Quality-related and Quality-irrelevant Fault Detection and Diagnosis in Batch Fermentation Process Based on NSSAE

-

摘要: 为了解决批次发酵过程中质量无关故障所可能引起的不必要停机,本文提出了噪声半监督堆叠自编码器(Noised semi-supervised stacked auto-encoder,NSSAE)算法以区分质量相关与质量无关故障。首先,基于互信息计算过程变量与质量变量间互信息,并对数据加入噪声以提高算法对质量相关信息挖掘能力。其次,构建NSSAE的过程监测模型,在模型的首层自编码器和最后一层自编码器中构建故障检测和质量相关检测指标,并利用核密度估计计算对应的控制极限。最后,利用深度重构贡献图(Deep reconstruction-based contribution,DRBC)定位故障根源。从数值仿真和乳酸菌批次发酵实验结果可知,本文提出的NSSAE算法能够准确区分质量相关与无关故障,首层的残差空间的检测指标的故障检测率接近100%,最后一层隐空间的检测指标能够准确识别质量相关故障和质量无关故障。基于DRBC诊断方法能在故障发生后准确识别发生故障的变量,该研究结果为批次发酵过程质量相关与质量无关故障监测问题提出了一种切实可行的过程监测方法。

-

关键词:

- 批次发酵过程 /

- 质量相关故障 /

- 噪声半监督堆叠自编码器 /

- 故障检测与诊断 /

- 深度重构贡献图

Abstract: To address potential unnecessary shutdowns caused by quality-unrelated faults during batch fermentation processes, the paper proposed a noise semi-supervised stacked auto-encoder (NSSAE) to differentiate the quality-relevant and the quality-irrelevant faults. First, mutual information was applied to calculate the contribution from the process variables to quality variables, where artificial noised was introduced to enhance the performance. Second, an NSSAE-based monitoring model was established, wherein indicators for faults and quality variations were separately constructed from the first layer and the last layer of the model. Upon which, kernel density estimation was used to calculate the thresholds for the indicators. Lastly, deep reconstruction-based contribution was used to locate the root cause. Based on the results of numerical simulations and lactic acid bacteria batch fermentation experiments, the NSSAE algorithm proposed in this paper demonstrated the ability to accurately distinguish between quality-related and quality-irrelevant faults. The fault detection rate using the detection index of the first layer of residual space approached 100%. Moreover, the detection index in the final layer of latent space could precisely identify both quality-related and quality-irrelevant faults. Utilizing the DRBC diagnostic method, the specific variable causing the fault can be accurately pinpointed post-fault occurrence. These findings suggest a practical and effective process monitoring method for addressing quality-related and quality-irrelevant fault monitoring issues in the batch fermentation process. -

人工智能技术的快速发展驱动了各领域的产业变革,其中,基于深度学习的人工智能技术在食品加工过程监测与控制领域初露头角[1−4]。得益于国家工业4.0的不断推进和传感器技术的快速进步,基于人工智能的建模和监测方法在批次发酵过程中得到了广泛应用[5−7]。批次发酵过程在现代食品加工领域占有不可或缺的地位,其被应用于生产乳制品,啤酒和食品添加剂等[8−9]。为了确保发酵过程中的安全性和发酵产品品质的一致性,有必要建立过程监测模型,及时监测生产过程中的异常情况,及时排查并处理故障情况。目前,针对批次发酵过程故障检测问题得到了研究人员的广泛关注[10−12]。

近年来,基于深度学习的人工智能方法在批次发酵过程检测中取得显著成果。Agarwal等[13]提出了一种基于自编码器(Auto-encoder,AE)的非监督过程监测算法,该算法通过优化损失函数以提高算法对生产过程中的故障敏感程度。Ren等[14]将长短期记忆神经单元添加到AE的编码层,以提取批次维度上的动态特性,并在青霉素发酵过程中验证了模型故障检测能力。Zhang等[15]考虑到变分自编码器对于过程数据非高斯性的改善效果,进一步将循环神经网络参数化的线性高斯动态结构引入到了变分自动编码器隐藏层中,以同时处理一般过程数据中的非高斯性,非线性以及动态特征,所提出的循环卡尔曼变分自编码器模型针对田纳西过程中的难检测故障获得了明显的检测效果提升。Chang等[16]提出了动态隐变量模糊广义神经网络模型,准确识别了异常数据与正常数据之间的细微差别。Jiang等[17]建立了二维深度相关表征学习深度算法,并在批次过程数据中验证了该算法的有效性。赵小强等[18]针对批次过程数据展开为二维后数据信息丢失问题,提出一种基于张量分解的时序扩展全局局部邻域保持嵌入算法,实现了批次过程中质量相关故障与质量无关的故障检测。上述方法针对批次过程建模方法提出了基于深度学习的算法,并且取得了较为不错的过程监测效果。但是,在实际的发酵过程,发酵的质量是整个生产过程中最需要关注的问题。若利用上述提出的方法,仅仅能检测发酵生产过程中的故障,并不能有效的判断该故障是否与发酵过程的质量变量有关。若发生的故障与发酵生产的质量变量无关且不会造成事故的情况下,如因为该质量无关的故障而选择停机则可能造成生产资源浪费和生产效率下降。因此,有必要建立针对批次过程可能出现的故障进行细化,区分生产过程中质量相关故障和质量无关故障[6,19−20]。

变分信息瓶颈算法具有提取质量相关信息并移除质量无关信息能力,因此被用于质量相关过程监测算法中。Wang等[21]提出将变分自编码器和变分信息瓶颈网络有机结合建立混合模型实现质量相关与质量无关故障检测。进一步提升质量相关故障的检测能力,Tang等[22]对这一混合模型提出了改进,将该模型的首层的权重依据过程变量与质量变量间的互信息(Mutual information,MI)值做出调整。赵小强等[23]利用互信息将过程变量划分为质量相关变量和质量无关变量,并在质量相关变量和质量无关变量的技术上建立了一种基于邻域保持嵌入极限学习算法。类似的,Zhu等 [24]和Huang等 [25]依据MI划分了质量相关和质量无关的过程故障检测算法。Yao等[26]划分了质量相关和质量无关子空间,并在两个子空间建立检测指标实现故障的在线监测。但是,上述中的质量变量是连续的,每个过程变量的采样点均有对应的质量变量。在实际发酵过程中,质量变量通常受到设备和经费限制,采用离线的采样测量的方法具有一定的滞后性,且质量变量不具有连续性。上述方法在实际应用中受到质量变量采集问题而受到限制。为解决质量变量不连续问题,半监督堆叠自编码器(Semi-supervised auto-encoder, SSAE)被提出[27]。该方法实现了更为抽象信息的提取与质量预测问题。

本研究针对批次过程发酵中质量变量不连续的问题和质量相关和质量无关故障监测问题,设计了噪声堆叠自编码器故障检测算法(Noised semi-supervised auto-encoder,NSSAE)和深度重构贡献图(Deep reconstruction-based contribution,DRBC)的故障诊断方法,实现了在质量不连续的情况下建立质量相关和质量无关故障监测问题,且采用DRBC诊断方法定位故障的根源,该方法为批次发酵过程的安全稳定运行提供一定的参考。

1. 材料与方法

1.1 材料与仪器

本实验涉及的发酵菌株为乳酸菌属植物乳杆菌,菌株号:HuNHHMY71L1 菌株来源于江南大学生物技术中心;氨水、氯化氢溶液 分析纯,国药集团化学试剂有限公司;MRS培养基 国药集团化学试剂有限公司。

T&J-Atype型5 L生物反应器 上海迪必尔公司;计算机,具体规格为:CPU Intel(R) Xeon(R) Silver 4210,英特尔公司;RAM Samsung 128 GB,三星电子公司;GPU NVIDIA Tesla V100,台达电子公司;754PC紫外分光光度计 上海菁华科技仪器有限公司;反压高压蒸汽灭菌器 致微(厦门)仪器有限公司。

1.2 实验方法

1.2.1 批次发酵过程数据采集

为了验证本文提出的模型在批次发酵过程中的故障检测能力,设计了仿真数据案例和实际植物乳杆菌发酵实验案例。

1.2.1.1 数值仿真

数值仿真案例由5个过程变量xi(i=1,2,...5)和1个质量变量y组成,数值仿真如下:

x1=N(1,0.012) (1) x2=N(1,0.012) (2) x3=sin(x1)+e1 (3) x4=x21−3x1+4+e2 (4) x5=x22+cos(x22)+1+e3 (5) y=x23+x4x3+x1+v (6) ei=N(0,0.0012),i=1,2,3 (7) v=N(0,0.0052) (8) 式中,e,v为高斯噪声。

从式中可知,质量变量y与变量x1、x3和变量x4有关,与过程变量x2和x5无关。因此当过程变量x1、x3和变量x4发生变化时,则质量变量会随之发生变化。当变量x2发生变化时,变量x5则会发生变化,但是质量变量并不会受到影响。

其次,设计了两个故障,分别为质量相关故障和质量无关故障。故障1:给变量x1在第200采样点时刻添加一个阶跃故障,故障幅值为5%。故障2:给变量x2在第200采样点时刻增加一个阶跃故障,故障幅值为5%。

1.2.1.2 植物乳杆菌发酵案例数据采集

在本节的发酵过程实验中,以植物乳杆菌HuNHHMY71L1作为发酵菌株,发酵条件参考文献[28]。发酵过程中保持温度在37 ℃,pH设定为6,酸液和碱液用于调节发酵过程中的pH。发酵后的2 h开始补料。发酵设备如图1所示。

发酵过程中采集的过程变量和质量变量名称和单位如表1所示。发酵过程设定间隔1 min采样,发酵开始后2 h开启后补料,补料物质为MRS培养基,补料速率200 mL/h,发酵持续8 h。共发酵24批次,取22批正常生产过程数据中的20批用于训练模型, 2批用于模型验证;2批故障数据验证模型的质量相关故障与质量无关故障的检测能力。具体故障如表2所示。根据植物乳杆菌的生长规律[28],当发酵过程中温度偏移小于0.5 ℃的情况下,植物乳杆菌的生长过程几乎不受影响。但是当发酵温度偏移2 ℃以上时,植物乳杆菌内酶活性受到温度影响,会导致质量发生变化。

表 1 植物乳杆菌发酵过程变量与质量变量Table 1. L. plantarum fermentation process variables and quality variables变量编号 变量 单位 变量编号 变量 单位 1 发酵温度 ℃ 5 酸补充量 mL 2 pH − 6 碱补充量 mL 3 溶解氧 % 7 补料 mL 4 搅拌速率 r/min y 浊度 − 表 2 植物乳杆菌发酵过程故障说明Table 2. L. plantarum fermentation process troubleshooting instructions故障编号 故障变量 故障幅值 故障类型 引入时间(min) 1 发酵温度 +3 ℃ 阶跃 120~480 2 发酵温度 +0.3 ℃ 阶跃 120~480 1.2.2 基于NSSAE模型的故障检测与诊断

受AE和堆叠自编码器(Stacked auto-encoder,SAE)启发,本文提出了基于NSSAE模型的质量相关故障与无关故障的检测与诊断方法。本节首先简要介绍AE和SAE结构。

1.2.2.1 AE与SAE

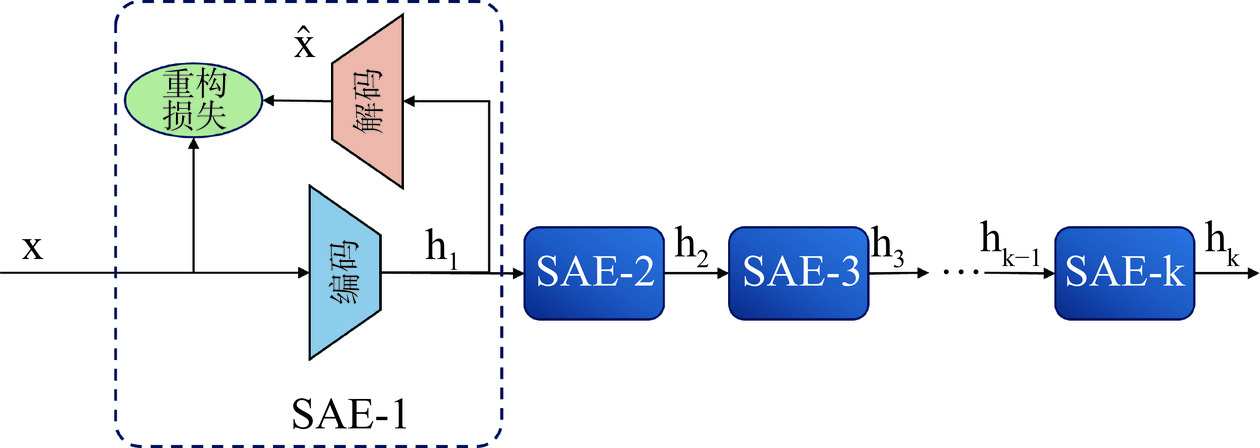

AE作为生成网络中的一种,其价值在于将原始数据压缩到低维空间,从而保留数据中具有价值的信息[29]。AE的结构图如图2所示,AE包含了编码fen(·)和解码fde(·)两个部分。在编码阶段,假设输入数据x经过编码被压缩到隐空间表征h=F(Wenx+ben)。隐空间表征h是对原始数据的潜在表征,去除了原始数据的冗余信息,尽可能地保留了原始数据的信息。在解码阶段,解码利用隐空间的潜在表征h重构与原始数据相同维度的数据ˆx=F(Wdeh+bde),且在模型训练过程中,使得生成的数据ˆx与原始数据尽可能相似。其中,F为非线性激活函数,Wen、ben为编码fen(·)的权重和偏执参数。Wde、bde为解码fde(·)的权重和偏执参数。模型在训练阶段的损失如下:

lossAE=‖ (9) 式中,lossAE表示自编码器的损失值,x和\hat {\rm x}代表AE的输入项和重构项。

AE在一定程度能够压缩原始数据获取输入数据的隐空间表征。为了进一步提升模型提取更加复杂更加抽象的表征,SAE被提出[30]。

SAE结构如图3所示,SAE的第一层输入为原始数据,除第一层外,每一层的输入为上一层的隐空间表征。每一层AE都包含着完整的AE结构。因此每一层都具有提取抽象特征的能力。随着后面每一层堆叠,更为复杂的抽象的数据信息被提取。在SAE的模型训练阶段,SAE分层训练,且按顺序进行。第一层的重构损失为:

\rm los{s_{{\text{SAE-1}}}} = \big\| { {x - \hat x} \big\|} _2^2 (10) 式中,lossSAE-1代表SAE的第一层损失值,x和\hat {\rm x}代表SAE的输入项和重构项。随后的每一层的重构损失为:

\rm los{s_{{\text{SAE-i}}}} = \big\| { {{h_{i - 1}} - {{\hat h}_{i - 1}}} \big\|} _2^2 (11) 式中,\rm {h_{i - 1}}代表SAE的第\rm i - 1的隐层表征,{\hat {\rm h}_{{\rm i} - 1}}代表SAE的第i层的重构。

1.2.2.2 数据加噪

为了提高建模算法对质量相关信息的挖掘能力,在建模前需要在标准化数据后对数据进行加噪处理。首先,采集正常批次发酵过程数据,包括过程变量数据\rm X \in {\mathbb{R}^{I \times J \times K}} 和质量变量数据\rm Y \in {\mathbb{R}^{I \times K}}。其中,I、J、K为批次维度、变量个数和采样次数。随后,对批次过程数据进行归一化处理。再次,计算每个过程变量\rm {x_j} \in X与质量变量\rm y \in Y 的互信息值\rm {I_j},具体计算公式如下[31−32]:

\rm {I}_{j}={\displaystyle \iint P({x}_{j},y){\mathrm{log}}_{2}\frac{P({x}_{j},y)}{P({x}_{j})P(y)}d{x}_{j}dy} (12) 式中, \rm P({x}_{j},y) 表示过程变量\rm {x_j}与质量变量y的联合概率密度;\rm P({x}_{j}) 、 \rm P(y) 表示过程变量\rm {x_j}和质量变量y的边缘概率密度函数。若过程变量\rm {x_j}与质量变量y的互信息值Ij较大,则代表过程变量xj与质量变量y具有强相关。反之两者是弱相关或相互独立。

最后,在计算过程变量与质量变量的互信息后,对过程变量数据进行加噪处理。降噪自编码器(Denoising auto-encoder,DAE)在普通AE的基础上对输入数据添加噪声,强迫AE从已添加噪声的数据中学习更加稳健和有用信息[33]。本文依据过程变量与互信息的值对批次发酵过程数据设计了加噪机制。具体的数据加噪处理如下:

\rm \tilde x = x_j+c\varepsilon /I_j (13) 式中,c为超参数,\varepsilon 为符合标准正态分布 \rm{N}(0,1) 的高斯噪声。

若互信息的质量值较大,则根据上式可以看出当前过程变量添加的噪声较小。反之,若过程变量与质量变量的互信息值较小,则添加的噪声较大。从上面分析可以得出,质量相关变量被添加的噪声幅值较小,质量弱相关或质量无关变量被添加的噪声幅值较大。对标准化后的数据进行加噪处理有以下两个原因,a.在建模过程中,建模算法被强迫学习到原始数据更有效信息。b.建模算法对质量相关变量的变化更加敏感,对质量无关变量的变化不敏感,即噪声的加入加强了算法对质量相关信息的敏感程度。

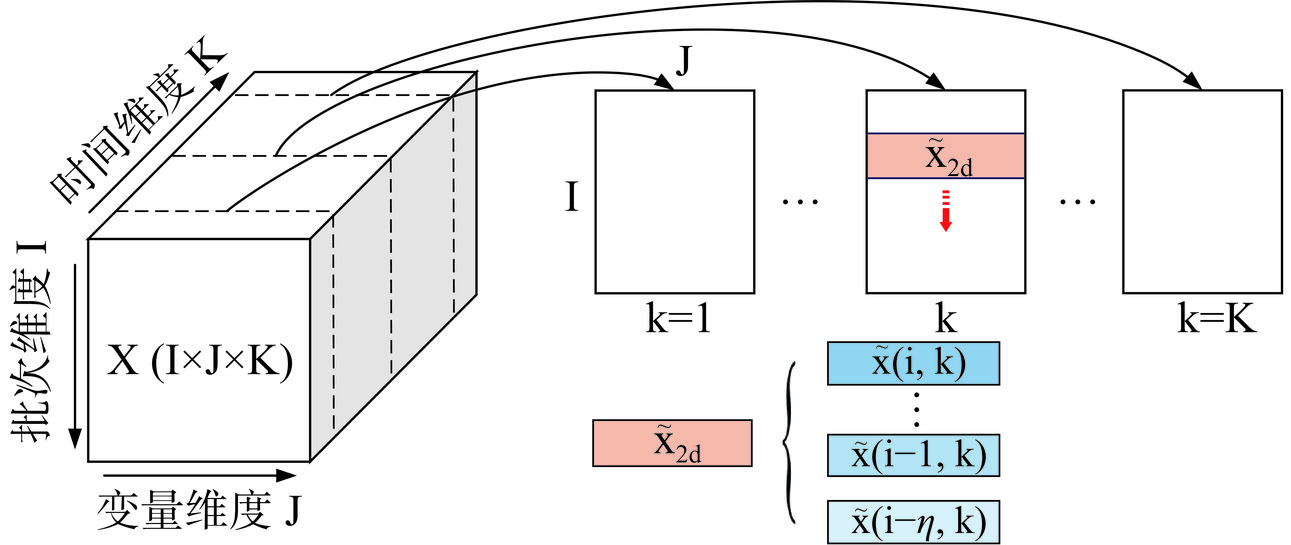

1.2.2.3 二维滑窗

与此同时,考虑到批次过程数据中的批次维度动态特性,建立了二维滑窗。批次维度的动态特性是指历史批次发酵采样值与当前批次发酵采样值呈现出相关性。因此在建模时,考虑批次维度动态特性能显著提高模型的故障检测能力,降低模型的误检率(False alarm rate,FAR)。二维批次滑窗的具体步骤如图4所示。首先确定批次维度的动态阶次\eta ,假设当为第i批次和第k次采样 \tilde{\rm x}\rm(i,k) ,当前采样的二维滑窗为 {\tilde{\rm x}}_{\text{2d}}=[{\tilde{\rm x}}(\text{i,k});{\tilde{\rm x}}(\text{i}-1,{\rm k});...,{\tilde{\rm x}}({\text{i}}-\eta+1,{\rm k})]^{\text{T}} 。本文考虑到批次维度动态特性,并利用二维滑窗获取用于模型训练的输入数据。

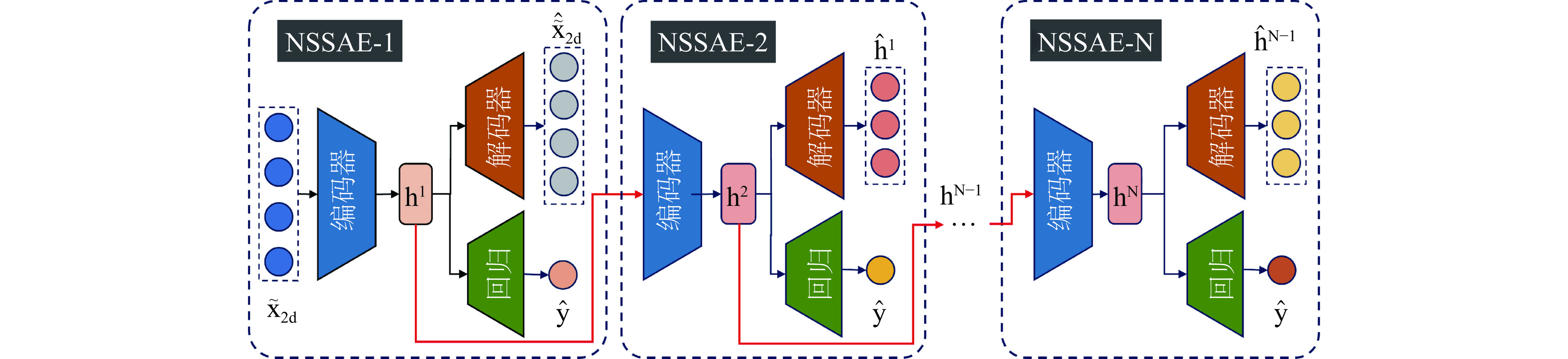

1.2.2.4 NSSAE模型构建

本文提出的NSSAE算法结构如图5所示。在结构上与原始的SAE相比,NSSAE多了一个回归结构。NSSAE在模型训练阶段能够利用有标签数据和无标签数据共同训练。具体来说,对于有标签的数据,即过程采样对应着存在质量变量,训练过程包含了重构损失项和回归损失。对于无标签数据,训练过程仅有重构损失。这样就解决质量变量不连续的问题,尤其对于批次发酵过程中质量变量难以在线实时采集的问题。

在NSSAE的训练过程中包含了预训练和微调两阶段,预训练过程NSSAE的每一层需要逐层训练,微调过程中利用有标签数据整体优化。对于预训练过程中,假设 {\tilde{\rm x}}_{\rm u}\rm(u=1,\mathrm{...},{N}_{u}) 为无标签过程数据, {\tilde{\rm x}}_{\rm l}\rm (l=1,\mathrm{...},{N}_{l}) 为有标签过程数据,\rm {y_l}为质量变量。NSSAE的结构如图5所示。对于NSSAE的第一层无标签输入数据而言,第一层的损失函数为:

\rm loss_u^{NSSAE-1}=\frac{1}{N_u}\sum_{u=1}^{N_u}\big\| {\tilde x}_u -{\hat{\tilde x}}_u \big\|_2^2 (14) 式中,{\text{loss}}_{\text{u}}^{\rm{NSSAE - 1}}为NSSAE的第一层的无标签数据的损失值,{\tilde {\rm x}_{\rm u}}和\rm {\hat{\tilde x}_u}分别为无标签过程数据和NSSAE的第1层重构项,\rm {N_u}为无标签数据的采样次数。

上式的目的是为了尽可能使重构数据接近输入数据,压缩隐空间表征提取到更为关键信息。对于有标签数据的损失则包含了重构和回归损失,即:

\rm loss_l^{NSSAE-1}=\frac{1}{N_l}\sum^{N_l}_{l=1}\left(\big\|{\tilde x}_l -{\hat{\tilde x}}_l\big\|_2^2 + \lambda\big\|y_l-{\hat y}_l\big\|_2^2\right) (15) 式中,\rm loss_{\text{l}}^{NSSAE - 1} 为NSSAE的第一层的有标签数据的损失值,\rm {\tilde x_l}和\rm {\hat {\tilde x}_l}分别为有标签过程数据和NSSAE的第1层重构项,\lambda 为预测损失权重参数。

为了使该算法尽可能使隐空间表征h提取质量相关信息。因此在训练过程中侧重于选择一个较大的预测损失参数\lambda 。NSSAE的第一层在预训练阶段的整体损失为:

\rm loss_{}^{NSSAE - 1} = \frac{1}{{{N_u}}}\sum\limits_{u = 1}^{{N_u}} { {\big\| {{{\tilde x}_u} - {{\hat {\tilde x}}_u}} \big\|} _2^2}+\frac{1}{{{N_l}}}\sum\limits_{l = 1}^{{N_l}} {\left( {\big\| { {{{\tilde x}_l} - {{\hat {\tilde x}}_l}} \big\|} _2^2+\lambda \big\| { {{y_l} - {{\hat y}_l}} \big\|} _2^2} \right)} (16) 随后深度学习在反向梯度优化过程中优化NSSAE第一层权重参数W1和偏置项参数b1。除NSSAE的第一层外,第n层的训练输入为上一层的隐空间表征。在第\rm n - 1层预训练结束后,则第n层的模型损失\rm los{s^{NSSAE - n}} 为:

\begin{array}{l}\rm los{s}^{NSSAE-n}=\dfrac{1}{{N}_{u}}\displaystyle\sum _{u=1}^{{N}_{u}}\big\|{h}_{u}^{n-1}-{\hat{h}}_{u}^{n-1}\big\|_{2}^{2}+\\\dfrac{1}{\rm{N}_{l}}\displaystyle\sum _{\rm l=1}^{\rm{N}_{\rm l}}\left(\big\|\rm{h}_{l}^{n-1}-{\hat{h}}_{l}^{n-1}\big\|_{2}^{2}+\lambda \big\|{\hat{y}}_{l}-{y}_{l}\big\|_{2}^{2}\right),\rm(n=2,\mathrm{...},N) \end{array} (17) 式中,\rm h_u^{n - 1} 和\rm \hat h_u^{n - 1}为无标签数据在NSSAE的第\rm n - 1 层的隐空间表征和无标签数据在NSSAE的第n层的重构项,\rm h_l^{n - 1} 和\rm \hat h_l^{n - 1}为有标签数据在NSSAE的第\rm n - 1 层的隐空间表征和有标签数据在NSSAE的第n层的重构项。

模型完成预训练后,微调阶段NSSAE模型仅在有标签的数据集\rm \{ {\tilde x_l}{y_l}\} 上训练。在建立模型后,在验证数据集合上筛选最优的超参数。

1.2.2.5 故障检测指标构建

为实现质量相关故障和质量无关故障的检测,本文在NSSAE的首层的重构损失建立过程检测指标SPE,该检测指标SPE用于表征当前发酵过程是否出现故障。该检测指标的计算公式如下:

\rm SPE = \big\|\tilde x - \hat {\tilde x}\big\|_2^2 (18) 式中,SPE为残差空间损失项,该指标衡量了当前输入与NSSAE算法间的相似度,\tilde {\rm x} 和 \rm \hat {\tilde x}为模型的输入项和重构项。若当前输入与历史出现偏差,则检测指标SPE出现异常。质量相关故障的检测指标在NSSAE的最后一层的浅空间建立。选在最后一层的隐空间建立的原因如下:NSSAE由多层堆叠而成。NSSAE由多层堆叠而成,且预测的损失权重设计较大,因此每一层的隐空间对质量相关隐空间表征能力加强。当质量相关变量发生变化时,隐空间表征则也会发生变化。因此,选用最后一层的隐空间表征建立质量相关故障表征指标T2。质量相关故障检测指标的计算公式如下:

\rm {T}_{}^{2}=({h}^{N})^{T}\Sigma {h}^{N} (19) 式中,\Sigma 为训练数据的隐空间表征\rm {h^N}的协方差矩阵。

上述两个故障检测指标的控制极限利用核密度估计函数计算[34−35]。

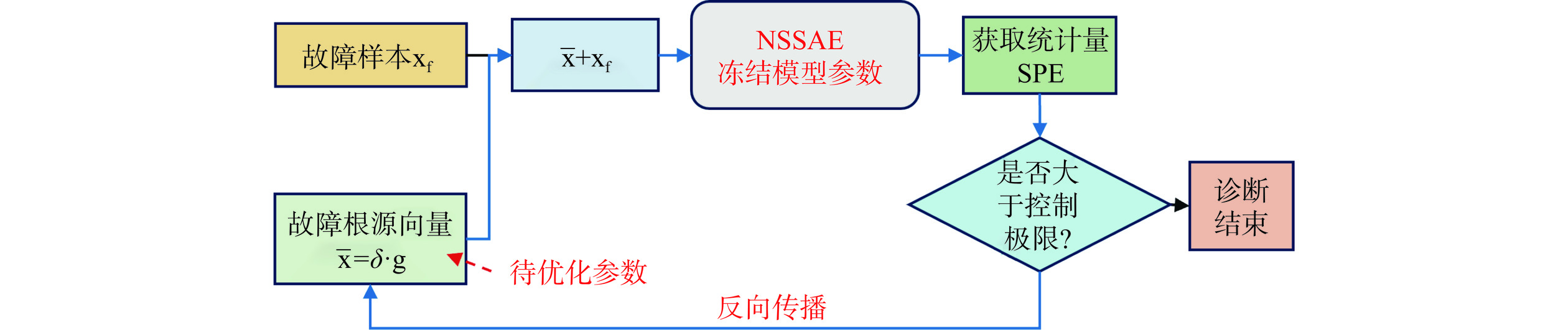

1.2.2.6 基于DRBC的故障诊断构建

故障诊断作为过程监测的重要组成部分,其价值在于定位故障变量,进而为故障排除提供信息指导。这里把DRBC故障诊断方法[11]架构在NSSAE模型上,具体结构见图6。

假设故障时刻的样本为\rm {x_f} \in {\mathbb{R}^J},定义一个幅值向量\rm g \in {\mathbb{R}^J}和故障方向向量\rm \delta \in {\mathbb{R}^J}。两个向量的矢量按元素相乘结果所得新矢量为\rm \overline{x}=\delta \cdot g,(\overline{x}\in {\mathbb{R}}^{J}) ,该向量内积也被称为故障根源向量。随后将故障样本\rm {x_f}与两个向量内积\rm \bar x相加得到\rm {x_f}+\bar x。随后利用模型计算检测指标SPE。若当前的检测指标超出控制极限,则将当前的SPE作为损失反向梯度优化故障根源向量,直至故障检测指标SPE低于控制极限。在整个诊断过程中冻结模型参数,将故障根源向量定义为待优化参数。反向梯度优化过程与模型训练中的网络参数优化过程类似。将检测指标SPE作为损失反向传播的原因有两点。a.在诊断过程完成时,检测指标SPE低于控制极限,则代表NSSAE算法的输入符合正常生产过程。b.检测指标SPE表征着质量相关故障和质量无关故障,只要发生故障均可以实现故障根源定位。

1.2.2.7 基于NSSAE建模与过程监测流程

基于NSSAE的过程监控框架包含离线建模和在线监测两个部分。

\bullet 离线建模

a 收集正常生产过程历史批次数据并标准化数据;

b 基于互信息对过程数据加噪,并利用二维滑窗获取输入数据;

c 构建NSSAE模型,并利用正常数据训练NSSAE模型;

d 计算统计量SPE和T2;

e 利用核密度估计函数计算控制极限。

\bullet 在线监测

i 在线采集数据并标准化;

ii 利用NSSAE计算统计量SPE和T2;

iii 判断统计量是否超出控制极限;

iv 若两个检测指标均没有超出控制极限则代表当前处于正常生产过程。若统计量SPE超出控制极限,则代表当前发生故障。进一步,若T2超出控制极限,则代表当前故障与质量相关,否则当前故障与质量无关。

1.3 数据处理

采用Excel 2019统计与整理实验数据,利用Python进行归一化处理、互信息计算、模型训练以及进行检测结果统计。归一化处理采用Z-Score处理方法,并基于Python绘制检测结果图和诊断图。

2. 结果与分析

本节将AE_y[24],SSAE[27]方法以及本章提出的NSSAE模型应用于数值仿真案例和植物乳杆菌发酵实验案例中,以验证NSSAE模型的有效性和优越性。

2.1 数值仿真案例结果与讨论

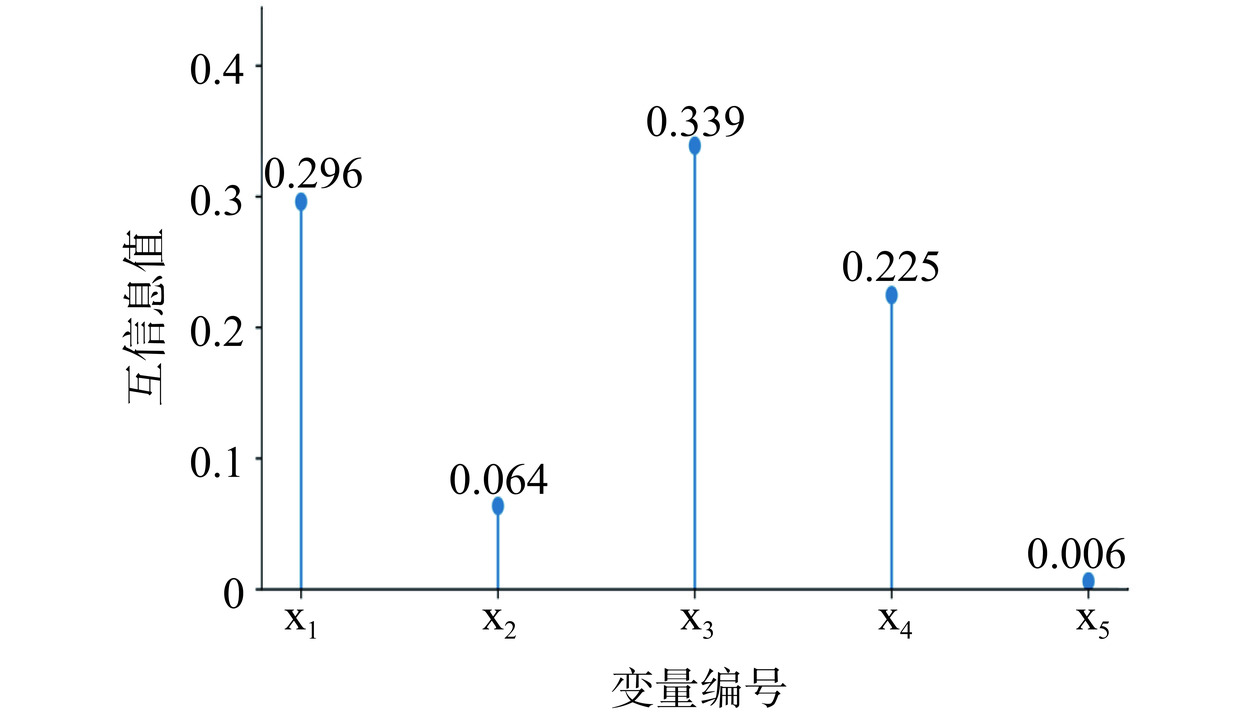

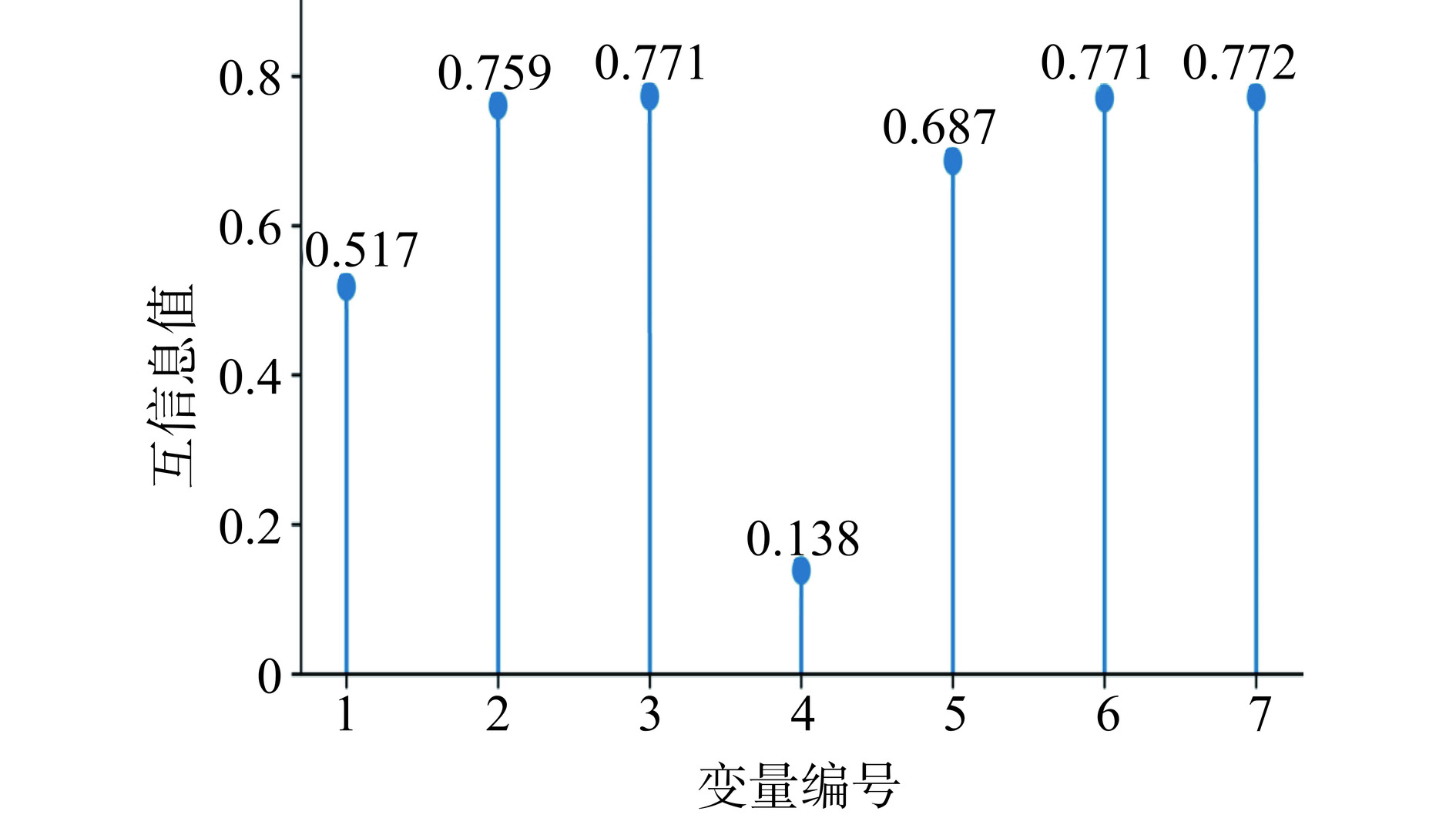

随后,计算过程变量与质量变量间的互信息值,具体计算方法参照式(12)。如图7所示,变量x1、x3和变量x4与质量变量y间的互信息值较大,表明这3个过程变量与质量变量相关。变量x2和x5的互信息值较小,表明这两个过程变量与质量变量无关。

随后,对过程变量加噪,超参数c设计为5。NSSAE设计为3层。损失函数中的预测损失权重\lambda 为0.8。批次维度动态阶次设计为6。设有标签的数据占数据集的80%。

AE_y、SSAE和NSSAE算法应用于数值仿真案例。AE_y的检测指标T2为质量相关故障检测指标,SPE为故障检测指标。类似的SSAE的隐空间检测指标与之类似。表3为质量相关故障和质量无关故障在3个模型下的检测结果。对于故障1(质量相关故障)由于故障幅值均为5%,各个模型在残差空间上均取得较好的检测结果。根据NSSAE在两个故障检测结果上的表现,模型将故障1识别为质量相关故障。对于故障2(质量无关故障),NSSAE的检测指标SPE的故障检测率达到100,质量相关故障检测指标T2的故障检测率为0。这代表NSSAE识别故障2为质量无关故障。相对比而言,AE_y对于质量相关故障的检测也取得了较好的效果。而SSAE在隐空间上的质量相关故障的故障检测率达到了52%。相比较所有模型的FAR,NSSAE具有最低的FAR,这进一步验证NSSAE模型具有良好的故障检测能力。

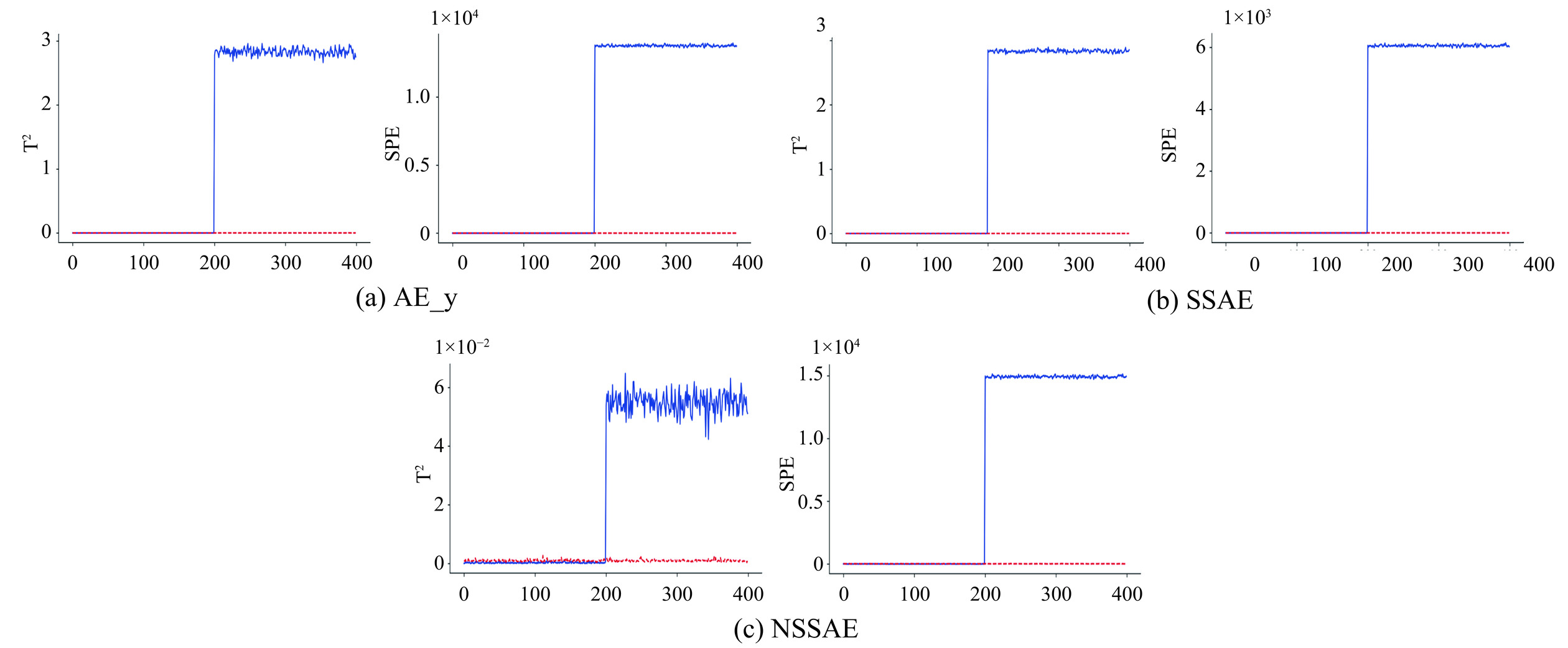

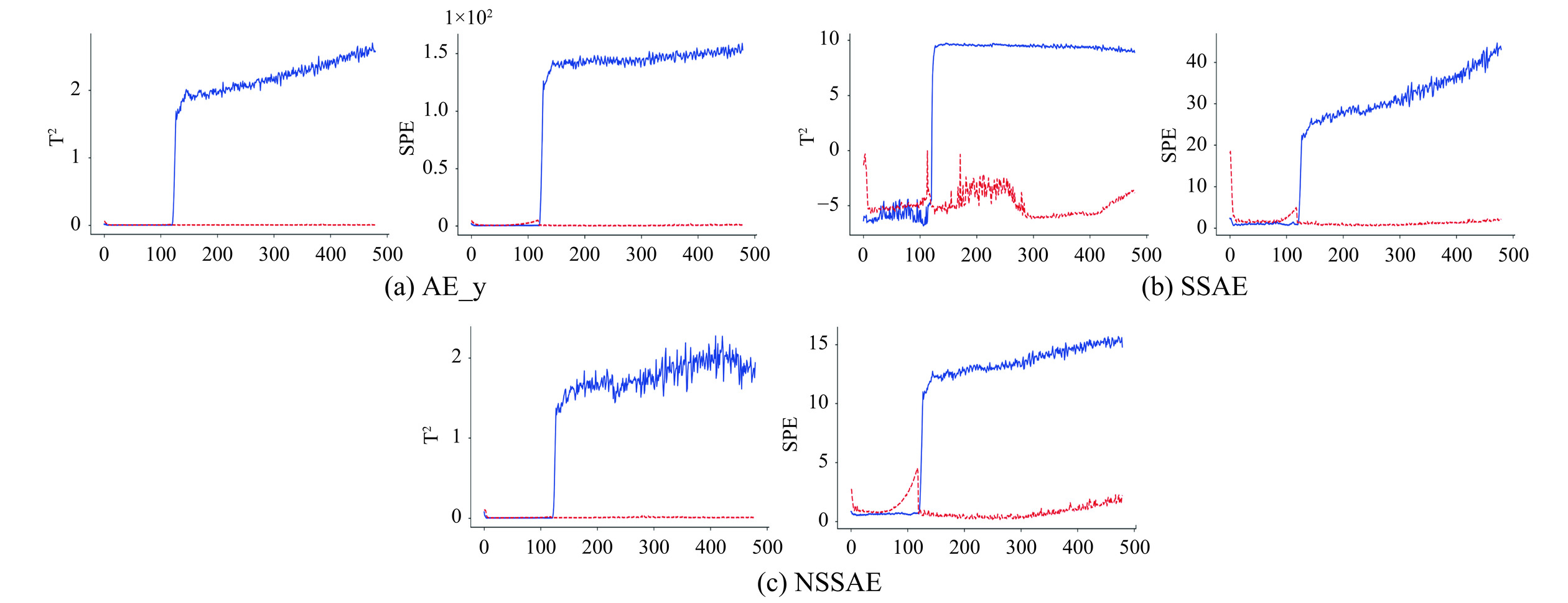

表 3 数值仿真案例故障检测结果Table 3. Numerical simulation case fault monitoring results故障编号 AE_y SSAE NSSAE T2 SPE FAR T2 SPE FAR T2 SPE FAR 1 100 100 3.25 100 100 2.75 100 100 0.125 2 4 100 3 52 100 1.75 0 100 1.25 图8为质量相关故障检测结果,其中,每张图的横轴代表采样时刻,纵轴代表检测指标值,图中的蓝色实线为检测指标,虚线为对应指标的控制限,若子图中的实线超出虚线则代表当前生产过程发生故障。对于质量相关故障,检测指标应在质量相关故障发生后,其值应超过控制极限。对比3个模型的检测结果可知,对于变量\rm {x_1}在200采样时刻发生故障后,各个模型的故障检测指标能迅速超出控制极限,进而出发故障报警。由于\rm {x_1}变量为质量相关变量,因此在故障发生后,质量相关故障检测表征应迅速超出控制极限。很显然,上述3个模型对于质量相关质量表征在200采样时刻均超出控制极限。这意味着上述模型具有较好的故障检测能力。

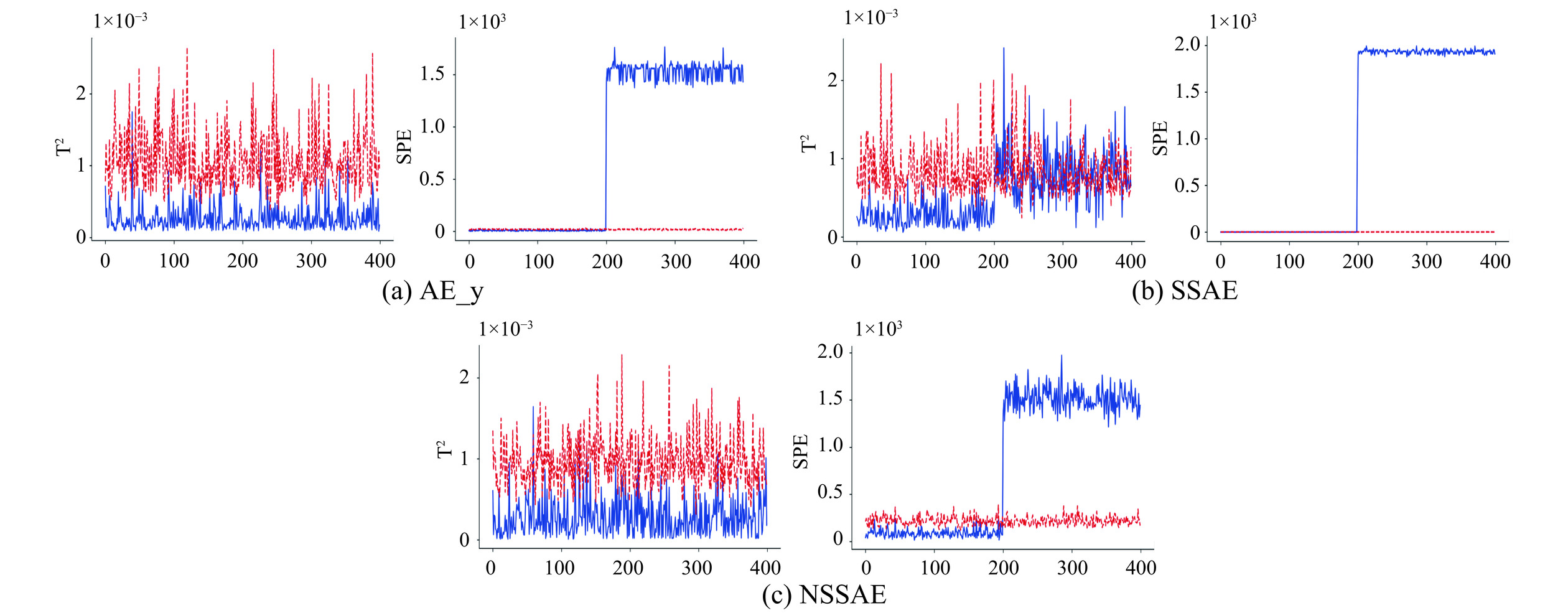

图9为质量无关故障在 AE_y、SSAE 和 NSSAE算法下的故障检测结果,其中,每张图的横轴代表采样时刻,纵轴代表检测指标值,图中蓝色实线为检测指标,红色虚线为对应故障检测指标的控制线。从图9(c)中可知,NSSAE模型在检测质量无关故障时,质量相关检测指标在故障发生后并不会超出控制极限,这也就意味着变量\rm {x_2}发生故障后并不会影响质量,这也与仿真数据实际相符。AE_y算法在质量相关故障的检测结果可以看出,在质量无关故障发生后,检测指标几乎不超出控制极限。上述3个模型在故障检测指标上具有相似的结论,即故障检测指标在200采样时刻后均超出控制极限,进而实现故障报警。值得注意的是,故障1和2的故障幅值均为5%,故障幅值较大,因此各个模型的故障检测指标均检测出故障。

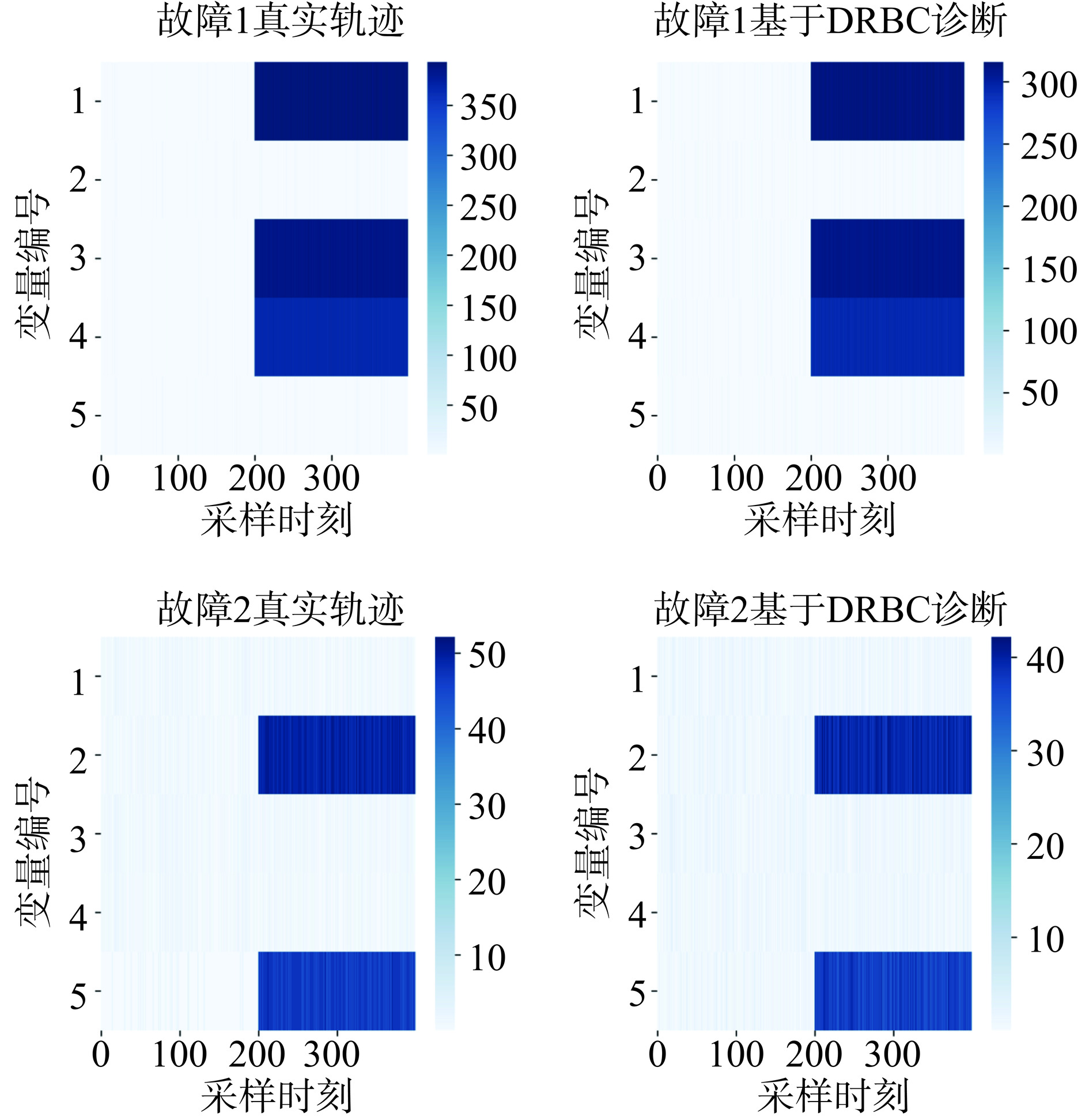

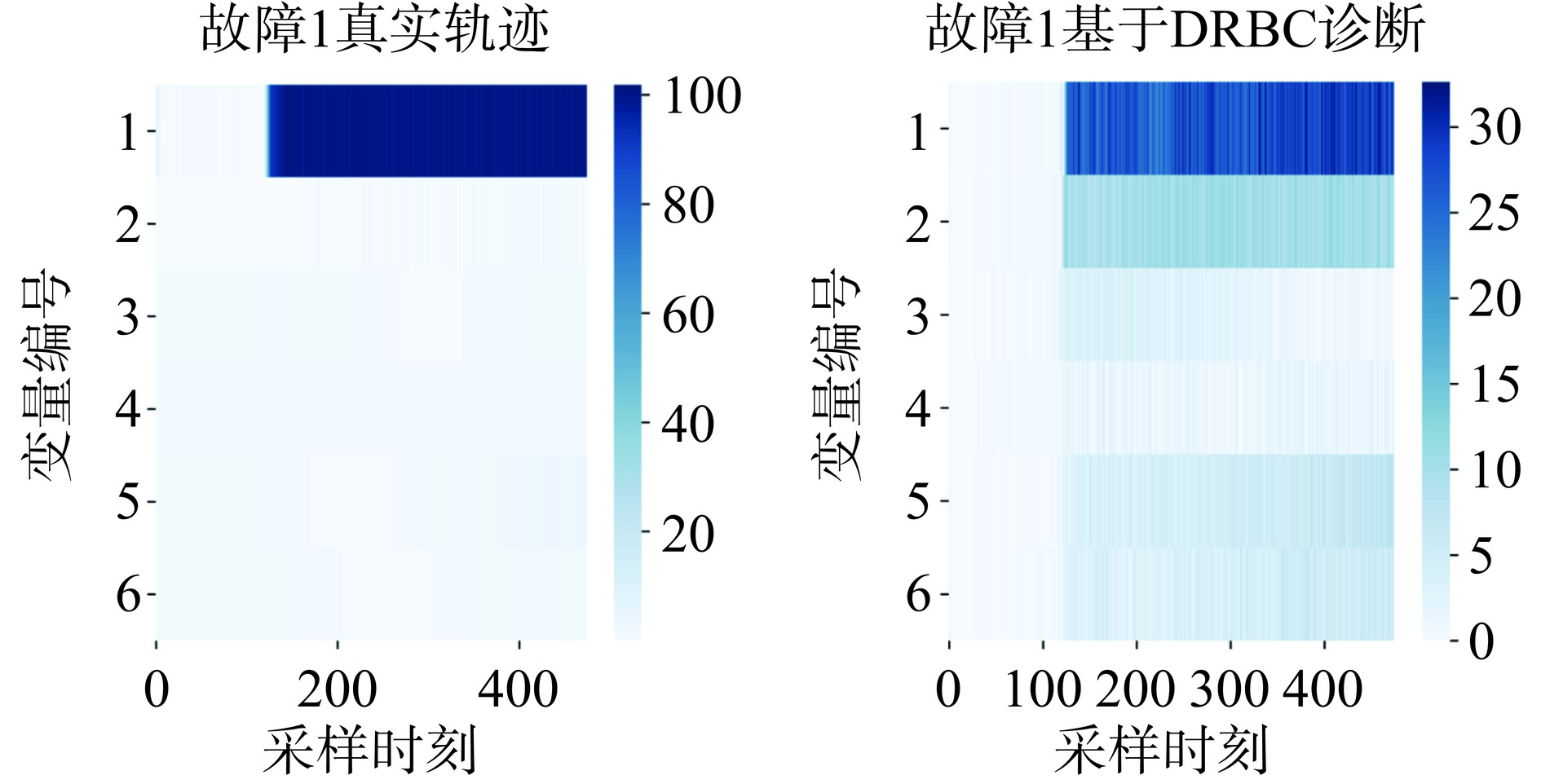

图10为故障1和2基于DRBC的诊断结果,每个图的横轴为采样时刻,纵轴代表变量编号,蓝色的深浅程度指示出故障的偏移程度。对于故障编号1,由于故障变量x1与变量x3和x4具有强相关性,因此当故障变量1出现异常后,会导致过程变量x1、x3和x4同时出现异常。对比图10中的故障编号1的真实轨迹和基于DRBC的诊断结果可知,故障诊断结果与真实轨迹相符,过程变量1,3,4被诊断出异常,从该结果可知基于DRBC的诊断方法能够准确定位故障变量。类似地,故障编号2由过程变量x2发生偏移导致过程变量x5也产生相应的故障。从图10中故障2的基于DRBC的诊断图可以看出故障变量编号为2,5。

2.2 植物乳杆菌发酵案例结果与讨论

图11为发酵过程的过程变量编号1~7与质量变量y间的互信息值。可以看出,搅拌速率与质量变量间的互信息值最低,搅拌与质量变量的相关性最小。其次,发酵温度与质量变量间的互信息值为0.517,这说明发酵温度与质量变量间存在相关性,但并不是强相关。NSSAE模型设计3层,损失函数中的预测损失权重\lambda 设计为0.8。批次维度动态阶次设计为6。定义有标签的数据占整体数据的80%。

由表4可得与数值仿真案例相似的结论,质量相关故障发生后,各个模型均取得了较为理想的故障检测结果。但是对与质量无关故障,NSSAE能够取得较好的故障检测结果,而对于NSSAE模型的质量相关故障检测指标\rm T_{}^2能表征该故障与质量变量间的影响较小。而对于其他模型,如AE_y和SSAE的质量相关故障检测指标的检测率为99.7%和28.8%,这意味着更高的质量相关故障的误报率。综合上述两个发酵过程的质量相关故障与质量无关故障,模型NSSAE能较为准确的区分质量相关故障和质量无关故障。

表 4 乳酸菌发酵案例故障检测结果Table 4. L. plantarum fermentation case faults detection results故障编号 AE_y SSAE NSSAE T2 SPE FAR T2 SPE FAR T2 SPE FAR 1 100 100 2 100 99.4 4.5 99.4 99.7 0.125 2 99.7 100 1.5 28.8 99.7 3.5 4.7 100 0.8 图12为AE_y、SSAE与本文提出的NSSAE在故障1情况下的故障检测结果。故障1为发酵温度在120采样时刻上升3 ℃,3个模型的检测结果均取得了较好的故障检测结果。温度偏移较大,因此对质量产生了一定的影响。因此质量相关故障检测指标在故障发生后超出控制极限。图13为3个模型对于质量无关故障的检测结果。从图13(c)结果可知,NSSAE的故障检测指标SPE能检测出故障,检测指标T2能检测出该故障为质量无关故障。因此,本文提出的故障检测结果具有较好的故障检测能力。

发酵过程故障1的诊断结果如图14所示。通过对比故障1的真实轨迹和基于DRBC的诊断结果可以看出,基于DRBC的诊断方法能定位故障变量。并且对故障幅值进行评估。但是在实际诊断过程中,由于故障幅值较大导致诊断过程次数难以估量,且诊断过程需要消耗大量时间。图14的诊断次数被限定在5000次。可以看出故障幅值的诊断结果仍与真实故障诊断结果存在差距。但基于DRBC的诊断方法依然识别了主要贡献变量,展现了良好的故障根源挖掘潜力。

3. 结论

在批次发酵过程监测中,质量相关与无关故障的细分对于避免盲目停机,维护过程效益具有重要意义。本文提出了一种基于NSSAE的批次过程故障检测和诊断方法,通过互信息对过程变量数据进行加噪,利用二维滑窗获取数据和建模,实现了质量相关和质量无关故障的在线监测和分析。文章在该算法基础上结合DRBC对故障根源进行了进一步分析。数值仿真和植物乳杆菌发酵实验对所提出的NSSAE算法有效性进行了验证。结果表明,NSSAE算法对于故障的识别率几乎接近100%,且相较于其他方法,能够准确区分定位质量相关故障,NSSAE的平均误检率为0.5%,故障检测方面具有较强的可信度。此外,基于DRBC的诊断结果表明该诊断方法能够定位故障变量。

-

表 1 植物乳杆菌发酵过程变量与质量变量

Table 1 L. plantarum fermentation process variables and quality variables

变量编号 变量 单位 变量编号 变量 单位 1 发酵温度 ℃ 5 酸补充量 mL 2 pH − 6 碱补充量 mL 3 溶解氧 % 7 补料 mL 4 搅拌速率 r/min y 浊度 − 表 2 植物乳杆菌发酵过程故障说明

Table 2 L. plantarum fermentation process troubleshooting instructions

故障编号 故障变量 故障幅值 故障类型 引入时间(min) 1 发酵温度 +3 ℃ 阶跃 120~480 2 发酵温度 +0.3 ℃ 阶跃 120~480 表 3 数值仿真案例故障检测结果

Table 3 Numerical simulation case fault monitoring results

故障编号 AE_y SSAE NSSAE T2 SPE FAR T2 SPE FAR T2 SPE FAR 1 100 100 3.25 100 100 2.75 100 100 0.125 2 4 100 3 52 100 1.75 0 100 1.25 表 4 乳酸菌发酵案例故障检测结果

Table 4 L. plantarum fermentation case faults detection results

故障编号 AE_y SSAE NSSAE T2 SPE FAR T2 SPE FAR T2 SPE FAR 1 100 100 2 100 99.4 4.5 99.4 99.7 0.125 2 99.7 100 1.5 28.8 99.7 3.5 4.7 100 0.8 -

[1] 裴昊. 人工智能计算机技术在食品工业中的应用研究[J]. 食品安全导刊,2022(16):133−135. [PEI H. Research on the application of artificial intelligence computer technology in the food industry[J]. Food Safety Guide,2022(16):133−135.] doi: 10.3969/j.issn.1674-0270.2022.16.spaqdk202216054 PEI H. Research on the application of artificial intelligence computer technology in the food industry[J]. Food Safety Guide, 2022(16): 133−135. doi: 10.3969/j.issn.1674-0270.2022.16.spaqdk202216054

[2] 杨鸿雁, 单紫轩, 赖亮, 等. 天然产物中抗微生物肽的高效筛选方法及研究进展[J]. 食品工业科技,2022,43(21):28−35. [YANG H Y, SHAN Z X, LAI L, et al. Efficient screening methods and research progress of antimicrobial peptides in natural products[J]. Food Industry Science and Technology,2022,43(21):28−35.] YANG H Y, SHAN Z X, LAI L, et al. Efficient screening methods and research progress of antimicrobial peptides in natural products[J]. Food Industry Science and Technology, 2022, 43(21): 28−35.

[3] KAKANI V, NGUYEN V H, KUMAR B P, et al. A critical review on computer vision and artificial intelligence in food industry[J]. Journal of Agriculture and Food Research,2020,2:100033. doi: 10.1016/j.jafr.2020.100033

[4] 王铖, 王珍珍, 陈其彪, 等. 基于机器学习的代谢组学解析腊八蒜储藏过程中代谢物差异[J]. 食品工业科技,2023,44(8):26−34. [WANG C, WANG Z Z, CHEN Q B, et al. Metabolomics analysis based on machine learning of metabolite differences during storage of Laba garlic[J]. Food Industry Science and Technology,2023,44(8):26−34.] WANG C, WANG Z Z, CHEN Q B, et al. Metabolomics analysis based on machine learning of metabolite differences during storage of Laba garlic[J]. Food Industry Science and Technology, 2023, 44(8): 26−34.

[5] 张群. 黄酒发酵过程品质稳定性监控技术研究及应用[J]. 食品与生物技术学报,2015,34(12):1344. [ZHANG Q. Research and application of quality stability monitoring technology in rice wine fermentation process[J]. Journal of Food and Biotechnology,2015,34(12):1344.] doi: 10.3969/j.issn.1673-1689.2015.12.018 ZHANG Q. Research and application of quality stability monitoring technology in rice wine fermentation process[J]. Journal of Food and Biotechnology, 2015, 34(12): 1344. doi: 10.3969/j.issn.1673-1689.2015.12.018

[6] JI C, MA F, WANG J, et al. Profitability related industrial-scale batch processes monitoring via deep learning based soft sensor development[J]. Computers & Chemical Engineering,2023,170:108125.

[7] CAVAGLIA J, SCHORN-GARCIA D, GIUSSANI B, et al. ATR-MIR spectroscopy and multivariate analysis in alcoholic fermentation monitoring and lactic acid bacteria spoilage detection[J]. Food Control,2020,109:106947. doi: 10.1016/j.foodcont.2019.106947

[8] 马春敏, 付佳宁, 吴巧艳, 等. 乳酸菌发酵在谷物产品中的应用及研究进展[J]. 食品安全质量检测学报,2023,14(22):29−38. [MA C M, Fu J N, WU Q Y, et al. Application and research progress of lactic acid bacteria fermentation in cereal products[J]. Journal of Food Safety and Quality Inspection,2023,14(22):29−38.] MA C M, Fu J N, WU Q Y, et al. Application and research progress of lactic acid bacteria fermentation in cereal products[J]. Journal of Food Safety and Quality Inspection, 2023, 14(22): 29−38.

[9] 陆宁云, 王福利, 高福荣, 等. 间歇过程的统计建模与在线监测[J]. 自动化学报,2006(3):400−410. [LU N Y, WANG F L, GAO F R, et al. Statistical modeling and online monitoring of intermittent processes[J]. Journal of Automation,2006(3):400−410.] LU N Y, WANG F L, GAO F R, et al. Statistical modeling and online monitoring of intermittent processes[J]. Journal of Automation, 2006(3): 400−410.

[10] YU W, ZHAO C, HUANG B. Stationary subspace analysis-based hierarchical model for batch processes monitoring[J]. IEEE Transactions on Control Systems Technology,2020,29(1):444−453.

[11] LIU Z, LOU X, ZHU J. Batch process monitoring with two-dimensional LSTM-variational auto-encoder[C]//2023 42nd Chinese Control Conference (CCC). IEEE, 2023:4945-4950.

[12] NADAL-REY G, MCCLURE D D, KAVANAGH J M, et al. Development of dynamic compartment models for industrial aerobic fed-batch fermentation processes[J]. Chemical Engineering Journal,2021,420:130402. doi: 10.1016/j.cej.2021.130402

[13] AGARWAL P, AGHAEE M, TAMER M, et al. A novel unsupervised approach for batch process monitoring using deep learning[J]. Computers & Chemical Engineering,2022,159:107694.

[14] REN J, NI D. A batch-wise LSTM-encoder decoder network for batch process monitoring[J]. Chemical Engineering Research and Design,2020,164:102−112. doi: 10.1016/j.cherd.2020.09.019

[15] ZHANG Z, ZHU J, ZHANG S, et al. Process monitoring using recurrent Kalman variational auto-encoder for general complex dynamic processes[J]. Engineering Applications of Artificial Intelligence,2023,123:106424. doi: 10.1016/j.engappai.2023.106424

[16] CHANG P, ZHANG R Y, DING C H. Dynamic hidden variable fuzzy broad neural network based batch process anomaly detection with incremental learning capabilities[J]. Expert Systems with Applications,2022,202:117390. doi: 10.1016/j.eswa.2022.117390

[17] JIANG Q, YAN S, YAN X, et al. Data-driven two-dimensional deep correlated representation learning for nonlinear batch process monitoring[J]. IEEE Transactions on Industrial Informatics,2019,16(4):2839−2848.

[18] 赵小强, 惠永永. 基于TTGNPE算法的间歇过程监控[J]. 控制与决策,2017,32(3):557−562. [ZHAO X Q, HUI Y Y. Intermittent process monitoring based on TTGNPE algorithm[J]. Control and Decision,2017,32(3):557−562.] ZHAO X Q, HUI Y Y. Intermittent process monitoring based on TTGNPE algorithm[J]. Control and Decision, 2017, 32(3): 557−562.

[19] ZHAO L, HUANG X, YU H. Quality-analysis-based process monitoring for multi-phase multi-mode batch processes[J]. Processes,2021,9(8):1321. doi: 10.3390/pr9081321

[20] TAO Y, SHI H, SONG B, et al. Parallel quality-related dynamic principal component regression method for chemical process monitoring[J]. Journal of Process Control,2019,73:33−45. doi: 10.1016/j.jprocont.2018.08.009

[21] WANG P, REN S, WANG Y, et al. Quality-related nonlinear process monitoring of power plant by a novel hybrid model based on variational autoencoder[J]. Control Engineering Practice,2022,129:105359. doi: 10.1016/j.conengprac.2022.105359

[22] TANG P, PENG K, DONG J. Nonlinear quality-related fault detection using combined deep variational information bottleneck and variational autoencoder[J]. ISA transactions,2021,114:444−454. doi: 10.1016/j.isatra.2021.01.002

[23] 赵小强, 张妍. 基于NPE-ELM的间歇过程质量相关故障检测[J]. 控制工程,2022,29(12):2284−2292. [ZHAO X Q, ZHANG Y. Quality-related fault detection in intermittent processes based on NPE-ELM[J]. Control Engineering,2022,29(12):2284−2292.] ZHAO X Q, ZHANG Y. Quality-related fault detection in intermittent processes based on NPE-ELM[J]. Control Engineering, 2022, 29(12): 2284−2292.

[24] ZHU J, SHI H, SONG B, et al. Information concentrated variational auto-encoder for quality-related nonlinear process monitoring[J]. Journal of Process Control,2020,94:12−25. doi: 10.1016/j.jprocont.2020.08.002

[25] HUANG J, YAN X. Related and independent variable fault detection based on KPCA and SVDD[J]. Journal of Process Control,2016,39:88−99. doi: 10.1016/j.jprocont.2016.01.001

[26] YAO H, ZHAO X, LI W, et al. Quality-related fault monitoring for multi-phase batch process based on multiway weighted elastic network[J]. Chemometrics and Intelligent Laboratory Systems,2022,223:104528. doi: 10.1016/j.chemolab.2022.104528

[27] YUAN X, OU C, WANG Y, et al. A novel semi-supervised pre-training strategy for deep networks and its application for quality variable prediction in industrial processes[J]. Chemical Engineering Science,2020,217:115509. doi: 10.1016/j.ces.2020.115509

[28] 张广敏, 王炜, 包慧芳, 等. 植物乳杆菌Lp-2的高密度发酵[J]. 中国生物工程杂志,2009,29(6):68−73. [ZHANG G M, WANG W, BAO H F, et al. High-density fermentation of Lactobacillus plantarum Lp-2[J]. Chinese Journal of Bioengineering,2009,29(6):68−73.] ZHANG G M, WANG W, BAO H F, et al. High-density fermentation of Lactobacillus plantarum Lp-2[J]. Chinese Journal of Bioengineering, 2009, 29(6): 68−73.

[29] WANG Y, YAO H, ZHAO S. Auto-encoder based dimensionality reduction[J]. Neurocomputing,2016,184:232−242. doi: 10.1016/j.neucom.2015.08.104

[30] ZABALZA J, REN J, ZHENG J, et al. Novel segmented stacked autoencoder for effective dimensionality reduction and feature extraction in hyperspectral imaging[J]. Neurocomputing,2016,185:1−10. doi: 10.1016/j.neucom.2015.11.044

[31] KRASKOV A, STÖGBAUER H, ANDRZEJAK R G, et al. Hierarchical clustering using mutual information[J]. Europhysics Letters,2005,70(2):278. doi: 10.1209/epl/i2004-10483-y

[32] RESHEF D N, RESHEF Y A, FINUCANE H K, et al. Detecting novel associations in large data sets[J]. Science,2011,334(6062):1518−1524. doi: 10.1126/science.1205438

[33] MAJUMDAR A. Blind denoising autoencoder[J]. IEEE Transactions on Neural Networks and Learning Systems,2018,30(1):312−317.

[34] ZHANG Z, ZHU J, GE Z. Industrial process modeling and fault detection with recurrent Kalman variational autoencoder[C]//2020 IEEE 9th Data Driven Control and Learning Systems Conference (DDCLS). IEEE, 2020:1370-1376.

[35] ZHU J, LIU Z, LOU X, et al. Time-specific thresholds for batch process monitoring:A study based on two-dimensional conditional variational auto-encoder[J]. Processes,2024,12(4):682. doi: 10.3390/pr12040682

下载:

下载:

下载:

下载: