Intermittent Microwave Drying Characteristics and Quality Changes of Xilin Fire Ginger Slices

-

摘要: 为提高西林火姜干燥效率,研究了西林火姜片微波间歇干燥特性,建立干燥动力学模型。以微波功率密度、间歇时间、铺料密度、切片厚度为考察因素,实时测定各条件下西林火姜片微波间歇干燥过程中水分变化,通过对4种常见干燥模型的拟合,优选出适用于西林火姜片微波间歇干燥的模型,并对其参数求解,得到可实时指导西林火姜片微波间歇干燥的模型。结果表明,西林火姜片在微波间歇干燥过程中有加速、恒速和降速三个阶段;微波功率密度越高、间歇时间越短、铺料密度越小和厚度越小,干燥速率越快,所需的干燥时间越短;西林火姜片微波间歇干燥较优微波功率密度0.9 W/g,间歇时间1.0 min,铺料密度0.6 g/cm2,切片厚度6 mm。Page模型最符合西林火姜片微波间歇干燥(R2=0.977),有效水分扩散系数为(0.9727~7.7815)×10-9 m2/s。建立的干燥动力学模型可以客观有效地反应西林火姜片微波间歇干燥过程,可为西林火姜片的微波干燥工艺提供理论参考。Abstract: In order to improve the drying efficiency, microwave intermittent drying characteristics of Xilin fire ginger slices were studied and drying kinetics model was established. Using microwave power density, intermittent time, laying density and slice thickness as the factors, the moisture changes in the microwave intermittent drying process of Xilin fire ginger slices under various conditions were measured in real time. By fitting four common drying models, the suitable model for microwave intermittent drying of Xilin fire ginger slices was optimized and its parameters were solved. A model for real time microwave intermittent drying of Xilin fire ginger slices was obtained. The results showed that there were three stages in the microwave intermittent drying process: Acceleration, constant speed and deceleration. The higher the microwave power density, the shorter the batch time, the smaller the laying density and the smaller the thickness, the faster the drying rate, the shorter the drying time required. The optimum microwave power density was 0.9 W/g, the intermittent drying time was 1.0 min, the laying density was 0.6 g/cm2, and the thickness of slices was 6 mm. The Page model was the most suitable for microwave intermittent drying (R2=0.977), and the effective water diffusion coefficient was (0.9727~7.7815)×10-9 m2/s. The drying kinetics model established can objectively and effectively reflect the microwave intermittent drying process of Xilin fire ginger slices, and can provide theoretical reference for microwave drying process of Xilin fire ginger slices.

-

Keywords:

- Xilin fire ginger /

- intermittent microwave /

- drying characteristics /

- kinetic model

-

西林火姜又名细肉姜、小黄姜,姜科属植物,草本多年生单子叶植物姜的地下根茎,一种常见的香辛调味料和传统中医药材[1]。西林火姜姜球较小,根、茎、皮、肉皆为淡黄色,肉质致密,姜香浓郁,因其姜辣素含量高,食用口感火辣,辛辣味浓,辛辣与香味和药效都优于大种生姜,故被称为“火姜”。西林火姜有益脾胃、除湿消痞、止咳祛痰等功效,是广西百色市西林县著名特产,已评为中国国家地理标志产品[2-3]。目前,以西林火姜为原料的加工品已有西林姜晶[4]、西林火姜枸杞复合型饮料[5]等。

西林火姜收获时间短,水分含量高,不利于贮藏和运输。因此将西林火姜加工制成干姜片和姜粉,不仅可以延长贮藏期,而且方便运输和进一步的深加工。在实际生产中,热风干燥是西林火姜干姜片的主要干燥方法,然而,热风干燥存在干燥时间长、能耗大、品质差等状况。微波是一种频率在300 MHz~300 GHz之间、波长1 mm~1 m的电磁波,它介于低频的无线电波和高频的红外线之间,属于非电离辐射[6-8]。微波干燥具有干燥速度快、干燥持续进行、易于控制等特点[9-10]。唐小闲等[11]以马蹄为原料,采用微波间歇方式对马蹄淀粉进行干燥,结果表明经微波间歇干燥后含水率达到淀粉安全含水率的标准,白度得到小幅提高,酸度下降,碘蓝值上升,综合品质得到提高。韩姝葶等[12]利用微波间歇干燥铁皮石斛,结果表明,微波间歇干燥可以在缩短干燥时间的同时,有效保留总酚及多糖类物质。李进一等[13]对发酵菜籽饼进行微波间歇干燥,结果表明,微波功率、间歇时间、微波加热时间对发酵菜籽饼的微波间歇干燥都有显著影响,选择适当的微波间歇干燥工艺能达到提高干燥速率和减少干燥能耗的目的。通过有效增加间歇这一步骤,能充分脱除西林火姜片水分,有效防止过热及局部焦糊,保证物料品质。然而,关于采用微波间歇干燥加工西林火姜的研究未见报道。

本研究以西林火姜为原料,采用微波间歇干燥技术制备干姜片。探究不同功率密度、不同间歇时间、不同铺料密度、不同切片厚度4个条件对西林火姜微波间歇干燥特性的影响,构建关于西林火姜微波间歇干燥的动力学模型,并对试验结果进行验证,为微波间歇干燥技术应用于西林火姜干燥提供试验依据。

1. 材料与方法

1.1 材料与仪器

西林火姜 取自广西西林县古障镇者黑村,个体完整、大小均匀、无机械伤的新鲜西林火姜。

Webox-A6型微波干燥机 株洲市微朗科技有限公司;JJ1000型电子天平 常熟市双杰测试仪器厂;DHS-20A型水分测定仪 力辰科技宁波有限公司。

1.2 实验方法

1.2.1 干燥工艺流程

西林火姜→清洗→沥干→切片→摆盘→微波间歇干燥→干片

1.2.2 功率密度对西林火姜微波间歇干燥特性的影响

在加热时间固定1 min,间歇时间为1 min,铺料密度为0.6 g/cm2,切片厚度为4 mm条件下,分别考察功率密度为0.3、0.6、0.9、1.2、1.5 W/g时对西林火姜微波间歇干燥特性的影响。利用间歇时间记录干燥过程中的重量,干燥至干基含水量小于0.12 g/g为止[14]。

1.2.3 间歇时间对西林火姜微波间歇干燥特性的影响

在加热时间固定1 min,功率密度为0.9 W/g,铺料密度为0.6 g/cm2,切片厚度为4 mm条件下,分别考察间歇时间为0.5、1.0、1.5、2.0 min时对西林火姜微波间歇干燥特性的影响。利用间歇时间记录干燥过程中的重量,干燥至干基含水量小于0.12 g/g为止。

1.2.4 铺料密度对西林火姜微波间歇干燥特性的影响

在加热时间固定1 min,功率密度为0.9 W/g,间歇时间为1.0 min,切片厚度为4 mm条件下,分别考察铺料密度为0.2、0.4、0.6、0.8 g/cm2时对西林火姜微波间歇干燥特性的影响。利用间歇时间记录干燥过程中的重量,干燥至干基含水量小于0.12 g/g为止。

1.2.5 切片厚度对西林火姜微波间歇干燥特性的影响

在加热时间固定1 min,功率密度为0.9 W/g,间歇时间为1.0 min,铺料密度为0.6 g/cm2的条件下,分别考察切片厚度为2、4、6、8 mm时对西林火姜微波间歇干燥特性的影响。利用间歇时间记录干燥过程中的重量,干燥至干基含水量小于0.12 g/g为止。

1.3 指标测定方法

1.3.1 含水量的计算方法

通过用DHS-20A型快速水分测定仪测定西林火姜的含水量。得到西林火姜平均初始含水量为80.01%。西林火姜干基含水量根据式(1)计算:

M=mt−mm (1) 式中,M—西林火姜微波干燥到t时刻时的干基含水量,g/g;mt—西林火姜微波干燥到t时刻时的质量,g;m—绝干西林火姜的质量,g[15]。

1.3.2 干燥速率的计算方法

干燥过程中干燥速率(Drying rate,DR)按公式(2)计算:

DR=Mt+Δt−MtΔt (2) 式中,DR—干燥速率,g/(g·min);Δt—相邻2次测定西林火姜的时间间隔,min;Mt+Δt—干燥至t+Δt时刻西林火姜的干基含水量,g/g;Mt—干燥至t时刻西林火姜的干基含水量,g/g[16]。

1.3.3 水分比的计算

水分比(Moisture ratio,MR)用于表示一定干燥条件下物料未被干燥除去的水分。干燥过程中MR计算按公式(3),(4)计算:

MR=Mt−MeMo−Me (3) 式中,MR—水分比;Mt—干燥至t时刻西林火姜的干基含水量,g/g;Me—西林火姜平衡干基含水量,g/g;M0—西林火姜初始干基含水量,g/g;由于西林火姜的平衡干基含水量Me远远小于M0和Mt,通常可以忽略不计,因此,可将式(3)简化成式(4)进行计算[17]:

MR=MtMo (4) 1.3.4 有效水分扩散系数

水分有效扩散系数(Effective diffusivity coefficient,Deff)是描述水分通过扩散迁移脱除的能力,可由第二菲克定律计算得到,干燥过程中Deff计算按公式(5),(6)计算:

MR=8π2exp(−π2DeffL2t) (5) 式中:MR—水分比;L—西林火姜的切片厚度,mm;t—干燥时间,min;Deff —水分有效扩散系数, m2/s。以lnMR对干燥时间t做直线方程,得到斜率k,代入公式(6)中求出Deff [8]。

k=−π2DeffL2 (6) 1.3.5 单位质量能耗的测定

单位质量能耗是单位产量所消耗的能量值,研究单位质量能耗可以更直观发现更为节能的微波加工西林火姜片的工艺参数。

e=p×t1000×m (7) 式中:e—单位质量能耗,W/(kJ/g); p—微波功率,W;m—除去的水分质量,g;t—微波加热时间,s[18]。

1.3.6 感官评价

对干燥后的西林火姜片进行感官评定,能直观评价不同实验条件下西林火姜干制品的品质。由10名感官评价员对西林火姜片的外观、口感、气味做出综合评定,评分标准如表1。

表 1 感官评价标准表Table 1. Standard table of sensory evaluations评价指标 评价标准 评分范围 外观色泽(30分) 无破损,颜色深黄明亮、色泽一致

稍有破损,颜色淡黄,不明亮、色泽较均匀

破损严重,颜色焦黑,不明亮、色泽不均匀21~30

11~20

0~10口感(40分) 口感佳,姜特有的辛辣味浓

口感一般,姜特有的辛辣味淡

口感差,无姜特有的辛辣味31~40

16~30

0~15风味(30分) 鲜香较好

鲜香一般

鲜香较差21~30

11~20

0~10总分 100 1.3.7 色泽测定

用CR-400型手持色差仪测定干燥前后西林火姜片L*、a*、b*值。L*值代表亮度从黑(L*=0)到白(L*=100);a*值代表红绿度从绿(-)到红(+);b*值代表黄蓝度从蓝(−)到黄(+)。每组实验测量6个样本,取其平均值。按公式(8)计算色差值[19]:

ΔE=√(L*1−L*0)2+(a*1−a*0)2+(b*1−b*0)2 (8) 式中:L1*、a1*、b1*为干燥前西林火姜片的色度值;L0*、a0*、b0*为干燥后西林火姜片的色度值。

1.3.8 综合指标

运用隶属度的综合评分法,将色差值、单位质量能耗、感官评分各项指标对西林火姜片干燥工艺进行综合评分[20]。感官评价指标都是越大越好,按式(9)计算。色差值和单位质量能耗指标都是越小越好,按式(10)计算,综合评分S按(11)计算。

I=ci−cmincmax−cmin (9) I=cmax−cicmax−cmin (10) 式中,I为隶属度;ci为指标值;cmin为指标最小值;cmax为指标最大值。

按式(11)进行加权得干燥工艺的综合评分S

S=aI1+bI2+cI3 (11) 式中,S为综合评分;I1为感官评分隶属度;I2为色差值隶属度;I3为单位质量能耗隶属度; a、b、c为各指标权重。

本文考虑以感官评价和色差值为主要指标,单位质量能耗为次要指标,于是取a=0.40,b=0.40,c=0.20。

1.3.9 干燥模型的拟合

本试验选用了4种最常见的干燥模型对西林火姜的干燥模型进行线性拟合[21],有利于对试验数据进行分析处理,4种动力学模型及其表达式见表2。

表 2 4 种动力学模型及其表达式Table 2. Four kinetic models and their expressions模型序号 模型名称 模型表达式 1 Logarithmic MR = aexp(-kt)+c 2 Handerson and Pabis MR= aexp(-kt) 3 Newton MR = exp(-kt) 4 Page MR = exp(-ktn) 注:a、n、k、c均表示待定常数;t表示时间,min。 1.4 数据处理

用Origin 8.0绘图,采用JMP 15.0 软件对西林火姜微波间歇干燥试验数据进行线性/非线性回归拟合,拟合度由决定系数R2、均方根误差RMSE和误差平方和SSE来评价, R2越大, RMSE和SSE越小则说明模型拟合效果越好[22]。

R2=1−∑ni=1(MRpre,i−MRexp,i)2∑ni=1(MRexp,i−¯MRexp,i)2 (12) RMSE=√∑ni=1(MRpre,i−MRexp,i)2n (13) SSE=∑ni=1(MRpre,i−MRexp,i)2 (14) 式中:MRexp,i,物料干燥试验时第i个水分比;MRpre,i,拟合模型时第i个水分比;n,试验测定数据个数;

¯MRexp,i 为试验中i个实际的均值[23]。2. 结果与分析

2.1 西林火姜微波间歇干燥特性

2.1.1 微波功率密度对西林火姜干燥间歇特性的影响

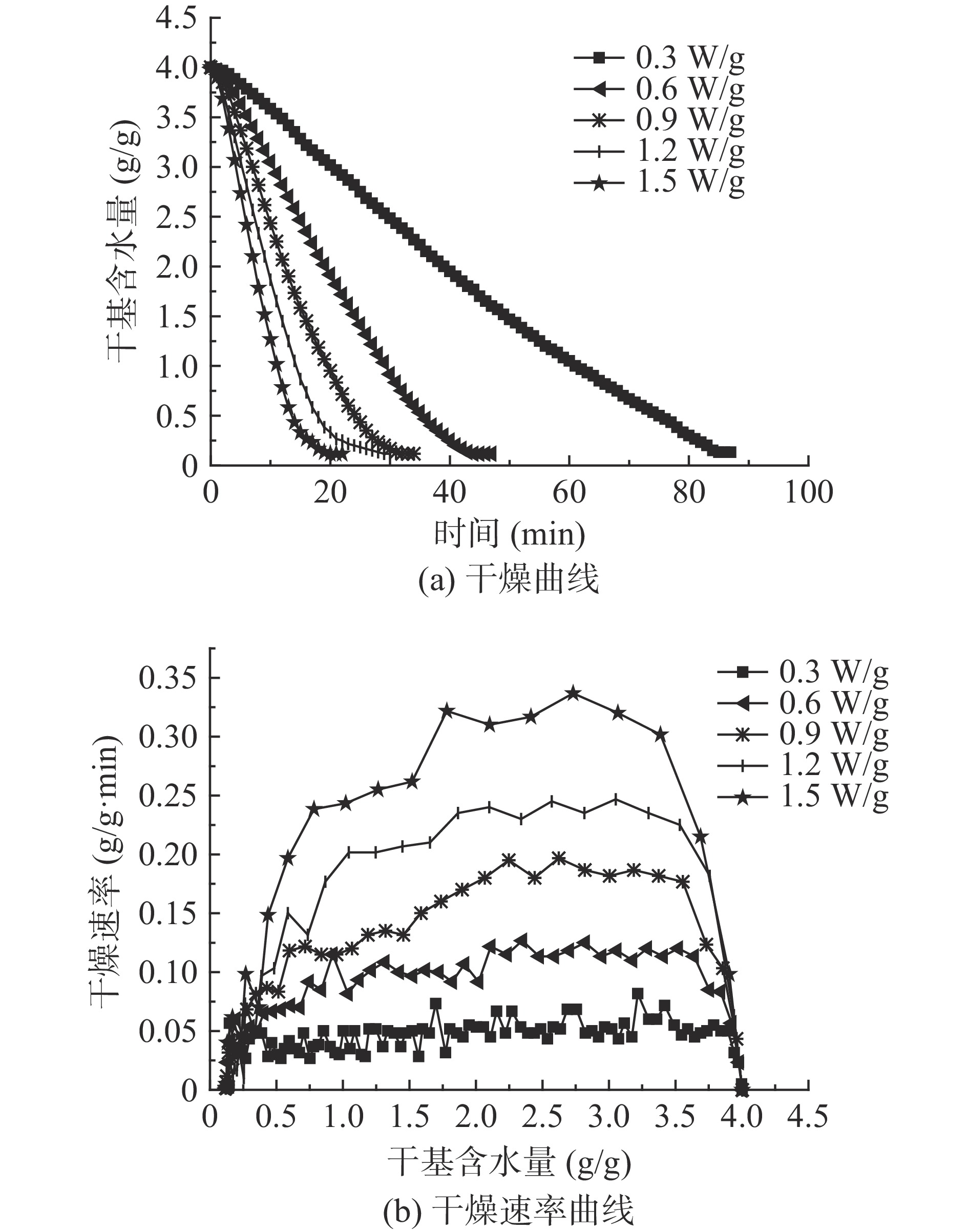

在1.2.2试验条件下,测得不同微波功率密度对西林火姜片微波干燥曲线和干燥速率曲线如图1所示。

由图1a可知,微波功率密度是影响西林火姜微波间歇干燥的重要因素,西林火姜的干基含水量随着干燥时间的延长持续降低,微波功率密度越大,西林火姜的干燥曲线斜率越大,干燥到相应干基含水量(低于0.12 g/g)的时间越短。当微波功率密度为1.5 W/g时,干基含水量达到要求(低于0.12 g/g)的时间为19 min,而微波功率密度为0.3 W/g时,干基含水量达到要求低于0.12 g/g的时间为84 min,时间相差3.42倍,这是由于其他条件固定时,单位质量物料吸收的微波能(即能量密度) 随着微波功率密度增大而增加,物料产生的热量更快,形成与周围热空气较大的水分梯度,加快了干燥速度,干燥时间就越短,因此,在一定的功率密度范围内,适当地提高微波功率密度可以缩短干燥时间[24]。

由图1b可知,5条不同微波功率密度的干燥速率曲线均有明显加速、恒速和降速三个阶段,其中,微波功率密度越大,干燥速率越大。随着微波功率密度增大,西林火姜片表面单位面积水分吸收的微波能就越多,从而加速了西林火姜片表面的水分迁移使干燥速率增大[25]。

2.1.2 微波功率密度对西林火姜干制品品质的影响

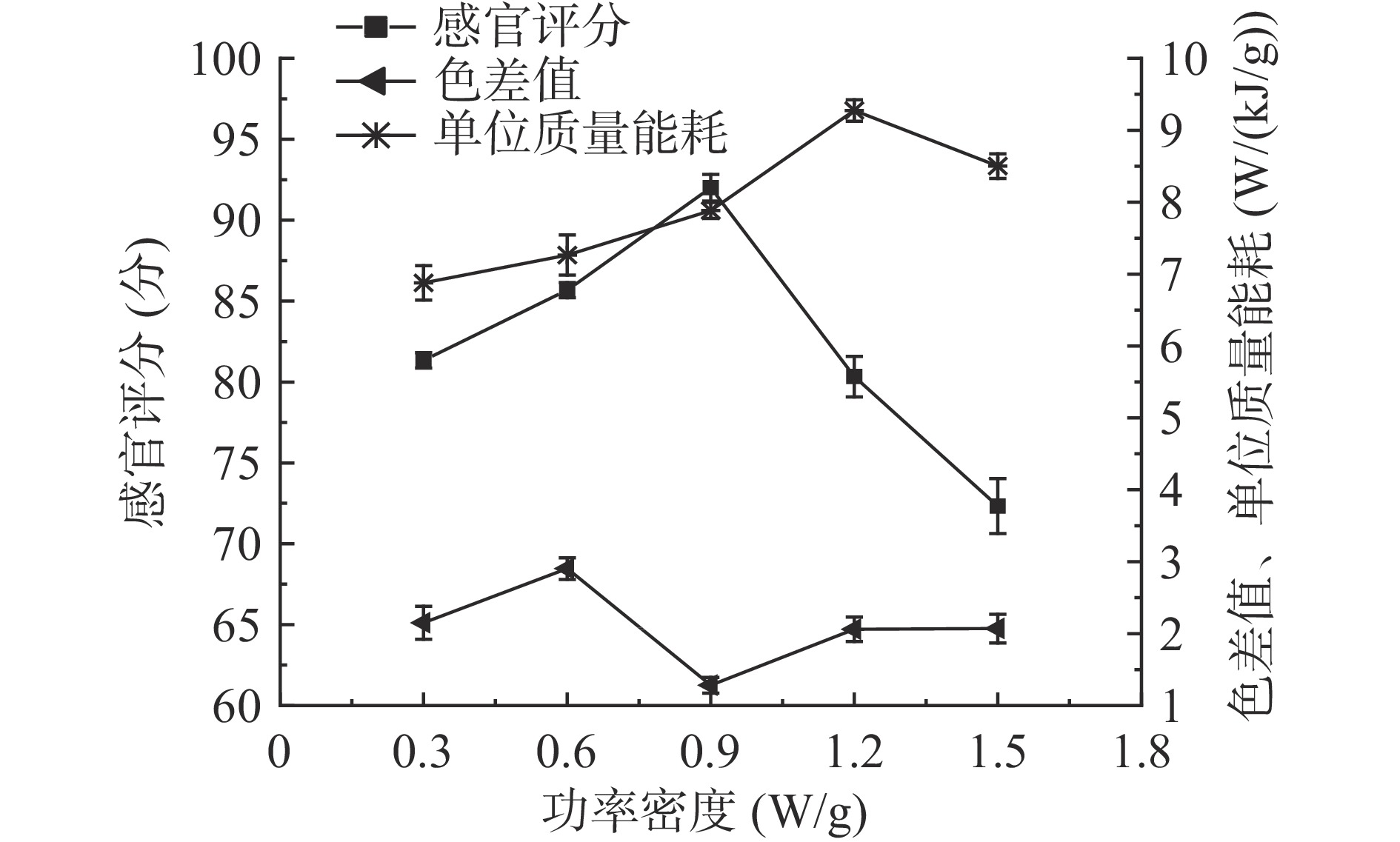

在1.2.2试验条件下,测得不同微波功率密度对西林火姜片干制品品质的影响如图2和图3所示。

由图2可知,在其他条件固定时,西林火姜片单位质量能耗随着微波功率密度的增大先上升后下降,原因是微波功率密度越小,水分含量越高,吸收微波的能力越强,消耗的能量越高,但随着功率密度的增大,含水率越来越低,到干燥后期,能够通过干燥去除的水分的质量变化不大,所以功率越大,单位质量能耗也越来越大。随着微波功率密度的增大,感官评价先上升后下降,微波功率密度过大导致西林火姜片部分焦化,功率过小造成西林火姜片软绵,口感不佳。在微波功率密度为0.9 W/g时,西林火姜片的色差值最小,说明该条件下获得的西林火姜片颜色、状态均较好。

由图3可知,当微波功率密度为0.9 W/g时综合评分最高。当微波功率密度为0.9 W/g时,感官评价为92 分,色差值为1.28,单位质量能耗是7.88 W/(kJ/g),综合评分是0.92。故最佳微波功率密度为0.9 W/g。

2.1.3 间歇时间对西林火姜微波间歇干燥特性的影响

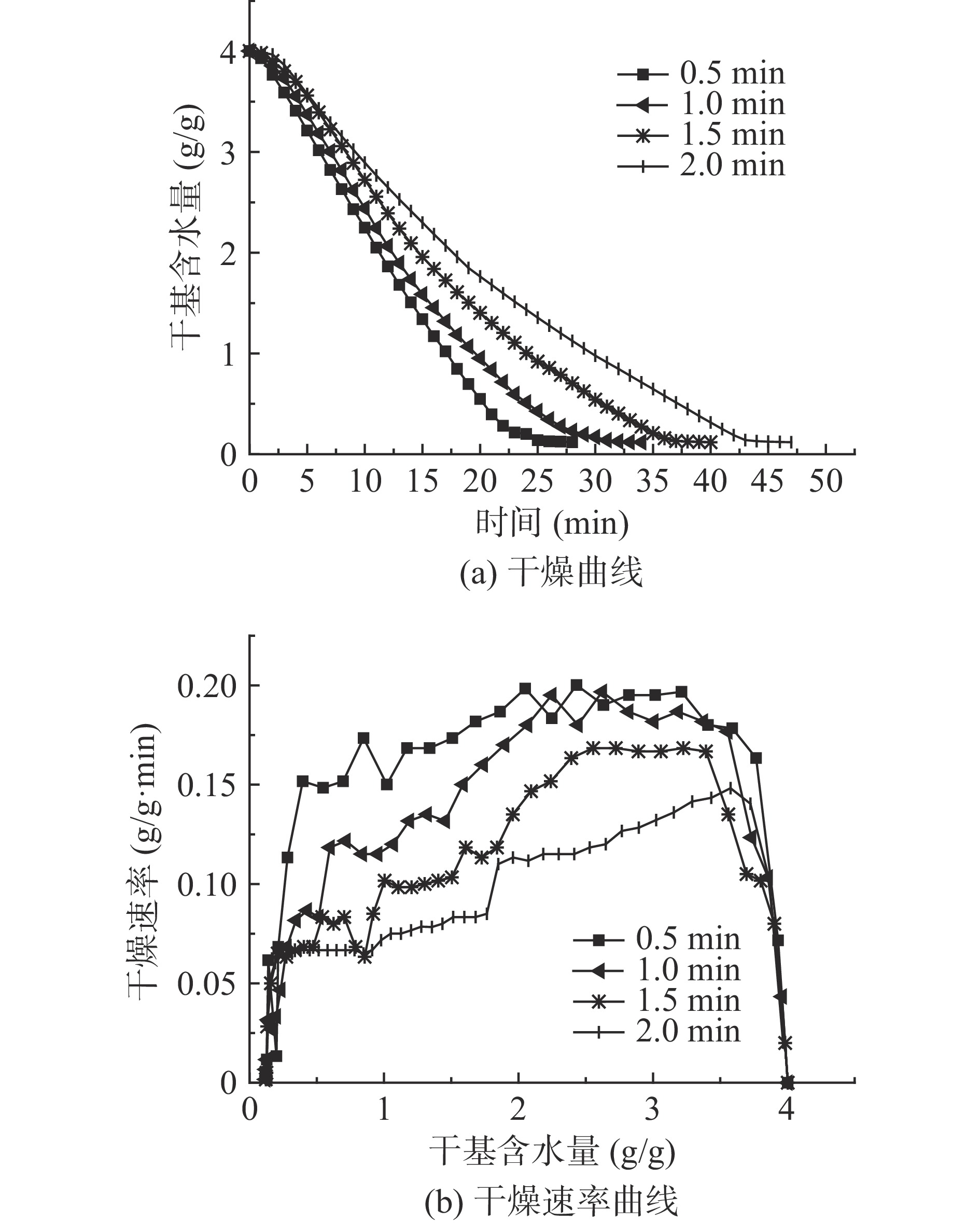

在1.2.3试验条件下,测得不同间歇时间对西林火姜片微波干燥曲线和干燥速率曲线如图4所示。

由图4a知,不同间歇时间西林火姜片微波干燥曲线线形相似,间歇时间越大,西林火姜的干燥曲线斜率越小,干燥到干基含水量低于0.12 g/g所需干燥时间越长。间歇时间分别为0.5、1.0、1.5、2.0 min时所需的干燥时间为25、31、35、43 min。

由图4b知,4条不同间歇时间的干燥速率曲线均有明显加速、恒速和降速三个阶段;间歇时间越大,干燥速率越小。随着干燥的进行,当间歇时间过短时,会造成局部过热,导致西林火姜片焦糊。当间歇时间过长时,所需的干燥总时间越长,且增加能耗。因此,有效增加间歇这一步骤,能充分脱除西林火姜片水分,有效防止局部焦糊,保证物料品质[26-27]。

2.1.4 间歇时间对西林火姜干制品品质的影响

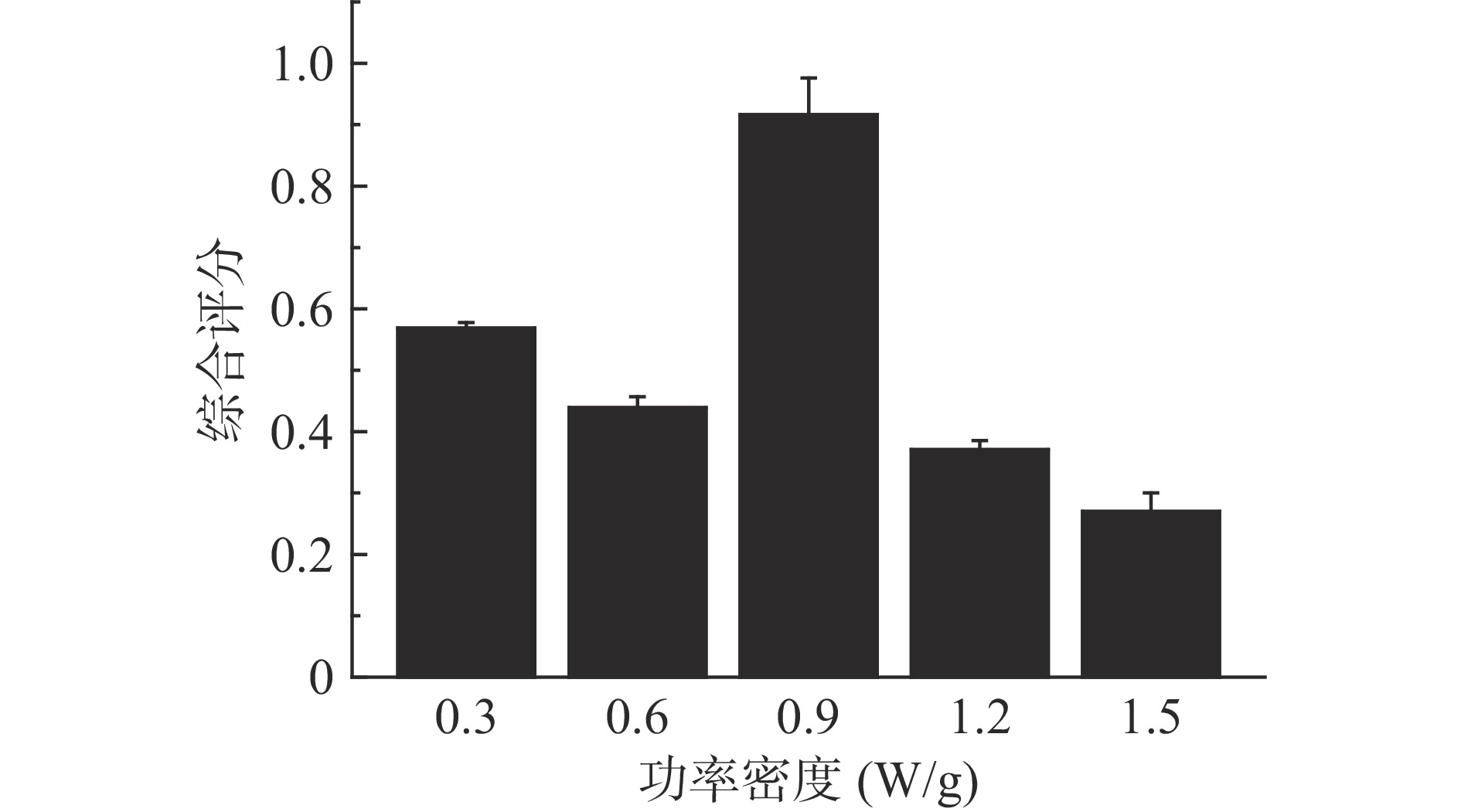

在1.2.3试验条件下,测得不同间歇时间对西林火姜片干制品品质的影响如图5和图6所示。

由图5可知,在其他条件固定时,西林火姜片单位质量能耗随着间歇时间的增加而增加,间歇时间过长会降低干燥效率,单位质量能耗高,所需的干燥时间越长。随着间歇时间的增加,感官评分呈先上升后下降的趋势,色差值呈下降的趋势,间歇时间过短会导致西林火姜片局部过热而出现部分焦糊,色差值越大;间歇时间过长造成西林火姜片软绵,口感不佳。

由图6可知,在其他条件固定时,综合评分随着间歇时间增加,呈先上升后下降趋势,当间歇时间为1.0 min时综合评分最高。当间歇时间为1.0 min时,感官评价为92分,色差值为1.28,单位质量能耗是7.88 W/(kJ/g),综合评分是0.94,故最佳间歇时间为1.0 min。

2.1.5 铺料密度对西林火姜微波间歇干燥特性的影响

在1.2.4试验条件下,测得不同铺料密度对西林火姜片微波干燥曲线和干燥速率曲线如图7所示。

由图7a知,铺料密度越大,西林火姜的干燥曲线斜率越小,干燥到干基含水量降至趋于平缓所需干燥时间越长。铺料密度分别为0.2、0.4、0.6、0.8 g/cm2时所需的干燥时间为22、26、32、34 min。

由图7b知,4条不同铺料密度的干燥速率曲线均有明显加速、恒速和降速三个阶段。随着铺料密度越大,干燥速率越小。这是由于在微波功率密度,间歇时间,切片厚度恒定的情况下,铺料密度越大,单位质量西林火姜片所分配到的微波功率减少,物料产生的热量越慢,干燥速率越小,因此所需的干燥时间越长[28]。

2.1.6 铺料密度对西林火姜干制品品质的影响

在1.2.4试验条件下,测得不同铺料密度对西林火姜片干制品品质的影响如图8和图9所示。

由图8可知,在其他条件固定时,随着铺料密度的增加,单位质量能耗明显增加,主要是因为单位质量西林火姜片所吸收微波越来越少,失水速度越来越慢,因此所消耗的能量越多。色差值随着铺料密度的增加,呈下降的趋势。随着铺料密度的增加,感官评分呈先上升后下降的趋势,主要是因为铺料密度过小会导致西林火姜片加热快,导致过热,出现部分焦糊的情况,品质差。

由图9可知,在其他条件固定时,综合评分随着铺料密度增加,呈先上升后下降趋势,当铺料密度为0.6 g/cm2时综合评分最高。当铺料密度为0.6 g/cm2时,感官评价为92分,色差值为1.28,单位质量能耗是7.88 W/(kJ/g),综合评分是0.83。故最佳铺料密度为0.6 g/cm2。

2.1.7 切片厚度对西林火姜微波间歇干燥特性的影响

在1.2.5试验条件下,测得不同切片厚度对西林火姜片微波干燥曲线和干燥速率曲线如图10所示。

由图10a知,随着干燥时间的增加,西林火姜片的干基含水量呈现降低趋势,且西林火姜的切片厚度越大,干燥曲线斜率越小,干燥到干基含水量低于0.12 g/g所需干燥时间越长。其中,在切片厚度分别为2、4、6、8 mm时所需的干燥时间分别为24、34、37、44 min。

由图10b知,4条不同切片厚度的干燥速率曲线均有明显加速、恒速和降速三个阶段;切片厚度越大,干燥速率越小。因为对于一定体积的物料来说,随着切片厚度的增大,延长了热量从外到内传递的距离,也延长了热量从内到外扩散的距离,内部水分迁移阻力变大,从而减慢了热量和水分的传递速度,传质与传热的速度也减慢,从而减少了干燥速率[29]。

2.1.8 切片厚度对西林火姜干制品品质的影响

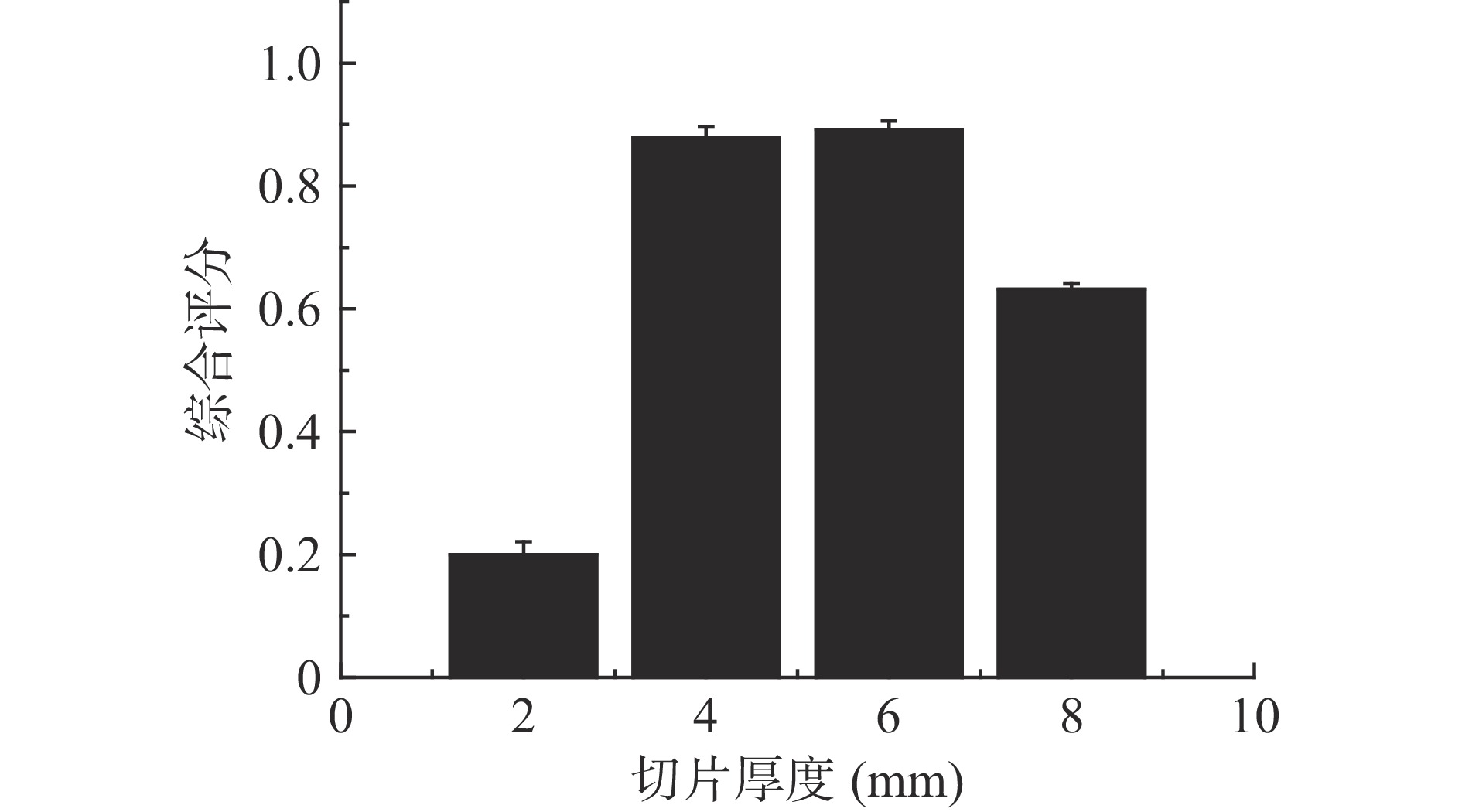

在1.2.5试验条件下,测得不同切片厚度对西林火姜片干制品品质的影响如图11和图12所示。

由图11可知,在其他条件固定时,切片厚度过大会降低干燥效率,单位质量能耗高,所需的干燥时间越长。随着切片厚度的增加,感官评分呈先上升后下降的趋势,主要是因为切片厚度过小,干燥速率过快,导致西林火姜片局部过热形成焦糊,切片厚度过大,干燥速率较慢,导致部分西林火姜片软绵,口感不佳。

由图12可知,在其他条件固定时,综合评分随着切片厚度增加,呈先上升后下降趋势,当切片厚度为6 mm时综合评分最高。当切片厚度为6 mm时,感官评价为94分,色差值为1.12,单位质量能耗是9.04 W/(kJ/g),综合评分是0.89,故最佳切片厚度为6 mm。

2.2 西林火姜片微波间歇干燥模型的拟合和建立

将不同微波功率密度、不同间歇时间、不同铺料密度、不同切片厚度下西林火姜片的水分比和干燥时间的干燥曲线进行非线性回归分析,进行最适模型的筛选,结果见表3。

表 3 4种动力学模型非线性回归拟合结果Table 3. Non-linear regression fitting results of four kinetic models模型

序号微波功率密度

(W/g)间歇时间

(min)铺料密度

(g/cm2)切片厚度

(mm)模型参数 决定系数R2 均方根误差

RMSE误差平方和

SSE0.3 1.0 0.6 4 a=2.1961,k=0.0072,c=−1.1680 0.99937 0.00755 0.00479 0.6 1.0 0.6 4 a=1.7073,k=0.0216,c=−0.6611 0.99570 0.02139 0.02013 0.9 1.0 0.6 4 a=1.3825,k=0.0455,c=−0.3309 0.99435 0.02487 0.01918 1.2 1.0 0.6 4 a=1.1909,k=0.0806,c=−0.1348 0.98831 0.03571 0.03442 1.5 1.0 0.6 4 a=1.2952,k=0.0881,c=−0.2615 0.99146 0.03173 0.01712 0.9 0.5 0.6 4 a=1.6020,k=0.0401,c=−0.5774 0.99310 0.02783 0.01937 1 0.9 1.0 0.6 4 a=1.3825,k=0.0455,c=−0.3309 0.99435 0.02487 0.01918 0.9 1.5 0.6 4 a=1.4056,k=0.0359,c=−0.3537 0.99710 0.01734 0.01113 0.9 2.0 0.6 4 a=1.3205,k=0.0416,c=−0.2538 0.99208 0.02053 0.01551 0.9 1.0 0.4 4 a=1.4210,k=0.0507,c=−0.3731 0.99230 0.029593 0.02280 0.9 1.0 0.6 4 a=1.3825,k=0.0455,c=−0.3309 0.99435 0.02487 0.01918 0.9 1.0 0.8 4 a=1.4186,k=0.0412,c=−0.3624 0.99351 0.02674 0.02360 0.9 1.0 0.6 2 a=1.7424,k=0.0366,c=−0.7088 0.99302 0.02834 0.01927 0.9 1.0 0.6 4 a=1.3825,k=0.0455,c=−0.3309 0.99435 0.02487 0.01918 0.9 1.0 0.6 6 a=1.3352,k=0.0409,c=−0.2900 0.99726 0.01674 0.01009 0.3 1.0 0.6 4 a=1.1201,k=0.0238 0.96714 0.05654 0.27170 0.6 1.0 0.6 4 a=1.1325,k=0.0519 0.96453 0.06439 0.18658 0.9 1.0 0.6 4 a=1.1176,k=0.0798 0.97436 0.05581 0.09967 1.2 1.0 0.6 4 a=1.0975,k=0.1082 0.97914 0.04987 0.06964 1.5 1.0 0.6 4 a=1.0857,k=0.1421 0.97466 0.05673 0.05794 0.9 0.5 0.6 4 a=1.1020,k=0.0908 0.96217 0.06773 0.11927 2 0.9 1.0 0.6 4 a=1.1176,k=0.0798 0.97436 0.05581 0.09967 0.9 1.5 0.6 4 a=1.1193,k=0.0642 0.97847 0.04975 0.09405 0.9 1.0 0.4 4 a=1.1154,k=0.0933 0.96942 0.06182 0.10319 0.9 1.0 0.6 4 a=1.1176,k=0.0798 0.97436 0.05581 0.09967 0.9 1.0 0.8 4 a=1.1255,k=0.0748 0.97173 0.05887 0.11784 0.9 1.0 0.6 2 a=1.1151,k=0.0918 0.95852 0.07177 0.12879 0.9 1.0 0.6 4 a=1.1176,k=0.0798 0.97436 0.05581 0.09967 0.9 1.0 0.6 6 a=1.10740,k=0.0682 0.98103 0.04660 0.08036 0.3 1.0 0.6 4 k=0.0210 0.97678 0.07060 0.42869 0.6 1.0 0.6 4 k=0.0457 0.97545 0.07869 0.28484 0.9 1.0 0.6 4 k=0.0715 0.98253 0.06816 0.15331 1.2 1.0 0.6 4 k=0.0991 0.98406 0.05835 0.09872 1.5 1.0 0.6 4 k=0.1312 0.98050 0.06317 0.07581 0.9 0.5 0.6 4 k=0.0824 0.97104 0.07580 0.15515 3 0.9 1.0 0.6 4 k=0.0715 0.98253 0.06816 0.15331 0.9 1.5 0.6 4 k=0.0572 0.98622 0.06396 0.15955 0.9 1.0 0.4 4 k=0.0839 0.97807 0.07285 0.14861 0.9 1.0 0.6 4 k=0.0715 0.98253 0.06816 0.15331 0.9 1.0 0.8 4 k=0.0666 0.91600 0.07224 0.18267 0.9 1.0 0.6 2 k=0.0822 0.96882 0.08182 0.17408 0.9 1.0 0.6 4 k=0.0715 0.98253 0.06816 0.15331 0.9 1.0 0.6 6 k=0.0616 0.98774 0.05867 0.06158 0.3 1.0 0.6 4 k=0.00302,n=1.50480 0.99467 0.02262 0.04350 0.6 1.0 0.6 4 k=0.00761,n=1.57056 0.99608 0.02138 0.02058 0.9 1.0 0.6 4 k=0.01899,n=1.48452 0.99834 0.01419 0.00644 1.2 1.0 0.6 4 k=0.03522,n=1.42088 0.99816 0.01507 0.00636 1.5 1.0 0.6 4 k=0.05054,n=1.44352 0.99826 0.01570 0.00444 0.9 0.5 0.6 4 k=0.02101,n=1.52849 0.99384 0.02787 0.02019 4 0.9 1.0 0.6 4 k=0.01899,n=1.48452 0.99834 0.01419 0.00644 0.9 1.5 0.6 4 k=0.01577,n=1.43946 0.99797 0.01474 0.00825 0.9 1.0 0.4 4 k=0.02147,n=1.52863 0.99810 0.01594 0.00686 0.9 1.0 0.6 4 k=0.01899,n=1.48452 0.99834 0.01419 0.00644 0.9 1.0 0.8 4 k=0.01535,n=1.52333 0.99824 0.01472 0.00736 0.9 1.0 0.6 2 k=0.01779,n=1.59572 0.99530 0.02491 0.01551 0.9 1.0 0.6 4 k=0.01899,n=1.48452 0.99834 0.01419 0.00644 0.9 1.0 0.6 6 k=0.01947,n=1.39962 0.99834 0.01343 0.00668 由表3可知,4种模型中Page的R2最高,均在0.99以上,其RMSE和SSE分别在0.01343~0.02787和0.00444~0.04350范围内变化,Page模型的拟合精度明显高于其他模型,说明能够采用Page 模型来描述西林火姜片微波间歇干燥过程中物料水分比的变化情况。因此,用Page模型可作为描述和预测西林火姜片微波间歇干燥的最优模型。

所以采用Page模型

ln(−lnMR)=lnk+nlnt 建立西林火姜微波间歇干燥动力学,令:lnk=a+bP+cX+dF+eH n=f+gP+hX+iF+jH 式中:P 为微波功率密度,w/g;X为间歇时间,min;F为铺料密度,g/cm2;H为切片厚度,mm;a、b、c、d、e、f、g、h、i、j 为待定系数,可得到:

ln(−lnMR)=a+bP+cX+dF+eH+(f+gP+hX+jH)lnt 将不同微波功率密度、不同间歇时间、不同铺料密度和不同切片厚度试验所得的数据依次代入,通过软件SPSS19.0对试验数据进行拟合得到各待定系数,为a=−3.357,b=1.566,c=−0.713,d=−1.219,e=−0.75,f=1.012,g=0.249,h=0.066,i=0.214,j=−0.013;F=2164.493,P<0.001;表明所求得的回归方程极显著:决定系数 R2=0.977,表明该模型有较高的拟合度。所得回归方程:

ln (−ln MR) = −3.357 + 1.566P − 0.713X−1.219F −0.75H+(1.012+0.249P+0.066X+0.214F−0.013H)ln t

由于

ln(−lnMR)=lnk+nlnt ,即可求得k=exp(−3.357+1.566P−0.713X−1.219F−0.75H),n=1.012+0.249P+0.066X+0.214F−0.013H 2.2.1 动力学模型的检验

为了检验回归模型和实验数据的准确性,设置实验条件为功率密度1.5 W/g,间歇时间1 min,铺料密度为0.4 g/cm2,切片厚度2 mm进行验证。拟合值和试验值结果见图13。

如图13所示,Page 方程的试验值与拟合值对比得出二者拟合比较好,Pearson相关系数为0.999,二者显著相关(P<0.05),说明Page 模型能够较好地反映和预测西林火姜微波干燥规律。

2.3 不同干燥条件下西林火姜片的有效水分扩散系数

有效水分扩散系数(Deff)是衡量干燥过程中物料水分蒸发速率快慢的重要指标,Deff越高,脱水能力越强,并且该系数对物料内部水分扩散过程的深入分析及干燥工艺的优化具有重要意义[30]。由表4可知,本实验有效水分扩散系数在(0.9727~7.7815)×10−9 m2/s之间,在食品干燥的有效水分扩散系数10−12~10-8 m2/s的范围内[31]。Deff随着微波功率密度和切片厚度的增加而增大,Deff随着间歇时间、铺料密度的增加而减小。因此,在干燥过程中,提高微波功率密度和切片厚度,降低间歇时间和铺料密度可以提升有效水分扩散系数,可以加快西林火姜片微波间歇干燥的质热传递,在实际应用中,可通过调节微波功率密度、间歇时间、铺料密度和切片厚度来改变干燥过程。

表 4 不同干燥条件下的有效水分扩散系数Table 4. Effective water diffusion coefficient under different drying conditions微波功

率密度

(W/g)间歇时间

(min)铺料密度

(g/cm2)切片厚

度(mm)ln MR-t

关系式有效扩

散系数

(10−9 m2/s)0.3 1.0 0.6 4 ln MR=−0.0006t+0.4038 0.9727 0.6 1.0 0.6 4 ln MR=−0.0013t+0.5175 2.1075 0.9 1.0 0.6 4 ln MR=−0.0019t+0.4510 3.0802 1.2 1.0 0.6 4 ln MR=−0.0023t+0.2856 3.7286 1.5 1.0 0.6 4 ln MR=−0.0033t+0.3665 5.3498 0.9 0.5 0.6 4 ln MR=−0.0024t+0.4972 3.8907 0.9 1.0 0.6 4 ln MR=−0.0019t+0.4510 3.0802 0.9 1.5 0.6 4 ln MR=−0.0015t+0.4422 2.4317 0.9 2.0 0.6 4 ln MR=−0.0013t+0.4311 2.1075 0.9 1.0 0.2 4 ln MR=−0.0027t+0.5212 4.3771 0.9 1.0 0.4 4 ln MR=−0.0023t+0.4737 3.7286 0.9 1.0 0.6 4 ln MR=−0.0019t+0.4510 3.0802 0.9 1.0 0.8 4 ln MR=−0.0018t+0.4669 2.9181 0.9 1.0 0.6 2 ln MR=−0.0024t+0.5241 0.9727 0.9 1.0 0.6 4 ln MR=−0.0019t+0.4510 3.0802 0.9 1.0 0.6 6 ln MR=−0.0016t+0.417 5.8361 0.9 1.0 0.6 8 ln MR=−0.0012t+0.4116 7.7815 3. 结论

a.西林火姜片微波间歇干燥过程中主要包括加速、恒速和降速三个阶段,其中,微波功率密度越高,间歇时间越短、铺料密度越小、切片厚度越小,其干燥速率越快,所需的干燥时间越短。通过对4种常见的动力学模型拟合分析,结果表明Page 模型最适合描述西林火姜片微波间歇干燥过程中水分变化规律的干燥模型,得到拟合方程为ln(−ln MR)=−3.357+1.566P−0.713X−1.219F−0.75H+(1.012+0.249P+0.066X+0.214F−0.013H)ln t通过该模型可以在确定微波功率密度、间歇时间、铺料密度和切片厚度的情况下准确地预测到任意时刻西林火姜片水分比的含量。

b.西林火姜片微波间歇干燥有效水分扩散系数随着微波功率密度、切片厚度的增加而增加,随着间歇时间、铺料密度的增加而减小。在微波功率密度0.3~1.5 W/g,间歇时间0.5~2.0 min,铺料密度0.2~0.8 g/cm2,切片厚度2~8 mm范围内,西林火姜片的微波间歇干燥有效水分扩散系数为(0.9727~7.7815)×10−9 m2/s,西林火姜片微波间歇干燥最佳微波功率密度0.9 W/g,间歇时间1.0 min,铺料密度0.6 g/cm2,切片厚度6 mm。

-

表 1 感官评价标准表

Table 1 Standard table of sensory evaluations

评价指标 评价标准 评分范围 外观色泽(30分) 无破损,颜色深黄明亮、色泽一致

稍有破损,颜色淡黄,不明亮、色泽较均匀

破损严重,颜色焦黑,不明亮、色泽不均匀21~30

11~20

0~10口感(40分) 口感佳,姜特有的辛辣味浓

口感一般,姜特有的辛辣味淡

口感差,无姜特有的辛辣味31~40

16~30

0~15风味(30分) 鲜香较好

鲜香一般

鲜香较差21~30

11~20

0~10总分 100 表 2 4 种动力学模型及其表达式

Table 2 Four kinetic models and their expressions

模型序号 模型名称 模型表达式 1 Logarithmic MR = aexp(-kt)+c 2 Handerson and Pabis MR= aexp(-kt) 3 Newton MR = exp(-kt) 4 Page MR = exp(-ktn) 注:a、n、k、c均表示待定常数;t表示时间,min。 表 3 4种动力学模型非线性回归拟合结果

Table 3 Non-linear regression fitting results of four kinetic models

模型

序号微波功率密度

(W/g)间歇时间

(min)铺料密度

(g/cm2)切片厚度

(mm)模型参数 决定系数R2 均方根误差

RMSE误差平方和

SSE0.3 1.0 0.6 4 a=2.1961,k=0.0072,c=−1.1680 0.99937 0.00755 0.00479 0.6 1.0 0.6 4 a=1.7073,k=0.0216,c=−0.6611 0.99570 0.02139 0.02013 0.9 1.0 0.6 4 a=1.3825,k=0.0455,c=−0.3309 0.99435 0.02487 0.01918 1.2 1.0 0.6 4 a=1.1909,k=0.0806,c=−0.1348 0.98831 0.03571 0.03442 1.5 1.0 0.6 4 a=1.2952,k=0.0881,c=−0.2615 0.99146 0.03173 0.01712 0.9 0.5 0.6 4 a=1.6020,k=0.0401,c=−0.5774 0.99310 0.02783 0.01937 1 0.9 1.0 0.6 4 a=1.3825,k=0.0455,c=−0.3309 0.99435 0.02487 0.01918 0.9 1.5 0.6 4 a=1.4056,k=0.0359,c=−0.3537 0.99710 0.01734 0.01113 0.9 2.0 0.6 4 a=1.3205,k=0.0416,c=−0.2538 0.99208 0.02053 0.01551 0.9 1.0 0.4 4 a=1.4210,k=0.0507,c=−0.3731 0.99230 0.029593 0.02280 0.9 1.0 0.6 4 a=1.3825,k=0.0455,c=−0.3309 0.99435 0.02487 0.01918 0.9 1.0 0.8 4 a=1.4186,k=0.0412,c=−0.3624 0.99351 0.02674 0.02360 0.9 1.0 0.6 2 a=1.7424,k=0.0366,c=−0.7088 0.99302 0.02834 0.01927 0.9 1.0 0.6 4 a=1.3825,k=0.0455,c=−0.3309 0.99435 0.02487 0.01918 0.9 1.0 0.6 6 a=1.3352,k=0.0409,c=−0.2900 0.99726 0.01674 0.01009 0.3 1.0 0.6 4 a=1.1201,k=0.0238 0.96714 0.05654 0.27170 0.6 1.0 0.6 4 a=1.1325,k=0.0519 0.96453 0.06439 0.18658 0.9 1.0 0.6 4 a=1.1176,k=0.0798 0.97436 0.05581 0.09967 1.2 1.0 0.6 4 a=1.0975,k=0.1082 0.97914 0.04987 0.06964 1.5 1.0 0.6 4 a=1.0857,k=0.1421 0.97466 0.05673 0.05794 0.9 0.5 0.6 4 a=1.1020,k=0.0908 0.96217 0.06773 0.11927 2 0.9 1.0 0.6 4 a=1.1176,k=0.0798 0.97436 0.05581 0.09967 0.9 1.5 0.6 4 a=1.1193,k=0.0642 0.97847 0.04975 0.09405 0.9 1.0 0.4 4 a=1.1154,k=0.0933 0.96942 0.06182 0.10319 0.9 1.0 0.6 4 a=1.1176,k=0.0798 0.97436 0.05581 0.09967 0.9 1.0 0.8 4 a=1.1255,k=0.0748 0.97173 0.05887 0.11784 0.9 1.0 0.6 2 a=1.1151,k=0.0918 0.95852 0.07177 0.12879 0.9 1.0 0.6 4 a=1.1176,k=0.0798 0.97436 0.05581 0.09967 0.9 1.0 0.6 6 a=1.10740,k=0.0682 0.98103 0.04660 0.08036 0.3 1.0 0.6 4 k=0.0210 0.97678 0.07060 0.42869 0.6 1.0 0.6 4 k=0.0457 0.97545 0.07869 0.28484 0.9 1.0 0.6 4 k=0.0715 0.98253 0.06816 0.15331 1.2 1.0 0.6 4 k=0.0991 0.98406 0.05835 0.09872 1.5 1.0 0.6 4 k=0.1312 0.98050 0.06317 0.07581 0.9 0.5 0.6 4 k=0.0824 0.97104 0.07580 0.15515 3 0.9 1.0 0.6 4 k=0.0715 0.98253 0.06816 0.15331 0.9 1.5 0.6 4 k=0.0572 0.98622 0.06396 0.15955 0.9 1.0 0.4 4 k=0.0839 0.97807 0.07285 0.14861 0.9 1.0 0.6 4 k=0.0715 0.98253 0.06816 0.15331 0.9 1.0 0.8 4 k=0.0666 0.91600 0.07224 0.18267 0.9 1.0 0.6 2 k=0.0822 0.96882 0.08182 0.17408 0.9 1.0 0.6 4 k=0.0715 0.98253 0.06816 0.15331 0.9 1.0 0.6 6 k=0.0616 0.98774 0.05867 0.06158 0.3 1.0 0.6 4 k=0.00302,n=1.50480 0.99467 0.02262 0.04350 0.6 1.0 0.6 4 k=0.00761,n=1.57056 0.99608 0.02138 0.02058 0.9 1.0 0.6 4 k=0.01899,n=1.48452 0.99834 0.01419 0.00644 1.2 1.0 0.6 4 k=0.03522,n=1.42088 0.99816 0.01507 0.00636 1.5 1.0 0.6 4 k=0.05054,n=1.44352 0.99826 0.01570 0.00444 0.9 0.5 0.6 4 k=0.02101,n=1.52849 0.99384 0.02787 0.02019 4 0.9 1.0 0.6 4 k=0.01899,n=1.48452 0.99834 0.01419 0.00644 0.9 1.5 0.6 4 k=0.01577,n=1.43946 0.99797 0.01474 0.00825 0.9 1.0 0.4 4 k=0.02147,n=1.52863 0.99810 0.01594 0.00686 0.9 1.0 0.6 4 k=0.01899,n=1.48452 0.99834 0.01419 0.00644 0.9 1.0 0.8 4 k=0.01535,n=1.52333 0.99824 0.01472 0.00736 0.9 1.0 0.6 2 k=0.01779,n=1.59572 0.99530 0.02491 0.01551 0.9 1.0 0.6 4 k=0.01899,n=1.48452 0.99834 0.01419 0.00644 0.9 1.0 0.6 6 k=0.01947,n=1.39962 0.99834 0.01343 0.00668 表 4 不同干燥条件下的有效水分扩散系数

Table 4 Effective water diffusion coefficient under different drying conditions

微波功

率密度

(W/g)间歇时间

(min)铺料密度

(g/cm2)切片厚

度(mm)ln MR-t

关系式有效扩

散系数

(10−9 m2/s)0.3 1.0 0.6 4 ln MR=−0.0006t+0.4038 0.9727 0.6 1.0 0.6 4 ln MR=−0.0013t+0.5175 2.1075 0.9 1.0 0.6 4 ln MR=−0.0019t+0.4510 3.0802 1.2 1.0 0.6 4 ln MR=−0.0023t+0.2856 3.7286 1.5 1.0 0.6 4 ln MR=−0.0033t+0.3665 5.3498 0.9 0.5 0.6 4 ln MR=−0.0024t+0.4972 3.8907 0.9 1.0 0.6 4 ln MR=−0.0019t+0.4510 3.0802 0.9 1.5 0.6 4 ln MR=−0.0015t+0.4422 2.4317 0.9 2.0 0.6 4 ln MR=−0.0013t+0.4311 2.1075 0.9 1.0 0.2 4 ln MR=−0.0027t+0.5212 4.3771 0.9 1.0 0.4 4 ln MR=−0.0023t+0.4737 3.7286 0.9 1.0 0.6 4 ln MR=−0.0019t+0.4510 3.0802 0.9 1.0 0.8 4 ln MR=−0.0018t+0.4669 2.9181 0.9 1.0 0.6 2 ln MR=−0.0024t+0.5241 0.9727 0.9 1.0 0.6 4 ln MR=−0.0019t+0.4510 3.0802 0.9 1.0 0.6 6 ln MR=−0.0016t+0.417 5.8361 0.9 1.0 0.6 8 ln MR=−0.0012t+0.4116 7.7815 -

[1] 张璐璐, 吴建文, 刘慧勤, 等. 西林火姜姜油树脂的成分分析[J]. 食品工业科技,2021,42(6):226−232. [ZHANG L L, WU J W, LIU H Q, et al. Composition analysis of Xilin fire ginger oleoresins[J]. Science and Technology of Food Industry,2021,42(6):226−232. [2] 黄皓, 周生茂, 尚小红, 等. 西林火姜健康组培苗快繁体系的建立[J]. 长江蔬菜,2016(20):25−29. [HUANG H, ZHOU S M, SHANG X H, et al. Establishment of rapid propagation system of healthy tissue culture seedlings of Xilin fire ginger[J]. Journal of Changjiang Vegetables,2016(20):25−29. doi: 10.3865/j.issn.1001-3547.2016.20.012 [3] 芦宇, 焦天慧, 李萌萌, 等. 生姜山药复合粉工艺优化及其体外模拟消化研究[J]. 中国食品学报,2018,18(11):81−89. [ LU Y, JIAO T H, LI M M, et al. Process optimizition of ginger-yam compound powder and its simulating digestion in virtro[J]. Journal of Chinese Institute of Food Science and Technology,2018,18(11):81−89. [4] 国家知识产权局. 西林姜晶[OL]. http://www.cgi.gov.cn/Products/Detail/1884/. State Intellectual Property Office, Xilin Jiang jing[OL]. http://www.cgi.gov.cn/Products/Detail/1884/

[5] 沈伟, 岑湘涛, 韦海婷, 等. 西林火姜枸杞复合型饮料的研制[J]. 农产品加工,2019(24):1−3. [SHEN W, CEN X T, WEI H T, et al. Development of xilin turmeric and Lycium barbarum compound beverage[J]. Farm Products Processing,2019(24):1−3. [6] LI Z, RAGHAVAN G S V, ORSAT V. Optimal power control strategies in microwave drying[J]. Journal of Food Engineering,2010,99(3):263−268. doi: 10.1016/j.jfoodeng.2010.02.024

[7] 刘盼盼, 任广跃, 段续, 等. 微波处理技术在食品干燥领域中的应用[J]. 食品与机械,2020,36(12):194−202. [ LIU P P, REN G Y, DUAN X, et al. Application of microwave treatment technology in the field of food drying[J]. Food & Machinery,2020,36(12):194−202. [8] XU W X, ISLAM M N, CAO X H, et al. Effect of relative humidity on drying characteristics of microwave assisted hot air drying and qualities of dried finger citron slices[J]. LWT,2020,137:110413.

[9] SU D, LV W, WANG Y, et al. Drying characteristics and water dynamics during microwave hot-air flow rolling drying of Pleurotus eryngii[J]. Drying Technology,2020,38(11):1493−1504. doi: 10.1080/07373937.2019.1648291

[10] CHEN C, YANG S, BU X. Microwave drying effect on pyrolysis characteristics and kinetics of microalgae[J]. BioEnergy Research,2019,12(2):400−408. doi: 10.1007/s12155-019-09970-z

[11] 唐小闲, 汤泉, 张巧, 等. 马蹄淀粉微波间歇干燥工艺研究[J]. 食品与机械,2018,34(4):211−215,220. [TANG X X, TANG Q, ZHANG Q, et al. Research on intermittent microwave drying of water chestnut starch[J]. Food & Machinery,2018,34(4):211−215,220. [12] 韩姝葶, 王婉馨, 袁国强, 等. 干燥方式对铁皮石斛品质的影响[J]. 食品科学,2019,40(3):142−148. [ HAN S T, WANG W X, YUAN G Q, et al. Effect of different drying methods on quality of Dendrobium officinale stems[J]. Food Science,2019,40(3):142−148. doi: 10.7506/spkx1002-6630-20180712-167 [13] 李进一, 袁建, 王明洁, 等. 发酵菜籽饼微波间歇干燥工艺研究[J]. 食品安全质量检测学报,2017,8(10):3997−4003. [LI J Y, YUAN J, WANG M J, et al. Optimization of microwave intermittent drying process of fermented rapeseed cake[J]. Journal of Food Safety & Quality,2017,8(10):3997−4003. doi: 10.3969/j.issn.2095-0381.2017.10.056 [14] 张凡. 姜片的微波与热风联合干燥工艺及动力学研究[D]. 长春: 吉林大学, 2015. ZHANG F. Research on combination drying process and kinetics of ginger slices using microwave-hot air dehydration[D]. Changchun: Jilin University, 2015.

[15] HUANG X, LI W, WANG Y, et al. Drying characteristics and quality of Stevia rebaudiana leaves by far-infrared radiation[J]. LWT- Food Science and Technology,2021,140:110638. doi: 10.1016/j.lwt.2020.110638

[16] 吴钊龙, 林芳, 陈振林, 等. 不同干燥方式对蚕蛹干制品品质的影响[J]. 保鲜与加工,2021,21(5):117−121. [WU Z L, LIN F, CHEN Z L, et al. Effect of different drying methods on the quality of silkworm pupa crisp[J]. Storage and Process,2021,21(5):117−121. [17] SUN X F, JIN X, FU N, et al. Effects of different pretreatment methods on the drying characteristics and quality of potatoes[J]. Food Science & Nutrition,2020,8(11):5767−5775.

[18] 林鸿. 铁皮石斛微波真空干燥特性及工艺优化研究[D]. 福州: 福建农林大学, 2020. LIN H. Study on microwave vacuum drying characteristics and process optimization of Dendrobium officinale[D]. Fuzhou: Fujian Agriculture and Forestry University, 2020.

[19] 孙宇, 霍瑞文, 李莹莹, 等. 蓝莓微波真空干燥特性及工艺研究[J]. 保鲜与加工,2021,21(6):57−65. [SUN Y, HUO R W, LI Y Y, et al. Study on microwave vacuum drying characteristics and technology of blueberry[J]. Storage and Process,2021,21(6):57−65. doi: 10.3969/j.issn.1009-6221.2021.06.010 [20] 李国鹏, 谢焕雄, 王嘉麟, 等. 鸡腿菇热风干燥工艺参数优化[J]. 农机化研究,2019,41(7):233−241. [LI G P, XIE H X, WANG J L, et al. Optimization of hot-air drying technology for Coprinus comatus[J]. Journal of Agricultural Mechanization Research,2019,41(7):233−241. doi: 10.3969/j.issn.1003-188X.2019.07.045 [21] 吴钊龙, 林芳, 陈振林, 等. 蚕蛹变温压差膨化干燥特性及其动力学模型研究[J]. 食品科技,2020,45(10):88−95. [WU Z L, LIN F, CHEN Z L, et al. Drying characteristics and kinetic modeling of silkworm pupa by explosion puffing drying at variable temperatures and pressure difference[J]. Food Science and Technology,2020,45(10):88−95. [22] 薛广, 李敏, 关志强. 基于Weibull函数的超声渗透罗非鱼片真空微波干燥模拟[J]. 食品与发酵工业,2020,46(1):157−165. [XUE G, LI M, GUAN Z Q. Simulation of vacuum microwave drying of Tilapia fillets by ultrasonic penetration based on Weibull function[J]. Food and Fermentation Industries,2020,46(1):157−165. [23] SHU B, WU G X, WANG Z N, et al. The effect of microwave vacuum drying process on citrus: Drying kinetics, physicochemical composition and antioxidant activity of dried citrus (Citrus reticulata Blanco) peel[J]. Journal of Food Measurement and Characterization,2020,32(11):1−10.

[24] HUANG D, MEN K Y, TANG X H, et al. Microwave intermittent drying characteristics of Camellia oleifera seeds[J]. Journal of Food Process Engineering,2020,44(1):13608.

[25] 代建武, 杨升霖, 王杰, 等. 微波真空干燥对香蕉片干燥特性及品质的影响[J]. 农业机械学报,2020,51(S1):493−500. [DAI J W, YANG S L, WANG J, et al. Effect of microwave vacuum drying conditions on drying characteristics and texture structure of banana chips[J]. Transactions of the Chinese Society for Agricultural Machinery,2020,51(S1):493−500. doi: 10.6041/j.issn.1000-1298.2020.S1.058 [26] DAI J W, XIAO H W, ZHANG L H, et al. Drying characteristics and modeling of apple slices during microwave intermittent drying[J]. Journal of Food Process Engineering,2019,42(6):13212.

[27] 盘喻颜, 段振华, 刘艳, 等. 火龙果片微波间歇干燥特性及其动力学研究[J]. 食品与机械,2019,35(3):195−201. [PAN Y Y, DUAN Z H, LIU Y, et al. Research on properties and kinetic model of intermittent microwave drying to pitaya slices[J]. Food & Machinery,2019,35(3):195−201. [28] 吴钊龙, 林芳, 陈振林, 等. 蚕蛹热泵干燥特性及其动力学模型研究[J]. 食品研究与开发,2020,41(18):1−6. [WU Z L, LIN F, CHEN Z L, et al. Heat pump drying characteristics and kinetic modeling of silkworm pupa[J]. Food Research and Development,2020,41(18):1−6. [29] LEE D Y, SO J D, JUNG H M, et al. Microwave drying characteristics of squash slices[J]. Korean Journal of Agricultural Science,2018,45(4):847−857.

[30] JIE W, JIAN W D, SHENG L Y, et al. Influence of pulsed vacuum drying on drying kinetics and nutritional value of corn kernels[J]. Journal of Food Process Engineering,2020,43(12):13550.

[31] 李叶贝, 任广跃, 屈展平, 等. 马铃薯小麦复合面条热泵干燥特性及数学模型的研究[J]. 中国粮油学报,2019,34(10):7−15. [ LI Y B, REN G Y, QU Z P, et al. Heat pump drying characteristics and mathematical model of potato wheat compound noodle[J]. Journal of the Chinese Cereals and Oils Association,2019,34(10):7−15. doi: 10.3969/j.issn.1003-0174.2019.10.003 -

期刊类型引用(6)

1. 李琳,崔彦阁,赵娟娟,石晓丹,许军星,孙路. 调整膳食纤维和肠道菌群对延缓饮食诱导性肥胖的影响研究. 医学动物防制. 2025(02): 177-181 .  百度学术

百度学术

2. 王远利,王菲,张权,汤木果,陶亮,田洋. 海棠果果酱的研制及其品质分析. 食品工业科技. 2024(11): 175-186 .  本站查看

本站查看

3. 毛欣欣,刘婧,梁文欧,蔡诗鸿,李彦勋. 果蔬加工副产物膳食纤维改性研究进展. 农产品加工. 2024(08): 94-98 .  百度学术

百度学术

4. 李国巍,石雨,张正海,姬妍茹,杨庆丽,董艳,高宝昌,李柏阳. 黑海棠果多酚提取工艺优化及抗氧化活性分析. 中国食品添加剂. 2024(12): 19-30 .  百度学术

百度学术

5. 李焱,林泳峰,刘文美,邹泽华,刘红,刘光明,刘庆梅. 食药同源植物多糖调控肠道稳态的研究进展. 食品安全质量检测学报. 2023(02): 25-33 .  百度学术

百度学术

6. 雷延玲. 遮荫条件下栽培模式对草莓品质和产量的影响. 北方果树. 2022(05): 14-17 .  百度学术

百度学术

其他类型引用(1)

下载:

下载:

下载:

下载: