Study on the Properties and Structure of Rice Starch-Monoglyceride Complexs

-

摘要: 为了减缓大米淀粉在食品加工过程中的老化,采用加热糊化法制备大米淀粉-不同单甘酯复合物,研究甘油单月桂酸酯(GML)、甘油单棕榈酸酯(GMP)和甘油单硬脂酸酯(GMS)三种单甘酯对复合物的理化和结构特性的影响。采用RVA、DSC、FTIR、XRD等方法测定了复合物的糊化特性、热特性、短程有序性及结晶结构。结果表明,不同单甘酯对复合物的复合指数具有显著影响(P<0.05),复合指数为GMP>GMS>GML;与原大米淀粉相比,复合物的溶解度、析水率、回生值以及短程有序性均显著下降(P<0.05),且不同复合物之间也存在显著差异(P<0.05),其中大米淀粉-甘油单棕榈酸酯的析水率、回生值和短程有序性最低,分别为25.58%、281.7 cP和0.58;差式扫描量热和X-射线衍射分析发现,与单甘酯复合后,淀粉由A型结晶结构转变为V型结晶结构。上述结果表明单甘酯的加入在一定程度上可延缓淀粉老化,大米淀粉-甘油单棕榈酸酯复合物抑制淀粉老化效果更好。Abstract: To slow down the aging of rice starch during food processing, rice starch-monoglyceride complexes were prepared by heating pasting method, and the effects of three monoglycerides, glycerol monolaurate(GML), glycerol monopalmitate (GMP) and glycerol monostearate (GMS), on the physicochemical and structural properties of the complexes were investigated. The pasting properties, thermal properties, short-range ordering and crystalline structure of the complexes were determined by RVA, DSC, FTIR and XRD. The results showed that different monoglycerides had significant effects on the complex index (P<0.05), and the complex index was GMP>GMS>GML. The solubility, precipitation rate, regeneration value and short-range orderliness of the complexes were significantly lower compared with the original rice starch (P<0.05), and there were also significant differences between the complexes (P<0.05). Among them, rice starch-glycerol monopalmitate had the lowest precipitation rate, regeneration value and short-range orderliness of 25.58%, 281.7 cP and 0.58, respectively. Differential scanning calorimetry and X-ray diffraction analysis revealed that the starch changed from A-type crystalline structure to V-type crystalline structure after compounding with monoglycerides. The above results indicated that the addition of monoglycerides could retard starch aging to some extent, and the rice starch-glycerol monopalmitate complexes were more effective in inhibiting starch aging.

-

Keywords:

- rice starch /

- monoglyceride /

- complex index /

- physicochemical properties /

- structural properties

-

大米是世界上主要的粮食作物之一,淀粉是大米的主要成分[1]。淀粉是一种可再生的植物资源,淀粉基食品在加工运输和储藏过程中极易发生老化现象,即糊化淀粉的无序结构重新形成有序结构,天然淀粉易凝沉老化等缺陷限制了其在食品加工和饲料加工工业中的应用,需要根据用途对淀粉进行不同的改性处理。现有研究通过化学修饰和物理方法抑制淀粉的老化,然而化学修饰存在一定的安全隐患。近年来,人们发现可以通过脂质等配体与淀粉之间的相互作用改变淀粉的性质,如降低淀粉的溶解性、糊黏度以及改善淀粉的抗老化性等[2-4]。淀粉和脂质可以通过疏水作用形成复合物,目前淀粉-脂质复合物的研究主要集中在淀粉-脂肪酸复合物,对淀粉-单甘酯复合物的研究较少。如董慧娜等[5]研究证实不同链长饱和脂肪酸与板栗淀粉复合均能阻碍板栗淀粉的短期老化。陈海华等[6]研究发现脂肪酸与玉米淀粉复合后淀粉颗粒的吸水膨胀受到抑制,淀粉的热稳定性提高,可有效抑制淀粉的长期老化。与脂肪酸相比单甘酯在热水中的分散性较好,无需预先分散于无水乙醇等介质中,即可在淀粉加热糊化时与淀粉复合,制得的复合物较为绿色安全[7-8]。娄雪等[9]研究发现单甘酯可与小麦直链淀粉形成复合物,使小麦淀粉由B型结晶结构转换为A型结晶结构,淀粉短程有序性降低。

本试验拟以大米淀粉为原料,以链长不同的三种单甘酯为配体,通过加热糊化的方法进行复合物的制备,通过复合物的复合指数、溶解度、冻融稳定性、糊化特性、热特性、短程有序性以及结晶结构等对大米淀粉复合物结构和性质进行表征与分析,以考察单甘酯对大米淀粉性质与结构的影响,对提升大米淀粉的抗老化性能具有指导意义。

1. 材料与方法

1.1 材料与仪器

大米淀粉(Rice Starch,RS) 上海源叶生物有限公司;甘油单月桂酸酯GML、甘油单棕榈酸酯GMP、甘油单硬脂酸酯GMS(食品级) 山东滨州金盛新材料科技有限责任公司;无水乙醇(分析纯) 国药集团化学试剂有限公司。

HH-4数显恒温水浴锅 常州荣华仪器制造有限公司;DF-101S集热式恒温加热磁力搅拌 河南省予华仪器有限公司;SHA-B水浴恒温振荡器 常州市国立试验设备研究所;QL901型漩涡混合器 泰州顺锦医疗器械有限公司;TG16高速离心机 上海卢湘仪离心机仪器有限公司;722可见光分光光度计 天津市泰斯特分析仪器有限公司;Spectrum 100傅立叶变换红外光谱仪、DSC4000差示扫描量热仪 美国PE公司;Rint-2000 X-射线衍射仪 日本理学公司。

1.2 实验方法

1.2.1 大米淀粉-不同单甘酯复合物的制备

参照张书艳等[10]的制备方法并做适当改进。称取一定量的大米淀粉,按1:10的比例加入蒸馏水,搅拌均匀后加入3%的甘油单月桂酸酯(以干淀粉质量计),80 ℃复合30 min,冷却至室温后4000 r/min离心15 min,用乙醇-水(50:50,V/V)洗涤离心2次,冷冻干燥,即得到大米淀粉-甘油单月桂酸酯复合物,研磨后过100目筛备用。大米淀粉-甘油单棕榈酸酯复合物(RS-GMP)和大米淀粉-甘油单硬脂酸酯复合物(RS-GMS)的制备方法同上。

1.2.2 复合指数测定

复合指数(Complex Index,CI)的测定参照孙圣麟等[11-12]的测定方法,并做适当改进。具体测定方法如下:准确称取0.3 g样品,加入4.7 mL去离子水,涡旋混合后置于沸水浴中糊化20 min,冷却至室温,加入25 mL去离子水,涡旋混合,在10000 r/min 转速下离心10 min,取0.5 mL上清液,加入15 mL去离子水和2 mL碘液,混合均匀后于690 nm测定样品的吸光度,以未复合单甘酯的大米淀粉作为对照。计算公式如下:

CI(%)=A0−AA0×100 式中,CI为复合指数(%);A0为对照组吸光度;A为复合物吸光度。

1.2.3 溶解度测定

溶解度的测定参照Chang等[13]的测定方法,并做适当修改。称取0.6 g样品于已知重量的离心管中,配成2%的淀粉悬浮液,涡旋混合后分别于55、65、75、85和95 ℃振荡水浴中处理30 min,冷却至室温后于10000 r/min转速下离心10 min。取上清液于已知重量经干燥的平皿中,105 ℃烘干至恒重,增加的质量即为溶解的样品的质量。计算公式如下:

S(%)=m3−m2m1×100 式中,S为溶解度(%);m1为样品重量(g);m2为平皿重量(g);m3为溶解样品和平皿总重量(g)。

1.2.4 冻融稳定性测定

冻融稳定性的测定参照孟爽[14]的测定方法。准确称取1.2 g的样品于已知质量离心管中,加入适当的蒸馏水配成质量分数为6%的淀粉糊,于沸水浴中糊化20 min,冷却至室温。于−18 ℃冰箱中冷冻22 h,解冻4 h,10000 r/min离心10 min,弃去上清液。 按下式计算析水率:

VC(%)=m2−m3m2−m1×100 式中,VC为析水率(%);m1为离心管重量(g);m2离心管和糊化样品总重量(g);m3为弃去上清液后离心管和样品总重量(g)。

1.2.5 糊化特性测定

采用快速粘度分析仪(RVA)测定大米淀粉及复合物的糊化特性。在仪器测试软件的样品重量计算器中,设置标准样品质量3.0 g、标准水重量25.0 g、水分基14%,输入待测样品的水分含量,根据修正后的样品质量和水重量称量样品[15]。测试程序:前10 s的转速为960 r/min,之后以160 r/min的转速匀速完成试验。温控步骤为首先50 ℃平衡1 min,以12 ℃/min的加热速率加热至95 ℃后保持2.5 min,之后以相同的速率冷却至50 ℃并保持2 min。测试完成后记录数据。

1.2.6 热性能测定

称取5.0 mg左右样品置于铝质坩埚内,加入15 μL去离子水(样品:水=1:3),密封压盖,平衡24 h。空铝质坩埚为对照,氮气为载气,用差示扫描量热仪测定,升温温度范围50~200 ℃,升温速率为10 ℃/min。通过 DSC 配套软件得到样品的起始温度TO、峰值温度TP、结束温度TC以及焓变△H[16]。

1.2.7 红外光谱分析

将大米淀粉-脂肪酸复合物和大米淀粉分别与KBr按1:10混匀研磨,取微量放在专用纸上,挤压3 s以上,用傅里叶变换红外光谱仪测定样品红外光谱,波数范围为4000~400 cm−1[17-18]。

1.2.8 结晶结构测定

参考董慧娜等[19]的测定方法。将样品平铺于玻璃样品板上,并置于X-射线衍射仪的载物台上,X衍射条件为Cu靶,电压40 kV,电流30 mA,扫描步长为0.02°,扫描速度5°/min,测定范围为5°~40°。

1.3 数据处理

试验采用SPSS 26.0和Microsoft Excel 2016软件进行数据分析,采用Origin绘图。试验数据均为3次平行试验的平均值,结果以Mean±SD表示。P<0.05为具有统计学意义的显著差异。

2. 结果与分析

2.1 不同单甘酯与大米淀粉的复合指数分析

淀粉的螺旋结构、脂质与淀粉疏水基的相互作用决定淀粉与脂质的复合程度[20]。复合指数是反映淀粉中直链淀粉与脂质复合程度的重要指标,复合物的复合指数越大,表明直链淀粉与碘结合的能力越弱,与脂质的复合程度越高。反之复合物的复合指数越小,复合程度越低。由表1可知,不同单甘酯对复合物复合指数具有显著影响(P<0.05),RS-GMP的复合指数>RS-GMS的复合指数>RS-GML的复合指数,即与大米淀粉的复合程度为:GMP>GMS>GML。相比于GML,GMP、GMS随着单甘酯碳链长度的增加,其与直链淀粉单螺旋内部的疏水作用力增强,与淀粉的结合能力增强[10]。而RS-GMS的复合指数小于RS-GMP,这可能是由于GMS的碳链过长,在淀粉加热糊化过程中的分散性较差,不利于进入直链淀粉单螺旋内,与淀粉接触和复合的几率减小,复合指数减小[19]。与江佳妮等[21]的研究结果相似,相比于12个碳和18个碳的脂肪酸,16个碳的脂肪酸更有利于复合物的形成。

表 1 大米淀粉-单甘酯复合物的复合指数Table 1. Complex index of rice starch-monoglycyrrhizin complexes样品 RS-GML RS-GMP RS-GMS CI(%) 63.38±2.16c 76.58±2.67a 71.98±1.13b 注:RS-GML、RS-GMP、RS-GMS分别为大米淀粉-甘油单月桂酸酯复合物、大米淀粉-甘油单棕榈酸酯复合物、大米淀粉-甘油单硬脂酸酯复合物。 2.2 不同单甘酯对大米淀粉溶解度的影响

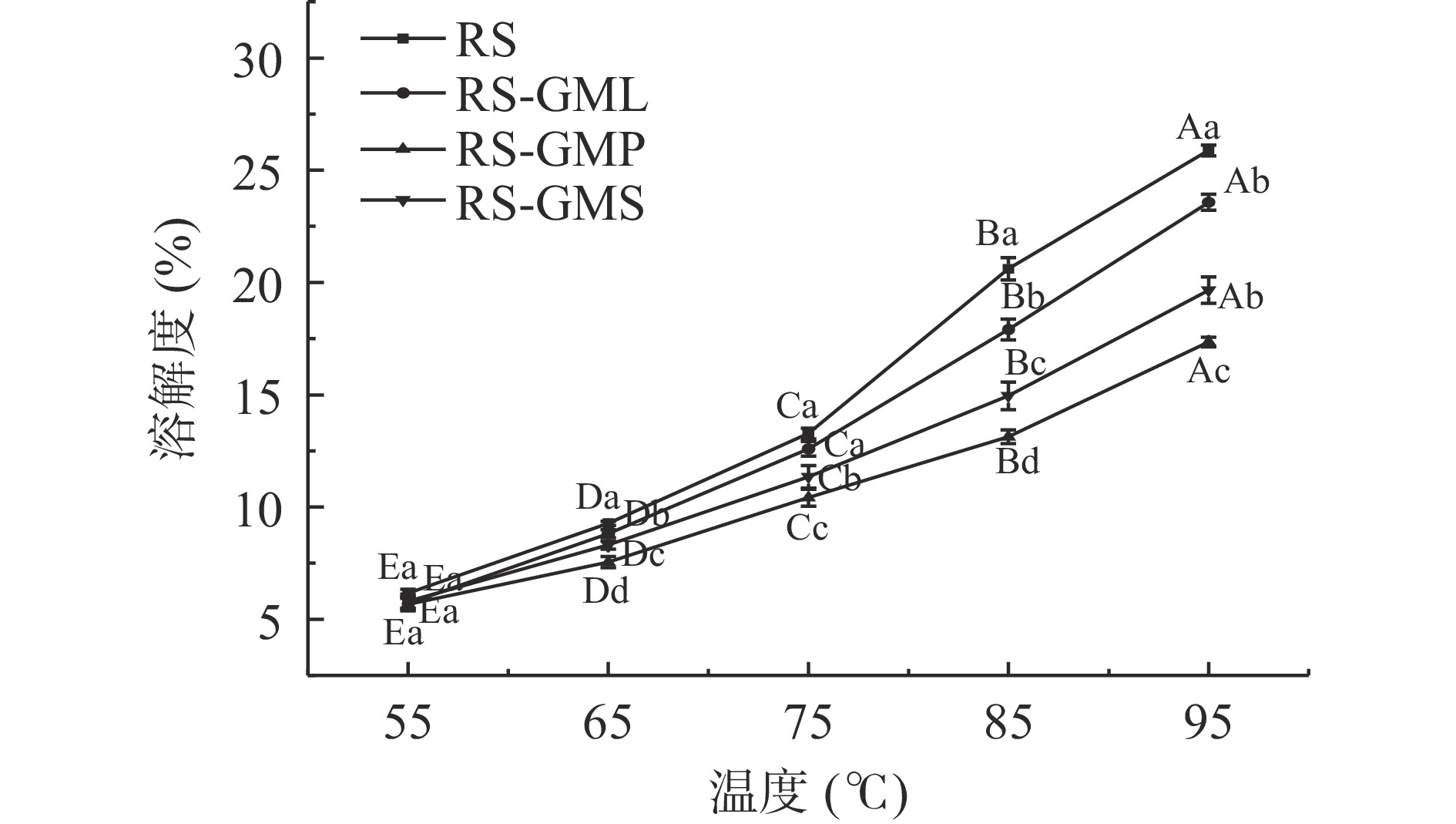

图1显示了大米淀粉与大米淀粉-单甘酯复合物在55~95 ℃不同温度下的溶解度。由图1可知,55 ℃时大米淀粉和复合物的溶解度无显著性差异(P>0.05),随着温度的升高,大米淀粉和复合物的溶解度显著增大(P<0.05),随着温度的上升,淀粉分子内的氢键被破坏,淀粉颗粒的吸水性增强,溶解度增大[22]。同时与原大米淀粉相比,与单甘酯复合后大米淀粉溶解度显著下降(P<0.05),在85和95 ℃时这种趋势更为明显,溶解度大小为RS>RS-GML>RS-GMS>RS-GMP,说明复合物的形成使淀粉的结构更加紧密,加热糊化过程中直链淀粉不易浸出,从而使溶解度下降[23-24]。Garcia等[25]的研究显示,在玉米淀粉中添加单硬脂酸甘油酯,也会使淀粉的溶解度下降。同时研究发现,复合物的溶解度与复合物的复合程度有关,复合指数越大,水分进入其内部结晶结构的难度越大,溶解度也就越小,Li等[26]和江佳妮等[21]的研究也曾得出相似的结论。

2.3 不同单甘酯对大米淀粉冻融稳定性的影响

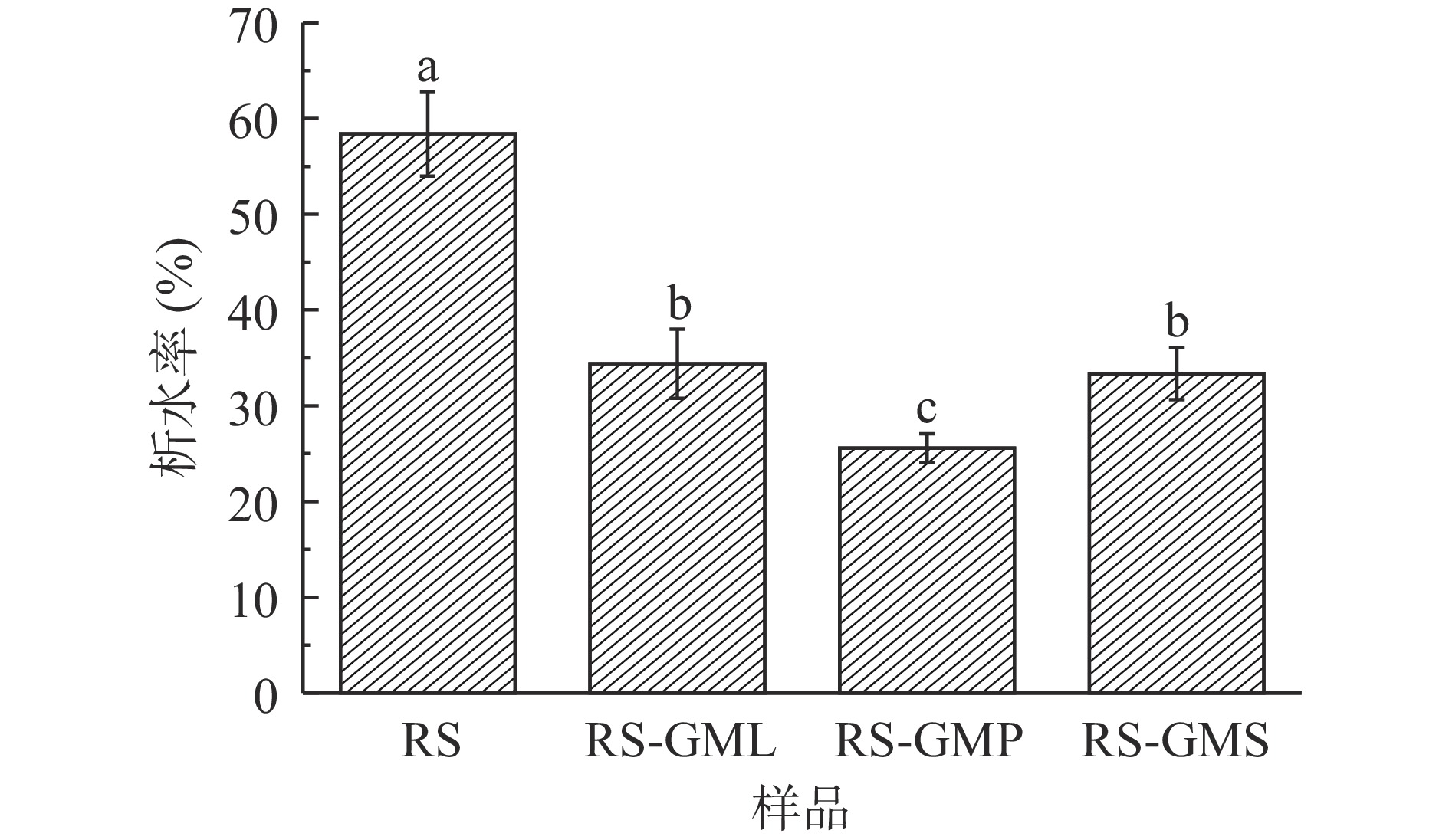

冻融稳定性代表淀粉分子在冻结和融化过程中保持原来性质的能力,通常用析水率来表示[27]。淀粉凝胶在冻结过程中形成冰晶,使得解冻过程中水分从淀粉凝胶的网络结构中析出,发生析水现象,淀粉的冻融稳定性反映淀粉的老化程度,析水率越小,淀粉的冻融稳定性越好,其老化程度越低[28]。大米淀粉和大米淀粉-单甘酯复合物的冻融稳定性如图2所示。由图2可知,与单甘酯复合后,大米淀粉的析水率均显著降低(P<0.05),RS-GMP的析水率最低,冻融稳定性更好。这是因为大米淀粉分子与单甘酯络合,空间位阻增大,抑制了淀粉分子之间的重新排列,极大地影响了冻融时淀粉的结构,阻碍了水分子的析出,降低了析水率,提高了淀粉的冻融稳定性[29-30]。同时析水率的变化与淀粉与脂质的复合程度密切相关。本试验中,大米淀粉和单甘酯的复合程度为RS-GMP>RS-GMS>RS-GML,析水率为RS-GMP<RS-GMS<RS-GML,复合程度越大,析水率越小。此结果表明,与原大米淀粉相比,单甘酯的加入降低了大米淀粉的析水率,大米淀粉-单甘酯复合物的形成使大米淀粉的冻融稳定性得到了提升,从而达到了延缓大米淀粉老化的目的。

2.4 不同单甘酯对大米淀粉糊化特性的影响

淀粉糊化是指淀粉颗粒由有序状态向无序状态转变的复杂过程。当淀粉在脂类存在下糊化时,淀粉分子和脂类倾向于形成单螺旋包合物,进而对淀粉糊化特性产生影响[31]。大米淀粉和复合物的糊化特征参数如表2所示。与原淀粉相比,大米淀粉-单甘酯复合物的峰值黏度、最低黏度和最终黏度均显著降低(P<0.05)。峰值黏度是指加热使样品开始糊化直至冷却之前所达到的最大的黏度值,加入单甘酯使大米淀粉的峰值黏度降低,这可能是因为大米淀粉与单甘酯形成单螺旋包合物后,单甘酯占据了淀粉颗粒螺旋腔内部,限制了淀粉在糊化过程中的吸水溶胀,降低了大米淀粉的峰值黏度[32]。衰减值是峰值黏度与最低黏度的差值,加入GMP和GMS后,衰减值显著减小(P<0.05),说明加入单甘酯后淀粉糊的热稳定性得到提升,淀粉颗粒不容易发生破裂[33]。回生值是最终黏度与最低黏度的差值,由表2可以看到大米淀粉的回生值显著高于大米淀粉-单甘酯复合物的回生值(P<0.05),回生值越高,抗老化性能越差;加入GMP后的大米淀粉,回生值最低,抗老化能力较好[34-35]。

表 2 大米淀粉和复合物的糊化特性Table 2. Pasting property of rice starch and its complexes样品 糊化温度

(℃)峰值黏度

(cP)最低黏度

(cP)最终黏度

(cP)衰减值

(cP)回生值

(cP)RS 91.2±0.1b 2307.7±22.9a 1454.7±40.5a 2028.7±40.1a 853.0±28.6a 574.0±2.6a RS-GML 94.7±0.4a 1239.0±19.1c 392.0±9.5d 825.0±25.4c 847.0±12.1a 433.0±16.5b RS-GMP 94.8±0.2a 1042.0±29.5d 492.7±28.00c 774.3±17.1c 549.3±11.9c 281.7±17.8d RS-GMS 95.0±0.1a 1374.0±23.0b 756.3±25.6b 1134.7±25.0b 617.7±15.5b 378.3±20.6c 2.5 不同单甘酯对大米淀粉热性能的影响

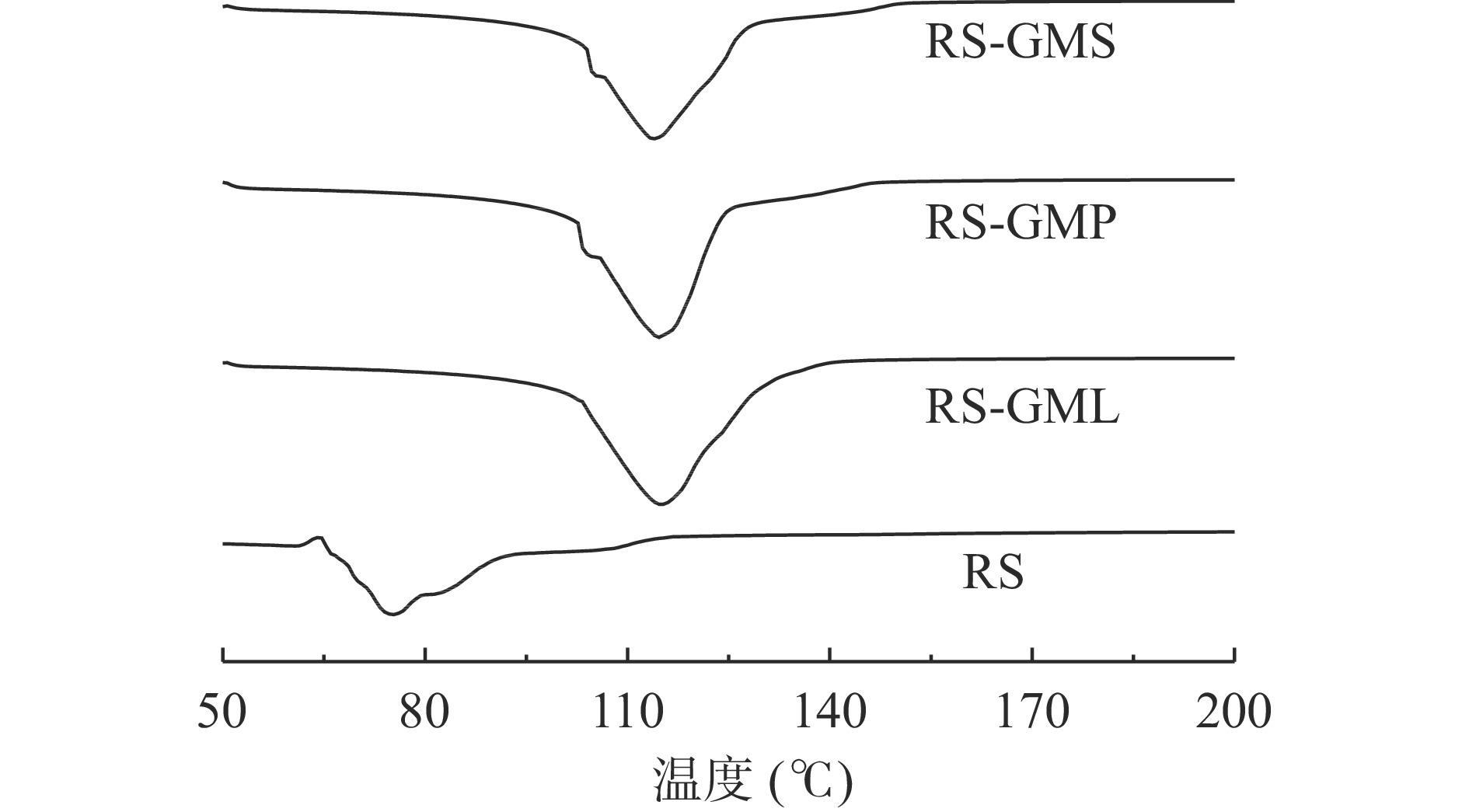

由表3可知,与单甘酯复合会对RS的热性能产生影响,与原RS相比,GML、GMP和GMS三种复合物的糊化起始温度TO、峰值温度TP、结束温度TC以及焓变△H均发生显著变化(P<0.05)。由图3可知,原RS在70~77 ℃出现一个吸热峰,为大米淀粉的糊化峰[36]。GML、GMP和GMS三种复合物均只含有一个吸热峰,温度范围分别为97~125 ℃、97~123 ℃、97~128 ℃,可以推断此吸热峰为大米淀粉-单甘酯复合物的熔融峰[37-38],且无游离脂质的熔融峰,说明复合物中游离脂质较少,不易被检出[9]。

表 3 大米淀粉和复合物的热特性Table 3. Thermal property of rice starch and its complexes样品 TO(℃) TP(℃) TC(℃) △H(J/g) RS 70.20±0.24c 75.10±0.17c 77.60±0.34d −383.40±5.19a RS-GML 97.66±0.05a 106.12±0.22a 125.28±0.43b −1477.61±31.78d RS-GMP 97.34±0.06b 105.05±0.11b 123.41±0.80c −1415.89±20.33c RS-GMS 97.62±0.17ab 105.44±0.49b 128.52±0.74a −1303.62±13.41b 2.6 红外光谱分析

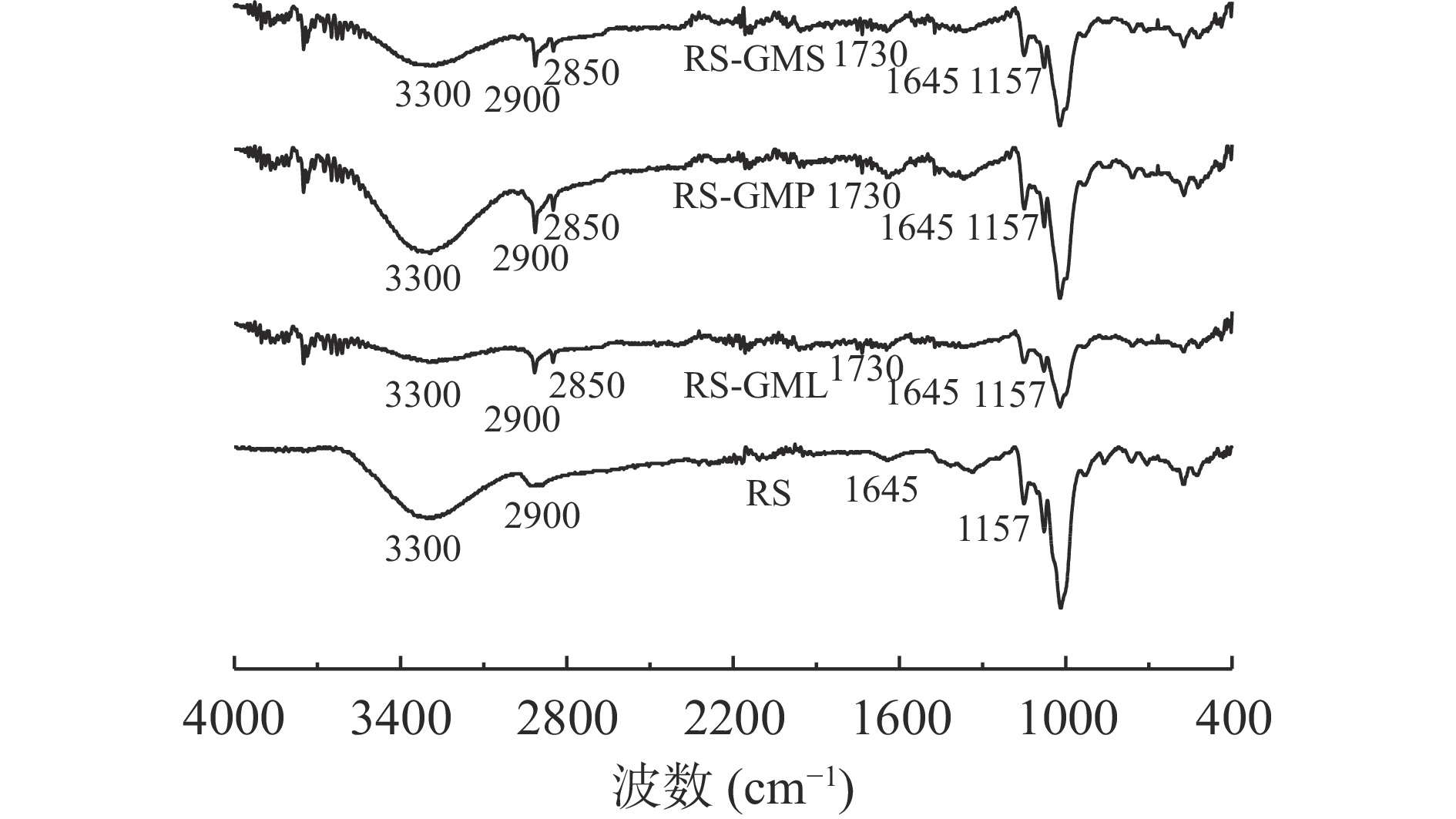

淀粉与脂质形成复合物后分子特征的变化可以通过傅立叶红外变换光谱(FT-IR)表征。通过谱图还可以检测淀粉-脂质复合物形成后是否有新的基团生成。大米淀粉及大米淀粉-单甘酯复合物的红外光谱如图4所示。由图4可知,大米淀粉和三种复合物均在3300和2900 cm−1附近出现了信号峰,其中3300 cm−1处的宽吸收峰是由淀粉中-OH振动产生的,2900 cm−1处的信号峰则为葡萄糖环上亚甲基的伸缩振动峰[39]。相比于大米淀粉,三种复合物均在2850和1730 cm−1附近出现了新的吸收峰,2850 cm−1处为单甘酯的亚甲基伸缩振动峰,1730 cm−1处是单甘酯的羰基伸缩振动峰[7]。1645和1157 cm−1处的吸收峰分别是由淀粉中的CHO和C-O基团的伸缩振动导致的,1100~700 cm−1内出现的特征峰是由D-吡喃葡萄糖-OH相连的C-O伸缩振动导致的[23]。以上结果表明,三种单甘酯均与淀粉形成了复合物,大米淀粉与单甘酯复合无新基团生成,淀粉与单甘酯间并未发生化学反应,而是通过疏水作用络合形成复合物[40]。1047 cm−1/1022 cm−1表示淀粉颗粒中结晶区与非结晶区的比率,反映淀粉的短程结构有序性,其比值与老化程度有协同作用[41]。经OMNIC处理后计算得出RS、RS-GML、RS-GMP和RS-GMS的1047 cm−1/1022 cm−1比值分别为0.75、0.71、0.58和0.67。与原RS相比,大米淀粉-单甘酯复合物在1047与1022 cm−1处的比值均下降,说明大米淀粉-单甘酯复合物的形成抑制了淀粉的重结晶,淀粉的短程有序性降低[32]。在3种复合物中,RS-GMP的1047 cm−1/1022 cm−1最小,有序淀粉含量较少,抗老化能力强。

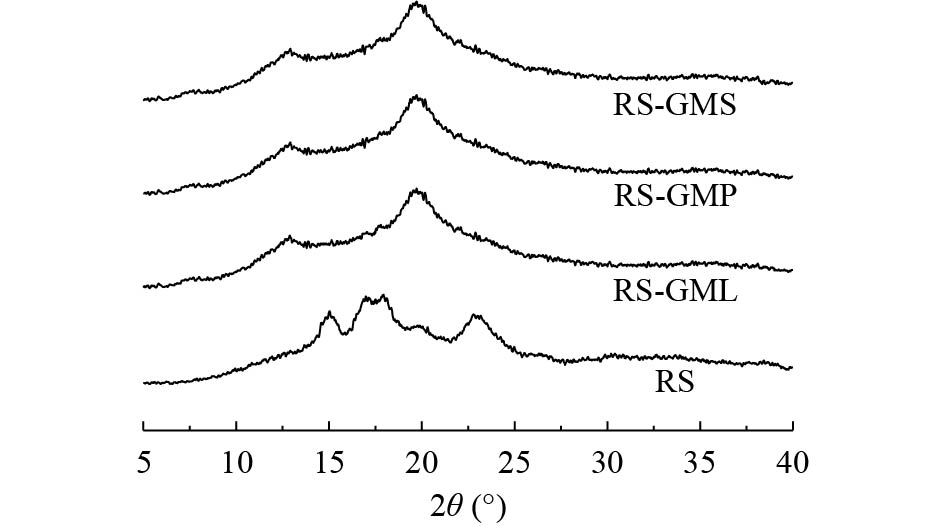

2.7 结晶结构分析

大米淀粉和复合物的X-射线衍射图谱如图5所示。由图5可知,大米淀粉在15°、17°、18°和23°附近出现衍射峰,说明大米淀粉属于典型A型结晶结构。大米淀粉与不同的单甘酯复合后,均在13°和20°附近显示出衍射峰,单甘酯的加入改变了淀粉的结晶结构,大米淀粉与单甘酯复合物的结晶结构属V型结晶结构,与Lu和Cai等[42-43]的研究结果一致。

3. 结论

本研究以大米淀粉为原料,研究不同链长单甘酯与大米淀粉复合对大米淀粉溶解度、冻融稳定性、糊化特性、热特性、短程有序性以及结晶结构的影响。试验表明,三种单甘酯与大米淀粉的复合程度为GMP>GMS>GML,GMP与大米淀粉的复合程度最高为76.58%;RS-GML、RS-GMP和RS-GMS的形成均能降低大米淀粉的溶解度、析水率、回生值以及有序淀粉含量,其中GMP的影响最为显著(P<0.05);DSC结果表明,大米淀粉和单甘酯通过疏水相互作用形成淀粉-脂质复合物;X-射线衍射图谱显示,大米淀粉-不同单甘酯复合物均在13°和20°处出现衍射峰,表明大米淀粉由A型结构转化成了V型结构。由上述结果可知,三种单甘酯的加入均可延缓大米淀粉的老化,其中GMP抑制大米淀粉老化的效果最为显著(P<0.05)。

-

表 1 大米淀粉-单甘酯复合物的复合指数

Table 1 Complex index of rice starch-monoglycyrrhizin complexes

样品 RS-GML RS-GMP RS-GMS CI(%) 63.38±2.16c 76.58±2.67a 71.98±1.13b 注:RS-GML、RS-GMP、RS-GMS分别为大米淀粉-甘油单月桂酸酯复合物、大米淀粉-甘油单棕榈酸酯复合物、大米淀粉-甘油单硬脂酸酯复合物。 表 2 大米淀粉和复合物的糊化特性

Table 2 Pasting property of rice starch and its complexes

样品 糊化温度

(℃)峰值黏度

(cP)最低黏度

(cP)最终黏度

(cP)衰减值

(cP)回生值

(cP)RS 91.2±0.1b 2307.7±22.9a 1454.7±40.5a 2028.7±40.1a 853.0±28.6a 574.0±2.6a RS-GML 94.7±0.4a 1239.0±19.1c 392.0±9.5d 825.0±25.4c 847.0±12.1a 433.0±16.5b RS-GMP 94.8±0.2a 1042.0±29.5d 492.7±28.00c 774.3±17.1c 549.3±11.9c 281.7±17.8d RS-GMS 95.0±0.1a 1374.0±23.0b 756.3±25.6b 1134.7±25.0b 617.7±15.5b 378.3±20.6c 表 3 大米淀粉和复合物的热特性

Table 3 Thermal property of rice starch and its complexes

样品 TO(℃) TP(℃) TC(℃) △H(J/g) RS 70.20±0.24c 75.10±0.17c 77.60±0.34d −383.40±5.19a RS-GML 97.66±0.05a 106.12±0.22a 125.28±0.43b −1477.61±31.78d RS-GMP 97.34±0.06b 105.05±0.11b 123.41±0.80c −1415.89±20.33c RS-GMS 97.62±0.17ab 105.44±0.49b 128.52±0.74a −1303.62±13.41b -

[1] 钟晓瑜, 杨志伟. 二氢杨梅素对大米淀粉回生的抑制作用[J]. 现代食品科技,2022,38(9):153−158. [ZHONG X Y, YANG Z W. Inhibitory effect of dihydromyricetin on rice starch regeneration[J]. Modern Food Science and Technology,2022,38(9):153−158. doi: 10.13982/j.mfst.1673-9078.2022.9.1362 ZHONG X Y, YANG Z W. Inhibitory effect of dihydromyricetin on rice starch regeneration[J]. Modern Food Science and Technology, 2022, 38(9): 153-158. doi: 10.13982/j.mfst.1673-9078.2022.9.1362

[2] WANG L, WANG W, WANG Y W, et al. Effects of fatty acid chain length on properties of potato starch–fatty acid complexes under partially gelatinization[J]. International Journal of Food Properties,2018,21(1):2121−2134. doi: 10.1080/10942912.2018.1489842

[3] 莫呈鹏, 余奔, 王鲁峰. 添加黄原胶和脂肪酸后玉米淀粉理化性质的变化[J]. 现代食品科技,2020,36(8):102−109. [MO C P, YU B, WANG L F. Changes of physicochemical properties of corn starch after adding xanthan gum and fatty acid[J]. Modern Food Science and Technology,2020,36(8):102−109. MO C P, YU B, WANG L F. Changes of physicochemical properties of corn starch after adding xanthan gum and fatty acid [J]. Modern Food Science and Technology, 2020, 36(8): 102-109.

[4] YU Z, WANG Y S, CHEN H H, et al. The gelatinization and retrogradation properties of wheat starch with the addition of stearic acid and sodium alginate[J]. Food Hydrocolloids,2018,81:77−86. doi: 10.1016/j.foodhyd.2018.02.041

[5] 董慧娜, 陈洁, 汪磊, 等. 不同蒸煮方式下不同链长脂肪酸对板栗淀粉特性的影响[J]. 食品安全质量检测学报,2022,13(18):6009−6016. [DONG H N, CHEN J, WANG L, et al. Effects of fatty acids with different chain lengths on the properties of chestnut starch under different cooking methods[J]. Journal of Food Safety & Quality,2022,13(18):6009−6016. doi: 10.3969/j.issn.2095-0381.2022.18.spaqzljcjs202218029 DONG H N, CHEN J, WANG L, et al. Effects of fatty acids with different chain lengths on the properties of chestnut starch under different cooking methods[J]. Journal of Food Safety & Quality, 2022, 13(18): 6009-6016. doi: 10.3969/j.issn.2095-0381.2022.18.spaqzljcjs202218029

[6] 陈海华, 王雨生, 王慧云, 等. 脂肪酸的链长和不饱和度对脂肪酸-普通玉米淀粉复合物理化性质的影响[J]. 中国粮油学报,2016,31(3):30−36. [CHEN H H, WANG Y S, WANG H Y, et al. Effects of fatty acids with different chain length and degree of unsaturation on physicochemical properties of normal corn starch[J]. Journal of the Chinese Cereals and Oils Association,2016,31(3):30−36. doi: 10.3969/j.issn.1003-0174.2016.03.006 CHEN H H, WANG Y S, WANG H Y, et al. Effects of fatty acids with different chain length and degree of unsaturation on physicochemical Properties of normal corn starch[J]. Journal of the Chinese Cereals and Oils Association, 2016, 31(3): 30-36. doi: 10.3969/j.issn.1003-0174.2016.03.006

[7] 杨留枝, 娄雪, 史苗苗, 等. 小麦直链淀粉-单甘酯-色氨酸三元复合物的制备及分析[J]. 河南农业大学学报,2021,55(3):477−484. [YANG L Z, LOU X, SHI M M, et al. Preparation and analysis of wheat straight-chain starch-monoglyceride-tryptophan ternary complexes[J]. Journal of Henan Agricultural University,2021,55(3):477−484. YANG L Z, LOU X, SHI M M, et al. Preparation and analysis of wheat straight-chain starch-monoglyceride-tryptophan ternary complexes[J]. Journal of Henan Agricultural University, 2021, 55(3): 477-484.

[8] VALERIO A, FIAMETTI K G, ROVANI S, et al. Enzymatic production of mono- and diglycerides in compressed n-butane and AOT surfactant[J]. Journal of Supercritical Fluids,2009,49(2):216−220. doi: 10.1016/j.supflu.2009.02.001

[9] 娄雪, 杨留枝, 史苗苗, 等. 小麦直链淀粉-单甘酯复合物的制备及表征[J]. 食品科技,2020,45(11):243−249. [LOU X, YANG L Z, SHI M M, et al. Preparation and characterization of wheat amylose-monoglyceride complex[J]. Food Technology,2020,45(11):243−249. doi: 10.13684/j.cnki.spkj.2020.11.039 LOU X, YANG L Z, SHI M M, et al. Preparation and characterization of wheat amylose-monoglyceride complex[J]. Food Technology, 2020, 45(11): 243-249. doi: 10.13684/j.cnki.spkj.2020.11.039

[10] 张书艳, 朱杰, 李琳, 等. 淀粉链/支比和脂肪酸链长对淀粉-脂肪酸复合物结晶结构的影响[J]. 中国粮油学报,2018,33(6):27−32. [ZHANG S Y, ZHU J, LI L, et al. Effect of starch chain/branching ratio and fatty acid chain length on the crystalline structure of starch-fatty acid complexes[J]. Chinese Journal of Cereals and Oils,2018,33(6):27−32. doi: 10.3969/j.issn.1003-0174.2018.06.006 ZHANG S Y, ZHU J, LI L, et al. Effect of starch chain/branching ratio and fatty acid chain length on the crystalline structure of starch-fatty acid complexes[J]. Chinese Journal of Cereals and Oils, 2018, 33(6): 27-32. doi: 10.3969/j.issn.1003-0174.2018.06.006

[11] 孙圣麟. 脂肪酸类型与淀粉来源对复合物结构和消化性能影响的研究[D]. 无锡: 江南大学, 2021. SUN S L. Study on the effect of fatty acid type and starch source on the structure and digestive properties of complexes[D]. Wuxi: Jiangnan University, 2021.

[12] CHAO C, YU J L, WANG S, et al. Mechanisms underlying the formation of complexes between Maize Starch and Lipids[J]. Journal of Agricultural and Food Chemistry, 2017: 272−278.

[13] CHANG F D, HE X W, HUANG Q. The physicochemical properties of swelled maize starch granules complexed with lauric acid[J]. Food Hydrocolloids,2013,32(2):365−372. doi: 10.1016/j.foodhyd.2013.01.021

[14] 孟爽. 高压均质法制备玉米淀粉—脂质复合物及其结构性质研究[D]. 哈尔滨: 哈尔滨工业大学, 2015. MENG S. Preparation and structural properties of corn starch-lipid complexes by high-pressure homogenization method[D]. Harbin: Harbin Institute of Technology, 2015.

[15] 王磊鑫, 吴娜娜, 吕莹果, 等. 挤压蒸煮加工米糠可溶和不溶膳食纤维对米淀粉性质的影响及其相互作用分析[J]. 食品科学,2022,43(16):107−113. [WANG L X, WU N N, LV Y G, et al. Effect of soluble and insoluble dietary fiber on rice starch properties and their interaction analysis in rice bran processed by extrusion cooking[J]. Food Science,2022,43(16):107−113. doi: 10.7506/spkx1002-6630-20210918-231 WANG L X, WU N N, LV Y G, et al. Effect of soluble and insoluble dietary fiber on rice starch properties and their interaction analysis in rice bran processed by extrusion cooking [J]. Food Science, 2022, 43(16): 107-113. doi: 10.7506/spkx1002-6630-20210918-231

[16] 杨伟军, 李宏升, 林莹. 脂肪酸对大米淀粉热特性及质构品质影响的研究[J]. 食品工业,2018,39(4):1−4. [YANG W J, LI H S, LIN Y. Effects of fatty acids on thermal properties, texture and quality of rice starch[J]. Food Industry,2018,39(4):1−4. YANG W J, LI H S, LIN Y. Effects of fatty acids on thermal properties, texture and quality of rice starch [J]. Food Industry, 2018, 39(4): 1-4.

[17] 张明月, 杨留枝, 史苗苗, 等. 超声辅助预处理法制备小麦淀粉-单甘酯复合物[J]. 食品科技,2019,44(11):279−284. [ZHANG M Y, YANG L Z, SHI M M, et al. Preparation of wheat starch-monoglyceride complex by ultrasound-assisted pretreatment[J]. Food Science and Technology,2019,44(11):279−284. doi: 10.13684/j.cnki.spkj.2019.11.049 ZHANG M Y, YANG L Z, SHI M M, et al. Preparation of wheat starch-monoglyceride complex by ultrasound-assisted pretreatment [J]. Food Science and Technology, 2019, 44(11): 279-284. doi: 10.13684/j.cnki.spkj.2019.11.049

[18] SAITO, WATANABE, SASAKI, et al. Effects of single ingestion of rice cracker and cooked rice with high resistant starch on postprandial glucose and insulin responses in healthy adults: two randomized, single-blind, cross-over trials[J]. Bioscience, Biotechnology, and Biochemistry,2020,84(2):365−371. doi: 10.1080/09168451.2019.1687282

[19] 董慧娜, 汪磊, 陈洁, 等. 板栗淀粉-脂质复合物对淀粉老化性质的影响[J]. 河南工业大学学报(自然科学版),2022,43(1):49−57. [DONG H N, WANG L, CHEN J, et al. Effect of chestnut starch-lipid complexes on the aging properties of starch[J]. Journal of Henan University of Technology (Natural Science Edition),2022,43(1):49−57. DONG H N, WANG L, CHEN J, et al. Effect of chestnut starch-lipid complexes on the aging properties of starch[J]. Journal of Henan University of Technology (Natural Science Edition), 2022, 43(1): 49-57.

[20] CA L, VRIES A, MARRINK S J. Amylose folding under the influence of lipids[J]. Carbohydrate Research,2012,364:1−7. doi: 10.1016/j.carres.2012.10.007

[21] 江佳妮, 向贵元, 邓佳宜, 等. 脂肪酸链长对高直链玉米淀粉—脂质复合物结构及理化性质的影响[J]. 食品与机械,2022,38(3):25−31. [JIANG J N, XIANG G Y, DENG J Y, et al. Effects of fatty acid chain length on Structure and Physicochemical Properties of high amylose corn starch-lipid Complex[J]. Food & Machinery,2022,38(3):25−31. JIANG J N, XIANG G Y, DENG J Y, et al. Effects of fatty acid chain length on Structure and Physicochemical Properties of high amylose corn starch-lipid Complex [J]. Food & Machinery, 2022, 38(3): 25-31.

[22] CORREIA P R, NUNES M C, BEIRAO-DA-COSTA M L. The effect of starch isolation method on physical and functional properties of portuguese nuts starches. I. Chestnuts (Castanea sativa Mill. var. Martainha and Longal) fruits[J]. Food Hydrocolloids,2012,27(1):256−263. doi: 10.1016/j.foodhyd.2011.05.010

[23] 张昀, 张康逸, 赵迪, 等. 糯麦淀粉-脂质复合物的结构及体外消化特性[J]. 食品工业科技,2022,43(20):97−106. [ZHANG Y, ZHANG K Y, ZHAO D, et al. Structure and in vitro digestion properties of waxy wheat starch-lipid complexes[J]. Science and Technology of Food Industry,2022,43(20):97−106. ZHANG Y, ZHANG K Y, ZHAO D, et al. Structure and in vitro digestion properties of waxy wheat starch-lipid complexes[J]. Science and Technology of Food Industry, 2022, 43(20): 97-106.

[24] LIU P F, KANG X M, CUI B, et al. Effects of amylose content and enzymatic debranching on the properties of maize starch-glycerol monolaurate complexes[J]. Carbohydrate Polymers,2019,222:115000. doi: 10.1016/j.carbpol.2019.115000

[25] GARCIA M C, FRANCO, CELIA M L. Effect of glycerol monostearate on the gelatinization behavior of maize starches with different amylose contents[J]. Starch-Stärke,2015,67(1−2):107−116.

[26] LI X, GAO X X, LU J, et al. Complex formation, physicochemical properties of different concentration of palmitic acid yam (Dioscorea pposita Thunb.) starch preparation mixtures[J]. LWT-Food Science and Technology,2019,101:130−137. doi: 10.1016/j.lwt.2018.11.032

[27] 林江涛, 孙灵灵, 岳清华. 不同粒度小麦粉淀粉的理化特性分析[J]. 现代食品科技,2022,38(8):193−198,192. [LIN J T, SUN L L, YUE Q H. Analysis of physicochemical properties of wheat flour starch with different particle sizes[J]. Modern Food Science and Technology,2022,38(8):193−198,192. doi: 10.13982/j.mfst.1673-9078.2022.8.1163 LIN J T, SUN L L, YUE Q H. Analysis of physicochemical properties of wheat flour starch with different particle sizes[J]. Modern Food Science and Technology, 2022, 38(8): 193-198, 192. doi: 10.13982/j.mfst.1673-9078.2022.8.1163

[28] ARUNVANART T, CHAROENREIN S. Effect of sucrose on the freeze-thaw stability of rice starch gels: Correlation with microstructure and freezable water[J]. Carbohydrate Polymers,2008,74(3):514−518. doi: 10.1016/j.carbpol.2008.04.002

[29] KAWAI K, TAKATO S, SASAKI T, et al. Complex formation, thermal properties, and in-vitro digestibility of gelatinized potato starch–fatty acid mixtures[J]. Food Hydrocolloids,2012,27(1):228−234. doi: 10.1016/j.foodhyd.2011.07.003

[30] FAROOQ A M, DHITAL S, LI C, et al. Effects of palm oil on structural andin vitro digestion properties of cooked rice starches[J]. International Journal of Biological Macromolecules,2018,107:1080−1085. doi: 10.1016/j.ijbiomac.2017.09.089

[31] FANTA G F, SHOGREN R L, SALCH J H. Steam jet cooking of high-amylose starch-fatty acid mixtures. An investigation of complex formation[J]. Carbohydrate Polymers,1999,38(1):1−6. doi: 10.1016/S0144-8617(98)00104-0

[32] 敖颖, 徐飞, 朱科学, 等. 菠萝蜜淀粉-月桂酸复合物的理化特性研究[J]. 食品科学技术学报,2022,40(2):98−107. [AO Y, XU F, ZHU K X, et al. Study on physicochemical properties of jackfruit seed starch-laurel acid complexes[J]. Journal of Food Science and Technology,2022,40(2):98−107. AO Y, XU F, ZHU K X, et al. Study on physicochemical properties of jackfruit seed starch-laurel acid complexes[J]. Journal of Food Science and Technology, 2022, 40(2): 98-107.

[33] 黄婷婷, 白羽嘉, 付文欠, 等. 3种改良剂种类对小麦复配粉粉质特性及面片品质影响的比较分析[J]. 现代食品科技,2021,37(11):270−280,221. [HUANG T T, BAI Y J, FU W Q, et al. Comparative analysis of the effects of three kinds of improver on the characteristics of wheat blended flour and dough quality[J]. Modern Food Science and Technology,2021,37(11):270−280,221. doi: 10.13982/j.mfst.1673-9078.2021.11.0136 HUANG T T, BAI Y J, FU W Q, et al. Comparative analysis of the effects of three kinds of improver on the characteristics of wheat blended flour and dough quality[J]. Modern Food Science and Technology, 2021, 37(11): 270-280, 221. doi: 10.13982/j.mfst.1673-9078.2021.11.0136

[34] TUFVESSON F, WAHLGREN M, ELIASSON A C. Formation of amylose-lipid complexes and effects of temperature treatment. Part 1. Monoglycerides[J]. Starch- Stärke,2010,55(2):61−71.

[35] 石少侠, 董瑶瑶, 李琪, 等. 淀粉-脂质复合物功能及营养特性研究进展[J]. 食品科学,2020,41(9):238−245. [SHI S X, DONG Y Y, LI Q, et al. Advances in functional and nutritional properties of starch-lipid complexes[J]. Food Science,2020,41(9):238−245. doi: 10.7506/spkx1002-6630-20190427-371 SHI S X, DONG Y Y, LI Q, et al. Advances in functional and nutritional properties of starch-lipid complexes[J]. Food Science, 2020, 41(9): 238-245. doi: 10.7506/spkx1002-6630-20190427-371

[36] 杨玥熹, 童姝, 顾振宇, 等. 不同链长单甘酯-籼米淀粉复合物结构及体外消化特性[J]. 中国粮油学报,2020,35(7):42−49. [YANG Y X, TONG S, GU Z Y, et al. Structure and in vitro digestibility of indica rice starch complex with different chain lengths[J]. Journal of the Chinese Cereals and Oils,2020,35(7):42−49. YANG Y X, TONG S, GU Z Y, et al. Structure and in vitro digestibility of indica rice starch complex with different chain lengths [J]. Journal of the Chinese Cereals and Oils, 2020, 35(7): 42-49.

[37] BILIADERIS C G, SENEVIRATNE H D. On the supermolecular structure and metastability of glycerol monostearate-amylose complex[J]. Carbohydrate Polymers,1990,13(2):185−206. doi: 10.1016/0144-8617(90)90083-5

[38] 黄强, 丁丽, 舒琴, 等. 食用油脂与加热方式对小麦淀粉结构和体外消化性的影响[J]. 华南理工大学学报(自然科学版),2018,46(11):9−15,38. [HUANG Q, DING L, SHU Q, et al. Effect of edible fats and heating methods on the structure and in vitro digestibility of wheat starch[J]. Journal of South China University of Technology (Natural Science Edition),2018,46(11):9−15,38. doi: 10.3969/j.issn.1000-565X.2018.11.002 HUANG Q, DING L, SHU Q, et al. Effect of edible fats and heating methods on the structure and in vitro digestibility of wheat starch[J]. Journal of South China University of Technology (Natural Science Edition), 2018, 46(11): 9-15, 38. doi: 10.3969/j.issn.1000-565X.2018.11.002

[39] WANG H S, WU Y M, WANG N F, et al. Effect of water content of high-amylose corn starch and glutinous rice starch combined with lipids on formation of starch-lipid complexes during deep-fat frying[J]. Food Chemistry,2019,278:515−522. doi: 10.1016/j.foodchem.2018.11.092

[40] WANG S J, WANG J R, YU J L, et al. Effect of fatty acids on functional properties of normal wheat and waxy wheat starches: A structural basis[J]. Food Chemistry,2016,190:285−292. doi: 10.1016/j.foodchem.2015.05.086

[41] XU J, ZHAO W, NING Y, et al. Comparative study of spring dextrin impact on amylose retrogradation[J]. Journal of Agricultural and Food Chemistry,2012,60(19):4970−4976. doi: 10.1021/jf2052477

[42] LU H, YANG Z, YU M, et al. Characterization of complexes formed between debranched starch and fatty acids having different carbon chain lengths[J]. International Journal of Biological Macromolecules,2021,167:595−604. doi: 10.1016/j.ijbiomac.2020.11.198

[43] CAI J J, CHAO C, NIU B, et al. New insight into the interactions among starch, lipid and protein in model systems with different starches[J]. Food Hydrocolloids,2020,112:106323.

-

期刊类型引用(13)

1. 高树财,闫格,胡桂芳,高火亮. 茶饮料中茶多酚含量测定方法的研究. 标准科学. 2025(01): 99-103 .  百度学术

百度学术

2. 邓婷婷,皮锦蝉,彭小平,姚于飞,李义全,李文娟. 茶多酚基于活性氧-线粒体途径发挥心血管保护作用的研究进展. 食品工业科技. 2025(04): 434-442 .  本站查看

本站查看

3. 蔡妙莹,钟雪莲,胡新涛,袁炎茹,梁花. 改性纤维中总多酚含量的测定. 中国纤检. 2025(03): 66-69 .  百度学术

百度学术

4. 苟祎,夏丽飞,马玉青,杨恺清,吴致远,普金霞,叶红,申时全. 不同花期紫娟茶树花的品质分析及加工工艺研究. 食品科技. 2025(02): 96-104 .  百度学术

百度学术

5. 黄珊由美,林东艺,马成英,荣杰峰,孙威江,黄艳. 茶饮料泡沫生成机理及控制技术研究进展. 茶叶科学. 2025(02): 181-190 .  百度学术

百度学术

6. 田宝明,叶芃,孔俊涛,杨开,孙培龙,陈红平,王舰,张相春. 茶多酚自组装纳米泡腾片的研制. 中国茶叶加工. 2024(02): 33-40 .  百度学术

百度学术

7. 陈俊婕,劳颖仪,陈晓维,余元善,温靖,吴继军,徐玉娟,肖更生,杨继国,唐延天,胡腾根. 茶多酚的功能活性及稳态化研究进展. 中国果菜. 2024(08): 25-31 .  百度学术

百度学术

8. 葛天睿,黄雪君,张娜,陈小强,沙如意,毛建卫. 茶多酚在医药和食品领域的应用研究进展. 食品安全质量检测学报. 2024(17): 176-184 .  百度学术

百度学术

9. 朱旋,田芸,孙海燕,王瑞,金文刚,陈琛. 茶多酚结合超高压处理对鲜切天麻贮藏品质的影响. 北方园艺. 2024(20): 83-90 .  百度学术

百度学术

10. 韩舒婷,华梓延,房耀维,杨光,侯晓月,周文梅,唐明,刘姝. 嗜热链球菌FUA329发酵绿茶浸提液及贮藏特性评价. 食品工业科技. 2024(21): 322-328 .  本站查看

本站查看

11. 辛皎瑜,钟雅静,沈启东,敖娜,梁玉文,付晶,刘春朋. 鹧鸪源大肠杆菌分离鉴定及茶多酚抑菌效果研究. 东北农业大学学报. 2024(07): 51-59 .  百度学术

百度学术

12. 陈晓真,韦怡含,蓝平,封余贤,黎笑笑,关欣,冯杰,何日梅. 茶多酚的提取纯化技术研究进展. 中国酿造. 2024(11): 20-25 .  百度学术

百度学术

13. 吴彤,刘丽莉,程伟伟,丁玥,徐宝成. NaCl和茶多酚对碱诱导鸡蛋清凝胶流变学特性及结构的影响. 食品与发酵工业. 2024(23): 194-201 .  百度学术

百度学术

其他类型引用(8)

下载:

下载:

下载:

下载: