Pretreatment of Curdlan and Its Effect on the Quality of Low Fat Beef Sausage

-

摘要: 为了研究预处理方法对可得然胶粘度、凝胶强度的影响,探索经过预处理的可得然胶对低脂牛肉肠的保水性和质构特性的影响,本实验分别采用高速斩拌、酸碱中和的方法对可得然胶进行预处理,研究两种预处理方法对可得然胶粘度及凝胶强度的影响。并在低脂牛肉肠的加工中,分别添加0.1%、0.3%、0.5%和0.7%经高速斩拌与酸碱中和预处理的可得然胶,测定低脂牛肉肠蒸煮损失、保水性、质构特性以及感官等指标,探究高速斩拌、酸碱中和预处理所得可得然胶的应用效果。结果表明:高速斩拌和酸碱中和预处理均能显著提升可得然胶的凝胶强度和粘度(P<0.05),其中,酸碱中和预处理可得然胶的粘度和凝胶强度更高,高速斩拌及碱溶的最适时间分别为5和15 min。随着高速斩拌、酸碱中和的可得然胶添加量的增加,低脂牛肉肠的蒸煮损失显著低于添加未处理可得然胶粉末的低脂牛肉肠(P<0.05),而非压出水分、保水性、硬度、咀嚼性、感官评分等均显著高于添加未处理可得然胶粉末的低脂牛肉肠(P<0.05),并且添加酸碱中和可得然胶的实验组效果更佳。因此,高速斩拌和酸碱中和预处理可以显著改善可得然胶的凝胶强度和粘度以及在低脂牛肉肠中的应用效果,并且酸碱中和预处理效果更佳。Abstract: In order to study the influence of different pretreatment methods on viscosity and gel strength of curdlan, investigate the effects of pretreated curdlan on water-holding capacity and texture properties of low fat beef sausage, the influence of high speed cutting and alkali-neutralization on viscosity and gel strength of curdlan was studied. Furthermore, in the preparation of the low fat beef sausage, curdlan pretreated by high speed cutting and alkali-neutralization was added at 0.1%, 0.3%, 0.5% and 0.7%. The effects were investigated by measuring cooking loss, water-holding capacity, textural properties and sensory score. The results showed that pretreatments of high speed cutting and alkali-neutralization enhanced viscosity and gel strength of curdlan significantly (P<0.05). Moreover, curdlan pretreated by alkali-neutralization showed higher viscosity and gel strength. Pretreatments of high speed cutting and alkali dissolving were optimal within 5 and 15 min respectively. Cooking loss of low fat beef sausage decreased significantly (P<0.05), non-expressible water, water-holding capacity, hardness, chewiness and sensory score of low fat beef sausage increased obviously with the increased addition of curdlan treated by high speed cutting and alkali-neutralization (P<0.05), in comparison to low fat beef sausage with non-treated curdlan powder. Furthermore, low fat beef sausage added curdlan treated by alkali-neutralization performed better in cooking loss, water-holding capacity, hardness, chewiness and sensory score. Therefore, pretreatments of high speed cutting and alkali-neutralization could be used to improve the viscosity, gel strength and application of curdlan effectively. Meanwhile, alkali-neutralization was the better one.

-

随着我国人均牛肉消费量的激增,牛肉加工品类也在不断丰富。低脂牛肉肠作为低温牛肉肉糜产品,能够充分利用牛肉分割过程中的碎肉,同时由于低胆固醇、高蛋白含量的营养特点备受消费者青睐[1]。但低脂牛肉肠存在脂肪或水分减少而导致适口性下降,感官品质劣变,如多汁性下降、切片性不佳、硬度降低和色泽变化等低脂肉制品的常见问题。低脂牛肉肠加工中常用植物蛋白、淀粉、亲水胶体等作为脂肪替代物,以减少蒸煮损失,改善产品质构[2-4]。

可得然胶由葡萄糖单体通过线性β-(1,3)糖苷键链接而成[5],能够根据不同的热处理条件形成低强度热可逆凝胶和高强度热不可逆凝胶[6],其独特的凝胶特性可以提高食品的食用品质[7],如改善食品的口感、质构和持水性等[8]。但是可得然胶不溶于水,这极大地影响了其在食品、医药和化妆品行业中的应用效果。迄今为止,可得然胶在鱼糜制品[9]、肠类[10]、西式火腿[11]、冷冻面条[12]等实际应用中多以粉末直接添加为主。近年来,国内外对可得然胶的预处理方法和添加方式进行了研究以期改善可得然胶的应用效果。Wu等[13]首次在重组带鱼凝胶中发现可得然胶以可逆凝胶的方式加入可以获得更好的凝胶强度,Jiang等[14]在法兰克福香肠中对比研究发现可得然胶以热可逆凝胶方式加入后能够与肌肉蛋白协同凝胶形成三维网状结构增强凝胶强度,而不可逆凝胶加入后只能相对独立的填充在肌肉凝胶中,此外在可得然胶的酶解中,相比于粉末可得然胶,经过加热及酸碱中和预处理后的可得然胶可以获得更高的水解效率[15-17]。

但是,不同预处理方法的可得然胶在牛肉制品中的应用研究尚未见报道。为了研究预处理方法对可得然胶的影响,探索经过预处理的可得然胶对低脂牛肉肠品质的影响,本研究将对比不同预处理方法的可得然胶粘度和凝胶强度,并探讨不同预处理可得然胶对低脂牛肉肠的加工特性,质构指标以及感官评分的影响,进而探索适合低脂牛肉肠生产的可得然胶的最佳预处理方法及添加量,为可得然胶在牛肉制品中的实际应用提供参考。

1. 材料与方法

1.1 材料与仪器

牛霖 上海市江杨南路批发市场;可得然胶 上海福乐贸易有限公司;食盐 上海中盐嘉青盐业有限公司;NaOH、HCl 分析纯,国药集团化学试剂有限公司;味精 上海味丹企业有限公司;D-异抗坏血酸钠 江西省德兴市百勤异VC钠有限公司;亚硝酸钠 湖北一航生物科技有限公司;呈味核苷酸二钠 希杰(聊城)生物科技有限公司;白胡椒粉、五香粉 上海味好美食品有限公司;复合磷酸盐 云南贝克吉利尼天创磷酸盐有限公司;葡萄糖、玉米淀粉 秦皇岛骊骅淀粉股份有限公司;纤维素肠衣 德国Kalle GmbH公司。

DV2T Viscometer粘度仪 美国Brookfield;CM-14斩拌机 西班牙MAINCA;TA-XT Plus型质构仪 英国Stable Micro Systems公司;FA25高速均质机 德国弗鲁克;KZ-50D蒸箱 佛山市德玛仕科技有限公司;JB-3磁力搅拌器 上海仪电科学仪器股份有限公司;TG16-WS台式高速离心机 上海卢湘仪离心机仪器有限公司。

1.2 实验方法

1.2.1 可得然胶的预处理

1.2.1.1 高速斩拌

将可得然胶分散于冰水中,分别高速斩拌1、3、5、7 min,控制料液温度不超过10 ℃,得到4%可得然胶的悬浮液,4 ℃冷藏待用。

1.2.1.2 酸碱中和处理

参考Li等[18]的方法略有改动:将可得然胶粉末缓慢加入到0.5 mol/L的NaOH溶液中,用磁力搅拌器在20 ℃分别搅拌0、15、30、60 min得到2% (w/v)不同碱溶时间的可得然胶碱溶液。随后向可得然胶碱溶液中缓慢滴加0.5 mol/L的HCl至pH中性。将所得可得然胶悬浮液以5000 r/min离心20 min,得到的可得然胶用5倍去离子水冲洗,如此重复3次。最后将可得然胶悬浮液调至4% (w/v),然后均质5 min,4 ℃冷藏待用。

1.2.2 可得然胶凝胶强度测定

取可得然胶粉末及预处理样品,参照国家标准GB 28304-2012[19]制备凝胶。采用TA-XT plus质构分析仪在凝胶强度的模式下采集数据,实验参数如下:探头型号为P/0.5,测试前速度、测试时速度、测试后速度均为1 mm/s,测试距离为10 mm,压缩比例50%,触发力为5 g。

1.2.3 可得然胶粘度测定

取可得然胶粉末及预处理样品,参照1.2.1制备悬浮液,然后用DV2T Visco-meter粘度仪测试样品粘度,粉末及高速斩拌处理组的测试条件:悬浮液温度20 ℃,1号转子,转子转速:30 r/min;酸碱中和处理组的测试条件:悬浮液温度20 ℃,2号转子,转子转速:6 r/min。

1.2.4 低脂牛肉肠的配方

参考彭增起等[20]的方法略有改动,低脂牛肉肠的配方如表1所示。

表 1 低脂牛肉肠的配方Table 1. Formula of low fat beef sausage配料 添加量(%) 配料 添加量(%) 牛霖 100 I+G 0.2 食盐 3.6 味精 0.8 亚硝酸钠 0.0015 五香粉 0.15 D-异抗坏血酸钠 0.06 白胡椒粉 0.15 复合磷酸盐 0.3 玉米淀粉 6 葡萄糖 2 冰水混合物 40 1.2.5 低脂牛肉肠的加工工艺

选用市售牛霖去除脂肪和筋膜,切成块后按配方要求加入食盐、葡萄糖、异抗坏血酸钠、亚硝酸钠、磷酸盐,混合均匀后置于0~4 ℃下腌制24 h。腌制后原料肉绞碎后加入冰水高速斩拌3 min之后,再分别加入0.1%、0.3%、0.5%、0.7%(可得然胶与总肉重的质量比)的不同预处理可得然胶、剩余碎冰,玉米淀粉,香辛料等辅料继续高速斩拌2 min。保持原料温度不超过10 ℃。斩拌充分后把原料填充到直径为45 mm的纤维素肠衣中,95 ℃蒸煮50 min。自然冷却至室温后,置于0~4 ℃冷藏,测定各项指标。

1.2.6 保水性测定

1.2.6.1 蒸煮损失(Cooking Losses, CL)

低脂牛肉肠在蒸煮前精确称量样品质量,低脂牛肉肠样品按照加工工艺的温度和时间进行蒸煮,待冷却至室温后,吸干表面水分,精确称量样品质量。蒸煮损失计算公式如下:

1.2.6.2 非压出水分(Non-expressible Water,NW)及保水性(Water-holding Capacity,WHC)

参照Thawatchai等[21]的方法,将牛肉肠切成10 mm厚度,称其质量为D,夹于上下各两层滤纸中,用TA-XT Plus质构仪进行挤压测试。挤压后称其质量为E,测定参数为:探头型号P50,保持10 kg压缩力压缩3 min,测前速率2.0 mm/s,测试速率0.5 mm/s,返回速率10.0 mm/s,触发力Auto-10 g。非压出水分及保水性计算公式如下:

1.2.7 质构分析

将肠切成2 cm长的圆柱,切面要平整垂直,每批制作10个平行样品。采用TA-XT plus质构分析仪进行全质构分析(Texture Profile Analysis,TPA),实验参数如下:探头型号为P/6,测试前速度为2 mm/s,测试时速度、测试后速度均为1 mm/s,压缩比例50%,触发力为5 g。

1.2.8 感官评定

参考Veli[22]的方法并做适当改动,邀请10名经过感官训练培训的评定员,其中5男5女,组成评定小组,采用双盲法进行检验。主要对产品的组织状态、多汁性、口感和整体可接受性进行评定。感官评价标准如表2所示。

表 2 感官评价标准Table 2. The standard of sensory evaluation评价指标 评分标准(满分9分) 7~9分 4~6分 1~3分 组织状态 切面光滑、

肉质紧密切面略粗糙、

肉质一般切面粗糙、肉质松散 多汁性 爽滑多汁 略湿润 湿润感弱,略粗糙 口感 肉质细腻,耐嚼,

弹性好肉质略微柴感、

弹性一般肉质有柴感、硬感、

弹性差整体可接受性 高(喜欢) 适中(接受) 低(不接受) 1.3 数据处理

本研究每组试验除特殊说明外均重复3次,结果以平均值±标准差表示。使用SPSS 23.0分析、Origin 2018作图,多重比较误差使用Duncan、LSD法表示,显著水平(P<0.05)。

2. 结果与分析

2.1 不同预处理对可得然胶粘度、凝胶强度的影响

2.1.1 高速斩拌预处理对可得然胶粘度、凝胶强度的影响

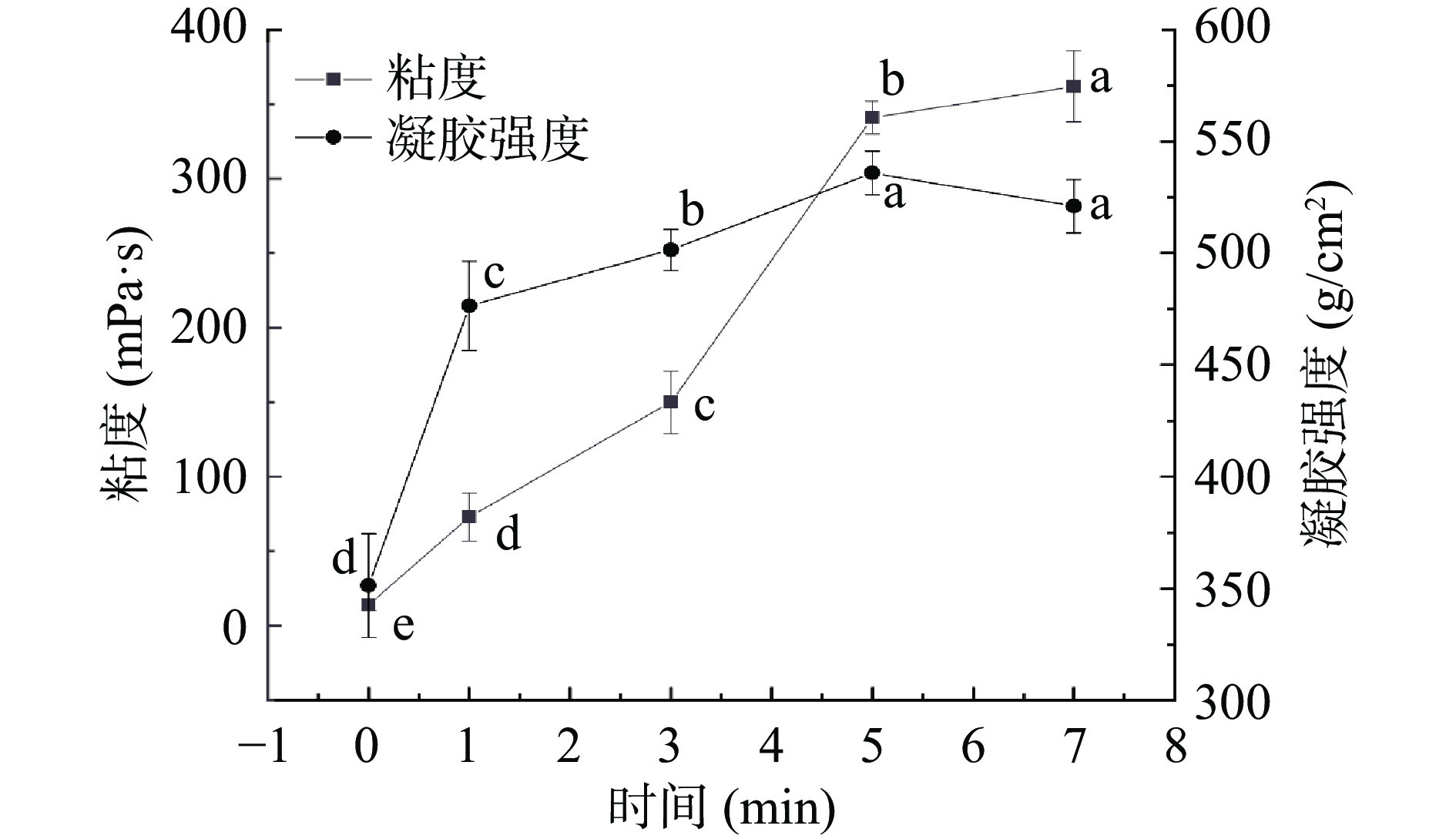

由图1可知,可得然胶的凝胶强度随着斩拌时间的增加而显著提升(P<0.05),粘度也迅速提高。可得然胶的水不溶性主要是由于可得然胶分子内和分子间的氢键形成的结晶区所致[23]。通过高速斩拌,可得然胶分子之间的分子链缠结点迅速被打开并来不及恢复[24],这有利于可得然胶与水分子通过氢键结合加速溶胀,粘度也随之上升,通过加热,可得然胶分子可以形成更多的三螺旋结构从而使其凝胶强度不断增加[11]。由于斩拌5 min以后凝胶强度和粘度变化不大,同时为避免斩拌升温,所以高速斩拌时间定为5 min。

![]() 图 1 高速斩拌预处理对可得然胶的粘度和凝胶强度的影响注:不同字母表示同一指标间差异显著(P<0.05),图2同。Figure 1. Effect of high speed cutting on viscosity and gel strength of curdlan

图 1 高速斩拌预处理对可得然胶的粘度和凝胶强度的影响注:不同字母表示同一指标间差异显著(P<0.05),图2同。Figure 1. Effect of high speed cutting on viscosity and gel strength of curdlan2.1.2 酸碱中和预处理对可得然胶的粘度、凝胶强度的影响

由图2可知,酸碱中和预处理对可得然胶的粘度和凝胶强度具有明显影响。一方面酸碱中和预处理后的粘度和强度明显高于对照、高速斩拌预处理组,这是由于氢氧化钠对可得然胶氢键的破坏更为充分,可得然胶分子加热后几乎都形成了三螺旋结构,而且螺旋之间距离变小,每个螺旋间作用力显著增强所致[11];但另一方面,在60 min内不同碱溶时间的可得然胶凝胶强度和中和后粘度无明显差异。说明可得然胶颗粒在碱液中均完全溶解,与叶剑等[25]的结果一致。但为了方便操作提升效率,后续实验中碱溶时间定为15 min。

2.2 不同预处理可得然胶添加量对低脂牛肉肠保水性的影响

蒸煮损失和保水性是决定低脂牛肉肠持水特性的重要指标。由表3可以看出,与对照组相比,随着可得然胶添加量的增加,粉末,高速斩拌及酸碱中和预处理三个实验组牛肉肠的蒸煮损失显著降低(P<0.05),非压出水分及保水性显著升高(P<0.05),这在牛肉饼[26],猪肉肠[27]中也有相应的报道。

表 3 不同预处理可得然胶添加量对低脂牛肉肠保水性的影响Table 3. Water-holding capacity of low fat beef sausage added with different concentration of curdlan评价

指标处理组 可得然胶添加量(%) 0.0 0.1 0.3 0.5 0.7 蒸煮

损失(%)粉末直接添加组 20.29±2.29a 19.58±0.52b 17.13±0.71d 16.70±1.52e 15.83±0.76f 高速斩拌处理组 20.29±2.29a 18.02±0.84c 16.27±0.15e 14.44±0.13h 14.20±0.26h 酸碱中和处理组 20.29±2.29a 15.23±0.14g 13.62±0.12i 11.16±0.07j 11.09±0.91j 非压出水分(%) 粉末直接添加组 90.17±1.26g 92.07±0.40f 94.60±0.53e 96.23±0.49d 97.50±0.70b 高速斩拌处理组 90.17±1.26g 93.20±0.82e 96.50±0.50d 97.57±1.16b 98.17±0.15a 酸碱中和处理组 90.17±1.26g 94.07±1.53e 96.73±0.49c 98.03±0.85a 98.77±0.51a 保水性(%) 粉末直接添加组 71.88±2.48g 74.04±0.39g 78.39±0.82e 80.16±1.18d 82.07±1.30c 高速斩拌处理组 71.88±2.48g 76.40±0.26f 80.80±0.56d 83.47±0.94b 84.23±0.16b 酸碱中和处理组 71.88±2.48g 79.74±1.35d 83.56±0.44b 87.09±0.72a 87.81±0.44a 注:不同字母表示同一评价指标差异显著(P<0.05),表4~表5同。 本文中不同预处理实验组之间也存在显著差异(P<0.05)。其中,高速斩拌及酸碱中和预处理实验组的蒸煮损失、非压出水分和保水性指标均显著优于粉末直接添加实验组(P<0.05),并且酸碱中和预处理实验组表现最佳。一方面这可能是由于可得然胶能束缚住更多的水分,从而可以有效地减少牛肉肠在蒸煮过程中水分的流失[28];另一方面,高速斩拌能够部分破坏可得然胶分子间和分子内部的氢键促进可得然胶的水合[29],而酸碱中和处理后的可得然胶无规则卷曲增加,分子粒径更小且形成了水合层覆盖在分子表面导致其具有更强的持水性能[18]。由此可见,添加高速斩拌及酸碱中和预处理的可得然胶更有效地提高了低脂牛肉肠的加工特性,进而改善香肠的整体品质,提升了产品出品率。

2.3 不同预处理可得然胶添加量对低脂牛肉肠质构的影响

不同可得然胶添加量对低脂牛肉肠质构的影响如表4所示,与对照组相比,随着不同处理方法的可得然胶添加量的添加,低脂牛肉肠的硬度,咀嚼性显著增强(P<0.05),与Lee等[10]及Kimura等[30]的结果一致。其中,高速斩拌及酸碱中和预处理实验组的硬度、咀嚼性均显著高于粉末直接添加实验组(P<0.05),并且酸碱中和预处理实验组最高,这与对加工特性的影响结果一致。

表 4 不同预处理可得然胶添加量对低脂牛肉肠质构特性的影响Table 4. Texture profiles of low fat beef sausage added with different concentration of curdlan评价

指标处理组 可得然胶添加量(%) 0.0 0.1 0.3 0.5 0.7 硬度 (g) 粉末直接添加组 1072.97±16.45g 1103.24±16.67g 1203.92±64.68f 1407.06±16.20d 1641.95±44.23b 高速斩拌处理组 1072.97±16.45g 1182.08±61.72f 1312.91±10.56e 1492.46±33.12c 1682.64±81.66b 酸碱中和处理组 1072.97±16.45g 1198.14±39.97f 1387.27±29.30d 1516.92±96.20c 1774.82±71.63a 粉末直接添加组 0.93±0.03a 0.91±0.05a 0.94±0.03a 0.90±0.01a 0.91±0.05a 弹性 高速斩拌处理组 0.93±0.03a 0.94±0.02a 0.93±0.06a 0.91±0.05a 0.89±0.08a 酸碱中和处理组 0.93±0.03a 0.95±0.06a 0.91±0.01a 0.89±0.08a 0.89±0.03a 咀嚼性(g) 粉末直接添加组 762.87±70.47f 709.03±46.20f 793.84±26.98e 980.48±34.24c 1073.49±93.94b 高速斩拌处理组 762.87±70.47f 860.69±79.44e 903.94±15.78d 994.71±29.56b 1108.40±78.46a 酸碱中和处理组 762.87±70.47f 860.43±39.15e 981.04±35.96c 1021.62±45.22b 1202.13±67.08a 粉末直接添加组 0.77±0.06a 0.71±0.02a 0.71±0.04a 0.77±0.03a 0.72±0.04a 内聚性 高速斩拌处理组 0.77±0.06a 0.78±0.04a 0.74±0.01a 0.73±0.02a 0.74±0.02a 酸碱中和处理组 0.77±0.06a 0.76±0.05a 0.78±0.01a 0.76±0.03a 0.76±0.03a 大量研究表明,可得然胶能够明显提升肌原纤维的水分保持能力,增强肌肉蛋白的凝胶强度,进而改善肉糜[31]和鱼糜[9]的食用品质。在凝胶机理上,Hu等[32]则进一步发现,可得然胶与肌球蛋白混合凝胶中的氢键的作用力增强改善了肌球蛋白的凝胶。在微观结构上,研究人员证实可得然胶以热可逆凝胶方式加入后能够穿透到肌肉蛋白的网状结构中并促使凝胶形成孔洞均一而且更加细小紧密网状结构[13-14]。

综上所述,酸碱中和预处理的可得然胶粒径更小,更易穿透到肌肉蛋白的网状结构中,而且三螺旋结构解离形成的水合层与肌球蛋白形成氢键的位点增多[18],这可能是酸碱中和预处理实验组硬度和咀嚼性更强的原因。

在高速斩拌、酸碱中和的可得然胶添加量从0.1%增加到0.7%时,低脂牛肉肠的硬度和咀嚼性显著提升(P<0.05),由此说明,0.1%及以上的预处理可得然胶的添加就能够显著提高低脂牛肉肠的质构特性。

2.4 不同预处理可得然胶添加量对低脂牛肉肠感官品质的影响

由表5可以看出,与对照组相比,随着可得然胶浓度的增加,肠体组织状态、多汁性,口感和总体可接受性均呈上升趋势,其中,高速斩拌和酸碱中和预处理实验组的组织状态、口感和总体接受性显著提升且优于粉末可得然胶实验组(P<0.05)。对照组产品组织松散,切面出现较多孔洞,口感柴,弹性和咀嚼性较差,无多汁感,总体接受性差。由此可知,随着高速斩拌及酸碱中和预处理可得然胶浓度的增加,低脂牛肉肠的组织更紧密、口感更好,整体可接受性更高,低脂牛肉肠的感官特性得到明显改善,并且酸碱中和预处理实验组表现最佳。这一结果也与质构分析的结果相一致。

表 5 不同预处理方法的可得然胶对低脂牛肉肠感官评分的影响(分)Table 5. Sensory quality of low fat beef sausage added with different concentration of curdlan (score)评价

指标处理组 可得然胶添加量(%) 0.0 0.1 0.3 0.5 0.7 组织

状态粉末直接添加组 6.05±0.16f 6.45±0.40e 7.13±0.47b 7.33±0.25a 7.43±0.18a 高速斩拌处理组 6.05±0.16f 6.58±0.38d 7.26±0.28a 7.43±0.19a 7.53±0.23a 酸碱中和处理组 6.05±0.16f 6.83±0.24c 7.31±0.27a 7.48±0.35a 7.58±0.24a 粉末直接添加组 6.03±0.12d 6.35±0.25c 6.95±0.28b 6.95±0.28b 7.08±0.23a 多汁性 高速斩拌处理组 6.03±0.12d 6.52±0.32c 7.03±0.16a 7.10±0.21a 7.24±0.33a 酸碱中和处理组 6.03±0.12d 6.59±0.34c 7.12±0.21a 7.22±0.25a 7.34±0.32a 粉末直接添加组 6.00±0.24c 6.13±0.28c 6.48±0.30c 7.02±0.48b 7.12±0.57a 口感 高速斩拌处理组 6.00±0.24c 6.35±0.28c 7.07±0.44b 7.27±0.25a 7.19±0.23a

整体可接受性酸碱中和处理组 6.00±0.24c 6.45±0.32c 7.14±0.21a 7.34±0.22a 7.42±0.18a 粉末直接添加组 6.05±0.16d 6.15±0.24d 6.65±0.41c 7.15±0.24b 7.19±0.26a 高速斩拌处理组 6.05±0.16d 6.30±0.35d 7.05±0.16b 7.30±0.26a 7.25±0.35a 酸碱中和处理组 6.05±0.16d 6.35±0.34c 7.12±0.21b 7.32±0.24a 7.50±0.33a 2.5 低脂牛肉肠理化指标间的相关性分析

试验针对低脂牛肉肠的理化指标进行相关性分析,结果如表6所示。一方面,保水性与硬度、咀嚼性和整体可接受性呈显著正相关(P<0.05),与组织状态、多汁性、口感呈极显著正相关(P<0.01)。另一方面,硬度与咀嚼性呈极显著正相关(P<0.01),与组织状态、多汁性、口感及整体可接受性呈显著正相关(P<0.05)。

表 6 低脂牛肉肠理化指标间的相关性分析Table 6. Correlation analysis among physicochemical indexes in low fat beef sausage指标 蒸煮损失 非挤压出水 保水性 硬度 弹性 咀嚼性 内聚性 组织状态 多汁性 口感 整体可接受性 蒸煮损失 1 −0.990** −0.998** −0.892* 0.720 −0.893* 0.347 −0.989** −0.977** −0.964** −0.938* 非挤压出水 1 0.997** 0.921* −0.769 0.926* −0.242 0.997** 0.996** 0.988** 0.972** 保水性 1 0.912* −0.752 0.914* −0.303 0.995** 0.988** 0.979** 0.959* 硬度 1 −0.847 0.996** −0.328 0.893* 0.909* 0.923* 0.947* 弹性 1 −0.810 0.086 −0.732 −0.777 −0.846 −0.889* 咀嚼性 1 −0.288 0.903* 0.918* 0.923* 0.943* 内聚性 1 −0.213 −0.159 −0.149 −0.139 组织状态 1 0.996** 0.981** 0.958* 多汁性 1 0.993** 0.977** 口感 1 0.994** 整体可接受性 1 注:*表示在P=0.05显著相关(双尾);**表示在P=0.01极显著相关(双尾)。 3. 结论

本文首先研究了高速斩拌和酸碱中和两种预处理方法对可得然胶的粘度、凝胶强度的影响,实验发现高速斩拌和酸碱中和预处理能够显著提升可得然胶的凝胶强度和粘度(P<0.05),并且酸碱中和预处理可得然胶粘度和凝胶强度更高,高速斩拌及碱溶的最适时间分别为5 和15 min。然后在此基础上,进一步研究了高速斩拌和酸碱中和两种预处理的可得然胶在低脂牛肉肠加工中的应用效果。结果表明:相比于添加未处理可得然胶粉末的低脂牛肉肠,添加高速斩拌和酸碱中和预处理的可得然胶粉末的低脂牛肉肠蒸煮损失显著降低(P<0.05),而非挤压出水、保水性、硬度、咀嚼性和感官评分均显著提升(P<0.05),并且添加酸碱中和可得然胶的实验组更佳,与凝胶强度及粘度测试结果一致。由此可知,高速斩拌和酸碱中和预处理可以显著提升可得然胶的凝胶强度和粘度,明显改善可得然胶在低脂牛肉肠中的应用效果且酸碱中和预处理效果更佳。

-

图 1 高速斩拌预处理对可得然胶的粘度和凝胶强度的影响

注:不同字母表示同一指标间差异显著(P<0.05),图2同。

Figure 1. Effect of high speed cutting on viscosity and gel strength of curdlan

表 1 低脂牛肉肠的配方

Table 1 Formula of low fat beef sausage

配料 添加量(%) 配料 添加量(%) 牛霖 100 I+G 0.2 食盐 3.6 味精 0.8 亚硝酸钠 0.0015 五香粉 0.15 D-异抗坏血酸钠 0.06 白胡椒粉 0.15 复合磷酸盐 0.3 玉米淀粉 6 葡萄糖 2 冰水混合物 40 表 2 感官评价标准

Table 2 The standard of sensory evaluation

评价指标 评分标准(满分9分) 7~9分 4~6分 1~3分 组织状态 切面光滑、

肉质紧密切面略粗糙、

肉质一般切面粗糙、肉质松散 多汁性 爽滑多汁 略湿润 湿润感弱,略粗糙 口感 肉质细腻,耐嚼,

弹性好肉质略微柴感、

弹性一般肉质有柴感、硬感、

弹性差整体可接受性 高(喜欢) 适中(接受) 低(不接受) 表 3 不同预处理可得然胶添加量对低脂牛肉肠保水性的影响

Table 3 Water-holding capacity of low fat beef sausage added with different concentration of curdlan

评价

指标处理组 可得然胶添加量(%) 0.0 0.1 0.3 0.5 0.7 蒸煮

损失(%)粉末直接添加组 20.29±2.29a 19.58±0.52b 17.13±0.71d 16.70±1.52e 15.83±0.76f 高速斩拌处理组 20.29±2.29a 18.02±0.84c 16.27±0.15e 14.44±0.13h 14.20±0.26h 酸碱中和处理组 20.29±2.29a 15.23±0.14g 13.62±0.12i 11.16±0.07j 11.09±0.91j 非压出水分(%) 粉末直接添加组 90.17±1.26g 92.07±0.40f 94.60±0.53e 96.23±0.49d 97.50±0.70b 高速斩拌处理组 90.17±1.26g 93.20±0.82e 96.50±0.50d 97.57±1.16b 98.17±0.15a 酸碱中和处理组 90.17±1.26g 94.07±1.53e 96.73±0.49c 98.03±0.85a 98.77±0.51a 保水性(%) 粉末直接添加组 71.88±2.48g 74.04±0.39g 78.39±0.82e 80.16±1.18d 82.07±1.30c 高速斩拌处理组 71.88±2.48g 76.40±0.26f 80.80±0.56d 83.47±0.94b 84.23±0.16b 酸碱中和处理组 71.88±2.48g 79.74±1.35d 83.56±0.44b 87.09±0.72a 87.81±0.44a 注:不同字母表示同一评价指标差异显著(P<0.05),表4~表5同。 表 4 不同预处理可得然胶添加量对低脂牛肉肠质构特性的影响

Table 4 Texture profiles of low fat beef sausage added with different concentration of curdlan

评价

指标处理组 可得然胶添加量(%) 0.0 0.1 0.3 0.5 0.7 硬度 (g) 粉末直接添加组 1072.97±16.45g 1103.24±16.67g 1203.92±64.68f 1407.06±16.20d 1641.95±44.23b 高速斩拌处理组 1072.97±16.45g 1182.08±61.72f 1312.91±10.56e 1492.46±33.12c 1682.64±81.66b 酸碱中和处理组 1072.97±16.45g 1198.14±39.97f 1387.27±29.30d 1516.92±96.20c 1774.82±71.63a 粉末直接添加组 0.93±0.03a 0.91±0.05a 0.94±0.03a 0.90±0.01a 0.91±0.05a 弹性 高速斩拌处理组 0.93±0.03a 0.94±0.02a 0.93±0.06a 0.91±0.05a 0.89±0.08a 酸碱中和处理组 0.93±0.03a 0.95±0.06a 0.91±0.01a 0.89±0.08a 0.89±0.03a 咀嚼性(g) 粉末直接添加组 762.87±70.47f 709.03±46.20f 793.84±26.98e 980.48±34.24c 1073.49±93.94b 高速斩拌处理组 762.87±70.47f 860.69±79.44e 903.94±15.78d 994.71±29.56b 1108.40±78.46a 酸碱中和处理组 762.87±70.47f 860.43±39.15e 981.04±35.96c 1021.62±45.22b 1202.13±67.08a 粉末直接添加组 0.77±0.06a 0.71±0.02a 0.71±0.04a 0.77±0.03a 0.72±0.04a 内聚性 高速斩拌处理组 0.77±0.06a 0.78±0.04a 0.74±0.01a 0.73±0.02a 0.74±0.02a 酸碱中和处理组 0.77±0.06a 0.76±0.05a 0.78±0.01a 0.76±0.03a 0.76±0.03a 表 5 不同预处理方法的可得然胶对低脂牛肉肠感官评分的影响(分)

Table 5 Sensory quality of low fat beef sausage added with different concentration of curdlan (score)

评价

指标处理组 可得然胶添加量(%) 0.0 0.1 0.3 0.5 0.7 组织

状态粉末直接添加组 6.05±0.16f 6.45±0.40e 7.13±0.47b 7.33±0.25a 7.43±0.18a 高速斩拌处理组 6.05±0.16f 6.58±0.38d 7.26±0.28a 7.43±0.19a 7.53±0.23a 酸碱中和处理组 6.05±0.16f 6.83±0.24c 7.31±0.27a 7.48±0.35a 7.58±0.24a 粉末直接添加组 6.03±0.12d 6.35±0.25c 6.95±0.28b 6.95±0.28b 7.08±0.23a 多汁性 高速斩拌处理组 6.03±0.12d 6.52±0.32c 7.03±0.16a 7.10±0.21a 7.24±0.33a 酸碱中和处理组 6.03±0.12d 6.59±0.34c 7.12±0.21a 7.22±0.25a 7.34±0.32a 粉末直接添加组 6.00±0.24c 6.13±0.28c 6.48±0.30c 7.02±0.48b 7.12±0.57a 口感 高速斩拌处理组 6.00±0.24c 6.35±0.28c 7.07±0.44b 7.27±0.25a 7.19±0.23a

整体可接受性酸碱中和处理组 6.00±0.24c 6.45±0.32c 7.14±0.21a 7.34±0.22a 7.42±0.18a 粉末直接添加组 6.05±0.16d 6.15±0.24d 6.65±0.41c 7.15±0.24b 7.19±0.26a 高速斩拌处理组 6.05±0.16d 6.30±0.35d 7.05±0.16b 7.30±0.26a 7.25±0.35a 酸碱中和处理组 6.05±0.16d 6.35±0.34c 7.12±0.21b 7.32±0.24a 7.50±0.33a 表 6 低脂牛肉肠理化指标间的相关性分析

Table 6 Correlation analysis among physicochemical indexes in low fat beef sausage

指标 蒸煮损失 非挤压出水 保水性 硬度 弹性 咀嚼性 内聚性 组织状态 多汁性 口感 整体可接受性 蒸煮损失 1 −0.990** −0.998** −0.892* 0.720 −0.893* 0.347 −0.989** −0.977** −0.964** −0.938* 非挤压出水 1 0.997** 0.921* −0.769 0.926* −0.242 0.997** 0.996** 0.988** 0.972** 保水性 1 0.912* −0.752 0.914* −0.303 0.995** 0.988** 0.979** 0.959* 硬度 1 −0.847 0.996** −0.328 0.893* 0.909* 0.923* 0.947* 弹性 1 −0.810 0.086 −0.732 −0.777 −0.846 −0.889* 咀嚼性 1 −0.288 0.903* 0.918* 0.923* 0.943* 内聚性 1 −0.213 −0.159 −0.149 −0.139 组织状态 1 0.996** 0.981** 0.958* 多汁性 1 0.993** 0.977** 口感 1 0.994** 整体可接受性 1 注:*表示在P=0.05显著相关(双尾);**表示在P=0.01极显著相关(双尾)。 -

[1] LI X Z, YAN C G, ZAN L S. Current situation and future prospects for beef production in China-a review[J]. Asian-Australasian Journal of Animal Sciences,2020,31(7):984−991.

[2] YI H C, CHO H, HONG J J, et al. Physicochemical and organoleptic characteristics of seasoned beef patties with added glutinous rice flour[J]. Meat Science,2012,92:464−468. doi: 10.1016/j.meatsci.2012.05.012

[3] TAHMASEBI M, LABBAFI M, EMAM D Z, et al. Manufacturing the novel sausages with reduced quantity of meat and fat: The product development, formulation optimization, emulsion stability and textural characterization[J]. LWT-Food Science and Technology,2016,68:76−84. doi: 10.1016/j.lwt.2015.12.011

[4] JAILSON P, HU H Y, XING L J, et al. Influence of rice flour, glutinous rice flour, and tapioca starch on the functional properties and quality of an emulsion-type cooked sausage[J]. Foods,2019,9(9):1−12.

[5] HATAKEYAMA T, IIJIMA M, HATAKEYAMA H. Role of bound water on structural change of water insoluble polysaccharides[J]. Food Hydrocolloids,2016,53:62−68. doi: 10.1016/j.foodhyd.2014.12.033

[6] FUNAMI T, YADA H, NAKAO Y. Curdlan properties for application in fat mimetics for meat products[J]. Journal of Food Science,1998,63:283−287.

[7] 丛峰松, 张洪斌, 张维杰. 可德胶及其在食品和医药领域上的应用[J]. 食品科学,2004,25(11):432−435. [CONG F S, ZHANG H B, ZHANG W J. The properties of curdlan and its applications in food and pharmaceutical fields[J]. Food Science,2004,25(11):432−435. doi: 10.3321/j.issn:1002-6630.2004.11.114 CONG F S, ZHANG H B, ZHANG W J. The properties of curdlan and its applications in food and pharmaceutical fields[J]. Food Science, 2004, 25(11): 432-435. doi: 10.3321/j.issn:1002-6630.2004.11.114

[8] LI Q R, WANG P S, MIAO S, et al. Curdlan enhances the structure of myosin gel model[J]. Food Science & Nutrition,2019,7(6):2123−2130.

[9] WEI Y, ZHANG T, YU F, et al. Effects of curdlan on the texture and structure of Alaska pollock surimi gels treated at 120 ℃[J]. International Journal of Food Properties,2018,21(1):1778−1788. doi: 10.1080/10942912.2017.1306557

[10] LEE C H, CHIN K B. Evaluation of physicochemical and textural properties of myofibrillar protein gels and low-fat model sausage containing various levels of curdlan[J]. Asian-Australasian Journal of Animal Sciences,2019,32(1):144−151. doi: 10.5713/ajas.18.0585

[11] 赵冰, 李家鹏, 陈文华, 等. 可得然胶凝胶特性及其在西式火腿中的应用研究[J]. 食品科学,2014,35(21):45−49. [ZHAO B, LI J P, CHEN W H, et al. Gel properties of curdlan gum and its application in western-style ham[J]. Food Science,2014,35(21):45−49. doi: 10.7506/spkx1002-6630-201421010 ZHAO B, LI J P, CHEN W H, et al. Gel properties of curdlan gum and its application in western-style ham[J]. Food Science, 2014, 35(21): 45-49. doi: 10.7506/spkx1002-6630-201421010

[12] LIANG Y, QU Z, LIU M, et al. Effect of curdlan on the quality of frozen-cooked noodles during frozen storage[J]. Journal of Cereal Science,2020,95:1−8.

[13] WU C H, YUAN C H, CHEN S G, et al. The effect of curdlan on the rheological properties of restructured ribbonfish (Trichiurus spp.) meat gel[J]. Food Chemistry,2015,179:222−231. doi: 10.1016/j.foodchem.2015.01.125

[14] JIANG S, CAO C A, XIA X F, et al. Enhancement of the textural and gel properties of frankfurters by adding thermo-reversible or thermo-irreversible curdlan gels[J]. Journal of Food Science,2019,84:1068−1077. doi: 10.1111/1750-3841.14595

[15] FU Y, CHENG L, MENG Y, et al. Cellulosimicrobium cellulans strain E4-5 enzymatic hydrolysis of curdlan for production of (1→3)-linked beta-D-glucan oligosaccharides[J]. Carbohydrate Polymers,2015,134:740−744. doi: 10.1016/j.carbpol.2015.08.019

[16] KOBAYASHI T, UCHIMURA K, KUBOTA T, et al. Biochemical and genetic characterization of beta-1, 3 glucanase from a deep subseafloor Laceyella putida[J]. Applied Microbiology and Biotechnology,2016,100(1):203−214. doi: 10.1007/s00253-015-6983-5

[17] KUMAGAI Y, OKUYAMA M, KIMURA A. Heat treatment of curdlan enhances the enzymatic production of biologically active beta-(1, 3)-glucan oligosaccharides[J]. Carbohydrate Polymers,2016,146:396−401. doi: 10.1016/j.carbpol.2016.03.066

[18] LI J, ZHU L, ZHENG Z Y, et al. A new effective process for production of curdlan oligosaccharides based on alkali-neutralization treatment and acid hydrolysis of curdlan particles in water suspension[J]. Applied Microbiology and Biotechnology,2013,97(19):8495−8503. doi: 10.1007/s00253-013-5125-1

[19] 中华人民共和国卫生部. GB 28304—2012 食品安全国家标准食品添加剂可得然胶[S]. 北京: 中国标准出版社, 2012. Ministry of Health, PRC. GB 28304-2012 National standard for food safety, food additive curdlan[S]. Beijing: China Standards Press, 2012

[20] 彭增起, 周光宏, 徐幸莲. 磷酸盐混合物和加水量对低脂牛肉灌肠硬度和保水性的影响[J]. 食品工业科技,2003,24(3):38−40. [PENG Z Q, ZHOU G H, XU X L. Effect of phosphate mixture and water addition on hardness and water-holding capacity of low fat beef sausage[J]. Science and Technology of Food Industry,2003,24(3):38−40. doi: 10.3969/j.issn.1002-0306.2003.03.016 PENG Z Q, ZHOU G H, XU X L. Effect of phosphate mixture and water addition on hardness and water-holding capacity of low fat beef sausage[J]. Science and Technology of Food Industry, 2003, 24(3): 38-40. doi: 10.3969/j.issn.1002-0306.2003.03.016

[21] THAWATCHAI S, ARUNEE A. Combination effects of ultra-high pressure and temperature on the physical and thermal properties of ostrich meat sausage (yor)[J]. Meat Science,2007,76(3):555−560. doi: 10.1016/j.meatsci.2007.01.007

[22] VELI G, ERSEL O, LEVENT A. Effects of packaging method and storage time on the chemical, microbiological, and sensory properties of Turkish pastirma-a dry cured beef product[J]. Meat Science,2008,80(2):335−344. doi: 10.1016/j.meatsci.2007.12.017

[23] XIAO M, JIANG M F, WU K, et al. Investigation on curdlan dissociation by heating in water[J]. Food Hydrocolloids,2017,70:57−64. doi: 10.1016/j.foodhyd.2017.03.018

[24] 金阳. 可德胶(Curdlan)多糖分子构象及其衍生物的研究[D]. 上海: 上海交通大学, 2006. JIN Y. Study on molecular conformation and derivatives of curdlan[D]. Shanghai: Shanghai Jiaotong University, 2006.

[25] 叶剑, 郑志永, 詹晓北, 等. 热凝胶在碱溶过程的流变学和质构学行为分析[J]. 食品与发酵工业,2018,44(11):82−88. [YE J, ZHENG Z Y, ZHAN X B, et al. Rheological and texture behavior analysis of curdlan during alkaline dissolution process[J]. Food and Fermentation Industries,2018,44(11):82−88. YE J, ZHENG Z Y, ZHAN X B, et al. Rheological and texture behavior analysis of curdlan during alkaline dissolution process[J]. Food and Fermentation Industries, 2018, 44(11): 82-88.

[26] AFSHARI R, HOSSEINI H, KHAKSAR R, et al. Investigation of the effects of inulin and β-glucan on the physical and sensory properties of low-fat beef burgers containing vegetable oils: Optimisation of the formulation using D-optimal mixture design[J]. Food Technology and Biotechnology,2015,53(4):436−445.

[27] LEE C H, CHIN K B. Evaluation of various salt contents on quality characteristics with or without curdlan of pork myofibrillar protein gels and the development of low‐salt pork sausages[J]. International Journal of Food Science & Technology,2019,54(2):550−557.

[28] 姜帅, 牛海力, 刘骞等. 添加可得然胶对法兰克福香肠品质特性的影响[J]. 食品工业科技,2017,38(19):218−226. [JIANG S, NIU H L, LIU Q, et al. Effect of curdlan addition on the quality of Frankfurt sausage[J]. Science and Technology of Food Industry,2017,38(19):218−226. JIANG S, NIU H L, LIU Q, et al. Effect of curdlan addition on the quality of Frankfurt sausage[J]. Science and Technology of Food Industry, 2017, 38(19): 218-226.

[29] 汪利文, 朱莉, 詹晓北. 一种新型复合凝胶的制备、特性表征及机理研究[J]. 食品与发酵工业,2019,45(11):1−6. [WANG L W, ZHU L, ZHAN X B. Preparation, characterization, and mechanisms of a novel composite gel[J]. Food and Fermentation Industries,2019,45(11):1−6. WANG L W, ZHU L, ZHAN X B. Preparation, characterization, and mechanisms of a novel composite gel[J]. Food and Fermentation Industries, 2019, 45(11): 1-6.

[30] KIMURA H, MORITAKA S, MISAKI M. Polysaccharide 13140: A new thermo-gelable polysaccharide[J]. Journal of Food Science,1973,38(4):668−670. doi: 10.1111/j.1365-2621.1973.tb02841.x

[31] FUNAMI T, YADA H, NAKAO Y. Thermal and rheological properties of curdlan gel in minced pork gel[J]. Food Hydrocolloids,1998,12(1):55−64. doi: 10.1016/S0268-005X(98)00045-9

[32] HU Y, LIU W, YUAN C, et al. Enhancement of the gelation properties of hairtail (Trichiurus haumela) muscle protein with curdlan and transglutaminase[J]. Food Chemistry,2015,176:115−122. doi: 10.1016/j.foodchem.2014.12.006

-

期刊类型引用(6)

1. 刘世昌,赵妍,刘旭光,龚志刚,吕好新. 不同温度对偏高水分玉米储藏品质变化规律的影响. 食品研究与开发. 2024(06): 40-47 .  百度学术

百度学术

2. 赵品,范磊,燕照玲,韩启忠,苏磊,李建林. 有机鲜食玉米规范化种植及发展思考. 种业导刊. 2024(02): 3-6 .  百度学术

百度学术

3. 赵琳,陈玉,骆乐谈,石江,王道泽. 不同保鲜方式下鲜食玉米品质变化规律的研究. 食品安全质量检测学报. 2024(08): 22-32 .  百度学术

百度学术

4. 李妍婷,张荣,姚研强,唐朝臣,韩金玲,王章英. 六个不同品种鲜食甘薯贮藏品质变化. 广东农业科学. 2024(08): 80-91 .  百度学术

百度学术

5. 邵子晗,张玮,宋玉,洪莹,陶澍,刘超,郄雪娇,龚勋,阮龙,曹磊. 鲜食糯玉米及其亲本贮藏过程中淀粉回生特性的研究. 玉米科学. 2024(08): 47-54 .  百度学术

百度学术

6. 马正龙,石占军,郑高山,范兴忠,张正洁,杨文霞. 鲜食糯玉米新品种酒糯5006的选育及栽培和制种技术. 农业科技通讯. 2024(12): 141-143+146 .  百度学术

百度学术

其他类型引用(2)

下载:

下载:

下载:

下载: