acid in the flavor of several common foods[J]. Science and Technology of Food Industry,2012,33(11):422−425. DENG W H, ZHAO Y, LI J K, et al. The role of free fatty acid in the flavor of several common foods[J]. Science and Technology of Food Industry, 2012, 33(11): 422-425.

[42] 刘丽丽, 杨辉, 荆雄, 等. 基于GC-IMS和电子鼻技术分析贮酒容器对凤香型白酒香气成分的影响[J]. 食品科学,2022,43(4):257−263. [LIU L L, YANG H, JING X, et al. Influence of different storage containers on the flavor of Fengxiang Baijiu composition based on GC-IMS and electronic nose technology[J]. Food Science,2022,43(4):257−263. LIU L L, YANG H, JING X, et al. Influence of different storage containers on the flavor of Fengxiang Baijiu composition based on GC-IMS and electronic nose technology[J]. Food Science, 2022, 43(4): 257-263.

[43] 徐梦婷, 邵淑贤, 陈静, 等. 不同茶树品种工夫红茶挥发性成分及其关键香气成分分析[J]. 现代食品科技,2023,39(1):281−290. [XU M T, SHAO S X, CHEN J. et al. Analysis of volatile components and key aroma components in congou black tea of different tea varieties[J]. Modern Food Science and Technology,2023,39(1):281−290. doi: 10.13982/j.mfst.1673-9078.2023.1.0219 XU M T, SHAO S X, CHEN J. et al. Analysis of volatile components and key aroma components in congou black tea of different tea varieties[J]. Modern Food Science and Technology, 2023, 39(1): 281-290. doi: 10.13982/j.mfst.1673-9078.2023.1.0219

[44] OLIVARES A, NAVARRO J L, FLORES M. Effect of fat content on aroma generation during processing of dry fermented sausages[J]. Meat Science,2011,87(3):264−273. doi: 10.1016/j.meatsci.2010.10.021

[45] 宋泽, 徐晓东, 许锐, 等. 不同部位牛肉炖煮风味特征分析[J]. 食品科学,2019,40(4):206−214. [SONG Z, XU X D, XU R, et al. Analysis of flavor characteristics of stewed beef from different carcass parts[J]. Food Science,2019,40(4):206−214. SONG Z, XU X D, XU R, et al. Analysis of flavor characteristics of stewed beef from different carcass parts[J]. Food Science, 2019, 40(4): 206-214.

[46] ZHANG L, LIU L, WANG K F, et al. Phosphate limitation increases coenzyme Q10 production in industrial Rhodobacter sphaeroides HY01[J]. Synthetic and Systems Biotechnology,2019,4(4):212−219. doi: 10.1016/j.synbio.2019.11.001

[47] HIERRO E, LORENZO D, ORDó EZ J. Contribution of the microbial and meat endogenous enzymes to the free amino acid and amine contents of dry fermented sausages[J]. Journal of Agricultural & Food Chemistry,1999,47(3):1156.

[48] GARCA I, DEZ V, ZUMALACRREGUI J M. Changes in nitrogen fractions and free amino acids during ripening of Spanish dried beef "cecina"[J]. Journal of Muscle Foods,2007,9(3):257−266.

[49] MONICA, ARMENTEROS, MARIA-CONCEPCION, et al. Biochemical and sensory properties of dry-cured loins as affected by partial replacement of sodium by potassium, calcium, and magnesium[J]. Journal of Agricultural and Food Chemistry,2009,57(20):9699−9705. doi: 10.1021/jf901768z

[50] 王琴, 李洪军, 杨莉, 等. 直投式商业发酵剂对发酵香肠品质特性的影响[J/OL]. 食品与发酵工业: 1−12[2023-05-23]. doi: 10.13995/j.cnki.11-1802/ts.033804. WANG Q, LI H J, YANG L, et al. Effect of direct-throwing commercial starter cultures on the quality characteristics of fermented sausages[J/OL]. Food and Fermentation Industries: 1−12[2023-05-23]. doi: 10.13995/j.cnki.11-1802/ts.033804.

下载:

下载:

下载:

下载: