Optimization of Preparation Process of Antarctic Krill Hydrolysate with Delicate Taste by Compound Enzyme Method

-

摘要: 以脱脂南极磷虾粉为原料,采用复配酶法制备鲜味酶解液。以感官评价、多肽得率、水解度等评价手段,进行外源酶的筛选及单因素实验。为进一步优化酶解液滋味,以呈鲜味的氨基酸总量为指标进行酶解工艺优化。结果表明:最佳酶解条件为:胰蛋白酶和胃蛋白酶复配比1:100,总加酶量为2800 U/g,料液比1:4 g·mL−1,酶解pH7.0,酶解温度40 ℃,酶解时间3 h,该条件下获得的酶解产物中鲜味游离氨基酸含量为331.79 mg/100 mL。除色氨酸外,其余八种必需氨基酸含量占总氨基酸的63.66%,游离苦味氨基酸占总氨基酸的27.83%,游离鲜甜味氨基酸占总氨基酸26.22%,与鲜味形成具有关键作用的游离谷氨酸和游离天冬氨酸共占总游离氨基酸的10.26%。本研究可为南极磷虾鲜味调味料等产品的开发提供理论基础和技术指导。Abstract: In this paper, defatted Antarctic krill powder was used as raw material to prepare hydrolysate with delicate taste by compound enzyme method. By means of sensory evaluation, peptide yield and degree of hydrolysis, the screening of exogenous enzymes and single factor experiments were carried out. In order to further optimize the taste of enzymatic hydrolysate, the total amount of amino acids with delicate flavor was used as the index to optimize the enzymatic hydrolysis condition. The results showed that the optimal hydrolysis conditions were as follows: The ratio of trypsin and pepsin 1:100, the total amount of enzyme 2800 U/g, the liquid and material ratio 1:4 g·mL−1, the pH of enzymatic hydrolysis 7.0, the temperature of enzymatic hydrolysis 40 ℃, and the time of enzymatic hydrolysis 3 h. Under these conditions, the content of free amino acids with delicate taste in the hydrolysate was 331.79 mg/100 mL. Except tryptophan, the remaining eight essential amino acids accounted for 63.66% of the total amino acids. Free bitter amino acids accounted for 27.83% of the total amino acids, and free sweet amino acids accounted for 26.22% of the total amino acids. Free glutamic acid and free aspartic acid, which played a key role in the formation of umami taste, accounted for 10.26% of the total free amino acids. This study could provide theoretical basis and technical guidance for the development of Antarctic krill flavoring products.

-

南极磷虾是全球海洋中最大的单种可捕生物资源,其贮存量约为6.5~10.0亿吨,近年来日益受到关注[1-2]。南极磷虾具有高蛋白[2]、低脂肪[3]、富含矿物质元素[4]以及富含DHA、EPA等优质不饱和脂肪酸[5]的营养特点,也是虾青素、磷脂、壳聚糖等热敏性营养物质的来源[6]。目前,南极磷虾通常被加工成南极磷虾油脂,剩余部分一般被简单加工成粉状的动物或水产饲料[7-9],使得脱脂南极磷虾粉产品附加值低。目前,对南极磷虾的深加工与应用少有报道。

南极磷虾肽具有降血压、抗氧化、抗疲劳、以及改善老年性骨质疏松症等功效[10-11],因而具有很大的开发潜力,但相关研发仍然较少。迄今为止,关于水产品酶法制备酶解液,提高产品可利用价值的研究报道屡见不鲜[12-16]。然而,这些报道侧重研究商业蛋白酶,如利用风味蛋白酶酶解,以水解度或总氮回收率为指标,检测产品的酶解效率,忽略了酶解程度对酶解产物部分滋味的影响。目前,已有多项关于酶解物呈味研究的实验,黄百祺等[17]研究了四种龟肉酶解液,发现呈甜味与苦味的氨基酸具有一定规律性,吴书建等[18]和于亚辉等[19]发现鱼虾贝类水解产物中的呈味物质主要有核苷酸、有机酸、无机离子、肽、游离氨基酸等,其中游离氨基酸和多肽的种类及含量在很大程度上影响酶解产物的风味特征,曾晨等[20]筛选出风味蛋白酶和木瓜蛋白酶为大黄鱼干鲜味肽酶解提取的复合酶,酶解效率高且所得酶解液分子量集中于鲜味肽相对分子量范围。1978年,Yamasaki等[21]在经过木瓜蛋白酶处理后的牛肉中分离出一种八肽(beefy meaty peptide,BMP),命名为鲜味肽(umami peptide)。自此以后鲜味肽广受关注,目前,对鲜味肽的定义为分子量在150~5000 Da之间,由氨基酸组成的一些具有鲜味或增强风味的多肽[22]。鲜味酶解液热量低,天然健康,易于食用,具有很好的开发前景和应用价值。

前期研究发现,南极磷虾中鲜甜味氨基酸含量丰富,而目前以鲜甜味游离氨基酸总量为指标评价南极磷虾蛋白酶解效果的研究尚未见报道。本研究以酶解效率为指标,以感官评价为手段,通过合理控制酶解时间及水解度,筛选出一种新型的复合蛋白酶。借助氨基酸组成分析,以鲜甜味游离氨基酸总量为指标,通过正交试验优化酶解条件,制备出一种呈鲜甜味的南极磷虾酶解液。

1. 材料与方法

1.1 材料与仪器

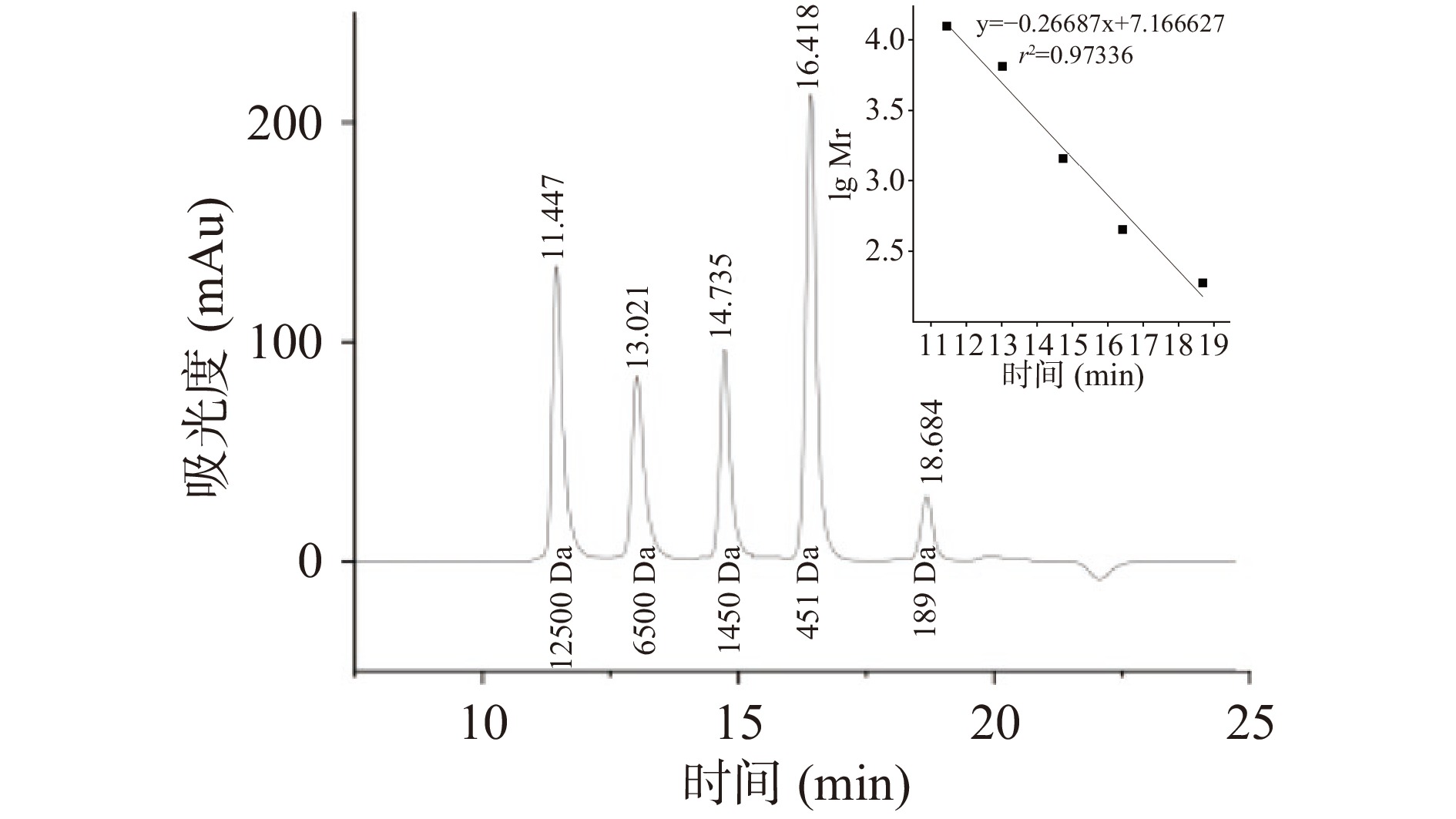

脱脂南极磷虾粉 山东鲁华海洋生物科技有限公司;风味蛋白酶(20万 U/g) 广州馨之味食品配料商城;胰蛋白酶(4000 U/g) 宁波鼎元食品科技有限公司;菠萝蛋白酶(5万 U/g)、碱性蛋白酶(10万 U/g)、胃蛋白酶(10万 U/g)、中性蛋白酶(10万 U/g)、木瓜蛋白酶(10万 U/g) 河南圣斯德实业有限公司;细胞色素C(12500 Da)、抑肽酶(6500 Da)、芽孢杆菌(1450 Da)、乙酰丙氨酸-酪氨酸-精氨酸(451 Da)、乙基丙氨酸(189 Da) Sigma公司;其他试剂 均为分析级。

DF-101S集热式恒温加热磁力搅拌器 河南省予华仪器有限公司;Allegra64R高速冷冻台式离心机 美国BECKMAN;电子天平 达俊电器有限公司;FA1204电子天平 常州市幸运电子设备有限公司;K9840自动凯氏定氮仪 济南海能仪器股份有限公司;L-8900全自动氨基酸分析仪 日立公司;TSK gel 2000色谱柱(7.8 mm×300 mm,粒径5 μm,) Waters高效液相色谱仪分析柱,日本Toko Seiki Ltd.;高效液相色谱 美国Agilent Technologies。

1.2 实验方法

1.2.1 酶解工艺流程

脱脂南极磷虾粉→控制适当料液比→调节pH(柠檬酸)→加酶→恒温酶解→灭酶(沸水浴15 min)→离心(8000 r/min,4 ℃,10 min),过滤取上清→鲜味酶解液。

具体操作步骤:将脱脂南极磷虾粉用纯水控制在一定的料液比后,用柠檬酸调节脱脂南极磷虾液至一定的pH后按照一定的比例添加各类酶,并在一定的温度下酶解一定时间,酶解结束后于沸水浴灭酶15 min。灭酶后的样品在8000 r/min,4 ℃的条件下离心10 min。离心结束后取上清液过滤后所得滤液即鲜味酶解液。

1.2.2 外源酶的筛选

以脱脂南极磷虾粉为原料,选择7种常见商品外源酶,即风味蛋白酶、胰蛋白酶、碱性蛋白酶、胃蛋白酶、菠萝蛋白酶、中性蛋白酶、木瓜蛋白酶,并在各自最适酶解条件下(产品厂家提供)进行酶解(条件见表1),沸水浴灭酶15 min,终止反应过程,冷却至室温后,8000 r/min条件下离心10 min,过滤取上清液,通过测定其水解度、多肽得率以及感官评价比较各酶的酶解效果。

表 1 外源酶的酶解条件Table 1. Enzymatic hydrolysis conditions of exogenous enzymes酶种类 加酶量(U·g−1) 温度(℃) pH 料液比(g·mL−1) 时间(h) 胰酶 2400 50 7.8~8.5 1:4 6 胃蛋白酶 2400 35 2.0~3.0 1:4 6 中性蛋白酶 2400 50 6.8~7.0 1:4 6 风味酶 2400 50 7.0 1:4 6 菠萝蛋白酶 2400 50 6.0~8.0 1:4 6 碱性蛋白酶 2400 50 10.0 1:4 6 木瓜蛋白酶 2400 50 6.0~7.0 1:4 6 1.2.3 多酶复合酶解配方的选择

参考吴书建等[18]的外源酶选择实验并结合外源酶筛选实验结果,将优选出的外源酶按以下6个配方进行多酶复合酶解(35 ℃,4 h),以滋味感官评价和酶解效率为指标,确定复合酶的最佳复配比例。其中,复配酶配方:两种最优酶1、酶2按酶1:酶2=1:7、1:15、1:50、1:100、1:150、1:200的添加比例进行复配。

1.2.4 复合酶解的单因素实验

1.2.4.1 外源酶加酶量的筛选

采用优选出的多酶复合配方,设置800、1000、1500、2400和3000 U/g五个水平加酶量,料液比1:4 g·mL−1,pH8.0,35 ℃条件下酶解4 h,以滋味感官评价和酶解效率为评价指标,优化加酶量。

1.2.4.2 外源酶料液比的筛选

采用优选出的多酶复合配方,2400 U·g−1样品的加酶量,设置1:3、1:4、1:5、1:6 g·mL−1四个水平料液比,pH8.0,35 ℃条件下酶解4 h,以滋味感官评价和酶解效率为评价指标,优化料液比。

1.2.4.3 外源酶酶解温度的筛选

采用优选出的多酶复合配方,加酶量2400 U·g−1、料液比1:4 g·mL−1,pH8.0,设置25、30、35、40、45 ℃五个酶解温度,酶解4 h,以滋味感官评价和酶解效率为评价指标,优化酶解温度。

1.2.4.4 外源酶酶解时间的筛选

采用优选出的多酶复合配方,加酶量2400 U·g−1、料液比1:4 g·mL−1,pH8.0,酶解温度40 ℃,设置1、2、3、4、5 h五个水平酶解时间,以滋味感官评价和酶解效率为评价指标,优化酶解时间。

1.2.4.5 酶解pH筛选

采用优选出的多酶复合配方,加酶量2400 U·g−1、料液比1:4 g·mL−1,酶解温度40 ℃,设置4.0、5.5、6.5、7.5、8.0五个水平pH,酶解4 h,以滋味感官评价和酶解效率为评价指标,优化酶解pH。

1.2.5 正交试验

根据单因素实验结果,选取加酶量、酶解pH、酶解温度、酶解时间进行四因素三水平正交优化实验。以鲜味肽、鲜味游离氨基酸、多肽得率为指标确定最佳酶解工艺。正交试验因素及水平见表2。

表 2 正交试验因素与水平表Table 2. Orthogonal experimental factors and level table水平 A加酶量(U·g−1) B温度(℃) C pH D时间(h) −1 2000 30 7.0 2.5 0 2400 35 7.5 3.0 1 2800 40 8.0 3.5 1.2.6 感官评价

参照GB/T 12312-2012 感官分析 味觉敏感度测定方法[23],感官评价标准见表3,从多名人员中筛选出10位感官评价人员,对酶解液进行感官评价,评定成员每评定一个样品前用蒸馏水漱口,取待评定样品1~2 mL置于口中,10 s后吐出,漱口取参比液品尝,鲜味参比样为谷氨酸钠溶液,浓度0、2、4、6、8、10、12、14、16、18和20 mg·mL−1对应的鲜味评分值为1、2、3、4、5、6、7、8、9和10分,对不同组分进行感官评价。为避免感官评价人员相互之间会产生主观影响,评价人员分开评定。

表 3 感官评价标准Table 3. Standard and scores of sensory evaluation项目 评分标准 评分(分) 色泽(满分3分) 色泽很深 1 色呈黄色 2 色呈淡黄色 3 香气(满分3分) 有明显腥味 1 无明显味道 2 有鲜虾味 3 滋味(满分4分) 有酸、苦涩、有异味 1 有甜味,欠鲜味、虾味 2 有甜味,有鲜味或虾味 3 有鲜甜味并伴随虾味 4 1.2.7 酶解效率测定

1.2.7.1 多肽得率的测定

取洁净的培养皿,称量质量m2,将离心(8000 r/min,4 ℃,10 min)过后的蛋白酶解液倒入,再将样品放入−80 ℃的冰箱中进行预冻3~4 h,冷冻3~4 h后取出放入冷冻干燥机中进行干燥,待完全干燥后取出并称量质量m1[24]。计算多肽得率。

多肽得率(%)=m1−m2M×100 (1) 式中:m1:干燥后培养皿的总质量,g;m2:空培养皿的质量,g;M:称取的脱脂南极磷虾粉的质量,g。

1.2.7.2 水解度(DH)的测定

水解度按照下式计算:

DH(%)=氨基态氮总氮×100 (2) 式中:DH表示水解度,%。

总氮含量根据国标GB 5009.5-2016 食品安全国家标准 食品中蛋白质的测定[25]中微量凯氏定氮法结合自动凯氏定氮仪进行测定。

氨基态氮含量参考ZB X 66038-1987 氨基态氮测定法[26],略有调整:吸取5.0 mL酶解液,定容至100 mL,吸取20 mL置于250 mL烧杯中,使用磁力搅拌器,用0.05 mol·L−1 NaOH标准液滴定至pH8.2。加入10.0 mL甲醛溶液,混匀,再用0.05 mol·L−1 NaOH溶液继续滴定至pH9.2,记下消耗NaOH溶液的毫升数。同时取未酶解的虾粉样品,做空白试验。

1.2.8 氨基酸组成测定

感官评分受主观影响因素较大,因此采用高效液相色谱法(HPLC)测定呈味氨基酸,此法对酶解液呈味特征具有较高的灵敏度与重现性[27]。

HPLC操作方法如下:

使用Waters高效液相色谱仪进行检测,分析柱选用TSK gel 2000色谱柱(7.8 mm×300 mm,粒径5 μm,),并使用UV检测器在220 nm下检测分离的样品。柱温保持在30 ℃;流动相为乙腈/水/三氟乙酸(45:55:0.1,v/v);流速保持在0.5 mL·min−1;进样量为10 μL。标准品:细胞色素C;抑肽酶;芽孢杆菌;乙酰丙氨酸-酪氨酸-精氨酸;乙基丙氨酸。由此得到的分子量分布标准曲线如图1:

1.2.8.1 总氨基酸组成测定

准确称取酶解液4 g,小心加入水解管中防止挂壁,继续加入1:1的分析纯盐酸约6 mol·L−1 4 mL,氮吹仪吹氮气15 min后封管。110 ℃水解24 h后,取出冷却开管。消解后的样品溶液过滤并定容至100 mL棕色容量瓶中。准确吸取定容后的样品2 mL,置氮吹仪上脱酸。温度60 ℃,脱至干燥。准确加入0.02 mol·L−1 HCl溶液20 mL旋涡器上混匀,取样品过0.22 µm滤膜过滤小柱,上机按GB/T 5009.124-2016 食品安全国家标准 食品中氨基酸的测定[28]方法进行氨基酸测定。

1.2.8.2 游离氨基酸组成测定

取1 mL酶解液,加入4 mL 5%磺酸水杨酸沉淀多肽及蛋白,用高速冷冻离心机18000 r·min−1离心30 min,取上清液保存,用0.45和0.22 µm滤膜过滤后上机分析,按GB/T 5009.124-2016 食品安全国家标准 食品中氨基酸的测定[28]方法进行氨基酸测定。

1.3 数据处理

采用SPSS软件对数据的差异性进行分析,采用方差分析(ANOVA)比较每组数据之间是否存在统计学差异(P<0.05为显著性差异),每组样品做3次平行试验,采用均值±标准差表示,采用Origin 9.0绘图。

2. 结果与分析

2.1 外源酶的筛选

2.1.1 不同外源酶对酶解液滋味的影响

脱脂南极磷虾粉经7种常见外源蛋白酶分别水解后,其酶解液感官滋味评定结果如表4所示,添加不同外源酶获得的各样品其感官评分存在着明显差异。这是因为,不同酶的作用位点不同,从而产生不同种类的氨基酸与多肽,不同的氨基酸均有不同的溶解性与味感,因此产生了不同味道的水解蛋白[29]。

表 4 不同外源酶处理后获得的酶解液感官评价结果Table 4. Sensory evaluation results of enzymatic hydrolysate after treatment with different exogenous enzymes组分 感官评价分值(分) 平均值(分) 感官鉴定 胰蛋白酶 3 4 5 3 5 4 5 3 5 3 4.0 溶液色泽较深,口感偏苦涩,后味有鲜味 胃蛋白酶 7 8 6 7 8 8 7 7 8 9 7.5 溶液色泽微黄色,具有微甜滋味 中性蛋白酶 4 5 3 4 3 3 4 3 3 4 3.6 溶液色泽较深,口感偏苦涩 风味蛋白酶 5 6 5 5 6 5 6 5 7 6 5.6 溶液色泽微黄色,具有微甜滋味 菠萝蛋白酶 6 7 6 7 7 8 7 6 6 6 6.6 溶液色泽黄色,无苦涩味 碱性蛋白酶 3 4 4 3 5 4 3 3 4 4 3.7 溶液色泽较深,口感偏苦涩、腥味重 木瓜蛋白酶 3 4 5 4 4 4 5 4 4 4 4.1 溶液色泽微黄,无明显苦涩味 2.1.2 不同外源酶对酶解液水解度和多肽得率的影响

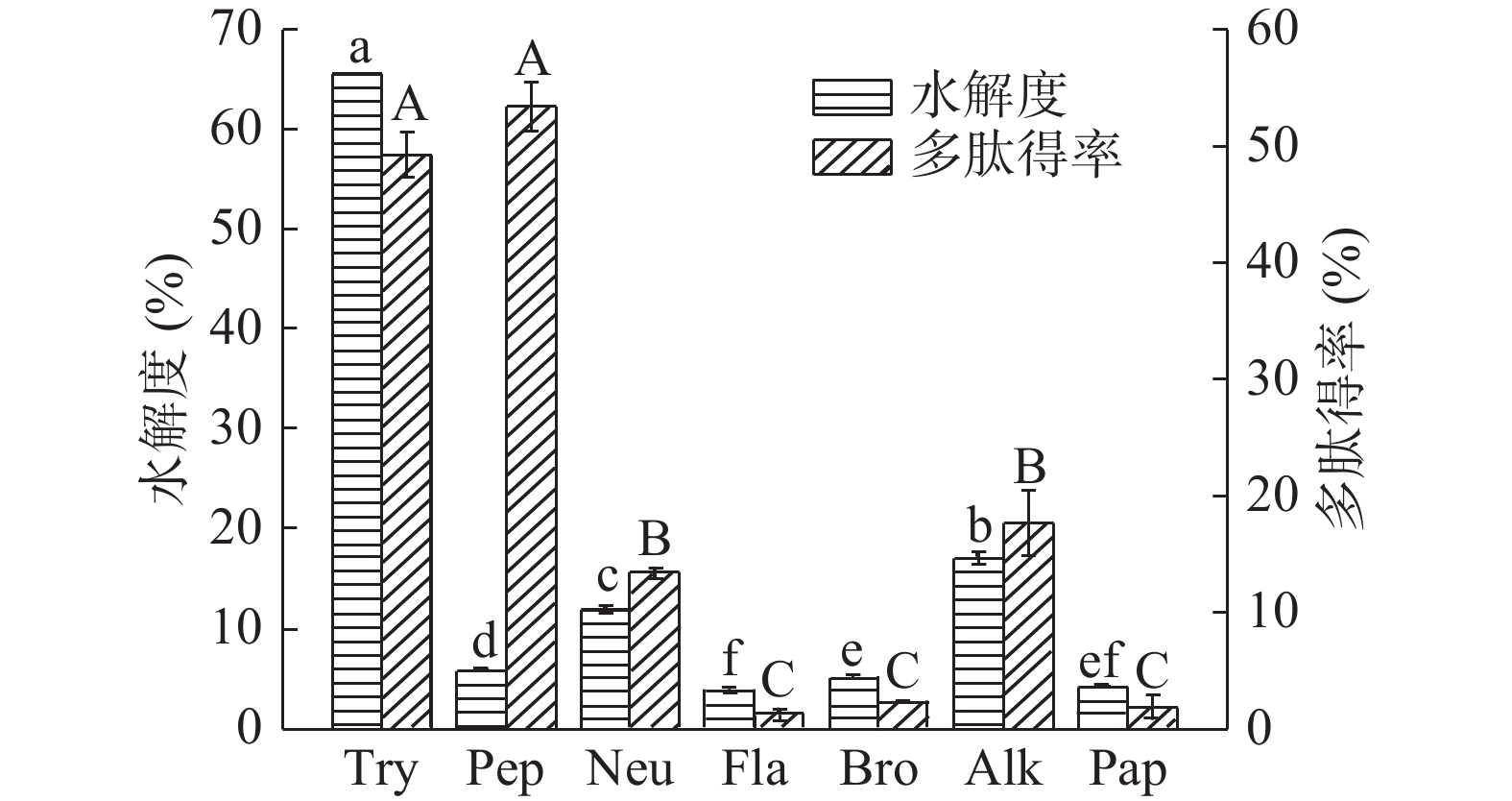

综合图2和表4可见,胰蛋白酶酶解液的酶解效率最佳,水解度DH最高可达到65%,多肽得率49%,但其感官评价较低。胃蛋白酶酶解液的多肽得率最高,感官评分最佳,但其DH较低。其他五种酶的DH、多肽得率均处于较低水平。单一外源酶作用效果虽各有优点,但酶解作用效果有限,各自单独作用效果无法同时达到滋味和酶解效率最优,添加外源酶辅助酶解法可改善酶解滋味及效率。因此,本研究拟采用单酶酶解效果最佳的胰蛋白酶和胃蛋白酶两种酶复合进行后续的酶解条件优化研究。

2.2 多酶复合配方的选择

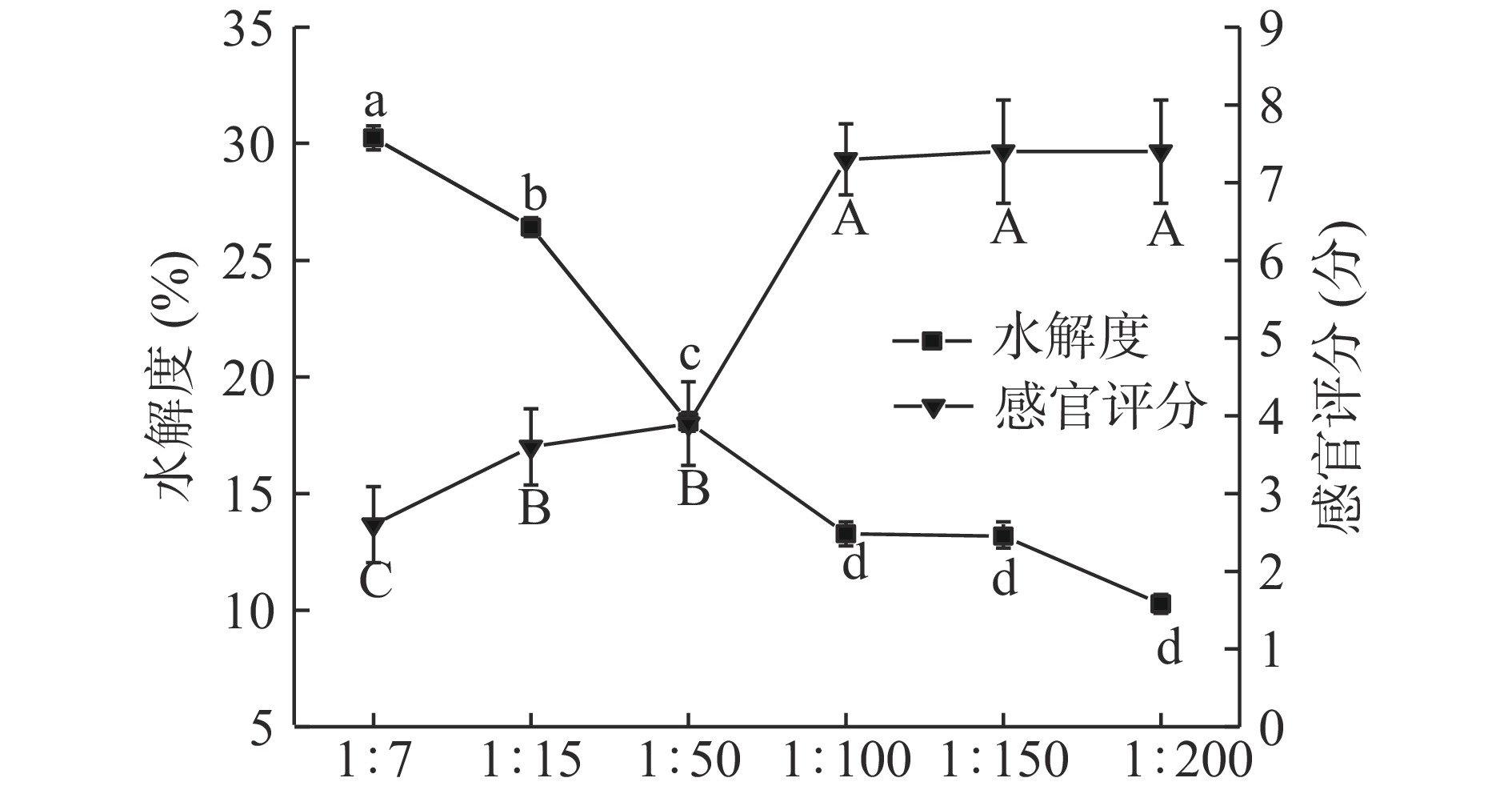

采用优选出的酶1(胰蛋白酶)和酶2(胃蛋白酶),按照1.2.3中的多酶复合配方酶解脱脂南极磷虾粉蛋白,其感官评分及酶解效果如图3所示。由图3可知,随着复配酶比例的增加,DH不断下降,感官评分不断提高。配方4(胰蛋白酶:胃蛋白酶=1:100)感官评分的增加值逐渐趋于平缓,DH变化也趋于稳定。有研究表明,DH与酶解液的滋味并不呈线性相关,DH越大,酶解液的感官评分不一定最好,并且随着DH增加,一些疏水性氨基酸暴露及肽的含量增加,反而影响酶解液的感官滋味[30]。结合图3趋势,本实验选择感官评分最优,水解度相对较好的配方4为最优条件(胰蛋白酶:胃蛋白酶=1:100),并进行后续研究。

2.3 复合酶解的单因素实验

2.3.1 加酶量对酶解液的影响

2.3.1.1 加酶量对酶解液滋味的影响

不同加酶量对酶解液的感官评分,结果如表5所示,不同外源酶添加量可对滋味造成显著性影响。1500、2400、3000 U/g样品加酶量获得的酶解液感官评分明显高于其他样品,拥有较好的感官滋味。

表 5 不同加酶量处理条件下的感官评价结果Table 5. Sensory evaluation results of different enzyme amounts加酶量(U/g) 感官评分(分) 平均值(分) 感官评价 800 2 3 4 2 2 2 3 2 3 2 2.5 苦味较浓,鲜味与虾味较淡 1000 4 3 4 4 5 3 4 4 4 4 3.9 微苦,有微鲜甜味与虾味 1500 7 8 7 7 7 6 8 7 6 7 7.0 微甜、有鲜味伴随一点微苦味 2400 7 8 8 7 7 8 7 8 7 8 7.5 有鲜甜味与虾味,微微涩 3000 8 9 8 8 8 8 7 8 8 8 8.0 具有鲜甜味,虾味较淡 2.3.1.2 加酶量对酶解液水解度和多肽得率的影响

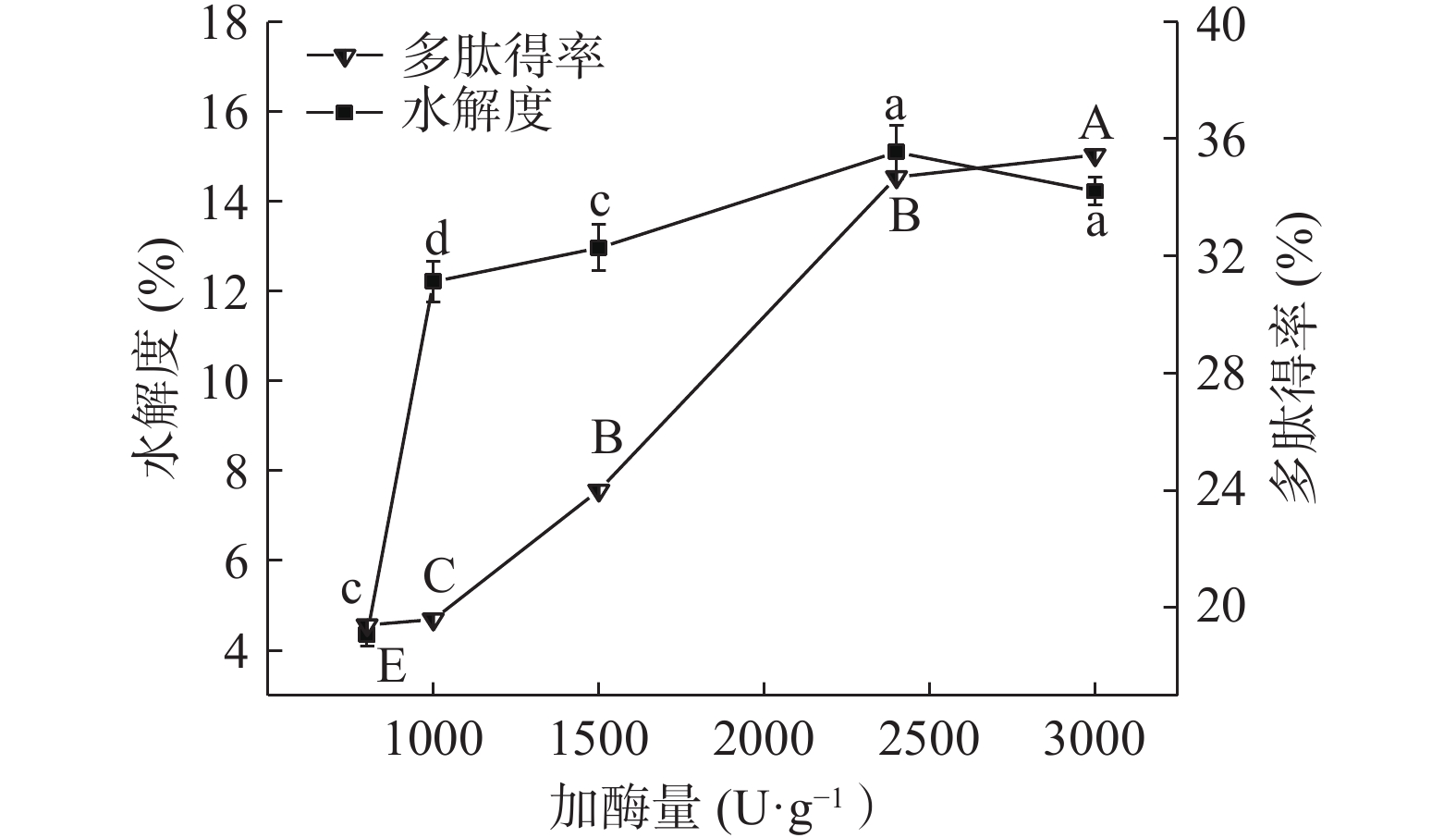

不同加酶量获得的酶解液的酶解效率结果如图4所示。可发现随着加酶量的增加,酶解液的DH和多肽得率均呈现先增加后平缓的趋势。当加酶量大于2400 U·g−1时,DH逐渐下降,多肽得率增加逐渐趋于平缓。可能由于酶解过程是底物与酶的特异性结合过程,在底物浓度保持不变的情况下,随着加酶量的增加,底物与酶接触的反应量增加,加酶量与反应速率成正相关,因此酶解效率大幅度增加。当加酶量与底物结合逐渐趋于饱和状态时,继续加酶时多肽得率涨幅逐渐趋于平缓。同时,复配酶之间可能还存在相互作用,在加酶量少时,相互作用影响不明显,而加酶量大时,相互作用明显,可能造成酶活力降低,导致水解度逐渐下降[31]。加酶量2400和3000 U·g−1的酶解效率、感官滋味均处于较优状态。但当加酶量增加值3000 U·g−1时,其酶解效率的增长趋势不如加酶量为2400 U·g−1,故从生产成本考虑选择2400 U·g−1的加酶量。

2.3.2 料液比对酶解液的影响

2.3.2.1 料液比对酶解液滋味的影响

不同料液比对酶解液的感官评分如表6所示,不同料液比对酶解液滋味造成的感官评分结果影响十分显著,其中料液比1:4与1:5 g·mL−1,在感官评分上明显优于其他样品。料液比高于1:6 g·mL−1时,滋味一般,鲜味较弱,由于加水量多,酶解液被稀释。料液比1:5 g·mL−1获得酶解液鲜味值最高(7.8分),但其苦涩味也明显高于其他料液比。因此,相比而言,在料液比1:4 g·mL−1条件下,酶解液具有更好的感官滋味,在感官滋味评分上获得较高得分。

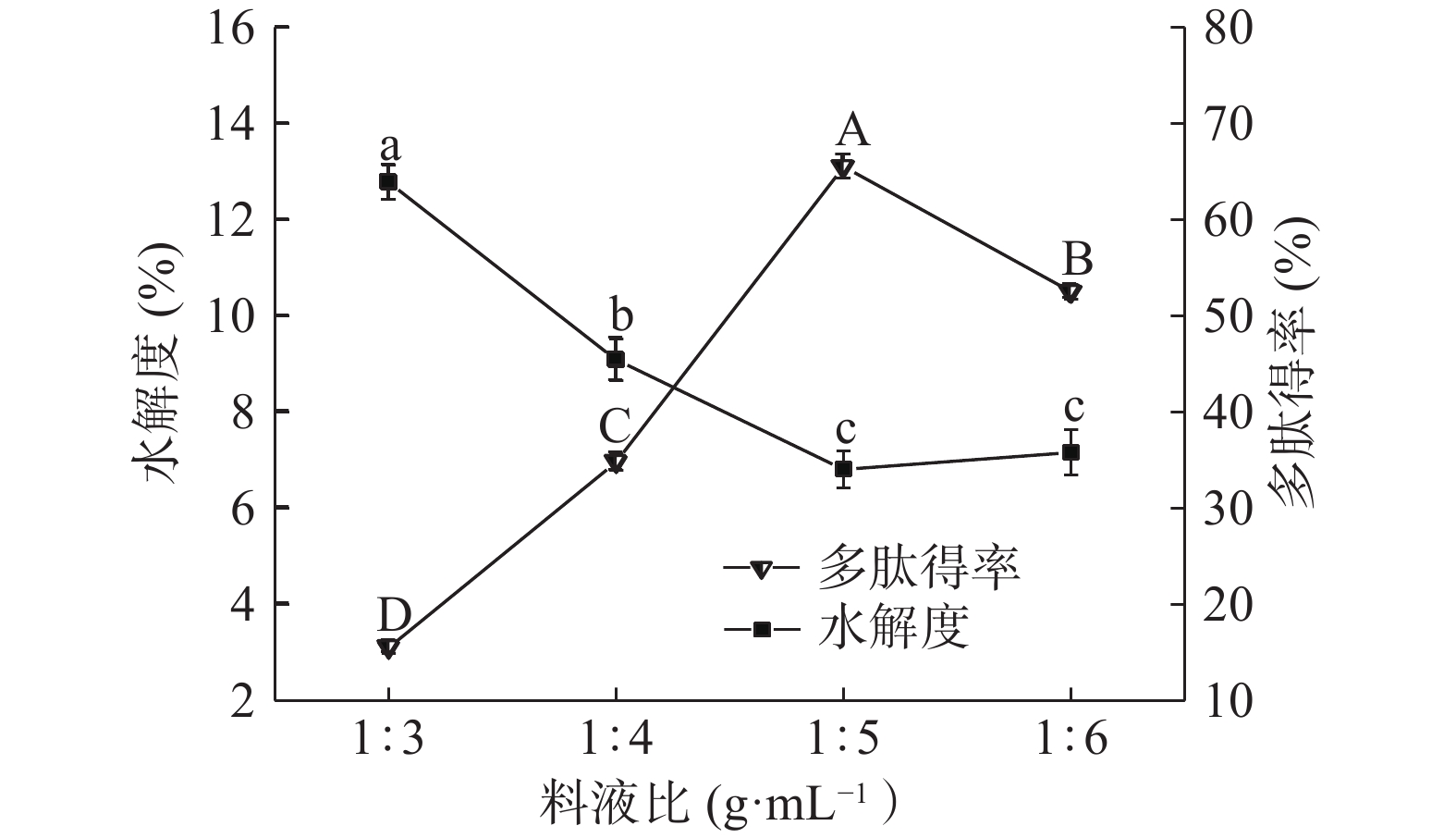

表 6 不同料液比处理条件下的感官评价结果Table 6. Sensory evaluation results under different solid-liquid ratio treatment conditions料液比(g·mL-1) 感官评分(分) 平均值(分) 感官评价 1:3 5 4 5 4 4 4 5 4 5 4 5.5 黄色、甜、微涩 1:4 7 8 8 8 9 8 8 9 9 7 8.1 淡黄色、甜、有鲜味与虾味 1:5 7 8 8 7 9 8 8 7 8 8 7.8 淡黄色、微甜、有鲜味、微涩 1:6 7 8 7 7 8 7 8 7 7 8 7.4 淡黄色、微涩、甜味与鲜味减弱 2.3.2.2 料液比对酶解液水解度和多肽得率的影响

不同料液比对酶解液酶解效率影响如图5所示。不同料液比之间的DH、多肽得率差异明显,多肽得率随料液比的增加而增加,之后逐渐降低,DH随着料液比增加而降低,渐渐趋于平缓。随着料液比的增加,相当于降低了反应体系中的酶浓度及底物浓度,从而使得酶促反应速度降低,水解度下降。料液比在1:3 g·mL−1时虽然水解度最大,但由于水解过程中水量过少,体系过于粘稠,出现结块贴壁等现象,导致酶解不充分。而当料液比为1:4 g·mL−1时,其水解度相比于前者下降不多,且多肽得率明显增加,当料液比为1:5 g·mL−1时多肽得率虽然增加,但DH过低。因此将料液比固定为1:4 g·mL−1,进行后续的实验。

2.3.3 酶解温度对酶解液的影响

2.3.3.1 酶解温度对酶解液滋味的影响

不同酶解温度对酶解液的感官评分结果如表7所示,不同样品之间滋味存在显著差异。胰蛋白酶和胃蛋白酶的最适温度存在一定的差异,不同温度对酶的反应作用具有显著的影响,从而导致配方4(胰蛋白酶:胃蛋白酶=1:100)对酶解液的酶解效率和滋味产生差异。酶解温度25与30 ℃获得的酶解液的感官滋味几乎相似,在鲜味上无明显差异,感官评分几乎一致。因此,该范围内存在具有更好滋味酶解液的最佳酶解温度。

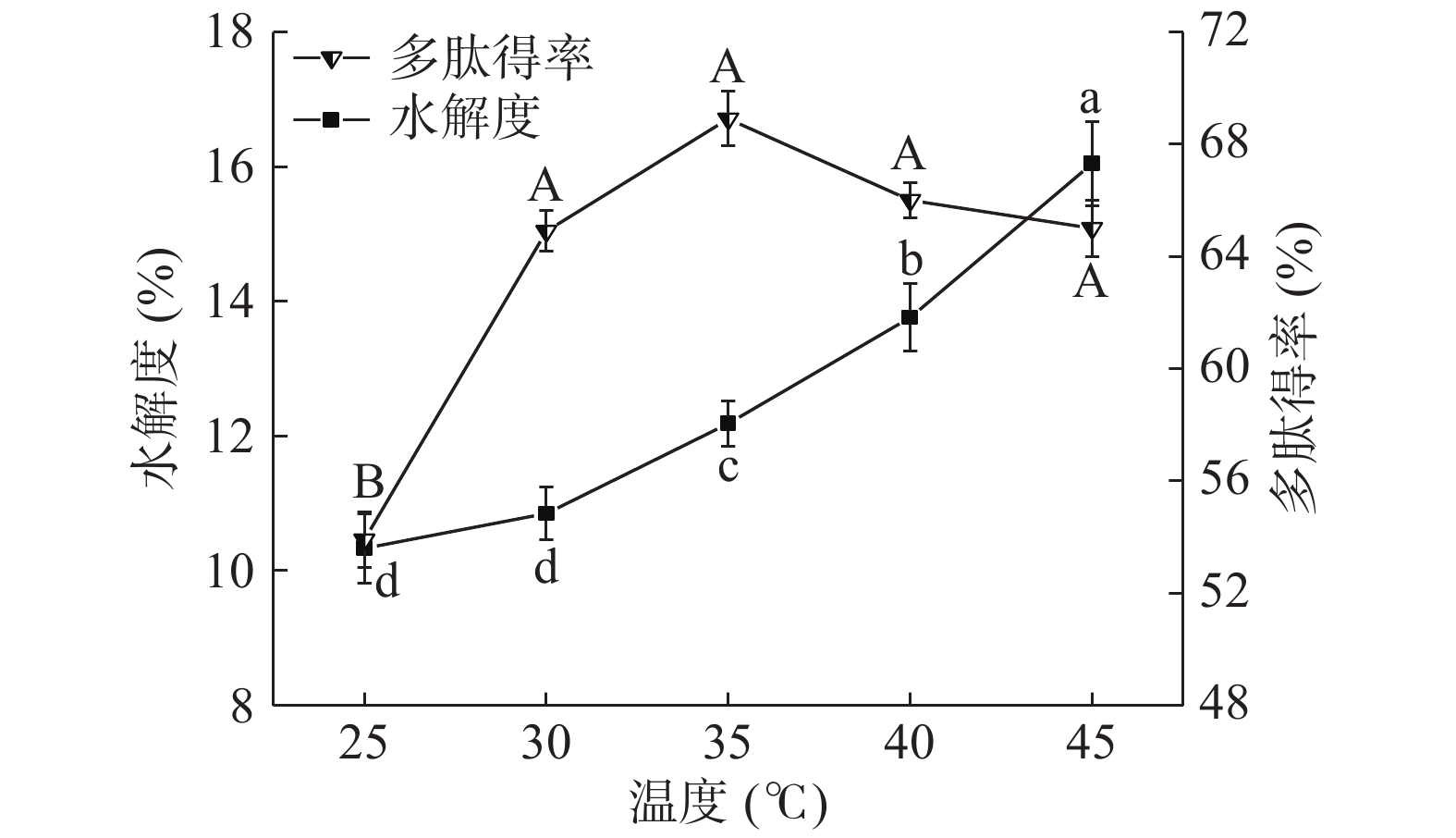

表 7 不同温度处理条件下的感官评价结果Table 7. Sensory evaluation results under different temperature treatment conditions温度(℃) 感官评分(分) 平均值(分) 感官评价 25 7 8 7 8 7 7 8 8 7 8 7.5 淡黄色、虾味、甜度适中、后味微腥 30 8 7 8 8 7 8 7 7 8 7 7.5 淡黄色、淡淡的虾味,甜度中等 35 8 9 7 8 7 8 9 8 8 8 8.0 淡黄色、虾味浓郁、甜度中等 40 7 8 7 8 7 7 7 7 7 7 7.0 淡黄色、微虾味、淡甜味、微涩 45 6 7 7 6 6 6 5 7 5 5 6.0 黄色、微苦味、虾味浓郁,微涩 2.3.3.2 酶解温度对酶解液水解度和多肽得率的影响

不同酶解温度条件下的酶解效率如图6所示,随着温度升高,DH升高,多肽得率呈先升高后平缓并逐渐下降的趋势。在25~45 ℃时,DH随着温度的增加而增加,多肽得率随着温度的增加先增加而后逐渐降低,在35 ℃时多肽得率最高,分析可能是由于温度在低于35 ℃时,随着温度的上升复合酶酶解效率加强,反应速度加快;而超过其最适温度范围时,酶活性降低。综合感官评价和酶解效率的综合得分,选择酶解温度为35 ℃。

2.3.4 酶解时间对酶解液的影响

2.3.4.1 酶解时间对酶解液滋味的影响

不同酶解时间对酶解液感官评分如表8所示,不同酶解时间对酶解液滋味评定具有明显影响,其中酶解时间在2、4 h的酶解液具有较好的感官评价结果,鲜味适当且口感良好,其中酶解4 h相比于2 h鲜味更加明显。

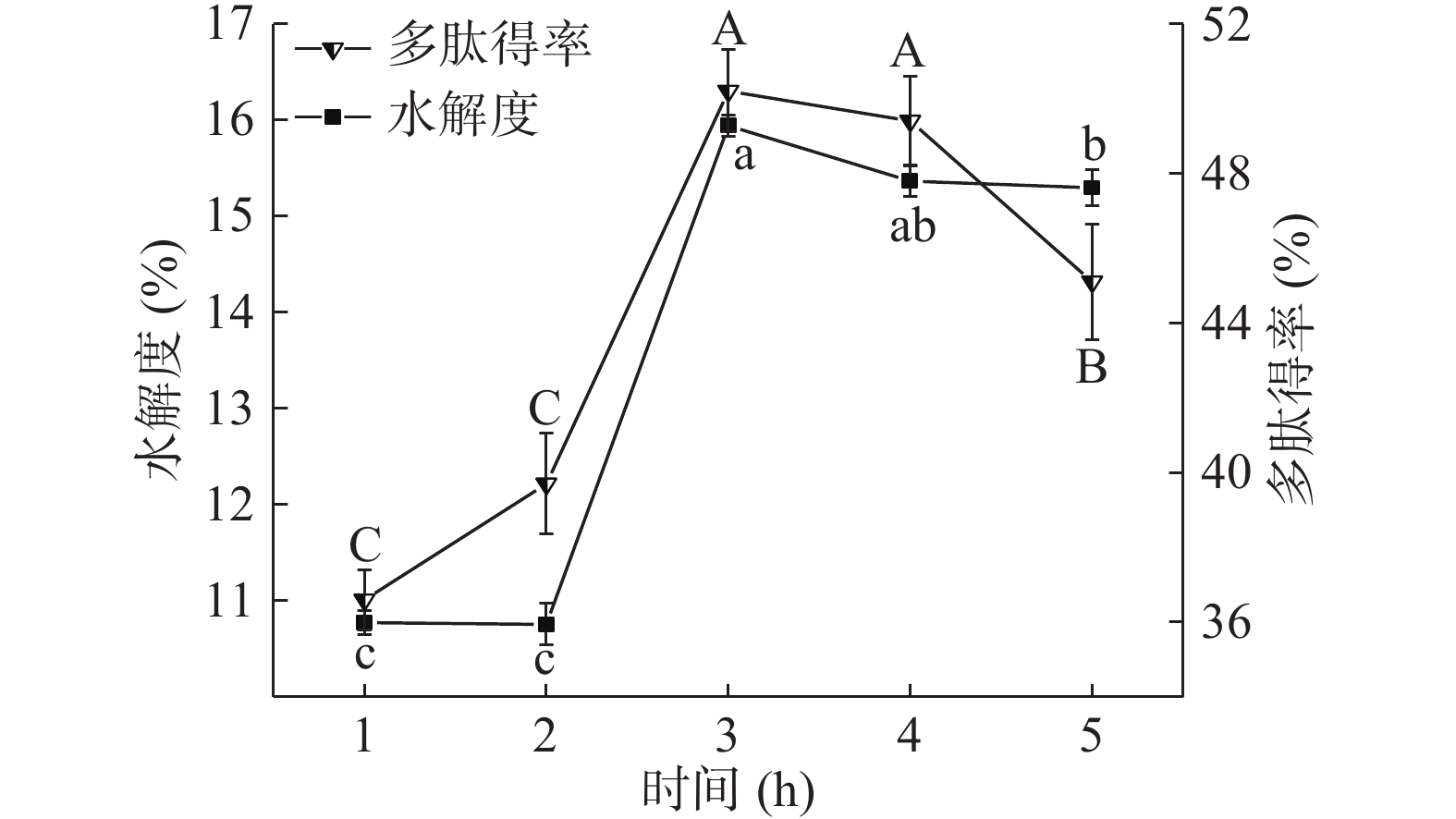

表 8 不同酶解时间处理条件下的感官评价结果Table 8. Sensory evaluation results under different enzymatic hydrolysis time treatment conditions时间(h) 感官评分(分) 平均值(分) 感官评价 1 4 5 5 6 4 4 5 5 6 5 4.9 淡黄色,微甜,无鲜味 2 7 8 8 9 8 8 7 8 9 7 7.9 淡黄色,鲜甜味有所增加 3 7 7 8 8 7 8 7 8 7 8 7.5 淡黄色,鲜甜味几乎没有变化,伴随一点微苦味 4 8 8 9 8 9 8 9 8 7 7 8.1 黄色、鲜甜味明显 5 7 7 8 8 8 7 7 8 7 8 7.5 黄色、甜度不变,鲜味淡一点,微腥 2.3.4.2 酶解时间对酶解液水解度和多肽得率的影响

酶解效率如图7所示,可发现酶解3 h的样品DH和多肽得率最高,分别为16%和50%。分析可能是在最初加入外源酶时,由于底物充足,酶解速度较快,以降解蛋白质为主,多肽得率及DH增加迅速,3 h以后随着酶解时间增加,底物开始减少,所以蛋白质分解速率降低,肽分解速率升高,肽得率降低。综合表8感官评分结果得外源酶酶解时间3 h最佳。

2.3.5 pH对酶解液的影响

2.3.5.1 pH对酶解液滋味的影响

不同pH对酶解液感官评分如表9所示,不同pH处理条件下对酶解液滋味评定具有明显影响,其中pH在7.5和8.0时酶解液具有较好的感官评价结果,鲜味适当且口感良好,感官评价结果表明,复合酶的最佳酶解pH在7.5~8.0之间。

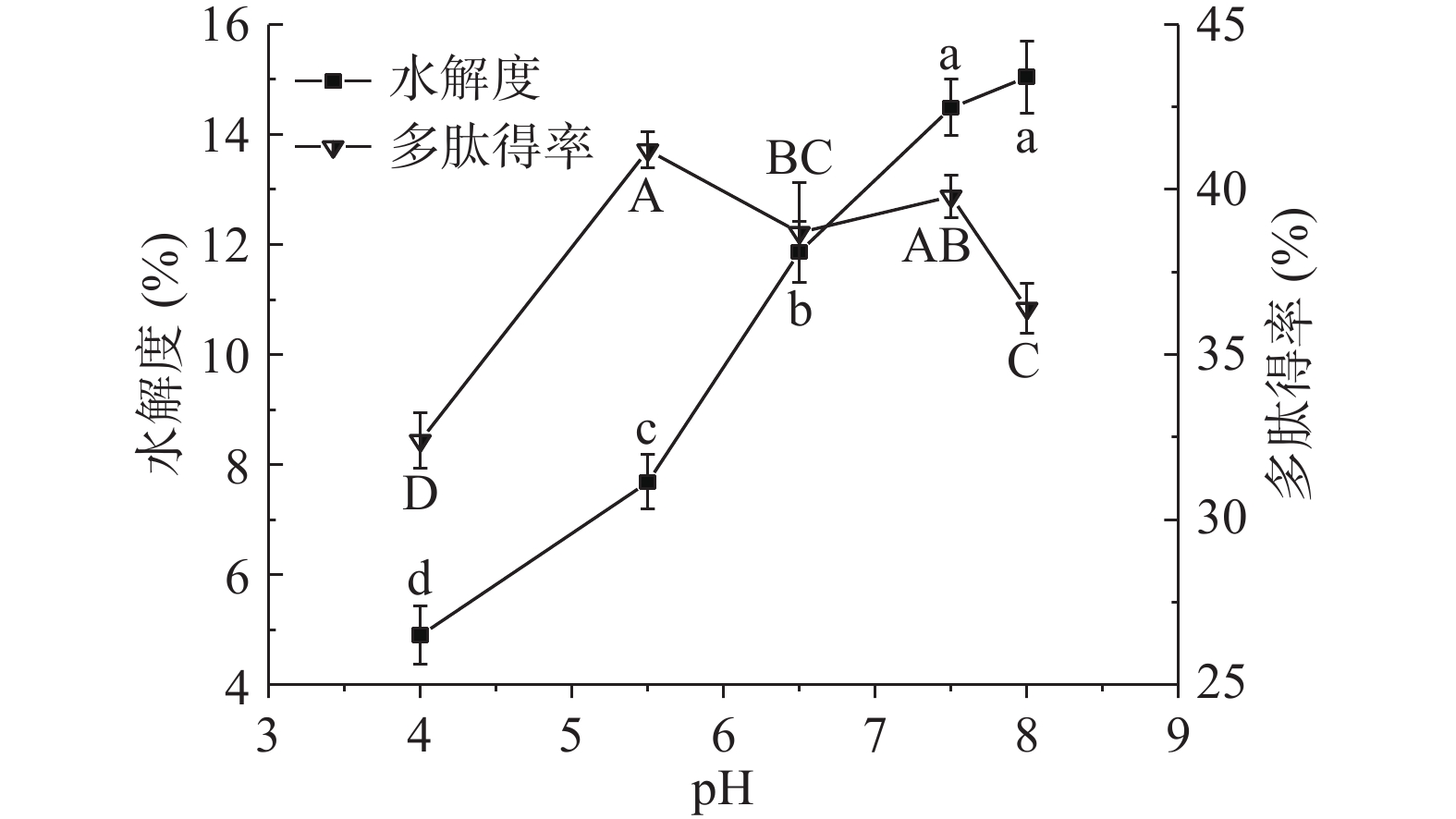

表 9 不同pH处理条件下的感官评价结果Table 9. Sensory evaluation results under different enzymatic hydrolysis pH treatment conditionspH 感官评分(分) 平均值(分) 感官评价 4.0 4 3 4 4 3 3 4 3 3 4 3.5 淡黄色、酸涩味,鲜味与虾味几乎没有感觉 5.5 5 5 6 5 4 6 5 6 5 5 5.2 淡黄色、有微鲜甜味与虾味微腥味 6.5 7 6 7 6 8 7 6 7 6 5 6.5 黄色、甜度略有增加、有鲜味伴随一点微苦味与腥味 7.5 8 9 7 8 7 8 9 8 8 8 8.0 黄色、甜度不变,有虾味和微鲜味 8.0 8 8 9 8 9 8 9 8 7 7 8.1 黄色、虾味淡一下,甜度加深,仍伴有鲜味 2.3.5.2 pH对酶解液水解度和多肽得率的影响

由图8可以看出,当pH低于7时,随着pH的升高,多肽得率增幅逐渐平缓并出现下降趋势,DH增长也趋于平缓,pH继续增加时DH无显著变化(P˃0.05)。这可能是由于每种酶都有其最适pH,当pH偏小或偏大,酶的反应速率都会受到一定程度的抑制,使得酶解不充分[32]。将水解度、多肽得率与酶解液感官评价结果综合分析,确定酶解的最适pH条件为7.5。

2.4 正交优化试验结果

氨基酸是蛋白质的主要组成成分,食品中氨基酸的种类和含量是衡量其营养质量和感官呈味特征的一项重要指标[33],如某些海产品中的特征“肉香”来源于组氨酸[34]。因此选择肽类氨基酸和游离氨基酸为正交实验指标进行研究。其中呈鲜味的氨基酸主要是天冬氨酸和谷氨酸,呈甜味的主要是丝氨酸、脯氨酸、甘氨酸、丙氨酸、苏氨酸,呈苦味的代表性氨基酸主要酪氨酸、组氨酸、精氨酸、缬氨酸[17]。

以鲜甜味游离氨基酸为指标,对正交试验结果进行极差分析得表10,发现各因素的影响程度依次为时间、加酶量、pH、温度,最佳试验组合为A3B3C1D1,即加酶量2800 U·g−1、温度40 ℃、pH7.0、酶解时间2.5 h。以鲜味肽为指标,对正交试验结果进行极差分析,发现各因素的影响程度依次为加酶量、pH、时间、温度,最佳试验组合为A2B2C3D2,即加酶解量2400 U·g−1、温度35 ℃、pH8.0、酶解时间3.0 h。以多肽得率为指标,对正交试验结果进行极差分析,发现各因素的影响程度依次为加酶量、温度、时间、pH,最佳试验组合为A3B3C1D2,即加酶量2800 U/g、温度40 ℃、pH7.0、酶解时间3.0 h。

表 10 脱脂南极磷虾蛋白水解液的正交试验方案与结果分析Table 10. Orthogonal experimental scheme and result analysis of defatted Antarctic krill protein hydrolysate实验号 因素 鲜甜味游离氨基酸

(mg/100 mL)鲜味肽

(mg/100 mL)多肽得率

(%)A加酶量(U·g−1) B温度

(℃)C pH D时间

(h)1 1 1 1 1 305.88 39.49 26.45±0.65 2 1 2 2 2 303.40 44.04 31.35±1.85 3 1 3 3 3 304.39 44.33 29.05±1.15 4 2 1 2 3 301.33 44.99 36.70±1.40 5 2 2 3 1 302.98 43.95 42.10±3.90 6 2 3 1 2 301.81 43.33 46.45±1.75 7 3 1 3 2 302.55 42.76 43.65±0.25 8 3 2 1 3 304.64 39.45 48.45±1.25 9 3 3 2 1 306.54 39.07 51.85±3.25 鲜甜味游离氨基酸K1 913.67 909.76 912.33 915.4 鲜甜味游离氨基酸K2 906.12 911.02 911.27 907.76 鲜甜味游离氨基酸K3 913.73 912.74 909.92 910.36 R 7.61 2.98 2.41 7.64 因素主次:D>A>B>C 鲜味肽 K1 127.86 127.24 122.27 122.51 鲜味肽 K2 132.27 127.44 128.1 130.13 鲜味肽 K3 121.28 126.73 131.04 128.77 极差R 10.99 0.71 8.77 7.62 因素主次: A>C>D>B 多肽得率K1 87.55 106.8 121.35 120.7 多肽得率K2 125.25 121.9 120.2 121.45 多肽得率K3 144.25 128.35 115.5 114.9 极差R 18.9 7.18 1.95 2.18 因素主次:A>B>D>C 上述三个组合中,均存在重合的最优条件,为使最终产品的该三个指标达到较优水平,认为最佳组合即为每组重合的最优条件组合。因此,判断最佳酶解工艺组合为A3B3C1D2,即加酶量2800 U·g−1、温度40 ℃、时间3.0 h、pH7.0,所得酶解液的鲜甜味游离氨基酸为331.79 mg/100 mL,鲜味肽为36.04 mg/100 mL,多肽得率为54.5%。

2.5 鲜味脱脂南极磷虾酶解液的氨基酸组成

考虑实际需要,对上述工艺条件进行了调整,确定实际最佳工艺条件为:加酶量2800 U·g−1、温度40 ℃、时间3.0 h、pH7.0。在此条件下进行三次验证试验以考察试验结果的可靠性,鲜甜味氨基酸结果如表11所示,多肽得率为54.5%。

表 11 脱脂南极磷虾酶解液的氨基酸组成(mg/100 mL)Table 11. Amino acid composition of Antarctic krill hydrolysate (mg/100 mL)氨基酸 游离氨基酸含量 总氨基酸含量 氨基酸 游离氨基酸含量 总氨基酸含量 甘氨酸▲ 27.63±0.17 30.73±0.26 苯丙氨酸 348.08±2.95 356.30±0.50 丙氨酸▲ 70.56±0.09 71.73±0.26 赖氨酸◆ 115.84±1.19 120.76±0.29 组氨酸◆ 27.47±0.00 30.42±0.05 异亮氨酸 44.79±1.33 45.58±0.59 酪氨酸◆ 46.47±0.33 50.92±0.12 ∑NEAA 459.94 482.21 丝氨酸▲ 33.97±0.50 35.79±0.32 ∑EAA 805.62 834.16 天冬氨酸● 41.06±0.59 42.56±0.57 ∑SUAA 331.79 343.38 谷氨酸● 88.80±0.00 90.75±0.28 ∑BAA 352.22 373.69 精氨酸◆ 106.03±0.71 110.55±0.10 ∑AA 1265.55 1316.36 脯氨酸▲ 17.96±0.06 18.78±0.46 ∑EAA/∑AA 63.66% 63.37% 亮氨酸 126.44±0.21 129.41±0.75 ∑EAA/∑NEAA 1.75 1.73 缬氨酸◆ 56.41±0.25 61.04±0.95 ∑SUAA/∑AA 26.22% 26.09% 苏氨酸▲ 51.82±0.32 53.06±0.07 ∑BAA/∑AA 27.83% 28.39% 蛋氨酸 62.23±0.24 68.01±0.02 注:苦味氨基酸(◆);鲜味氨基酸(●);甜味氨基酸(▲);必需氨基酸(EAA);非必需氨基酸(NEAA);鲜甜味氨基酸(SUAA);苦味氨基酸(BAA);总氨基酸(AA);天冬氨酸、谷氨酸含量,一部分分别由天冬酰胺、谷氨酰胺转化而来。 食物的感官风味主要来源于食品中的蛋白质降解生成的氨基酸或小分子肽,以及其他相关的衍生物。因此氨基酸的组成对酶解产物的风味具有重要影响。南极磷虾粉在酶解过程中会导致疏水性氨基酸增多,产物苦味增加[35],鲜甜味氨基酸能掩盖苦味,因此食物的鲜甜味及苦味与人们是否能接纳或排斥该种食物紧密相关。

从表11可以看出,虽然色氨酸没有测出,但其余八种必需氨基酸的含量占到了总氨基酸的63.66%,说明酶解液必需氨基酸含量高,具有较好的营养价值。最佳工艺条件下获得水解物的游离氨基酸组成中,游离苦味氨基酸占总氨基酸的27.83%,游离鲜甜味氨基酸占总氨基酸26.22%,与鲜味形成具有关键作用的游离谷氨酸和游离天冬氨酸共占总游离氨基酸的10.26%,游离鲜甜味氨基酸含量较高,是酶解液具有良好风味的基础[36]。获得的水解物总氨基酸组成中,鲜甜味氨基酸占总氨基酸26.09%,苦味氨基酸占总氨基酸的28.39%,ΣEAA/ΣAA与ΣEAA:ΣNEAA分别为63.37%和1.73:1。水解物的总游离氨基酸占总氨基酸的96.14%,总游离苦味氨基酸占总苦味氨基酸的92.46%。游离鲜甜味氨基酸占总鲜甜味氨基酸的96.62%,其中游离鲜味氨基酸占总鲜味氨基酸97.42%,游离甜味氨基酸占总甜味氨基酸的96.12%。

同时,从氨基酸的组成中可以看到,赖氨酸的组成含量较高,赖氨酸是米、面中的第一限制氨基酸。因此可以将南极磷虾酶解液,添加到有需要的食品中,可以实现氨基酸互补,从而达到提高食品的营养价值。获得的水解物氨基酸组成营养价值高,且具有良好鲜甜味滋味,为脱脂南极磷虾粉进一步的开发利用奠定了研究基础。

3. 结论

单一外源酶作用效果虽各有优点,但酶解过程控制不佳会导致酶解液苦涩味偏重,无法同时使滋味和酶解效率达到最优。不同酶在不同作用时间对南极磷虾蛋白水解作用位点不同,因此选用多酶复合酶解,可优化酶解滋味及效果,减少苦味肽与疏水性氨基酸的生成,使得大量鲜甜味氨基酸得以释放,改善了酶解液的风味,提高了南极磷虾粉蛋白酶解效率。单因素实验和正交试验确定了具有良好感官滋味及多肽得率的最佳酶解条件为:加酶量2800 U·g−1,温度40 ℃,时间3.0 h,pH7.0,该酶解条件下获得的酶解液具有良好鲜味,为脱脂南极磷虾粉的加工利用及深入研究提供理论基础和技术指导。

-

表 1 外源酶的酶解条件

Table 1 Enzymatic hydrolysis conditions of exogenous enzymes

酶种类 加酶量(U·g−1) 温度(℃) pH 料液比(g·mL−1) 时间(h) 胰酶 2400 50 7.8~8.5 1:4 6 胃蛋白酶 2400 35 2.0~3.0 1:4 6 中性蛋白酶 2400 50 6.8~7.0 1:4 6 风味酶 2400 50 7.0 1:4 6 菠萝蛋白酶 2400 50 6.0~8.0 1:4 6 碱性蛋白酶 2400 50 10.0 1:4 6 木瓜蛋白酶 2400 50 6.0~7.0 1:4 6 表 2 正交试验因素与水平表

Table 2 Orthogonal experimental factors and level table

水平 A加酶量(U·g−1) B温度(℃) C pH D时间(h) −1 2000 30 7.0 2.5 0 2400 35 7.5 3.0 1 2800 40 8.0 3.5 表 3 感官评价标准

Table 3 Standard and scores of sensory evaluation

项目 评分标准 评分(分) 色泽(满分3分) 色泽很深 1 色呈黄色 2 色呈淡黄色 3 香气(满分3分) 有明显腥味 1 无明显味道 2 有鲜虾味 3 滋味(满分4分) 有酸、苦涩、有异味 1 有甜味,欠鲜味、虾味 2 有甜味,有鲜味或虾味 3 有鲜甜味并伴随虾味 4 表 4 不同外源酶处理后获得的酶解液感官评价结果

Table 4 Sensory evaluation results of enzymatic hydrolysate after treatment with different exogenous enzymes

组分 感官评价分值(分) 平均值(分) 感官鉴定 胰蛋白酶 3 4 5 3 5 4 5 3 5 3 4.0 溶液色泽较深,口感偏苦涩,后味有鲜味 胃蛋白酶 7 8 6 7 8 8 7 7 8 9 7.5 溶液色泽微黄色,具有微甜滋味 中性蛋白酶 4 5 3 4 3 3 4 3 3 4 3.6 溶液色泽较深,口感偏苦涩 风味蛋白酶 5 6 5 5 6 5 6 5 7 6 5.6 溶液色泽微黄色,具有微甜滋味 菠萝蛋白酶 6 7 6 7 7 8 7 6 6 6 6.6 溶液色泽黄色,无苦涩味 碱性蛋白酶 3 4 4 3 5 4 3 3 4 4 3.7 溶液色泽较深,口感偏苦涩、腥味重 木瓜蛋白酶 3 4 5 4 4 4 5 4 4 4 4.1 溶液色泽微黄,无明显苦涩味 表 5 不同加酶量处理条件下的感官评价结果

Table 5 Sensory evaluation results of different enzyme amounts

加酶量(U/g) 感官评分(分) 平均值(分) 感官评价 800 2 3 4 2 2 2 3 2 3 2 2.5 苦味较浓,鲜味与虾味较淡 1000 4 3 4 4 5 3 4 4 4 4 3.9 微苦,有微鲜甜味与虾味 1500 7 8 7 7 7 6 8 7 6 7 7.0 微甜、有鲜味伴随一点微苦味 2400 7 8 8 7 7 8 7 8 7 8 7.5 有鲜甜味与虾味,微微涩 3000 8 9 8 8 8 8 7 8 8 8 8.0 具有鲜甜味,虾味较淡 表 6 不同料液比处理条件下的感官评价结果

Table 6 Sensory evaluation results under different solid-liquid ratio treatment conditions

料液比(g·mL-1) 感官评分(分) 平均值(分) 感官评价 1:3 5 4 5 4 4 4 5 4 5 4 5.5 黄色、甜、微涩 1:4 7 8 8 8 9 8 8 9 9 7 8.1 淡黄色、甜、有鲜味与虾味 1:5 7 8 8 7 9 8 8 7 8 8 7.8 淡黄色、微甜、有鲜味、微涩 1:6 7 8 7 7 8 7 8 7 7 8 7.4 淡黄色、微涩、甜味与鲜味减弱 表 7 不同温度处理条件下的感官评价结果

Table 7 Sensory evaluation results under different temperature treatment conditions

温度(℃) 感官评分(分) 平均值(分) 感官评价 25 7 8 7 8 7 7 8 8 7 8 7.5 淡黄色、虾味、甜度适中、后味微腥 30 8 7 8 8 7 8 7 7 8 7 7.5 淡黄色、淡淡的虾味,甜度中等 35 8 9 7 8 7 8 9 8 8 8 8.0 淡黄色、虾味浓郁、甜度中等 40 7 8 7 8 7 7 7 7 7 7 7.0 淡黄色、微虾味、淡甜味、微涩 45 6 7 7 6 6 6 5 7 5 5 6.0 黄色、微苦味、虾味浓郁,微涩 表 8 不同酶解时间处理条件下的感官评价结果

Table 8 Sensory evaluation results under different enzymatic hydrolysis time treatment conditions

时间(h) 感官评分(分) 平均值(分) 感官评价 1 4 5 5 6 4 4 5 5 6 5 4.9 淡黄色,微甜,无鲜味 2 7 8 8 9 8 8 7 8 9 7 7.9 淡黄色,鲜甜味有所增加 3 7 7 8 8 7 8 7 8 7 8 7.5 淡黄色,鲜甜味几乎没有变化,伴随一点微苦味 4 8 8 9 8 9 8 9 8 7 7 8.1 黄色、鲜甜味明显 5 7 7 8 8 8 7 7 8 7 8 7.5 黄色、甜度不变,鲜味淡一点,微腥 表 9 不同pH处理条件下的感官评价结果

Table 9 Sensory evaluation results under different enzymatic hydrolysis pH treatment conditions

pH 感官评分(分) 平均值(分) 感官评价 4.0 4 3 4 4 3 3 4 3 3 4 3.5 淡黄色、酸涩味,鲜味与虾味几乎没有感觉 5.5 5 5 6 5 4 6 5 6 5 5 5.2 淡黄色、有微鲜甜味与虾味微腥味 6.5 7 6 7 6 8 7 6 7 6 5 6.5 黄色、甜度略有增加、有鲜味伴随一点微苦味与腥味 7.5 8 9 7 8 7 8 9 8 8 8 8.0 黄色、甜度不变,有虾味和微鲜味 8.0 8 8 9 8 9 8 9 8 7 7 8.1 黄色、虾味淡一下,甜度加深,仍伴有鲜味 表 10 脱脂南极磷虾蛋白水解液的正交试验方案与结果分析

Table 10 Orthogonal experimental scheme and result analysis of defatted Antarctic krill protein hydrolysate

实验号 因素 鲜甜味游离氨基酸

(mg/100 mL)鲜味肽

(mg/100 mL)多肽得率

(%)A加酶量(U·g−1) B温度

(℃)C pH D时间

(h)1 1 1 1 1 305.88 39.49 26.45±0.65 2 1 2 2 2 303.40 44.04 31.35±1.85 3 1 3 3 3 304.39 44.33 29.05±1.15 4 2 1 2 3 301.33 44.99 36.70±1.40 5 2 2 3 1 302.98 43.95 42.10±3.90 6 2 3 1 2 301.81 43.33 46.45±1.75 7 3 1 3 2 302.55 42.76 43.65±0.25 8 3 2 1 3 304.64 39.45 48.45±1.25 9 3 3 2 1 306.54 39.07 51.85±3.25 鲜甜味游离氨基酸K1 913.67 909.76 912.33 915.4 鲜甜味游离氨基酸K2 906.12 911.02 911.27 907.76 鲜甜味游离氨基酸K3 913.73 912.74 909.92 910.36 R 7.61 2.98 2.41 7.64 因素主次:D>A>B>C 鲜味肽 K1 127.86 127.24 122.27 122.51 鲜味肽 K2 132.27 127.44 128.1 130.13 鲜味肽 K3 121.28 126.73 131.04 128.77 极差R 10.99 0.71 8.77 7.62 因素主次: A>C>D>B 多肽得率K1 87.55 106.8 121.35 120.7 多肽得率K2 125.25 121.9 120.2 121.45 多肽得率K3 144.25 128.35 115.5 114.9 极差R 18.9 7.18 1.95 2.18 因素主次:A>B>D>C 表 11 脱脂南极磷虾酶解液的氨基酸组成(mg/100 mL)

Table 11 Amino acid composition of Antarctic krill hydrolysate (mg/100 mL)

氨基酸 游离氨基酸含量 总氨基酸含量 氨基酸 游离氨基酸含量 总氨基酸含量 甘氨酸▲ 27.63±0.17 30.73±0.26 苯丙氨酸 348.08±2.95 356.30±0.50 丙氨酸▲ 70.56±0.09 71.73±0.26 赖氨酸◆ 115.84±1.19 120.76±0.29 组氨酸◆ 27.47±0.00 30.42±0.05 异亮氨酸 44.79±1.33 45.58±0.59 酪氨酸◆ 46.47±0.33 50.92±0.12 ∑NEAA 459.94 482.21 丝氨酸▲ 33.97±0.50 35.79±0.32 ∑EAA 805.62 834.16 天冬氨酸● 41.06±0.59 42.56±0.57 ∑SUAA 331.79 343.38 谷氨酸● 88.80±0.00 90.75±0.28 ∑BAA 352.22 373.69 精氨酸◆ 106.03±0.71 110.55±0.10 ∑AA 1265.55 1316.36 脯氨酸▲ 17.96±0.06 18.78±0.46 ∑EAA/∑AA 63.66% 63.37% 亮氨酸 126.44±0.21 129.41±0.75 ∑EAA/∑NEAA 1.75 1.73 缬氨酸◆ 56.41±0.25 61.04±0.95 ∑SUAA/∑AA 26.22% 26.09% 苏氨酸▲ 51.82±0.32 53.06±0.07 ∑BAA/∑AA 27.83% 28.39% 蛋氨酸 62.23±0.24 68.01±0.02 注:苦味氨基酸(◆);鲜味氨基酸(●);甜味氨基酸(▲);必需氨基酸(EAA);非必需氨基酸(NEAA);鲜甜味氨基酸(SUAA);苦味氨基酸(BAA);总氨基酸(AA);天冬氨酸、谷氨酸含量,一部分分别由天冬酰胺、谷氨酰胺转化而来。 -

[1] SIMON C J, TRUONG H H, NOBLE T H, et al. Microbial biomass, marine invertebrate meals and feed restriction influence the biological and gut microbiota response of shrimp Penaeus monodon[J]. Aquaculture,2020,520(4):734679.

[2] 刘永新, 李梦龙, 方辉, 等. 南极磷虾的资源概况与生态系统功能[J]. 水产学杂志,2019,32(1):55−60. [LIU Y X, LI M L, FANG H, et al. Resources status and ecosystem function in Antarctic krill[J]. Chinese Journal of Fisheries,2019,32(1):55−60. doi: 10.3969/j.issn.1005-3832.2019.01.010 [3] YIN L A, JIANG X M, FAN Y, et al. Preparation, gel electrophoresis analysis, and nutritional evaluation of a functional krill protein concentrate with low fluoride level from Antarctic krill (Euphausia superba)[J]. Journal of Aquatic Food Product Technology,2017,26(8):958−968. doi: 10.1080/10498850.2017.1364315

[4] 王凌云, 邓尚贵, 李钰金, 等. 南极磷虾蛋白粉的制备工艺[J]. 食品与发酵工业,2019,45(6):133−138. [WANG L Y, DENG S G, LI Y J, et al. A preparation process to produce Antarctic krill protein powder[J]. Food and Fermentation Industries,2019,45(6):133−138. [5] 邱卫华, 余丽萍, 谢营梁. 南极磷虾粉的营养与功能[J]. 现代渔业信息与战略,2010,25(8):14−16. [QIU W H, YU L P, XIE Y L. Nutrition composition and function of Antarctic krill meal[J]. Fishery Information & Strategy,2010,25(8):14−16. [6] 冯迪娜, 袁玥, 苏学锋, 等. 南极磷虾资源综合利用研究现状[J]. 食品研究与开发,2015,36(8):120−122. [FENG D N, YUAN Y, SU X F, et al. Research status of comprehensive utilization for Antarctic krill resource[J]. Food Research and Development,2015,36(8):120−122. doi: 10.3969/j.issn.1005-6521.2015.08.032 [7] 谈俊晓, 赵永强, 李来好, 等. 南极磷虾综合利用研究进展[J]. 广东农业科学,2017,44(3):143−150. [TAN J X, ZHAO Y Q, LI L H, et al. Research progress on comprehensive utilization of Antarctic krill[J]. Guangdong Agricultural Sciences,2017,44(3):143−150. [8] 李翔, 徐国辉, 姜光朋, 等. 南极磷虾粉替代鱼粉对公子小丑鱼生长性能、饲料利用和体色的影响[J]. 青岛农业大学学报(自然科学版),2019,36(3):213−217. [LI X, XU G H, JIANG G M, et al. Effect of fish meal replaced by Antarctic krill meal on growth performance, feed utilization and body color of juvenile ocellaris clownfish[J]. Journal of Qingdao Agricultural University (Natural Science),2019,36(3):213−217. [9] XU H G, ZHAO M, ZHENG K K, et al. Antarctic krill (Euphausia superba) meal in the diets improved the reproductive performance of tongue sole (Cynoglossus semilaevis) broodstock[J]. Aquaculture Nutrition,2017,23(6):1287−1295. doi: 10.1111/anu.12503

[10] 徐恺, 刘云, 王亚恩, 等. 南极磷虾脱脂蛋白肽抗疲劳和耐缺氧实验研究[J]. 食品科学,2011,3(11):310−313. [XU K, LIU Y, WANG Y E, et al. Anti-fatigue and anti-hypoxia functions of degreased peptides from Antarctic krill in mice[J]. Food Science,2011,3(11):310−313. [11] 王一名, 毛相朝, 曹雪, 等. 磷酸化南极磷虾肽调控Wnt/β-连接蛋白通路改善大鼠骨质疏松症[J]. 中国食品学报,2018,18(3):8−15. [WANG Y M, MAO X C, CAO X, et al. Phosphorylated peptides from Antarctic krill improving osteoporosis in ovariectomized female rats through Wnt/β-catenin signaling pathway[J]. Journal of Chinese Institute of Food Science and Technology,2018,18(3):8−15. [12] ISSA K M, CHEORUN J, RIZWAN T M. Meat flavor precursors and factors influencing flavor precursors-a systematic review[J]. Meat Science,2015,110(8):278−284.

[13] NOMAN A, XU Y S, AL-BUKHAITI W Q, et al. Influence of enzymatic hydrolysis conditions on the degree of hydrolysis and functional properties of protein hydrolysate obtained from Chinese sturgeon(Acipenser sinensis) by using papain enzyme[J]. Process Biochemistry,2018,67(4):19−28.

[14] 涂丹, 张益奇, 叶繁, 等. 酶解制备鱼鳞蛋白降血压肽的工艺优化[J]. 核农学报,2019,33(1):120−128. [TU D, ZHANG Y Q, YE F, et al. Optimization of the preparation process of fish scale protein blood pressure reducing peptide by enzymatic hydrolysis[J]. Journal of Nuclear Agricultural Sciences,2019,33(1):120−128. doi: 10.11869/j.issn.100-8551.2019.01.0120 [15] 丁慧璞, 欧阳伟虹, 黄玉婷, 等. 小黄鱼边角料的酶解工艺及酶解液性能研究[J]. 核农学报,2020,34(9):2021−2031. [DING H P, OUYANG W H, HUANG Y T, et al. Study on enzymatic solution technology and enzymatic solution performance of little yellow fish scrap[J]. Journal of Nuclear Agricultural Sciences,2020,34(9):2021−2031. doi: 10.11869/j.issn.100-8551.2020.09.2021 [16] 林海燕, 王珊珊, 孙珊, 等. 响应面法优化南极磷虾亚铁螯合肽制备工艺及其理化性质[J]. 食品工业科技,2019,40(21):166−173. [LIN H Y, WANG S S, SUN S, et al. Optimization of preparation of iron-chelating peptides from Antarctic krill by response surface methodology and its physicochemical properties[J]. Science and Technology of Food Industry,2019,40(21):166−173. [17] 黄百祺, 黄创成, 吴巨贤, 等. 4种龟肉酶解液的氨基酸及呈味特性比较[J]. 食品研究与开发,2021,42(8):12−17. [HUANG B Q, HUANG C H, WU J X, et al. Amino acids and flavor properties of 4 tortoise ase solutions were compared[J]. Food Research and Development,2021,42(8):12−17. [18] 吴书建, 张佳男, 高世珏, 等. 南美白对虾虾头制备鲜味水解物的研究[J]. 食品工业科技,2019,40(4):34−42,50. [WU S J, ZHANG J N, GAO S Y, et al. Preparation of hydrolysate with umami from white shrimp(Penaeus vannamei) head[J]. Science and Technology of Food Industry,2019,40(4):34−42,50. [19] 于亚辉, 陈沁雯, 李晓婷, 等. 基于主成分分析法的鸡汤与不同鸡肉酶解液中游离氨基酸的对比分析[J]. 河南农业大学学报,2020,54(4):681−688. [YU Y H, CHEN Q W, LI X T, et al. Comparative analysis of chicken soup and free amino acids in different chicken enzyme solutions based on main component analysis[J]. Journal of Henan Agricultural University,2020,54(4):681−688. [20] 曾晨, 陈逸菲, 林慧敏, 等. 东海大黄鱼干呈味肽提取工艺[J]. 食品科技,2021,46(5):117−122. [ZENG C, CHEN Y F, LIN H M, et al. Peptide extraction process of dried rhubarb croaker in the East China Sea[J]. Food Science and Technology,2021,46(5):117−122. [21] YAMASAKI Y, MAEKAWA K. A peptide with delicious taste[J]. Agricultural and Biological Chemistry,1975,23(1):49−53. doi: 10.1021/jf60197a003

[22] 张佳汇, 王芳, 闫丹丹. 鲜味肽介绍及其在调味料中应用的探讨[J]. 食品工业,2021,42(5):204−207. [ZHANG J H, WANG F, YAN D D. Introduction of umami peptide and its application in seasonings[J]. The Food Industry,2021,42(5):204−207. [23] 中华人民共和国国家质量监督检验检疫总局. GB/T 12312感官分析—味觉敏感度测定方法[S]. 北京: 中国标准出版社, 2012. General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China. GB/T 12312 Sensory analysis-method for determination of sensitivity to taste[S]. Beijing: Standards Press of China, 2012.

[24] 李明杰. 南极大磷虾多肽制备工艺优化、脱氟及其体外活性的研究[D]. 青岛: 中国海洋大学, 2012. LI M J. Optimization of preparation process, defluorination and in vitro activity of Antarctic krill polypeptide[D]. Qingdao: Ocean University of China, 2012.

[25] 中华人民共和国卫生部. GB 5009.5食品安全国家标准 食品中蛋白质的测定[S]. 北京: 中国标准出版社, 2016. Ministry of Health of the People's Republic of China. GB 5009.5 National standards for food safety determination of protein in food[S]. Beijing: Standards Press of China, 2016.

[26] 中华人民共和国专业标准. ZB X 66038-1987氨基态氮测定方法[S]. 上海: 上海市科学酿造研究所, 1987. Professional Standards of the People’s Republic of China. ZB X 66038-1987 Determination of amino nitrogen[S]. Shanghai: Shanghai Scientific Brewing Institute, 1987.

[27] 赵静, 丁奇, 孙颖, 等. 香菇菌汤及酶解液中滋味成分及呈味特性的对比分析[J]. 食品科学,2016,37(24):99−104. [ZHAO J, DING Q, SUN Y, et al. Comparison of taste compounds and taste characteristics of shiitake mushroom soup and enzymatic hydrolysate[J]. Food Science,2016,37(24):99−104. doi: 10.7506/spkx1002-6630-201624015 [28] 中华人民共和国卫生部. GB/T 5009.124 食品安全国家标准 食品中氨基酸的测定[S]. 北京: 中国标准出版社, 2016. Ministry of Health of the People’s Republic of China. GB/T 5009.124 National food safety standards determination of amino acids in food[S]. Beijing: Standards Press of China, 2016.

[29] 林娈, 陈丽娇, 董乐. 文蛤肉酶法水解条件的优化及最适蛋白酶的选择[J]. 保鲜与加工,2009,9(5):48−52. [LIN Y, CHEN L J, DONG L. Optimization of hydrolysis conditions and selection of optimal protease[J]. Storage and Process,2009,9(5):48−52. doi: 10.3969/j.issn.1009-6221.2009.05.014 [30] 戴志远, 郭瑞, 张燕平, 等. 动物蛋白水解酶法制备梅鱼鲜味酶解液的研究[J]. 食品与发酵工业,2011,3(8):71−75. [DAI Z Y, GUO R, ZHANG Y P, et al. Preparation of fish umami enzyme solution by animal proteolysase method[J]. Food and Fermentation Industry,2011,3(8):71−75. [31] DEEPA B, ANURADHA C V. Effects of linalool on inflammation, matrix accumulation and podocyte loss in kidney of streptozotocin-induced diabetic rats[J]. Toxicology Mechanisms and Methods,2013,23(4):223−234. doi: 10.3109/15376516.2012.743638

[32] 杨杰. 鱼骨营养成分分析及鱼骨休闲食品的研制[D]. 石河子: 石河子大学, 2018. YANG J. The analysis of fish bone nutrition and the development of fish bone leisure food[D]. Xinjiang: Shihezi University, 2018.

[33] 宋武刚. 响应面法优化武定鸡风味基料加工工艺的研究[D]. 昆明: 云南农业大学, 2017. SONG W G. Study on the processing process of flavor base by response method[D]. Kunming: Yunnan Agricultural University, 2017.

[34] FAN Y, YIN L, XUE Y, et al. Analyzing the flavor compounds in Chinese traditional fermented shrimp pastes by HS-SPME-GC/MS and electronic nose[J]. Journal of Ocean University of China,2017,16(2):311−318. doi: 10.1007/s11802-017-3194-y

[35] 郭兴峰, 魏芳, 周祥山, 等. 苦味肽的形成机理及脱苦技术研究进展[J]. 食品研究与开发,2017,38(21):207−211. [GUO X F, WEI F, ZHOU X S, et al. Research progress of bitter peptide formation mechanism and technology[J]. Food Research and Development,2017,38(21):207−211. doi: 10.3969/j.issn.1005-6521.2017.21.041 [36] 陈怡颖, 丁奇, 赵静, 等. 鸡汤及鸡肉酶解液中游离氨基酸及呈味特性的对比分析[J]. 食品科学,2015,36(16):107−111. [CHEN Y Y, DING Q, ZHAO J, et al. Comparative analysis of free amino acids and flavor properties in chicken soup and chicken enzyme solution[J]. Food Science,2015,36(16):107−111. doi: 10.7506/spkx1002-6630-201516019 -

期刊类型引用(2)

1. 解鹏,高岳,吴晨奇,崔保威,王芳,王慧,范娜. 不同种类原料肉对发酵香肠理化品质及风味特性的影响. 肉类研究. 2025(03): 29-34 .  百度学术

百度学术

2. 左敏,纪慧卓,苏礼君,张玉玉,颜文婧,张青川,孔建磊. 人工智能在食品安全中的最新应用及进展. 中国食品学报. 2024(10): 1-13 .  百度学术

百度学术

其他类型引用(0)

下载:

下载:

下载:

下载: