Effect of Adding Pleurotus eryngii Powder on Physicochemical Properties of Soybean Protein Isolate-Konjac Flour Based Simulated Fat

-

摘要: 为了增加模拟脂肪的肥膘肉丁口感并提升其在食品加工中的实用性,本研究以大豆分离蛋白、魔芋粉和大豆油为主要原料制备模拟脂肪,通过测定模拟脂肪的质构、热稳定性和微观结构等理化性质,探究杏鲍菇粉对模拟脂肪理化性质的影响,以及模拟脂肪对鱼糜制品品质的影响。结果显示,模拟脂肪的硬度、凝胶强度和熔融温度在杏鲍菇粉添加量为1.0%时达到最大,分别为533.97 g,128.71 g·mm和147.78 ℃。模拟脂肪的L*值随杏鲍菇粉添加量的增加而下降,而a*和b*值却出现上升趋势。杏鲍菇粉添加量不高于1.0%时,模拟脂肪中具有分布均匀的小油滴,凝胶网络结构致密。利用模拟脂肪代替鱼糜制品中50%的猪油时,产品的硬度和感官评分均最高。因此,添加杏鲍菇粉可以作为改善模拟脂肪质构和热稳定性的一种有效方法,且添加量为1.0%时结果最佳,制备的模拟脂肪可以用于改善鱼糜制品的品质。Abstract: To enhance the taste of simulated fat and improve its practicability in food processing, simulated fat was prepared using soybean protein isolate, konjac flour, and soybean oil as the main raw materials in this study. The effects of the Pleurotus eryngii powder on the physicochemical properties of the simulated fat was investigated by measuring the texture, thermal stability and microstructure of simulated fat and other physicochemical properties. Additionally, the effect of the simulated fat on the quality of surimi products was investigated. The results showed that the simulated fat with 1.0% of P. eryngii powder exhibited the highest hardness, gel strength and melting temperature, namely 533.97 g, 128.71 g·mm and 147.78 ℃, respectively. As the amount of P. eryngii powder increased, the L* value of the simulated fat decreased, whereas the a* and b* values increased. The simulated fat with no more than 1.0% of P. eryngii powder contains evenly distributed small oil droplets and had a dense network structure. Surimi products indicated the highest hardness and sensory scores when 50% the simulated fat was used to replace lard. Therefore, adding 1.0% of P. eryngii powder can improve the texture properties and thermal stability of the simulated fat, thus the enabling it to improve the quality of surimi products.

-

Keywords:

- Pleurotus eryngii powder /

- simulated fat /

- gel property /

- surimi gel

-

脂肪不仅可以为人体提供能量和必需脂肪酸,还会赋予食品特殊的风味和良好的质地[1]。随着人们饮食结构中脂肪摄入比例的提高,高胆固醇和饱和脂肪酸引起的糖尿病[2]、心血管疾病和肥胖症等疾病的比例逐渐增加[3]。近年来低脂食品的研发逐渐受到广泛关注,但是降低脂肪含量会对食品的感官特性产生负面影响。鱼糜制品是典型的低脂食品,因其低脂肪、高蛋白且食用方便等特点而深受消费者的喜爱[4−5]。鱼糜在漂洗过程中去除了大量的水溶性蛋白和脂质,其风味、滋味和营养价值均有所降低,通过添加油脂虽然能提高鱼糜制品风味品质,但油脂的添加会降低鱼糜制品的低脂属性 [6−7]。因此,有必要寻找合适的脂肪替代品提高消费者对低脂食品的可接受度[8]。

植物基模拟脂肪是以植物胶体和改性淀粉等碳水化合物或植物蛋白等为原料制备的,可以模拟出脂肪润滑细腻的口感特性[9]。大豆分离蛋白(soy protein isolate,SPI)是应用最广泛的植物蛋白,具有良好的凝胶性和乳化性,可以与多糖混合制备具有良好口感的模拟脂肪[10]。魔芋粉(konjac flour,KF)是魔芋葡甘聚糖的粗制品或精制品,具有良好的保水性、凝胶性和乳化性,可以增强蛋白凝胶的强度和持水能力[11]。以单一的蛋白质或多糖为基质制备的模拟脂肪的稳定性差,难以应用在高温和油炸等食品加工过程中,且口感与传统脂肪的相似度低[12−13]。然而,复合模拟脂肪虽然具有较高的硬度、粘弹性和风味等品质,但缺乏肥膘肉丁的口感[14]。据报道,食用菌可用于制备植物基人造肉或添加至肉制品中以改善产品的质地和风味[15−17]。其中,杏鲍菇(Pleurotus eryngii)呈味丰富,肉质肥厚,含有丰富的蛋白质和膳食纤维,与肥膘肉丁具有相似的口感[18]。然而,有关杏鲍菇对模拟脂肪的理化性质及其对肉制品感官特性的影响却未见报道。

本文探究杏鲍菇粉添加量对TGase诱导的SPI-KF基模拟脂肪性质的影响。测定了模拟脂肪的凝胶特性、水分分布、热稳定性和微观结构,以及探究SPI-KF基模拟脂肪对鱼糜凝胶品质的影响,结果将为植物基模拟脂肪的性质改良和应用提供理论依据。

1. 材料与方法

1.1 材料与仪器

SPI(蛋白质含量91%) 临沂山松生物制品有限公司(中国临沂);KF 绿新(福建)食品有限公司;杏鲍菇 福建盛耳食品有限公司,杏鲍菇片粉碎后,取经过20、60目筛网之后粉末;大豆油 益海嘉里食品营销有限公司(厦门);谷氨酰胺转氨酶(100 U/g) 南宁庞博生物工程有限公司;冷冻金线鱼鱼糜 石狮正源水产科技开发有限公司;猪油 当地超市,购买的猪肥膘在约120 ℃下加热制备得到;尼罗红、异硫氰酸荧光素(fluorescein isothiocyanate,FITC) 阿拉丁试剂有限公司(中国上海)。

FA-25均质机 上海费鲁克科技发展有限公司;TA-XT Plus质构仪 英国Stable Micro System公司;Nicolet iS50傅里叶变换红外光谱仪 美国赛默飞世尔科技有限公司;S-4800电子扫描显微镜 日本东京日立制造所;Q2000差示扫描量热仪 美国TA instrument;TCS SP8共聚焦激光扫描显微镜 徕卡显微系统(上海)贸易有限公司。

1.2 实验方法

1.2.1 模拟脂肪的制备

将SPI粉末(2.0 g)分散在纯水(20.0 g)后再放在75 ℃水浴保温搅拌30 min得到SPI溶液。将KF粉末(0.2 g)分散在纯水(12.5 g)中后再放在沸水浴中加热30 min得到KF溶液。将杏鲍菇粉(0、0.5、1.0、1.5、2.0 g)、TGase(0.2 g)加入纯水(7.5 g)中并搅拌得到杏鲍菇粉分散液。将获得的SPI溶液和KF溶液混合后加入大豆油(60.0 g)并均质(19000 r/min)2 min,然后加入杏鲍菇粉分散液并均质1 min,得到杏鲍菇粉含量为0、0.5%、1.0%、1.5%、2.0%的乳液。将获得的乳液填充在不锈钢模具(直径3 cm,高3 cm的圆柱形模具)中,50 ℃水浴保温1 h后用碎冰冷却得到模拟脂肪,将其放置于4 ℃冰箱中保存。

1.2.2 模拟脂肪的表征

1.2.2.1 全质构分析(texture profile analysis,TPA)

参考Fang等[19]方法稍作修改,选用P/36R探头,测试速率1 mm/s,2次测定时间间隔5 s,测定压缩比30%,触发力5.0 g。测定硬度、弹性、内聚性、咀嚼性和粘性等参数。

参考Fang等[19]方法稍作修改,选用P/5S球型探头,测试速率1 mm/s,穿刺距离为10 mm,触发力5.0 g,测定凝胶强度。

1.2.2.2 色泽

使用色差仪对样品进行色度值测定,使用前用标准白板进行校准。结果以亮度值(L*)、红度值(a*)和黄度值(b*)表示。总色差(∆E)计算公式如下:

ΔE=√(L∗−L∗0)2+(a∗−a∗0)2+(b∗−b∗0)2 式中,L*、a*、b*为添加杏鲍菇粉样品的色度值,L0*、a0*、b0*为未添加杏鲍菇样品的色度值。

1.2.2.3 低场核磁共振(low field nuclear magnetic resonance,LF-NMR)

参照Huang等[20]的方法并稍作修改,样品为高度约3 cm、直径3 cm的圆柱体,测试条件为:测试温度34 ℃,累加次数20次,重复间隔时间(TR)2.0 s,回波间隔3.0 ms,回波个数2048。

1.2.2.4 差示扫描量热法(differential scanning calorimetry,DSC)

参照Zhang等[21]的方法并稍作修改,取2 mg左右样品置于铝盘中并用铝盖密封。以5 ℃/min的加热速率从20 ℃升温至180 ℃,记录变性温度峰值(Td)和变形焓值(∆H)。

1.2.2.5 傅里叶变换红外光谱(Fourier transform infrared spectroscopy,FTIR)

参照Zhao等[22]的方法并稍作修改,使用Nicolet iS50 ATR-FTIR光谱仪在25 ℃下进行。在4000~800 cm−1范围内,以4 cm−1的分辨率进行16次累积。利用Peakfitv 4.12软件对酰胺Ⅰ带(1600~1700 cm−1)光谱进行反卷积和高斯拟合,计算模拟脂肪二级结构中α-螺旋、β-折叠、β-转角和无规卷曲的相对含量。

1.2.2.6 微观结构

激光扫描共聚焦显微镜(confocal laser scanning microscope,CLSM):参照曹艳芸等[23]的方法并稍作修改,用FITC(1 mg/mL溶于异丙醇)对乳液中蛋白质进行染色,用尼罗红对乳液中油染色。以20 μL/g蛋白的比例对SPI进行染色,使用尼罗红以1 mg/30 g的比例对大豆油进行染色。染色在避光条件下进行。染色后的模拟脂肪样品切成3.0 mm×3.0 mm×2.0 mm薄片置于显微培养皿中央进行拍照。用552 nm处通道来激发FITC染色的蛋白质,用488 nm处通道来激发尼罗红染色的脂肪,调整观察模式为红色(尼罗红、油)和绿色(FITC、蛋白质)荧光,获得模拟脂肪的CLSM图像。

扫描电子显微镜(scanning electron microscope,SEM):参照Fang等[19]的方法并稍作修改,将模拟脂肪样品切成3.0 mm×3.0 mm×2.0 mm薄片,用2.5%戊二醛溶液在4 ℃下固定过夜后,再用0.1 mol/L磷酸盐缓冲液(pH7.2)漂洗15 min,重复3次。依次用30%、50%、60%、70%、80%、90%、100%乙醇进行梯度脱水。经CO2临界点干燥仪干燥后,喷金并进行扫描电镜观察。

1.2.3 鱼糜凝胶的制备

参考Fang等[19]方法制备金线鱼鱼糜凝胶。金线鱼鱼糜提前在4 ℃冰箱解冻过夜,将解冻的鱼糜(150 g)放入研钵中擂溃3 min,然后加入NaCl(4.5 g)继续擂溃15 min。将模拟脂肪和猪油混合后(0:8、2:6、4:4、6:2和8:0,w/w)并以8.0 g/100 g鱼糜的比例加入盐擂后的鱼糜中,加入盐擂后的鱼糜并擂溃5 min至混合均匀。以上过程在碎冰上进行以保证整个过程温度控制在10 ℃以内。将擂溃好的样品填充至不锈钢模具中,两端用橡胶垫片密封,置于水浴锅中在40 ℃下加热1 h,再于90 ℃下继续加热15 min。将含有鱼糜凝胶的不锈钢模具放入碎冰中冷却至少30 min。将制备好的鱼糜凝胶从模具中取出,置于4 ℃冰箱平衡24 h,进行后续指标检测。

1.2.4 鱼糜凝胶的表征

1.2.4.1 TPA

TPA的测定参考Zhang等[24]的方法。选用P/36R探头,测试速率1 mm/s,2次测定时间间隔5 s,测定压缩比30%,触发力5.0 g。测定鱼糜凝胶的硬度、弹性、咀嚼性、内聚性和粘性等参数。

1.2.4.2 破断强度和破断距离

参考Zhang等[24]方法稍作修改。选用P/5S球型探头,测试速率1 mm/s,穿刺距离为20 mm,触发力5.0 g,测定鱼糜凝胶破断力(g)和破断距离(mm)。

1.2.4.3 感官评价

参考Fang等[19]的方法进行感评价,并稍作修改。将金线鱼鱼糜凝胶煮沸3 min后,切成1.5 cm×1.5 cm×1.5 cm大小的块状,60 ℃水浴中保温,10位经过培训的人员对其进行感官评价,评价小组成员由5名男性和5名女性组成。采用五分制进行感官评价,风味(1:风味极差,无油脂香味;5:风味极佳,有浓郁油脂香味)、多汁性(1:极干、无汁液感;5:汁液感强)、咀嚼性(1:咀嚼性极差,不耐咀嚼,颗粒感较大或无颗粒感;5:咀嚼性好,有嚼劲,有轻微颗粒感)。评分越高,表明鱼糜凝胶品质越好。在评价每个样品之前,感官评价人员要求用温水漱口,以减少样品之前的相互干扰。

1.3 数据处理

所有实验均设定5个平行,实验结果以平均值±标准偏差表示。数据采用SPSS 26软件进行显著性分析和方差分析,P<0.05表示数据间存在显著性差异。采用Origin 2021软件进行数据整理和作图。

2. 结果与分析

2.1 杏鲍菇粉添加量对模拟脂肪理化性质的影响

2.1.1 凝胶特性

为了探究杏鲍菇粉添加量对模拟脂肪凝胶特性的影响,对模拟脂肪的TPA和凝胶强度进行测定。如表1所示,随杏鲍菇粉添加量的增加,模拟脂肪的硬度、粘性、咀嚼性和凝胶强度呈现先增大后减小的趋势,在杏鲍菇粉添加量为1.0%时最大。添加杏鲍菇粉会使模拟脂肪的内聚性下降,而对弹性没有显著影响(P>0.05)。这是因为添加的杏鲍菇粉会吸收模拟脂肪中的自由水,导致凝胶体系中SPI的相对浓度提高,从而促进了凝胶网络的形成。然而,因为杏鲍菇粉中含有较多的膳食纤维[25],当杏鲍菇粉添加量高于1.0%时可能会阻碍蛋白质间的相互作用[26−27],结果导致模拟脂肪的硬度、粘性和凝胶强度发生下降。

表 1 添加杏鲍菇粉对SPI-KF基模拟脂肪凝胶特性的影响Table 1. Effect of adding P. eryngii powder on the gel properties of SPI-KF based simulated fat杏鲍菇粉添加量(%) 硬度(g) 弹性 内聚性 粘性(g) 咀嚼性(g) 凝胶强度(g·mm) 0 341.58±5.15d 0.96±0.00a 0.92±0.01a 313.67±3.63c 302.13±3.75c 101.27±4.19c 0.5 429.90±36.43c 0.96±0.00a 0.91±0.00a 390.77±16.73b 376.67±16.58b 120.05±6.95b 1.0 533.97±26.71a 0.96±0.01a 0.88±0.01a 468.42±24.38a 449.63±23.63a 128.71±3.31a 1.5 469.06±25.99b 0.96±0.03a 0.73±0.07b 345.47±50.88c 332.48±49.50bc 102.73±2.09c 2.0 413.02±39.02c 0.95±0.02a 0.56±0.04c 233.63±34.29d 222.86±35.94d 100.04±2.21c 注:同列不同小写字母表示差异显著(P<0.05);表2~表4同。 2.1.2 色泽

杏鲍菇粉添加量对模拟脂肪色泽的影响如表2所示。随杏鲍菇粉添加量的增加,L*值逐渐降低,而a*值、b*值和ΔE值逐渐增大,表明添加杏鲍菇粉会使模拟脂肪的色泽变暗变黄。模拟脂肪色泽的变化可能与杏鲍菇粉的色泽(L*=57.37,a*=1.38,b*=16.39)有关。ΔE表示人眼在统一色彩空间中感知到的色差单位,当ΔE>1时色泽的差异才能被肉眼区别[28]。在本研究中,当杏鲍菇粉添加量为0.5%时,肉眼就能辨别模拟脂肪色泽发生变化。

表 2 添加杏鲍菇粉对SPI-KF基模拟脂肪色泽的影响Table 2. Effect of adding P. eryngii powder on the color of SPI-KF based simulated fat杏鲍菇粉添加量

(%)L* a* b* ΔE 0 96.48±0.26a −1.04±0.05d 6.23±0.34d − 0.5 95.57±0.63b −0.82±0.04c 7.28±0.25c 1.50±0.43b 1.0 94.99±0.21b −0.67±0.10b 7.72±0.51bc 2.16±0.48b 1.5 93.60±0.44c −0.55±0.10a 8.06±0.69ab 3.48±0.70a 2.0 93.34±0.59c −0.48±0.10a 8.41±0.36a 3.88±0.64a 2.1.3 低场核磁共振

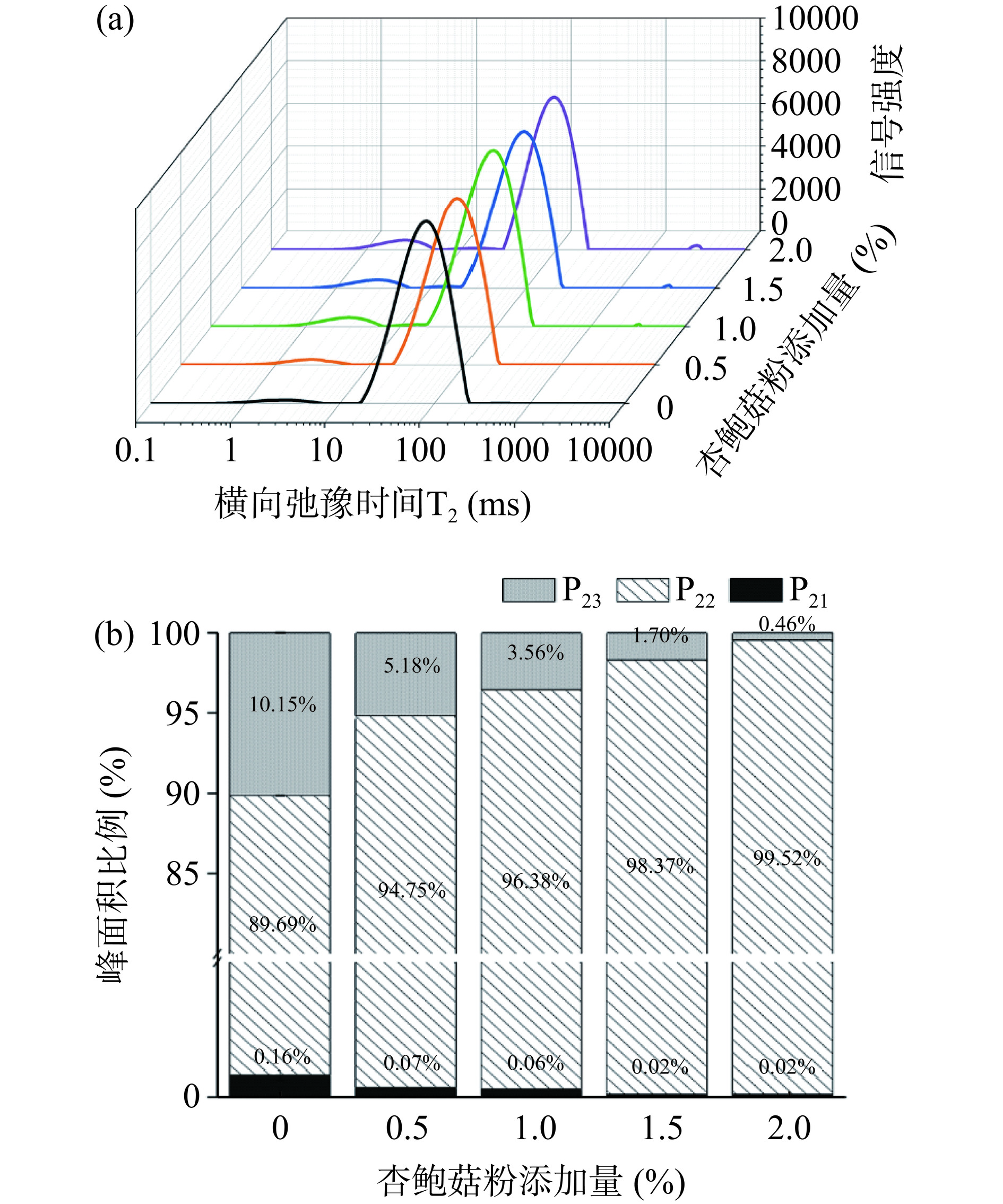

利用LF-NMR技术检测模拟脂肪中水分的流动性和分布情况(图1)。横向弛豫时间T21对应的是与蛋白质结合紧密的结合水,T22是被困在蛋白质网络中的不易流动水,T23蛋白质网络结构外的自由水[29]。随杏鲍菇粉添加量的增加,T21、T22和T23峰值左移且弛豫时间缩短(图1a),表明水的迁移率越低。这可归因于水分子和大分子之间键合能力增强[30]。

杏鲍菇粉添加量对模拟脂肪结合水(P21)、不易流动水(P22)和自由水(P23)相对含量的影响如图1(b)所示。伴随杏鲍菇粉添加量的增加,P21、P23逐渐降低,而P22逐渐增大,表明杏鲍菇粉的添加会使模拟脂肪中部分结合水和自由水向不易流动水状态迁移。据研究报道,双孢菇粉和大豆油的添加改变了鸡肉糜凝胶中水与蛋白质的结合状态,增强了凝胶对水的结合能力,减弱了水分的自由度[31]。

2.1.4 差示扫描量热分析

如图2所示,随杏鲍菇粉添加量的增加,模拟脂肪的熔融温度(Tm)和焓值呈现先上升后下降的趋势,在添加量为1.0%时Tm最高为147.78 ℃,焓值最高为754.8 J/g。研究表明,Tm和焓值的提高代表凝胶网络结构更加稳定,样品熔融需要吸收更高的热量[31−32]。因此,添加少量杏鲍菇粉使得植物基模拟脂肪的热稳定性提高,而进一步增加杏鲍菇粉含量可能会破坏凝胶网络结构的致密性,导致其热稳定性降低。

2.1.5 傅里叶变换红外光谱

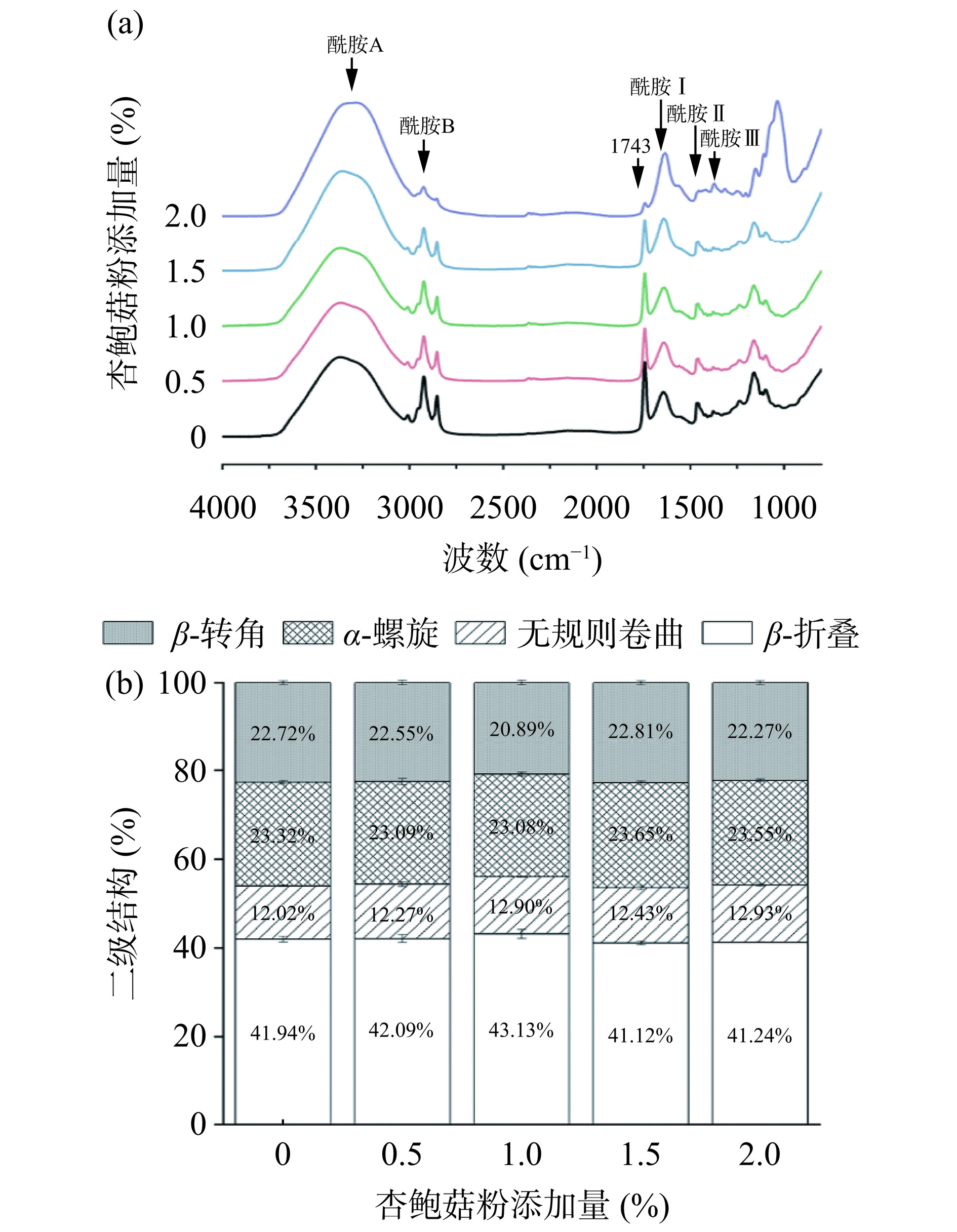

图3(a)为不同杏鲍菇粉添加量的模拟脂肪的FTIR光谱。波数3355 cm−1处为酰胺A带吸收峰,通常用于研究氢键的变化;波数1743 cm−1处是大豆油的特征峰[33];酰胺I(1643 cm−1)、酰胺II(1457 cm−1)和酰胺III(1377 cm−1)是SPI的特征峰[34]。随杏鲍菇粉添加量的增加,酰胺A带吸收峰强度逐渐增加,峰型变宽且向低波数方向移动,表明添加杏鲍菇粉可以增强模拟脂肪中氢键相互作用[35]。油特征峰强度随杏鲍菇粉添加量的增加逐渐减弱,这与模拟脂肪中油相对含量随杏鲍菇粉的增加而减少有关。

利用Peak Fit v4.12软件对酰胺I带(1600~1700 cm−1)光谱进行分析,结果如图3(b)所示。β-折叠相对含量随杏鲍菇粉添加量的增加先增大后减小,α-螺旋相对含量随杏鲍菇粉添加量的增加先减小后增大,无规卷曲、β-转角相对含量无明显变化。在杏鲍菇粉添加量为1.0%时,β-折叠相对含量最高,表明形成的模拟脂肪凝胶网络结构最稳定[36],这与TPA、凝胶强度和热稳定性分析的结果相一致。

2.1.6 微观结构

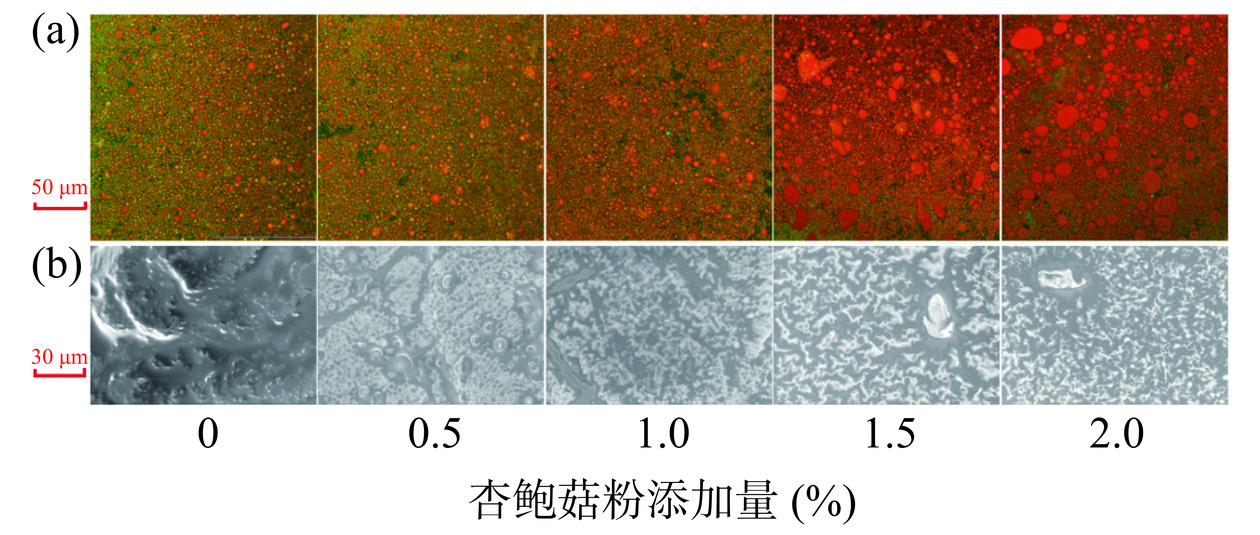

杏鲍菇粉添加量对模拟脂肪的油滴微观形貌的影响如图4(a)所示。在杏鲍菇粉添加量不高于1.0%时,模拟脂肪中的油滴(红色)粒径较小且均匀分布。当杏鲍菇粉添加量进一步增加时,模拟脂肪中的油滴粒径逐渐增大,表明添加的杏鲍菇粉超过一定的量时会导致油滴相互聚集。这一结果可能是因为过量的杏鲍菇粉破坏了模拟脂肪凝胶网络结构,从而导致模拟脂肪的硬度、凝胶强度(表1)和热稳定性下降(图2)。

杏鲍菇粉添加量对模拟脂肪微观形貌的影响如图4(b)所示。未添加杏鲍菇粉的模拟脂肪的表面较为光滑致密。添加杏鲍菇粉后,模拟脂肪中可以观察到大块颗粒物质。当杏鲍菇粉含量不高于1.0%时,模拟脂肪中未发现明显絮状结构。然而,继续增加杏鲍菇粉添加量会导致絮状结构逐渐明显,这可能是因为油滴的聚集破坏了蛋白网络结构,导致模拟脂肪结构致密性下降。Zhou等[37]在研究肌原纤维蛋白-脂质复合凝胶时也发现,小油滴可以充当活性填料,而油滴聚集变大后会破坏网络结构,导致网络结构孔隙增加,致密性变差。

2.2 模拟脂肪对金线鱼鱼糜凝胶物性的影响

2.2.1 模拟脂肪对金线鱼鱼糜凝胶TPA的影响

鱼糜产品在制备过程中经过漂洗会除去大部分油脂,导致风味、口感和营养成分有所下降。因此,常通过添加外源油脂来改善鱼糜产品的风味和品质。本研究选取杏鲍菇粉添加量为1.0%的模拟脂肪与猪油混合作为外源油脂,研究了植物基模拟脂肪和猪油比例对鱼糜凝胶的质构特性和感官评价的影响。

如表3所示,随模拟脂肪比例的增加,鱼糜凝胶的硬度、粘性、咀嚼性呈现先上升后下降的趋势,且在模拟脂肪:猪油比例为4:4时最高,而模拟脂肪比例对鱼糜凝胶的弹性和内聚性无显著影响。有研究报道,模拟脂肪可作为活性填料填充在凝胶基质的空腔中,促进致密凝胶网络结构的形成[38],从而增强鱼糜凝胶的硬度和咀嚼性。进一步增大模拟脂肪比例时,过量的固体颗粒导致蛋白质链之间的分子间距离增加,从而阻碍了蛋白质间的相互作用,破坏了蛋白质网络结构[39],导致硬度、粘性和咀嚼性降低。

表 3 模拟脂肪对金线鱼鱼糜凝胶TPA的影响Table 3. Effect of simulated fat on the TPA of surimi gel of golden fillet模拟脂肪:猪油(w/w) 硬度(g) 弹性 内聚性 粘性(g) 咀嚼性(g) 0:8 1465.13±87.91b 0.89±0.04a 0.84±0.03a 1233.00±64.39b 1100.44±80.68b 2:6 1483.94±65.87b 0.93±0.02a 0.83±0.01a 1232.77±63.47b 1151.02±47.81b 4:4 1655.81±34.01a 0.95±0.05a 0.88±0.04a 1459.31±82.27a 1391.28±142.17a 6:2 1560.48±70.21ab 0.89±0.04a 0.85±0.00a 1327.19±56.44b 1185.47±76.64b 8:0 1550.69±30.95ab 0.90±0.03a 0.87±0.02a 1343.55±19.51b 1208.87±55.38b 2.2.2 模拟脂肪对金线鱼鱼糜凝胶破断强度和破断距离的影响

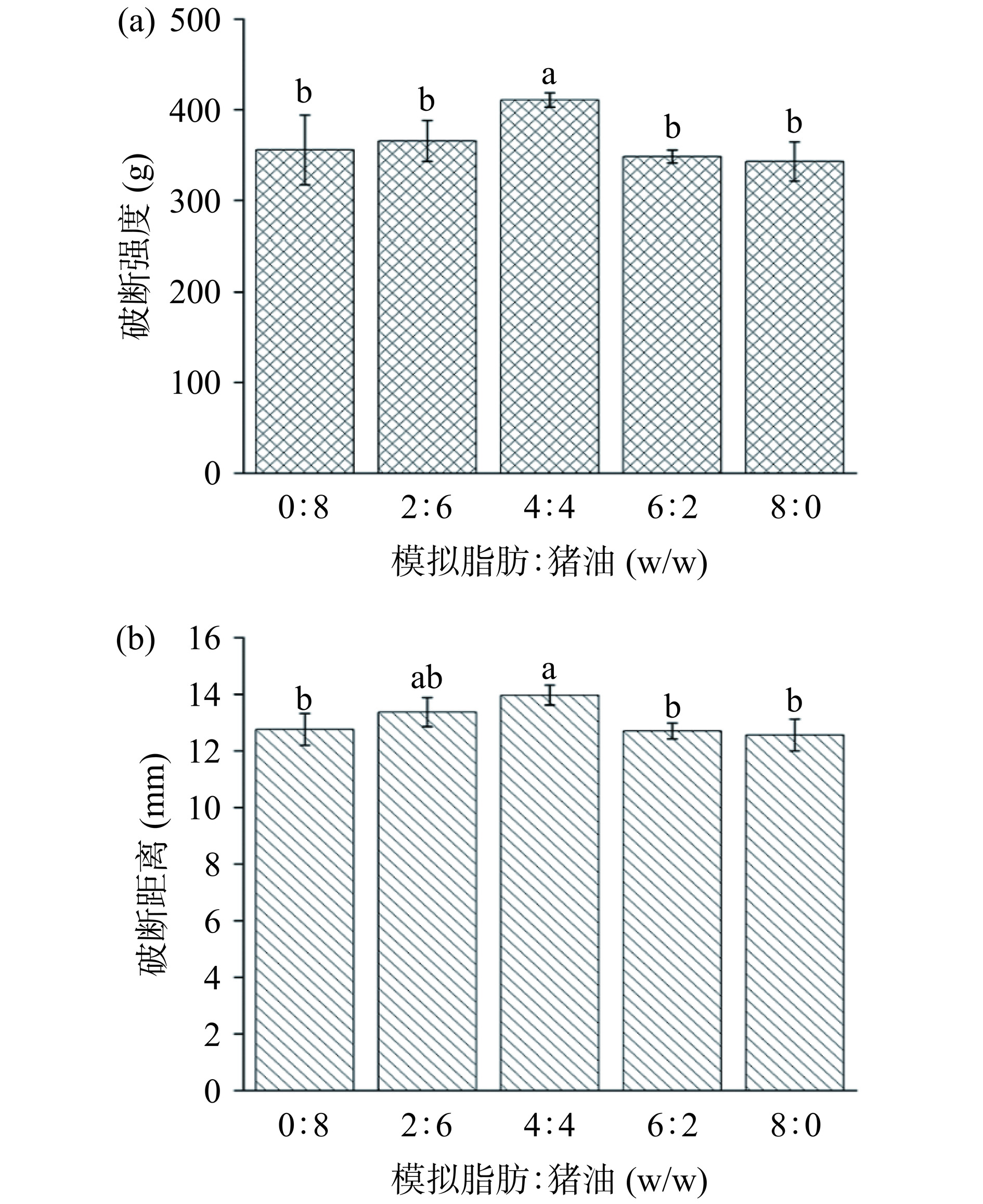

如图5所示,鱼糜凝胶破断强度和破断距离随模拟脂肪比例的增加呈现先上升后下降的趋势,在模拟脂肪:猪油的比例为4:4时最高,这一趋势与鱼糜凝胶TPA的变化趋势相一致。低含量模拟脂肪可作为活性填料提高凝胶网络结构的致密性,而过量的模拟脂肪颗粒阻碍鱼糜凝胶中的蛋白质相互作用,从而降低了凝胶强度[40]。因此,当添加的模拟脂肪:猪油的比例为4:4时可以有效促进致密凝胶结构的形成,从而提高鱼糜的破断强度。

2.2.3 模拟脂肪对金线鱼鱼糜凝胶感官评价的影响

如表4所示,随着模拟脂肪比例的增加,鱼糜凝胶的风味评分逐渐提高,多汁性和咀嚼性评分先上升后下降。在模拟脂肪和猪油比例为4:4时评分结果最好,硬度和弹性较好,接受度较高,这与TPA测定的结果一致。因此,同时添加模拟脂肪和猪油可以改善鱼糜凝胶的感官特性,增加油脂特有的香味,提高口感与风味的感官评分。Tobin等[41]报道,脂肪可以和食物中其他成分相互作用,从而改善法兰克福香肠的口感和风味。

表 4 模拟脂肪对金线鱼鱼糜凝胶感官评价的影响Table 4. Effect of simulated fat on sensory evaluation of surimi gel of golden fillet模拟脂肪:猪油(w/w) 风味 多汁性 咀嚼性 0:8 2.40±0.66b 2.70±0.64b 2.90±0.70b 2:6 2.90±0.83ab 3.10±0.83ab 2.90±0.70b 4:4 3.5 0±0.50a 3.70±0.64a 3.60±0.92a 6:2 3.60±0.80a 3.20±0.98ab 3.10±0.70ab 8:0 3.60±0.66a 3.20±0.87ab 3.10±1.04ab 3. 结论

本研究揭示了杏鲍菇粉添加量对SPI-KF基模拟脂肪理化性质的影响规律,并初步探究模拟脂肪对鱼糜制品品质的影响。添加少量杏鲍菇粉能够有效改善模拟脂肪的理化性质,在杏鲍菇粉添加量为1.0%时模拟脂肪具有最高的硬度、凝胶强度和热稳定性,这是因为粒径小的油滴能均匀分布在形成的模拟脂肪致密的凝胶网络结构中。使用模拟脂肪部分替代猪油可以显著提高鱼糜制品的硬度、凝胶强度和感官评分。因此,适量添加杏鲍菇粉可以提高模拟脂肪的质构特性和热稳定性,制备的模拟脂肪可用于改善鱼糜凝胶的口感和风味。本研究结果可为模拟脂肪的性质改良及应用提供理论依据,后续可进一步研究添加模拟脂肪的鱼糜制品在贮藏过程中的品质变化。

-

表 1 添加杏鲍菇粉对SPI-KF基模拟脂肪凝胶特性的影响

Table 1 Effect of adding P. eryngii powder on the gel properties of SPI-KF based simulated fat

杏鲍菇粉添加量(%) 硬度(g) 弹性 内聚性 粘性(g) 咀嚼性(g) 凝胶强度(g·mm) 0 341.58±5.15d 0.96±0.00a 0.92±0.01a 313.67±3.63c 302.13±3.75c 101.27±4.19c 0.5 429.90±36.43c 0.96±0.00a 0.91±0.00a 390.77±16.73b 376.67±16.58b 120.05±6.95b 1.0 533.97±26.71a 0.96±0.01a 0.88±0.01a 468.42±24.38a 449.63±23.63a 128.71±3.31a 1.5 469.06±25.99b 0.96±0.03a 0.73±0.07b 345.47±50.88c 332.48±49.50bc 102.73±2.09c 2.0 413.02±39.02c 0.95±0.02a 0.56±0.04c 233.63±34.29d 222.86±35.94d 100.04±2.21c 注:同列不同小写字母表示差异显著(P<0.05);表2~表4同。 表 2 添加杏鲍菇粉对SPI-KF基模拟脂肪色泽的影响

Table 2 Effect of adding P. eryngii powder on the color of SPI-KF based simulated fat

杏鲍菇粉添加量

(%)L* a* b* ΔE 0 96.48±0.26a −1.04±0.05d 6.23±0.34d − 0.5 95.57±0.63b −0.82±0.04c 7.28±0.25c 1.50±0.43b 1.0 94.99±0.21b −0.67±0.10b 7.72±0.51bc 2.16±0.48b 1.5 93.60±0.44c −0.55±0.10a 8.06±0.69ab 3.48±0.70a 2.0 93.34±0.59c −0.48±0.10a 8.41±0.36a 3.88±0.64a 表 3 模拟脂肪对金线鱼鱼糜凝胶TPA的影响

Table 3 Effect of simulated fat on the TPA of surimi gel of golden fillet

模拟脂肪:猪油(w/w) 硬度(g) 弹性 内聚性 粘性(g) 咀嚼性(g) 0:8 1465.13±87.91b 0.89±0.04a 0.84±0.03a 1233.00±64.39b 1100.44±80.68b 2:6 1483.94±65.87b 0.93±0.02a 0.83±0.01a 1232.77±63.47b 1151.02±47.81b 4:4 1655.81±34.01a 0.95±0.05a 0.88±0.04a 1459.31±82.27a 1391.28±142.17a 6:2 1560.48±70.21ab 0.89±0.04a 0.85±0.00a 1327.19±56.44b 1185.47±76.64b 8:0 1550.69±30.95ab 0.90±0.03a 0.87±0.02a 1343.55±19.51b 1208.87±55.38b 表 4 模拟脂肪对金线鱼鱼糜凝胶感官评价的影响

Table 4 Effect of simulated fat on sensory evaluation of surimi gel of golden fillet

模拟脂肪:猪油(w/w) 风味 多汁性 咀嚼性 0:8 2.40±0.66b 2.70±0.64b 2.90±0.70b 2:6 2.90±0.83ab 3.10±0.83ab 2.90±0.70b 4:4 3.5 0±0.50a 3.70±0.64a 3.60±0.92a 6:2 3.60±0.80a 3.20±0.98ab 3.10±0.70ab 8:0 3.60±0.66a 3.20±0.87ab 3.10±1.04ab -

[1] 杨扬, 张玲玲, 李永祥, 等. 蛋白质基质脂肪模拟物制备方法及其应用的研究进展[J]. 中国油脂,2017,42(5):28−33. [YANG Yang, ZHANG Lingling, LI Yongxiang, et al. Advance in preparation and application of protein-based fat mimetic[J]. China Oils and Fats,2017,42(5):28−33.] doi: 10.3969/j.issn.1003-7969.2017.05.008 YANG Yang, ZHANG Lingling, LI Yongxiang, et al. Advance in preparation and application of protein-based fat mimetic[J]. China Oils and Fats, 2017, 42(5): 28−33. doi: 10.3969/j.issn.1003-7969.2017.05.008

[2] ARON W J, WARMBRUNN M V, NIEUWDORP M, et al. Metabolism and metabolic disorders and the microbiome:The intestinal microbiota associated with obesity, lipid metabolism, and metabolic health—pathophysiology and therapeutic strategies[J]. Gastroenterology,2021,160(2):573−599. doi: 10.1053/j.gastro.2020.10.057

[3] MARTINS A J, VICENTE A A, CUNH R L, et al. Edible oleogels:An opportunity for fat replacement in foods[J]. Food & Function,2018,9(2):758−773.

[4] 宋春勇, 洪鹏志, 周春霞. 负载白藜芦醇的红花籽油乳液对金线鱼鱼糜凝胶品质的影响[J]. 食品科学,2022,43(24):102−109. [SONG Chunyong, HONG Pengzhi, ZHOU Chunxia. Effect of safflower seed oil emulsion loaded with resveratrol on the quality of Nemipterus virgatus surimi gel[J]. Food Science,2022,43(24):102−109.] doi: 10.7506/spkx1002-6630-20211017-178 SONG Chunyong, HONG Pengzhi, ZHOU Chunxia. Effect of safflower seed oil emulsion loaded with resveratrol on the quality of Nemipterus virgatus surimi gel[J]. Food Science, 2022, 43(24): 102−109. doi: 10.7506/spkx1002-6630-20211017-178

[5] JIAO X, CAO H, FAN D, et al. Effects of fish oil incorporation on the gelling properties of silver carp surimi gel subjected to microwave heating combined with conduction heating treatment[J]. Food Hydrocolloids,2019,94:164−173. doi: 10.1016/j.foodhyd.2019.03.017

[6] 沈志文, 王璇, 李赤翎, 等. 油脂对鱼糜凝胶品质的影响研究进展[J]. 中国油脂,2023,48(9):37−42,74. [SHEN Zhiwen, WANG Xuan, LI Ciling, et al. Research progress on the effects of oil on the qualities of surimi gel[J]. China Oils and Fats,2023,48(9):37−42,74.] SHEN Zhiwen, WANG Xuan, LI Ciling, et al. Research progress on the effects of oil on the qualities of surimi gel[J]. China Oils and Fats, 2023, 48(9): 37−42,74.

[7] 赵洪雷, 聂凯, 徐永霞, 等. 甘油二酯油对白鲢鱼糜凝胶品质的影响[J]. 食品与发酵工业,2024,50(13):232−238. [ZHAO Honglei, NIE Kai, XU Yongxia, et al. Effects of diacylglycerol oil on gel quality of silver carp surimi[J]. Food and Fermentation Industries,2024,50(13):232−238.] ZHAO Honglei, NIE Kai, XU Yongxia, et al. Effects of diacylglycerol oil on gel quality of silver carp surimi[J]. Food and Fermentation Industries, 2024, 50(13): 232−238.

[8] PENG X, YAO Y. Carbohydrates as fat replacers[J]. Annual Review of Food Science and Technology,2017,8:331−351. doi: 10.1146/annurev-food-030216-030034

[9] 黄璐, 任雨晴, 赵迪, 等. 植物基脂肪模拟物对肉制品质量影响及应用研究进展[J]. 食品工业科技,2023,44(8):461−468. [HUANG Lu, RENG Yuqing, ZHAO Di, et al. Research progress on the effect of plant-based fat simulants on meat product quality and application[J]. Science and Technology of Food Industry,2023,44(8):461−468.] HUANG Lu, RENG Yuqing, ZHAO Di, et al. Research progress on the effect of plant-based fat simulants on meat product quality and application[J]. Science and Technology of Food Industry, 2023, 44(8): 461−468.

[10] SUN L, CHEN W, LIU Y, et al. Soy protein isolate/cellulose nanofiber complex gels as fat substitutes:Rheological and textural properties and extent of cream imitation[J]. Cellulose,2015,22:2619−2627. doi: 10.1007/s10570-015-0681-4

[11] 刘璐, 庞杰. 魔芋葡甘聚糖复合凝胶网络结构的研究进展[J]. 粮油食品科技,2021,29(2):129−134. [LIU Lu, PANG Jie. Research progress on material and composite structure of konjac glucomannan composite gel[J]. Science and Technology of Cereals, Oils and Foods,2021,29(2):129−134.] LIU Lu, PANG Jie. Research progress on material and composite structure of konjac glucomannan composite gel[J]. Science and Technology of Cereals, Oils and Foods, 2021, 29(2): 129−134.

[12] YASHINI M, SUNIL C K, SAHANA S, et al. Protein-based fat replacers-a review of recent advances[J]. Food Reviews International, 2021, 37(2):197−223.

[13] RATHER S A, MASOODI F A, AKHTER R, et al. Effects of guar gum as a fat substitute in low fat meat emulsions[J]. Journal of Food Processing and Preservation,2017,41(6):e13249. doi: 10.1111/jfpp.13249

[14] GAO Y, ZHAO Y, YAO Y, et al. Recent trends in design of healthier fat replacers:Type, replacement mechanism, sensory evaluation method and consumer acceptance[J]. Food Chemistry,2024,47:138982.

[15] HASHEMPOUR B F, KHORSRAVI D K, HOSSEINI H, et al. Mycoproteins as safe meat substitutes[J]. Journal of Cleaner Production,2020,253:119958. doi: 10.1016/j.jclepro.2020.119958

[16] 李春兰, 邹玉峰, 张玉洁, 等. 食用菌在肉制品中的应用研究进展[J]. 肉类研究,2022,36(8):49−56. [LI Chunlan, ZOU Yufeng, ZHANG Yujie, et al. Progress in application of edible mushrooms in meat products[J]. Meat Research,2022,36(8):49−56.] LI Chunlan, ZOU Yufeng, ZHANG Yujie, et al. Progress in application of edible mushrooms in meat products[J]. Meat Research, 2022, 36(8): 49−56.

[17] CERON M I, RANGEL E, LORENZO J M, et al. Reduction of salt and fat in frankfurter sausages by addition of Agaricus bisporus and Pleurotus ostreatus flour[J]. Foods,2020,9(6):760. doi: 10.3390/foods9060760

[18] PATINHO I, SALDANA E, SELANI M M, et al. Use of Agaricus bisporus mushroom in beef burgers:Antioxidant, flavor enhancer and fat replacing potential[J]. Food Production, Processing and Nutrition,2019,1:1−15. doi: 10.1186/s43014-019-0001-8

[19] FANG Q, SHI L, REN Z, et al. Effects of emulsified lard and TGase on gel properties of threadfin bream (Nemipterus virgatus) surimi[J]. LWT,2021,146:111513. doi: 10.1016/j.lwt.2021.111513

[20] HUANG L, SHI L, REN Z, et al. Effect of transglutaminase concentration in curing solution on the physicochemical properties of salted large yellow croaker (Pseudosciaena crocea)[J]. Food Chemistry:X,2022,14:100277.

[21] ZHANG X, CHEN X, GONG Y, et al. Emulsion gels stabilized by soybean protein isolate and pectin:Effects of high intensity ultrasound on the gel properties, stability and β-carotene digestive characteristics[J]. Ultrasonics Sonochemistry,2021,79:105756. doi: 10.1016/j.ultsonch.2021.105756

[22] ZHAO Y, REN Z, SHI L, et al. Effects of pre-emulsion prepared using sucrose esters with different hydrophile-lipophile balances on characteristics of soy protein isolate emulsion films[J]. Food Research International,2023,165:112542. doi: 10.1016/j.foodres.2023.112542

[23] 曹艳芸, 林金瓯, 韩剑众. EGCG修饰对乳清蛋白乳液冷凝胶特性的影响[J]. 中国食品学报,2022,22(3):18−26. [CAO Yanyun, LIN Jinou, HAN Jianzhong, et al. Effect of EGCG binding on the gel properties of whey protein cold-set emulsion gel[J]. Journal of Chinese Institute of Food Science and Technology,2022,22(3):18−26.] CAO Yanyun, LIN Jinou, HAN Jianzhong, et al. Effect of EGCG binding on the gel properties of whey protein cold-set emulsion gel[J]. Journal of Chinese Institute of Food Science and Technology, 2022, 22(3): 18−26.

[24] ZHANG E, ZHAO Y, REN Z, et al. Comparative effects of W/O and O/W emulsions on the physicochemical properties of silver carp surimi gels[J]. Food Chemistry:X,2023,20:100988.

[25] 邹何, 夏雪, 王粟萍, 等. 杏鲍菇相关研究进展及其产业开发现状[J]. 食品工业,2019,40(2):276−283. [ZOU He, XIA Xue, WANG Suping, et al. Research progress and industry development status of Pleurotus eryngi[J]. The Food Industry,2019,40(2):276−283.] ZOU He, XIA Xue, WANG Suping, et al. Research progress and industry development status of Pleurotus eryngi[J]. The Food Industry, 2019, 40(2): 276−283.

[26] KURT A, GENCCELEP H. Enrichment of meat emulsion with mushroom (Agaricus bisporus) powder:Impact on rheological and structural characteristics[J]. Journal of Food Engineering,2018,237:128−136. doi: 10.1016/j.jfoodeng.2018.05.028

[27] HAN M, BERTRAM H C. Designing healthier comminuted meat products:Effect of dietary fibers on water distribution and texture of a fat-reduced meat model system[J]. Meat Science,2017,133:159−165. doi: 10.1016/j.meatsci.2017.07.001

[28] GROBELNA A, KALISZ S, KIELISZEK M. The effect of the addition of blue honeysuckle berry juice to apple juice on the selected quality characteristics, anthocyanin stability, and antioxidant properties[J]. Biomolecules,2019,9(11):744. doi: 10.3390/biom9110744

[29] SHU X, WEI Y, LUO X, et al. κ-Carrageenan/konjac glucomannan composite hydrogel filled with rhamnolipid-stabilized nanostructured lipid carrier:Improvement of structure and properties[J]. Food Hydrocolloids,2023,134:108088. doi: 10.1016/j.foodhyd.2022.108088

[30] NAN H, ZHOU H, LI B, et al. Effects of Agaricus bisporus alone or in combination with soybean oil or water as fat substitutes on gel properties, rheology, water distribution, and microstructure of chicken batters[J]. Food Science and Technology,2022,42:e116121. doi: 10.1590/fst.116121

[31] HAN C, YANG X, LI L. Physicochemical properties and microstructure of soybean protein isolate-vegetable oil complex gels induced by lactic acid bacteria:Effects of vegetable oil types and concentrations[J]. Food Hydrocolloids,2023,145:109109. doi: 10.1016/j.foodhyd.2023.109109

[32] LIU Y, HUANG Y, WANG Y, et al. Application of cod protein-stabilized and casein-stabilized high internal phase emulsions as novel fat substitutes in fish cake[J]. LWT,2023,173:114267. doi: 10.1016/j.lwt.2022.114267

[33] HU S, WU J, ZHU B, et al. Low oil emulsion gel stabilized by defatted Antarctic krill (Euphausia superba) protein using high-intensity ultrasound[J]. Ultrasonics Sonochemistry,2021,70:105294. doi: 10.1016/j.ultsonch.2020.105294

[34] ZHAO Y, REN Z, SHI L, et al. Effect of W/O pre-emulsion prepared with different emulsifiers on the physicochemical properties of soy protein isolate-based emulsion films[J]. Food Hydrocolloids,2023,139:108440. doi: 10.1016/j.foodhyd.2022.108440

[35] ZHAO S, YUAN X, YANG L, et al. The effects of modified quinoa protein emulsion as fat substitutes in frankfurters[J]. Meat Science,2023,202:109215. doi: 10.1016/j.meatsci.2023.109215

[36] KANG Z L, CHEN F, MA H J. Effect of pre-emulsified soy oil with soy protein isolate in frankfurters:A physical-chemical and Raman spectroscopy study[J]. LWT,2016,74:465−471. doi: 10.1016/j.lwt.2016.08.011

[37] ZHOU X, CHEN H, LYU F, et al. Physicochemical properties and microstructure of fish myofibrillar protein-lipid composite gels:Effects of fat type and concentration[J]. Food Hydrocolloids,2019,90:433−442. doi: 10.1016/j.foodhyd.2018.12.032

[38] YU J, SONG L, XIAO H, et al. Structuring emulsion gels with peanut protein isolate and fish oil and analyzing the mechanical and microstructural characteristics of surimi gel[J]. LWT,2022,154:112555. doi: 10.1016/j.lwt.2021.112555

[39] YU N, XU Y, JIANG Q, et al. Molecular forces involved in heat-induced freshwater surimi gel:Effects of various bond disrupting agents on the gel properties and protein conformation changes[J]. Food Hydrocolloids,2017,69:193−201. doi: 10.1016/j.foodhyd.2017.02.003

[40] GANI A, BENJAKUL S. Impact of virgin coconut oil nanoemulsion on properties of croaker surimi gel[J]. Food Hydrocolloids,2018,82:34−44. doi: 10.1016/j.foodhyd.2018.03.037

[41] TOBIN B D, O'SULLIVAN M G, HAMILL R M, et al. Effect of varying salt and fat levels on the sensory and physiochemical quality of frankfurters[J]. Meat Science,2012,92(4):659−666. doi: 10.1016/j.meatsci.2012.06.017

下载:

下载:

下载:

下载: