Research Progress of High Hydrostatic Pressure Technology and Its Applications in Dairy Products

-

摘要: 高静水压技术是一种重要的非热物理技术,其能耗小、无污染、效率高、对食品品质几乎无影响。因此,在食品加工中有较好的应用前景。乳及乳制品作为人们日常消费的食品,其营养物质组成丰富,也具有诸多有益的生理功能,对改善人体健康、预防疾病有重要价值。本文系统地总结了高静水压技术的特点、作用机制以及近年来在乳制品方面应用的研究状况,旨在为高静水压技术在科学研究和食品加工应用提供一定的理论参考。Abstract: High hydrostatic pressure (HHP) technology is an important non-thermal physical technology with low energy consumption, no pollution, high efficiency and almost no effect on food quality. Therefore, it has a better application prospect in food processing. As a food for daily consumption, milk and dairy products are rich in nutrient composition and also have many beneficial physiological functions, which are of great value for improving human health and preventing diseases. This paper systematically summarizes the characteristics, mechanisms, and applications of HHP technology in dairy products in recent years. It aims to provide some theoretical reference for the application of HHP technology in scientific research and food processing.

-

乳制品市场占有率呈现逐年增长的趋势,为迎合消费者的需求,对产品质量提出更高的标准,同时需要最大限度保留其原有的营养价值,并确保食品的安全性[1-3]。杀菌处理是食品加工过程中的重要环节,保证了食品在储存过程中安全食用,控制微生物污染所引起的腐败变质。热处理是用来延长食品保质期的传统技术,如巴氏杀菌、高温短时杀菌,能够达到减少腐败微生物存活率的目的,但伴随着化学反应发生和原料本身的物化性质改变,如维生素、风味物质遭到破坏,而且高温处理也降低了食品的新鲜度,严重影响了产品的营养价值和感官特性。如今,消费者对更天然、更美味、更健康、更安全的食品的需求日益增加。因此,在食品领域内对于新兴非热加工技术相关的研究也越来越多,如超声、脉冲电场、微波等[2]。其中,高静水压(high hydrostatic pressure,HHP)表现出许多明显优势,能够在室温下灭活微生物和特定的酶,延长产品的保质期,并保证其在消费时的安全性[4]。压力的变化可以改变一些食物分子的化学构型,影响化学反应和酶反应的速率,同时,破坏微生物的细胞结构,导致内容物的溢出[5]。特别是与热处理的同类产品相比,HHP对最终产品的感官和营养特性影响较小,从而能够获得具有较高可接受性和较好感官特性的食物。酪蛋白是牛乳中的主要蛋白质,HHP处理可以使酪蛋白胶粒的直径变小,表面暴露出的疏水性基团增加,加速乳清蛋白变性,使其黏度、溶解性、乳化性、持水性均有明显的提高[6]。近年来,HHP技术在乳制品加工过程的应用明显增加,成为当今热门的研究话题之一。

本文对HHP非热处理技术在乳制品中应用的状况做了较系统的整理,探究基于HHP的乳制品加工的可行性与时效性,并针对现有问题提出了改善建议,旨在为后期的研究提供一定的理论支撑。

1. 高静水压技术简介

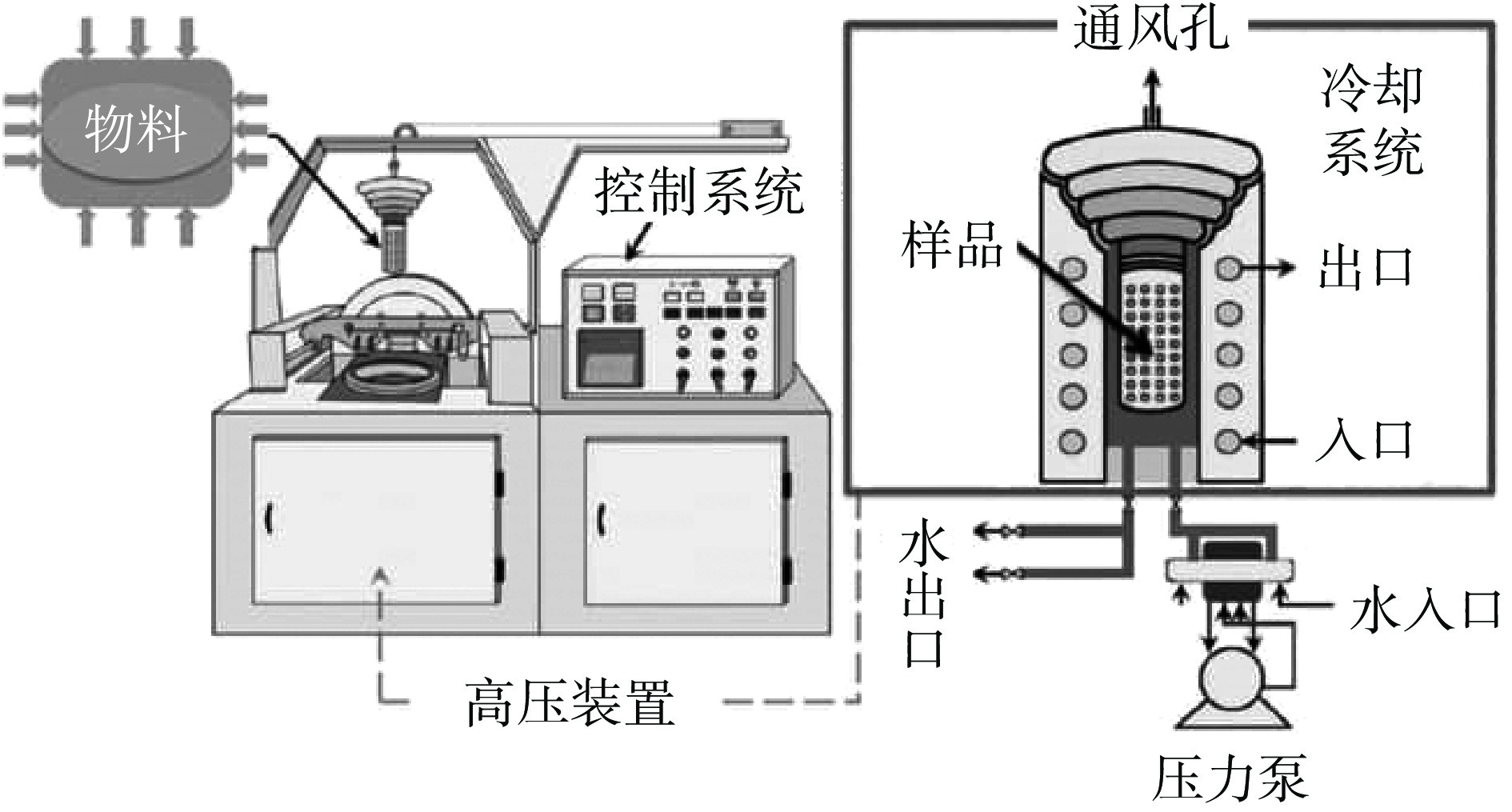

高静水压技术,也称为超高压(ultra-high pressure,UHP)或高压处理(high-pressure processing,HPP),主要由闭合的高压容器、压力产生系统(即起直接作用的活塞或间接作用的液压泵)、压力传递介质和温度控制系统组成(图1)。通常,将待处理样品经软包装后置于液体介质(一般是水)中,使用100~1000 MPa压力在常温或低温条件下作用一段时间,从而达到杀菌的目的,对食品的感官特性、营养成分、挥发性风味物质等品质的影响很小[7-9]。其中,常用的作用压力为200、400或600 MPa。物料在高压下的变化主要受到3种形式的制约,遵循勒夏特列原理(又称平衡移动原理)、微观有序原理和帕斯卡原理[10-12]。HHP技术不受物料状态、大小或成分差异的限制,产生的压力都可以均匀地作用在被加工样品的各个位置[13]。针对不同类型的物料,采用连续式和间歇式施压处理对其品质将达到不同程度的影响[14]。

HHP处理是纯粹的物理过程,只作用于样品的分子间疏水相互作用、氢键等非共价键结构,同时使微生物形态、酶的构象和结构发生改变而失活。但是,对物料中含有的维生素、色素、香气成分等小分子物质无显著的影响,能够在保证食品安全的同时,保留其原有风味与营养成分[15],是一种多作用位点、高效能的食品加工应用技术。其杀菌机理多数认为是通过调控微生物的生理特性来保证食品的新鲜度。在高压条件下,微生物的细胞膜会受到损伤,蛋白质发生变性,抑制DNA等遗传物质的复制,内容物渗出,细胞内pH下降,破坏菌体蛋白的非共价键,这些是导致微生物失活的重要原因[16]。HHP适用于食品加工中,主要在于:a.引起微生物的失活,如细菌、病毒和影响人类健康的寄生虫;b.发生食品基质的物理和化学修饰,如低温烹饪;c.促进保质期的延长,导致生物体失活或者酶部分失活[17]。

2. HHP在乳制品中的应用

在乳制品工业中,微生物侵入是主要的污染源,巴氏杀菌是常用的热处理方法。热处理对乳制品的色泽、风味以及维生素造成较大损失和破坏。基于此,新的非热杀菌处理技术,如HHP处理,已被证明能够有效地减少牛奶和其他乳制品(奶酪、冰淇淋、酸乳等)中的腐败微生物超标,延长其保质期,同时保留香气和维生素含量[18-21]。本文以HHP技术为研究对象,重点分析其在液态乳、奶酪、酸乳及奶油制品的应用。

2.1 液态乳

HHP应用在液态乳中的目的是杀灭有害微生物,进而延长产品的货架期。HHP杀菌原理不同于热处理杀菌,在高压处理过程中,细胞的复制和再生机制被破坏,细胞内部的酶系统也会被干扰,细胞膜结构改变,细胞内外营养物质的运输受到影响。其杀菌效果取决于高压处理条件(压力、时间、温度、循环次数等)、微生物特性以及生理状态等诸多因素。通常,在600 MPa压力下处理数分钟,对牛乳中存在的食源性病原微生物的灭活是有效的[22]。同时,还会改变原料乳中一些乳清蛋白和酪蛋白的结构和功能,这与蛋白质的功能性质(溶解性、乳化性等)紧密相关。随着压力的增加,液态乳中的非酪蛋白氮的含量降低,这主要是由于乳清蛋白的变性和沉淀[23-25]。Liu等[26]以新鲜全脂牛乳为实验原料,比较HHP处理、巴氏杀菌对样品品质的影响,结果表明,在600 MPa下处理5 min对牛乳营养物质的损失较少,且效果较好,可应用到替代传统巴氏杀菌当中。任杰等[27]以牛初乳为研究对象,比较不同HHP处理下,免疫球蛋白G(IgG)活性的保留程度。结果表明,高压处理改变了IgG的分子结构,使得活性有所降低,在200 MPa、30 ℃和20 min条件下,IgG活性最好,检出质量浓度最高。IgG作为牛乳中重要的功能蛋白组成,能够增强机体的免疫能力,起到抵抗疾病的预防作用,有益于机体健康[28]。

2.2 奶酪

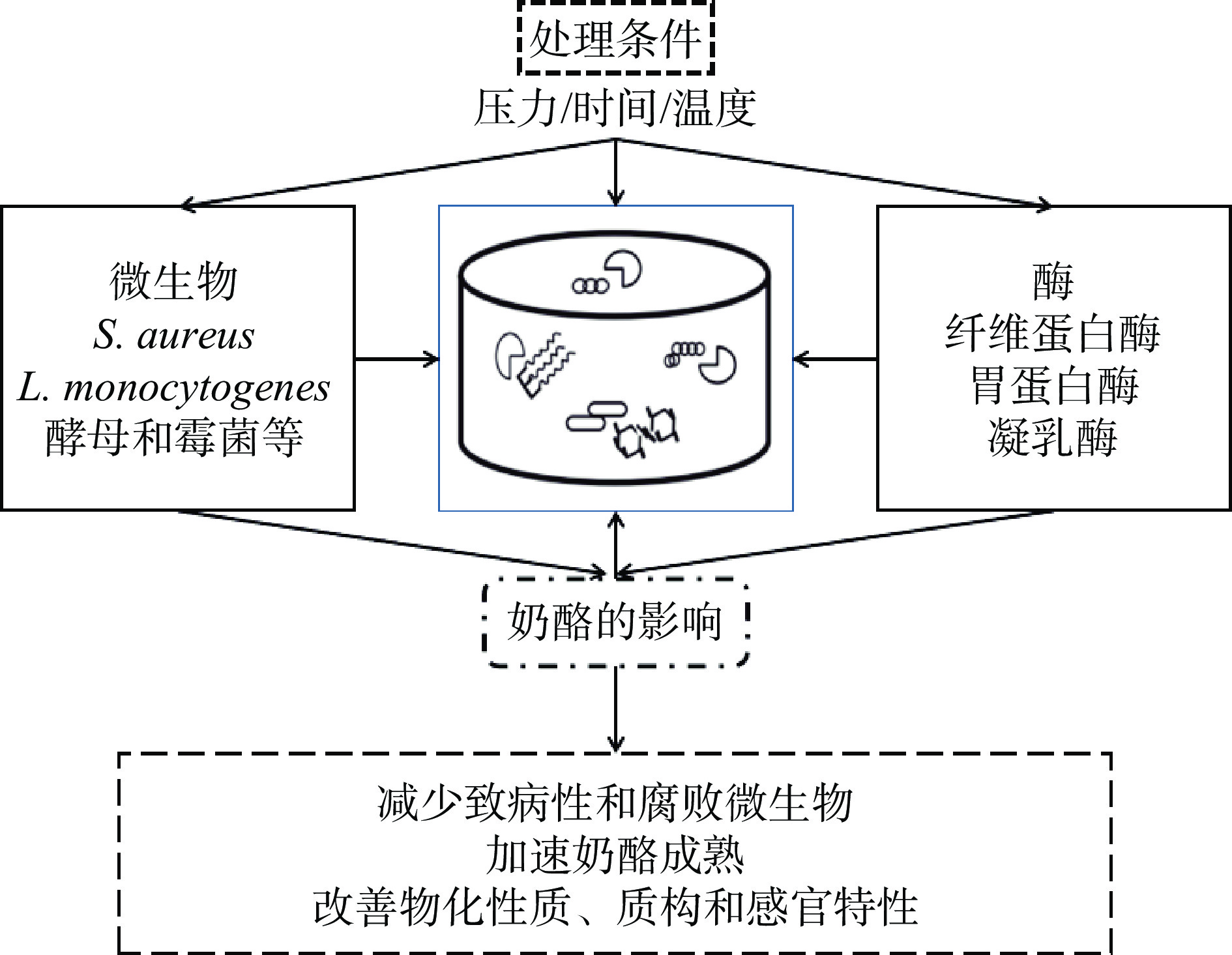

奶酪又称干酪,是一种营养价值很高的乳制品,是在原料乳中加入适量的乳酸菌或凝乳酶,使蛋白质发生凝固,并加盐、压榨排除乳清之后的产品。在奶酪成熟和体内消化过程中,酪蛋白被水解,产生具有抗氧化能力的多肽。受原料乳类型、加工技术、成熟时间等因素影响,使得奶酪在质地、味道和形状方面有广泛的多样性。HHP作为一种新兴的冷杀菌技术,除了可处理奶酪用原料乳达到杀菌效果外,还会对奶酪及其成熟过程中的理化特性产生影响,如图2所示。

2.2.1 减少奶酪中致病性和腐败微生物

通常,500 MPa的压力水平能够杀死大部分革兰氏阴性病原体,即使300 MPa的压力水平对一些细菌物种也是致命的[29]。比如,单增李斯特菌存在可引起人类和动物的侵袭性疾病。约99%的人类李斯特菌病感染是由食源性引起的,它能够在低温、高盐和酸性环境下生长。这通常与食用乳制品有关,例如成熟的软奶酪、墨西哥式软奶酪、巧克力牛奶[30-31]。López-pedmonte等[32]探究HHP对奶酪中单增李斯特菌的数量变化的影响。在500 MPa处理10 min时,菌株第1 d的减少量约为5 lg CFU/g,储藏30 d后计数仍低于规定限量值。Zhang等[33]评估HHP对奶酪中嗜热链球菌3种噬菌体(ϕAbc2、ALQ13.2和DT1)活力的影响。噬菌体生存能力的降低与压力(400~600 MPa)和保持时间(0~30 min)成正比。当在600 MPa下处理小于5 min可使噬菌体ϕAbc2和DT1完全失活。罗克福尔青霉(Penicillium roqueforti)是一种生长速度快的丝状真菌,其增殖是引起冷藏食品、面包和新鲜蔬菜出现腐败的重要原因[34]。Martínez-Rodríguez等[35]研究HHP对罗克福尔青霉的菌丝发育、孢子活力和酶活性影响。结果表明,压力处理能够控制蓝纹奶酪的青霉菌丝生长、灭活孢子和改变酶活性,这对于延长奶酪食品的保质期具有重要意义。另有报道,在较低压力(200 MPa)下处理10 min对奶酪中酪丁酸梭菌孢子的萌发影响不明显,但较高HHP(≥300 MPa)处理时会明显增加微生物的致死率,孢子数量从4.79~4.98 lg CFU/mL降至1.03~2.99 lg CFU/mL[36]。总体而言,HHP处理表现出显著的优势,对于致病性和腐败微生物的清除和抑制效果很好。压力越高,杀菌效果越好,且相同压力下杀菌效果在一定程度上也会随着保压时间的延长而增强[37]。

2.2.2 加速奶酪成熟

成熟是奶酪制作的关键步骤,涉及蛋白质水解、糖酵解等生化过程。成熟周期的长短将会影响奶酪最终的质地和风味。通常,奶酪的成熟周期较长,需要数周到数月,对于制作商而言,加速奶酪的成熟能够显著提高经济效益[38]。蛋白水解通过产生短肽和氨基酸对风味产生直接影响,其中一些短肽和氨基酸会导致苦味(如β-酪蛋白水解),促使奶酪基质中风味物质的释放。游离氨基酸是一系列分解代谢反应的中间产物,进而形成重要的风味化合物[39]。通过HHP处理使酶活性或底物反应发生改变,缩短奶酪的成熟时间。Costabel等[40]发现Reggianito奶酪制作后用400 MPa的HHP处理提高Reggianito奶酪的蛋白质水解速率,加速Regginito奶酪的成熟过程,而100 MPa处理没有显著影响。Calzada等[41]探究高压处理对布里奶酪成熟和冷藏过程中脂解及挥发性化合物的影响。在120 d,经过高压处理奶酪的总游离脂肪酸含量降低88.5%;而含硫化合物、吡嗪类和胺类,在对照组的奶酪中从60~120 d急剧增加,这些化合物会产生明显的不良气味。Delgado等[42]测定不同HHP处理对山羊乳奶酪成熟过程中风味物质的影响。在第50 d经400 MPa处理的奶酪中,酸类物质的水平显著高于其他批次,如丙酸、己酸、庚酸和癸酸,并对奶酪酯类挥发性化合物的保留率最高。Delgado等[43]也研究了HHP处理对卡萨尔奶酪储存过程中物化性质、蛋白质水解和质地变化的规律,发现600 MPa高压处理可以作为一种有效的方式来延迟与长期储存相关蛋白质水解的过度成熟。目前,为迎合消费者饮食理念,控制食品中钠盐含量成为一种新趋势,由此低钠奶酪的出现在国外市场受到青睐。盐(NaCl)影响着酪蛋白的构象、奶酪的水分含量、蛋白质网络的水合作用、奶酪中微生物和相关酶活性[44]。Ozturk等[45]研究马苏里拉奶酪成熟过程在4 ℃冷藏条件下品质的变化。600 MPa下处理3 min的低钠马苏里拉奶酪的蛋白水解速率低,在成熟过程中硬度基本不变,而未处理组奶酪的硬度显著下降。HHP处理的低钠奶酪在成熟过程中的苦味和酸度无显著差异,当对低钠奶酪进行500 MPa压力水平的处理可以改善低钠奶酪的品质[46]。

2.2.3 改善奶酪物化性质、微观结构和感官特性

奶酪的物化性质、微观结构和感官特性对成品的品质是极为重要的。研究表明,HHP处理不会改变奶酪中的灰分、脂肪、蛋白质以及水分的含量[47-50]。奶酪的质地和力学性能是由其微观结构决定的,该结构包含多孔的连续蛋白质基质,其空间被分布在酪蛋白网络中的脂肪球所占据。Serrano等[51]研究中等强度HHP加工对切达奶酪的微观结构、质地和感官特性的影响。结果发现,短时间和中等时间HHP处理加速了切达奶酪的易碎性。感官评价表明,1 d中等时间的HHP处理和27 d未处理的奶酪切碎后的样品具有相似的感官属性。而压力改变不影响成熟奶酪的力学性能,蛋白的水解也不受抑制。Ávila等[52]研究HHP处理对真空包装绵羊乳奶酪品质的影响,发现300 MPa处理避免了奶酪起泡缺陷。此外,高压处理使得奶酪内部的颜色被破坏,造成亮度损失,黄度增加。这些变化不仅取决于奶酪制作的工艺,还取决于奶酪的类型[29]。经过高压处理后,奶酪的质构发生了明显的变化,有利于改善奶酪的品质特性。

2.3 酸乳

酸乳的营养价值高,风味独特,对人体健康有积极作用,受到广大消费者的喜爱。酸乳根据状态的不同可分为:凝固型酸乳、搅拌型酸乳和直饮型酸乳3种[53]。原料乳在发酵过程中的变化包括:酪蛋白微团的收缩或破裂;乳清蛋白的变性,尤其是β-乳球蛋白;矿物质平衡的改变[54]。酸乳最常见的品质不良问题是凝固型酸乳的低刚性、搅拌型酸乳的低粘度,进而出现乳清-水相分离。基于HHP处理,有3种方式已被应用于改善酸乳的品质和延长贮藏期[55]。一是用高压处理过的鲜乳发酵制得酸乳,二是高压处理包装的发酵酸乳成品,三是高压条件下进行酸乳发酵。在酸乳制作中,预先HHP处理的鲜乳显示出更高的酸化率,并且能够在较高的pH下凝结。与由非加压鲜乳所制成的酸乳相比,经HHP处理后制成的酸乳不易塌陷,表现出较低的乳清分离量(持水力提高约10%)和较强的凝胶强度[56-57]。Tsevdou等[58]监测牛奶经高压或谷氨酰胺转胺酶处理对乳酸发酵过程中风味化合物的影响,结果发现,HHP处理显著提高了挥发性风味物质产生的速率,乙醛和双乙酰除外。冷藏期间加压处理可以避免酸乳出现后酸化,这归因于HHP处理抑制乳糖代谢和运输相关酶的活性,尤其是乳糖脱氢酶和β-D-半乳糖苷酶。同样,ATP酶活性也被抑制或降低,避免酸性物质在酸乳中产生[59]。HHP处理的酸乳在4周的贮藏期内仍具有恒定的酸度,从而保证Ca、P等矿物质的稳定性。高压处理(400 MPa/15 min)也可以灭活酸乳发酵剂,从而防止过度酸化和产品变质。然而,对发酵剂的影响取决于菌种的特性,例如,嗜热链球菌对HHP耐受性更强[60]。

2.4 奶油制品

冰淇淋是一种复杂的多相胶体系统,在冷冻状态下由冰晶、气室和分散在连续冷冻浓缩的水相中的部分聚结脂肪滴组成,在水相中含有部分溶质,如糖类、蛋白质和盐[61]。在冰淇淋生产中,HHP技术的作用主要与其对水的固-液相转变的影响以及诱导乳清蛋白部分变性的能力有关,这为冰淇淋结构和质地改善提供了一种新的方法[62]。在充气乳制品乳状液的生产中,HHP处理能够破坏乳清蛋白之间的分子间疏水和静电相互作用,这将增加乳清蛋白的表面疏水性,降低界面张力和脂肪滴界面上蛋白质吸附能力,促进脂肪滴的部分聚集,增强起泡能力和物理稳定性。张林[63]研究HHP处理对冰淇淋混合料及其制得的冰淇淋影响,HHP处理对乳脂肪球的粒径影响不大,但明显提高冰淇淋混合物的黏度,具有更高的抗融化性。

生产与全脂冰淇淋质地相似的低脂冰淇淋,一般需要在冰淇淋混合物中加入部分乳清蛋白,使得在冰淇淋制作过程中具有更好地发泡性能,阻止冰晶的过度生长,并在冻结时保持气泡数量,获得较好的感官和质地特性[64]。Lim等[65]研究HHP处理对乳清蛋白浓缩物制作的低脂冰淇淋的质地和感官性质的影响,乳清蛋白经HHP处理对低脂冰淇淋混合物的膨胀率和泡沫稳定性以及低脂冰淇淋的硬度均表现出积极的影响。Oh等[66]研究HHP和蔗糖聚酯影响可可黄油的多态转变,在60或21 ℃下,可可黄油熔体经HHP处理不影响温度波动期间结晶为V型的可可黄油从V型向VI型的转变速率。同样,使用100、300或600 MPa的HHP处理不会改变可可黄油结晶从V型向VI型转变的速率。Chauhan等[67]确定了消费者能够区分HHP处理和未处理的新鲜乳清蛋白浓缩物、含有和不含双乙酰的低脂冰淇淋之间差异的能力。进一步研究乳清蛋白浓缩物对双乙酰的结合特性以及HHP在低脂冰淇淋中的应用潜力,对于低脂冰淇淋制作技术的创新提供新的思路。

3. 结论与展望

本文总结了HHP非热处理技术在液态乳、奶酪、酸乳等乳制品加工领域的应用。相比传统热处理,HHP技术展现出诸多的优势,能够延长产品的货架期、杀灭原料中腐败微生物、抑制氧化酶的活性、改善产品的质地和风味,满足消费者对新鲜、营养和健康乳制品的需求。然而,由于处理过程的高压环境,对加工设备的空间尺寸、承装容器及密封材料的耐受性有较为严格的要求,设备的维修成本较为昂贵。随着科技水平的迅猛发展,新型复合易成型、低密度、耐压材料的出现,将有助于解决这一技术应用上的限制。

作为一种高效、绿色的食品加工技术,HHP处理不需要提供额外的热能、工作条件温和,受到国内外学者的广泛关注。今后,该技术的研究有望着重围绕以下3个方面进行。a.解析该技术的分子作用机制,如改善质构、清除腐败菌、降低褐变、维持次级代谢物的稳定等;b.比较协同其他处理方法(如超声-HHP处理、微波-HHP处理等)与常规或单一处理的差异,以便采用更有效经济的加工方式;c.评估HHP对不同食品原料内在特性的影响,如pH、功能特性、蛋白质构象等。

-

[1] COUTINHO N, SILVEIRA M, ROCHA R, et al. Cold plasma processing of milk and dairy products[J]. Trends in Food Science & Technology,2018,74:56−68.

[2] NUNES L, TAVARES G. Thermal treatments and emerging technologies: Impacts on the structure and techno-functional properties of milk proteins[J]. Trends in Food Science & Technology,2019,90:88−99.

[3] VERRUCK S, BALTHAZAR C, ROCHA R, et al. Dairy foods and positive impact on the consumer's health[M]. Advances in Food and Nutrition Research, 2019, 89: 95-164.

[4] LEE J, CHOI E, CHANG J, et al. Effect of high hydrostatic pressure (HHP) and supercooling storage in leaf mustard (Brassica juncea L. ) kimchi: Modelling of microbial activity and preservation of physicochemical properties[J]. LWT-Food Science and Technology,2021,145:111325. doi: 10.1016/j.lwt.2021.111325

[5] SERMENT-MORENO V, JACOBO-VELAZQUEZ D, TORRES J, et al. Microstructural and physiological changes in plant cell induced by pressure: Their role on the availability and pressure-temperature stability of phytochemicals[J]. Food Engineering Reviews,2017,9(4):314−334. doi: 10.1007/s12393-017-9158-6

[6] 周炜, 印伯星, 杨仁琴, 等. 乳品加工中超高压技术对乳品质量的影响及其应用前景分析[J]. 现代食品,2019,13:94−96. [ZHOU Wei, YIN Boxing, YANG Renqin, et al. The influence and prospect of ultra-high pressure technology in dairy processing on the quality of dairy products[J]. Modern Food,2019,13:94−96. [7] LEITE T, DE JESUS A, SCHMIELE M, et al. High pressure processing (HPP) of pea starch: Effect on the gelatinization properties[J]. LWT-Food Science and Technology,2017,76:361−369. doi: 10.1016/j.lwt.2016.07.036

[8] DERMESONLOUOGLOU E, ANGELIKAKI F, GIANNAKOUROU M, et al. Minimally processed fresh-cut peach and apricot snacks of extended shelf-life by combined osmotic and high pressure processing[J]. Food and Bioprocess Technology,2019,12:371−386. doi: 10.1007/s11947-018-2215-1

[9] ZHAO Y, WANG P, ZHAN P, et al. Aroma characteristics of cloudy kiwifruit juices treated with high hydrostatic pressure and representative thermal processes[J]. Food Research International,2021,139:109841. doi: 10.1016/j.foodres.2020.109841

[10] ELAMIN W, ENDAN J, YOSUF Y, et al. High pressure processing technology and equipment evolution: A review[J]. Journal of Engineering Science and Technology Review,2015,8(5):75−83. doi: 10.25103/jestr.085.11

[11] HUANG H, HSU C, YANG B, et al. Potential utility of high-pressure processing to address the risk of food allergen concerns[J]. Comprehensive Reviews in Food Science & Food Safety,2013,13:78−90.

[12] CAMPUS M. High pressure processing of meat, meat products and seafood[J]. Food Engineering Reviews,2010,2(4):256−273. doi: 10.1007/s12393-010-9028-y

[13] ALI A, YEOH W, FORNEY C, et al. Advances in postharvest technologies to extend the storage life of minimally processed fruits and vegetables[J]. Critical Reviews in Food Science and Nutrition,2017,58(15):1−18.

[14] 刘杨铭, 卢士玲, 王庆玲, 等. 超高压杀菌对酱卤肉制品的影响研究进展[J]. 肉类研究,2017(8):55−59. [LIU Yangming, LU Shiling, WANG Qingling, et al. Progress in research on the effect of ultrahigh pressure sterilization on soy sauce and pot-roast meat products[J]. Meat Research,2017(8):55−59. [15] 崔燕, 林旭东, 康孟利, 等. 超高压技术在水产品贮藏与加工中的应用研究进展[J]. 食品科学,2016,37(21):291−299. [CUI Yan, LIN Xudong, KANG Mengli, et al. Advances in application of ultra high pressure for preservation and processing of aquatic products[J]. Food Science,2016,37(21):291−299. [16] HUANG M, ZHANG M, BHANDARI B. Recent development in the application of alternative sterilization technologies to prepared dishes-A review[J]. Critical Reviews in Food Science and Nutrition,2018,59(7):1188−1196.

[17] AGANOVIC K, HERTEL C, VOGEL R, et al. Aspects of high hydrostatic pressure food processing: perspectives on technology and food safety[J]. Comprehensive Reviews in Food Science & Food Safety,2021,20:3225−3266.

[18] AHMAD T, BUTT M, AADIL R, et al. Impact of nonthermal processing on different milk enzymes[J]. International Journal of Dairy Technology,2019,72(4):481−495. doi: 10.1111/1471-0307.12622

[19] BARBA F, ESTEVE M, FRIGOLA A. High pressure treatment effect on physicochemical and nutritional properties of fluid foods during storage-A review[J]. Comprehensive Reviews in Food Science & Food Safety,2012,11(3):307−322.

[20] CHANDAN R, KILARA A, SHAH N. Potential applications of nonthermal processing technologies in the dairy industry[M]. Dairy Processing and Quality Assurance, 2015, 528-551.

[21] VOIGT D, KELLY A, HUPPERTZ T. High-pressure processing of milk and dairy products[M]. Emerging Dairy Processing Technologies, 2015, 71-92.

[22] TRUJILLO A, CAPELLAS M, SALDO J, et al. Applications of high-hydrostatic pressure on milk and dairy products: A review[J]. Innovative Food Science & Emerging Technologies,2002,3(4):295−307.

[23] MUNIR M, NADEEM M, QURESHI T, et al. Effects of high pressure, microwave and ultrasound processing on proteins and enzyme activity in dairy systems-A review[J]. Innovative Food Science & Emerging Technologies,2019,57:102192.

[24] BOGAHAWATHTHA D, BUCKOW R, CHANDRAPALA J, et al. Comparison between thermal pasteurization and high pressure processing of bovine skim milk in relation to denaturation and immunogenicity of native milk proteins[J]. Innovative Food Science & Emerging Technologies,2018,47:301−308.

[25] SCOLLARD P, BERESFORD T, NEEDS E, et al. Plasmin activity, β-lactoglobulin denaturation and proteolysis in high pressure treated milk[J]. International Dairy Journal,2000,10(12):835−841. doi: 10.1016/S0958-6946(01)00028-0

[26] LIU G, CARØE C, QIN Z, et al. Comparative study on quality of whole milk processed by high hydrostatic pressure or thermal pasteurization treatment[J]. LWT-Food Science and Technology,2020,127:109370. doi: 10.1016/j.lwt.2020.109370

[27] 任杰, 胡志和, 孙振刚, 等. 高静水压处理对牛初乳中IgG的影响[J]. 食品科学,2015,36(3):63−67. [REN Jie, HU Zhihe, SUN Zhengang, et al. Effects of high hydrostatic pressure on IgG in bovine colostrum[J]. Food Science,2015,36(3):63−67. [28] 罗娇依, 刘彤彤, 曹进, 等. 反相高效液相色谱法测定牛初乳保健食品中免疫球蛋白G的含量[J]. 中国食物与营养,2022,28(9):20−26. [LUO Jiaoyi, LIU Tongtong, CAO Jin, et al. Determination of immunoglobulin G in bovine colostrum supplement by reverse high-performance liquid chromatography[J]. Food and Nutrition in China,2022,28(9):20−26. [29] NUÑEZ M, CALZADA J, OLMO A. High pressure processing of cheese: lights, shadows and prospects[J]. International Dairy Journal,2019,100:104558.

[30] CARMINATI D, GATTI M, BONVINI B, et al. High-pressure processing of Gorgonzola cheese: Influence on Listeria monocytogenes inactivation and on sensory characteristics[J]. Journal of Food Protection,2004,67(8):1671−1675. doi: 10.4315/0362-028X-67.8.1671

[31] LUNDéN T, KORKEALA H. Human listeriosis outbreaks linked to dairy products in Europe[J]. Journal of Dairy Science,2004,87:6−12. doi: 10.3168/jds.S0022-0302(04)70056-9

[32] LOPEZPEDEMONTE T, ROIGSAGUES A, DELAMO S, et al. Reduction of counts of Listeria monocytogenes in cheese by means of high hydrostatic pressure[J]. Food Microbiology,2007,24(1):59−66. doi: 10.1016/j.fm.2006.03.008

[33] ZHANG L, QU M, YAO J, et al. Effect of high hydrostatic pressure on the viability of Streptococcus thermophilus bacteriophages isolated from cheese[J]. Innovative Food Science & Emerging Technologies,2015,29:113−118.

[34] PITT J, HOCKING A. Penicillium and related genera[M]. Fungi and Food Spoilage, 1997, 169-274.

[35] MARTíNEZ-RODRíGUEZ Y, ACOSTA-MUñIZ C, OLIVAS G, et al. Effect of high hydrostatic pressure on mycelial development, spore viability and enzyme activity of Penicillium roqueforti[J]. International Journal of Food Microbiology,2014,168−169(1):42−46.

[36] ÁVILA M, GóMEZ-TORRES N, DELGADO D, et al. Application of high pressure processing for controlling Clostridium tyrobutyricum and late blowing defect on semi-hard cheese[J]. Food Microbiology,2016,60:165−173. doi: 10.1016/j.fm.2016.07.008

[37] 熊孜, 廖李, 乔宇, 等. 超高压处理对果蔬质量的影响[J]. 湖北农业科学,2020,59(9):145−150. [XIONG Z, LIAO L, QIAO Y, et al. Effect of ultra -high pressure treatment on the quality of fruits and vegetables[J]. Hubei Agricultural Sciences,2020,59(9):145−150. [38] NOVELLA-RODRíGUEZ S, VECIANA-NOGUéS M, SALDO J, et al. Effects of high hydrostatic pressure treatments on biogenic amine contents in goat cheeses during ripening[J]. Journal of Agricultural and Food Chemistry,2002,50(25):7288−7292. doi: 10.1021/jf025665u

[39] MCSWEENEY P. Biochemistry of cheese ripening: Introduction and overview[J]. International Journal of Dairy Technology,2004,57:127−144. doi: 10.1111/j.1471-0307.2004.00147.x

[40] COSTABEL L M, BERGAMINI C, VAUDAGNA S R, et al. Effect of high-pressure treatment on hard cheese proteolysis[J]. Journal of Dairy Science,2016,99(6):4220−4232. doi: 10.3168/jds.2015-9907

[41] CALZADA J, DEL OLMO A, PICON A, et al. Effect of high-pressure-processing on lipolysis and volatile compounds of Brie cheese during ripening and refrigerated storage[J]. International Dairy Journal,2014,39(2):232−239. doi: 10.1016/j.idairyj.2014.07.007

[42] DELGADO F, GONZáLEZ-CRESPO J, CAVA R, et al. Changes in the volatile profile of a raw goat milk cheese treated by hydrostatic high pressure at different stages of maturation[J]. International Dairy Journal,2011,21(3):135−141. doi: 10.1016/j.idairyj.2010.10.006

[43] DELGADO F, RODRíGUEZ-PINILLA J, MáRQUEZ G, et al. Physicochemical, proteolysis and texture changes during the storage of a mature soft cheese treated by high-pressure hydrostatic[J]. European Food Research and Technology,2015,240(6):1167−1176. doi: 10.1007/s00217-015-2420-3

[44] JOHNSON M, KAPOOR R, MCMAHON D, et al. Reduction of sodium and fat levels in natural and processed cheeses: Scientific and technological aspects[J]. Comprehensive Reviews in Food Science & Food Safety,2010,8(3):252−268.

[45] OZTURK M, GOVINDASAMY-LUCEY S, JAEGGI J, et al. Investigating the properties of high-pressure-treated, reduced-sodium, low-moisture, part-skim Mozzarella cheese during refrigerated storage[J]. Journal of Dairy Science,2018,101(8):6853−6865. doi: 10.3168/jds.2018-14415

[46] OZTURK M, GOVINDASAMY-LUCEY S, JAEGGI J, et al. Low-sodium Cheddar cheese: Effect of fortification of cheese milk with ultrafiltration retentate and high-hydrostatic pressure treatment of cheese[J]. Journal of Dairy Science,2015,98(10):6713−6726. doi: 10.3168/jds.2015-9549

[47] MOSCHOPOULOU E, ANISA T, KATSAROS G, et al. Application of high-pressure treatment on ovine brined cheese: Effect on composition and microflora throughout ripening[J]. Innovative Food Science & Emerging Technologies,2010,11(4):543−550.

[48] KOCA N, BALASUBRAMANIAN V, HARPER J. High-pressure effects on the microstructure, texture, and color of white-brined cheese[J]. Journal of Food Science,2011,76:399−404. doi: 10.1111/j.1750-3841.2011.02201.x

[49] RYNNE N, BERESFORD T, GUINEE T, et al. Effect of high-pressure treatment of 1 day-old full-fat Cheedar cheese on subsequent quality and ripening[J]. Innovative Food Science & Emerging Technologies,2008,9:29−40.

[50] SANDRA S, STANDFORD M, MEUNIER G. The use of high-pressure processing in the production of Queso Fresco cheese[J]. Journal of Food Science,2004,69(4):153−158. doi: 10.1111/j.1365-2621.2004.tb06340.x

[51] SERRANO J, VELAZQUEZ G, LOPETCHARAT K, et al. Moderately high hydrostatic pressure processing to reduce production costs of shredded cheese: Microstructure, texture, and sensory properties of shredded milled curd cheddar[J]. Journal of Food Science,2006,70(4):286−293.

[52] ÁVILA M, GÓMEZ-TORRES N, DELGADO D, et al. Effect of high-pressure treatments on proteolysis, volatile compounds, texture, colour, and sensory characteristics of semi-hard raw ewe milk cheese[J]. Food Research International,2017,100:595−602. doi: 10.1016/j.foodres.2017.07.043

[53] LOVEDAY S, SARKAR A, SINGH H. Innovative yoghurts: Novel processing technologies for improving acid milk gel texture[J]. Trends in Food Science & Technology,2013,33(1):5−20.

[54] HUPPERTZ T, KELLY A, FOX P. Effects of high pressure on constituents and properties of milk[J]. International Dairy Journal,2002,12:561−572. doi: 10.1016/S0958-6946(02)00045-6

[55] LOPES R P, MOTA M J, SOUSA S, et al. Combined effect of pressure and temperature for yogurt production[J]. Food Research International,2019,122:222−229. doi: 10.1016/j.foodres.2019.04.010

[56] HARTE F, LUEDECKE L, SWANSON B, et al. Low-fat set yogurt made from milk subjected to combinations of high hydrostatic pressure and thermal processing[J]. Journal of Dairy Science,2003,86:1074−1082. doi: 10.3168/jds.S0022-0302(03)73690-X

[57] HARTE F, AMONTE M, LUEDECKE L, et al. Yield stress and microstructure of set yogurt made from high-hydrostatic pressure-treated full-fat milk[J]. Journal of Food Science,2002,67:2245−2250. doi: 10.1111/j.1365-2621.2002.tb09535.x

[58] TSEVDOU M, SOUKOULIS C, CAPPELLIN L, et al. Monitoring the effect of high pressure and transglutaminase treatment of milk on the evolution of flavour compounds during lactic acid fermentation using PTR-TOF-MS[J]. Food Chemistry,2013,138(4):2159−2167. doi: 10.1016/j.foodchem.2012.12.007

[59] DESHWAL G, TIWARI S, KUMAR A, et al. Review on factors affecting and control of post-acidification in yoghurt and related products[J]. Trends in Food Science & Technology,2021,109:499−512.

[60] REPS A, JANKOWSKA A, WISNIEWSKA K. The effect of high pressure on selected properties of yoghurt[J]. High Pressure Research,2009,29:33−37. doi: 10.1080/08957950802593782

[61] 高鑫, 李博, 刘小杰. 超高压在乳品加工中的应用研究进展[J]. 乳业科学与技术,2021,44(2):37−42. [GAO X, LI B, LIU X. Recent progress in the application of ultra-high pressure in dairy processing[J]. Journal of Dairy Science and Technology,2021,44(2):37−42. [62] HUPPERTZ T, SMIDDY M, UPADHYAY V, et al. High pressure-induced changes in bovine milk: A review[J]. International Journal of Dairy Technology,2006,59:58−66. doi: 10.1111/j.1471-0307.2006.00246.x

[63] 张林. 超高压均质-磷脂改性大豆分离蛋白的制备及在冰淇淋加工中的应用[D]. 哈尔滨: 东北农业大学, 2018. ZHANG Lin. Ultra high pressure homogeneous-hospholipid modified soyprotein isolate and its application in ice cream[D]. Harbin: Northeast Agricultural University, 2018.

[64] PADIERNOS C A, LIM S Y, SWANSON B G, et al. High hydrostatic pressure modification of whey protein concentrate for use in lowfat whipping cream improves foaming properties[J]. Journal of Dairy Science,2009,92(7):3049−3056. doi: 10.3168/jds.2008-1997

[65] LIM S, SWANSON B, ROSS C, et al. High hydrostatic pressure modification of whey protein concentrate for improved body and texture of low fat ice cream[J]. Journal of Dairy Science,2008,91(4):1308−1316. doi: 10.3168/jds.2007-0391

[66] OH J, SWANSON B. Polymorphic transitions of cocoa butter affected by high hydrostatic pressure and sucrose polyesters[J]. Journal of the American Oil Chemists' Society,2006,83(12):1007−1014. doi: 10.1007/s11746-006-5155-2

[67] CHAUHAN J, LIM S, POWERS J, et al. Low-fat ice cream flavor not modified by high hydrostatic pressure treatment of whey protein concentrate[J]. Journal of Dairy Science,2010,93(4):1452−1458. doi: 10.3168/jds.2009-2688

-

期刊类型引用(3)

1. 温娅晴,郭梦姚. 超临界二氧化碳萃取技术及其在油脂中的应用研究进展. 食品安全质量检测学报. 2025(02): 286-295 .  百度学术

百度学术

2. 毕玉莹,杨啸吟,张一敏,朱立贤,梁荣蓉,毛衍伟,左惠心,牛乐宝. 不同超高压处理对DFD牛肉肉色及货架期的影响. 肉类研究. 2024(04): 30-35 .  百度学术

百度学术

3. 殷献华,殷诚,孟晶晶,钱静. 不同贮藏温度下酸乳品质变化及货架期预测. 乳业科学与技术. 2023(05): 38-42 .  百度学术

百度学术

其他类型引用(0)

下载:

下载:

下载:

下载: