Optimization of Extraction Process of Aqueous Extract of Rehmannia glutinosa Based on Entropy Weight Method in Cooperation with Analytic Hierarchy Process and Back Propagation Neural Network with Multiple Indicators

-

摘要: 目的:基于熵权法(Entropy Weight Method, EWM)-层次分析(Analytic Hierarchy Process, AHP)和反向传播神经网络(Back Propagation Neural Network, BPNN)对地黄水提物超声提取工艺进行优化。方法:以超声温度、超声时间、料液比为正交试验考察因素,梓醇、地黄苷D、益母草苷,地黄多糖含量以及水溶性浸出物得率为指标,采用EWM-AHP法确定各指标权重,从而得到多指标综合得分;再以正交试验工艺条件为输入,综合得分为输出,建立并训练BPNN模型,寻找地黄提取最佳工艺。结果:BPNN优选工艺为在60 ℃下,加33倍水,提取70 min,梓醇、地黄苷D、益母草苷,地黄多糖含量以及水溶性浸出物得率平均值分别为17.04 、3.75、10.57、24.86 mg/g 、0.82 g/g,综合得分为97.74;正交试验最佳工艺为提取温度50 ℃,加25倍水,提取1 h,梓醇、地黄苷D、益母草苷,地黄多糖含量以及水溶性浸出物得率平均值分别为12.72、2.58、8.20、25.02 mg/g、0.80 g/g,综合得分为97.26。结论:本研究确定BPNN优选工艺为最优,为EWM-AHP法结合BPNN在提取工艺中的应用提供了参考。Abstract: Objective: To optimize the ultrasonic extraction process of aqueous extract of Rehmannia glutinosa based on entropy weight method (EWM) together with analytic hierarchy process (AHP) and back propagation neural network (BPNN). Methods: Taking ultrasonic temperature, ultrasonic time, solid-liquid ratio as orthogonal test factors, catalpa, rehmannioside D, ajugol, rehmannioside polysaccharide content, and the yield of water-soluble extract as indexes, EWM-AHP method was used to determine the weight of each index, to obtain the comprehensive score of multiple indexes. Then, the experimental process conditions were used as the input and the synthesis score was used as the output to build and train a BPNN model to find the best process for the extraction process of Rehmannia glutinosa. Results: The preferred process of BPNN was extraction at 60 ℃ with 33 times of water for 70 min. The mean values of catalpa, rehmannioside D, ajugol, rehmannioside polysaccharide content, and the yield of water-soluble extract were 17.04, 3.75, 10.57, 24.86 mg/g and 0.82 g/g, respectively, with a combined score of 97.74; The best process of the orthogonal test was extraction at 50 ℃ with 25 times of water for 1 h. The mean values of catalpa, rehmannioside D, ajugol, rehmannioside polysaccharide content, and the yield of water-soluble extract were 12.72, 2.58, 8.20, 25.02 mg/g and 0.80 g/g, respectively, with a combined score of 97.26. Conclusion: This study determined that the BPNN preferred process was optimal and provided a reference for the application of the EWM-AHP method combined with BPNN in the extraction process.

-

地黄(Rehmannia glutinosa Libosch),玄参科植物的新鲜或干燥块根,具有清热凉血、养阴生津等功效[1]。《神农本草经》中记载地黄有“久服,轻身不老”的作用,主要含有环烯醚萜类、苯乙醇苷类、糖类、核苷类等成分[2-5]。中国国家卫生部于2002年将其列入可用于保健食品的名单。地黄常以水煎的形式用于临床和生活中,研究表明地黄水提物对糖尿病[6]、糖尿病性肌萎缩[7]、抑郁症[8]、骨质流失[9]等疾病有潜在治疗效果,具有开发利用价值和研究意义。

目前地黄提取工艺研究多数仅以多糖[10]、梓醇[11]等单个成分含量作为评价指标,而以多项指标开展综合评价的工艺研究鲜见报道。研究表明,环烯醚萜苷类为地黄主要功效成分,其中梓醇、地黄苷D和益母草苷不仅为地黄原型入血成分[12],还具有广泛的生理活性,如降糖[13]、抗炎[14]、抗肿瘤[15]等,故本研究将这三种成分确立为评价指标。地黄多糖类成分具有抗炎、抑制血管钙化[16-17]等作用,因此和水溶性浸出物一起被纳入评价指标。此外,相较于回流、浸提等传统提取方法,超声提取凭借其快速便捷,提取效率高等优势在地黄提取工艺中得到广泛使用[18-19]。

多指标多因素提取工艺研究常采用正交试验设计,具有高效经济的优势,但存在取样点有限,不够全面的问题。客观赋权法熵权法(Entropy Weight Method,EWM)和主观赋权法层次分析法(Analytic Hierarchy Process,AHP)常应用于多指标问题研究,将两者结合,既能通过主观经验对指标重要性进行排序分配,又能客观反映指标信息,使权重系数更加科学合理[20-22]。反向传播神经网络(Back Propagation Neural Network, BPNN)对此类多维非线性问题展现出良好解决能力[23],利用BPNN建立模型,可以模拟范围内多个点,弥补正交试验的不足,从而进行全局寻优,更好地反映不同因素不同水平对提取物质量的影响。

因此,本研究以梓醇、地黄苷D、益母草苷、多糖含量及水溶性浸出物为评价指标,引入EWM和AHP确定权重系数,利用BPNN在正交试验基础上建立模型,从而多维度评价并优化地黄水提物提取工艺,为相关研究提供新思路和新案例。

1. 材料与方法

1.1 材料与仪器

地黄药材 2021年7月购于四川省成都市荷花池市场,经成都中医药大学药学院裴瑾教授鉴定为玄参科植物地黄(Rehmannia glutinosa Libosch.)的干燥根茎,生产批号:20210703;梓醇对照品(批号MUST-18103011,纯度≥98%) 成都曼思特生物科技有限公司;地黄苷D对照品(批号DSTDD010701,纯度≥98%)、益母草苷对照品(批号DSTDY016301,纯度≥98%) 乐美天医药德思特生物有限公司、D-葡萄糖对照品(批号PS1231-0100,纯度≥98%) 成都普思生物科技股份有限公司;乙腈 色谱纯,美国fisher公司。

TU-1901型双光束紫外可见分光光度计 北京普析通用仪器有限责任公司;DHG-9023A型电热恒温鼓风干燥箱 上海精宏实验设备有限公司;JY-10型超声波清洗机 湖北鼎泰生化科技设备制造有限公司;BT25S型十万分之一电子天平 北京赛多利斯仪器系统有限公司。

1.2 实验方法

1.2.1 HPLC法测定梓醇、地黄苷D、益母草苷含量

1.2.1.1 色谱条件

根据参考文献[24],色谱柱为中谱AQ-C18柱(250 mm×4.6 mm,5 μm),流动相为乙腈-水,梯度洗脱:0~10 min,1%乙腈;10~13 min,1%~4%乙腈;13~31 min,4%乙腈;31~34 min,4%~1%乙腈;波长:203 nm;流速0.8 mL/min,进样量10 μL,理论塔板数不低于5000。

1.2.1.2 对照品溶液的制备

分别取梓醇、地黄苷D和益母草苷对照品适量,精密称定,置于5 mL量瓶中,加水溶解并定容至刻度,摇匀,得梓醇、地黄苷D和益母草苷浓度为3.045、0.580、1.750 mg/mL的对照品溶液。

1.2.1.3 供试品溶液的制备

综合参考文献[11, 25-26],取粉碎后过60目筛的细粉,取约1 g,精密称定,置具塞锥形瓶中,精密加入25 mL水,称定重量,在超声功率40 kHz,超声温度60 ℃下提取1 h,室温下放冷,再称定重量,用纯水补足减失的重量,摇匀,滤过,精密量取滤液1 mL,即得。

1.2.1.4 标准曲线的绘制

精密吸取“1.2.1.2”项下的对照品溶液,将其分别稀释0、2、4、8、16、32倍,再分别吸取10 μL于高效液相色谱仪测定,以各待测成分的峰面积(y)对进样浓度(x,μg/mL)绘制标准曲线。

1.2.1.5 方法学考察

结合参考文献[24],对HPLC法进行精密度、重复性、稳定性、加样回收率的方法学考察。

1.2.1.6 含量测定

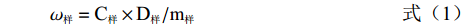

取各提取物溶液,在上述所建立色谱条件下进行HPLC测定,记录峰面积。根据线性回归方程,采用外标法根据下方公式计算3个成分的含量。

ω样=C样×D样/m样 (1) 式(1)中,ω样:指标成分含量,mg/g;C样:通过线性回归方程得到的指标成分质量浓度,mg/mL;D样:各指标成分供试品的稀释倍数;m样:各供试品称样量,g。

1.2.2 紫外分光光度法测定多糖含量

采用苯酚-硫酸法测定多糖含量[27],取D-葡萄糖对照品适量,精密称定并定容至25 mL,得每1 mL含D-葡萄糖119.2 μg的对照品溶液。精密量取对照品溶液0.1、0.2、0.4、0.6、0.8、1.0 mL,加水至2 mL,加入5 %苯酚溶液1 mL,摇匀,迅速加入浓硫酸5 mL,放冷至室温,再置90 ℃水浴中加热15 min,取出,冷却5 min。以相应试剂为空白,参照紫外-可见分光光度法[28],在490 nm的波长处测定吸光度,以浓度(X)对吸光度(Y)作线性回归。根据参考文献[25]制备供试品溶液,取1.2.1.3项下滤液1 mL,加入4倍量的无水乙醇,在4 ℃冰箱中醇沉12 h,5000 r/min离心过滤10 min,将得到的多糖沉淀加50 ℃热水溶解,定容至5 mL即得。同时根据上述条件进行精密度、重复性、稳定性、加样回收率的方法学考察。

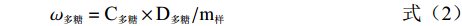

取供试品溶液适量,依法测定吸光度,供试品多糖含量按照下式计算。

ω多糖=C多糖×D多糖/m样 (2) 式(2)中,ω多糖:多糖成分含量,mg/g;C多糖:通过多糖线性回归方程得到的多糖质量浓度,mg/mL;D多糖:多糖的稀释倍数;m样:各供试品称样量,g。

1.2.3 水溶性浸出物得率测定

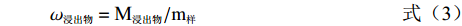

精密吸取各提取液,置烘干恒重的蒸发皿中,水浴蒸干后,置烘箱105 ℃干燥3 h,取出后置干燥器中冷却30 min迅速称重。水溶性浸出物的质量和原药材质量的比即为水溶性浸出物得率[28],按照下式计算。

ω浸出物=M浸出物/m样 (3) 式(3)中,ω浸出物:水溶性浸出物得率,g/g;M浸出物:水溶性浸出物质量,g;m样:各供试品称样量,g。

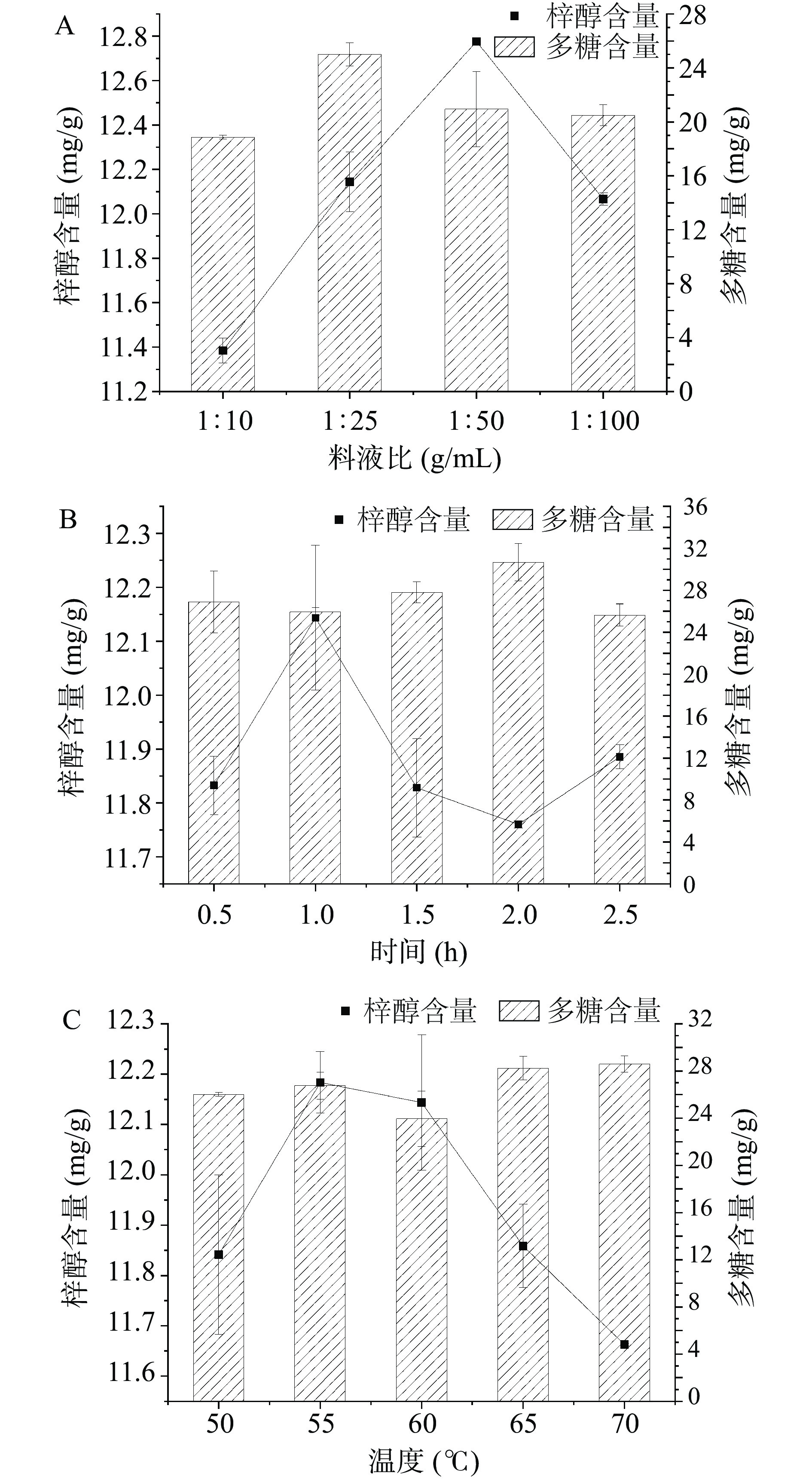

1.2.4 地黄水提物提取工艺单因素实验

因为梓醇和多糖为地黄常见有效成分,因此单因素考察选择梓醇、多糖含量作为评价指标,固定因素水平为提取温度为60 ℃,提取1.0 h,料液比1:25 g/mL,在进行单因素考察时,保持其他固定水平不变,分别考察不同料液比(1:10、1:25、1:50、1:100 g/mL)、超声温度(50、55、60、65、70 ℃)、提取时间(0.5、1、1.5、2、2.5 h)对梓醇、多糖含量的影响。

1.2.5 地黄水提物提取工艺正交试验优化

基于单因素考察结果,确定地黄正交工艺考察因素水平,以梓醇、地黄苷D、益母草苷3种指标成分含量,地黄多糖含量,水溶性浸出物得率为综合评分指标,设计正交试验(表1)。制备提取液供试品,按“1.2.1.6”“1.2.2”“1.2.3”项下方法测定各部分指标。

表 1 地黄提取工艺正交试验因素水平Table 1. Factors level of orthogonal test of Rehmannia glutinosa extraction process水平 提取温度(℃) 提取时间(h) 料液比(g/mL) A B C 1 50 0.5 1:25 2 55 1.0 1:50 3 60 1.5 1:100 1.3 数据处理及实验验证

每个实验均平行3次;数据绘图采用Origin 2022学生版软件;方差分析使用SPSS 25软件;EWM、AHP法以及EWM-AHP法使用Microsoft Excel 2016计算;BPNN模型采用MATLAB R2016b建立并分析。

1.3.1 EWM法确定权重

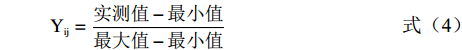

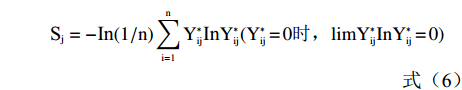

EWM法[29]确定权重需要经过标准化(式4),归一化(式5),计算信息熵(式6),最后得到指标权重(式7)。

Yij=实测值−最小值最大值−最小值 (4) Y∗ij=Yijn∑i=1Yij(i=1,2,…,n;j=1,2,3,4,5) (5) Sj=−In(1/n)n∑i=1Y∗ijInY∗ij(Y∗ij=0时,limY∗ijInY∗ij=0) (6) Wj=1−Sj∑nj=1Sj (7) 式中,Yij表示第i次实验时第j个评价指标标准化后的值,Y*ij表示第i次试验时第j个评价指标的归一化值,n表示试验次数,Sj表示第j个评价指标的信息熵值,Wj表示第j个评价指标的熵权值。

1.3.2 AHP法确定权重

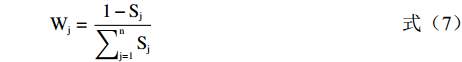

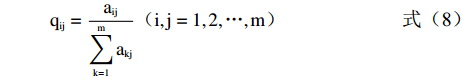

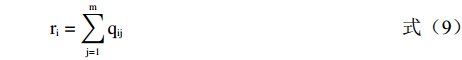

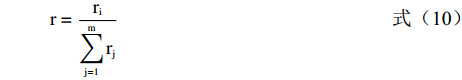

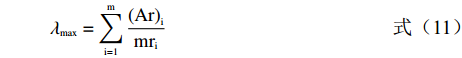

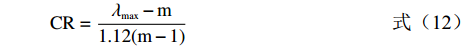

AHP根据各指标重要性主观赋予数值,将复杂多指标系统层次化后再通过逐层比较进行分析。在计算中,一致性比值(Consistency Ratio, CR)小于0.1表明矩阵具有一致性,数值设置以及权重系数可靠。按照常见指标成分及其重要性进行排序:梓醇=多糖>地黄苷D>益母草苷>水溶性浸出物,并赋值组成判断矩阵A(表2)。根据参考文献[30],先将判断矩阵每一列归一化(式8),随后按行相加(式9),再将得到的结果归一化(式10)可得所求的权重向量。通过计算判断矩阵的最大特征根(式11)进而求出CR值(式12)。

表 2 指标成对比较的判断优先矩阵Table 2. Judgment precedence matrix for paired comparison of indicators指标成分 梓醇 地黄苷D 地黄多糖 益母草苷 水溶性浸出物 梓醇 1 2 1 3 4 地黄苷D 1/2 1 1/2 2 3 地黄多糖 1 2 1 3 4 益母草苷 1/3 1/2 1/3 1 2 水溶性浸出物 1/4 1/3 1/4 1/2 1 qij=aijm∑k=1akj(i,j=1,2,…,m) (8) ri=m∑j=1qij (9) r=rim∑j=1rj (10) λmax=m∑i=1(Ar)imri (11) CR=λmax−m1.12(m−1) (12) 式中,aij表示判断矩阵A中第i行第j个指标的值;akj表示判断矩阵A第j个指标所在第K列的求和值;K表示列数;m表示指标成分个数;qij表示a矩阵中第i行第j个指标的按列归一化后的值;ri表示将q矩阵第i行相加的值;rj表示将q矩阵第j行列相加的值;r表示所求的权重值;

λ max表示判断矩阵A的最大特殊根;CR表示一次性比值;1.12为常数,表示m=5时的平均随机一致性指标。1.3.3 EWM-AHP法确定权重及综合得分计算

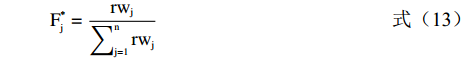

按下式计算EMW-AHP法复合权重,并通过复合权重计算提取物综合得分。

F*j=rwj∑nj=1rwj (13) 式中:r和wj分别为EWM及AHP法所得权重系数;F*j表示各个相应指标的EWM-AHP复合权重。

Z=F*梓醇×100×(梓醇含量/梓醇含量最大值)+F*多糖×100×(地黄多糖含量/地黄多糖含量最大值)+F*地黄苷D×100×(地黄苷D含量/地黄苷D含量最大值)+F*益母草苷×100×(益母草苷含量/益母草苷含量最大值)+ F*水溶性浸出物×100×(水溶性浸出物含量/水溶性浸出物含量最大值) 式(14)

式中,Z代表EWM-AHP复合评分,F*代表各指标相对应的EWM-AHP复合权重。

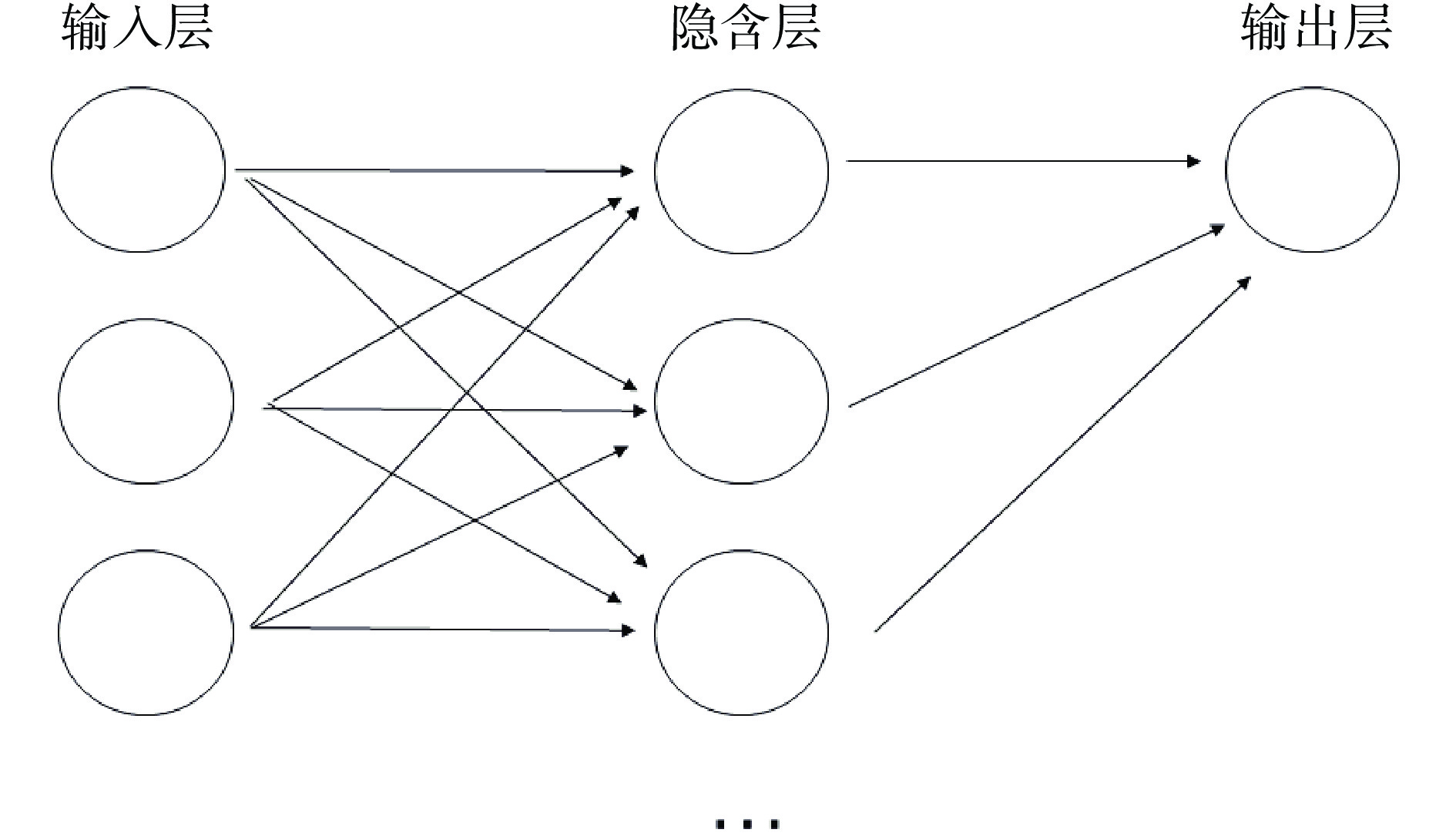

1.3.4 BPNN优选工艺

使用MATLAB R2016b软件进行BPNN建模以及工艺寻优,本实验使用3层结构BPNN,输入节点为正交考察工艺因素,输出节点为EWM-AHP法综合得分,构建网络并训练,以实测值和网络预测值进行回归分析评价模型性能。根据正交考察因素,设置不同的输入,通过建立的BPNN映射关系进行评分预测,选择最高评分为BPNN优选工艺。

1.3.5 提取工艺验证

以BPNN优选工艺及正交试验优选工艺为基础,分别平行提取3份,筛选最佳提取工艺。

2. 结果与分析

2.1 梓醇、地黄苷D、益母草苷以及多糖含量测定

2.1.1 梓醇、地黄苷D、益母草苷、多糖线性关系

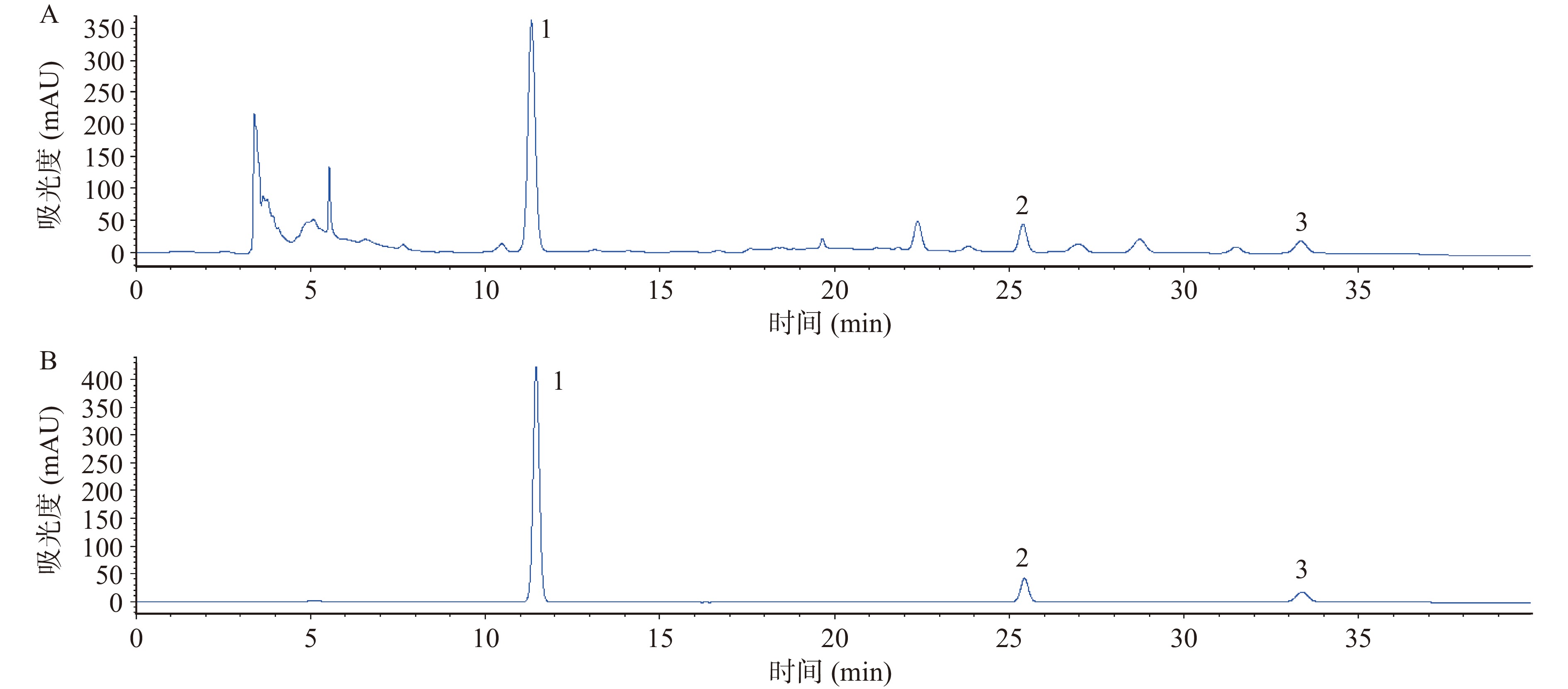

“1.2.1.1”项色谱条件下对照品及样品的色谱图显示梓醇、地黄苷D、益母草苷在检测波长下分离良好,与对照品保留时间相同,见图1。

“1.2.1.4”以及“1.2.2”项下分别得到梓醇、地黄苷D、益母草苷、多糖的回归方程、相关系数(R)及线性范围,见表3,显示梓醇、地黄苷D、益母草苷分别在0.034~1.047、0.037~1.141、0.048~1.390 mg/mL范围内与色谱峰面积呈良好的线性关系,多糖在0.005096~0.05960 mg/mL范围内与吸光度值呈良好的线性关系。

表 3 线性关系考察结果Table 3. Linear relationship examination results成分 回归方程 相关系数(R) 线性范围(mg/mL) 梓醇 Y=8903.4X+9E−13 0.9998 0.034~1.047 地黄苷D Y=5877.5X+3.6383 0.9997 0.037~1.141 益母草苷 Y=1299.9X+1.5741 1.0000 0.048~1.390 多糖 Y = 0.014X+0.0073 0.9995 0.005096~0.05960 2.1.2 梓醇、地黄苷D、益母草苷、多糖方法学考察结果

“1.2.1.5”以及“1.2.2”项下测得梓醇、地黄苷D、益母草苷、多糖的精密度、重复性、稳定性和加样回收率结果见表4。结果表明梓醇、地黄苷D、益母草苷以及多糖含量测定方法的精密度和重复性良好,供试品溶液在12 h内稳定,加样回收率合格,方法可靠,符合定量分析的要求。

表 4 精密度、重复性、稳定性和加样回收率结果Table 4. Precision, repeatability, stability and recovery results指标性成分 精密度 重复性 稳定性 加样回收率 RSD

(%)含量

(mg/g)RSD

(%)RSD

(%)平均加样回

收率(%)RSD

(%)梓醇 0.02 10.68 1.20 1.36 95.98 1.09 地黄苷D 0.74 2.217 1.56 1.33 102.04 1.49 益母草苷 0.47 7.639 2.00 2.08 98.69 3.84 地黄多糖 0.08 26.62 0.79 1.40 102.36 2.19 2.2 单因素实验

如图2A所示,随着料液比的增加,梓醇和多糖含量均呈现先上升后下降的趋势,推测可能是料液比增加到一定程度后,二者物质溶出达到限量,而当料液比过高时,物质与溶出的杂质充分接触,结构发生变化,从而导致含量下降。梓醇在料液比1:50 g/mL时达到峰值,多糖在料液比1:25 g/mL的时候达到峰值,由于梓醇含量变化趋势较大,多糖含量变化趋势较小,选择1:25、1:50、1:100 g/mL进行后续考察。

如图2B所示,随着时间的增加,提取物中梓醇含量呈现先上升后下降的趋势,在1 h时梓醇含量达到峰值,结合田春莲等[31]的研究,推测可能是因为梓醇不稳定,超声时间越长越容易破坏结构。多糖含量随时间变化略有上升,在2 h达到峰值后下降,与张骆琪等[25]的结果一致,但其含量波动不明显,综合考虑,选择0.5、1、1.5 h进行后续考察。

如图2C所示,提取物中梓醇含量随温度增加而上升,60 ℃后趋于下降,梓醇对热不稳定,超声温度过高可能会导致梓醇分解,这一现象与熊辉等[11]研究结果一致,而多糖含量在这几个温度下无较大差异。因此,选择50、55、60 ℃进行后续考察。

2.3 正交试验优化工艺

EWM最大优点是避免了主观因素,得到的权重更具客观性。AHP法优势在于定量表达评价人员的主观判断。基于单因素考察结果,提取温度(A)、提取时间(B)、料液比(C)为考察因素,D项为设置的误差项。正交试验各指标含量结果见表5。EWM法、AHP法以及EWM-AHP法所得多指标权重系数见表6。比较EWM法、AHP法以及EWM-AHP法三者得到的权重系数值发现,EWM法虽避免了人为影响因素,但地黄苷D权重数值过大,忽视了指标间的轻重关系;AHP法中梓醇和多糖的权重远高于水溶性浸出物,可能是因为矩阵中的“倒数”赋值而出现的“意见放大”现象。二者结合以后,降低了单一方法带来的分析偏差,使评分更全面、公正、符合实际。

表 5 地黄提取工艺L9(34)正交试验结果Table 5. Orthogonal test results of extraction technology L9(34) of Rehmannia glutinosa实验号 A B C D 梓醇

(mg/g)地黄苷D

(mg/g)益母草苷

(mg/g)地黄多糖

(mg/g)水溶性浸

出物(g/g)1 1 1 1 1 11.84 2.94 7.49 21.88 0.8117 2 1 2 2 2 12.19 2.41 7.27 18.80 0.8456 3 1 3 3 3 12.68 2.34 7.25 13.48 0.8716 4 2 1 2 3 12.06 2.37 7.38 17.56 0.8412 5 2 2 3 1 12.73 2.40 7.30 16.89 0.8347 6 2 3 1 2 11.87 2.34 7.24 22.87 0.8143 7 3 1 3 2 12.15 2.42 7.03 13.66 0.8535 8 3 2 1 3 11.82 2.36 7.56 24.77 0.8271 9 3 3 2 1 11.96 2.36 7.16 24.97 0.8201 表 6 EWM、AHP、EWM-AHP法权重系数Table 6. EWM, AHP and EWM-AHP weight coefficient方法 权重系数 梓醇 多糖 地黄苷D 益母草苷 水溶性浸出物 EWM法 0.2182 0.1380 0.4059 0.0889 0.1490 AHP法 0.3186 0.3186 0.1841 0.1100 0.0687 EWM-AHP法 0.3339 0.2111 0.3589 0.0470 0.0492 表7显示,运用EWM-AHP复合评分结果分析C>A>B,即各因素对EWM-AHP复合评分的影响为料液比>提取温度>提取时间。由A1>A3>A2,B2>B1>B3,C1>C3>C2可知最佳工艺为A1B2C1,即每1 g地黄粉末,用25 mL纯水提取,在提取温度50 ℃条件下提取1 h。方差结果(表8)表明,各因素对EWM、AHP法以及EWM-AHP法中综合评分影响程度较小,无显著性差异P>0.05。

表 7 EWM -AHP法复合评分的正交结果Table 7. Orthogonal results of EWM-AHP composite scoring method分析

方法实验号 A B C D EWM

法综合

评分AHP

法综合

评分EWM-

AHP复

合评分1 1 1 1 1 95.75 93.36 94.71 2 1 2 2 2 87.65 86.91 86.62 3 1 3 3 3 84.95 81.05 82.64 4 2 1 2 3 86.07 84.77 84.65 5 2 2 3 1 86.99 85.58 86.06 6 2 3 1 2 87.52 90.38 87.93 7 3 1 3 2 84.36 79.79 81.89 8 3 2 1 3 89.17 93.26 89.78 9 3 3 2 1 88.97 93.23 90.06 EWM

法综合

评分K1 268.34 266.18 272.44 271.70 K2 260.58 263.81 262.68 259.53 K3 262.50 261.44 256.30 260.20 R 7.77 4.74 16.14 12.17 AHP法

综合

评分K1 261.31 257.92 276.99 272.16 K2 260.73 265.74 264.92 257.08 K3 266.28 264.65 246.41 259.07 R 5.55 7.82 30.58 15.09 EWM-AHP

复合

评分K1 263.98 261.26 272.43 270.84 K2 258.65 262.46 261.33 256.45 K3 261.73 260.64 250.60 257.07 R 5.33 1.82 21.83 14.39 表 8 方差分析Table 8. Analysis of variance分析方法 方差来源 离差平方和 自由度 F值 P EWM综合评分 A 26.3980 2 0.5110 0.6620 B 34.8360 2 0.6740 0.5970 C 291.7830 2 5.6480 0.1500 D(误差) 51.6580 2 − − AHP法综合评分 A 7.5980 2 0.1700 0.8550 B 12.6200 2 0.2830 0.7800 C 158.1600 2 3.5430 0.2200 D(误差) 44.6340 2 − − EWM-AHP复合评分法 A 5.0770 2 0.1080 0.9020 B 0.5210 2 0.0110 0.9890 C 81.8120 2 1.7410 0.3650 D(误差) 46.9880 2 − − 2.4 BPNN数据分析

2.4.1 BPNN模型建立

本实验采用3层结构的BPNN建立模型,输入节点数为3个,即超声温度(A)、超声时间(B)、料液比(C),输出节点数为1个,即综合评分。原理见图3。

2.4.2 BPNN网络训练及参数

采用上述确定的BP网络结构,使用MATLAB R2016b软件的神经网络工具包,建立工艺参数矩阵为输入,综合评分矩阵为输出,其余采用默认设置,成功建立一个隐含层为10的BP模型,得到各因素水平与地黄多指标评分的映射关系。网络的训练均方误差曲线见图4,正交数据实测值与预测值的比较见图5,表明该网络模型性能良好,能够有效预测不同工艺下地黄提取物的综合得分。

2.4.3 BPNN预测最佳工艺

BPNN应用广泛,具有优良的映射能力,可对多维非线性因素进行仿真模拟以及筛选优化,将其与传统正交试验结合,基于少量实验数据即可准确预测范围内的所有条件,简单便捷。在正交试验参数基础上,设置地黄提取物提取温度50~60 ℃(步长5 ℃),提取时间30~90 min(步长10 min),料液比0.04(1:25 g/mL)~0.01(1:100 g/mL)(步长0.01),通过所建立的模型计算复合评分,预测评分结果见表9,将分数从低到高排列。从表中可以看到,三种因素的交互影响导致预测评分变化的复杂性,选择表7 EWM-AHP复合评分中的最高评分94.71为最小值进行筛选后分析(表9序号78~84),可以看出,随着超声温度的上升,超声时间也随之延长才能保持分数稳定;当料液比为0.03(1:33 g/mL)时,分数数值稳定且高分数量明显多于其他参数。BPNN预测最佳工艺为料液比1:33 g/mL,在60 ℃下超声70 min。

表 9 BPNN预测数据Table 9. Prediction data of BPNN序号 超声温度(℃) 时间(min) 料液比 分数 序号 超声温度(℃) 时间(min) 料液比 分数 1 50 70 0.04 81.81 43 55 40 0.02 89.85 2 50 70 0.03 81.82 44 60 90 0.04 90.06 3 60 30 0.02 81.89 45 60 70 0.01 90.49 4 50 60 0.03 81.98 46 55 50 0.04 90.60 5 50 90 0.01 82.64 47 60 40 0.04 90.84 6 50 60 0.04 82.82 48 60 60 0.02 91.37 7 50 90 0.02 83.42 49 60 80 0.01 91.41 8 50 80 0.04 83.53 50 55 50 0.01 91.49 9 55 30 0.01 83.62 51 55 30 0.03 91.52 10 50 80 0.02 83.79 52 50 40 0.03 91.55 11 50 80 0.03 83.99 53 50 40 0.02 91.65 12 50 80 0.01 84.05 54 55 80 0.01 91.69 13 55 70 0.04 84.55 55 50 60 0.01 91.74 14 60 30 0.01 84.56 56 60 90 0.01 91.78 15 50 70 0.02 84.79 57 50 50 0.01 91.87 16 50 90 0.03 84.88 58 60 50 0.03 92.03 17 60 40 0.02 84.95 59 55 40 0.03 92.09 18 50 50 0.04 85.40 60 60 50 0.04 92.18 19 55 80 0.04 85.78 61 50 30 0.02 92.38 20 55 90 0.04 85.90 62 55 70 0.03 92.39 21 60 30 0.03 86.08 63 55 40 0.04 92.46 22 50 50 0.03 86.32 64 55 50 0.03 92.64 23 55 90 0.03 86.37 65 55 30 0.04 92.83 24 50 60 0.02 86.62 66 60 70 0.02 92.87 25 50 90 0.04 86.67 67 60 90 0.02 92.91 26 55 60 0.04 86.70 68 55 80 0.02 93.08 27 55 90 0.01 86.90 69 55 60 0.01 93.22 28 55 40 0.01 87.40 70 55 70 0.01 93.41 29 55 30 0.02 87.53 71 55 60 0.03 93.46 30 50 70 0.01 87.76 72 60 80 0.02 93.53 31 60 40 0.01 87.90 73 55 50 0.02 93.69 32 55 90 0.02 87.93 74 50 30 0.03 94.41 33 60 40 0.03 87.96 75 60 60 0.04 94.53 34 50 30 0.01 88.16 76 60 90 0.03 94.64 35 60 50 0.02 88.94 77 60 80 0.04 94.68 36 55 80 0.03 88.96 78 50 30 0.04 94.71 37 60 50 0.01 89.24 79 60 60 0.03 96.75 38 50 50 0.02 89.46 80 60 70 0.04 96.82 39 50 40 0.01 89.62 81 55 70 0.02 97.13 40 60 30 0.04 89.68 82 55 60 0.02 97.29 41 50 40 0.04 89.75 83 60 80 0.03 98.10 42 60 60 0.01 89.78 84 60 70 0.03 98.69 2.5 工艺验证

正交试验所得最佳工艺参数为提取温度50 ℃,加25倍水,提取1 h;BPNN优化工艺为在60 ℃下,加33倍水,提取70 min。二者验证结果见表10,比较发现BPNN优化工艺评分最高,表明BPNN预测结果较为可靠,可用于提取工艺优化。

表 10 工艺验证结果(ˉx ±s, n=3)Table 10. Process verification results (ˉx ±s, n=3)分组 梓醇(mg/g) 地黄多糖(mg/g) 地黄苷D(mg/g) 益母草苷(mg/g) 水溶性浸出物(g/g) 复合评分均值 BPNN最佳工艺 17.04±0.10 24.86±2.54 3.75±0.15 10.57±0.86 0.82±0.0058 97.74 正交最优工艺 12.72±0.30 25.02±0.49 2.58±0.04 8.20±0.36 0.80±0.0058 97.26 3. 结论

本研究选择地黄中三种有效成分梓醇、地黄苷D、益母草苷以及多糖、水溶性浸出物为评价指标,在单因素考察基础上进行正交试验,通过EWM-AHP法得到各指标对应权重,计算综合得分,再利用BPNN在正交结果上进行建模。比较BPNN以及正交试验优选工艺,结合验证发现BPNN优选工艺最优,即在60 ℃下,加33倍水,提取70 min,综合得分为97.74。研究结果表明,BPNN模型预测可靠,可有效优化提取工艺,为提取物工艺优化提供了新的研究思路。

-

表 1 地黄提取工艺正交试验因素水平

Table 1 Factors level of orthogonal test of Rehmannia glutinosa extraction process

水平 提取温度(℃) 提取时间(h) 料液比(g/mL) A B C 1 50 0.5 1:25 2 55 1.0 1:50 3 60 1.5 1:100 表 2 指标成对比较的判断优先矩阵

Table 2 Judgment precedence matrix for paired comparison of indicators

指标成分 梓醇 地黄苷D 地黄多糖 益母草苷 水溶性浸出物 梓醇 1 2 1 3 4 地黄苷D 1/2 1 1/2 2 3 地黄多糖 1 2 1 3 4 益母草苷 1/3 1/2 1/3 1 2 水溶性浸出物 1/4 1/3 1/4 1/2 1 表 3 线性关系考察结果

Table 3 Linear relationship examination results

成分 回归方程 相关系数(R) 线性范围(mg/mL) 梓醇 Y=8903.4X+9E−13 0.9998 0.034~1.047 地黄苷D Y=5877.5X+3.6383 0.9997 0.037~1.141 益母草苷 Y=1299.9X+1.5741 1.0000 0.048~1.390 多糖 Y = 0.014X+0.0073 0.9995 0.005096~0.05960 表 4 精密度、重复性、稳定性和加样回收率结果

Table 4 Precision, repeatability, stability and recovery results

指标性成分 精密度 重复性 稳定性 加样回收率 RSD

(%)含量

(mg/g)RSD

(%)RSD

(%)平均加样回

收率(%)RSD

(%)梓醇 0.02 10.68 1.20 1.36 95.98 1.09 地黄苷D 0.74 2.217 1.56 1.33 102.04 1.49 益母草苷 0.47 7.639 2.00 2.08 98.69 3.84 地黄多糖 0.08 26.62 0.79 1.40 102.36 2.19 表 5 地黄提取工艺L9(34)正交试验结果

Table 5 Orthogonal test results of extraction technology L9(34) of Rehmannia glutinosa

实验号 A B C D 梓醇

(mg/g)地黄苷D

(mg/g)益母草苷

(mg/g)地黄多糖

(mg/g)水溶性浸

出物(g/g)1 1 1 1 1 11.84 2.94 7.49 21.88 0.8117 2 1 2 2 2 12.19 2.41 7.27 18.80 0.8456 3 1 3 3 3 12.68 2.34 7.25 13.48 0.8716 4 2 1 2 3 12.06 2.37 7.38 17.56 0.8412 5 2 2 3 1 12.73 2.40 7.30 16.89 0.8347 6 2 3 1 2 11.87 2.34 7.24 22.87 0.8143 7 3 1 3 2 12.15 2.42 7.03 13.66 0.8535 8 3 2 1 3 11.82 2.36 7.56 24.77 0.8271 9 3 3 2 1 11.96 2.36 7.16 24.97 0.8201 表 6 EWM、AHP、EWM-AHP法权重系数

Table 6 EWM, AHP and EWM-AHP weight coefficient

方法 权重系数 梓醇 多糖 地黄苷D 益母草苷 水溶性浸出物 EWM法 0.2182 0.1380 0.4059 0.0889 0.1490 AHP法 0.3186 0.3186 0.1841 0.1100 0.0687 EWM-AHP法 0.3339 0.2111 0.3589 0.0470 0.0492 表 7 EWM -AHP法复合评分的正交结果

Table 7 Orthogonal results of EWM-AHP composite scoring method

分析

方法实验号 A B C D EWM

法综合

评分AHP

法综合

评分EWM-

AHP复

合评分1 1 1 1 1 95.75 93.36 94.71 2 1 2 2 2 87.65 86.91 86.62 3 1 3 3 3 84.95 81.05 82.64 4 2 1 2 3 86.07 84.77 84.65 5 2 2 3 1 86.99 85.58 86.06 6 2 3 1 2 87.52 90.38 87.93 7 3 1 3 2 84.36 79.79 81.89 8 3 2 1 3 89.17 93.26 89.78 9 3 3 2 1 88.97 93.23 90.06 EWM

法综合

评分K1 268.34 266.18 272.44 271.70 K2 260.58 263.81 262.68 259.53 K3 262.50 261.44 256.30 260.20 R 7.77 4.74 16.14 12.17 AHP法

综合

评分K1 261.31 257.92 276.99 272.16 K2 260.73 265.74 264.92 257.08 K3 266.28 264.65 246.41 259.07 R 5.55 7.82 30.58 15.09 EWM-AHP

复合

评分K1 263.98 261.26 272.43 270.84 K2 258.65 262.46 261.33 256.45 K3 261.73 260.64 250.60 257.07 R 5.33 1.82 21.83 14.39 表 8 方差分析

Table 8 Analysis of variance

分析方法 方差来源 离差平方和 自由度 F值 P EWM综合评分 A 26.3980 2 0.5110 0.6620 B 34.8360 2 0.6740 0.5970 C 291.7830 2 5.6480 0.1500 D(误差) 51.6580 2 − − AHP法综合评分 A 7.5980 2 0.1700 0.8550 B 12.6200 2 0.2830 0.7800 C 158.1600 2 3.5430 0.2200 D(误差) 44.6340 2 − − EWM-AHP复合评分法 A 5.0770 2 0.1080 0.9020 B 0.5210 2 0.0110 0.9890 C 81.8120 2 1.7410 0.3650 D(误差) 46.9880 2 − − 表 9 BPNN预测数据

Table 9 Prediction data of BPNN

序号 超声温度(℃) 时间(min) 料液比 分数 序号 超声温度(℃) 时间(min) 料液比 分数 1 50 70 0.04 81.81 43 55 40 0.02 89.85 2 50 70 0.03 81.82 44 60 90 0.04 90.06 3 60 30 0.02 81.89 45 60 70 0.01 90.49 4 50 60 0.03 81.98 46 55 50 0.04 90.60 5 50 90 0.01 82.64 47 60 40 0.04 90.84 6 50 60 0.04 82.82 48 60 60 0.02 91.37 7 50 90 0.02 83.42 49 60 80 0.01 91.41 8 50 80 0.04 83.53 50 55 50 0.01 91.49 9 55 30 0.01 83.62 51 55 30 0.03 91.52 10 50 80 0.02 83.79 52 50 40 0.03 91.55 11 50 80 0.03 83.99 53 50 40 0.02 91.65 12 50 80 0.01 84.05 54 55 80 0.01 91.69 13 55 70 0.04 84.55 55 50 60 0.01 91.74 14 60 30 0.01 84.56 56 60 90 0.01 91.78 15 50 70 0.02 84.79 57 50 50 0.01 91.87 16 50 90 0.03 84.88 58 60 50 0.03 92.03 17 60 40 0.02 84.95 59 55 40 0.03 92.09 18 50 50 0.04 85.40 60 60 50 0.04 92.18 19 55 80 0.04 85.78 61 50 30 0.02 92.38 20 55 90 0.04 85.90 62 55 70 0.03 92.39 21 60 30 0.03 86.08 63 55 40 0.04 92.46 22 50 50 0.03 86.32 64 55 50 0.03 92.64 23 55 90 0.03 86.37 65 55 30 0.04 92.83 24 50 60 0.02 86.62 66 60 70 0.02 92.87 25 50 90 0.04 86.67 67 60 90 0.02 92.91 26 55 60 0.04 86.70 68 55 80 0.02 93.08 27 55 90 0.01 86.90 69 55 60 0.01 93.22 28 55 40 0.01 87.40 70 55 70 0.01 93.41 29 55 30 0.02 87.53 71 55 60 0.03 93.46 30 50 70 0.01 87.76 72 60 80 0.02 93.53 31 60 40 0.01 87.90 73 55 50 0.02 93.69 32 55 90 0.02 87.93 74 50 30 0.03 94.41 33 60 40 0.03 87.96 75 60 60 0.04 94.53 34 50 30 0.01 88.16 76 60 90 0.03 94.64 35 60 50 0.02 88.94 77 60 80 0.04 94.68 36 55 80 0.03 88.96 78 50 30 0.04 94.71 37 60 50 0.01 89.24 79 60 60 0.03 96.75 38 50 50 0.02 89.46 80 60 70 0.04 96.82 39 50 40 0.01 89.62 81 55 70 0.02 97.13 40 60 30 0.04 89.68 82 55 60 0.02 97.29 41 50 40 0.04 89.75 83 60 80 0.03 98.10 42 60 60 0.01 89.78 84 60 70 0.03 98.69 表 10 工艺验证结果(

ˉx ±s, n=3)Table 10 Process verification results (

ˉx ±s, n=3)分组 梓醇(mg/g) 地黄多糖(mg/g) 地黄苷D(mg/g) 益母草苷(mg/g) 水溶性浸出物(g/g) 复合评分均值 BPNN最佳工艺 17.04±0.10 24.86±2.54 3.75±0.15 10.57±0.86 0.82±0.0058 97.74 正交最优工艺 12.72±0.30 25.02±0.49 2.58±0.04 8.20±0.36 0.80±0.0058 97.26 -

[1] 张维方, 樊克锋, 雷敬卫, 等. 地黄药材的红外指纹图谱及多元统计分析[J]. 光谱学与光谱分析,2021,41(11):3392−3398. [ZHANG W F, FAN K F, LEI J W, et al. Infrared fingerprint and multivariate statistical analysis of Rehmannia glutinosa[J]. Spectroscopy and Spectral Analysis,2021,41(11):3392−3398. ZHANG W F, FAN K F, LEl J W, et al. Infrared fingerprint and multivariate statistical analysis of Rehmannia glutinosa[J]. Spectroscopy and Spectral Analysis, 2021, 41(11): 3392-3398.

[2] THU V K, THOA N T, HIEN N T T, et al. Iridoid glycosides link with phenylpropanoids from Rehmannia glutinosa[J]. Natural Product Research,2021(5):1−6.

[3] 徐卓, 戴新新, 宿树兰, 等. 基于UPLC-TQ-MS的地黄中核苷类和氨基酸类成分动态积累研究[J]. 中草药,2021,52(23):7323−7330. [XU Z, DAI X X, XIU S L, et al. Analysis of dynamic accumulation of nucleosides and amino acids in Rehmannia glutinosa based on UPLC-TQ-MS[J]. Chinese Traditional and Herbal Drug,2021,52(23):7323−7330. doi: 10.7501/j.issn.0253-2670.2021.23.027 XU Z, DAI X X, XIU S L, et al. Analysis of dynamic accumulation of nucleosides and amino acids in Rehmannia glutinosa based on UPLC-TQ-MS[J]. Chinese Traditional and Herbal Drug, 2021, 52(23): 7323-7330. doi: 10.7501/j.issn.0253-2670.2021.23.027

[4] 汪程远, 张浩, 孟莉, 等. 大孔吸附树脂分离纯化生地黄中苷类与糖类[J]. 中药材,2003(3):202−204. [WANG C Y, SUN H, MENG L, et al. Separation and purification of polysaccharides from Rehmannia glutinosa by macroporous adsorption resin[J]. Journal of Chinese Medicinal Materials,2003(3):202−204. doi: 10.3321/j.issn:1001-4454.2003.03.022 WANG C Y, SUN H, MENG L, et al. Separation and purification of polysaccharides from Rehmannia glutinosa by macroporous adsorption resin[J]. Journal of Chinese Medicinal Materials, 2003(3): 202-204. doi: 10.3321/j.issn:1001-4454.2003.03.022

[5] 陈金鹏, 张克霞, 刘毅, 等. 地黄化学成分和药理作用的研究进展[J]. 中草药,2021(6):1772−1784. [CHEN J P, ZHANG K X, LIU Y, et al. Research progress on chemical constituents and pharmacological actions of Rehmannia glutinosa[J]. Chinese Traditional and Herbal Drug,2021(6):1772−1784. doi: 10.7501/j.issn.0253-2670.2021.06.028 CHEN J P, ZHANG K X, LIU Y, et al. Research progress on chemical constituents and pharmacological actions of Rehmannia glutinosa[J]. Chinese Traditional and Herbal Drug, 2021(6): 1772-1784. doi: 10.7501/j.issn.0253-2670.2021.06.028

[6] JO R, MIN J R, JEONG S H. Anti-diabetic effects of water extracts of Rehmannia glutinosa Libosch root in 3T3-L1 adipocytes and C57BL/KsJ-db/db mice[J]. Journal of the Korean Society of Food Science and Nutrition,2018,47(10):957−965. doi: 10.3746/jkfn.2018.47.10.957

[7] TSENG Y T, CHANG W H, LIN C C, et al. Protective effects of Liuwei dihuang water extracts on diabetic muscle atrophy[J]. Phytomedicine, 2018, 53: 96-106.

[8] ZHOU X D, SHI D D, ZHANG Z J, et al. Ameliorative effects of Radix rehmanniae extract on the anxiety and depression like symptoms in ovariectomized mice: A behavioral and molecular study[J]. Phytomedicine,2019,63:153012. doi: 10.1016/j.phymed.2019.153012

[9] GONG W, ZHANG N D, CHENG G, et al. Rehmannia glutinosa Libosch extracts prevent bone loss and architectural deterioration and enhance osteoblastic bone formation by regulating the IGF-1/PI3K/mTOR pathway in streptozotocin-induced diabetic rats[J]. International Journal of Molecular Sciences,2019,20(16):3964. doi: 10.3390/ijms20163964

[10] 曹瑞, 张红, 师延琼, 等. 响应面法分析优化生地黄提取工艺研究[J]. 医学研究杂志,2014,43(2):69−72. [CAO R, ZHANG H, SHI Y Q, et al. Optimization of extraction technology of Rehmannia glutinosa by response surface methodology[J]. Journal of Medical Research,2014,43(2):69−72. CAO R, ZHANG H, SHI Y Q, et al. Optimization of extraction technology of Rehmannia glutinosa by response surface methodology[J]. Journal of Medical Research, 2014, 43(2): 69-72.

[11] 熊辉, 朱军, 陈琴华. 地黄不同提取工艺中梓醇含量的比较[J]. 中国医院药学杂志,2015,35(17):1610−1612. [XIONG H, ZHU J, CHEN Q H. Comparison of contents of catalpol in Radix Rehmanniae by different extraction methods[J]. Chinese Journal of Hospital Pharmacy,2015,35(17):1610−1612. doi: 10.13286/j.cnki.chinhosppharmacyj.2015.17.21 XIONG H, ZHU J, CHEN Q H. Comparison of contents of catalpol in Radix Rehmanniae by different extraction methods[J]. Chinese Journal of Hospital Pharmacy, 2015, 35(17): 1610-1612. doi: 10.13286/j.cnki.chinhosppharmacyj.2015.17.21

[12] 王慧森, 刘明, 李更生, 等. 鲜地黄提取物中3种原型入血成分的含量测定[J]. 中国实验方剂学杂志,2013,19(12):66−70. [WANG H S, LIU M, LI G S, et al. Determination for three prototype constituents into the blood from extract of fresh Rehmannia qlutinosa[J]. Chinese Journal of Experimental Traditional Medical Formulae,2013,19(12):66−70. [WANG H S, LIU M, LI G S, et al. Determination for three prototype constituents into the blood from extract of fresh Rehmannia qlutinosa[J]. Chinese Journal of Experimental Traditional Medical Formulae, 2013, 19(12): 66-70].

[13] BHATTAMISRA S K, KOH H M, LIM S Y, et al. Molecular and biochemical pathways of catalpol in alleviating diabetes mellitus and its complications[J]. Biomolecules,2021,11(2):27.

[14] BI J J, LI J, CHEN S J, et al. Catalpol ameliorates type II collagen-induced arthritis in rats and inhibits LPS-stimulated inflammatory response in SW982 human synovial cells[J]. Journal of Functional Foods,2019,59:291−300. doi: 10.1016/j.jff.2019.05.050

[15] 田平平, 潘颖, 施维, 等. 地黄中益母草苷对食管癌细胞增殖抑制作用的研究[J]. 园艺与种苗,2021,41(10):13−15,17. [TIAN P P, PAN Y, SHI W, et al. Inhibitory effect of ajugol in Rehmannia qlutinosa on the proliferation of esophageal carcinoma cells[J]. Horticulture & Seed,2021,41(10):13−15,17. TIAN P P, PAN Y, SHI W, et al. Inhibitory effect of ajugol in Rehmannia qlutinosa on the proliferation of esophageal carcinoma cells[J]. Horticulture & Seed, 2021, 41(10): 13-15, 17.

[16] ZHOU J, XU G, YAN J Y, et al. Rehmannia glutinosa (Gaertn. ) DC. polysaccharide ameliorates hyperglycemia, hyperlipemia and vascular inflammation in streptozotocin-induced diabetic mice[J]. Journal of Ethnopharmacology,2015,164:229−238. doi: 10.1016/j.jep.2015.02.026

[17] 高帅, 泮思林, 杜占慧, 等. 地黄多糖抑制大鼠主动脉血管钙化的实验研究[J]. 中华实验外科杂志,2021(8):1466−1469. [GAO S, PAN S L, DU Z H, et al. Inhibitory effect of Rehmannia glutinosa polysaccharide on aortic calcification in rats[J]. Chinese Journal of Experimental Surgery,2021(8):1466−1469. doi: 10.3760/cma.j.cn421213-20210116-00057 GAO S, PAN S L, DU Z H, et al. Inhibitory effect of Rehmannia glutinosa polysaccharide on aortic calcification in rats[J]. Chinese Journal of Experimental Surgery, 2021(8): 1466-1469. doi: 10.3760/cma.j.cn421213-20210116-00057

[18] 潘小红, 李涛, 殷帅, 等. 超声波辅助提取对地黄中药材及成方制剂含量测定的影响[J]. 中医药导报,2020,26(8):12−15,23. [PAN X H, LI T, YIN S, et al. Effect of ultrasonic-assisted extraction on the content determination of dihuang (Radix Rehmanniae) and its preparations[J]. Guiding Journal of Traditional Chinese Medicine and Pharmacy,2020,26(8):12−15,23. PAN X H, LI T, YIN S, et al. Effect of ultrasonic-assisted extraction on the content determination of dihuang (Radix Rehmanniae) and its preparations[J]. Guiding Journal of Traditional Chinese Medicine and Pharmacy, 2020, 26(8): 12-15, 23.

[19] 张红果, 张汝学, 贾正平, 等. 正交实验法优选地黄寡糖有效部位的提取工艺[J]. 中国实验方剂学杂志,2010,16(5):27−29. [ZHANG H G, ZHANG R X, JIA Z P, et al. Orthogonal experiment was used to optimize the extraction process of oligosaccharide from Rehmannia glutinosa[J]. Chinese Journal of Experimental Traditional Medical Formulae,2010,16(5):27−29. doi: 10.3969/j.issn.1005-9903.2010.05.007 ZHANG H G, ZHANG R X, JIA Z P, et al. Orthogonal experiment was used to optimize the extraction process of oligosaccharide from Rehmannia glutinosa[J]. Chinese Journal of Experimental Traditional Medical Formulae, 2010, 16(5): 27-29. doi: 10.3969/j.issn.1005-9903.2010.05.007

[20] 尤游, 张林静. 基于组合赋权和BPNN的高校学生综合素质评价研究[J]. 安徽电子信息职业技术学院学报,2021,20(5):5−9. [YOU Y, ZHANG L J. Research on comprehensive quality evaluation of college students based on combined weight and BP neural network[J]. Journal of Anhui Yocatlonal College of Electronic& Information Technology,2021,20(5):5−9. doi: 10.3969/j.issn.1671-802X.2021.05.002 YOU Y, ZHANG L J. Research on comprehensive quality evaluation of college students based on combined weight and BP neural network[J]. Journal of Anhui Yocatlonal College of Electronic& Information Technology, 2021, 20(5): 5-9. doi: 10.3969/j.issn.1671-802X.2021.05.002

[21] 黄露, 徐顶巧, 乐世俊, 等. 基于层次分析-熵权法和网络药理学的野马追质量标志物研究[J]. 中国中药杂志,2021,46(21):5545−5554. [HUANG L, XU D Q, LE S J, et al. Research on Q-markers of Eupatorium lindleyanum based on analytic hierarchy process-entropy weight method and network pharmacology[J]. China Journal of Chinese Materia Medica,2021,46(21):5545−5554. HUANG L, XU D Q, LE S J, et al. Research on Q-markers of Eupatorium lindleyanum based on analytic hierarchy process-entropy weight method and network pharmacology[J]. China Journal of Chinese Materia Medica, 2021, 46(21): 5545-5554.

[22] 谢平, 魏海峰, 温仁华, 等. 基于BPNN-遗传算法和信息熵理论优化凉粉草煎煮提取工艺[J]. 中国中医药信息杂志,2021,29(2):86−92. [XIE P, WEI H F, WEN R H, et al. Optimization on extraction process of Mesona chinensis Benth. based on BP neural network genetic algorithm and information entropy theory[J]. Chinese Journal of Information on TCM,2021,29(2):86−92. XIE P, WEI H F, WEN R H, et al. Optimization on extraction process of Mesona chinensis Benth. based on BP neural network genetic algorithm and information entropy theory[J]. Chinese Journal of Information on TCM, 2021, 29(2): 86-92.

[23] 张晓萍, 张建民. 基于BPNN的复合型挑坎体型参数反演研究[J]. 水利水电技术(中英文),2021,53(4):138−147. [ZHANG X P, ZHANG J M. Study on shape parameter inversion of compound bucket based on BP neural network[J]. Water Resources and Hydropower Engineering,2021,53(4):138−147. ZHANG X P, ZHANG J M. Study on shape parameter inversion of compound bucket based on BP neural network[J]. Water Resources and Hydropower Engineering, 2021, 53(4): 138-147.

[24] 张留记, 王建霞, 屠万倩, 等. 生地黄与熟地黄中5个苷类成分和总多糖的含量比较[J]. 天然产物研究与开发,2019,31(4):566−571. [ZHANG L J, WANG J X, TU W Q, et al. Comparation of the contents of 5 glycosides and total polysaccharides in Rehmanniae Radix and Rehmanniae Radix Praeparata[J]. Natural Product Research and Development,2019,31(4):566−571. ZHANG L J, WANG J X, TU W Q, et al. Comparation of the contents of 5 glycosides and total polysaccharides in Rehmanniae Radix and Rehmanniae Radix Praeparata[J]. Natural Product Research and Development, 2019, 31(4): 566-571.

[25] 张骆琪, 刘苏伟, 王飞, 等. 地黄多糖超声提取工艺优化及其抗氧化活性[J]. 中成药,2018,40(12):2662−2667. [ZHANG L Q, LIU S W, WANG F, et al. Polysaccharides from Rehmannia glutinosa, their ultrasonic extraction process optimization and antioxidant activity[J]. Chinese Traditional Patent Medicine,2018,40(12):2662−2667. doi: 10.3969/j.issn.1001-1528.2018.12.010 ZHANG L Q, LIU S W, WANG F, et al. Polysaccharides from Rehmannia glutinosa, their ultrasonic extraction process optimization and antioxidant activity[J]. Chinese Traditional Patent Medicine, 2018, 40(12): 2662-2667. doi: 10.3969/j.issn.1001-1528.2018.12.010

[26] 扈本荃, 徐玥, 吴曼, 等. 地黄饮超声提取工艺的研究[J]. 化学工程师,2021,35(12):71−73,19. [HU B Q, XU Y, WU M, et al. Study on the medthod for ultrasonic extraction of Dihuang Yin by orthogonal experiment[J]. Chemical Engineer,2021,35(12):71−73,19. HU B Q, XU Y, WU M, et al. Study on the medthod for ultrasonic extraction of Dihuang Yin by orthogonal experiment[J]. Chemical Engineer, 2021, 35(12): 71-73, 19.

[27] 祁小妮, 林楠楠, 李振亮, 等. 生地黄多糖提取工艺的优化及抗氧化活性研究[J]. 食品与发酵工业,2016,42(2):231−235. [QI X N, LIN N N, LI Z L, et al. Optimization of Rehmannia glutinosa polysaccharide extraction process and antioxidant activity study[J]. Food and Fermentation Industries,2016,42(2):231−235. QI X N, LIN N N, LI Z L, et al. Optimization of Rehmannia glutinosa polysaccharide extraction process and antioxidant activity study[J]. Food and Fermentation Industries, 2016, 42(2): 231-235.

[28] 国家药典委员会. 中华人民共和国药典. 四部[S]. 北京: 中国医药科技出版社, 2020. National Pharmacopoeia Commission. Pharmacopoeia of the People’s Republic of China. Four Parts[S]. Beijing: China Pharmaceutical Science and Technology Press, 2020.

[29] 刘路路, 李可, 韦智江, 等. 基于响应面法和熵权法优化连翘叶中连翘酯A、连翘苷和芦丁提取工艺[J]. 食品工业科技,2022,43(2):166−173. [LIU L L, LI K, WEI Z J, et al. Optimization of extraction process of forsythioside A, forsythin and rutin from Forsythia suspensa leaves based on response surface methodology and entropy weight method[J]. Science and Technology of Food Industry,2022,43(2):166−173. LIU L L, LI K, WEI Z J, et al. Optimization of extraction process of forsythioside A, forsythin and rutin from Forsythia suspensa leaves based on response surface methodology and entropy weight method[J]. Science and Technology of Food Industry, 2022, 43(2): 166-173.

[30] 钱怡洁, 皮文霞, 朱广飞, 等. 基于熵权法结合层次分析法和反向传播神经网络优选酒萸肉蒸制工艺[J]. 中草药,2021,52(22):6816−6824. [QIAN Y J, PI W X, ZHU G F, et al. Optimization of processing technology of wine-steamed Corni Fructus based on entropy method combined with analytic hierarchy process and BP neural network[J]. Chinese Traditional and Herbal Drugs,2021,52(22):6816−6824. doi: 10.7501/j.issn.0253-2670.2021.22.006 QIAN Y J, PI W X, ZHU G F, et al. Optimization of processing technology of wine-steamed Corni Fructus based on entropy method combined with analytic hierarchy process and BP neural network[J]. Chinese Traditional and Herbal Drugs, 2021, 52(22): 6816-6824. doi: 10.7501/j.issn.0253-2670.2021.22.006

[31] 田春莲, 丁文. 湖北地黄梓醇超声波提取及含量测定[J]. 安徽农业科学,2009,37(28):13788−13789,13792. [TIAN C L, DING W. Ultrasonic extraction and content determination of Rehmannia glutinosa in Hubei[J]. Journal of Anhui Agricultural Sciences,2009,37(28):13788−13789,13792. doi: 10.3969/j.issn.0517-6611.2009.28.133 TIAN C L, DING W. Ultrasonic extraction and content determination of Rehmannia glutinosa in Hubei[J]. Journal of Anhui Agricultural Sciences, 2009, 37(28): 13788-13789, 13792. doi: 10.3969/j.issn.0517-6611.2009.28.133

下载:

下载:

下载:

下载: