| [1] |

Paul J Y, Khanna H, Kleidon J, et al. Golden bananas in the field: Elevated fruit pro-vitamin A from the expression of a single banana transgene[J]. Plant Biotechnol J,2016,15:520.

|

| [2] |

Fernando I, Fei J, Stanley R, Rouillard V. Evaluating packaging performance for bananas under simulated vibration[J]. Food Packaging and Shelf Life,2020,23:100428. doi: 10.1016/j.fpsl.2019.100428

|

| [3] |

Forster M, Rodríguez E R, Martín J D, et al. Distribution of nutrients in edible banana pulp[J]. Food Technology and Biotechnology,2003,41:167−172.

|

| [4] |

Hiago de O Gomes, Jorge Marcell C Menezes, José Galberto M da Costa, et al. Evaluating the presence of pesticides in bananas: An integrative review[J]. Ecotoxicology and Environmental Safety,2020,189:110016. doi: 10.1016/j.ecoenv.2019.110016

|

| [5] |

Mathew N S, Negi P S. Traditional uses, phytochemistry and pharmacology of wild banana ( Musa acuminata Colla): A review[J]. Ethnopharmacol,2017,196:124−140. doi: 10.1016/j.jep.2016.12.009

|

| [6] |

Singh B, Singh J P, Kaur A, et al. Bioactive compounds in banana and their associated health benefits-a review[J]. Food Chem,2016,206:1−11. doi: 10.1016/j.foodchem.2016.03.033

|

| [7] |

Pereira A, Maraschin M. Banana ( Musa spp) from peel to pulp: ethnopharmacology, source of bioactive compounds and its relevance for human health[J]. Ethnopharmacol,2015,160:149−163. doi: 10.1016/j.jep.2014.11.008

|

| [8] |

Ahmed Z F R, Palta J P. Postharvest dip treatment with a natural lysophospholipid plus soy lecithin extended the shelf life of banana fruit[J]. Postharvest Biol Technol,2016,113:58−65. doi: 10.1016/j.postharvbio.2015.10.016

|

| [9] |

Hailu M, Workneh T S, Belew D. Review on postharvest technology of banana fruit. Afr[J]. Biotechnol,2013,12:635−647. doi: 10.5897/AJBX12.020

|

| [10] |

Bapat V A, Trivedi P K, Ghosh A, et al. Ripening of fleshy fruit: Molecular insight and the role of ethylene[J]. Biotechnology Advances, 2010, 28: 94–107.

|

| [11] |

Shan W, Kuang J, Chen L, et al. Molecular characterization of banana NAC transcription factors and their interactions with ethylene signalling component EIL during fruit ripening[J]. Journal of Experimental Botany, 2012, 63: 5171–5187.

|

| [12] |

Xiao Y Y, Chen J Y, Kuang J F, et al. Banana ethylene response factors are involved in fruit ripening through their interactions with ethylene biosynthesis genes[J]. Journal of Experimental Botany, 2013, 64: 2499–2510.

|

| [13] |

|

| [14] |

Pauline M, Alexandre O, Andoseh B K, et al. Production technique and sensory evaluation of traditional alcoholic beverage based maize and banana[J]. International Journal of Gastronomy & Food Science,2017,10:11−15.

|

| [15] |

|

| [16] |

Friedman M, Brandon D L. Nutritional and health benefits of soy proteins[J]. Journal of Agricultural and Food Chemistry,2001,49(3):1069−1086. doi: 10.1021/jf0009246

|

| [17] |

Ma L, Li B, Han F X, et al. Evaluation of the chemical quality traits of soybean seeds, as related to sensory attributes of soymilk[J]. Food Chemistry,2015,173:694−701. doi: 10.1016/j.foodchem.2014.10.096

|

| [18] |

Nishinari K, Fang Y, Guo S, et al. Soy proteins: A review on composition, aggregation and emulsification[J]. Food Hydrocolloids,2014,39:301−318. doi: 10.1016/j.foodhyd.2014.01.013

|

| [19] |

Tang C H. Emulsifying properties of soy proteins: A critical review with emphasis on the role of conformational flexibility[J]. Critical Reviews in Food Science and Nutrition,2017,57(12):2636−2679. doi: 10.1080/10408398.2015.1067594

|

| [20] |

Peng I C, Quass D W, Dayton W R, et al. The physicochemical and functional properties of soybean 11S globulinea review[J]. Cereal Chemistry, 1984, 61 (6): 480−490.

|

| [21] |

Xiang H, Sun-Waterhouse D, Cui C, et al. Modification of soy protein isolate by glutaminase for nanocomplexation with curcumin[J]. Food Chemistry,2018,268:504−512. doi: 10.1016/j.foodchem.2018.06.059

|

| [22] |

|

| [23] |

Manassero C A, Speroni F, Vaudagna S R. High hydrostatic pressure treatment improves physicochemical properties of calcium- and soybean protein-added peach juice[J]. Lebensmittel Wissenschaft Und Technologie,2019,101:54−60. doi: 10.1016/j.lwt.2018.11.021

|

| [24] |

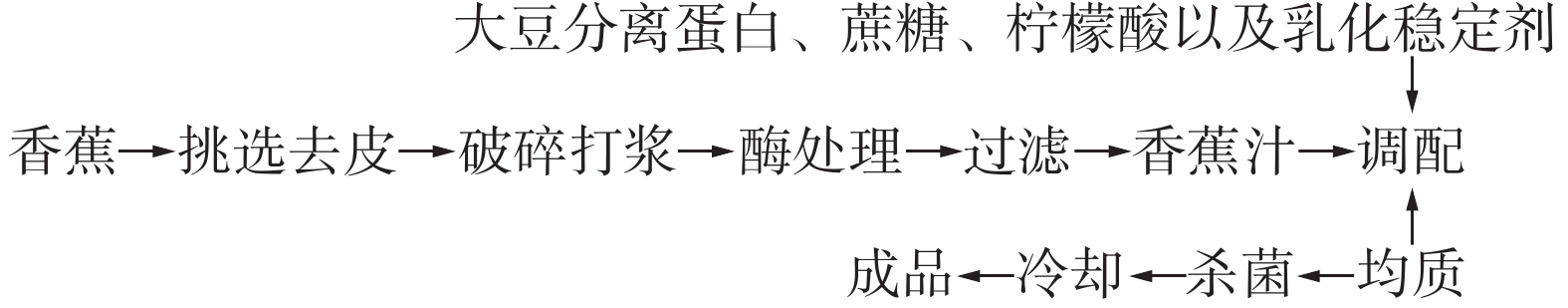

郝记明, 聂凌鸿. 调配型香蕉饮料的研制[J]. 食品工业科技,1997(3):55−56.

|

| [25] |

|

| [26] |

翟胜江, 刘福林. 大豆苹果乳饮料的研制[J]. 食品工业,2000(2):16−17.

|

| [27] |

刘振学, 王力. 实验设计与数据处理(第二版)[M]. 北京: 化学工业出版社, 2015: 111−124.

|

| [28] |

Box G E P, Hunter W G. Statistics for experiments: An introduction to design, data analysis and model building[M]. New Nork: Wiley, 1990.

|

| [29] |

Yamazaki, Kushida N, Oguchi A, et al. Response surface design and analyses[M]. New York: Marcel Dekker Inc, 1987: 149−205.

|

| [30] |

|

| [31] |

|

| [32] |

高春梅, 柳明珠, 吕少瑜, 等. 海藻酸钠水凝胶的制备及其在药物释放中的应用[J]. 化学进展,2013,25(6):1012−1022.

|

| [33] |

杨金姝. 羧甲基纤维素钠在食品工业中的应用研究[J]. 农产品加工(学刊),2014(22):76−78.

|

| [34] |

龙肇, 赵强忠, 赵谋明. 单甘酯和蔗糖酯复配比例对核桃乳稳定性的影响[J]. 食品与发酵工业,2009(5):181−184.

|

DownLoad:

DownLoad: