| [1] |

ZHU F. Structure, physicochemical properties, modifications, and uses of sorghum starch[J]. Comprehensive Reviews in Food Science and Food Safety,2014,13(4):597−610. doi: 10.1111/1541-4337.12070

|

| [2] |

申瑞玲, 陈明, 任贵兴. 高粱淀粉的研究进展[J]. 中国粮油学报,2012,27(7):123−128. [SHEN R L, CHEN M, REN G X. Research progress of the sorghum starch[J]. Journal of the Chinese Cereals and Oils Association,2012,27(7):123−128.

SHEN R L, CHEN M, REN G X. Research progress of the sorghum starch[J]. Journal of the Chinese Cereals and Oils Association, 2012, 27(7): 123-128.

|

| [3] |

刘庆芳, 祁瑜婷, 杜方岭. 高粱淀粉的研究与发展[J]. 农产品加工,2016(18):54−56. [LIU Q F, QI Y T, DU F L. Research and development of sorghum starch[J]. Farm Products Processing,2016(18):54−56.

LIU Q F, QI Y T, DU F L. Research and development of sorghum starch[J]. Farm Products Processing, 2016(18): 54-56.

|

| [4] |

苏会波, 林海龙. 难消化糊精的研究进展[J]. 食品与生物技术学报,2014,33(1):1−7. [SU H B, LIN H L. Research progress and market status of health food-indigestible dextrin[J]. Journal of Food Science and Biotechnology,2014,33(1):1−7.

SU H B, LIN H L. Research progress and market status of health food-indigestible dextrin[J]. Journal of Food Science and Biotechnology, 2014, 33(1): 1-7.

|

| [5] |

王六强, 张新武, 马飞飞, 等. 抗性糊精的生产应用现状研究与展望[J]. 农产品加工,2020(6):76−80. [WANG L Q, ZHANG X W, MA F F, et al. Research and prospect of production and application of resistant dextrin[J]. Farm Products Processing,2020(6):76−80.

WANG L Q, ZHANG X W, MA F F, et al. Research and prospect of production and application of resistant dextrin[J]. Farm Products Processing, 2020(6): 76-80.

|

| [6] |

任国宝, 任晨刚, 郇美丽, 等. 膳食纤维对小麦粉品质的影响[J]. 中国粮油学报,2020,35(2):6−11. [REN G B, REN C G, HUAN M L, et al. Effect of dietary fiber on flour quality[J]. Journal of the Chinese Cereals and Oils Association,2020,35(2):6−11.

REN G B, REN C G, HUAN M L, et al. Effect of dietary fiber on flour quality[J]. Journal of the Chinese Cereals and Oils Association, 2020, 35(2): 6-11.

|

| [7] |

KAMILA K, EWA N. Enzyme-resistant dextrins from potato starch for potential application in the beverage industry[J]. Carbohydrate Polymers,2017,172(5):152−158.

|

| [8] |

MARCIO S, MARIA C C N M, ANDREA C D S B, et al. Dietary fiber as fat substitute in emulsified and cooked meat model system[J]. LWT-Food Science and Technology,2015,61(1):105−111. doi: 10.1016/j.lwt.2014.11.037

|

| [9] |

TRITHAVISUP K, KRUSONG K. In-depth study of the changes in properties and molecular structure of cassava starch during resistant dextrin preparation[J]. Food Chemistry,2019(12):49−53.

|

| [10] |

HOBDEN M R, AETITIAL G D, IAN R, et al. Potential anti-obesogenic properties of non-digestible carbohydrates: Specific focus on resistant dextrin[J]. Proceedings of the Nutrition Society,2015,74:1−10. doi: 10.1017/S0029665114001566

|

| [11] |

张松, 苏永平, 李涛, 等. 膳食纤维的功能特性及其在食品领域的研究进展[J]. 食品研究与开发,2018,39(17):214−218. [ZHANG S, SU Y P, LI T, et al. Functional characteristics of dietary fiber and research progress in food field[J]. Food Research and Development,2018,39(17):214−218.

ZHANG S, SU Y P, LI T, et al. Functional characteristics of dietary fiber and research progress in food field[J]. Food Research andDevelopment, 2018, 39(17): 214-218.

|

| [12] |

黄政, 孙江文, 徐勇, 等. 抗性糊精的研究与应用进展[J]. 海南师范大学学报(自然科学版),2018,31(4):418−428. [HUANG Z, SUN J W, XU Y, et al. Advance on research and application of resistant dextrin[J]. Journal of Hainan Normal University (Natural Science Edition),2018,31(4):418−428.

HUANG Z, SUN J W, XU Y, et al. Advance on research and application of resistant dextrin[J]. Journal of Hainan Normal University(Natural Science Edition), 2018, 31(4): 418-428.

|

| [13] |

BA K, BLECKER C, DANTHINE S, et al. Physicochemical characterization of dextrins prepared with amylases from sorghum malt[J]. Starch-Stärke,2013,65(11-12):962−968.

|

| [14] |

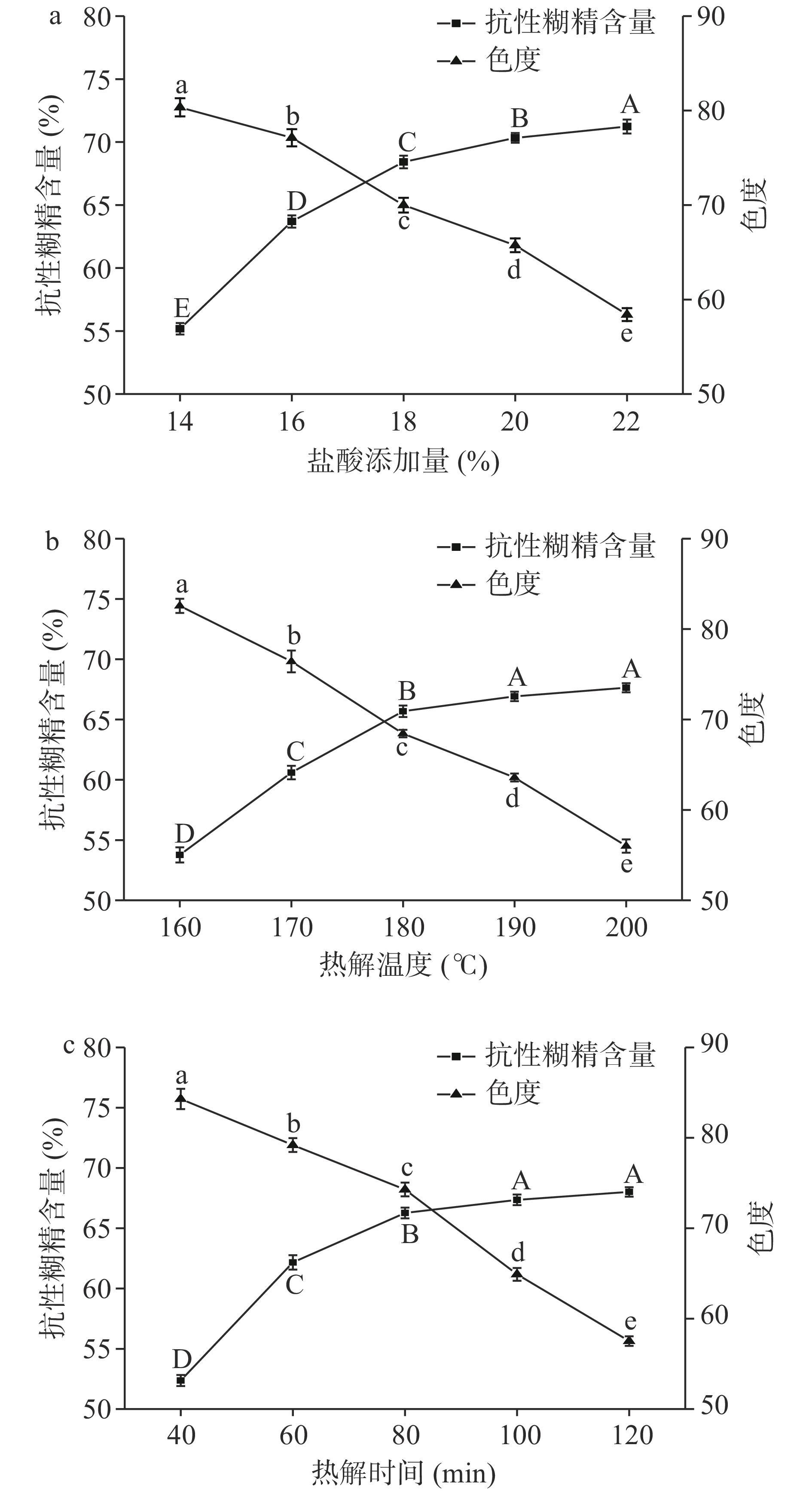

张婷, 李佳瑶, 安双双, 等. 高粱抗性糊精的制备工艺优化及结构表征[J]. 食品科技,2020,342(4):238−243. [ZHANG T, LI J Y, AN S S, et al. Preparation process optimization and structure characterization of sorghum resistant dextrin[J]. Food Science and Technology,2020,342(4):238−243.

ZHANG T, LI J Y, AN S S, et al. Preparation process optimization and structure characterization of sorghum resistant dextrin[J]. Food Science and Technology, 2020, 342(4): 238-243.

|

| [15] |

常江涛, 刘洁, 刘亚伟. 糯性低葡萄糖当量麦芽糊精的制备及结构表征[J]. 河南工业大学学报(自然科学版),2022,43(4):70−76. [CHANG J T, LIU J, LIU Y W. Preparation and structure characterization of low dextrose equivalent maltodextrin from waxy rice starch[J]. Journal of Henan University of Technology (Natural Science Edition),2022,43(4):70−76.

CHANG J T, LIU J, LIU Y W. Preparation and structure characterization of low dextrose equivalent maltodextrin from waxy rice starch[J]. Journal of Henan University of Technology(Natural Science Edition), 2022, 43(4): 70-76.

|

| [16] |

|

| [17] |

张吉军, 曹龙奎, 衣淑娟, 等. 微波间歇干燥对北方粳高粱蛋白质及淀粉品质的影响[J]. 食品科学,2022,43(7):52−60. [ZHANG J J, CAO L K, YI S J, et al. Effect of intermittent microwave drying on protein and starch quality of non-glutinous sorghum[J]. Food Science,2022,43(7):52−60.

ZHANG J J, CAO L K, YI S J, et al. Effect of intermittent microwave drying on protein and starch quality of non-glutinous sorghum[J]. Food Science, 2022, 43(7): 52-60.

|

| [18] |

朱洁. 抗性糊精的工艺及特性研究[D]. 天津: 天津科技大学, 2010

ZHU J. Study on technology and properties of indigestible dextrin[D]. Tianjing: Tianjin University of Science and Technology, 2010.

|

| [19] |

甄远航. 抗性糊精的分离纯化及其在面制品中的应用研究[D]. 无锡: 江南大学, 2021

ZHEN Y H. Isolation and purification of resistant dextrin and its application in flour product[D]. Wuxi: Jiangnan University, 2021.

|

| [20] |

刘晚霞. 绿豆渣抗性糊精的模拟移动床色谱纯化及其特性研究[D]. 大庆: 黑龙江八一农垦大学, 2021

LIU W X. Study on high efficiency purification technology and molecular characteristics of mung bean resistant dextrin[D]. Daqing: Heilongjiang Bayi Agricultural University, 2021.

|

| [21] |

张新武, 朱博博, 黄继红, 等. 抗性糊精的焙烤制备工艺技术研究[J]. 农产品加工,2018(22):33−36. [ZHANG X W, ZHU B B, HUANG J H, et al. Study on baking preparation technology of resistant dextrin[J]. Farm Products Processing,2018(22):33−36.

ZHANG X W, ZHU B B, HUANG J H, et al. Study on baking preparation technology of resistant dextrin[J]. Farm Products Processing, 2018(22): 33-36.

|

| [22] |

BARCZYNSKA R, SLIZEWSKAB K, JOCHYMA K. The tartaric acid-modified enzyme-resistant dextrin from potato starch as potential prebiotic[J]. Journal of Functional Food,2012(4):954−962.

|

| [23] |

吕行, 黄继红, 纪小国, 等. “干热三步法”制备抗性糊精的工艺及其表征[J]. 食品工业,2019,40(2):95−99. [LÜ X, HUANG J H, JI X G, et al. Technology and characterization of preparation of resistant dextrin by “dry heat three-step method”[J]. The Food Industry,2019,40(2):95−99.

LV X, HUANG J H, JI X G, et al. Technology and Characterization of Preparation of Resistant Dextrin by“Dry Heat Three-step Method”[J]. The Food Industry, 2019, 40(2): 95-99.

|

| [24] |

HIDALGO A, FONGARO L, BRANDOLINI A. Colour screening of whole meal flours and discrimination of seven Triticum subspecies[J]. Journal of Cereal Science,2017,77:9−16. doi: 10.1016/j.jcs.2017.07.006

|

| [25] |

刘德志, 王维浩, 全志刚, 等. 绿豆抗性糊精的结构表征及抗消化特性研究[J]. 食品工业科技,2022,43(11):119−125. [LIU D Z, WANG W H, QUAN Z G, et al. Study on structure characterization and anti digestion properties of mung bean resistant dextrin[J]. Science and Technology of Food Industry,2022,43(11):119−125.

LIU D Z, WANG W H, QUAN Z G, et al. Study on structure characterization and anti digestion properties of mung bean resistant dextrin[J]. Science and Technology of Food Industry, 2022, 43(11): 119-125.

|

| [26] |

季瑞雪. 知母多糖理化性质及生物活性研究[D]. 大庆: 黑龙江八一农垦大学, 2021

JI R X. Research on physicochemical properties and biological activities of polysaccharides from Anemarrhena asphodeloides rhizomes[D]. Daqing: Heilongjiang Bayi Agricultural University, 2021.

|

| [27] |

BAI Y J, SHI Y C. Chemical structures in pyrodextrin determined by nuclear magnetic resonance spectroscopy[J]. Carbohydrate Polymers,2016:426−433.

|

| [28] |

ENGLYST H N, KINGMAN S M, CUMMINGS J H. Classification and measurement of nutritionally important starch fractions[J]. European Journal of Clinical Nutrition,1992,46(2):33−50.

|

| [29] |

陆勇, 郭丽慧, 李学红, 等. 高粱淀粉的理化特性及其水解率的研究[J]. 食品工业,2015,36(9):29−33. [LU Y, GUO L H, LI X H. The physical and chemical properties and hydrolysis rate of sorghum starch research[J]. The Food Industry,2015,36(9):29−33.

LU Y, GUO L H, LI X H. The physical and chemical properties and hydrolysis rate of sorghum starch research[J]. The Food Industry, 2015, 36(9): 29-33.

|

| [30] |

大隈一裕, 西端丰秀. 水溶性膳食纤维Fibersol-2[J]. 中国食品添加剂,2003(5):11−16. [OKUMA Y Y, XIDUAN C X. Watersoluble dietary fiber Fibersol-2[J]. China Food Additives,2003(5):11−16.

OKUMA Y Y, XIDUAN C X. Watersoluble dietary fiber fibersol-2[J]. China Food Additives, 2003(5): 11-16.

|

| [31] |

HAN X, KANG J, BAI Y, et al. Structure of pyrodextrin in relation to its retrogradation properties[J]. Food Chemistry,2018,242(MAR.1):169−173.

|

| [32] |

张颖. 抗性糊精的纯化及应用特性研究[D]. 无锡: 江南大学, 2015

ZHANG Y. Study on purification and application of resistant dextrin[D]. Wuxi: Jiangnan University, 2015.

|

| [33] |

赵姝婷, 全志刚, 王娟, 等. 硒化绿豆抗性淀粉制备工艺优化及抗氧化活性分析[J]. 中国粮油学报,2022,37(9):246−255. [ZHAO S T, QUAN Z G, WANG J, et al. Preparation process of resistant starch of selenized mung bean-resistant starch and analysis of antioxidant activity[J]. Journal of the Chinese Cereals and Oils Association,2022,37(9):246−255.

ZHAO S T, QUAN Z G, WANG J, et al. Preparation process of resistant starch of selenized mung bean-resistant starch and analysis of antioxidant activity[J]. Journal of the Chinese Cereals and Oils Association, 2022, 37(9): 246-255.

|

| [34] |

竺鉴博, 李朝阳, 贾鹏禹, 等. 响应面法优化豌豆渣抗性糊精的制备工艺[J]. 食品工业,2019,40(12):65−69. [ZHU J B, LI Z Y, JIA P Y, et al. Response surface methodology optimization for resistant dextrin preparation from pea residue[J]. The Food Industry,2019,40(12):65−69.

ZHU J B, LI Z Y, JIA P Y, et al. Response surface methodology optimization for resistant dextrin preparation from pea residue[J]. The Food Industry, 2019, 40(12): 65-69.

|

| [35] |

FAKOOR M, BA K M, SOLEYMANI M. Optimal design of the satellite constellation arrangement reconfiguration process[J]. Advances in Space Research,2016:372−386.

|

| [36] |

黄政. 水溶性抗性糊精的性质及其对面粉加工品质的影响[D]. 广州: 华南理工大学, 2019

HUANG Z. Properties of water-soluble resistant dextrin and its effects on the processing quality of flour products[D]. Guangzhou: South China University of Technology, 2019.

|

| [37] |

李良玉, 刘晚霞, 李朝阳, 等. 绿豆抗性糊精的高效纯化技术及分子特性研究[J]. 中国食品学报,2020,20(10):134−141. [LI L Y, LIU W X, LI C Y, et al. High efficiency purification technology and molecular characteristics of mung bean resistant dextrin[J]. Chinese Journal of Food,2020,20(10):134−141.

LI L Y, LIU W X, LI C Y, et al. High efficiency purification technology and molecular characteristics of mung bean resistant dextrin[J]. Chinese Journal of Food, 2020, 20(10): 134-141.

|

| [38] |

WANG H S, ZAINABU M, ZHENG R N. Characterization of microwave-synthesized polydextrose and its radical-scavenging activity[J]. Taylor and Francis,2018,37(1):44−56.

|

| [39] |

JOANNA T B, WIOLETTA B, ARTUR S, et al. Molecular and supermolecular structure of commercial pyrodextrins[J]. Journal of Food Science,2016,81(7−9):C2135.

|

| [40] |

徐佩琳. 酸热法和微波预处理—酶法制备山药抗性糊精及其特性研究[D]. 合肥: 合肥工业大学, 2018

XU P L. Preparation and characterization of yam resistant dextrin by acid heating method and microwave pretreatment-enzymolysis method[D]. Hefei: Hefei University of Technology, 2018.

|

| [41] |

武小辉. 麦芽糊精的交联聚合技术及其特性研究[D]. 郑州: 河南工业大学, 2016

WU X H. Study on cross-linking polymerization technology and characteristics of maltodextrin[D]. Zhengzhou: Henan University of Technology, 2016.

|

| [42] |

WEIL W, WEIL R C, KEAWSOMPONG S, et al. Pyrodextrins from waxy and normal tapioca starches: Molecular structure and in vitro digestibility[J]. Carbohydrate Polymers,2021,252(11):117140.

|

| [43] |

李梦楠, 张黎明, 郝利民, 等. 茶多酚-高直链玉米淀粉共研磨混合物的制备与结构表征[J]. 食品工业科技,2019,40(7):1−4. [LI M N, ZHANG L M, HAO L M, et al. Preparation and structure characterization of tea polyphenols-high-amylose maize starch co-grinding mixtures[J]. Science and Technology of Food Industry,2019,40(7):1−4.

Preparation and structure characterization of tea polyphenols-high-amylose maize starch co-grinding mixtures[J]. Science and Technology of Food Industry, 2019, 40(7): 1−4, 10.

|

DownLoad:

DownLoad: