Optimization of Steam Microwave Curing Process by Response Surface-Principal Component Analysis

-

摘要: 本文以新疆天山特一粉及相关添加剂为原料,以剪切力(延展性、硬度、咀嚼性)、蒸煮特性(吸水指数、烹调损失率)、淀粉糊化度、感官评价为评价指标进行单因素实验及相关性分析,探究微波火力、蒸汽微波熟化时间、蒸汽量对面片品质的影响,在此基础上,结合响应面与主成分分析法优化面片的蒸汽微波熟化工艺。结果表明:微波火力为60%、蒸汽微波熟化时间为3 min、蒸汽量为12 L熟化面片,在此条件下,其延展性为98.155 g·s硬度为2204.46 g、咀嚼性为5200.52 g·s、吸水指数为142.516%、蒸煮损失率为2.79%、感官得分为91.8分、规范化综合得分为0.946,与预测的数值基本一致。本试验通过响应面-主成分分析法优化面片的蒸汽微波熟化工艺对实际生产具有指导意义。Abstract: In the experiment, used Xinjiang Tianshan Special Flour and related additives as raw materials with shear force (ductility, hardness, chewability) and cooking characteristics (water absorption index, cooking loss rate), starch gelatinization degree and sensory evaluation as evaluation indices. The effects on microwave firepower, steam microwave curing time and steam quantity on dough slice quality, on the basis, the steam microwave curing process was optimized by combining response surface and principal component analysis. The results show that: Under the conditions of 60% microwave power, 3 min steam microwave curing time and 12 L steam quantity, ductility was 98.155 g·s, hardness was 2204.46 g, chewability was 5200.52 g·s, water absorption index was 142.516%, cooking loss rate was 2.79%, sensory score was 91.8 and standardized score was 0.946, which were basically consistent with the predicted value. Through the experiment, steam microwave curing process was optimized by response surface analysis (RSM) and principal component analysis (PCA), which had guiding significance for practical production.

-

汤饭“揪片子”是新疆特色民族美食,极大体现了西北餐饮的特色,以面片为主,汤料为羊肉汤,配料为各类蔬菜例如洋葱、恰玛古等,色香味俱全,大家日常饮食不可缺的面食之一。现如今,新疆特色民族食品尚未得到全面开发,处于开发的初级阶段,因此,汤饭面片方便化,制作工艺工业化,市场前景广阔。

大多数食物必须经过烹饪熟化后才能食用,目前,常见的熟化烹饪方式主要有水煮、汽蒸、微波、炸制、炒制等,在熟化过程中食物的特性及品质都会有一定程度的影响,熟化方式对其品质的影响较大[1]。其中,水煮是最常见的熟化烹饪工艺,但水煮使食物中的可溶性物质溶解于汤中,一些金属物质也会损失,降低食物的营养品质,张钟等[2]研究了水煮对方便面品质的影响,结果表明,水煮方便面吸水指数较大,干物质失落率较高生产成本增加;汽蒸加工的主要依靠水蒸气供热且不与水直接接触,一定程度上减少了水溶性有营养物质流失,Yang等[3]研究烹饪方式对塌棵菜营养物质的影响,结果表明汽蒸较水煮更能较大程度的保留L-抗坏血酸的含量;微波熟化具有受热而均匀,升温速度快,干净清洁易于控制等特点[4],王春霞等[5]得出微波加蒸汽熟化对冷冻馒头的温度、含水量、质构特性等品质特性的作用最为理想,陈舒唱等[6]研究表明蒸汽微波熟化冻结油塔子仅需4 min,不仅节省时间提高效率,而且能更好的保持其风味及口感,Pronyk等[7]研究表明面条经热蒸汽进行预糊化处理,干燥时采用过热蒸汽技术, 所得面条复水后较硬、粘性低和弹性较好。

目前,关于对汤饭面片进行蒸汽微波熟化的研究较少,为促进汤饭面片工业化生产,本试验将面片通过不同蒸汽微波熟化条件进行熟制,测定其剪切特性、蒸煮特性及感官评价等品质指标,并对其进行响应面结合主成分分析优化其熟化工艺,为新疆汤饭方便面片工业化生产提供参考。

1. 材料与方法

1.1 材料与仪器

市售小麦面粉(蛋白质11%) 新疆天山面粉(集团)有限公司产品;黄原胶、三聚磷酸钠 河南格贝达生物科技有限公司;谷阮粉 封丘县华丰粉业有限公司;变性马铃薯淀粉 盛达食品添加剂有限公司;糖化酶(10万U/mL) 源叶生物科技有限公司;盐酸、硫酸 天津市光复精细化工研究所;碘 天津市北联精细化学品开发有限公司;碘化钾 湖北省医药公司化玻站经销;氢氧化钠、硫代硫酸钠 天津市致远化学试剂有限公司,以上药品均为分析纯。

9109-1型压面机 宝优尼公司;RT-350型面片机 睿特机械有限责任公司;MZ-57W型微波炉 青岛海尔微波制品有限公司;微波炉专用蒸笼 浙江龙士达家居用品有限公司;ACS-JE 21型电子秤 广东香山衡器集团股份有限公司;FL-1型封闭电炉、FW-100型高速万能粉碎机 北京市永光明医疗仪器有限公司;TA-XT Plus型物性测定仪 英国Stable Microsystems公司。

1.2 实验方法

1.2.1 面片制作

面粉中加入四种添加剂(三聚磷酸钠0.3 g/100 g、黄原胶0.3 g/100 g、谷阮粉1.5 g/100 g、马铃薯变性淀粉10 g/100 g),加水量为45 g/100 g(按面粉质量计算),加水和面至面团揉成团,面团使用自封袋密封常温熟化30 min,用压面机反复压延5次,形成厚为1~1.5 mm面带,用自制针板(10×10 cm的针板,材质是塑料,铁针长25 mm,直径0.8 mm,平均一个针板大约有3000个针)将面带上下两面扎透(防止蒸汽微波熟化时膨化鼓起),再把面带切成2 cm×2 cm的小方片。

1.2.2 面片熟化工艺单因素实验

1.2.2.1 蒸汽微波熟化装置图

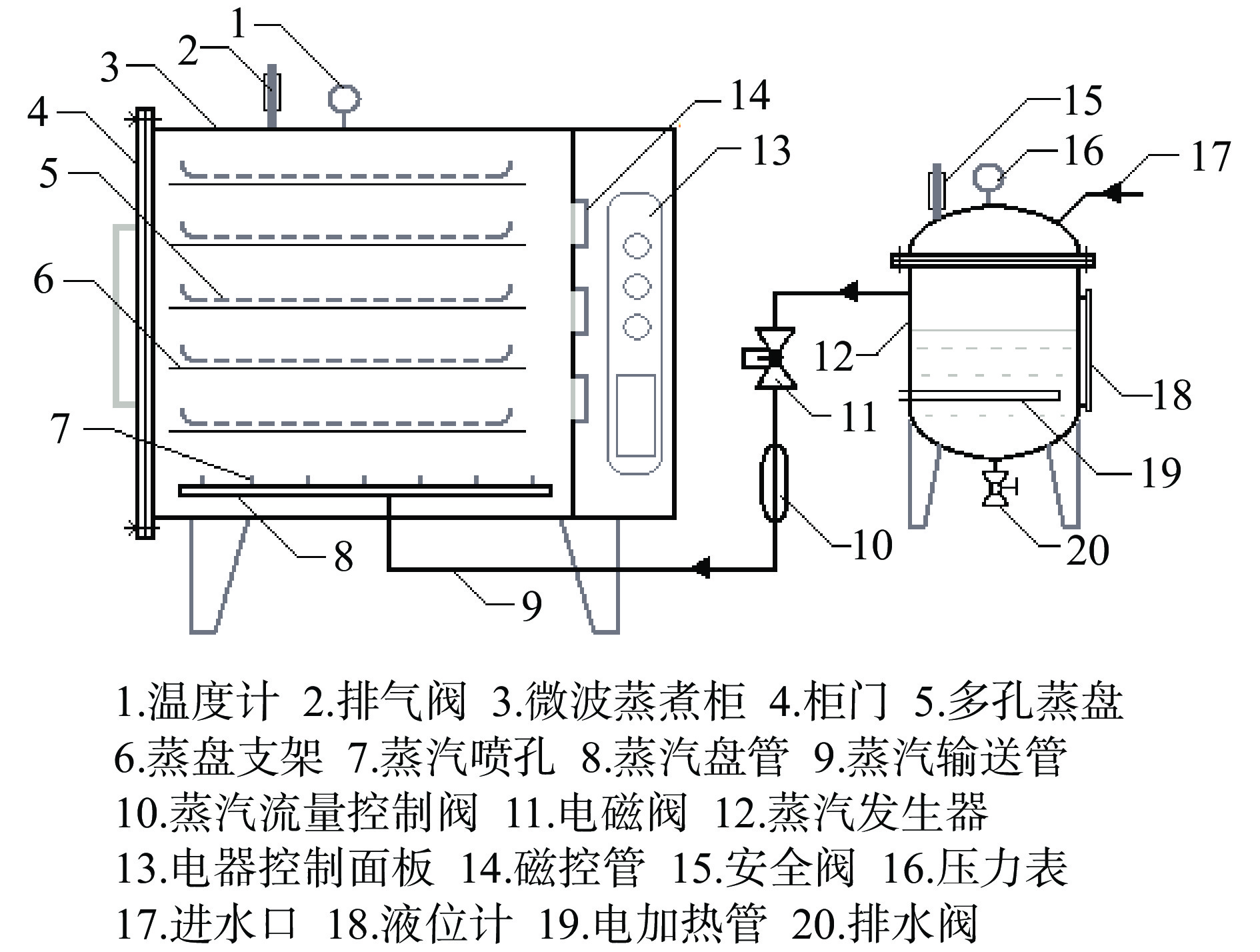

图1为面片蒸汽微波熟化装置图,该装置主要由微波炉、蒸汽发生器组成,微波炉提供面片熟化所需热量,蒸汽发生器提供湿度,通过控制微波火力的大小、熟化时间及蒸汽流量进行面片熟化的研究。

1.2.2.2 微波火力对面片品质的影响

将制作好的面片取50 g均匀摊放在微波炉专用蒸盘里,蒸汽发生器产生蒸汽,蒸汽从喷孔喷出进行熟化,蒸汽微波熟化时间为3 min,蒸汽量(通过液位计记录熟化时液位变化可知道水蒸发的体积,可将其转化为蒸汽量,蒸汽流量阀控制蒸汽量)为12 L,微波火力分别设为20%、40%、60%、80%、100%;分别测定其剪切特性、蒸煮特性、感官评分及淀粉糊化度。

1.2.2.3 蒸汽微波熟化时间对面片品质的影响

蒸汽量为12 L,微波火力设为60%,蒸汽微波熟化时间分别设为1、2、3、4、5 min时对面片剪切特性、蒸煮特性、感官评分及淀粉糊化度的影响。

1.2.2.4 蒸汽量对面片品质的影响

微波火力为60%,蒸汽微波熟化时间为3 min,蒸汽量分别为4、8、12、16、20 L时对面片剪切特性、蒸煮特性、感官评分及淀粉糊化度的影响。

1.2.3 面片熟化工艺响应面试验设计

在单因素实验的基础上,以微波火力、蒸汽微波熟化时间、蒸汽量为单因素,以面片的剪切特性、蒸煮特性、感官评分及淀粉糊化度为响应值,根据Box-Behnken响应面中心组合设计响应面试验,试验因素及水平见表1。

表 1 响应面试验因素水平设计Table 1. Response surface test factor level水平 因素 微波火力(%) 蒸汽微波熟化时间(min) 蒸汽量(L) −1 40 2 8 0 60 3 12 1 80 4 16 1.2.4 面片剪切特性的测定

取5 g左右面片放入250 mL沸水中,立即加盖直到面片无硬心,用镊子将其捞出放入冷水中浸泡1 min,用滤网除去水分,检测其剪切力2 min之内完成,防止复水后面片自然风干造成发粘重现性不佳。

其剪切力的测定参数为:探头,A/LKB-F;测试模式,压缩测定;测前速度,1.00 mm/s;测中速度,0.17 mm/s;测后速度,10.00 mm/s;目标模式,应变;应变,90%;触发模式,自动力;触发力,15.0 g。

1.2.5 面片蒸煮特性的测定

1.2.5.1 面片吸水指数的测定

参考王乐等[8]研究测定面片的吸水指数,准确称取Ma克面片,放入烧杯中加沸水约5倍于面片质量即刻加盖,直到面片无硬心,将其用镊子夹出放入冷水中1 min,其表面水分用滤纸吸干称重Mb克,按照式(1)计算其吸水指数;

X=(Mb−Ma)Ma×100 (1) 式中:X为吸水指数,%;Ma为样品的初始重量,g;Mb为样品吸水后的重量,g。

1.2.5.2 面片蒸煮损失率的测定

参照国标LS/T 3212-2021《挂面》[9],测定其蒸煮损失率,精确称取约5 g面片,置于250 mL沸水的烧杯中并加盖,直到面片无硬心,用镊子将其挑出,面汤冷却后,转入250 mL容量瓶中定容混匀,于恒质的100 mL烧杯中倒入25 mL面汤,放在可调式电炉将大部分水分蒸掉,再加入25 mL面汤继续蒸发至近干,于烘箱内(约105 ℃)烘至恒重,按照式(2)计算面片烹调损失率;

S=5NY×(1−S1)×100 (2) 式中:S为面片的烹调损失率,%;N为150 mL面汤中干物质质量,g;Y为样品质量,g;S1为面片的水分含量。

1.2.6 面片微观结构的测定

使用场发射电子扫描显微镜(SEM)对不同干燥方式处理的面片的表面、横截面在500、1000的放大倍数下观察其微观结构并进行拍摄。

1.2.7 面片淀粉糊化度的测定

参考熊易强[10]的方法进行测定,淀粉糊化度的测定使用酶水解法,将面片用万能粉碎机粉碎,分别称取粉碎的面片1.00 g,置于A1、A2两个三角瓶中,另取一三角瓶为B,加蒸馏水50 mL于三个三角瓶中,将A1于电炉上持续微沸20 min,冷却至室温后,分别加入2 mL糖化酶,于恒温水浴锅(50 ℃)中摇动保温1 h,取出即刻加2 mL盐酸以终止糖化,并定容过滤,取滤液10 mL,分别加入碘液及氢氧化钠,严密放置15 min后,迅速加硫酸摇匀,并用硫代硫酸钠溶液滴定至无色,记录消耗的量,其淀粉糊化度的计算如式(3)。

糊化度=V0−V2V0−V1×100 (3) 式中:V0为滴定B瓶溶液所消耗的硫代硫酸钠,mL;V1为滴定A1样品所消耗的硫代硫酸钠,mL;V2为滴定A2样品所消耗的硫代硫酸钠,mL。

1.2.8 感官评价

参考国标方便面感官评价方法(GB/T 25005-2010)[11]进行调整制作表2面片感官评价指标及标准,由学习过感官评定的人员(6名)按照表2对其不同熟化条件下的面片进行感官评分,对数据进行整理得出结果。

表 2 面片感官评价指标及标准Table 2. Sensory evaluation indexes and standards of facial plates项 目 评分标准 分值(分) 色泽 色泽均匀,色泽乳白,奶黄色,亮度较好8.5~10分;色泽较均匀,黄色,亮度一般6~8.4分;色泽不均匀,暗淡,发灰,亮度较差1~5.9分 10 表观状态 表面较光滑,结构细密,无膨胀8.5~10分;表面光滑结构稍稀疏,稍许膨胀6~8.4分;表面粗糙结构稀疏,膨胀1~5.9分 10 适口性(软硬度) 牙咬断面片力度适中17~20分;偏硬或偏软12~16.9分;太硬或太软1~11.9分 20 韧性 咀嚼有咬劲,富有弹性 21~25分;咀嚼、弹性一般15~20.9分;咀嚼咬劲差,弹性小1~14.9分 25 黏性 咀嚼爽口,不黏牙21~25分;咀嚼爽口,稍黏牙15~20.9分;不爽口,较黏牙1~14.9分 25 光滑性 口感较光滑4.3~5分;口感稍光滑3~4.2分;光滑程度差1~2.9分 5 食味 具有香味4.3~5分;无异味3~4.2分;有异味1~2.9分 5 总分 100 1.2.9 主成分分析

对面片品质的各指标进行主成分分析,得到原始数据的特征值、贡献率及累积贡献率,对特征向量值大于1的因子提取主成分,面片品质的综合评分按式(4)进行计算面片各个实验组的综合得分后按式(5)将得到的综合评分F进行规范化处理,分别计算其综合评分和规范化综合评分。

F=(F1Y1+F2Y2+F3Y3)C (4) 式中,F为综合评分;F1、F2和F3为主成分1、2和3的得分;Y1、Y2、Y3为主成分的特征值;C为累积特征值。

Z=(F−Fmin)(Fmax−Fmin) (5) 式中,Z为规范化综合评分;F为综合评分;Fmax为综合评分最大值;Fmin为综合评分最小值。

1.3 数据处理

本文试验所得数值为三次重复并取其平均值,IBM SPSS Statistics 20进行显著性及主成分分析,显著水平P<0.05,Origin 2018 64Bit绘图,Design Expert 10进行响应面设计及分析。

2. 结果与分析

2.1 单因素实验结果

2.1.1 微波火力对面片剪切特性、蒸煮特性、感官评分影响及相关性分析

表3为蒸汽微波熟化时间为3 min,蒸汽量为12 L,不同的微波火力下对面片剪切力、蒸煮特性及感官评分的影响,食物的质构参数反应食品组织结构及状态的一个物理指标,一般烹调方式会导致食物质构的变化[12-13],面片的质构用延展性、硬度及咀嚼性三个指标表示。由表3可知,随着微波火力的增加面片的硬度、咀嚼性整体呈现上升的趋势,微波处理使面片水分含量较低,面片的硬度提高,咀嚼性也相应上升,当火力为100%时面片的硬度最大为2682.757 g,火力60%时其硬度较小为2110.43 g,且两者差异性显著(P

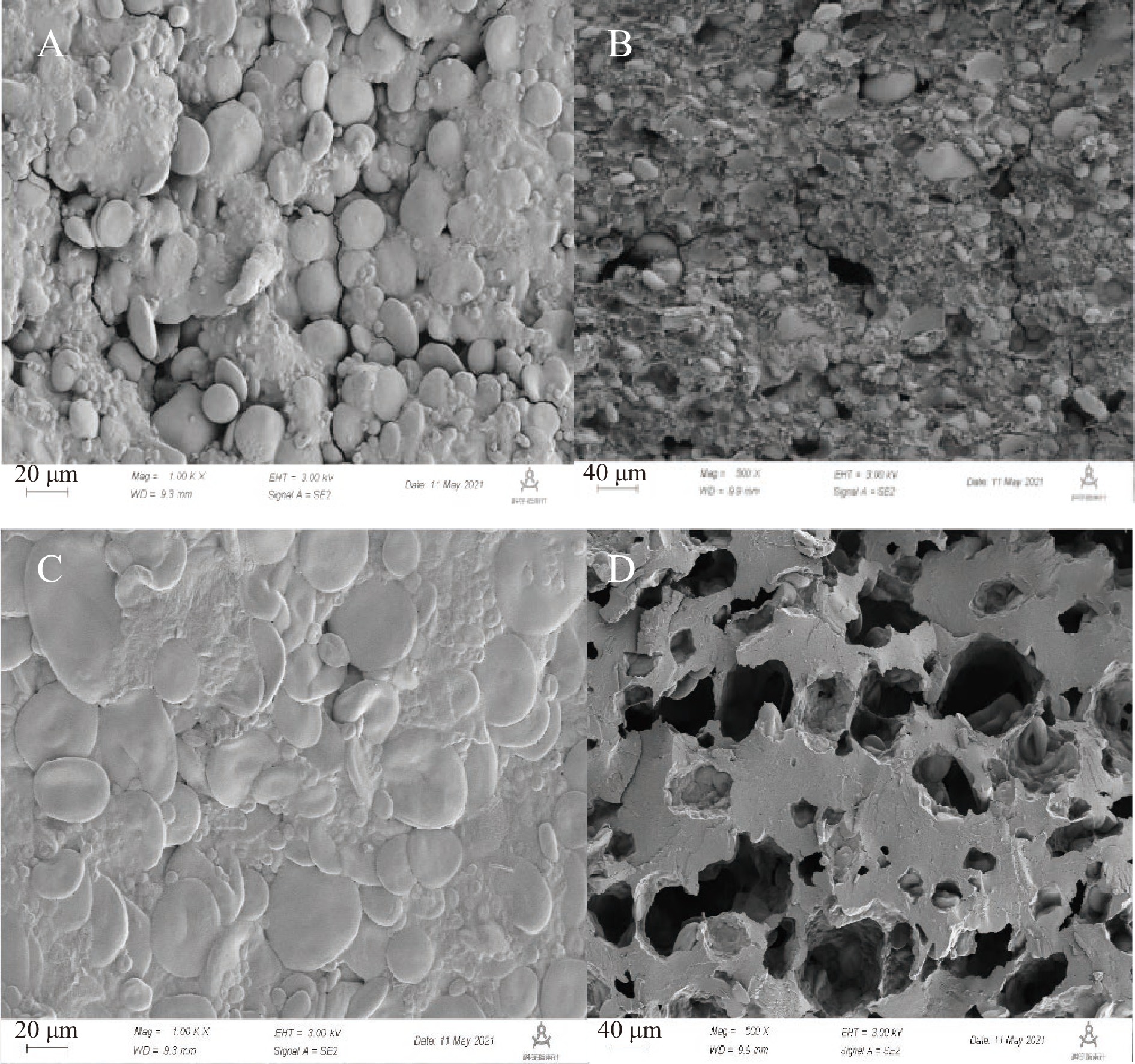

<0.05 ),可能是由于一定的微波火力与蒸汽量改善面片的品质,其咀嚼性在火力为100%、60%时较大分别为5512.201 g·s、5573.902 g·s且两者无显著性差异(P>0.05 ),面片的延展性呈现先上升再下降的趋势,一定的熟化方式改善面片的品质。表 3 微波火力对面片剪切特性、蒸煮特性及感官评分的影响Table 3. Effects of microwave irradiation on shear characteristics, cooking characteristics and sensory score of surface plates火力(%) 延展性(g·s) 硬度(g) 咀嚼性(g·s) 吸水指数(%) 蒸煮损失率(%) 感官评分(分) 20 50.30±7.74ab 1240.43±72.38a 3293.12±91.21a 105.57±0.64a 6.22±0.09c 71.27±0.06a 40 58.13±6.53bc 1217.19±69.19a 4233.34±60.38b 114.55±0.94c 6.03±0.02b 81.23±0.15d 60 100.12±5.25d 2110.43±88.88b 5573.90±31.73c 120.31±1.01e 5.36±0.12a 90.33±0.78e 80 64.04±6.79c 1929.73±19.34b 5392.43±36.86c 118.04±0.53d 6.00±0.02b 78.97±0.49c 100 44.87±6.89a 2682.76±26.34c 5512.20±31.01c 108.21±0.73b 6.48±0.06d 73.60±0.66b 注:同列不同小写字母表示差异显著(P<0.05);表5同。 吸水指数则代表面片的吸水能力,吸水能力越强,面片中淀粉糊化更为彻底,面片的口感较好,蒸煮损失率表现面片的稳定性,数值越大,面汤越浑浊,产品的品质就越差[14],由表3可知,在火力为60%面片的吸水指数最大,火力20%时最小分别为120.314%、105.574%两则之间差异性显著(P<0.05),在火力为60%时面片的蒸煮损失率最小为5.365%,可能由于火力较小时面片未熟化淀粉脱落,火力较大时面片水分含量较低其结构较紧密不易吸水,微波是由内而外进行加热的,因此,适量的微波能使面片内部存有空隙,结构松散,易于面片吸水如图2C、图2D所示,由表3也可以看出,火力为60%时面片的感官评价也最高。

表4为不同微波火力下面片的剪切特性、蒸煮品质及感官评价的相关性分析,由表可知,面片的硬度与咀嚼性呈极显著正相关(0.654**),咀嚼性与吸水指数呈正相关(0.566*),蒸煮损失率与吸水指数、感官评分、延展性呈极显著负相关(−0.812**、−0.915**、−0.905**),吸水指数与感官评价、延展性呈现极显著正相关(0.892**、0.777**),感官评价与延展性呈现极显著正相关(0.897**),从Pearson相关系数的数值来看,面片的蒸煮损失率与吸水指数,蒸煮损失率与感官评价、延展性,吸水指数与感官评价,感官评价与延展性相关系数值在0.8以上,说明,随着火力的增加,面片的蒸煮损失率整体呈现先下降再上升的趋势,其延展性、感官评价、吸水指数在一定范围内变化趋势相一致。

表 4 不同微波火力下面片的剪切特性、蒸煮特性及感官评价的相关性分析Table 4. Correlation analysis of shear characteristics, cooking characteristics and sensory evaluation of the lower plate under different microwave fires指标 硬度 咀嚼性 蒸煮损失率 吸水指数 感官评价 延展性 硬度 1 咀嚼性 0.654** 1 蒸煮损失率 0.060 −0.254 1 吸水指数 0.099 0.566* −0.812** 1 感官评价 0.095 0.455 −0.915** 0.892** 1 延展性 0.045 0.406 −0.905** 0.777** 0.897** 1 注:**表示在0.01水平(双侧)上显著相关;*表示在0.05水平(双侧)上显著相关;表6同。 2.1.2 蒸汽微波熟化时间对面片剪切特性、蒸煮特性及感官评分影响

表5为当微波火力为60%,蒸汽量为12 L,不同的蒸汽微波熟化时间对面片剪切特性、蒸煮特性及感官评分的影响,由表可知,面片的延展性随着蒸汽微波熟化时间的增加呈现先上升再下降的趋势,其硬度及咀嚼性则大致为上升的趋势,时间为3 min时其延展性、硬度、咀嚼性数值较高,可能是由于面片短时间的蒸汽微波熟化,面片吸收的微波能较少、糊化程度低,面片原有的组织结构及含水量等未受到较大的影响,但面片表面的淀粉遇热水易脱落,这也是面片吸水指数较低,蒸煮损失率较高的原因,长时间的熟制一定的蒸汽量与足够的微波能,淀粉经过胀润,面片糊化程度较高,且体积明显膨胀结构松散则其吸水指数高、损失率低[15],随着微波的继续(蒸汽量是一定的),面片的水分含量随之减少,其硬度及咀嚼性会有较小程度的增大,这时面片蒸煮损失率较高,吸水少,在熟制时间为3 min时,面片的吸水指数较高为120.314%,但其蒸煮损失率较低为5.363%,综合说明其熟制时间3 min时能够改善面片的品质。

表 5 熟化时间对面片剪切特性、蒸煮特性及感官评分的影响Table 5. Effects of curing time on shearing characteristics, cooking characteristics and sensory score of the sheet时间(min) 延展性(g·s) 硬度(g) 咀嚼性(g·s) 吸水指数(%) 蒸煮损失率(%) 感官评分(分) 1 72.11±1.82b 1921.67±89.90a 2476.64±72.75a 108.32±1.33a 6.28±0.06d 75.91±0.56a 2 81.65±6.51c 2051.17±9.51ab 4439.37±43.99b 114.42±0.75b 5.95±0.08c 85.32±0.70b 3 98.12±5.25d 2120.43±88.88ab 5549.90±31.73c 119.82±1.00d 5.42±0.12a 89.73±0.78e 4 69.13±4.73b 2178.17±45.96c 5532.18±41.97c 119.15±0.85d 5.58±0.05b 88.30±0.40d 5 57.89±2.72a 2141.52±36.68ab 5622.94±56.18c 116.71±0.58c 6.18±0.07d 86.93±0.92c 表6为不同的蒸汽微波熟化时间条件下面片的剪切特性、蒸煮特性及感官评价的相关性分析,由表可知,面片的硬度与咀嚼性显著性正相关(0.604*),蒸煮损失率与咀嚼性呈显著性负相关(−0.603*),吸水指数与硬度显著性正相关(0.621*),吸水指数与咀嚼性呈现极显著性正相关(0.907**),吸水指数与蒸煮损失率呈现极显著性负相关(−0.814**),感官评价与硬度、咀嚼性及吸水指数呈极显著性正相关(0.665**、0.929**、0.964**),感官评价与蒸煮损失率呈极显著负相关(−0.745**),延展性与蒸煮损失率呈显著性负相关(−0.632*),由Pearsion相关系数的数值来看,随着熟制时间的延长,面片的感官评价与其硬度、咀嚼性及吸水指数在一定范围内变化相一致,与其蒸煮损失率则相反,这与面片的剪切特性、蒸煮特性及感官评价所得结果相一致。

表 6 不同蒸汽微波熟化时间下面片的剪切特性、蒸煮特性及感官评价的相关性分析Table 6. Correlation analysis of shear characteristics, cooking characteristics and sensory evaluation of the lower slices with different microwave cooking time指标 硬度 咀嚼性 蒸煮损失率 吸水指数 感官评价 延展性 硬度 1 咀嚼性 0.604* 1 蒸煮损失率 −0.308 −0.603* 1 吸水指数 0.621* 0.907** −0.814** 1 感官评价 0.665** 0.929** −0.745** 0.964** 1 延展性 −0.021 0.062 −0.632* 0.276 0.301 1 2.1.3 蒸汽量对面片剪切特性、蒸煮特性及感官评分影响

表7为当微波火力为60%,蒸汽微波熟化时间为3 min时,不同蒸汽量对面片剪切特性、蒸煮特性及感官评分的影响,由表可知,面片的延展性呈现先增大再减小的趋势,其硬度、咀嚼性则大致为逐渐下降的趋势,在蒸汽量为20 L时其延展性、硬度及咀嚼性值较小,蒸汽量为4 L时其硬度与咀嚼性数值较大,可能是由于蒸汽量较小面片的体积没有发生较明显的变化,面片表层透明内有白心,说明面片没有完全糊化[15],再加上足够的的微波能量,则其硬度、咀嚼性较大,而延展性较小,这也是面片吸水指数在蒸汽量较小时吸水少,蒸煮损失率较高的原因;蒸汽量过大时,面片与蒸汽之间的初始温差大,面片表面出现“露水”,此时的水蒸气转化为液体,封闭空间里湿度增大,水分子具有向面片内部渗透的趋势[16],加上微波加热由内而外的特点,面片含水量的增加,导致其延展性、硬度、咀嚼性相对有所升高,吸水指数较4 L时较大,蒸煮损失率变化不大,感官评分较低的原因。因此,适当的蒸汽量有助于改善面片的品质,本文研究蒸汽量为12 L时面片的品质较好,感官评分较高为90.333分。

表 7 蒸汽量对面片剪切特性、蒸煮特性及感官评分的影响Table 7. Effects of steam on shear characteristics, cooking characteristics and sensory score蒸汽量(L) 延展性(g·s) 硬度(g) 咀嚼性(g·s) 吸水指数(%) 蒸煮损失率(%) 感官评分(分) 4 48.39±6.47a 3571.91±40.98e 4655.75±51.76c 96.40±0.67a 7.32±0.11e 76.58±0.25b 8 70.31±1.71b 2967.96±36.37d 4527.18±40.19c 118.42±0.99c 6.54±0.13c 85.24±0.33c 12 75.12±5.25c 2110.43±88.88c 5513.90±31.73d 120.31±1.00e 5.36±0.12a 90.33±0.78d 16 69.75±5.78b 1493.54±34.13b 3639.24±19.16b 118.99±1.36cd 6.08±0.07b 89.13±0.54d 20 42.22±3.62a 669.47±13.39a 2369.62±43.61a 112.51±0.60b 6.06±0.09d 74.82±1.57a 表8为不同的蒸汽量下面片的剪切特性、蒸煮特性及感官评价的相关性分析,由表可知,面片的硬度与咀嚼性、吸水指数、感官评价、延展性呈极显著负相关(−0.787**、−0.857**、−0.664**、−0.777**),硬度与蒸煮损失率极显著正相关(0.991**),咀嚼性与延展性呈极显著正相关(0.773**),咀嚼性与蒸煮损失率呈极显著负相关(−0.775**),蒸煮损失率与吸水指数、延展性呈极显著负相关(−0.826**、−0.770**),感官评价与蒸煮损失率呈显著性负相关(-0.594*),吸水指数与感官评价、延展性呈极显著正相关(0.750**、0.765**),从Pearsion数值的变化来看,其与面片的剪切特性、蒸煮特性及感官评价的结果相一致。

表 8 不同蒸汽量下面片的剪切特性、蒸煮特性及感官评价的相关性分析Table 8. Correlation analysis of shear characteristics, cooking characteristics and sensory evaluation of lower slices with different steam volumes指标 硬度 咀嚼性 蒸煮损失率 吸水指数 感官评价 延展性 硬度 1 咀嚼性 −0.787** 1 蒸煮损失率 0.991** −0.775** 1 吸水指数 −0.857** 0.464 −0.826** 1 感官评价 −0.664** 0.219 −0.594* 0.750** 1 延展性 −0.777** 0.773** −0.770** 0.765** 0.235 1 2.1.4 不同的微波火力、微波蒸汽时间及蒸汽量对面片淀粉糊化度的影响

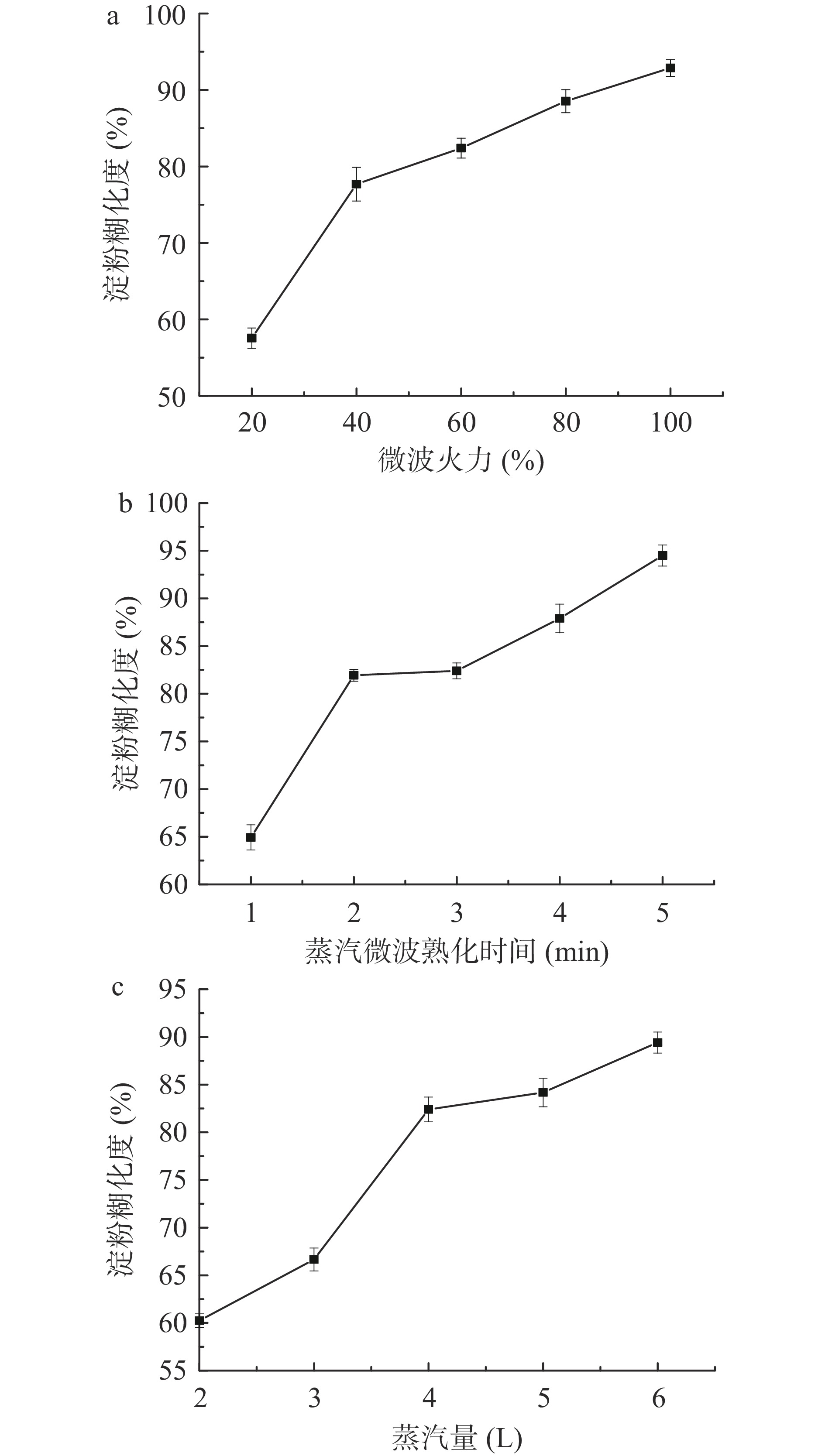

图3为不同的微波火力、蒸汽微波熟化时间及蒸汽量对面片淀粉糊化度的影响。淀粉的糊化是淀粉的结构由β型转为α型,前者淀粉分子未经糊化,后者是高温或高压的条件下使未糊化的淀粉分子吸水膨胀,也就是食物的熟化程度[17]。由图3可知,面片的淀粉糊化度随着微波火力、蒸汽微波熟化时间、蒸汽量的增大,呈现逐渐上升的趋势,足够的微波能、熟制时间及蒸汽量使面片内部由氢键集合在一起形成的微晶束吸水膨胀、结构遭到破化,支链淀粉分解成直链淀粉,面片淀粉糊化;在微波火力20%时面片的淀粉糊化度最低为57.551%,蒸汽微波熟化时间为5 min时面片的淀粉糊化度最高为94.495%,根据国标方便面理化指标(GB 9848-88)规定,油炸方便面的糊化度>85.0%,热风干燥面糊化度>80.0%,面片糊化度较低,泡食时面片不能完全熟化,食用后则会出现不消化、腹胀等症状[18],糊化度较高则会影响其食用品质与感官,因此,控制适当的微波火力、蒸汽微波熟化时间及蒸汽量有利于改善面片的品质,经研究当微波火力60%、蒸汽微波熟化时间3 min、蒸汽量12 L时面片的淀粉糊化度为82.396%,其品质较好。

2.2 响应面-主成分分析试验结果

2.2.1 响应面试验结果

在单因素的基础上,进行Box-Behnken试验,其试验设计及结果如表9所示,根据表9的试验数据进行主成分分析。

表 9 面片熟化工艺的响应面试验设计及结果Table 9. Response surface test design and results of surface curing process实验号 微波火力(%) 时间(min) 蒸汽量(L) 延展性(g·s) 硬度

(g)咀嚼性

(g·s)吸水指数(%) 蒸煮损失率(%) 淀粉糊化度(%) 感官得分(分) 1 0 0 0 108.16 2304.46 5099.52 141.52 2.88 78.24 91.20 2 1 0 1 25.49 536.23 2544.32 127.40 3.49 88.34 72.50 3 −1 0 −1 34.66 1450.78 3777.29 120.01 3.75 78.73 81.40 4 0 −1 1 77.95 576.33 4273.85 128.77 4.29 88.98 84.40 5 0 1 1 40.05 554.06 1131.12 128.82 3.78 88.45 83.30 6 −1 1 0 47.06 620.87 2982.77 101.23 4.08 77.49 84.30 7 0 0 0 106.16 1904.46 4899.52 135.52 2.67 79.52 89.20 8 0 0 0 103.16 2104.46 5045.52 138.52 2.77 80.24 88.60 9 1 −1 0 56.61 541.70 1751.00 115.40 3.79 88.43 80.40 10 −1 0 1 74.72 1007.35 1783.02 108.31 3.92 82.31 83.50 11 −1 −1 0 83.58 536.24 3525.87 126.03 4.64 82.99 82.30 12 0 0 0 100.16 2164.46 4609.52 138.52 2.85 80.24 90.60 13 1 1 0 39.48 526.58 2229.35 126.10 3.75 87.92 79.20 14 1 0 −1 76.47 668.10 2251.52 116.41 3.02 85.30 86.50 15 0 −1 −1 65.54 281.93 2017.39 132.82 3.45 88.40 89.10 16 0 0 0 98.16 2204.46 5200.52 142.52 2.79 81.24 91.80 17 0 1 −1 60.92 1531.95 4661.54 124.32 3.29 79.84 87.60 2.2.2 面片熟化工艺的主成分分析

采用IBM SPSS Statistics 20对表9中面片品质的各指标数据进行主成分分析[19-21],根据累积贡献率大于85%的原则,由表10可知,累计贡献率达到88.129%(>85%),根据各个指标的特征向量值(表11)可以看出,决定第1主成分的指标主要是硬度、咀嚼性、感官的得分、延展性;决定第2主成分的是吸水指数、淀粉糊化度。说明提取得2个主成分能够全面反映面片的品质信息。

表 10 面片品质中主成分的特征值及贡献率Table 10. Characteristic values and contribution rates of principal components in surface quality主成分 特征值 贡献率(%) 累积贡献率(%) 1 4.562 65.169 65.169 2 1.031 14.722 79.891 3 0.577 8.238 88.129 4 0.499 7.123 95.252 5 0.174 2.483 97.736 6 0.108 1.548 99.284 7 0.050 0.716 100.000 表 11 主要指标的特征向量Table 11. Characteristic direction of main indicators指标 第1主成分 第2主成分 硬度 0.939 −0.129 咀嚼性 0.868 −0.141 感官得分 0.835 0.014 延展性 0.845 0.091 蒸煮损失率 −0.772 −0.252 吸水指数 0.689 0.636 淀粉α度 −0.667 0.719 根据第1主成分、第2主成分得分,按照式(1)计算面片试验组的综合评分F[22],由于各个指标间不同的单位和变异程度,为消除量纲影响和变量自身变异大小和数值大小的影响[23],对综合评分进行规范化处理得到规范化综合评分(表12),再以规范化综合评分作为响应值进行响应面分析。

表 12 主成分得分值及规范化综合得分Table 12. Principal component scores and standardized comprehensive scores序号 第1主成分 第2主成分 综合得分 规范化综合得分 1 3.37 1.74 2.45 1.00 2 −2.59 −0.78 −1.8 0.00 3 −0.53 0.05 −0.34 0.344 4 −0.88 −1.11 −0.73 0.252 5 −2.09 −0.62 −1.46 0.08 6 −1.49 −0.71 −1.07 0.172 7 2.76 1.34 1.99 0.892 8 2.8 1.29 2.02 0.899 9 −2.28 −1.42 −1.69 0.0259 10 −1.32 −0.88 −0.99 0.191 11 −1.05 −0.34 −0.74 0.249 12 2.77 1.29 1.99 0.892 13 −2.13 −0.8 −1.5 0.306 14 −0.57 −0.5 −0.44 0.32 15 −0.85 −0.18 −0.58 0.287 16 3.1 1.31 2.22 0.946 17 0.97 0.31 0.68 0.584 2.2.3 面片熟化工艺的响应面分析

2.2.3.1 响应面优化面片熟化工艺

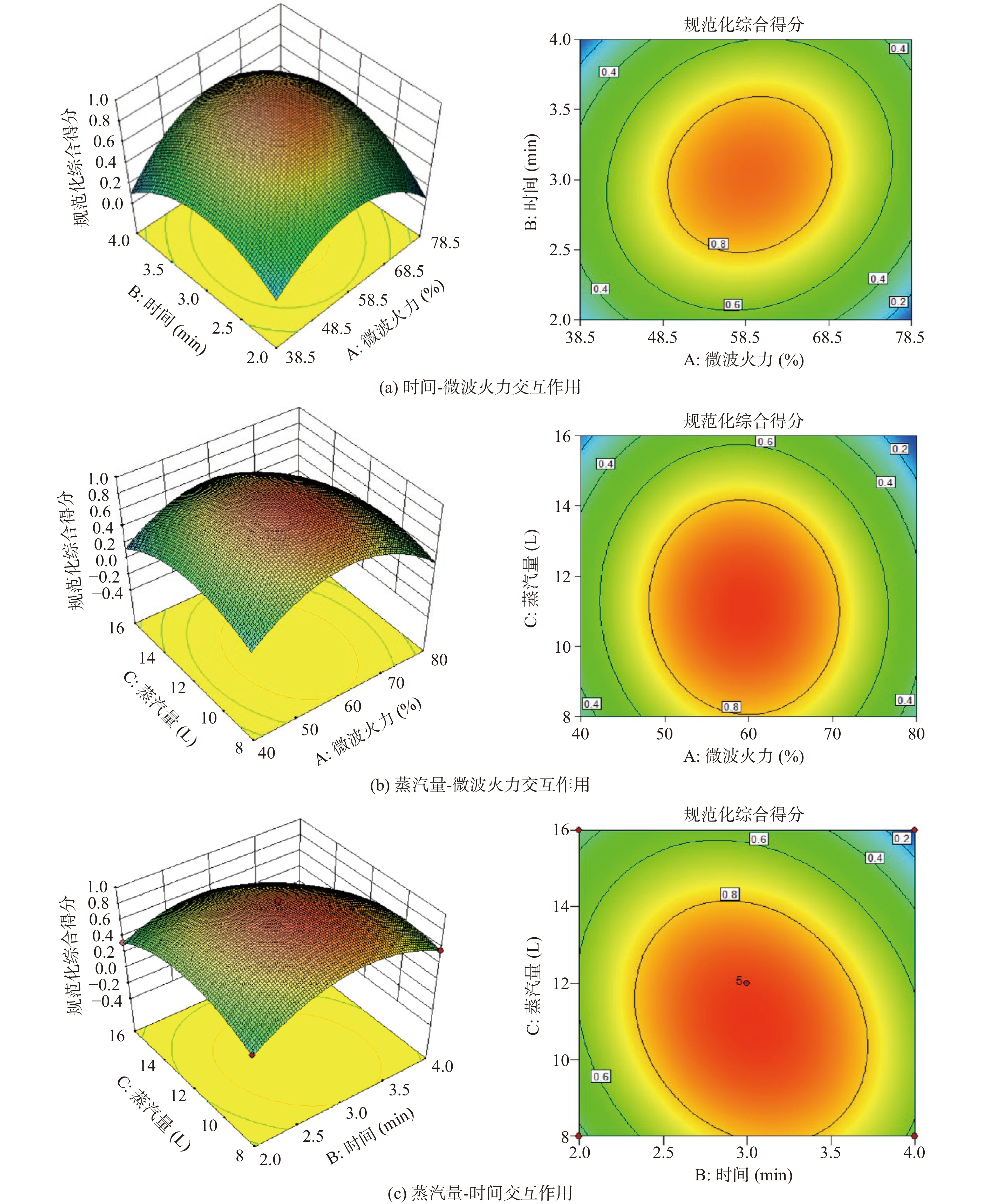

使用Design Expert 10软件对表9及表12中的规范化综合评分的数据进行处理得到回归模型方程:Z=0.92−0.039A+0.044B−0.13C+0.089AB−0.039AC−0.11BC−0.14A2−0.32B2−0.3C2

由表13可知,响应面回归模型P<0.01,失拟值P值为0.723(>0.05),差异不显著;模型决定系数R2=0.9823,说明模型与实验数据拟合效果较好,自变量与响应值之间的线性关系显著,表明所得回归模型方程可确定面片最佳的熟化工艺。表13中因素A、B的P<0.05,达到显著型的影响水平,因素C的P<0.01,达到极显著的影响水平;交互项AB、BC的P<0.01,达到极显著性影响水平;二次项A2、B2、C2的P<0.01,对响应值的影响极显著。通过对其P值影响水平的比较,各因素的效应关系为C>B>A。

表 13 回归模型方差分析Table 13. Analysis of variance of regression model项目 平方和 自由度 均方 F值 P值 显著性 模型 1.944 9 0.216 100.856 <0.0001 ** A-微波火力 0.012 1 0.012 5.792 0.047 * B-时间 0.015 1 0.015 7.110 0.032 * C-蒸汽量 0.131 1 0.131 60.969 0.0001 ** AB 0.032 1 0.032 14.962 0.006 ** AC 0.006 1 0.006 2.878 0.134 BC 0.050 1 0.050 23.536 0.002 ** A2 0.701 1 0.701 327.545 <0.0001 ** B2 0.441 1 0.441 205.960 <0.0001 ** C2 0.380 1 0.380 177.432 <0.0001 ** 残差 0.015 7 0.002 失拟值 0.004 3 0.001 0.463 0.723 纯误差 0.011 4 0.003 总和 1.959 16 R2 0.9823 R2Adj 0.9725 2.2.3.2 交互作用分析

响应面能够直观的反映各因素与规范化综合得分之间的关系及各因素之间的相互作用,响应面3D图中曲线越弯曲说明因素对结果的影响越大,等高线越密集且呈椭圆形说明各因素间交互作用显著,反之,各因素间的影响不大[24]。由图4可看出,蒸汽微波熟化时间与蒸汽量、微波火力的响应面曲线较弯曲且等高线呈椭圆形,说明AB、BC的交互作用极显著P<0.01,也表明对规范化综合得分的影响越大,微波火力与蒸汽量的等高线趋于圆形,表明AC交互作用不显著P>0.05,表明AC对响应值规范化综合得分的影响不显著。

2.2.4 验证实验

根据响应面分析软件得出面片熟化的最佳工艺参数为:微波火力为59.669%、蒸汽微波熟化时间为3.023 min、蒸汽量为11.998 L,在此工艺条件下其规范化综合得分为0.96分。通过对预测工艺优化请确定条件进行调整微波火力为60%、蒸汽微波熟化时间为3 min、蒸汽量为12 L熟化面片,最终得到其延展性为98.155 g·s、硬度为2204.46 g、咀嚼性为5200.52 g·s、吸水指数为142.516%、蒸煮损失率为2.79%、感官得分为91.8分、规范化综合得分为0.946,与预测的数值基本一致,因此该模型基本准确,能够确定面片的熟化工艺条件,表明响应面结合主成分分析法得到的面片熟化工艺参数对面片的生产具有参考指导意义。

3. 结论

本研究以新疆天山特一粉为原料并加入相关添加剂,在单因素的基础上,通过响应面结合主成分分析法优化面片熟化工艺,最优参数:微波火力为60%、蒸汽微波熟化时间为3 min、蒸汽量为12 L,在此条件下,其延展性为98.155 g·s、硬度为2204.46 g、咀嚼性为5200.52 g·s、吸水指数为142.516%、蒸煮损失率为2.79%、感官得分为91.8分,面片熟化工艺优化理论综合评分为0.923,与实测值规范化综合得分0.946基本一致,在实验过程中蒸汽量对面片熟化的影响较大。经验证,该模型准确可靠,能够较好的预测试验结果,此参数优化面片的熟化工艺,在实际生产中具有较好的参考指导价值。

-

表 1 响应面试验因素水平设计

Table 1 Response surface test factor level

水平 因素 微波火力(%) 蒸汽微波熟化时间(min) 蒸汽量(L) −1 40 2 8 0 60 3 12 1 80 4 16 表 2 面片感官评价指标及标准

Table 2 Sensory evaluation indexes and standards of facial plates

项 目 评分标准 分值(分) 色泽 色泽均匀,色泽乳白,奶黄色,亮度较好8.5~10分;色泽较均匀,黄色,亮度一般6~8.4分;色泽不均匀,暗淡,发灰,亮度较差1~5.9分 10 表观状态 表面较光滑,结构细密,无膨胀8.5~10分;表面光滑结构稍稀疏,稍许膨胀6~8.4分;表面粗糙结构稀疏,膨胀1~5.9分 10 适口性(软硬度) 牙咬断面片力度适中17~20分;偏硬或偏软12~16.9分;太硬或太软1~11.9分 20 韧性 咀嚼有咬劲,富有弹性 21~25分;咀嚼、弹性一般15~20.9分;咀嚼咬劲差,弹性小1~14.9分 25 黏性 咀嚼爽口,不黏牙21~25分;咀嚼爽口,稍黏牙15~20.9分;不爽口,较黏牙1~14.9分 25 光滑性 口感较光滑4.3~5分;口感稍光滑3~4.2分;光滑程度差1~2.9分 5 食味 具有香味4.3~5分;无异味3~4.2分;有异味1~2.9分 5 总分 100 表 3 微波火力对面片剪切特性、蒸煮特性及感官评分的影响

Table 3 Effects of microwave irradiation on shear characteristics, cooking characteristics and sensory score of surface plates

火力(%) 延展性(g·s) 硬度(g) 咀嚼性(g·s) 吸水指数(%) 蒸煮损失率(%) 感官评分(分) 20 50.30±7.74ab 1240.43±72.38a 3293.12±91.21a 105.57±0.64a 6.22±0.09c 71.27±0.06a 40 58.13±6.53bc 1217.19±69.19a 4233.34±60.38b 114.55±0.94c 6.03±0.02b 81.23±0.15d 60 100.12±5.25d 2110.43±88.88b 5573.90±31.73c 120.31±1.01e 5.36±0.12a 90.33±0.78e 80 64.04±6.79c 1929.73±19.34b 5392.43±36.86c 118.04±0.53d 6.00±0.02b 78.97±0.49c 100 44.87±6.89a 2682.76±26.34c 5512.20±31.01c 108.21±0.73b 6.48±0.06d 73.60±0.66b 注:同列不同小写字母表示差异显著(P<0.05);表5同。 表 4 不同微波火力下面片的剪切特性、蒸煮特性及感官评价的相关性分析

Table 4 Correlation analysis of shear characteristics, cooking characteristics and sensory evaluation of the lower plate under different microwave fires

指标 硬度 咀嚼性 蒸煮损失率 吸水指数 感官评价 延展性 硬度 1 咀嚼性 0.654** 1 蒸煮损失率 0.060 −0.254 1 吸水指数 0.099 0.566* −0.812** 1 感官评价 0.095 0.455 −0.915** 0.892** 1 延展性 0.045 0.406 −0.905** 0.777** 0.897** 1 注:**表示在0.01水平(双侧)上显著相关;*表示在0.05水平(双侧)上显著相关;表6同。 表 5 熟化时间对面片剪切特性、蒸煮特性及感官评分的影响

Table 5 Effects of curing time on shearing characteristics, cooking characteristics and sensory score of the sheet

时间(min) 延展性(g·s) 硬度(g) 咀嚼性(g·s) 吸水指数(%) 蒸煮损失率(%) 感官评分(分) 1 72.11±1.82b 1921.67±89.90a 2476.64±72.75a 108.32±1.33a 6.28±0.06d 75.91±0.56a 2 81.65±6.51c 2051.17±9.51ab 4439.37±43.99b 114.42±0.75b 5.95±0.08c 85.32±0.70b 3 98.12±5.25d 2120.43±88.88ab 5549.90±31.73c 119.82±1.00d 5.42±0.12a 89.73±0.78e 4 69.13±4.73b 2178.17±45.96c 5532.18±41.97c 119.15±0.85d 5.58±0.05b 88.30±0.40d 5 57.89±2.72a 2141.52±36.68ab 5622.94±56.18c 116.71±0.58c 6.18±0.07d 86.93±0.92c 表 6 不同蒸汽微波熟化时间下面片的剪切特性、蒸煮特性及感官评价的相关性分析

Table 6 Correlation analysis of shear characteristics, cooking characteristics and sensory evaluation of the lower slices with different microwave cooking time

指标 硬度 咀嚼性 蒸煮损失率 吸水指数 感官评价 延展性 硬度 1 咀嚼性 0.604* 1 蒸煮损失率 −0.308 −0.603* 1 吸水指数 0.621* 0.907** −0.814** 1 感官评价 0.665** 0.929** −0.745** 0.964** 1 延展性 −0.021 0.062 −0.632* 0.276 0.301 1 表 7 蒸汽量对面片剪切特性、蒸煮特性及感官评分的影响

Table 7 Effects of steam on shear characteristics, cooking characteristics and sensory score

蒸汽量(L) 延展性(g·s) 硬度(g) 咀嚼性(g·s) 吸水指数(%) 蒸煮损失率(%) 感官评分(分) 4 48.39±6.47a 3571.91±40.98e 4655.75±51.76c 96.40±0.67a 7.32±0.11e 76.58±0.25b 8 70.31±1.71b 2967.96±36.37d 4527.18±40.19c 118.42±0.99c 6.54±0.13c 85.24±0.33c 12 75.12±5.25c 2110.43±88.88c 5513.90±31.73d 120.31±1.00e 5.36±0.12a 90.33±0.78d 16 69.75±5.78b 1493.54±34.13b 3639.24±19.16b 118.99±1.36cd 6.08±0.07b 89.13±0.54d 20 42.22±3.62a 669.47±13.39a 2369.62±43.61a 112.51±0.60b 6.06±0.09d 74.82±1.57a 表 8 不同蒸汽量下面片的剪切特性、蒸煮特性及感官评价的相关性分析

Table 8 Correlation analysis of shear characteristics, cooking characteristics and sensory evaluation of lower slices with different steam volumes

指标 硬度 咀嚼性 蒸煮损失率 吸水指数 感官评价 延展性 硬度 1 咀嚼性 −0.787** 1 蒸煮损失率 0.991** −0.775** 1 吸水指数 −0.857** 0.464 −0.826** 1 感官评价 −0.664** 0.219 −0.594* 0.750** 1 延展性 −0.777** 0.773** −0.770** 0.765** 0.235 1 表 9 面片熟化工艺的响应面试验设计及结果

Table 9 Response surface test design and results of surface curing process

实验号 微波火力(%) 时间(min) 蒸汽量(L) 延展性(g·s) 硬度

(g)咀嚼性

(g·s)吸水指数(%) 蒸煮损失率(%) 淀粉糊化度(%) 感官得分(分) 1 0 0 0 108.16 2304.46 5099.52 141.52 2.88 78.24 91.20 2 1 0 1 25.49 536.23 2544.32 127.40 3.49 88.34 72.50 3 −1 0 −1 34.66 1450.78 3777.29 120.01 3.75 78.73 81.40 4 0 −1 1 77.95 576.33 4273.85 128.77 4.29 88.98 84.40 5 0 1 1 40.05 554.06 1131.12 128.82 3.78 88.45 83.30 6 −1 1 0 47.06 620.87 2982.77 101.23 4.08 77.49 84.30 7 0 0 0 106.16 1904.46 4899.52 135.52 2.67 79.52 89.20 8 0 0 0 103.16 2104.46 5045.52 138.52 2.77 80.24 88.60 9 1 −1 0 56.61 541.70 1751.00 115.40 3.79 88.43 80.40 10 −1 0 1 74.72 1007.35 1783.02 108.31 3.92 82.31 83.50 11 −1 −1 0 83.58 536.24 3525.87 126.03 4.64 82.99 82.30 12 0 0 0 100.16 2164.46 4609.52 138.52 2.85 80.24 90.60 13 1 1 0 39.48 526.58 2229.35 126.10 3.75 87.92 79.20 14 1 0 −1 76.47 668.10 2251.52 116.41 3.02 85.30 86.50 15 0 −1 −1 65.54 281.93 2017.39 132.82 3.45 88.40 89.10 16 0 0 0 98.16 2204.46 5200.52 142.52 2.79 81.24 91.80 17 0 1 −1 60.92 1531.95 4661.54 124.32 3.29 79.84 87.60 表 10 面片品质中主成分的特征值及贡献率

Table 10 Characteristic values and contribution rates of principal components in surface quality

主成分 特征值 贡献率(%) 累积贡献率(%) 1 4.562 65.169 65.169 2 1.031 14.722 79.891 3 0.577 8.238 88.129 4 0.499 7.123 95.252 5 0.174 2.483 97.736 6 0.108 1.548 99.284 7 0.050 0.716 100.000 表 11 主要指标的特征向量

Table 11 Characteristic direction of main indicators

指标 第1主成分 第2主成分 硬度 0.939 −0.129 咀嚼性 0.868 −0.141 感官得分 0.835 0.014 延展性 0.845 0.091 蒸煮损失率 −0.772 −0.252 吸水指数 0.689 0.636 淀粉α度 −0.667 0.719 表 12 主成分得分值及规范化综合得分

Table 12 Principal component scores and standardized comprehensive scores

序号 第1主成分 第2主成分 综合得分 规范化综合得分 1 3.37 1.74 2.45 1.00 2 −2.59 −0.78 −1.8 0.00 3 −0.53 0.05 −0.34 0.344 4 −0.88 −1.11 −0.73 0.252 5 −2.09 −0.62 −1.46 0.08 6 −1.49 −0.71 −1.07 0.172 7 2.76 1.34 1.99 0.892 8 2.8 1.29 2.02 0.899 9 −2.28 −1.42 −1.69 0.0259 10 −1.32 −0.88 −0.99 0.191 11 −1.05 −0.34 −0.74 0.249 12 2.77 1.29 1.99 0.892 13 −2.13 −0.8 −1.5 0.306 14 −0.57 −0.5 −0.44 0.32 15 −0.85 −0.18 −0.58 0.287 16 3.1 1.31 2.22 0.946 17 0.97 0.31 0.68 0.584 表 13 回归模型方差分析

Table 13 Analysis of variance of regression model

项目 平方和 自由度 均方 F值 P值 显著性 模型 1.944 9 0.216 100.856 <0.0001 ** A-微波火力 0.012 1 0.012 5.792 0.047 * B-时间 0.015 1 0.015 7.110 0.032 * C-蒸汽量 0.131 1 0.131 60.969 0.0001 ** AB 0.032 1 0.032 14.962 0.006 ** AC 0.006 1 0.006 2.878 0.134 BC 0.050 1 0.050 23.536 0.002 ** A2 0.701 1 0.701 327.545 <0.0001 ** B2 0.441 1 0.441 205.960 <0.0001 ** C2 0.380 1 0.380 177.432 <0.0001 ** 残差 0.015 7 0.002 失拟值 0.004 3 0.001 0.463 0.723 纯误差 0.011 4 0.003 总和 1.959 16 R2 0.9823 R2Adj 0.9725 -

[1] 俞明君. 烹饪加工方式对香菇营养特性和抗氧化活性的影响研究[D]. 新乡: 河南科技学院, 2020. YU Mingjun. Effects of cooking methods on nutritional characteristics and antioxidant activity of Lentinus edodes [D]. Xinxiang: Henan Institute of Science and Technology, 2020.

[2] 张钟, 卫定军, 戴震亚, 等. 不同熟制干制方法对方便面品质的影响[J]. 粮油食品科技,2006(5):35−36. [ZHANG Zhong, WEI Dingjun, DAI Zhenya, et al. Effects of different ripening and drying methods on quality of instant noodles[J]. Cereals, Oils and Food Science and Technology,2006(5):35−36. doi: 10.3969/j.issn.1007-7561.2006.05.015 ZHANG ZHONG, WEI DINGJUN, DAI ZHENYA, et al. Effects of different ripening and drying methods on quality of instant noodles [J]. Cereals, Oils and Food Science and Technology, 2006(5): 35-36. doi: 10.3969/j.issn.1007-7561.2006.05.015

[3] YANG W, LU X, ZHANG Y, et al. Effect of cooking methods on the health‐promoting compounds, antioxidant activity and nitrate of tatsoi (Brassica rapa L. ssp. narinosa)[J]. Journal of Food Processing and Preservation,2019(8):43.

[4] AYAPPA K G, DAVIS H T, CRAPISTE G, et al. Microwave heating: An evaluation of power formulations[J]. Chemical Eng Sci,1991,46(4):1005−1016. doi: 10.1016/0009-2509(91)85093-D

[5] 王春霞, 周国燕. 微波加热对冷冻馒头品质特性的影响[J]. 食品科学,2013,34(3):11−15. [WANG Chunxia, ZHOU Guoyan. Effects of microwave heating on quality characteristics of frozen steamed bread[J]. Food Science,2013,34(3):11−15. WANG CHUNXIA, ZHOU GUOYAN. Effects of microwave heating on quality characteristics of frozen steamed bread[J]. Food Science, 2013, 34(3): 11-15.

[6] 陈舒唱, 刘世忍, 王辉 等. 不同冻结温度对微波-蒸汽熟化油塔子的影响[J]. 中国粮油学报,2021,17(8):1−12. [CHEN Shuchang, LIU Shiren, WANG Hui, et al. Effects of different freezing temperatures on microwave-steam ripening oil tower[J]. Journal of the Chinese Cereals and Oils Society,2021,17(8):1−12. doi: 10.3969/j.issn.1003-0174.2021.08.002 CHEN SHUCHANG, LIU SHIREN, WANG HUI, et al. Effects of different freezing temperatures on microwave-steam ripening oil tower[J]. Journal of the Chinese Cereals and Oils Society, 2021, 17(8): 1-12. doi: 10.3969/j.issn.1003-0174.2021.08.002

[7] PRONYK C, CENKOWSKI S, MUIR W E, et al. Effects of dough resting time and saturated steam pre-treatment on the textural properties of superheated steam processed instant asian noodles, Minneapolis, MN, United states, 2007 [C]// American Society of Agricultural and Biological Engineers, 2007.

[8] 王乐, 黄峻榕, 张宁 等. 马铃薯面条制作工艺及品质研究[J]. 食品研究与开发,2017,38(1):78−82. [WANG Le, HUANG Junrong, ZHANG Ning, et al. Research on production technology and quality of potato noodle[J]. Food Research and Development,2017,38(1):78−82. doi: 10.3969/j.issn.1005-6521.2017.01.018 WANG LE, HUANG JUNRONG, ZHANG NING, et al. Research on production technology and quality of potato noodle [J]. Food Research and Development, 2017, 38(1): 78-82. doi: 10.3969/j.issn.1005-6521.2017.01.018

[9] 中华人民共和国卫生健康委员会, 国家标准化管理委员会. GB/T 3212-2021 食品安全国家标准 挂面[S]. 北京: 中国标准出版社, 2021. National Health Commission of The People's Republic of China, Standardization Administration. GB/T 3212-2021 National Standard for Food Safety Noodle[S]. Beijing: Standards Press of China, 2021.

[10] 熊易强. 饲料淀粉糊化度(熟化度)的测定[J]. 饲料工业,2000(3):30−31. [XIONG Yiqiang. Determination of gelatinization degree (curing degree) of feed starch[J]. Feed Industry,2000(3):30−31. doi: 10.3969/j.issn.1001-991X.2000.03.012 XIONG YIQIANG. Determination of gelatinization degree (curing degree) of feed starch [J]. Feed Industry, 2000(3): 30-31. doi: 10.3969/j.issn.1001-991X.2000.03.012

[11] 中华人民共和国卫生健康委员会, 国家标准化管理委员会. GB/T 25005-2010 感官分析 方便面感官评价方法[S]. 北京: 中国标准出版社, 2010. National Health Commission of The People's Republicof China, Standardization Administration. GB/T 25005-2010 Sensory analysis. Sensory evaluation method of instant noodles [S]. Beijing: Standards Press of China, 2010.

[12] 林玉锋, 黄后培, 刘嘉怡 等. 不同烹饪方式对牡蛎蛋白质营养品质的影响[J]. 食品科技,2020,45(7):143−151. [LIN Yufeng, HUANG Houpei, LIU Jiayi, et al. Effects of different cooking methods on protein nutritional quality of oyster[J]. Food Science and Technology,2020,45(7):143−151. LIN YUFENG, HUANG HOUPEI, LIU JIAYI, et al. Effects of different cooking methods on protein nutritional quality of oyster [J]. Food Science and Technology, 2020, 45(7): 143-151.

[13] ZENG S, CHEN B, ZENG H, et al. Effect of microwave irradiation on the physicochemical and digestive properties of lotus seed starch[J]. Journal of Agricultural & Food Chemistry,2016,52(1):95−110.

[14] 胡舰. 非油炸膨化方便面的研制及其营养卫生学评价[D]. 扬州: 扬州大学, 2019. HU Jian. Development and nutrition and hygiene evaluation of non-fried puffed instant noodles [D]. Yangzhou: Yangzhou University, 2019.

[15] 吴昊, 陈存社, 杨菊芳 等. 不同压力蒸汽对面条汽蒸处理效果的比较研究[J]. 食品工业科技,2013,34(21):111−114. [WU Hao, CHEN Cunshe, YANG Jufang, et al. Comparison of steam treatment effect on noodle under different pressure[J]. Science and Technology of Food Industry,2013,34(21):111−114. WU HAO, CHEN CUNSHE, YANG JUFANG, et al. Comparison of steam treatment effect on noodle under different pressure [J]. Science and Technology of Food Industry, 2013, 34(21): 111-114.

[16] 苗延涛. 谈方便面蒸煮生产工艺技术[J]. 商业科技开发,1996(4):30−31. [MIAO Yantao. Discussion on the cooking technology of instant noodles[J]. Commercial Science and Technology Development,1996(4):30−31. MIAO YANTAO. Discussion on the cooking technology of instant noodles [J]. Commercial Science and Technology Development, 1996(4): 30-31.

[17] 唐连香, 高长胜, 王旭东 等. 方便面熟化度的测定[J]. 食品科技,1999(5):47−48. [TANG Lianxiang, GAO Changsheng, WANG Xudong, et al. Determination of ripening degree of instant noodles[J]. Food Science and Technology,1999(5):47−48. TANG LIANXIANG, GAO CHANGSHENG, WANG XUDONG, et al. Determination of ripening degree of instant noodles [J]. Food Science and Technology, 1999(5): 47-48.

[18] 胡秋龙, 杨代明, 言剑 等. 方便粉熟化度的分析方法研究[J]. 食品与机械,2010,26(4):70−72. [HU Qiulong, YANG Daiming, YAN Jian, et al. Study on Analysis method of curing degree of instant powder[J]. Food and Machinery,2010,26(4):70−72. HU QIULONG, YANG DAIMING, YAN JIAN, et al. Study on Analysis method of curing degree of instant powder [J]. Food and Machinery, 2010, 26(04): 70-72.

[19] GUILLEN-CASLA V, ROSALES-CONRADO N, LEÓN-GONZÁLEZ M E, et al. Principal component analysis (PCA) and multiple linear regression (MLR) statistical tools to evaluate the effect of E-beam irradiation on ready-to-eat food[J]. Journal of Food Composition and Analysis,2011,24(3):456−464. doi: 10.1016/j.jfca.2010.11.010

[20] CHUN M H, KIM E K, KANG R L, et al. Quality control of Schizonepeta tenuifolia Briq by solid-phase microextraction gas chromatography/mass spectrometry and principal component analysis[J]. Microchemical Journal,2010,95(1):25−31. doi: 10.1016/j.microc.2009.09.009

[21] BEATRIZ S, SIQUEIRA, PRISCILA Z, et al. Analyses of technological and biochemical parameters related to the HTC phenomenon in carioca bean genotypes by the use of PCA[J]. LWT-Food Science and Technology,2016,65(1):939−945.

[22] GHOSH D, CHATTOPADHYAY P. Application of principal component analysis (PCA) as a sensory assessment tool for fermented food products[J]. Journal of Food Science and Technology,2012,49(3):328−334. doi: 10.1007/s13197-011-0280-9

[23] 公艳, 熊双丽, 彭凌 等. 响应面-主成分分析法优化马铃薯挂面工艺[J]. 食品工业科技,2017,38(23):143−150,158. [GONG Yan, XIONG Shuangli, PENG Ling, et al. Optimization of potato noodle technology by Response Face-principal Component Analysis[J]. Science and Technology of Food Industry,2017,38(23):143−150,158. GONG YAN, XIONG SHUANGLI, PENG LING et al. Optimization of potato noodle technology by Response Face-principal Component Analysis[J]. Science and Technology of Food Industry, 2017, 38(23): 143-150, 158.

[24] 肖世娣, 王菁, 薛逸轩 等. 响应面-主成分分析法优化仙人掌发酵酒工艺[J]. 食品工业科技,2019,40(15):113−119,128. [XIAO Shidi, WANG Jing, XUE Yixuan, et al. Optimization of cactus fermented wine process by response surface methodology and principal component analysis[J]. Science and Technology of Food Industry,2019,40(15):113−119,128. XIAO SHIDI WANG JING, XUE YIXUAN et al. Optimization of cactus fermented wine process by response surface methodology and principal component analysis [J]. Science and Technology of Food Industry, 2019, 40(15): 113-119, 128.

-

期刊类型引用(2)

1. 蒋亚吉,丁雪梅,刘亚萍,孟金明. 风吹豆豉牛肉干加工工艺的研究. 粮食与油脂. 2023(12): 102-107 .  百度学术

百度学术

2. 罗秋霞,何江红,刘倩,夏龙,李杨,张惠,程利思,刘承慈,苏雨婷,曾义星. 不同大米对八宝粥食用品质的影响. 粮食与食品工业. 2022(04): 33-36 .  百度学术

百度学术

其他类型引用(1)

下载:

下载:

下载:

下载: