| [1] |

景娴, 江海, 杜欢欢, 等. 我国山药研究进展[J]. 安徽农业科学,2016,44(15):114−117. [JING X, JIANG T, DU H H, et al. Research progress on dioscorea opposita in China[J]. Journal of Anhui Agricultural Sciences,2016,44(15):114−117. doi: 10.3969/j.issn.0517-6611.2016.15.040

JING X, JIANG T, DU H H, et al. Research progress on dioscorea opposita in China[J]. Journal of Anhui Agricultural Sciences, 2016, 44(15): 114-117. doi: 10.3969/j.issn.0517-6611.2016.15.040

|

| [2] |

ZHOU S Y, HUANG G L, CHEN G Y, et al. Extraction, structural analysis, derivatization and antioxidant activity of polysaccharide from Chinese yam[J]. Food Chemistry,2021,361:130089. doi: 10.1016/j.foodchem.2021.130089

|

| [3] |

LI Q, LI X J, REN Z Y, et al. Physicochemical properties and antioxidant activity of Maillard reaction products derived from dioscorea opposita polysaccharides[J]. LWT,2021,149:111833. doi: 10.1016/j.lwt.2021.111833

|

| [4] |

周子丹, 彭文君, 倪家宝, 等. 不同干燥方式对油菜蜂花粉色泽、酚酸含量和抗氧化活性的影响[J]. 食品科学,2021,42(17):76−83. [ZHOU Z D, PENG W J, NI J B, et al. Effects of different drying methods on color, phenolic acids contents and antioxidant activity of rape bee pollen[J]. Food Science,2021,42(17):76−83. doi: 10.7506/spkx1002-6630-20210204-071

ZHOU Z D, PENG W J, NI J B, et al. Effects of different drying methods on color, phenolic acids contents and antioxidant activity of rape bee pollen[J]. Food Science, 2021, 42(17): 76-83. doi: 10.7506/spkx1002-6630-20210204-071

|

| [5] |

尹晓峰, 杨玲. 调味农产品干燥预处理技术研究进展[J]. 现代农业,2022,545(5):43−48. [YIN X F, YANG L. Research progress on dried pretreatment technology of seasoned agricultural products[J]. Modern Agriculture,2022,545(5):43−48. doi: 10.3969/j.issn.1008-0708.2022.05.012

YIN X F, YANG L. Research progress on dried pretreatment technology of seasoned agricultural products[J]. Modern Agriculture, 2022, 545(5): 43-48. doi: 10.3969/j.issn.1008-0708.2022.05.012

|

| [6] |

谭舒丹, 张茜, 许钰, 等. 浆果干燥预处理技术研究进展[J]. 食品科技,2022,47(7):46−51. [TAN S D, ZHANG Q, XU Y, et al. Research progress of berry drying pretreatment technology[J]. Food Science and Technology,2022,47(7):46−51. doi: 10.3969/j.issn.1005-9989.2022.7.spkj202207007

|

| [7] |

李红娟, 张茜, 杨旭海, 等. 果蔬预处理现状分析及未来发展趋势[J]. 江苏农业科学,2015,43(5):271−272,361. [LI H J, ZHANG Q, YANG X H, et al. Current situation analysis and future development trend of fruit and vegetable pretreatment[J]. Jiangsu Agricultural Sciences,2015,43(5):271−272,361. doi: 10.15889/j.issn.1002-1302.2015.05.090

LI H J, ZHANG Q, YANG X H, et al. Current situation analysis and future development trend of fruit and vegetable pretreatment[J]. Jiangsu Agricultural Sciences, 2015, 43(5): 271-272, 361. doi: 10.15889/j.issn.1002-1302.2015.05.090

|

| [8] |

安可婧, 魏来, 唐道邦, 等. 果蔬干燥前处理技术的应用及研究进展[J]. 现代食品科技,2019,35(6):314−321. [AN K J, WEI L, TANG D B, et al. Application and research progress of pretreatment technology for drying of fruits and vegetables[J]. Modern Food Science and Technology,2019,35(6):314−321. doi: 10.13982/j.mfst.1673-9078.2019.6.042

AN K J, WEI L, TANG D B, et al. Application and research progress of pretreatment technology for drying of fruits and vegetables[J]. Modern Food Science and Technology, 2019, 35(6): 314-321. doi: 10.13982/j.mfst.1673-9078.2019.6.042

|

| [9] |

YUCEL U, ALPASH, BAYINDIRLI A. Evaluation of high pressure pretreatment for enhancing the drying rates of carrot, apple, and green bean[J]. Journal of Food Engineering,2010,98(2):266−272. doi: 10.1016/j.jfoodeng.2010.01.006

|

| [10] |

吴亚丽, 郭玉明. 高压脉冲电场预处理对土豆真空冷冻干燥的影响[J]. 山西农业大学学报(自然科学版),2010,30(5):464−467. [WU Y L, GUO Y M. Effect of high pulsed electrical field pretreatment on vacuum freeze-drying of potato[J]. Journal of Shanxi Agricultural University (Natural Science Edition),2010,30(5):464−467. doi: 10.3969/j.issn.1671-8151.2010.05.019

WU Y L, GUO Y M. Effect of high pulsed electrical field pretreatment on vacuum freeze-drying of potato[J]. Journal of Shanxi Agricultural University (Natural Science Edition), 2010, 30(5): 464-467. doi: 10.3969/j.issn.1671-8151.2010.05.019

|

| [11] |

RAMÍREZ C, TRONCOSO E, MUOZ J, et al. Microstructure analysis on pretreated apple slices and its effect on water release during air drying[J]. Journal of Food Engineering,2011,106(3):253−261. doi: 10.1016/j.jfoodeng.2011.05.020

|

| [12] |

郭婷, 何新益, 邓放明, 等. 冻融处理对变温压差膨化干燥甘薯粉特性的影响[J]. 中国粮油学报,2017,32(12):12−18. [GUO T, HE X Y, DENG F G, et al. Effect of freeze-thaw treatment on the product quality of explosion puffing drying sweet potato powder[J]. Journal of the Chinese Cereals and Oils Association,2017,32(12):12−18. doi: 10.3969/j.issn.1003-0174.2017.12.003

GUO T, HE X Y, DENG F G, et al. Effect of freeze-thaw treatment on the product quality of explosion puffing drying sweet potato powder[J]. Journal of the Chinese Cereals and Oils Association, 2017, 32(12): 12-18. doi: 10.3969/j.issn.1003-0174.2017.12.003

|

| [13] |

康晓鸥, 张淼, 方倩, 等. 切片厚度和斜度对怀山药干燥特性的影响[J]. 农产品加工,2017(12):5−8. [KANG X O, ZHANG M, FANG Q, et al. Effect of the slice thickness and slice angle on the drying characteristics of dioscorea opposite thunb[J]. Farm Products Processing,2017(12):5−8. doi: 10.16693/j.cnki.1671-9646(X).2017.06.030

KANG X O, ZHANG M, FANG Q, et al. Effect of the slice thickness and slice angle on the drying characteristics of dioscorea opposite thunb[J]. Farm Products Processing, 2017(12): 5-8. doi: 10.16693/j.cnki.1671-9646(X).2017.06.030

|

| [14] |

张莉会, 吕亭逸, 乔宇, 等. 超声结合超高压预处理对冻干草莓片品质的影响[J]. 食品工业科技,2020,41(14):15−21,28. [ZHANG L H, LV T Y, QIAO Y, et al. Effect of ultrasound and ultrahigh pressure pretreatment on quality of freeze-dried strawberry slices[J]. Science and Technology of Food Industry,2020,41(14):15−21,28. doi: 10.13386/j.issn1002-0306.2020.14.003

ZHANG L H, LV T Y, QIAO Y, et al. Effect of ultrasound and ultrahigh pressure pretreatment on quality of freeze-dried strawberry slices[J]. Science and Technology of Food Industry, 2020, 41(14): 15-21, 28. doi: 10.13386/j.issn1002-0306.2020.14.003

|

| [15] |

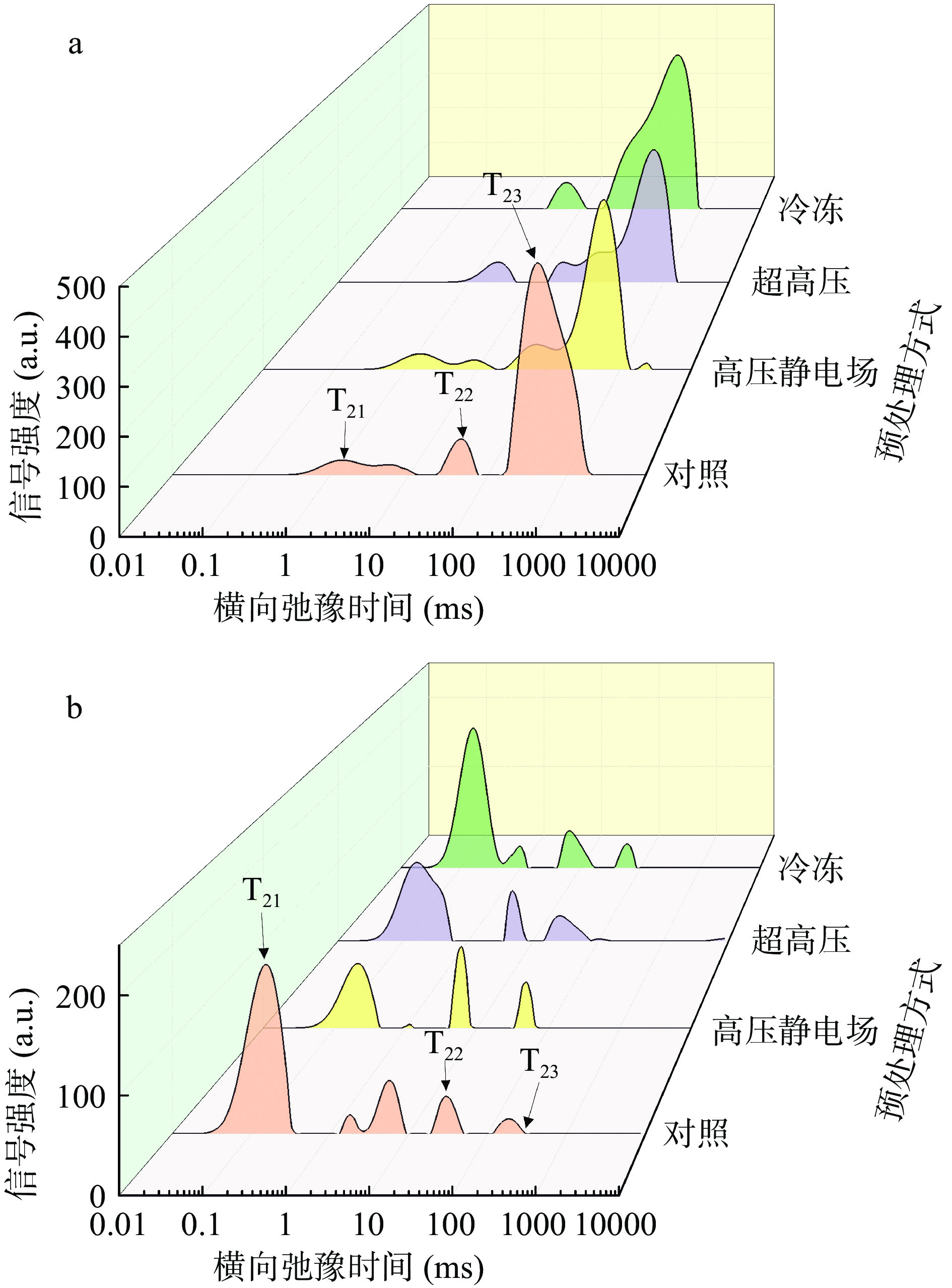

徐馨, 柯亚婕, 汤尚文, 等. 热风干燥过程中山药水分状态的变化研究[J]. 保鲜与加工,2020,20(2):177−180. [XU X, KE Y J, TANG S W, et al. Water status of Chinese yam during hot air drying[J]. Storage and Process,2020,20(2):177−180. doi: 10.3969/j.issn.1009-6221.2020.02.030

|

| [16] |

黄纪民, 吴钊龙, 李浩, 等. 西林火姜片微波间歇干燥特性及品质变化[J]. 食品工业科技,2022,43(5):61−70. [HUANG J M, WU Z L, LI H, et al. Intermittent migcrowave drying characteristics and quality changes of xilin fire inger slices[J]. Science and Technology of Food Industry,2022,43(5):61−70. doi: 10.13386/j.issn1002-0306.2021050255

HUANG J M, WU Z L, LI H, et al. Intermittent migcrowave drying characteristics and quality changes of xilin fire inger slices[J]. Science and Technology of Food Industry, 2022, 43(5): 61-70. doi: 10.13386/j.issn1002-0306.2021050255

|

| [17] |

雷佩佩. 基于单细胞测序解析猪精原细胞的异质性[D]. 杨凌: 西北农林科技大学, 2021

LEI P P. The analysis of heterogeneity in porcine spermatogonia based on the single cell sequencing[D]. Yangling: Northwest Agriculture & Forestry University, 2021.

|

| [18] |

董亚辉. 山药不同品种形态、生理、产量和品质比较研究[D]. 新乡: 河南师范大学, 2020

DONG Y H. Comparative study on morphology, physiology, yield and quality of differ varieties of dioscorea opposita thumb[D]. Xinxiang: Henan Normal University, 2020.

|

| [19] |

徐欣然, 王明, 刘莉, 等. 燕麦秸秆纤维素测定方法比较及响应面优化分析[J]. 饲料研究,2020,43(3):68−73. [XU X R, WANG M, LIU L, et al. Comparison of methods for determination of oat straw cellulose and optimization analysis of response surface[J]. Feed Research,2020,43(3):68−73. doi: 10.13557/j.cnki.issn1002-2813.2020.03.018

M, LIU L, et al. Comparison of methods for determination of oat straw cellulose and optimization analysis of response surface[J]. Feed Research, 2020, 43(3): 68-73. ] doi: 10.13557/j.cnki.issn1002-2813.2020.03.018

|

| [20] |

马丽, 乔军, 吕春晶, 等. 不同质地葡萄果实果胶含量及基因表达差异分析[J]. 江苏农业科学,2022,50(13):64−69. [MA Li, QIAO J, LÜ C J, et al. Differential analysis of pectin content and gene expression in grapes with different textures[J]. Jiangsu Agricultural Sciences,2022,50(13):64−69. doi: 10.15889/j.issn.1002-1302.2022.13.011

MA Li, QIAO J, LV C J, et al. Differential analysis of pectin content and gene expression in grapes with different textures[J]. Jiangsu Agricultural Sciences, 2022, 50(13): 64-69. doi: 10.15889/j.issn.1002-1302.2022.13.011

|

| [21] |

QIU Y, BI J F, JIN X, et al. An understanding of the changes in water holding capacity of rehydrated shit ake mushroom ( Lentinula edodes) from cell wall, cell membrane and protein[J]. Food Chemistry,2021,351:129230. doi: 10.1016/j.foodchem.2021.129230

|

| [22] |

季蕾蕾, 木泰华, 孙红男. 不同干燥方式对甘薯叶片水分迁移、微观结构、色泽及复水性能影响的比较[J]. 食品科学,2020,41(11):90−96. [JI L L, MU T H, SUN H N. Comparative effect of different drying processes on mass migration, microstructure, color and rehydration property of sweet potato leaves[J]. Food science,2020,41(11):90−96. doi: 10.7506/spkx1002-6630-20190528-337

JI L L, MU T H, SUN H N. Comparative effect of different drying processes on mass migration, microstructure, color and rehydration property of sweet potato leaves[J]. Food science, 2020, 41(11): 90-96. doi: 10.7506/spkx1002-6630-20190528-337

|

| [23] |

CHENG S S, WANG X, LI R, et al. Influence of multiple freeze-thaw cycles on quality characteristics of beef semimembranous muscle: With emphasis on water status and distribution by LF-NMR and MRI[J]. Meat Science,2019,147:44−52. doi: 10.1016/j.meatsci.2018.08.020

|

| [24] |

王杏娣, 谢超, 梁瑞萍, 等. 低压静电场处理对竹节虾(Penaeus japonicus)微冻贮藏过程中品质的影响[J]. 食品工业科技,2020,41(7):1−6,12. [[WANG X D, XIE C, LIANG R P, et al. Effect of low voltage electrostatic field treatment on the quality of Penaeus japonicus during microfreezing storage[J]. Science and Technology of Food Industry,2020,41(7):1−6,12.

[WANG X D, XIE C, LIANG R P, et al. Effect of low voltage electrostatic field treatment on the quality of Penaeus japonicus during microfreezing storage[J]. Science and Technology of Food Industry, 2020, 41(7): 1-6, 12.

|

| [25] |

曲敏, 王宇, 陈红丽, 等. 寒地冬小麦冰结构蛋白对冷冻豆腐品质及蛋白性质的抗冻保护作用[J]. 现代食品科技,2023,39(4):126−135. [QU M, WANG Y, CHEN H L, et al. Antifreeze protective effect of winter wheat ice structural protein on frozen tofu quality and protein properties in cold region[J]. Modern Food Science and Technology,2023,39(4):126−135. doi: 10.13982/j.mfst.1673-9078.2023.4.0482

QU M, WANG Y, CHEN H L, et al. Antifreeze protective effect of winter wheat ice structural protein on frozen tofu quality and protein properties in cold region[J]. Modern Food Science and Technology, 2023, 39(4): 126-135. doi: 10.13982/j.mfst.1673-9078.2023.4.0482

|

| [26] |

常江, 巩雪, 孙智慧. 超高压处理对扇贝界面闭壳肌结构的影响[J]. 中国食品学报,2022,22(8):136−144. [CHANG J, GONG X, SUN Z H. Effects of ultra-high pressure treatment on the structure of interface adductor muscle of scallop[J]. Journal of Chinese Institute of Food Science and Technology,2022,22(8):136−144. doi: 10.16429/j.1009-7848.2022.08.015

CHANG J, GONG X, SUN Z H. Effects of ultra-high pressure treatment on the structure of interface adductor muscle of scallop[J]. Journal of Chinese Institute of Food Science and Technology, 2022, 22(8): 136-144. doi: 10.16429/j.1009-7848.2022.08.015

|

| [27] |

孙卿. 基于低场核磁共振与近红外组合的典型果蔬干燥品质智能检测研究[D]. 无锡: 江南大学, 2022

SUN Q. A study on intelligent drying quality detection of typical fruits and vegetables based on the combination of LF-NMR and NIR[D]. Wuxi: Jiangnan University, 2022.

|

| [28] |

CHENG H, SONG S, JUNG E Y, et al. Comparison of beef quality influenced by freeze-thawing among different beef cuts having different muscle fiber characteristics[J]. Meat Science,2020,169:108206. doi: 10.1016/j.meatsci.2020.108206

|

| [29] |

黄欢. 超高压处理对鲜切马铃薯质地及风味品质的影响[D]. 呼和浩特: 内蒙古农业大学, 2020

HUANG H. Effects of ultra-high pressure treatment on texture and flavor quality of fresh-cut potatoes[D]. Hohhot: Inner Mongolia University, 2020.

|

| [30] |

高悦, 江依, 赖璐莹, 等. 超高压和热处理酸辣藕丁菜肴品质变化及货架期预测[J]. 食品与发酵工业,2020,46(22):134−141. [GAO Y, JIANG Y, LAI L Y, et al. Quality change and shelf life prediction of hot and sour lotus root dish by high hydrostatic pressure and heat treatment[J]. Food and Fermentation Industries,2020,46(22):134−141. doi: 10.13995/j.cnki.11-1802/ts.022948

GAO Y, JIANG Y, LAI L Y, et al. Quality change and shelf life prediction of hot and sour lotus root dish by high hydrostatic pressure and heat treatment[J]. Food and Fermentation Industries, 2020, 46(22): 134-141. doi: 10.13995/j.cnki.11-1802/ts.022948

|

| [31] |

武新慧. 基于高压脉冲电场预处理果蔬黏弹性动力学性质及介电特性研究[D]. 晋中: 山西农业大学, 2017

WU X H. The effect of high pulsed electric field on the viscoelastic dynamics and dielectric properties of fruits and vegetables[D]. Jinzhong: Shanxi Agricultural University, 2017.

|

| [32] |

马有川. 预处理对苹果脆片真空冷冻干燥特性和品质的影响研究[D]. 北京: 中国农业科学院, 2021

MA Y C. Effect of pretreatment on vacuum freeze-drying characteristics and quality of apple chips[D]. Peking: Chinese Academy of Agricultural Sciences, 2021.

|

| [33] |

GALLE A, LAUTNER S, FLEXAS J, et al. Environmental stimuli and physiological responses: The current view on electrical signalling[J]. Environmental and Experimental Botany,2015,114:15−21. doi: 10.1016/j.envexpbot.2014.06.013

|

| [34] |

戴瀚铖. 鲜切桃品种筛选及高压静电场保鲜技术研究[D]. 杭州: 浙江农林大学, 2021

DAI H C. Study on selection of fresh-cut peach varieties and fresh-keeping technology in high voltage electrostatic field[D]. Hangzhou: Zhejiang Agricultural and Forestry University, 2021.

|

| [35] |

李汴生, 苏芳萍, 朱悦夫, 等. 超高压处理对不同果蔬结构和性质的影响[J]. 高压物理学报,2018,32(3):152−162. [LI B S, SU F P, ZHU Y F, et al. Effect of high pressure processing on texture and quality of fruits and vegetables[J]. Chinese Journal of High Pressure Physics,2018,32(3):152−162. doi: 10.11858/gywlxb.20170668

LI B S, SU F P, ZHU Y F, et al. Effect of high pressure processing on texture and quality of fruits and vegetables[J]. Chinese Journal of High Pressure Physics, 2018, 32(3): 152-162. doi: 10.11858/gywlxb.20170668

|

| [36] |

魏巍. 水稻OsEXPB1基因的抗旱相关功能研究和花中过表达启动子活性的比较[D]. 上海: 复旦大学, 2014

WEI W. Function of OsEXPB1 gene under drought stress and comparison of the promoters activity in transgene vector[D]. Shanghai: Fudan University, 2014.

|

| [37] |

WANG Q, LI Y, SUN D W, et al. Enhancing food processing by pulsed and high voltage electric fields: principles and applications[J]. Critical Reviews in Food Science and Nutrition,2018,58(13):2285−2298. doi: 10.1080/10408398.2018.1434609

|

| [38] |

PARNIAKOV O, BALS O, LEBOVKA N, et al. Pulsed electric field assisted vacuum freeze-drying of apple tissue[J]. Innovative Food Science & Emerging Technologies,2016,35:52−57.

|

| [39] |

徐欣. 基于干燥效率及品质控制的黄秋葵扫频超声联合冻融预处理研究[D]. 镇江: 江苏大学, 2021

XU X. Study on pretreatments of okra by flat sweep frequency pulsed ultrasound and freeze-thaw based on drying efficiency and quality control[D]. Zhenjiang: Jiangsu University, 2021.

|

| [40] |

NERI L, GIANCATERINO M, ROCCHI R, et al. Pulsed electric fields (PEF) as hot air drying pretreatment: Effect on quality and functional properties of saffron (Crocus sativus L.)[J]. Innovative Food Science & Emerging Technologies,2021,67:102592.

|

| [41] |

李想. 脉冲电场和超声波联合预处理强化香菇热风干燥研究[D]. 广州: 华南理工大学, 2021

LI X. Combined effects of pulsed electric field and ultrasound pretreatments on mass transfer and quality of mushrooms[D]. Guangzhou: South China University of Technology, 2021.

|

| [42] |

卫晨曦, 张清安, 宋云. 模型体系法研究脱苦杏仁干制过程中的非酶褐变反应[J]. 陕西师范大学学报(自然科学版),2021,49(1):112−117. [WEI C X, ZHANG Q A, SONG Y. Non-enzymatic browning mechanism study of debitterized apricot kernels during drying process using model system method[J]. Journal of Shaanxi Normal University (Natural Science Edition),2021,49(1):112−117.

WEI C X, ZHANG Q A, SONG Y. Non-enzymatic browning mechanism study of debitterized apricot kernels during drying process using model system method[J]. Journal of Shaanxi Normal University (Natural Science Edition), 2021, 49(1): 112-117.

|

| [43] |

PONGSETKUL J, BENJAKUL S. Development of modified atmosphere packaging (MAP) on shelf-life extension of pla-duk-ra (dried fermented catfish) stored at room temperature[J]. Food Control,2021,124:107882. doi: 10.1016/j.foodcont.2021.107882

|

| [44] |

郝启栋, 乔旭光, 郑振佳, 等. 超高压和超声波预处理对蒜片热风干燥过程及品质的影响[J]. 农业工程学报,2021,37(3):278−286. [HAO Q D, QIAO X G, ZHENG Z J, et al. Effects of ultrahigh pressure and ultrasound pretreatments on hot-air drying process and quality of garlic slices[J]. Transactions of the Chinese Society of Agricultural Engineering,2021,37(3):278−286. doi: 10.11975/j.issn.1002-6819.2021.03.033

HAO Q D, QIAO X G, ZHENG Z J, et al. Effects of ultrahigh pressure and ultrasound pretreatments on hot- air drying process and quality of garlic slices[J]. Transactions of the Chinese Society of Agricultural Engineering, 2021, 37(3): 278-286. doi: 10.11975/j.issn.1002-6819.2021.03.033

|

| [45] |

陈佳楠. 菠萝切片真空冷冻干燥工艺研究及优化[D]. 天津: 天津商业大学, 2022.

CHEN J N. Study and optimization of vacuum freeze drying technology of pineapple slices[D]. Tianjin: Tianjin University of Commerce, 2022.

|

DownLoad:

DownLoad: