Optimization of Preparation Process and Quality Analysis of Seabuckthorn Lyophilized Powder Effervescent Tablets

-

摘要: 为开发功能性沙棘冻干粉泡腾片,本研究以外观、口感和崩解时限为考察指标,通过模糊数学结合响应面优化试验确定最佳制备工艺,并对该泡腾片进行品质分析。结果表明:最佳配方为沙棘冻干粉添加量40.00%、崩解剂酸碱比1:1.28、崩解剂添加量41.89%、羧甲基纤维素钠(CMC-Na)含量3%;在此条件下制得的沙棘冻干粉泡腾片表面光滑,口感良好,具有沙棘独特的香气,综合评分为79.80±1.20;泡腾片中VC含量为5.85 mg/g,黄酮含量为5.26 mg/g,对DPPH自由基清除率达56.8%,对羟基自由基清除率达54.9%。本研究提升了沙棘的附加值,为沙棘功能性产品的开发提供了一定的理论基础。Abstract: To develop functional seabuckthorn lyophilized effervescent tablets, in this study, the appearance, taste and disintegration time were taken as the inspection indicators, the best preparation process was determined through fuzzy mathematics combined with response surface optimization test, and the quality of the effervescent tablets was analyzed. The results showed that the optimum formula was as follows: The additive amount of seabuckthorn lyophilized powder was 40.00%, the acid base ratio of disintegrant was 1:1.28, the additive amount of disintegrant was 41.89%, and the amount of sodium carboxymethyl cellulose (CMC-Na) was 3%. Under the best process conditions, the effervescent tablets have smooth surface, good taste and unique aroma of seabuckthorn, reaching a comprehensive score of 79.80±1.20. The effervescent tablets contained 5.85 mg/g of vitamin C and 5.26 mg/g of flavonoids, and the scavenging rates of DPPH free radicals and hydroxyl free radicals were 56.8% and 54.9%, respectively. This study enhanced the added value of seabuckthorn, and provided a theoretical basis for the development of seabuckthorn functional products.

-

沙棘,胡颓子科沙棘属,又名醋柳,享有“世界植物之奇”“维生素宝库”之称[1],是集经济、生态和社会效益于一身的药食同源植物[2]。沙棘富含维生素(A、C和E)、黄酮、氨基酸等活性物质和多种微量元素[3-6],具有抗氧化[7-8]、抑制肿瘤[9]、增强机体免疫力[10]、治疗心脑血管疾病[11]等功效。大健康时代背景下,“浑身是宝”的沙棘成为健康食品业的发展新动力。目前,已有沙棘的产品包括了沙棘汁饮料、沙棘酒、沙棘原浆、沙棘果酱等沙棘系列功能性食品等不同种类[12-15]。

泡腾片作为一种固体饮料具有体积小、便于携带保存、食用方式简单、崩解速度快、生物利用率高等优点[16-17]。泡腾片溶解于饮用水后,在泡腾崩解剂的作用下,会产生大量二氧化碳,使饮用入口时有汽水般的美感,有时崩解产生的气泡还会使在水中的泡腾片上下翻滚,使其崩解和融化加速,在工作的同时还可以起到缓解压力作用[18]。近年来,研究者更加注重泡腾片的营养与保健功能,开展了诸如黑枸杞提取物泡腾片[19]、白芸豆水提物泡腾片[20]、荔枝草泡腾片[21]、蓝靛果冻干粉泡腾片[22]等的制备工艺研究。尚无沙棘冻干粉泡腾片制备相关的文献报道。

因此,本试验以沙棘为原料,结合沙棘营养价值丰富和泡腾片吸收利用率高的优势,采用干法制粒压片法制备沙棘冻干粉泡腾片,并通过模糊数学结合响应面试验优化其最佳制备工艺,最终以泡腾片的外观、口感、崩解时限、VC含量、黄酮含量、DPPH自由基清除率、羟基自由基清除率为指标对沙棘冻干粉泡腾片进行品质评价。研究结果可为沙棘冻干粉泡腾片的研究和推向市场提供一些理论依据,也为沙棘的进一步研究和开发提供参考。

1. 材料与方法

1.1 材料与仪器

沙棘 山西吕梁醋柳山有限公司;乙酸铅、硫酸铜、酒石酸钾钠、无水葡萄糖、乙醇、亚甲蓝、氢氧化钠、亚铁氰化钾、硝酸铝、亚硝酸钠、偏磷酸、草酸、2,6-二氯靛酚、白陶土、活性炭、醋酸铵、硫酸亚铁、七水合硫酸亚铁、氯化铁、过氧化氢、碳酸钠 均为分析纯,北京化工厂;柠檬酸、羧甲基纤维素钠 均为食品级,浙江一诺生物科技有限公司;L(+)抗坏血酸标准品 天津市凯通化学试剂有限公司;二苯基苦肼基自由基(DPPH)标准品 上海蓝季生物试剂有限公司。

FW-100高速粉碎机 永光明医疗仪器有限公司;SJIA-10N-60D真空冷冻干燥机 双嘉仪器有限公司;FA2004电子天平 佑科仪器仪表有限公司;752N Plus紫外可见分光光度计 菁华科技仪器有限公司;MPLK-901恒温鼓风干燥箱、HH-S28恒温水浴锅 金坛大地自动化仪器厂;J03-0.4A压片机 万博仪器仪表有限公司。

1.2 实验方法

1.2.1 沙棘冻干粉的制备

将沙棘果清洗挑选去杂,置于高速破壁机榨汁处理,制备成沙棘全果浆。然后置于培养皿中进行真空冷冻干燥[23],试验条件为:冷阱温度−50 ℃、真空度50 Pa,预冻时间4 h,干燥时间为20 h。接着转入真空干燥箱,在30 ℃条件下真空干燥4 h,以减少冻干后产品的吸湿性。干燥完毕后,粉碎并过80目筛,收集过筛后的产品于密封袋中保存。得到的沙棘冻干粉含水量为6.62%。

1.2.2 沙棘冻干粉泡腾片的制备

采用干法制粒方式[21],将酸源(柠檬酸)、碱源(碳酸氢钠)与沙棘冻干粉、甜味剂、粘合剂(羧甲基纤维素钠)按比例进行混合,再加入填充剂(玉米淀粉)、润滑剂(聚乙二醇-6000)和引湿剂(食用盐),均匀混合后用压片机进行压片,片剂经干燥后即得沙棘冻干粉泡腾片,控制单片重量在1.5 g左右。

1.2.3 单因素实验

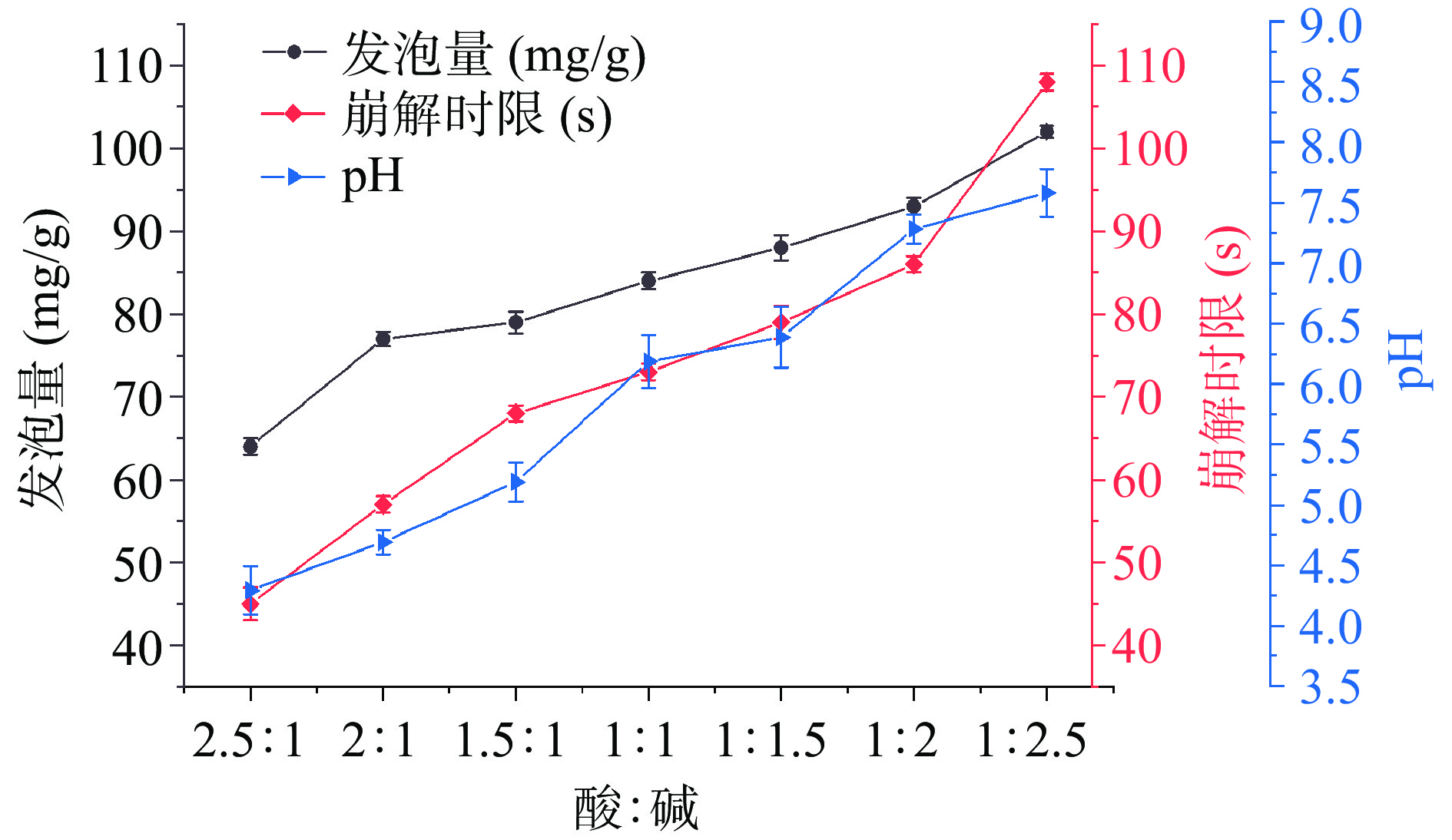

1.2.3.1 崩解剂酸碱比的确定

固定沙棘冻干粉添加量40%、崩解剂添加量45%、甜味剂添加量1.5%、聚乙二醇6000添加量 3%、食用盐添加量1%、羧甲基纤维素钠(CMC-Na)添加量3%,酸碱比按照2.5:1、2:1、1.5:1、1:1、1:1.5、1:2、1:2.5的质量比进行单因素实验,余下部分用玉米淀粉进行填充,按1.2.2方法制备沙棘泡腾片。准确称量3 g泡腾片溶于50 mL水中,直到无气泡产生且溶解完全停止,以发泡量、崩解时限和pH为评价指标,确定崩解剂酸碱比。

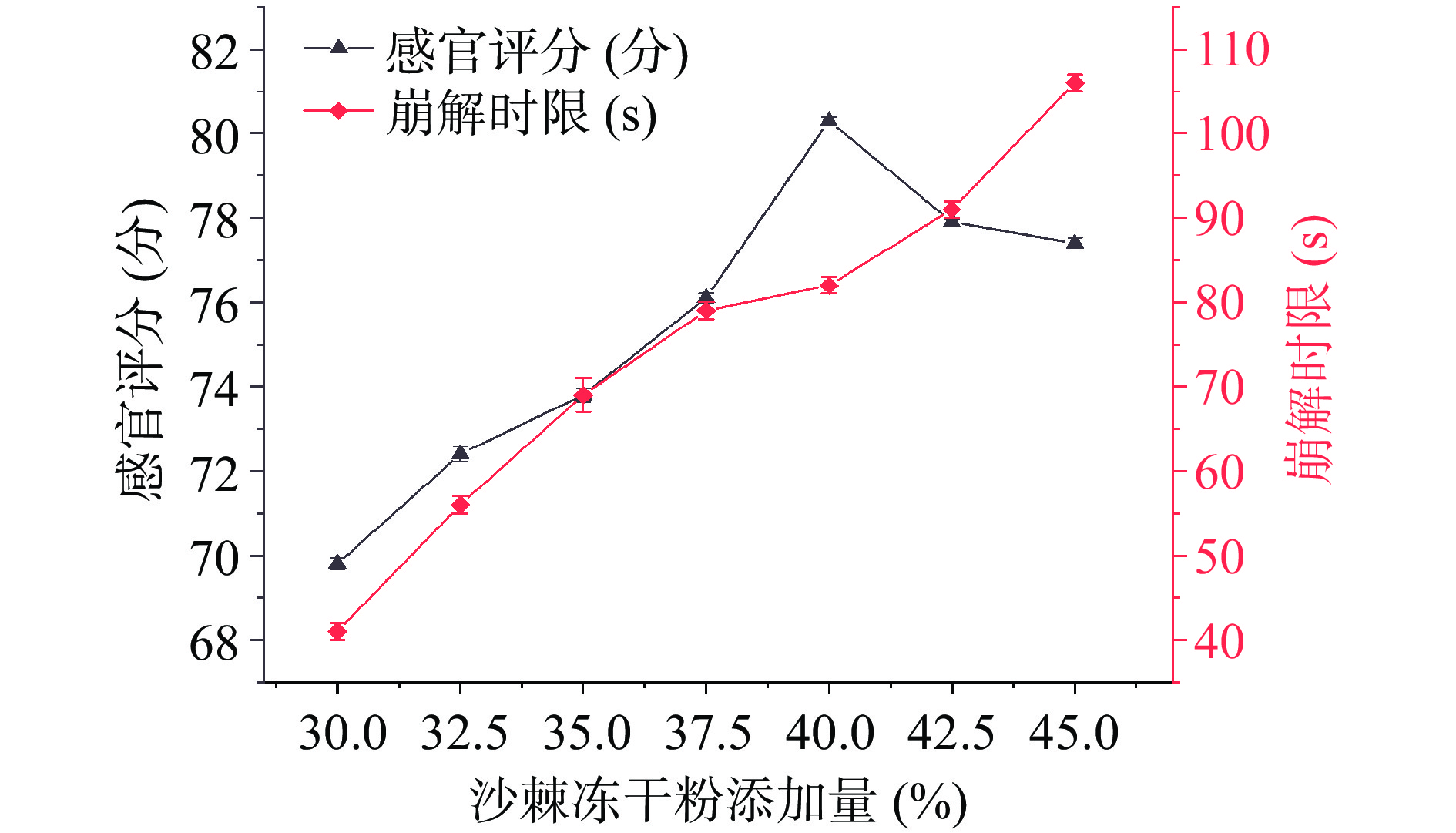

1.2.3.2 沙棘冻干粉添加量的确定

固定崩解剂添加量为45%、崩解剂酸碱比1:1.25、甜味剂添加量1.5%、聚乙二醇6000添加量3%、食用盐添加量1%、羧甲基纤维素钠(CMC-Na)添加量3%,分别按32.5%、35%、37.5%、40%、42.5%添加沙棘冻干粉,余下部分用玉米淀粉进行填充。准确称量3 g泡腾片溶于50 mL水中,直到无气泡产生且溶解完全停止。以感官评分和崩解时限为评价指标,考察沙棘冻干粉的添加量。

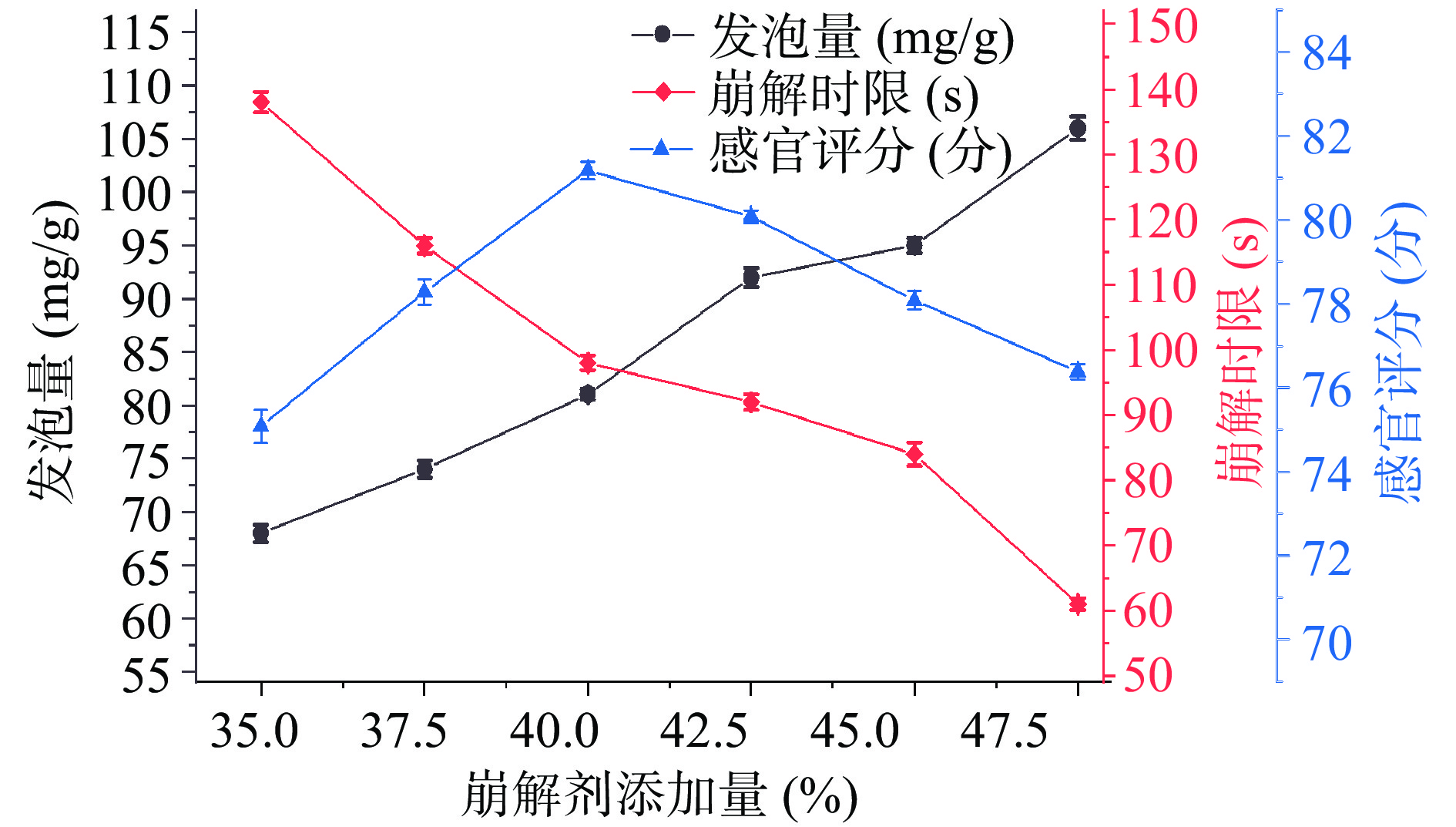

1.2.3.3 崩解剂添加量的确定

固定沙棘冻干粉添加量40%、崩解剂酸碱比1:1.25、甜味剂添加量1.5%、聚乙二醇6000添加量 3%、食用盐添加量1%、羧甲基纤维素钠(CMC-Na)添加量3%,崩解剂添加量按35%、37.5%、40%、42.5%、45%进行单因素实验,余下部分用玉米淀粉进行填充,按1.2.2方法制备沙棘泡腾片。准确称量3 g泡腾片溶于50 mL水中,直到无气泡产生且溶解完全停止。以感官评分、崩解时限和发泡量为评价指标,确定崩解剂的添加量。

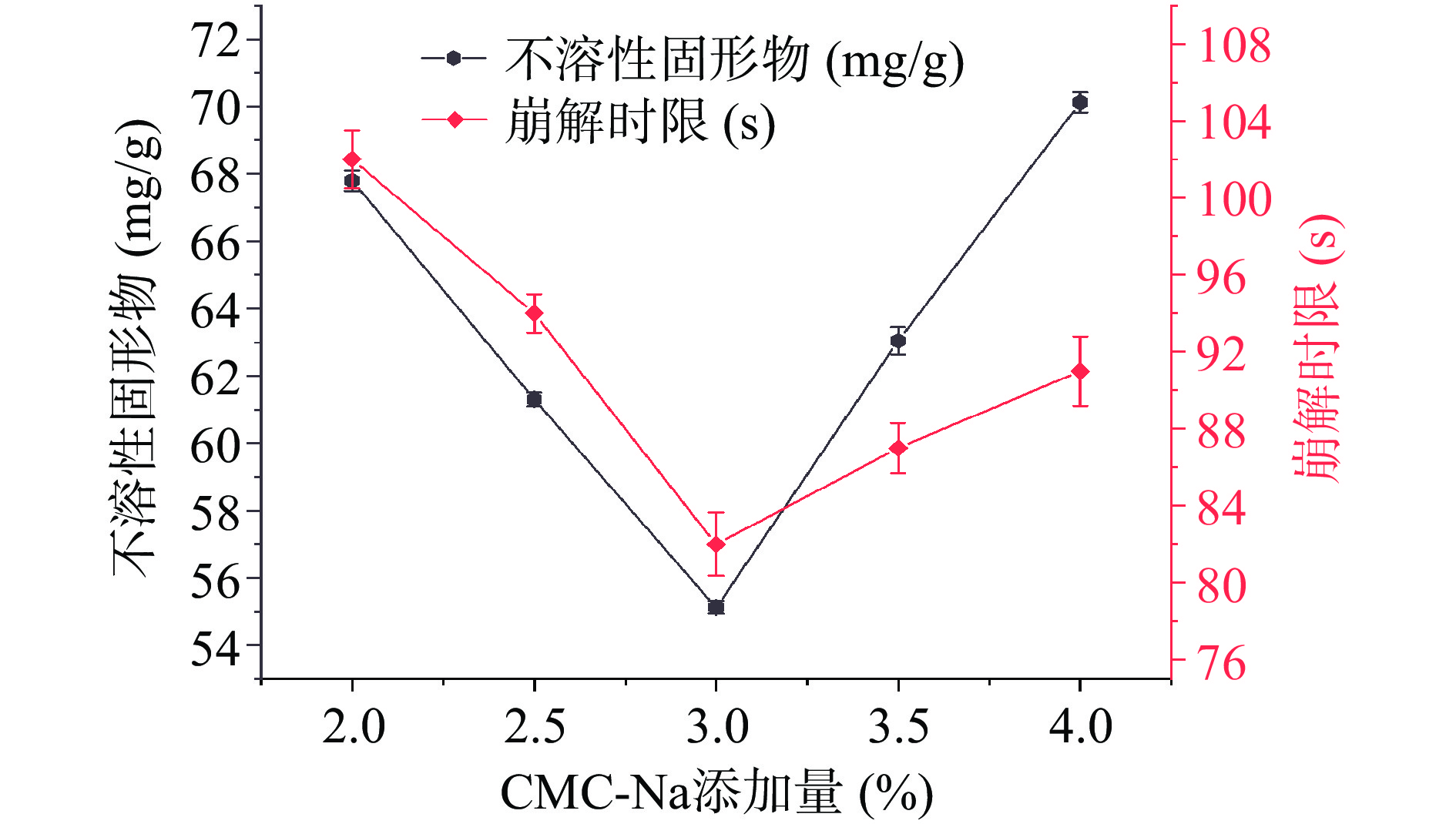

1.2.3.4 羧甲基纤维素钠添加量的确定

固定崩解剂添加量为45%,沙棘冻干粉添加量为40%、崩解剂酸碱比1:1.25、甜味剂添加量1.5%、聚乙二醇6000添加量3%、食用盐添加量1%,羧甲基纤维素钠添加量分别按2.0%、2.5%、3.0%、3.5%、4.0%进行单因素实验,余下部分用玉米淀粉进行填充,按1.2.2方法制备沙棘泡腾片。准确称量3 g泡腾片溶于50 mL水中,直到无气泡产生且溶解完全停止。以溶液中不溶性固形物、崩解时限为评价指标,确定羧甲基纤维素钠添加量。

1.2.4 响应面优化试验

以单因素实验结果为基础,以沙棘冻干粉添加量、崩解剂酸碱比、崩解剂添加量作为试验因素,以外观、口感、崩解时限为评价指标,根据模糊数学评定方法得到的沙棘冻干粉泡腾片质量综合评分为响应值,设计3因素3水平响应面试验,因素与水平见表1。

表 1 响应面试验因素和水平Table 1. The factors and levels of response surface test水平 因素 A 沙棘冻干粉(%) B 崩解剂酸碱比 C 崩解剂添加量(%) -1 37.5 1:1 40.0 0 40.0 1:1.25 42.5 1 42.5 1:1.5 45.0 1.2.5 模糊数学综合评定模型的建立

以外观、口感、崩解时限作为考察指标[24],得到因素集U=[外观(u1),口感(u2),崩解时限(u3)],设置权重向量A=[外观(a1),口感(a2),崩解时间(a3)],根据各评价指标对沙棘冻干粉泡腾片的影响程度,选取10位健康志愿评价人员对外观、口感、崩解时限三项指标进行权重打分,将各因素所得总分除以全部因素之和得到权重系数分别为0.2、0.5、0.3。以优(90分),良(70分),中(50分),差(30分)为评语集,得到评价集V=[优(90分),良(70分),中(50分),差(30分)]。其中外观和口感的评价标准依据表2,崩解时间的评价标准如下:优(85~95 s),良(75~84 s;96~105 s),中(65~74 s;106~115 s),差(小于64 s;大于116 s)。S为从U到V的模糊映射;R为综合评价结果集,计算公式为R=A×S。

表 2 感官评价标准表Table 2. Sensory evaluation standard table评价指标 评价等级 评价标准 分值 外观 优 片剂外形完整,无破损,液体澄清、无沉淀 31~40 良 片剂外形有轻微破损或液体有少许浑浊 21~30 中 片剂外形有较大破损或液体有不明显沉淀 11~20 差 片剂外形有较大破损或液体浑浊,有明显沉淀 0~10 口感 优 沙棘的独特香味浓郁,持久,口感酸甜适中,柔和可口 46~60 良 有沙棘的独特香味,较持久,口感偏甜,柔和带腻 31~45 中 有沙棘的独特香味,不持久,口感过甜,过于甜腻 16~30 差 沙棘的独特香味较淡,无回味,口感偏酸 0~15 根据外观(u1)、口感(u2)评价结果,建立模糊关系矩阵,计算出R并分别与评价集中各对应分值相乘,将结果加和崩解时间(u3)所得R与评价集中对应分值的积,即得总评分值。

1.2.6 泡腾片质量评价

1.2.6.1 感官评分

选择10名健康志愿评价人员,2 h前除水外未进食。评价前漱口,泡腾片形成溶液后,依次对各组样品进行外观观察,品尝[24-25],评价标准按表2。

1.2.6.2 崩解时限

按照《中国药典》2020年版的要求测定[26]。

1.2.6.3 pH的测定

采用酸度计测定。

1.2.6.4 发泡量

采用质量损失法[25],取泡腾片1片,研磨,精密称取一定量片粉于已精密称质量的含水烧杯中,待其发泡完全,再精密称量烧杯及溶液总质量m2。发泡量(mg/g)=(m1−m2)/m,m指片粉质量,m1指发泡前含水烧杯加片粉的质量,m2指发泡后含水烧杯加片粉的质量。

1.2.6.5 吸湿率

选取片重在2.9~3.2 g之间的沙棘冻干粉泡腾片,设定温度为(25±1) ℃,相对湿度为80%±2%中放置24 h,对比放置前后重量差[27]。吸湿百分率(%)=(W2−W1)/W1×100,W1指吸湿前泡腾片的重量,W2指吸湿后泡腾片的重量。

1.2.6.6 VC含量的测定

采用GB5009.86-2016《食品安全国家标准 食品中抗坏血酸的测定》中2,6-二氯靛酚法进行测定。

1.2.6.7 黄酮含量的测定

以芦丁标准品为对照,采用亚硝酸钠-硝酸铝-氢氧化钠分光光度法检测[28]。所得标准曲线为y=0.1159x+0.0742,R2=0.9924。

1.2.6.8 抗氧化性测定

待测液的制备:精密称取0.500 g 泡腾片粉末置于50 mL容量瓶中,60%乙醇溶解,定容。摇匀后过滤,滤液作为待测液,备用。

DPPH自由基清除能力测定:参考胡栋宝等[29-30]方法稍作修改,取2.0 mL上述待测液加入2.0 mL DPPH溶液,避光反应30 min,于517 nm处测定吸光度值A1;同时测定样品空白吸光度A2,以及不加样品液的空白样的吸光度A0。以VC为阳性对照。DPPH自由基清除率(%)=[1−(A1−A2)/A0)]×100。

对羟基自由基清除能力测定:参考李燕凌[31]的方法稍作修改,移取1.0 mL上述待测液,先后添加1.0 mL 4.5 mmol/L FeSO4、4.5 mmol/L水杨酸-乙醇、1 mL 4.4 mmol/L H2O2,混合后置于37 ℃水浴反应30 min,于520 nm处测定待测液吸光度A1,同时测定样品空白吸光度A2,以及不加样品液的空白样的吸光度A0。以VC为阳性对照。羟基自由基清除率(%)=[1−(A1−A2)/A0)]×100。

1.3 数据处理

每个实验重复3次取平均值,结果以平均值±标准差表示。采用Excel 2013和SPSS20.0软件进行数据处理及统计分析。

2. 结果与分析

2.1 单因素实验

2.1.1 酸碱比的确定

由图1可见,崩解剂酸碱比对泡腾片发泡量、崩解时限、溶液pH均有显著的影响(P<0.05)。当酸源与碱源的添加比例为1:1时,溶液的pH为6.2,接近最佳pH6.0,且品尝起来酸度适中,气泡产量适宜,有碳酸饮料的口感;色泽美观,香味协调适中,口味酸甜、口感顺滑;酸源与碱源添加比例过高或过低时,都会导致泡腾片崩解时限偏离最优值,也可能破坏沙棘冻干粉中黄酮类成分的结构[25],从而影响泡腾制剂的作用效果,且呈现过重的酸味或碱味,影响口感。综上,选择1:1、1:1.25、1:1.5的酸源与碱源添加比例进行响应面优化。

2.1.2 沙棘冻干粉添加量的确定

由图2可见,沙棘冻干粉添加量对泡腾片感官评分、崩解时限均有显著的影响(P<0.05)。随着冻干粉添加量的增加,崩解时间逐渐延长,在添加量为42.5%时,崩解时限最理想;汤液和片剂色泽随冻干粉添加量的增加逐渐变深,且在添加量超过40%后,压片过程中有粘连情况出现,片剂破损情况较多;口感随着冻干粉添加量的增加变化明显,在添加量低于40%时,汤液沙棘口感少,存在明显的碱味,香气持久性差,回味少,在添加量大于40%后,沙棘味逐渐变重且汤液逐渐变酸,酸甜味不均衡;同时不溶性固形物随冻干粉添加量的增加而变多。故沙棘冻干粉添加量选择37.5%、40.0%和42.5%进行响应面优化。

2.1.3 泡腾崩解剂添加量的确定

由图3可知,崩解剂添加量对泡腾片感官评分、发泡量、崩解时限均有显著的影响(P<0.05)。随着崩解剂添加量的增加,泡腾片感官评分呈现先上升后下降的趋势,40%时感官最佳。崩解剂添加量为40%~45.0%时,泡腾片发泡量较高、崩解时限也较短,片剂上下翻腾效果较好,此时感官较好。崩解剂添加量超过45.0%时,碱味逐渐变重,酸甜味逐渐不均衡。综合考虑,选取40.0%、42.5%和45.0%进行响应面优化。

2.1.4 羧甲基纤维素钠添加量的确定

由图4可见,羧甲基纤维素钠添加量对泡腾片不溶性固形物及崩解时限的影响显著(P<0.05),呈现先下降后上升的趋势。在添加量为3%时,汤液的乳化效果最好,汤液均匀度最佳,无明显的油层上浮,可见颗粒物也较少;添加量低于3%时对崩解时间整体影响不明显,当添加量大于3%时,由于片剂粘度的增加,对泡腾片的崩解有明显的抑制作用。同时在压片过程中添加羧甲基纤维素钠,对压片有较好的辅助作用。综上,确定羧甲基纤维素钠最佳添加量为3%。

2.2 响应面试验及其结果

2.2.1 响应面优化及结果

根据三因素三水平的响应面试验设计,进行17组试验,各组评价结果见表3。

表 3 沙棘冻干粉泡腾片评价结果Table 3. Summary of results of seabuckthorn freeze-dried effervescent tablets序号 外观 口感 崩解时限(s) 综合评分 优 良 中 差 优 良 中 差 1 0 8 2 0 0 8 2 0 70 67.2 2 0 7 3 0 2 7 1 0 70 69.4 3 7 2 3 2 1 0 5 4 90 72.2 4 1 1 4 4 8 2 0 0 70 71.7 5 8 2 0 0 8 1 1 0 50 74.3 6 6 2 2 0 4 6 0 0 70 75.6 7 8 2 0 0 2 8 0 0 70 75.8 8 0 5 5 0 3 6 1 0 70 69.3 9 0 7 2 1 0 8 2 0 90 72.2 10 6 3 1 0 4 1 0 5 90 73.1 11 0 4 6 0 0 2 8 0 90 65.8 12 1 9 0 0 3 6 1 0 70 72.3 13 8 2 0 0 7 3 0 0 70 80.3 14 9 1 0 0 6 4 0 0 70 79.9 15 3 6 1 0 5 4 1 0 90 80.6 16 6 4 0 0 8 2 0 0 70 80.2 17 5 4 0 1 3 5 2 0 90 78.4 现以组1样品的模糊关系矩阵S1为例进行数据处理,其余S2~S17同S1方法。

S1=

R=A×S1=(0.25,0.45)×

将结果分别与评价集中各对应分值相乘,并加和崩解时限(u3)所得R值与其对应分值的积,即得出总评分值Y1,即综合评分Y1=0×90+0.56×70+0.14×50+0×30+70×0.30=67.2。其余2~17组类推,最终得到17组样品的全部模糊综合评分值,见表4。

表 4 响应面试验设计及结果Table 4. Design and results of response surface methodology序号 A B C Y:综合评分 1 −1 −1 0 67.2 2 1 −1 0 69.4 3 −1 1 0 72.2 4 1 1 0 71.7 5 −1 0 −1 74.3 6 1 0 −1 75.6 7 −1 0 1 75.8 8 1 0 1 69.3 9 0 −1 −1 72.2 10 0 1 −1 73.1 11 0 −1 1 65.8 12 0 1 1 72.3 13 0 0 0 80.3 14 0 0 0 79.9 15 0 0 0 80.6 16 0 0 0 80.2 17 0 0 0 78.4 2.2.2 模型建立及显著性检验

对表4试验数据进行二次多项回归拟合,得到多元回归方程为:

Y=74.68−0.10A+1.85B−0.95C−0.15AB−1.35AC+1.85BC−1.87A2−6.37B2−1.96C2

回归模型的方差分析结果见表5。该试验模型P值为0.0001,说明模型总体极显著,方程拟合度好,方程失拟项P=0.1597>0.05,相对于纯误差,失拟项是不显著的,说明该模型是可行的,回归方程可以较好地描述各因素与综合评分之间的关系[32]。模型的F值为27.75,说明模型具有显著性。只有0.01%的几率会因为噪音而出现如此大的“F值”。因此,可用此模型对沙棘冻干粉泡腾片的工艺条件结果进行分析和预测。

表 5 回归模型方差分析Table 5. Analysis of variance for the regression model变异源 平方和 自由度 均方 F值 P>F 显著性 模型 344.28 9 38.25 27.72 0.0001 ** A 1.53 1 1.53 1.11 0.3272 # B 27.01 1 27.01 19.57 0.0031 ** C 18.00 1 18.00 13.04 0.0086 ** AB 1.82 1 1.82 1.32 0.2882 # AC 15.21 1 15.21 11.02 0.0128 * BC 7.84 1 7.84 5.68 0.0486 * A2 49.46 1 49.46 35.84 0.0005 ** B2 168.58 1 168.58 122.15 <0.0001 ** C2 30.75 1 30.75 22.28 0.0022 ** 残差误差 9.66 7 1.38 失拟项 6.67 3 2.22 2.98 0.1597 # 纯误差 2.99 4 0.75 总和 353.94 16 注:“*”表示差异显著(0.01<P<0.05),“**”表示差异极显著(P<0.01),“#”表示差异不显著(P>0.05)。 由表5方差分析结果可知,一次项B、C和二次项A2、B2、C2对结果的影响极显著(P<0.01),交互项AC、BC对结果影响显著(P<0.05);一次项A及交互项AB对结果影响不显著(P>0.05)。由F值大小可知,各因素对沙棘泡腾片感官评分的影响程度依次为:崩解剂酸碱比(B)>崩解剂添加量(C)>沙棘冻干粉添加量(A)。

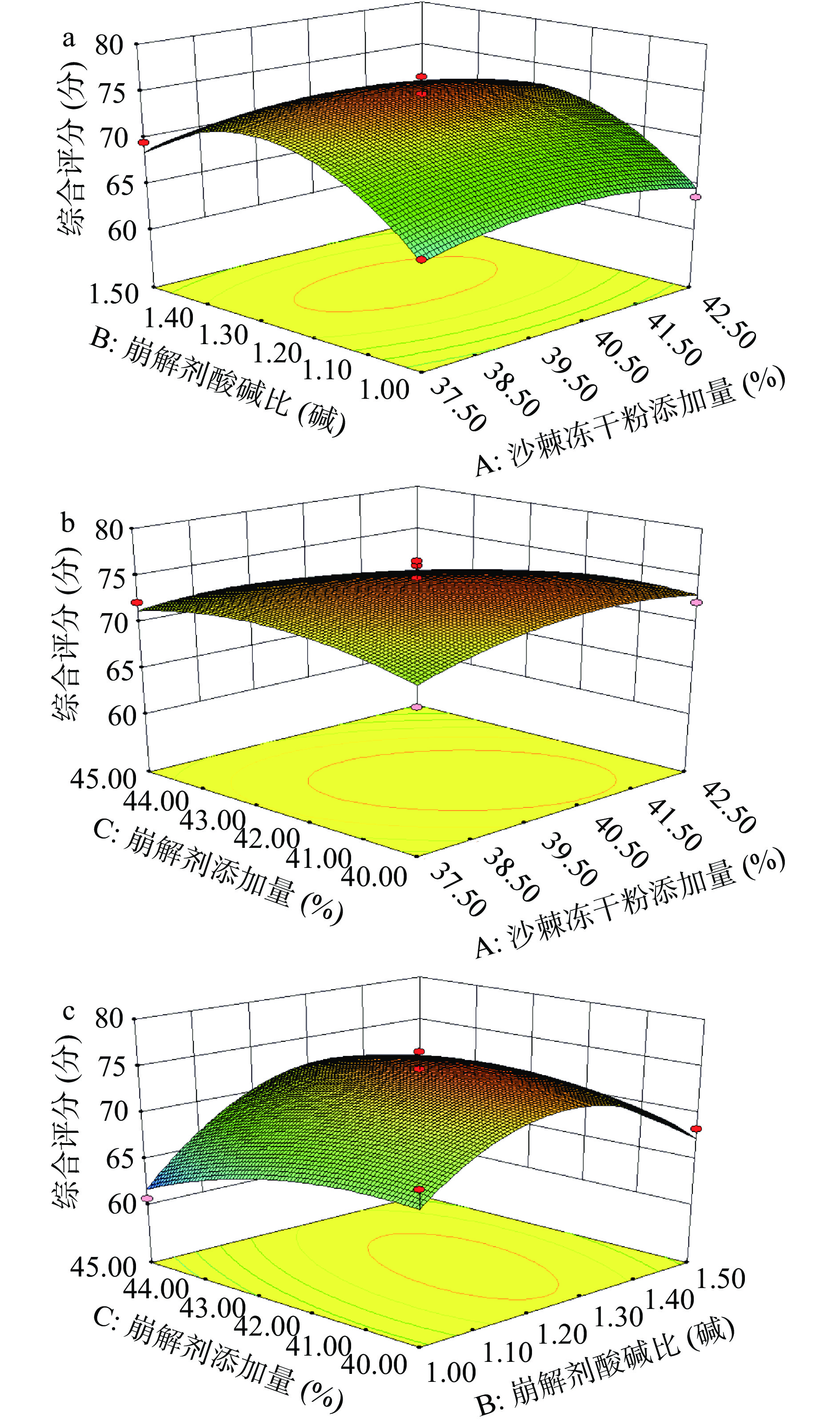

2.2.3 响应曲面分析

通过软件对回归方程进行分析,得到沙棘冻干粉泡腾片制备工艺中两个交互项之间的响应面图及等高线图,见图5。响应曲面均为开口向下的凸形曲面,说明沙棘冻干粉泡腾片综合评分存在最大值。其中,如图5(a)~(c)所示,随着崩解剂酸碱比的改变,响应面图的陡峭程度有较为显著的变化,相应的等高线图的变化也较为明显,说明崩解剂酸碱比对沙棘冻干粉泡腾片的综合评分有较为显著的影响,同样地,崩解剂添加量也有显著影响;另外,AC和BC对应的响应面等高线呈椭圆形,说明其交互作用显著。以上结果与表5中响应面方差分析结果一致。

2.2.4 最优工艺确定与验证

根据 Design-Expert软件分析可预测出当沙棘冻干粉添加量为39.99%、崩解剂酸碱比为1:1.28、崩解剂添加量为41.89%时,泡腾片质量综合评分可达到80.17。为验证结果,从而得到沙棘冻干粉泡腾片最优制备条件。考虑实验可操作性,调整制备条件为:沙棘冻干粉添加量为40.00%、崩解剂酸碱比为1:1.28、崩解剂添加量为41.89%,在此条件下重复3次试验,沙棘冻干粉泡腾片的综合评分为79.80±1.20,与模型预测值差值为0.46%,接近理论预测值。

2.3 沙棘泡腾片的品质评价

由表6可知,最优配方制备得到的沙棘冻干粉泡腾片的pH、崩解时限均符合《中国药典》的规定。沙棘冻干粉泡腾片外观平整、光滑,无肉眼可见的杂质和异物;泡腾后溶液清澈透明,无杂质,有独特的沙棘风味,口感酸甜适中、清爽可口。泡腾片中VC含量为5.85±0.26 mg/g,黄酮含量为5.26±0.22 mg/g,对DPPH自由基、羟基自由基的清除率分别达56.8%±0.3%、54.9%±0.4%,VC分别为89.5%±0.5%、82.5%±0.6%。在阴凉干燥、密封贮存条件下,保存3个月后仍保持了良好的品质,与刚制备好的泡腾片差异不显著(P<0.05)。

表 6 沙棘冻干粉泡腾片的品质评价Table 6. Quality evaluation of effervescent tablets项目 放置0个月 放置3个月 外观 片剂外形完整光滑,无破损,液体澄清无沉淀 片剂外形完整光滑,无破损,液体澄清无沉淀 口感 有沙棘的独特香味,口感酸甜适中,清爽可口 有沙棘的独特香味,口感酸甜适中,清爽可口 平均崩解时限(s) 92.0±1.6 91.0±0.6 发泡量(mg/g) 81 80 pH 5.9±0.3 5.8±0.5 吸湿率(%) 1.30 1.35 VC含量(mg/g) 5.85±0.26 5.73±0.74 黄酮含量(mg/g) 5.26±0.22 5.18±0.30 DPPH自由基清除率(%) 56.8±0.3 55.7±0.5 羟基自由基清除率(%) 54.9±0.4 53.2±0.4 3. 结论

本试验以沙棘为原料,首先采用真空冷冻干燥技术制备沙棘冻干粉,最大程度保留沙棘营养成分,然后采用干法制粒压片法制备沙棘冻干粉泡腾片,并通过响应面试验优化其最佳制备工艺。结果表明,泡腾片最佳配方为:沙棘冻干粉添加量40.00%、崩解剂酸碱比1:1.28、崩解剂添加量41.89%、羧甲基纤维素钠3%,由此配方制得的泡腾片表面光滑细腻,外形完整,油脂上浮较少,溶液呈现均匀的乳浊液状态,具有沙棘独特的香气,持久性强,口感良好、起效迅速,同时具有抗氧化的保健功效。本试验结合了沙棘营养价值丰富与泡腾片吸收利用率高的优势,既确保了沙棘营养成分的极大利用与释放,又能赋予泡腾片新的风味。研究结果可为沙棘冻干粉泡腾片的研究和推向市场提供一些理论依据,也为沙棘的进一步研究和开发提供参考。

-

表 1 响应面试验因素和水平

Table 1 The factors and levels of response surface test

水平 因素 A 沙棘冻干粉(%) B 崩解剂酸碱比 C 崩解剂添加量(%) -1 37.5 1:1 40.0 0 40.0 1:1.25 42.5 1 42.5 1:1.5 45.0 表 2 感官评价标准表

Table 2 Sensory evaluation standard table

评价指标 评价等级 评价标准 分值 外观 优 片剂外形完整,无破损,液体澄清、无沉淀 31~40 良 片剂外形有轻微破损或液体有少许浑浊 21~30 中 片剂外形有较大破损或液体有不明显沉淀 11~20 差 片剂外形有较大破损或液体浑浊,有明显沉淀 0~10 口感 优 沙棘的独特香味浓郁,持久,口感酸甜适中,柔和可口 46~60 良 有沙棘的独特香味,较持久,口感偏甜,柔和带腻 31~45 中 有沙棘的独特香味,不持久,口感过甜,过于甜腻 16~30 差 沙棘的独特香味较淡,无回味,口感偏酸 0~15 表 3 沙棘冻干粉泡腾片评价结果

Table 3 Summary of results of seabuckthorn freeze-dried effervescent tablets

序号 外观 口感 崩解时限(s) 综合评分 优 良 中 差 优 良 中 差 1 0 8 2 0 0 8 2 0 70 67.2 2 0 7 3 0 2 7 1 0 70 69.4 3 7 2 3 2 1 0 5 4 90 72.2 4 1 1 4 4 8 2 0 0 70 71.7 5 8 2 0 0 8 1 1 0 50 74.3 6 6 2 2 0 4 6 0 0 70 75.6 7 8 2 0 0 2 8 0 0 70 75.8 8 0 5 5 0 3 6 1 0 70 69.3 9 0 7 2 1 0 8 2 0 90 72.2 10 6 3 1 0 4 1 0 5 90 73.1 11 0 4 6 0 0 2 8 0 90 65.8 12 1 9 0 0 3 6 1 0 70 72.3 13 8 2 0 0 7 3 0 0 70 80.3 14 9 1 0 0 6 4 0 0 70 79.9 15 3 6 1 0 5 4 1 0 90 80.6 16 6 4 0 0 8 2 0 0 70 80.2 17 5 4 0 1 3 5 2 0 90 78.4 表 4 响应面试验设计及结果

Table 4 Design and results of response surface methodology

序号 A B C Y:综合评分 1 −1 −1 0 67.2 2 1 −1 0 69.4 3 −1 1 0 72.2 4 1 1 0 71.7 5 −1 0 −1 74.3 6 1 0 −1 75.6 7 −1 0 1 75.8 8 1 0 1 69.3 9 0 −1 −1 72.2 10 0 1 −1 73.1 11 0 −1 1 65.8 12 0 1 1 72.3 13 0 0 0 80.3 14 0 0 0 79.9 15 0 0 0 80.6 16 0 0 0 80.2 17 0 0 0 78.4 表 5 回归模型方差分析

Table 5 Analysis of variance for the regression model

变异源 平方和 自由度 均方 F值 P>F 显著性 模型 344.28 9 38.25 27.72 0.0001 ** A 1.53 1 1.53 1.11 0.3272 # B 27.01 1 27.01 19.57 0.0031 ** C 18.00 1 18.00 13.04 0.0086 ** AB 1.82 1 1.82 1.32 0.2882 # AC 15.21 1 15.21 11.02 0.0128 * BC 7.84 1 7.84 5.68 0.0486 * A2 49.46 1 49.46 35.84 0.0005 ** B2 168.58 1 168.58 122.15 <0.0001 ** C2 30.75 1 30.75 22.28 0.0022 ** 残差误差 9.66 7 1.38 失拟项 6.67 3 2.22 2.98 0.1597 # 纯误差 2.99 4 0.75 总和 353.94 16 注:“*”表示差异显著(0.01<P<0.05),“**”表示差异极显著(P<0.01),“#”表示差异不显著(P>0.05)。 表 6 沙棘冻干粉泡腾片的品质评价

Table 6 Quality evaluation of effervescent tablets

项目 放置0个月 放置3个月 外观 片剂外形完整光滑,无破损,液体澄清无沉淀 片剂外形完整光滑,无破损,液体澄清无沉淀 口感 有沙棘的独特香味,口感酸甜适中,清爽可口 有沙棘的独特香味,口感酸甜适中,清爽可口 平均崩解时限(s) 92.0±1.6 91.0±0.6 发泡量(mg/g) 81 80 pH 5.9±0.3 5.8±0.5 吸湿率(%) 1.30 1.35 VC含量(mg/g) 5.85±0.26 5.73±0.74 黄酮含量(mg/g) 5.26±0.22 5.18±0.30 DPPH自由基清除率(%) 56.8±0.3 55.7±0.5 羟基自由基清除率(%) 54.9±0.4 53.2±0.4 -

[1] 董诗婷, 陈云, 高群玉. 沙棘果生物活性成分及其功能的研究进展[J]. 中国酿造,2020,39(2):26−32. [DONG Shiting, CHEN Yun, GAO Qunyu. Research progress on bioactive compounds and function of sea buckthorn berry[J]. China Brewing,2020,39(2):26−32. [2] 姚娜娜, 车凤斌, 李永海, 等. 沙棘的营养价值及综合开发利用概述[J]. 保鲜与加工,2020(2):234−240. [YAO Nana, CHE Fengbin, LI Yonghai, et al. Nutritional value and comprehensive development and utilization of Hipopophae rhamnoides[J]. Storage and Process,2020(2):234−240. [3] 吕兆林, 袁玮琼, 张柏林, 等. 沙棘果实中主要活性成分质量分布[J]. 北京林业大学学报,2021,43(1):144−152. [LÜ Zhaolin, YUAN Weiqiong, ZHANG Bolin, et al. A review on mass distribution of active components from Hippophae rhamnoides fruits[J]. Journal of Beijing Forestry University,2021,43(1):144−152. [4] FATIMA T, KESARI V, WATT I, et al. Metabolite profiling and expression analysis of flavonoid, vitamin C and tocopherol biosynthesis genes in the antioxidant-rich sea buckthorn (Hippophae rhamnoides L. )[J]. Phytochemistry,2015,118:181−191. doi: 10.1016/j.phytochem.2015.08.008

[5] 胡高爽, 高山, 王若桦, 等. 沙棘活性物质研究及开发利用现状[J]. 食品研究与开发,2021,42(3):218−224. [HU Gaoshuang, GAO Shan, WANG Ruohua, et al. Research on development and utilization of active substances in seabuckthorn[J]. Food Research and Development,2021,42(3):218−224. [6] URSACHE F M, GHINEA I O, TURTURICA M, et al. Phytochemicals content and antioxidant properties of sea buckthorn (Hippophae rhamnoides L. ) as affected by heat treatment-quantitative spectroscopic and kinetic approaches[J]. Food Chemistry,2017,233:442−449. doi: 10.1016/j.foodchem.2017.04.107

[7] YAN X T, LEE S H, LI W, et al. Evaluation of the antioxidant and anti-osteoporosis activities of chemical constituents of the fruits of Prunus mume[J]. Food Chemistry,2014,156:408−36. doi: 10.1016/j.foodchem.2014.01.078

[8] GEETHA S, ASHEESH G. Medicinal and therapeutic potential of Sea buckthorn (Hippophae rhamnoides L.)[J]. Journal of Ethnopharmacology,2011,138(2):268−278. doi: 10.1016/j.jep.2011.09.024

[9] WANG H L, GAO T T, DU Y Z, et al. Anticancer and immunostimulating activities of a novel homogalacturonan from Hippophae rhamnoides L. berry[J]. Carbohydrate Polymers,2015,131:288−296. doi: 10.1016/j.carbpol.2015.06.021

[10] ZHANG G K, LIU Y F, LIU P, et al. Active components from sea buckthorn (Hippophae rhamnoides L. ) regulate hepatic stellate cell activation and liver fibrogenesis[J]. Journal of Agricultural and Food Chemistry,2018,66(46):12257−12264. doi: 10.1021/acs.jafc.8b05306

[11] 周浩楠, 胡娜, 董琦, 等. 沙棘化学成分及药理作用的研究进展[J]. 华西药学杂志,2020,35(2):211−217. [ZHOU Haonan, HU Na, DONG Qi, et al. Research progress on the chemical composition and pharmacological action of Hippophae rhamnoides[J]. West China Journal of Pharmaceutical Sciences,2020,35(2):211−217. [12] 刘君丽. 沙棘功能性食品的开发研究现状[J]. 食品安全导刊,2017(6):54−55. [LIU Junli. Development and research status of seabuckthorn functional food[J]. China Food Safety,2017(6):54−55. [13] 周巍熹. 沙棘系列产品开发研究[D]. 成都: 西华大学, 2014 ZHOU Weixi. Product development and research of sea buckthorn[D]. Chengdu: Xihua University, 2014.

[14] 赵荣敏. 响应面优化沙棘蓝莓复合饮料发酵工艺及品质分析[J]. 美食研究,2021,38(3):90−95. [ZHAO Rongmin. Optimization of fermentation and quality analysis of composite beverage with seabuckthorn and blueberry by response surface methodology[J]. Journal of Researches on Dietetic Science and Culture,2021,38(3):90−95. [15] 王瑶, 徐春晖, 杜俊民. 欧李山楂沙棘复合饮料的研制及其抗疲劳研究[J]. 保鲜与加工,2022,22(4):46−51,58. [WANG Yao, XU Chunhui, DU Junmin. Study on the preparation and anti-fatigue effect of compound beverage of Cerasus humilis, Hawthorn and Hippophae rhamnoides[J]. Storage and Process,2022,22(4):46−51,58. [16] 张宏康, 李德荣, 徐乐冰, 等. 泡腾片固体饮料加工技术现状及发展趋势[J]. 食品研究与开发,2016,37(12):187−192. [ZHANG Hongkang, LI Derong, XU Lebing, et al. Research advance on the processing technology of effervescent solid beverage[J]. Food Research and Development,2016,37(12):187−192. [17] 王春贺. 复方山楂泡腾片的研究[D]. 长春: 吉林大学, 2017 WANG Chunhe. Study on compound hawthorn effervescent tablets[D]. Changchun: Jilin University, 2017.

[18] NAJI T S, EMADZADEH B, SHAHIDI N M, et al. Physico-chemical and antioxidant properties of barberry juice powder and its effervescent tablets[J]. Chemical and Biological Technologies in Agriculture,2021,8(23):1−11.

[19] 王青霞, 李建颖, 杨航. 黑果枸杞提取物泡腾片的制备及其质量评价[J]. 天然产物研究与开发,2019,31(6):1030−1037. [WANG Qingxia, LI Jianying, YANG Hang. Preparation and quality evaluation of Lycium Ruthenicum Murr extract effervescent tablet[J]. Natural Product Research and Development,2019,31(6):1030−1037. [20] 刘淑敏, 姚远铃, 刘美玲, 等. 白芸豆水提物泡腾片制备工艺的优化及质量评价[J]. 食品研究与开发,2020,41(16):126−132. [LIU Shumin, YAO Yuanling, LIU Meiling, et al. Optimization of preparation technology and quality evaluation of white kidney bean extract effervescent tablets[J]. Food Research and Development,2020,41(16):126−132. doi: 10.12161/j.issn.1005-6521.2020.16.020 [21] 王艺萌, 国佳鑫, 孔庆新, 等. 荔枝草泡腾片的制备工艺及质量评价[J]. 食品工业科技,2019,40(2):165−169. [WANG Yimeng, GUO Jiaxin, KONG Qingxin, et al. Preparation technology and quality evaluation of Salvia plebeia R. Br. effervescent tablets[J]. Food Industry Technology,2019,40(2):165−169. [22] 陈冰瑶. 蓝靛果全果冻干粉泡腾片的研制[D]. 沈阳: 沈阳农业大学, 2020 CHEN Bingyao. Preparation of the effervescent tablets of the whole fruit freeze-dried powder of indigo fruit[D]. Shenyang: Shenyang Agricultural University, 2020.

[23] 李勇, 郑义, 时培宁, 等. 复合山楂果粉加工工艺研究[J]. 保鲜与加工,2017,17(1):65−69. [LI Yong, ZHENG Yi, SHI Peining, et al. Study on processing technology of compound hawthorn fruit powder[J]. Storage and Process,2017,17(1):65−69. [24] 王文宝, 杨俊涛, 郭留成, 等. 模糊综合评价法优选小儿消食泡腾片的处方工艺[J]. 中国医院药学杂志,2019,39(7):662−665. [WANG Wenbao, YANG Juntao, GUO Liucheng, et al. Optimization of prescription technology of pediatric digestion effervescent tablets by fuzzy comprehensive evaluation[J]. Chinese Journal of Hospital Pharmacy,2019,39(7):662−665. [25] 郑丹丹, 王京龙, 张立华, 等. 竹叶提取物泡腾片的制备工艺优化及其质量分析[J]. 食品科学,2016,37(8):39−44. [ZHENG Dandan, WANG Jinglong, ZHANG Lihua, et al. Optimized preparation and quality analysis of bamboo leaf extract effervescent tablets[J]. Food Science,2016,37(8):39−44. [26] 国家药典委员会. 中国药典[M]. 北京: 中国医药科技出版社, 2020 Chinese Pharmacopoeia Commission. Chinese pharmacopoeia[M]. Beijing: China Medical Science and Technology Press, 2020.

[27] 杨梅, 余建强, 郑萍, 等. 复方枸杞泡腾片的制备及含量测定[J]. 食品研究与开发,2019,40(22):138−144. [YANG Mei, YU Jianqiang, ZHENG Ping, et al. Preparation and content determination of compound Lycium barbarum effervescent tablets[J]. Food Research and Development,2019,40(22):138−144. doi: 10.12161/j.issn.1005-6521.2019.22.023 [28] 米智, 刘荔贞, 武晓红. 响应面法优化沙棘果粉黄酮提取工艺的研究[J]. 中国调味品,2020,45(10):148−152. [MI Zhi, LIU Lizhen, WU Xiaohong. Optimization of extraction procss of flavonoids from Hippophar rhamnoides Linn. powder by response surface methodology[J]. China Condiment,2020,45(10):148−152. [29] 胡栋宝, 黄淑佩, 祝晓慧, 等. 响应面优化鸡油菌多酚的超声辅助提取工艺及其抗氧化活性[J]. 食品工业科技,2022,43(18):177−184. [HU Dongbao, HUANG Shupei, ZHU Xiaohui, et al. Ultrasound-assisted extraction of polyphenols from the mushroom of Cantharelles cibarius and its antioxidant activity[J]. Food Industry Technology,2022,43(18):177−184. [30] SULIMAN R S, ALI H S, ALHELAL K, et al. Antioxidant properties of solenostemma argel effervescent tablets[J]. Current Pharmaceutical Biotechnology,2019,20(8):679−688. doi: 10.2174/1389201020666190617165300

[31] 李燕凌, 张志旭, 胡令. 茯苓多糖抗氧化性研究[J]. 天然产物研究与开发,2012,24(8):1126−1128. [LI Yanling, ZHANG Zhixu, HU Ling. Antioxidation of polysaccharides from Poria cocos[J]. Natural Product Research and Development,2012,24(8):1126−1128. [32] 许粟, 姚绍炉, 刘宇泽, 等. 响应面优化淀粉型刺梨凝胶软糖配方工艺[J]. 食品工业科技,2022,43(17):241−248. [XU Su, YAO Shaolu, LIU Yuze, et al. Optimization of preparation processing of starchy Roxburgh rose gel soft sweet by response surface analysis[J]. Science and Technology of Food Industry,2022,43(17):241−248. -

期刊类型引用(5)

1. 陈聪,薛桥丽,胡永金,魏美娟,陈中爱. 云南木姜子醇提物抑菌活性及其稳定性研究. 食品工业科技. 2023(16): 147-154 .  本站查看

本站查看

2. 段雪娟,黄煜强,张潼,韩雅莉,吴克刚,黄庶识. 肉桂醛熏蒸对金黄色葡萄球菌胞内生物大分子的影响. 中国食品学报. 2023(10): 90-100 .  百度学术

百度学术

3. 张文艳,李俊杰,艾玲松,李茂东,赵仲霞,师睿. 青花椒总生物碱对金黄色葡萄球菌抑菌活性研究. 工业微生物. 2023(06): 50-54 .  百度学术

百度学术

4. 王建梅,王国盼,陆安静,秦琳,鲁艳柳,白朝钧,何芋岐,谭道鹏. 金钗石斛提取物对5种耐药菌的体外抑菌活性评价. 遵义医科大学学报. 2022(03): 334-338 .  百度学术

百度学术

5. 黄藩,王迎春,叶玉龙,龚雪蛟,黄颖博,熊元元. 变温萎凋技术对贡眉白茶品质的影响. 中国农学通报. 2022(19): 159-164 .  百度学术

百度学术

其他类型引用(6)

下载:

下载:

下载:

下载: