Effect of Micronized Buckwheat on Dough Characteristic and Noodle Quality

-

摘要: 采用超微粉碎工艺对荞麦进行粉碎并与小麦粉混合制备混合粉,研究了超微粉碎荞麦粉添加量(0~20%)对混合粉溶剂保持力(solvent retention capacity,SRC)、糊化特性、面团的热机械特性和面条蒸煮特性、质构特性影响。结果表明,随着超微粉碎荞麦粉添加量的增加,混合粉的蔗糖SRC、碳酸钠SRC和乳酸SRC显著增加(P<0.05),荞麦粉添加量为20%时,混合粉的蔗糖SRC、碳酸钠SRC和乳酸SRC最高,分别为182.69%、223.02%、177.98%。混合粉峰值黏度、谷值黏度和最终黏度呈先减小后增加的趋势,在添加量为12%时最小,分别为242.00、202.00、408.50 cP。在0~20%范围内,混合粉吸水率从56.80%增加到60.50%;形成时间和稳定时间都随添加的增加而降低,形成时间从3.34 min减低到2.40 min,稳定时间从5.87 min降低到4.61 min。糊化特性、热稳定性和回生值随超微粉碎荞麦粉添加量的增加而降低。面条的硬度、黏度和回复性随超微粉碎荞麦粉的增加总体呈先增加后减小的趋势。Abstract: Buckwheat was micronized and mixed with wheat flour. The addition (0~20%) of micronized buckwheat powder on the solvent retention capacity (SRC), pasting, thermo-mechanical of mixed flour, cooking and texture properties of noodle were systematically studied. The results indicated that sucrose SRC, sodium carbonate SRC and lactic acid SRC significantly increased with the increasing of micronized buckwheat powder addition (P<0.05), which was 182.69%, 223.02%, 177.98% with 20% addition, respectively. The peak viscosity, valley viscosity, and final viscosity of mixed powder decreased firstly and then increased, and the lowest values were 242.00, 202.00 and 408.50 cP when the addition was 12%. The addition ranged from 0 to 20%, the water absorption rate of dough increased from 56.80% to 60.50%. However, the development and stability time decreased with addition of micronized buckwheat from 3.34 to 2.40 min, 5.87 to 4.61 min, respectively. Gelatinization property, thermal stability and setback value of the dough decreased with the increase of micronized buckwheat powder addition. The hardness, viscosity and resilience of noodles increased firstly and then decreased with the increasing of micronized buckwheat powder addition.

-

Keywords:

- buckwheat /

- superfine grinding /

- dough /

- noodles /

- cooking characteristics /

- texture property

-

荞麦作为一种古老的杂粮作物,主要分布在我国干旱和半干旱地区[1-2]。荞麦富含抗性淀粉和黄酮类物质(主要是槲皮素和槲皮素糖苷),具有改善糖尿病、肥胖症、冠心病等慢性疾病的功效[3-4]。在不同种植区被制成不同荞麦制品,如荞麦挂面、荞麦馒头、荞麦碗托、荞麦饸络等[5-9]。荞麦面条是荞麦的主要制品之一,也是最容易被消费者接受的荞麦产品。荞麦粉的添加会影响面条感官、质构和营养指标。荞麦中直链淀粉含量高,淀粉不易糊化,蒸煮时淀粉易从面条中脱落,导致面条的断条率和蒸煮损失率增加[10];荞麦蛋白和小麦蛋白的差异较大,在和面过程中不能形成面筋网络,过量的荞麦添加会降低面团的网络强度、连续性和均匀性,使面团弹性、韧性和延伸性劣化,进而使得面条品质下降[11-12]。

超微粉碎能使得物料尺寸大大降低,并使物料具有更好的溶解性、分散性、吸附性,进而盖面面团和面条的特性。徐小云等[13]研究显示,添加超微麦麸后,面团的吸水率、峰值黏度和淀粉热凝胶稳定性显著增加,面团形成时间减少;面团T2弛豫时间显著缩短,自由水含量逐渐降低;面团中蛋白质α-螺旋和β-折叠含量上升,β-转角和无规则卷曲含量下降;面筋网络的连续性和致密性得到改善。郑万琴等[14]认为超微粉碎不仅可以提高薯渣用量,还能降低其对面团流变品质的不利影响。Niu等[15]发现粒径更小的小麦全粉能减低面团的峰值黏度、谷值黏度和最终黏度,增加面团稳定时间,面条的硬度、弹性、黏结性和回弹性,超微粉碎是提升全谷物面团的有效途径。而超微粉碎后的荞麦添加对面团特性和面条品质的影响还不明确,因此本文将系统研究超微粉碎荞麦粉添加对混合粉溶剂保持力、糊化特性、热机械特性和面条蒸煮、质构特性影响,以期为荞麦面条的品质提升和相关产品开发提供重要理论依据。

1. 材料与方法

1.1 材料与仪器

高筋小麦粉 五得利面粉集团公司;去壳荞麦米 五常彩桥米业有限公司;乳酸、蔗糖、碳酸钠 分析纯,国药集团化学试剂有限公司。

ZNC-300超微粉碎机 北京永恒鑫盛科技公司;FC1-220型电动压面机 武汉丰创机械设备有限公司;TA-XTPlus质构仪 英国Stable Micro System;RAV 4500快速黏度测定仪 瑞典波通科技公司;Mixolab 2混合试验仪 法国肖邦技术公司;ASM-DA1000和面机 北美电器有限公司;FW-100型气流超微粉碎机 天津泰斯特仪器有限公司。

1.2 实验方法

1.2.1 荞麦超微粉碎处理

荞麦经过常规粉碎后过60目筛,在超微粉碎机中粉碎30 min过400目筛网后备用。

1.2.2 混合粉与添加荞麦粉面条的制备

称取不同质量的超微处理后的荞麦粉与高筋小麦粉混合,制成含有0%、4%、8%、12%、16%、20%荞麦粉的混合粉,备用。

在混合粉中加入适量水,和面8~10 min,温度35 ℃、湿度85%熟化30 min后,反复压延5次,最后在压辊轧距间隙2.0 mm处压片并切成直径2.0 mm圆面条,室温晾干,备用。

1.2.3 混合粉溶剂保持能力(solvent retention capacity,SRC)

参照GB/T 35866-2018的方法进行测定。基本操作如下:准确称量的5.000 g混合粉(m)于已称重的离心管(m1)中并加入25.00 g溶液(去离子水,50%蔗糖溶液(质量分数),5%碳酸钠溶液(质量分数),5%乳酸溶液(质量分数)),剧烈摇动使其混合均匀,置于试管架上膨胀20 min,期间在5、10、15、20 min时快速摇动5 s。最后一次摇动后,在1000×g离心力下离心15 min,弃上清液后将试管倒立10 min称重(m2),测定之前测定混合粉水分M1,按照下式计算SRC。

SRC(%)=(m2−m1 m×100−14100−M1−1)×100 1.2.4 混合粉糊化特性测定

参照GB/T 24853-2010的方法进行测定。主要过程如下:称取2.5 g混合粉(湿基水分质量分数14%),加25 mL去离子水。0~20 s在960 r/min条件下从室温加热至25 ℃,然后在160 r/min条件下恒温60 s,在840 s内逐渐升温至95 ℃后恒温600 s,570 s内降温至50 ℃后恒温570 s,根据糊化曲线计算峰值黏度、谷值黏度、衰减值、最终黏度、回生值等。

1.2.5 混合粉热机械特性测定

参照GB/T 37511-2019采用Mixolab 2对混合粉的热机械特性进行测定。试验协议为Chopin+,搅拌刀转速为80 r/min,面团质量为75 g,水箱温度为30 ℃,目标扭矩为1.1±0.05 N·m。运行过程中温度设置分为三个阶段:第一阶段(恒温阶段),30 ℃保持8 min;第二阶段(升温阶段),以4 ℃/min升温到90 ℃,并在此温度下保持10 min;第三阶段(降温阶段),以4 ℃/min从90 ℃降温到50 ℃,并在此温度下保持5 min。

1.2.6 荞麦面条蒸煮特性测定

荞麦面条最佳蒸煮时间、蒸煮断条率、蒸煮吸水率和蒸煮损失率的测定参照LS/T 3212-2021进行。

1.2.7 面条质构特性分析

面条在最佳蒸煮时间下蒸煮后,过凉水10 s,对其进行TPA、剪切力和拉伸强度测定,每次测定最少重复6次。测定参数参考相关文献[16]。

TPA测定:探头型号:P36/R。参数设定:模式:压缩;测试前运行速度:1 mm/s;测试速度:5 mm/s;测试结束返回速度:5 mm/s;压缩程度:75%;触发形式:自动-5 g。

剪切力测定:探头型号:A/LKB-F。参数设定:模式:压缩;测试前运行速度:2 mm/s;测试速度:0.8 mm/s;测试结束返回速度:0.8 mm/s;压缩程度:90%;触发形式:自动-3 g。

拉伸强度测定:探头型号:Code A/SPR。参数设定:模式:拉伸;测试前速度:2 mm/s;测试速度:2 mm/s;测试结束返回速度:10 mm/s;触发距离:100 mm;触发形式:Auto-0.5 g。

1.3 数据处理

试验重复3次,结果用

ˉx ±s表示,列表或采用Origin 2018对所得数据进行作图处理。用SPSS通过一元方差分析(One-Way ANOVA)进行多个组间平均数的比较,如组间存在显著性差异(P<0.05),则采用Duncan检验进行组间多重比较。2. 结果与分析

2.1 超微粉碎荞麦粉添加量对混合粉溶剂保持力的影响

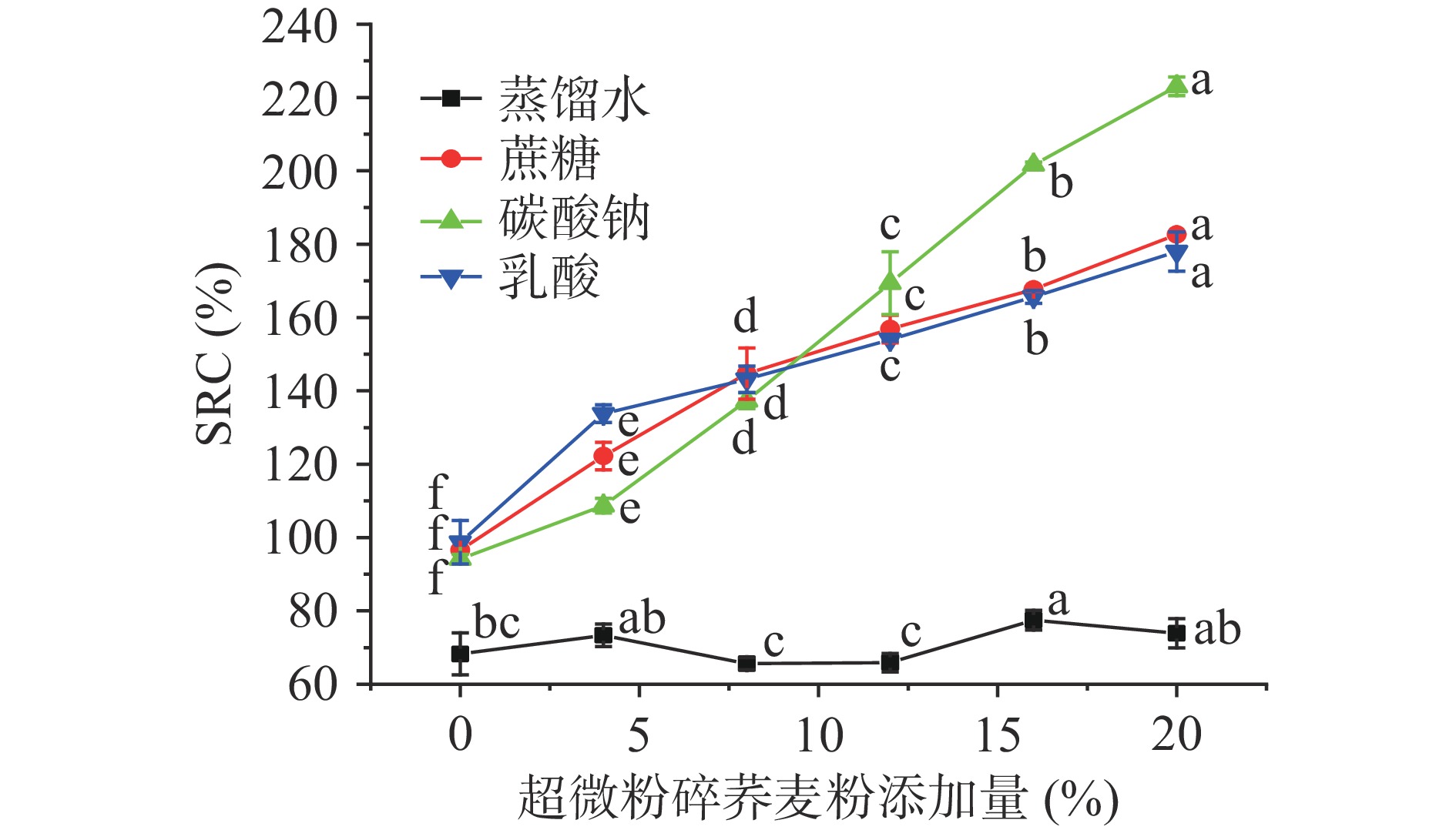

超微粉碎荞麦粉添加量对混合粉溶剂保持力的影响见图1。由图1可见,随着超微粉碎荞麦粉添加量的增加,混合粉的蔗糖SRC、碳酸钠SRC和乳酸SRC显著增加(P<0.05)。当荞麦粉添加量为20%时,混合粉的蔗糖SRC、碳酸钠SRC和乳酸SRC分别为182.66%、223.02%、177.99%。蔗糖SRC是模拟饼干或高糖饼干环境,与混合粉中聚阿拉伯糖木糖相关;碳酸钠SRC与破碎淀粉含量相关;乳酸SRC与面团谷蛋白网络形成和谷蛋白网络强度有关[17-18]。荞麦中含有较高的膳食纤维,通过粉碎将部分不可溶性的膳食纤维变成可溶性膳食纤维;超微粉碎在降低荞麦粒径时会使完整的淀粉颗粒变成破损淀粉。因此,超微粉碎荞麦粉的添加会导致混合粉蔗糖SRC、碳酸钠SRC升高。乳酸SRC随着超微粉碎荞麦粉的添加量的增加而增加,说明超微粉碎荞麦粉的添加会促进谷蛋白网络的形成。蒸馏水SRC与面粉全部组成有关,反映了混合粉综合特性[19-20]。而蒸馏水SRC随着荞麦添加量的变化规律不明显,说明超微粉碎荞麦粉的添加对混合粉吸水性无明显的影响。

![]() 图 1 超微粉碎荞麦粉添加量对混合粉溶剂保持力的影响注:不同小写字母表示差异显著,P<0.05;图2同。Figure 1. Effects of micronized buckwheat addition on SRC of mixed powder

图 1 超微粉碎荞麦粉添加量对混合粉溶剂保持力的影响注:不同小写字母表示差异显著,P<0.05;图2同。Figure 1. Effects of micronized buckwheat addition on SRC of mixed powder2.2 超微粉碎荞麦粉添加量对混合粉糊化特性的影响

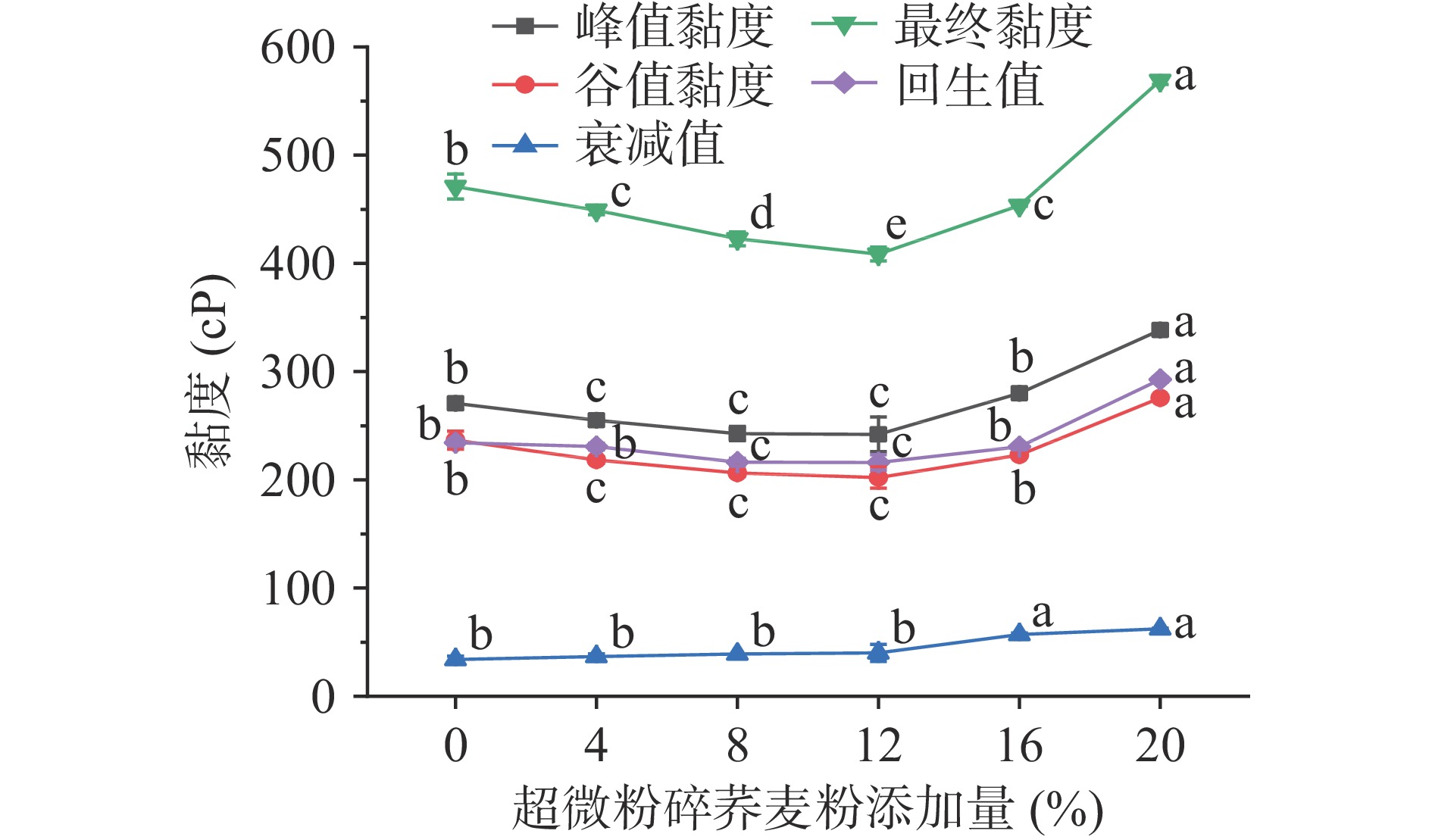

超微粉碎荞麦粉添加对混合粉糊化特性影响见图2。由图2可见,随着超微粉碎荞麦粉添加量的增加,混合粉的峰值黏度、谷值黏度、最终黏度都呈先减小后增加的趋势。峰值黏度、谷值黏度、最终黏度在添加量为12%时最小,分别为242.00、202.00、408.50 cP;之后随着超微粉碎荞麦粉添加量的增加而增加,添加量为20%时最大,分别为3383.33、275.67、569.00 cP。研究发现随淀粉含量降低面团峰值黏度、谷值黏度、最终黏度降低,而随破碎淀粉含量的增加峰值黏度、谷值黏度、最终黏度呈增加趋势[21-22]。荞麦中淀粉含量低于小麦粉,超微粉碎荞麦粉的添加导致混合粉中淀粉总含量降低;此外,通过超微粉碎荞麦粉中破碎淀粉含量大大增加,随着超微粉碎荞麦粉添加量的增加混合粉中破碎淀粉含量也逐渐增加。因此,在淀粉含量和破碎淀粉的相互作用下,混合粉的糊化特性呈现先降低后增加的趋势。回生值随超微粉碎荞麦粉添加量的增加呈先上升后下降,这说明在添加8%~12%时不容易回生,过多的荞麦粉添加会导致面条熟化后更加容易回生。衰减值与淀粉粒膨胀后的强度有关,衰减值越小说明淀粉热糊稳定性越好[23]。衰减值随着超微粉碎荞麦粉添加量的增加而增加,说明超微粉碎荞麦粉添加导致淀粉热稳定性下降,但是在添加量为0~12%内回生值之间无显著性差异(P>0.05)。

2.3 超微粉碎荞麦粉添加对面团蛋白组分热机械特性影响

超微粉碎荞麦粉添加对面团蛋白组分热机械特性影响见表1。由表1可见,添加超微粉碎荞麦粉后,面团的吸水率显著增加,在0~20%范围内,吸水率从56.80%增加到60.50%,增加了3.7%。这主要是因为破碎淀粉结晶区被破坏,能够使水分子进入淀粉颗粒内部[24]。面团形成时间和稳定时间都随超微粉碎荞麦粉的添加而减小,未添加荞麦粉时面团形成时间为3.34 min,添加荞麦粉后面团形成时间显著降低(P<0.05),但是不同添加量之间无显著性差异(P>0.05);稳定时间从未添加时的5.87 min降低到4.61 min。有研究发现添加常规粉碎的荞麦粉,面团的吸水率、形成时间和稳定时间随着添加量的增加而增加;而添加超微粉碎荞麦粉面团的吸水率、形成时间和稳定时间随着添加量的增加而降低,粒径越小这种趋势越明显[25-26]。

表 1 超微粉碎荞麦粉添对面团蛋白组分热机械特性的影响Table 1. Effects of micronized buckwheat addition on the thermomechanical characteristic of protein of mixed powder超微粉碎荞麦粉添加量(%) 吸水率(%) 形成时间(min) 稳定时间(min) C1-C2(N·m) α(N·m·min−1) 0 56.80±0.35f 3.34±0.18a 5.87±0.23a 0.68±0.01d −0.070±0.005a 4 57.10±0.00e 2.63±0.06b 5.20±0.00b 0.72±0.01c −0.063±0.002a 8 57.90±0.00d 2.35±0.13b 5.03±0.12bc 0.74±0.02b −0.063±0.004a 12 59.00±0.00c 2.48±0.16b 4.83±0.15cd 0.76±0.01ab −0.064±0.003a 16 59.90±0.00b 2.47±0.21b 4.82±0.08cd 0.77±0.01ab −0.066±0.004a 20 60.50±0.00a 2.40±0.19b 4.61±0.04d 0.78±0.01a −0.066±0.003a 注:不同小写字母表示,同列数据差异显著,P<0.05;表2~表4同。 C1-C2值表示面团的弱化度,反映了面条在搅拌过程中对机械搅拌的承受能力。从表中能看出随着荞麦粉添加量的增加,表明面团弱化度呈随着超微粉碎荞麦粉添加量的增加而增加。荞麦中不含面筋蛋白,荞麦的添加会使得混合粉的面筋被稀释,降低混合粉面筋强度,弱化度增加[27]。α为加热作用下蛋白质网络弱化的速度,各个添加量之间无显著性差异(P>0.05),说明超微粉碎荞麦粉的添加对混合粉蛋白网络弱化速度无显著影响(P>0.05)。

2.4 超微粉碎荞麦粉添加对面团淀粉组分热机械特性的影响

超微粉碎荞麦粉添加对面团淀粉组分热机械特性影响见表2。C3-C2值表示淀粉的糊化特性,差值越大,表示混合粉中淀粉糊化特性越强,黏度变化大。从表中能看出,随着超微荞麦粉添加量的增加C3-C2值逐渐降低,添加量为20%时仅为1.26 N·m,这说明荞麦添加使混合粉的淀粉糊化特性减低,面团峰值黏度降低,淀粉颗粒膨胀程度减低。C3-C4差值表示淀粉的热稳定性,差值越小表示淀粉热稳定性越强。C5-C4值表示淀粉回生特性,其差值越小说明淀粉不易回生。由表2可以看出,在超微粉碎荞麦粉添加量为0~4%时,C3-C4值均为−0.03 N·m,说明混合粉在淀粉在糊化过程热稳定性中有增加趋势;而在添加量为8%~20%范围内,混合粉中淀粉热稳定性降低,但他们之间无显著性差异(P>0.05)。随着超微粉碎荞麦粉添加量的增加,混合粉的C5-C4值从1.13 N·m降低到0.74 N·m,说明了超微粉碎荞麦粉的添加能够延缓面团的回生性,这与前任结论相同[28]。β和γ值分别为淀粉糊化速度和淀粉酶水解淀粉的速度,淀粉糊化速度先减小后增加,添加量为8%~16%时无显著性差异(P>0.05);淀粉酶水解淀粉的速度降低,从正值变为负值。

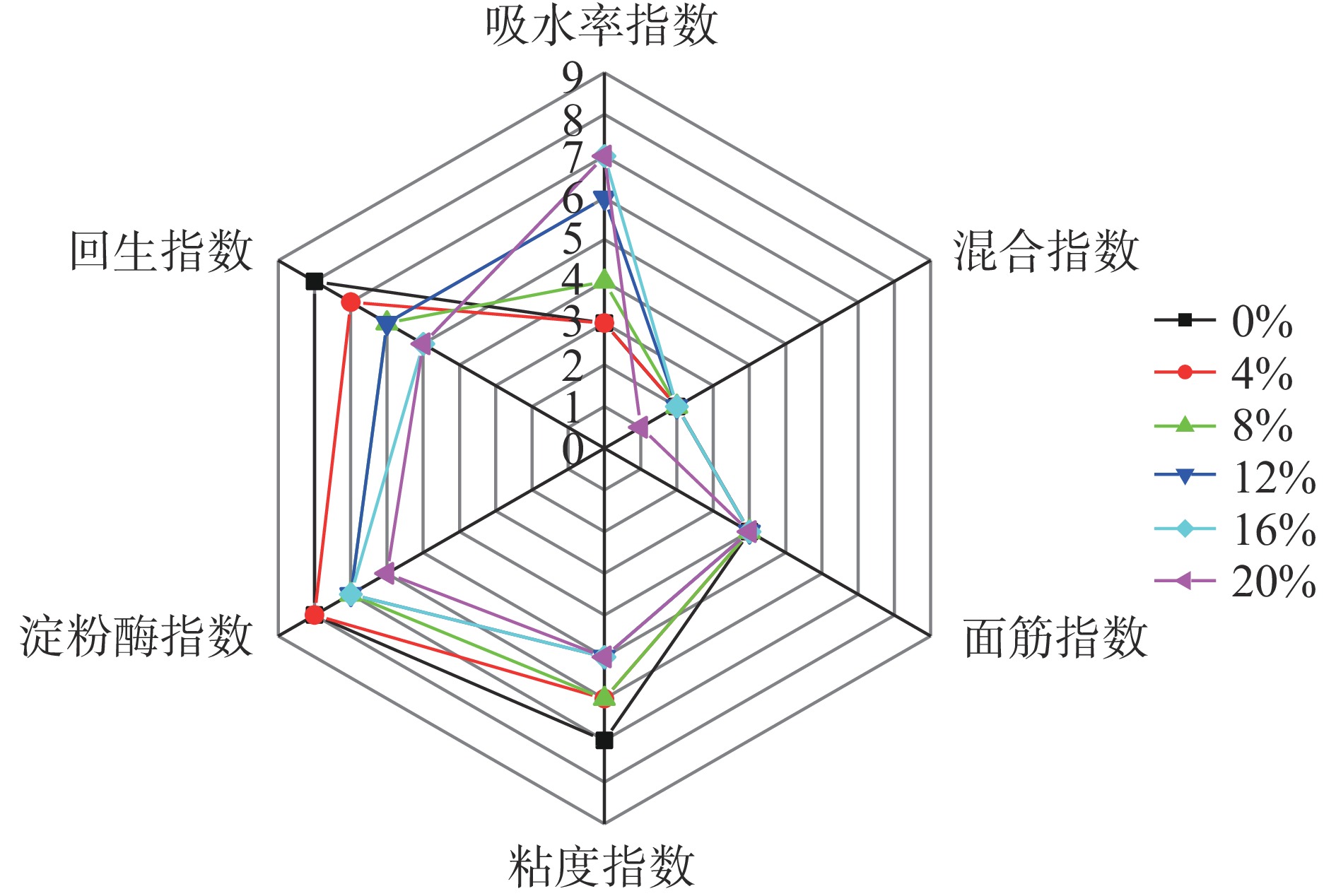

表 2 超微粉碎荞麦粉添加对面团淀粉组分热机械特性的影响Table 2. Effects of micronized buckwheat addition on the thermomechanical characteristic of starch of mixed powder超微粉碎荞麦粉添加量(%) C3-C2(N·m) C3-C4(N·m) C5-C4(N·m) β(N·m·min−1) γ(N·m·min−1) 0 1.47±0.01a −0.03±0.04b 1.13±0.04a 0.578±0.009a 0.007±0.009a 4 1.38±0.01b −0.03±0.01b 1.04±0.03b 0.455±0.056ab 0.007±0.006a 8 1.37±0.02b 0.05±0.01a 0.94±0.03c 0.113±0.028c −0.015±0.026a 12 1.33±0.01c 0.06±0.01a 0.82±0.03d 0.214±0.040c −0.023±0.013a 16 1.31±0.02c 0.09±0.01a 0.77±0.02e 0.131±0.008c −0.018±0.029a 20 1.26±0.01d 0.08±0.01a 0.74±0.01e 0.347±0.154b −0.006±0.009a 添加超微粉碎荞麦粉对面团指数影响见图3。由图3可见,随着挤压荞麦粉添加量的增加,面团的吸水指数增加,而混合指数、黏度指数、淀粉酶指数和回生指数下降,面筋指数不变。这说明添加荞麦粉后面团吸水率增加,面团稳定性、黏度、酶活降低,而产品不易回生,货架期较长[29]。

2.5 超微粉碎荞麦粉添加量对面条蒸煮特性的影响

超微粉碎荞麦粉添加对面条蒸煮特性影响见表3。由表3可见,未添加超微粉碎荞麦粉的蒸煮时间为5.00 min,添加荞麦粉后蒸煮时间有小幅增加,在添加量为12%时蒸煮时间最大为6.00 min。面条蒸煮断条率不超过5%,符合LS/T 3212-2021的规定。面条蒸煮吸水率在荞麦添加量为0~16%范围无显著性差异(P>0.05),添加量为20%时蒸煮吸水率最低为181.25%。未添加超微粉碎荞麦粉时蒸煮损失率为3.22%;添加荞麦粉后蒸煮损失率显著增加(P<0.05),但是添加量4%~20%范围内蒸煮损失率之间无显著性差异(P>0.05)。研究发现在面粉中添加超微粉碎荞麦粉导致面团中破损淀粉含量增加,一定范围内,随着破损淀粉含量的增加面团内部面筋网络结构的强度和稳定性增加,提升面条品质;但是过量的破损淀粉导致面团结构松散,降低面条品质[30]。

表 3 超微粉碎荞麦粉添加量对面条蒸煮特性的影响Table 3. Effects of micronized buckwheat addition on the cooking characteristic of noodles超微粉碎荞麦粉添加量(%) 蒸煮时间(min) 蒸煮断条率(%) 蒸煮吸水率(%) 蒸煮损失率(%) 0 5.00 2.50 188.45±8.04ab 3.22±0.45a 4 5.50 5.00 192.68±5.86ab 6.29±0.50b 8 5.50 2.50 195.52±13.29ab 6.41±0.61b 12 6.00 2.50 201.47±3.37a 6.87±0.49b 16 5.50 5.00 196.09±5.11a 6.57±0.08b 20 5.50 5.00 181.25±5.73b 6.65±0.59b 2.6 超微粉碎荞麦粉添加对面条质构特性影响

超微粉碎荞麦粉添加对面条质构特性的影响见表4。由表4可见,随着超微粉碎荞麦粉添加量的增加面条硬度、黏度和回复性总体呈先增加后减小的趋势,荞麦粉添加量12%时硬度和黏性最高分别为5516.17 g、33.67 g·s,添加量16%时回复性最大。拉伸距离和剪切力总体呈减小的趋势,拉升距离在添加量为20%时最小为38.82 mm;与小麦面条相比,添加荞麦粉后面条剪切力显著降低(P<0.05)。通过超微粉碎处理后荞麦粉具有较小的粒径,较高的破碎淀粉含量,小粒径有利于面团致密网状结构的形成,较高的破碎淀粉能够提高面条的黏结作用,使得淀粉、蛋白、纤维等组成之间结合程度加强,提升了面条的紧实度[21],但是过多荞麦粉的添加导致面筋蛋白被稀释,因此也会导致面条品质劣化。

表 4 超微粉碎荞麦粉添加对面条质构特性影响Table 4. Effects of micronized buckwheat on the textural characteristic of noodles超微粉碎荞麦粉添加量(%) 硬度(g) 黏性(g·s) 回复性(%) 拉伸强度(g) 拉伸距离(mm) 剪切力(g) 0 3766.31±304.54d 16.99±1.32e 35.16±1.52d 26.76±4.74ab 54.02±9.86a 159.20±12.69a 4 4075.11±316.7c 22.88±5.63cd 47.87±1.76b 27.56±2.67a 52.01±3.08a 108.28±9.76bc 8 4133.65±174.34c 19.92±0.07de 46.89±0.60b 23.26±0.56b 58.84±2.78a 99.38±10.53c 12 5516.17±242.76a 33.67±0.31a 42.29±1.43c 24.22±0.26ab 50.59±4.00ab 117.26±2.57b 16 4621.75±123.63b 25.5±2.47bc 50.31±2.27a 26.74±0.89ab 42.48±5.76bc 118.99±6.28b 20 4403.45±70.18bc 29.2±2.55b 46.29±0.80b 26.12±0.49ab 38.82±5.46c 122.45±6.18b 3. 结论

随着超微粉碎荞麦粉添加量的增加,混合粉的蔗糖、碳酸钠和乳酸SRC显著增加(P<0.05),超微粉碎荞麦粉添加量为20%时,混合粉的蔗糖SRC、碳酸钠SRC和乳酸SRC分别为182.69%、223.02%、177.98%。混合粉峰值黏度、谷值黏度、最终黏度呈先减小后增加的趋势,在添加量为12%时最小,分别为242.00、202.00、408.50 cP。面团的吸水率随着超微粉碎荞麦粉添加量的增加而增加,在0~20%范围内,吸水率从56.80%增加到60.50%;随超微粉碎荞麦粉添加量的增加面团的形成时间和稳定时间都减小,未添加荞麦粉时面团形成时间为3.34 min,添加荞麦粉后面团形成时间显著降低(P<0.05),稳定时间从5.87 min降低到4.61 min。糊化特性、热稳定性和回生值随着超微粉碎荞麦粉添加量的增加而降低。面条的硬度、黏度和回复性随超微粉碎荞麦粉的增加总体呈先增加后减小的趋势。

-

图 1 超微粉碎荞麦粉添加量对混合粉溶剂保持力的影响

注:不同小写字母表示差异显著,P<0.05;图2同。

Figure 1. Effects of micronized buckwheat addition on SRC of mixed powder

表 1 超微粉碎荞麦粉添对面团蛋白组分热机械特性的影响

Table 1 Effects of micronized buckwheat addition on the thermomechanical characteristic of protein of mixed powder

超微粉碎荞麦粉添加量(%) 吸水率(%) 形成时间(min) 稳定时间(min) C1-C2(N·m) α(N·m·min−1) 0 56.80±0.35f 3.34±0.18a 5.87±0.23a 0.68±0.01d −0.070±0.005a 4 57.10±0.00e 2.63±0.06b 5.20±0.00b 0.72±0.01c −0.063±0.002a 8 57.90±0.00d 2.35±0.13b 5.03±0.12bc 0.74±0.02b −0.063±0.004a 12 59.00±0.00c 2.48±0.16b 4.83±0.15cd 0.76±0.01ab −0.064±0.003a 16 59.90±0.00b 2.47±0.21b 4.82±0.08cd 0.77±0.01ab −0.066±0.004a 20 60.50±0.00a 2.40±0.19b 4.61±0.04d 0.78±0.01a −0.066±0.003a 注:不同小写字母表示,同列数据差异显著,P<0.05;表2~表4同。 表 2 超微粉碎荞麦粉添加对面团淀粉组分热机械特性的影响

Table 2 Effects of micronized buckwheat addition on the thermomechanical characteristic of starch of mixed powder

超微粉碎荞麦粉添加量(%) C3-C2(N·m) C3-C4(N·m) C5-C4(N·m) β(N·m·min−1) γ(N·m·min−1) 0 1.47±0.01a −0.03±0.04b 1.13±0.04a 0.578±0.009a 0.007±0.009a 4 1.38±0.01b −0.03±0.01b 1.04±0.03b 0.455±0.056ab 0.007±0.006a 8 1.37±0.02b 0.05±0.01a 0.94±0.03c 0.113±0.028c −0.015±0.026a 12 1.33±0.01c 0.06±0.01a 0.82±0.03d 0.214±0.040c −0.023±0.013a 16 1.31±0.02c 0.09±0.01a 0.77±0.02e 0.131±0.008c −0.018±0.029a 20 1.26±0.01d 0.08±0.01a 0.74±0.01e 0.347±0.154b −0.006±0.009a 表 3 超微粉碎荞麦粉添加量对面条蒸煮特性的影响

Table 3 Effects of micronized buckwheat addition on the cooking characteristic of noodles

超微粉碎荞麦粉添加量(%) 蒸煮时间(min) 蒸煮断条率(%) 蒸煮吸水率(%) 蒸煮损失率(%) 0 5.00 2.50 188.45±8.04ab 3.22±0.45a 4 5.50 5.00 192.68±5.86ab 6.29±0.50b 8 5.50 2.50 195.52±13.29ab 6.41±0.61b 12 6.00 2.50 201.47±3.37a 6.87±0.49b 16 5.50 5.00 196.09±5.11a 6.57±0.08b 20 5.50 5.00 181.25±5.73b 6.65±0.59b 表 4 超微粉碎荞麦粉添加对面条质构特性影响

Table 4 Effects of micronized buckwheat on the textural characteristic of noodles

超微粉碎荞麦粉添加量(%) 硬度(g) 黏性(g·s) 回复性(%) 拉伸强度(g) 拉伸距离(mm) 剪切力(g) 0 3766.31±304.54d 16.99±1.32e 35.16±1.52d 26.76±4.74ab 54.02±9.86a 159.20±12.69a 4 4075.11±316.7c 22.88±5.63cd 47.87±1.76b 27.56±2.67a 52.01±3.08a 108.28±9.76bc 8 4133.65±174.34c 19.92±0.07de 46.89±0.60b 23.26±0.56b 58.84±2.78a 99.38±10.53c 12 5516.17±242.76a 33.67±0.31a 42.29±1.43c 24.22±0.26ab 50.59±4.00ab 117.26±2.57b 16 4621.75±123.63b 25.5±2.47bc 50.31±2.27a 26.74±0.89ab 42.48±5.76bc 118.99±6.28b 20 4403.45±70.18bc 29.2±2.55b 46.29±0.80b 26.12±0.49ab 38.82±5.46c 122.45±6.18b -

[1] GE Ruihong, WANG Hui. Nutrient components and bioactive compounds in tartary buckwheat bran and flour as affected by thermal processing[J]. International Journal of Food Properties,2020,23(1):127−137. doi: 10.1080/10942912.2020.1713151

[2] QU Yang, FENG Baili. Straw mulching improved yield of field buckwheat (Fagopyrum) by increasing water-temperature use and soil carbon in rain-fed farmland[J]. Acta Ecologica Sinica,2020,42(1):11−16.

[3] YANG J, LEE J, SUNG J. Influence of acid treatment on flavonoid content and biological activity in tartary buckwheat grains and its application for noodles[J]. LWT,2021,145:111488. doi: 10.1016/j.lwt.2021.111488

[4] XIAO Yu, WU Xing, YAO Xinshuo, et al. Metabolite profiling, antioxidant and α-glucosidase inhibitory activities of buckwheat processed by solid-state fermentation with Eurotium cristatum YL-1[J]. Food Research International,2021,143:110262. doi: 10.1016/j.foodres.2021.110262

[5] 尉腾. 甜荞麦粉的营养复配及其面团、馒头品质研究[D]. 杨凌: 西北农林科技大学, 2020 WEI Teng. Study on nutritional compound of sweet buckwheat flour and quality of its dough and steamed bread[D]. Yangling: Northwest A&F University, 2020.

[6] 彭湃, 王柯, 王晓龙, 等. 燕麦、荞麦面条品质提升研究进展[J]. 中国粮油学报,2021,36(4):153−160. [PENG Pai, WANG Ke, WANG Xiaolong, et al. Research progress on quality improvement of oat and buckwheat noodles[J]. Journal of the Chinese Cereals and Oils Association,2021,36(4):153−160. [7] 翟小童. 不同品种荞麦挤压面条的品质评价研究[J]. 中国食物与营养,2013,19(1):51−55. [ZHAI Xiaotong. Quality evaluation of buckwheat spaghetties produced by different buckwheat varieties[J]. Food and Nutrition in China,2013,19(1):51−55. [8] WU Nana, TIAN Xiaohong, LIU Yanxiang, et al. Quality, texture and antioxidant properties of dried noodles enhanced with tartary buckwheat flour[J]. Food Science and Technology Research,2017,23(6):783−792. doi: 10.3136/fstr.23.783

[9] SUN Xuyang, YU Chen, FU Meixia, et al. Extruded whole buckwheat noodles: Effects of processing variables on the degree of starch gelatinization, changes of nutritional components, cooking characteristics and in vitro starch digestibility[J]. Food & Function,2019,10(10):6362−6373.

[10] 马雨洁, 刘航, 许芳溢, 等. 淀粉组成对荞麦面条食用和烹调品质的影响[J]. 食品工业科技,2012,33(19):49−52. [MA Yujie, LIU Hang, XU Fangyi, et al. Effect of starch composition on the cooking and sensory quality of buckwheat noodles[J]. Science and Technology of Food Industry,2012,33(19):49−52. [11] 王瑞斌. 荞麦粉挤压改性及其对面条质量特性的影响研究[D]. 北京: 中国农业科学院, 2018 WANG Ruibin. Modification of buckwheat flour by extruder and effects on noodle quality[D]. Beijing: Chinese Academy of Agricultural Sciences, 2018.

[12] GUO Xiaona, YAO Huiyuan. Fractionation and characterization of tartary buckwheat flour proteins[J]. Food Chemistry,2006,98(1):90−94. doi: 10.1016/j.foodchem.2005.05.055

[13] 徐小云, 徐燕, 汪名春, 等. 麦麸超微粉碎对面团流变学特性与网络结构的影响[J]. 安徽农业大学学报,2018,45(6):977−982. [XU Xiaoyun, XU Yan, WANG Mingchun, et al. Effect of superfine-grinding of wheat bran on the rheological property and gluten network of dough[J]. Journal of Anhui Agricultural University,2018,45(6):977−982. [14] 郑万琴, 魏枭, 谢勇, 等. 超微粉碎薯渣纤维对小麦面团流变特性的影响[J]. 食品与发酵工业,2020,46(8):192−198. [ZHENG Wanqin, WEI Xiao, XIE Yong, et al. Effects of ultrafine pulverized sweet potato residue cellulose on rheological properties of wheat doughs[J]. Food and Fermentation Industries,2020,46(8):192−198. [15] NIU Meng, HOU Gary, LEE Bon, et al. Effects of fine grinding of millfeeds on the quality attributes of reconstituted whole-wheat flour and its raw noodle products[J]. LWT - Food Science and Technology,2014,57:58−64. doi: 10.1016/j.lwt.2014.01.021

[16] 施建斌, 隋勇, 蔡沙, 等. 挤压处理荞麦对面团特性和面条品质的影响[J]. 食品工业科技,2022,43(9):172−177. [SHI Jianbin, SUI Yong, CAI Sha, et al. Effect of extruded buckwheat powder on dough characteristic and noodle quality[J]. Science and Technology of Food Industry,2022,43(9):172−177. [17] DUYVEJONCK A, LAGRAIN B, PAREYT B, et al. Relative contribution of wheat flour constituents to solvent retention capacity profiles of European wheats[J]. Journal of Cereal Science,2011,53(3):312−318. doi: 10.1016/j.jcs.2011.01.014

[18] JEON S, BAIK B, KWEON M. Solvent retention capacity application to assess soft wheat flour quality for making white-salted noodles[J]. Cereal Chemistry,2019,96(3):497−507. doi: 10.1002/cche.10150

[19] KAUR A, SINGH N, KAUR S, et al. Relationships of flour solvent retention capacity, secondary structure and rheological properties with the cookie making characteristics of wheat cultivars[J]. Food Chemistry,2014,158:48−55. doi: 10.1016/j.foodchem.2014.02.096

[20] LANGÓ B, BÓNA L, NG P, et al. Evaluation of carbohydrate properties and end-use quality of hexaploid triticale and its relationship to solvent retention capacity[J]. Journal of Cereal Science,2018,84:95−102. doi: 10.1016/j.jcs.2018.10.005

[21] 程佳钰, 高利, 汤晓智. 超微粉碎对苦荞面条品质特性的影响[J]. 食品科学,2021,42(15):99−105. [CHENG Jiayu, GAO Li, TANG Xiaozhi. Effect of ultrafine grinding on the quality of tartary buckwheat noodles[J]. Food Science,2021,42(15):99−105. [22] 王军, 程晶晶, 王周利, 等. 黑小豆超微全粉对面团流变学特性及馒头品质的影响[J]. 中国食品学报,2019,19(1):103−110. [WANG Jun, CHENG Jingjing, WANG Zhouli, et al. Effect of superfine grinded whole black kidney bean powder on rheological properties of flour dough and quality of steamed bread[J]. Journal of Chinese Institute of Food Science and Technology,2019,19(1):103−110. [23] 徐斌, 孙伊琳, 刘淑一, 等. 预糊化处理对高含量燕麦挂面品质的影响[J]. 现代食品科技,2019,35(6):139−144. [XU Bin, SUN Yilin, LIU Shuyi, et al. Effect of pregelatinization on the quality of noodles with a high oat flour content[J]. Modern Food Science and Technology,2019,35(6):139−144. [24] 王晓曦, 王忠诚, 曹维让, 等. 小麦破损淀粉含量与面团流变学特性及降落数值的关系[J]. 郑州工程学院学报,2001(3):53−57. [WANG Xiaoxi, WANG Zhongcheng, CAO Weirang, et al. The relationship between damage starch content in wheat flour and rheological properties and falling number[J]. Journal of Zhengzhou Institute of Technology,2001(3):53−57. [25] 汪丽萍, 田晓红, 刘明, 等. 苦荞超微粉对苦荞小麦混合粉及其挂面品质的影响[J]. 粮油食品科技,2015,23(1):1−4. [WANG Liping, TIAN Xiaohong, LIU Ming, et al. Influence of micronized buckwheat flour on the quality of buckwheat-wheat mixed flour and dried noodle[J]. Science and Technology of Cereals, Oils and Foods,2015,23(1):1−4. [26] 袁添瑨. 藜麦面条加工工艺研究[D]. 郑州: 河南工业大学, 2020 YUAN Tianjin. The processing technology study of quinoa noodles [D]. Zhengzhou: Henan University of Technology, 2020.

[27] 崔明敏, 李芳, 刘英. 燕麦-小麦预混和面条粉流变学特性研究[J]. 粮食加工,2015,40(1):38−42. [CUI Mingmin, LI Fang, LIU Ying. Analysis on flour and gelatinization properties of oat-wheat premixed noodles flour[J]. Grain Processing,2015,40(1):38−42. [28] 周小理, 马思佳, 朱思怡, 等. 苦荞-小麦混合粉面团特性及其鲜湿面条的研制[J]. 现代食品科技,2021,37(8):168−175. [ZHOU Xiaoli, MA Sijia, ZHU Siyi, et al. Characteristics of tartary buckwheat flour dough and development of fresh and wet noodles[J]. Modern Food Science and Technology,2021,37(8):168−175. [29] 张纷, 赵亮, 靖卓, 等. 藜麦-小麦混合粉面团特性及藜麦馒头加工工艺[J]. 食品科学,2019,40(14):323−332. [ZHANG Fen, ZHAO Liang, JING Zhuo, et al. Dough characteristics of quinoa-wheat composite flour and optimization of mantou processing[J]. Food Science,2019,40(14):323−332. [30] 张玉荣, 高佳敏, 周显青, 等. 谷物磨粉工艺对其淀粉损伤及特性影响研究进展[J]. 中国粮油学报,2017,32(3):135−140. [ZHANG Yurong, GAO Jiamin, ZHOU Xianqing, et al. A review of effects of grain processing on starch damage and properties[J]. Journal of the Chinese Cereals and Oils Association,2017,32(3):135−140. -

期刊类型引用(6)

1. 宋巧英. 超声辅助深共熔溶剂提取栀子黄酮及其对HepG2细胞的降血糖作用. 精细化工. 2024(10): 2223-2230 .  百度学术

百度学术

2. 杨春晖,王文平,续丹丹,崔宇倩,鞠岩,许春艳,吕小婷. 不同原料酿造酱油功能成分及抗氧化活性比较. 食品工业科技. 2023(14): 318-325 .  本站查看

本站查看

3. 白琨,李艳,蔡伟. 和田茴香籽总黄酮提取及体内抗氧化活性研究. 中国调味品. 2023(08): 199-202 .  百度学术

百度学术

4. 周煜凡,冯疆涛,白冰瑶. 响应面法优化新疆纸皮核桃分心木中总黄酮提取工艺. 食品工业. 2023(09): 40-45 .  百度学术

百度学术

5. 郑沛,文敏,刘秋叶,王潇,左亚杰. 半枝莲总黄酮提取工艺优化及抗氧化、抗肿瘤活性评价. 食品工业科技. 2023(23): 194-202 .  本站查看

本站查看

6. 张晨,赵金,严俊杰,苗人云,林俊彬,李翔,周向荣,张攀,甘炳成. 响应面法优化黑皮鸡枞总黄酮提取工艺. 中国调味品. 2022(11): 138-143 .  百度学术

百度学术

其他类型引用(8)

下载:

下载:

下载:

下载: