Effects of Ultrasonic Waves Assisted Vacuum Tumbling on Texture and Flavor Quality of Beef Balls

-

摘要: 以传统处理组(CON)为空白对照,分别采用真空滚揉(VT)、超声波(UW)和超声波协同真空滚揉(VT+UW)三种方式处理牛肉糜,统一制作牛肉丸,分别测定各处理组牛肉丸的蒸煮损失率、质构特性、微观结构及挥发性风味,探究不同处理方式对牛肉丸理化特性及其挥发性风味的影响。结果表明:与对照组相比,三种处理方式均可显著降低牛肉丸的蒸煮损失率(P<0.05),其中VT+UW处理可显著提高牛肉丸的硬度、胶粘性、咀嚼性,并降低其粘附性(P<0.05)。微观结果显示:VT+UW处理可促进牛肉丸形成更加致密的内部凝胶网络结构。气相色谱-质谱联用技术(gas chromatograph-mass spectrometry,GC-MS)结果显示:VT+UW处理组样品中烃类物质含量增加,醛类和醇类物质含量减少,其中真空滚揉协同超声处理10 min(VT+UW1)的牛肉丸样品挥发性风味物质总量最高,为16.16 mg/kg。相对气味活度值(ROAV)显示壬醛、(Z)-3,7-二甲基-2,6-辛二烯醛、(+)-柠檬烯和邻-异丙基苯为牛肉丸的特征风味物质,且在VT+UW组中含量较高,进一步显示超声波协同真空滚揉处理可通过丰富特征风味化合物来优化牛肉丸风味。研究表明,适宜的超声波协同真空滚揉处理不仅可降低牛肉丸的蒸煮损失率,还可有效改善其质构特性和风味特征。Abstract: The present study investigated the effects of ultrasonic waves assisted vacuum tumbling on eating quality of beef meatballs. Taking the traditional treatment group (CON) as the blank control, the beef surimi was treated by vacuum tumbling (VT), ultrasonic waves (UW) and ultrasonic waves assisted vacuum tumbling (VT+UW) respectively, and then uniformly made into beef meatballs. The cooking loss, texture characteristics, microstructure and volatile flavor of meatballs treated with different processing methods were measured. Results showed that the cooking loss of beef meatballs was significantly decreased (P<0.05) by the three treatments. VT+UW treatment could significantly improve the hardness, gumminess and chewiness of meatballs, and reduce the adhesion (P<0.05). The result of paraffin section demonstrated that VT+UW treatment could promote the formation of a denser inner gel network structure. The total amount of volatile flavor substances in beef meatballs identified by gas chromatograph-mass spectrometry (GC-MS) was up to 16.16 mg/kg after 10 min of ultrasonic waves assisted vacuum tumbling treatment (VT+UW1). Moreover, the contents of hydrocarbons in VT+UW treatment group increased, while the contents of aldehydes and alcohols decreased. The relative odor activity value (ROAV) showed that nonanal, (Z)-3,7-dimethyl-2,6-octadienal, (+)-limonene and O-isopropylbenzene were the characteristic flavor substances of beef meatballs, and reached a relatively higher content in VT+UW group. It was further confirmed that VT+UW treatment was more beneficial to improve the flavor of beef meatballs by enriching the characteristic flavor compounds. The results indicated that suitable VT+UW treatment could not only reduce the cooking loss of beef meatballs, but also improve the texture and flavor characteristics of beef meatballs.

-

Keywords:

- beef meatballs /

- ultrasonic waves /

- vacuum tumbling /

- texture /

- volatile flavor compounds

-

牛肉丸作为中国传统小吃,因食用方便、选料苛刻、制作精细、口味独特、美味营养,深受消费者的欢迎[1]。相比鸡肉、猪肉,牛肉由于肌肉纤维较粗[2],在加工过程中易出现凝胶流变性差、蒸煮损失率大、质构特性差等问题,进而影响其最终品质[3]。近年来,研究人员在探索高效、合理的牛肉丸加工方式上进行了大量研究,且多集中于添加亲水胶体[4]、膳食纤维[5]、酶类[6]、多糖[7]等辅料配方的优化上,工艺改良方面研究较少。

超声波(ultrasound waves,UW)作为一种非热加工方式,在肉类工业中应用广泛,其对肌肉嫩化[8]、辅助腌制[9]、增强凝胶[10]、改善风味[11]等方面均有促进作用。真空滚揉(vacuumtumbling treatment,VT)通过机械运动对肉进行翻滚、摔打,从而削弱肌纤维强度,以此达到增加嫩度[12]、改善质构的目的[13-14]。研究表明,超声联合滚揉腌制可以通过促进水分的均匀分布与迁移,破坏肌纤维结构的形式,加快腌制速率,提高鸡胸肉的保水性和嫩度,改变鸡胸肉挥发性风味成分的种类及含量[15];超声波辅助变压滚揉处理可以有效提高腌制吸收率、改善鸡肉嫩度[16];在改善鸭肉食用品质方面显著优于传统的真空滚揉工艺[17]。但已有超声辅助滚揉技术的研究少有加入真空条件,仅Zhang等[18]研究了超声辅助真空滚揉处理对猪肉肌原纤维蛋白的氧化和理化特性的影响,但未研究处理对于猪肉食用品质的影响。

因此,本研究以巴西牛后腿肉为实验对象,采用超声波技术(UW)、真空滚揉工艺(VT)及超声波协同真空滚揉工艺(VT+UW)对牛肉糜进行加工处理,并统一制作牛肉丸。在测定不同处理组牛肉丸蒸煮损失率和质构特性的基础上,观察牛肉丸内部凝胶网络结构,并采用气相色谱-质谱联用技术(gas chromatograph-mass spectrometry,GC-MS)测定牛肉丸挥发性风味物质的变化,探究不同处理方式对于牛肉丸食用品质的影响,以期为揭示高品质牛肉丸的品质形成规律,并明确其合理加工方式提供依据。

1. 材料与方法

1.1 材料与仪器

巴西牛后腿肉(大黄瓜条,−20 ℃真空冻藏)、食盐、味精、白糖、小麦粉、木薯粉、牛油、葱、姜、胡椒粉 扬州大润发超市;高弹素、卡拉胶、复配磷酸盐(三聚磷酸钠24%、焦磷酸钠21%、六偏磷酸钠14%、磷酸三钠4%、焦磷酸二氢二钠3%、碳酸钠7%、碳酸氢钠8%、氯化钾3%、食用盐15%、食用葡萄糖1%) 食品级,河南万邦化工科技有限公司;2-甲基-3-庚酮、无水乙醇、二甲苯、苏木素染液套装、盐酸、氨水、中性树胶 国药集团化学试剂有限公司;4%戊二醛溶液 南京森贝伽生物科技有限公司。

俏媳妇12-22型绞肉机 镇江洋诚机械有限公司;飞利浦HR3865型高速破壁料理机 飞利浦(中国)投资有限公司;亿闽信430型真空包装机 泉州市亿闽信贸易有限公司;赣云GY-3S-38型三速制冷打浆机 江西赣云食品机械有限公司;THC-1000SF超声波煎煮锅 济宁天华超声电子仪器有限公司;HKS-30VT型真空滚揉机 无锡哈克逊工贸有限公司;FA1004(1/1000)型电子天平 浙江力辰仪器科技有限公司;TA-XT Plus质构仪 英国Stab Micro System公司;Trace ISQ II气质联用仪 美国热电公司;Supelco 75 µm Carboxen萃取头 上海楚定分析仪器有限公司;Nikon Eclipse E100正置光学显微镜 日本尼康。

1.2 实验方法

1.2.1 牛肉丸基础配方

牛肉丸配方在苏博等[19]的研究基础上进行修改。按照牛肉的重量百分比添加,高弹素0.6%、食盐1%、味精1.1%、白糖1.1%、卡拉胶0.6%、复配磷酸盐0.4%、小麦粉3%、木薯粉3%、牛油18%、葱姜冰水5.2%(水:姜:葱=10:1:1,破壁机打匀,过滤)、胡椒粉0.1%。

1.2.2 牛肉丸的制备

选择巴西牛后腿肉,剔除表面可见筋膜和脂肪,通过直径为3 mm的绞肉机孔板绞制成肉糜并随机分为4个处理组,分别为:

传统处理组(CON组):牛肉糜添加辅料后倒入三速制冷打浆机中,打浆上劲,记为CON;

超声波处理组(UW组):牛肉糜打浆上劲后进行UW处理(120 W,25 kHz),UW处理时间分别为10、20、30 min,记为UW1、UW2、UW3;

真空滚揉组(VT组):牛肉糜进行VT处理(0.08 MPa、12 r/min、60 min)后打浆上劲,记为VT;

超声波协同真空滚揉处理组(VT+UW组):牛肉糜进行VT处理(0.08 MPa、12 r/min、60 min)后打浆上劲,然后进行UW处理(120 W,25 kHz),UW处理时间分别为10、20、30 min,记为VT+UW1、VT+UW2、VT+UW3。

以上所有处理过程中温度均保持在4 ℃。

将处理过的牛肉糜加工成丸(控制肉丸质量为26 g左右),并于45 ℃恒温水槽中定型10 min,然后升温至100 ℃煮制8 min。捞出牛肉丸,等其冷却至室温后用厨房纸擦干表面水分,真空包装后置于−18 ℃冻藏。

1.2.3 蒸煮损失率的测定

参照Barekat等[20]方法,略作修改。肉糜经手挤成丸,称量m1,然后加工为成品牛肉丸,冷却至室温后用厨房纸吸干表面水分,称量m2。

蒸煮损失率(%)=m1−m2m1×100 1.2.4 质构特性的测定

取成品牛肉丸样品,切割成1.5 cm×1.5 cm×1 cm方柱体,用TA-XT Plus质构仪对牛肉丸样品的硬度、粘附性、内聚性、弹性、胶粘性和咀嚼性进行测定,测定参数:P/36.5柱形探头,速度60 mm/min,测试形变量50%,触发力0.5 N。各组牛肉丸选取3个平行样。

1.2.5 微观结构观察

石蜡切片参考Wang等[21]的方法,略作修改。取4%戊二醛溶液固定组织样品,按如下步骤进行石蜡包埋、切片与观察处理:

a. 脱水、浸蜡、切片、脱蜡:二甲苯 20 min→二甲苯 20 min→无水乙醇 5 min→无水乙醇 5 min→75%酒精5 min→自来水洗。

b. 苏木素染色:使用苏木素染色3~5 min,盐酸水溶液分化,氨水水溶液返蓝,水洗。

c. 伊红染液染色:依次入85%、95%的梯度酒精脱水,使用伊红染液染色5 min。

d. 脱水封片:无水乙醇 5 min→无水乙醇 5 min→无水乙醇 5 min→二甲苯 5 min→二甲苯 5 min透明,中性树胶封片。

e. 使用光学显微镜放大400倍镜检。每个样品选取3个不同的观察视野。

1.2.6 挥发性风味物质的测定

参照AlDalali等[22]的顶空固相微萃取-气相色谱-质谱联用法测定。将牛肉丸样品切碎混匀并称取2 g放入10 mL顶空小瓶,然后加入内标化合物2-甲基-3-庚酮(0.816 mg/L)1 μL以及饱和食盐水1 mL,采用75 μm CAR/PDMS萃取头进行风味吸附。吸附条件如下:提取温度为80 ℃,提取时间为50 min。解吸时间:5 min。

GC条件:色谱柱为DB-5MS(30 m×0.25 mm×0.25 μm);色谱柱起始温度40 ℃,保持2 min,以5 ℃/min升到160 ℃,保持1 min,再以10 ℃/ min升到250 ℃,保持4 min;用氮气做载气,流量1 mL/min。

MS条件:接口温度:250 ℃;离子源温度230 ℃,全扫描模式,扫描范围45~450 m/amu,电子能量70 eV。

定性分析:采用计算机谱库(NIST/Wiley)检索匹配测出的挥发性风味物质。

定量分析:计算每一种挥发性风味物质相对于内标物2-甲基-3-庚酮的含量,公式如下:

C=AX×C0×V×1000A0×m 式中:C为测定的挥发性化合物含量(μg/kg);Ax为测定挥发性化合物的峰面积(AU·min);C0为内标物质量浓度(0.816 μg/μL);A0为内标物的峰面积(AU·min);V为内标物的进样量(μL);m为测定样品的质量(kg)。

ROAV分析:相对气味活度值(ROAV)可以用来评价风味物质的贡献程度[23],计算公式如下:

ROAV≈CiCmax×TmaxTi×100 式中:Cmax和Tmax为所有风味物质中最大的百分比含量和感觉阈值(μg/kg);Ci和Ti为对应挥发性化合物的百分比含量和感觉阈值(μg/kg)。

1.3 数据处理

每组实验重复测定3次,取平均值±标准差,采用SPSS 26.0软件进行数据统计及显著性分析,P<0.05表示差异显著。用Origin 2019软件作图。

2. 结果与分析

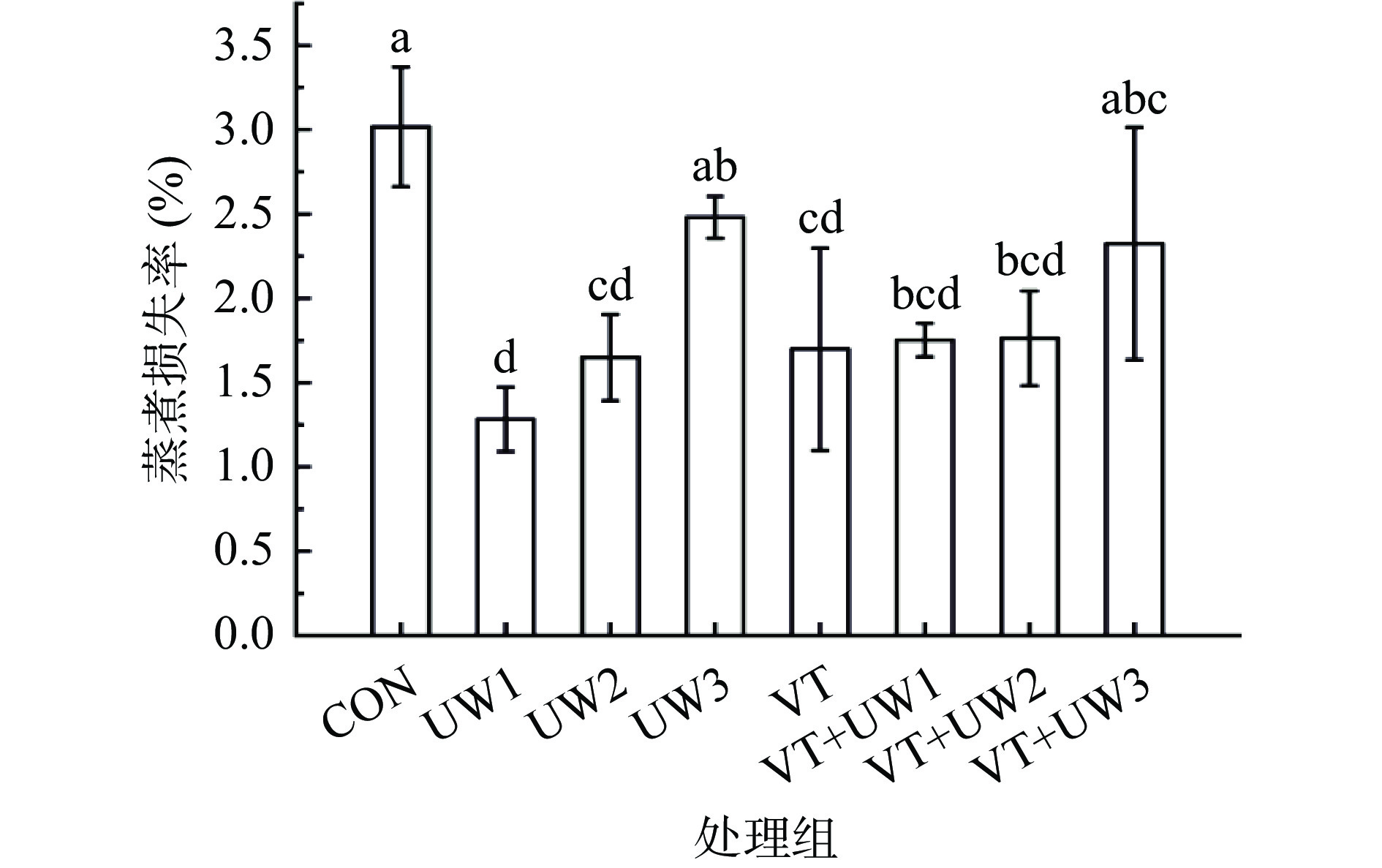

2.1 蒸煮损失

蒸煮损失可以用于衡量肌肉品质和感官质量,并表征加热后的肉凝胶对于水分和脂肪的留存能力,从而对肉丸的多汁性、口感与风味产生影响[24]。由图1可知,相比对照组(CON),10、20 min的超声波处理(UW1、UW2)、真空滚揉处理(VT)和10、20 min的超声波协同真空滚揉处理(VT+UW1、VT+UW2)处理均可显著降低牛肉丸的蒸煮损失率(P<0.05),其中,UW1组的蒸煮损失率最低。由于UW处理可加速肌球蛋白和肌动蛋白溶出,导致各类物质及亲水基团进入肌肉内部,更多的水分被保留[25],这与邹云鹤[26]的研究结果相似。随着UW处理时间的增加,牛肉丸的蒸煮损失率呈现上升的趋势,这是因为超声时间过长会导致蛋白质网状结构遭到破坏,增大凝胶孔洞引起水分流失,最终导致蒸煮损失增加。VT处理可以加速腌制液的扩散,增加细胞的通透性,促进盐溶性蛋白的析出,从而对蒸煮损失产生影响[27]。结果显示:适宜的超声波处理、真空滚揉处理以及超声波协同真空滚揉处理均可达到降低牛肉丸蒸煮损失率的目的。

2.2 质构特性

由表1可知,与对照组相比,三种处理方式均可显著提升牛肉丸的硬度、咀嚼性和胶粘性(P<0.05)。已知硬度是食物达到一定形变所需要的力,在一定程度上与食物中的水分含量有关[28]。相关研究表明,肉糜保水性越好,质构硬度越小[29]。相比CON组和UW组,VT+UW处理由于机械作用较强,会在一定程度上破坏肌肉组织,增大出水和出油率,从而使牛肉丸的硬度显著增加(P<0.05),这与蒸煮损失率的结果相同。表1还表明,单独UW处理可导致样品的粘附性显著增加(P<0.05),主要与超声波的空化作用导致肌肉蛋白形成丰富的丝状纤维有关。随着机械作用的增加,VT和VT+UW处理则显著降低了牛肉丸的粘附性(P<0.05)。不同处理方式对牛肉丸的弹性和内聚性影响不显著(P>0.05)。结果表明,三种处理方式均可有效改善牛肉丸的质构特性,其中在短时间的超声波协同真空滚揉(VT+UW1)处理组中最明显。

表 1 不同处理方式对牛肉丸质构特性的影响Table 1. Effects of different treatment methods on texture characteristics of beef balls处理组 硬度(N) 粘附性(mJ) 内聚性(Ratio) 弹性(mm) 胶粘性(N) 咀嚼性(mJ) CON 37.20±4.75d 1.14±0.05b 0.40±0.05b 3.35±0.62a 16.40±3.12d 53.73±6.38d UW1 45.53±2.31c 1.43±0.18ab 0.46±0.03ab 3.62±0.34a 20.83±2.39c 75.01±2.89c UW2 46.47±4.91c 1.52±0.06a 0.43±0.01ab 3.51±0.07a 21.67±2.4bc 77.7±10.18bc UW3 50.33±1.06bc 1.65±0.18a 0.46±0.01ab 3.39±0.11a 23.23±0.32bc 78.75±2.82bc VT 47.47±2.11c 0.44±0.11c 0.46±0.03ab 3.71±0.08a 21.77±1.14bc 80.57±2.91bc VT+UW1 54.97±1.23b 0.46±0.26c 0.44±0.02ab 3.58±0.06a 24.40±1.71bc 87.45±5.26b VT+UW2 55.77±3.91ab 0.44±0.12c 0.42±0.04ab 3.50±0.06a 25.23±1.63ab 88.80±6.72b VT+UW3 62.27±3.37a 0.60±0.13c 0.47±0.02a 3.31±0.33a 29.03±2.23a 102.57±2.12a 注:同列不同字母表示差异显著(P<0.05)。 2.3 微观结构

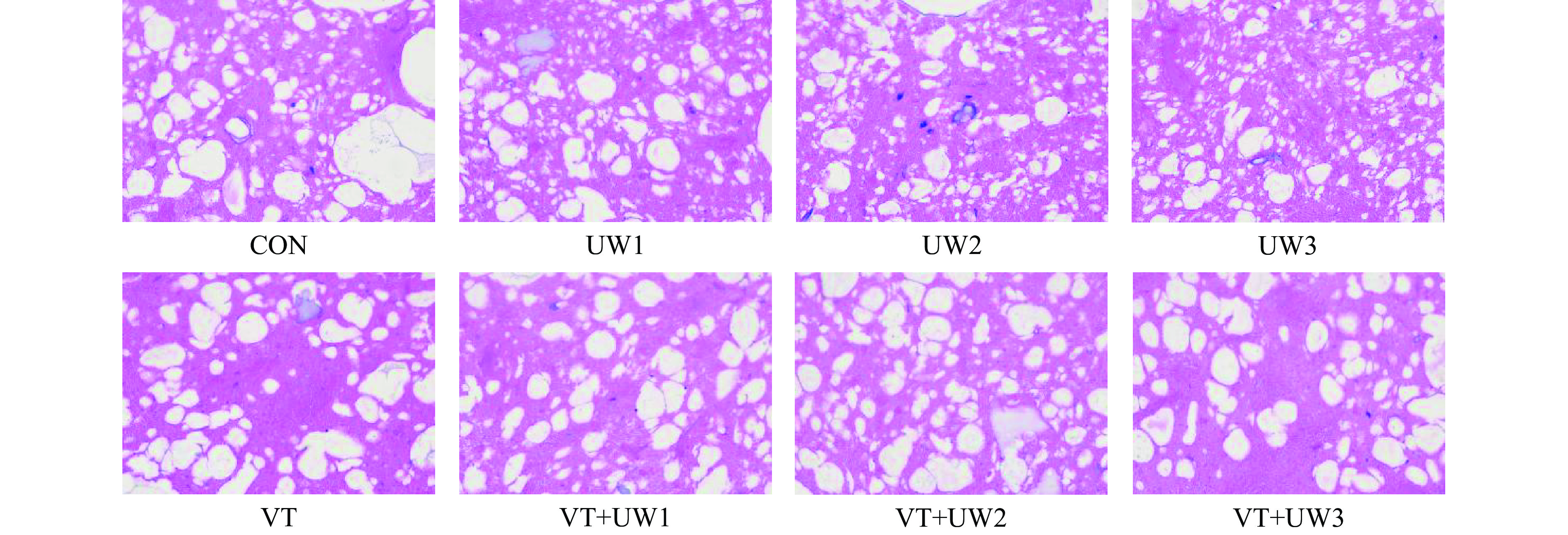

如图2所示,牛肉丸内部有大量形状不一的圆形空腔结构,其中较小体积的空腔是水分或空气,较大体积的空腔是脂肪球[30]。其中CON组牛肉丸内部空腔较大,且分布杂乱,显示其内部结构较为松散。经过UW处理,牛肉丸的结构状态有所改善,脂肪球大小均匀,内含空气和水分的空腔有所增加,这是由于UW处理后形成了更加致密的蛋白质网状结构,使得更多的水分和脂质被截留,蒸煮损失相比CON组显著降低。随着UW处理时间的增加,小孔腔的数量呈现先增加后减少的趋势。一般认为,相比于体积较大的孔腔,小体积孔腔更不容易被压垮,一旦撤去外力,凝胶更易恢复原来的形状,可赋予牛肉丸更好的弹性[25]。因此,长时间(30 min)超声波处理后的牛肉丸,其弹性反而降低。协同真空滚揉处理后,牛肉丸内部的孔腔数量相对CON组减少,结构更加紧凑,与质构特性的结果一致。而相比UW组,VT+UW处理组牛肉丸中含空气或水分的孔腔减少,凝胶网络结构变得松散,牛肉凝胶的持水性呈现下降趋势,蒸煮损失率增加,同时,小孔腔的减少使得牛肉丸弹性下降,VT+UW3组牛肉丸的弹性最低(3.31±0.33 mm)。有学者研究发现凝胶网络结构疏松、孔隙变大是持水性与质构下降的原因[31],这表明了劣化的凝胶网络结构是凝胶品质下降的直接原因。综上,进行10和20 min的超声波协同真空滚揉工艺可以使牛肉丸的凝胶结构更加紧凑。

2.4 挥发性风味物质

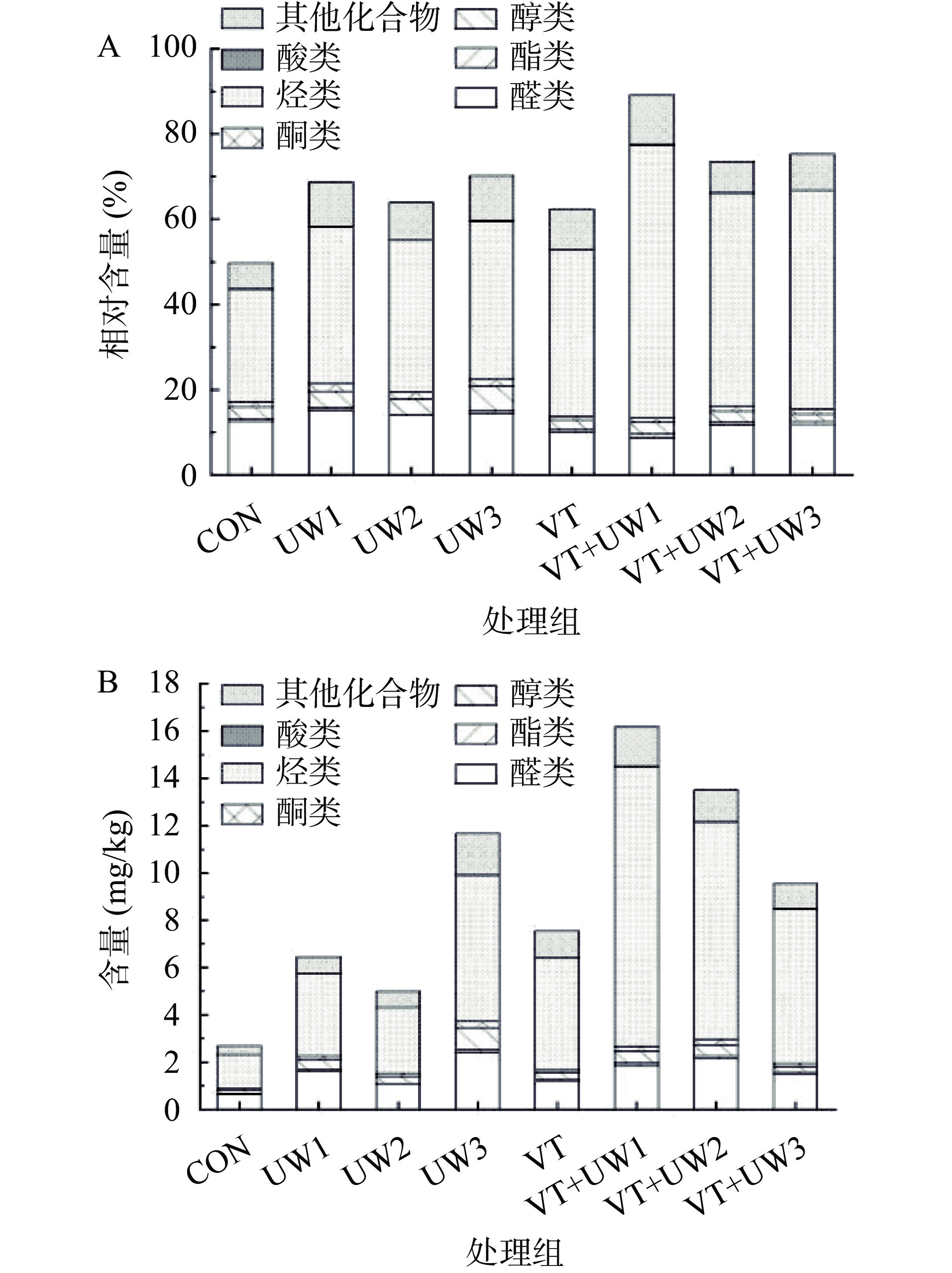

采用顶空固相微萃取技术结合气相色谱-质谱联用技术(HS-SPME-GC-MS)对不同处理方式的牛肉丸中挥发性风味物质进行鉴定,查找检出的73种挥发性风味物质的气味阈值(见表2)[32],并计算其ROAV值,结果如表2所示。不同样品组共检测出挥发性风味物质73种,包括19种醛类、1种酯类、11种醇类、5种酮类、17种烃类、2种酸类以及18种其他化合物。其中,烃类的含量在牛肉丸挥发性风味物质总含量中占比最高,约占风味物质总含量的52%~73%;醛类次之,约占风味物质总含量的11%~25%。

表 2 不同处理组的挥发性风味物质的阈值、含量及ROAV值Table 2. Thresholds, contents and ROAV values of volatile flavor compounds in different treatment groups分类 化合物名称 保留时间(min) 阈值(μg/L) ROAV值 含量(μg/kg) 气味描述[33-34] CON UW1 UW2 UW3 VT VT+UW1 VT+UW2 VT+UW3 CON UW1 UW2 UW3 VT VT+UW1 VT+UW2 VT+UW3 醛类 总计 643.42 1628.44 1091.55 2411.20 1208.32 1843.93 2153.37 1496.53 壬醛 15.24 0.0031 53.42 75.89 67.95 27.24 51.77 15.28 46.31 26.01 198.50 337.70 240.50 595.30 387.90 509.83 586.64 545.22 油脂气味、

甜橙气息(E)-3,7-二甲基-2,6-辛二烯醛 20.41 0.012 6.98 14 13.68 5.09 5.88 − 6.26 − 100.52 335.03 187.72 431.08 170.85 − 307.64 − (Z)-3,7-二甲基-2,6-辛二烯醛 19.52 0.0088 7.36 13.74 14.45 4.98 5.57 1.3 5.93 1.26 77.94 175.94 145.01 309.44 118.12 124.28 213.85 75.41 正己醛 5.46 0.23 0.26 0.6 0.62 0.19 0.33 0.14 0.32 0.16 71.63 237.18 162.69 311.00 181.52 356.25 301.49 247.44 油脂气味、青草气味、苹果香味 苯甲醛 10.5 0.085 0.58 1.2 1.09 0.32 0.66 0.18 0.67 0.24 59.02 172.18 105.42 191.93 135.64 166.23 233.40 139.33 苦杏仁味 2-甲基-2-戊烯醛 6.28 0.25 0.12 0.22 0.31 0.1 0.15 0.05 0.14 0.05 36.31 99.91 88.86 172.38 88.08 141.21 139.02 76.28 草莓香气 庚醛 8.47 0.26 0.07 0.17 0.16 0.05 0.09 0.03 0.09 0.04 22.68 74.26 46.09 94.50 54.79 91.84 91.85 72.25 苯乙醛 13.27 0.0017 9 20.37 18.5 6.94 − 3.72 11.91 4.74 18.19 52.74 36.01 83.53 − 68.23 81.82 54.66 风信子香气、杏仁及樱桃香味 正戊醛 3.32 0.85 0.01 0.04 0.04 0.01 − 0.01 0.02 0.01 13.31 52.69 38.15 75.60 − 95.07 60.59 56.15 反式-2-壬醛 17.05 0.00009 100 − − − 100 − 100 27.08 10.57 − − − 21.93 − 36.74 16.63 十五醛 31.64 1 0.01 0.01 − − − 0.01 0.01 − 10.75 21.75 − 35.20 − 59.26 27.69 28.74 癸醛 18.5 0.0026 2.6 6.54 − 1.36 2.31 0.76 2.94 1.59 8.16 29.23 − 24.86 13.98 20.84 31.86 27.72 脂蜡香、似甜橙油与柠檬油香气 3-甲硫基丙醛 8.68 0.06 0.11 0.25 0.23 0.08 0.15 0.04 0.12 0.05 8.25 23.20 15.88 35.70 21.64 25.73 30.19 20.17 香茅醛 16.77 0.00044 14.32 23.76 − − 12.5 − − 5.11 7.59 16.65 − − 13.89 − − 14.75 青柑橘样香气 异戊醛 2.77 0.00035 − − 62.53 20.22 − − − 5.36 − − 25.21 50.70 − − − 12.95 苹果香气、

桃子香味柠檬醛 20.41 0.00015 − − − − − 100 − 100 − − − − − 160.59 − 101.86 柠檬香味 (Z)-2-壬烯醛 17.05 0.000039 − − − − − 60.73 − − − − − − − 24.57 − − 反-2-十二烯醛 17.97 0.011 − − − − − − 0.25 − − − − − − − 10.60 − 正辛醛 11.84 0.17 − − − − − − − 0.01 − − − − − − − 6.98 脂蜡香、果香茉莉气息 酯类 总计 23.84 58.89 − 107.34 71.63 118.94 104.35 84.85 乙酸乙烯酯 2.19 1.4 0.01 0.03 − 0.01 0.02 0.01 0.02 0.01 23.84 58.89 − 107.34 71.63 118.94 104.35 84.85 醇类 总计 158.35 395.90 297.46 941.60 270.76 490.92 470.20 223.43 芳樟醇 15.17 0.0024 15.38 31.04 33.62 13.76 18.75 7.4 18.94 − 44.50 111.08 92.61 233.46 108.84 190.92 185.99 − 铃兰香气 alpha-松油醇 18.32 9.18 − 0.01 0.01 − − − − − 34.27 94.16 56.71 147.88 69.29 95.06 115.56 59.06 丁香香气 丙硫醇 2.34 0.0031 8.13 12.02 19.41 5.71 6.77 − 6.39 − 30.26 55.06 68.58 124.87 51.08 − 80.67 − 臭鼬鼠味 桉叶油醇 12.81 0.0921 0.21 0.57 0.56 0.34 0.05 0.17 0.06 0.07 23.44 87.55 58.51 218.75 10.79 171.16 22.33 41.71 樟脑气息、清凉的草药味道 甲硫醇 1.62 0.001 12.15 − − − − − − − 14.78 − − − − − − − 令人不愉快的臭味 4-萜烯醇 17.78 0.59 0.02 0.03 0.03 − 0.02 0.01 0.02 0.01 11.10 24.38 21.05 − 30.76 33.77 36.69 23.77 辛香、壤香、青香和木香 (2R,5R)-2-甲基-5-丙烷-2-基双环[3.1.0]己烷-2-醇 13.67 9.6 − − − − − − − − − 23.67 − − − − − 38.83 乙醇 1.73 0.62 − − − 0.04 − − − 0.01 − − − 157.18 − − − 60.07 酒的气味、刺激性辛辣味 异蒲勒醇 20.92 1 − − − − − − − − − − − 6.88 − − − − 玫瑰叶和香茅香 萜品烯-4-醇 17.78 0.59 − − − 0.01 − − − − − − − 52.59 − − − − 辛香、壤香、青香和木香 桉油烯醇 30.43 0.0921 − − − − − − 0.08 − − − − − − − 28.97 − 酮类 总计 67.15 176.71 130.98 252.88 111.50 214.71 234.45 144.18 6-甲基-5-庚烯-2-酮 11.23 0.01889 2.5 5.22 5.5 1.6 2.09 0.75 2.31 0.79 56.83 141.14 119.15 213.49 95.77 153.10 178.81 101.00 水果香气 胡椒酮 20.06 0.68 0.01 0.01 0.02 0.01 0.01 − 0.01 − 6.66 15.23 11.83 28.43 15.72 20.23 26.04 13.77 樟脑气味 3-庚酮 7.94 0.12 0.03 − − − − − − − 3.66 − − − − − − − 水果、青草和油脂似香气 1-巯基-2-丙酮 5.2 0.019 − 0.55 − − − 0.15 0.38 0.17 − 15.67 − − − 29.34 29.61 21.39 2-莰酮 16.69 2.84 − − − − − − − − − 4.67 − 10.96 − 12.05 − 8.02 樟木气味 烃类 总计 1424.92 3480.86 2784.09 6168.55 4728.68 11805.94 9172.15 6513.54 (+)-柠檬烯 12.68 0.045 9.74 19.61 22.35 6.66 26.72 10.38 24.69 9.6 525.85 1255.73 1149.96 2110.80 2910.36 5027.85 4538.99 2923.64 橙子香气 β-石竹烯 24.86 12 0.03 0.05 0.05 0.02 0.03 0.01 0.03 0.01 434.97 840.25 722.24 1565.68 838.27 1330.49 1282.59 621.50 丁香似香味 3-蒈烯 11.97 9.3 0.02 − − 0.02 − 0.04 0.05 0.03 256.67 − 17.04 1405.92 − 3596.12 1812.36 1908.72 松木样香气 水芹烯 11.9 3.4 0.02 0.04 − 0.01 0.04 0.02 0.04 0.01 85.25 187.37 − 318.20 314.04 570.77 508.81 316.36 月桂烯 11.34 0.1125 0.34 0.64 0.8 0.21 1.04 0.34 0.98 0.34 46.49 110.92 103.31 170.18 284.71 414.91 448.42 261.33 甜橘味、香脂气 萜品油烯 14.56 0.2 0.12 0.11 0.13 0.12 0.27 0.1 0.38 0.1 28.36 43.40 29.02 163.13 130.85 216.73 306.08 130.03 松木树脂香气 左旋-beta-蒎烯 10.92 2 0.01 0.02 0.02 0.01 0.02 0.01 0.01 0.01 19.91 74.55 46.85 152.94 73.77 305.58 114.86 156.52 蒎烯 9.42 0.0053 1.44 100 100 − − − 2.12 1.73 8.93 754.30 605.48 − − − 45.52 61.95 莰烯 9.98 28 − − − − − − − − 7.79 23.61 16.21 58.83 − 57.25 21.58 27.05 类似樟脑香气 γ-松油烯 13.66 55 − − − − − − − − 6.98 − − − 30.81 56.40 46.07 − 柑橘、柠檬香气 alpha-律草烯 25.84 0.16 0.02 0.31 0.32 0.07 0.18 0.06 − 0.02 3.71 78.80 57.89 81.68 67.83 96.35 − 27.04 丁香似香味 α-蒎烯 9.44 0.1 − 0.22 0.22 0.1 0.11 − − − − 36.75 25.29 72.68 26.63 − − − 松萜气味 p-伞花烃 12.38 0.8 − 0.02 − − − − − − − 26.93 − − − − − − 癸烷 11.68 3.6 − − − − − − − − − 20.25 − 25.07 − 36.03 − 24.35 十二烷 18.24 0.77 − 0.02 0.01 0.01 0.01 0.01 0.01 0.01 − 18.74 10.81 28.23 20.78 50.16 33.78 32.07 十四烷 24.16 40 − − − − − − − − − 9.28 − 15.20 10.10 12.46 13.11 − 松油烯 12.26 7.9 − − − − − − − − − − − − 20.53 34.85 − 23.00 柑橘和柠檬似香气 酸类 总计 5.01 8.10 − 24.00 − 21.23 19.33 13.02 油酸 20.76 44 − − − − − − − − 5.01 8.10 − 24.00 − 21.23 19.33 − 类似猪油的气味 正壬酸 20.77 0.12 − − − − − − − 0.02 − − − − − − − 13.02 其他化

合物总计 354.45 694.75 686.58 1762.29 1153.21 1669.77 1354.56 1068.01 1,2-二甲苯 7.42 1.6 − − 0.01 − − − 0.01 − 6.96 − 22.83 − − 58.69 48.17 36.17 类似甲苯的臭味 1,3-二乙基苯 10.73 0.39 − 0.01 − 0.01 − − − − − 2.67 − 18.15 − − − − 1-甲基-4-(1-甲基乙烯基)苯 14.76 1.6625 0.01 − − − 0.01 − − − 12.37 − − − 41.37 59.25 − 36.99 2,6-二甲基吡嗪 8.87 1.72 − − − − − − − − − − − − − − 25.54 14.76 咖啡和炒花

生的气味4-烯丙基苯甲醚 21.02 0.00013 − − − 30.84 − − − 14.42 − − − 27.47 − − − 12.17 大茴香似香气 4-异丙基甲苯 12.54 7.2 − − − − − − − 0.01 − − − − − − − 478.55 对二甲苯 7.43 0.0081 − 3.15 − 0.76 2.04 − − − − 27.81 − 42.68 39.78 − − − 对特辛基苯酚 29.96 2.7 − 0.01 − − − − − − − 22.52 13.48 − 27.70 − − 19.05 对特辛基酚聚氧乙烯醚 29.22 2.7 0.04 0.09 0.07 0.02 0.02 0.01 0.01 0.01 127.99 28.53 201.26 449.51 162.45 209.37 148.56 111.53 二硫化碳 1.92 0.65 0.08 0.26 0.2 0.06 0.14 0.05 0.07 0.05 63.15 238.98 145.23 279.41 212.60 357.94 199.27 216.10 不愉快的烂萝卜味 茴香脑 21.03 0.0218 0.62 0.75 0.53 − 0.23 − − − 16.33 27.79 13.61 − 12.69 − − − 茴香、辛香料、

甘草的气味甲苯 4.62 0.3 0.03 0.09 0.11 0.03 0.07 0.03 0.07 0.03 10.43 49.31 37.41 56.19 47.24 98.79 87.79 64.46 间二甲苯 7.13 0.18 0.01 − − − 0.04 − − 0.01 2.77 − − − 17.28 − − 17.03 邻-异丙基苯 12.54 0.0045 15.4 29.19 36.63 11.64 47.22 17.68 43.4 1.54 83.20 197.24 188.56 368.83 515.02 856.65 797.25 47.49 十四醛三聚物 33.21 0.11 0.24 0.48 0.32 0.14 0.23 − − − 31.26 79.17 40.79 108.10 61.34 − − − 油脂和鸢尾

似桃子香气石竹素 29.22 0.41 − 0.03 0.02 0.01 0.02 − 0.02 0.01 − 20.72 9.95 33.50 15.74 − 25.93 13.72 烯丙基甲基硫醚 3.72 0.0005 − − 5.47 100 − − − − − − 3.18 353.02 − − − − 乙基苯 7.13 0.026 − − 0.34 0.14 − 0.11 0.21 − − − 10.30 25.43 − 29.08 22.06 − 由图3可知,不同处理组牛肉丸的风味物质的相对含量差异较大。UW处理后,牛肉丸中的醛类、醇类物质的相对含量相较于CON组明显增加。相比CON组,VT处理组、VT+UW处理组,牛肉丸中的醛类和醇类物质的相对含量均减少,而烃类物质的相对含量增加,在VT+UW1组中达最大值,为64.41%。从含量上来看,相比CON组,UW或VT处理明显增加了牛肉丸中所含挥发性风味物质的含量,两者协同后其挥发性风味物质的含量更高。随着超声时间的增加,VT+UW处理组牛肉丸中风味物质含量逐渐降低,但仍远高于CON组。其中VT+UW1组的挥发性风味物质总量最高,为16.16 mg/kg,是CON组的6.03倍,表明VT+UW处理可以有效增加牛肉丸中挥发性物质的总含量。挥发性风味物质中对整体风味有主要贡献的物质可以用相对气味活度值(ROAV)进行衡量。一般被认为当ROAV≥1时,该物质为样品中的特征风味化合物,且ROAV值越大,表明其对风味贡献越大[33]。如表2所示,壬醛、(Z)-3,7-二甲基-2,6-辛二烯醛、(+)-柠檬烯和邻-异丙基苯在所有处理组中的ROAV值均大于1,可被认定为是牛肉丸的主要特征性风味物质。

经比较发现,不同处理组牛肉丸样品的香气组成均存在差异,并且同种物质的ROAV值也有明显差别。其中,壬醛属于醛类物质,具有强烈的脂香味和柑橘香气,对比CON组,经VT+UW处理后,其含量明显增加。癸醛ROAV值大于0.01,有似甜橙油与柠檬油以及玫瑰样香气,能较好地修饰牛肉丸的风味。CON组所特有的甲硫醇具有令人不愉快的臭味,但经过UW、VT+UW处理后甲硫醇消失,使得牛肉丸的风味得到一定程度的改善。值得注意的是,呈浓郁柠檬香味的柠檬醛和(Z)-2-壬烯醛仅存在于VT+UW组中,且ROAV值较大,对牛肉丸的风味有重要贡献。综合比较,发现处理方式对牛肉丸的特征风味有显著影响,其中VT+UW处理可以有效调节关键气味化合物的种类、含量及相对气味活度,从而优化牛肉丸风味。

3. 结论

超声波辅助(UW)、真空滚揉(VT)以及超声波协同真空滚揉处理(VT+UW)均可有效降低牛肉丸的蒸煮损失率,提高牛肉丸的质构特性和风味品质。与传统处理组相比,超声波协同真空滚揉处理不仅使牛肉丸的内部结构更加细致紧密,还能有效够提高牛肉丸中挥发性风味物质的总量,并通过降低醛类和醇类物质含量,和增加烃类物质含量来改善牛肉丸的风味。其中,以经10 min超声波协同真空滚揉处理后的牛肉丸品质最佳。为了更好地阐明超声波协同真空滚揉处理对改善牛肉丸品质的相关机制,还需要进一步探索两者的协同作用对于牛肉丸凝胶保水性及蛋白质结构的影响。

-

表 1 不同处理方式对牛肉丸质构特性的影响

Table 1 Effects of different treatment methods on texture characteristics of beef balls

处理组 硬度(N) 粘附性(mJ) 内聚性(Ratio) 弹性(mm) 胶粘性(N) 咀嚼性(mJ) CON 37.20±4.75d 1.14±0.05b 0.40±0.05b 3.35±0.62a 16.40±3.12d 53.73±6.38d UW1 45.53±2.31c 1.43±0.18ab 0.46±0.03ab 3.62±0.34a 20.83±2.39c 75.01±2.89c UW2 46.47±4.91c 1.52±0.06a 0.43±0.01ab 3.51±0.07a 21.67±2.4bc 77.7±10.18bc UW3 50.33±1.06bc 1.65±0.18a 0.46±0.01ab 3.39±0.11a 23.23±0.32bc 78.75±2.82bc VT 47.47±2.11c 0.44±0.11c 0.46±0.03ab 3.71±0.08a 21.77±1.14bc 80.57±2.91bc VT+UW1 54.97±1.23b 0.46±0.26c 0.44±0.02ab 3.58±0.06a 24.40±1.71bc 87.45±5.26b VT+UW2 55.77±3.91ab 0.44±0.12c 0.42±0.04ab 3.50±0.06a 25.23±1.63ab 88.80±6.72b VT+UW3 62.27±3.37a 0.60±0.13c 0.47±0.02a 3.31±0.33a 29.03±2.23a 102.57±2.12a 注:同列不同字母表示差异显著(P<0.05)。 表 2 不同处理组的挥发性风味物质的阈值、含量及ROAV值

Table 2 Thresholds, contents and ROAV values of volatile flavor compounds in different treatment groups

分类 化合物名称 保留时间(min) 阈值(μg/L) ROAV值 含量(μg/kg) 气味描述[33-34] CON UW1 UW2 UW3 VT VT+UW1 VT+UW2 VT+UW3 CON UW1 UW2 UW3 VT VT+UW1 VT+UW2 VT+UW3 醛类 总计 643.42 1628.44 1091.55 2411.20 1208.32 1843.93 2153.37 1496.53 壬醛 15.24 0.0031 53.42 75.89 67.95 27.24 51.77 15.28 46.31 26.01 198.50 337.70 240.50 595.30 387.90 509.83 586.64 545.22 油脂气味、

甜橙气息(E)-3,7-二甲基-2,6-辛二烯醛 20.41 0.012 6.98 14 13.68 5.09 5.88 − 6.26 − 100.52 335.03 187.72 431.08 170.85 − 307.64 − (Z)-3,7-二甲基-2,6-辛二烯醛 19.52 0.0088 7.36 13.74 14.45 4.98 5.57 1.3 5.93 1.26 77.94 175.94 145.01 309.44 118.12 124.28 213.85 75.41 正己醛 5.46 0.23 0.26 0.6 0.62 0.19 0.33 0.14 0.32 0.16 71.63 237.18 162.69 311.00 181.52 356.25 301.49 247.44 油脂气味、青草气味、苹果香味 苯甲醛 10.5 0.085 0.58 1.2 1.09 0.32 0.66 0.18 0.67 0.24 59.02 172.18 105.42 191.93 135.64 166.23 233.40 139.33 苦杏仁味 2-甲基-2-戊烯醛 6.28 0.25 0.12 0.22 0.31 0.1 0.15 0.05 0.14 0.05 36.31 99.91 88.86 172.38 88.08 141.21 139.02 76.28 草莓香气 庚醛 8.47 0.26 0.07 0.17 0.16 0.05 0.09 0.03 0.09 0.04 22.68 74.26 46.09 94.50 54.79 91.84 91.85 72.25 苯乙醛 13.27 0.0017 9 20.37 18.5 6.94 − 3.72 11.91 4.74 18.19 52.74 36.01 83.53 − 68.23 81.82 54.66 风信子香气、杏仁及樱桃香味 正戊醛 3.32 0.85 0.01 0.04 0.04 0.01 − 0.01 0.02 0.01 13.31 52.69 38.15 75.60 − 95.07 60.59 56.15 反式-2-壬醛 17.05 0.00009 100 − − − 100 − 100 27.08 10.57 − − − 21.93 − 36.74 16.63 十五醛 31.64 1 0.01 0.01 − − − 0.01 0.01 − 10.75 21.75 − 35.20 − 59.26 27.69 28.74 癸醛 18.5 0.0026 2.6 6.54 − 1.36 2.31 0.76 2.94 1.59 8.16 29.23 − 24.86 13.98 20.84 31.86 27.72 脂蜡香、似甜橙油与柠檬油香气 3-甲硫基丙醛 8.68 0.06 0.11 0.25 0.23 0.08 0.15 0.04 0.12 0.05 8.25 23.20 15.88 35.70 21.64 25.73 30.19 20.17 香茅醛 16.77 0.00044 14.32 23.76 − − 12.5 − − 5.11 7.59 16.65 − − 13.89 − − 14.75 青柑橘样香气 异戊醛 2.77 0.00035 − − 62.53 20.22 − − − 5.36 − − 25.21 50.70 − − − 12.95 苹果香气、

桃子香味柠檬醛 20.41 0.00015 − − − − − 100 − 100 − − − − − 160.59 − 101.86 柠檬香味 (Z)-2-壬烯醛 17.05 0.000039 − − − − − 60.73 − − − − − − − 24.57 − − 反-2-十二烯醛 17.97 0.011 − − − − − − 0.25 − − − − − − − 10.60 − 正辛醛 11.84 0.17 − − − − − − − 0.01 − − − − − − − 6.98 脂蜡香、果香茉莉气息 酯类 总计 23.84 58.89 − 107.34 71.63 118.94 104.35 84.85 乙酸乙烯酯 2.19 1.4 0.01 0.03 − 0.01 0.02 0.01 0.02 0.01 23.84 58.89 − 107.34 71.63 118.94 104.35 84.85 醇类 总计 158.35 395.90 297.46 941.60 270.76 490.92 470.20 223.43 芳樟醇 15.17 0.0024 15.38 31.04 33.62 13.76 18.75 7.4 18.94 − 44.50 111.08 92.61 233.46 108.84 190.92 185.99 − 铃兰香气 alpha-松油醇 18.32 9.18 − 0.01 0.01 − − − − − 34.27 94.16 56.71 147.88 69.29 95.06 115.56 59.06 丁香香气 丙硫醇 2.34 0.0031 8.13 12.02 19.41 5.71 6.77 − 6.39 − 30.26 55.06 68.58 124.87 51.08 − 80.67 − 臭鼬鼠味 桉叶油醇 12.81 0.0921 0.21 0.57 0.56 0.34 0.05 0.17 0.06 0.07 23.44 87.55 58.51 218.75 10.79 171.16 22.33 41.71 樟脑气息、清凉的草药味道 甲硫醇 1.62 0.001 12.15 − − − − − − − 14.78 − − − − − − − 令人不愉快的臭味 4-萜烯醇 17.78 0.59 0.02 0.03 0.03 − 0.02 0.01 0.02 0.01 11.10 24.38 21.05 − 30.76 33.77 36.69 23.77 辛香、壤香、青香和木香 (2R,5R)-2-甲基-5-丙烷-2-基双环[3.1.0]己烷-2-醇 13.67 9.6 − − − − − − − − − 23.67 − − − − − 38.83 乙醇 1.73 0.62 − − − 0.04 − − − 0.01 − − − 157.18 − − − 60.07 酒的气味、刺激性辛辣味 异蒲勒醇 20.92 1 − − − − − − − − − − − 6.88 − − − − 玫瑰叶和香茅香 萜品烯-4-醇 17.78 0.59 − − − 0.01 − − − − − − − 52.59 − − − − 辛香、壤香、青香和木香 桉油烯醇 30.43 0.0921 − − − − − − 0.08 − − − − − − − 28.97 − 酮类 总计 67.15 176.71 130.98 252.88 111.50 214.71 234.45 144.18 6-甲基-5-庚烯-2-酮 11.23 0.01889 2.5 5.22 5.5 1.6 2.09 0.75 2.31 0.79 56.83 141.14 119.15 213.49 95.77 153.10 178.81 101.00 水果香气 胡椒酮 20.06 0.68 0.01 0.01 0.02 0.01 0.01 − 0.01 − 6.66 15.23 11.83 28.43 15.72 20.23 26.04 13.77 樟脑气味 3-庚酮 7.94 0.12 0.03 − − − − − − − 3.66 − − − − − − − 水果、青草和油脂似香气 1-巯基-2-丙酮 5.2 0.019 − 0.55 − − − 0.15 0.38 0.17 − 15.67 − − − 29.34 29.61 21.39 2-莰酮 16.69 2.84 − − − − − − − − − 4.67 − 10.96 − 12.05 − 8.02 樟木气味 烃类 总计 1424.92 3480.86 2784.09 6168.55 4728.68 11805.94 9172.15 6513.54 (+)-柠檬烯 12.68 0.045 9.74 19.61 22.35 6.66 26.72 10.38 24.69 9.6 525.85 1255.73 1149.96 2110.80 2910.36 5027.85 4538.99 2923.64 橙子香气 β-石竹烯 24.86 12 0.03 0.05 0.05 0.02 0.03 0.01 0.03 0.01 434.97 840.25 722.24 1565.68 838.27 1330.49 1282.59 621.50 丁香似香味 3-蒈烯 11.97 9.3 0.02 − − 0.02 − 0.04 0.05 0.03 256.67 − 17.04 1405.92 − 3596.12 1812.36 1908.72 松木样香气 水芹烯 11.9 3.4 0.02 0.04 − 0.01 0.04 0.02 0.04 0.01 85.25 187.37 − 318.20 314.04 570.77 508.81 316.36 月桂烯 11.34 0.1125 0.34 0.64 0.8 0.21 1.04 0.34 0.98 0.34 46.49 110.92 103.31 170.18 284.71 414.91 448.42 261.33 甜橘味、香脂气 萜品油烯 14.56 0.2 0.12 0.11 0.13 0.12 0.27 0.1 0.38 0.1 28.36 43.40 29.02 163.13 130.85 216.73 306.08 130.03 松木树脂香气 左旋-beta-蒎烯 10.92 2 0.01 0.02 0.02 0.01 0.02 0.01 0.01 0.01 19.91 74.55 46.85 152.94 73.77 305.58 114.86 156.52 蒎烯 9.42 0.0053 1.44 100 100 − − − 2.12 1.73 8.93 754.30 605.48 − − − 45.52 61.95 莰烯 9.98 28 − − − − − − − − 7.79 23.61 16.21 58.83 − 57.25 21.58 27.05 类似樟脑香气 γ-松油烯 13.66 55 − − − − − − − − 6.98 − − − 30.81 56.40 46.07 − 柑橘、柠檬香气 alpha-律草烯 25.84 0.16 0.02 0.31 0.32 0.07 0.18 0.06 − 0.02 3.71 78.80 57.89 81.68 67.83 96.35 − 27.04 丁香似香味 α-蒎烯 9.44 0.1 − 0.22 0.22 0.1 0.11 − − − − 36.75 25.29 72.68 26.63 − − − 松萜气味 p-伞花烃 12.38 0.8 − 0.02 − − − − − − − 26.93 − − − − − − 癸烷 11.68 3.6 − − − − − − − − − 20.25 − 25.07 − 36.03 − 24.35 十二烷 18.24 0.77 − 0.02 0.01 0.01 0.01 0.01 0.01 0.01 − 18.74 10.81 28.23 20.78 50.16 33.78 32.07 十四烷 24.16 40 − − − − − − − − − 9.28 − 15.20 10.10 12.46 13.11 − 松油烯 12.26 7.9 − − − − − − − − − − − − 20.53 34.85 − 23.00 柑橘和柠檬似香气 酸类 总计 5.01 8.10 − 24.00 − 21.23 19.33 13.02 油酸 20.76 44 − − − − − − − − 5.01 8.10 − 24.00 − 21.23 19.33 − 类似猪油的气味 正壬酸 20.77 0.12 − − − − − − − 0.02 − − − − − − − 13.02 其他化

合物总计 354.45 694.75 686.58 1762.29 1153.21 1669.77 1354.56 1068.01 1,2-二甲苯 7.42 1.6 − − 0.01 − − − 0.01 − 6.96 − 22.83 − − 58.69 48.17 36.17 类似甲苯的臭味 1,3-二乙基苯 10.73 0.39 − 0.01 − 0.01 − − − − − 2.67 − 18.15 − − − − 1-甲基-4-(1-甲基乙烯基)苯 14.76 1.6625 0.01 − − − 0.01 − − − 12.37 − − − 41.37 59.25 − 36.99 2,6-二甲基吡嗪 8.87 1.72 − − − − − − − − − − − − − − 25.54 14.76 咖啡和炒花

生的气味4-烯丙基苯甲醚 21.02 0.00013 − − − 30.84 − − − 14.42 − − − 27.47 − − − 12.17 大茴香似香气 4-异丙基甲苯 12.54 7.2 − − − − − − − 0.01 − − − − − − − 478.55 对二甲苯 7.43 0.0081 − 3.15 − 0.76 2.04 − − − − 27.81 − 42.68 39.78 − − − 对特辛基苯酚 29.96 2.7 − 0.01 − − − − − − − 22.52 13.48 − 27.70 − − 19.05 对特辛基酚聚氧乙烯醚 29.22 2.7 0.04 0.09 0.07 0.02 0.02 0.01 0.01 0.01 127.99 28.53 201.26 449.51 162.45 209.37 148.56 111.53 二硫化碳 1.92 0.65 0.08 0.26 0.2 0.06 0.14 0.05 0.07 0.05 63.15 238.98 145.23 279.41 212.60 357.94 199.27 216.10 不愉快的烂萝卜味 茴香脑 21.03 0.0218 0.62 0.75 0.53 − 0.23 − − − 16.33 27.79 13.61 − 12.69 − − − 茴香、辛香料、

甘草的气味甲苯 4.62 0.3 0.03 0.09 0.11 0.03 0.07 0.03 0.07 0.03 10.43 49.31 37.41 56.19 47.24 98.79 87.79 64.46 间二甲苯 7.13 0.18 0.01 − − − 0.04 − − 0.01 2.77 − − − 17.28 − − 17.03 邻-异丙基苯 12.54 0.0045 15.4 29.19 36.63 11.64 47.22 17.68 43.4 1.54 83.20 197.24 188.56 368.83 515.02 856.65 797.25 47.49 十四醛三聚物 33.21 0.11 0.24 0.48 0.32 0.14 0.23 − − − 31.26 79.17 40.79 108.10 61.34 − − − 油脂和鸢尾

似桃子香气石竹素 29.22 0.41 − 0.03 0.02 0.01 0.02 − 0.02 0.01 − 20.72 9.95 33.50 15.74 − 25.93 13.72 烯丙基甲基硫醚 3.72 0.0005 − − 5.47 100 − − − − − − 3.18 353.02 − − − − 乙基苯 7.13 0.026 − − 0.34 0.14 − 0.11 0.21 − − − 10.30 25.43 − 29.08 22.06 − -

[1] 郑海云. 香辛料提取物对潮汕牛肉丸品质影响的研究[D]. 广州: 华南理工大学, 2018. ZHENG H Y. Study on the effect of spices extracts on quality of Chaoshan beef balls[D]. Guangzhou: South China University of Technology, 2018.

[2] PICARD B, GAGAOUA M. Muscle fiber properties in cattle and their relationships with meat qualities: An overview[J]. Journal of Agricultural and Food Chemistry,2020,68(22):6021−6039. doi: 10.1021/acs.jafc.0c02086

[3] 孙路, 黄群, 唐道邦, 等. 锤打工艺对牛肉糜凝胶特性影响的机理[J]. 食品与机械,2020,36(6):23−27, 49. [SUN L, HUANG Q, TANG D B, et al. Effect of hammering process on gel properties of beef gel[J]. Food & Machinery,2020,36(6):23−27, 49. doi: 10.13652/j.issn.1003-5788.2020.06.004 [4] DEMIRCI Z O, YILMAZ I, DEMIRCI A Ş. Effects of xanthan, guar, carrageenan and locust bean gum addition on physical, chemical and sensory properties of meatballs[J]. Journal of Food Science and Technology,2014,51(5):36−42.

[5] NIU Y G, FANG H C, HUO T Y, et al. A novel fat replacer composed by gelatin and soluble dietary fibers from black bean coats with its application in meatballs[J]. LWT,2020,122(C):109000.

[6] 邹金, 罗晶晶, 王玉荣, 等. 添加谷氨酰胺转氨酶对鲊广椒肉丸品质的影响[J]. 食品研究与开发,2018,39(18):118−123. [ZOU J, LUO J J, WANG Y R, et al. Effect of addition of glutamine transaminase on the product quality of Zhaguangjiao meatball[J]. Food Research and Development,2018,39(18):118−123. doi: 10.3969/j.issn.1005-6521.2018.18.021 [7] 白建. 生姜多糖对鸡肉丸冷藏期间理化特性及抗氧化能力的影响[J]. 中国调味品,2021,46(12):70−73. [BAI J. Effect of ginger polysaccharides on physicochemical properties and antioxidant capacity of chicken meatballs during refrigerated storage[J]. China Condiment,2021,46(12):70−73. doi: 10.3969/j.issn.1000-9973.2021.12.012 [8] ESMERALDA P G, ALMA DELIA A R, IVAN G G, et al. Ultrasound as a potential process to tenderize beef: Sensory and technological parameters[J]. Ultrasonics Sonochemistry,2019,53:134−141. doi: 10.1016/j.ultsonch.2018.12.045

[9] SANCHES M A R, COLOMBO S P M O, BARRETTO T L, et al. Technological and diffusion properties in the wet salting of beef assisted by ultrasound[J]. LWT,2021,149:112036. doi: 10.1016/j.lwt.2021.112036

[10] 高廷轩, 邓绍林, 赵雪, 等. 多糖协同超声波处理对低盐鸡肉糜凝胶特性的影响[J]. 食品科学,2021,42(19):148−156. [GAO T X, DENG S L, ZHAO X, et al. Synergistic effects of polysaccharide and ultrasonic treatment on gel properties of low-salt minced chicken meat[J]. Food Science,2021,42(19):148−156. doi: 10.7506/spkx1002-6630-20201102-016 [11] ZOU Y H, KANG D C, LIU R, et al. Effects of ultrasonic assisted cooking on the chemical profiles of taste and flavor of spiced beef[J]. Ultrasonics Sonochemistry,2018,46:36−45. doi: 10.1016/j.ultsonch.2018.04.005

[12] CHAO Z Z, FENG Y, WEI T, et al. Application of a pressure-transform tumbling assisted curing technique for improving the tenderness of restructured pork chops[J]. LWT-Food Science and Technology,2019,111:125−132. doi: 10.1016/j.lwt.2019.05.029

[13] 赵改名, 银峰, 祝超智, 等. 滚揉腌制对牛肉盐水火腿品质的影响[J]. 食品科学,2020,41(15):72−78. [ZHAO G M, YIN F, ZHU C Z, et al. Effect of tumbling on the quality of beef brined ham[J]. Food Science,2020,41(15):72−78. doi: 10.7506/spkx1002-6630-20190627-365 [14] HAN D J, JEONG J Y, CHOI J H, et al. Effects of curing methods on the quality characteristics of pork jerky[J]. Food Science and Technology Research,2011,17(3):179−186. doi: 10.3136/fstr.17.179

[15] 佟荟全, 杨丽芳, 肖志超, 等. 超声联合滚揉腌制对鸡胸肉品质的影响研究[J]. 核农学报,2022,36(4):777−787. [TONG H Q, YANG L F, XIAO Z C, et al. Effects of ultrasonic combined tumbling curing on the quality of chicken breast meat[J]. Journal of Nuclear Agricultural Sciences,2022,36(4):777−787. doi: 10.11869/j.issn.100-8551.2022.04.0777 [16] 冯婷, 孙京新, 徐幸莲, 等. 超声波辅助变压滚揉对鸡肉腌制品质的影响[J]. 现代食品科技,2015,31(5):248−254, 315. [FENG T, SUN J X, XU X L, et al. Effect of vacuum-pressure alternating tumbling aided by ultrasonic waves on the quality of marinated chicken[J]. Modern Food Science and Technology,2015,31(5):248−254, 315. doi: 10.13982/j.mfst.1673-9078.2015.5.039 [17] 于林宏, 孙京新, 李鹏, 等. 超声波辅助变压滚揉工艺对鸭肉食用品质的影响[J]. 肉类研究,2016,30(12):17−21. [YU L H, SUN J X, LI P, et al. Effects of ultrasound-aided pressure swing tumbling on the eating quality of duck[J]. Meat Research,2016,30(12):17−21. [18] ZHANG R Y, XING L J, KANG D C, et al. Effects of ultrasound-assisted vacuum tumbling on the oxidation and physicochemical properties of pork myofibrillar proteins[J]. Ultrasonics Sonochemistry,2021,74:105582. doi: 10.1016/j.ultsonch.2021.105582

[19] 苏博, 聂乾忠, 石秀清. 复配亲水胶体对牛肉丸品质特性的影响[J]. 食品与机械,2015,31(2):32−37. [SU B, NIE Q Z, SHI X Q. Effect of compound hydrocolloids on quality of beef meat fillet[J]. Food & Machinery,2015,31(2):32−37. doi: 10.13652/j.issn.1003-5788.2015.02.007 [20] BAREKAT S, SOLTANIZADEH N. Application of high-intensity ultrasonic radiation coupled with papain treatment to modify functional properties of beef Longissimus lumborum[J]. Journal of Food Science and Technology,2019,56(1):224−232. doi: 10.1007/s13197-018-3479-1

[21] WANG T, NING Z X, WANG X P, et al. Effects of ultrasound on the physicochemical properties and microstructure of salted-dried grass carp (Ctenopharyngodon idella)[J]. Journal of Food Process Engineering,2018,41(1):e12643−e1264. doi: 10.1111/jfpe.12643

[22] ALDALALI S, LI C, XU B C. Evaluation of the effect of marination in different seasoning recipes on the flavor profile of roasted beef meat via chemical and sensory analysis[J]. Journal of Food Biochemistry,2021:e13962.

[23] 刘登勇, 周光宏, 徐幸莲. 确定食品关键风味化合物的一种新方法: “ROAV”法[J]. 食品科学,2008,29(7):370−374. [LIU D Y, ZHOU G H, XU X L. “ROAV” method: A new method fordetermining key odor compounds of Rugao ham[J]. Food Science,2008,29(7):370−374. doi: 10.3321/j.issn:1002-6630.2008.07.082 [24] 刘树萍, 冯爽, 陆家慧, 等. 黑豆豆腐替代脂肪对肉丸品质特性的影响[J]. 食品工业科技,2022,43(8):41−49. [LIU S P, FENG S, LU J H, et al. Effect of replacing fat with black bean Tofu on quality characteristics of meatballs[J]. Science and Technology of Food Industry,2022,43(8):41−49. doi: 10.13386/j.issn1002-0306.2021070214 [25] WANG J Y, YANG Y L, TANG X Z, et al. Effects of pulsed ultrasound on rheological and structural properties of chicken myofibrillar protein[J]. Ultrasonics Sonochemistry,2017,38:225−233. doi: 10.1016/j.ultsonch.2017.03.018

[26] 邹云鹤. 超声波辅助煮制对酱卤牛肉品质的影响研究[D]. 南京: 南京农业大学, 2018, 5: 42. ZOU Y H. Effects of ultrasound assisted cooking on the quality of spiced beef[D]. Nanjing: Nanjing Agricultural University, 2018, 5: 42.

[27] 李雪蕊, 徐宝才, 徐学明. 滚揉里程对牛排品质影响及工艺优化[J]. 食品与生物技术学报,2018,37(4):417−423. [LI X R, XU B C, XU X M. Effects of different tumbling mileages on beef steak quality and process optimization[J]. Journal of Food Science and Biotechnology,2018,37(4):417−423. doi: 10.3969/j.issn.1673-1689.2018.04.013 [28] PAN Q, YANG G H, WANG Y, et al. Application of ultrasound-assisted and tumbling dry-curing techniques for reduced-sodium bacon[J]. Journal of Food Processing and Preservation,2020,44(8):e14607.

[29] 赵改名, 孟子晴, 祝超智, 等. 不同食用胶与牛肉糜结合力及凝胶性能的比较[J]. 现代食品科技,2020,36(4):185−191. [ZHAO G M, MENG Z Q, ZHU C Z, et al. Comparison of the binding and gel properties between different edible gums and beef paste[J]. Modern Food Science and Technology,2020,36(4):185−191. doi: 10.13982/j.mfst.1673-9078.2020.4.025 [30] 韩芳蕊. 甘薯膳食纤维对肌原纤维蛋白凝胶特性的影响[D]. 南京: 南京农业大学, 2019. HAN F R. Effect of sweet potato dietary fiber on the gelling properties of myofibrillar protein[D]. Nanjing: Nanjing Agricultural University, 2019.

[31] 曹云刚, 王凡, 艾娜丝, 等. 苹果膳食纤维对猪肉肌原纤维蛋白凝胶性能的影响[J]. 农业机械学报,2020,51(7):365−371. [CAO Y G, WANG F, AI N S, et al. Effect of apple dietary fiber on gel properties of porcine myofibrillar protein[J]. Transactions of the Chinese Society for Agricultural Ma,2020,51(7):365−371. doi: 10.6041/j.issn.1000-1298.2020.07.041 [32] 里奥·范海默特. 化合物嗅觉阈值汇编[M]. 第二版. 北京: 科学出版社, 2018: 1−398. LEO V. Compilation of compound olfactory thresholds[M]. 2nd ed. Beijing: Science Press, 2018: 1−398.

[33] 吴丹璇, 高子武, 吴鹏, 等. 偏最小二乘回归分析市售牛肉丸感官特性与挥发性风味化合物的关系[J]. 现代食品科技,2022,38(3):276−285. [WU D X, GAO Z W, WU P, et al. Correlation analysis of sensory attributes and volatile compounds of commercial beef meatballs by partial least squares regression[J]. Modern Food Science and Technology,2022,38(3):276−285. [34] 孙宝国. 食用调香术[M]. 北京: 化学工业出版社, 2010: 20−28. SUN B G. Flavoring technology for food[M]. Beijing: Chemical Industry Press, 2010: 20−28.

下载:

下载:

下载:

下载: