Effect of Konjac Glucomannan Addition on Quality of Black Buckwheat Noodles

-

摘要: 为提高黑荞麦面条的品质,本文系统研究了魔芋葡甘聚糖(konjac glucomannan,KGM)添加对黑荞麦混合面粉溶剂保持力(solvent retention capacity,SRC)、混合特性和面条的质构、蒸煮、消化特性等指标的影响。结果表明,随着KGM添加黑荞麦混合粉的SRC呈上升的趋势,面团的吸水率、形成时间和稳定时间也呈上升的趋势,但弱化度C1-C2值和淀粉回生特性C5-C4值呈下降的趋势,在3%时分别下降了0.18 N·m和1.14 N·m。黑荞麦面条的蒸煮时间、断条率和蒸煮损失率随KGM添加呈下降的趋势,而拉伸强度和剪切力总体呈上升的趋势,在添加量2.5%时最大,分别为31.11 g和426.07 g。此外,添加KGM后黑荞麦面条的巯基含量总体无明显差异,二硫键含量显著提高(P<0.05)。在消化特性的研究中发现,KGM添加后黑荞麦面条的淀粉水解率、RS含量和eGI值无明显差异,与常规工艺制备的黑荞麦面条相近。综合各指标,黑荞麦面团的品质在KGM添加量3%时最佳,因为在此添加量下混合面粉的SRC和混合特性最佳;而面条的品质在KGM添加量为2.5%时提升最大,在此添加量下面条的蒸煮和质构等特性最佳。Abstract: In order to improve the quality of black buckwheat noodles, this paper systematically investigated the effects of konjac glucomannan (KGM) addition on the solvent retention capacity (SRC) and mixing characteristics of black buckwheat mixed powder, as well as the texture, cooking, digestive properties of the noodles were determined. Results showed that the SRC of black buckwheat mixed powder increased with the KGM addition. The water absorption rate, development time, and stability time of the dough also increased, while the weakening degree C1-C2 values and starch retrogradation characteristics C5-C4 values showed a decreasing trend, decreasing by 0.18 N·m and 1.14 N·m respectively at 3%. The cooking time, cooking broken rate, and cooking loss rate of black buckwheat noodles decreased with the addition of KGM, while the tensile strength and shear force showed an overall increasing trend, reaching their maximum at 2.5% addition, at 31.11 g and 426.07 g respectively. Furthermore, there was no significant difference in the sulfhydryl content of black buckwheat noodles after KGM addition, while the disulfide bond content significantly increased (P<0.05). In the study of digestion properties, there was no significant difference in starch hydrolysis rate, resistant starch content, and eGI value of black buckwheat noodles after KGM addition, which were similar to those prepared by conventional methods. The quality of buckwheat dough was best at 3% of KGM, because the SRC and mixing characteristics of the flour blend were best at this level of addition, while the quality of noodles was most improved at 2.5% of KGM, and the cooking and textural characteristics of the noodles were best at this level of addition.

-

荞麦属于蓼科荞麦属,富含可溶性膳食纤维、维生素、矿物质、酚类化合物和黄酮类化合物等营养物质,具有良好的保健功能[1−2]。荞麦一般分为甜荞和苦荞两个品种[3]。甜荞的植株通常呈现相对较低的矮小形态,其生长周期短,对湿润温暖气候环境有较好的适应性[4]。甜荞主要用于食品加工,例如面粉和面条的生产。其籽粒不仅在口感上具有独特之处,而且富含多种营养成分,包括膳食纤维、蛋白质、维生素和矿物质等,对人体健康具有积极影响[5]。苦荞植株相对较高,生长期较长,更适应寒冷和高海拔的环境[6]。苦荞麦的种子富含生物活性物质,如黄酮类化合物、植物鞣质等,具有一定的药用价值[7]。苦荞因其特殊的味道和保健功效,在一些地区被用于制作苦荞茶、苦荞酒等保健食品,被认为具有清热解毒、降脂减肥的功效,备受健康食品市场关注[8]。

荞麦挂面作为传统的面制品,约占我国杂粮挂面市场四分之三的份额,深受消费者喜爱[9]。然而,荞麦中的面筋含量极低,难以用传统的小麦面条加工方法加工成荞麦面条[10]。在面条加工中,添加不同的功能性成分已经成为改善面条品质和提高其营养价值的常见方法之一。作为一种天然的多糖类化合物,魔芋葡甘聚糖具有良好的黏度、稳定性和水溶性[11]。KGM在食品加工中具有良好的流变特性,可以形成稳定的凝胶结构。这种凝胶具有优异的弹性和咀嚼感,使得其在面条、果冻等食品制品中的应用具有显著的效果。此外,KGM凝胶的持水性很好,能够延缓食品的脱水和品质变化,提高食品的质感和口感[12]。Meng等[13]研究发现,加入一定量的KGM可以提高小麦粉的热稳定性和抗老化能力,改善面团的黏弹性,降低面团的硬度和黏滞度。葛珍珍等[14]发现随着KGM添加量的增加,面条的硬度、咀嚼性逐渐增大,并且适当添加KGM可以使面条内部结构变得均匀。综上所述,在小麦粉和面条制作中添加适量的KGM可以显著改善产品的品质。

黑荞麦作为一种特殊的荞麦品种,以其深褐色、无苦味和丰富的营养成分而备受关注[15]。然而,在面条生产中,黑荞麦面条的加工和质量控制仍然存在挑战,例如面条的弹性差、蒸煮损失和断条率较高、口感偏硬以及谷蛋白等营养成分缺失等。因此,探索添加功能性成分对黑荞麦面条品质的影响,以及KGM在其中的潜在应用,对于提高黑荞麦面条的加工技术和产品质量具有重要意义。本研究将深入探讨KGM在黑荞麦面条制备中的作用机制,对混合粉SRC、混合特性和面条蒸煮、质构特性、游离巯基和二硫键含量以及消化特性进行研究。这有助于深化对黑荞麦与KGM相互作用的理解,为未来功能性食品的开发提供重要的理论依据。

1. 材料与方法

1.1 材料与仪器

五得利高筋小麦粉 五得利面粉集团公司;黑荞麦粉 赤峰锦秋农副产品有限公司;魔芋葡甘聚糖 河南万邦实业有限公司;α-淀粉酶(30 U/mg)、淀粉葡糖苷酶(105 U/g)、胰蛋白酶(250 U/mg) 上海源叶生物科技有限公司。

FC1-220型电动压面机 武汉丰创机械设备有限公司;Mixolab 2混合试验仪 法国肖邦技术公司;TA-XTPlus质构仪 英国Stable Micro System;UV-2800分光光度计 优尼科。

1.2 实验方法

1.2.1 混合粉和面条制备

向小麦粉中添加适量的黑荞麦粉,制成含有8%黑荞麦粉的混合面粉;然后分别称取不同质量的KGM与之混合,制成含有0、0.5%、1.0%、1.5%、2.0%、2.5%、3.0%KGM的混合粉。最后参照葛珍珍等[14]的方法进行面条的制备。在混合粉中加入适量水,和面10 min,然后将面团放入醒发箱中熟化30 min。使用压面机在压辊轧距间隙分别为3 mm和2 mm的位置压制面片,然后在压辊轧距间隙2.0 mm处压片之后切成直径2.0 mm圆面条,备用。

1.2.2 混合粉溶剂保持能力

参照GB/T 35866-2018《粮油检验 小麦粉溶剂保持力的测定》进行测定,对纯小麦粉和混合粉的蒸馏水SRC、蔗糖SRC、碳酸钠SRC和乳酸SRC进行测定。

1.2.3 混合粉热机械特性测定

参照GB/T 37511-2019《粮油检验 小麦粉面团流变学特性测试 混合试验仪法》进行测定。

1.2.4 面条蒸煮特性测定

参照GB/T 40636-2021《挂面》进行测定。

1.2.5 面条质构特性分析

参照施建斌等[16]的方法进行测定。面条在最佳蒸煮时间下蒸煮后,过凉水10 s,然后进行剪切力测定和拉伸强度测定,每个试样作6次平行实验。具体方法如下:剪切力测定:将3根面条水平放置于载物台上,面条之间要有一定间隔,具体参数为:测试前速度:2 mm/s;测试速度:0.8 mm/s;测试后速度:0.8 mm/s;压缩程度:90%;触发力:5 g。拉伸强度测定:每次将1 根面条缠绕固定在两个平行的摩擦轮之间(面条在被拉的过程中不能松动),上面的轮子匀速地向上拉伸面条,直至面条断裂,具体参数为:测试前速度:2 mm/s;测试速度:2 mm/s;测试后速度:10 mm/s;触发距离:100 mm;触发力:0.5 g。

1.2.6 游离巯基和二硫键测定

参照Zhang等[17]的方法对游离巯基和二硫键含量进行测定。取75 mg面条冻干粉,与1 mL Tris-甘氨酸缓冲液混合均匀,再加入4.7 g盐酸胍,定容至10 mL。测巯基时,取1 mL样品液,加入4 mL脲-盐酸胍溶液和0.05 mL Ellman试剂,在412 nm波长下测吸光度。测二硫键时,取1 mL样品液,加入0.05 mL巯基乙醇和4 mL脲-盐酸胍溶液,于25 ℃恒温1 h,然后加10 mL 12%三氯乙酸,再恒温1 h,5000×g离心10 min。用5 mL 12%三氯乙酸清洗沉淀2次,将沉淀溶解在10 mL 8 mol/L脲中,加0.04 mL Ellman试剂,在412 nm波长下测吸光度。按照式(1)和式(2)分别计算游离巯基和二硫键含量:

-SH (μmol/g)=73.53×A×DC (1) -S-S- (μmol/g)=N1−N22 (2) 式中:A为样品412 nm处吸光值;D为稀释因子;C为样品浓度,mg/mL;N1、N2分别为还原前后巯基含量,μmol/g。

1.2.7 面条淀粉消化特性和血糖生成指数

面条淀粉含量参照 GB 5009.9-2023《食品中淀粉的测定》进行测定。参照熊添等[18]的方法,并进行少许修改。取0.5 g煮熟的黑荞麦面条于50 mL离心管中,加入5 mL 0.01 mol/L NaOH溶液和15 mL 0.1 mol/L的磷酸盐标准缓冲液(pH6.8),然后加入适量α-淀粉酶、淀粉葡糖苷酶和胰蛋白酶,随后使样品在37 ℃下恒温水浴振荡3 h,分别在0、20、60、90、120、150和180 min下取出0.1 mL消化液,加入0.5 mL无水乙醇灭酶。采用DNS法测定消化液中葡萄糖含量并计算淀粉水解率。淀粉的体外消化水解曲线符合一级反应方程式。通过对水解曲线下面积的积分(areas under curve,AUC)计算淀粉的水解指数(hydrolysis index,HI),进而估算黑荞麦面条的血糖生成指数(estimated glycemic index,eGI)。其具体计算公式如下:

HI=AUC样品AUC白面包×100 (3) eGI=39.71+0.549×HI (4) 1.3 数据处理

实验重复3次,结果用平均值±标准差(x±s)表示,采用Excel 2019列表或采用Origin 2018对所得数据进行作图处理。用SPSS通过一元方差分析(One-Way ANOVA)进行多个组间平均数的比较,如果组间存在显著性差异(P<0.05),则采用Duncan检验进行组间多重比较。

2. 结果与分析

2.1 KGM添加对混合粉溶剂保持力的影响

KGM添加对混合面粉溶剂保持力的影响见图1。从图中可以看出,纯小麦粉的蒸馏水SRC、蔗糖SRC、碳酸钠SRC和乳酸SRC分别为57.04%、92.24%、67.61%和92.24%,而未添加KGM时蒸馏水SRC、蔗糖SRC、碳酸钠SRC和乳酸SRC分别为45.99%、70.02%、46.75%和66.52%,说明黑荞麦粉的添加显著降低了面团的溶剂保持力(P<0.05)。黑荞麦粉中阿拉伯木聚糖和破损淀粉含量很低,因此加入后降低了黑荞麦面团的蔗糖SRC和碳酸钠SRC[19]。随着KGM的添加,面团的溶剂保持力总体呈上升趋势,在添加量为3%时达到最高,蒸馏水SRC、蔗糖SRC、碳酸钠SRC和乳酸SRC分别为61.45%、94.76%、89.94%和115.36%,相对于纯小麦粉提高了7.73%、2.73%、33.02%和25.06%。乳酸SRC反映了面筋的品质和功能,由于黑荞麦粉中的膳食纤维含量远大于小麦粉,因此加入后会破坏面筋的网络结构,使乳酸SRC下降[20]。在黑荞麦面团中加入KGM后吸水率呈上升的趋势,这是因为KGM具有大量的亲水基团,这些亲水基团可以在溶胀过程中吸收更多的水[13]。此外,KGM与面团中的蛋白质相互作用形成了线性的抗性框架,可以结合更多的可溶性物质[21],因此随KGM添加量的增加蔗糖SRC、碳酸钠SRC和乳酸SRC呈上升的趋势。综上所述,添加KGM至混合面粉中显著提高了面团的溶剂保持力(P<0.05),尤其在添加量为3%时效果最佳,这有助于改善黑荞麦面团的吸水和结合可溶性物质的能力。

2.2 KGM添加对面团混合特性的影响

KGM添加对面团混合特性的影响见表1。从表中可看出,纯小麦粉的吸水率为59.40%,添加8%黑荞麦粉后吸水率为55.00%,说明黑荞麦粉的加入显著降低了面团的吸水率(P<0.05);在混合面粉中加入KGM后吸水率呈上升的趋势,在添加量为3%时相对于添加量0%时提高了23.81%,相对于纯小麦粉提高了14.63%。这是因为黑荞麦粉中膳食纤维含量较高,加入后会破坏小麦面筋蛋白形成的网络结构,从而导致面团的吸水率下降[15];而加入KGM后吸水率增加,这是因为KGM具有大量的亲水基团,这些亲水基团在溶胀过程中可以吸收更多的水[13]。纯小麦粉的形成时间和稳定时间分别为7.88 min和5.28 min,在加入8%黑荞麦粉后分别降低了1.01 min和0.54 min;在混合面粉中加入KGM后形成时间和稳定时间总体都呈上升的趋势,在添加量3%时最大,分别为8.14 min和7.12 min。黑荞麦面团的形成时间上升,这可能与KGM在面团混合过程中和面筋蛋白竞争吸收水分并干扰面筋蛋白网络结构的形成有关[22];而稳定时间上升是因为KGM具有很强的增粘性和黏性,当添加量较高时,它可以在面粉中形成稠密的凝胶网络结构,这种凝胶网络可以在加热过程中保持形状,阻碍面粉中水分的释放,从而延长了面团达到稳定状态所需的时间[21]。弱化度C1-C2值反映了面筋网络结构的强度,弱化度较差的样品具有较强的面筋蛋白强度[23]。纯小麦粉的蛋白的弱化度C1-C2值为0.56 N·m,添加黑荞麦粉后显著上升(P<0.05),为0.71 N·m;但在混合面粉中加入KGM后C1-C2值降低,随着添加量的增加总体呈下降的趋势,在3%时降低了0.18 N·m。黑荞麦蛋白的成分主要为白蛋白和球蛋白,面筋网络结构形成能力较差,因此加入后会导致面团的筋力降低,弱化度C1-C2值提高[24];而加入KGM后C1-C2值下降,这是因为添加KGM后增加了面筋的吸水性,稀释了面筋蛋白的浓度。

表 1 KGM添加对面团混合特性的影响Table 1. Effect of KGM addition on dough mixing characteristicsKGM添加量(%) 吸水率(%) 形成时间(min) 稳定时间(min) C1-C2(N·m) C3-C2(N·m) C3-C4(N·m) C5-C4(N·m) 小麦粉 59.40±0.00e 7.88±0.14ab 5.28±0.13bc 0.56±0.03de 1.40±0.00c 0.03±0.03a 1.52±0.13b 0 55.00±0.00g 6.87±0.10d 4.74±0.41c 0.71±0.01a 1.53±0.01a −0.36±0.02e 1.86±0.01a 0.5 56.60±0.35f 5.91±0.23e 4.77±0.12c 0.69±0.02ab 1.50±0.01b −0.21±0.01d 1.47±0.03b 1.0 59.50±0.00e 6.04±0.30e 4.71±0.24c 0.67±0.01b 1.48±0.03b −0.16±0.02c 1.23±0.06c 1.5 62.00±0.00d 6.92±0.02d 4.93±0.30c 0.63±0.02c 1.41±0.00c −0.16±0.02c 1.04±0.06d 2.0 63.20±0.00c 7.36±0.17c 5.40±0.09bc 0.61±0.01c 1.39±0.01c −0.10±0.01b 0.93±0.02e 2.5 65.13±0.64b 7.58±0.23bc 5.89±0.87b 0.57±0.01d 1.36±0.01d −0.07±0.01b 0.88±0.03e 3.0 68.10±0.00a 8.14±0.07a 7.12±0.20a 0.53±0.01e 1.27±0.01e −0.01±0.06a 0.72±0.03f 注:同列不同小写字母表示有显著性差异,P<0.05,表2~表3同。 淀粉糊化特性C3-C2值在KGM添加量0%时为1.53 N·m,相对于纯小麦粉提高了9.28%,但随着KGM的添加C3-C2值呈下降的趋势,在添加量3%时最低,相对于KGM添加量0%时降低了16.99%。C3-C4值为面团的热稳定性,其中纯小麦粉的C3-C4值最高,为0.03 N·m,正值表明其在加热过程中热稳定性下降;加入黑荞麦粉后C3-C4值显著下降(P<0.05),为−0.36 N·m,说明加入黑荞麦粉后提高了面团的热稳定性;黑荞麦面团的C3-C4值随KGM的添加呈上升的趋势,在添加量3%时为−0.01 N·m,相对于0%时增加了0.35 N·m,说明KGM的加入降低了黑荞麦面团的热稳定性。这是因为KGM会破坏小麦淀粉和荞麦淀粉的晶体结构,因此随添加量增加面团的热稳定性下降[25]。淀粉回生特性C5-C4值在KGM添加量0%时为1.86 N·m,相对于纯小麦面团提高了18.27%;加入KGM后C5-C4值下降,并且随添加量的增加呈下降的趋势,说明KGM的加入能够抑制黑荞麦面团的回生特性。KGM可能在淀粉周围形成了屏障,阻止了直链淀粉在糊化过程中的扩散;并且溶出的直链淀粉会与KGM相互作用,导致KGM-直链淀粉复合物的形成,从而抑制了黑荞麦面团的回生[26]。综上所述,添加KGM能够提升面团的吸水率、形成时间和稳定时间,降低面团的弱化度和回生特性,但会在一定程度上降低面团的热稳定性。

2.3 KGM添加对面条蒸煮特性的影响

KGM添加对黑荞麦面条蒸煮特性的影响见表2。从表中可以看出,小麦粉面条的蒸煮时间最长为473.33 s,加入黑荞麦粉后面条的蒸煮时间显著下降(P<0.05),降低了103.33 s;加入KGM后,黑荞麦面条的蒸煮时间呈下降的趋势,在添加量3%时最低,相对于0%降低了19.81%。黑荞麦粉中淀粉含量比小麦粉少,且没有谷蛋白,无法形成面筋网络结构,导致水分更容易进入面条内部,因此缩短了蒸煮时间;而KGM具有很强的吸水性,它能够吸收大量水分并形成凝胶状物质,这种凝胶状物质可以迅速将水分锁定在面条中,使面条更快地吸收水分并熟化。与纯小麦面条相比,黑荞麦面条的蒸煮断条率显著增加(P<0.05),增加了8.33%;在黑荞麦面条中加入KGM后,面条的蒸煮断条率得到明显改善,随KGM添加量的增加呈下降的趋势。这是因为黑荞麦粉中膳食纤维含量较高,加入后破坏了面筋蛋白形成的网络结构,从而增加了蒸煮断条率[15]。而KGM的加入能够加强面筋蛋白之间的交联,使网络结构更加稳定、紧密,进而改善了黑荞麦面条断条率高的问题[27]。

表 2 KGM添加对黑荞麦面条蒸煮特性的影响Table 2. Effect of KGM addition on cooking characteristics of black buckwheat noodlesKGM添加量

(%)蒸煮时间

(s)断条率

(%)蒸煮吸水率

(%)蒸煮损失率

(%)小麦粉 473.33±5.77a 0.00±0.00d 213.20±14.73a 13.06±0.45b 0 370.00±10.00b 8.33±1.44a 163.39±3.49bcd 14.90±0.58a 0.5 353.33±5.77c 6.67±1.44ab 162.75±19.25bcd 13.43±0.45b 1.0 343.33±5.77c 5.83±1.44bc 173.50±6.57bc 12.34±0.12bc 1.5 330.00±0.00d 5.00±0.00bc 183.09±5.91b 12.23±0.55bc 2.0 316.67±5.77e 4.17±1.44c 155.11±11.21cd 11.31±0.33c 2.5 306.67±5.77ef 4.17±1.44c 155.90±10.40cd 9.01±1.98d 3.0 296.67±5.77f 1.25±1.77d 142.03±6.63d 9.53±0.37d 加入黑荞麦粉后,面条的蒸煮吸水率显著降低(P<0.05),从213.20%降低到163.39%;在黑荞麦面条中加入KGM后,面条的蒸煮吸水率呈先上升后下降的趋势,在添加量1.5%时最高,为183.09%,在添加量3%时最低,为142.03%。此外,黑荞麦面条的蒸煮损失率在KGM添加量0%时最大,随添加量的增加总体呈下降的趋势,在添加量2.5%时最低,为9.01%。黑荞麦粉中膳食纤维含量较高,过高的膳食纤维会破坏蛋白质-淀粉网络结构的连续性,阻碍了面筋网络的形成,导致面条的持水性降低,进而减少了蒸煮吸水率,并使蒸煮损失增加。KGM结构中有很多的亲水基团,这些亲水基团通过氢键允许更多的水相互作用,导致黑荞麦面条的吸水率上升;但是过多的KGM反而会限制淀粉颗粒的膨胀,而淀粉糊化是蒸煮过程中样品吸水率增加的主要原因,因此KGM添加量过多会导致蒸煮吸水率下降[28]。此外,添加KGM可能会在淀粉颗粒周围形成保护网络,从而减少膨胀颗粒的自发破裂,降低了淀粉的溶出率,使黑荞麦面条在蒸煮过程中的损失率下降[29]。综上所述,KGM的添加能够显著改善黑荞麦面条的蒸煮特性,包括降低蒸煮时间、断条率和蒸煮损失率以及提高蒸煮吸水率,尤其在添加量为2.5%时效果最佳。

2.4 KGM添加对面条质构特性的影响

KGM对黑荞麦面条质构特性的影响见表3。从表中可以看出,纯小麦粉的拉伸强度为25.13 g,添加黑荞麦粉后面条的拉伸强度显著下降(P<0.05),为16.39 g;在黑荞麦面条中加入KGM后面条的拉伸强度显著提高(P<0.05),但在添加量0.5%~2%时无显著差异(P>0.05),在添加量为2.5%时拉伸强度最大,为31.11 g。小麦面条的拉伸距离最大,为44.74 mm,显著高于黑荞麦面条(P<0.05);在黑荞麦面条中加入KGM后面条的拉伸距离呈先上升后下降的趋势,在添加量1.5%时最大,为40.35 mm。小麦面条的剪切力最小,为238.75 g,加入黑荞麦粉后面条的剪切力无显著差异(P>0.05),但随着KGM的添加黑荞麦面条的剪切力总体呈上升的趋势,在添加量为2.5%时最大,为426.07 g。黑荞麦粉中淀粉颗粒较大,并且不含面筋蛋白,加入后会稀释面筋蛋白的浓度,导致黑荞麦面条的面筋网络形成能力下降,降低了面条的拉伸强度和拉伸距离[30]。KGM吸收水分形成稳定的凝胶结构,补充了面团的面筋网络结构,并且KGM充分水合后会增强淀粉分子的糊化,因此加入后会增强面条的拉伸强度和剪切力[13]。但是当KGM添加量过高时,KGM会与淀粉分子形成复合物,并且容易结块,无法很好地填充面团的面筋网络结构,导致拉伸强度、拉伸距离和剪切力下降[31]。综合各指标,KGM添加量在1.5%~2.5%之间时面条的质构特性最佳。

表 3 KGM添加对黑荞麦面条质构特性的影响Table 3. Effect of KGM addition on texture characteristics of black buckwheat noodlesKGM添加量(%) 拉伸强度(g) 拉伸距离(mm) 剪切力(g) 小麦粉 25.13±1.13b 44.74±3.08a 238.75±10.12e 0 16.39±0.86d 26.00±2.21d 248.84±5.39e 0.5 20.79±1.49c 31.81±3.42c 274.31±24.20c 1.0 22.26±0.70c 38.38±2.57b 296.71±20.34cd 1.5 20.70±1.15c 40.35±3.73b 293.01±10.12cd 2.0 20.44±0.77c 26.12±1.86d 312.05±19.52bc 2.5 31.11±3.03a 27.52±1.97d 426.07±35.10a 3.0 25.29±1.57b 26.10±2.57d 329.95±25.51b 2.5 KGM添加对游离巯基和二硫键含量的影响

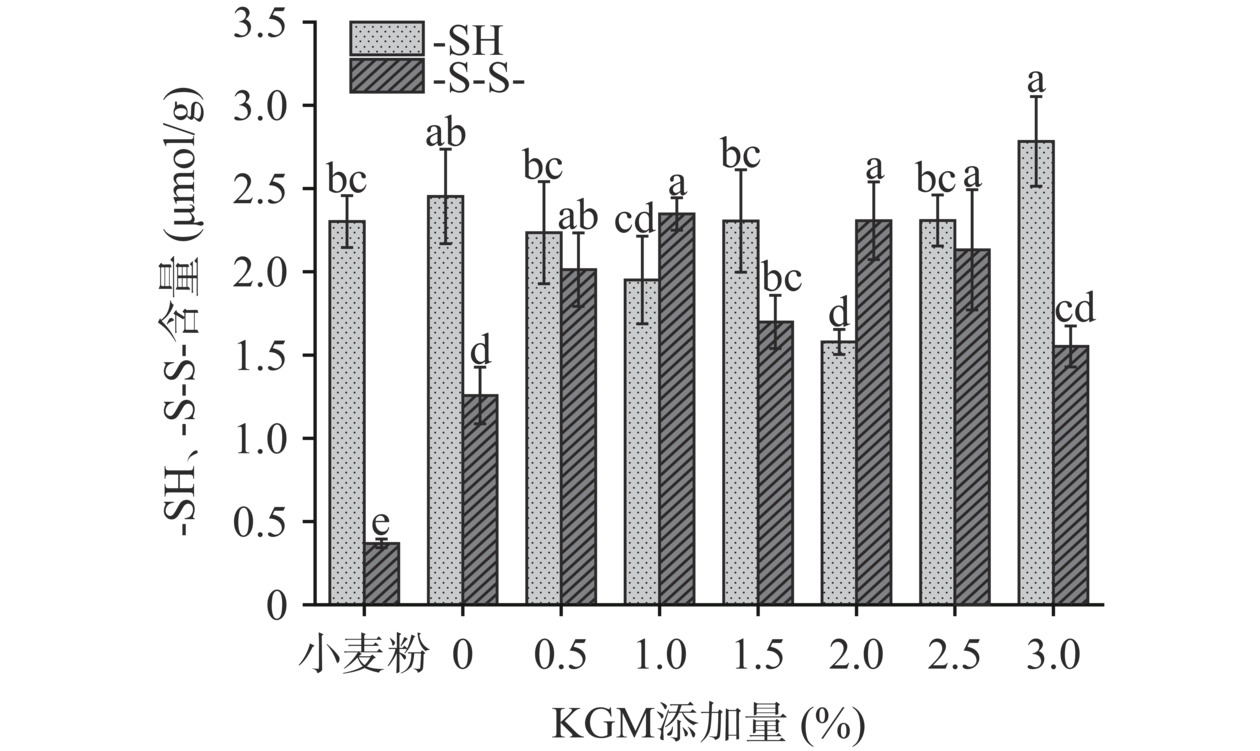

KGM添加对黑荞麦面条游离巯基和二硫键含量的影响见图2。从图中可以看出,小麦面条的游离巯基含量为2.30 μmol/g,黑荞麦面条为2.45 μmol/g,其间无显著差异(P>0.05)。在KGM添加量2%时黑荞麦面条的游离巯基含量最低,为1.57 μmol/g,其它添加量无明显差异。此外,小麦面条的二硫键含量最低,为0.36 μmol/g,添加黑荞麦粉后面条的二硫键含量显著提高(P<0.05),为1.25 μmol/g;在黑荞麦面条中加入KGM后,二硫键含量总体呈上升的趋势。游离的巯基和二硫键都是蛋白质聚合所必需的官能团,可以反映面筋网络的形成程度,对面制品的品质影响很大[32]。向黑荞麦面条中加入KGM后二硫键含量提高,这是因为KGM能够吸收水分形成稳定的凝胶结构,加强了面筋蛋白间的交联作用,这也是面条的拉伸强度和剪切力增强的原因之一[13]。Zhou等[33]研究发现在面团混合过程中加入KGM会减少巯基含量,并且二硫键含量得到增加,这是因为KGM分子中D-葡萄糖和D-甘露糖上的活性羟基通过自由基清除作用发生反应,可能部分阻止了巯基/二硫键交换过程中自由基的积累,从而缓解了面团混合过程中蛋白质分子的聚集。综上所述,KGM的添加会降低黑荞麦面条的游离巯基含量并提高二硫键含量,加强面筋蛋白间的交联作用;在KGM添加量2%时效果最显著,有助于改善面条的品质。

2.6 KGM添加对面条淀粉消化特性的影响

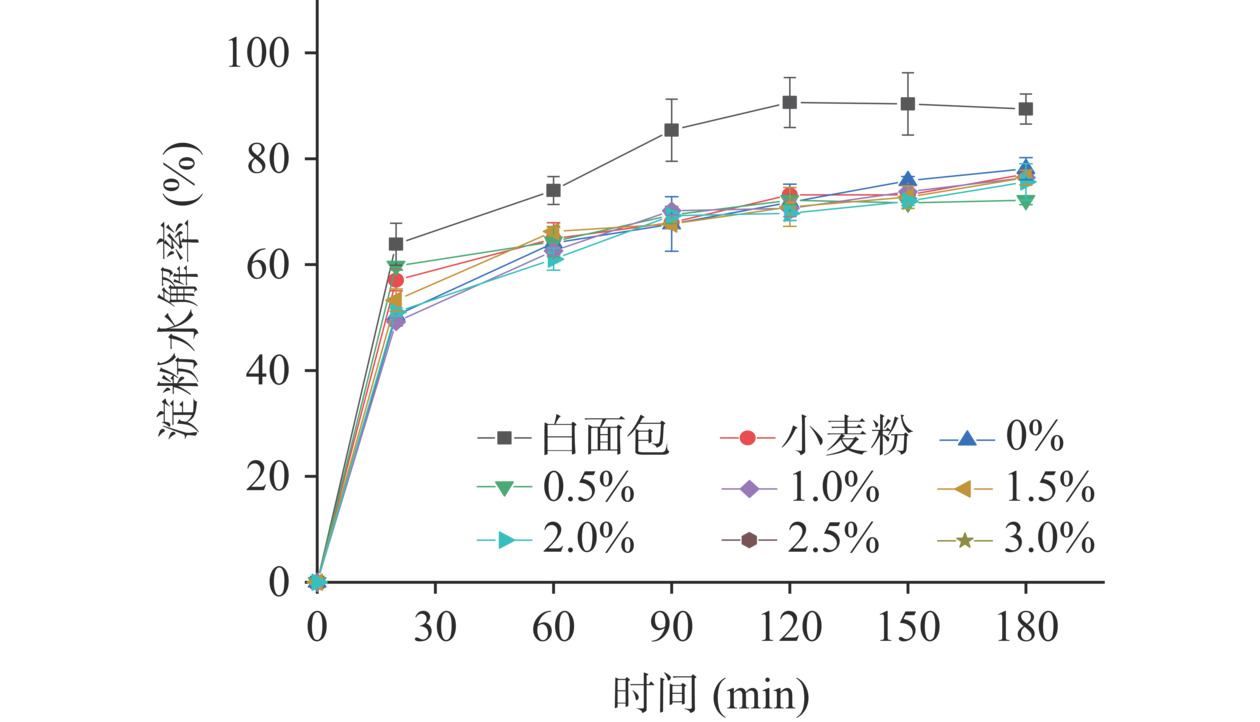

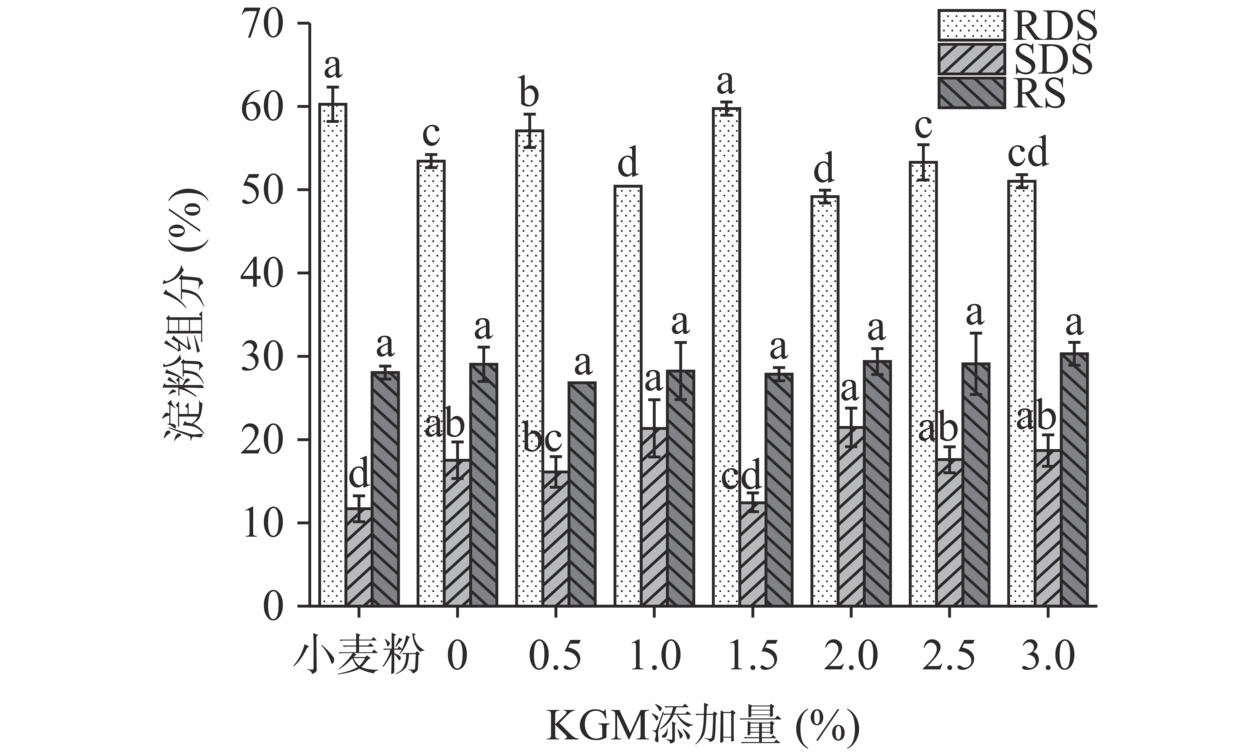

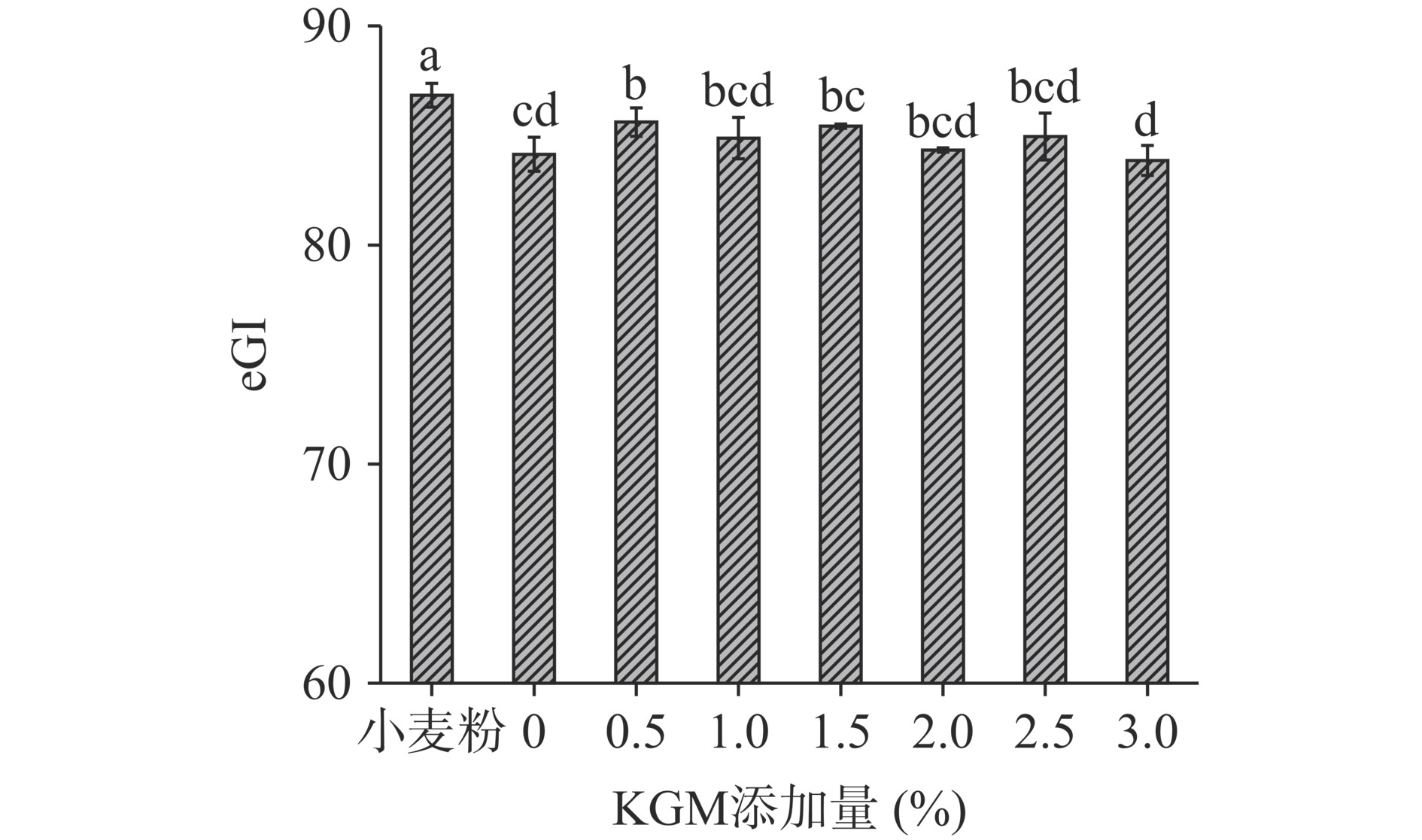

KGM添加对黑荞麦面条淀粉水解率的影响见图3。从图中可以看出,白面包的淀粉水解率最高,其他几组的淀粉水解率总体上无显著差异(P>0.05)。KGM添加对黑荞麦面条快速消化淀粉(rapidly digestible starch,RDS)、慢速消化淀粉(slowly digestible starch,SDS)和抗性淀粉(resistant starch,RS)含量的影响见图4。从图中可以看出,小麦面条的RDS含量为60.26%,加入黑荞麦粉后RDS含量显著降低(P<0.05),为53.43%;在0.5%和1.5% KGM添加量时,黑荞麦面条的RDS含量显著提高(P<0.05)。小麦面条的SDS含量最低,为11.69%,加入黑荞麦粉后面条的SDS含量显著提高(P<0.05);KGM添加量在1.5%时黑荞麦面条的SDS含量显著降低(P<0.05),但在其它添加量时无显著差异(P>0.05)。由图5可知,小麦面条的eGI值最高,为86.83,加入黑荞麦粉后eGI值显著下降(P<0.05);在黑荞麦面条中加入0.5%KGM后,eGI值显著提高(P<0.05),其它添加量并无显著差异(P>0.05),说明KGM的添加对黑荞麦面条淀粉消化的影响很小。

黑荞麦粉中的植酸和单宁等物质含量比小麦粉高,加入后和消化酶形成复合物,降低了消化酶的活性,因此eGI值下降[34]。KGM加入后RS和eGI值无显著差异的原因有两个:一方面,KGM的加入破坏了小麦淀粉的原始晶体结构,可能导致淀粉的水解速率增加;另一方面,添加KGM有助于使小麦淀粉的结构更加紧凑,并且形成的网络结构会在糊化淀粉周围形成屏障,反而抑制了淀粉的消化[35−36]。因此,添加KGM对黑荞麦面条淀粉消化率的影响较小。Zhou等[37]研究发现高浓度的KGM(3%~5%)能够抑制消化,而低浓度的KGM则会促进小麦淀粉消化。这是因为KGM分子倾向于附着在淀粉颗粒表面,在外围形成隔层,阻断了酶与淀粉的接触。此外,随着KGM比例的增加,KGM的增稠作用可能会限制传质并进一步抑制淀粉溶胀;其次,KGM的增稠作用还可以通过抑制浸出淀粉分子的重排形成半晶体结构来降低淀粉消化速率[38]。而当添加量较低时,KGM可以使淀粉酶更容易水解淀粉的无定形区域,因此会导致水解率过高[39]。综上所述,KGM添加对黑荞麦面条的淀粉消化率影响较小。

3. 结论

研究发现,随着KGM添加量的增加,混合面粉的溶剂保持力呈上升的趋势,在KGM添加量3%时蒸馏水SRC、蔗糖SRC、碳酸钠SRC和乳酸SRC分别提高了15.46%、24.74%、43.19%和48.84%;黑荞麦面团的吸水率、形成时间和稳定时间呈上升的趋势,但是弱化度C1-C2值和淀粉回生特性C5-C4值呈下降的趋势,在3%分别下降了0.18 N·m和1.14 N·m。黑荞麦面条的蒸煮时间、断条率和蒸煮损失率随KGM添加呈下降的趋势,而拉伸强度和剪切力总体呈上升的趋势,在添加量2.5%时最大,分别为31.11 g和426.07 g。此外,添加KGM后黑荞麦面条的巯基含量无明显差异,二硫键含量显著提高(P<0.05),在添加量1%、2%和2.5%时最大,但是其间无显著差异(P>0.05)。在消化特性的研究中发现,KGM添加后黑荞麦面条的淀粉水解率、RS含量和eGI值无明显差异,与常规工艺制备的黑荞麦面条相近。综上所述,黑荞麦混合面粉的溶剂保持力和混合特性在KGM添加量3%时最佳,而黑荞麦面条的蒸煮和质构等特性在KGM添加量为2.5%时最佳。本研究揭示了利用魔芋葡甘聚糖改善黑荞麦面条品质的潜力,为食品加工领域提供了新的技术路径,有望促进面食工业的进一步发展。

-

表 1 KGM添加对面团混合特性的影响

Table 1 Effect of KGM addition on dough mixing characteristics

KGM添加量(%) 吸水率(%) 形成时间(min) 稳定时间(min) C1-C2(N·m) C3-C2(N·m) C3-C4(N·m) C5-C4(N·m) 小麦粉 59.40±0.00e 7.88±0.14ab 5.28±0.13bc 0.56±0.03de 1.40±0.00c 0.03±0.03a 1.52±0.13b 0 55.00±0.00g 6.87±0.10d 4.74±0.41c 0.71±0.01a 1.53±0.01a −0.36±0.02e 1.86±0.01a 0.5 56.60±0.35f 5.91±0.23e 4.77±0.12c 0.69±0.02ab 1.50±0.01b −0.21±0.01d 1.47±0.03b 1.0 59.50±0.00e 6.04±0.30e 4.71±0.24c 0.67±0.01b 1.48±0.03b −0.16±0.02c 1.23±0.06c 1.5 62.00±0.00d 6.92±0.02d 4.93±0.30c 0.63±0.02c 1.41±0.00c −0.16±0.02c 1.04±0.06d 2.0 63.20±0.00c 7.36±0.17c 5.40±0.09bc 0.61±0.01c 1.39±0.01c −0.10±0.01b 0.93±0.02e 2.5 65.13±0.64b 7.58±0.23bc 5.89±0.87b 0.57±0.01d 1.36±0.01d −0.07±0.01b 0.88±0.03e 3.0 68.10±0.00a 8.14±0.07a 7.12±0.20a 0.53±0.01e 1.27±0.01e −0.01±0.06a 0.72±0.03f 注:同列不同小写字母表示有显著性差异,P<0.05,表2~表3同。 表 2 KGM添加对黑荞麦面条蒸煮特性的影响

Table 2 Effect of KGM addition on cooking characteristics of black buckwheat noodles

KGM添加量

(%)蒸煮时间

(s)断条率

(%)蒸煮吸水率

(%)蒸煮损失率

(%)小麦粉 473.33±5.77a 0.00±0.00d 213.20±14.73a 13.06±0.45b 0 370.00±10.00b 8.33±1.44a 163.39±3.49bcd 14.90±0.58a 0.5 353.33±5.77c 6.67±1.44ab 162.75±19.25bcd 13.43±0.45b 1.0 343.33±5.77c 5.83±1.44bc 173.50±6.57bc 12.34±0.12bc 1.5 330.00±0.00d 5.00±0.00bc 183.09±5.91b 12.23±0.55bc 2.0 316.67±5.77e 4.17±1.44c 155.11±11.21cd 11.31±0.33c 2.5 306.67±5.77ef 4.17±1.44c 155.90±10.40cd 9.01±1.98d 3.0 296.67±5.77f 1.25±1.77d 142.03±6.63d 9.53±0.37d 表 3 KGM添加对黑荞麦面条质构特性的影响

Table 3 Effect of KGM addition on texture characteristics of black buckwheat noodles

KGM添加量(%) 拉伸强度(g) 拉伸距离(mm) 剪切力(g) 小麦粉 25.13±1.13b 44.74±3.08a 238.75±10.12e 0 16.39±0.86d 26.00±2.21d 248.84±5.39e 0.5 20.79±1.49c 31.81±3.42c 274.31±24.20c 1.0 22.26±0.70c 38.38±2.57b 296.71±20.34cd 1.5 20.70±1.15c 40.35±3.73b 293.01±10.12cd 2.0 20.44±0.77c 26.12±1.86d 312.05±19.52bc 2.5 31.11±3.03a 27.52±1.97d 426.07±35.10a 3.0 25.29±1.57b 26.10±2.57d 329.95±25.51b -

[1] SKŘIVAN P, CHRPOVÁ D, KLITSCHOVÁ B, et al. Buckwheat flour (Fagopyrum esculentum Moench)—A contemporary view on the problems of its production for human nutrition[J]. Foods,2023,12(16):3055. doi: 10.3390/foods12163055

[2] LI L, LIETZ G, SEAL C. Buckwheat and CVD risk markers:A systematic review and meta-analysis[J]. Nutrients,2018,10(5):619. doi: 10.3390/nu10050619

[3] BURATTI S, GIOVANELLI G, BENEDETTI S, et al. Impact of gelatinization on common (Fagopyrum esculentum) and tartary (Fagopyrum tataricum) buckwheat:Effect on taste and flavor assessed by e-senses in relation to phenolic compounds[J]. European Food Research and Technology,2022,248(10):2521−2530. doi: 10.1007/s00217-022-04066-z

[4] ZARGAR S M, HAMI A, MANZOOR M, et al. Buckwheat OMICS:Present status and future prospects[J]. Crit Rev Biotechnol, 2023:1−18.

[5] WU D, WANG J, LI J, et al. Physicochemical properties and biological functions of soluble dietary fibers isolated from common and tartary buckwheat sprouts[J]. LWT,2023,183:114944. doi: 10.1016/j.lwt.2023.114944

[6] LUTHAR Z, GOLOB A, GERM M, et al. Tartary buckwheat in human nutrition[J]. Plants (Basel),2021,10(4):700. doi: 10.3390/plants10040700

[7] ZOU L, WU D, REN G, et al. Bioactive compounds, health benefits, and industrial applications of tartary buckwheat (Fagopyrum tataricum)[J]. Critical Reviews in Food Science and Nutrition,2023,63(5):657−673. doi: 10.1080/10408398.2021.1952161

[8] JHA R, ZHANG K, HE Y, et al. Global nutritional challenges and opportunities:Buckwheat, a potential bridge between nutrient deficiency and food security[J]. Trends in Food Science & Technology,2024,145:104365.

[9] 薛超强. 低升糖指数苦荞挂面的研制及品质改良[D]. 无锡:江南大学, 2023. [XUE Chaoqiang. Development and quality improvement of tartary buckwheat dried noodles with low glycemic index[D]. Wuxi:Jiangnan University, 2023.] XUE Chaoqiang. Development and quality improvement of tartary buckwheat dried noodles with low glycemic index[D]. Wuxi: Jiangnan University, 2023.

[10] PULIGUNDLA P, LIM S. Buckwheat noodles:Processing and quality enhancement[J]. Food Science and Biotechnology,2021,30(12):1471−1480. doi: 10.1007/s10068-021-00960-6

[11] SUN Y, XU X, WU Z, et al. Structure, merits, gel formation, gel preparation and functions of konjac glucomannan and its application in aquatic food preservation[J]. Foods,2023,12(6):1215. doi: 10.3390/foods12061215

[12] LI J, LIU M, QIN G, et al. Classification, gelation mechanism and applications of polysaccharide-based hydrocolloids in pasta products:A review[J]. International Journal of Biological Macromolecules,2023,248:125956. doi: 10.1016/j.ijbiomac.2023.125956

[13] MENG K, GAO H, ZENG J, et al. Rheological and microstructural characterization of wheat dough formulated with konjac glucomannan[J]. J Sci Food Agric,2021,101(10):4373−4379. doi: 10.1002/jsfa.11078

[14] 葛珍珍, 张圆圆, 李盈, 等. 魔芋葡甘聚糖对面条质构及微观结构的影响[J]. 粮食与油脂,2021,34(9):67−72. [GE Zhenzhen, ZHANG Yuanyuan, LI Ying, et al. Effect of konjac glucomannan on the texture and microstructure of noodles[J]. Cereals & Oils,2021,34(9):67−72.] GE Zhenzhen, ZHANG Yuanyuan, LI Ying, et al. Effect of konjac glucomannan on the texture and microstructure of noodles[J]. Cereals & Oils, 2021, 34(9): 67−72.

[15] ZHENG F, XU Q, ZENG S, et al. Multi-scale structural characteristics of black tartary buckwheat resistant starch by autoclaving combined with debranching modification[J]. Int J Biol Macromol,2023,249:126102. doi: 10.1016/j.ijbiomac.2023.126102

[16] 施建斌, 隋勇, 熊添, 等. 芦笋粉添加对面团和面条特性的影响[J]. 食品工业科技,2024,45(5):62−69. [SHI Jianbin, SUI Yong, XIONG Tian, et al. Effects of asparagus powder addition on dough and noodles properties[J]. Science and Technology of Food Industry,2024,45(5):62−69.] SHI Jianbin, SUI Yong, XIONG Tian, et al. Effects of asparagus powder addition on dough and noodles properties[J]. Science and Technology of Food Industry, 2024, 45(5): 62−69.

[17] ZHANG L, GUAN E, YANG Y, et al. Impact of wheat globulin addition on dough rheological properties and quality of cooked noodles[J]. Food Chemistry,2021,362:130170. doi: 10.1016/j.foodchem.2021.130170

[18] 熊添, 刘书锐, 隋勇, 等. 不同品种甘薯生全粉对面条品质的影响[J]. 食品科技,2023,48(4):162−167. [XIONG Tian, LIU Shurui, SUI Yong, et al. Effect of different varieties of raw sweet potato flour on the quality of noodles[J]. Food Science and Technology,2023,48(4):162−167.] XIONG Tian, LIU Shurui, SUI Yong, et al. Effect of different varieties of raw sweet potato flour on the quality of noodles[J]. Food Science and Technology, 2023, 48(4): 162−167.

[19] LAI S, LIU J, ZHANG Y, et al. Effects of wheat bran micronization on the quality of reconstituted whole-wheat flour and its cooked noodles[J]. Processes,2022,10(5):1001. doi: 10.3390/pr10051001

[20] 施建斌, 隋勇, 蔡沙, 等. 荞麦粉对面团特性和面条品质的影响[J]. 粮食与油脂,2023,36(5):49−53. [SHI Jianbin, SUI Yong, CAI Sha, et al. Effect of buckwheat flour on dough characteristics and noodle quality[J]. Cereals & Oils,2023,36(5):49−53.] SHI Jianbin, SUI Yong, CAI Sha, et al. Effect of buckwheat flour on dough characteristics and noodle quality[J]. Cereals & Oils, 2023, 36(5): 49−53.

[21] 周松超, 梅新, 隋勇, 等. 马铃薯鲜湿面的制备及其品质评价[J]. 食品安全质量检测学报,2024,15(3):26−35. [ZHOU Songchao, MEI Xin, SUI Yong, et al. Preparation and quality evaluation of fresh wet potato noodles[J]. Journal of Food Safety & Quality,2024,15(3):26−35.] ZHOU Songchao, MEI Xin, SUI Yong, et al. Preparation and quality evaluation of fresh wet potato noodles[J]. Journal of Food Safety & Quality, 2024, 15(3): 26−35.

[22] BUCSELLA B, TAKACS A, VIZER V, et al. Comparison of the effects of different heat treatment processes on rheological properties of cake and bread wheat flours[J]. Food Chem,2016,190:990−996. doi: 10.1016/j.foodchem.2015.06.073

[23] ROSELL C M, COLLAR C, HAROS M. Assessment of hydrocolloid effects on the thermo-mechanical properties of wheat using the Mixolab[J]. Food Hydrocolloids,2007,21(3):452−462. doi: 10.1016/j.foodhyd.2006.05.004

[24] BENDER D, NEMETH R, CAVAZZI G, et al. Characterization of rheological properties of rye arabinoxylans in buckwheat model systems[J]. Food Hydrocolloids,2018,80:33−41. doi: 10.1016/j.foodhyd.2018.01.035

[25] WANG Y, CHEN Y, ZHOU Y, et al. Effects of konjac glucomannan on heat-induced changes of wheat gluten structure[J]. Food Chem,2017,229:409−416. doi: 10.1016/j.foodchem.2017.02.056

[26] ZHANG L, ZENG L, WANG X, et al. The influence of konjac glucomannan on the functional and structural properties of wheat starch[J]. Food Sci Nutr,2020,8(6):2959−2967. doi: 10.1002/fsn3.1598

[27] 施建斌, 隋勇, 蔡沙, 等. 荞麦面条配方优化及其体外消化特性[J]. 食品研究与开发,2023,44(10):153−161. [SHI Jianbin, SUI Yong, CAI Sha, et al. Optimization of buckwheat noodle formula and lts starch digestibility in vitro[J]. Food Research and Development,2023,44(10):153−161.] SHI Jianbin, SUI Yong, CAI Sha, et al. Optimization of buckwheat noodle formula and lts starch digestibility in vitro[J]. Food Research and Development, 2023, 44(10): 153−161.

[28] CHARLES A L, HUANG T C, LAI P Y, et al. Study of wheat flour–cassava starch composite mix and the function of cassava mucilage in Chinese noodles[J]. Food Hydrocolloids,2007,21(3):368−378. doi: 10.1016/j.foodhyd.2006.04.008

[29] ZHAO D, ZHOU Y, LIU H, et al. Effects of dough mixing time before adding konjac glucomannan on the quality of noodles[J]. J Food Sci Technol,2017,54(12):3837−3846. doi: 10.1007/s13197-017-2831-1

[30] 闫铭欢, 王立博, 陈静, 等. 甜荞全谷物粉对小麦面团流变特性及鲜湿面条品质的影响[J]. 食品科学,2024,45(10):72−79. [YAN Minghuan, WANG Libo, CHEN Jing, et al. Effects of common buckwheat whole grain flour on rheological properties of wheat dough and quality of fresh wet noodles[J]. Food Science,2024,45(10):72−79.] YAN Minghuan, WANG Libo, CHEN Jing, et al. Effects of common buckwheat whole grain flour on rheological properties of wheat dough and quality of fresh wet noodles[J]. Food Science, 2024, 45(10): 72−79.

[31] MIR S A, SHAH M A, NAIK H R, et al. Influence of hydrocolloids on dough handling and technological properties of gluten-free breads[J]. Trends in Food Science & Technology,2016,51:49−57.

[32] 李平. 螺旋藻粉对面团特性及面条品质的影响研究[D]. 郑州:河南工业大学, 2023. [LI Ping. Effect of spirulina powder on the properties of dough and the quality of noodle[D]. Zhengzhou:Henan University of Technology Master, 2023.] LI Ping. Effect of spirulina powder on the properties of dough and the quality of noodle[D]. Zhengzhou: Henan University of Technology Master, 2023.

[33] ZHOU Y, ZHAO D, FOSTER T J, et al. Konjac glucomannan-induced changes in thiol/disulphide exchange and gluten conformation upon dough mixing[J]. Food Chemistry,2014,143:163−169. doi: 10.1016/j.foodchem.2013.07.088

[34] THANUSHREE M P, SUDHA M L, MARTIN A, et al. Enhancing the nutritional and quality profiles of buckwheat noodles:Studies on the effects of methods of milling and improvers[J]. LWT,2022,160:113286. doi: 10.1016/j.lwt.2022.113286

[35] WANG K, WU K, XIAO M, et al. Structural characterization and properties of konjac glucomannan and zein blend films[J]. Int J Biol Macromol,2017,105(1):1096−1104.

[36] YUAN Y, WANG L, MU R J, et al. Effects of konjac glucomannan on the structure, properties, and drug release characteristics of agarose hydrogels[J]. Carbohydr Polym,2018,190:196−203. doi: 10.1016/j.carbpol.2018.02.049

[37] ZHOU Y, QIN J, WANG Y, et al. Gastrointestinal and metabolic effects of noodles-based konjac glucomannan in rats[J]. Food Nutr Res, 2019, 63.

[38] GE Z, WANG W, GAO S, et al. Effects of konjac glucomannan on the long-term retrogradation and shelf life of boiled wheat noodles[J]. Journal of the Science of Food and Agriculture,2022,102(2):644−652. doi: 10.1002/jsfa.11393

[39] DHITAL S, WARREN F J, BUTTERWORTH P J, et al. Mechanisms of starch digestion by alpha-amylase-structural basis for kinetic properties[J]. Crit Rev Food Sci Nutr,2017,57(5):875−892. doi: 10.1080/10408398.2014.922043

-

期刊类型引用(12)

1. 刘帅,荣晓辉,张书锋,屈磊,刘芳,井娟. 纳豆激酶递送系统研究进展. 中国现代应用药学. 2024(09): 1295-1302 .  百度学术

百度学术

2. 施雅,朱佳妮,赵博,米飞,顾然. 常见发酵食品中生物活性物质对心脏功能影响的研究进展. 食品与发酵科技. 2024(03): 92-98 .  百度学术

百度学术

3. 祁红兵,宋军霞,毛艳红. 纳豆固体发酵抗氧化功能研究. 农产品加工. 2024(18): 1-4+9 .  百度学术

百度学术

4. 屈家亮,柳惠平,张佑红. 纳豆激酶研究进展. 武汉工程大学学报. 2024(05): 527-533 .  百度学术

百度学术

5. 吴丹,杨苗苗,杜小平,祁蒙,杨水云. 依赖于豆粕原材料的纳豆激酶制备和纯化工艺研究. 中国调味品. 2023(03): 79-85 .  百度学术

百度学术

6. Chunfang Wang,Jinpeng Chen,Wenguo Tian,Yanqi Han,Xu Xu,Tao Ren,Chengwang Tian,Changqing Chen. Natto: A medicinal and edible food with health function. Chinese Herbal Medicines. 2023(03): 349-359 .  必应学术

必应学术

7. 王刚,王芝玉,安荣荣,滕玉婷,古梅,刘霞,高慧娟,董瑞丽. 固态发酵条件对纳豆激酶活性的影响及发酵条件的优化. 粮食加工. 2023(05): 33-37 .  百度学术

百度学术

8. 任莉莉,张胜海,程昆木,杨凌鉴,黄九林. 模拟体内环境下血栓形成及药物溶栓作用. 粘接. 2022(02): 1-5 .  百度学术

百度学术

9. 潘钰,夏海华,叶阳,曲晓军,于冲. 纳豆软胶囊功效成分安全性及免疫功能研究. 中国调味品. 2022(06): 84-89 .  百度学术

百度学术

10. 洪奕,夏海华,田洁萍,张淑梅,于冲,田缘,闫更轩,潘钰. 响应面法优化豆粕固体发酵产纳豆激酶培养条件. 中国调味品. 2022(08): 41-45 .  百度学术

百度学术

11. 樊璐,李宏梁,吕名蕊,严烨,黄峻榕. 纳豆糕点的制备及活菌数变化特性的研究. 农产品加工. 2022(15): 15-17+21 .  百度学术

百度学术

12. 高梦迪,苏钱琙,李杰,樊学晶,王朝阳,邓立高,李坚斌. 纳豆激酶微生物生产研究进展. 大豆科学. 2022(06): 740-746 .  百度学术

百度学术

其他类型引用(9)

下载:

下载:

下载:

下载: