Extraction Optimization, Composition Analysis of Volatile Oil from Litsea lancilimba Merr. and Its Antioxidant Activity

-

摘要: 为研究大果木姜子挥发油的最优提取工艺及其成分组成和抗氧化活性,以大果木姜子挥发油得率为指标,在单因素实验基础上,采用响应面法对提取工艺进行优化;采用气相色谱-质谱法(GC-MS)分析挥发油的组成;运用清除DPPH·试验初步评价大果木姜子挥发油的体外抗氧化活性。结果表明,最佳提取工艺为浸泡时间5 h,料液比1:5 g/mL,提取时间8 h,在上述条件下,实际得率为10.67%。从大果木姜子挥发油中鉴定出74个成分,占挥发油总量的93.175%,其中相对含量高于3%的分别为1,8-桉叶素(21.854%)、正癸酸(12.893%)、β-蒎烯(4.873%)、对伞花烃(4.579%)、α-蒎烯(4.452%)、月桂酸(3.734%)、α-萜品烯醇(3.188%);大果木姜子挥发油抗氧化活性随着浓度的增加而逐渐升高,当浓度在1.0~6.0 mg/mL范围内时,最高清除率为92.94%。优化的工艺适用于大果木姜子挥发油的提取,大果木姜子挥发油中含有多种成分,其中以萜类、烃类及酸类成分为主,抗氧化结果提示其具有一定的体外抗氧化能力。

-

关键词:

- 大果木姜子 /

- 挥发油 /

- 响应面法 /

- 气相色谱-质谱法(GC-MS) /

- 体外抗氧化活性

Abstract: In order to study the optimal extraction process, composition and antioxidant activity of the Litsea lancilimba Merr. volatile oil, using the extraction rate of the Litsea lancilimba Merr. volatile oil as index, based on the single factor test, the response surface method was used to investigate the extraction process; GC-MS was used to analysis the composition of volatile oil; DPPH· scavenging test was used to evaluate the in vitro antioxidant activity of Litsea lancilimba Merr. volatile oil. The results showed that the best extraction process was soak time 5 h, 5 times the material-liquid ratio, and extraction time 8 h. Under the above conditions, the extraction rate was 10.67%. 74 components were identified from the Litsea lancilimba Merr. volatile oil by GC-MS, accounting for 93.175% of the total volatile oil. Among them, the relative contents higher than 3% were 1, 8-cineole (21.854%), n-decanoic acid (12.893%), β-pinene (4.873%), p-cymene (4.579%), α-pinene (4.452%), lauric acid (3.734%), α-terpinenol (3.188%). The total antioxidant activity of Litsea lancilimba Merr. volatile oil gradually increased with the increase of the concentration. When the concentration was in the range of 1.0~6.0 mg/mL, the highest clearance rate was 92.94%. The optimized process was suitable for the extraction of Litsea lancilimba Merr. volatile oil. There were many components in the Litsea lancilimba Merr. volatile oil, among which terpenoids, hydrocarbons and acids were the main components. The antioxidant results indicate that it has a certain in vitro antioxidant capacity. -

大果木姜子(Litsea lancilimba Merr.)为樟科樟属植物米槁(Cinnamomum migao C)的干燥成熟果实,又名毛丹母、青吐木等,主要分布在我国贵州、广西、云南等西北地区[1]。大果木姜子为药食两用植物,贵州民间多直接将其腌制做泡菜食用。大果木姜子油不仅可以用于调味、去腥,起到健脾开胃的效果,还具有抗心绞痛[2-3]、抗肿瘤[4-5]、抗炎镇痛[6]、抑菌[7]等药理作用,近年来陆续有相关制剂如:理气活血滴丸、心胃丹胶囊、米槁心乐滴丸、米槁精油滴丸上市[8]。研究表明挥发油类成分是大果木姜子的活性成分,且有报道挥发油类成分具有极好的抗氧化作用,可作为潜在的天然抗氧化剂使用[9-11],但目前并无大果木姜子挥发油抗氧化作用的相关报道。

挥发油常用的提取方法包括水蒸气蒸馏法[12]、超临界CO2萃取法[13]及超声辅助提取法[14],其中,水蒸气蒸馏法因不使用有机溶剂、不会对提取得到的挥发油造成污染、成本低等优点,仍是使用最为广泛的经典方法[15],但参考文献中采用水蒸气蒸馏法提取大果木姜子挥发油得率均较低,造成了大果木姜子植物资源的浪费[16-17]。基于此,本实验以大果木姜子为原料,采用水蒸气蒸馏法提取其挥发油,利用响应面法优化提取工艺,同时采用气相色谱-质谱法(GC-MS)对最优工艺提取得到的挥发油进行成分及相对含量分析,并探讨大果木姜子挥发油清除DPPH·的活性,以期为大果木姜子挥发油的充分利用及在抗氧化方面的研究及开发利用奠定基础,为大果木姜子的合理开发利用提供依据。

1. 材料与方法

1.1 材料与仪器

大果木姜子(Litsea lancilimba Merr.) 贵州省黔西南州册亨县双江镇林木村,经贵州中医药大学孙庆文教授鉴定,该品为樟科樟属植物米槁(Cinnamomum migao.C)的干燥成熟果实;维生素C(纯度≥99.0%) 成都第一制药有限公司;DPPH(1,1-二苯基-2-三硝基苯肼,纯度≥97.0%) 梯希布(上海)化成工业发展有限公司;无水乙醇(乙醇质量分数≥99.7%) 天津市富宇精细化工有限公司。

6890-5975C型气相色谱-质谱联用仪 美国安捷伦公司;TU-1810型紫外可见分光光度计 北京普析通用仪器有限公司;JM·A1002型电子天平 余姚纪铭称重校验设备有限公司;RRH-A1000型高速多功能粉碎机 上海绿沃工贸有限公司,RE-2000A型旋转蒸发仪 上海亚荣生化仪器厂;ZNHW型数显电热套 上海力辰邦西仪器科技有限公司;GG-17挥发油测定器 蜀牛玻璃仪器有限公司。

1.2 实验方法

1.2.1 大果木姜子挥发油的提取

按2020版《中国药典》(四部)通则2204“挥发油测定法甲法”提取大果木姜子挥发油。取供试品20 g,粉碎至颗粒度为35目,以水为提取溶剂在一定料液比下浸泡一段时间,在一定的电热套功率下提取一定时间后,静置1 h,于挥发油测定器下端缓慢放掉水层,于水油交界处开始收集挥发油,以13000 r/min离心10 min使油水分离后,采用移液枪吸取上层油相,即得大果木姜子挥发油[18]。

1.2.2 大果木姜子挥发油提取工艺的单因素实验

1.2.2.1 浸泡时间对得率的影响

精密称取35目大果木姜子粉末20 g,料液比为1:7(g/mL),浸泡时间分别为0、1、2、3、4、5 h,在电热套功率为100 kW下提取8 h,静置1 h后分离挥发油,考察浸泡时间对挥发油得率的影响。

1.2.2.2 提取功率对得率的影响

精密称取35目大果木姜子粉末20 g,料液比为1:7(g/mL),浸泡3 h,分别在电热套功率为60、100、140、180、220 kW下提取8 h,静置1 h后分离挥发油,考察不同提取功率对挥发油得率的影响。

1.2.2.3 料液比对得率的影响

精密称取35目大果木姜子粉末20 g,料液比分别为1:3、1:4、1:5、1:6、1:7(g/mL),浸泡3 h,在电热套功率为100 kW下提取8 h,静置1 h后分离挥发油,考察不同料液比对挥发油得率的影响。

1.2.2.4 提取时间对得率的影响

精密称取35目大果木姜子粉末20 g,料液比为1:7(g/mL),浸泡3 h,在电热套功率为100 kW下提取,提取时间分别为2、4、6、8、10、12 h,静置1 h后分离挥发油,考察不同提取时间对挥发油得率的影响。

1.2.3 响应面优化试验

大果木姜子中油类成分含量高,物料颗粒过细将无法过筛,故固定物料颗粒度为35目。选取浸泡时间(A)、料液比(B)和提取时间(C)作为Box-Behnken试验设计的3个因素,以大果木姜子挥发油得率为响应值,结合响应面法的设计原理[19],设计三因素三水平的响应面试验,因素水平表见表1。

表 1 大果木姜子挥发油响应面因素水平表Table 1. Response surface factor level table of the volatile oil of Litsea lancilimba Merr.因素 水平 −1 0 1 A浸泡时间(h) 0 2.5 5 B料液比(g/mL) 1:2 1:4 1:6 C提取时间(h) 6 8 10 1.2.4 大果木姜子挥发油得率的计算

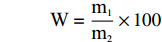

设定挥发油质量为m1,药材样品质量为m2。大果木姜子挥发油得率按下式计算:

W=m1m2×100 式中:W表示大果木姜子挥发油得率,%;m1表示大果木姜子挥发油重量,g;m2表示大果木姜子重量,g。

1.2.5 GC-MS分析条件

色谱条件[18]:色谱柱为HP-5 MS(60 m×0.25 mm×0.25 μm)弹性石英毛细管柱,柱温70 ℃,保持2 min,以3 ℃/min升温至190 ℃,以10 ℃/min升温至310 ℃,运行时间:54 min;汽化室温度250 ℃;载气为高纯He(99.999%);柱前压18.34 psi,载气流量1.0 mL/min;分流进样,分流比:50:1;溶剂延迟时间:6 min。

质谱条件:离子源为EI源;离子源温度230 ℃;四极杆温度150 ℃;电子能量70 eV;发射电流34.6 μA;倍增器电压1953 V;接口温度280 ℃;质量范围29~500 amu。

1.2.6 DPPH自由基清除试验

将大果木姜子挥发油用无水乙醇配制成浓度为0.5、1、1.5、2、4、6、8、10 mg/mL八个浓度,各取2 mL,加入0.080 mg/mL的DPPH·贮备液2 mL,摇匀,避光静置30 min后,以无水乙醇为参比液,测定反应体系在波长517 nm处的吸光度(Ai),同时测定2 mL DPPH·溶液与等体积无水乙醇混合液的吸光度(Ac)及2 mL试样液与等体积无水乙醇混合液的吸光度(Aj),维生素C作为阳性对照(浓度分别为0.5、1、1.5、2、4、6、8、10 μg/mL)[20-21]。

DPPH自由基清除率按下式来计算:

DPPH自由基清除率(%)=Ac−(Ai−Aj)Ac×100 1.3 数据处理

采用Excel 2010、SPSS 23.0、Prism 8.0.1进行数据统计分析,P<0.05表示差异显著,P<0.01表示差异极显著,所有数据均表示为平均值±标准差。Design-Expert V8.0.6软件进行响应面分析。

2. 结果与分析

2.1 单因素实验结果

2.1.1 浸泡时间对得率的影响

结果见图1:不同浸泡时间下挥发油得率存在显著性差异(P<0.05)。浸泡时间在0~3 h之间时,挥发油得率随着时间的延长而增加,2 h和3 h之间存在显著性差异;当浸泡时间≥3 h时,挥发油的得率达到最高,为10.44%,各组之间无显著性差异,得率不再随时间的延长而增加。可能是由于此时浸提液已经达到饱和状态,再继续浸提会使杂质成分溶出,与挥发油竞争溶出空间导致得率下降[22]。考虑到实验时间及成本,故在做响应面试验时,选取浸泡时间为0、2.5和5.0 h三个水平。

2.1.2 提取功率对得率的影响

结果见图2:电热套不同提取功率下挥发油得率无显著性差异(P>0.05)。当电热套提取功率>100 kW时,挥发油得率呈现逐渐降低的趋势,可能是随着提取功率的增大,局部提取温度升高,导致部分挥发油成分被破坏[23],得率下降。但总体变化较小,表明提取功率对挥发油得率的影响不大。因此后续实验固定提取功率为100 kW。

2.1.3 料液比对得率的影响

结果见图3:不同料液比下挥发油得率存在显著性差异(P<0.05)。随着料液比的增加,挥发油的得率出现先增加后减小的趋势。当料液比为1:5、1:6 g/mL时,挥发油的得率达到最高,继续增加料液比,挥发油的得率呈现下降趋势,可能是因为在一定的料液比范围内,挥发油的浸出传质系数升高,但当料液比过大时,反而减慢了挥发油的扩散速度[24]。结合实际情况,在做响应面试验时,选取料液比1:2、1:4和1:6 g/mL作为三个水平。

2.1.4 提取时间对得率的影响

结果见图4:不同提取时间下挥发油得率存在显著性差异(P<0.05)。随着提取时间的增加,得率逐渐增加。当提取时间为8 h时,增幅变缓;当提取时间≥10 h时,得率不再增加,可能是因为此时挥发油溶液趋于饱和,继续提取反而导致挥发油中的成分损失[22]。考虑到提取时间为8 h后的得率增幅较小,结合实际提取成本,选取浸泡时间6、8和10 h作为三个水平。

2.2 响应面优化试验

2.2.1 响应面优化结果及分析

以浸泡时间、料液比和提取时间为自变量,大果木姜子的挥发油得率为因变量,采用Design-Expert软件对各因素回归分析,以确定大果木姜子挥发油的最优提取工艺,结果见表2。

表 2 大果木姜子挥发油响应面试验设计与结果Table 2. Response surface experiment design and results of Litsea lancilimba Merr. volatile oil实验号 A浸泡时间 B料液比 C提取时间 得率(%) 1 1 −1 0 8.37 2 0 0 0 10.47 3 1 0 1 9.37 4 1 1 0 9.74 5 0 0 0 10.43 6 0 0 0 10.19 7 0 0 0 10.08 8 −1 1 0 9.14 9 0 −1 1 8.72 10 −1 0 1 9.44 11 −1 −1 0 8.40 12 1 0 −1 9.87 13 0 0 0 10.17 14 −1 0 −1 7.96 15 0 1 −1 8.46 16 0 −1 −1 8.40 17 0 1 1 9.72 2.2.2 响应面方差结果分析

模型P<0.01,表明回归模型极显著。失拟项P>0.05,表明失拟项不显著。从F值可以看出,在所选的各因素水平范围内,料液比对挥发油得率的影响最大,提取时间影响次之,浸泡时间的影响最小。在此模型中,一次项B、二次项A2、B2和C2、交互项AC对结果影响极显著(P<0.01),一次项A、C对结果影响显著(P<0.05),其他各项均对试验影响不显著,提示各试验因子与响应值不是简单的线性关系。对各因素进行拟合,得到二次回归方程:Y=10.27+0.30A+0.39B+0.32C+0.16AB−0.49AC+0.23BC−0.51A2−0.85B2−0.60C2。模型中回归方程的决定系数R2=0.9536,校正测定系数R2adj=0.8939,说明模型精确度高,试验设计可靠,可准确地对试验结果进行预测和分析,变异系数CV=2.87%,表明试验结果与真实值存在2.87%的偏差,模型可靠性较高。噪音信号比为10.824(>4),说明本模型能真实地反映实验结果[25]。结果见表3。

表 3 大果木姜子挥发油响应面方差分析Table 3. Response surface variance analysis of volatile oil of Litsea lancilimba Merr.方差来源 平方和 自由度 均方差 F值 P值 显著性 模型 10.31 9 1.15 16.03 0.0007 ** A 0.72 1 0.72 10.08 0.0156 * B 1.24 1 1.24 17.41 0.0042 ** C 0.82 1 0.82 11.46 0.0117 * AB 0.1 1 0.1 1.4 0.275 AC 0.97 1 0.97 13.62 0.0077 ** BC 0.22 1 0.22 3.03 0.1253 A2 1.1 1 1.1 15.45 0.0057 ** B2 3.01 1 3.01 42.15 0.0003 ** C2 1.5 1 1.5 21.02 0.0025 ** 残差 0.5 7 0.071 失拟差 0.38 3 0.13 4.32 0.0956 纯误差 0.12 4 0.029 总离差 10.81 16 注:*表示P<0.05,结果具有显著性,**表示P<0.01,结果具有极显著性。 2.2.3 因素间的交互作用

三维响应面图曲线越陡,显示得率受该因素影响越大;反之,曲线越缓,表明得率受该因素影响越小。等高线图椭圆表示该两两因素对实验结果影响较重,若较圆的话则影响较小。由图5可见浸泡时间和提取时间的等高线图呈椭圆形,三维响应面图曲线较陡,表明二者的交互作用对得率的影响明显。提取时间与料液比交互作用对挥发油得率的影响次之,料液比和浸泡时间交互作用对挥发油得率的影响最小。

2.3 大果木姜子挥发油提取工艺的验证

通过Design-Expert 8.0.6对回归方程求解,结合实际生产需要确定大果木姜子挥发油的最佳提取条件为浸泡时间5 h,料液比1:5 g/mL,提取时间8 h,此条件下得率的理论值为10.15%。按照上述响应面软件分析的大果木姜子挥发油的最佳提取工艺平行提取5次,其得率分别为10.64%、10.80%,10.54%、11.08%、10.29%,平均得率为10.67%,与预测值10.15%差距较小,RSD为0.29%,表明该实验提取工艺稳定可靠。

2.4 GC-MS分析大果木姜子挥发油成分

对总离子流图中的各峰经质谱计算机数据系统检索及核对Nist 17和Wiley 275标准质谱图,确定各化学成分,用峰面积归一化法测定各化学成分的相对质量分数。大果木姜子挥发油中共分离得到81个化合物,最终鉴定出74个化合物,主要包括烃类(27种)、醇类(19种)、酮类(10种)、酯类(4种)、醛类(3种)、萜类(3种)、酸类(2种)、酚类(2种)、其它(4种),占总挥发油的93.175%。总离子流图见图6,分析结果见表4。

表 4 大果木姜子挥发油化学成分及含量Table 4. Chemical constituents and contents of Litsea lancilimba Merr.volatile oil 分类 序号 保留时间(min) 化合物 分子式 相对含量(%) 烃类 1 9.813 三环烯 C10H16 0.021 2 9.879 α-侧柏烯 C10H16 0.486 3 10.185 α-蒎烯 C10H16 4.452 4 10.629 葑烯 C10H16 0.020 5 10.707 莰烯 C10H16 1.122 6 10.862 侧柏-2,4(10)-二烯 C10H14 0.069 7 11.507 香桧烯 C10H16 1.576 8 11.724 β-蒎烯 C10H16 4.873 9 11.981 β-月桂烯 C10H16 0.262 10 12.497 蒈烯 C10H16 0.019 11 12.642 α-水芹烯 C10H16 0.257 12 12.884 δ-3-蒈烯 C10H16 0.061 13 13.116 δ-3-蒈烯 C10H16 0.184 14 13.306 邻伞花烃 C10H14 0.047 15 13.468 对伞花烃 C10H14 4.579 16 13.703 柠檬烯 C10H16 1.883 17 14.800 γ-松油烯 C10H16 0.336 18 16.060 α-异松油烯 C10H16 0.360 19 27.693 α-荜澄茄油烯 C15H24 0.035 20 28.911 α-胡椒烯 C15H24 0.290 21 30.844 α-葎草烯 C15H24 0.124 22 32.266 丁子香烯 C15H24 0.124 23 32.573 别香树烯 C15H24 0.040 24 33.633 芹子烯 C15H24 0.553 25 34.975 δ-杜松烯 C15H24 0.219 26 35.834 α-白菖烯 C15H20 0.577 27 37.588 氧化丁香烯 C15H24O 1.160 醇类 1 16.442 芳樟醇 C10H18O 0.267 2 17.559 反式-薄荷-2-烯-1-醇 C10H18O 0.242 3 18.430 松香芹醇 C10H16O 1.215 4 18.616 马鞭草烯醇 C10H16O 0.779 5 19.604 内-莰醇 C10H18O 1.284 6 20.088 4-松油醇 C10H18O 0.891 7 20.450 对伞花-8-醇 C10H14O 0.396 8 20.74 α-萜品烯醇 C10H18O 3.188 9 20.986 桃金娘烯醇 C10H16O 1.079 10 22.192 枯烯醇 C9H12O 0.378 11 23.325 香叶醇 C10H18O 0.067 12 25.100 对伞花-7-醇 C10H14O 1.135 13 36.07 榄香醇 C15H26O 0.863 14 37.388 (-)斯巴醇 C15H24O 2.660 15 38.035 愈创木醇 C15H26O 1.011 16 39.362 γ-桉叶油醇 C15H26O 0.132 17 39.602 异桉叶油醇 C15H24O 0.137 18 40.139 α-桉叶油醇 C15H26O 0.581 19 40.692 异愈创木醇 C15H26O 0.465 酮类 1 17.353 侧柏酮 C10H16O 0.019 2 18.794 (-)-莰酮 C10H16O 0.036 3 19.203 桧酮 C9H14O 0.245 4 19.450 松香芹酮 C10H14O 0.463 5 20.581 隐酮 C9H14O 2.803 6 21.570 苯贝酮 C10H14O 0.350 7 23.042 香匠酮 C10H14O 0.226 8 23.545 胡椒酮 C10H16O 0.047 9 26.026 6-羟基卡沃坦丙酮 C10H16O2 0.033 10 26.736 左旋香芹酮 C10H16O 0.226 酯类 1 24.874 乙酸龙脑酯 C12H20O2 0.697 2 26.305 癸酸甲酯 C11H22O2 0.091 3 34.695 十二烷酸甲酯 C13H26O2 0.053 4 49.78 反戊基癸酸酯 C20H34O2 0.080 酚类 1 21.886 反式香芹酚 C10H16O 0.285 2 25.504 香芹酚 C10H14O 0.814 萜类 1 30.697 α-檀香萜 C15H24 0.079 2 12.114 2,3-脱氢-1,8-桉叶素 C10H16O 0.196 3 13.877 1,8-桉叶素 C10H18O 21.854 醛类 1 22.904 枯茗醛 C10H12O 1.254 2 24.50 水芹醛 C10H16O 0.785 3 17.741 α-龙脑烯醛 C10H16O 0.183 酸类 1 29.896 正癸酸 C10H20O2 12.893 2 37.031 月桂酸 C12H24O2 3.734 其它 1 34.280 二氢沉香呋喃 C15H26O 0.214 2 35.331 阔叶缬草醚 C15H26O 0.134 3 15.193 反式-香桧烯水合物 C10H18O 0.588 4 38.591 (-)-蛇麻烯环氧化物II C15H24O 0.872 总计 93.175 由大果木姜子挥发油各成分相对含量可知以烃类(23.729%)、萜类(22.129%)、醇类(16.77%)、酸类(16.627%)成分为主。其中1,8-桉叶素的含量达到了21.854%,其它相对含量高于3%的分别为正癸酸(12.893%)、β-蒎烯(4.873%)、对伞花烃(4.579%)、α-蒎烯(4.452%)、月桂酸(3.734%)、α-萜品烯醇(3.188%)。文献报道1,8-桉叶素、月桂酸、α-蒎烯均具有抑菌作用[26-28],其中月桂酸及其酯类是食品和化妆品中最有效的抗菌剂。α-萜品烯醇则具有平喘抗炎的效果[29]。本研究采用水蒸气蒸馏法提取得到的大果木姜子挥发油中1,8-桉叶素、月桂酸、α-蒎烯含量明显高于其它文献所报道(其它文献报道1,8-桉叶素最高含量为9.87%,月桂酸最高含量为3.184%,α-蒎烯最高含量为1.012%)[19,30-31],上述分析表明该产地大果木姜子挥发油可能具有较好的抑菌平喘效果。

2.5 大果木姜子挥发油成分的DPPH自由基清除能力

不同浓度的大果木姜子挥发油对DPPH自由基的清除率见图7。结果表明大果木姜子挥发油抗氧化活性随质量浓度的增加而逐渐升高,在质量浓度达到6.0 mg/mL后对DPPH自由基清除率的增幅变缓,当质量浓度为10.0 mg/mL时,样品清除率为95.80%,此时的抗氧化能力接近于质量浓度为6 μg/mL的VC。采用Prism 8.0.1计算得其IC50值为0.2434 mg/mL,结果表明大果木姜子挥发油对DPPH自由基具有较好的清除能力,说明其具有一定的体外抗氧化活性。有文献报道,1,8-桉叶素、α-蒎烯等均具有较高的抗氧化活性[32-33],推测这些成分可能与大果木姜子挥发油的抗氧化活性有一定的关系。

3. 结论

本实验采用响应面法确定了大果木姜子挥发油最优提取工艺为浸泡时间5 h,料液比1:5 g/mL,提取时间8 h,得率可达10.67%,与理论值比较无显著性差异,表明该提取工艺稳定可行,提高了大果木姜子挥发油的得率。对该产地的大果木姜子挥发油化学组成及相对含量进行了分析,共鉴定了74种成分,占总挥发油量的93.175%,主要为烃类(23.729%)、萜类(22.129%)、醇类(16.77%)、酸类(16.627%),为后续大果木姜子挥发油生物活性研究提供了依据。抗氧化作用研究表明大果木姜子挥发油对DPPH自由基的具有较好的清除作用,具有一定的抗氧化活性。后续将继续对大果木姜子挥发油进行更为全面的抗氧化作用研究,同时进行量效相关性分析,以期得到具有较强抗氧化作用的天然活性成分。

-

表 1 大果木姜子挥发油响应面因素水平表

Table 1 Response surface factor level table of the volatile oil of Litsea lancilimba Merr.

因素 水平 −1 0 1 A浸泡时间(h) 0 2.5 5 B料液比(g/mL) 1:2 1:4 1:6 C提取时间(h) 6 8 10 表 2 大果木姜子挥发油响应面试验设计与结果

Table 2 Response surface experiment design and results of Litsea lancilimba Merr. volatile oil

实验号 A浸泡时间 B料液比 C提取时间 得率(%) 1 1 −1 0 8.37 2 0 0 0 10.47 3 1 0 1 9.37 4 1 1 0 9.74 5 0 0 0 10.43 6 0 0 0 10.19 7 0 0 0 10.08 8 −1 1 0 9.14 9 0 −1 1 8.72 10 −1 0 1 9.44 11 −1 −1 0 8.40 12 1 0 −1 9.87 13 0 0 0 10.17 14 −1 0 −1 7.96 15 0 1 −1 8.46 16 0 −1 −1 8.40 17 0 1 1 9.72 表 3 大果木姜子挥发油响应面方差分析

Table 3 Response surface variance analysis of volatile oil of Litsea lancilimba Merr.

方差来源 平方和 自由度 均方差 F值 P值 显著性 模型 10.31 9 1.15 16.03 0.0007 ** A 0.72 1 0.72 10.08 0.0156 * B 1.24 1 1.24 17.41 0.0042 ** C 0.82 1 0.82 11.46 0.0117 * AB 0.1 1 0.1 1.4 0.275 AC 0.97 1 0.97 13.62 0.0077 ** BC 0.22 1 0.22 3.03 0.1253 A2 1.1 1 1.1 15.45 0.0057 ** B2 3.01 1 3.01 42.15 0.0003 ** C2 1.5 1 1.5 21.02 0.0025 ** 残差 0.5 7 0.071 失拟差 0.38 3 0.13 4.32 0.0956 纯误差 0.12 4 0.029 总离差 10.81 16 注:*表示P<0.05,结果具有显著性,**表示P<0.01,结果具有极显著性。 表 4 大果木姜子挥发油化学成分及含量

Table 4 Chemical constituents and contents of Litsea lancilimba Merr.

volatile oil 分类 序号 保留时间(min) 化合物 分子式 相对含量(%) 烃类 1 9.813 三环烯 C10H16 0.021 2 9.879 α-侧柏烯 C10H16 0.486 3 10.185 α-蒎烯 C10H16 4.452 4 10.629 葑烯 C10H16 0.020 5 10.707 莰烯 C10H16 1.122 6 10.862 侧柏-2,4(10)-二烯 C10H14 0.069 7 11.507 香桧烯 C10H16 1.576 8 11.724 β-蒎烯 C10H16 4.873 9 11.981 β-月桂烯 C10H16 0.262 10 12.497 蒈烯 C10H16 0.019 11 12.642 α-水芹烯 C10H16 0.257 12 12.884 δ-3-蒈烯 C10H16 0.061 13 13.116 δ-3-蒈烯 C10H16 0.184 14 13.306 邻伞花烃 C10H14 0.047 15 13.468 对伞花烃 C10H14 4.579 16 13.703 柠檬烯 C10H16 1.883 17 14.800 γ-松油烯 C10H16 0.336 18 16.060 α-异松油烯 C10H16 0.360 19 27.693 α-荜澄茄油烯 C15H24 0.035 20 28.911 α-胡椒烯 C15H24 0.290 21 30.844 α-葎草烯 C15H24 0.124 22 32.266 丁子香烯 C15H24 0.124 23 32.573 别香树烯 C15H24 0.040 24 33.633 芹子烯 C15H24 0.553 25 34.975 δ-杜松烯 C15H24 0.219 26 35.834 α-白菖烯 C15H20 0.577 27 37.588 氧化丁香烯 C15H24O 1.160 醇类 1 16.442 芳樟醇 C10H18O 0.267 2 17.559 反式-薄荷-2-烯-1-醇 C10H18O 0.242 3 18.430 松香芹醇 C10H16O 1.215 4 18.616 马鞭草烯醇 C10H16O 0.779 5 19.604 内-莰醇 C10H18O 1.284 6 20.088 4-松油醇 C10H18O 0.891 7 20.450 对伞花-8-醇 C10H14O 0.396 8 20.74 α-萜品烯醇 C10H18O 3.188 9 20.986 桃金娘烯醇 C10H16O 1.079 10 22.192 枯烯醇 C9H12O 0.378 11 23.325 香叶醇 C10H18O 0.067 12 25.100 对伞花-7-醇 C10H14O 1.135 13 36.07 榄香醇 C15H26O 0.863 14 37.388 (-)斯巴醇 C15H24O 2.660 15 38.035 愈创木醇 C15H26O 1.011 16 39.362 γ-桉叶油醇 C15H26O 0.132 17 39.602 异桉叶油醇 C15H24O 0.137 18 40.139 α-桉叶油醇 C15H26O 0.581 19 40.692 异愈创木醇 C15H26O 0.465 酮类 1 17.353 侧柏酮 C10H16O 0.019 2 18.794 (-)-莰酮 C10H16O 0.036 3 19.203 桧酮 C9H14O 0.245 4 19.450 松香芹酮 C10H14O 0.463 5 20.581 隐酮 C9H14O 2.803 6 21.570 苯贝酮 C10H14O 0.350 7 23.042 香匠酮 C10H14O 0.226 8 23.545 胡椒酮 C10H16O 0.047 9 26.026 6-羟基卡沃坦丙酮 C10H16O2 0.033 10 26.736 左旋香芹酮 C10H16O 0.226 酯类 1 24.874 乙酸龙脑酯 C12H20O2 0.697 2 26.305 癸酸甲酯 C11H22O2 0.091 3 34.695 十二烷酸甲酯 C13H26O2 0.053 4 49.78 反戊基癸酸酯 C20H34O2 0.080 酚类 1 21.886 反式香芹酚 C10H16O 0.285 2 25.504 香芹酚 C10H14O 0.814 萜类 1 30.697 α-檀香萜 C15H24 0.079 2 12.114 2,3-脱氢-1,8-桉叶素 C10H16O 0.196 3 13.877 1,8-桉叶素 C10H18O 21.854 醛类 1 22.904 枯茗醛 C10H12O 1.254 2 24.50 水芹醛 C10H16O 0.785 3 17.741 α-龙脑烯醛 C10H16O 0.183 酸类 1 29.896 正癸酸 C10H20O2 12.893 2 37.031 月桂酸 C12H24O2 3.734 其它 1 34.280 二氢沉香呋喃 C15H26O 0.214 2 35.331 阔叶缬草醚 C15H26O 0.134 3 15.193 反式-香桧烯水合物 C10H18O 0.588 4 38.591 (-)-蛇麻烯环氧化物II C15H24O 0.872 总计 93.175 -

[1] 张小波, 周涛, 郭兰萍, 等. 苗药大果木姜子挥发油成分变化及其地理分布[J]. 生态学报,2011,31:5299−5306. [ZHANG X B, ZHOU T, GUO L P, et al. Volatile oil contents correlate with geographical distribution patterns of the miao ethnic herb Cinnamomum migao[J]. Acta Ecol Sinica,2011,31:5299−5306. ZHANG X B, ZHOU T, GUO L P, et al. Volatile oil contents correlate with geographical distribution patterns of the miao ethnic herb Cinnamomum migao[J]. Acta Ecol Sinica, 2011, 31: 5299-5306.

[2] 韩轶, 吴宗贵, 张雪娟, 等. 理气活血滴丸治疗老年慢性稳定型心绞痛有效性及安全性的随机对照多中心临床研究[J]. 中国循证心血医学杂志,2021,13(2):186−189,193. [HAN Y, WU Z G, ZHANG X J, et al. A randomized controlled multicenter clinical study on the efficacy and safety of liqi huoxue dropping pills in the treatment of elderly chronic stable angina pectoris[J]. Chin J Evid Based Cardiovasc Med,2021,13(2):186−189,193. HAN Y, WU Z G, ZHANG X J, et al. A randomized controlled multicenter clinical study on the efficacy and safety of liqi huoxue dropping pills in the treatment of elderly chronic stable angina pectoris[J]. Chin J Evid Based Cardiovasc Med, 2021, 13(2): 186-189, 193.

[3] 伍柏灵. 大果木姜子油治疗房颤大鼠的作用机制研究[D]. 贵阳: 贵州中医药大学, 2019: 20-28. WU B L. Study on the mechanism of the treatment of atrial fibrillation rats with Cinnamomum migao[D]. Guiyang: Guizhou University of Traditional Chinese Medicine, 2019: 20-28.

[4] 杨燕, 胡万福. MTT法检测复方大果木姜子软胶囊抗肿瘤作用[J]. 三峡大学学报(自然科学版),2017,39(S1):15−17. [YANG Y, HU W F. MTT method to detect the anti-tumor effect of compound Cinnamomum migao soft capsule[J]. Journal of China Three Gorges University (Natural Sciences),2017,39(S1):15−17. YANG Y, HU W F. MTT method to detect the anti-tumor effect of compound Cinnamomum migao soft capsule[J]. Journal of China Three Gorges University (Natural Sciences), 2017, 39(S1): 15-17.

[5] 胡万福, 杨燕, 邱德文. 复方大果木姜子软胶囊对小鼠骨髓癌细胞的增殖抑制实验研究[J]. 中国医药导刊,2013,15(10):1697−1698. [HU W F, YANG Y, QIU D W. Experimental study of Cinnamomum migao soft capsule inhibition on proliferation of mouse cell line SP2/0 in vitro[J]. Chinese Journal of Medicinal Guide,2013,15(10):1697−1698. doi: 10.3969/j.issn.1009-0959.2013.10.081 HU W F, YANG Y, QIU D W. Experimental study of Cinnamomum migao soft capsule inhibition on proliferation of mouse cell line SP2/0 in vitro[J]. Chinese Journal of Medicinal Guide, 2013, 15(10): 1697-1698. doi: 10.3969/j.issn.1009-0959.2013.10.081

[6] 刘同祥, 刘庆山, 申刚义, 等. 大果木姜子镇痛作用活性部位筛选[J]. 北京中医药大学学报,2010,33(8):550−551. [LIU T X, LIU Q S, SHEN G Y, et al. Filtration of active fractions with analgesic effect from Daguoamujiangzi (Cinnamomum migao)[J]. Journal of Beijing University of Traditional Chinese Medicine,2010,33(8):550−551. LIU T X, LIU Q S, SHEN G Y, et al. Filtration of active fractions with analgesic effect from Daguoamujiangzi (Cinnamomum migao)[J]. Journal of Beijing University of Traditional Chinese Medicine, 2010, 33(8): 550-551.

[7] 陈达, 杨佃志. 大果木姜子不同组方提取物体外抗菌试验研究[J]. 中国民族民间医药,2010,19(18):42,44. [CHEN D, YANG D Z. Study on the antibacterial test of different formulas extracted from Daguomujiangzi in vitro[J]. Chinese Journal of Ethnomedicine and Ethnopharmacy,2010,19(18):42,44. doi: 10.3969/j.issn.1007-8517.2010.18.036 CHEN D, YANG D Z. Study on the antibacterial test of different formulas extracted from Daguomujiangzi in vitro[J]. Chinese Journal of Ethnomedicine and Ethnopharmacy, 2010, 19(18): 42, 44. doi: 10.3969/j.issn.1007-8517.2010.18.036

[8] 邱德文, 杜茂端. 贵州苗药大果木姜子研究及产业化[C]//贵州省自然科学优秀学术论文集贵州省科学技术协会专题资料汇编, 2005: 470−474. QIU D W, DU M D. Research and industrialization of Guizhou Miao medicine Daguomujiangzi[C]//Guizhou Province natural science excellent academic paper collection, 2005: 470−474.

[9] 万敏, 姚于飞, 付王威, 等. 黄金茶挥发油提取工艺优化、成分分析及抗氧化研究[J]. 食品工业科技,2021,42(15):150−156. [WAN M, YAO Y F, FU W W, et al. Extraction process optimization, composition analysis of essential oil from Chimonanthus nitens oliv and its antioxidant activity[J]. Science and Technology of Food Industry,2021,42(15):150−156. WAN M, YAO Y F, FU W W, et al. Extraction process optimization, composition analysis of essential oil from Chimonanthus nitens oliv and its antioxidant activity[J]. Science and Technology of Food Industry, 2021, 42(15): 150-156.

[10] HATEM A, ABDEL R A, ABDELHAKIM A, et al. Effect of nanoencapsulation on volatile constituents, and antioxidant and anticancer activities of Algerian Origanum glandulosum Desf. essential oil[J]. Sci Rep,2020,10:2812. doi: 10.1038/s41598-020-59686-w

[11] RAMZI A M, OMAR M N, EBTESAM S A, et al. Chemical composition, in vitro antimicrobial, free-radical-scavenging and antioxidant activities of the essential oil of Leucas inflata benth[J]. Molecules,2017,22(3):367. doi: 10.3390/molecules22030367

[12] KUANG C L, LYU D, SHEN G H, et al. Chemical composition and antimicrobial activities of volatile oil extracted from Chrysanthemum morifolium Ramat.[J]. J Food Sci Technol,2018,55(7):2786−2794. doi: 10.1007/s13197-018-3203-1

[13] 齐富友, 蹇顺华, 刘吟, 等. 白苏叶挥发油超临界CO2萃取工艺优化、成分分析及抗氧化活性研究[J]. 食品与机械,2021,37(12):142−148. [QI F Y, JIAN S H, LIU Y, et al. Extraction process optimization, composition analysis of volatile oil from Perilla frutescens leaf and its antioxidant activity[J]. Food and Machinery,2021,37(12):142−148. QI F Y, JIAN S H, LIU Y, et al. Extraction process optimization, composition analysis of volatile oil from Perilla frutescens leaf and its antioxidant activity[J]. Food and Machinery, 2021, 37(12): 142-148.

[14] 王飞娟, 杨长花, 刘峰, 等. 响应面法优化细辛挥发油超声辅助提取工艺[J]. 化学与生物工程,2022,39(1):21−24,39. [WANG F J, YANG C H, LIU F, et al. Optimization of ultrasonic-assisted extraction process of Asarum volatile oil from Asari radix et Rhizoma by response surface methodology[J]. Chemical and Biological Engineering,2022,39(1):21−24,39. doi: 10.3969/j.issn.1672-5425.2022.01.005 1): 21-24, 39. WANG F J, YANG C H, LIU F, et al. Optimization of ultrasonic-assisted extraction process of Asarum volatile oil from Asari radix et Rhizoma by response surface methodology[J]. Chemical and Biological Engineering, 2022, 39(1): 21-24, 39. doi: 10.3969/j.issn.1672-5425.2022.01.005

[15] 国家药典委员会. 中华人民共和国药典[S]. 四部. 北京: 中国医药科技出版社, 2020: 233. National Pharmacopoeia Commission. Pharmacopoeia of the People's Republic of China[S]. Four. Beijing: China Medical Science and Technology Press, 2020: 233.

[16] 武孔云, 李灿, 梁云霞, 等. 水蒸气蒸馏提取米槁精油的工艺研究[J]. 中国野生植物资源,2014,33(4):17−18,27. [WU K Y, LI C, LIANG Y X, et al. Study on the extraction conditions of Cinnamomum migao H. W. Li essential oil by steam distillation[J]. Chinese Wild Plant Reasources,2014,33(4):17−18,27. doi: 10.3969/j.issn.1006-9690.2014.04.005 WU K Y, LI C, LIANG Y X, et al. Study on the extraction conditions of Cinnamomum migao H. W. Li essential oil by steam distillation[J]. Chinese Wild Plant Reasources, 2014, 33(4): 17-18, 27. doi: 10.3969/j.issn.1006-9690.2014.04.005

[17] 张永萍, 林亚平, 邱德文, 等. 大果木姜子挥发油的提取工艺研究[J]. 中国中药杂志,2005,30(14):1120−1122. [ZHANG Y P, LIN Y P, QIU D W, et al. Study on the extraction technology of volatile oil from Cinnamomum migao H. W. Li[J]. China Journal of Chinese Materia Medica,2005,30(14):1120−1122. doi: 10.3321/j.issn:1001-5302.2005.14.021 ZHANG Y P, LIN Y P, QIU D W, et al. Study on the extraction technology of volatile oil from Cinnamomum migao H. W. Li[J]. China Journal of Chinese Materia Medica, 2005, 30(14): 1120-1122. doi: 10.3321/j.issn:1001-5302.2005.14.021

[18] 黄凯, 刘杰, 黄彩河, 等. 不同来源大果木姜子挥发油及脂肪油成分的比较分析[J]. 中国药房,2020,31(16):1961−1966. [HUANG K, LIU J, HUANG C H, et al. Comparative analysis of volatile oil and fatty oil constituents from Cinnamomum migao in different sources[J]. China Pharmacy,2020,31(16):1961−1966. doi: 10.6039/j.issn.1001-0408.2020.16.08 HUANG K, LIU J, HUANG C H, et al. Comparative analysis of volatile oil and fatty oil constituents from Cinnamomum migao in different sources[J]. China Pharmacy, 2020, 31(16): 1961-1966. doi: 10.6039/j.issn.1001-0408.2020.16.08

[19] MACRCOS A B, RICARDO E S, ELIANE P O, et al. Response surface methodology (RSM) as a tool for optimization in analytical chemistry[J]. Talanta,2008,76:965−977. doi: 10.1016/j.talanta.2008.05.019

[20] NIDAL A J, ABDEL N Z, ALADDIN A, et al. Investigation the efficiency of various methods of volatile oil extraction from Trichodesma africanum and their impact on the antioxidant and antimicrobial activities[J]. J Intercult Ethnopharmacol,2016,5(3):250−256. doi: 10.5455/jice.20160421065949

[21] 任文静, 董梅月, 冯俊杰, 等. 北豆根脂肪油提取工艺优化及其抗氧化活性研究[J]. 中国现代应用药学,2021,38(4):420−425. [REN W J, DONG M Y, FENG J J, et al. Study on extraction process and antioxidant activity of Menispermi rhizoma fatty oil[J]. Chinese J Mod Appl Pharm,2021,38(4):420−425. REN W J, DONG M Y, FENG J J, et al. Study on extraction process and antioxidant activity of Menispermi rhizoma fatty oil[J]. Chinese J Mod Appl Pharm, 2021, 38(4): 420-425.

[22] 韩冰, 张天琪, 郑野. 响应面法优化茴香精油提取工艺及其微乳特性和货架期研究[J/OL]. 食品工业科技, 2022, https://doi.org/10.13386/j.issn1002-0306.2021110199. HAN B, ZHANG T Q, ZHENG Y, et al. Optimization of extraction process, microemulsion characteristics and shelf life of fennel essential oil by response surface methodology[J]. Science and Technology of Food Industry, 2022, https://doi.org/10.13386/j.issn1002-0306.2021110199.

[23] 刘嘉琪, 杨涛, 缪芝硕, 等. 响应面优化栀子果实不同部位油脂提取工艺及其脂肪酸分析[J]. 食品工业科技,2020,41(23):114−121,128. [LIU J Q, YANG T, MIAO Z S, et al. Optimization of extraction technologies of different parts of Gardenia jasminoides oils by response surface methodology and their fatty acids analysis[J]. Science and Technology of Food Industry,2020,41(23):114−121,128. LIU J Q, YANG T, MIAO Z S, et al. Optimization of extraction technologies of different parts of Gardenia jasminoides oils by response surface methodology and their fatty acids analysis[J]. Science and Technology of Food Industry, 2020, 41 (23): 114-121, 128.

[24] 林毅, 黄梅, 吴桂苹, 等. 响应面法优化熏干草果油树脂提取工艺及成分分析[J]. 食品工业科技,2022,43(1):163−171. [LIN Y, HUANG M, WU G P, et al. Optimization of extraction process and component analysis of oleoresin from smoked Amomum tsao-ko by response surface methodology[J]. Science and Technology of Food Industry,2022,43(1):163−171. doi: 10.13386/j.issn1002-0306.2021040002 LIN Y, HUANG M, WU G P, et al. Optimization of extraction process and component analysis of oleoresin from smoked Amomum tsao-ko by response surface methodology[J]. Science and Technology of Food Industry, 2022, 43(1): 163-171. doi: 10.13386/j.issn1002-0306.2021040002

[25] SRIDHAR K, CHARLES A L. In vitro antioxidant activity of Kyoho grape extracts in DPPH and ABTS assays: Estimation methods for EC50 using advanced statistical programs[J]. Food Che-mistry,2019,275(1):41−49.

[26] 侯明槠, 常聪, 陈林霖, 等. 桉油精的药理作用研究进展[J]. 中国现代应用药学,2021,38(16):2023−2032. [HOU M Z, CHANG C, CHEN L L, et al. Research progress in pharmacological effects of 1, 8-Cineole[J]. Chin J Mod Appl Pharm,2021,38(16):2023−2032. HOU M Z, CHANG C, CHEN L L, et al. Research progress in pharmacological effects of 1, 8-Cineole[J]. Chin J Mod Appl Pharm, 2021, 38(16): 2023-2032.

[27] KHORAMNIA A, EBRAHIMPOUR A, GHANBARI R, et al. Improvement of medium chain fatty acid content and antimicrobial activity of coconut oil via solid-state fermentation using a Malaysian Geotrichum candidum[J]. Biomed Research International,2013,2013:954542.

[28] 夏忠弟, 余俊龙. α-蒎烯对白色念珠菌生物合成的影响[J]. 中国现代医学杂志,2000,10(1):44−46. [XIA Z D, YU J L. Effects of α-pinene on the biosynthesis of Candida albicans[J]. China Journal of Modern Medicine,2000,10(1):44−46. doi: 10.3969/j.issn.1005-8982.2000.01.022 XIA Z D, YU J L. Effects of α-pinene on the biosynthesis of Candida albicans[J]. China Journal of Modern Medicine, 2000, 10(1): 44-46. doi: 10.3969/j.issn.1005-8982.2000.01.022

[29] 朱婉萍. 天然产物α-萜品烯醇的结构修饰及平喘活性研究[D]. 杭州: 浙江大学, 2016, 1-2. ZHU W P. The structural modifacation and anti-asthma evaluation of natural product α-terpineol[D]. Hangzhou: Zhejiang University, 2016, 1-2.

[30] 赵立春, 邱明华, 邱德文, 等. 苗药大果木姜子果实挥发油化学成分研究[J]. 西北药学杂志,2009,24(5):353−354. [ZHAO L C, QIU M H, QIU D W, et al. GC-MS analysis of chemical constituents of essential oils isolated from the fruit of Cinnamomum migao H. W. Li[J]. Northwest Pharmaceutical Journal,2009,24(5):353−354. doi: 10.3969/j.issn.1004-2407.2009.05.008 ZHAO L C, QIU M H, QIU D W, et al. GC-MS analysis of chemical constituents of essential oils isolated from the fruit of Cinnamomum migao H. W. Li[J]. Northwest Pharmaceutical Journal, 2009, 24(5): 353-354. doi: 10.3969/j.issn.1004-2407.2009.05.008

[31] 张永萍, 邱德文, 郑亚玉, 等. 大果木姜子挥发油的GC-MS分析[J]. 中国医药学报,2003,18(2):119−120. [ZHANG Y P, QIU D W, ZHENG Y Y, et al. GC-MS analysis of volatile oil of Cinnamomum migao H. W. Li[J]. China Journal of Traditional Chinese Medicine and Pharmacy,2003,18(2):119−120. doi: 10.3969/j.issn.1673-1727.2003.02.020 ZHANG Y P, QIU D W, ZHENG Y Y, et al. GC-MS analysis of volatile oil of Cinnamomum migao H. W. Li[J]. China Journal of Traditional Chinese Medicine and Pharmacy, 2003, 18(2): 119-120. doi: 10.3969/j.issn.1673-1727.2003.02.020

[32] 尹晓燕, 王燕燕. 1, 8-桉叶素药理作用及其机制研究进展[J]. 生命的化学,2020,40(11):2026−2034. [YIN X Y, WANG Y Y. Research progress on pharmacological activities and mechanism of 1, 8-cineole[J]. Chemistry of Life,2020,40(11):2026−2034. YIN X Y, WANG Y Y. Research progress on pharmacological activities and mechanism of 1, 8-cineole[J]. Chemistry of life, 2020, 40(11): 2026-2034.

[33] WANG W, WU N, ZU Y G, et al. Antioxidative activity of Rosmarinus officinalis L. essential oil compared to its main components[J]. Food Chemistry,2008,108(3):1019−1022. doi: 10.1016/j.foodchem.2007.11.046

下载:

下载:

下载:

下载: