Effect of Combined Germination-Fermentation Treatment on the Structure and Physicochemical Properties of Foxtail Millet Starch

-

摘要: 为了探究发芽-发酵联合处理对谷子淀粉结构和理化性质的影响,以长杂谷466为原料,先进行发芽处理,再进行食窦魏斯氏菌发酵处理,采用碱提法提取淀粉,并对其直链淀粉含量、分子量、微观形貌、粒度分布、短程有序结构、糊化特性和热力学特性等结构和理化性质进行分析。结果表明:经发芽-发酵联合处理后,谷子总淀粉含量显著降低(P<0.05),淀粉颗粒表面出现明显的裂痕,更多的淀粉颗粒表面出现大而深的孔洞,破坏了淀粉颗粒的完整性,显著减小了淀粉粒径(P<0.05),增加了淀粉的结晶度和有序化程度。与单独发芽相比,发芽-发酵联合处理使谷子淀粉具有更高的直链淀粉含量(24.53%)、回生值(2754 cP)、糊化温度(76.9 ℃)、∆H(11.3 J/g)和Tc(79.0 ℃),且具有更低的峰值黏度(4593 cP)和崩解值(2926 cP)。综上所述,发芽-发酵联合处理对谷子淀粉结构、糊化特性和热力学特性有显著影响。相比发芽处理,发芽-发酵联合处理后谷子淀粉的抗消化性、抗膨胀性、热稳定性和抗剪切力更好,本研究结果将为谷子全谷物食品的开发提供理论依据。Abstract: To investigate the effects of combined germination-fermentation treatment on structural and physicochemical properties of foxtail millet starch. Starch was extracted from Changzagu 466 using an alkaline extraction method. Changzagu 466 was first germinated and then fermented by Weissella cibaria. Properties such as amylose content, molecular weight, morphology structure, granule size, short-range ordered structure, pasting properties, and thermal properties of starch from foxtail millet were analyzed. The results showed that the combined germination-fermentation treatment resulted in a significant decrease (P<0.05) in its total starch content of foxtail millet. Obvious cracks appeared on the surface of starch granules, and more granules appeared to large and deep pores on the surface, which destroyed the integrity of the granules. This significantly reduced (P<0.05) starch particle size and increased starch crystallinity and the degree of starch ordering. The combined germination-fermentation treatment resulted in foxtail millet starch with higher amylose content (24.53%), setback viscosity (2754 cP), pasting temperature (76.9 ℃), ∆H (11.3 J/g), and Tc (79.0 ℃), but lower peak viscosity (4593 cP) and breakdown viscosity (2926 cP) compared to germination alone. In conclusion, the combined germination-fermentation treatment had a significant effect on the structure, pasting characteristics, and thermodynamic properties of foxtail millet starch. Compared to the germination treatment alone, foxtail millet starch subjected to the combined germination-fermentation treatment had better anti-digestion, anti-swelling force, heat resistance and shear resistance. The results of this study would provide a theoretical basis for the development of whole foxtail milllet.

-

谷子(Setaria italica L.)是一种药食两用的优质杂粮,由胚、胚乳和麸皮组成的健康全谷,富含蛋白质、膳食纤维、矿物质、生物活性成分和抗氧化性物质等多种功能营养成分[1],具有降血糖、抗氧化、降血压、调节免疫等功能作用[2−3]。尽管谷子作为全谷,营养价值高,但是存在口感粗糙、营养物质生物利用度低以及加工产品单一等问题,不被消费者接受,制约了谷物产品的应用及消费。

改善谷物品质的加工方法有很多种,如超声、挤压、发芽和发酵等,其中发芽和发酵两种方法被认为是谷物加工的理想方法[4]。发芽是一种简单经济有效的提高谷物品质的加工方法。在发芽过程中,内源酶被激活,淀粉、蛋白质和纤维等生物大分子物质被水解,质地软化[5]。研究表明,发芽处理使淀粉酶活性提高,这改变了淀粉分子大小,降低了面包硬度,从而改善了面包品质[6]。发芽的谷物已被用作天然功能性食品,具有较高的营养价值[7]。此外,发酵是谷物加工中重要的方法之一,在发酵过程中,通过微生物产生的酶和有机酸来改变淀粉结构[8],进而影响其品质特性。Falade等[9]研究表明发酵可以改变淀粉颗粒,使面团具有更强的粘性、柔软性和更小的弹性,改善了玉米面包的品质。乳酸菌是发酵谷物中应用最广泛的菌种之一,不同的乳酸菌对谷物的发酵效果不同,其产品品质存在差异。食窦魏斯氏菌属于乳酸菌,具有产胞外多糖、免疫调节和抗氧化等益生特性,不仅可以改善食品品质,增强食品的风味和可接受性,还可抑制有害菌的生长,调节肠道微生物[10]。与单独发芽或发酵相比,发芽-发酵联合处理能更有效提高谷物粉的理化特性[11]。Wei等[12]研究表明,适度发芽处理能有效提高发酵糙米糕的综合品质。发酵后的发芽小米可用于生产高附加值的食品和饮料[13]。此外在淀粉相关特性修饰方面,先发芽再发酵比单独发芽或发酵更有效[14],因此,采用发芽和食窦魏斯氏菌发酵联合处理技术,在改善谷物品质方面和全谷物食品开发方面具有潜在的应用前景。

淀粉是谷子中的主要成分,淀粉特性是影响谷子品质的重要因素。发芽或发酵能改变淀粉的理化特性,现有研究主要集中在单独发芽或发酵对糙米[15]、青稞[16]、玉米[17]、高粱[18]和糜子[8]等谷物淀粉结构和理化性质的影响,而关于发芽-发酵联合处理对谷子中淀粉结构和理化性质的研究甚少,且不同种类的乳酸菌对淀粉结构和理化性质影响有所差异[19]。本研究采用前期从小米发糕发酵剂中筛选获得的食窦魏斯氏菌(Weissella cibaria)作为发酵剂[20],以长杂谷466为原料,其具有丰产性好,抗逆性强,平均亩产500多kg,于2017年获评国家一级优质米,已在山西、河北、内蒙等中晚熟区大面积推广应用。将原料先进行发芽处理,再进行发酵,用碱提法提取淀粉,深入研究发芽-发酵联合处理对谷子淀粉结构和理化性质的影响,为全谷物食品的开发利用提供理论依据。

1. 材料与方法

1.1 材料与仪器

长杂谷466 山西农业大学谷子研究所选育的优质谷子杂交种。2022年种植于山西省长治市武乡县上司乡圪佬湾村,10月收获,储存于4 ℃冰箱中保存备用;食窦魏斯氏菌(发酵剂) 从小米发糕发酵剂中筛选获得[20]。

Anke低速离心机 上海安亭科学仪器公司;Matersizer 3000马尔文激光粒度仪 Malvern Instruments Ltd Worcestershire UK;X'Pert Pro X射线衍射仪 PANalytical;Q2000差示热值扫描仪 TA Instruments;HITACHI Regulus 8100高分辨场发射扫描电子显微镜 日立;Nicolet iZ-10傅里叶变换红外光谱仪 Thermo;Newport Scientific快速粘度分析仪(RVA) Newport Scientific Pty Ltd。

1.2 实验方法

1.2.1 谷子预处理及淀粉样品的制备

1.2.1.1 发芽、发芽-发酵联合处理的谷子制备

发芽谷子(GFM)制备[21]:将大小一致、颗粒饱满的谷子(250 g)清洗干净,用0.1%次氯酸钠溶液消毒30 min,然后用超纯水彻底冲洗干净,在(25±2) ℃的超纯水中浸泡12 h,取出并沥干水分,单层平铺于放有纱布的托盘中,并在籽粒上方覆盖湿润的纱布。在(25±2) ℃(湿度80%~90%)的黑暗环境中发芽48 h,期间每隔12 h喷洒一次水,保持湿润的环境。发芽结束后,将其放在(45±2) ℃的干燥箱中干燥12 h,密封保存。

发芽-发酵联合处理谷子(GFFM)制备:取上述发芽的谷子,置于250 mL烧杯中,将发芽谷子与无菌水按比例1:3(m:v)混合,然后按1%接种量接种活化好的食窦魏斯氏菌(菌密度为108 CFU/mL)到混合物中,在37 ℃下密封发酵24 h,然后,在(45±2) ℃的干燥箱中干燥12 h,密封保存。

1.2.1.2 谷子、发芽谷子和发芽-发酵联合处理的谷子淀粉样品的制备

从谷子(FM)、发芽谷子(GFM)和发芽-发酵联合处理的谷子(GFFM)中提取淀粉,三种淀粉均采用碱提法制备,参照Bian等[8]和Sun等[22]方法并进行改进,先用砻谷机进行脱壳处理,再用粉碎机将小米磨成粉,过100目筛,取200 g小米粉加入0.1 mol/L NaOH溶液,按料液比1:5(W/V)混合,料理机搅拌15 min(每5 min暂停2 min),置于4 ℃冰箱中静置12 h,弃去上层黄色物质,剩下溶液过200目筛,用超纯水多次冲洗筛网,直到白色物质全部洗出,将上清液4500 r/min 离心10 min,弃去上清液和黄色沉淀,水洗沉降物离心,多次重复此步骤,直至上层液体澄清。用0.1 mol/L HCl调节pH至中性,离心,将沉淀放入烘箱中,在40 ℃下干燥24 h,过100目筛即为制备好的淀粉,密封保存。

1.2.2 总淀粉、直链淀粉测定

总淀粉含量采用AOAC 996.11方法测定,直链淀粉含量按照GB/T 15683-2008《大米 直链淀粉含量测定》进行测定。

1.2.3 扫描电镜分析

淀粉样品过100目筛,制成浓度为15%(w/w)淀粉悬浮液,用移液枪吸取,滴在铜台的导电胶上,在37 ℃过夜,离子溅射仪喷金后,用扫描电镜观察。

1.2.4 粒度分布测定

淀粉粒度测定值是由激光粒度仪Matersizer 3000进行计算,测量范围为0.1~2000 μm的粒度。具体步骤为:称取纯化的淀粉100 mg,用去离子水悬浮,制成浓度为1%(w/w)的淀粉悬浮液,在仪器的分散池中,上机检测,测定淀粉颗粒直径。

1.2.5 XRD衍射分析

用X射线衍射仪对淀粉样品进行分析,将研磨过筛后的淀粉样品置于载物台上,压紧,铺均匀,在4°~60°扫描范围,0.02°步长,以4°/min扫描速度,用NaI晶体闪烁计数器测量X-射线的强度。

1.2.6 红外扫描分析

称取干燥的淀粉样品(约5 mg)与溴化钾粉末按1:50(m/m)混合,用模具压制成片,用傅里叶变换红外光谱仪扫描,在4000~400 cm−1范围,以4.00 cm−1光谱分辨率,扫描32次。

1.2.7 分子质量分析

采用凝胶色谱-示差-多角度激光光散射系统分析淀粉的分子质量,参照李祥栋等[23]的方法,称取已纯化淀粉5 mg,加5 mL流动相DMSO,80 ℃加热溶解3 h,上机检测。

1.2.8 淀粉糊化特性分析

参考Siroha等[24]的方法,对淀粉糊化特性通过RVA快速粘度仪进行测定,称取3 g淀粉,加入蒸馏水,配成12%的淀粉乳(干基计),装入铝筒中,混合均匀,然后运行程序进行测定。

1.2.9 淀粉热特性测定

称取3.0 mg淀粉样品,加入6.0 mg的去离子水,4 ℃平衡24 h,由30 ℃升温至105 ℃,以10 ℃/min的速度,采用差示热值扫描仪扫描热量变化。

1.3 数据处理

实验测定指标进行三次重复,结果以平均值±标准差表示,采用SPSS26进行单因素方差分析和Duncan检验(P<0.05),用Origin2021作图和数据处理。

2. 结果与分析

2.1 谷子中总淀粉含量和直链淀粉含量分析

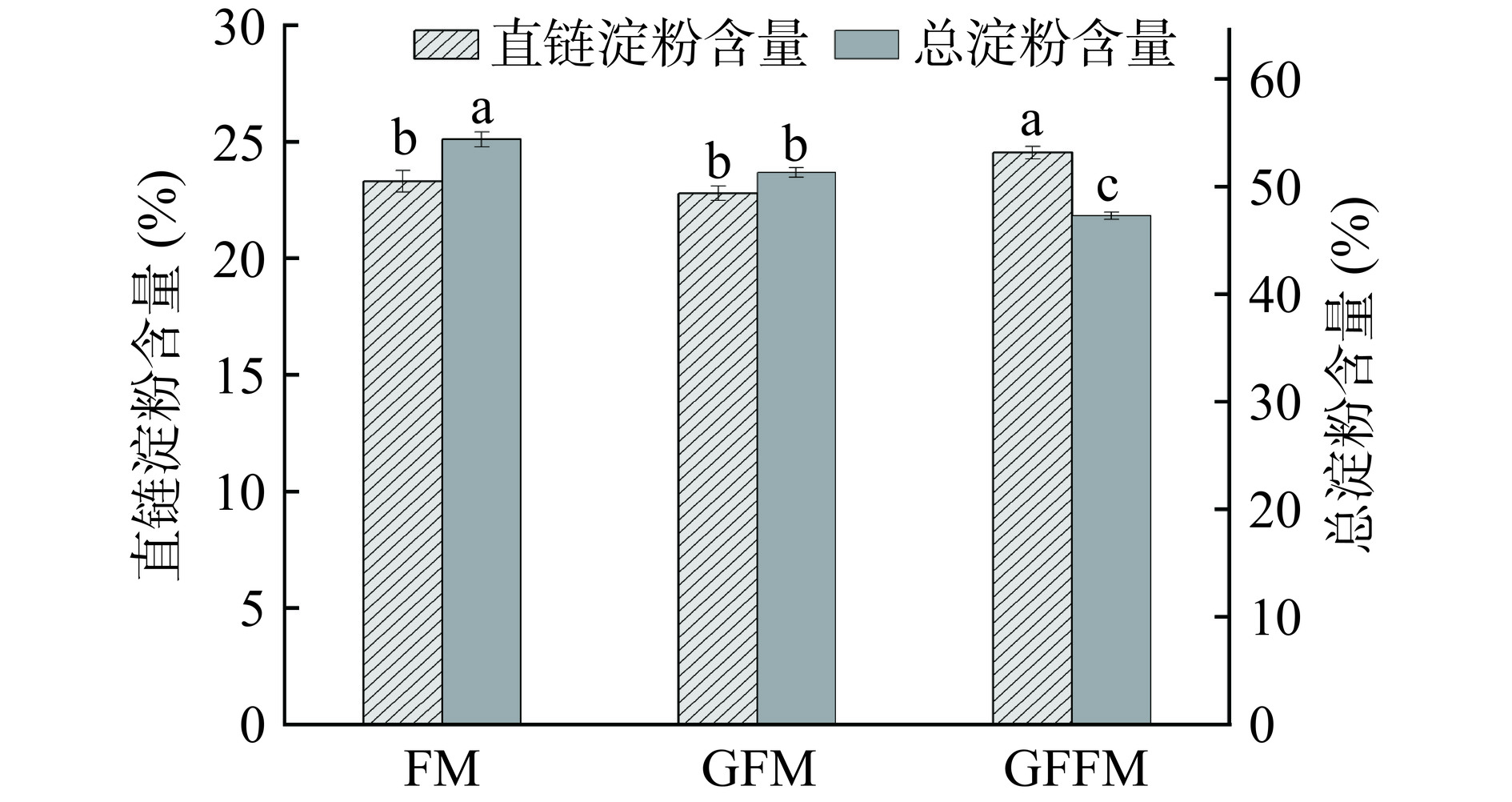

发芽、发芽-发酵联合处理对谷子总淀粉含量和直链淀粉含量的影响见图1。原谷子中的淀粉含量为54.38%,与韦露露等[25]研究小米淀粉(53.71%~67.36%)的结果相似,相比小米的淀粉范围(50%~80%),其淀粉含量偏低。与未处理谷子相比,发芽、发芽-发酵联合处理后谷子总淀粉含量显著下降(P<0.05),且发芽-发酵联合处理后总淀粉含量最低,为47.28%。总淀粉含量的降低是由于发芽、发芽-发酵过程中,产生的淀粉酶将淀粉降解成还原糖,使总淀粉含量降低[26]。直链淀粉是影响谷子淀粉结构、糊化特性、热力学特性及食用品质的重要因素之一,与淀粉消化率呈负相关[27]。谷子原淀粉的直链淀粉含量为23.30%,经过发芽处理,谷子直链淀粉含量略有下降,但差异不显著(P>0.05)。而在发芽-发酵联合处理后,直链淀粉含量显著增加,可能是由于发芽谷子在乳酸菌发酵过程中,产生一些酶(β-淀粉酶)或有机酸,引起支链淀粉短侧链部分断裂,支链淀粉脱支,小分子直链淀粉的产生导致发酵24 h的直链淀粉含量增加[28],这与Bian等[8]研究结果一致。综上表明,相比发芽处理,GFFM的总淀粉含量降低,直链淀粉含量增加,说明GFFM淀粉具有较好的抗消化性。

2.2 淀粉颗粒形貌结构及粒径分布

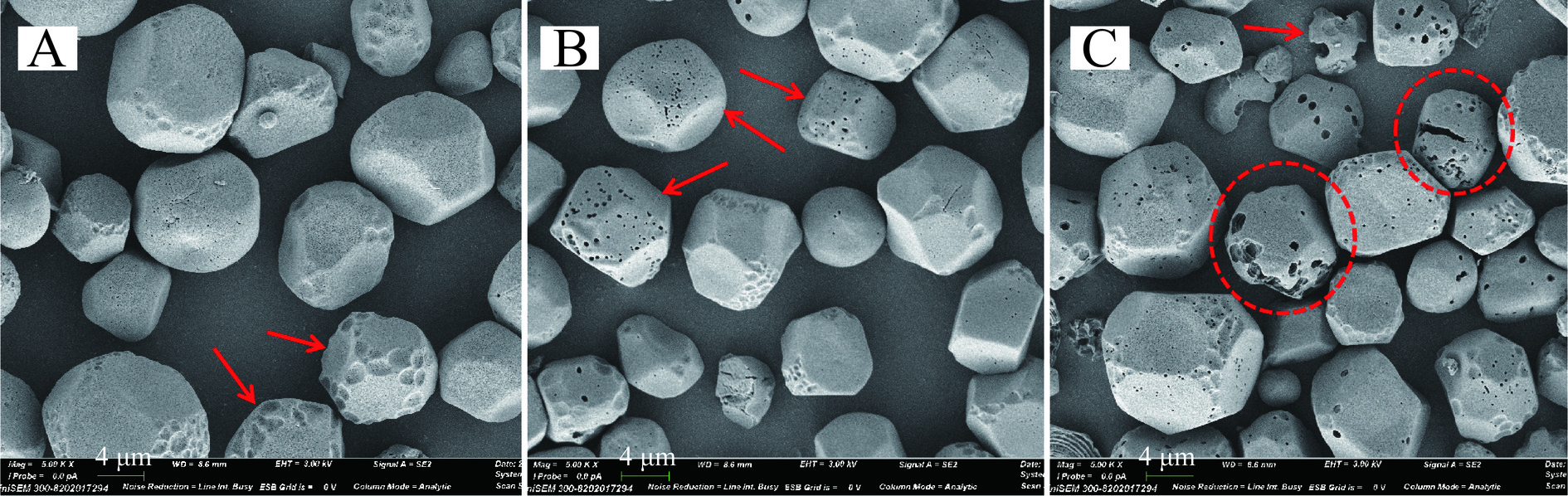

图2为谷子淀粉发芽、发芽-发酵联合处理前后的微观结构图。FM淀粉颗粒主要呈不规则的多边形,较少的淀粉颗粒呈球形,部分淀粉表面有浅凹痕。经发芽处理后的谷子淀粉表面有轻微的侵蚀迹象,淀粉表面出现了细小的孔洞,淀粉颗粒完整性未被破坏,这是由于发芽过程中,淀粉酶渗到淀粉内部由内向外发生水解,导致淀粉颗粒内部出现细小的孔洞。Ma等[29]研究发现发芽后的玉米淀粉颗粒表面也出现细小的孔洞,与本文研究结果一致。相对于发芽谷子淀粉颗粒,发芽-发酵联合处理的谷子淀粉颗粒表面出现裂纹和更多的孔洞,且孔洞变得深而大,表面变粗糙,出现不完整的淀粉颗粒,这表明发芽-发酵联合处理对谷子淀粉的破坏程度更大。

淀粉的粒度是决定食品质地的主要因素之一,淀粉颗粒越大,其加工后的食品质地较硬[30]。表1可知谷子经发芽、发芽-发酵联合处理后淀粉的粒度分布,FM淀粉的体积平均粒径D[4,3]为11.8,经发芽、发芽-发酵联合处理后,谷子淀粉的粒径均降低,且GFFM淀粉粒径降低程度高于GFM淀粉,这可能与发芽-发酵过程中淀粉颗粒表面被侵蚀、降解和破坏有关,表明发芽-发酵联合处理后,淀粉颗粒显著(P<0.05)变小,相比GFM淀粉,GFFM淀粉适宜加工成硬度较小的食品。

表 1 发芽、发芽-发酵联合处理对谷子淀粉体积平均粒径、相对结晶度、R1047/1022和分子量的影响Table 1. Effects of germination, combined germination-fermentation on the granule size, degree of crystallinity, R1047/1022 and molecular weight of foxtail millet starch处理 D[4,3](μm) 相对结晶度(%) R1047/1022 Mn(×104 kDa) Mw(×104 kDa) Mw/Mn FM 11.80±0.00a 18.67±0.02c 0.750±0.015c 9.46±0.09a 17.39±0.85b 1.84±0.12b GFM 11.50±0.06b 18.78±0.03b 0.800±0.002a 8.52±0.25b 19.79±0.81a 2.32±0.16a GFFM 11.30±0.10c 19.36±0.08a 0.774±0.008b 9.23±0.31a 19.63±0.84a 2.13±0.02a 注:Mn为数均分子量;Mw为重均分子量;Mw/Mn为多分散指数;D[4,3]为体积加权平均值;R1047/1022为1047/1022 cm−1;不同小写字母表示数据差异显著,P<0.05。 2.3 淀粉XRD衍射和相对结晶度

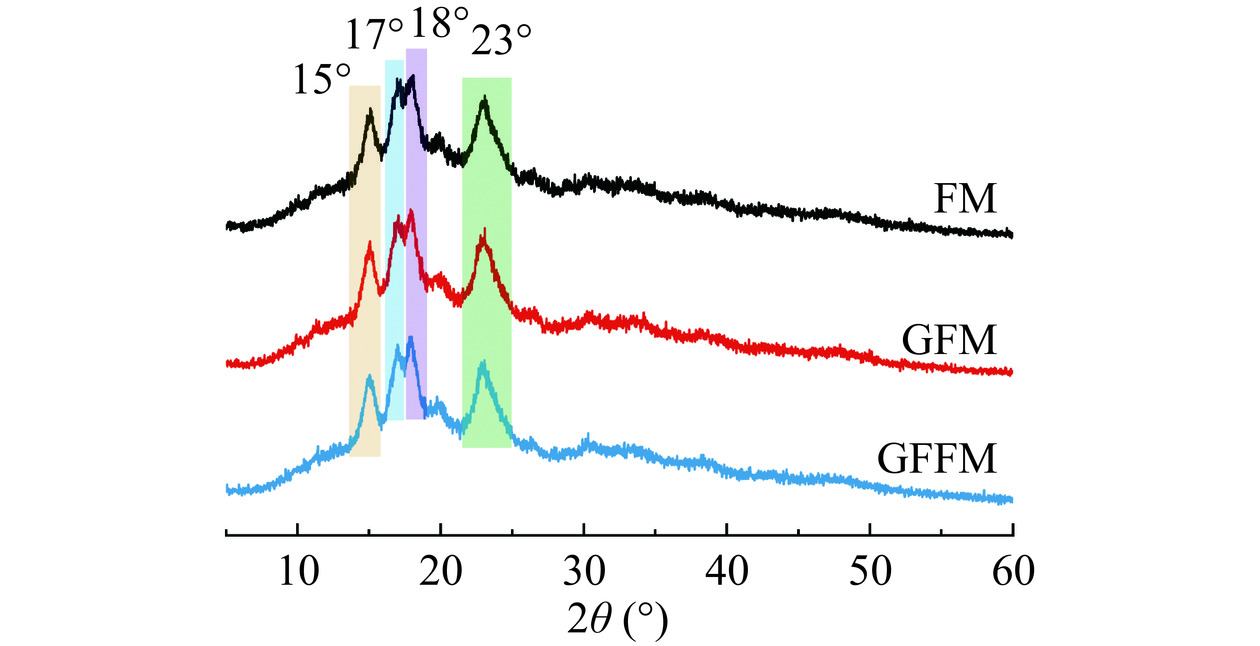

淀粉的颗粒是由直链淀粉分子和支链淀粉分子通过氢键结合构成高度有序的晶体结构,由无定形区和结晶区组成,结晶区在X射线衍射图谱上表现为衍射尖峰,主要由支链淀粉组成,通过双螺旋结构有序排列,而无定形区,其衍射图谱为弥散衍射峰,无序排列构成[31]。 如图3所示, FM淀粉在衍射角2θ为15°和23°有较强的单衍射峰,且在17°和18°处有双衍射峰,表现为典型的A型淀粉晶体结构。谷子经过发芽、发芽-发酵联合处理之后,其淀粉颗粒特征衍射峰出现的位置未发生变化,表明淀粉的结晶类型未受发芽、发芽-发酵联合处理的影响。由XRD图谱计算得出的结晶度如表1所示,FM淀粉结晶度为18.67%,谷子经过发芽后,GFM淀粉结晶度增加,Liu等[32]研究发现玉米淀粉在发芽48 h,淀粉结晶度增加,并达到最高,这与本研究结果一致。发芽-发酵联合处理后,与FM相比,其淀粉结晶度显著增加(P<0.05),并高于GFM的淀粉结晶度,这可能是由于酶在发芽的初期攻击淀粉的无定形区,导致结晶区面积相对增加,然后经过乳酸菌发酵,产生有机酸(乳酸),水解淀粉的长支链,生成大量的中间体和短支链淀粉,导致发酵24 h的相对结晶度增加[33]。综合分析表明,发芽-发酵联合处理增加了谷子淀粉的结晶度。

2.4 淀粉短程有序结构

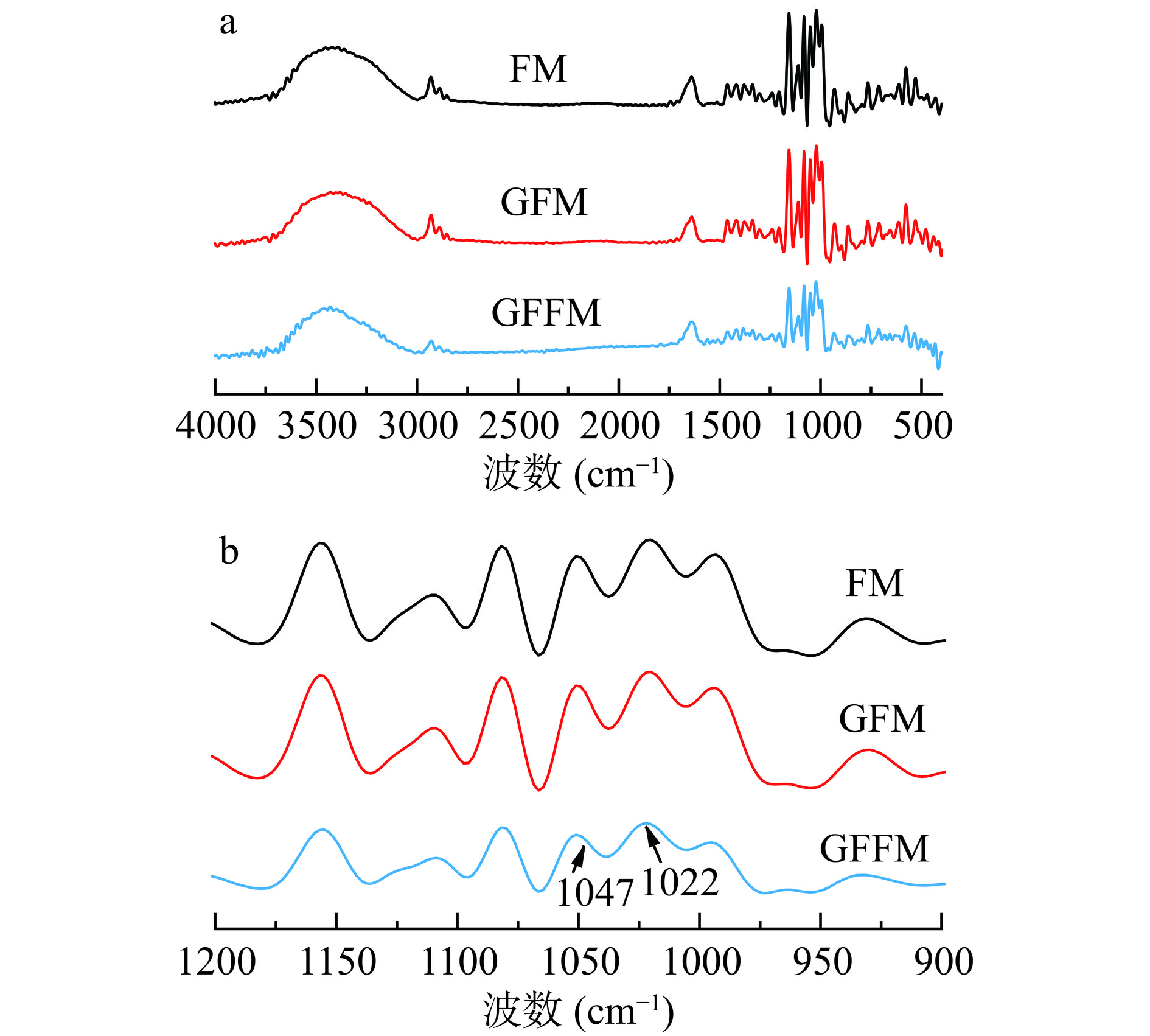

利用FTIR分析了FM、GFM和GFFM的淀粉在4000~400 cm−1区域的短程有序结构,如图4a所示,FM、GFM和GFFM淀粉图谱特征峰的位置和形状未发生变化,没有出现新的吸收峰,表明发芽、发芽-发酵联合处理未引起淀粉官能团的改变。图4b显示的是FM、GFM和GFFM淀粉在900~1200 cm−1范围内傅里叶红外区卷积图谱。1047 cm−1和1022 cm−1红外吸收峰分别代表淀粉结构的有序化区域和无定型域,其两峰的比值用R1047/1022表示,反映了淀粉的有序化程度[34]。R1047/1022值越高,淀粉分子有序化程度越高[35]。表1可知FM、GFM和GFFM淀粉的红外光谱峰强度R1047/1022值,由表1可知,FM淀粉的R1047/1022值为0.75,发芽使谷子淀粉R1047/1022值增加,可能是由于酶水解,无序结构的初始破坏引起表面分子的重新排列,从而导致发芽48 h的短程有序结构增强[32]。与FM相比,发芽-发酵联合处理下,淀粉R1047/1022值增加,表明发芽-发酵联合处理增加了淀粉分子间和淀粉分子内的氢键,可能是由于发芽-发酵过程中产生的短链分子具有很强的相互作用力,使短链淀粉分子聚集在一起,有利于形成短程有序结构[36]。

2.5 淀粉分子量分析

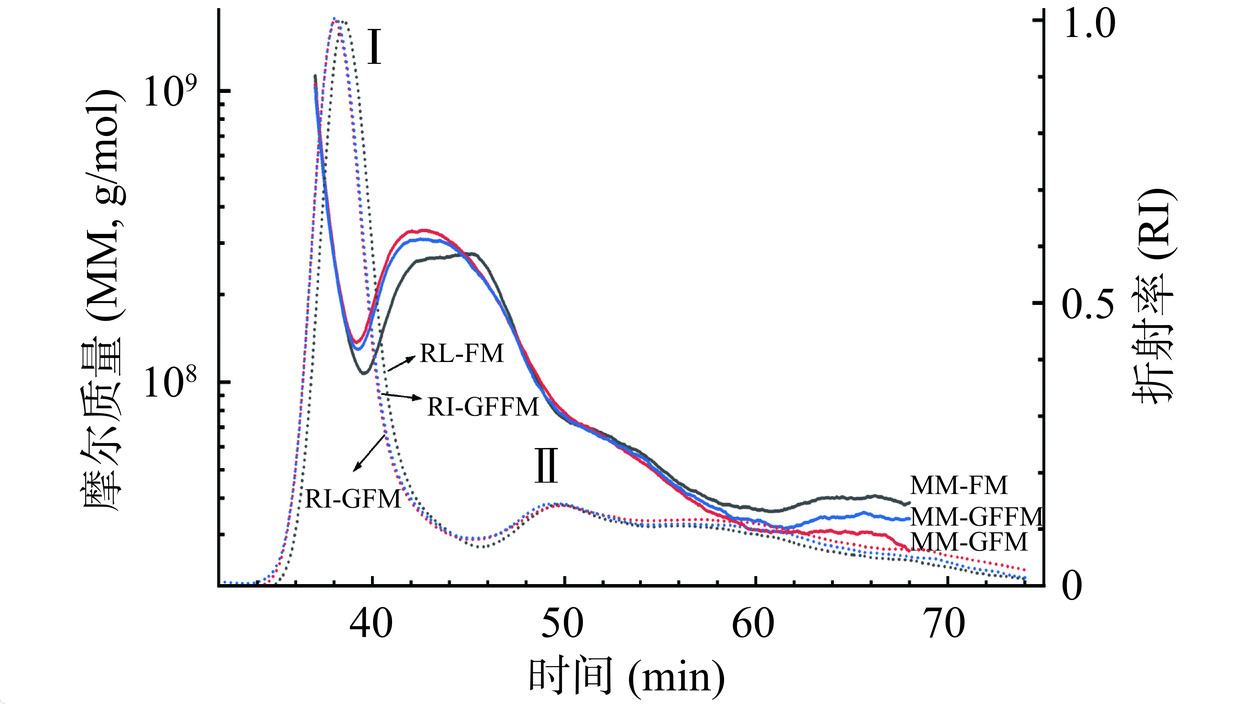

FM、GFM和GFFM淀粉的绝对分子量图如图5所示,FM、GFM和GFFM的数均分子量(Mn)、重均分子量(Mw)和多分散指数(Mw/Mn)见表1。由图5可知,在FM、GFM和GFFM淀粉分子量图谱中观察到明显组分峰,第Ⅰ峰为高分子质量峰,为支链淀粉,第Ⅱ峰为低分子质量峰,为直链淀粉。与FM相比,谷子经过发芽处理后淀粉的重均分子量(Mw)增加,而数均分子量(Mn)降低。Wu等[37]研究发芽时间对不同水稻品种糙米粉和淀粉理化性质的影响,发现发芽后水稻淀粉的Mw增加,Mn降低,这与本研究结果一致。与GFM相比,发芽-发酵联合处理后,Mw降低,而Mn增加。多分散指数(Mw/Mn)是淀粉分子量的重要参数,Mw/Mn比值高低反映聚合物分子量分布的宽窄和组分的复杂程度,Mw/Mn越接近于1,表明组分越单一,分布窄,Mw/Mn比值越高,分子量分布越宽,组分越复杂[38]。由表1的结果可知,GFM淀粉的Mw/Mn的值高于FM,Xu等[39]研究发现类似结果,GFFM淀粉的Mw/Mn的值略高于FM,低于GFM。相比单独发芽,GFFM淀粉分布变窄,可能是由于发芽-发酵联合处理过程中,在酸的作用下,部分短支链淀粉发生水解,生成小分子物质[40]。

2.6 淀粉糊化特性

表2为发芽、发芽-发酵联合处理下谷子淀粉的糊化特性。发芽、发芽-发酵联合处理后淀粉的峰值黏度显著低于谷子原淀粉(P<0.05),且发芽-发酵联合处理峰值黏度最低,已有研究表明糊化特性的峰值黏度与直链淀粉含量呈负相关[41],此结果与发芽-发酵联合处理后谷子直链淀粉含量相互印证。崩解值是衡量淀粉热糊稳定性和抗剪切性的重要指标[42],崩解值越大,热糊稳定性和抗剪切性越差。FM淀粉的崩解值显著高于GFM和GFFM(P<0.05),表明谷子原淀粉的热糊稳定性差,淀粉颗粒在加热过程中溶胀后易破裂。相比发芽处理,GFFM淀粉的崩解值较低,表明发芽-发酵联合处理后的谷子淀粉的热稳定性和抗剪切性更好,这种淀粉特性将在布丁型产品和高温加工的产品中可能有潜在应用前景[42]。发芽、发芽-发酵两种处理间对崩解值影响差异不显著(P>0.05)。Li等[43]研究发现高粱和小米淀粉在发芽过程中崩解值降低,这可能是由于发芽过程中,酶被激活,淀粉降解导致峰值黏度和谷值黏度降低,进而使崩解值降低。研究表明,糯谷发酵24 h的淀粉崩解值无显著变化[44],这与本研究结果一致。回生值反映淀粉的冷糊稳定性,回生值越大表明淀粉越易老化。FM淀粉回生值最小,表明谷子原淀粉不易老化,谷子经过发芽、发芽-发酵联合处理后,淀粉的回生值显著高于谷子原淀粉(P<0.05),且发芽-发酵联合处理后淀粉回生值显著高于单独发芽处理(P<0.05),这在发酵的糜子淀粉中也发现类似结果[8],表明发芽-发酵联合处理后淀粉更易老化。糊化温度的高低反映淀粉糊化的难易和膨胀程度,淀粉的糊化温度越高,抗膨胀性越高[45]。FM淀粉糊化温度最低,GFM和GFFM显著高于FM(P<0.05),且GFFM淀粉高于GFM淀粉,表明GFFM淀粉具有更高的抗膨胀性,这可能是由于发酵过程中,产生小分子物质(如糖),与水分子结合,抑制了淀粉的水化膨胀,使糊化温度升高[46],表明发芽-发酵联合处理后的淀粉更难发生糊化。

表 2 发芽、发芽-发酵联合处理对谷子淀粉糊化特性的影响Table 2. Effects of germination, combined germination-fermentation on pasting properties of foxtail millet starch处理 峰值黏度(cP) 谷值黏度(cP) 崩解值(cP) 最终黏度(cP) 回生值(cP) 糊化温度(℃) FM 5235.5±4.5a 1978.0±82.0a 3257.5±77.5a 3951.0±91.0b 1973.0±9.0c 75.0±0.4b GFM 4783.5±11.5b 1772.5±42.0b 3011.0±54.0b 4014.5±7.5b 2242.0±50.0b 76.5±0.4a GFFM 4593.0±23.0c 1667.5±9.5b 2925.5±32.5b 4421.5±28.5a 2754.0±19.0a 76.9±0.0a 注:同列不同小写英文字母表示数据差异显著,P<0.05。 2.7 淀粉热力学特性

谷子经发芽、发芽-发酵联合处理前后淀粉的起始糊化温度(To)、峰值温度(Tp)、终止温度(Tc)和糊化焓(∆H)见表3,谷子经过发芽处理后,其淀粉的To和Tp高于谷子原淀粉,而Tc和∆H与谷子原淀粉无显著差异(P>0.05)。与FM相比,发芽-发酵联合处理显著提高了淀粉的To、Tp、Tc和∆H值,研究发现∆H与淀粉的结晶度呈正相关[47],这与本研究结果相一致。糊化焓(∆H)是指崩解淀粉从有序的晶体结构(双螺旋结构)向无定形结构转变时所需要的能量[48]。∆H值越大,淀粉的热稳定性越强,其晶体结构越不易破坏。发芽-发酵联合处理使谷子淀粉∆H值增加,这是由于发芽后的谷子经过乳酸菌发酵,淀粉颗粒非结晶区被破坏,结晶度增加,结晶区相对比例增加,需要更高的能量来破坏淀粉的结晶区,∆H值增加[46],表明发芽-发酵联合处理后谷子淀粉具有更有序化的双螺旋结构。

表 3 发芽、发芽-发酵联合处理对谷子淀粉热力学特性的影响Table 3. Effect of germination, combined germination-fermentation on thermal property of foxtail millet starch处理 To(℃) Tp(℃) Tc(℃) ∆H(J/g) FM 64.1±0.5b 70.5±0.0b 78.5±0.2b 10.57±0.01b GFM 66.1±0.4a 71.2±0.3a 78.4±0.1b 10.77±0.02b GFFM 66.8±0.7a 71.4±0.1a 79.0±0.1a 11.30±0.40a 注:To为起始糊化温度;Tp为峰值温度;Tc为终止温度;∆H为糊化焓。 3. 结论

研究发芽-发酵联合处理对谷子淀粉结构和理化性质的影响。发芽-发酵联合处理降低谷子总淀粉含量,显著增加了淀粉的直链含量,使淀粉颗粒表面出现明显的裂纹,更多颗粒表面产生大而深的孔洞,破坏了淀粉颗粒的完整性。发芽处理降低了直链淀粉的含量,使淀粉颗粒产生一定程度的破坏,表面凹痕变深,且出现了明显的孔洞。发芽、发芽-发酵两种处理未改变谷子淀粉A型晶体结构类型,但显著减小淀粉的平均粒径(P<0.05),增加了淀粉的相对结晶度和有序化程度,且发芽-发酵联合处理的结果更为明显。对重均分子量(Mw)、谷值黏度、崩解值和糊化温度这些指标,发芽、发芽-发酵两种处理间无显著差异(P>0.05)。与单独发芽处理相比,发芽-发酵联合处理能明显提高谷子淀粉回生值、Tc和糊化焓∆H。综上所述,发芽-发酵联合处理改变了谷子淀粉结构,影响了淀粉的理化性质,进而可以改善谷子的加工品质,对谷子全谷物开发具有潜在的应用价值。

-

表 1 发芽、发芽-发酵联合处理对谷子淀粉体积平均粒径、相对结晶度、R1047/1022和分子量的影响

Table 1 Effects of germination, combined germination-fermentation on the granule size, degree of crystallinity, R1047/1022 and molecular weight of foxtail millet starch

处理 D[4,3](μm) 相对结晶度(%) R1047/1022 Mn(×104 kDa) Mw(×104 kDa) Mw/Mn FM 11.80±0.00a 18.67±0.02c 0.750±0.015c 9.46±0.09a 17.39±0.85b 1.84±0.12b GFM 11.50±0.06b 18.78±0.03b 0.800±0.002a 8.52±0.25b 19.79±0.81a 2.32±0.16a GFFM 11.30±0.10c 19.36±0.08a 0.774±0.008b 9.23±0.31a 19.63±0.84a 2.13±0.02a 注:Mn为数均分子量;Mw为重均分子量;Mw/Mn为多分散指数;D[4,3]为体积加权平均值;R1047/1022为1047/1022 cm−1;不同小写字母表示数据差异显著,P<0.05。 表 2 发芽、发芽-发酵联合处理对谷子淀粉糊化特性的影响

Table 2 Effects of germination, combined germination-fermentation on pasting properties of foxtail millet starch

处理 峰值黏度(cP) 谷值黏度(cP) 崩解值(cP) 最终黏度(cP) 回生值(cP) 糊化温度(℃) FM 5235.5±4.5a 1978.0±82.0a 3257.5±77.5a 3951.0±91.0b 1973.0±9.0c 75.0±0.4b GFM 4783.5±11.5b 1772.5±42.0b 3011.0±54.0b 4014.5±7.5b 2242.0±50.0b 76.5±0.4a GFFM 4593.0±23.0c 1667.5±9.5b 2925.5±32.5b 4421.5±28.5a 2754.0±19.0a 76.9±0.0a 注:同列不同小写英文字母表示数据差异显著,P<0.05。 表 3 发芽、发芽-发酵联合处理对谷子淀粉热力学特性的影响

Table 3 Effect of germination, combined germination-fermentation on thermal property of foxtail millet starch

处理 To(℃) Tp(℃) Tc(℃) ∆H(J/g) FM 64.1±0.5b 70.5±0.0b 78.5±0.2b 10.57±0.01b GFM 66.1±0.4a 71.2±0.3a 78.4±0.1b 10.77±0.02b GFFM 66.8±0.7a 71.4±0.1a 79.0±0.1a 11.30±0.40a 注:To为起始糊化温度;Tp为峰值温度;Tc为终止温度;∆H为糊化焓。 -

[1] 高婧, 梁志宏. 小米功能成分及新产品研发进展[J]. 中国粮油学报,2021,36(3):169−177. [GAO J, LING Z H. Research progress of millet functional ingredients and new products development[J]. Journal of the Chinese Cereals and Oils Association,2021,36(3):169−177.] doi: 10.3969/j.issn.1003-0174.2021.03.028 GAO J, LING Z H. Research progress of millet functional ingredients and new products development[J]. Journal of the Chinese Cereals and Oils Association, 2021, 36(3): 169−177. doi: 10.3969/j.issn.1003-0174.2021.03.028

[2] SABUZ A A, RANA M R, AHMED T, et al. Health-promoting potential of millet:A review[J]. Separations,2023,10(2):80. doi: 10.3390/separations10020080

[3] PREMACHANDRAN K, WILSON ALPHONSE C R, SOUNDHARAPANDIYAN N. Nourishing the cognition with millets:a comprehensive review of their nutritional impact and potential as cognitive enhancers[J]. Molecular Nutrition & Food Research,2023,67(24):2300450.

[4] MUSHTAQ B S , AL-ANSI W , DHUNGLE A , et al. Influence of pretreatments combined with extrusion on γ-amino butyric acid, nutritional composition and physicochemical properties of foxtail millet (Setaria italica)[J]. Journal of Cereal Science, 2021:10335.

[5] 武伟超, 桑若杰, 刘磊, 等. 发芽、发酵对谷物营养和功能活性成分的影响及其应用研究进展[J]. 食品工业科技,2023,44(7):411−418. [WU W C, SANG R J, LIU L, et al. Research progress on the effects of germination and fermentation on the nutritional and functional active ingredients of cereals and their applications[J]. Science and Technology of Food Industry,2023,44(7):411−418.] WU W C, SANG R J, LIU L, et al. Research progress on the effects of germination and fermentation on the nutritional and functional active ingredients of cereals and their applications[J]. Science and Technology of Food Industry, 2023, 44(7): 411−418.

[6] WUNTHUNYARAT W, SEO H S, WANGY J. Effects of germination conditions on enzyme activities and starch hydrolysis of long-grain brown rice in relation to flour properties and bread qualities[J]. Journal of Food Science,2020,85(2):349−357. doi: 10.1111/1750-3841.15008

[7] DING J, ULANOV A V, DONG M, et al. Enhancement of gama-aminobutyric acid (GABA) and other health-related metabolites in germinated red rice (Oryza sativa L.) by ultrasonication[J]. Ultrasonics Sonochemistry,2018,40:791−797. doi: 10.1016/j.ultsonch.2017.08.029

[8] BIAN X, CHEN J, YANG Y, et al. Effects of fermentation on the structure and physical properties of glutinous proso millet starch[J]. Food Hydrocolloids,2022,123:107144. doi: 10.1016/j.foodhyd.2021.107144

[9] FALADE A T, EMMAMBUX M N, BUYS E M, et al. Improvement of maize bread quality through modification of dough rheological properties by lactic acid bacteria fermentation[J]. Journal of Cereal Science,2014,60(3):471−476. doi: 10.1016/j.jcs.2014.08.010

[10] 黄倩, 梁安健, 朱鹏程, 等. 魏斯氏菌胞外多糖在发酵食品中的应用进展[J]. 食品科学,2024,45(4):352−359. [HUANG Q, LIANG A J, ZHU P C, et al. Progress in the application of extracellular polysaccharides of Weissiella in fermented foods[J]. Food Science,2024,45(4):352−359.] doi: 10.7506/spkx1002-6630-20230312-111 HUANG Q, LIANG A J, ZHU P C, et al. Progress in the application of extracellular polysaccharides of Weissiella in fermented foods[J]. Food Science, 2024, 45(4): 352−359. doi: 10.7506/spkx1002-6630-20230312-111

[11] AZEEZ S O, CHINMA C E, BASSEY S O, et al. Impact of germination alone or in combination with solid-state fermentation on the physicochemical, antioxidant, in vitro digestibility, functional and thermal properties of brown finger millet flours[J]. LWT,2021,154:112734.

[12] WEI S, WANG N, HUANG X, et al. Effect of germination on the quality characteristics and volatile compounds of fermented brown rice cake[J]. Food Bioscience,2022,50:102165. doi: 10.1016/j.fbio.2022.102165

[13] SUDHA A, DEVI K S, SANGEETHA V, et al. Development of fermented millet sprout milk beverage based on physicochemical property studies and consumer acceptability data[J]. Agricultural and Food Sciences,2016,75:239−243.

[14] MONTEMURRO M, PONTONIO E, GOBBETTI M, et al. Investigation of the nutritional, functional and technological effects of the sourdough fermentation of sprouted flours[J]. International Journal of Food Microbiology,2019,302:47−58. doi: 10.1016/j.ijfoodmicro.2018.08.005

[15] WANG H, XIAO N, DING J, et al. Effect of germination temperature on hierarchical structures of starch from brown rice and their relation to pasting properties[J]. International Journal of Biological Macromolecules,2020,147:965−972. doi: 10.1016/j.ijbiomac.2019.10.063

[16] BAI J, HUANG J, FENG J, et al. Combined ultrasound and germination treatment on the fine structure of highland barley starch[J]. Ultrasonics Sonochemistry,2023,95:106394. doi: 10.1016/j.ultsonch.2023.106394

[17] WU W, ZHANG X, QU J, et al. The effects of fermentation of Qu on the digestibility and structure of waxy maize starch[J]. Frontiers in Plant Science,2022,13:984795. doi: 10.3389/fpls.2022.984795

[18] YANG C, LÜ P, HAN H, et al. Investigation of changes in the fine structure of sorghum starch in the baijiu fermentation process[J]. Food Hydrocolloids, 2024:109905.

[19] ZHANG T, HONG S, ZHANG J R, et al. The effect of lactic acid bacteria fermentation on physicochemical properties of starch from fermented proso millet flour[J]. Food Chemistry,2024,437:137764. doi: 10.1016/j.foodchem.2023.137764

[20] 张桂英, 朱静, 张喜文, 等. 小米发糕发酵剂中乳酸菌的筛选及其在小米发糕中的应用[J]. 中国粮油学报,2019,34(12):78−86. [ZHANG G Y, ZHU J, ZHANG X W, et al. Screening of lactic acid bacteria from sourdough of fermented millet cakeand its application in the fermented millet cake[J]. Journal of the Chinese Cereals and Oils Association,2019,34(12):78−86.] doi: 10.3969/j.issn.1003-0174.2019.12.014 ZHANG G Y, ZHU J, ZHANG X W, et al. Screening of lactic acid bacteria from sourdough of fermented millet cakeand its application in the fermented millet cake[J]. Journal of the Chinese Cereals and Oils Association, 2019, 34(12): 78−86. doi: 10.3969/j.issn.1003-0174.2019.12.014

[21] SHARMA R, SHARMA S. Anti-nutrient & bioactive profile, in vitro nutrient digestibility, techno-functionality, molecular and structural interactions of foxtail millet (Setaria italica L.) as influenced by biological processing techniques[J]. Food Chemistry, 2021:130815.

[22] SUN X, SALEH A S M, LU Y, et al. Effects of ultra-high pressure combined with cold plasma on structural, physicochemical, and digestive properties of proso millet starch[J]. International Journal of Biological Macromolecules,2022,212:146−154. doi: 10.1016/j.ijbiomac.2022.05.128

[23] 李祥栋, 陆秀娟, 潘虹, 等. 薏米淀粉的结构表征与糊化特性[J]. 中国粮油学报,2024,39(7):86−93. [[LI X D, LU X J, PAN H, et al. Structural characterization and gelatinization properties of starch in coix seed[J]. Journal of the Chinese Cereals and Oils Association,2024,39(7):86−93.] [LI X D, LU X J, PAN H, et al. Structural characterization and gelatinization properties of starch in coix seed[J]. Journal of the Chinese Cereals and Oils Association, 2024, 39(7): 86−93.

[24] SIROHA A K, SANDHU K S, KAUR M, et al. Physicochemical, rheological, morphological and in vitro digestibility properties of pearl millet starch modified at varying levels of acetylation[J]. International Journal of Biological Macromolecules,2019,131:1077−1083. doi: 10.1016/j.ijbiomac.2019.03.179

[25] 韦露露, 秦礼康, 文安燕, 等. 基于主成分分析的不同品种小米品质评价[J]. 食品工业科技,2019,40(9):49−56. [WEI L L, QIN L K, WEN A Y, et al. Quality evaluation of different varieties millet based on principal components analysis[J]. Science and Technology of Food Industry,2019,40(9):49−56.] WEI L L, QIN L K, WEN A Y, et al. Quality evaluation of different varieties millet based on principal components analysis[J]. Science and Technology of Food Industry, 2019, 40(9): 49−56.

[26] MOHAN B H, MALLESHI N G, KOSEKI T. Physico-chemical characteristics and non-starch polysaccharide contents of Indica and Japonica brown rice and their malts[J]. LWT-Food Science and Technology,2010,43(5):784−791. doi: 10.1016/j.lwt.2010.01.002

[27] ZURAK D, KLJAK K, GRBESA D. The composition of floury and vitreous endosperm affects starch digestibility kinetics of the whole maize kernel[J]. Journal of Cereal Science,2020,95:103079. doi: 10.1016/j.jcs.2020.103079

[28] MACIEJ, FIEDOROWICZ, LIDIA, et al. Comparison of molecular structure and selected physicochemical properties of spelt wheat and common wheat starches[J]. Journal of Food & Nutrition Research,2014,53(1):31−38.

[29] MA X, LIU Y, LIU J, et al. Changes in starch structures and in vitro digestion characteristics during maize (Zea mays L.) germination[J]. Food Science & Nutrition,2020,8(3):1700−1708.

[30] ZHANG X, KUANG L, ZHAO H, et al. The difference in the starch properties related to eating and cooking quality among six indica-japonica rice hybrids[J]. Acta Physiologiae Plantarum,2021,43:1−9. doi: 10.1007/s11738-020-03172-3

[31] ZHANG G, VENKATACHALAM M, HAMAKER B R. Structural basis for the slow digestion property of native cereal starches[J]. Biomacromolecules,2006,7(11):3259−3266. doi: 10.1021/bm060343a

[32] LIU L, JIANG X, CHEN Y, et al. Germination-induced modifications of starch structure, flour-processing characteristics, and in vitro digestive properties in maize[J]. Food Chemistry:X, 2024:101430.

[33] XU M, ZOU J, ZHAO X, et al. Effect of lactobacteria fermentation on structure and physicochemical properties of Chinese yam starch (Dioscorea opposita Thunb.)[J]. Food Chemistry,2022,387:132873. doi: 10.1016/j.foodchem.2022.132873

[34] LI Y, WANG H, WANG L, et al. Multi-scale structure and digestive property of bran starch in different particle size wheat bran[J]. Food Chemistry,2023,414:135744. doi: 10.1016/j.foodchem.2023.135744

[35] DENG C, WANG B, JIN Y, et al. Effects of starch multiscale structure on the physicochemical properties and digestibility of Radix Cynanchi bungei starch[J]. Int J Biol Macromol,2023,253:126873. doi: 10.1016/j.ijbiomac.2023.126873

[36] ZHAO T, LI X P, ZHU R Z, et al. Effect of natural fermentation on the structure and physicochemical properties of wheat starch[J]. Carbohydrate Polymers,2019:163−169.

[37] WU F, CHEN H, YANG N, et al. Effect of germination time on physicochemical properties of brown rice flour and starch from different rice cultivars[J]. Journal of Cereal Science,2013,58:263−271.

[38] 张攀峰, 陈玲, 李晓玺, 等. 不同直链/支链比的玉米淀粉分子质量及其构象[J]. 食品科学,2010,31(19):157−160. [ZHANG P F, CHEN L, LI X X, et al. Molecular mass and conformation of corn starches with D different amylose/amylopectin ratios[J]. Food Science,2010,31(19):157−160.] ZHANG P F, CHEN L, LI X X, et al. Molecular mass and conformation of corn starches with D different amylose/amylopectin ratios[J]. Food Science, 2010, 31(19): 157−160.

[39] XU J, ZHANG H, GUO X , et al. The impact of germination on the characteristics of brown rice flour and starch[J]. Journal of the Science of Food and Agriculture, 2012, 92(2):380-387.

[40] 曹龙奎, 寇芳, 康丽君, 等. 自然发酵对小米淀粉分子结构及凝胶特性的影响[J]. 食品科学,2017,38(14):127−131. [CAO L K, KOU F, KANG L J, et al. Effect of natural fermentation on the gel properties and molecular structure of millet starch[J]. Food Science,2017,38(14):127−131.] CAO L K, KOU F, KANG L J, et al. Effect of natural fermentation on the gel properties and molecular structure of millet starch[J]. Food Science, 2017, 38(14): 127−131.

[41] CHUNG H-J, LIU Q, LEE L, et al. Relationship between the structure, physicochemical properties and in vitro digestibility of rice starches with different amylose contents-ScienceDirect[J]. Food Hydrocolloids,2011,25(5):968−975. doi: 10.1016/j.foodhyd.2010.09.011

[42] 张素敏, 崔艳, 陈振家, 等. 压热改性对黄米淀粉多尺度结构及理化性质的影响[J]. 食品工业科技,2024,45(18):80−87. [ZHANG S M, CUI Y, CHEN Z J, et al. Effect of antoclaving treatment modifications on muti-scale structure and physicochemical properties of yellow rice starch[J]. Science and Technology of Food Industry,2024,45(18):80−87.] ZHANG S M, CUI Y, CHEN Z J, et al. Effect of antoclaving treatment modifications on muti-scale structure and physicochemical properties of yellow rice starch[J]. Science and Technology of Food Industry, 2024, 45(18): 80−87.

[43] LI C, OH S G, LEE D H, et al. Effect of germination on the structures and physicochemical properties of starches from brown rice, oat, sorghum, and millet[J]. International Journal of Biological Macromolecules,2017,105:931−939. doi: 10.1016/j.ijbiomac.2017.07.123

[44] CHANG L, DANG Y, YANG M, et al. Effects of Lactobacillus plantarum fermentation on the structure, physicochemical properties, and digestibility of foxtail millet starches[J]. International Journal of Biological Macromolecules,2024,270:132496. doi: 10.1016/j.ijbiomac.2024.132496

[45] LI W, SHU C, ZHANG P, et al. Properties of starch separated from ten mung bean varieties and seeds processing characteristics[J]. Food and Bioprocess Technology,2011,4:814−821. doi: 10.1007/s11947-010-0421-6

[46] WEI C, GE Y, ZHAO S, et al. Effect of fermentation time on molecular structure and physicochemical properties of corn ballast starch[J]. Frontiers in Nutrition,2022,9:885662. doi: 10.3389/fnut.2022.885662

[47] HONG J, GUO W, CHEN P, et al. Effects of bifidobacteria fermentation on physico-chemical, thermal and structural properties of wheat starch[J]. Foods,2022,11(17):2585. doi: 10.3390/foods11172585

[48] LI P, HE X, DHITAL S, et al. Structural and physicochemical properties of granular starches after treatment with debranching enzyme[J]. Carbohydr Polym,2017,169:351−356. doi: 10.1016/j.carbpol.2017.04.036

-

期刊类型引用(1)

1. 章紫英 ,周汉昌 ,黄思远 ,李婷 ,余林 ,况小宝 . 烟熏对食品风味及安全性影响研究进展. 食品工业. 2024(11): 270-276 .  百度学术

百度学术

其他类型引用(0)

下载:

下载:

下载:

下载: