Preparation of Glutinous Millet Resistant Starch by Thermal-press Processing Method and the Effect of Its Addition Amount on the Texture and GI of Biscuits

-

摘要: 本文以抗性淀粉产率为测定指标,对不同淀粉乳浓度、压热时间和压热温度对黄米抗性淀粉制备的影响进行了系统分析,在对压热处理前后黄米淀粉的理化性质与微观结构进行比较的基础上,研究了不同黄米抗性淀粉的添加量对饼干的质构和GI值的影响。结果表明:淀粉乳浓度为10%、压热时间为40 min、压热温度为120 ℃的条件下,压热法制备的黄米抗性淀粉的产率最佳,其产率可达30.64%。进一步的检测分析结果显示,与黄米淀粉相比,经压热处理制备的黄米抗性淀粉的透光率、溶解度和膨胀力均明显下降。与黄米淀粉颗粒粒径较小、表面相对光滑平整不同,经压热处理制备的黄米抗性淀粉呈片状、表面粗糙且存在孔状凹陷。将制备的抗性淀粉代替部分面粉制作饼干时发现,随着抗性淀粉添加量的增大,饼干的剪切力增大,GI值明显降低,使得饼干从高GI值食品转化为了中GI值食品,符合消费者对中低GI值食品的需求。Abstract: In this study, the effects of starch emulsion concentration, autoclave time and autoclave temperature on the preparation of glutinous millet resistant starch (GMRS) were systematically investigated by using the yield of GMRS as the detection index. Then, the physicochemical properties and microstructure of glutinous millet starch (GMS) before and after autoclave treatment were further analyzed and compared. The influence of different ratio of GMRS addition on the texture and GI value of biscuits were studied. The results showed that the optimum conditions for the preparation of GMRS by autoclave method were starch emulsion concentration of 10%, autoclave time of 40 min, and autoclave temperature of 120 ℃. Under these conditions, the yield of GMRS was 30.64%. Further detection indicated that compared with GMS, the light transmittance, solubility and swelling power of GMRS were decreased significantly. Unlike GMS, which had small particle size and relatively smooth surface, the morphology of GMRS prepared by autoclave method was flaky and rough surface with pore like depression. The data of the further experiments, in which GMRS was used to replace part of the flour to make biscuits, showed that with the increasing of the amount of GMRS, the shear force of biscuits increased, and the GI value decreased significantly, the biscuits could be transformed from high GI value food to medium GI value food, meeting the needs of consumers for low GI value food.

-

黄米,由糜子籽粒去皮后制成,栽培历史十分悠久,在我国古代农业领域占有重要地位[1-2]。黄米营养参数与比普通谷物类更优。研究表明黄米的蛋白质含量近似于玉米,约为11.3%~12.7%,脂肪的平均含量为3.23%[3-4],脂肪酸含量较高,尤其是不饱和脂肪酸含量超过了总脂肪酸含量的九成。黄米还是高钙、高铁食物,其含量是大米、小麦、玉米等作物的数倍[5]。黄米中淀粉含量与大米、小米等的淀粉含量相近[6,7],约为67.6%~75.1%,是制备抗性淀粉的优良原料。

抗性淀粉是指一类不能够被人体小肠吸收利用的淀粉及其分解产物[8-10]。抗性淀粉的分解需要在肠道菌群的协助下进行,但其同样可以促进肠道有益菌群的生长繁殖,增大粪便体积,促进肠道的蠕动,不仅可以显著预防痔疮、便秘等疾病,还可以稀释一些刺激癌细胞生长的有毒物质[11-13]。同时,抗性淀粉还会参与调控机体糖代谢、脂质代谢、脂肪酸的摄入与氧化等生理过程,在维持或改善机体血糖水平、脂质代谢平衡方面都发挥着重要的作用[14-16]。由于其具有能够抑制餐后血糖的快速升高,以及可以减少人体血清中的胆固醇和甘油三酯的含量等优点,越来越受到人们的关注。制备抗性淀粉的方法主要有物理法、化学法和生物法,物理法主要有压热法、超声法和微波法[17-19],常用的物理方法有湿热处理、压热处理等。

饼干是我们生活中最常见也是最重要的焙烤食品之一,传统的饼干也是常见的高GI值的食品,降低饼干的GI将会成为开发新型饼干产品的主要目标之一[20-22]。有研究表明抗性淀粉可以有效地缓解高血糖症[23-24],目前将抗性淀粉添加到饼干的加工中已经成为饼干加工研究与应用的热点之一。

因此,本文以黄米淀粉为原料,研究压热法制备黄米抗性淀粉的工艺,再对制备的抗性淀粉的透光率、溶解度、膨胀力等理化性质及微观结构进行测定,最后将制备的抗性淀粉代替部分面粉制作抗性淀粉饼干,研究了不同抗性淀粉的添加量对质构特性和血糖生成指数等的影响,以期为黄米的开发利用提供依据。

1. 材料与方法

1.1 材料与仪器

黄米 山西东方亮生命科技股份有限公司;低筋面粉、黄油、蔗糖、膨松剂、食盐、鸡蛋等饼干原料 均为食品级,购于本地超市;植物抗性淀粉(rs)酶联免疫分析试剂盒 上海将来实业股份有限公司;普鲁兰酶(2000 u/mL) 北京酷尔化学科技有限公司;淀粉转葡萄糖苷酶(50000 u/g) 江苏博立生物制品有限公司;胃蛋白酶(250 u/mg) 合肥千盛生物科技有限公司;α-淀粉酶(3700 u/g) 北京奥博星生物技术有限责任公司;胰酶(250 u/mg) 广州达晖生物技术股份有限公司;NaOH、HCL、Tris-HCL、无水乙醇、KBr、NaCl、MgCl2、CaCl2等试剂 均为分析纯,购于国药集团化学试剂有限公司。

WFM-10型超微粉碎震荡磨 江阴市祥达机器制造有限公司;KDC-1044L型大容量低速离心机 安徽中科中佳科学仪器有限公司;SCIENTZ-30YD/A型冷冻干燥机 宁波新芝冻干设备股份有限公司;DZKW-4型电子恒温水浴锅 北京中兴伟业仪器有限公司;JJ-1型大功率电动搅拌器 常州国华电器有限公司;SpectraMax i3x型多功能酶标仪 美国Molecular Devices公司;LS-75HD型立式压力蒸汽灭菌器 江阴滨江医疗设备有限公司;TMS-Pro型质构仪 美国Food Technology Corporation公司。

1.2 实验方法

1.2.1 黄米抗性淀粉的制备

称取适量黄米淀粉于250 mL的锥形瓶中,加入蒸馏水,配成一定浓度的黄米淀粉乳,用玻璃棒搅拌均匀,放入立式压力蒸汽灭菌器中进行压热处理,取出后,在室温下自然冷却,放入4 ℃冰箱中贮藏24 h后,将内容物在−18 ℃冰箱中冷冻过夜,再进行冷冻干燥处理,从而得到黄米抗性淀粉。

1.2.2 黄米抗性淀粉含量的测定

根据植物抗性淀粉(RS)酶联免疫分析试剂盒的使用方法进行实验操作,将酶标板置于酶标仪中,在450 nm下测定各孔吸光度;制作标准曲线(y=0.0028X−0.0358,R2=0.9997)根据所得吸光度确定稀释样品中抗性淀粉含量,乘以稀释倍数,除以样品质量,即可得到样品中抗性淀粉含量。抗性淀粉的产率按以下公式计算:

抗性淀粉产率(%)=(抗性淀粉含量/总淀粉含量)×100 1.2.3 黄米抗性淀粉制备最佳条件的筛选

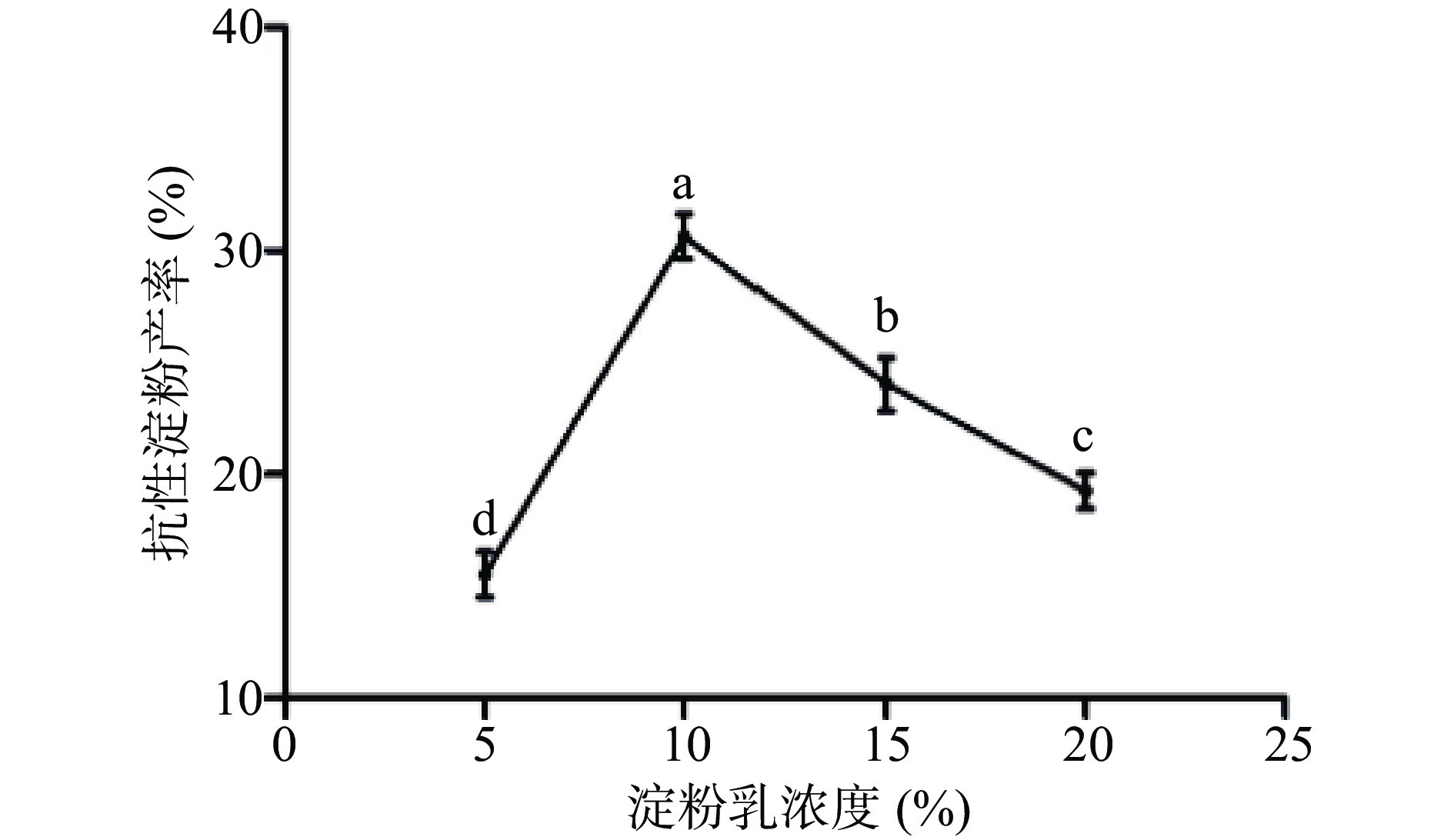

1.2.3.1 黄米淀粉乳浓度对抗性淀粉产率的影响

称取适量黄米淀粉于250 mL的锥形瓶中,加入蒸馏水,分别配成5%、10%、15%、20%的黄米淀粉乳,用玻璃棒搅拌均匀,放入立式压力蒸汽灭菌锅中,在120 ℃条件下压热40 min,压热后在室温下自然冷却,放入4 ℃冰箱中贮藏24 h后,将内容物进行冻干处理,取出粉碎,过100目筛。

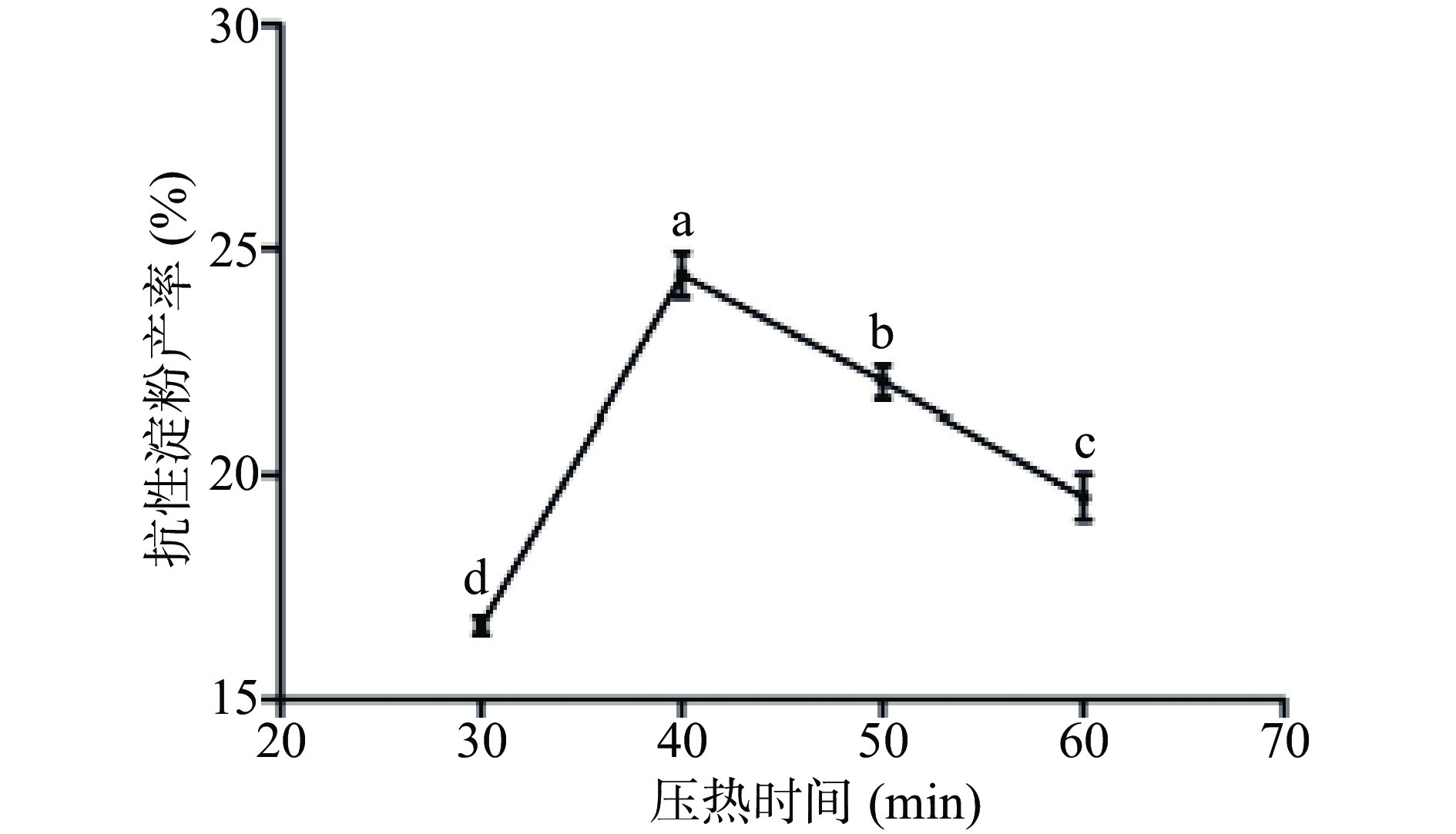

1.2.3.2 压热时间对抗性淀粉产率的影响

称取15 g黄米淀粉于锥形瓶中,配成15%的黄米淀粉乳,放置于立式压力蒸汽灭菌锅中,分别设置压热时间为30、40、50、60 min,压热温度为120 ℃。压热后在室温下自然冷却,放入4 ℃冰箱中贮藏24 h后,将内容物进行冻干处理,取出粉碎,过100目筛。

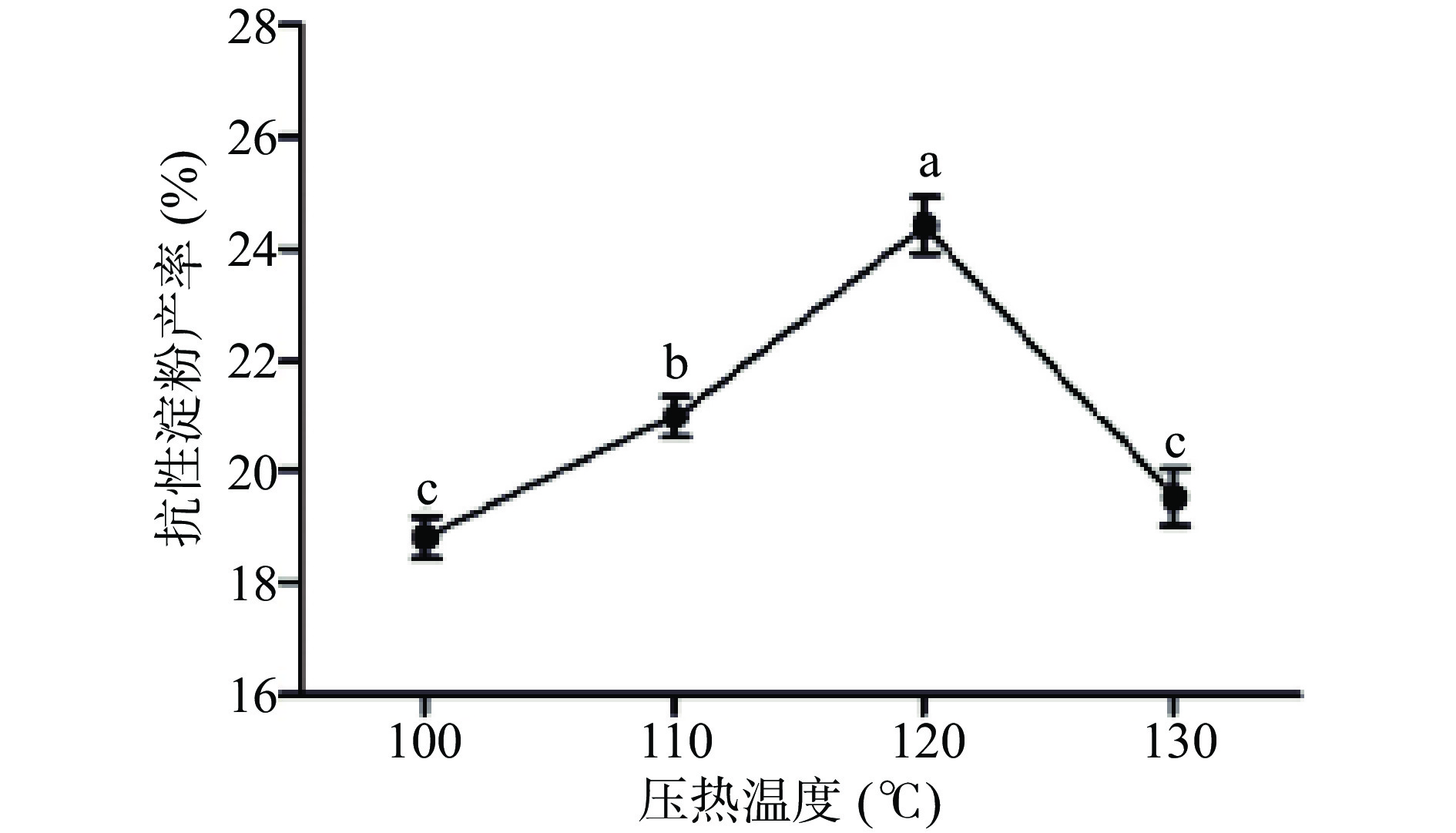

1.2.3.3 压热温度对抗性淀粉产率的影响

将浓度为15%的黄米淀粉乳,放置于立式压力蒸汽灭菌锅中,分别在100、110、120、130 ℃,压热时间为40 min条件下进行压热处理,压热后在室温下自然冷却,放入冰箱中贮藏24 h后,将内容物进行冻干处理,取出粉碎,过100目筛。

1.2.4 压热处理前后黄米淀粉理化性质的测定

1.2.4.1 压热处理前后黄米淀粉透光率的测定

配制质量分数为1%的压热前后的黄米淀粉乳,在沸水中水浴30 min后冷却至室温(25 ℃左右),将其倒入比色皿中,同时利用蒸馏水作为本次试验的空白组,置于620 nm波长的分光光度计下测定其透光率T[25]。

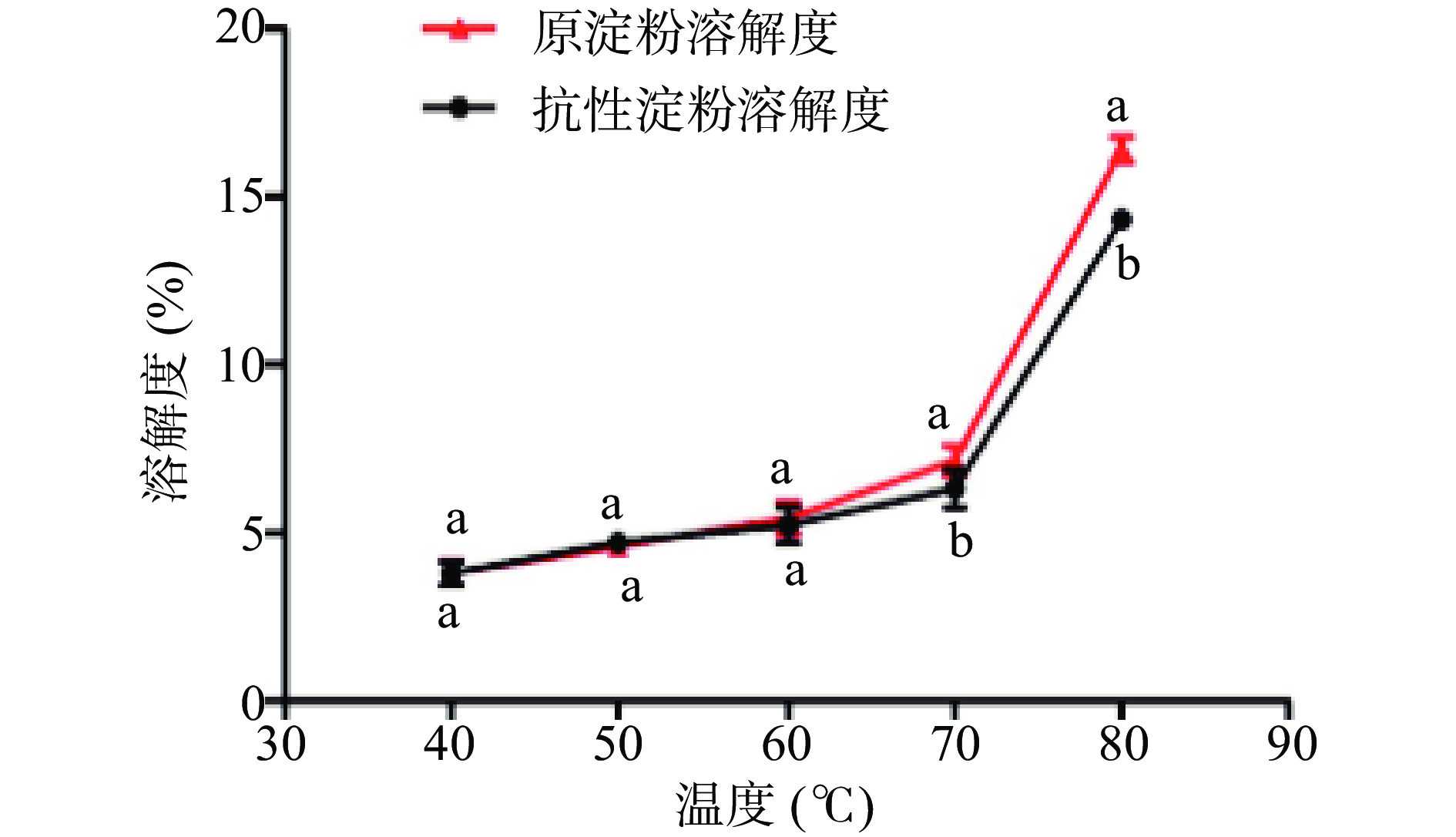

1.2.4.2 压热处理前后黄米淀粉溶解度和膨胀力的测定

准确称取一定量(M)的压热前后的黄米淀粉,加入适量蒸馏水配成质量分数为1%的淀粉乳,分别设置双数显恒温磁力搅拌器的温度为40、50、60、70、80 ℃,对淀粉乳进行加热搅拌30 min,然后将样品倒入离心管中,在3000 r/min下离心10 min,收集上清液,在105 ℃下干燥后恒重后称其质量(m),沉淀重量为m1[26]。按照公式计算溶解度(%)和膨胀力(g/g)。

溶解度=m/M×100 膨胀力=m1/(M−m) 1.2.5 黄米淀粉和黄米抗性淀粉的电镜测试

根据陈燕[27]的研究方法利用扫描电子显微镜对黄米淀粉及黄米抗性淀粉的微观结构进行测定。将淀粉样品研磨成粉,称取一定质量压热处理前后淀粉样品均匀置于样品台上,进行喷金处理,在500倍下拍摄样品形貌。

1.2.6 黄米抗性淀粉的添加对饼干的质构及GI值的影响

1.2.6.1 黄米抗性淀粉韧性饼干的制作

基础配方:低筋面粉200 g,黄油30 g,白砂糖16 g,水40 mL,全蛋液60 g,食盐2 g,膨松剂2 g。在基础配方的基础上分别加入0、50、100 g黄米抗性淀粉代替面粉制作抗性淀粉饼干。将黄油、水、食盐、白砂糖隔温水溶化后稍放凉把蛋液加入,搅匀,低筋面粉、抗性淀粉与膨松剂混匀过筛,将上述液体倒入面粉中。揉5 min,加保鲜膜室温放置30 min,擀平,用模具压花,放入烤箱内焙烤,设置焙烤温度为上火160 ℃,下火180 ℃,焙烤时间为10 min。

1.2.6.2 黄米抗性淀粉饼干的质构特性检测

采用三点弯曲测试黄米饼干质构。程序选择三点弯曲(100 N力量感应元);当探头移动到两个支撑点下2 cm时给予探头一个阻力,从而使探头停止运动完成位移零点设置;设置回程距离为30 mm;放置样品进行检验,并进行三次平行试验,取平均值。

1.2.6.3 黄米抗性淀粉饼干体外消化实验

首先制作葡萄糖标准曲线,得到回归方程y=0.4471x−0.00214,R2=0.9991。将面粉饼干、添加25%和50%的黄米抗性淀粉饼干研磨成粉并各称取1 g,置于50 mL锥形瓶中,加入3 mL磷酸缓冲液(0.1 moL/mL,pH6.9)和1 mL α-淀粉酶溶液,摇匀,加入10 mL磷酸缓冲液(0.1 mol/mL,pH6.9)、6 mL NaCl溶液(0.4 g/L)和0.05 g胃蛋白酶,使用2 moL/mL的HCl溶液调至pH为1.5,于37 ℃下搅拌30 min,加入10 mL磷酸缓冲液(0.1 moL/mL,pH6.9),加入质量分数为50%的NaOH调至溶液pH为6.9,加入0.2 mL MgCl2-CaCl2溶液、0.2 mL胰酶溶液、0.4 mL淀粉转葡萄糖苷酶溶液,加入蒸馏水至50 mL,于37 ℃摇床中,170 r/min摇床振荡反应,取1 mL水解样液,置于沸水中5 min,灭酶,冷却至室温,取上清液进行后续实验[12]。

取4 mL斐林试剂和6 mL蒸馏水混匀,作为空白试剂,测定溶液在590 nm的吸光度。

取1 mL水解液于试管中,加入0.1 mL淀粉转葡萄糖苷酶溶液和3.9 mL蒸馏水,混匀。取2 mL混合后的溶液,加入4 mL斐林试剂和3 mL蒸馏水,混匀,测定溶液在590 nm的吸光度。带入标准曲线中,计算得出葡萄糖含量,得到淀粉水解率,并绘制水解率与时间的关系曲线。

淀粉水解率(%)=(取样点水解葡萄糖含量×0.9/总淀粉含量)×100 以淀粉水解率为纵坐标,时间为横坐标,绘制淀粉水解率曲线,计算曲线下面积(AUC)进而计算得出HI,

HI=AUC样品/AUC白面包×100 以白面包(或葡萄糖)作为对照,进而计算得出GI,

GI=0.862HI+8.189 。1.3 数据处理

本文中所有数据统计都采用SPSS16.0进行分析。所有的图都是采用GraphPad Prism5进行绘制。

2. 结果与分析

2.1 单因素实验

2.1.1 淀粉乳浓度对抗性淀粉产率的影响

如图1所示,过低或过高的淀粉乳浓度都会降低抗性淀粉的产率,当淀粉乳浓度为10%时,抗性淀粉产率最高。这说明过大或过小的淀粉乳浓度都不利于抗性淀粉的生成。当淀粉乳浓度过低时,淀粉分子之间相互分离,不容易缔合,从而使其在重结晶的过程中不利于抗性淀粉的形成;淀粉乳浓度过大时,由于黏度较大,水分含量较低,淀粉颗粒无法充分溶胀,使得淀粉分子之间不易接近,难以形成有序排列,使得抗性淀粉产率降低[28]。因此,适宜的淀粉乳浓度选择为10%。

2.1.2 压热时间对抗性淀粉产率的影响

如图2所示为120 ℃条件下压热不同时间后抗性淀粉的产率。随着时间的延长,抗性淀粉产率呈先增加后减小的趋势。这是由于在较短时间内,直链和支链淀粉分子运动不充分,并未被完全释放,一定程度上影响了抗性淀粉的产生,而压热时间过长又导致淀粉分子分解过度,支链和直链淀粉被完全释放,甚至分解出更多的支链淀粉,它们之间剧烈运动,不易结晶[29]。因此,适宜的压热时间选择为40 min。

2.1.3 压热温度对抗性淀粉产率的影响

如图3所示,随着压热温度的升高,黄米抗性淀粉的产率也在不断增加,在120 ℃条件下抗性淀粉产率最高。随着压热温度的继续升高,黄米抗性淀粉的产率又呈现下降的趋势。这就说明,抗性淀粉只有在适当高温的条件下才可以提高其含量。因为此时黄米淀粉乳黏度降低,一定程度上促进了淀粉分子间的氢键遭到破坏,大量的支链和直链淀粉分子溶出后再重新聚合排列形成致密的晶体结构,进而增加了黄米抗性淀粉的产率[30]。因此,适宜的压热温度选择为120 ℃。

2.2 黄米淀粉及抗性淀粉理化性质分析

2.2.1 黄米淀粉及抗性淀粉透光率的测定

由表1可知,经过压热处理之后的黄米淀粉透光率显著下降(P<0.05),这是由于抗性淀粉中的直链淀粉相互聚集使得淀粉发生凝沉,分子之间的缔合作用使得光通过淀粉乳时发生散射现象,从而引起抗性淀粉透光率的下降[31]。

2.2.2 黄米淀粉及抗性淀粉溶解度的测定

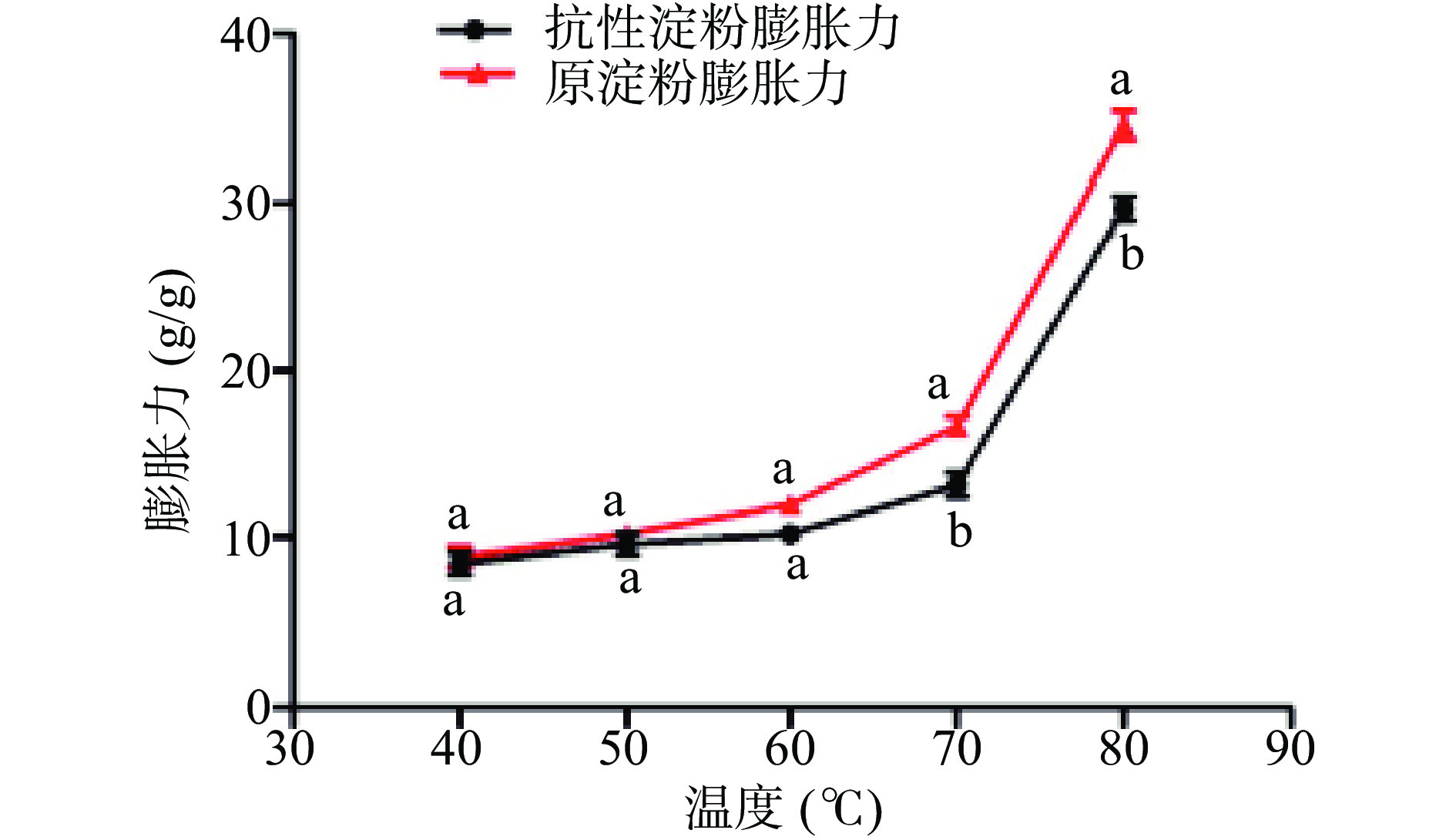

黄米淀粉与黄米抗性淀粉在不同温度下的溶解度和膨胀力如图4、图5所示。由图4可以看出,当温度在40~60 ℃范围内时,二者的溶解度差异并不显著,但随着温度的持续升高(70~90 ℃),两种淀粉的溶解度均呈现明显上升的趋势,且原淀粉的溶解度显著高于抗性淀粉(P<0.05),这是由于原淀粉在经过高温高压处理之后容易形成致密的结晶,结晶体结构稳定,同时也增强了直链淀粉与支链淀粉之间的结合力,使得淀粉溶解度降低[32]。由图5可知,随着温度升高,黄米淀粉和黄米抗性淀粉的膨胀力均呈明显上升的趋势;相同温度下,黄米淀粉的膨胀力均高于黄米抗性淀粉的膨胀力,尤其当温度在70 ℃以上时,黄米淀粉的膨胀力显著高于黄米抗性淀粉(P<0.05)。这是由于淀粉经过压热法受高温高压作用,使得淀粉分子形成致密的晶体结构,使得抗性淀粉的膨胀力降低。

2.3 黄米淀粉和黄米抗性淀粉扫描电镜结果分析

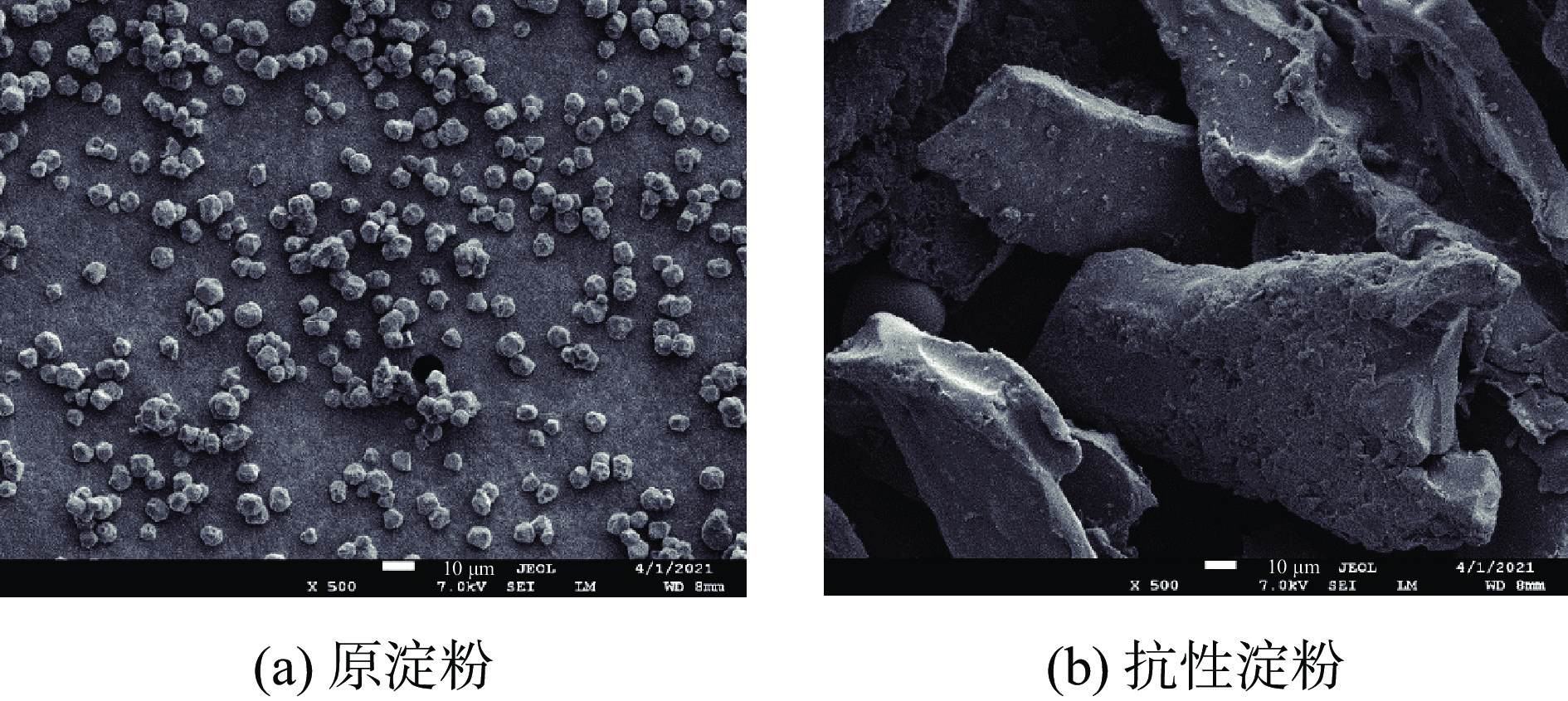

如图6所示,压热前后黄米淀粉的形貌发生了明显的变化,原淀粉颗粒分明,形态大部分为多边形结构,表面相对光滑平整,无孔隙裂痕,颗粒比较分散,但比较规整,颗粒粒径较小;而抗性淀粉呈片状,表面粗糙,存在孔状凹陷,这是由于淀粉分子在经过高温高压处理后,颗粒结构遭到严重破坏,淀粉发生糊化现象,可溶性淀粉分子被分解,表面形成了孔状,且形状不规则。

2.4 黄米抗性淀粉饼干的应用分析

2.4.1 黄米抗性淀粉饼干质构特性的分析

分析表2可知,随着抗性淀粉添加量的增加,饼干的剪切力显著上升(P<0.05)。这是由于抗性淀粉可以直接影响面筋网状结构,而随着饼干内抗性淀粉含量的增加,抗性淀粉对饼干面团结构的影响愈发显著,导致饼干硬度上升。然而,饼干的硬度在合适范围内时,消费者才会有较好的口感,因此,需要综合考虑口感等因素才能决定抗性淀粉的最佳添加量[32]。

表 2 饼干质构特性对比Table 2. Comparison of biscuit texture characteristics品种 面粉饼干 添加25%黄米抗性

淀粉饼干添加50%黄米抗性

淀粉饼干剪切力(N) 67.98±0.03c 68.72±0.03b 72.86±0.03a 表 3 黄米抗性淀粉添加量对饼干GI值的影响Table 3. Effect of adding amount of glutinous millet resistant starch on GI value of biscuits样品 GI值 面粉饼干 78.73±0.02b 添加25%黄米抗性淀粉饼干 64.37±0.05c 添加50%黄米抗性淀粉饼干 57.49±0.01d 对照(白面包) 100a 2.4.2 血糖生成指数结果分析

如表3所示,面粉饼干的GI值高达78.73,为高GI值食品(GI>70);而加入黄米抗性淀粉之后,饼干的GI值显著下降(P<0.05),随着抗性淀粉添加量的增加,饼干的GI值逐渐减小,成为中GI值食品(50≤GI≤70)。饼干GI值的下降,是由于压热处理后黄米淀粉中抗性淀粉的含量增加,抗性淀粉一定程度上抑制了血糖指数的升高,随着所添加到面团中的压热处理后的淀粉的比例不断升高,所制作的饼干中的抗性淀粉含量也逐渐升高,淀粉消化减缓,故GI值降低。

3. 结论

压热法制备黄米抗性淀粉的最佳工艺条件是:淀粉乳浓度10%,压热时间40 min,压热温度为120 ℃,在此工艺条件下,黄米抗性淀粉的产率为30.64%。对制备的抗性淀粉的理化性质、微观结构等方面分析可知,黄米抗性淀粉的透光率、溶解度和膨胀力均比原淀粉明显下降。经扫描电镜分析发现抗性淀粉表面疏松,呈片状,表面粗糙,存在孔状凹陷且形态不规则不完整,与黄米淀粉的颗粒形貌有明显的差异。将黄米抗性淀粉代替部分面粉作成饼干,随着抗性淀粉添加量的增大,饼干的剪切力明显上升,说明抗性淀粉对面筋的网状结构造成了明显影响;同时,饼干的GI值降低,使得饼干从高GI值食品转化为了中GI值食品,符合消费者对中低GI值食品的需求,对人体健康具有潜在价值。

-

表 1 黄米淀粉和黄米抗性淀粉透光率的比较

Table 1 Comparison of light transmittance between yellow rice starch and yellow rice resistant starch

表 2 饼干质构特性对比

Table 2 Comparison of biscuit texture characteristics

品种 面粉饼干 添加25%黄米抗性

淀粉饼干添加50%黄米抗性

淀粉饼干剪切力(N) 67.98±0.03c 68.72±0.03b 72.86±0.03a 表 3 黄米抗性淀粉添加量对饼干GI值的影响

Table 3 Effect of adding amount of glutinous millet resistant starch on GI value of biscuits

样品 GI值 面粉饼干 78.73±0.02b 添加25%黄米抗性淀粉饼干 64.37±0.05c 添加50%黄米抗性淀粉饼干 57.49±0.01d 对照(白面包) 100a -

[1] 王富. 黄米在烘焙食品中的应用[J]. 中国食品工业,2021(7):126−128. [WANG F. Application of yellow rice in bakery[J]. China Food Industry,2021(7):126−128. [2] 边鑫, 陈镜如, 杨杨, 等. 自然发酵对大黄米加工特性及黏豆包熟面团品质的影响[J]. 中国酿造,2022,41(2):193−197. [BIAN X, CHEN J R, YANG Y, et al. Effects of natural fermentation on the processing characteristics of big yellow rice and the quality of dough made with sticky beans[J]. China Brewing,2022,41(2):193−197. doi: 10.11882/j.issn.0254-5071.2022.02.032 [3] YOUSAF L, HOU D Z, LIAQAT H, et al. Millet: A review of its nutritional and functional changes during processing[J]. Food Res Int,2021,142(3):110197.

[4] PARK J, SUNG J M, CHOI Y S, et al. Effect of natural fermentation on milled rice grains: Physicochemical and functional properties of rice flour[J]. Food Hydrocoll,2020,108:106005. doi: 10.1016/j.foodhyd.2020.106005

[5] SILVA G L P, BENTO J A C, JU′ NIOR M S S, et al. Trend of modification by autoclave at low pressure and by natural fermentation in sweet potato and cassava starches[J]. Polysaccharides,2021,2(2):354−372. doi: 10.3390/polysaccharides2020023

[6] 郑楠楠. 谷子和黍子营养功能成分和抗氧化作用的差异化研究[D]. 天津: 天津科技大学, 2018 ZHENG N N. Differential study on nutritional functional components and antioxidation of millet and millet[D]. Tianjin: Tianjin University of Science and Technology, 2018.

[7] 段伟, 吴月蛟, 沈群. 黄米挂面品质改善研究[J]. 中国食品学报,2018,18(4):162−168. [DUAN W, WU Y J, SHEN Q. Study on quality improvement of yellow rice noodles[J]. Journal of Chinese Institute of Food Science and Technology,2018,18(4):162−168. [8] RAIGOND P, EZEKIEL R, RAIGOND B. Resistant starch in food: A review[J]. Journal of the Science of Food and Agriculture,2015,95(10):1968−1978. doi: 10.1002/jsfa.6966

[9] 余佳浩, 倪晓瑜, 黄秀彦, 等. 不同品种山药蒸制过程中淀粉消化率及抗氧化活性[J]. 食品科学,2022,43(15):52−60. [YU J H, NI X Y, HUANG X Y, et al. Starch digestibility and antioxidant activity of different varieties of yam during steaming[J]. Food Science,2022,43(15):52−60. [10] 常青, 郑东宝, 张怡, 等. 生姜抗性淀粉对高脂血症大鼠降血脂作用和胆汁酸代谢的影响[J]. 食品科学,2022,43(15):52−60. [CHANG Q, ZHENG D B, ZHANG Y, et al. Effect of ginger resistant starch on blood lipid lowering and bile acid metabolism in hyperlipidemic rats[J]. Food Science,2022,43(15):52−60. [11] 迟治平, 迟云平, 迟元魁, 等. 微波制备高粱抗性淀粉工艺的优化研究[J]. 中国食品添加剂,2021(8):15−21. [CHI Z P, CHI Y P, CHI Y K, et al. Study on the optimization of microwave assisted preparation of sorghum resistant starch[J]. China Food Additives,2021(8):15−21. [12] 闫晨苗. 低GI马铃薯面包工艺的研究及品质分析[D]. 邯郸: 河北工程大学, 2020 YAN C M. Study on the technology and quality analysis of low GI potato bread[D]. Handan: Hebei University of Engineering, 2020.

[13] WANG Q, ZHENG Y, ZHUANG W, et al. Genome-wise transcriptional changes in type 2 diabetic mice supplemented with lotus seed resistant starch[J]. Food Chemistry,2018,264:427−434. doi: 10.1016/j.foodchem.2018.05.056

[14] LI L, LIU Z, WANG T, et al. Starch isolated from different hullessbarley cultivars differs in their chemical and structural characterisics[J]. Food Science & Nutrition,2019,7(7):2374−2380.

[15] 亢灵涛, 宋莹, 刘思含, 等. 压热法制备甘薯抗性淀粉的工艺优化[J]. 食品工业科技,2019,40(1):162−167. [KANG L T, SONG Y, LIU S H, et al. Optimization of the process for preparing sweet potato resistant starch by autoclave method[J]. Science and Technology of Food Industry,2019,40(1):162−167. [16] SHEN R L, ZHANG W L, DONG J L, et al. Sorghum resistant starch reduces adiposity in high-fat diet-induced over-weight and obses rats via mechanisms involving adipokines and intestinal flora[J]. Food and Agricultural Immunology,2015,26(1):120−130. doi: 10.1080/09540105.2013.876976

[17] 高慧颖, 王琦, 赖呈纯, 等. 添加抗性淀粉对饼干质构特性和体外血糖生成指数的影响[J]. 福建农业科技,2019(10):27−33. [GAO H Y, WANG Q, LAI C C, et al. Effect of adding resistant starch on biscuit texture properties and in vitro glycemic index[J]. Fujian Agricultural Science and Technology,2019(10):27−33. [18] 牛博文, 徐薇, 张彧. 不同化学方法制备的抗性淀粉理化性质及表征研究[J]. 食品工业科技,2020,41(17):19−23. [NIU B W, XU W, ZHANG Y. Study on physicochemical properties and characterization of resistant starch prepared by different chemical methods[J]. Science and Technology of Food Industry,2020,41(17):19−23. [19] HE X, GONG X, LI W, et al. Preparation and characterization of amphiphilic composites made with doublemodified(etherified and esterified) potato starches[J]. Starch-Starke,2019,71(9−10):1900089. doi: 10.1002/star.201900089

[20] J MAJZOOBI M, BEPARVA P, FARAHNAKY A, et al. Effects of malic acid and citric acid on the functional properties of native and cross-linked wheat starches[J]. Starch-Strke,2014,66(5−6):491−495. doi: 10.1002/star.201300188

[21] 张焕新, 张伟, 金征宇. 抗性淀粉饼干的研制及血糖指数评价[J]. 中国粮油学报,2013,29(9):32−37. [ZHANG H X, ZHANG W, JIN Z Y. Development of resistant starch biscuits and evaluation of glycemic index[J]. Journal of China Cereals and Oils,2013,29(9):32−37. [22] 程冰, 李梦琴, 赵龙珂, 等. 马铃薯抗性淀粉对韧性饼干品质及消化性能的控制[J]. 食品安全质量检测学报,2022,13(12):3746−3753. [CHENG B, LI M Q, ZHAO L K, et al. The control of potato resistant starch on the quality and digestibility of tough biscuits[J]. Journal of Food Safety and Quality Inspection,2022,13(12):3746−3753. doi: 10.3969/j.issn.2095-0381.2022.12.spaqzljcjs202212002 [23] 冷志富, 杜双奎, 蔡萌, 等. 普鲁兰酶酶法制备玉米抗性淀粉工艺优化[J]. 中国粮油学报,2014,29(8):28−32,37. [LENG Z F, DU S K, CAI M, et al. Optimization of the preparation of corn resistant starch by pullulan enzyme[J]. Chinese Journal of Cereals and Oils,2014,29(8):28−32,37. [24] 韩丽瑶, 李梁, 张博辉, 等. 压热法制备黑青稞抗性淀粉工艺及性质研究[J]. 食品研究与开发,2020,41(10):115−121. [HAN L Y, LI L, ZHANG B H, et al. Study on technology and properties of preparation of black highland barley resistant starch by autoclave method[J]. Food Research and Development,2020,41(10):115−121. doi: 10.12161/j.issn.1005-6521.2020.10.020 [25] LE Q T, LEE C K, KIM Y W. Amylolytically-resistant tapioca starch modified by combined treatment of branching enzyme and maltogenic amylase[J]. Carbohydrate Polymers,2009,75(1):9−14. doi: 10.1016/j.carbpol.2008.06.001

[26] 杨帆, 肖华西, 林亲录, 等. 超声波-湿热法结合酸水解制备大米抗性淀粉及其理化性质研究[J]. 中国粮油学报,2018,33(7):43−50. [YANG F, XIAO H X, LIN Q L, et al. Study on preparation of rice resistant starch by ultrasonic hydrothermal method combined with acid hydrolysis and its physicochemical properties[J]. Journal of China Cereals and Oils,2018,33(7):43−50. doi: 10.3969/j.issn.1003-0174.2018.07.008 [27] 陈燕. 苦荞抗性淀粉的制备、理化性质及其应用研究[D]. 成都: 西华大学, 2017 CHEN Y. Preparation, physicochemical properties and application of tartary buckwheat resistant starch [D]. Chengdu: Xihua University, 2017.

[28] 李蔚青. 脚板薯RS3型抗性淀粉的制备及在苏打饼干中的应用[D]. 南昌: 南昌大学, 2015 LI W Q. Preparation of RS3 type resistant starch from sweet potato and its application in soda biscuits[D]. Nanchang: Nanchang University, 2015.

[29] 徐鑫, 于明, 毛红艳, 等. 压热法制备鹰嘴豆抗性淀粉的研究[J]. 新疆农业科学,2016,53(12):2250−2257. [XU X, YU M, MAO H Y, et al. Study on preparation of chickpea resistant starch by autoclave method[J]. Xinjiang Agricultural Science,2016,53(12):2250−2257. doi: 10.6048/j.issn.1001-4330.2016.12.012 [30] 潘元风, 唐书泽, 戴远威, 等. 不同压热条件对蚕豆抗性淀粉制备的影响[J]. 食品工业科技,2008(5):94−96. [PAN Y F, TANG S Z, DAI Y W, et al. Effect of different autoclave conditions on the preparation of broad bean resistant starch[J]. Science and Technology of Food Industry,2008(5):94−96. [31] AKHILA R, SUDHA J D, ABRAHAM T E. Enzymatic modification of cassava starch by fungal lipase[J]. Industrial Crops & Products,2007,27(1):50−59.

[32] 尹乐斌, 何平, 刘桠丽, 等. 豌豆抗性淀粉制备工艺优化及理化性质研究[J]. 中国酿造,2022,41(2):198−203. [YIN L B, HE P, LIU Y L, et al. Optimization of the preparation process and physicochemical properties of pea resistant starch[J]. China Brewing,2022,41(2):198−203. doi: 10.11882/j.issn.0254-5071.2022.02.033 -

期刊类型引用(5)

1. 马雪莹,刘璐璐,陆佩瑶,张思佳,白心怡,冯永巍,黄晓东. 基于血糖管理的特殊食品开发进展分析. 现代食品. 2024(02): 116-119 .  百度学术

百度学术

2. 张素敏,崔艳,陈振家,王晓闻. 压热改性对黄米淀粉多尺度结构及理化性质的影响. 食品工业科技. 2024(18): 80-87 .  本站查看

本站查看

3. 马天琛,张津铭,张诺,张竞文,常丹妮,曹炜. 糜子抗性淀粉的制备及其在食品中的应用研究进展. 食品研究与开发. 2024(22): 212-217 .  百度学术

百度学术

4. 郭硕,刘景圣,郑明珠. 热处理过程中食品组分与淀粉相互作用研究进展. 食品安全质量检测学报. 2023(01): 17-24 .  百度学术

百度学术

5. 邵颖,刘晓媛,魏宗烽,李坤. 板栗RS_3型抗性淀粉的制备方法筛选及其压热法制备工艺优化. 粮食与油脂. 2023(11): 100-104+114 .  百度学术

百度学术

其他类型引用(2)

下载:

下载:

下载:

下载: