Preparation, Properties and Structural Characterization of Gelatin Essential Oils Edible Films of Different Types of Pectin

-

摘要: 为葡聚糖在可食膜中的应用提供数据支持,以期开发出性能更好的可食性薄膜。本研究将肉桂醛、丁香酚和茴香醛精油进行复配,探究其对大肠杆菌、绿脓杆菌、枯草芽孢杆菌和兰黑紫色杆菌的抑菌性能。以明胶为主要成膜基质,复合精油为抑菌剂,探究添加不同种类葡聚糖对明胶基可食膜的影响。采用红外光谱、X-射线衍射和扫描电子显微镜对4种复合可食膜进行了结构表征研究。结果表明:精油的最佳组合为体积比1:1的肉桂醛和丁香酚精油。对大肠杆菌和绿脓杆菌最低抑菌浓度为0.156 μL/mL;对枯草芽孢杆菌和兰黑紫色杆菌最低抑菌浓度为0.313 μL/mL。加入葡聚糖可以明显改善明胶基可食膜和明胶基精油可食膜的机械性能、阻隔性能和热稳定性。力学性能断裂时的抗拉力(TS)由35%~40%增长到45%~55%、伸长长度(E)由15~17 MPa提高到20~23 MPa;水蒸气透过率(WVP)可由30.04×10−2 g·mm/(m2·h·kPa)下降至22.31×10−2 g·mm/(m2·h·kPa);油透率(PO)可由139.12 g·mm·m−2·d−1降至108.21 g·mm·m−2·d−1;氧透过率(PV)可由5.72 g/100 g降至3.46 g/100 g。通过红外光谱、X-射线衍射和热稳定分析,可以证明葡聚糖与精油、明胶两种高分子之间有较强的相互作用和较好的相容性。以最低抑菌浓度添加复合精油的膜液对供试菌有明显抑菌效果,抑菌圈从0~5 mm变为15~20 mm,达到中敏。Abstract: In this study, the essential oils cinnamaldehyde, eugenol, and anisaldehyde were complexed to investigate their bacteriostatic properties against Escherichia coli, Pseudomonas aeruginosa, Bacillus subtilis, and Pseudomonas oryzae. Utilizing gelatin as the primary film-forming matrix and the complexed essential oils as bacteriostatic agents, we examined the effects of incorporating various types of dextran into gelatin-based edible films. The objective was to provide data to support the use of dextran in edible films, aiming to develop films with enhanced performance. Performance characterization studies of four composite edible films were conducted using infrared spectroscopy, X-ray diffraction, and scanning electron microscopy. The results indicated that the optimal combination of essential oils was a 1:1 ratio of cinnamaldehyde to eugenol, yielding the lowest inhibitory concentration of 0.156 μL/mL for both Escherichia coli and Pseudomonas aeruginosa, and 0.313 μL/mL for Bacillus subtilis and Pseudomonas lanceolatus. Additionally, the incorporation of dextran significantly enhanced the mechanical properties, barrier properties, and thermal stability of both gelatin-based edible films and those infused with essential oils. Specifically, the mechanical properties improved as follows: tensile strength at break (TS) increased from 35%~40% to 45%~55%; elongation (E) rose from 15~17 MPa to 20~23 MPa; water vapor permeability (WVP) decreased from 30.04×10−2 g·mm/(m²·h·kPa) to 22.31×10−2 g·mm/(m²·h·kPa); oil permeability (PO) was reduced from 139.12 g·mm·m−2·d−1 to 108.21 g·mm·m−2·d−1; and oxygen permeability (PV) decreased from 5.72 g/100 g to 3.46 g/100 g. Infrared spectroscopy, X-ray diffraction, and thermal stability analyses revealed strong interactions and improved compatibility between the dextran, essential oils, and gelatin. Furthermore, the film solution containing compound essential oil at the lowest inhibitory concentration demonstrated a significant antibacterial effect against the test bacteria, and the inhibition circle changed from 0~5 mm to 15-20 mm, reaching a medium sensitivity.

-

近年来,随着环保意识的增强,食品保鲜膜的研究从聚丙烯、聚乙烯等化合物制造的保鲜膜转移到了以多糖、蛋白质、油脂等为原材料制造的可食性薄膜上。在制造可食膜的研究中多糖的使用逐渐受到国内外学者的关注。从众多研究中可以发现加入多糖和精油可以有效提高薄膜的机械性能[1]、生物降解性能[2,3]、抗菌性能等。因此,多糖作为原料生产用于食品包装应用的多功能材料具有较高的潜力[4−6]。

添加植物精油的可食性抗菌薄膜是一款功能性薄膜,可以将纯天然抗菌的精油加入可食性物质中,以产生抗菌、抗氧化和保鲜的效果[7]。不同的膜基料中含有不同功能基团,能够和植物精油中的功能成分相互作用,从而将精油均匀分散在膜中,使精油在食品表面缓慢释放[8,9]。含精油型复合可食膜以精油为抗菌剂,多糖和蛋白质为成膜材料,不但可保证膜的整体性,还能利用膜基质的相互作用产生稳定的乳液结构,干燥后形成具有多孔网络结构的膜,该膜带有明显的阻水性和良好的选择透气性、抗菌性能等特点。此类膜具有较好的综合性能,在食品行业的应用范围较广。

明胶是动物体中的胶原在热、酸、碱或酶的条件下适度水解和热变性得到的产物,广泛应用在食品领域中[10]。由明胶制成的食用薄膜在热封、阻隔性和生物相容性方面表现出良好的性能。然而,由于明胶中存在大量亲水基团(如羟基和羧基),其耐水性差,吸水率高。明胶膜都存在机械力学性能较差的特点,如抗拉强度和断裂伸长率低水蒸气透过率更高的特点,在潮湿的环境中容易滋生微生物,导致食品腐败变质。因此需要对明胶进行改性,主要的改性方法有化学交联法、物理处理法生物高分子共混法等[11]。β-葡聚糖活性结构主要是以葡萄糖为单体组成的多聚糖,其中多数是与β-1,3键结合,它同时也是葡萄糖链连接结构的重要途径[12]。β-葡聚糖具备有良好的成膜效果[4]。目前国内外关于可食膜的研究多糖类膜使用淀粉、壳聚糖和纤维素较多,对于葡聚糖的研究较少[13]。并且选用魔芋葡甘聚糖和燕麦β-葡聚糖的研究较多。

因此,本文重点探究常见谷物β-葡聚糖[14](青稞β-葡聚糖、燕麦β-葡聚糖)、微生物来源β-葡聚糖(酵母β-葡聚糖)以及近年来成为多糖类研究热点的魔芋葡甘聚糖[15]对于精油、多糖与明胶共混法制备的可食膜的机械性能、阻隔性能和抗菌性能的影响。以期开发出综合性能较好的可食膜。

1. 材料与方法

1.1 材料与仪器

大肠杆菌(Escherichia coli)、兰黑紫色杆菌(Janthinobacterium)、绿脓杆菌(Pseudomonas aeruginosa)、枯草芽孢杆菌(Bacillus sp.) 由石河子大学食品学院畜产品加工与安全控制中心提供;青稞β-葡聚糖,酵母β-葡聚糖,魔芋葡甘聚糖、燕麦β-葡聚糖和明胶 同凌生物科技有限公司;肉桂醛精油(Cinnamaldehyde essential oil,CMAO)、丁香酚精油(Eugenol oil,EO)、茴香醛精油(cinnamaldehyde oil,CO) 上海一诺科技有限公司;食品级冰乙酸 广州奥本生物科技有限公司;食品级甘油 广州涵元贸易有限公司;吐温-80 上海麦克林生化科技有限公司;LB培养基 上海麦克林公司。

ZXRD-7080全自动新型鼓风干燥箱 上海智诚仪器设备制造有限公司;H1M多功能酶标仪 美国伯腾仪器有限公司;TA.XTPlus质构仪 英国Stable Micro System公司;Nicolet IS10傅里叶变换红外光谱(Fourier transform infrared spectroscopy,FT-IR)仪 美国赛默飞世尔公司;XRD-6100型X-射线衍射仪(X-Ray Diffraction,XRD) 日本岛津制作所;NR110+手持色差仪 深圳市三恩时科技有限公司;SU8010含台式电脑HPZ30型场发射扫描电子显微镜 日本日立公司;DSC100L差示扫描量热仪(Differential Scanning Calorimeter,DSC) 美国TA仪器有限公司;Mitutoyo 电子数显/机械螺旋测微器 日本三丰。

1.2 实验与方法

1.2.1 复配精油抑菌性能研究

制备细菌菌悬液:将大肠杆菌、绿脓杆菌、枯草芽孢杆菌和兰黑紫色杆菌使用平板划线方法激活,重复三代后进行试验。挑取适合菌落,用生理盐水稀释,稀释至浓度为1×107~1×108 CFU/mL的菌悬液以备实验。

1.2.1.1 单一/复合精油对供试菌的抑菌圈测定

通过牛津杯法测定抑菌圈直径。参考洪石希等[16]方法稍作修改,在无菌条件下,采用平板涂布法取200 μL菌悬液涂于凝固的培养基上制成含菌平板,于含菌平板中央放置牛津杯,在牛津杯中加入100 μL精油作为直接接触组。以无菌水作为空白对照组。细菌37 ℃培养24 h后采用十字交叉法测量抑菌圈直径,试验重复3次。抑菌圈直径≤7 mm视为无抗菌作用;7 mm<抑菌圈直径≤10 mm为钝敏;10 mm<抑菌圈直径<20 mm为中敏;抑菌圈直径≥20 mm为高敏。

1.2.1.2 单一/复合精油最低抑菌浓度(minimum inhibitory concentration,MIC)测定

参考于芯宜等[17]方法,采用常量稀释法测定MIC,在5 mL的LB培养基的灭菌试管中,加入范围在0.039~5 μL/mL的植物精油,随后加入50 μL供试菌菌悬液。以无菌水作为空白对照组。37 ℃培养24 h,观察培养基浑浊程度,若试管呈现澄清状态,则为MIC。

1.2.1.3 复配精油抑制浓度分数指数(fractional inhibitory concentration index,FICI)测定

采用棋盘稀释法测定复配精油的联合抑菌活性,在柴向华等[18]方法稍作修改。以4×4矩阵排列16支无菌试管,加入5 mL液体培养基,A精油沿纵轴顺序二倍稀释,B精油沿横轴顺序二倍稀释,精油浓度分别为1/8 MIC、1/4 MIC、1/2 MIC及MIC。随后加入菌悬液,37 ℃培养24 h。计算方法参考谢姊欢[19]公式(1):

FICI=FICA+FICB=A联合MICA单独MIC+B联合MICB单独MIC (1) 式中,FICA是指A精油抑制浓度分数;FICB是指A精油抑制浓度分数;A单独MIC是指在未复配前,单一A精油的最低抑菌浓度;B单独MIC是指在未复配前,单一A精油的最低抑菌浓度;A联合MIC 是指A和B两种精油进行组合后,通过酶标仪测定OD600,得到16种AB组合中的最优抑菌组合的A精油浓度;B联合MIC是指A和B两种精油进行组合后,通过酶标仪测定OD600,得到16种AB组合中的最优抑菌组合的B精油浓度。

FICI指数判定标准为:FICI≤0.5时,表现为协同作用;0.5<FICI≤1时,表现为相加作用;1<FICI≤2时,表现为无关;FICI>2时,表现为拮抗作用。

1.2.1.4 不同配比复配精油对供试菌的抑菌效果测定

采用牛津杯法,设置CMAO-EO体积比为1:4、1:3、1:2、1:1、2:1、4:1进行抑菌圈直径测定。方法如1.2.1.1。

1.2.1.5 复配精油MIC测定

根据1.2.1.4测得的抑菌圈直径,选定复配精油的最佳配比。重复1.2.1.2所述步骤,观察96孔板中LB液体培养基,不浑浊的孔所对应的抑菌剂的浓度即为该抑菌剂的MIC。

1.2.2 制膜及膜性质研究

1.2.2.1 复合膜制备工艺

参照前期实验结果以及黄艳等[20]的方法并加以改进制备β葡聚糖明胶复合可食膜工艺优化方案如下:制备2%葡萄糖醋酸水溶液(1%醋酸)、2.5%明胶水溶液。将葡聚糖醋酸水溶液与明胶水溶液1:1等量混合,400 r/min常温搅拌2 h,加入1.5%(以复合膜液中葡聚糖聚糖和明胶的总质量为基准)的甘油作为增塑剂,1%的Tween-80作为助溶剂,搅拌30 min。再分别加入0、0.313 μL/mL的肉桂醛-丁香酚精油(V:V=1:1),搅拌1 h。将复合膜液超声消泡30 min,倒入模具,放置于鼓风干燥器中烘干。用2.5%明胶水溶液制备明胶膜(Check,CK);用2.5%明胶水溶液和0.313 μL/mL的肉桂醛-丁香酚精油(V:V=1:1)制备明胶精油复合可食膜(Check-1,CK-1);用2%葡萄糖醋酸水溶液(1%醋酸)和2.5%明胶水溶液制备魔芋葡甘聚糖明胶可食膜(Konjac glucomannan gelatin edible film,KGMF)、酵母β-葡聚糖明胶可食膜(Yeast β-Dextran gelatin edible film,YDF)、燕麦β-葡聚糖明胶可食膜(Oats β-Dextran gelatin edible film,ODF)和青稞β-葡聚糖明胶可食膜(Barley β-glucan Gelatin edible film,BGF);用2%葡萄糖醋酸水溶液(1%醋酸)、2.5%明胶水溶液和0.313 μL/mL的肉桂醛-丁香酚精油(V:V=1:1)制备魔芋葡甘聚糖明胶精油可食膜(Konjac glucomannan gelatin essential oil edible film,KGMOF)、酵母β-葡聚糖明胶精油可食膜(Yeast β-Dextran gelatin essential oil edible film,YDOF)、燕麦β-葡聚糖明胶精油可食膜(Oats β-Dextran gelatin essential oil edible film,ODOF)和青稞β-葡聚糖明胶精油可食膜(Barley β-glucan Gelatin essential oil edible film,BGOF)

1.2.2.2 复合可食膜力学性能的测定

参照赵恩靓[21]等的方法并稍作修改。测定复合膜的厚度后,将复合膜裁剪成规格为20 mm*40 mm的长条状,用质构仪的夹具将复合膜两端夹紧,设置夹具初始间距20 mm,拉伸速度50 mm/min,拉伸距离20 mm,重复3次,记录膜断裂时的抗拉力(tensile strength,TS)和伸长长度(elongation,E)。用公式(2)、(3)计算:

TS=FLW (2) 式中:TS—抗拉力,MPa;F—膜断裂时的最大拉力,N;L—复合膜的平均厚度,mm;W—复合膜的宽度,mm

E=L−L0L0 (3) 式中:E—伸长长度,%;L—膜断裂时的长度,mm;L0—膜测试时的长度,mm。

1.2.2.3 膜厚度测定

膜厚度采用螺旋测微仪测定,在样品上任意选取5个点,测量其厚度,取平均值。

1.2.2.4 膜色度测定

方法参照任圆圆[22]等人并稍作修改,采用色差仪进行测定,测定L*、a*、b*,其中标准色卡为L*=91.6,a*=1.51,b*=−6.7。总色差用ΔE表示,用公式(4)计算:

ΔE=√(ΔL*)2+(Δa*)2+(Δb*)2 (4) 注:ΔL*、Δa*、Δb*表示样品颜色与标准色卡的差值。

1.2.2.5 膜透明度(Opacity)测定

方法参照王丽媛[23]等人并稍作修改,将膜裁剪成1 cm宽的长条,采用紫外分光光度计在600 nm波长下测量膜的吸光度值,每个样品重复三次,公式如下:

Opacity=A600d (5) 注:A600—复合膜膜在600 nm下膜的吸光度值;d—复合膜厚度,mm。

1.2.2.6 水蒸气透过率测定

参照鄢煦等[24]方法并稍作修改,将复合膜固定于装有无水CaCl2的三角中,将其放置在相对湿度保持75%的干燥器中,7 d后记录质量。

可食膜的水蒸气透过率(WVP)计算公式如下:

WVP=Δm×dS×Δt×ΔP (6) 式中:WVP—水蒸气透过率,g·mm·m−2d−1kPa−1;Δm—复合膜质量的变化量,g;d—复合膜厚度,mm;S—复合膜面积,m2;Δt—时间变化量,d;ΔP—复合膜内外蒸汽压差,kPa。重复三组,取平均值。

1.2.2.7 可食用膜的氧气阻隔性能测定

用硫代硫酸钠滴定法[25,26],称取等量植物油于三角瓶中,以样品复合膜密封瓶口,放入50℃恒温恒湿箱里静置5 d,以过氧化值(Peroxide Value,PV)反映可食膜的阻氧性,重复3组,取平均值。计算公式(7):

PV=0.1269×c×(V−V0)m (7) 式中:PV—过氧化值(g/100 g);V—滴定时消耗Na2S2O3标准溶液的体积(mL);V0—空白对照组消耗Na2S2O3标准溶液的体积(mL);c—Na2S2O3标准溶液的浓度(mol/L);0.1269—1 mL Na2S2O3对应碘的克数;m—待滴定油脂质量(g)。

1.2.2.8 可食用膜的油阻隔性能测定

在试管中加入等量的植物油,用复合膜密封包裹,将试管倒置于滤纸上,在25℃条件下静置1 d后,测量滤纸质量[20,25],重复3组,取平均值。可食膜的油透过系数(PO)计算公式为(8):

PO=Δm×dS×t (8) 式中:PO—油透过系数,g·mm·m−2·d−1;Δm—滤纸试验前后质量差,g;d—可食膜厚度,mm;S—滤纸透油部分的面积,m2;t=1 d。

1.2.2.9 膜液抑菌圈测定

按照1.2.2.1制备复合膜液并超声30 min以作备用。采用牛津杯法,并按照1.2.1.1方法测定抑菌圈直径。

1.2.3 不同种类葡聚糖复合可使用膜结构表征

1.2.3.1 可食膜的FT-IR图谱分析

将膜裁剪成适合大小,烘干干燥6 h,采用FT-IR红外光谱仪Atr模式对膜样品进行测定,在500~4000㎝−1范围扫描,生成膜的红外光谱[4,27]。

1.2.3.2 XRD测定可食膜结晶结构

将膜裁剪成适合大小,采用X射线衍射仪对膜样品进行分析。参数设置为扫描角2θ,起始角度5°,终止角度45°,铜靶,滤波片Ni,扫描速度2°/min。

1.2.3.3 DSC测定可食膜热稳定性

准确称取一定量的复合膜,密封在铝盘中,DSC参考方娟丽等[28]的方法进行测定。条件为:升温速度20℃/min,测试温度范围20~250℃。

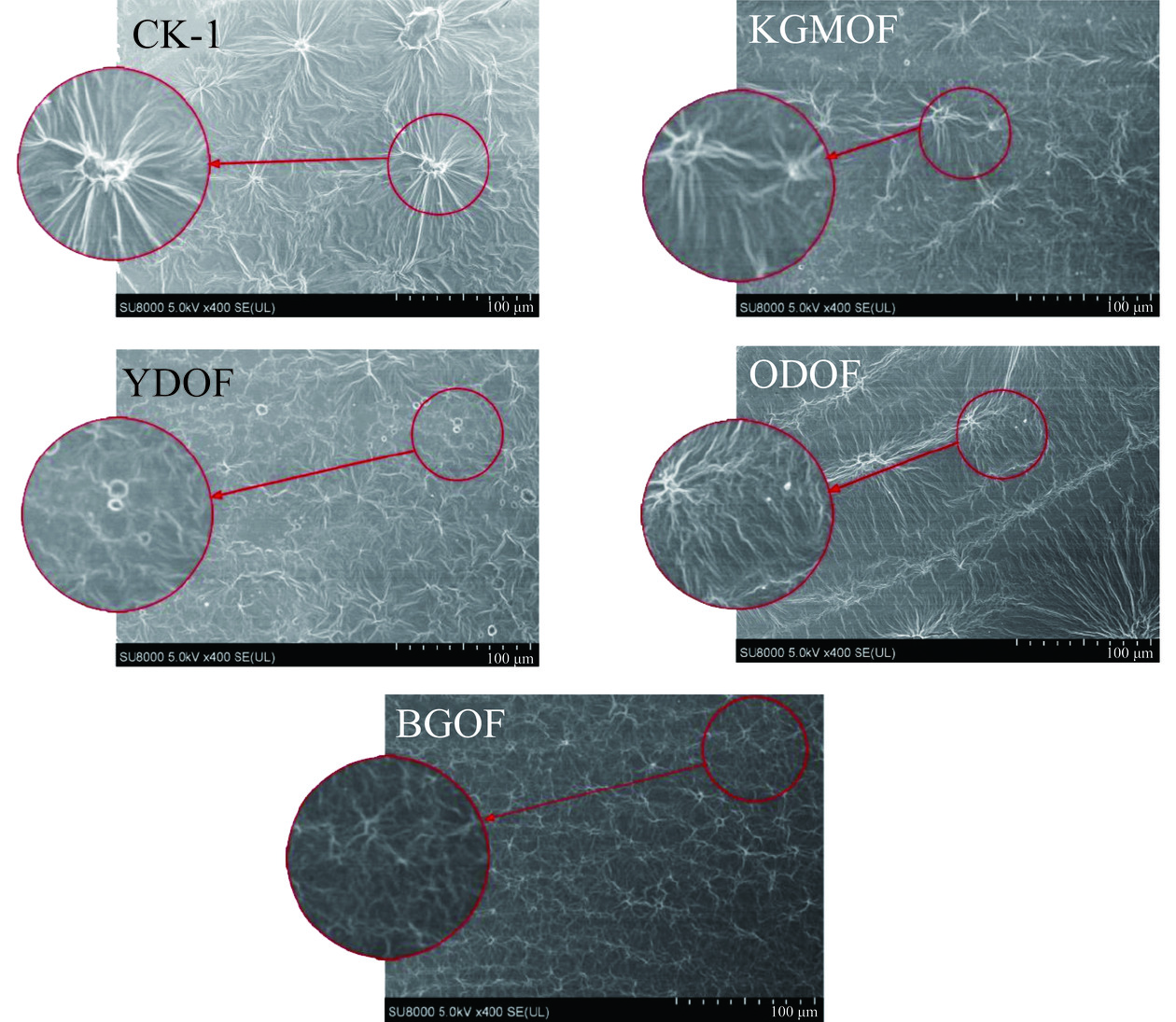

1.2.2.4 可食膜 SEM扫描电镜观察

将复合可食膜充分干燥后裁剪成适合大小,固定在样品台上,喷金。用SU8010含台式电脑HPZ30型场发射扫描电子显微镜在不同放大倍数下观察样品复合可食膜的微观结构[29]。

1.3 数据处理

统计分析方法使用SPSS 26.0,对所有结果进行了3次的重复检验,结果以“平均数±标准偏差”形式显示,并使用Origin 2022进行数据绘图。

2. 结果与分析

2.1 复配精油的确定

2.1.1 单一/复配精油的抑菌圈直径分析

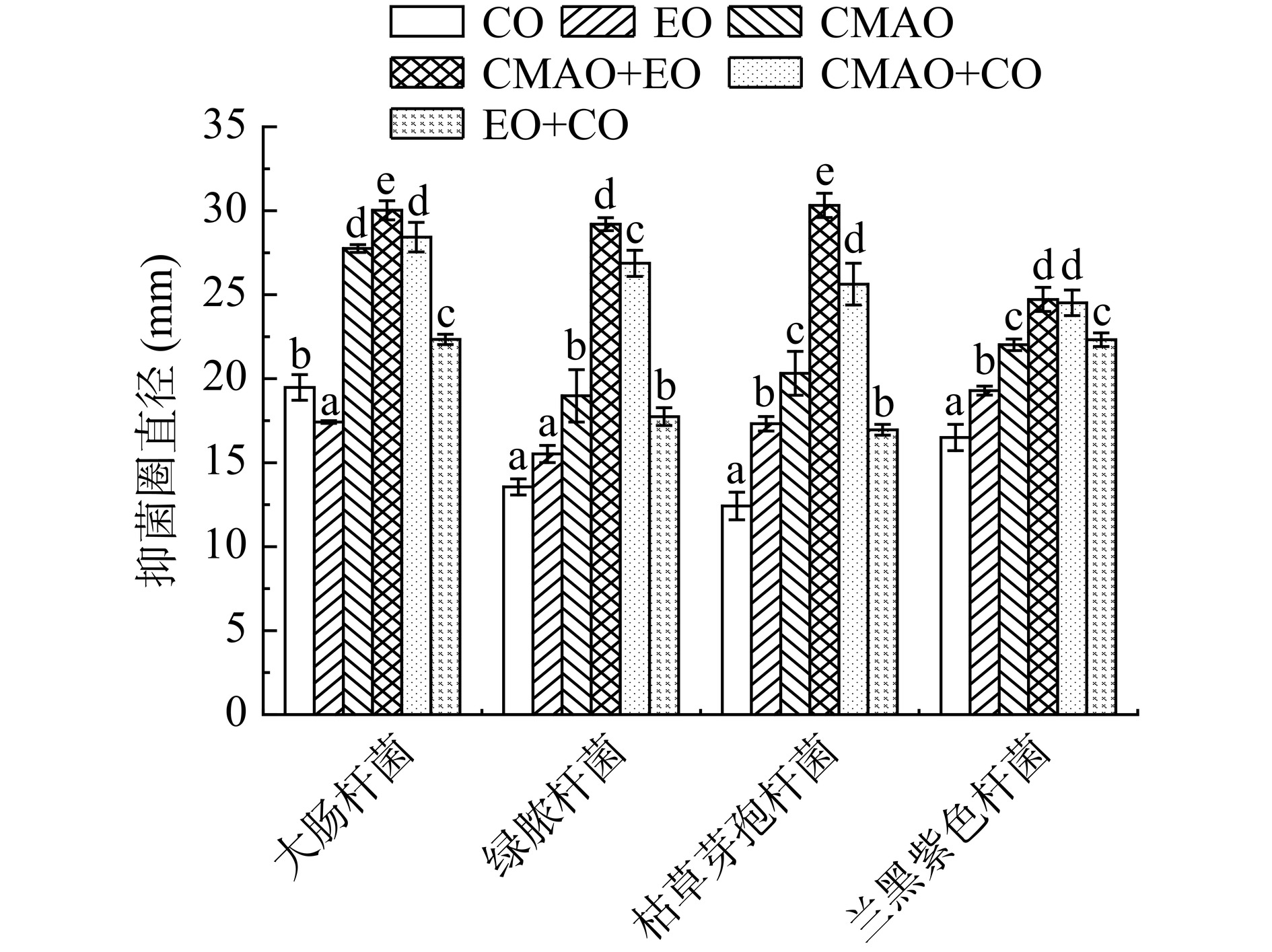

选用肉桂醛(CMAO)、丁香酚(EO)和茴香醛(CO)作为抑菌剂分析单一/复配精油对供试菌抑菌情况。由图1可知,在单一精油作用下,CMAO对4种供试菌的抑菌作用最显著(P<0.05),郑锋[30]对肉桂、丁香、大蒜、生姜、百里香、鼠尾草、迷迭香、芥末和牛至精油的抑菌性研究中也发现肉桂精油抑菌活性高于其他香辛料。

在复合精油(V:V=1:1)作用下,抑菌圈直径普遍大于单一精油抑菌圈直径,抑菌圈直径均>20 mm,表现为高敏。其中CMAO-EO复合精油的抑菌作用最好。单一精油与复合精油抑菌圈直径存在显著性差异(P<0.05)。

2.1.2 单方精油的MIC及复合精油的FICI值分析

由表1可知,与空白组相比,3种精油对供试菌均有抑制作用,其中CMAO对4种供试菌(大肠杆菌、绿脓杆菌、枯草芽孢杆菌、兰黑紫色杆菌)抑菌效果最强,MIC值均为0.313 μL/mL,这可能是因为肉桂醛改变细胞膜的通透性从而使DNA、RNA和蛋白质释放[31];Na+、K+等泄漏,电导率提高,或者使细胞内ATP酶含量下降,最终杀死细菌[32]。薛金昌等[33]研究的肉桂醛对大肠杆菌和金黄色葡萄球菌的最低抑制浓度(MIC)为0.4 μg/mL,对枯草芽孢杆菌的MIC为0.3 μg/mL。与本实验结果相似。

表 1 单方/复方精油最低抑菌浓度(MIC)Table 1. Minimum inhibitory concentration of unilateral essential oil (MIC)供试菌 精油 最低抑菌浓度(μL/mL) MIC 5.000 2.500 1.250 0.625 0.313 0.156 0.078 0.039 大肠杆菌 CMAO − − − − − ++ ++ ++ 0.313 EO − − − − + ++ ++ ++ 0.625 CO − − − + ++ ++ ++ ++ 1.250 CMAO-EO − − − − − − ++ ++ 0.156 空白 ++ ++ ++ ++ ++ ++ ++ ++ − 绿脓杆菌 CMAO − − − − − ++ ++ ++ 0.313 EO − − − − ++ ++ ++ ++ 0.625 CO − − − + ++ ++ ++ ++ 1.250 CMAO-EO − − − − − − ++ ++ 0.156 空白 ++ ++ ++ ++ ++ ++ ++ ++ − 枯草芽孢杆菌 CMAO − − − − − ++ ++ ++ 0.313 EO − − − + + ++ ++ ++ 1.250 CO − − − + + ++ ++ ++ 1.250 CMAO-EO − − − − − + ++ ++ 0.313 空白 ++ ++ ++ ++ ++ ++ ++ ++ − 兰黑紫色杆菌 CMAO − − − − − ++ ++ ++ 0.313 EO − − − + ++ ++ ++ ++ 1.250 CO − − − − ++ ++ ++ ++ 0.625 CMAO-EO − − − − − + ++ ++ 0.313 空白 ++ ++ ++ ++ ++ ++ ++ ++ − 注:“−”表示澄清无菌,“+”表示少量菌,“++”表示大量菌。 由表2可知,CMAO-EO复配精油对4种供试菌的FICI≤0.500,表明CMAO和EO对供试菌的抑菌效果为协同作用,在谢姊欢[19]的研究中肉桂-山苍子复配精油对沙门氏菌及灰葡萄孢霉的FICI指数为0.5,表现为协同作用。说明复配精油之间存在相互作用,可增加抑菌性能。CMAO-CO仅对兰黑紫色杆菌表现为协同作用,FICI为0.5;其他FICI值均介于0.500~1.000,为相加作用。EO-CO复配精油对4种供试菌的FICI指数均处于0.500~1.000之间,为相加作用。综上所述,复配精油的抑菌效果优于单一精油的抑菌效果,CMAO与EO对于4种供试菌抑菌效果最好,即选定CMAO与EO为复配精油种类。

表 2 复配精油FICI指数Table 2. FICI index of compound essential oil供试菌 MIC CMAO - EO CMAO -CO EO -CO FICI CMAO EO CMAO CO EO CO 大肠杆菌 单MIC 0.313 0.625 0.313 1.250 0.625 1.250 联MIC 0.078 0.156 0.078 0.625 0.156 0.625 FICI 0.500 0.750 0.750 绿脓杆菌 单MIC 0.313 0.625 0.313 1.250 0.625 1.250 联MIC 0.078 0.156 0.156 0.313 0.313 0.625 FICI 0.500 0.750 1.000 枯草芽孢杆菌 单MIC 0.313 1.250 0.313 1.250 1.250 1.250 联MIC 0.078 0.313 0.156 0.625 0.625 0.625 FICI 0.500 1.000 1.000 兰黑紫色杆菌 单MIC 0.313 1.250 0.313 0.625 1.250 0.625 联MIC 0.078 0.313 0.078 0.313 0.625 0.313 FICI 0.500 0.750 1.000 2.1.3 不同配比复配精油对供试菌的抑菌圈直径及MIC分析。

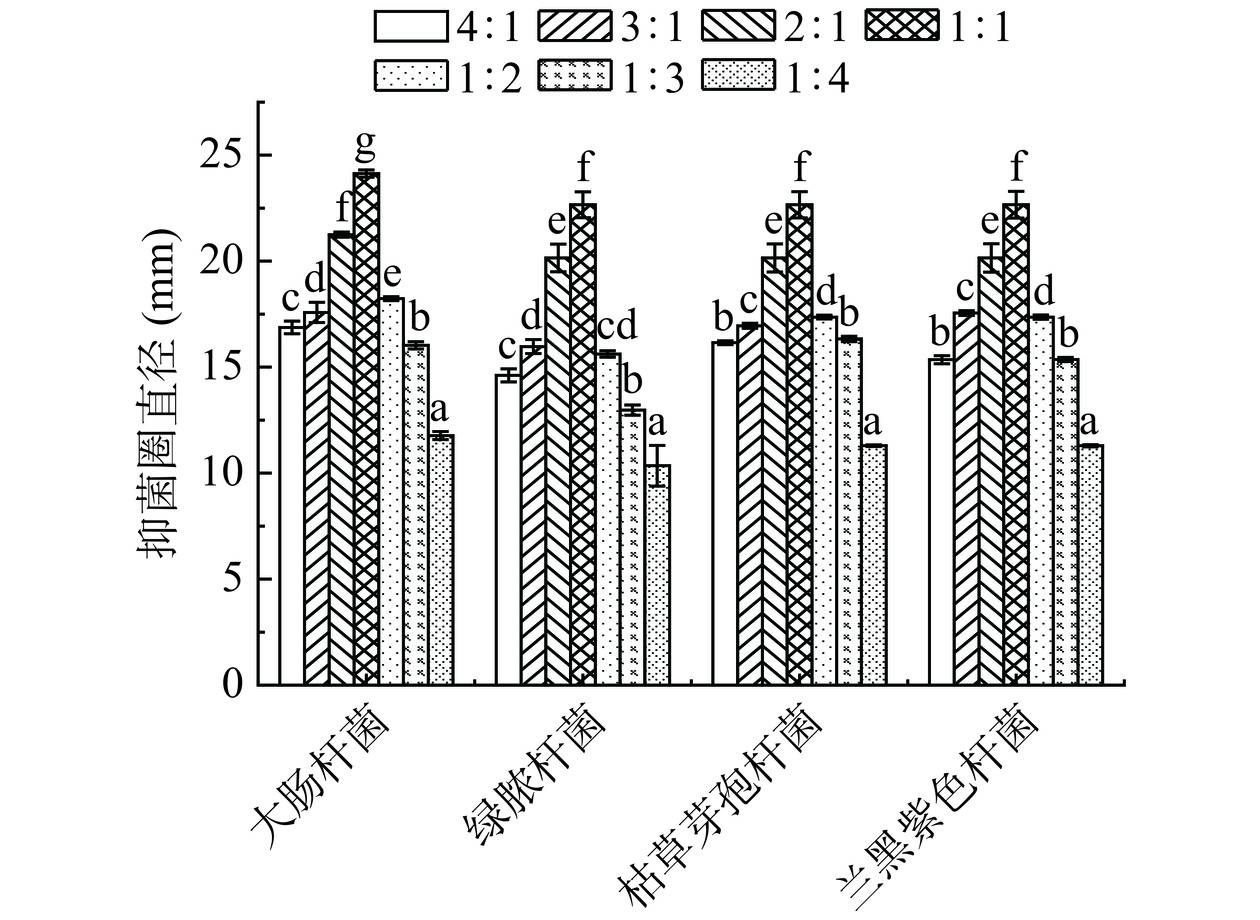

由图2所示,不同配比的复合精油对4种供试菌抑菌效果均具有显著性差异(P<0.05)。当CMAO∶EO的体积比为4:1、3:1、1:2、1:3时,复合精油对4种供试菌的抑菌圈直径均在10~20 mm之间,精油的抑菌作用表现为中敏;当CMAO:EO的体积比为2:1和1:1时,抑菌圈直径超过20 mm,抑菌作用表现为高敏,其中当体积比为1:1时,抑菌直径最大。综上所述,当CMAO:EO(1:1)时,抑菌效果最优。由表1可知,CMAO∶EO的体积比为1:1时得到复配精油对大肠杆菌和绿脓杆菌MIC值为0.156 μL/mL,枯草芽孢杆菌和蓝黑紫色杆菌MIC值为0.313 μL/mL。这可能是由于细菌与真菌的生理生长、细胞结构等不同,继而抑菌机制可能存在较大差异[19]。吕好新等[34]发现 V肉桂精油:V山苍子精油=3:5时结合扫描电镜结果发现,经肉桂-山苍子复合精油处理的黑曲霉BQM菌丝体损伤严重,发生皱缩、干瘪、凹陷等变形现象。

2.2 不同种类葡聚糖明胶精油复合可食膜力学性能分析

由表3可知,添加不同种类的葡聚糖以及添加精油均对复合可食膜的TS和E有显著性影响(P<0.05)。对比CK和YDF、KGMF、ODF、BGF以及CK-1和YDOF、KGMOF、ODOF、BGOF可以明显看出添加不同种类的葡聚糖提高了明胶基可食膜及明胶精油复合可食膜的TS和E值。这可能是加入葡聚糖后与明胶形成了新的化学键,增强了膜内基质的相互作用[35],使可食膜更加稳定,从而提高了复合可食膜的力学性能。在Chang[36]等人的研究中也发现在支链淀粉复合膜中加入葡聚糖可显著提高所得薄膜的TS和E值。

表 3 不同葡聚糖复合可食膜厚度及力学性能Table 3. Thickness and mechanical properties of edible films composed of different pectinsFilms 厚度(mm) E(%) TS(MPa) CK 0.087±0.007 35.07±0.64a 17.46±0.32b CK-1 0.086±0.004 38.76±0.46b 16.06±0.22a YDF 0.114±0.009 45.32±0.54c 21.67±0.28e YDOF 0.112±0.003 48.62±1.04e 20.65±0.32cd KGMF 0.093±0.017 48.06±0.32de 22.72±0.36fg KGMOF 0.090±0.010 52.34±1.02g 21.21±1.32de ODF 0.121±0.007 47.13±0.42d 22.08±0.22ef ODOF 0.118±0.007 50.23±0.42f 20.08±1.02c BGF 0.104±0.012 49.14±0.46ef 23.32±0.24g BGOF 0.102±0.012 54.35±0.46h 22.15±0.44ef 注:表内数据均以平均值±标准差为结果,同一列不同字母用来表示具有显著性差异,P<0.05;表4/5同。 添加精油后可食膜的机械性能相对与葡聚糖明胶复合膜也有明显的变化,E值升高,TS下降。这可能是因为精油具有疏水性,其与葡聚糖间的相互作用力和水分子与葡聚糖间的相互作用力相互影响[37,38]。唐森[37]等人也发现在壳聚糖膜中添加连翘精油,可食膜的TS呈减小的趋势。由表3可知,在葡聚糖精油可食膜中:BGOF的E值和TS值最大,可以达到54.35%和22.15 MPa。与CK-1比较,葡聚糖的加入增加了精油可食膜的综合力学性能,由E和TS可得到力学性能排序为:BGOF>KGMOF>ODOF>YDOF。

由表3可知,添加葡聚糖后可食薄膜的厚度都有所增加,其中添加魔芋葡甘聚糖对可食膜厚度的影响最小,对比CK膜厚度只增加了0.06 mm。添加燕麦β葡聚糖对膜厚度的影响最大,对比CK膜厚度增加了0.34 mm。添加精油后薄膜厚度相对于葡聚糖明胶可食膜没有显著性变化(P>0.05)。

2.3 不同种类葡聚糖复合可食膜的颜色及透明度分析

可食膜的色度和不透明度也是评判可食膜品质的重要指标,其可以保护包装食品不受紫外辐射而导致食品氧化,但较深颜色和高不透明度的可食膜会模糊消费者视线[39−40]。由表4可见,添加不同种类葡聚糖会使明胶可食膜和明胶精油可食膜亮度和色差降低,a*值、b*值和不透明度升高。色度值和不透明度均体现出显著性差异(P<0.05)。这可能是因为添加多糖影响了O-H键的弯曲和伸缩振动,从而影响了氢键的形成。使薄膜形成了均一稳定的结构,从而将明胶膜的透光率降低,不透明度升高。李晨辉[41]等人也发现了在可食膜中添加壳聚糖会使薄膜的透明度降低。

表 4 不同种类葡聚糖复合可食膜色度及透明度Table 4. Color and transparency of different types of pectin composite edible films可食膜 L* a* b* ΔE Opacity CK 50.19±0.34g 0.56±0.02e 0.43±0.13e 42.03±0.21a 1.02±0.13a CK-1 47.45±0.12f 0.43±0.04bcde 0.22±0.12cde 44.70±0.17b 1.18±0.06ab YDF 43.19±0.24e 0.21±0.06a 0.11±0.12bcd 48.90±0.27c 1.06±0.26a YDOF 42.56±0.26de 0.16±0.06a −0.25±0.10a 49.48±0.28cd 1.31±0.14bc KGMF 42.12±1.02de 0.47±0.03de 0.16±0.10bcde 49.96±1.03cd 1.32±0.03bcd KGMOF 39.34±0.72b 0.27±0.13abc −0.05±0.03abc 52.69±0.47f 1.53±0.12cde ODF 41.69±0.36d 0.41±0.01bcde 0.25±0.26de 50.40±0.44de 1.42±0.06bcd ODOF 37.42±0.42a 0.34±0.21abcd −0.27±0.04a 54.57±0.88g 1.67±0.5de BGF 40.59±0.87c 0.45±0.03cde 0.17±0.11bcde 51.48±0.73e 1.24±0.12ab BGOF 39.48±0.33b 0.25±0.16ab −0.07±0.02ab 52.56±0.37f 1.42±0.13bcd 在四种葡聚糖明胶精油复合可食膜中,YDOF可食膜的亮度最高,a*值、b*值和不透明度最低,感观最好。KGMOF和ODOF的b*值距标准比色卡b*为−6.7较远,数值较大,ΔE较大,不透明度可达到1.53和1.67。故可食膜颜色偏黄,颜色较深、不透明度偏高。综合色差和不透明度可得排序为YDOF>BGOF>KGMOF>ODOF。

2.4 不同种类葡聚糖复合可食膜阻隔性能分析

阻隔性能是食品包装膜的重要指标之一[40,42]。由表5可知,不同种类葡聚糖以及添加精油对可食膜的水蒸气透过率、阻氧性和阻油性均有显著性影响(P<0.05)。对比CK和YDF、KGMF、ODF、BGF以及CK-1和YDOF、KGMOF、ODOF、BGOF,添加葡聚糖可有效降低可食膜的水蒸气透过率,提高了阻氧率和阻油率。这可能因为葡聚糖和明胶、精油大分子之间发生了相互作用,形成了更致密的膜结构,孙嘉临等[43]人的研究中发现添加植物精油以及多酚可使膜基质分散体系的稳定性增强,从而增强薄膜阻隔性能,与本实验结论一致。同时,还发现含精油的可食膜水蒸气透过率高于不含精油的可食膜。对比CK和CK-1的WVP值从26.81×10−2 g·mm/(m2·h·kPa)上升到30.04×10−2 g·mm/(m2·h·kPa),这可能是因为精油对可食用膜的影响类似于疏水性脂类物质,为向亲水性聚合物薄膜中添加疏水性脂质使可食膜的阻水性下降[44]。其中BGF水蒸气透过率最低,WVP可达22.31×10−2 g·mm/(m2·h·kPa);BGOF阻油性能最好,PO值可达106.21 g·mm·m−2·d−1;YDOF阻氧性能最好,PV为3.46(g/100 g)。

表 5 不同种类葡聚糖复合可食膜水蒸气透过率,阻氧率及油透率Table 5. Water vapor permeability, oxygen resistance, and oil permeability of different types of pectin composite edible filmsFilms WVP×10−2g·mm/(m2·h·kPa) PV(g/100g) PO(g·mm·m−2·d−1) CK 26.81±0.13d 6.36±0.43f 139.12±0.84h CK-1 30.04±0.08g 5.72±0.12e 123.25±0.64f YDF 23.66±0.32b 4.06±0.24b 121.78±0.87e YDOF 27.34±0.62de 3.46±0.15a 116.92±0.52d KGMF 24.71±0.56c 5.83±0.22e 128.93±1.02g KGMOF 28.76±0.44f 4.92±0.12cd 119.26±0.48d ODF 24.68±0.52c 5.85±0.14e 118.46±0.92d ODOF 27.82±0.24e 5.02±0.26d 108.21±0.82b BGF 22.31±0.34a 4.57±0.16c 115.34±0.52c BGOF 26.88±0.42d 3.94±0.08b 106.21±0.72a 2.5 不同种类葡聚糖明胶/精油复合膜抑菌性能分析

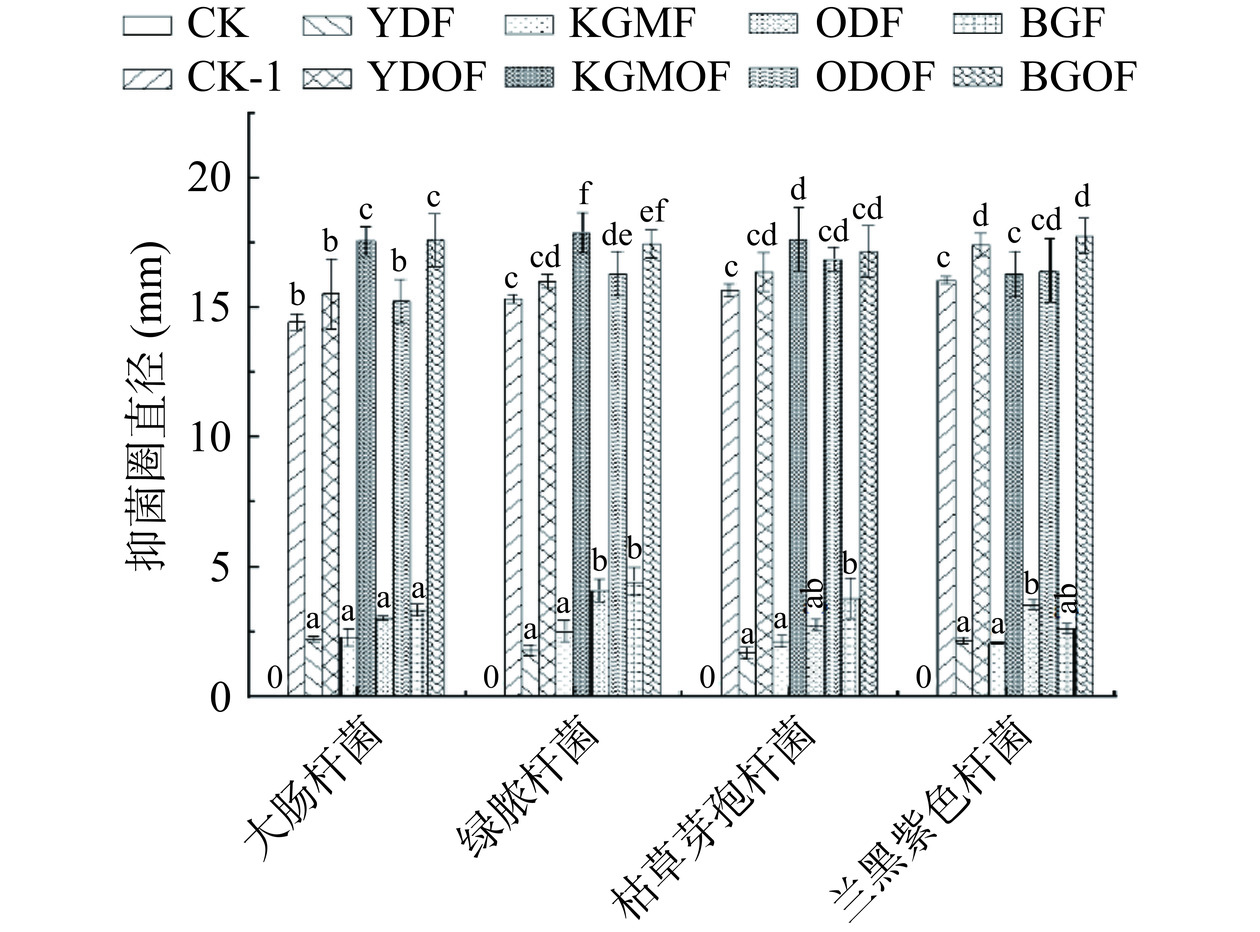

由图3可知,明胶溶液和明胶葡聚糖混合溶液对于供试菌基本没有抑菌作用。当添加精油后膜液对供试菌的抑菌圈均在15~20 mm之间,达到中敏范围。这可能是肉桂醛-茴香醛精油具有疏水性,可直接作用于磷脂双分子层,影响细胞膜的通透性,使细胞膜破裂,所以抑菌效果明显[45]。从图中看出葡聚糖精油可食膜抑菌圈大于明胶精油膜,且不同种类葡聚糖明胶精油膜液的抑菌圈有显著性差异(P<0.05)。这可能是因为葡聚糖的加入使膜基质间分子排序发生变化,从而降低了复合可食膜对精油的包裹,使精油的抗菌物质不能直接作用于细菌[46]。其中BGOF的抑菌效果最好,YDOF的抑菌效果最差。Guo等[47]发现负载肉桂醛乳胶膜有较强的抑菌效果。Zhou等[48]发现羧甲基化酵母β-葡聚糖抗氧化、抗感染、抗炎和细胞增殖等方面表现出突出的效果,与本实验结果一致。

2.6 不同种类葡聚糖明胶精油复合可食膜FT-IR分析

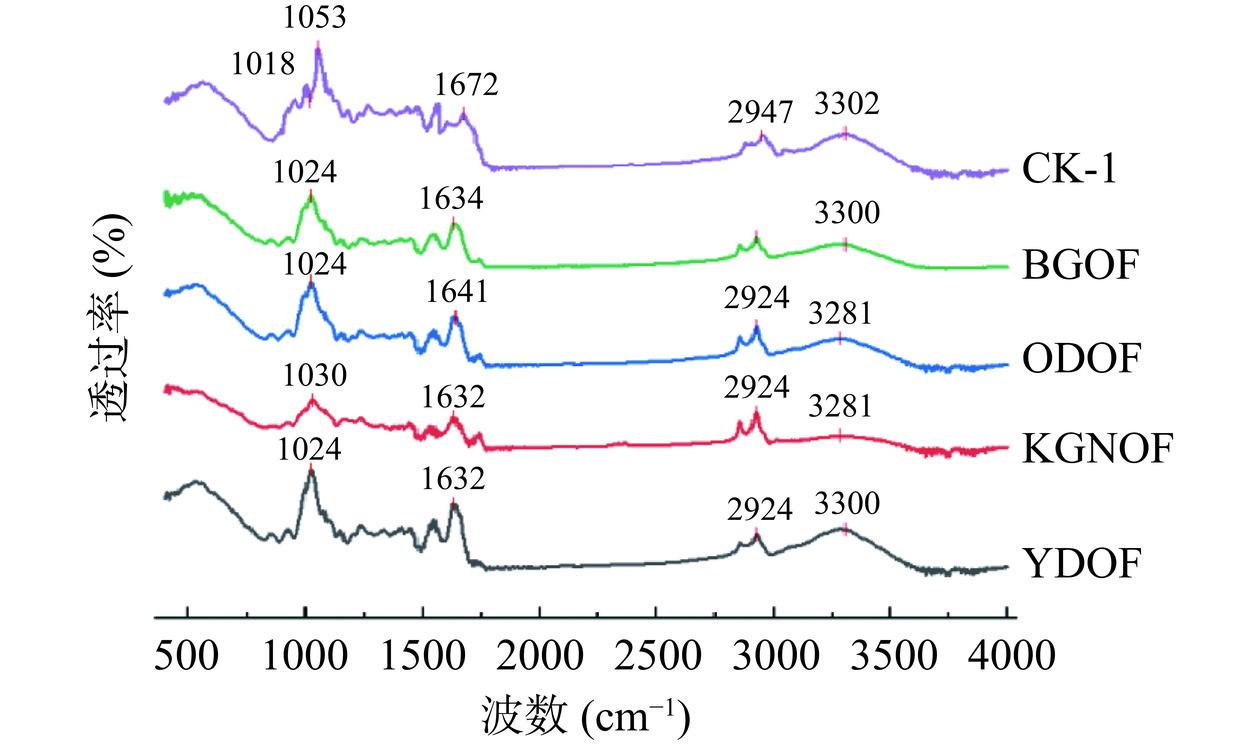

图4所示为CK-1、BGOF、YDOF、ODOF和KGMOF的红外光谱图。在CK-1的红外光谱图中,3301 cm−1左右的吸收峰是明胶分子中-OH与-NH伸缩振动峰重叠形成的多重吸收峰[49];2946 cm−1吸收峰通常与烷基C-H键的伸缩振动相关,尤其是较长的烷基链[28]。可能与精油中烷基链的存在有关,或者是明胶中的烷基链在复合过程中发生了变化。明胶和多糖都属于高分子多糖,由于分子结构的相似,它们的红外光谱图也相似[22,39,50]。BGOF、YDOF、ODOF和KGMOF在波数3285 cm−1左右的吸收峰均宽而强,波束相较于CK-1发生了不同程度的移动。且在3000~2800 cm−1范围内,观察到它们都有属于糖类的特征吸收峰。在1640、1540和1053 cm−1左右的吸收峰通常与C=O键的伸缩振动、N-H键的弯曲振动以及C-O键的伸缩振动相关[51],在CK-1中,可能与明胶中的羧酸或精油中的酮相关、明胶中的酰胺键和明胶中的羟基或精油中的醚键相关。相比CK-1,BGOF、YDOF、ODOF和KGMOF的波峰均向短波方向移动。说明精油中的羟基和明胶中的氨基、巯基以及葡聚糖羟基之间发生了分子间相互作用(如疏水相互作用、静电相互作用等)[52]。

这些现象表明,葡聚糖与明胶、精油之间可能存在分子间氢键作用,形成分子相连,增加了它们之间的相互作用力,从而使复合体系变得更加稳定。这种分子间相互作用有利于提高膜基质之间的相容性,有助于形成更加均匀、致密的复合膜结构。在Piermaria等[53]人的研究中,也发现添加葡聚糖会使多糖基膜分子间相互作用增强,是良好的制膜基质。Wu等[54]人利用傅利叶红外光谱分析时发现魔芋葡甘聚糖与其他多糖之间存在相互作用,可由此推测膜基质之间存在较强的分子间氢键。与本实验现象一致。

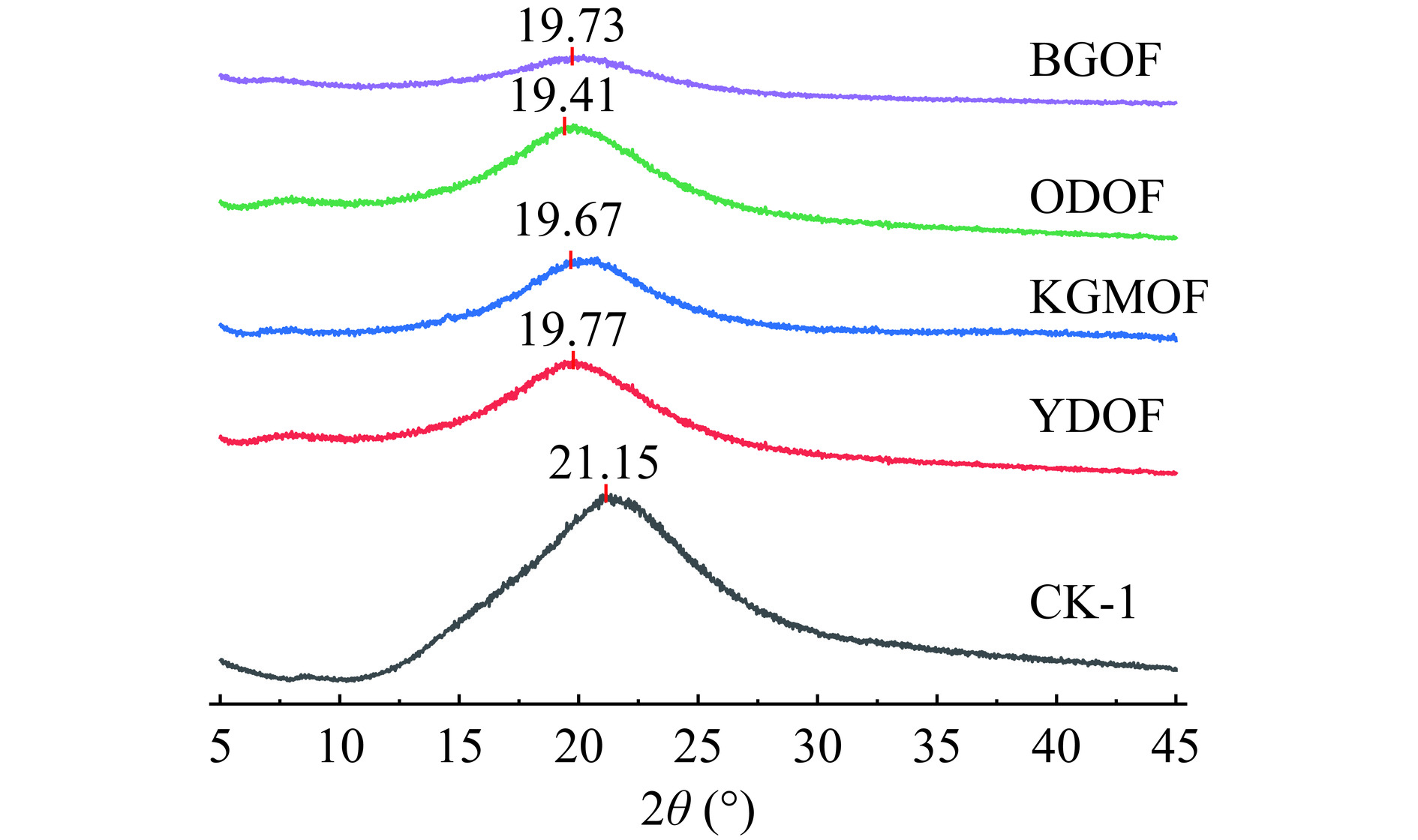

2.7 不同种类葡聚糖复合可食膜力XRD分析

图5所示为CK-1,BGOF、YDOF、ODOF和KGMOF的X射线衍射图。可以看出添加不同种类的葡聚糖的明胶精油可食膜XRD的变化规律。由于明胶和4种葡聚糖都属于高分子多糖,从而5种复合膜衍射谱图的都在20°左右出现了峰值,且总体形态相似。由图5可以看出,CK-1在21.15°处有一个强且宽衍射峰,随着不同种类葡聚糖的加入,复合膜在21.15°处的衍射峰明显减弱,且最高峰不同程度的向左平移,说明4种葡聚糖、精油与明胶间发生了强烈的相互作用从而改变了各自的结晶度,证明了膜基质间具有良好的相容性,此结果与红外分析的结论相一致。在王丽媛等[23]人的研究中,发现壳聚糖明胶复合膜也有类似的现象,实验证明了明胶与壳聚糖间具有较强的相互作用,致使明胶和壳聚糖本身的结晶情况发生改变。

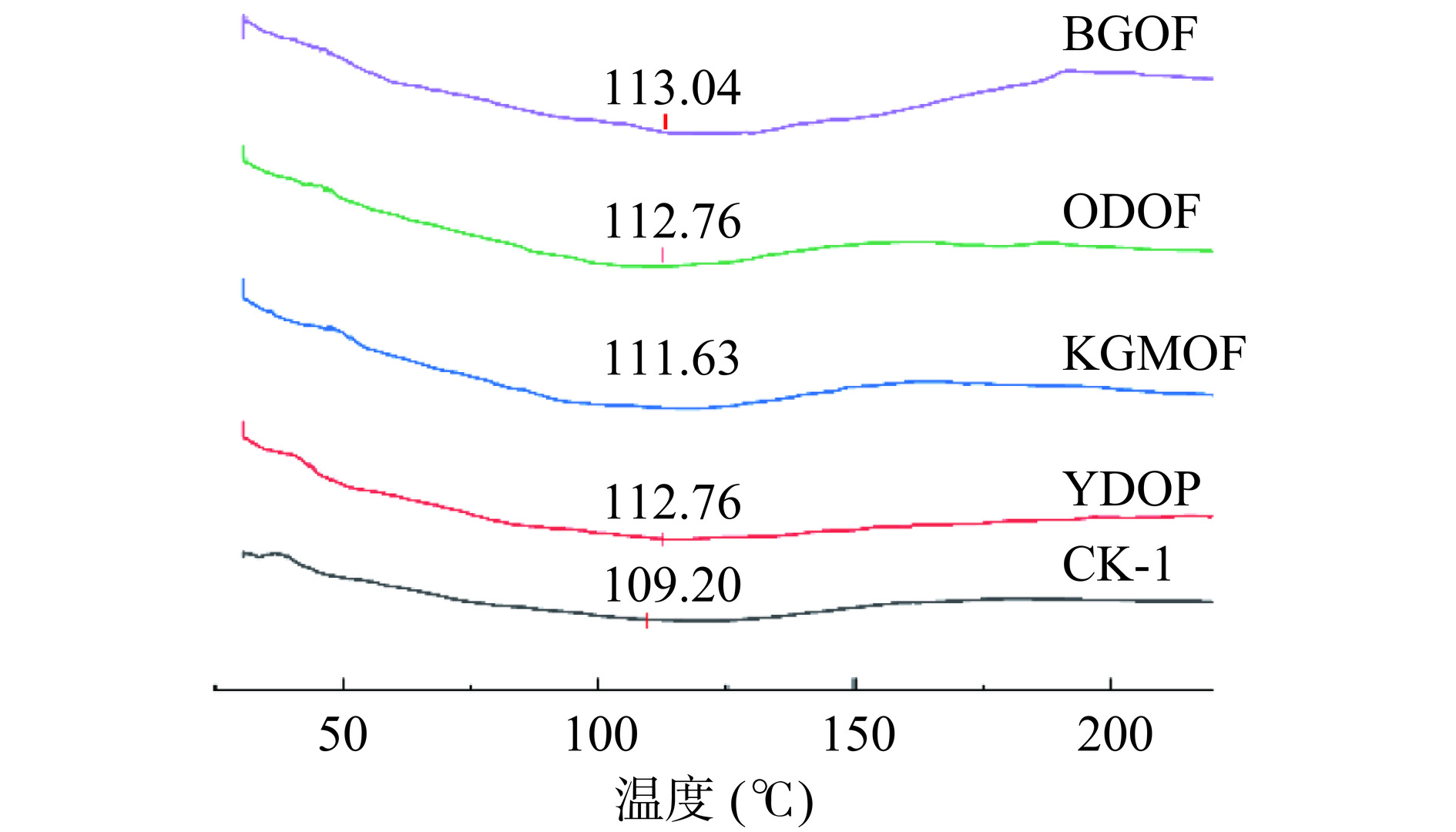

2.8 不同种类葡聚糖复合可食膜DSC测试结果分析

通过分析DSC曲线能够了解可食薄膜的热玻璃化转变情况和以及可食薄膜与基底聚合物间的热相容性[42]。对于水溶胶成膜后的样品,其玻璃化温度难以测得,因此转变为对其热特性曲线中水链结晶进行分析[55]。

由图6可以看出,在50~120 ℃区间内4种葡聚糖明胶精油复合可食膜的DSC曲线均出现一个宽吸收峰,该吸收峰主要由水链结晶熔融吸热所导致的。一般情况,三种高分子混合时,若其间具有强烈的相容性则会改变各自的水链结晶。由图6可见CK-1的吸热熔融峰出现在109.20 ℃,而BGOF、YDOF、ODOF和KGMOF熔融峰出现在相对较高的温度,分别为113.04、112.76、112.76和111.63 ℃。这主要是由于加入葡聚糖后的可食性复合膜中氢键的相互作用强于CK-1。与FT-IR分析结论一致。

2.9 不同种类葡聚糖复合可食膜SEM分析

图7为CK-1,BGOF、YDOF、ODOF和KGMOF表面结构扫描图,薄膜均呈半透明状且无裂纹。CK-1表面较粗糙,可以观察到部分区域团聚现象较为明显,且有大量褶皱部分,但随着葡聚糖的添加,可食膜的团聚现象改善,褶皱减轻,表面逐渐变光滑、平整。这主要是由于葡聚糖的加入改变了成膜基质的组成,使得膜基质分子间的交联作用更加强烈,这和FT-IR与XRD的现象相一致。同时,在KGMOF和YDOF中可以观察到较多的小气泡,这是因为粘液在薄膜中保留了间质水。在热成型过程中,水试图通过蒸汽作用逸出,但甘油和葡聚糖的塑化作用在薄膜基质中起到屏障作用,形成小口袋[55,56]。这些小气泡可能会影响薄膜的阻隔性能,在阻氧率(PO)和水蒸气透过率(WVP)数据中也可以体现出BGOF和ODOF的阻隔性能优于其它两种葡聚糖明胶复合膜。

3. 结论

本研究在明胶基可食膜的基础上,以CMAO、EO和CO为抑菌剂,添加青稞β-葡聚糖、燕麦β-葡聚糖、酵母β-葡聚糖和魔芋葡甘聚糖制备复合可食膜。通过CMAO、EO和CO的复配,发现在复合可食膜中添加0.313 μL/mL的 CMAO-EO(V/V,1:1) 对大肠杆菌、绿脓杆菌、枯草芽孢杆菌和蓝黑紫色杆菌的抑菌效果最好,与单一精油和其他配比组合精油有显著性差异(P<0.05)。与CK和CK-1相比,随着葡聚糖的添加,复合可食膜的机械性能,阻隔性和抗菌性显著增加(P<0.05)。TS、E、△E和不透明度升高、WVP、PO及PV值降低、抑菌圈直径增大。通过结构表征来看,复合膜的膜基质间高分子(明胶、精油和葡聚糖)之间存在显著的相互作用,并且具有良好的相互兼容性,影响了复合可食膜的热稳定性和微观形态。在葡聚糖精油明胶复合可食膜中,青稞β-葡聚糖复合可食膜的TS、E值最高,WVP和PO值最低,机械性能和抑菌性最好,水蒸气透过率和油透率最低;酵母β-葡聚糖使复合膜的PV值最低,阻氧能力最好,但抑菌性最差;魔芋葡甘聚糖对复合薄膜的机械性能和抗菌性改变较为显著,但阻隔性能最弱;燕麦β-葡聚糖相较于其他葡聚糖复合膜不透明度和ΔE值最高,可适用于避光性食品。上述结果表明葡聚糖的加入可制备出优良阻隔性能和抗菌性能的复合可食膜,为可食膜膜基质的选择提供数据支撑。

-

表 1 单方/复方精油最低抑菌浓度(MIC)

Table 1 Minimum inhibitory concentration of unilateral essential oil (MIC)

供试菌 精油 最低抑菌浓度(μL/mL) MIC 5.000 2.500 1.250 0.625 0.313 0.156 0.078 0.039 大肠杆菌 CMAO − − − − − ++ ++ ++ 0.313 EO − − − − + ++ ++ ++ 0.625 CO − − − + ++ ++ ++ ++ 1.250 CMAO-EO − − − − − − ++ ++ 0.156 空白 ++ ++ ++ ++ ++ ++ ++ ++ − 绿脓杆菌 CMAO − − − − − ++ ++ ++ 0.313 EO − − − − ++ ++ ++ ++ 0.625 CO − − − + ++ ++ ++ ++ 1.250 CMAO-EO − − − − − − ++ ++ 0.156 空白 ++ ++ ++ ++ ++ ++ ++ ++ − 枯草芽孢杆菌 CMAO − − − − − ++ ++ ++ 0.313 EO − − − + + ++ ++ ++ 1.250 CO − − − + + ++ ++ ++ 1.250 CMAO-EO − − − − − + ++ ++ 0.313 空白 ++ ++ ++ ++ ++ ++ ++ ++ − 兰黑紫色杆菌 CMAO − − − − − ++ ++ ++ 0.313 EO − − − + ++ ++ ++ ++ 1.250 CO − − − − ++ ++ ++ ++ 0.625 CMAO-EO − − − − − + ++ ++ 0.313 空白 ++ ++ ++ ++ ++ ++ ++ ++ − 注:“−”表示澄清无菌,“+”表示少量菌,“++”表示大量菌。 表 2 复配精油FICI指数

Table 2 FICI index of compound essential oil

供试菌 MIC CMAO - EO CMAO -CO EO -CO FICI CMAO EO CMAO CO EO CO 大肠杆菌 单MIC 0.313 0.625 0.313 1.250 0.625 1.250 联MIC 0.078 0.156 0.078 0.625 0.156 0.625 FICI 0.500 0.750 0.750 绿脓杆菌 单MIC 0.313 0.625 0.313 1.250 0.625 1.250 联MIC 0.078 0.156 0.156 0.313 0.313 0.625 FICI 0.500 0.750 1.000 枯草芽孢杆菌 单MIC 0.313 1.250 0.313 1.250 1.250 1.250 联MIC 0.078 0.313 0.156 0.625 0.625 0.625 FICI 0.500 1.000 1.000 兰黑紫色杆菌 单MIC 0.313 1.250 0.313 0.625 1.250 0.625 联MIC 0.078 0.313 0.078 0.313 0.625 0.313 FICI 0.500 0.750 1.000 表 3 不同葡聚糖复合可食膜厚度及力学性能

Table 3 Thickness and mechanical properties of edible films composed of different pectins

Films 厚度(mm) E(%) TS(MPa) CK 0.087±0.007 35.07±0.64a 17.46±0.32b CK-1 0.086±0.004 38.76±0.46b 16.06±0.22a YDF 0.114±0.009 45.32±0.54c 21.67±0.28e YDOF 0.112±0.003 48.62±1.04e 20.65±0.32cd KGMF 0.093±0.017 48.06±0.32de 22.72±0.36fg KGMOF 0.090±0.010 52.34±1.02g 21.21±1.32de ODF 0.121±0.007 47.13±0.42d 22.08±0.22ef ODOF 0.118±0.007 50.23±0.42f 20.08±1.02c BGF 0.104±0.012 49.14±0.46ef 23.32±0.24g BGOF 0.102±0.012 54.35±0.46h 22.15±0.44ef 注:表内数据均以平均值±标准差为结果,同一列不同字母用来表示具有显著性差异,P<0.05;表4/5同。 表 4 不同种类葡聚糖复合可食膜色度及透明度

Table 4 Color and transparency of different types of pectin composite edible films

可食膜 L* a* b* ΔE Opacity CK 50.19±0.34g 0.56±0.02e 0.43±0.13e 42.03±0.21a 1.02±0.13a CK-1 47.45±0.12f 0.43±0.04bcde 0.22±0.12cde 44.70±0.17b 1.18±0.06ab YDF 43.19±0.24e 0.21±0.06a 0.11±0.12bcd 48.90±0.27c 1.06±0.26a YDOF 42.56±0.26de 0.16±0.06a −0.25±0.10a 49.48±0.28cd 1.31±0.14bc KGMF 42.12±1.02de 0.47±0.03de 0.16±0.10bcde 49.96±1.03cd 1.32±0.03bcd KGMOF 39.34±0.72b 0.27±0.13abc −0.05±0.03abc 52.69±0.47f 1.53±0.12cde ODF 41.69±0.36d 0.41±0.01bcde 0.25±0.26de 50.40±0.44de 1.42±0.06bcd ODOF 37.42±0.42a 0.34±0.21abcd −0.27±0.04a 54.57±0.88g 1.67±0.5de BGF 40.59±0.87c 0.45±0.03cde 0.17±0.11bcde 51.48±0.73e 1.24±0.12ab BGOF 39.48±0.33b 0.25±0.16ab −0.07±0.02ab 52.56±0.37f 1.42±0.13bcd 表 5 不同种类葡聚糖复合可食膜水蒸气透过率,阻氧率及油透率

Table 5 Water vapor permeability, oxygen resistance, and oil permeability of different types of pectin composite edible films

Films WVP×10−2g·mm/(m2·h·kPa) PV(g/100g) PO(g·mm·m−2·d−1) CK 26.81±0.13d 6.36±0.43f 139.12±0.84h CK-1 30.04±0.08g 5.72±0.12e 123.25±0.64f YDF 23.66±0.32b 4.06±0.24b 121.78±0.87e YDOF 27.34±0.62de 3.46±0.15a 116.92±0.52d KGMF 24.71±0.56c 5.83±0.22e 128.93±1.02g KGMOF 28.76±0.44f 4.92±0.12cd 119.26±0.48d ODF 24.68±0.52c 5.85±0.14e 118.46±0.92d ODOF 27.82±0.24e 5.02±0.26d 108.21±0.82b BGF 22.31±0.34a 4.57±0.16c 115.34±0.52c BGOF 26.88±0.42d 3.94±0.08b 106.21±0.72a -

[1] SAEIDNEJAD A H, RAJAEI P. Chemical composition, antimicrobial activity and biological properties of essential oils[J]. International Journal of Life Sciences,2015,9(2):9−13. doi: 10.3126/ijls.v9i2.12043

[2] 李元政, 胡文忠, 萨仁高娃, 等. 天然植物提取物的抑菌机理及其在果蔬保鲜中的应用[J]. 食品与发酵工业,2019,45(14):239−244. [LI Y Z, HU W Z, SARENGOVA, et al. Bacteriostatic mechanisms of natural plant extracts and their applications in fruit and vegetable preservation[J]. Food and Fermentation Industry,2019,45(14):239−244.] LI Y Z, HU W Z, SARENGOVA, et al. Bacteriostatic mechanisms of natural plant extracts and their applications in fruit and vegetable preservation[J]. Food and Fermentation Industry, 2019, 45(14): 239−244.

[3] 魏丽莎, 季艳霞, 康振桥, 等. 肿瘤靶向纳米制剂研究进展[J]. 国际药学研究杂志,2014,41(1):68−74,4. [WEI L S, JI Y X, KANG Z Q, et al. Research progress of tumour-targeted nano-formulations[J]. International Journal of Pharmaceutical Research,2014,41(1):68−74,4.] WEI L S, JI Y X, KANG Z Q, et al. Research progress of tumour-targeted nano-formulations[J]. International Journal of Pharmaceutical Research, 2014, 41(1): 68−74,4.

[4] 李帅, 孙帆. 可食膜的制备及其在食品工业中的研究进展[J]. 农业科技与信息,2023(8):145−148. [LI S, SUN F. Preparation of edible film and its research progress in food industry[J]. Agricultural Science and Information,2023(8):145−148.] doi: 10.3969/j.issn.1003-6997.2023.08.034 LI S, SUN F. Preparation of edible film and its research progress in food industry[J]. Agricultural Science and Information, 2023(8): 145−148. doi: 10.3969/j.issn.1003-6997.2023.08.034

[5] 孙朋朋, 王薇, 刘英, 等. 多糖类型对泥鳅鱼皮胶原可食膜性能的影响[J]. 食品与机械,2022,38(5):87−93. [SUN P P, WANG W, LIU Y, et al. Effects of polysaccharide types on the properties of collagen edible film of mudskipper fish skin[J]. Food and Machinery,2022,38(5):87−93.] SUN P P, WANG W, LIU Y, et al. Effects of polysaccharide types on the properties of collagen edible film of mudskipper fish skin[J]. Food and Machinery, 2022, 38(5): 87−93.

[6] NEŠIĆ A, CABRERA-BARJAS G, DIMITRIJEVIĆ-BRANKOVIĆ S, et al. Prospect of polysaccharide-based materials as advanced food packaging[J]. Molecules,2019,25(1):135−136. doi: 10.3390/molecules25010135

[7] AHMAD M, BENJAKUL S, PRODPRAN T, et al. Physico-mechanical and antimicrobial properties of gelatin film from the skin of unicorn leatherjacket incorporated with essential oils[J]. Food Hydrocolloids,2012,28(1):189−199. doi: 10.1016/j.foodhyd.2011.12.003

[8] MA Q, ZHANG Y, CRITZER F, et al. Physical, mechanical, and antimicrobial properties of chitosan films with microemulsions of cinnamon bark oil and soybean oil[J]. Food Hydrocolloids,2016,52:533−542. doi: 10.1016/j.foodhyd.2015.07.036

[9] PERDONES Á, VARGAS M, ATARéS L, et al. Physical, antioxidant and antimicrobial properties of chitosan–cinnamon leaf oil films as affected by oleic acid[J]. Food Hydrocolloids,2014,36:256−264. doi: 10.1016/j.foodhyd.2013.10.003

[10] 张跃宏, 代浪浪, 杨晨, 等. 明胶基薄膜的制备方法及在食品包装中的应用研究进展[J]. 精细化工,2024,41(12):2603−2615. [ZHANG Yuehong, Dai Langlang, YANG Chen, et al. Research progress on the preparation method of gelatin-based film and its application in food packaging[J]. Fine Chemical Industry,2024,41(12):2603−2615.] ZHANG Yuehong, Dai Langlang, YANG Chen, et al. Research progress on the preparation method of gelatin-based film and its application in food packaging[J]. Fine Chemical Industry, 2024, 41(12): 2603−2615.

[11] 李越, 李娇, 李欣, 等. 明胶基可食性包装膜的改性及应用研究进展[J]. 食品安全导刊,2023(7):121−123. [LI Y, LI J, LI X, et al. Progress in the modification and application of gelatin-based edible packaging films[J]. Food Safety Journal,2023(7):121−123.] LI Y, LI J, LI X, et al. Progress in the modification and application of gelatin-based edible packaging films[J]. Food Safety Journal, 2023(7): 121−123.

[12] 李蔼琪, 金磊, 王欣, 等. 燕麦β-葡聚糖益生元组合配方对肠道健康的改善作用[J]. 营养学报,2024,46(3):228−234. [LI Aiqi, JIN Lei, WANG Xin, et al. Improvement of intestinal health by oat β-glucan prebiotic combination formula[J]. Journal of Nutrition,2024,46(3):228−234.] doi: 10.3969/j.issn.0512-7955.2024.03.006 LI Aiqi, JIN Lei, WANG Xin, et al. Improvement of intestinal health by oat β-glucan prebiotic combination formula[J]. Journal of Nutrition, 2024, 46(3): 228−234. doi: 10.3969/j.issn.0512-7955.2024.03.006

[13] 马胜亮, 刘文良, 胡亮. 可食性绿色包装膜的研究进展[J]. 包装工程,2020,41(23):90−97. [MA S L, LIU W L, HU L. Research progress of edible green packaging film[J]. Packaging Engineering,2020,41(23):90−97.] MA S L, LIU W L, HU L. Research progress of edible green packaging film[J]. Packaging Engineering, 2020, 41(23): 90−97.

[14] 申瑞玲, 陈文文. 全谷物食品重要膳食纤维组分——谷物β-葡聚糖的最新研究进展[J]. 粮油食品科技,2022,30(2):31−40,12. [SHEN R L, CHEN W W. Recent research progress on grain β-glucan, an important dietary fibre component of whole grain foods[J]. Grain, Oil and Food Science and Technology,2022,30(2):31−40,12.] SHEN R L, CHEN W W. Recent research progress on grain β-glucan, an important dietary fibre component of whole grain foods[J]. Grain, Oil and Food Science and Technology, 2022, 30(2): 31−40,12.

[15] 向飞, 吴考, 肖满, 等. 魔芋葡甘聚糖基可食膜的成膜机理研究进展[J]. 食品工业科技,2020,41(5):340−347,353. [XIANg F, WU K, XIAO M, et al. Progress of film-forming mechanism of konjac glucan-based edible film[J]. Food Industry Science and Technology,2020,41(5):340−347,353.] XIANg F, WU K, XIAO M, et al. Progress of film-forming mechanism of konjac glucan-based edible film[J]. Food Industry Science and Technology, 2020, 41(5): 340−347,353.

[16] 洪石希, 杨思, 杨辉, 等. 艾叶复方精油乳对脂溢性脱发相关致病菌抑制作用研究[J]. 江西中医药大学学报,2024,36(1):98−101. [HONG S X, YANG S, YANG H, et al. Inhibitory effect of mugwort compound essential oil milk on pathogenic bacteria associated with seborrheic alopecia[J]. Journal of Jiangxi University of Traditional Chinese Medicine,2024,36(1):98−101.] HONG S X, YANG S, YANG H, et al. Inhibitory effect of mugwort compound essential oil milk on pathogenic bacteria associated with seborrheic alopecia[J]. Journal of Jiangxi University of Traditional Chinese Medicine, 2024, 36(1): 98−101.

[17] 于芯宜, 徐家延, 陈方圆, 等. 5种植物精油抗菌性能研究及特征成分分析[J]. 保鲜与加工,2022,22(10):1−9. [YU X Y, XU J Y, CHEN F Y, et al. Antimicrobial properties of five essential oils and analysis of their characteristic components[J]. Preservation and Processing,2022,22(10):1−9.] YU X Y, XU J Y, CHEN F Y, et al. Antimicrobial properties of five essential oils and analysis of their characteristic components[J]. Preservation and Processing, 2022, 22(10): 1−9.

[18] 柴向华, 邹冬锌, 吴克刚, 等. 肉桂精油复配香芹酚和百里香酚对食用畜禽有害微生物熏蒸的抗菌活性[J]. 现代食品科技,2024,40(2):187−95. [CHAI X H, ZOU D X, WU K G, et al. Antimicrobial activity of cinnamon essential oil compounded with carvacrol and thymol against the fumigation of harmful microorganisms in edible livestock and poultry[J]. Modern Food Science and Technology,2024,40(2):187−95.] CHAI X H, ZOU D X, WU K G, et al. Antimicrobial activity of cinnamon essential oil compounded with carvacrol and thymol against the fumigation of harmful microorganisms in edible livestock and poultry[J]. Modern Food Science and Technology, 2024, 40(2): 187−95.

[19] 谢姊欢. 复配精油—壳聚糖/明胶复合膜的制备及应用[D]. 南昌:江西农业大学, 2022. [Xie Z H. Preparation and application of composite essential oil-chitosan/gelatin composite membrane[D]. Nanchang:Jiangxi Agricultural University, 2022.] Xie Z H. Preparation and application of composite essential oil-chitosan/gelatin composite membrane[D]. Nanchang: Jiangxi Agricultural University, 2022.

[20] 黄艳, 张媛, 徐小青, 等. 魔芋葡甘聚糖可食膜配方优化[J]. 食品工业科技,2016,37(4):330−336. [HUANG Y, ZHANG Y, XU X Q, et al. Optimisation of konjac glucan edible film formulation[J]. Food Industry Science and Technology,2016,37(4):330−336.] HUANG Y, ZHANG Y, XU X Q, et al. Optimisation of konjac glucan edible film formulation[J]. Food Industry Science and Technology, 2016, 37(4): 330−336.

[21] 赵恩靓, 贾文倩, 王一宁, 等. 改性纳米纤维素/玉米醇溶蛋白可食膜的制备及性能研究[J]. 包装工程,2023,44(17):1−8. [ZHAO E L, JIA W Q, WANG Y N, et al. Preparation and properties of modified nanocellulose/corn alcohol soluble protein edible film[J]. Packaging Engineering,2023,44(17):1−8.] ZHAO E L, JIA W Q, WANG Y N, et al. Preparation and properties of modified nanocellulose/corn alcohol soluble protein edible film[J]. Packaging Engineering, 2023, 44(17): 1−8.

[22] 任圆圆, 周珏君, 刘琴, 等. 人心果多糖/壳聚糖复合可食膜的制备及性能分析[J]. 粮食与油脂,2023,36(8):109−114. [REN Y Y, ZHOU J J, LIU Q, et al. Preparation and performance analysis of edible film made of human heart fruit polysaccharide/chitosan composite[J]. Grain and Fats,2023,36(8):109−114.] doi: 10.3969/j.issn.1008-9578.2023.08.023 REN Y Y, ZHOU J J, LIU Q, et al. Preparation and performance analysis of edible film made of human heart fruit polysaccharide/chitosan composite[J]. Grain and Fats, 2023, 36(8): 109−114. doi: 10.3969/j.issn.1008-9578.2023.08.023

[23] 王丽媛, 李红艳, 刘天红, 等. 明胶-壳聚糖可食膜的制备及性能表征[J]. 保鲜与加工,2016,16(5):10−16. [WANG L Y, LI H Y, LIU T H, et al. Preparation and property characterisation of gelatin-chitosan edible film[J]. Preservation and Processing,2016,16(5):10−16.] WANG L Y, LI H Y, LIU T H, et al. Preparation and property characterisation of gelatin-chitosan edible film[J]. Preservation and Processing, 2016, 16(5): 10−16.

[24] 鄢煦, 陶宇轩, 叶子健, 等. 魔芋葡甘聚糖/乙基纤维素/玉米醇溶蛋白复合膜的制备与性能表征[J]. 食品工业科技,2023,44(2):2852−92. [YAN X, TAO Y X, ZE Z J, et al. Preparation and performance characterisation of konjac glucan/ethyl cellulose/corn alkyd protein composite membrane[J]. Food Industry Science and Technology,2023,44(2):2852−92.] YAN X, TAO Y X, ZE Z J, et al. Preparation and performance characterisation of konjac glucan/ethyl cellulose/corn alkyd protein composite membrane[J]. Food Industry Science and Technology, 2023, 44(2): 2852−92.

[25] 刘莹, 许琳, 刘颖. 壳聚糖/香菇多糖可食性膜的性能研究及表征[J]. 食品工业科技,2015,36(12):287−290. [LIU Y, XU L, LIU Y. Performance study and characterisation of chitosan/shiitake mushroom polysaccharide edible membrane[J]. Food Industry Science and Technology,2015,36(12):287−290.] LIU Y, XU L, LIU Y. Performance study and characterisation of chitosan/shiitake mushroom polysaccharide edible membrane[J]. Food Industry Science and Technology, 2015, 36(12): 287−290.

[26] 高凌云, 张本山. 木薯氧化淀粉-壳聚糖复合膜的成膜特性研究[J]. 食品工业科技,2010,31(10):322,324,337−324,337. [GAO L Y, ZHANG B S. Study on the film formation characteristics of cassava oxidised starch-chitosan composite film[J]. Food Industry Science and Technology,2010,31(10):322,324,337−324,337.] GAO L Y, ZHANG B S. Study on the film formation characteristics of cassava oxidised starch-chitosan composite film[J]. Food Industry Science and Technology, 2010, 31(10): 322,324,337−324,337.

[27] 王卓, 赵忠昂, 南翔彬, 等. 魔芋葡甘聚糖复合膜的制备工艺研究[J]. 现代食品,2023,29(21):159−162. [WANG Z, ZHAO Z A, NAN X B, et al. Preparation process of konjac glucan composite film[J]. Modern Food,2023,29(21):159−162.] WANG Z, ZHAO Z A, NAN X B, et al. Preparation process of konjac glucan composite film[J]. Modern Food, 2023, 29(21): 159−162.

[28] 方娟丽, 熊群燕, 龚锐枝, 等. 黄皮多糖/壳聚糖复合可食膜的制备、结构表征及理化性质[J]. 现代食品科技,2024,40(8):263−273. [FANG J L, XIONG Q Y, GONG R Z, et al. Preparation, structural characterisation, and physicochemical properties of edible membranes of yellow skin polysaccharide/chitosan composite[J]. Modern Food Science and Technology,2024,40(8):263−273.] FANG J L, XIONG Q Y, GONG R Z, et al. Preparation, structural characterisation, and physicochemical properties of edible membranes of yellow skin polysaccharide/chitosan composite[J]. Modern Food Science and Technology, 2024, 40(8): 263−273.

[29] MASTANEH J, MEHRDAD N, TAGHI G M, et al. Physicochemical and structural characterization of sodium caseinate based film-forming solutions and edible films as affected by high methoxyl pectin[J]. International Journal of Biological Macromolecules,2020,165(PB):1949−1959.

[30] 郑锋. 外界因素对肉桂精油抑菌活性的影响研究[D]. 上海:上海应用技术大学, 2016. [ZHENG Feng. Study on the effect of external factors on the antibacterial activity of cinnamon essential oil[D]. Shanghai:Shanghai Institute of Technology, 2016.] ZHENG Feng. Study on the effect of external factors on the antibacterial activity of cinnamon essential oil[D]. Shanghai: Shanghai Institute of Technology, 2016.

[31] 张嘉祺, 闵德栋, 刘云国. 植物精油抑菌机制及其在食用菌保鲜中的应用进展[J]. 中国果菜,2024,44(4):9−13. [ZHANG Jiaqi, MIN Dedong, LIU Yunguo. Bacteriostatic mechanism of essential oils and their application in preservation of edible mushrooms[J]. China Fruit and Vegetable,2024,44(4):9−13.] ZHANG Jiaqi, MIN Dedong, LIU Yunguo. Bacteriostatic mechanism of essential oils and their application in preservation of edible mushrooms[J]. China Fruit and Vegetable, 2024, 44(4): 9−13.

[32] 杨柳. 两亲性淀粉/肉桂醛的抗菌机理及其在聚乙烯醇/明胶复合膜中的应用[D]. 太原:太原理工大学, 2023. [YANG L. Antimicrobial mechanism of amphiphilic starch/cinnamaldehyde and its application in poly(vinyl alcohol)/gelatin composite film[D]. Taiyuan:Taiyuan University of Technology, 2023.] YANG L. Antimicrobial mechanism of amphiphilic starch/cinnamaldehyde and its application in poly(vinyl alcohol)/gelatin composite film[D]. Taiyuan: Taiyuan University of Technology, 2023.

[33] 薛京昌, 徐晓怡, 郑海松. 肉桂醛对4种常见细菌的体外抑菌实验研究[J]. 检验检疫学刊,2013,23(4):50−53. [XUE J C, XU X Y, ZHENG H S. In vitro inhibition of four common bacteria by cinnamaldehyde[J]. Journal of Inspection and Quarantine,2013,23(4):50−53.] doi: 10.3969/j.issn.1674-5354.2013.04.013 XUE J C, XU X Y, ZHENG H S. In vitro inhibition of four common bacteria by cinnamaldehyde[J]. Journal of Inspection and Quarantine, 2013, 23(4): 50−53. doi: 10.3969/j.issn.1674-5354.2013.04.013

[34] 吕好新, 赵玲丽, 霍珊珊, 等. 肉桂-山苍子复合植物精油对发霉花生黑曲霉BQM菌的抑菌效果[J]. 中国食品学报,2021,21(12):222−229. [LÜ Haoxin, ZHAO Lingli, HUO Shanshan, et al. Inhibitory effect of cinnamon-sanguisorba composite essential oil on Aspergillus niger BQM in mouldy peanuts[J]. Chinese Food Journal,2021,21(12):222−229.] LÜ Haoxin, ZHAO Lingli, HUO Shanshan, et al. Inhibitory effect of cinnamon-sanguisorba composite essential oil on Aspergillus niger BQM in mouldy peanuts[J]. Chinese Food Journal, 2021, 21(12): 222−229.

[35] AZARI S S, ALIZADEH A, ROUFEGARINEJAD L, et al. Preparation and characterization of gelatin/β-glucan nanocomposite film incorporated with ZnO nanoparticles as an active food packaging system[J]. Journal of Polymers and the Environment, 2020:1−10.

[36] CHANG J, LI W, LIU Q, et al. Preparation, properties, and structural characterization of β-glucan/pullulan blend films[J]. International Journal of Biological Macromolecules,2019,140:1269−1276. doi: 10.1016/j.ijbiomac.2019.08.208

[37] 唐森, 付美杨, 韦巧艳, 等. 壳聚糖-连翘精油复合可食膜的制备及其在草莓中保鲜应用[J]. 食品研究与开发,2023,44(21):98−105. [[TANG S, FU M Y, WEI Q Y, et al. Preparation of chitosan-conjugate essential oil composite edible film and its application in strawberry preservation[J]. Food Research and Development,2023,44(21):98−105.] doi: 10.12161/j.issn.1005-6521.2023.21.014 [TANG S, FU M Y, WEI Q Y, et al. Preparation of chitosan-conjugate essential oil composite edible film and its application in strawberry preservation[J]. Food Research and Development, 2023, 44(21): 98−105. doi: 10.12161/j.issn.1005-6521.2023.21.014

[38] 王娇. 明胶基可食性复合膜的制备及性能研究[D]. 杨凌:西北农林科技大学, 2022. [WANG J. Preparation and properties of gelatin-based edible composite film[D]. Yanglin:Northwest A&F University, 2022.] WANG J. Preparation and properties of gelatin-based edible composite film[D]. Yanglin: Northwest A&F University, 2022.

[39] 孙海涛, 赵兵兵, 钟子杰, 等. 黑木耳多糖对大豆分离蛋白可食膜性质的影响及表征[J]. 食品科技,2022,47(6):229−234. [SUN H T, ZHAO B B, ZHONG Z J, et al. Influence of Nigella sativa polysaccharides on the edible membrane properties of soybean isolate proteins and their characterisation[J]. Food Science and Technology,2022,47(6):229−234.] doi: 10.3969/j.issn.1005-9989.2022.6.spkj202206034 SUN H T, ZHAO B B, ZHONG Z J, et al. Influence of Nigella sativa polysaccharides on the edible membrane properties of soybean isolate proteins and their characterisation[J]. Food Science and Technology, 2022, 47(6): 229−234. doi: 10.3969/j.issn.1005-9989.2022.6.spkj202206034

[40] SU J-F, YUAN X-Y, HUANG Z, et al. Physicochemical properties of soy protein isolate/carboxymethyl cellulose blend films crosslinked by Maillard reactions:Color, transparency and heat-sealing ability[J]. Materials Science & Engineering C,2011,32(1):40−46.

[41] 李晨辉, 黄丽, 白淑艳, 等. 明胶与多糖复合膜制备及对冷藏虹鳟脂质氧化的影响[J]. 食品与发酵工业,2024,50(19):209−215. [LI Chenhui, HUANG Li, BAI Shuyan, et al. Preparation of gelatin and polysaccharide composite membrane and its effect on lipid oxidation in refrigerated rainbow trout[J]. Food and Fermentation Industry,2024,50(19):209−215.] LI Chenhui, HUANG Li, BAI Shuyan, et al. Preparation of gelatin and polysaccharide composite membrane and its effect on lipid oxidation in refrigerated rainbow trout[J]. Food and Fermentation Industry, 2024, 50(19): 209−215.

[42] XU J, XIA R, ZHENG L, et al. Plasticized hemicelluloses/chitosan-based edible films reinforced by cellulose nanofiber with enhanced mechanical properties[J]. Carbohydrate Polymers, 2019:224.

[43] 孙嘉临, 袁玉娇, 李思琪, 等. 大豆分离蛋白基复合精油可食膜的制备及表征[J]. 中国果菜,2021,41(12):27−36. [SUN J L, YUAN Y J, LI S Q, et al. Preparation and characterisation of soybean isolate protein-based composite edible oil membrane[J]. Chinese Fruit and Vegetable,2021,41(12):27−36.] SUN J L, YUAN Y J, LI S Q, et al. Preparation and characterisation of soybean isolate protein-based composite edible oil membrane[J]. Chinese Fruit and Vegetable, 2021, 41(12): 27−36.

[44] 李继蕊, 孙骞. 肉桂精油可食性膜的制备与性能分析[J]. 安徽农业科学,2021,49(20):189−191. [LI J R, SUN Q. Preparation and performance analysis of edible film with cinnamon essential oil[J]. Anhui Agricultural Science,2021,49(20):189−191.] doi: 10.3969/j.issn.0517-6611.2021.20.049 LI J R, SUN Q. Preparation and performance analysis of edible film with cinnamon essential oil[J]. Anhui Agricultural Science, 2021, 49(20): 189−191. doi: 10.3969/j.issn.0517-6611.2021.20.049

[45] 黄梓炜, 吴雪辉, 周悦, 等. 肉桂精油可食性复合膜的抑菌性能研究[J]. 中国调味品,2022,47(12):22−25. [HUANG Z W, WU X H, ZHOU Y, et al. Study on the antibacterial property of edible composite film with cinnamon essential oil[J]. China Flavourings,2022,47(12):22−25.] doi: 10.3969/j.issn.1000-9973.2022.12.005 HUANG Z W, WU X H, ZHOU Y, et al. Study on the antibacterial property of edible composite film with cinnamon essential oil[J]. China Flavourings, 2022, 47(12): 22−25. doi: 10.3969/j.issn.1000-9973.2022.12.005

[46] 李莹, 杨欣悦, 王雪羽, 等. 壳聚糖基复合膜的成膜机理和特性研究进展[J]. 食品工业科技,2022,43(7):430−438. [LI Y, YANG X Y, WANG X Y, et al. Advances in film-forming mechanism and properties of chitosan-based composite films[J]. Food Industry Science and Technology,2022,43(7):430−438.] LI Y, YANG X Y, WANG X Y, et al. Advances in film-forming mechanism and properties of chitosan-based composite films[J]. Food Industry Science and Technology, 2022, 43(7): 430−438.

[47] Guo S , Liang D , Liu Q , et al. Cinnamaldehyde emulsions for a composite film based on polyvinyl alcohol/hydrophobically modified konjac glucomannan matrix:Degradability and bacteriostatic properties [J]. Food Packaging and Shelf Life, 2024, 44:101318-101318.

[48] ZONGBAO Z, JIANGWEI X, SHENG H, et al. A wet-adhesive carboxymethylated yeast β-glucan sponge with radical scavenging, bacteriostasis and anti-inflammatory functions for rapid hemostasis[J]. International Journal of Biological Macromolecules,2023,230:123158. doi: 10.1016/j.ijbiomac.2023.123158

[49] ANDRIATI N, ARUM W P, SUPRIYADI, et al. Characterization of tuna skin gelatin edible films with various plasticizers-essential oils and their effect on beef appearance[J]. Journal of Food Processing and Preservation,2021,45(9):15701.

[50] 亓伟杰, 连子腾, 代世成, 等. 不同浓度大豆分离蛋白对壳聚糖-纳米纤维可食膜结构及性能的影响[J]. 中国食品学报,2023,23(6):267−275. [QI, W J, LIAN, Z T, DAI, S C, et al. Effects of different concentrations of soybean isolate protein on the structure and properties of chitosan-nanofibre edible membrane[J]. Chinese Journal of Food,2023,23(6):267−275.] QI, W J, LIAN, Z T, DAI, S C, et al. Effects of different concentrations of soybean isolate protein on the structure and properties of chitosan-nanofibre edible membrane[J]. Chinese Journal of Food, 2023, 23(6): 267−275.

[51] JIANFEI Z, XIAOMEI C, TINGTING H, et al. Characterization and antioxidant properties of chitosan/ethyl-vanillin edible films produced via Schiff-base reaction[J]. Food Science and Biotechnology,2022,32(2):157−167.

[52] 王耀, 陈萍, 王朋凯, 等. 百里香精油/磷酸化淀粉晶/明胶复合膜的制备及性能研究[J]. 食品与发酵工业,2023,49(13):191−199. [WANG Y, CHEN P, WANG P K, et al. Preparation and properties of thyme essential oil/phosphorylated starch crystals/gelatin composite film[J]. Food and Fermentation Industry,2023,49(13):191−199.] WANG Y, CHEN P, WANG P K, et al. Preparation and properties of thyme essential oil/phosphorylated starch crystals/gelatin composite film[J]. Food and Fermentation Industry, 2023, 49(13): 191−199.

[53] PIERMARIA J, BOSCH A, PINOTTI A, et al. Kefiran films plasticized with sugars and polyols:water vapor barrier and mechanical properties in relation to their microstructure analyzed by ATR/FT-IR spectroscopy[J]. Food Hydrocolloids,2011,25(5):1261−1269. doi: 10.1016/j.foodhyd.2010.11.024

[54] WU C, PENG S, WEN C, et al. Structural characterization and properties of konjac glucomannan/curdlan blend films[J]. Carbohydrate Polymers,2012,89(2):497−503. doi: 10.1016/j.carbpol.2012.03.034

[55] GUTIéRREZ T J, MORALES N J, PéREZ E, et al. Physico-chemical properties of edible films derived from native and phosphated cush-cush yam and cassava starches[J]. Food Packaging and Shelf Life,2015(3):1−8.

[56] ZHAO Q, DONG B, CHEN J, et al. Effect of drying methods on physicochemical properties and antioxidant activities of wolfberry (Lycium barbarum) polysaccharide[J]. Carbohydrate Polymers,2015,127:176−181. doi: 10.1016/j.carbpol.2015.03.041

下载:

下载:

下载:

下载: