Effect of Steam Treatment on the Flavor Quality of Yixian Dark Tea

-

摘要: 为探究蒸汽处理对黟县黑毛茶陈化的作用,本研究通过感官审评结合顶空固相微萃取-气相色谱-质谱联用技术、氨基酸分析仪及高效液相分析仪分析了蒸汽处理对黑毛茶风味品质的影响。结果表明,蒸汽处理能够加快黑毛茶陈化,促进陈香和醇厚风味的生成。感官评价显示,第三次蒸汽处理后风味最佳。挥发性物质分析显示,蒸汽处理后挥发性物质总量先降后增,在第三、第四次蒸汽处理后香气总量较高,分别为9113.62、10222.82 μg/kg;蒸汽处理后呈现花香、甜香风味的壬醛、反-2-辛烯醛、二氢芳樟醇大量生成,而芳樟醇、香叶醇及二甲基硫含量则显著减少(P<0.05)。滋味物质分析显示,蒸汽处理后,样品中儿茶素总量和表型儿茶素(表没食子儿茶素、表没食子酸儿茶素没食子酸酯)含量显著降低(P<0.05),而没食子酸和非表型的儿茶素、没食子儿茶素没食子酸酯含量则增加;游离氨基酸总量在第三次蒸汽处理后增加最为显著(P<0.05),尤其是茶氨酸增加了13.1%。正交偏最小二乘判别分析模型(Orthogonal partial least squares-discriminant analysis,OPLS-DA)显示不同蒸汽处理的黑毛茶差异明显,结合变量投影重要性(Variable important for the projection,VIP)、香气活度值(Odor active value,OAV)、滋味活度值(Dose-over-threshold factors,DOT),筛选出壬醛、癸醛、二甲基硫、1-辛烯-3-酮、反-2-辛烯醛、正己醛、没食子儿茶素、表没食子儿茶素没食子酸酯、表没食子儿茶素、茶氨酸等物质,是影响样品间香气与滋味变化的重要因子。本研究结果为加快黟县黑毛茶的陈化提供了一种可用的新思路及参考依据。

-

关键词:

- 黟县黑茶 /

- 蒸汽作用 /

- 风味品质 /

- 正交偏最小二乘判别分析

Abstract: To investigate the aging effect of steaming to Yixian dark tea, the flavor quality and metabolite profiles of Yixian dark tea after steaming treatments were analyzed by sensory evaluation, headspace solid-phase microextraction-gas chromatography-mass spectrometry (HP-SPME-GCMS), amino acid analyzer and high-performance liquid chromatography (HPLC). The results showed that the steam treatment could accelerate the aging of black tea, promote the generation of aged aroma and rich flavor. Sensory evaluation showed that, the third steaming obtained the pleasant flavor compared to other dark tea samples. The total volatiles concentration decreased first and then increased after steam treatment, and the total aroma content increased in the third (9113.62 μg/kg) and forth (10222.82 μg/kg) times of steaming. The nonanal, trans-2-octenal and dihydrolinalool with a flowery and sweet odor showed an increasing tendency during steaming, whereas linalool, geraniol and dimethylsulfide showed a decrease in concentrations (P<0.05). The total catechins concentration and concentrations of episturcture catechins such as epigallocatechin and epigallocatechin gallate decreased with steaming (P<0.05). In contrast, concentrations of gallic acid and nonepistructure catechin and gallocatechin gallate increased after steaming, especially theanine (P<0.05), of which content increased by 13.1%. Nonanal, decanal, dimethyl sulfide, 1-octen-3-one, trans-2-octenal, hexanal, epigal-locatechin, epigallocatechin gallate, epigallocatechin, and theanine were the key differential metabolites between dark tea samples according to orthogonal partial least squares-discriminant analysis, variable important for the projection, odor active value, and dose-over-threshold factors. This study would give a insight into improving the rapid aging of Yixian dark tea. -

黑茶属于后发酵茶,是我国六大茶类之一[1],产区广、种类多,具有“越陈越香”“越陈越醇”的特性[2]。黟县黑茶是黑茶大类中的一类,主产于安徽黟县,是采用黄山当地的茶树鲜叶为原料,经杀青、揉捻、渥堆、初干、复堆、足干等工艺制作成黑毛茶,后经陈化、蒸压定型制作成相应产品[3]。

陈化工艺是黑茶提升风味品质的关键步骤,在陈化的作用下,黑茶干茶色泽呈现棕褐色变化,青草气消散、涩感降低,陈香和陈醇滋味显露[4]。其中,香气和滋味是陈化风味变化的关键。研究表明,雪松醇、己醛、壬醛、(E)-2-辛烯醛、癸醛、苯甲醛、(E)-2-壬烯醛、二氢猕猴桃内酯、β-环柠檬醛、1-辛烯-3-醇等是黑茶陈化中重要的特征性香气物质[5];黄酮类物质、茶色素、游离氨基酸、茶多酚等是影响滋味醇厚的重要因子[6]。目前,自然陈化是黑茶陈化贮藏的主要方式,其中,温度、湿度、氧气、光线等外界条件对黑茶陈化风味的形成有重要影响,特别是温度和湿度因子[7]。环境温、湿度的升高可以加快黑茶陈化,但长时间高温湿热,易引起霉变;低温低湿仓储条件陈化品质较好,但陈化速率缓慢[8−9]。此外,现有研究多数集中于陈化环境因子、时间及风味变化等方面[10],还尚未形成一种较优的人工控制的快速陈化方法。鉴于此,有必要进一步探索新型的陈化方法。基于黑茶陈化与温、湿度高度相关,本文提出利用高温水蒸汽对黑毛茶进行快速加湿加热,使茶叶中物质发生转化,以达到快速陈化的目的,同时实现人工控制。但蒸汽处理后,相关陈化风味及物质变化机制的研究有待深入。

本实验利用水蒸汽处理黟县黑毛茶,结合感官审评、顶空固相微萃取-气相色谱-质谱联用技术、氨基酸分析及高效液相等方法,开展蒸汽处理对黟县黑毛茶风味品质变化的影响研究,探究高温蒸汽对加快黑毛茶陈化的作用,以期开发出一种人工可控化的黑毛茶快速陈化方法。

1. 材料与方法

1.1 材料与仪器

茶鲜叶 为舒茶早鲜叶(一芽二、三叶),采自安徽省农业科学院茶叶研究所试验茶园基地;7种儿茶素类物质标准品:没食子酸(Gallic acid,GA)、儿茶素(Catechin,C)、没食子儿茶素(Epigallocatechin,GC)、表儿茶素(Epicatechin,EC)、表没食子儿茶素(Epigallocatechin,EGC)、表儿茶素没食子酸酯(Epicatechin gallate,ECG)、表没食子儿茶素没食子酸酯(Epigallocatechin gallate,EGCG)、没食子儿茶素没食子酸酯(Gallocatechin gallate,GCG) 上海源叶生物科技有限公司;咖啡碱标准品(Caffeine,CAF) 北京海岸鸿蒙标准物质技术有限责任公司;游离氨基酸标准品、癸酸乙酯(99%) 美国Sigma-Aldrich公司;茶氨酸标准品 北京百灵威科技有限公司;氨基酸流动相:试剂A、试剂B、试剂C、试剂D 德国赛卡姆公司;茚三酮 上海麦克林生化科技有限公司。

60型斗式烘干机 浙江春江茶叶机械有限公司;S-433D 氨基酸分析仪 德国Sykam公司;Chromaster高效液相色谱仪 日本日立公司;QP2020气相色谱质谱联用仪(Gas chromatography-mass spectrometry,GC-MS) 日本岛津公司;色谱柱DB-5 MS(30 m×0.25 mm×0.25 μm) 美国安捷伦公司;C18色谱柱(2.1 mm×100 mm,1.9 μm) 美国沃特世科技有限公司。

1.2 实验方法

1.2.1 茶样制备

黟县黑毛茶工艺流程:鲜叶 → 摊放(时间:4 h) → 杀青(温度:300 ℃,时间:100 s) → 热揉捻(时间:8 min) → 渥堆(温度:45 ~ 55 ℃,时间:12 ~ 16 h) → 毛火(温度:120 ℃,时间:15 min) → 摊凉(时间:1 h) → 足火(温度:90 ℃,时间:30 min) → 黑毛茶[3]。

蒸汽处理方法:将5 kg黑毛茶沸水蒸汽蒸15 min,迅速装入竹篓内,保持高湿热作用6 h,后80 ℃烘至含水率8%,自然放置10 d,此为1次蒸汽处理。

实验分组:对照组(CK):以未进行蒸汽处理的黑毛茶为对照;CL1组:蒸汽处理1次,即按蒸汽处理方法进行1次蒸汽处理;CL2组:蒸汽处理2次;CL3组:蒸汽处理3次;CL4组:蒸汽处理4次。

芳樟醇加热反应:以50 μg/g的芳樟醇标准品水溶液进行蒸汽加热1.5 h处理,未加热芳樟醇标准品水溶液为对照。

1.2.2 感官审评方法

依据国家茶叶审评标准GB/T 23776-2018,准确称取3 g黑毛茶,加入150 mL沸水,冲泡4 min后倒出茶汤,并由3位专业审评人员对茶汤香气、滋味进行评价描述,并按NY/T 787-2004《茶叶感官审评通用方法》,对样品香气、滋味分别进行评分,满分为100分。

1.2.3 挥发性化合物分析

采用顶空固相微萃取(Headspace-solid phase microextraction,HS-SPME)技术吸附香气成分[11],准确称取0.5 g样品于萃取瓶中,加入0.15 g氯化钠和5 mL沸水,立即用锡箔纸密封瓶口,60 ℃平衡5 min后,将SPME萃取头(50/30 μm,DVB/CAR/PDMS)插入萃取瓶中,在60 ℃恒温水浴下顶空吸附40 min。萃取完毕后,将萃取头插入气相色谱仪中进行检测,每个样品重复3次。

GC-MS分析条件与文献[12]一致。SPME纤维在250 ℃温度下解吸,以10:1的比例进行分流。GC梯度程序如下:40 ℃保持5 min;以速度为3 ℃/min从40 ℃到110 ℃,并保持3 min;以5 ℃/min的速度从110 ℃降至200 ℃,并保持1 min;以15 ℃/min的速度从200 ℃升至260 ℃,并保持3 min。载气为高纯氦气(> 99.99%),其中载气流速为1 mL/min。MS操作条件为:230 ℃离子源,250 ℃界面,0.1 kV电压,30~600 m/z扫描范围,5次扫描/s。

化合物于NIST数据库中检索比对进行化合物定性。定量采用癸酸乙酯标准曲线(内标),通过将化合物峰面积代入癸酸乙酯标准曲线计算相对含量[13]。

1.2.4 游离氨基酸、儿茶素和咖啡碱含量测定

称取0.25 g茶样,加入25 mL沸水,100 ℃水浴浸提20 min,每隔10 min振荡一次;浸提完毕后冷却,过滤,定容至25 mL容量瓶;将提取液分别稀释10倍和6倍,并用0.45 μm滤膜过滤,用于游离氨基酸、儿茶素和咖啡碱含量分析,每个样品重复3次。

游离氨基酸分析方法[14]。流动相梯度为:0~1 min(80% A,20% B);1~3 min(79% A,21% B);3~8 min(61% A,39% B);8~20 min(43% A,57% B);20~24 min(43% A,57% B);24~36 min(100% B);36~42 min(100% C);42~47 min(76% C,24% D);47~61 min(76% C,24% D);61~61.1 min(100% D);61.1~68 min(100% D);68~68.1 min(100% A);68.1~84 min(100% A)。检测波长分别为570 nm和440 nm,每个样品重复3次。

儿茶素和咖啡碱含量测定分析方法[15]。检测条件:C18色谱柱,检测波长:278 nm,柱温:35 ℃,流动相:A相:2%乙酸;B相:乙腈。梯度洗脱条件:0~3 min(95% A),3~5 min(80% A),5~18 min(95% A),流速:0.2 mL/min,进样量5 μL。

1.2.5 挥发性化合物OAV和非挥发性化合物DOT计算

OAV按照公式(1)计算:

OAV=CiTi (1) DOT按照公式(2)计算:

DOT=CiTi (2) 式中,Ci表示化合物相对含量;Ti表示化合物阈值。

1.3 数据处理

利用Excel软件进行数据统计;TBtools V 1.046进行热图绘制;GraphPad Prsim 9进行绘制柱状图;SPSS19.0进行单因素方差分析(P<0.05);SIMCA 14.0 软件对样品主成分进行正交偏最小二乘判别分析(Orthogonal partial least squares discriminant analysis,OPLS-DA)。

2. 结果与分析

2.1 感官品质分析

不同蒸汽处理样品感官结果显示(表1),蒸汽处理对黑毛茶感官香气和滋味影响较大,与CK相比,CL3、CL4香气风味变纯正、略带有陈香,得分较高,分别为91.0、91.5;CL2、CL3滋味变醇较厚,得分较高,分别为90.0、90.5。综合感官审评结果,三次蒸汽处理更有利于黑毛茶陈化风味的形成。由此表明:蒸汽处理控制在一定程度范围内,能够提升黑毛茶香气和滋味,加快其陈化。

表 1 不同蒸汽处理样品感官审评结果Table 1. Sensory evaluation results of different steam treated samples样品 香气 滋味 得分 评语 得分 评语 CK 89.0 较纯,略闷 88.5 较醇 CL1 89.5 较纯 89.0 较醇 CL2 89.5 较纯 90.0 醇较厚 CL3 91.0 纯正,稍带陈香 90.5 醇较厚 CL4 91.5 纯正,有陈香 87.5 醇和,回口稍薄 2.2 蒸汽处理对黟县黑毛茶香气的影响

2.2.1 蒸汽处理对挥发性化合物的影响

对不同蒸汽处理样品进行GC-MS检测,共鉴定出56种挥发性化合物(表2),包括醛类19种、醇类16种、酮类8种、酯类6种、烯类1种、其他物质6种,其中,46种挥发性化合物为共有化合物,与CK相比,处理样品中新检测到6种香气物质,分别是二氢芳樟醇、苯乙醇、棕榈酸甲酯、奥苷菊环、1-甲基萘和1,2-二羟基萘。醛类、醇类为挥发性化合物的主要成分,占比达到67.87%~73.35%。5类茶样的香气总量约为6337.39~10222.82 μg/kg,其中第一次、第二次蒸汽处理后,香气总量显著降低(P<0.05),而第三次、第四次蒸汽处理后,香气总量显著增加(P<0.05)。

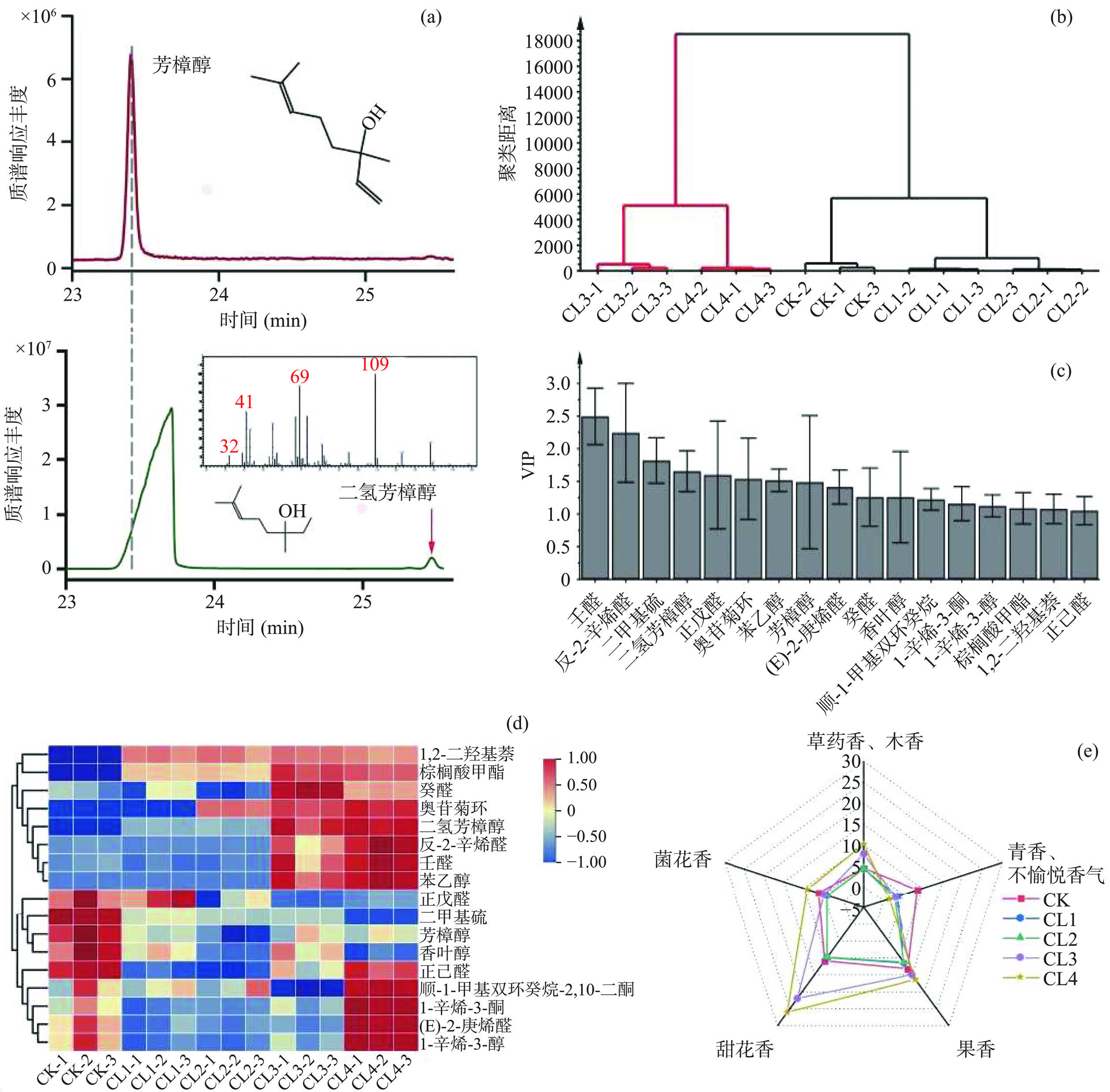

表 2 不同蒸汽处理样品挥发性化合物含量Table 2. Volatile compound content in samples treated with different steam treatments类别 化合物 相对含量(μg/kg) CK CL1 CL2 CL3 CL4 醛类(19) 异戊醛 145.62±2.69ab 135.78±6.47b 142.26±6.70ab 148.99±0.36a 135.41±4.00b 2-甲基丁醛 144.38±4.28a 133.07±6.07b 135.38±5.10ab 137.45±1.75ab 122.94±1.49c 正戊醛 355.89±47.77a 344.26±23.88a 266.53±32.4b 244.61±1.69b 260.54±4.02b 正己醛 235.79±10.22a 141.07±4.92d 131.39±5.15d 177.99±12.22c 215.83±7.44b 庚醛 136.64±8.25a 105.7±3.67c 103.27±1.59c 122.47±4.62b 119.5±1.00b (E)-2-庚烯醛 233.16±29.42b 138.11±19.06c 140.19±8.94c 143.67±8.82c 340.15±13.67a 正辛醛 185.33±8.30b 138.06±6.70c 144.67±7.26c 176.25±15.76b 208.47±2.51a (E,E)-2,4-庚二烯醛 103.88±1.35b 102.18±2.43b 111.18±5.39a 108.58±0.17ab 113.62±1.76a 苯乙醛 121.51±5.46c 111.81±3.72c 114.5±3.53c 174.86±10.97a 141.92±4.84b 反-2-辛烯醛 134.89±9.60c 112.76±7.22c 112.29±4.50c 449.08±93.44b 840.31±165.96a 壬醛 336.2±30.89c 260.02±32.46c 275.19±25.57c 827.13±181.08b 1141.11±133.72a 反式-2-壬醛 104.83±1.65a 100.61±2.97a 100.75±6.58a 103.85±1.83a 106.5±0.72a 藏红花醛 105.06±2.90ab 111.58±5.76a 106.52±3.51ab 104.64±0.32ab 98.99±3.04b 癸醛 177.98±11.31cd 185.47±30.74c 144.88±9.94d 312.23±16.88a 231.77±2.20b β-环柠檬醛 116.82±4.14b 122.67±3.93b 113.47±2.57b 154.41±11.03a 145.52±2.17a 反式-2-癸烯醛 110.23±3.78bc 101.65±3.95c 104.05±2.82c 114.39±7.42b 145.41±0.64a 总计 2845.3±128.19c 2647.6±128.44cd 2246.51±80.06d 3826.97±342.49b 4692.8±281.86a 醇类(16) 1-戊醇 195.91±19.78a 154.34±6.82b 137.06±7.8b 143.93±0.67b 145.22±10.39b 1-辛烯-3-醇 199.99±22.75b 129.07±8.02c 128.94±4.81c 151.03±12.27c 269.19±6.28a 2-乙基己醇 103.86±1.61b 106.28±5.1ab 102.96±3.56b 112.3±2.49a 106.89±1.33ab 反-2-辛烯醇 123.26±6.26b 103.55±1.86c 106.84±1.65c 106.78±0.74c 135.46±1.28a 2-异丙基-5-甲基-1-庚醇 106.31±2.43b 105.5±3.08b 105.19±5.56b 129.15±4.23a 131.48±2.87a 反-Α,Α-5-三甲基-5-乙烯基四氢化-2-呋喃甲醇 108.02±1.68a 103.16±2.3ab 98.61±2.84b 98.69±3.25b 97.79±0.18b 芳樟醇 435.09±65.87a 289.68±8.37b 218.25±27.29b 297.77±24.32b 294.87±15.38b 二氢芳樟醇 0.00±0.00c 126.47±3.73b 127.1±9.44b 370.39±51.12a 395.33±19.50a 苯乙醇 0.00±0.00c 0.00±0.00c 0.00±0.00c 224.84±35.87b 311.34±41.12a 2-癸烯-1-醇 104.29±3.17c 107.55±7.58bc 104.83±2.89c 130.59±0.77b 202.41±21.78a 1-壬醇 113.05±5.21ab 107.99±5.62ab 104.26±4.43b 115.66±1.52a 105.37±4.23ab α-松油醇 102.90±6.63b 102.34±3.57b 102.70±2.38b 114.54±3.04a 118.68±1.54a 香叶醇 252.03±45.33a 180.46±8.96bc 135.96±3.65c 190.55±13.54b 132.77±7.88c 反式-橙花叔醇 97.07±3.03a 98.11±2.46a 97.71±3.94a 106.85±7.63a 99.53±0.56a (+)-雪松醇 117.09±4.30b 118.07±1.15b 121.03±2.55b 171.11±15.64a 155.67±3.57a 叶绿醇 96.31±0.93b 101.04±3.57ab 99.05±2.46ab 145.22±0.47a 103.5±1.31ab 总计 2123.08±184.15b 1933.61±40.77bc 1790.48±49.31c 2609.40±113.62a 2805.49±4.71a 酮类(8) 4-甲基-3戊烯-2-酮 154.22±8.94a 144.63±4.42a 123.48±4.47b 115.65±4.81bc 102.89±4.83c 1-辛烯-3-酮 174.89±18.53b 120.49±9.01c 127.04±2.91c 145.01±14.86c 282.92±9.94a 2,5-辛二酮 126.15±4.22c 158.18±9.02b 139.72±3.87c 137.73±8.2c 167.04±3.8a 2,2,6-三甲基环己酮 112.21±2.48a 111.81±2.33a 108.55±1.98a 111.97±2.23a 118.50±0.16b 茉莉酮 110.58±4.61a 105.09±3.77ab 105.12±1.12ab 107.79±3.55a 99.51±0.06b 香叶基丙酮 128.86±5.12c 135.30±10.04bc 123.20±3.46c 188.91±19.07a 153.63±2.8b 顺-1-甲基双环癸烷-2,10-二酮 184.34±24.72b 170.97±11.88b 172.31±22.22b 112.51±5.96c 236.37±3.87a 植酮 96.39±1.3a 131.77±43.18a 105.29±2.25a 135.29±4.34a 126.44±3.76a 总计 1087.65±52.57b 1078.23±8.59b 1004.71±31.73b 1054.87±53.4b 1287.30±0.76a 酯类(6) 2-甲基-3-氧代丁酸甲酯 132.59±9.50abc 139.22±11.08ab 126.29±5.30bc 146.88±7.52a 120.12±0.76c 己酸叶醇酯 102.51±2.89a 104.53±2.57a 101.95±2.88a 105.44±3.94a 98.93±4.85a 水杨酸异辛酯 100.09±4.62a 103.43±5.49a 103.65±4.40a 109.32±4.29a 110.09±0.16a 邻苯二甲酸二异丁酯 119.03±6.87d 139.54±4.13c 135.59±8.70c 201.96±6.84a 158.75±3.43b 棕榈酸甲酯 0.00±0.00d 100.56±0.69c 99.99±2.76c 132.09±5.29a 123.91±1.96b 邻苯二甲酸二丁酯 106.58±10.04b 116.80±19.16ab 107.98±3.80b 163.73±43.26a 120.49±0.47ab 总计 560.79±6.46c 704.08±37.67b 675.44±9.67b 859.43±71.13a 732.28±3.51b 烯类(1) 2,5,5-三甲基-2-己烯 109.96±1.68b 99.97±1.92c 101.70±1.56c 100.94±0.74c 129.75±3.75a 其他 (6) 二甲基硫 387.49±23.26a 126.02±7.00b 98.00±5.34c 99.16±0.53c 0.00±0.00d 甲氧基苯肟 144.99±8.37a 129.64±4.10b 118.55±2.74c 132.74±2.35b 132.44±0.97b 茶吡咯 91.66±2.06a 99.15±2.60a 100.21±3.49a 104.68±0.57a 106.70±3.60a 奥苷菊环 0.00±0.00d 0.00±0.00d 101.73±2.43c 113.7±3.41b 124.75±4.06a 1-甲基萘 0.00±0.00b 0.00±0.00b 0.00±0.00b 109.05±7.68a 115.01±0.78a 1,2-二羟基萘 0.00±0.00c 100.31±2.29ab 100.06±4.90ab 102.68±1.13a 96.32±2.13b 其他物质 593.58±24.44b 455.12±11.78d 518.55±17.89c 662.01±8.77a 575.21±11.54b 香气总量 7320.37±393.10c 6918.61±214.17cd 6337.39±50.61d 9113.62±590.14b 10222.82±257.59a 注:同行不同小写字母表示样品间存在显著差异,P<0.05;表3同。 不同蒸汽处理的样品中,醛类、醇类及杂环化合物含量变化最大。蒸汽处理后,反-2-辛烯醛、壬醛、癸醛大量增加,芳樟醇、香叶醇、二甲基硫等物质的含量显著减少(P<0.05)。补充实验显示,芳樟醇在蒸汽处理后能够生成二氢芳樟醇(图1a),推测黑毛茶中新生成的二氢芳樟醇,部分来源于芳樟醇的氧化。壬醛的增加可能是蒸汽湿热作用促进了茶叶中油酸降解而生成[16]。二甲基硫被认为是绿茶中关键的香气物质之一[17],呈玉米香味或不愉悦气味[18],在黟县黑毛茶中含量相对较高,蒸汽处理后其含量大量减少,说明蒸汽处理导致呈现绿茶香气风味的物质减少,有助于向陈化香气风味转变。

对挥发性物质进行OPLS-DA分析,拟合参数R2X=0.944,R2Y=0.978,Q2=0.85,200次的交叉检验验证(R2=0.424,Q2=−0.954),Q2回归直线与纵轴的截距小于0,说明模型不存在过度拟合现象,模型较为可靠。聚类结果显示(图1b),CK聚为一类、CL1、CL2聚为一类,CL3与CL4聚为一类,表明不同蒸汽处理,样品香气间有较大差异。以VIP>1且P<0.05,筛选出壬醛、反-2-辛烯醛、奥苷菊环、癸醛、二氢芳樟醇等17种挥发性物质(图1c),是区分不同蒸汽处理样品分类的关键差异香气物质。17种关键差异香气物质热图显示(图1d),蒸汽处理后,正戊醛、芳樟醇、香叶醇、二甲基硫等香气物质含量降低,壬醛、反-2-辛烯醛、奥苷菊环、癸醛、二氢芳樟醇、苯乙醇、1,2-二羟基萘、棕榈酸甲酯等香气物质含量明显增加,(E)-2-庚烯醛、顺-1-甲基双环癸烷-2,10-二酮、1-辛烯-3-酮、1-辛烯-3-醇等香气物质含量先降低、后显著增加(P<0.05)。

2.2.2 关键物质呈香特征变化

挥发性物质对样品香气风味特征的贡献,取决于物质含量和气味阈值[19]。气味阈值是指香气物质能被感知到的最低浓度,香气活度值(OAV)是香气物质含量与气味阈值的比值,表征了香气物质对香气风味的贡献程度[20],当香气物质OAV>1时,被认为是关键香气物质,决定香气风味的类型,0.1<OAV<1时,被定义为修饰性香气物质,对香气风味形成有辅助影响[21]。对鉴定出的56种香气物质进行OAV值和风味特征分析(表3),发现OAV>1的关键香气物质有14种,0.1<OAV<1的修饰性香气物质共有13种。结合关键差异香气物质(VIP>1、P<0.05)分析表明,壬醛、癸醛、1-辛烯-3-醇、1-辛烯-3-酮、二甲基硫、反-2-辛烯醛、正己醛被认为是影响样品间香气风味特征的关键。其中,正己醛、芳樟醇仅在CK中为关键香气物质,蒸汽处理后变为修饰性香气物质,反-2-辛烯醛、β-环柠檬醛在CL3与CL4中变为关键香气物质。

表 3 关键物质香气特征与气味活度值Table 3. Aroma characteristics and odor activity values of substances物质 阈值[22](μg/kg) 香气特征[23] 气味活度值(OAV值) CK CL1 CL2 CL3 CL4 反-2-辛烯醛 3 脂肪和草药,坚果 0.90 0.75 0.75 2.99 5.60 β-环柠檬醛 3 薄荷、果香、木香 0.78 0.82 0.76 1.03 0.97 α-松油醇 4.6 茴香、木香、花香、新鲜 0.45 0.44 0.45 0.50 0.52 (+)-雪松醇 1 木香 2.34 2.36 2.42 3.42 3.11 草药香、木香 4.47 4.37 4.38 7.94 10.20 正戊醛 12 刺激性气味 0.59 0.57 0.44 0.41 0.43 正己醛 4.5 青草气 1.05 0.63 0.58 0.79 0.96 二甲基硫 1.1 不愉悦气味、玉米香 7.05 2.29 1.78 1.80 0.00 青香、不愉悦香气 8.69 3.49 2.80 3.00 1.39 正辛醛 0.7 果香 5.30 3.94 4.13 5.04 5.96 癸醛 3 甜橙和橘子香气 1.19 1.24 0.97 2.08 1.55 反式-2-癸烯醛 0.4 类似甜橙香气, 5.51 5.08 5.20 5.72 7.27 癸醛 3 甜橙和橘子香气 1.19 1.24 0.97 2.08 1.55 果香 13.19 11.5 11.27 14.92 16.33 苯乙醛 4 花香 0.61 0.56 0.57 0.87 0.71 壬醛 1.1 橙子、玫瑰香 6.11 4.73 5.00 15.04 20.75 芳樟醇 6 花香 1.45 0.97 0.73 0.99 0.98 香叶醇 7.5 甜香、玫瑰花香 0.67 0.48 0.36 0.51 0.35 叶绿醇 0.64 雅致的花香、膏香香韵 2.01 3.16 3.10 4.54 3.23 甜花香 10.85 9.9 9.76 21.95 26.02 1-辛烯-3-醇 1 蘑菇、菌花香 4.00 2.58 2.58 3.02 5.38 1-辛烯-3-酮 1.5 蘑菇味,菌花香 2.33 1.61 1.69 1.93 3.77 菌花香 6.33 4.19 4.27 4.95 9.15 基于香气物质呈香特征和OAV值,构建黑毛茶香气风味变化的雷达图(表3、图1e)。与对照组相比,前二次蒸汽处理后,呈现草药香、木香、甜花香、果香等风味特征减少,在第三次、第四次蒸汽处理后明显增加;菌花香风味在第四次蒸汽处理后明显增加,前三次均呈现降低;青草气及不愉悦气味、玉米味(绿茶风味特征)在蒸汽处理后即呈现明显降低。由此表明,第三次、第四次蒸汽处理后,能够明显增加黑毛茶的草药香、木香、甜花香、果香及菌花香,降低青草气及不愉悦香气。

2.3 蒸汽处理对黟县黑毛茶滋味品质的影响

2.3.1 主要滋味物质分析

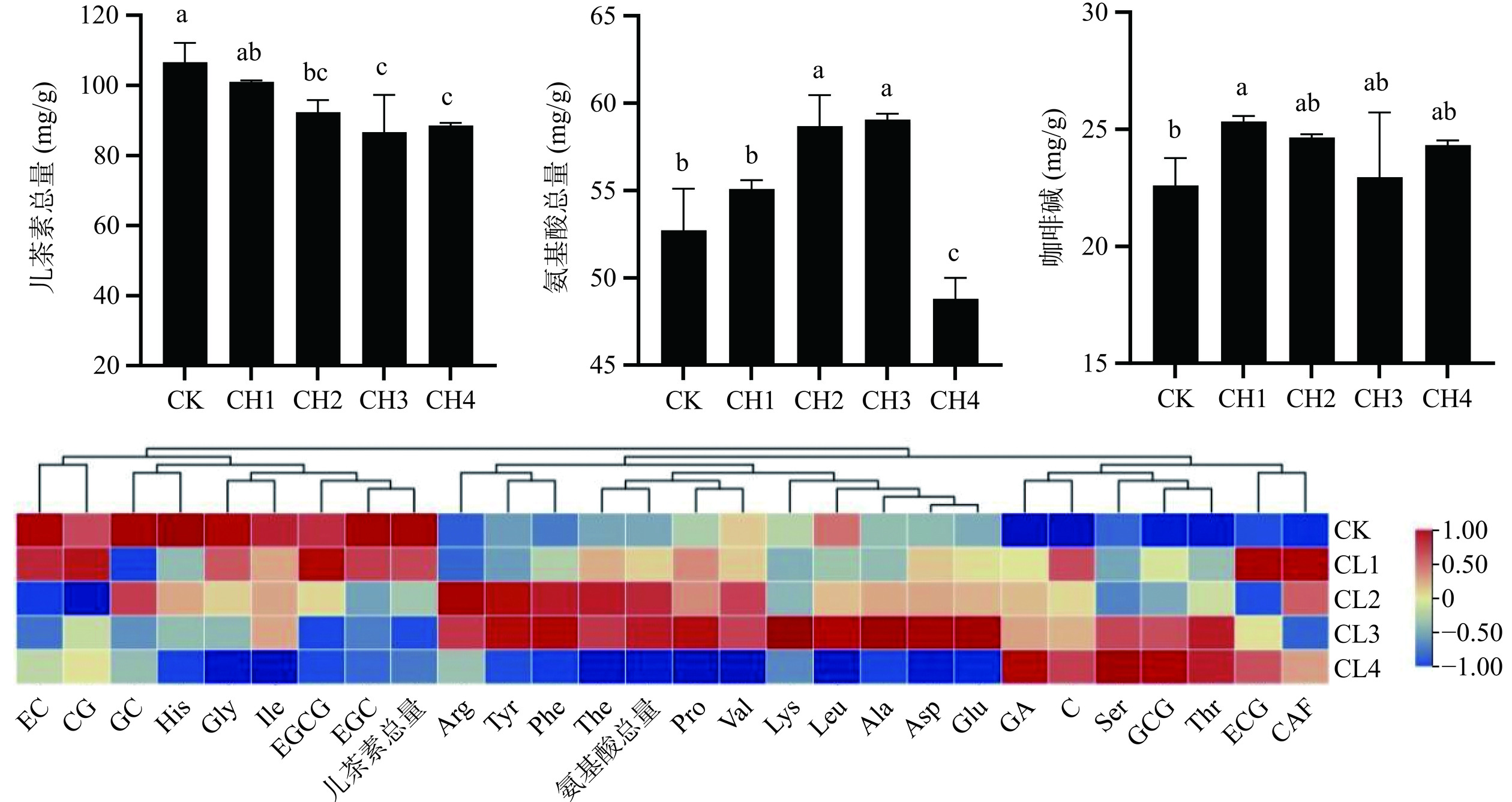

儿茶素、游离氨基酸和咖啡碱是黑毛茶主要滋味物质,图2显示,蒸汽处理后,样品中儿茶素总量明显降低,且第二、三、四次蒸汽处理显著降低(P<0.05);氨基酸总量在第二次、第三次蒸汽处理后显著增加(P<0.05),第四次蒸汽处理后显著降低(P<0.05);CAF含量在第一次蒸汽处理后显著增加(P<0.05),之后未有显著性变化。同时,随着蒸汽次数的增加,表型儿茶素如EGC、EGCG等含量减少,GA、C、GCG等含量增加,这与前人研究结果一致[24],可能由于热处理过程中,部分儿茶素会在黄烷-3-醇的C-2位置发生异构化。同时,Arg、Tyr、The、Phe、Pro、Val、Lys、Leu、Ala、Asp、Glu等在前三次蒸汽处理中含量明显增加,且The含量增加最明显。已有研究报导,黑毛茶在自然存放中,氨基酸含量总体减少,这与本研究中氨基酸含量的变化相反[23]。石碧滢[25]研究了白茶自然贮藏中化合物的变化,发现茶多酚的快速降低以及游离氨基酸的缓慢下降,即酚氨比的降低,能够促使茶汤由清鲜口感向甜、醇、陈等口感转变。由此推测,蒸汽处理后黑毛茶酚氨比值的降低可促使茶汤滋味向甜、醇、陈转变。

2.3.2 蒸汽处理后黑毛茶关键差异物质分析

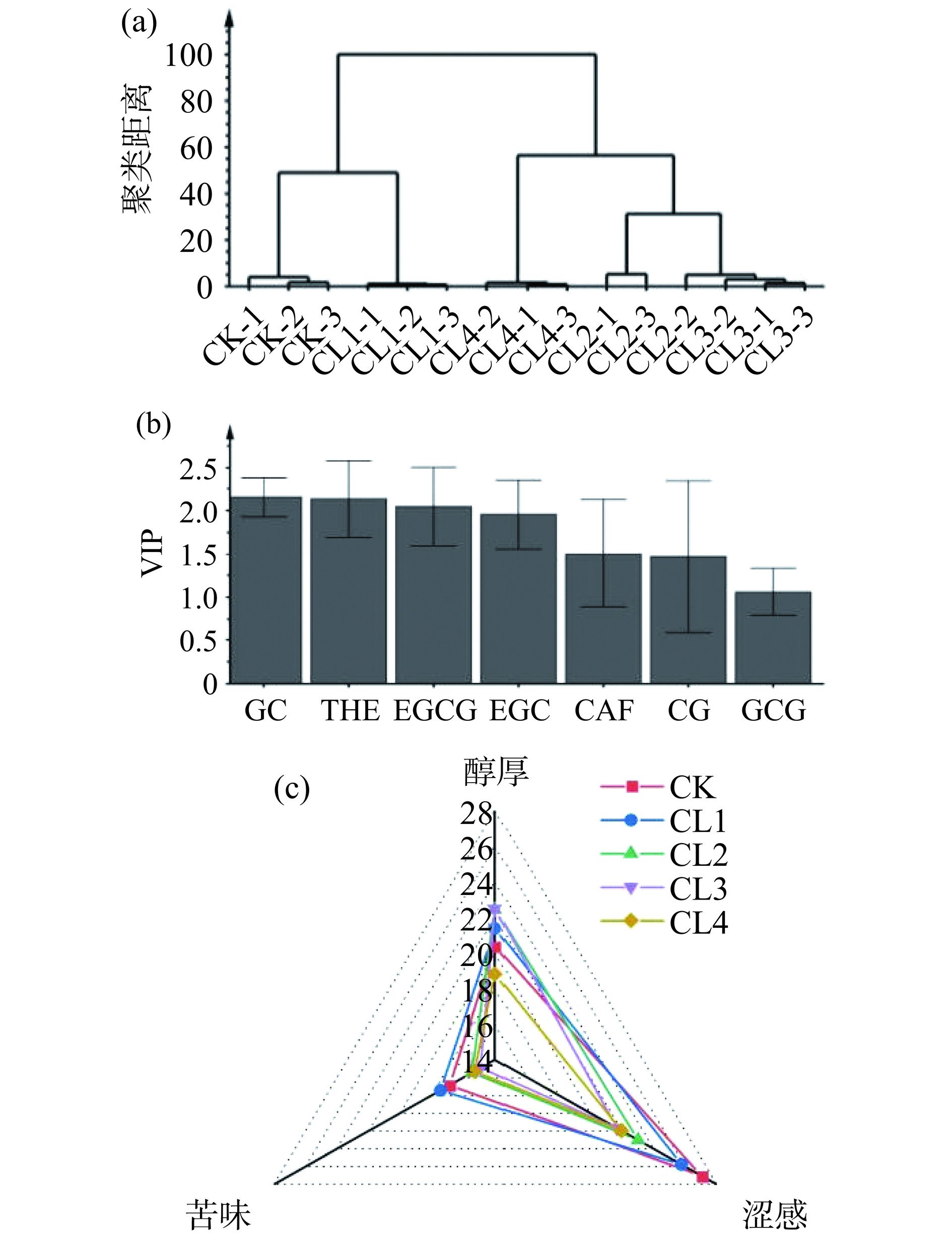

对样品中主要滋味物质进行OPLS-DA分析,拟合参数R2X=0.988,R2Y=0.944,Q2=0.557,200次置换检验(R2=0.391、Q2=−1.39),证明OPLS-DA模型可靠。聚类结果显示(图3a),湿热作用处理的样品分为3类,CK与CL1聚为一类,CL2与CL3聚为一类,CL4聚为一类,表明蒸汽作用导致样品有较大差异。VIP>1显示,GC、THE、EGCG、EGC、CAF、CG、GCG等7种滋味物质(图3b),是区分样品间差异的关键物质。

2.3.3 关键物质滋味特征变化

滋味活度值(DOT值)是用来描述物质呈味强度的指标,它可以用来衡量物质对人味觉感知的程度,通常对滋味特征起决定性作用的是阈值较低的滋味物质[26]。一般认为DOT>1,表示该物质对滋味有显著贡献;当0.1<DOT<1时,可被认为该物质对滋味具有重要的修饰作用[27]。表4是滋味物质的DOT值,结果显示,DOT>1的滋味物质有5种,0.1<DOT<1的滋味物质有8种。结合关键差异代谢物,GC、EGCG、EGC、CAF、CG被认为是影响样品滋味风味变化的关键物质,GCG、THE被认为对样品滋味风味变化具有重要修饰作用。

表 4 样品中主要物质滋味特征与活度值Table 4. Taste characteristics and activity values of the main substances in the sample编号 化合物名称 滋味特征[28] 阈值[29](mg/L) 滋味活度值(DOT) CK CL1 CL2 CL3 CL4 1 GA 涩感 34.00 0.45 0.63 0.65 0.66 0.76 2 GC 苦味 499.22 0.48 0.19 0.41 0.24 0.27 涩感 101.00 2.39 0.92 2.04 1.19 1.34 3 EGC 苦味 498.78 1.17 1.08 0.89 0.86 0.84 涩感 79.56 7.36 6.78 5.56 5.39 5.27 4 C 苦味 249.64 0.16 0.24 0.22 0.22 0.24 涩感 200.29 0.20 0.29 0.27 0.28 0.30 5 EGCG 苦味 100.84 8.12 8.34 7.54 6.69 6.70 涩感 73.34 11.17 11.46 10.36 9.20 9.22 6 EC 苦味 249.63 0.66 0.65 0.57 0.58 0.61 涩感 249.63 0.66 0.65 0.57 0.58 0.61 7 GCG 苦味 151.26 0.21 0.39 0.33 0.49 0.57 涩感 100.84 0.30 0.30 0.30 0.30 0.30 8 ECG 苦味 79.63 0.39 0.43 0.39 0.41 0.42 涩感 59.72 0.52 0.58 0.52 0.54 0.56 9 CG 苦味 75.20 2.68 2.80 1.86 2.38 2.44 涩感 50.87 3.97 4.13 2.75 3.52 3.61 10 咖啡碱 苦味 155.00 2.92 3.27 3.18 2.96 3.14 11 天冬氨酸Asp 鲜醇 530.00 0.104 0.105 0.106 0.109 0.102 12 苏氨酸 Thr 甜醇 4760.00 0.002 0.002 0.002 0.003 0.003 13 丝氨酸 Ser 甜醇 3150.00 0.008 0.008 0.008 0.009 0.009 14 谷氨酸Glu 鲜醇 588.00 0.168 0.171 0.173 0.180 0.164 15 茶氨酸 The 鲜醇 1050.00 0.662 0.712 0.759 0.749 0.600 16 脯氨酸 Pro 甜醇 2990.00 0.003 0.001 0.003 0.003 0.003 17 甘氨酸 Gly 甜醇 2630.00 0.002 0.002 0.002 0.001 0.001 18 丙氨酸 Ala 甜醇 1070.00 0.013 0.013 0.014 0.014 0.013 19 缬氨酸 Val 苦味 2340.00 0.004 0.004 0.004 0.004 0.004 20 异亮氨酸 Ile 苦味 1310.00 0.018 0.017 0.017 0.017 0.012 21 亮氨酸 Leu 苦味 1300.00 0.017 0.017 0.017 0.018 0.015 22 酪氨酸 Tyr 苦味 725.00 0.008 0.009 0.010 0.010 0.008 23 苯丙氨酸 Phe 苦味 9600.00 0.002 0.002 0.002 0.002 0.002 24 组氨酸 His 苦味 6980.00 0.0005 0.0004 0.0004 0.0004 0.0003 25 赖氨酸 Lys 苦味 11700.00 0.002 0.002 0.002 0.003 0.001 26 精氨酸 Arg 苦味 12200.00 0.003 0.003 0.004 0.004 0.004 27 氨基酸总量

(DOT总值)醇厚 − 1.02 1.07 1.12 1.12 0.94 内含成分的DOT值和呈味特征体现了对滋味风味的贡献。以DOT值和呈味特征,构建蒸汽处理后滋味风味变化的雷达图(图3c)。与CK相比,蒸汽处理后CL2、CL3、CL4苦味和涩感呈现明显降低,CL2、CL3醇厚滋味增加,CL4醇厚滋味低于对照,说明本研究中第二次和第三次蒸汽处理后滋味更优。

3. 讨论

黑茶自然陈化后主要呈现药香、木香、陈香、菌香等特征。本研究发现,蒸汽处理后,带有草药香、花果香、菌花香等香气风味的物质含量增加,特别是壬醛、癸醛、1-辛烯-3-醇、1-辛烯-3-酮、二甲基硫、反-2-辛烯醛、正己醛等对香气风味的改变具有重要作用。壬醛、癸醛被认为是蒸汽处理导致甜花香、果香增加的关键,1-辛烯-3-醇、1-辛烯-3-酮是导致菌花香增加的关键,反-2-辛烯醛是导致草药香增加的关键,正己醛、二甲基硫是青草气及不愉悦香气降低的关键。谌滢[4]在黑茶陈化研究中指出,陈化后以果香、花香和木香为主的醇类、醛类、酮类物质增加,特征性香气物质为雪松醇、己醛、辛醛、壬醛、(E)-2-辛烯醛、癸醛、苯甲醛、2,3-辛二酮等。舒娜[30]在六堡茶关键风味物质研究中,指出1-辛烯-3-醇是“菌香型”关键香气物质。这与本研究的结果具有一定的相似性。研究表明,蒸汽处理中二氢芳樟醇增加来源于芳樟醇,醛类物质增加可能来源于油脂氧化。刘盼盼[31]在青砖茶特征香气形成机制研究中,指出青砖茶从陈化到成品茶,脂肪酸降解,并以α-亚麻酸和亚油酸作为目标脂质前体物,模拟渥堆发酵参数作为反应条件,经过GC-MS检测与鉴定分析,检测出反-2-辛烯醛、壬醛、1-辛烯-3-醇。因此,蒸汽中的高湿热易导致油酸自氧化与降解[32],形成壬醛、癸醛、反-2-辛烯醛与1-辛烯-3-醇的[33],后者进一步氧化能够形成1-辛烯-3-酮[34]。

自然陈化对黑茶的主要滋味成分有显著影响,形成了独特的“陈醇润活”的滋味特征[35],其中,呈味物质的含量、比例与滋味风味形成密切相关[36]。本研究发现,蒸汽处理能够显著降低儿茶素类物质含量,增加游离氨基酸含量,滋味向醇厚变化。其中,GC、EGCG、EGC、CAF、CG、GCG、The被认为是影响样品滋味变化的关键因子。研究表明,GC、EGCG、EGC、CG、GCG等主要与苦涩有关[37],花果香红茶在贮藏中游离氨基酸及其衍生物含量的减少,是茶汤鲜爽味、浓厚度降低的重要原因[38]。同时,也有研究发现EGC与回甘有关[39]。但茶的回甘,一般指喝茶苦涩感之后,口腔和喉咙中持续感受到回甜,并伴有唾液分泌的感觉[40],目前尚不清楚具体哪些物质赋予了茶汤回甘。吴俊等[41]在武夷岩茶的贮藏研究中,岩茶贮藏中酸味有增加,但滋味与感官特征相关性分析,并未显示没食子酸与酸味有显著相关性。同时,岩茶贮藏中可溶性糖和黄酮含量显著升高,与滋味的变化有相关性。因而蒸汽处理对黑毛茶中非主要滋味物质含量的影响如何,还有待进一步探究。

4. 结论

本文研究了蒸汽处理对黟县黑毛茶风味品质的影响,发现蒸汽处理能够快速黑毛茶陈化,降低渥堆带来的闷味,使黑毛茶向陈香和醇厚风味变化。物质变化显示,蒸汽处理能够促使具有花香、甜香风味的壬醛、反-2-辛烯醛、二氢芳樟醇大量增加,且在第三次、四次蒸汽处理中香气物质变化最剧烈,其中,二氢芳樟醇部分来源于芳樟醇湿热氧化,壬醛、反-2-辛烯醛可能来源于油脂的氧化。蒸汽处理使黑毛茶中儿茶素总量显著降低(P<0.05),游离氨基酸总量在前三次蒸汽处理中显著增加(P<0.05),且THE增加最多。OPLS-DA结果显示,壬醛、癸醛、1-辛烯-3-醇、1-辛烯-3-酮、二甲基硫、反-2-辛烯醛、正己醛等是影响样品间香气风味变化的重要因子,GC、EGCG、EGC、CAF、CG、GCG、The是影响样品间滋味变化的重要因子。综上所述,三次蒸汽处理后黑毛茶风味品质更佳。本文为探究蒸汽处理对黟县黑毛茶风味品质的提升提供了科学见解,表明适度利用蒸汽作用,能够达到黑毛茶快速陈化的目的,这为加快黟县黑毛茶陈化提供一种可用的新技术方法。但蒸汽处理对黑毛茶物质转化形成的机理尚不清晰,如何控制好蒸汽处理黑毛茶,还有待深入探究。

-

表 1 不同蒸汽处理样品感官审评结果

Table 1 Sensory evaluation results of different steam treated samples

样品 香气 滋味 得分 评语 得分 评语 CK 89.0 较纯,略闷 88.5 较醇 CL1 89.5 较纯 89.0 较醇 CL2 89.5 较纯 90.0 醇较厚 CL3 91.0 纯正,稍带陈香 90.5 醇较厚 CL4 91.5 纯正,有陈香 87.5 醇和,回口稍薄 表 2 不同蒸汽处理样品挥发性化合物含量

Table 2 Volatile compound content in samples treated with different steam treatments

类别 化合物 相对含量(μg/kg) CK CL1 CL2 CL3 CL4 醛类(19) 异戊醛 145.62±2.69ab 135.78±6.47b 142.26±6.70ab 148.99±0.36a 135.41±4.00b 2-甲基丁醛 144.38±4.28a 133.07±6.07b 135.38±5.10ab 137.45±1.75ab 122.94±1.49c 正戊醛 355.89±47.77a 344.26±23.88a 266.53±32.4b 244.61±1.69b 260.54±4.02b 正己醛 235.79±10.22a 141.07±4.92d 131.39±5.15d 177.99±12.22c 215.83±7.44b 庚醛 136.64±8.25a 105.7±3.67c 103.27±1.59c 122.47±4.62b 119.5±1.00b (E)-2-庚烯醛 233.16±29.42b 138.11±19.06c 140.19±8.94c 143.67±8.82c 340.15±13.67a 正辛醛 185.33±8.30b 138.06±6.70c 144.67±7.26c 176.25±15.76b 208.47±2.51a (E,E)-2,4-庚二烯醛 103.88±1.35b 102.18±2.43b 111.18±5.39a 108.58±0.17ab 113.62±1.76a 苯乙醛 121.51±5.46c 111.81±3.72c 114.5±3.53c 174.86±10.97a 141.92±4.84b 反-2-辛烯醛 134.89±9.60c 112.76±7.22c 112.29±4.50c 449.08±93.44b 840.31±165.96a 壬醛 336.2±30.89c 260.02±32.46c 275.19±25.57c 827.13±181.08b 1141.11±133.72a 反式-2-壬醛 104.83±1.65a 100.61±2.97a 100.75±6.58a 103.85±1.83a 106.5±0.72a 藏红花醛 105.06±2.90ab 111.58±5.76a 106.52±3.51ab 104.64±0.32ab 98.99±3.04b 癸醛 177.98±11.31cd 185.47±30.74c 144.88±9.94d 312.23±16.88a 231.77±2.20b β-环柠檬醛 116.82±4.14b 122.67±3.93b 113.47±2.57b 154.41±11.03a 145.52±2.17a 反式-2-癸烯醛 110.23±3.78bc 101.65±3.95c 104.05±2.82c 114.39±7.42b 145.41±0.64a 总计 2845.3±128.19c 2647.6±128.44cd 2246.51±80.06d 3826.97±342.49b 4692.8±281.86a 醇类(16) 1-戊醇 195.91±19.78a 154.34±6.82b 137.06±7.8b 143.93±0.67b 145.22±10.39b 1-辛烯-3-醇 199.99±22.75b 129.07±8.02c 128.94±4.81c 151.03±12.27c 269.19±6.28a 2-乙基己醇 103.86±1.61b 106.28±5.1ab 102.96±3.56b 112.3±2.49a 106.89±1.33ab 反-2-辛烯醇 123.26±6.26b 103.55±1.86c 106.84±1.65c 106.78±0.74c 135.46±1.28a 2-异丙基-5-甲基-1-庚醇 106.31±2.43b 105.5±3.08b 105.19±5.56b 129.15±4.23a 131.48±2.87a 反-Α,Α-5-三甲基-5-乙烯基四氢化-2-呋喃甲醇 108.02±1.68a 103.16±2.3ab 98.61±2.84b 98.69±3.25b 97.79±0.18b 芳樟醇 435.09±65.87a 289.68±8.37b 218.25±27.29b 297.77±24.32b 294.87±15.38b 二氢芳樟醇 0.00±0.00c 126.47±3.73b 127.1±9.44b 370.39±51.12a 395.33±19.50a 苯乙醇 0.00±0.00c 0.00±0.00c 0.00±0.00c 224.84±35.87b 311.34±41.12a 2-癸烯-1-醇 104.29±3.17c 107.55±7.58bc 104.83±2.89c 130.59±0.77b 202.41±21.78a 1-壬醇 113.05±5.21ab 107.99±5.62ab 104.26±4.43b 115.66±1.52a 105.37±4.23ab α-松油醇 102.90±6.63b 102.34±3.57b 102.70±2.38b 114.54±3.04a 118.68±1.54a 香叶醇 252.03±45.33a 180.46±8.96bc 135.96±3.65c 190.55±13.54b 132.77±7.88c 反式-橙花叔醇 97.07±3.03a 98.11±2.46a 97.71±3.94a 106.85±7.63a 99.53±0.56a (+)-雪松醇 117.09±4.30b 118.07±1.15b 121.03±2.55b 171.11±15.64a 155.67±3.57a 叶绿醇 96.31±0.93b 101.04±3.57ab 99.05±2.46ab 145.22±0.47a 103.5±1.31ab 总计 2123.08±184.15b 1933.61±40.77bc 1790.48±49.31c 2609.40±113.62a 2805.49±4.71a 酮类(8) 4-甲基-3戊烯-2-酮 154.22±8.94a 144.63±4.42a 123.48±4.47b 115.65±4.81bc 102.89±4.83c 1-辛烯-3-酮 174.89±18.53b 120.49±9.01c 127.04±2.91c 145.01±14.86c 282.92±9.94a 2,5-辛二酮 126.15±4.22c 158.18±9.02b 139.72±3.87c 137.73±8.2c 167.04±3.8a 2,2,6-三甲基环己酮 112.21±2.48a 111.81±2.33a 108.55±1.98a 111.97±2.23a 118.50±0.16b 茉莉酮 110.58±4.61a 105.09±3.77ab 105.12±1.12ab 107.79±3.55a 99.51±0.06b 香叶基丙酮 128.86±5.12c 135.30±10.04bc 123.20±3.46c 188.91±19.07a 153.63±2.8b 顺-1-甲基双环癸烷-2,10-二酮 184.34±24.72b 170.97±11.88b 172.31±22.22b 112.51±5.96c 236.37±3.87a 植酮 96.39±1.3a 131.77±43.18a 105.29±2.25a 135.29±4.34a 126.44±3.76a 总计 1087.65±52.57b 1078.23±8.59b 1004.71±31.73b 1054.87±53.4b 1287.30±0.76a 酯类(6) 2-甲基-3-氧代丁酸甲酯 132.59±9.50abc 139.22±11.08ab 126.29±5.30bc 146.88±7.52a 120.12±0.76c 己酸叶醇酯 102.51±2.89a 104.53±2.57a 101.95±2.88a 105.44±3.94a 98.93±4.85a 水杨酸异辛酯 100.09±4.62a 103.43±5.49a 103.65±4.40a 109.32±4.29a 110.09±0.16a 邻苯二甲酸二异丁酯 119.03±6.87d 139.54±4.13c 135.59±8.70c 201.96±6.84a 158.75±3.43b 棕榈酸甲酯 0.00±0.00d 100.56±0.69c 99.99±2.76c 132.09±5.29a 123.91±1.96b 邻苯二甲酸二丁酯 106.58±10.04b 116.80±19.16ab 107.98±3.80b 163.73±43.26a 120.49±0.47ab 总计 560.79±6.46c 704.08±37.67b 675.44±9.67b 859.43±71.13a 732.28±3.51b 烯类(1) 2,5,5-三甲基-2-己烯 109.96±1.68b 99.97±1.92c 101.70±1.56c 100.94±0.74c 129.75±3.75a 其他 (6) 二甲基硫 387.49±23.26a 126.02±7.00b 98.00±5.34c 99.16±0.53c 0.00±0.00d 甲氧基苯肟 144.99±8.37a 129.64±4.10b 118.55±2.74c 132.74±2.35b 132.44±0.97b 茶吡咯 91.66±2.06a 99.15±2.60a 100.21±3.49a 104.68±0.57a 106.70±3.60a 奥苷菊环 0.00±0.00d 0.00±0.00d 101.73±2.43c 113.7±3.41b 124.75±4.06a 1-甲基萘 0.00±0.00b 0.00±0.00b 0.00±0.00b 109.05±7.68a 115.01±0.78a 1,2-二羟基萘 0.00±0.00c 100.31±2.29ab 100.06±4.90ab 102.68±1.13a 96.32±2.13b 其他物质 593.58±24.44b 455.12±11.78d 518.55±17.89c 662.01±8.77a 575.21±11.54b 香气总量 7320.37±393.10c 6918.61±214.17cd 6337.39±50.61d 9113.62±590.14b 10222.82±257.59a 注:同行不同小写字母表示样品间存在显著差异,P<0.05;表3同。 表 3 关键物质香气特征与气味活度值

Table 3 Aroma characteristics and odor activity values of substances

物质 阈值[22](μg/kg) 香气特征[23] 气味活度值(OAV值) CK CL1 CL2 CL3 CL4 反-2-辛烯醛 3 脂肪和草药,坚果 0.90 0.75 0.75 2.99 5.60 β-环柠檬醛 3 薄荷、果香、木香 0.78 0.82 0.76 1.03 0.97 α-松油醇 4.6 茴香、木香、花香、新鲜 0.45 0.44 0.45 0.50 0.52 (+)-雪松醇 1 木香 2.34 2.36 2.42 3.42 3.11 草药香、木香 4.47 4.37 4.38 7.94 10.20 正戊醛 12 刺激性气味 0.59 0.57 0.44 0.41 0.43 正己醛 4.5 青草气 1.05 0.63 0.58 0.79 0.96 二甲基硫 1.1 不愉悦气味、玉米香 7.05 2.29 1.78 1.80 0.00 青香、不愉悦香气 8.69 3.49 2.80 3.00 1.39 正辛醛 0.7 果香 5.30 3.94 4.13 5.04 5.96 癸醛 3 甜橙和橘子香气 1.19 1.24 0.97 2.08 1.55 反式-2-癸烯醛 0.4 类似甜橙香气, 5.51 5.08 5.20 5.72 7.27 癸醛 3 甜橙和橘子香气 1.19 1.24 0.97 2.08 1.55 果香 13.19 11.5 11.27 14.92 16.33 苯乙醛 4 花香 0.61 0.56 0.57 0.87 0.71 壬醛 1.1 橙子、玫瑰香 6.11 4.73 5.00 15.04 20.75 芳樟醇 6 花香 1.45 0.97 0.73 0.99 0.98 香叶醇 7.5 甜香、玫瑰花香 0.67 0.48 0.36 0.51 0.35 叶绿醇 0.64 雅致的花香、膏香香韵 2.01 3.16 3.10 4.54 3.23 甜花香 10.85 9.9 9.76 21.95 26.02 1-辛烯-3-醇 1 蘑菇、菌花香 4.00 2.58 2.58 3.02 5.38 1-辛烯-3-酮 1.5 蘑菇味,菌花香 2.33 1.61 1.69 1.93 3.77 菌花香 6.33 4.19 4.27 4.95 9.15 表 4 样品中主要物质滋味特征与活度值

Table 4 Taste characteristics and activity values of the main substances in the sample

编号 化合物名称 滋味特征[28] 阈值[29](mg/L) 滋味活度值(DOT) CK CL1 CL2 CL3 CL4 1 GA 涩感 34.00 0.45 0.63 0.65 0.66 0.76 2 GC 苦味 499.22 0.48 0.19 0.41 0.24 0.27 涩感 101.00 2.39 0.92 2.04 1.19 1.34 3 EGC 苦味 498.78 1.17 1.08 0.89 0.86 0.84 涩感 79.56 7.36 6.78 5.56 5.39 5.27 4 C 苦味 249.64 0.16 0.24 0.22 0.22 0.24 涩感 200.29 0.20 0.29 0.27 0.28 0.30 5 EGCG 苦味 100.84 8.12 8.34 7.54 6.69 6.70 涩感 73.34 11.17 11.46 10.36 9.20 9.22 6 EC 苦味 249.63 0.66 0.65 0.57 0.58 0.61 涩感 249.63 0.66 0.65 0.57 0.58 0.61 7 GCG 苦味 151.26 0.21 0.39 0.33 0.49 0.57 涩感 100.84 0.30 0.30 0.30 0.30 0.30 8 ECG 苦味 79.63 0.39 0.43 0.39 0.41 0.42 涩感 59.72 0.52 0.58 0.52 0.54 0.56 9 CG 苦味 75.20 2.68 2.80 1.86 2.38 2.44 涩感 50.87 3.97 4.13 2.75 3.52 3.61 10 咖啡碱 苦味 155.00 2.92 3.27 3.18 2.96 3.14 11 天冬氨酸Asp 鲜醇 530.00 0.104 0.105 0.106 0.109 0.102 12 苏氨酸 Thr 甜醇 4760.00 0.002 0.002 0.002 0.003 0.003 13 丝氨酸 Ser 甜醇 3150.00 0.008 0.008 0.008 0.009 0.009 14 谷氨酸Glu 鲜醇 588.00 0.168 0.171 0.173 0.180 0.164 15 茶氨酸 The 鲜醇 1050.00 0.662 0.712 0.759 0.749 0.600 16 脯氨酸 Pro 甜醇 2990.00 0.003 0.001 0.003 0.003 0.003 17 甘氨酸 Gly 甜醇 2630.00 0.002 0.002 0.002 0.001 0.001 18 丙氨酸 Ala 甜醇 1070.00 0.013 0.013 0.014 0.014 0.013 19 缬氨酸 Val 苦味 2340.00 0.004 0.004 0.004 0.004 0.004 20 异亮氨酸 Ile 苦味 1310.00 0.018 0.017 0.017 0.017 0.012 21 亮氨酸 Leu 苦味 1300.00 0.017 0.017 0.017 0.018 0.015 22 酪氨酸 Tyr 苦味 725.00 0.008 0.009 0.010 0.010 0.008 23 苯丙氨酸 Phe 苦味 9600.00 0.002 0.002 0.002 0.002 0.002 24 组氨酸 His 苦味 6980.00 0.0005 0.0004 0.0004 0.0004 0.0003 25 赖氨酸 Lys 苦味 11700.00 0.002 0.002 0.002 0.003 0.001 26 精氨酸 Arg 苦味 12200.00 0.003 0.003 0.004 0.004 0.004 27 氨基酸总量

(DOT总值)醇厚 − 1.02 1.07 1.12 1.12 0.94 -

[1] 夏涛. 制茶学[M]. 第三版. 北京:中国农业出版社, 2015:151−153. [XIA T. Tea making[M]. Third Edition. Beijing:China Agricultural Press, 2015:151−153.] XIA T. Tea making[M]. Third Edition. Beijing: China Agricultural Press, 2015: 151−153.

[2] 沈杉杉, 宁井铭. 黑茶贮藏过程中品质变化规律研究进展[J]. 茶业通报,2022,44(3):112−117. [SHEN B B, NING J M. Research progress on the change rule of black tea quality in storage process[J]. Journal of Tea Business,2022,44(3):112−117.] SHEN B B, NING J M. Research progress on the change rule of black tea quality in storage process[J]. Journal of Tea Business, 2022, 44(3): 112−117.

[3] 王辉, 刘亚芹, 雷攀登, 等. 渥堆对黑茶色泽形成的作用及适度判别分析[J]. 中国茶叶加工,2022(4):29−38. [WANG H, LIU Y Q, LEI P D, et al. Effect of pile-fermentation on the color formation of dark tea and its moderate discrimination analysis[J]. China Tea Processing,2022(4):29−38.] WANG H, LIU Y Q, LEI P D, et al. Effect of pile-fermentation on the color formation of dark tea and its moderate discrimination analysis[J]. China Tea Processing, 2022(4): 29−38.

[4] 谌滢. 黑茶陈化过程中品质转化研究[D]. 长沙:湖南农业大学, 2018. [SHEN Y. The research on quality variationof aging Dark tea[D]. Changsha:Hunan Agricultural University, 2018.] SHEN Y. The research on quality variationof aging Dark tea[D]. Changsha: Hunan Agricultural University, 2018.

[5] DU L P, LI J X, LI W, et al. Characterization of volatile compounds of Pu-erh tea using solid-phase microextraction and simultaneous distillation-extraction coupled with gas chromatography-mass spectrometry[J]. Food Research International,2014,57:61−70. doi: 10.1016/j.foodres.2014.01.008

[6] XU S S, WANG J J, WEI Y M, et al. Metabolomics based on UHPLC-Orbitrap-MS and global natural product social molecular networking reveals effects of time scale and environment of storage on the metabolites and taste quality of raw Pu-erh tea[J]. Journal of Agricultural and Food Chemistry,2019,67(43):12084−12093. doi: 10.1021/acs.jafc.9b05314

[7] 李适, 谌滢, 傅冬和, 等. 不同年份茯砖茶感官品质研究[J]. 茶叶科学,2016,36(5):500−504. [LI S, SHEN Y, FU D H, et al. Organoleptic quality analysis of fuzhuan brick teas in different storage years[J]. Journal of Tea Science,2016,36(5):500−504.] LI S, SHEN Y, FU D H, et al. Organoleptic quality analysis of fuzhuan brick teas in different storage years[J]. Journal of Tea Science, 2016, 36(5): 500−504.

[8] 念晓. 干仓贮藏与湿仓贮藏对普洱茶化学成分的影响[J]. 广东化工,2018,45(3):60−61. [NIAN X. The influence of dry storage and wet storage on the chemical compositions of Pu'er tea[J]. Guangdong Chemical Industry,2018,45(3):60−61.] doi: 10.3969/j.issn.1007-1865.2018.03.029 NIAN X. The influence of dry storage and wet storage on the chemical compositions of Pu'er tea[J]. Guangdong Chemical Industry, 2018, 45(3): 60−61. doi: 10.3969/j.issn.1007-1865.2018.03.029

[9] 许腾升, 刘洋, 李亚莉, 等. 不同仓储地区普洱茶品质差异研究[J]. 保鲜与加工,2016,16(4):89−93,98. [XU T S, LIU Y, LI Y L, et al. Quality difference of Pu-erh tea in different preservation areas[J]. Storage and Process,2016,16(4):89−93,98.] XU T S, LIU Y, LI Y L, et al. Quality difference of Pu-erh tea in different preservation areas[J]. Storage and Process, 2016, 16(4): 89−93,98.

[10] 谌滢, 李适, 刘仲华, 等. 黑茶陈化机制研究进展[J]. 湖南农业科学,2016(12):118−122. [CHEN Y, LI S, LIU Z H, et al. Research progress on aging mechanism of black tea[J]. Hunan Agricultural Sciences,2016(12):118−122.] CHEN Y, LI S, LIU Z H, et al. Research progress on aging mechanism of black tea[J]. Hunan Agricultural Sciences, 2016(12): 118−122.

[11] HAN Z X, RANA M M, LIU G F, et al. Green tea flavour determinants and their changes over manufacturing processes[J]. Food Chemistry,2016,212(1):739−748.

[12] XU Y J, LIU Y Q, YANG J H, et al. Manufacturing process differences give Keemun dark teas their distinctive aromas[J]. Food Chemistry:X,2023,19:100865.

[13] 张晓磊, 周汉琛, 刘亚芹, 等. 基于代谢组学分析低温烘焙对白化品种绿茶风味品质的影响[J]. 食品工业科技,2024,45(17):1−11. [ZHANG X L, ZHOU H C, LIU Y Q, et al. Metabolomics analysis of effects of low-temperature baking on the flavor of albino green tea[J]. Science and Technology of Food Industry,2024,45(17):1−11.] ZHANG X L, ZHOU H C, LIU Y Q, et al. Metabolomics analysis of effects of low-temperature baking on the flavor of albino green tea[J]. Science and Technology of Food Industry, 2024, 45(17): 1−11.

[14] 刘亚芹, 王辉, 杨霁虹, 等. 基于滋味成分变化的祁门红茶发酵程度差异研究[J]. 茶叶通讯,2022,49(2):193−201. [LIU Y Q, WANG H, YANG J H, et al. Research on the difference of the fermentation degree of keemun dark tea based on the changes of taste components[J]. Journal of Tea Communication,2022,49(2):193−201.] LIU Y Q, WANG H, YANG J H, et al. Research on the difference of the fermentation degree of keemun dark tea based on the changes of taste components[J]. Journal of Tea Communication, 2022, 49(2): 193−201.

[15] YANG J H, ZHOU H C, LIU Y Q, et al. Chemical constituents of green teas processed from albino tea cultivars with white and yellow shoots[J]. Food Chemistry: Molecular Sciences, 2022, 5: 100-143.

[16] 查旻昱, 吴悠, 张梁, 等. 茶叶中挥发性香气物质研究进展[J]. 食品安全质量检测学报,2020,13(11):4299−4302. [ZHA M Y, WU Y, ZHANG L. Research advances on volatile aroma compounds of tea[J]. Journal of Food Safety and Quality,2020,13(11):4299−4302.] ZHA M Y, WU Y, ZHANG L. Research advances on volatile aroma compounds of tea[J]. Journal of Food Safety and Quality, 2020, 13(11): 4299−4302.

[17] 舒畅. 龙井茶特征香气成分分析与鉴定研究[D]. 上海:上海应用技术学院, 2016. [SHU C. Characterization of aroma-active components of longjing tea[D]. Shanghai:Shanghai Institute of Technology, 2016.] SHU C. Characterization of aroma-active components of longjing tea[D]. Shanghai: Shanghai Institute of Technology, 2016.

[18] 刘爱杰, 殷刚, 曹莉莉. 啤酒中二甲基硫的形成与控制探讨[J]. 啤酒科技,2007(10):49−51. [LIU A J, YIN G, CAO L L. Discussion on the formation and control of dimethyl sulfur in beer[J]. Beer Science and Technology,2007(10):49−51.] LIU A J, YIN G, CAO L L. Discussion on the formation and control of dimethyl sulfur in beer[J]. Beer Science and Technology, 2007(10): 49−51.

[19] 罗红玉, 王奕, 谷雨, 等. 干燥工艺对重庆沱茶及其毛茶风味品质的影响[J]. 食品科学,2022,43(22):259−266. [LUO H Y, WANG Y, GU Y, et al. Effect of drying process on the flavor quality of chongqing tuo tea and crude tea for making it[J]. Food Science,2022,43(22):259−266.] LUO H Y, WANG Y, GU Y, et al. Effect of drying process on the flavor quality of chongqing tuo tea and crude tea for making it[J]. Food Science, 2022, 43(22): 259−266.

[20] 李扬, 李妍, 李栋, 等. 基于OAV和嗅闻技术分析乳脂的关键风味化合物[J]. 食品科学,2023,44(6):262−267. [LI Y, LI Y, LI D, et al. Analysis of key flavor compounds in dairy fat products using relative odor activity value and olfactometry[J]. Food Science,2023,44(6):262−267.] LI Y, LI Y, LI D, et al. Analysis of key flavor compounds in dairy fat products using relative odor activity value and olfactometry[J]. Food Science, 2023, 44(6): 262−267.

[21] YANG Y Q, ZHU H K, CHEN J Y, et al. Characterization of the key aroma compounds in dark teas with different aroma types by using gas chromatography electronic nose, gas chromatography-ion mobility spectrometry, and odor activity value analysis[J]. LWT-Food Science and Technology,2022,163:113492. doi: 10.1016/j.lwt.2022.113492

[22] FENG Z H, LI M, LI Y F, et al. Characterization of the key aroma compounds in infusions of four white teas by the sensomics approach[J]. European Food Research and Technology,2022,248(5):1299−1309. doi: 10.1007/s00217-022-03967-3

[23] 谢娇枚. 黑毛茶存放过程中品质化学研究[D]. 长沙:湖南农业大学, 2013. [XIE J M. Studies on the chemical quality of raw dark tea during storage[D]. Changsha:Hunan Agricultural University, 2013.] XIE J M. Studies on the chemical quality of raw dark tea during storage[D]. Changsha: Hunan Agricultural University, 2013.

[24] WU L Y, HUANG X J, LIU S R, et al. Understanding the formation mechanism of Oolong tea characteristic non-volatile chemical constitutes during manufacture process by using integrated widely-targed metabolome and DIA proteome analysis[J]. Food Chemistry,2020,310:125941. doi: 10.1016/j.foodchem.2019.125941

[25] 石碧滢, 周承哲, 田采云, 等. 不同贮藏时间白牡丹茶风味品质差异分析[J]. 食品科学,2023,44(14):313−325. [SHI B Y, ZHOU C Z, TIAN C Y, et al. Differences in flavor quality between white peony tea with different storage times[J]. Food Science,2023,44(14):313−325.] SHI B Y, ZHOU C Z, TIAN C Y, et al. Differences in flavor quality between white peony tea with different storage times[J]. Food Science, 2023, 44(14): 313−325.

[26] 黄藩, 罗凡, 胥亚琼, 等. 四川绿茶滋味品质分析及风味轮构建[J]. 西南农业学报,2023,36(5):943−951. [HUANG F, LUO F, XU Y Q, et al. Taste quality analysis and flavor wheel establishment of Sichuan green tea[J]. Southwest China Journal of Agricultural Sciences,2023,36(5):943−951.] HUANG F, LUO F, XU Y Q, et al. Taste quality analysis and flavor wheel establishment of Sichuan green tea[J]. Southwest China Journal of Agricultural Sciences, 2023, 36(5): 943−951.

[27] 李翔, 许彦, 冯婷婷, 等. 基于滋味品质的万州区主栽茶树品种绿茶差异分析[J]. 食品科学,2024,45(16):131−139. [LI Xiang, XU Yan, FENG Tingting, et al. Differences in taste quality among green teas made from major cultivars in Wanzhou district, Chongqing[J]. Food Science,2024,45(16):131−139.] LI Xiang, XU Yan, FENG Tingting, et al. Differences in taste quality among green teas made from major cultivars in Wanzhou district, Chongqing[J]. Food Science, 2024, 45(16): 131−139.

[28] LIU Z Y, YANG T, DAI Y Q, et al. Research progress of tea taste based on molecular sensory science[J]. Science and Technology of Food Industry,2021,42(4):337−343,355.

[29] 彭艾婧. 基于感官组学的名优绿茶浓、涩、鲜、甜滋味特征研究[D]. 杭州:浙江大学, 2021. [PENG A Q. Study on taste characteristics of strong feeling, astringency, umami and sweetness of famous green teas based on sensory omics[D]. Hangzhou:Zhejiang University, 2021.] PENG A Q. Study on taste characteristics of strong feeling, astringency, umami and sweetness of famous green teas based on sensory omics[D]. Hangzhou: Zhejiang University, 2021.

[30] 舒娜. 六堡茶关键风味物质研究[D]. 重庆:西南大学, 2021. [SHU N. Rresearch on key flavor components of liupao tea[D]. Chongqing:Southwest University, 2021.] SHU N. Rresearch on key flavor components of liupao tea[D]. Chongqing: Southwest University, 2021.

[31] 刘盼盼. 青砖茶香味品质化学及特征香气形成机制[D]. 长沙:湖南农业大学. [LIU P P. The chemical basis of flavor quality and formation mechanism of characteristic aroma in Qingzhuan tea[D]. Changsha:Hunan Agricultural University, 2022.] LIU P P. The chemical basis of flavor quality and formation mechanism of characteristic aroma in Qingzhuan tea[D]. Changsha: Hunan Agricultural University, 2022.

[32] CAO J, JIANG X, CHEN Q, et al. Oxidative stabilities of olive and camellia oils:Possible mechanism of aldehydes formation in oleic acid triglyceride at high temperature[J]. LWT,2020,118:108858. doi: 10.1016/j.lwt.2019.108858

[33] COSSIGNANI L, GIUA L, SIMONETTI M S, et al. Volatile compounds as indicators of conjugated and unconjugated linoleic acid thermal oxidation[J]. European Journal of Lipid Science and Technology,2014,116(4):407−412. doi: 10.1002/ejlt.201300205

[34] DING A, ZHU M, QIAO X, et al. Effect of fatty acids on the flavor formation of fish sauce[J]. LWT,2020,134:110259. doi: 10.1016/j.lwt.2020.110259

[35] 詹冬梅, 傅海峰, 周承哲, 等. 贮藏年份及压饼方式对寿眉风味品质的影响[J]. 食品与生物技术学报,2022,41(5):81−89. [ZHAN D M, FU H F, ZHOU C Z, et al. Effect of storage years and pressing methods on the flavor quality of shoumei[J]. Journal of Food Science and Biotechnology,2022,41(5):81−89.] ZHAN D M, FU H F, ZHOU C Z, et al. Effect of storage years and pressing methods on the flavor quality of shoumei[J]. Journal of Food Science and Biotechnology, 2022, 41(5): 81−89.

[36] 马林龙, 刘艳丽, 曹丹, 等. 不同茶树品种(系)的绿茶滋味分析及评价模型构建[J]. 农业工程学报,2020,36(10):277−286. [MA L L, LIU Y L, CAO D, et al. Analysis and evaluation model for the taste quality of green tea made from various cultivars or strains[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE),2020,36(10):277−286.] MA L L, LIU Y L, CAO D, et al. Analysis and evaluation model for the taste quality of green tea made from various cultivars or strains[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(10): 277−286.

[37] ZHANG Y N, YIN J F, CHEN J X, et al. Improving the sweet after-taste of green tea infusion with tannase[J]. Food Chemistry,2016,192:470−476. doi: 10.1016/j.foodchem.2015.07.046

[38] 宋振硕, 卫聿铭, 李铁汉, 等. 室温贮藏对花果香红茶风味品质的影响[J]. 食品科学,2024,45(2):258−267. [SONG Z S, WEI Y M, LI T H, et al. Changes in the flavor quality of flower and fruit scented black tea stored at room temperature[J]. Food Science,2024,45(2):258−267.] SONG Z S, WEI Y M, LI T H, et al. Changes in the flavor quality of flower and fruit scented black tea stored at room temperature[J]. Food Science, 2024, 45(2): 258−267.

[39] LIU P P, YIN J F, CHEN G S, et al. Flavor characteristics and chemical compositions of oolong tea processed using different semi-fermentation times[J]. Journal of Food Science and Technology,2018,55(3):1185−1195. doi: 10.1007/s13197-018-3034-0

[40] CHONG P H, CHEN J S, YIN D T, et al. 'Oral' tribology study on saliva-tea compound mixtures:Correlation between sweet aftertaste(Huigan) perception and friction coefficient[J]. Food Research In-ternational,2019,125:108642. doi: 10.1016/j.foodres.2019.108642

[41] 吴俊, 王治会, 李晶, 等. 不同贮藏时间武夷岩茶风味品质化学差异[J]. 食品科学,2024,45(4):214−224. [WU J, WANG Z H, LI J, et al. Dynamic changes in flavor quality of wuyi rock tea at different storage times[J]. Food Science,2024,45(4):214−224.] WU J, WANG Z H, LI J, et al. Dynamic changes in flavor quality of wuyi rock tea at different storage times[J]. Food Science, 2024, 45(4): 214−224.

-

期刊类型引用(0)

其他类型引用(1)

下载:

下载:

下载:

下载: