Ultrasonic and Microwave-assisted Solid-Liquid Extraction of Ginkgo biloba Phenolics: Study about Mass Transfer and PID Control

-

摘要: 本文采用超声和微波辅助提取银杏叶多酚,通过构建扩散模型,研究了超声和微波场下银杏叶多酚提取的传质机制,进一步建立了关于银杏叶多酚提取过程的比例-积分-微分(PID)控制算法。结果表明:与摇床振荡提取相比,超声和微波辅助提取均可促进银杏叶内多酚的释放,增强银杏叶颗粒内部多酚分子扩散能力。相较超声处理,微波场下多酚提取效率更高,且多酚扩散能力更强,颗粒内外多酚浓度差值更早到达峰值。料液比为1:40 g/mL时,103.7 W/L超声和4800 W/L微波作用下,多酚的De值分别为6.4×10−11 m2/s、1.4×10−10~1.7×10−10 m2/s,多酚平衡提取量分别为27.492±2.666和28.453±1.115 mg/g。另一方面,与传统PID和模糊PID控制器相比,基于遗传算法(GA)和粒子群算法(PSO)优化的两种模糊PID控制器均可较好地对目标多酚提取过程实施有效控制,具有超调量小、收敛速度快等优点。当微波功率为4800 W/L、料液比为1:20 g/mL时,最佳控制算法为PSO优化的模糊PID,PSO因子为4.1350、0.1100、0.0001,此时粒子群算法优化的模糊PID控制器收敛时间最少,为0.5 min左右,且有最小的超调量,为1.12%。该研究为超声和微波辅助银杏叶多酚固液萃取的数字化仿真控制提供了理论依据。Abstract: In this study, both ultrasound and microwave techniques were utilized to intensify the extraction of phenolics from Ginkgo biloba leaves. A diffusion-based mathematical model was developed to explore the mass transfer mechanism about the studied extraction processes, and PID control algorithms were implemented to accurately control the extraction process. The results showed that ultrasound and microwave-assisted methods significantly enhanced the release and diffusion of polyphenol compared to the traditional shaker oscillation method. Compared with ultrasound-assisted extraction, microwave-assisted extraction demonstrated superior efficiency and diffusion effectiveness, quickly reached the maximum polyphenol content gradient across the leaf particles. With a solvent-to-liquid ratio of 1:40 g/mL, the effective diffusion coefficient (De) of polyphenol was determined to be 6.4×10−11 m2/s under ultrasound treatment (103.7 W/L) and ranged from 1.4×10−10 to 1.7×10−10 m2/s under microwave treatment (4800 W/L). The equilibrium polyphenol extraction yields were 27.492±2.666 mg/g for ultrasound treatment at 103.7 W/L and 28.453±1.115 mg/g for microwave treatment at 4800 W/L. Furthermore, fuzzy-PID controllers optimized by genetic algorithms or particle swarm optimization (PSO) algorithms outperformed traditional PID controller and individual fuzzy-PID controller to control the extraction process, achieving faster convergence with minimal overshoot. Specifically, under microwave power of 4800 W/L and a solvent-to-liquid ratio of 1:20 g/mL, the fuzzy-PID controller optimized by PSO algorithm proved optimal, with PSO factors set at 4.1350, 0.1100, and 0.0001. The corresponding convergence time was approximately 0.5 minutes and an overshoot was 1.12%. This study provides a theoretical foundation for digitalizing the ultrasonic and microwave-assisted extraction processes of polyphenol from Ginkgo biloba leaves.

-

Keywords:

- Ginkgo biloba leaves /

- extraction /

- polyphenol /

- ultrasound /

- microwave /

- mass transfer /

- PID control

-

银杏(Ginkgo biloba)为银杏科银杏属植物,被誉为植物界“活化石”[1]。银杏果、叶富含生物活性物质,具有较高的医用价值。其中,银杏叶中含有黄酮、酚酸等酚类化合物,具有改善大脑中的血液流动、缓解焦虑、抗氧化等活性,对心脑血管疾病等具有疗效,可在食品加工、医疗保健等方面发挥作用[2]。活性物质分离是银杏叶高值化利用的关键环节。传统及现代化萃取技术包括固液萃取、液液萃取、超临界流体萃取、双水相萃取、超声辅助萃取、微波辅助萃取等。大量研究表明,固液萃取过程中引入超声和微波可提高萃取效率和萃取量,降低溶剂使用量,且成本可控,具备较好的产业化应用前景[3−5]。但是,现有研究大多集中于萃取工艺优化和功能组分分析,鲜见基于数学仿真的超声、微波提取传质理论研究和过程控制报道。当前,数字化已是各个领域发展的重要方向[6−8]。为促进银杏叶高效利用和银杏产业绿色发展,亟需针对包含银杏叶组分萃取在内的银杏叶加工技术,开展数字化理论及应用研究。

酚类化合物提取的传质阻力主要是内部扩散[9],因此建立多酚萃取传质模型对于提高提取效率很有必要。相关研究主要采用传统经验公式来进行仿真,包括一阶和二阶动力学方程、Fick第二扩散定律解析方程、Peleg模型[10−13]等。但这些模型大都对物理传质过程缺乏解读,无法揭示萃取物在物料内部随时空变化的规律。另一方面,研究人员成功采用基于牛顿质量守衡定律和Fick第二扩散定律的偏微分方程对固液萃取进行了仿真[14],Spigno等[15]采用一阶动力学和简化的传质模型来模拟水相微波辅助提取红茶粉中总酚,深入探究溶质从颗粒表面转移到溶液以及在溶剂内扩散的全过程;Tao等[16]采用Fick第二定律构建关于超声辅助提取葡萄渣多酚的传质模型,确定葡萄渣内酚类物质的有效扩散系数。综上,通过物理理论结合数值计算,可数字化表征提取过程中银杏叶多酚萃取的时空变化规律,可视化展示萃取全过程,为萃取过程的数字化控制提供理论依据。

数字化技术包括计算机仿真控制、云计算、大数据、人工智能、移动互联网、物联网、区块链等。计算机PID仿真控制是采用计算机对一个系统的结构和行为进行动态演示,以评价或预测目标系统的行为效果,是科学研究和解决问题的有效方法。PID控制器的基本结构由三个部分组成,包括比例环节(P)、积分环节(I)和微分环节(D)。为使PID控制系统快速、稳定达到设定值,并保持较小的稳态误差,需要合理调节三个PID参数。PID控制参数优化算法包括模糊算法[17](Fuzzy)、遗传算法[18](GA)、粒子群算法[19](PSO)等。当前,PID参数优化算法在工程仿真控制领域已被广泛应用。Liang等[20]研究基于模糊算法的远程无线传输节流PID控制系统,发现模糊PID控制算法在模型参数变化时动态响应快、无超调、无静差,自适应能力强;Hassan等[21]采用GA优化电动助力转向控制系统,发现与传统PID控制器相比,遗传算法控制器可最大限度降低能耗;Gün等[22]使用PSO算法优化四旋翼控制的PID参数,可提高四旋翼飞行器的能量效率。因此,将PID控制理论和参数优化算法用于银杏叶多酚萃取过程的仿真控制,有助于进一步提高银杏叶多酚的萃取效率,控制萃取成本,减少能耗,实现萃取过程的绿色化升级。

综上,本文采用超声和微波辅助提取银杏叶多酚,研究不同条件下多酚萃取的动力学过程,构建银杏叶多酚萃取的物理传质模型,深入解析萃取过程中多酚在银杏叶颗粒内部的传质机制,在此基础上,比较传统PID、模糊PID算法(Fuzzy PID)、遗传算法优化模糊PID算法(GA-Fuzzy PID)、粒子群算法优化模糊PID算法(PSO-Fuzzy PID)四种控制算法对银杏叶多酚萃取过程的控制效果。通过上述数学手段研究,可加深对不同物理场下银杏叶多酚萃取过程的数字化理解,有助于固液萃取过程的数字化升级。

1. 材料与方法

1.1 材料与仪器

银杏叶(品种:大佛指) 泰州农牧职业技术学院提供;福林酚、酚类物质标品、单体银杏酸标品 上海源叶生物科技有限公司;甲醇(色谱纯) 美国天地有限公司;冰乙酸(色谱纯) 上海麦克林生化科技有限公司;乙腈(色谱纯) 国药集团化学试剂有限公司;其他试剂 均为国产分析纯。

Bettersize 2000LD型激光粒度仪 丹东百特仪器有限公司;XSJ-650 W型超声波发生器、DL-1005型冷却循环水系统 无锡新上佳生物科技有限公司;WBFY-201型微波发生器 南京孝马机电设备有限公司;LC-OES-60型三叶片搅拌桨 上海力辰邦熙仪器科技有限公司;SPH-100B型恒温培养箱振荡器 上海世平实验设备有限公司;RDXL12SD型T型热电偶 美国OMEGA公司;JA2003型电子天平 上海精密科学仪器有限公司;UV-5100B型紫外可见分光光度计 上海元析仪器有限公司;LC-2010AHT型液相色谱仪 日本SHIMADZU公司;1525型液相色谱仪 美国Waters公司。

1.2 实验方法

1.2.1 银杏叶预处理

银杏叶采用60 ℃热风干制3 h,使银杏叶水分含量降至0.05 g/g DM。烘干后制粉,并过80目筛。通过激光粒度仪分析,得出银杏叶粉平均粒径为73.69 μm。样品置于−18 ℃下避光贮存。

1.2.2 银杏叶多酚固液萃取

1.2.2.1 超声强化萃取

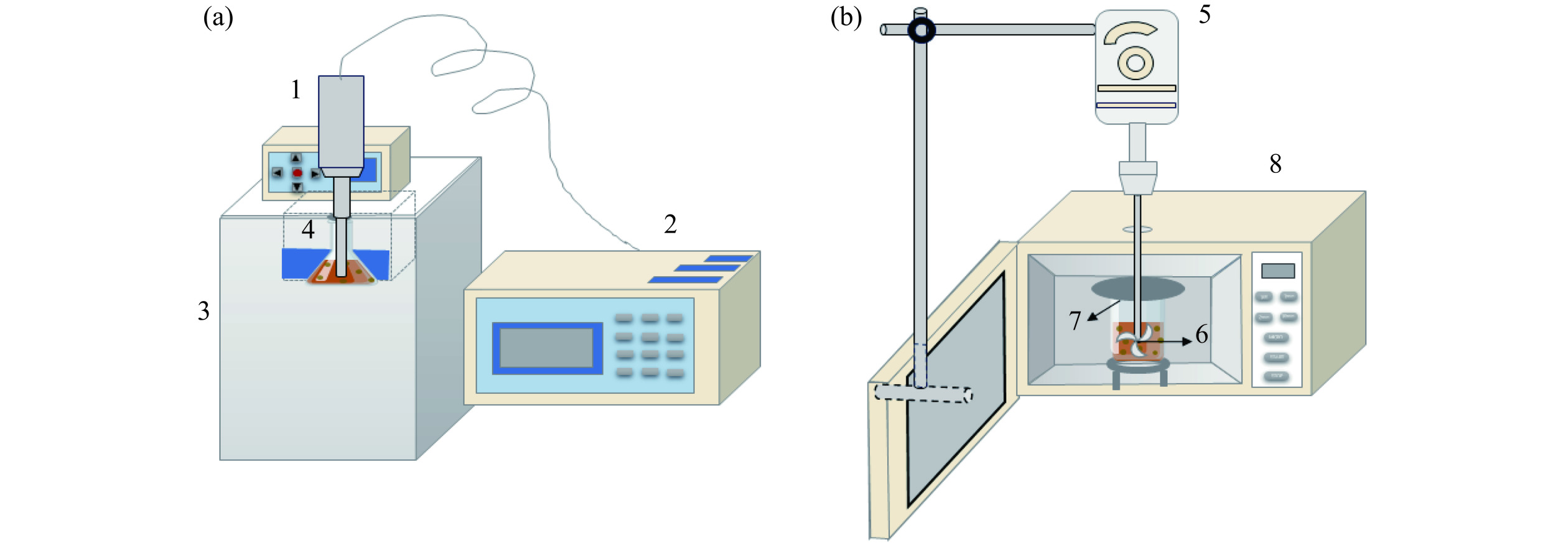

准确称量一定量的银杏叶粉到三角瓶中,按照设定的料液比加入50%乙醇水溶液(v/v),并快速插入20 kHz的超声探头进行超声强化萃取,超声探头固定在液面下方2.5 cm处,超声工作方式为脉冲式(5 s开5 s关)。所用设备工作原理示意图见图1a。萃取过程在冷却循环水系统中进行,温度控制在35 ℃,并采用封口膜密封瓶口(图1a)。提取过程中定期取样,分析上清液中总酚、单体酚及单体银杏酸含量变化。

萃取过程中选用的乙醇水溶液体积分别为50、100、200 mL,进一步采用量热法[23]测定得出3个体积下超声输出功率分别为103.7、47.0、22.3 W/L。在此基础上选择3个料液比水平(1:20、1:30、1:40 g/mL),并运用全阶乘设计法设计实验,共计9组超声处理(其中,组别命名方式为,超声辅助提取_功率-料液比,如US_103.7 W/L-1:20)。

1.2.2.2 微波强化萃取

准确称量一定量的银杏叶粉添加到烧杯中,按照设定的料液比加入50%乙醇水溶液(v/v),并快速置于微波提取装置内,并在烧杯内插入三叶片搅拌桨,叶片转速为160 r/min,半径为2.45 cm,微波处理过程中采用封口膜密封(图1b),微波实际输出功率为4800 W/L。为避免溶剂沸腾,微波工作模式为脉冲形式(5 s开,40 s关),并采用T型热电偶记录溶剂温度变化。提取过程中定期取样,分析上清液中总酚、单体酚及单体银杏酸含量变化(其中,组别命名方式为:微波辅助提取_功率-料液比,如MW_4800 W/L-1:20)。

萃取过程中选用的乙醇水溶液体积为50 mL,在此基础上选择3个料液比水平(1:20、1:30、1:40 g/mL),共计3组微波处理。

1.2.2.3 摇床振荡萃取

准确称量一定量的银杏叶粉到三角瓶中,按照设定的料液比最大值1:40 g/mL加入50%乙醇水溶液(v/v),并放入250 r/min的振荡摇床中进行提取。振荡摇床温度设置为25 ℃,提取时间为2 h,并采用封口膜密封瓶口。提取过程中定期取样,分析上清液中总酚含量变化。

1.2.3 理化分析

1.2.3.1 总酚含量测定

采用Folin–Ciocalteu法测定银杏叶提取液中总酚含量[24],以没食子酸为标品建立标准曲线,总酚提取量表示为mg/g银杏叶粉,计算公式如下:

W(mg/g)=C×D×Vm (1) 式中:W表示总酚提取量,mg/g;C表示根据吸光度值计算出的银杏叶提取液总酚的质量浓度,mg/mL;D表示溶液稀释倍数;V表提取溶剂体积,mL;m表示银杏叶粉取样量,g。

1.2.3.2 单体酚含量测定

单体酚含量参照Liao等[25]的方法进行分析。银杏叶提取液过0.45 μm有机滤膜后用于液相检测。采用SHIMADZU液相色谱仪进行分析,色谱柱为Inertsil ODS-3柱(4.6 mm×250 mm,5 μm)。酚酸类组分检测波长为280 nm,黄酮类组分检测波长为350 nm。流动相A为含1%(v/v)醋酸的水溶液,流动相B为含1%(v/v)醋酸的甲醇溶液。洗脱条件为:0~10 min,10~26% B;10~25 min,26~40% B;25~45 min,40~65% B;45~55 min,65~95% B;55~58 min,95~10% B;58~65 min,10% B。柱温25 ℃,流速0.6 mL/min,进样量20 μL。采用酚类物质标品建立标准曲线,单体酚的提取量表示为mg/g银杏叶粉,计算公式如下:

W(mg/g)=C×Vm (2) 式中:W表示单体酚的提取量,mg/g;C表示根据液相峰面积值计算出的银杏叶提取液单体酚的质量浓度,mg/mL;V表示提取溶剂体积,mL;m表示银杏叶粉取样量,g。

1.2.3.3 银杏酸含量测定

单体银杏酸含量参照He等[26]的方法进行分析。银杏叶提取液过0.45 μm有机滤膜后用于液相检测。使用Waters液相色谱仪进行分析,色谱柱为YMC Carotenoid(4.6×150 mm,3 μm)。银杏酸检测波长为310 nm,流动相为含8%(v/v)冰醋酸的甲醇溶液(其中冰醋酸为含3%(v/v)醋酸的水溶液)。采用等度洗脱法,柱温30 ℃,流速0.8 mL/min,进样量20 μL。采用单体银杏酸标品建立标准曲线,单体银杏酸的提取量表示为mg/g 银杏叶粉。计算公式如下:

W(mg/g)=C×Vm (3) 式中:W表示单体银杏酸的提取量,mg/g;C表示根据液相峰面积值计算出的银杏叶提取液单体银杏酸的质量浓度,mg/mL;V表示提取溶剂体积,mL;m表示银杏叶粉取样量,g。

1.2.4 传质建模

采用基于Newton质量平衡定律和Fick扩散定律的扩散模型模拟超声和微波提取银杏叶多酚的传质过程。模型基于下述假设[27]:银杏叶粉颗粒被看作球体;提取前多酚在银杏叶粉内部分布均匀;忽略提取过程中银杏叶粉颗粒的破裂、溶胀等因素;假设超声萃取过程中溶剂温度保持不变,但考虑微波萃取过程中温度的变化。

基于上述条件,银杏叶粉球体颗粒内多酚扩散方程为:

∂CE,S∂t=De(1x2∂∂x(x2∂CE,S∂x)) (4) 式中:CE,S为提取过程中银杏叶颗粒内总酚含量,mg/cm³;t为提取时间,s;De为银杏叶颗粒内酚类物质的有效扩散系数,m2/s;x为银杏叶径向距离,cm。

提取初始条件为:

CE,L=0,CE,S=CE,S,0,t=0 (5) 式中:CE,L为溶剂内总酚含量,mg/cm3;CE,S为银杏叶颗粒内总酚含量,mg/cm3;CE,S,0为t=0时银杏叶颗粒内总酚含量,mg/cm3。

提取边界条件为:

∂CE,S∂x|x=0=0 (6) D0exp(−EaRT)S∂CE,S∂x|x=Rp=VdCE,Ldt (7) 式中:D0为前因子,m2/s;Ea为表观活化能,J/mol;Rp为银杏叶颗粒半径,cm;V为溶剂体积,mL;S为银杏叶颗粒表面积,cm2;R为摩尔气体常数,8.314 J/(mol·K);T为温度,K;公式(7)表示银杏叶颗粒内部释放的多酚可瞬间溶解在溶剂中。

采用阿伦尼乌斯方程表示微波提取过程中温度T对多酚扩散系数De的影响[28]:

De=D0exp(−EaRT) (8) 将公式(8)代入公式(4)和(7)中,得出公式(9)和(10)。

∂CE,S∂t=D0exp(−EaRT)(1x2∂∂x(x2∂CE,S∂x)) (9) D0exp(−EaRT)S∂CE,S∂x|x=Rp=VdCE,Ldt (10) 采用MATLAB R2022b(Mathworks,美国)中pdepe算法求解上述偏微分方程[29]。不断迭代微波提取模型中的D0和Ea值、以及超声提取模型中的De值,使模型AAD值达到最小,并同时计算R2:

AAD(%)=[n∑i=1(|Ci,e−Ci,p|/Ci,e)n]×100 (11) R2=1−n∑i=1(ci,e−ci,p)2n∑i=1(ci,e−ci,avg)2 (12) 式中:AAD为绝对平均偏差,%;Ci,e为银杏叶颗粒酚类提取量的实验值,mg/g;Ci,p为银杏叶颗粒酚类提取量的预测值,mg/g;R2为相关系数平方;Ci,avg为银杏叶颗粒中酚类物质提取量实验值平均值,mg/g;n为实验数据数量。

1.2.5 提取过程的PID控制方法

1.2.5.1 PID控制模型

采用PID算法构建超声和微波提取银杏叶多酚过程的控制算法[30]。PID控制器是输出控制量控制被控对象的一种控制器[31],其中,输出控制量(多酚提取量)是由目标值与实际值间误差的比例(P)、积分(I)和微分(D)值,通过线性组合的方式构成,被控对象为银杏叶多酚提取过程。PID控制器原理为首先设定某个输出目标值(如多酚提取量的最大值),PID反馈系统传回计算输出值,如与目标不一致,则存在一个误差,PID根据此误差调整输入值(经过重新计算的银杏叶多酚提取量),直至PID系统传回的计算银杏叶多酚提取量输出值达到设定的输出目标值。

整个PID控制闭环中,给定目标值(多酚提取量)为r(t),目标偏差为e(t)(多酚设定提取量与计算输出值间的差值,即e(t)=r(t)−y(t),被控对象输出量为y(t)(银杏叶多酚提取量)。PID控制器函数的计算公式如下:

u(t)=Kp(e(t)+1Ti∫t0e(t)dt+Tdde(t)dt) (13) 式中:u(t)为PID控制函数,Kp为比例系数,Ti为积分时间常数,Td为微分时间常数。

为描述PID控制器的动态特性,需要引进传递函数。在PID控制器中,传递函数是指控制器的输出与输入之间的关系,可以表示为:

G(s)=Kp+Kis+Kds (14) 式中:G(s)为传递函数,s为Laplace变换的复变量,Ki为积分系数,Kd为微分系数。

实验中将提取动力学实验数据导入Matlab中System identification app来获取银杏叶多酚提取过程的传递函数。由于银杏叶多酚提取动力学曲线在跃阶输入下,输出不能立即达到稳态值,这与一阶惯性低通滤波的输出特点相似,因此选择一阶惯性传递函数作为银杏叶多酚提取过程被控对象的传递函数,同时按照一阶惯性传递函数特点设置1个极值点和0个零点[32]。

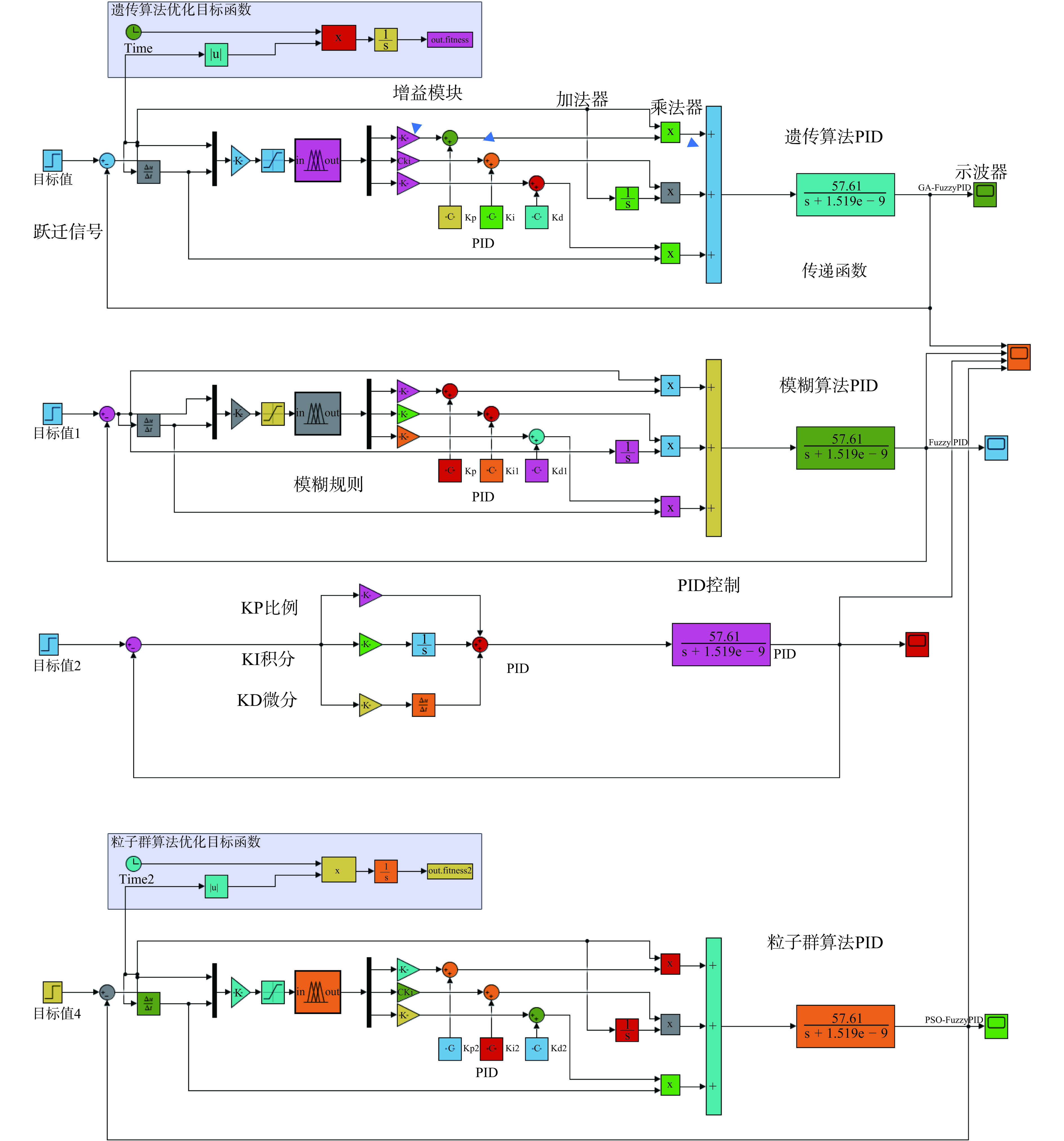

获取每组银杏叶多酚提取实验数据的传递函数,将传递函数输出到PID模型,并通过PID调节器,多次迭代调整,获取符合实验的Kp、Ki、Kd值。本研究中,分别采用模糊控制算法、带有遗传算法的模糊控制算法(GA-Fuzzy)、带有粒子群优化算法的模糊控制算法(PSO-Fuzzy)优化PID模型中的Kp、Ki、Kd值。

1.2.5.2 模糊控制算法优化PID控制参数

模糊算法(Fuzzy Algorithm,Fuzzy)主要通过将人类的模糊概念和语言转化为数学表达的一种算法,常用于处理模糊或不确定的问题。模糊PID控制器(Fuzzy-PID)以误差e(PID系统传回的计算银杏叶多酚提取量输出值与设定值差值)和误差变化率(ec=de/dt)作为输入,并利用模糊控制规则在线对PID参数进行修改[33],以满足不同时刻e和ec对PID参数自整定的要求,并对每一组提取实验数据进行测试。模糊算法原理可参考[34]。

1.2.5.3 带有遗传算法的模糊控制算法优化PID控制参数

遗传算法(Gene tic Algorithm,GA)源于对生物系统进行计算机模拟的研究,借鉴达尔文进化论与孟德尔遗传学说,能够自适应地控制搜索过程并求得最佳解。在模糊PID控制模型基础上,采用遗传算法优化PID控制参数,并将P、I、D分别设为Kp、Ki、Kd三个位置变量。在此基础上,进而求出三个GA因子ΔKp、ΔKi、ΔKd。其中,遗传种群初始规模为50,种群迭代次数为3,交叉概率为0.6,适应度较高能存活到下一代个体为10。同时,设置PID优化范围为[0 0 0]~[Kp Ki Kd]/2,并对每一组提取实验数据进行测试。遗传算法原理可参考[29]。

1.2.5.4 带有粒子群优化算法的模糊控制算法优化PID控制参数

粒子群优化算法(Particle Swarm Optimization,PSO)是通过模拟鸟群捕食行为设计的种群智能算法[35]。在模糊PID控制模型基础上,采用粒子群优化算法优化PID控制参数,并把P、I、D三个参数设为Kp、Ki、Kd三个位置变量,进而求出三个PSO因子ΔKp、ΔKi、ΔKd。其中,粒子群优化迭代次数为4次,粒子群规模为10,惯性因子为0.6,加速常数为4,并设置PID优化范围为[0 0 0]~[Kp Ki Kd]/2,同时对每一组提取实验数据进行测试。粒子群优化算法原理可参考[36]。

为方便对比数据,将传统的PID算法、模糊PID算法、遗传算法优化的模糊PID算法、粒子群算法优化的模糊PID算法结构图按图2方式组合。

1.3 数据处理

每个实验设置三次重复,结果以平均值±标准差的形式表示。使用Statistix9.0进行单因素方差分析(ANOVA),采用Fisher’s LSD法分析,P<0.05,表示具有显著差异。实验数据通过Excel 2021、Origin 2022进行绘图。

2. 结果与分析

2.1 提取动力学特性分析

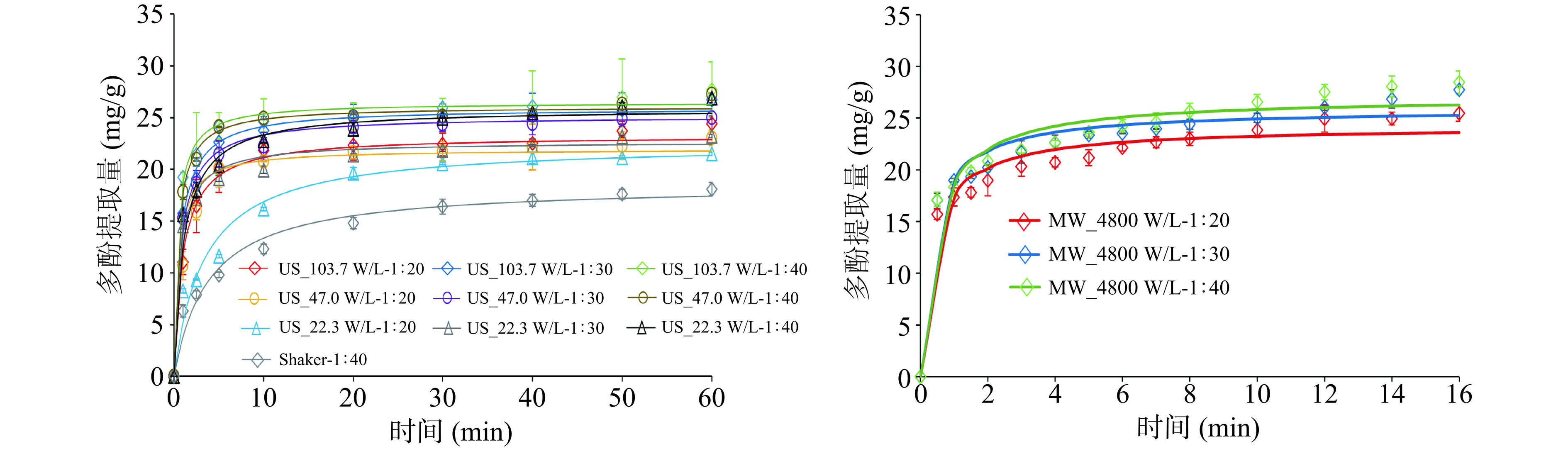

图3为不同提取条件下提取动力学曲线。由图可知,超声、微波辅助萃取银杏叶多酚大约在40 min与16 min达到平衡,其中,超声功率为103.7 W/L,料液比为1:40时,多酚提取量最高,为27.492±2.666 mg/g。微波功率为4800 W/L,料液比为1:40时,多酚提取量达到28.453±1.115 mg/g。摇床振荡的平衡提取时间约为50 min,平衡提取量为18.081±1.348 mg/g。可以看出微波辅助萃取、超声辅助萃取、摇床振荡萃取且均达到提取平衡条件下,提取量呈递减趋势。推测其原因可能是,微波与超声的热和非热效应、空化效应提高了银杏叶多酚提取效率,且微波的热和非热效应,会引起极性分子快速旋转和排列,分子间摩擦力增加,产生更多热量,进一步提升提取效率[37]。以上结果说明,与摇床振荡相比,超声和微波均可促进银杏叶中酚类物质的释放,且微波比超声具有更高的提取效率。Xu等[28]在关于超声、微波和机械搅拌增强核桃衣多酚固液萃取研究中,同样发现微波与超声可显著增强多酚提取效率。

当超声功率与温度相同时,US_103.7 W/L-1:20和US_103.7 W/L-1:40的平衡提取量分别为24.400±1.026和27.492±2.666 mg/g;微波功率与温度条件下相同时,MW_4800 W/L-1:20和MW_4800 W/L-1:40的平衡提取量分别为25.477±0.798和28.453±1.115 mg/g,可以看出随着料液比的提高,多酚提取量呈增加趋势。以上数据进一步说明,同一微波、超声条件下,料液比的提高有助于多酚提取量的提高。当料液比为1:30、提取温度为35 ℃时,22.3、47.0和103.7 W/L超声作用下的平衡提取量分别为23.201±0.965、25.003±1.163、26.735±0.791 mg/g,可以得出随着超声功率的提高,多酚提取量呈增加趋势。推测其原因可能是超声功率的提高可增强空化效应,促进银杏叶多酚的释放和溶解。以上结果说明,超声功率的增强,提高了银杏叶多酚的提取量。Cravotto等[38]在关于超声和水力空化辅助萃取植物组分的研究中,同样发现超声空化效应可在植物提取方面发挥关键作用。

2.2 传质模型建立

2.2.1 模型精度

通过扩散仿真研究不同提取条件下银杏叶内多酚分子扩散的传质机理。由图3可知,提取动力学实验结果与仿真结果吻合度较高。表1为不同提取条件下模型各项参数。其中,模型AAD值在8.57%~9.77%之间,R2值在0.971~0.996之间,预测精度较高。

表 1 不同提取条件下模型各项数据Table 1. Model data under different extraction conditions提取条件 De(m2/s) AAD(%) R2 MW_4800 W/L-1:20 1.0×10−10~1.3×10−10 9.62 0.995 MW_4800 W/L-1:30 1.2×10−10~1.5×10−10 9.27 0.994 MW_4800 W/L-1:40 1.4×10−10~1.7×10−10 9.26 0.986 US_103.7 W/L-1:20 3.6×10−11 9.71 0.981 US_103.7 W/L-1:30 6.2×10−11 9.58 0.996 US_103.7 W/L-1:40 6.4×10−11 9.19 0.993 US_47.0 W/L-1:20 3.3×10−11 8.57 0.971 US_47.0 W/L-1:30 6.0×10−11 8.71 0.992 US_47.0 W/L-1:40 6.2×10−11 9.16 0.979 US_22.3 W/L-1:20 2.8×10−11 9.56 0.971 US_22.3 W/L-1:30 5.9×10−11 9.77 0.972 US_22.3 W/L-1:40 6.1×10−11 9.71 0.971 Shaker-1:40 2.2×10−11 9.39 0.985 注:US为超声辅助提取,MW为微波辅助提取,Shaker为对照组摇床振荡辅助提取。 2.2.2 不同提取条件对多酚内部扩散系数De的影响

表1为不同提取条件下模型各项数据,由表可知,相较于对照组De值(2.2×10−11 m2/s),超声和微波提取条件下De值分布在2.8×10−11 m2/s到1.7×10−10 m2/s之间。超声提取过程中多酚De值为2.8×10−11~6.4×10−11 m2/s,当超声功率为103.7 W/L,料液比为1:40时,De在超声组中最高,当超声功率为22.3 W/L,料液比为1:20时,De在超声组中最低;MW_4800 W/L-1:20、MW_4800 W/L-1:30和MW_4800 W/L-1:40条件下多酚De范围分别为1.0×10−10~1.3×10−10 m2/s、1.2×10−10~1.5×10−10 m2/s、1.4×10−10~1.7×10−10 m2/s。

以上数据可以看出,超声与微波提取过程中De值均明显高于对照组,且微波条件下De值比超声条件下De值更高。推测其原因可能是超声空化效应、微波热和非热效应均可增强银杏叶颗粒内部多酚分子扩散系数,提升了多酚提取效率与提取量,且微波热和非热效应对多酚扩散能力的增强作用优于超声空化。微波处理下环境温度升高了48.9 ℃,可促进银杏叶颗粒中多酚的迁移运动[37],同时,微波非热效应可在细胞壁上产生压力梯度,并在细胞膜上产生孔洞,导致银杏叶颗粒内多酚的释放性与扩散性增强[39]。而超声空化效应在溶液中会产生空化气泡[40],使银杏叶颗粒内形成微孔或微通道,但空化气泡难以渗透到细胞内部,导致多酚扩散系数增幅小于微波处理。以上结果说明,超声与微波提取均提高了银杏叶多酚分子的扩散能力,且微波促进多酚扩散能力更显著,与Mkaouar等[41]研究橄榄叶多酚提取的De值结果变化趋势一致。Xu等[28]研究超声、微波和机械搅拌增强核桃皮衣多酚固液萃取机理的研究中同样发现多酚在微波处理下分子扩散能力最强。

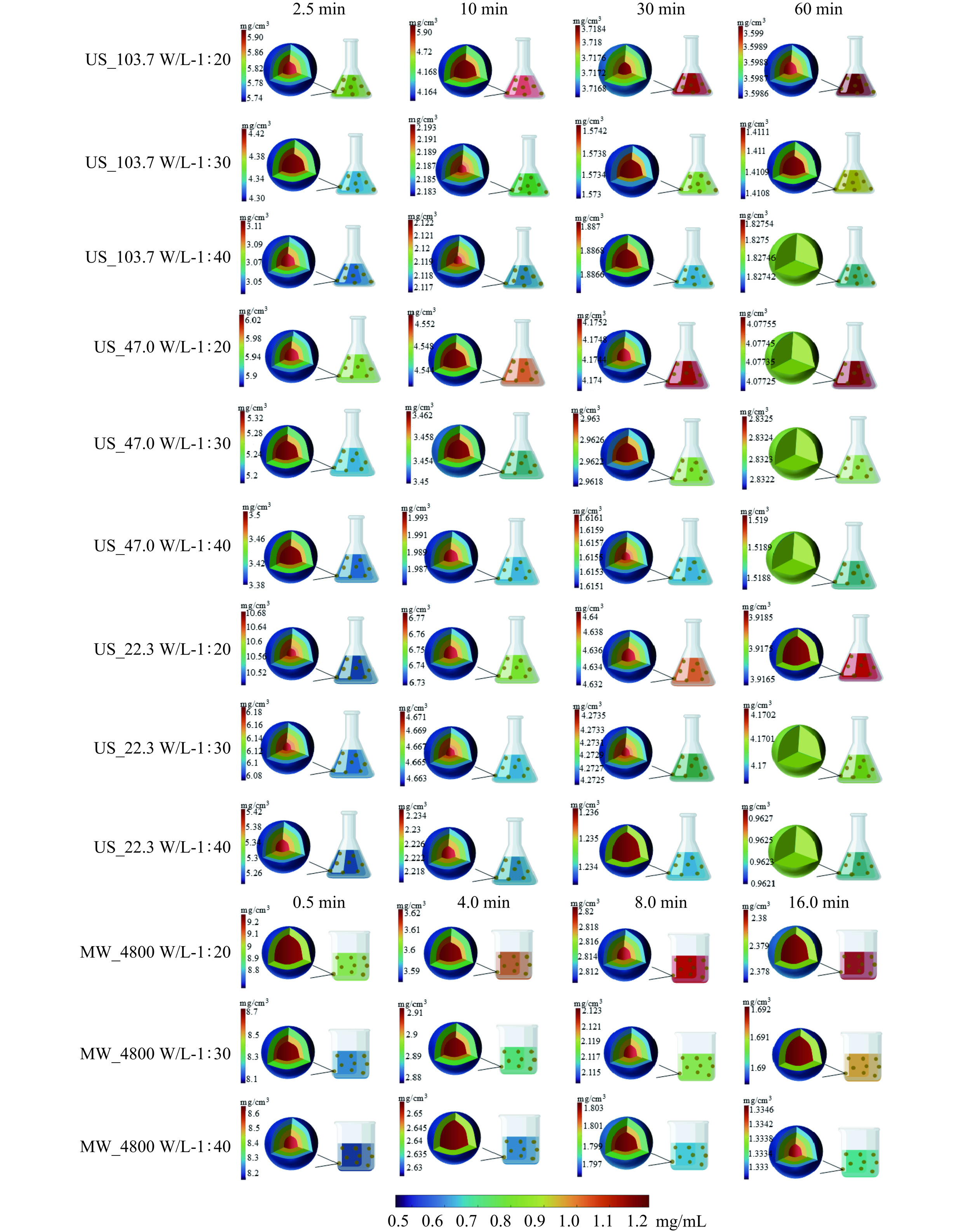

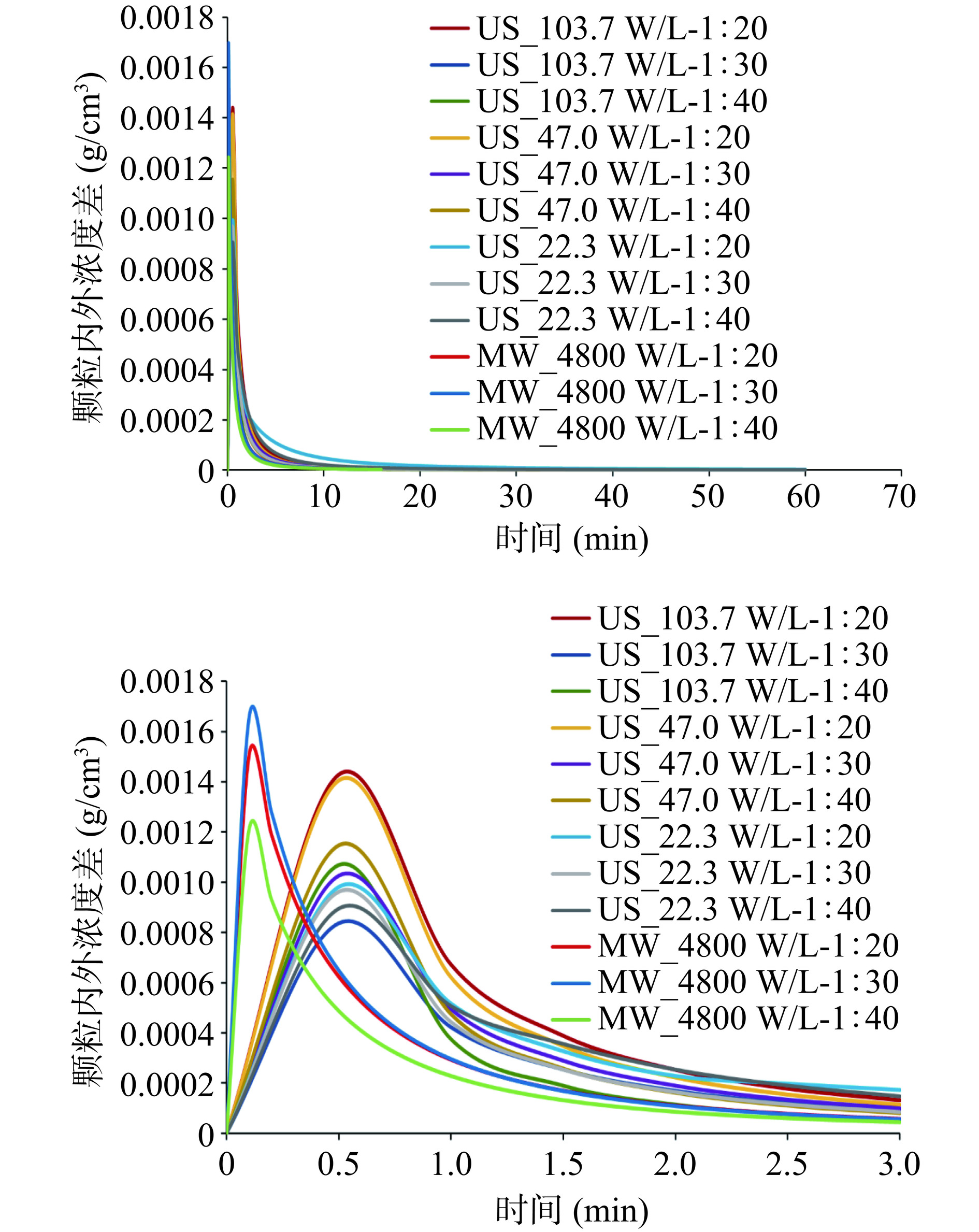

2.2.3 银杏叶粉颗粒内部多酚浓度梯度变化

图4为基于数值模拟得出的银杏叶颗粒内部和萃取溶剂中多酚浓度变化规律。由图可知,提取前期,银杏叶粉颗粒内外多酚浓度差(PCD)较高,随着提取时间的增加,颗粒内外多酚浓度差逐渐降低,提取平衡时颗粒内多酚浓度梯度可忽略,且溶剂中多酚浓度不断增加。同时,微波处理下,银杏叶颗粒内多酚浓度差消减显著快于超声处理,表明微波处理下提取过程易于达到平衡。

为探究提取过程中银杏叶颗粒内部多酚迁移情况,进一步计算了银杏叶颗粒内外浓度差随时间的变化规律(图5)。由图可知,MW_4800 W/L-1:20、MW_4800 W/L-1:30和MW_4800 W/L-1:40处理下PCD在0.09~0.2 min之间达到最高值,分别为0.00150、0.00165和0.00121 g/cm3,其后PCD快速下降,并趋近于0。超声处理下PCD均在0.5 min后达到最高值,其中,US_103.7 W/L-1:20和US_47.0 W/L-1:20处理下的PCD最大值分别为0.00142和0.00141 g/cm3,其余超声处理下的PCD值均小于微波处理组。可以看出,相较超声处理,微波处理下PCD值更早到达顶峰,且到达时间更短。依据菲克扩散定律可知,物料浓度梯度是分子扩散运动的驱动力[42]。推测其原因可能是,微波处理下银杏多酚可在提取早期获得较大传质推动力,增强了多酚的提取效率,进而提高PCD值。以上结果说明,相较于超声萃取,微波萃取条件下,银杏叶颗粒内部多酚迁移变化更显著,提取效率更高。Xu等[28]研究超声、微波和机械搅拌增强核桃皮衣多酚固液萃取机理的研究中,同样发现多酚在微波处理下颗粒内部多酚迁移变化更明显。

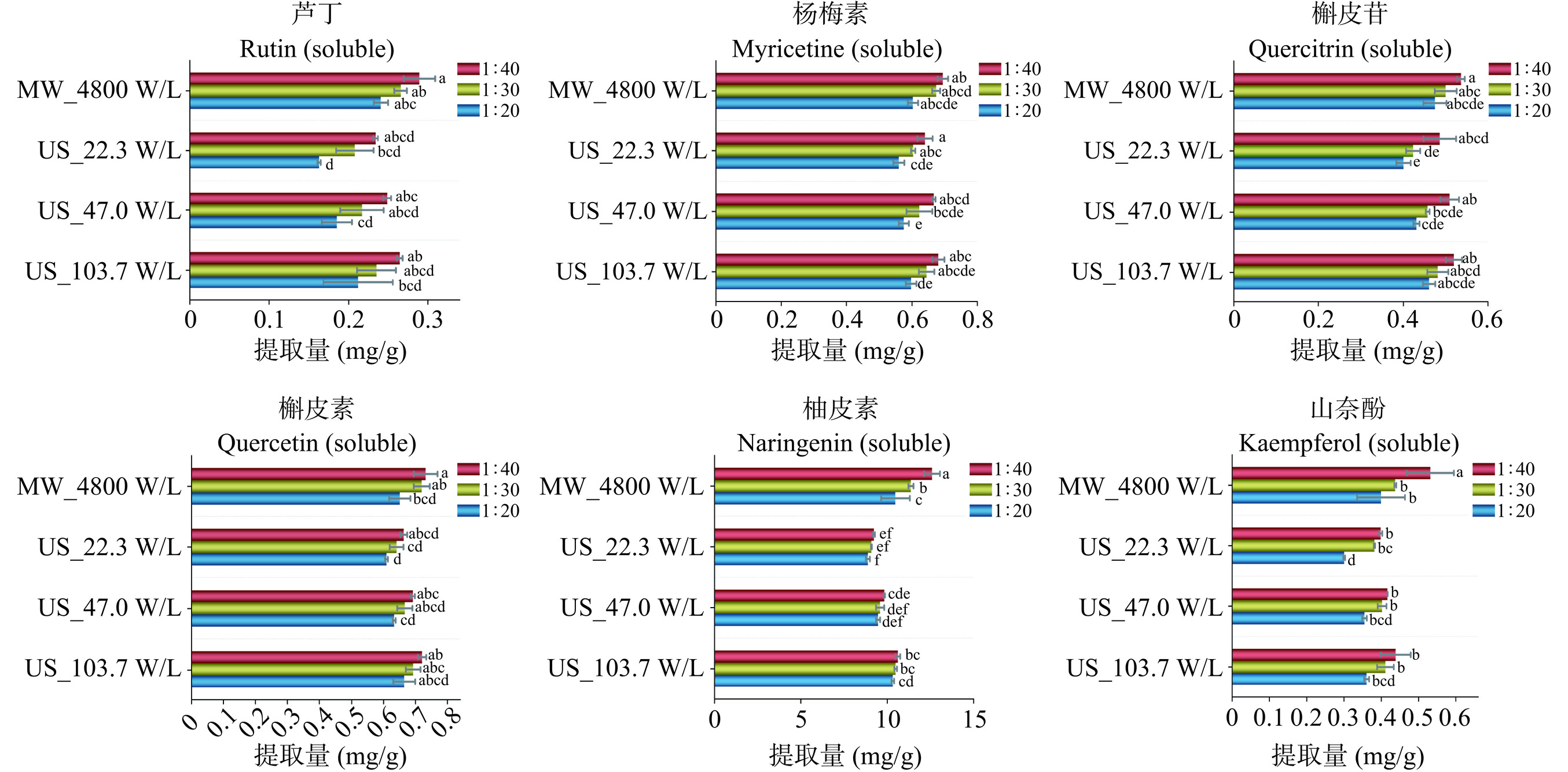

2.2.4 不同提取条件下单体类黄酮类多酚提取量

图6为不同提取条件下单体类黄酮类多酚的含量。银杏叶粉中主要包含6种类黄酮类物质,其中,提取平衡时,柚皮素(8.88~12.59 mg/g)、杨梅素(0.57~0.69 mg/g)和槲皮素(0.61~0.73 mg/g)的提取量较高。当料液比为1:40时,MW_4800 W/L、US_103.7 W/L、US_47.0 W/L、US_22.3 W/L下的柚皮素提取量分别为12.59±0.461、10.62±0.137、9.83±0.036、9.23±0.054 mg/g;当料液比为1:30时,MW_4800 W/L下的杨梅素提取量为0.67±0.012 mg/g,比US_103.7 W/L、US_47.0 W/L、US_22.3 W/L高4.56%、8.72%和11.71%。可以看出,单体类黄酮类多酚的提取量随着微波超声处理条件下功率的降低,呈递减趋势。推测其原因可能是,微波和超声的热和非热效应与空化效应提高了银杏叶单体类黄酮类多酚提取效率。以上结果说明,超声和微波均可促进银杏叶中单体类黄酮类多酚物质的释放,且微波比超声具有较高的提取量。Xu等[28]在采用超声、微波和机械搅拌增强核桃衣多酚固液萃取结果显示,同样发现微波可显著增强萃取单体类黄酮类多酚的效率。

![]() 图 6 不同提取条件下银杏叶内单体类黄酮类多酚的提取量注:不同小写字母表示处理之间的显著性差异(P<0.05);图7同。Figure 6. Extraction yields of individual flavonoid polyphenol from Ginkgo biloba leaf under different extraction methods

图 6 不同提取条件下银杏叶内单体类黄酮类多酚的提取量注:不同小写字母表示处理之间的显著性差异(P<0.05);图7同。Figure 6. Extraction yields of individual flavonoid polyphenol from Ginkgo biloba leaf under different extraction methods2.2.5 不同提取条件下单体银杏酸提取量

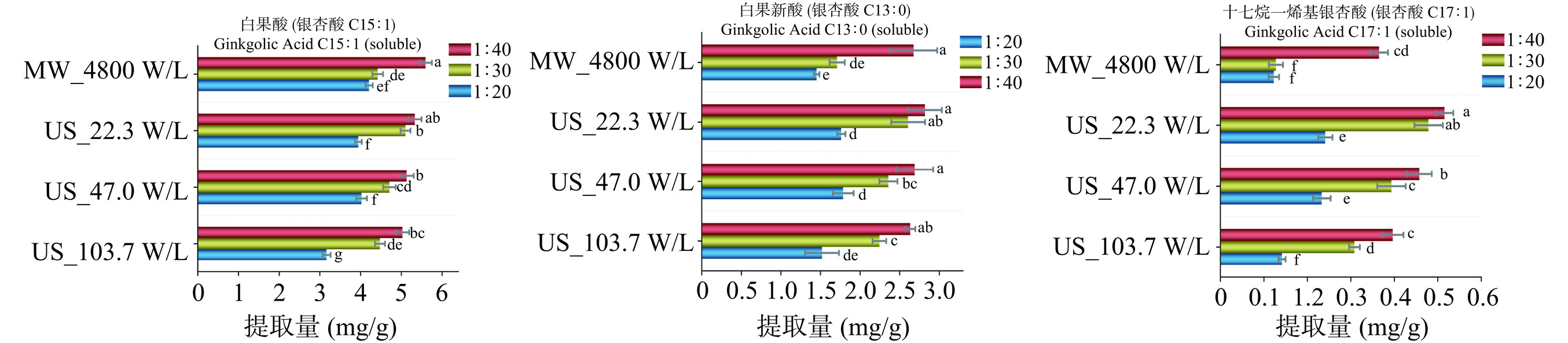

银杏叶中除了含有多酚等生物活性物质外,还含有微毒性组分,包括银杏酸、4'-O-甲基吡哆醇、氢氰酸等[43],其中,银杏酸具有较高的细胞毒性,可抑制心脏的线粒体呼吸功能[44]。微毒性组分含量是银杏叶活性物质提取中需要关注的部分。图7为不同提取过程达到平衡后三种单体银杏酸的提取量。由图可知,本研究采用的提取条件下,白果酸(银杏酸C15:1)的提取量范围为3.16~5.59 mg/g,白果新酸(银杏酸C13:0)的提取量范围为1.45~2.82 mg/g,十七烷一烯基银杏酸(银杏酸C17:1)的提取量范围为0.13~0.52 mg/g。当料液比1:40时,MW_4800 W/L、US_103.7 W/L、US_47.0 W/L、US_22.3 W/L条件下的白果新酸提取量分别为2.68±0.297、2.63±0.064、2.691±0.232和2.821±0.211 mg/g,可以分析出,单体银杏酸提取量,随着微波超声处理条件下功率的降低,呈现差异较小。推测其原因可能是,本实验条件下料液比较高,银杏酸可充分溶解在溶剂中,导致不同提取条件下银杏酸提取量差异较小。以上结果说明,料液比较高条件下,超声和微波促进银杏叶中单体银杏酸的释放程度差别不大。耿敬章等[45]在采用乙醇浸提银杏中种皮提取银杏酸的研究结果显示,过高的料液比同样导致银杏酸提取量的变化不显著。

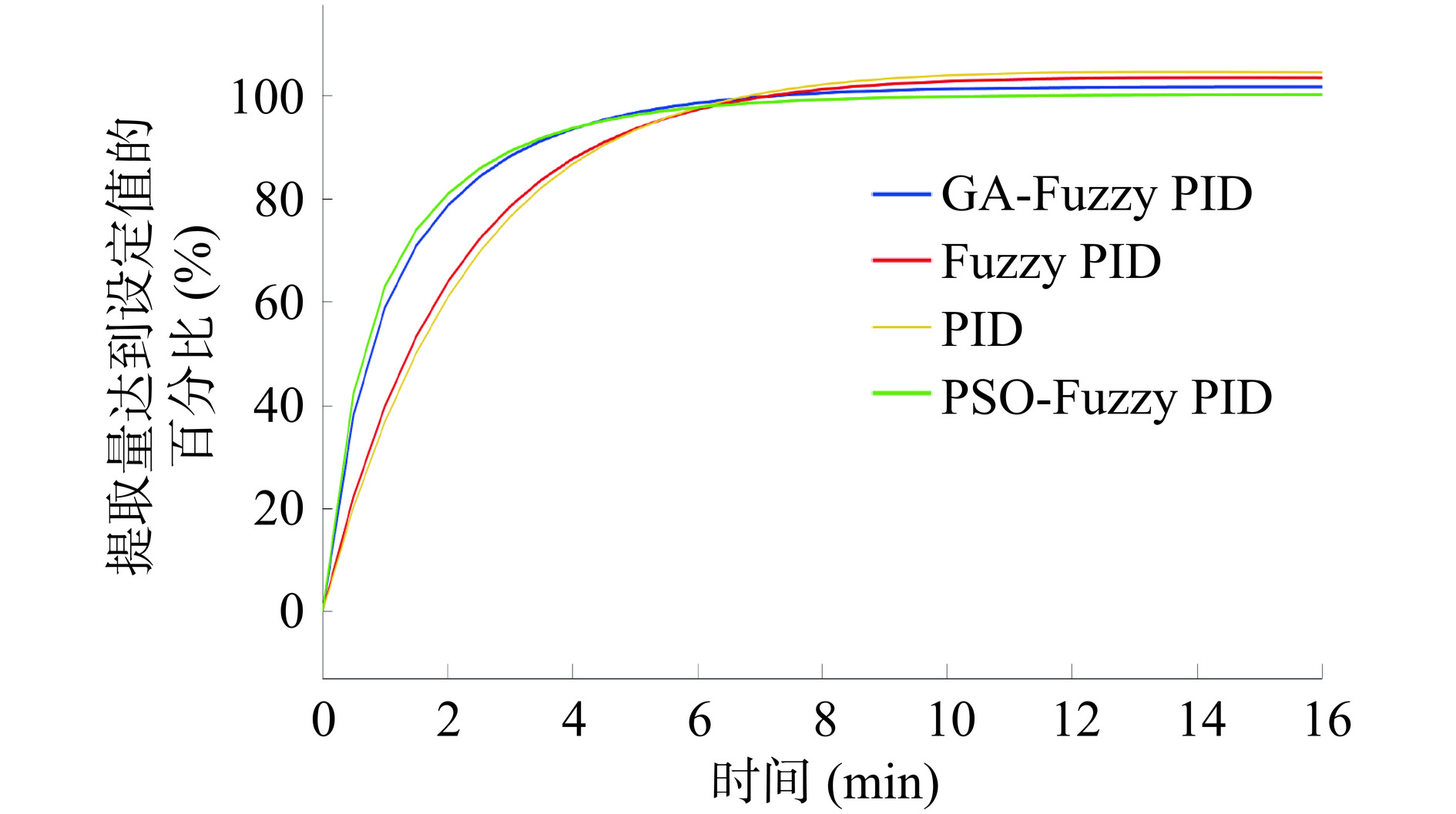

2.3 超声和微波辅助提取银杏叶多酚过程的PID建模控制

计算机PID仿真控制是运用计算机对一个系统的结构和行为进行动态演示,以评价或预测目标系统的行为效果,具有过程精准放大和控制等优点。通过构建银杏叶多酚提取过程的数字化PID控制算法,可实现提取过程的数字化控制。

图8为运用传统PID、模糊PID(Fuzzy-PID)、遗传算法优化的模糊PID(GA-Fuzzy PID)、粒子群算法优化的模糊PID(PSO-Fuzzy PID),仿真得出MW_4800 W/L-1:20条件下银杏叶多酚的提取曲线。由图可知,当提取过程设定的目标值为1(即提取量达到设定值的百分比为100%)时,传统PID控制器超调量(实际仿真输出量的最大值减去设定值,并与设定值之比的百分数)较大(4.44%),且控制器进入收敛状态时间(实际仿真值趋向设定值并达到平稳状态所用时间)也最长(2.5 min);模糊PID控制器超调量(3.39%)小于PID控制器,且收敛速度(2.0 min)也快于传统PID;遗传算法优化的模糊PID控制器超调量(1.63%)进一步小于模糊PID,控制器进入稳定状态的速度(1.5 min)也更快。四种控制器中,粒子群算法优化的模糊PID控制器超调量最小(1.12%),控制器也最快进入稳定状态(0.5 min),表明粒子群算法优化的模糊PID控制器控制性能最优。另一方面,经编程曲线计算,PSO-Fuzzy PID大约需10 min达到设定提取量,略慢于Fuzzy-PID和GA-Fuzzy PID。实际应用中,对控制对象施加影响的主要因素是控制器的超调量和收敛稳定时间[46]。因此,在MW_4800 W/L-1:20的微波提取条件下,PSO-Fuzzy PID控制效果最优,仿真曲线提取效率更高,稳定性更好,符合数字化仿真控制的要求。

其他提取条件下,GA-Fuzzy PID和PSO-Fuzzy PID两种算法均可较好地对目标提取过程实施控制。GA算法是一种高效、并行、全局搜索的方法,能够自适应地控制搜索过程从而求得最佳解;PSO算法具有不依赖于问题信息、算法通用性强、需要调整的参数少、原理简单、容易实现、收敛速度快等优点[47]。单独模糊算法和传统PID不具备GA-Fuzzy PID和PSO-Fuzzy的特点,因此,提取过程控制效果较差。

表2为不同银杏叶多酚提取条件下传统PID、Fuzzy-PID、GA-Fuzzy PID、PSO-Fuzzy PID仿真过程中对应的传递函数、PID系数、模糊增益因子、GA增益因子、PSO增益因子。由表可知,不同提取条件下传递函数、GA因子或PSO因子各异,但不同料液比下,PID系数与模糊增益因子也可能相同。譬如,当超声提取功率为22.3 W/L时,1:20、1:30和1:40的料液比下所对应的PID系数均为0.0108(Kp)、0.0005(Ki)和0.0075(Kd)。当超声提取功率为47.0 W/L时,1:20、1:30和1:40的料液比下所对应的模糊增益因子均为0.003、0.00002、0.0001。这可能是传统PID与模糊PID模型精度小,导致PID系数与模糊增益因子相同。由于以上参数不能精确衡量不同提取条件下四种算法控制器的性能,因此需要计算四种PID控制器的超调量和收敛稳定时间两个主要影响因素[46]。

表 2 不同提取条件下的传递函数、PID系数、模糊增益因子、GA因子、PSO因子Table 2. Transfer functions, PID factors, Fuzzy gain factors, GA gain factors, PSO gain factors under different extraction methods提取条件 传递函数 PID系数 模糊增益因子 GA增益因子 PSO增益因子 MW_4800 W/L -1:20 0.05595S+1.37e−9 Kp=8.27,Ki=0.22,Kd=0.41 0.5,0.05,0.1 3.9067,0.1078,0.1466 4.1350,0.1100,0.0001 MW_4800 W/L-1:30 57.61S+1.519e−9 Kp=0.0072,Ki 0.0005,Kd=0.0031 0.004,0.00015,0.00018 0.0035,0.0001,0.0001 0.0036,0.0001,0.0001 MW_4800 W/L-1:40 41.89S+2.395e−7 Kp=0.0113,Ki=0.0010,Kd=0.0043 0.002,0.00002,0.0001 0.0051,0.0001,0.0009 0.0056,0.0001,0.0022 US_103.7 W/L-1:20 41.59S+2.145e−9 Kp=0.0100,Ki=0.0008,Kd=0.0040 0.002,0.00002,0.0001 0.0047,0.0001,0.0002 0.0050,0.0001,0.0001 US_103.7 W/L-1:30 8.77S+8.252e−10 Kp=0.0432,Ki=0.0030,Kd=0.0207 0.01,0.00002,0.0001 0.0212,0.0001,0.0002 0.0216,0.0001,0.0001 US_103.7 W/L-1:40 8.061S+1.414e−9 Kp=0.0470,Ki=0.0033,Kd=0.0225 0.01,0.00002,0.0001 0.0229,0.0001,0.0022 0.0235,0.0001,0.0001 US_47.0W/L-1:20 39.91S+1.579e−8 Kp=0.0115,Ki=0.0010,Kd=0.0045 0.003,0.00002,0.0001 0.0057,0.0001,0.0004 0.0057,0.0001,0.0022 US_47.0W/L-1:30 53.78S+5.498e−7 Kp=0.0115,Ki=0.0010,Kd=0.0045 0.003,0.00002,0.0001 0.0054,0.0001,0.0001 0.0057,0.0001,0.0001 US_47.0 W/L-1:40 48.41S+1.639e−11 Kp=0.0115,Ki=0.0010,Kd=0.0045 0.003,0.00002,0.0001 0.0057,0.0001,0.0001 0.0057,0.0001,0.0001 US_22.3 W/L-1:20 24.26S+1.667e−8 Kp=0.0108,Ki=0.0005,Kd=0.0075 0.003,0.00002,0.0001 0.0054,0.0002,0.0008 0.0054,0.0003,0.0001 US_22.3 W/L-1:30 46.1S+8.735e−9 Kp=0.0108,Ki=0.0005,Kd=0.0075 0.002,0.00002,0.0001 0.0051,0.0001,0.0004 0.0054,0.0003,0.0001 US_22.3 W/L-1:40 48.2S+4.457e−10 Kp=0.0108,Kp=0.0005,Kd=0.0075 0.0026,0.00002,0.0001 0.0054,0.0003,0.0001 0.0054,0.0001,0.0001 表3为不同提取条件下的超调量、收敛状态时间、最佳算法的选择。由表可知,超声和微波提取条件下,超调量分布在0.03%~10.27%之间,稳态时间分布于0.5 min到21.0 min之间。总体上,超调量在微波条件下(1.12%~10.27%)比超声条件下(0.03%~2.12%)更高;但收敛状态时间在微波条件下(0.5~4.0 min)远低于超声(7.5~21.0 min)。此外,最佳算法根据控制器的超调量和收敛稳定时间进行衡量。以上及表格数据可以看出,不同提取条件下,最佳算法均呈现GA算法或PSO算法。推测其原因可能是,相较于传统PID和模糊算法,GA算法和PSO算法的超调量与收敛稳态时间更小。以上结果表明,PID控制器中,GA算法和PSO算法稳定性较好,具有较高的控制性能。Manuel等[48]采用不同算法优化PID和模糊逻辑控制器,从而对直流电机进行控制和性能分析,同样发现不同实验条件中最优控制性能的算法同样包括GA算法和PSO算法。

表 3 不同提取条件下的超调量、收敛状态时间、最佳算法Table 3. Overshooting, convergence state time, optimal algorithm under different extraction methods提取条件 超调量(%) 收敛状态时间(min) 最佳算法 PID Fuzzy-PID GA-Fuzzy PID PSO-Fuzzy PID PID Fuzzy-PID GA-Fuzzy PID PSO-Fuzzy PID MW_4800 W/L-1:20 4.44 3.39 1.63 1.12 2.5 2.0 1.5 0.5 PSO MW_4800 W/L -1:30 10.27 5.86 4.68 5.23 4.0 3.0 2.5 3.0 GA MW_4800 W/L -1:40 9.06 7.44 4.39 5.91 4.0 3.5 3.0 3.5 GA US_103.7 W/L-1:20 0.12 0.08 0.05 0.07 11.0 9.0 8.0 9.0 GA US_103.7 W/L-1:30 0.19 0.16 0.15 0.13 11.0 10.0 10.0 9.5 PSO US_103.7 W/L-1:40 0.19 0.18 0.15 0.14 11.5 10.5 9.5 9.5 PSO US_47.0 W/L-1:20 0.06 0.04 0.03 0.04 9.5 8.5 7.5 8.0 GA US_47.0 W/L-1:30 0.06 0.05 0.03 0.04 9.0 9.0 8.5 8.5 GA US_47.0 W/L-1:40 0.06 0.05 0.04 0.03 10.0 8.5 8.5 8.0 PSO US_22.3 W/L-1:20 2.12 1.40 0.93 1.17 19.0 16.0 14.5 16.0 GA US_22.3 W/L-1:30 1.15 0.81 0.52 0.72 18.0 18.0 17.0 17.0 GA US_22.3 W/L-1:40 0.78 0.72 0.66 0.49 21.0 19.0 18.5 17.5 PSO 综上,GA-Fuzzy PID与PSO-Fuzzy PID具有超调量小、收敛速度快、控制提取时间精准的优点,同时,上述算法对数学模型要求低,适用性强,可为银杏叶多酚萃取过程中的精准控制提供理论依据,实现萃取过程的仿真控制,有助于进一步提高银杏叶多酚的萃取效率,控制萃取成本,实现萃取过程的绿色化升级。

3. 结论

本文采用超声和微波两种方式辅助萃取银杏叶多酚,构建了多酚提取传质物理模型和PID控制算法,从而探究了超声和微波条件下多酚提取传质机制和过程控制方法。相较摇床振荡提取,超声和微波辅助提取条件下银杏叶内多酚的释放能力更强,银杏叶颗粒内部多酚分子扩散系数更大。同时,微波比超声具有更高的提取效率、更强的多酚扩散能力。当料液比为1:40、微波和超声的功率分别为4800 W/L和103.7 W/L时,微波和超声下的多酚平衡提取量分别为28.453±1.115 mg/g和27.492±2.666 mg/g,多酚De值分别为1.4×10−10~1.7×10−10、6.4×10−11 m2/s。另一方面,相较传统PID和模糊PID控制器的控制性能,GA-Fuzzy PID和PSO-Fuzzy PID两种控制器稳定性更强,收敛稳定时间更短。当微波功率为4800 W/L,料液比为1:20时,最佳算法为粒子群优化算法,收敛时间为0.5 min,超调量为1.12%,GA-Fuzzy PID和Fuzzy-PID收敛时间分别为1.5 min和2.0 min,超调量分别为1.63%和3.39%。通过构建传质数学模型和PID控制算法,可为银杏叶多酚萃取过程中的精准控制提供理论依据。

-

图 6 不同提取条件下银杏叶内单体类黄酮类多酚的提取量

注:不同小写字母表示处理之间的显著性差异(P<0.05);图7同。

Figure 6. Extraction yields of individual flavonoid polyphenol from Ginkgo biloba leaf under different extraction methods

表 1 不同提取条件下模型各项数据

Table 1 Model data under different extraction conditions

提取条件 De(m2/s) AAD(%) R2 MW_4800 W/L-1:20 1.0×10−10~1.3×10−10 9.62 0.995 MW_4800 W/L-1:30 1.2×10−10~1.5×10−10 9.27 0.994 MW_4800 W/L-1:40 1.4×10−10~1.7×10−10 9.26 0.986 US_103.7 W/L-1:20 3.6×10−11 9.71 0.981 US_103.7 W/L-1:30 6.2×10−11 9.58 0.996 US_103.7 W/L-1:40 6.4×10−11 9.19 0.993 US_47.0 W/L-1:20 3.3×10−11 8.57 0.971 US_47.0 W/L-1:30 6.0×10−11 8.71 0.992 US_47.0 W/L-1:40 6.2×10−11 9.16 0.979 US_22.3 W/L-1:20 2.8×10−11 9.56 0.971 US_22.3 W/L-1:30 5.9×10−11 9.77 0.972 US_22.3 W/L-1:40 6.1×10−11 9.71 0.971 Shaker-1:40 2.2×10−11 9.39 0.985 注:US为超声辅助提取,MW为微波辅助提取,Shaker为对照组摇床振荡辅助提取。 表 2 不同提取条件下的传递函数、PID系数、模糊增益因子、GA因子、PSO因子

Table 2 Transfer functions, PID factors, Fuzzy gain factors, GA gain factors, PSO gain factors under different extraction methods

提取条件 传递函数 PID系数 模糊增益因子 GA增益因子 PSO增益因子 MW_4800 W/L -1:20 0.05595S+1.37e−9 Kp=8.27,Ki=0.22,Kd=0.41 0.5,0.05,0.1 3.9067,0.1078,0.1466 4.1350,0.1100,0.0001 MW_4800 W/L-1:30 57.61S+1.519e−9 Kp=0.0072,Ki 0.0005,Kd=0.0031 0.004,0.00015,0.00018 0.0035,0.0001,0.0001 0.0036,0.0001,0.0001 MW_4800 W/L-1:40 41.89S+2.395e−7 Kp=0.0113,Ki=0.0010,Kd=0.0043 0.002,0.00002,0.0001 0.0051,0.0001,0.0009 0.0056,0.0001,0.0022 US_103.7 W/L-1:20 41.59S+2.145e−9 Kp=0.0100,Ki=0.0008,Kd=0.0040 0.002,0.00002,0.0001 0.0047,0.0001,0.0002 0.0050,0.0001,0.0001 US_103.7 W/L-1:30 8.77S+8.252e−10 Kp=0.0432,Ki=0.0030,Kd=0.0207 0.01,0.00002,0.0001 0.0212,0.0001,0.0002 0.0216,0.0001,0.0001 US_103.7 W/L-1:40 8.061S+1.414e−9 Kp=0.0470,Ki=0.0033,Kd=0.0225 0.01,0.00002,0.0001 0.0229,0.0001,0.0022 0.0235,0.0001,0.0001 US_47.0W/L-1:20 39.91S+1.579e−8 Kp=0.0115,Ki=0.0010,Kd=0.0045 0.003,0.00002,0.0001 0.0057,0.0001,0.0004 0.0057,0.0001,0.0022 US_47.0W/L-1:30 53.78S+5.498e−7 Kp=0.0115,Ki=0.0010,Kd=0.0045 0.003,0.00002,0.0001 0.0054,0.0001,0.0001 0.0057,0.0001,0.0001 US_47.0 W/L-1:40 48.41S+1.639e−11 Kp=0.0115,Ki=0.0010,Kd=0.0045 0.003,0.00002,0.0001 0.0057,0.0001,0.0001 0.0057,0.0001,0.0001 US_22.3 W/L-1:20 24.26S+1.667e−8 Kp=0.0108,Ki=0.0005,Kd=0.0075 0.003,0.00002,0.0001 0.0054,0.0002,0.0008 0.0054,0.0003,0.0001 US_22.3 W/L-1:30 46.1S+8.735e−9 Kp=0.0108,Ki=0.0005,Kd=0.0075 0.002,0.00002,0.0001 0.0051,0.0001,0.0004 0.0054,0.0003,0.0001 US_22.3 W/L-1:40 48.2S+4.457e−10 Kp=0.0108,Kp=0.0005,Kd=0.0075 0.0026,0.00002,0.0001 0.0054,0.0003,0.0001 0.0054,0.0001,0.0001 表 3 不同提取条件下的超调量、收敛状态时间、最佳算法

Table 3 Overshooting, convergence state time, optimal algorithm under different extraction methods

提取条件 超调量(%) 收敛状态时间(min) 最佳算法 PID Fuzzy-PID GA-Fuzzy PID PSO-Fuzzy PID PID Fuzzy-PID GA-Fuzzy PID PSO-Fuzzy PID MW_4800 W/L-1:20 4.44 3.39 1.63 1.12 2.5 2.0 1.5 0.5 PSO MW_4800 W/L -1:30 10.27 5.86 4.68 5.23 4.0 3.0 2.5 3.0 GA MW_4800 W/L -1:40 9.06 7.44 4.39 5.91 4.0 3.5 3.0 3.5 GA US_103.7 W/L-1:20 0.12 0.08 0.05 0.07 11.0 9.0 8.0 9.0 GA US_103.7 W/L-1:30 0.19 0.16 0.15 0.13 11.0 10.0 10.0 9.5 PSO US_103.7 W/L-1:40 0.19 0.18 0.15 0.14 11.5 10.5 9.5 9.5 PSO US_47.0 W/L-1:20 0.06 0.04 0.03 0.04 9.5 8.5 7.5 8.0 GA US_47.0 W/L-1:30 0.06 0.05 0.03 0.04 9.0 9.0 8.5 8.5 GA US_47.0 W/L-1:40 0.06 0.05 0.04 0.03 10.0 8.5 8.5 8.0 PSO US_22.3 W/L-1:20 2.12 1.40 0.93 1.17 19.0 16.0 14.5 16.0 GA US_22.3 W/L-1:30 1.15 0.81 0.52 0.72 18.0 18.0 17.0 17.0 GA US_22.3 W/L-1:40 0.78 0.72 0.66 0.49 21.0 19.0 18.5 17.5 PSO -

[1] LIU L, WANG Y, ZHANG J, et al. Advances in the chemical constituents and chemical analysis of Ginkgo biloba leaf, extract, and phytopharmaceuticals[J]. Journal of Pharmaceutical and Biomedical Analysis,2021,193:113704. doi: 10.1016/j.jpba.2020.113704

[2] WANG H, SHI M, CAO F, et al. Ginkgo biloba seed exocarp:A waste resource with abundant active substances and other components for potential applications[J]. Food Research International,2022,160:111637. doi: 10.1016/j.foodres.2022.111637

[3] LI H, DENG Z, WU T, et al. Microwave-assisted extraction of phenolics with maximal antioxidant activities in tomatoes[J]. Food Chemistry,2012,130(4):928−936. doi: 10.1016/j.foodchem.2011.08.019

[4] SELVAKUMAR P, KARTHIK V, KUMAR P S, et al. Enhancement of ultrasound assisted aqueous extraction of polyphenols from waste fruit peel using dimethyl sulfoxide as surfactant:Assessment of kinetic models[J]. Chemosphere,2021,263:128071. doi: 10.1016/j.chemosphere.2020.128071

[5] DIAS A L B, DE AGUIAR A C, ROSTAGNO M A. Extraction of natural products using supercritical fluids and pressurized liquids assisted by ultrasound:Current status and trends[J]. Ultrasonics Sonochemistry,2021,74:105584. doi: 10.1016/j.ultsonch.2021.105584

[6] MOSCHKO L, BLAŽEVIĆ V. Managing digitization of industrial incumbents through innovation-oriented leadership[J]. Industrial Marketing Management,2023,113:232−242. doi: 10.1016/j.indmarman.2023.06.009

[7] SCHWEN L O, KIEHL T R, CARVALHO R, et al. Digitization of pathology labs:A review of lessons learned[J]. Laboratory Investigation,2023,103(11):100244. doi: 10.1016/j.labinv.2023.100244

[8] ZHAO L, RAO X, LIN Q. Study of the impact of digitization on the carbon emission intensity of agricultural production in China[J]. Science of the Total Environment,2023,903:166544. doi: 10.1016/j.scitotenv.2023.166544

[9] GONG W, LI D, WU Y, et al. Sequential phenolic acid co-pigmentation pretreatment and contact ultrasound-assisted air drying to intensify blackberry drying and enhance anthocyanin retention:A study on mass transfer and phenolic distribution[J]. Ultrasonics Sonochemistry,2021,80:105788. doi: 10.1016/j.ultsonch.2021.105788

[10] AMENDOLA D, DE FAVERI D M, SPIGNO G. Grape marc phenolics:Extraction kinetics, quality and stability of extracts[J]. Journal of Food Engineering,2010,97(3):384−392. doi: 10.1016/j.jfoodeng.2009.10.033

[11] BOGDANOV M G, SVINYAROV I. Ionic liquid-supported solid–liquid extraction of bioactive alkaloids. II. kinetics, modeling and mechanism of glaucine extraction from Glaucium flavum cr.[J]. Separation and Purification Technology,2013,103:279−288. doi: 10.1016/j.seppur.2012.10.035

[12] RUI Z, SI R J, DAN D L, et al. Dehydration of apple slices by sequential drying pretreatments and airborne ultrasound-assisted air drying:Study on mass transfer, profiles of phenolics and organic acids and PPO activity[J]. Innovative Food Science & Emerging Technologies,2022,75:102871.

[13] PETTINATO M, CASAZZA A, PEREGO P. The role of heating step in microwave-assisted extraction of polyphenols from spent coffee grounds[J]. Food and Bioproducts Processing,2019,114:227−234. doi: 10.1016/j.fbp.2019.01.006

[14] GARCIA-PEREZ J V, GARCÍA-ALVARADO M A, CARCEL J A, et al. Extraction kinetics modeling of antioxidants from grape stalk:Influence of drying conditions[J]. Journal of Food Engineering,2010,101(1):49−58. doi: 10.1016/j.jfoodeng.2010.06.008

[15] SPIGNO G, DE FAVERI D M. Microwave-assisted extraction of tea phenols:A phenomenological study[J]. Journal of Food Engineering,2009,93(2):210−217. doi: 10.1016/j.jfoodeng.2009.01.006

[16] TAO Y, ZHANG Z, SUN D W. Kinetic modeling of ultrasound-assisted extraction of phenolic compounds from grape marc:Influence of acoustic energy density and temperature[J]. Ultrasonics Sonochemistry,2014,21(4):1461−1469. doi: 10.1016/j.ultsonch.2014.01.029

[17] LIU Z, LIU Z, LIU J, et al. Thermal management with fast temperature convergence based on optimized fuzzy PID algorithm for electric vehicle battery[J]. Applied Energy,2023,352:121936. doi: 10.1016/j.apenergy.2023.121936

[18] TUNG C C, LAI Y Y, CHEN Y Z, et al. Optimization of mechanical properties of bio-inspired voronoi structures by genetic algorithm[J]. Journal of Materials Research and Technology,2023,26:3813−3829. doi: 10.1016/j.jmrt.2023.08.210

[19] ZHUANG Y, SHARMA S, SUBUDHI B, et al. Efficient collision-free path planning for autonomous underwater vehicles in dynamic environments with a hybrid optimization algorithm[J]. Ocean Engineering,2016,127:190−199. doi: 10.1016/j.oceaneng.2016.09.040

[20] LIANG H, MA B, ZUO K, et al. Fuzzy immune algorithm based remote wireless transmission for throttled PID control strategy[J]. Physical Communication,2020,41:101105. doi: 10.1016/j.phycom.2020.101105

[21] HASSAN M K, AZUBIR N A M, NIZAM H M I, et al. Optimal design of electric power assisted steering system using GA-PID method[J]. Procedia Engineering,2012,41:614−621. doi: 10.1016/j.proeng.2012.07.220

[22] GÜN A. Attitude control of a quadrotor using PID controller based on differential evolution algorithm[J]. Expert Systems with Applications,2023,229:120518. doi: 10.1016/j.eswa.2023.120518

[23] 龚文进. 接触式超声强化干燥黑莓过程中多酚和细胞壁组分衍化 规律及其互作行为研究[D]. 南京:南京农业大学, 2022. [GONG W J. Diffraction patterns of polyphenols and cell wall components and their interactions during contact ultrasonic intensive drying of blackberries[D]. Nanjing:Nanjing Agricultural University, 2022.] GONG W J. Diffraction patterns of polyphenols and cell wall components and their interactions during contact ultrasonic intensive drying of blackberries[D]. Nanjing: Nanjing Agricultural University, 2022.

[24] TAO Y, LI D, SIONG C, et al. Comparison between airborne ultrasound and contact ultrasound to intensify air drying of blackberry:Heat and mass transfer simulation, energy consumption and quality evaluation[J]. Ultrasonics Sonochemistry, 2021, 72:105410.

[25] LIAO W, SHEN J, MANICKAM S, et al. Investigation of blueberry juice fermentation by mixed probiotic strains:Regression modeling, machine learning optimization and comparison with fermentation by single strain in the phenolic and volatile profiles[J]. Food Chemistry,2023,405:134982. doi: 10.1016/j.foodchem.2022.134982

[26] HE J, XIE B. Reversed-phase argentation high-performance liquid chromatography in phytochemical analysis of ginkgolic acids in leaves from Ginkgo biloba L.[J]. Journal of Chromatography A,2002,943(2):303−309. doi: 10.1016/S0021-9673(01)01444-3

[27] YANG T, YUE W, YONG B H, et al. Insight into mass transfer during ultrasound-enhanced adsorption/desorption of blueberry anthocyanins on macroporous resins by numerical simulation considering ultrasonic influence on resin properties[J]. Chemical Engineering Journal,2020,380:122530. doi: 10.1016/j.cej.2019.122530

[28] XU H, FEI Q, MANICKAM S, et al. Mechanistic study of the solid-liquid extraction of phenolics from walnut pellicle fibers enhanced by ultrasound, microwave and mechanical agitation forces[J]. Chemosphere,2022,309:136451. doi: 10.1016/j.chemosphere.2022.136451

[29] 孙玉玉. 内生乳杆菌发酵白果汁减毒增效及过程智能优化研究[D]. 南京:南京农业大学, 2023. [SUN Y Y. Research on the reduction of toxicity and efficiency of white fruit juice fermented byLactobacillus endophyticus and the intelligent optimization of the process[D]. Nanjing:Nanjing Agricultural University, 2023.] SUN Y Y. Research on the reduction of toxicity and efficiency of white fruit juice fermented by Lactobacillus endophyticus and the intelligent optimization of the process[D]. Nanjing: Nanjing Agricultural University, 2023.

[30] SIVA K P, GOPI K R P V. Fractional-order PID controller for blood pressure regulation using genetic algorithm[J]. Biomedical Signal Processing and Control,2024,88:105564. doi: 10.1016/j.bspc.2023.105564

[31] SHAN B, PANG Y, ZHENG Q, et al. Improved ANFIS combined with PID for extractive distillation process control of benzene–isopropanol–water mixtures[J]. Chemical Engineering Science,2023,269:118464. doi: 10.1016/j.ces.2023.118464

[32] 周廷慰. 不同类型粒子群算法对传递函数辨识仿真研究[J]. 白城师范学院学报,2023,37(2):28−34. [ZHOU T W. Simulation study on transfer function identification by different types of particle swarm algorithms[J]. Journal of Baicheng Normal College,2023,37(2):28−34.] ZHOU T W. Simulation study on transfer function identification by different types of particle swarm algorithms[J]. Journal of Baicheng Normal College, 2023, 37(2): 28−34.

[33] 高阳, 陈焰, 司兴登. 基于模糊PID参数自整定真空冶炼炉温度控制系统的研究[J]. 贵州大学学报,2013,30(1):43−46. [GAO Y, CHEN Y, SI X D. Research on temperature control system of vacuum smelting furnace based on fuzzy PID parameter self-tuning[J]. Journal of Guizhou University,2013,30(1):43−46.] GAO Y, CHEN Y, SI X D. Research on temperature control system of vacuum smelting furnace based on fuzzy PID parameter self-tuning[J]. Journal of Guizhou University, 2013, 30(1): 43−46.

[34] 侯云辉, 孟廷豪. 基于模糊算法的加热炉温度控制系统探究[J]. 工业炉,2022,44(5):50−53. [HOU Y H, MENG T H. Exploration of heating furnace temperature control system based on fuzzy algorithm[J]. Industrial Furnace,2022,44(5):50−53.] HOU Y H, MENG T H. Exploration of heating furnace temperature control system based on fuzzy algorithm[J]. Industrial Furnace, 2022, 44(5): 50−53.

[35] 罗杰, 周仲礼, 邹天一. 基于PSO-CNN的深部找矿预测模型构建[J]. 成都理工大学学报,2022,49(6):697−708. [LUO J , ZHOU Z L, ZOU T Y. Construction of a prediction model for deep-searching mineralization based on PSO-CNN[J]. Journal of Chengdu University of Technology,2022,49(6):697−708.] LUO J , ZHOU Z L, ZOU T Y. Construction of a prediction model for deep-searching mineralization based on PSO-CNN[J]. Journal of Chengdu University of Technology, 2022, 49(6): 697−708.

[36] 何嘉威. 粒子群优化算法改进及其在智能电网经济优化调度应用[D]. 南京:南京邮电大学, 2022. [HE J W. Improvement of particle swarm optimization algorithm and its application on economic dispatching of smart grid[D]. Nanjing:Nanjing University of Posts and Telecommunications, 2022.] HE J W. Improvement of particle swarm optimization algorithm and its application on economic dispatching of smart grid[D]. Nanjing: Nanjing University of Posts and Telecommunications, 2022.

[37] PEREZ E E, CARELLI A A, CRAPISTE G H. Temperature dependent diffusion coefficient of oil from different sunflower seeds during extraction with hexane[J]. Journal of Food Engineering,2011,105(1):180−185. doi: 10.1016/j.jfoodeng.2011.02.025

[38] CRAVOTTO G, CRAVOTTO C, VESELOV V V. Innovative Food Processing Technologies[M]. Oxford:Elsevier, 2021:359-366.

[39] KANNO M, NAKAMURA K, KANAI E, et al. Theoretical verification of nonthermal microwave effects on intramolecular reactions[J]. The Journal of Physical Chemistry A,2012,116(9):2177−2183. doi: 10.1021/jp212460v

[40] ARRUDA H S, SILVA E K, PEREIRA G A, et al. Effects of high-intensity ultrasound process parameters on the phenolic compounds recovery from araticum peel[J]. Ultrasonics Sonochemistry,2019,50:82−95. doi: 10.1016/j.ultsonch.2018.09.002

[41] MKAOUAR S, GELICUS A, BAHLOUL N, et al. Kinetic study of polyphenols extraction from olive (Olea europaea L.) leaves using instant controlled pressure drop texturing[J]. Separation and Purification Technology,2016,161:165−171. doi: 10.1016/j.seppur.2016.02.002

[42] DOS SANTOS T J P, TAVARES F W, ABREU C R A. Fick diffusion coefficients via molecular dynamics:An alternative approach in the fourier domain[J]. Journal of Molecular Liquids,2021,329:115460. doi: 10.1016/j.molliq.2021.115460

[43] WANG Y, TAO Y, ZHANG X, et al. Metabolic profile of ginkgo kernel juice fermented with lactic aicd bacteria:A potential way to degrade ginkgolic acids and enrich terpene lactones and phenolics[J]. Process Biochemistry,2019,76:25−33. doi: 10.1016/j.procbio.2018.11.006

[44] 孙锴. 银杏酸对心脏线粒体功能的影响[J]. 中国药理通讯, 2007, 24(3):35. [SUN K. Effects of ginkgolic acid on cardiac mitochondrial function[J]. Chinese Pharmacology Letters, 2007, 24(3):35.] SUN K. Effects of ginkgolic acid on cardiac mitochondrial function[J]. Chinese Pharmacology Letters, 2007, 24(3): 35.

[45] 耿敬章, 彭浩. 银杏酸的提取及性质研究[J]. 饮料工业,2012,15(10):21−24. [GENG J Z, PENG H. Extraction and characterization of ginkgolic acid[J]. Beverage Industry,2012,15(10):21−24.] doi: 10.3969/j.issn.1007-7871.2012.10.005 GENG J Z, PENG H. Extraction and characterization of ginkgolic acid[J]. Beverage Industry, 2012, 15(10): 21−24. doi: 10.3969/j.issn.1007-7871.2012.10.005

[46] SHAN B, ZHENG Q, CHEN Z, et al. Dynamic control and performance comparison of conventional and dividing wall extractive distillation for benzene/isopropanol/water separation[J]. Journal of the Taiwan Institute of Chemical Engineers,2021,128:73−86. doi: 10.1016/j.jtice.2021.08.005

[47] ŞENER R, KOÇ M A, ERMIŞ K. Hybrid ANFIS-PSO algorithm for estimation of the characteristics of porous vacuum preloaded air bearings and comparison performance of the intelligent algorithm with the ANN[J]. Engineering Applications of Artificial Intelligence,2024,128:107460. doi: 10.1016/j.engappai.2023.107460

[48] MANUEL N L, İNANÇ N, LÜY M. Control and performance analyses of a DC motor using optimized PIDs and fuzzy logic controller[J]. Results in Control and Optimization,2023,13:100306. doi: 10.1016/j.rico.2023.100306

-

期刊类型引用(11)

1. 刘影,庞富,陈佳鸿,陈炯葵,蔡烁仪. 本草清咽润喉糖的配方优化及抗氧化研究. 农产品加工. 2024(21): 41-46 .  百度学术

百度学术

2. 张敏君,段雪伟,王燕,杨慧文,刘冰,向文静,由天辉. 构树根皮活性成分乙醇提取工艺优化及其抗氧化活性分析. 食品工业科技. 2023(11): 196-203 .  本站查看

本站查看

3. 王蕙雯. 豫西自然发酵柿子醋抗氧化性研究. 江苏调味副食品. 2023(03): 20-23 .  百度学术

百度学术

4. 裴文清,吕泸楠,王靖宇,浦思琦,雷霜,王春丽. 木瓜皮多酚和黄酮提取工艺优化及酪氨酸酶与胰脂肪酶抑制活性研究. 食品工业科技. 2022(01): 188-195 .  本站查看

本站查看

5. 周新崇,易灿,刘进兵. 微波辅助提取崀山脐橙皮总黄酮及生物活性研究. 邵阳学院学报(自然科学版). 2022(02): 87-95 .  百度学术

百度学术

6. 张清月,董姝慧,李胤豪,赵艳丽,史彬林,闫素梅. 诺丽果不同提取物抗氧化能力的比较研究. 中国粮油学报. 2022(05): 144-150 .  百度学术

百度学术

7. 关随霞,王蕙雯,杨肖瑞,郭淑敏,张翅,张培杰,李道敏. 大青叶总黄酮提取工艺优化及抗氧化性研究. 中国食品添加剂. 2022(09): 138-144 .  百度学术

百度学术

8. 陈慧玲,刘芳,钟恒勤,王伟枫. 超声波辅助乙醇提取百香果皮黄酮的工艺优化及黄酮抗氧化性测定. 宁德师范学院学报(自然科学版). 2022(03): 280-287 .  百度学术

百度学术

9. 任海云,韩瑞,张磊. 基于Box-Behnken响应面法优化党参抗氧化活性组分提取工艺. 中医药信息. 2022(12): 5-10 .  百度学术

百度学术

10. 赵雨晴,王宝庆,徐汉,刘楠楠. 醉鱼草总黄酮的提取及抗氧化活性研究. 化学试剂. 2021(07): 979-985 .  百度学术

百度学术

11. 杨青青,龚吉军. 响应面法优化超声辅助葛根浸提工艺及浸提液抗氧化活性研究. 食品安全质量检测学报. 2021(13): 5409-5417 .  百度学术

百度学术

其他类型引用(3)

下载:

下载:

下载:

下载: